Patents

Literature

245results about How to "Guaranteed molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

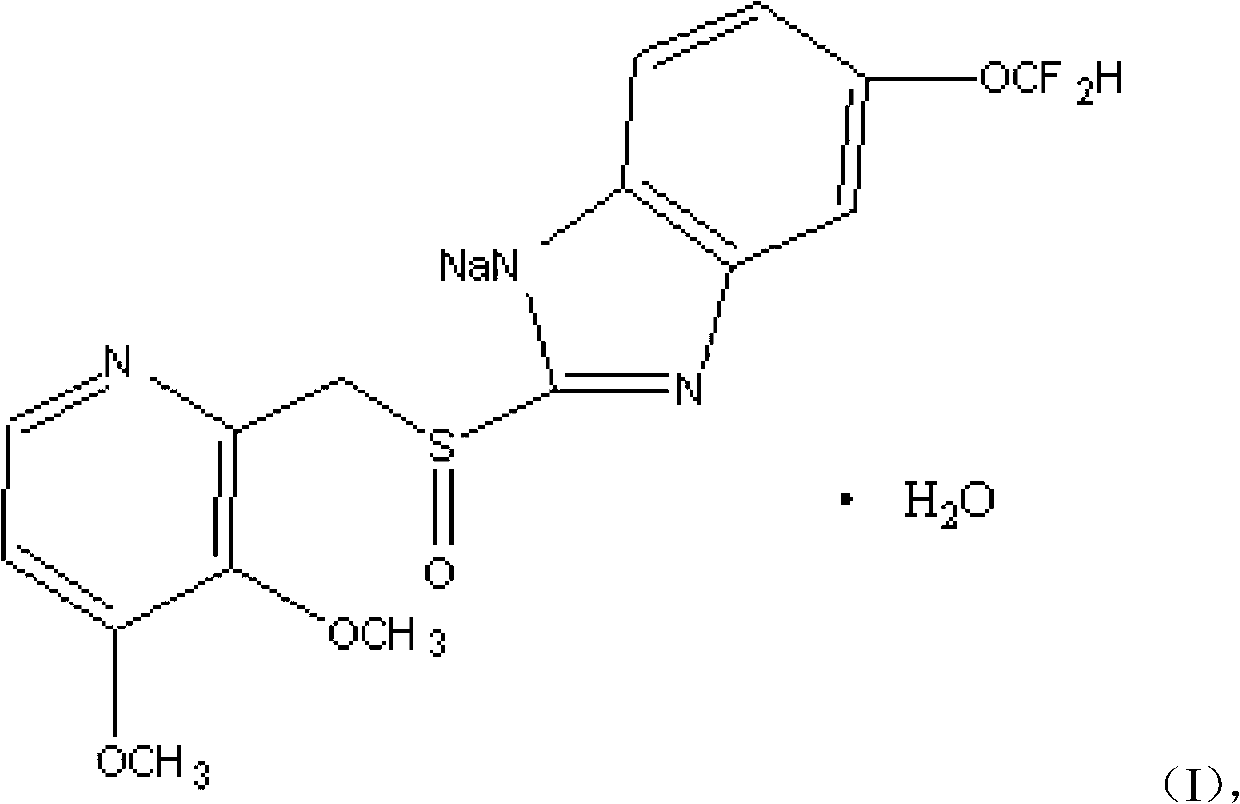

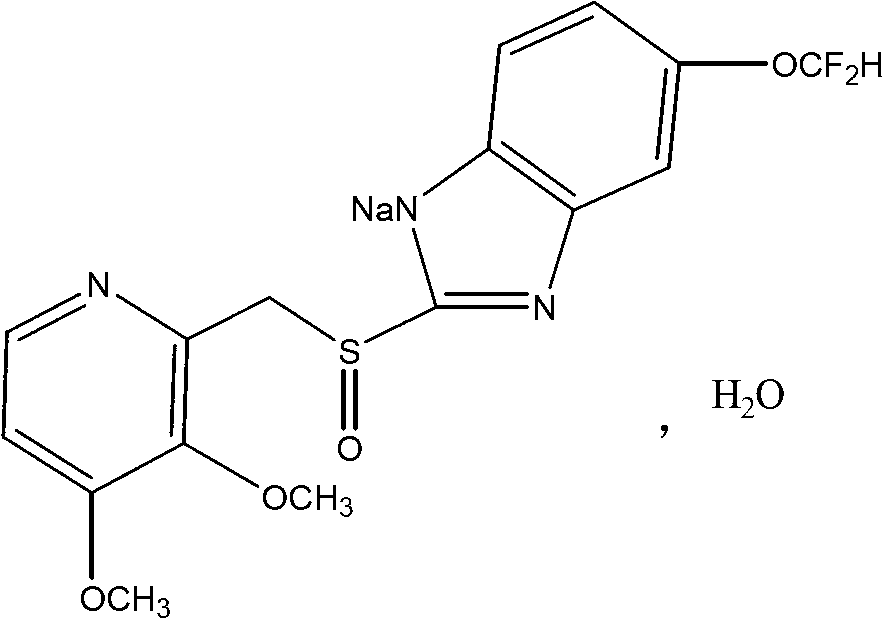

Pantoprazole compound, preparation methods and pharmaceutical preparations thereof

ActiveCN102796078AGood resolubilityHigh clarityOrganic active ingredientsPowder deliverySolubilityDrug compound

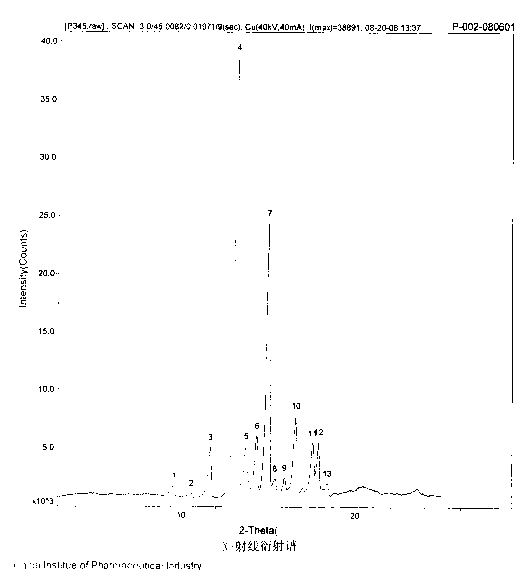

The invention belongs to the technical field of pharmaceutical compounds, and relates to a pantoprazole sodium compound entity, especially a pantoprazole sodium crystal form, preparation methods and pharmaceutical preparations thereof. The pantoprazole sodium compound is crystal, and measured by X-diffraction powder diffraction, and the diffraction pattern has the following diffraction angles (2Theta) in turn: 9.5 degrees, 10.4 degrees, 11.6 degrees, 13.1 degrees, 13.8 degrees, 14.2 degrees, 15.0 degrees, 15.3 degrees, 15.9 degrees, 16.5 degrees, 17.5 degrees, 18.0 degrees and 18.2 degrees. The pantoprazole sodium compound entity may be associated with a variety of lyophilization supporting agents and the prepared lyophilized powder for injection has good solubility, good clarity and low content of related substances, etc. simultaneously the use level of the used lyophilization supporting agent is relatively less, the cost of the products is reduced, and the stability and quality of the products are improved.

Owner:杭州澳亚生物技术股份有限公司

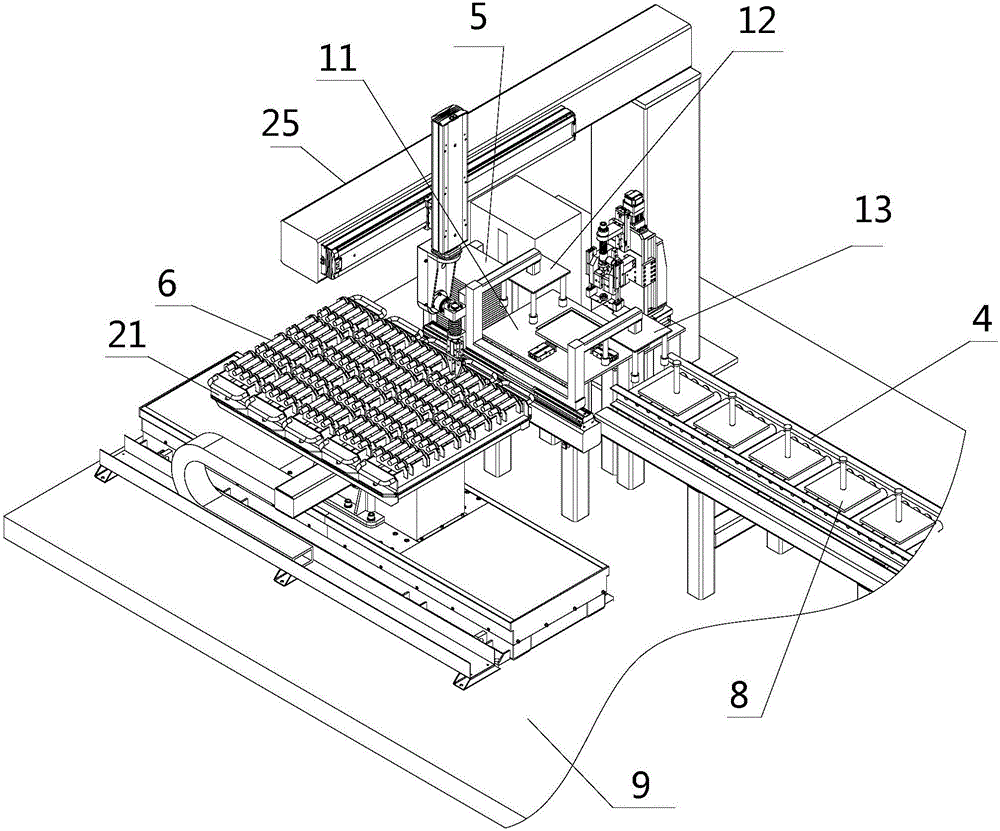

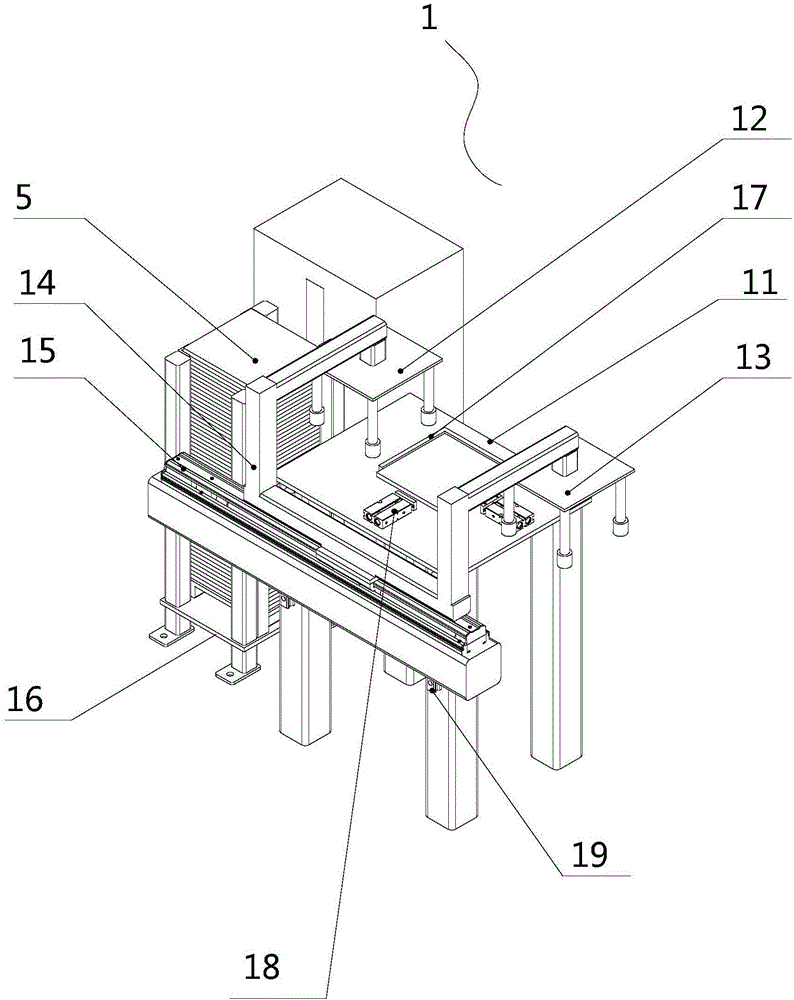

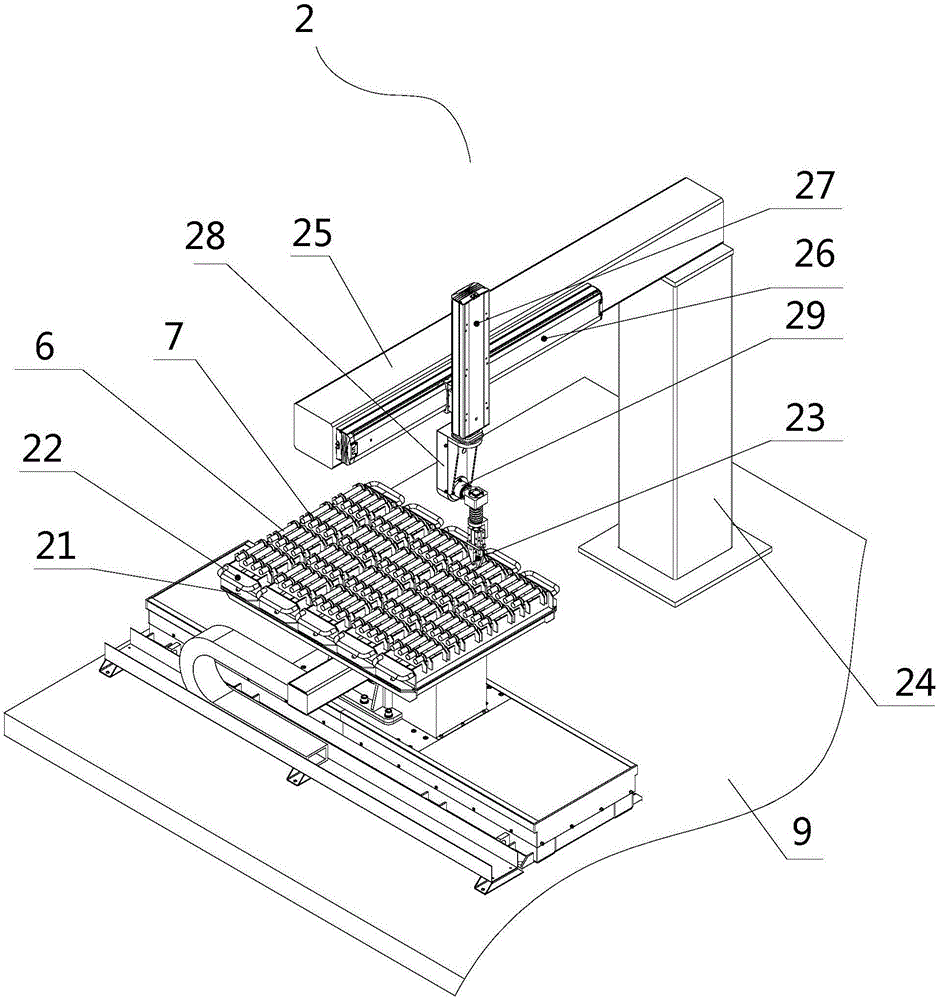

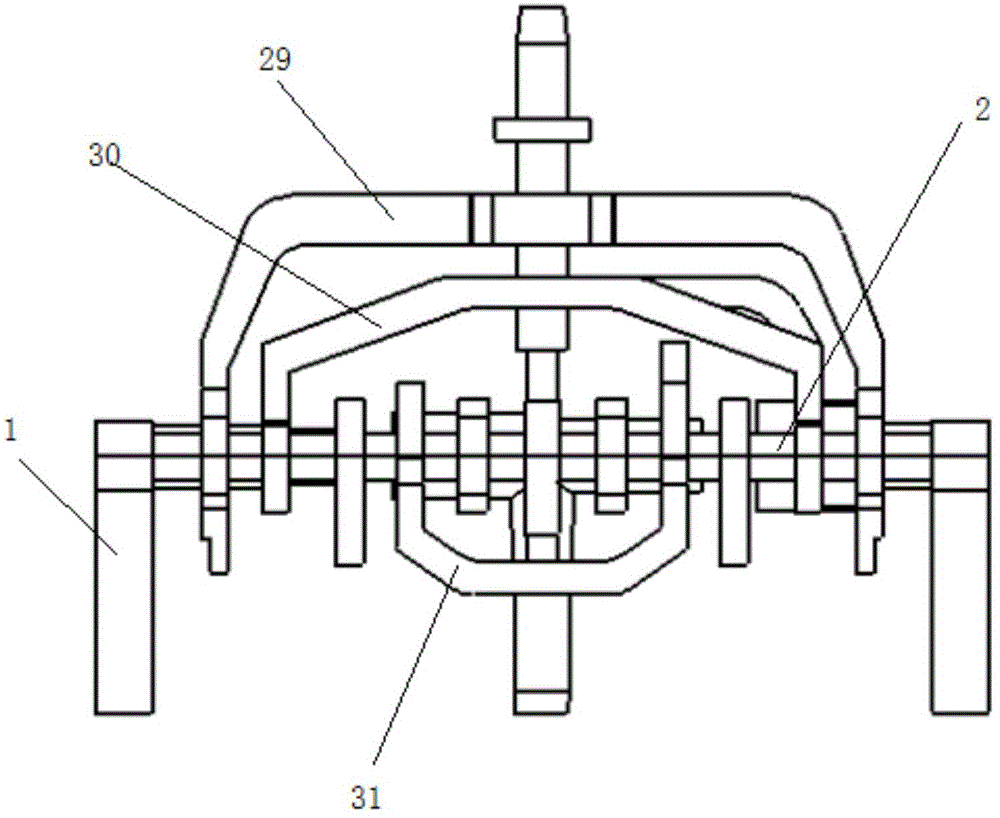

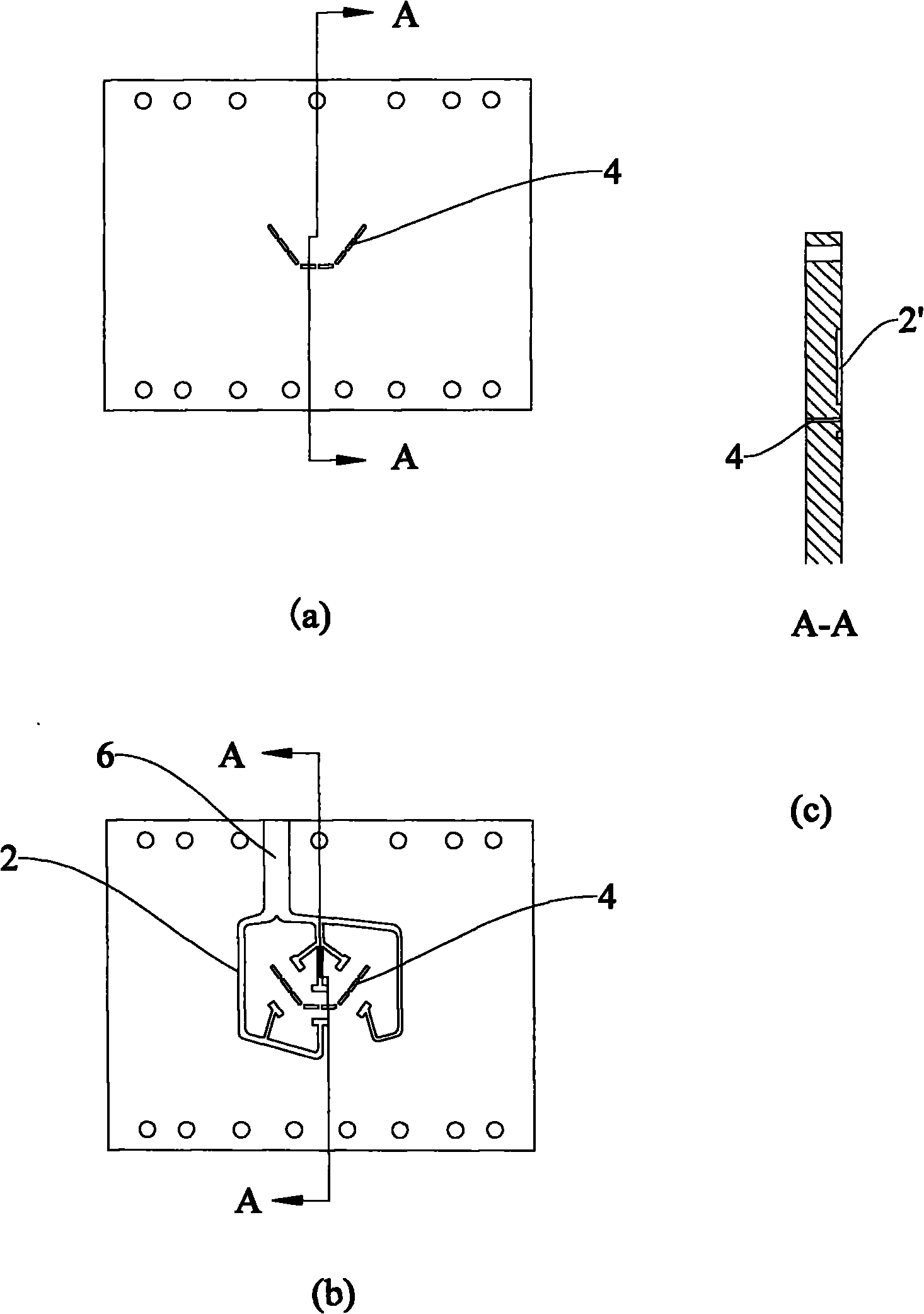

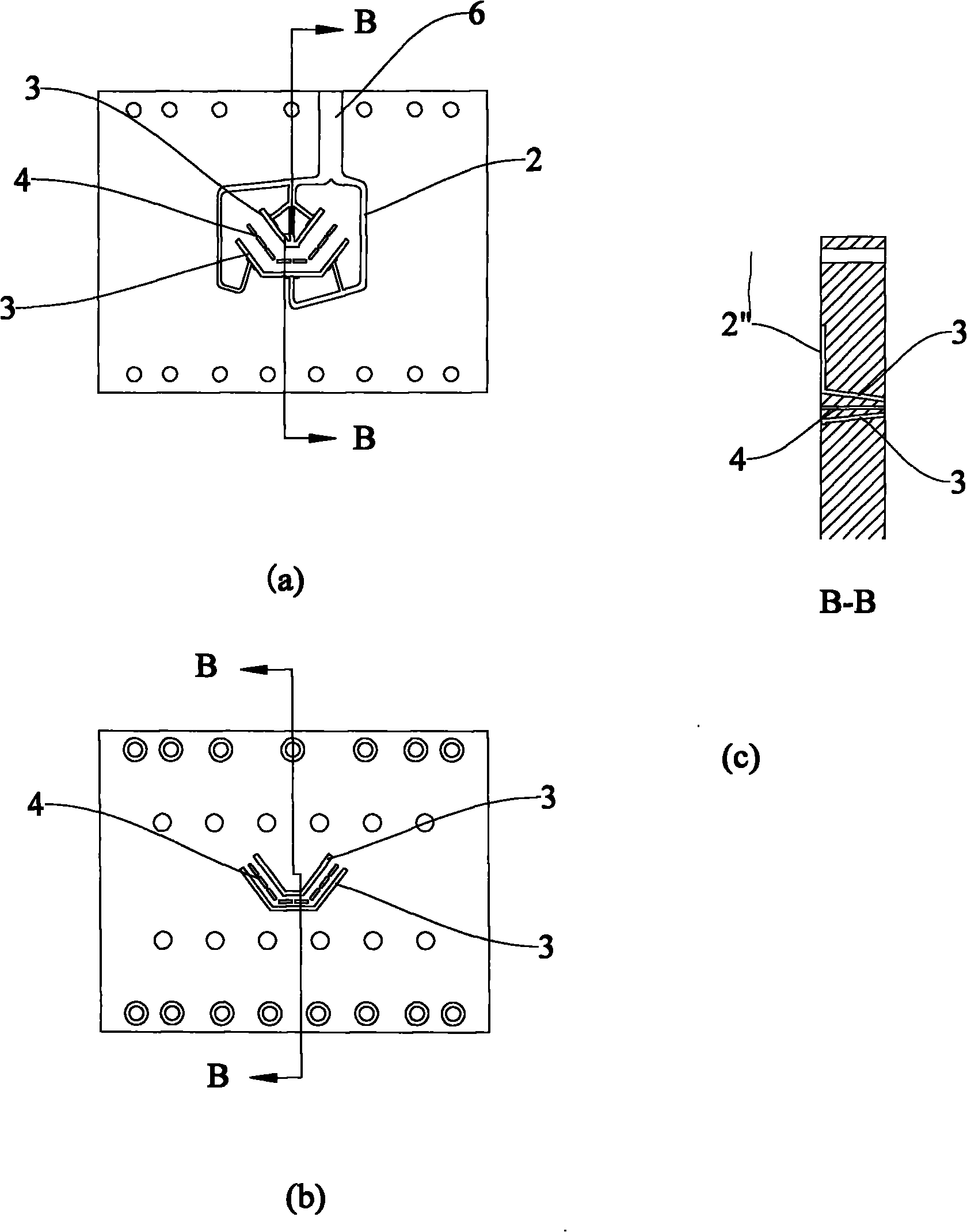

Full-automatic box plate and screw welding device for anchoring box

ActiveCN106425051AIngenious structural designCompact layoutWelding accessoriesStud weldingEngineering

The invention discloses a full-automatic box plate and screw welding device for an anchoring box. The full-automatic box plate and screw welding device comprises a box plate and finished product synchronous-transfer mechanism, a screw feeding mechanism, a stud welding mechanism and a finished product delivery mechanism, wherein the box plate and finished product synchronous-transfer mechanism comprises a material tray positioning rack, a sucking disc material-taking device and a box plate storage plate, the sucking disc material-taking device comprises left and right electromagnetic sucking discs arranged side by side, and the two electromagnetic sucking discs are connected together through a sucking disc supporting frame. The screw feeding mechanism comprises a screw storage pallet and a screw taking manipulator. The stud welding mechanism comprises a base, a welding bearing frame, a welding bearing plate, a metal chuck, a stud welding machine and a ceramic ring compression piece. Compared with the prior art, the full-automatic box plate and screw welding device has the following advantages that automatic feeding, automatic welding and automatic delivery are integrated, the welding quality and production efficiency are greatly improved, and the welding device is ingenious in structural design, compact in layout and suitable for popularization and usage.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Full penetration welding process

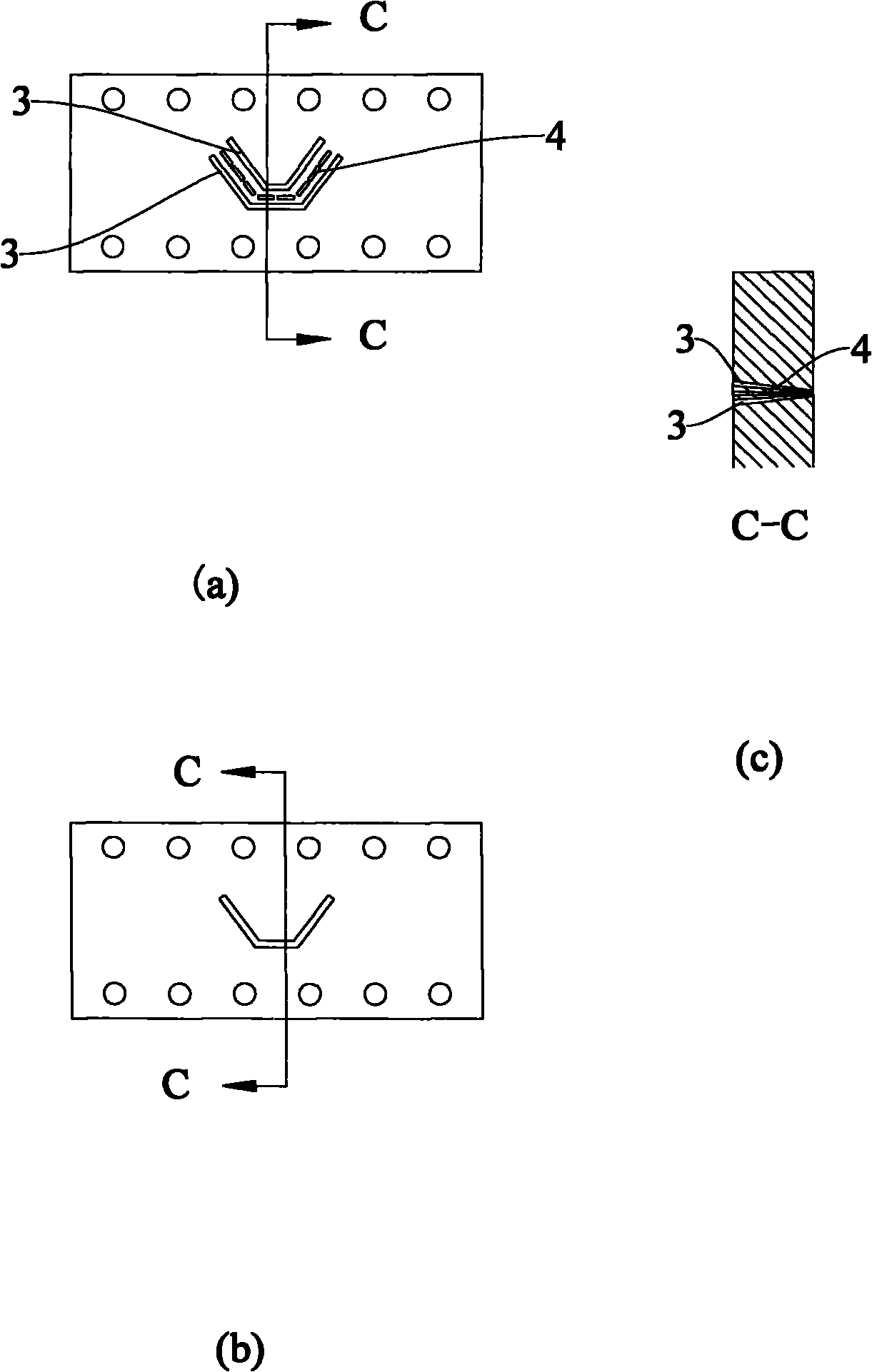

InactiveCN105436674AImprove the force characteristicsImprove welding qualityArc welding apparatusMetal working apparatusFillet weldStructural engineering

The invention relates to a full penetration welding process. On the condition that the angle of an assembly bevel is 47 degrees, deep penetration welding backing welding is carried out at the downhand position through an arc-gathering pulse deep penetration welding machine by adopting solid wires, and then cosmetic welding is carried out at the downhand position or the boat-shaped position by adopting flux-cored wires. The process has the advantages of mainly realizing full penetration welding of fillet welds of U-shaped ribs with the thickness being 8 mm and being of great significance in improving the mechanical characteristics of the fillet welds of the U-shaped ribs, improving the weld quality of the U-shaped ribs and prolonging service life of bridges. The arc-gathering pulse deep penetration welding machine is mainly adopted for the full penetration welding process, arc permeation can be obviously improved, the power of penetrating the root of the assembly bevel can be improved, and formation of the weld roots can be guaranteed.

Owner:SHANGHAI ZHENHUA HEAVY IND

Large-duty loader hydraulic valve body casting mold and manufacturing method

ActiveCN105772646ACompact and reasonable structureStrong reliabilityFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a large-duty loader hydraulic valve body casting mold. The large-duty loader hydraulic valve body casting mold comprises an upper shell mold body, a lower shell mold body, a sand core and a pouring and riser system. The sand core comprises a core head, a main core body and small core bodies. The main core body is composed of seven longitudinal arbors and four transverse arbors, and the longitudinal arbors and the transverse arbors are horizontally arranged in the same plane. The main core is provided with a plurality of convex blocks. Installation grooves are formed in the convex blocks. The small core bodies are fixed to the main core body through the installation grooves. The pouring and riser system comprises two exothermic and insulating risers with the diameter being 90 mm and the height being 120 mm. The large-duty loader hydraulic valve body casting mold has the advantages of being reasonable and compact in structure, high in reliability and convenient to assemble and cast, the straightness of a blank casted through a main valve hole is controlled to be smaller than 0.8 mm, assembly errors of a complex sand core are avoided, the casting defects of shrinkage cavities, shrinkage porosity, internal pores and the like of a casting piece are overcome, and the compactness of the internal structure is improved, so that leakage is avoided under a high-pressure working condition with the rated pressure being larger than or equal to 35 Mpa; and the casting qualified rate is improved greatly, and the casting cost is reduced.

Owner:NANTONG ENMAI PRECISION MACHINERY SCI & TECH CO LTD

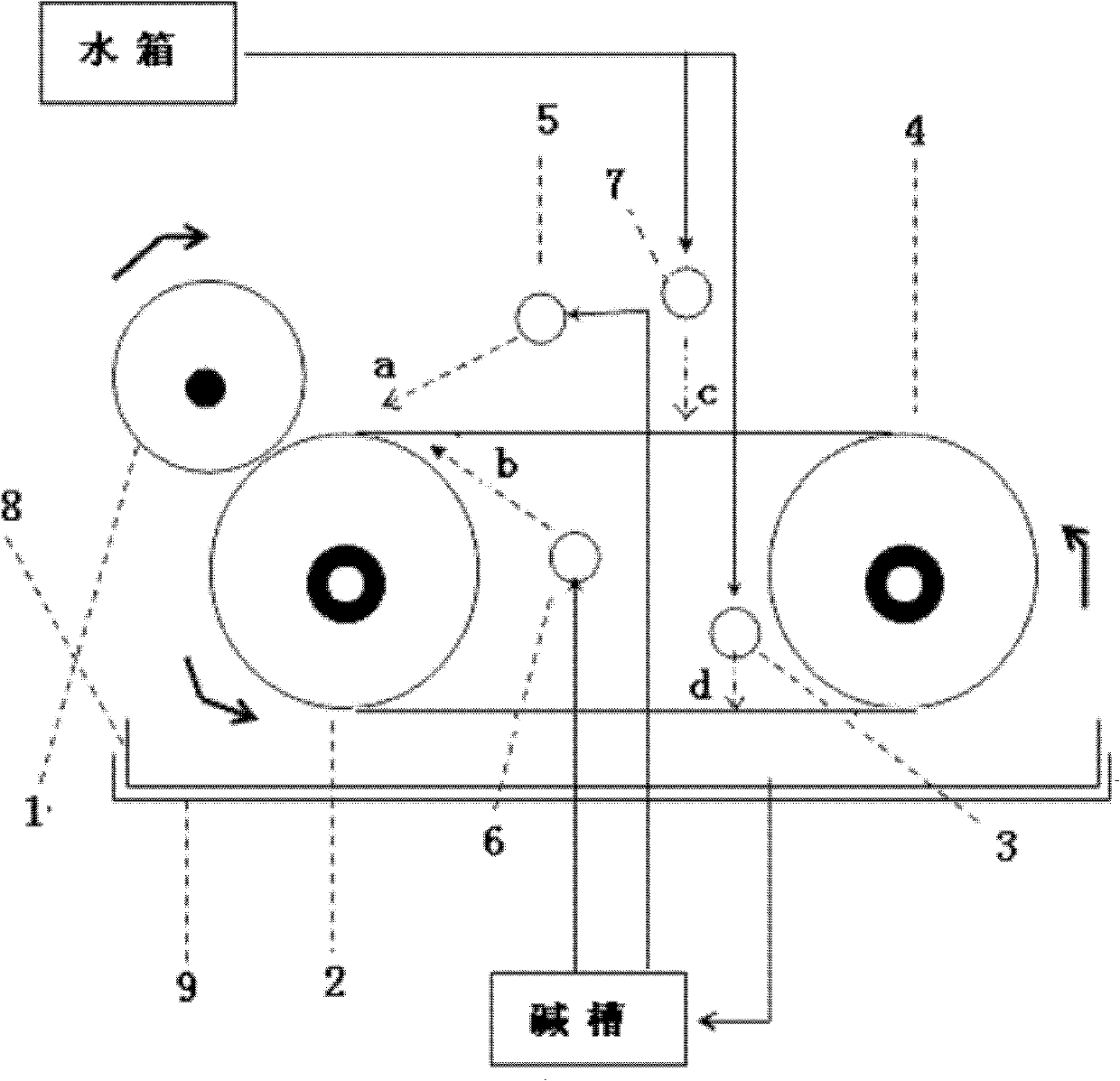

Cotton sliver mercerizing process and mercerizing device utilizing same

InactiveCN102704225AImprove spinning efficiencyHigh glossMercerising of yarns/threads/filamentsMercerising of sliversComposite materialPolymer chemistry

Disclosed are a cotton sliver mercerizing process and a mercerizing device utilizing the same, which belong to the technical field of textile technology. The cotton sliver mercerizing process includes: a, cotton sliver pretreatment step including dewing cotton slivers and dewatering the same or squeezing water out of the same to form wet cotton slivers with certain liquid content; b, a cotton sliver reeling step including reeling the wet cotton slivers on a reeling machine and fixing the cotton slivers by lay bands; c, a covering step including wrapping the reeled cotton slivers with the wrapping cloth integrally; and d, a mercerizing step realized by concentrated spraying and instant squeezing. The sliver cottons are mercerized effectively by dewing to reinforce and by means of concentrated spraying and instant squeezing, and alkali content of the cotton slivers is controlled all the time, so that the cotton slivers cannot be dissolved due to excessive swelling, and the difficult problem of failure in mercerizing the cotton slivers without twist is solved. In addition, the mercerized cotton slivers are bright, smooth and fluffy, and dye color yield is increased by 20%-30%.

Owner:WUXI NON SIZING TECH

Fresh potato biscuit

InactiveCN103070216AGreat tasteGuaranteed moldingDough treatmentBakery productsGlucose syrupMouthfeel

The invention relates to a potato food, in particular to a fresh potato biscuit. The fresh potato biscuit comprises the following components of raw materials in parts by weight: 35 to 37 parts of flour, 10 to 12 parts of sugar, 30 to 32 parts of mashed potato, 7 to 9 parts of palm oil, 1 to 3 parts of glucose syrup, 4 to 6 parts of starch, 2 to 4 parts of water, 1 to 3 parts of milk powder and 0.83 to 1.29 parts of auxiliary materials. The fresh potato biscuit prepared from the mashed potato has the beneficial effects that no raw material is wasted, the requirements on the quality and the type of potatoes are not high, the current potatoes in China can meet the requirements on the selection of the raw material, the biscuit contributes to the deep processing on the potatoes in China, the biscuit has good mouthfeel, and the requirement of people on changing the taste of the potatoes is met.

Owner:NINGXIA GUOSHENG FOOD

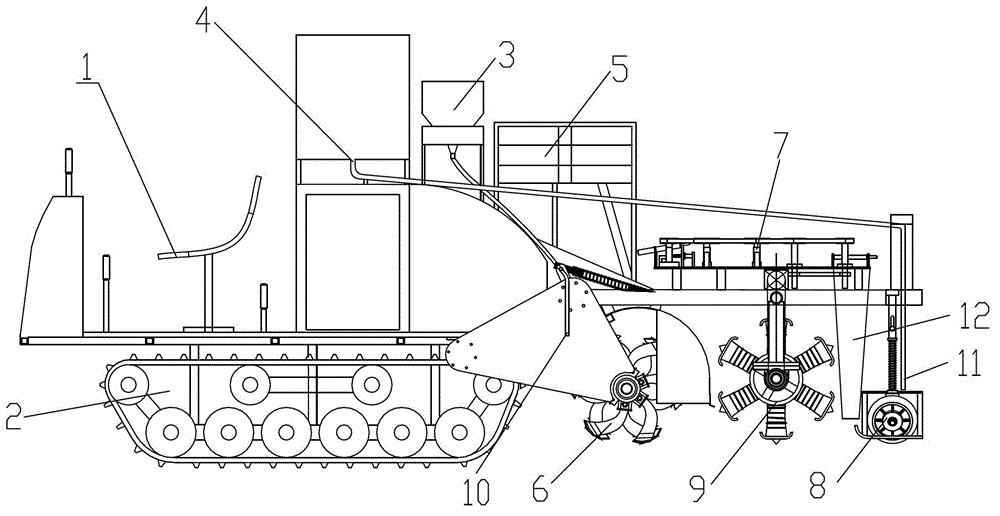

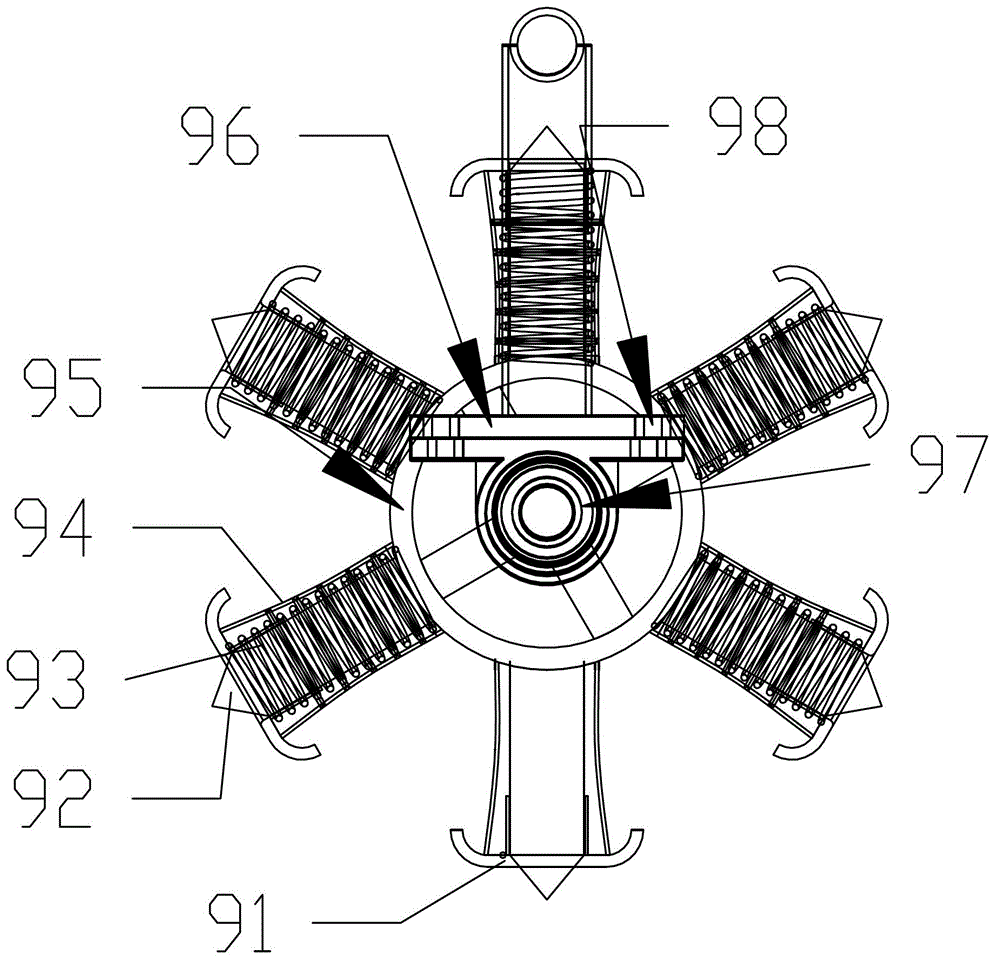

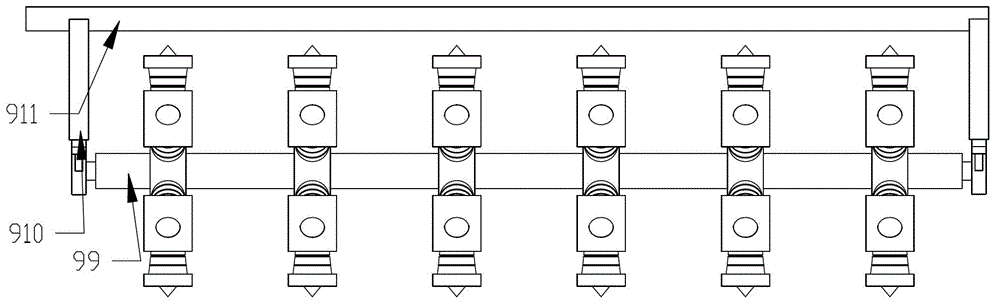

Multifunctional rape transplanter

ActiveCN103141195AGuaranteed growth qualityLabor savingTransplantingFurrow making/coveringVehicle frameAgricultural engineering

The invention discloses a multifunctional rape transplanter. The multifunctional rape transplanter comprises a vehicle frame and a trailer frame, wherein the trailer frame is mounted at the rear side of the vehicle frame, an operating system, a traveling system, a fertilizing system, a watering system, a pot seedling tray rack and a box moving system are mounted on the vehicle frame, a rotary-tillage furrowing system, a hole digging system, a seedling pulling, conveying and falling device and a soil covering and compacting system are mounted on the trailer frame, the rotary-tillage furrowing system, the hole digging system and the soil covering and compacting system are sequentially mounted from front to back, a seedling guide cup of the seedling pulling, conveying and falling device is arranged between the hole digging system and the soil covering and compacting system, the fertilizing port of the fertilizing system is arranged at the front side of the rotary-tillage furrowing system, the water outlet of the watering system is arranged at the rear side of the soil covering and compacting system, and the pot seedling tray rack is connected with the pot seedling outlet of the box moving system and the entrance of the seedling pulling, conveying and falling device. The multifunctional rape transplanter is simple in structure, convenient in use, simple to process and manufacture and good in economical efficiency.

Owner:HUNAN AGRICULTURAL UNIV

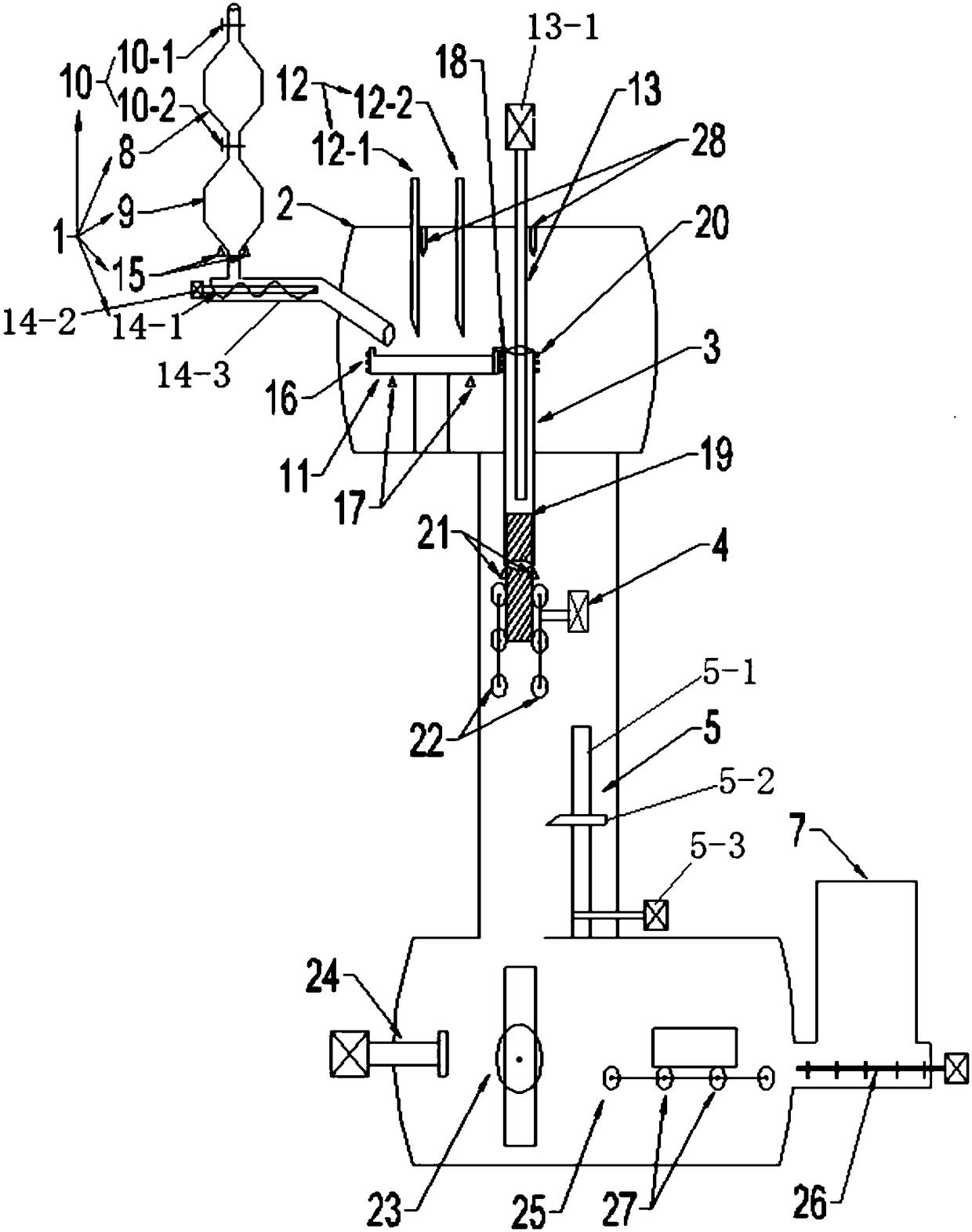

Titanium and titanium alloy short-process preparation device and method

ActiveCN108546831AEasy to control speedOptimal Placement Jam ControlIncreasing energy efficiencyLiquid metalHearth

The invention belongs to the field of titanium alloy preparation devices, and discloses a titanium and titanium alloy short-process preparation device and method. The titanium and titanium alloy short-process preparation device specifically comprises a feeding mechanism, a smelting chamber, a crystallizing mechanism, a roller wheel conveying mechanism, a cutoff mechanism, an automatic turnover device, an automatic push mechanism and a horizontal conveying track. The feeding mechanism continuously conveys raw materials to a water-cooling copper hearth in the smelting chamber, the raw materialsare smelted through plasma guns to form liquid metal, the liquid metal overflows to the crystallizing mechanism to conduct forming of pipes or bars, then the pipes or the bars are conveyed by the roller wheel conveying mechanism and cut by the cutoff mechanism to form pipes or bars with the set value lengths, and the pipes or the bars with the fixed lengths fall into the automatic turnover device,are overturned and then are pushed out by the automatic push mechanism to the horizontal conveying track so as to be conveyed out. According to the titanium and titanium alloy short-process preparation device and method, the raw material continuity design is adopted, the preparation technological process is shortened, and therefore rapid forming of the bars or the pipes with different specifications from titanium sponges is achieved, and the preparation technology is continuous.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

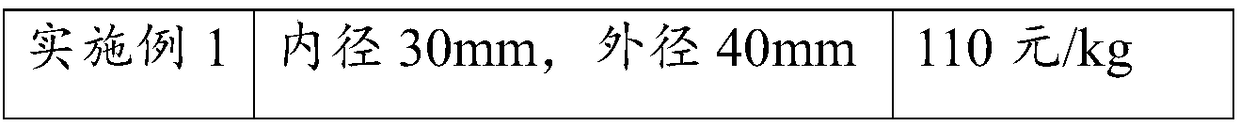

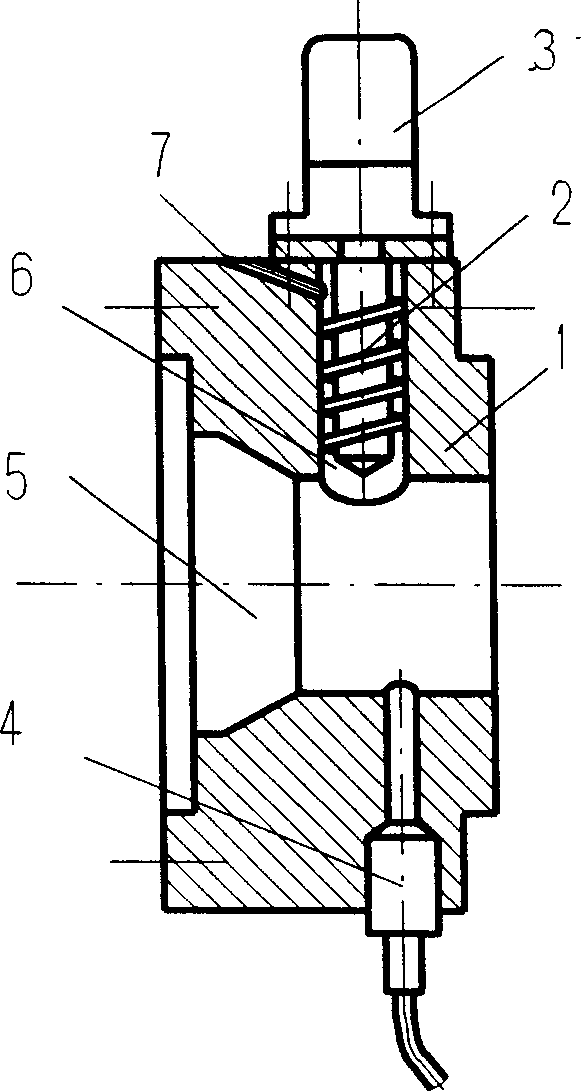

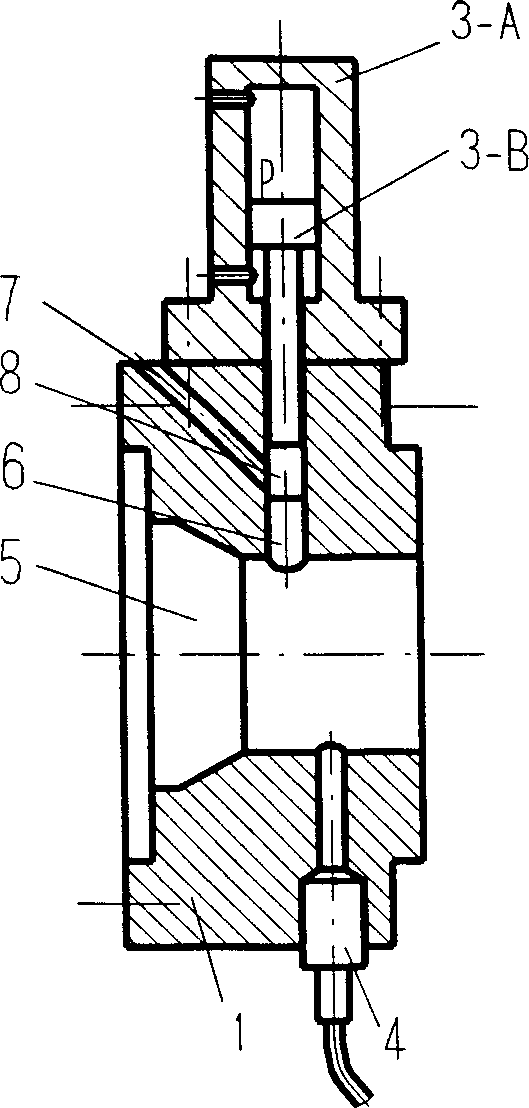

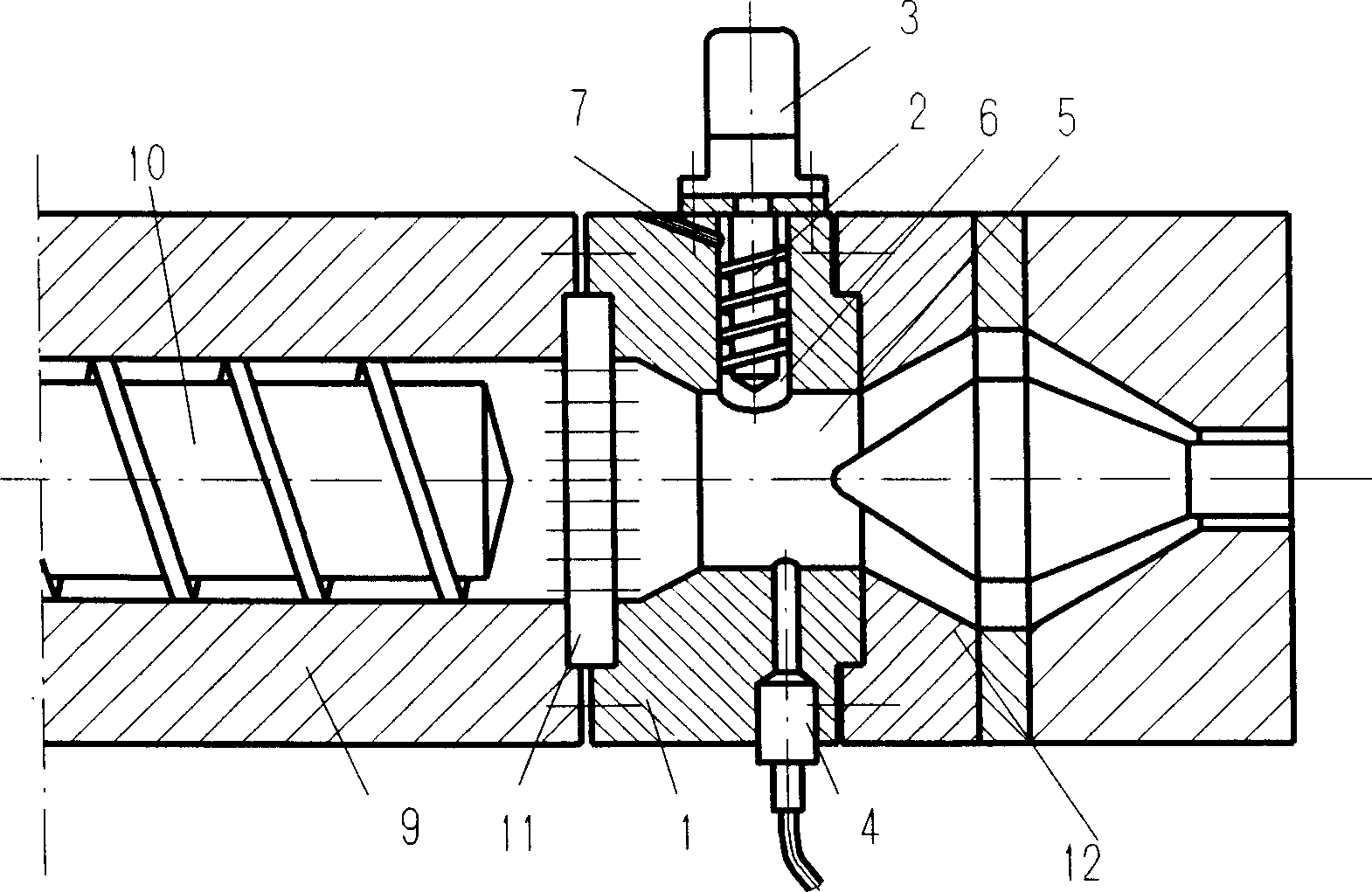

Screw extrusion melt pressure stabilizing device and method

A pressure stabilizer for the molten material extruded out by screw extruder is characterized by that a connecting body with pressure stabilizing hole on its side wall is arranged between the cylinder and head piece of extruder, and a pressure stabilizing part driven by its driver moves in said pressure stabilizing hole to apply or release the pressure to or from the extruded material which flows through the central channel of said connecting body. Its method includes sensing the pressure value of the extruded material, comparing it with its setting, and controlling the movement of said pressure stabilizing part.

Owner:BEIJING UNIV OF CHEM TECH

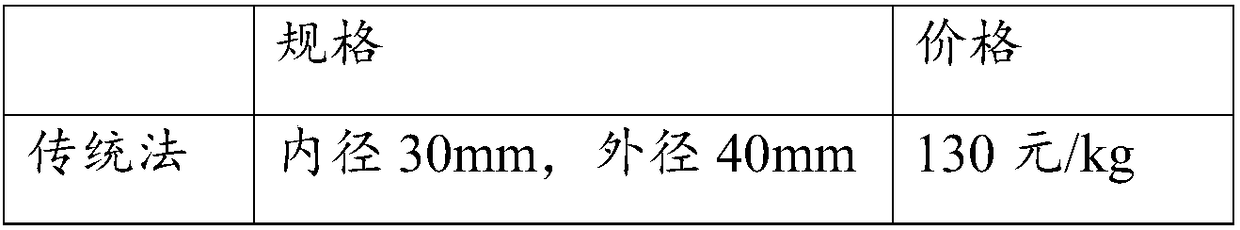

Preparing method for molybdenum and molybdenum alloy pipe

ActiveCN105964721AImprove hot working plasticityUniform wall thicknessRoll mill control devicesMetal rolling arrangementsAlloyPipe

The invention belongs to the technical field of powder metallurgy machining, and particularly relates to a preparing method for a molybdenum and molybdenum alloy pipe. The technology steps of molybdenum and molybdenum alloy pipe blank preparing, molybdenum pipe hot rolling, molybdenum pipe warm rolling and surface treatment and control over the technology conditions are adopted, and the super-long and thin-wall seamless molybdenum and molybdenum alloy pipe is prepared. Due to the comprehensive effects of hot rolling and warm rolling, the molybdenum and molybdenum alloy pipe prepared through the method achieves the beneficial effects that the molybdenum pipe is super long, thin in wall and seamless, the yield is high, and the comprehensive utilization rate of materials is high. The large deformation rate is achieved when molybdenum and a molybdenum alloy are used for preparing the pipe, an inner structure of the molybdenum pipe is refined and homogenized, and the mechanical performance is excellent; and an existing molybdenum pipe preparing technology is simplified, the materials are saved, and implementation is easy.

Owner:JINDUICHENG MOLYBDENUM CO LTD +1

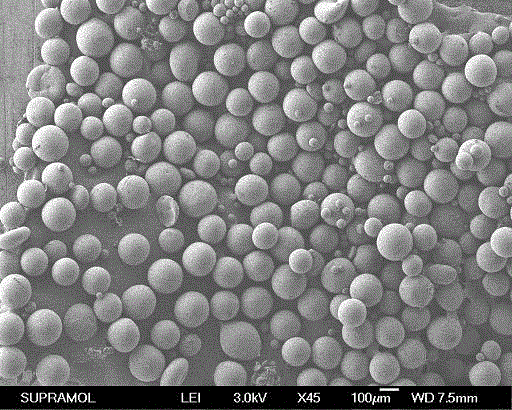

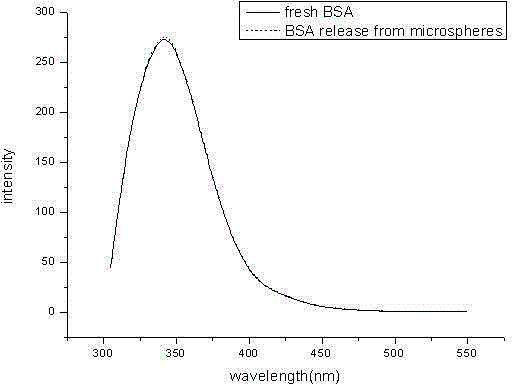

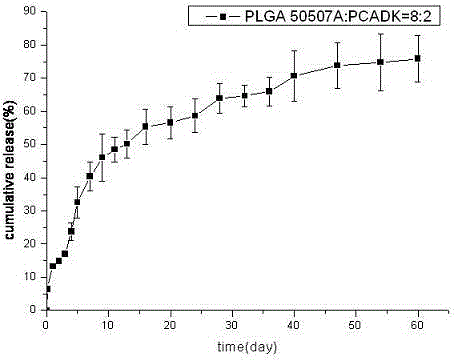

Preparation method of protein drug long-acting preparation using polyketal as matrix

InactiveCN103977410AFacilitated releaseImprove bioavailabilityPeptide/protein ingredientsPharmaceutical non-active ingredientsMicrosphereProtein activity

The invention discloses a preparation method of a protein drug long-acting preparation using polyketal as a matrix; the polyketal as the matrix is mixed with a biodegradable polymer material to prepare the protein-drug-packaging long-acting preparation, wherein the mass ratio of polyketal to other biodegradable polymer material is 9:1-1:9, and the mass ratio is preferably 4:6-2:8; the polyketal is used as the matrix to avoid adverse effects of acidic degradation products on protein activity in the storage and release process of a common protein long-acting preparation, and the problems of incomplete release and low bioavailability of the protein drug long-acting sustained-release preparation can be solved, addition of other biodegradable polymer material provides mechanical support and ensures molding of the protein drug long-acting sustained-release preparation. The protein drug long-acting preparation is rounding and uniform in micro spherical morphology, strong in mechanical properties and more complete in release.

Owner:李又欣 +1

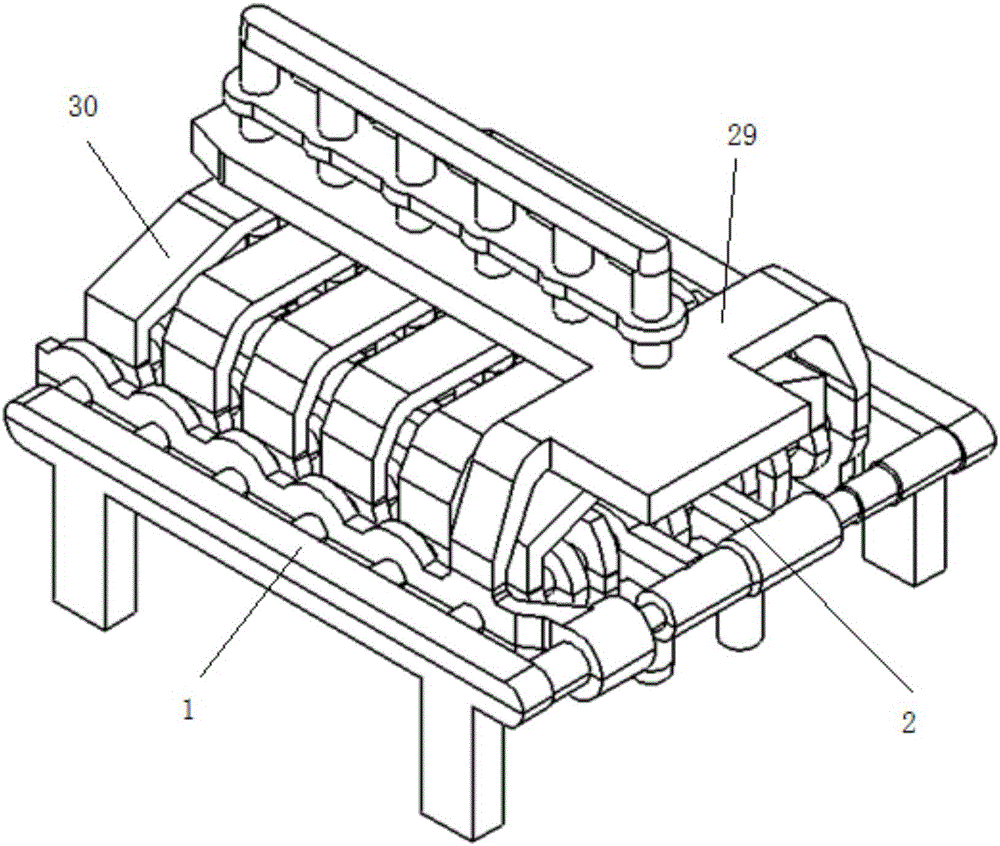

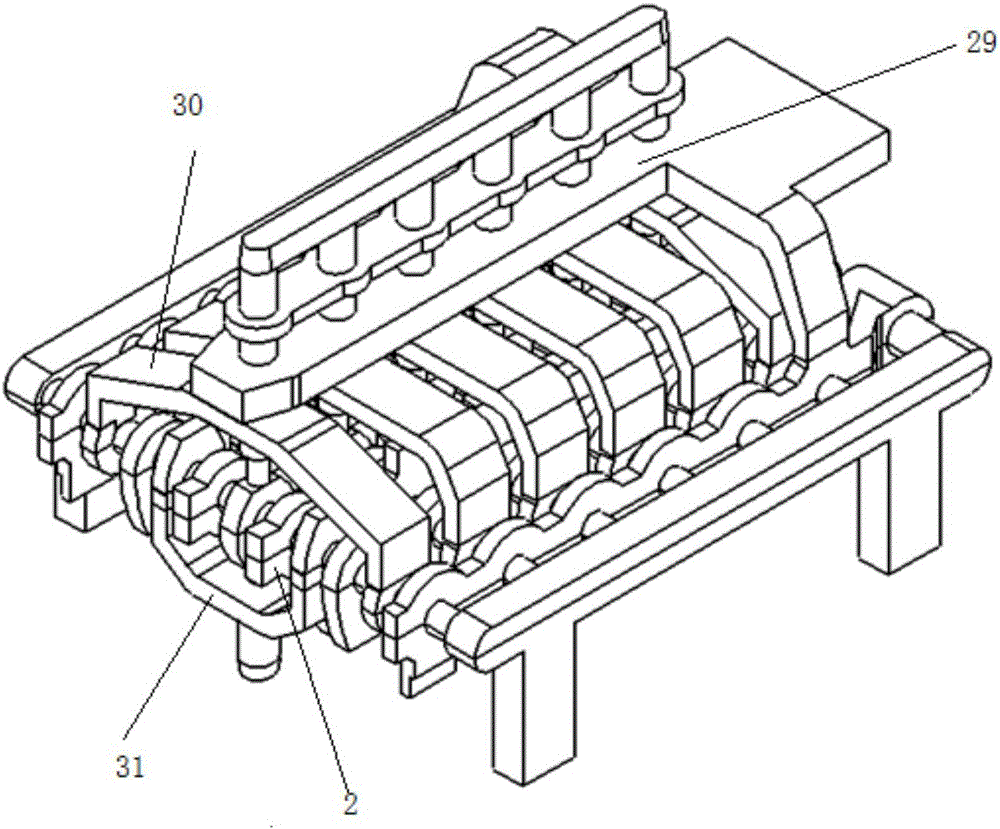

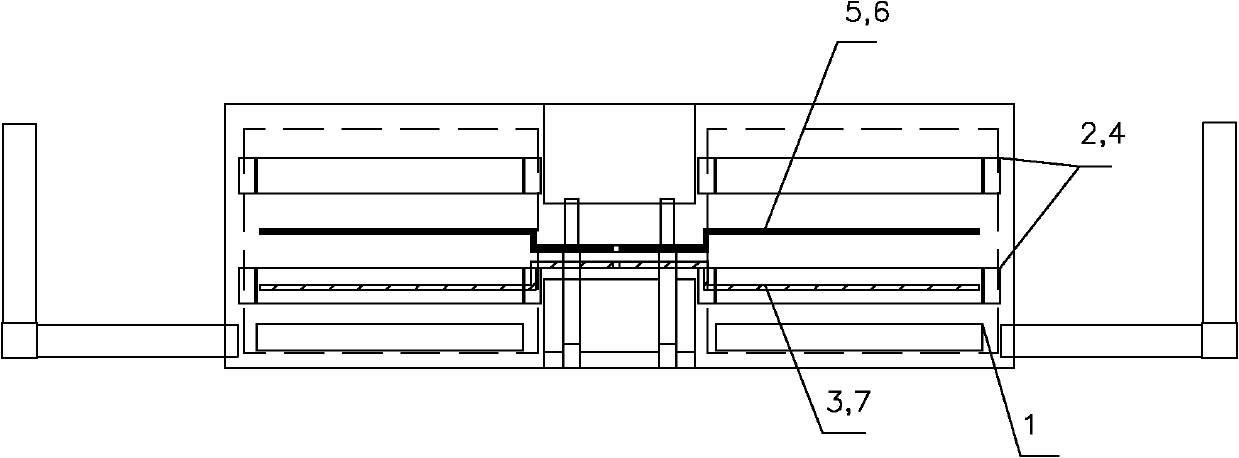

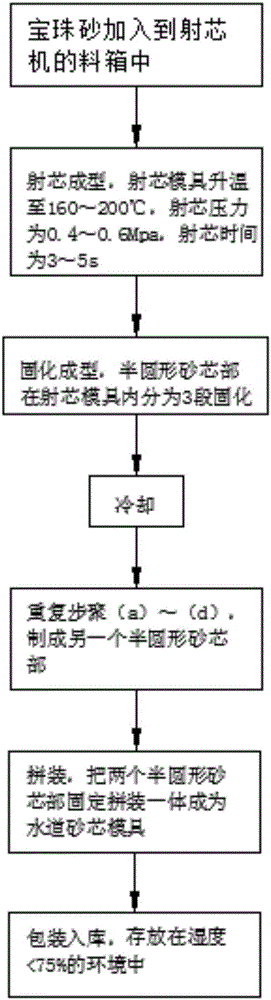

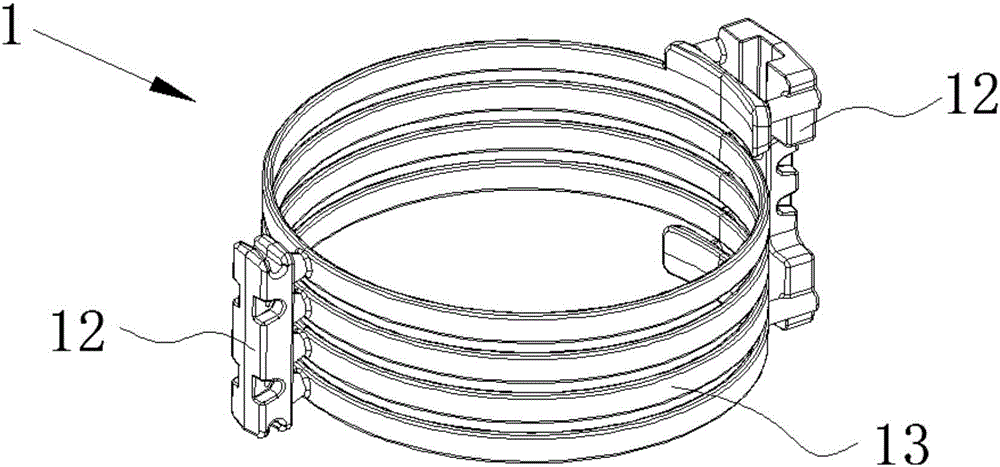

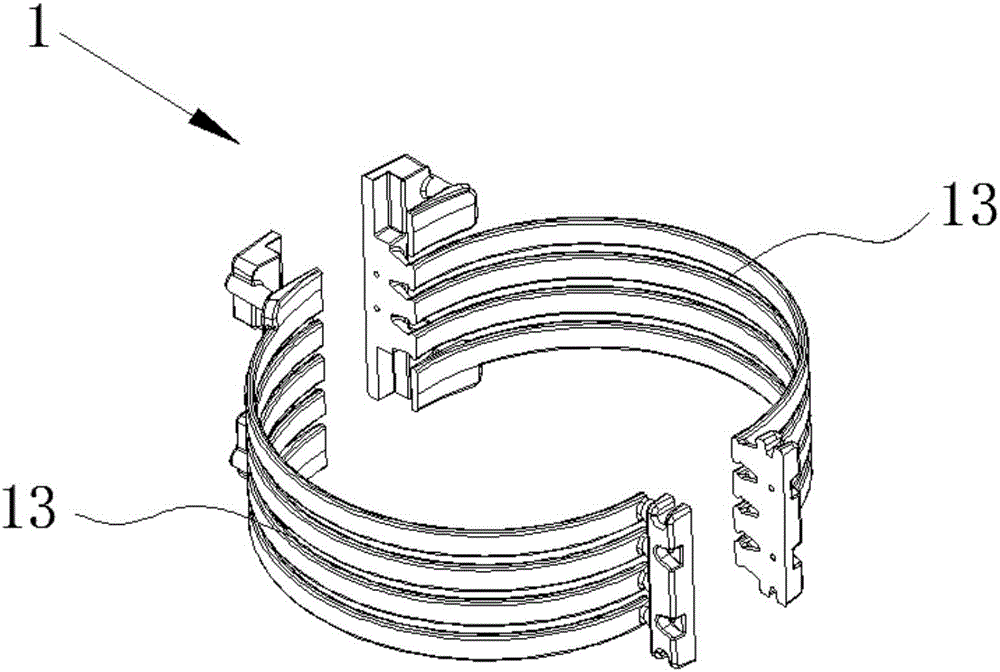

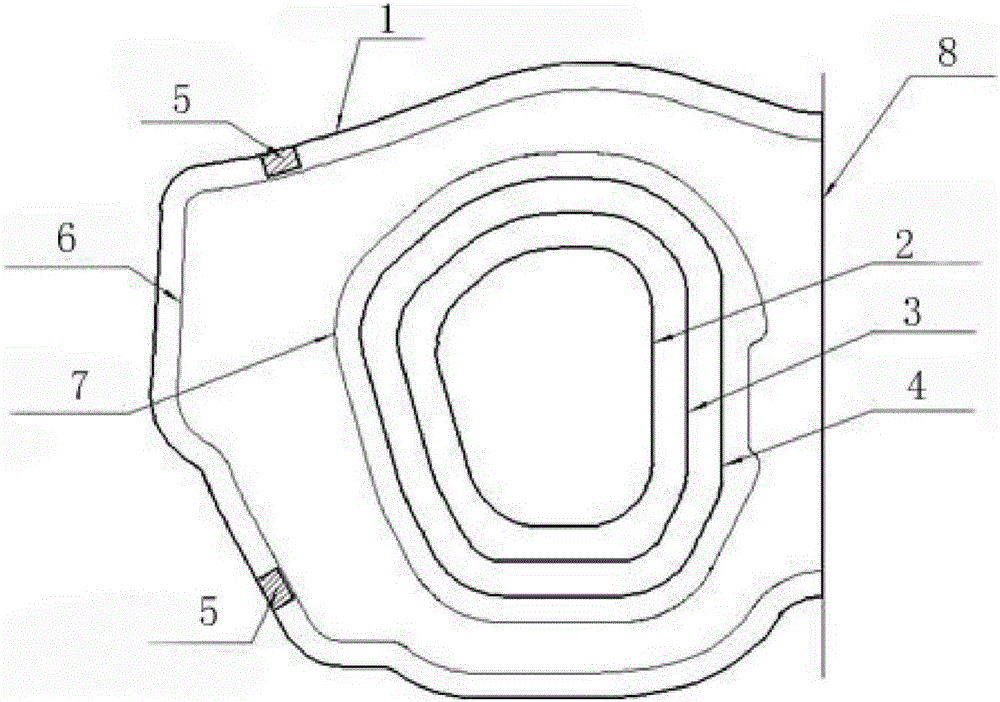

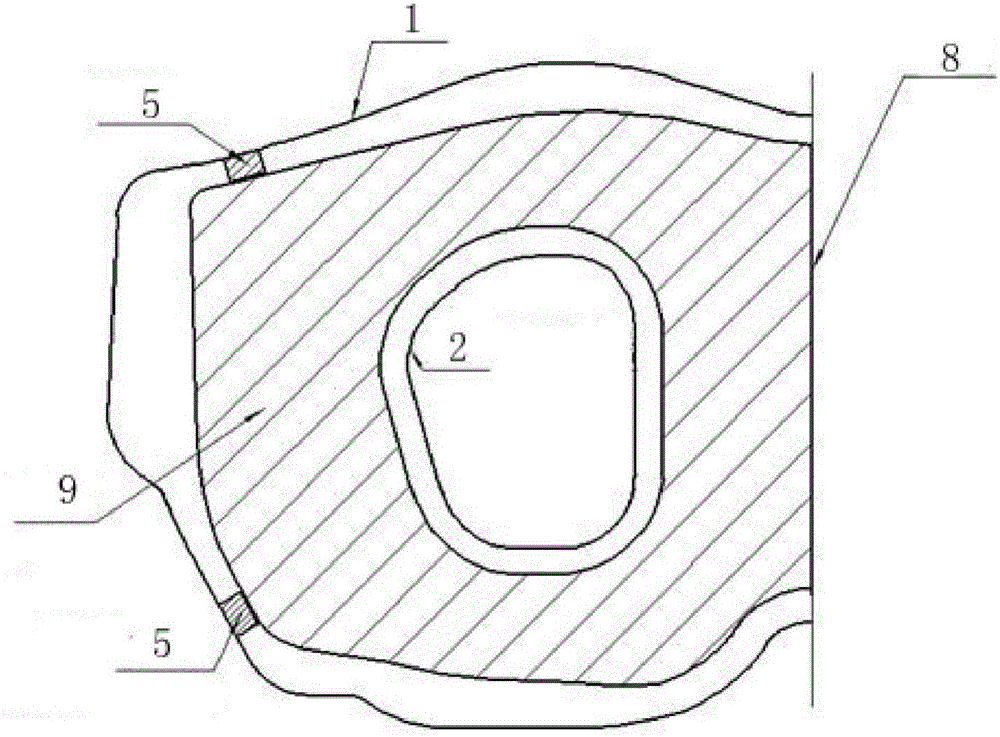

Manufacturing process and structure for sand core mold of spiral water channel of new energy water-cooled motor enclosure

ActiveCN106392014AFast curing speedLong storage timeFoundry mouldsFoundry coresNew energyWater channel

The invention relates to a manufacturing process and a structure for a sand core mold of a spiral water channel of a new energy water-cooled motor enclosure. The manufacturing process comprises the following steps of: (a) adding a raw material: adding fused ceramsite into a workbin of a core shooting machine; (b) performing core shooting forming; (c) performing curing forming, a semi-circular sand core part is cured in three sections; (d) performing cooling; (e) repeating steps (a)-(d) to manufacture another semi-circular sand core part; (f) performing splicing: fixedly splicing the two semi-circular sand core parts together to form the sand core mold of the water channel; and (g) performing packaging and being put in storage: storing the mold in an environment, the humidity of which is less than 75%. The sand core mold of the spiral water channel manufactured by the method provided by the invention has the advantages of being fast in forming and curing speed, short in consumed time, high-temperature-resistant, hard to fall apart, long in storable time, smooth in surface, dampproof and the like, the structural stability of the sand core mold of the spiral water channel is fundamentally improved, the spiral water-cooled channel of the motor enclosure can be normally formed, and actual production needs are satisfied.

Owner:惠州古川科技有限公司

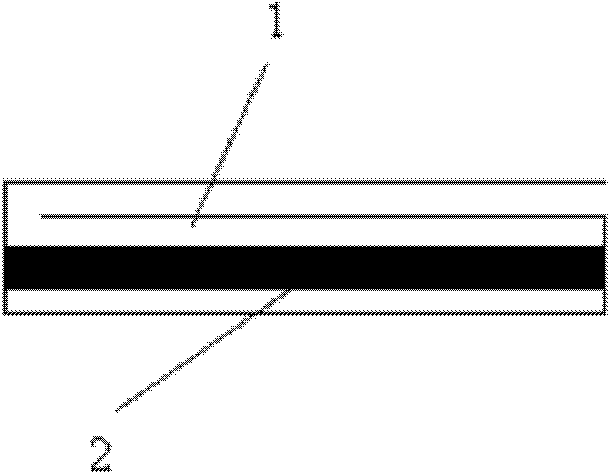

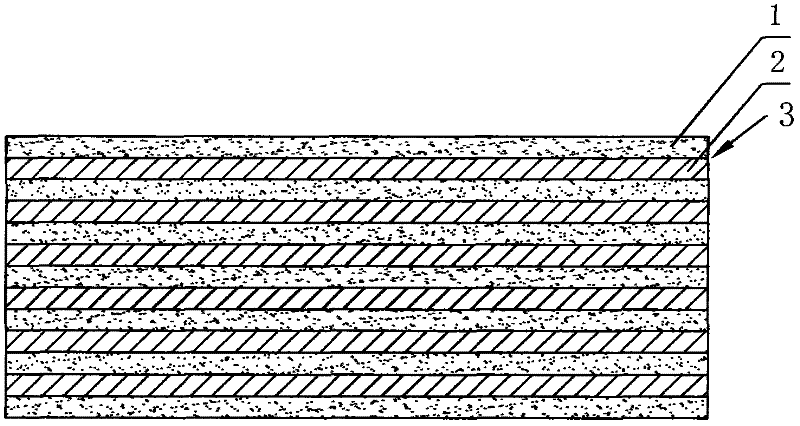

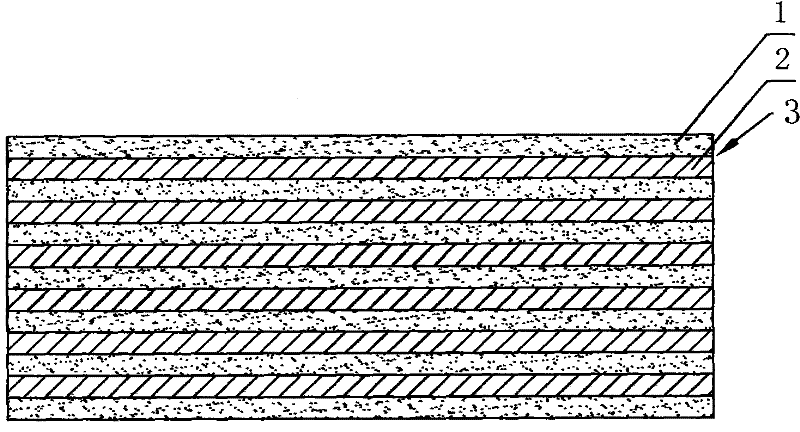

Low-temperature co-firing ceramic wave-absorbing material and preparation method thereof

ActiveCN102219523ADoes not damage the absorbing performanceImprove absorbing performanceShieldingMetallurgySlurry

The invention discloses a preparation method of a low-temperature co-firing ceramic wave-absorbing material. The method is characterized by comprising the following steps: casting ceramic slurry on a flaky wave-absorbing material by utilizing a waterfall casting process, and then filming; and laminating multiple pieces of flaky wave-absorbing materials with ceramic films and then carrying out low-temperature sintering at the temperature less than 1000 DEG C. According to the method provided by the invention, the low-temperature co-firing ceramic wave-absorbing material is prepared by using the waterfall casting process and the low-temperature sintering process, thus the method is low in cost, simple in process and suitable for industrial production. The finished product obtained finally has the advantages of good wave-absorbing property and certain high temperature resistant performance because the finished product is made of a ceramic base, thereby achieving wide application.

Owner:WEIFANG JIANA NEW MATERIALS

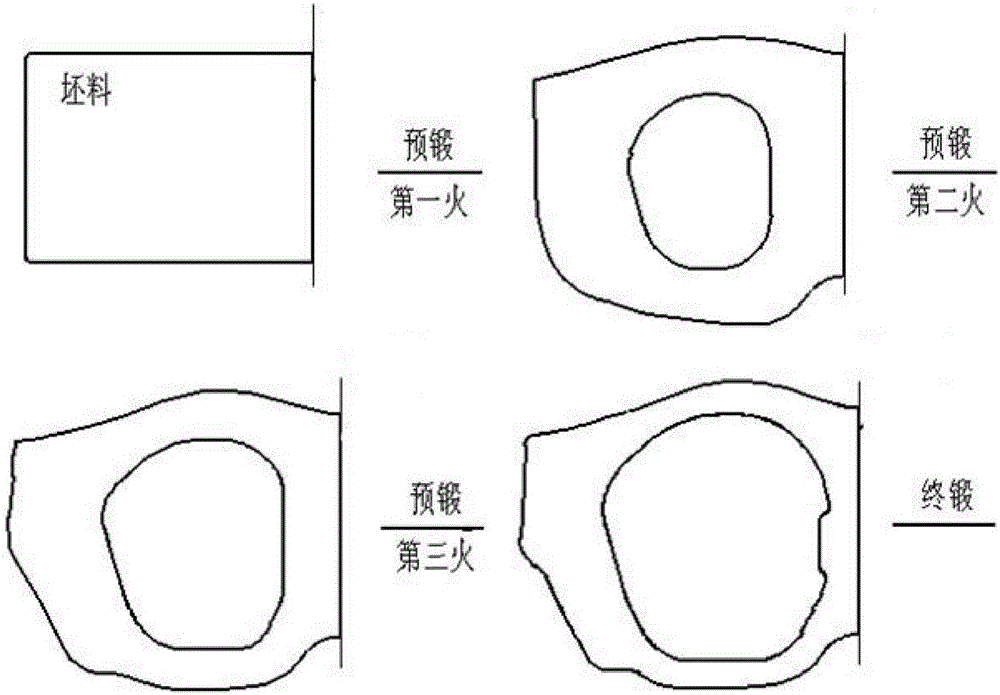

Thermal-covering process for thermal forming of super-large titanium alloy whole frame die forging

The invention relates to the field of forging of large die forgings, and discloses a thermal-covering process for thermal forging of a super-large titanium alloy whole frame die forging. The process includes the following steps of pre-heating a blank, coating the blank with a protective lubricant, heating the blank to a forging temperature and conducting heat preservation, covering the outer surface of the titanium blank with a covering material through a binder, placing the blank into an electric furnace again to be heated after thermal-covering is completed, and taking the blank out of the furnace to be forged after being heated to the forging temperature. The process is simple in operation, low in cost and capable of preventing the surface temperature of the blank from descending too fast in the transferring and producing procedures and ensuring the effect that the blank is at a high start-forging temperature during die forging; and material flowing of the forging is facilitated, the tonnage of equipment can be lowered, and the problems of poor filling and the non-uniform structure property of the forging during existing production of the super-large titanium alloy whole frame die forging can be solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

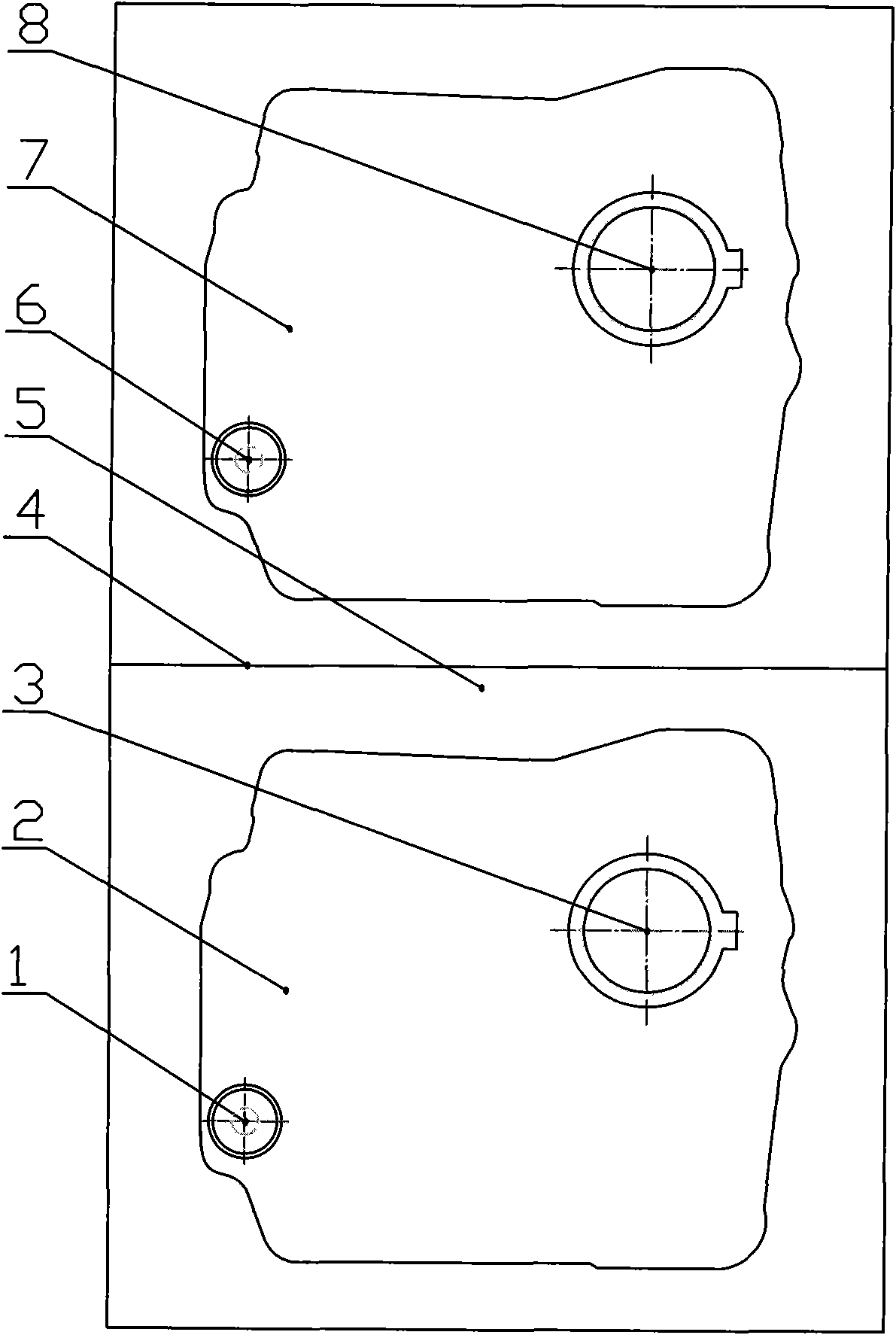

Manufacturing method of plastic fuel tank

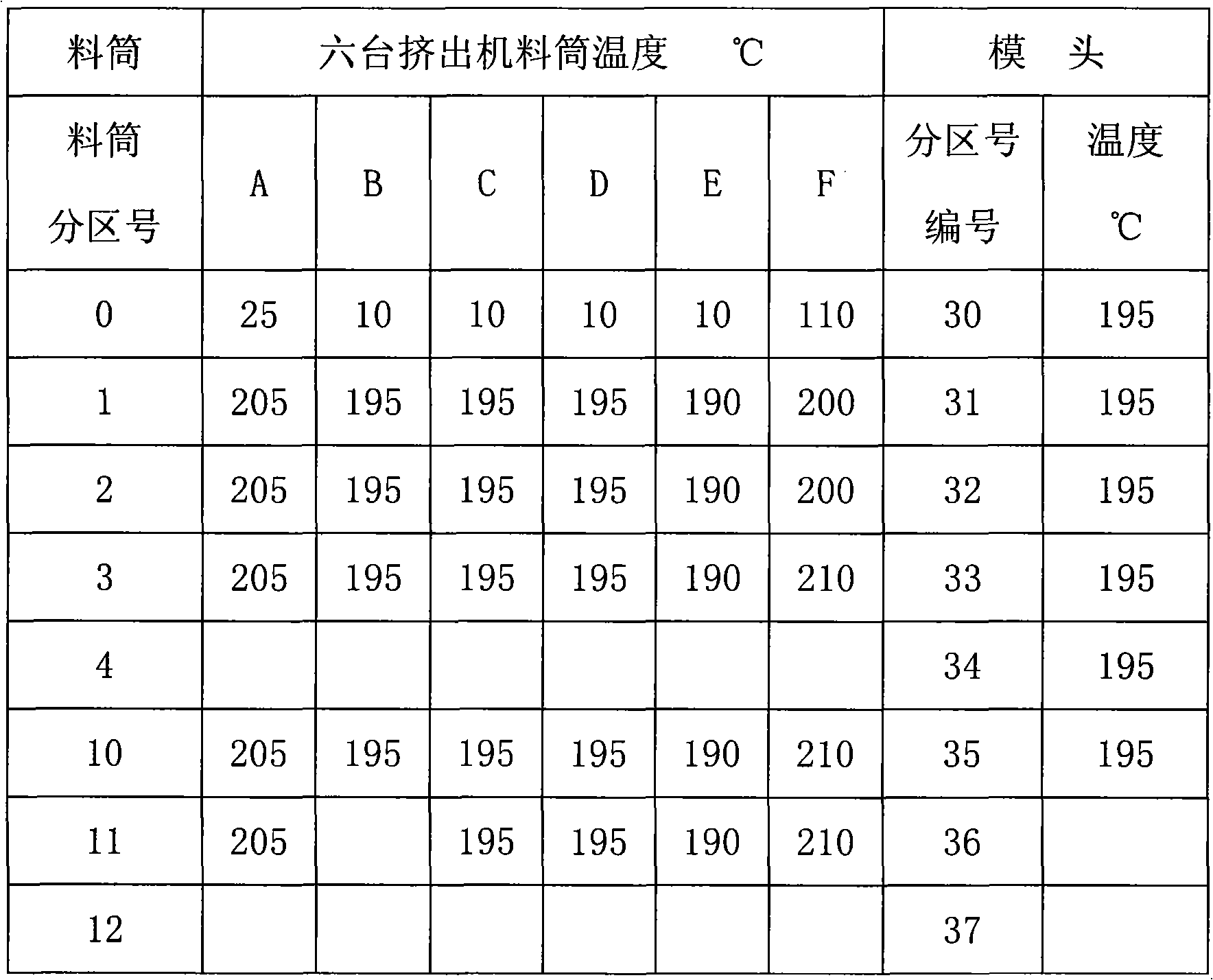

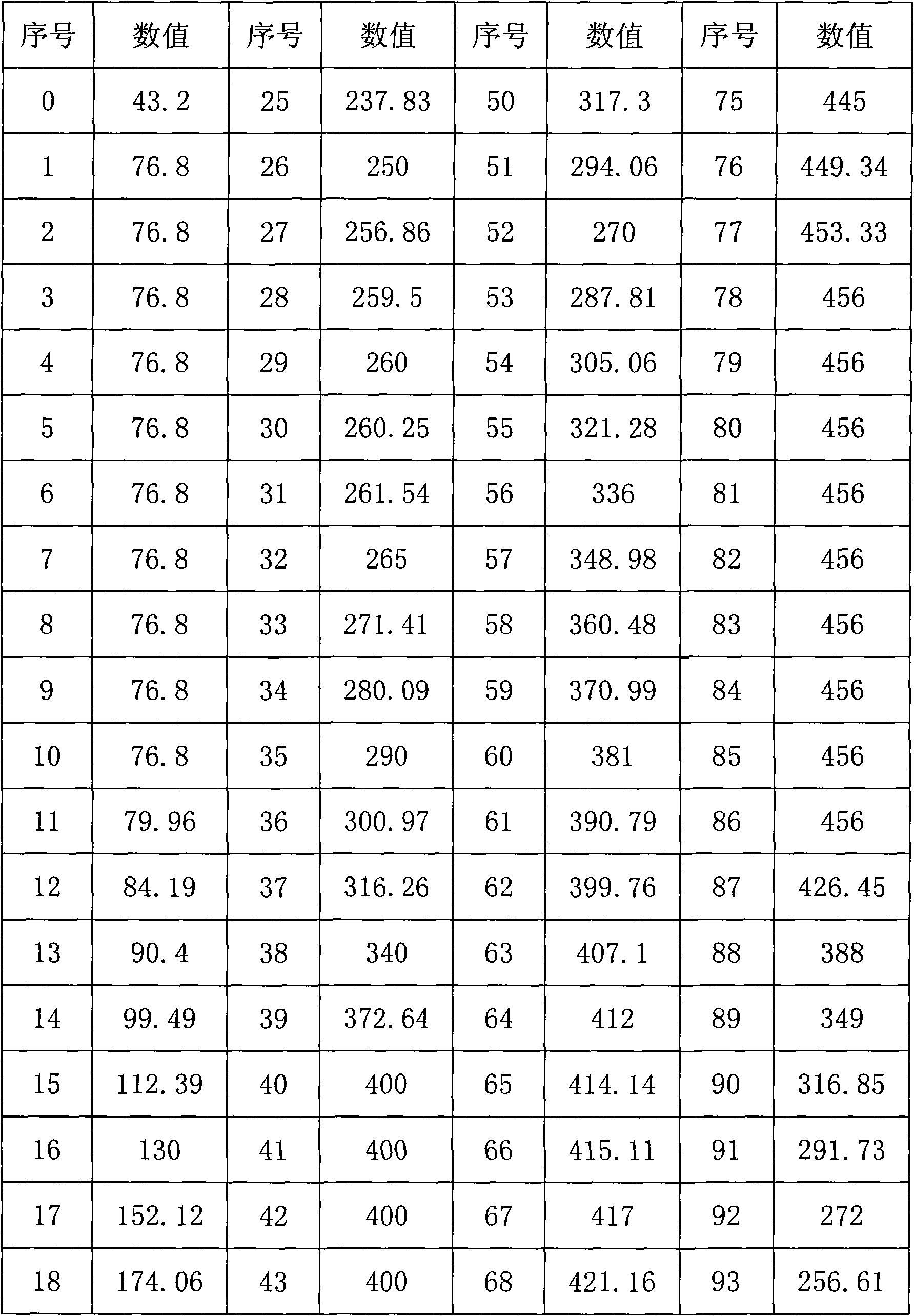

The invention discloses a manufacturing method of a plastic fuel tank, which comprises the following steps: six special extruding machines with automatic weighing control are used to pump out qualitative and quantitative melting stocks and continuously extrude out a molding blank by a coextrusion mold head, the molding blank comprises six layers from inside to outside, and the ratio of the thicknesses of the six layers which are respectively high density polyethylene, sizing, barrier material, sizing, returns and high density polyethylene is 37:1.5:2:1.5:46:12; a blowing mold is internally provided with mold cavities of two fuel tanks, each mold cavity is respectively provided with an air inlet hole and an air return hole, a material overflow area is arranged between the two mold cavities, and the middle part of the material overflow area is provided with a split line. The manufacture method adopts a single-station blow molding machine and can manufacture two fuel tanks in one mold in a blow molding way once, thereby greatly enhancing the production efficiency, reducing the occupation of production space, lowering the investment and energy-consumption of the blow molding machine and also reducing the raw material consumption of single fuel tank.

Owner:YAPP AUTOMOTIVE PARTS

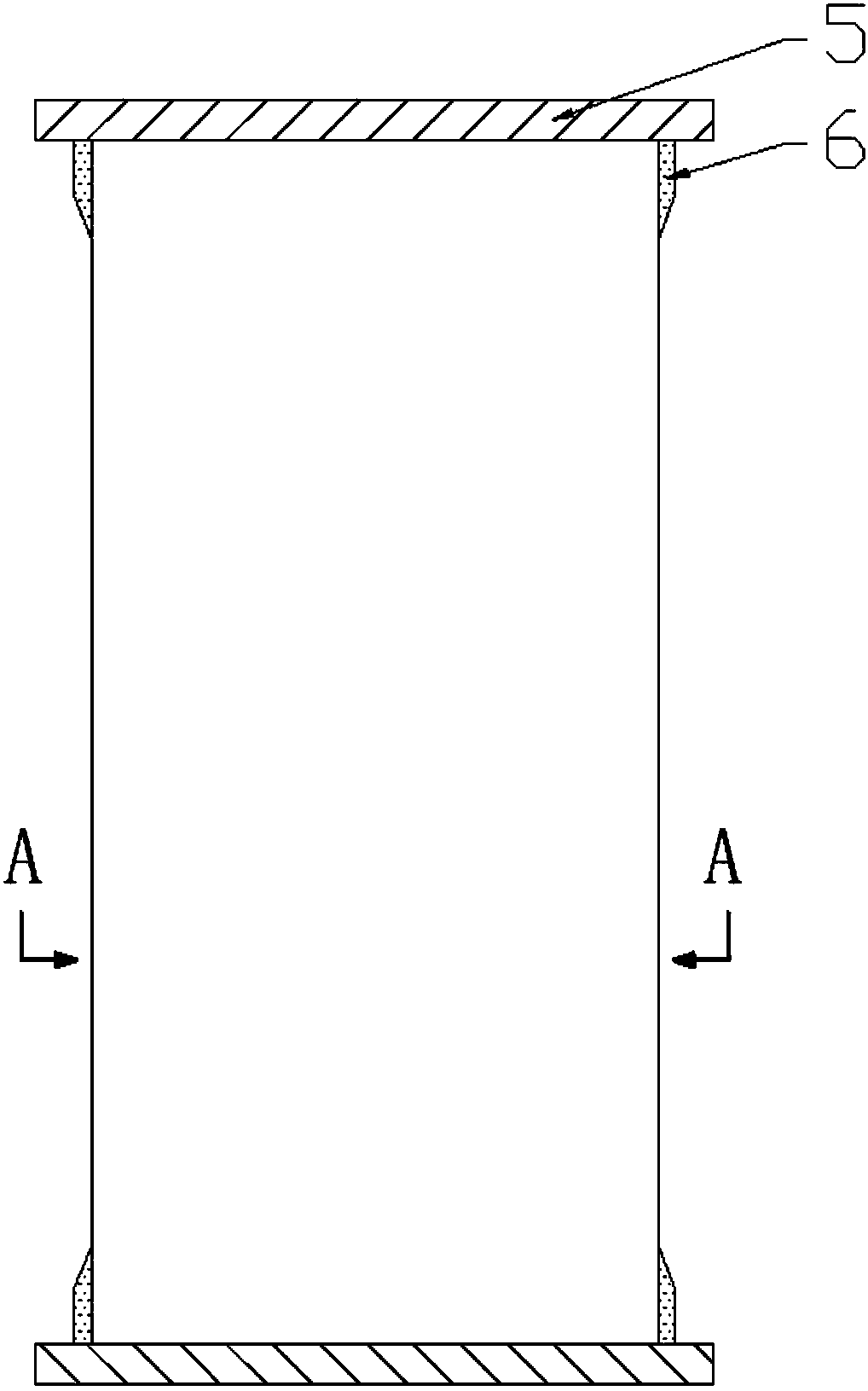

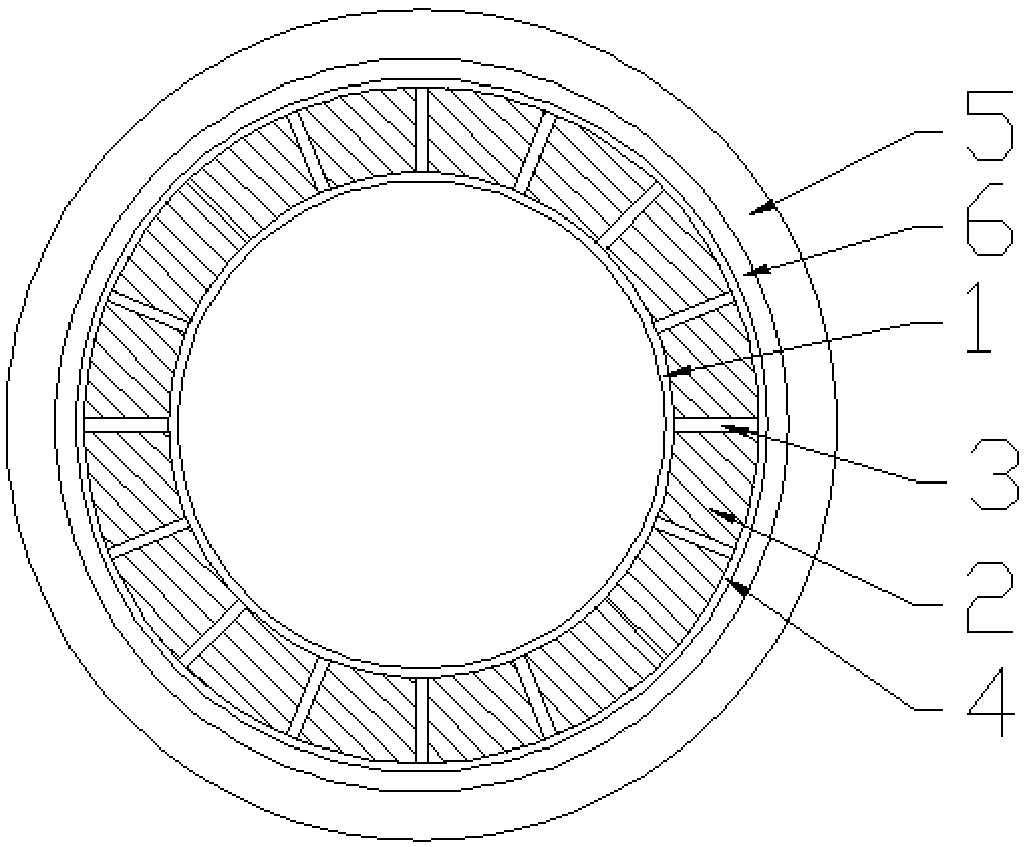

Lattice enhanced type composite material foam core sandwich supporting column and preparation method thereof

The invention discloses a lattice enhanced type composite material foam core sandwich supporting column and a preparation method thereof. A supporting column main body comprises a composite material inner skin and a composite material outer skin which are in cylindrical shapes, foam plate strips are arranged between the composite material inner skin and the composite material outer skin, compositematerial lattices are arranged between the foam plate strips, and the composite material lattices are distributed between the foam plate strips at equal intervals to connect the composite material inner skin with the composite material outer skin together. Supporting face connection flanges for being connected with a top structure or connected with another same supporting column are arranged at the two ends of the supporting column. End enhancing parts are arranged at the two ends of the outer skin of the supporting column. The lattice enhanced type composite material foam core sandwich supporting column can sharply improve the bearing efficiency under the precondition that the self weight of the structure is hardly increased, and meanwhile, the preparation method is low in cost and stable in property, and can prepare the lattice enhanced type composite material foam core sandwich supporting columns with large sizes.

Owner:ARMY ENG UNIV OF PLA

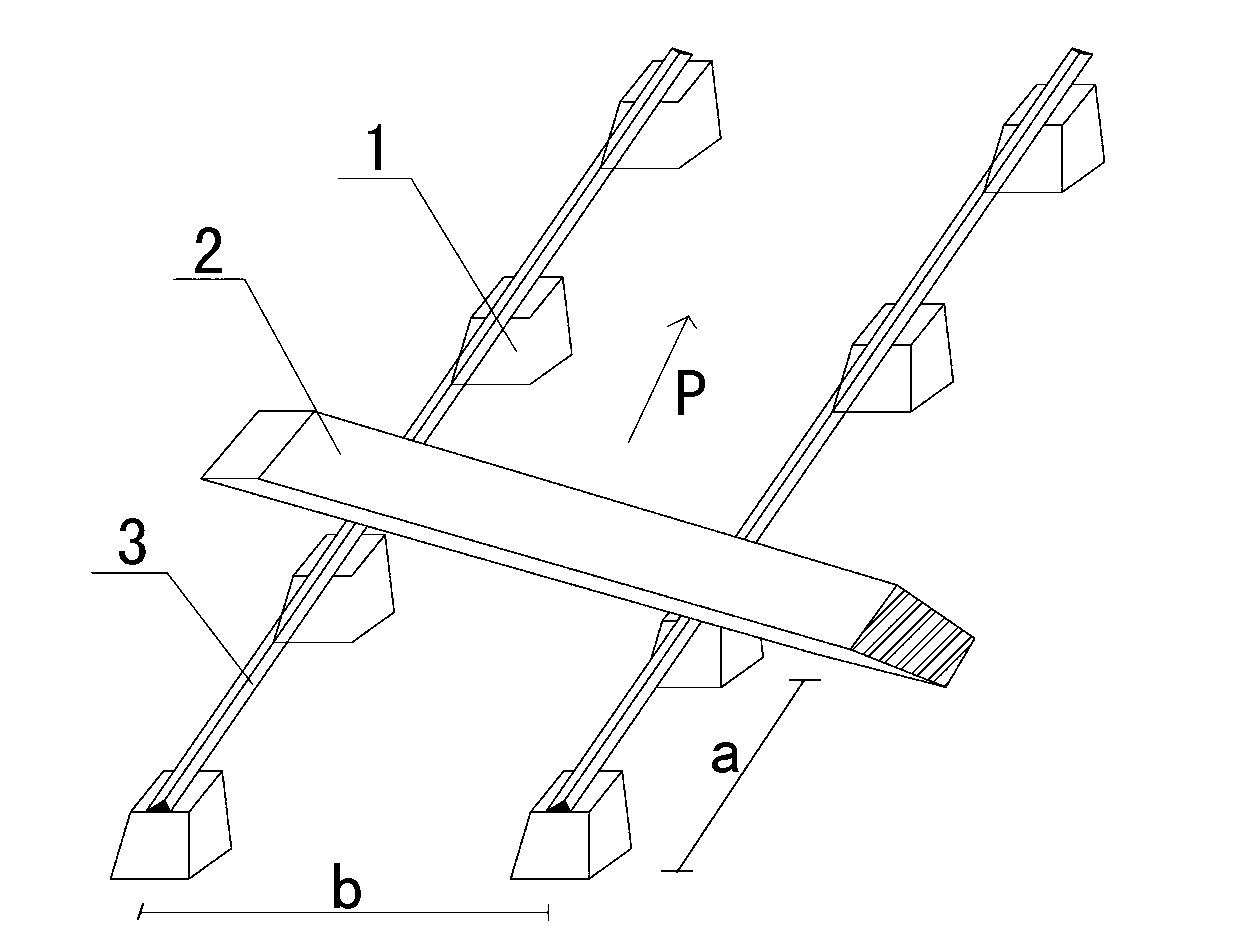

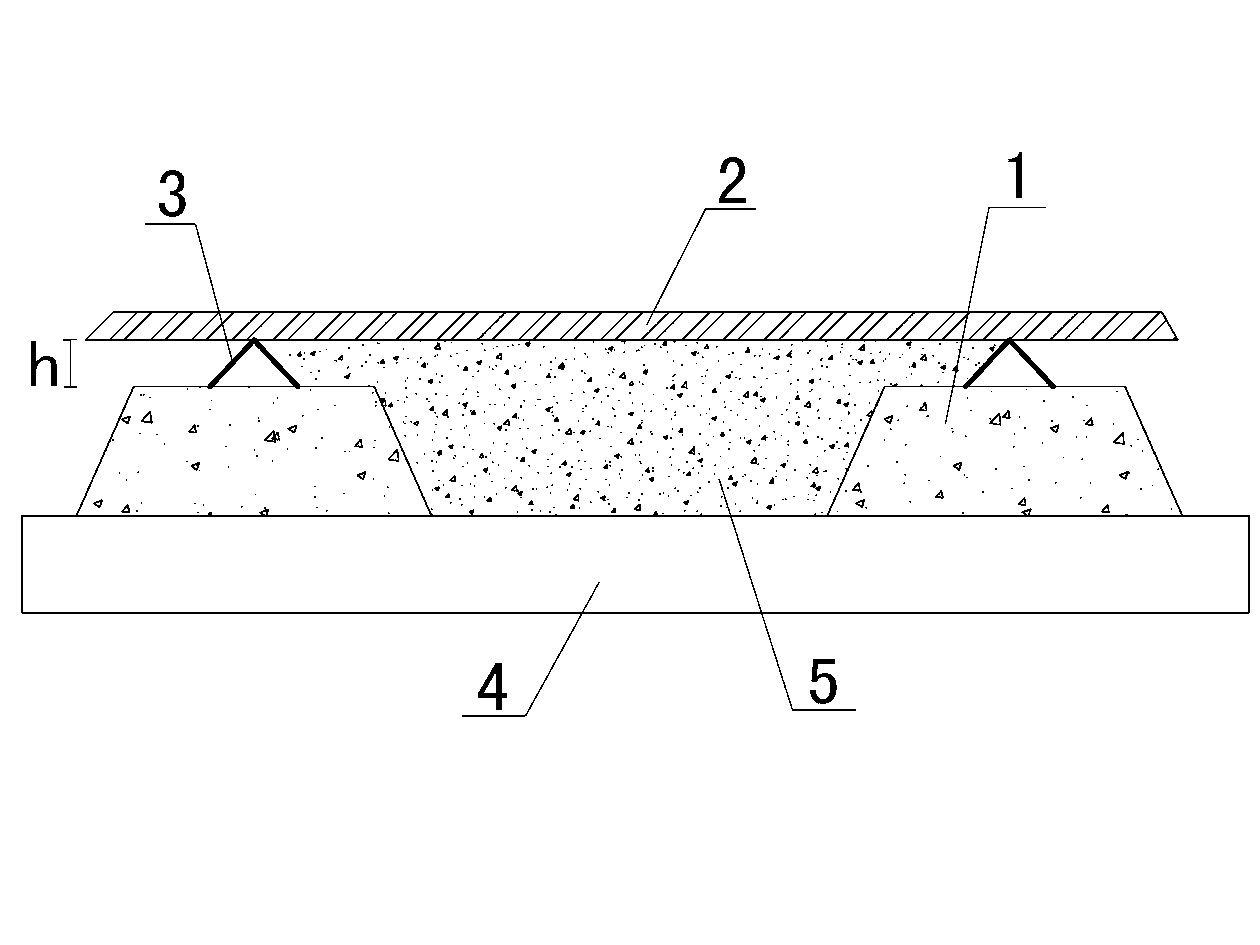

Ash smearing device and construction method in large-area ground flatness control of ash smearing device

InactiveCN103255906AGuaranteed moldingMeet construction requirementsBuilding constructionsBottom ashStructural engineering

The invention discloses an ash smearing device and a construction method in large-area ground flatness control of an ash smearing device. The ash smearing device comprises ash cakes and a scraping lever. The ash cakes are symmetrically arranged on ground base layers of the left side and the right side of the ground to be cast, and multiple ash cakes of the left side and the right side of the ground to be cast are arranged at intervals in a concrete casting direction. The ash cakes of either of the left side and the right side are provided with an angle iron guide rail, and the scraping lever is arranged between two angle steel guide rails. The construction method comprises the following steps that a level controlling line is confirmed, the ground base layer is cleaned, the ash cakes are set, the angle steel guide rails are placed, and concrete casting is performed. The ash smearing device and the construction method in large-area ground flatness control of the ash smearing device solve the technical problem that in a traditional ash smearing project, even if the flatness of the upper surfaces of the ash cakes can be ensured, when casting bottom ash is cast by exceeding the thickness of the ash cakes and the lever is scraped, the requirement for flatness of the large-area ground can still not be met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

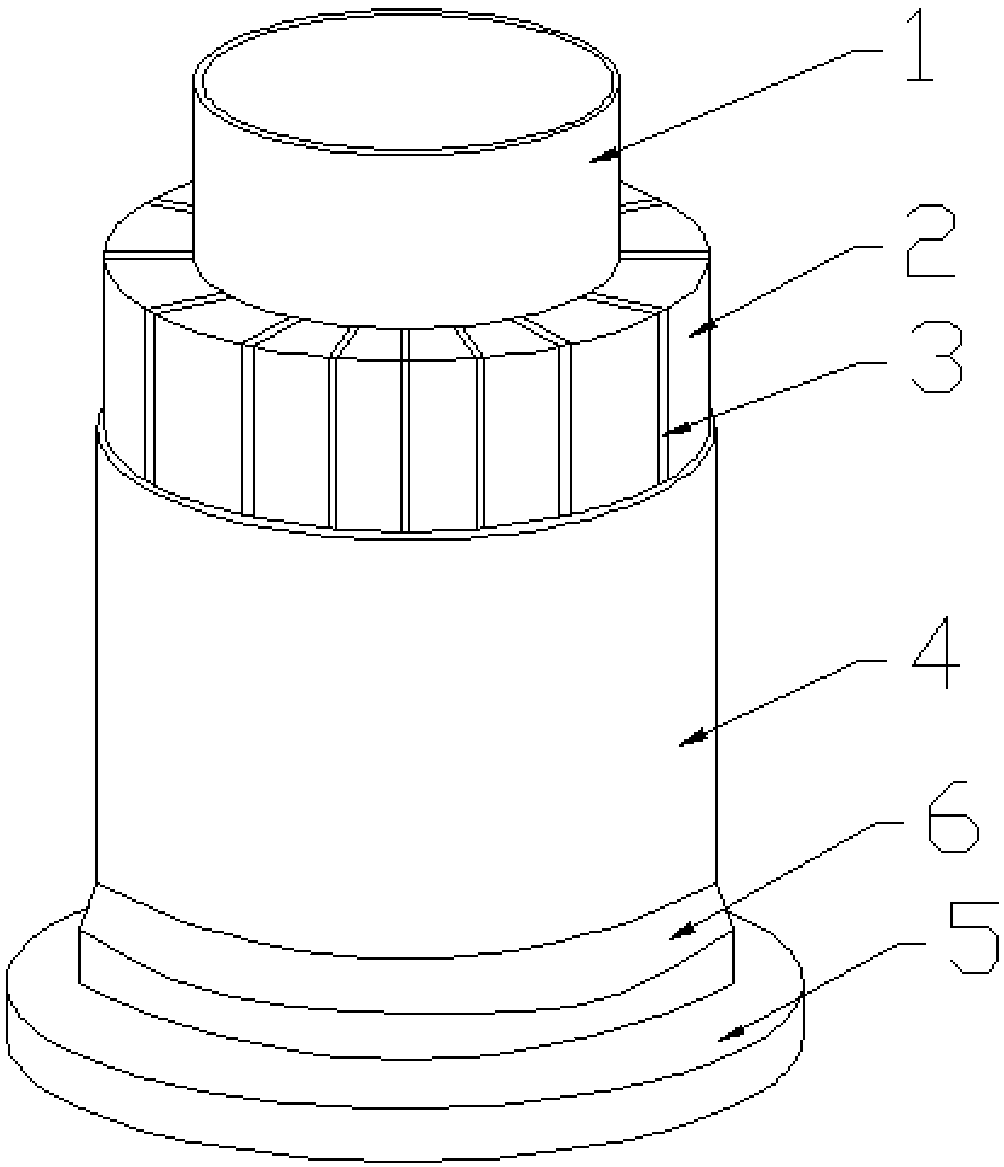

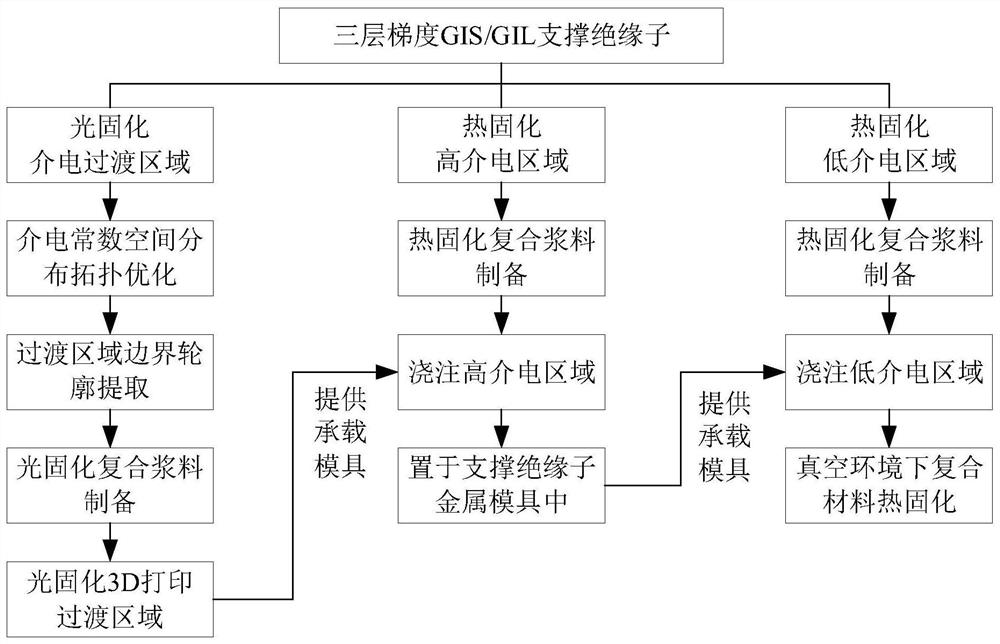

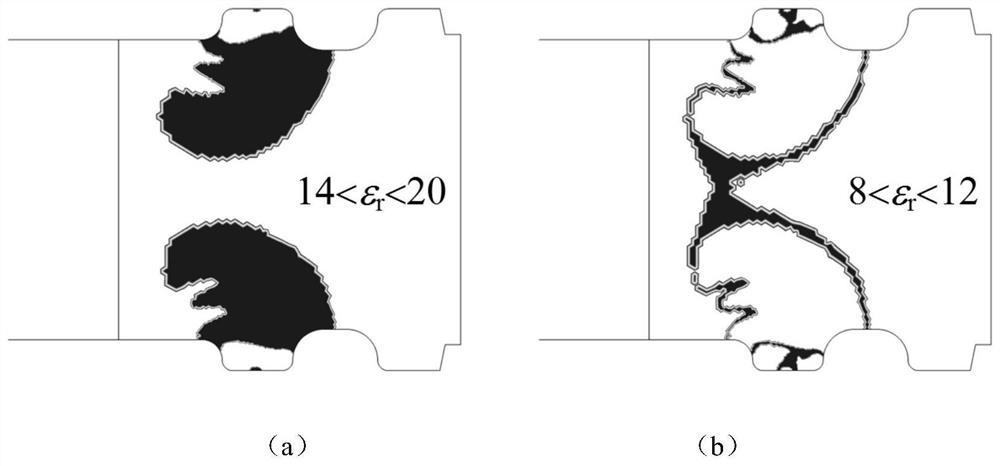

Preparation method of three-layer gradient GIS/GIL supporting insulator

ActiveCN113284684AGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator, which aims at reducing the electric field intensity of an insulator along a surface or a local region as an optimization target, and solves the optimal spatial distribution of a dielectric constant in the supporting insulator by using a variable density algorithm. According to the optimization result, the dielectric constant change area is divided into a dielectric constant transition area and a high dielectric area, the combination contour of the dielectric constant transition area is extracted, and then a hollow dielectric constant transition area with a support and a resin sprue gate is generated through photocuring 3D printing; a thermocurable high-dielectric composite material is prepared by adopting a high-dielectric filler / polymer blending mode, and then the high-dielectric composite material is poured into the dielectric constant transition area and integrally put into a metal mold for fixing; and a thermocurable high-dielectric composite material is prepared in a low-dielectric filler / polymer blending mode, then the thermocurable high-dielectric composite material is poured into a metal mold, and the three-layer gradient GIS / GIL supporting insulator can be obtained after curing is completed in vacuum.

Owner:XI AN JIAOTONG UNIV

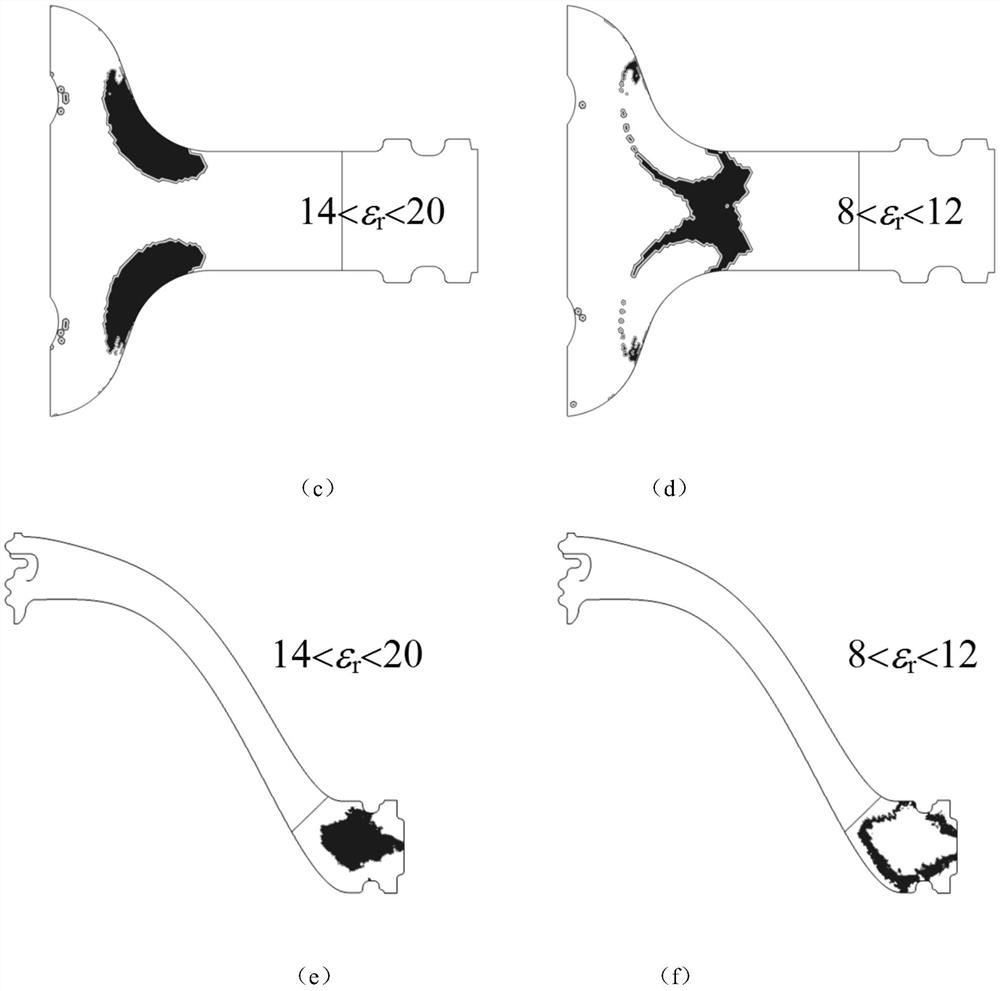

Lumbricus protein composite tablet candy and preparation method thereof

The invention relates to a lumbricus protein composite tablet candy and a preparation method thereof. The lumbricus protein composite tablet candy comprises the following raw materials by weight percentage: 10-20% of lumbricus protein powder, 15-25% of soybean protein, 35-50% of sorbitol, 2% of xylo-oligosaccharide, 3% of maltodextrin, and 20% of microcrystalline cellulose. The preparation method comprises the following main steps: 1) crushing; 2) mixing; 3) granulating; 4) tabletting; and 5) packaging. The lumbricus protein composite tablet candy takes lumbricus protein powder and soybean protein powder as main functional components, and takes sorbitol, microcrystalline cellulose and maltodextrin as auxiliary materials. Long-term usage of the lumbricus protein composite tablet candy has the functions of resisting fatigue and enhancing immunity.

Owner:HARBIN MO MEDICAL BIOLOGICAL TECH CO LTD

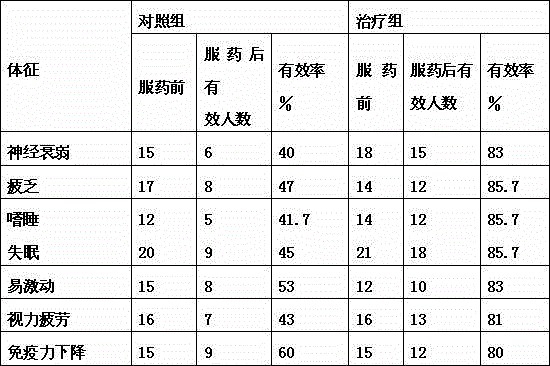

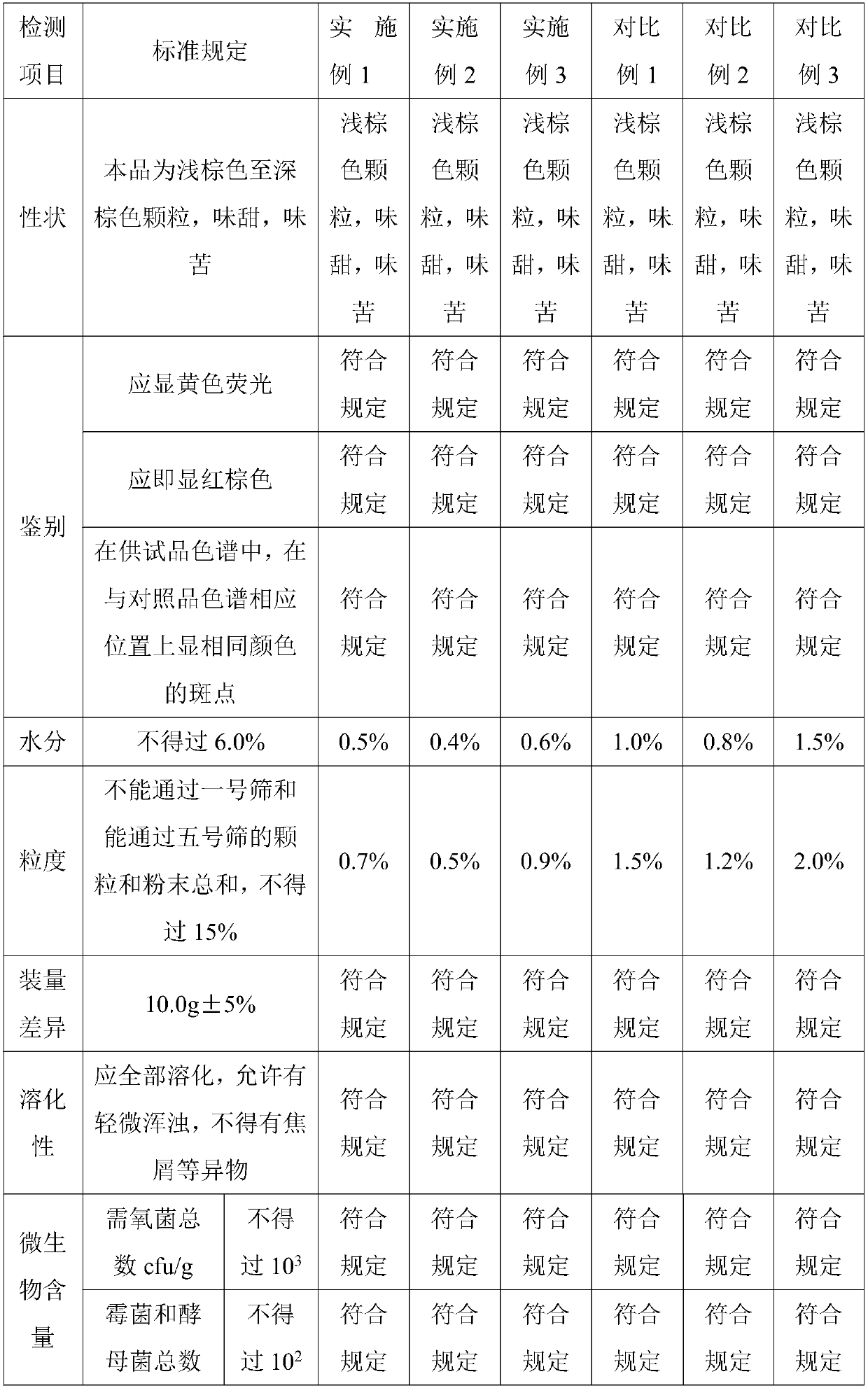

Ganmaoling granules and preparation method thereof

ActiveCN107669780ALow moisture absorptionHigh dissolution ratePharmaceutical non-active ingredientsGranular deliveryPeppermintsBeta-Cyclodextrins

The invention belongs to the technical field of traditional Chinese medicine, and specifically relates to ganmaoling granules and a preparation method thereof. The ganmaoling granules include, by weight parts, 450-530 parts of evodia lepta, 300-350 parts of spanishneedles herb, 200-300 parts of wild chrysanthemum, 700-780 parts of holly root, 15-25 parts of acetaminophen, 0.1-0.7 parts of chlorpheniramine maleate, 0.2-0.6 part of caffeine, 0.1-0.3 part of peppermint oil, 200-300 parts of lactose, 100-200 parts of debranched starch, 60-120 parts of microcrystalline cellulose, 5-10 parts of beta-cyclodextrin, 3-5 parts of polyvinylpyrrolidone and 80-120 parts of ethanol. The ganmaoling granules prepared by the method have low hygroscopicity, are easy to disintegrate, have high bioavailability, good stability and high safety, and have significant effects on the inhibition of pneumonia and death protection of influenza virus-infected mice.

Owner:GUANGDONG YILI GROUP PHARMA

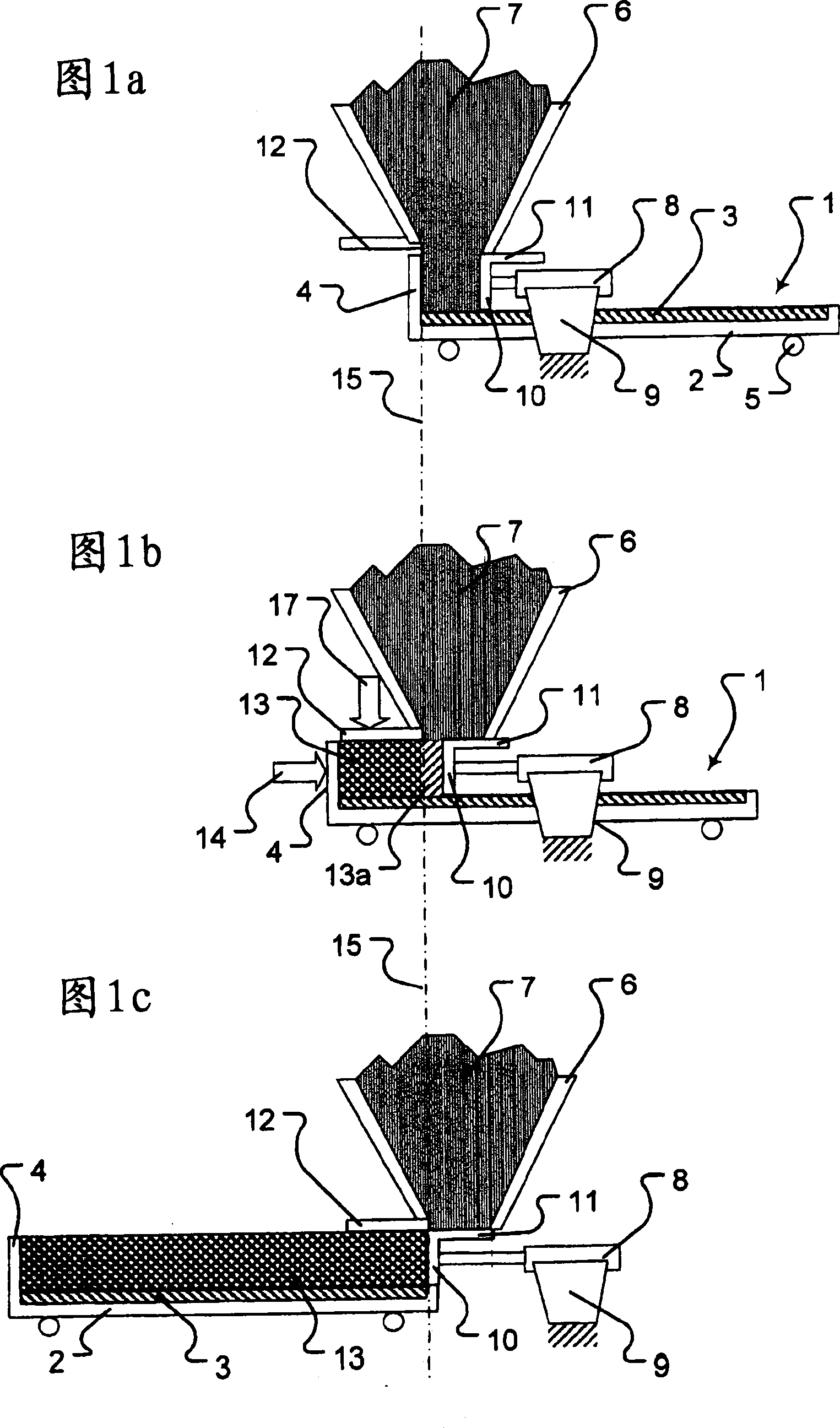

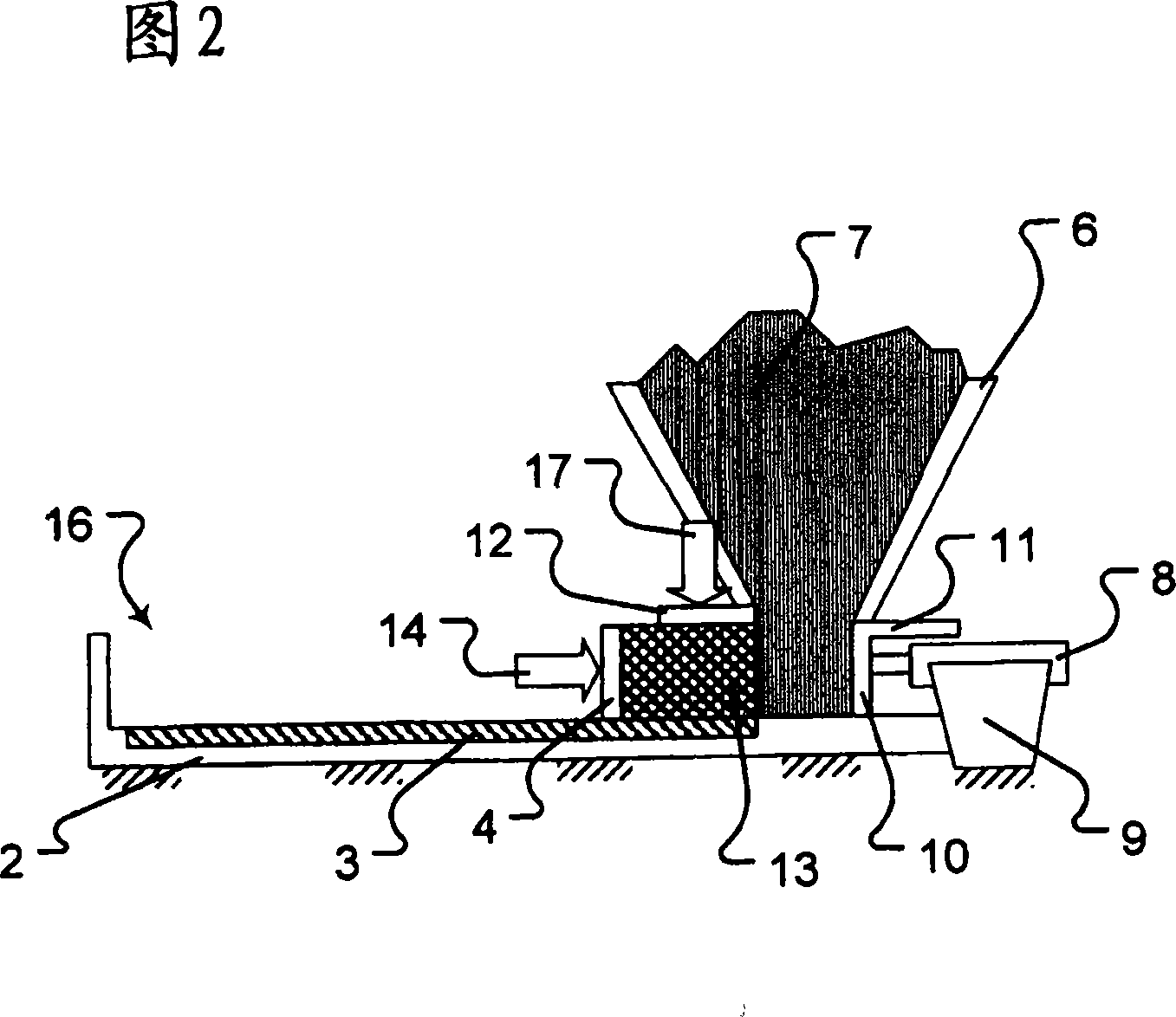

Process and device for producing horizontally tamped coal cakes

Owner:ТІССЕНКРУПП УДЕ ҐМБГ

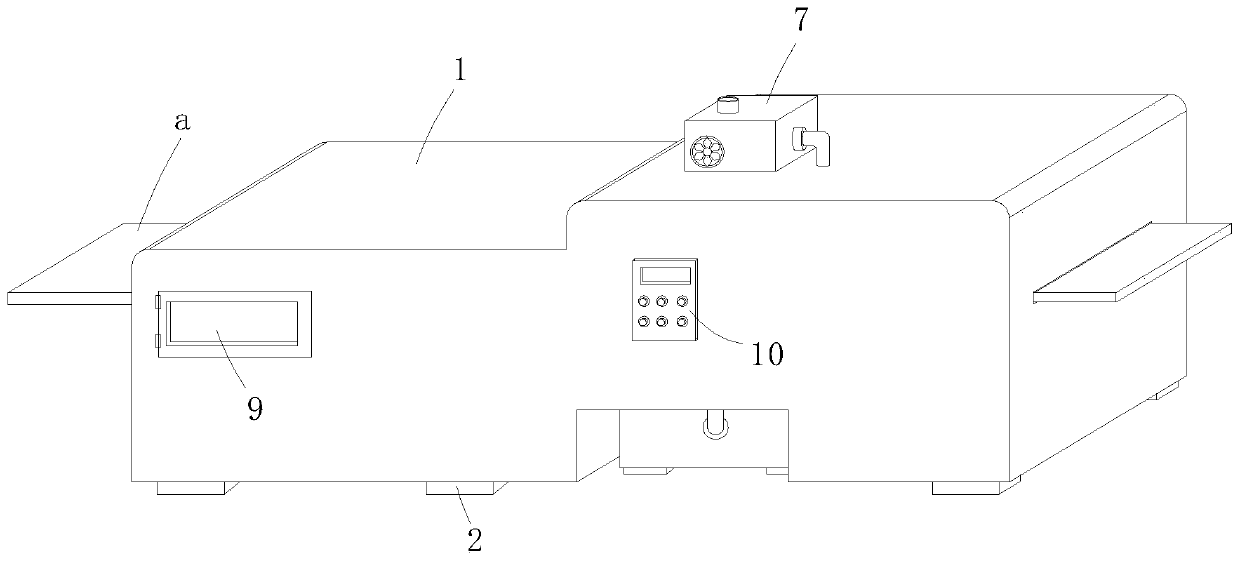

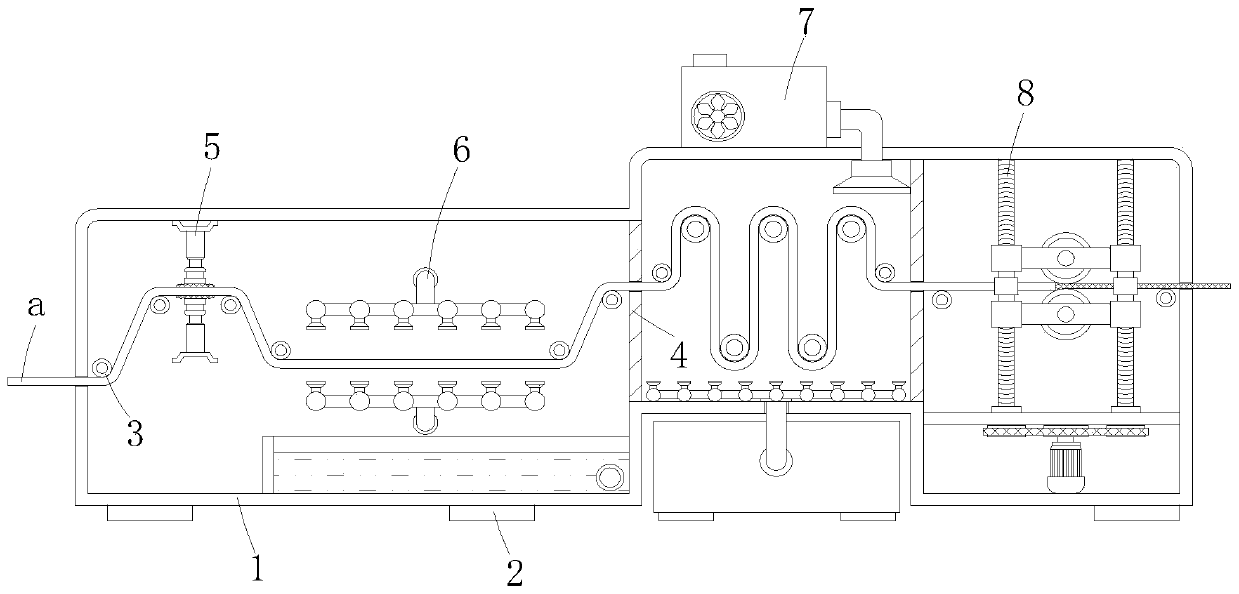

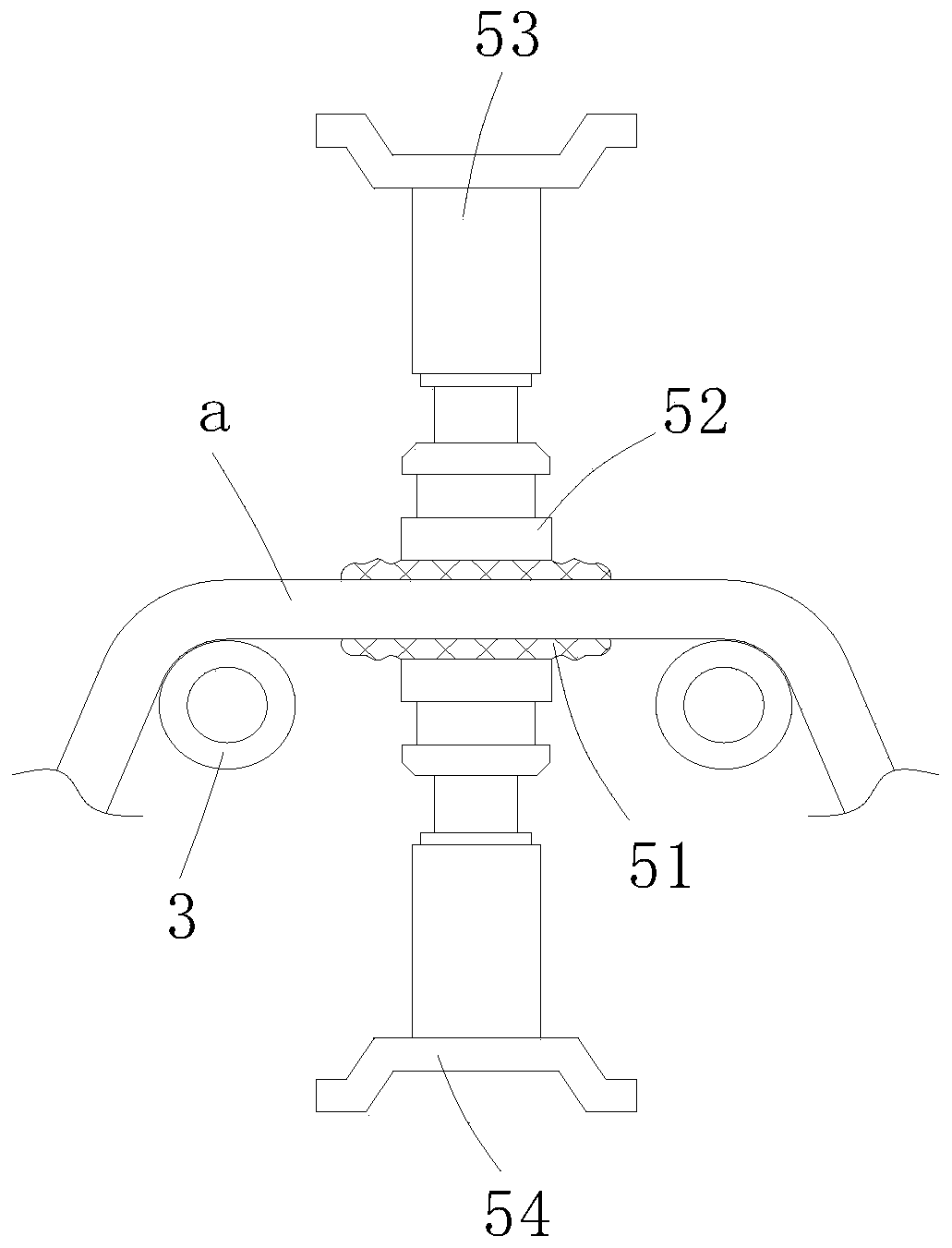

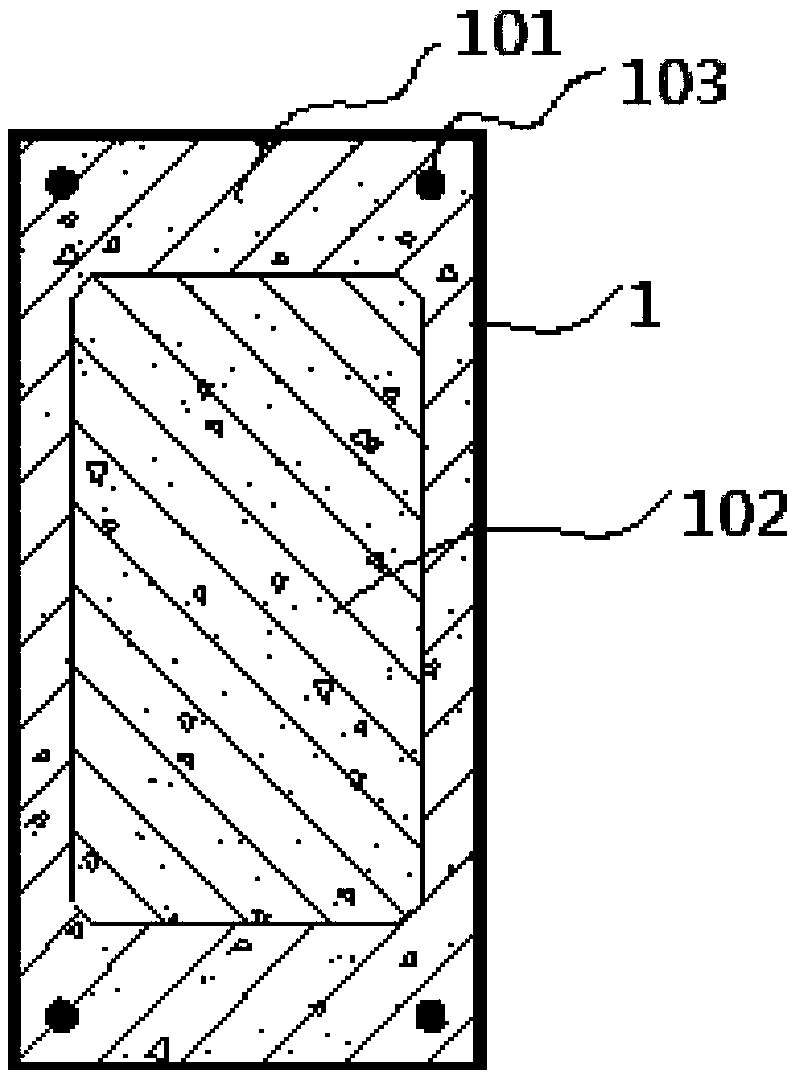

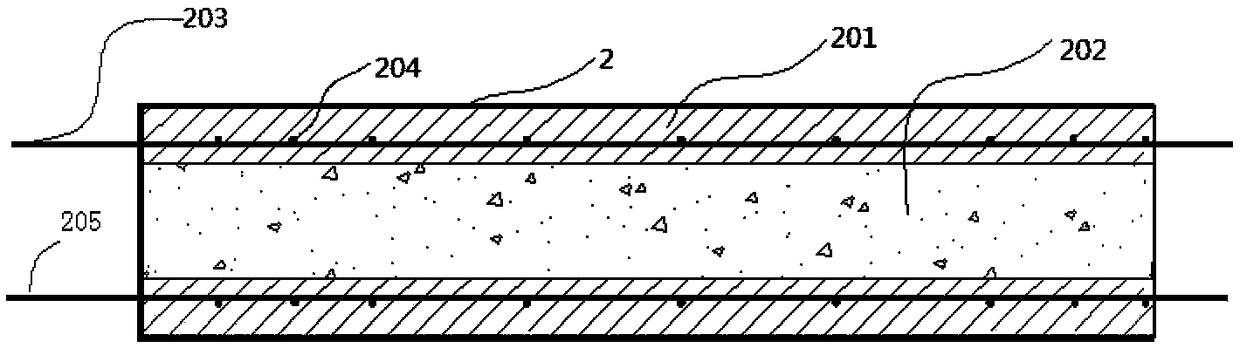

Coating and rolling device for battery production

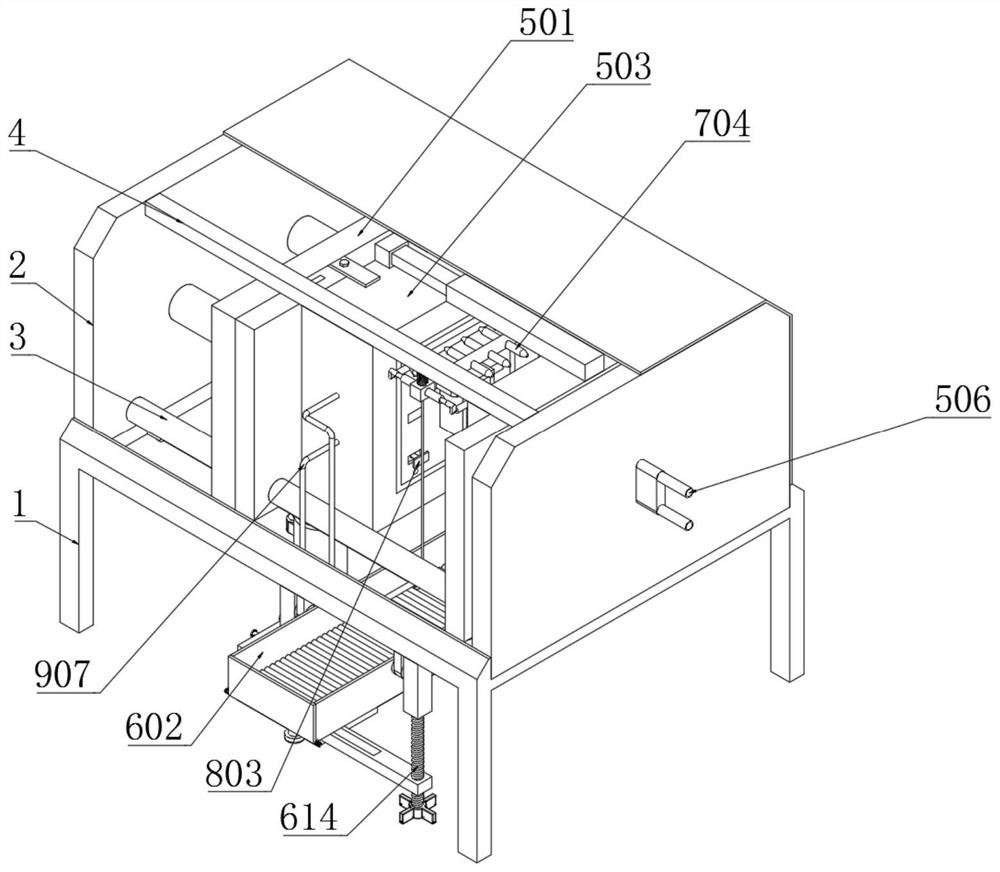

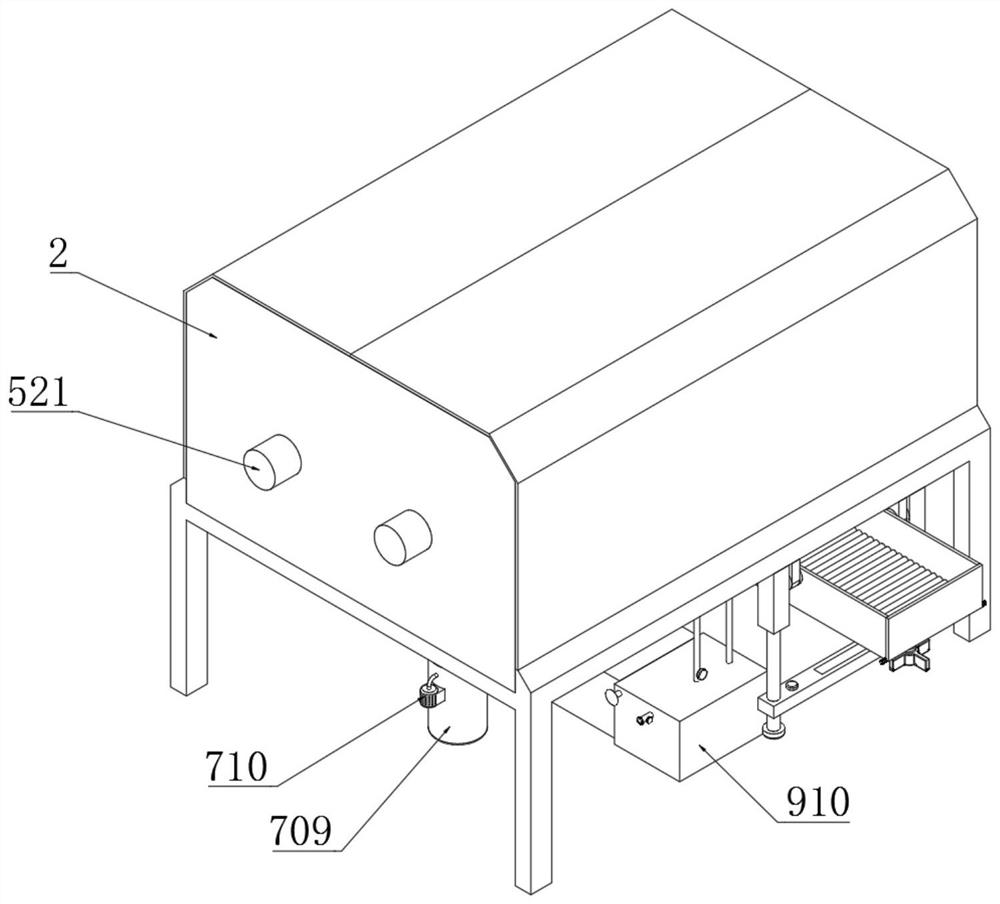

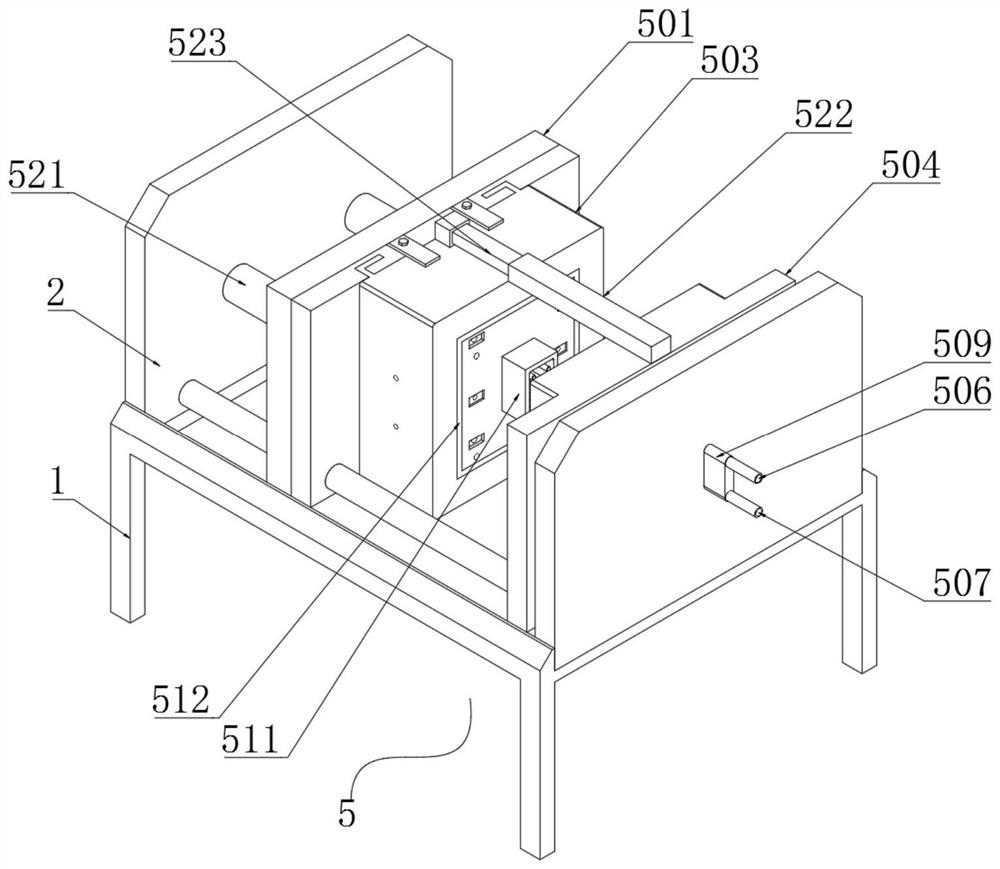

InactiveCN111495656AIncrease productivityGuaranteed moldingPretreated surfacesCleaning using toolsEngineeringPole piece

The invention relates to the technical field of battery production equipment, and provides a coating and rolling device for battery production. The coating and rolling device aims to solve the problems that a traditional battery pole piece coating and rolling processing production efficiency is low, meanwhile, a pole piece is exposed in air for a long time, and the controllability of the product quality is extremely poor. The coating and rolling device comprises a device outer shell and a plurality of supporting legs installed at the lower end of the device outer shell; a feeding port and a discharging port are formed in the opposite side walls of the device outer shell respectively, a plurality of rotating rollers used for current collector transmission and tension are installed on the inner wall of the device outer shell, two partition plates are vertically installed in an inner cavity of the device outer shell, the two partition plates sequentially divide the inner cavity of the device outer shell into a coating cavity, a drying cavity and a rolling cavity from left to right in the movement direction of the current collector, a coating mechanism is arranged in the coating cavity, a drying mechanism is arranged in the drying cavity, and a rolling mechanism is arranged in the rolling cavity. The device is particularly suitable for coating and rolling processing of the batterypole piece, and has higher social use value and application prospect.

Owner:安徽奥邦科技有限公司

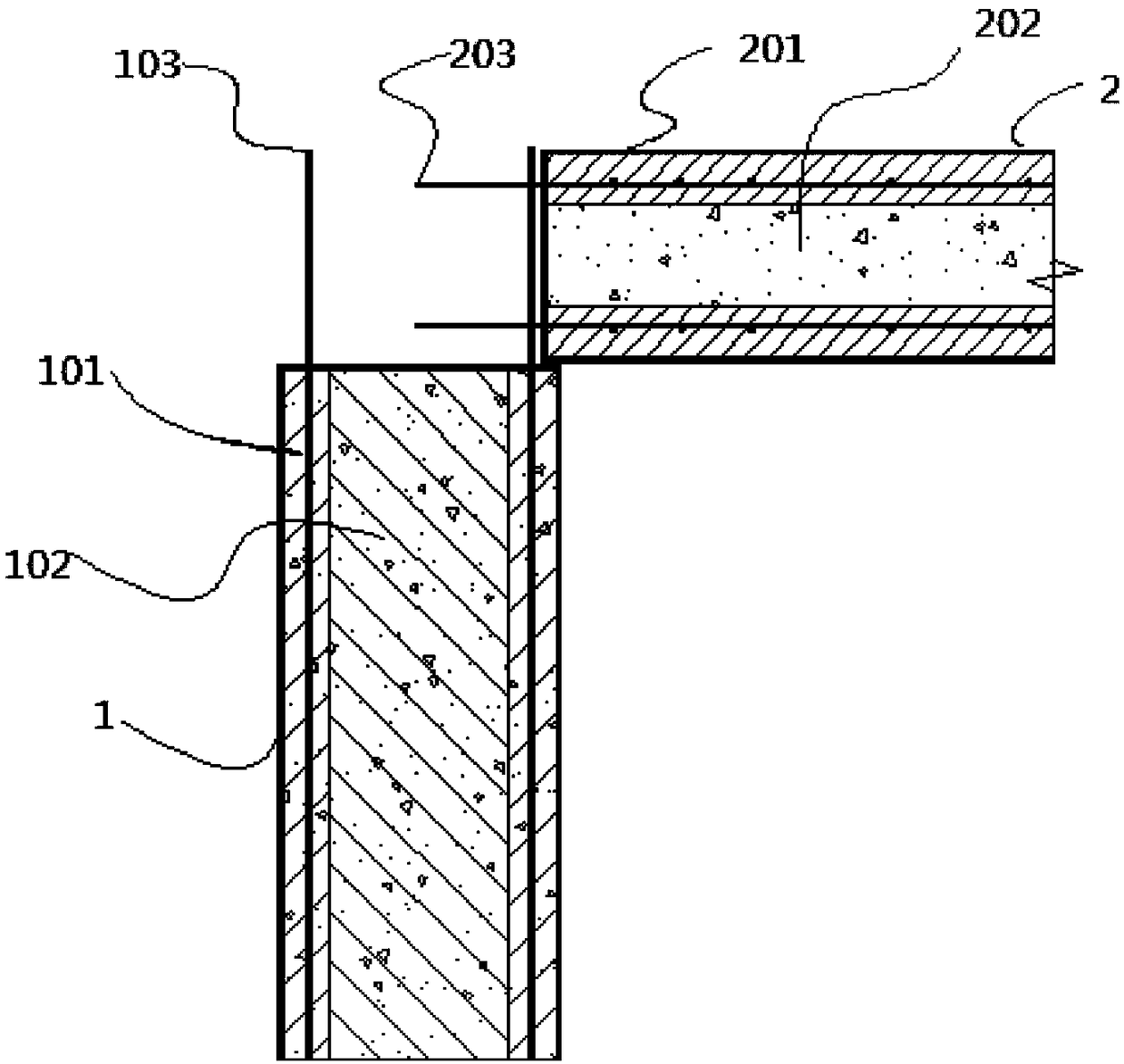

Frame structure system and construction method thereof

ActiveCN108343148AHigh strengthImprove stress resistanceProtective buildings/sheltersShock proofingConcrete beamsLap joint

The invention provides a frame structure system and a construction method thereof. The frame structure system comprises a plurality of composite columns and composite beams. Each composite column comprises a prefabricated column mold shell and a cast-in-situ concrete column inner core. Each composite beam comprises a prefabricated beam mold shell and a cast-in-situ concrete beam inner core. The top side of each prefabricated beam mold shell is provided with a grouting hole and an exhaust hole. 1-20cm of the end head of each composite beam is in lap joint with the edge of the top side of the corresponding composite column. The composite beams and the composite columns are connected through cast-in-situ concrete to form beam-column joints. The end heads of beam rebars of the composite beamsextend out of the ends of prefabricated beam mold shells and are anchored in the cast-in-situ concrete of the beam-column joints. The construction method comprises the following steps that prefabricated column mold shells are hoisted to the predetermined positions; the cast-in-situ concrete beam inner cores of the composite columns are formed through grouting; the prefabricated beam mold shells are hoisted, and 1-20cm of the end heads of the prefabricated beam mold shells are in lap joint with the edges of the top sides of the prefabricated column mold shells; templates at the beam-column joints are erected; the cast-in-situ concrete beam inner cores of the composite beams are formed through grouting; the concrete at the beam-column joints is grouted; and the steps are repeated until construction of the building frame is completed.

Owner:江苏千禧杭萧装配式建筑科技有限公司

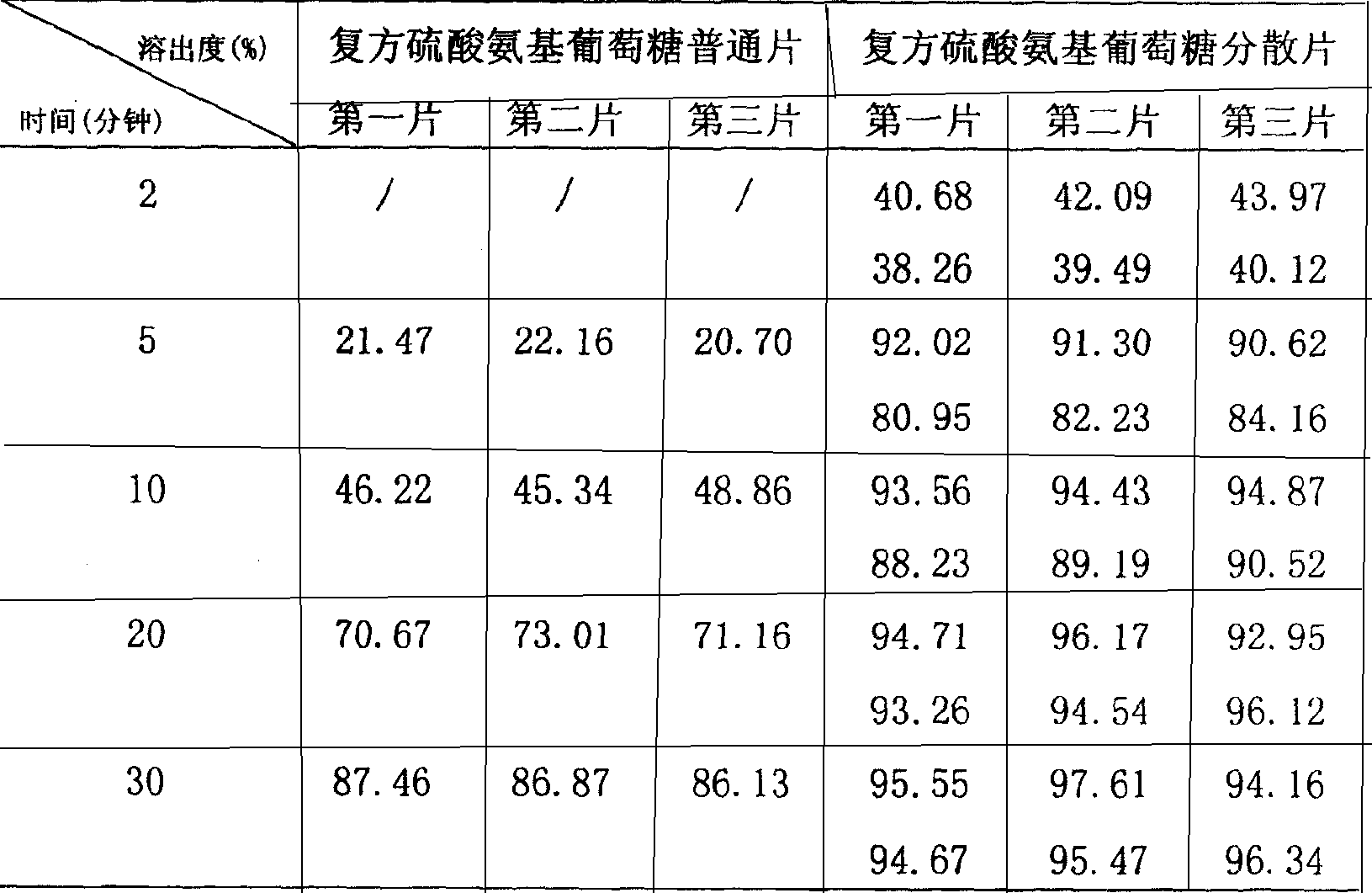

Compound glucosamine sulfate dispersible tablet formulation and its preparation method

ActiveCN1762379AMolding reductionGuaranteed moldingOrganic active ingredientsSkeletal disorderCross-linkAlcohol

The invention relates to the field of pharmacy, particularly a compound glucosamine sulfate dispersible tablet preparation, wherein the main compositions include glucosamine sulfate and chondroitin sulfate, the auxiliary materials include excipient (e.g. starch and microcrystalline cellulose), disintegrating agent (e.g. cross-linked polyplasdone), lubricant (e.g. magnesium stearate) and humectant (e.g. anhydrous alcohol).

Owner:GUANGZHOU YIPINHONG PHARMA +4

Plastic guardrail plate mould and plastic guardrail plate molding process adopting mould

InactiveCN101804689AEnsure safetyReduce maintenance costsDomestic articlesPlastic bagMaterials science

The invention relates to a plastic guardrail plate mould which comprises n layers of plastic rib passages, n+1 layers of molten plastic passages and molten plastic filling passages, wherein the n layers of plastic rib passages for arranging plastic ribs are molded inside the mould, the n+1 layers of molten plastic passages are used for molding molten plastics of a plate body, and the molten plastic filling passages for filling the molten plastics are communicated with the inlets of the molten plastic passages; the plastic rib passages and the molten plastic passages are alternately arranged, and each layer of plastic rib passage is clamped between the molten plastic passages; and the plastic rib passages and the molten plastic passages are converged at the molding outlet of a plastic guardrail plate at the outlet end of the mould, wherein the n is a natural number larger than or equal to 1. The invention solves the technical problem that the physical characteristic of the plastic ribs is difficult to ensure in the process of manufacturing the plastic guardrail plate containing the plastic ribs.

Owner:井志田

Dyeing process for all-cotton fluorescent yarns

The invention discloses a dyeing process for all-cotton fluorescent yarns. The process comprises the steps of winding, bleaching and dyeing. A dyeing solution uniformly penetrates through the yarns by reducing the density and the size of cheeses so as to reduce the chromatic aberration; by virtue of two times of bleaching, the whiteness of the yarns is improved; a fluorescent active dye and a common active dye are compounded according to a certain ratio and are used for dyeing the yarns and the ratio is determined according to required dyeing so as to guarantee that one-time dyed rate of dyeing is more than 90% and the dyeing defect is reduced to 2%; a weakly cationic softening agent is added into the dyeing solution; after dyeing is finished, a full-automatic rotary table is used for dehydrating so as to guarantee cheese molding and reduce a rewinding procedure, and furthermore, the fluorescent loss of the yarns is reduced.

Owner:张家港市金陵纺织有限公司

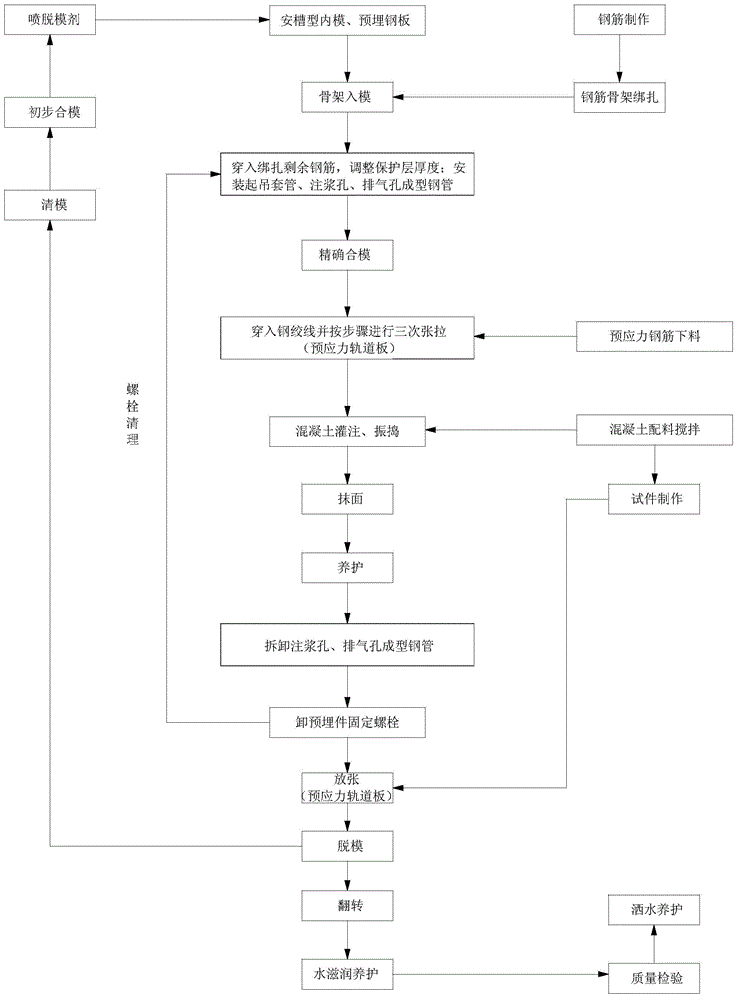

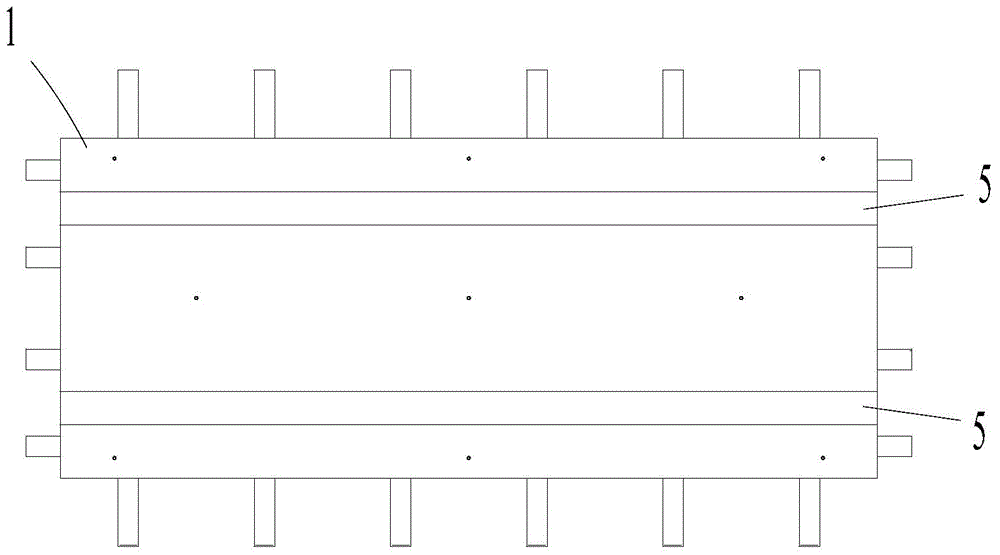

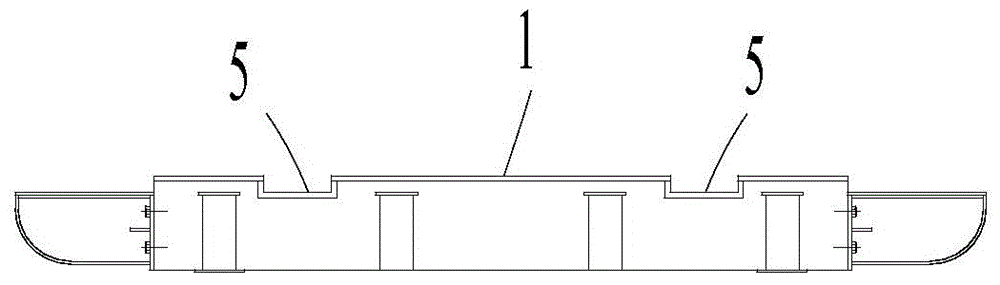

Manufacturing process of streetcar rail plate

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

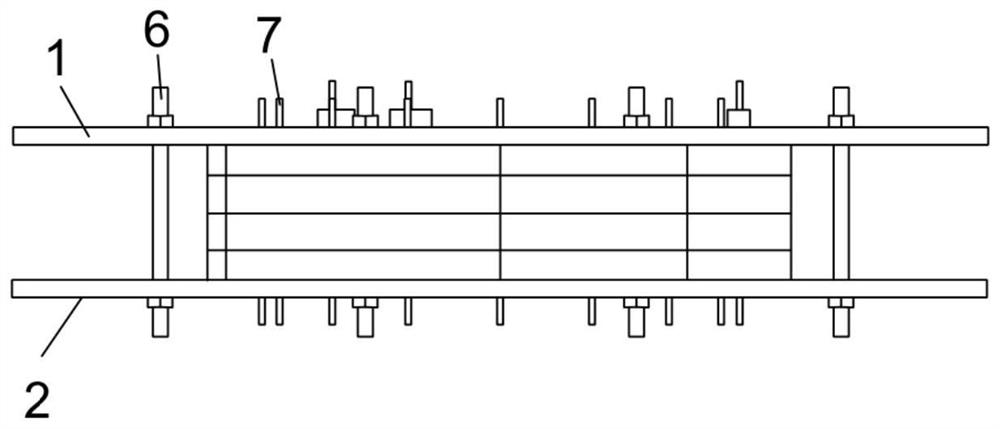

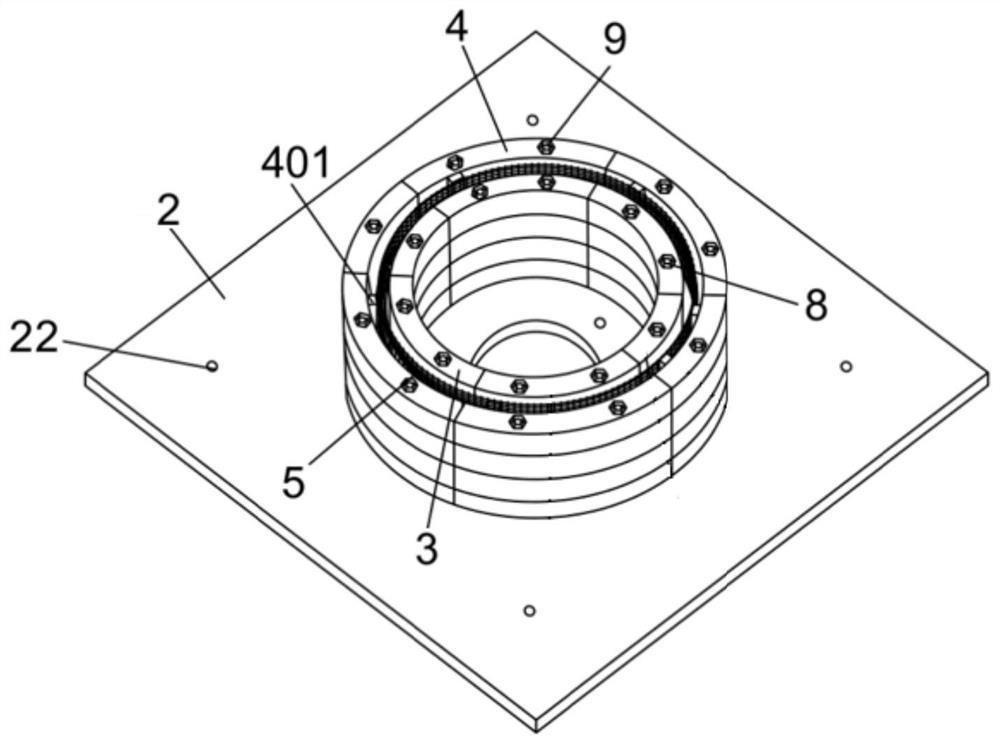

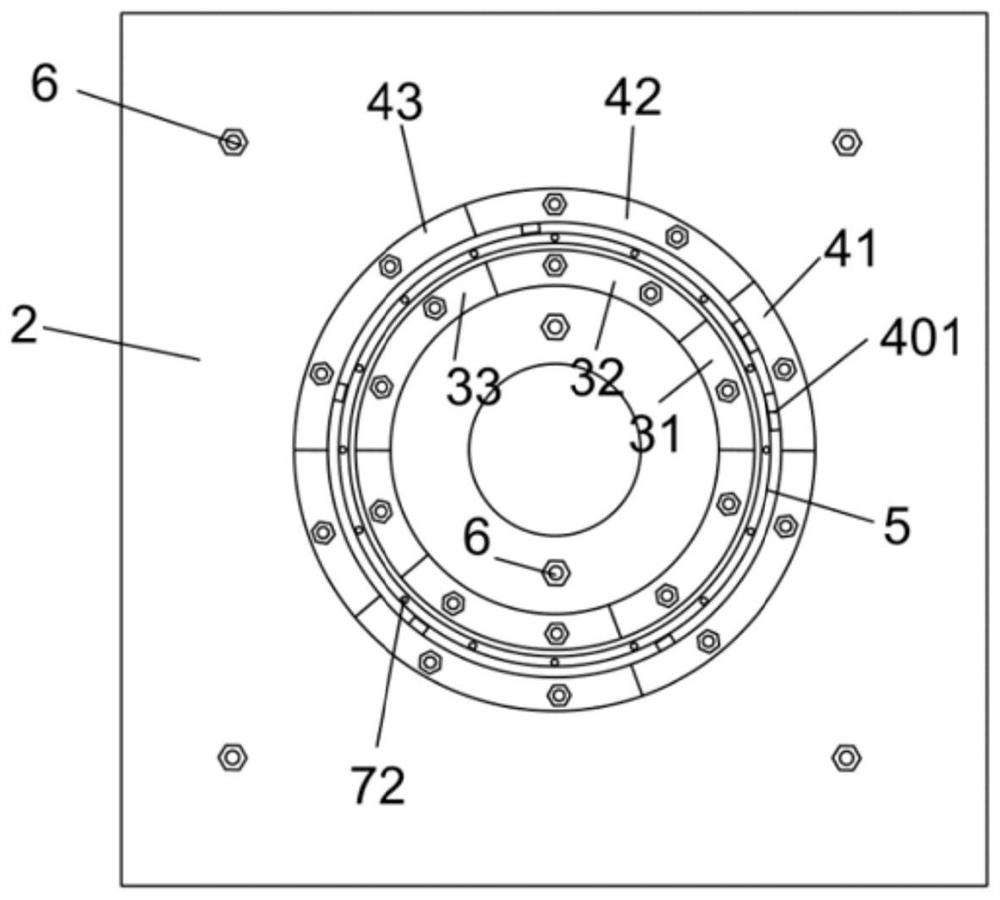

Pouring mold and pouring method for gypsum shield segment model

The invention provides a pouring mold and a pouring method for a gypsum shield segment model. The pouring mold comprises an upper cover plate, a lower cover plate, an inner mold body, an outer mold body and cover plate fixing bolts, wherein the upper cover plate and the lower cover plate are arranged in parallel up and down; the inner mold body and the outer mold body are both vertically fixed between the upper cover plate and the lower cover plate, the inner mold body is sleeved with the outer mold body, the inner mold body and the outer mold body are arranged in a spaced mode, and a gypsum pouring area is formed between the inner mold body and the outer mold body; and the upper cover plate and the lower cover plate are fixedly connected together through the cover plate fixing bolts. According to the pouring mold, the inner mold body and the outer mold body are arranged between the upper cover plate and the lower cover plate, the gypsum pouring area is formed between the inner mold body and the outer mold body, and the upper cover plate and the lower cover plate are fixed through the cover plate fixing bolts, so that molding of the gypsum shield segment model is ensured, refined simulation of a gypsum shield segment is realized, and the mechanical behavior characteristics of the segment are fully researched; and the structure is fine, operation is feasible, the test result can be real and reliable, adjustment can be carried out according to actual design, and effective guidance can be provided for actual engineering construction.

Owner:CHANGAN UNIV +2

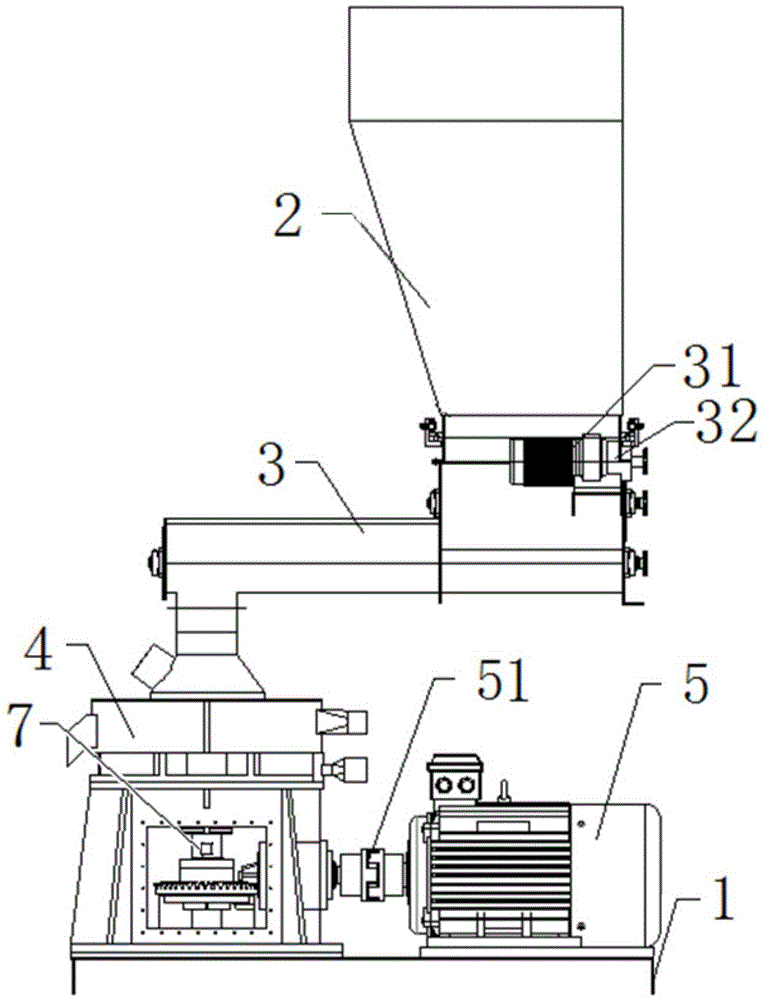

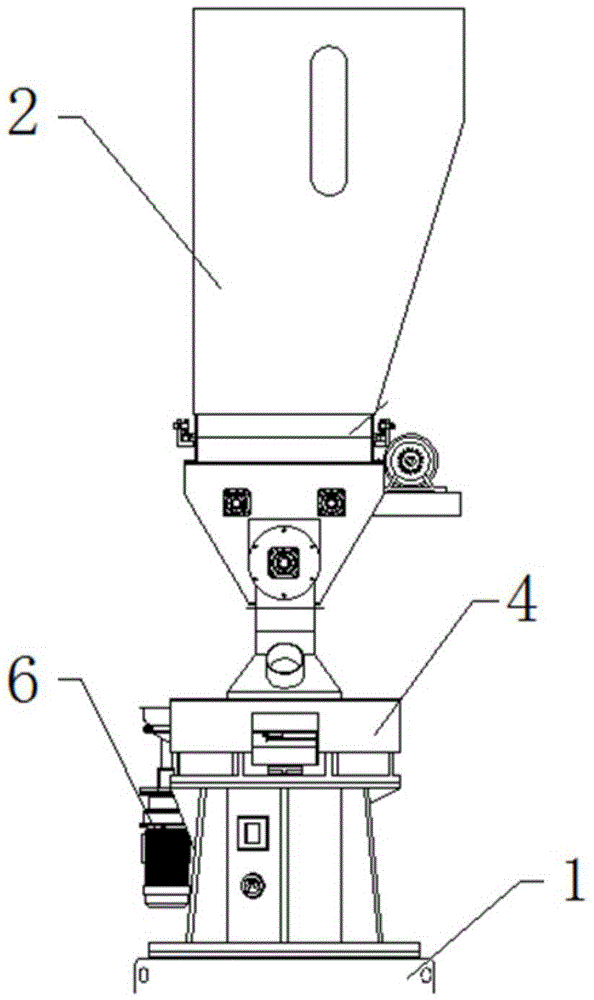

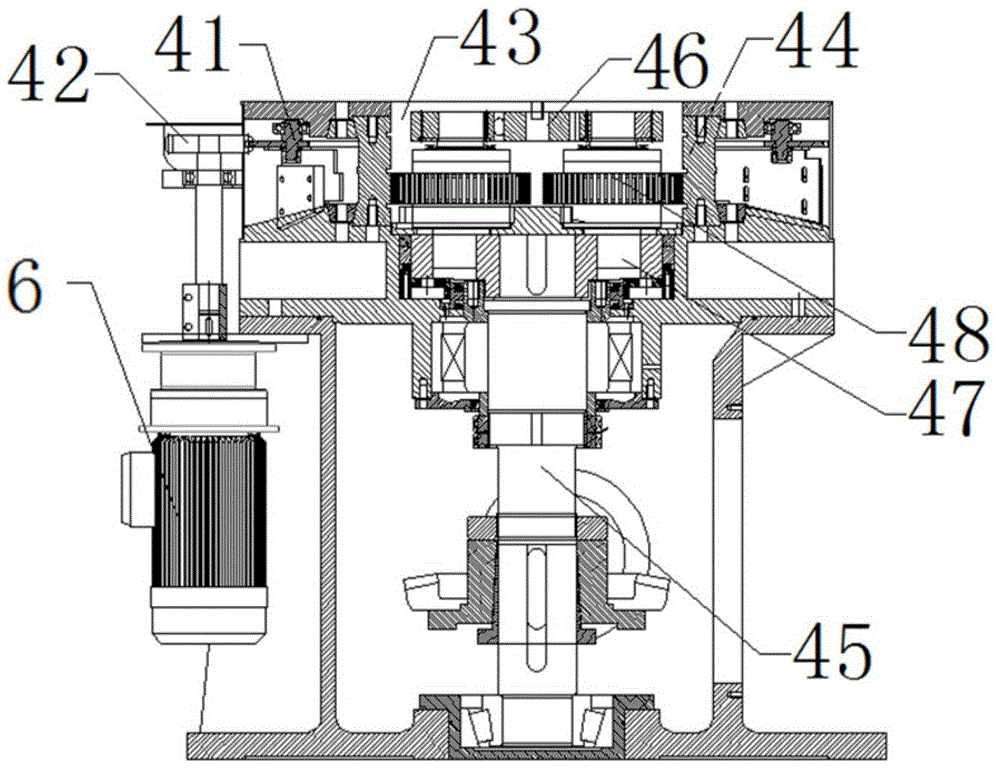

High-strength granulation machine

ActiveCN105617935AImprove carrying capacitySmall footprintGranulation by pressingElectric machineryUltimate tensile strength

The invention discloses a high-strength granulation machine which mainly comprises a support, a to-be-granulated material bin, a feeder, a pressing device, a main motor, a distributing motor and a pressure self-regulating device. The high-strength granulation machine has the technical advantages that spiral bevel gears comprise gear shafts and bevel gears which mesh with one another in pairs, accordingly, the raw material utilization rate can be increased, and the yield can be increased by 20% at least as compared with the traditional machine with identical power; the high-strength granulation machine comprises the pressure self-regulating device, accordingly, pressures of a spindle pressure plate and pressure rollers can be automatically regulated, the high-strength granulation machine is low in energy consumption and is environmentally friendly, and the service life of equipment can be prolonged; products produced by the aid of the high-strength granulation machine are high in granular forming rate and strength and basically free of cracking or powder; the high-strength granulation machine has obvious merits when used for straw materials and has a broad application prospect.

Owner:TAICANG TAIBANG ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com