High-strength granulation machine

A granulator, high-strength technology, applied in the direction of mold extrusion granulation, raw material granulation method, chemical instrument and method, etc., can solve the problems of low raw material utilization rate, low granule forming rate, granule cracking, etc., and achieve The effect of stable transmission ratio, high carrying capacity and long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

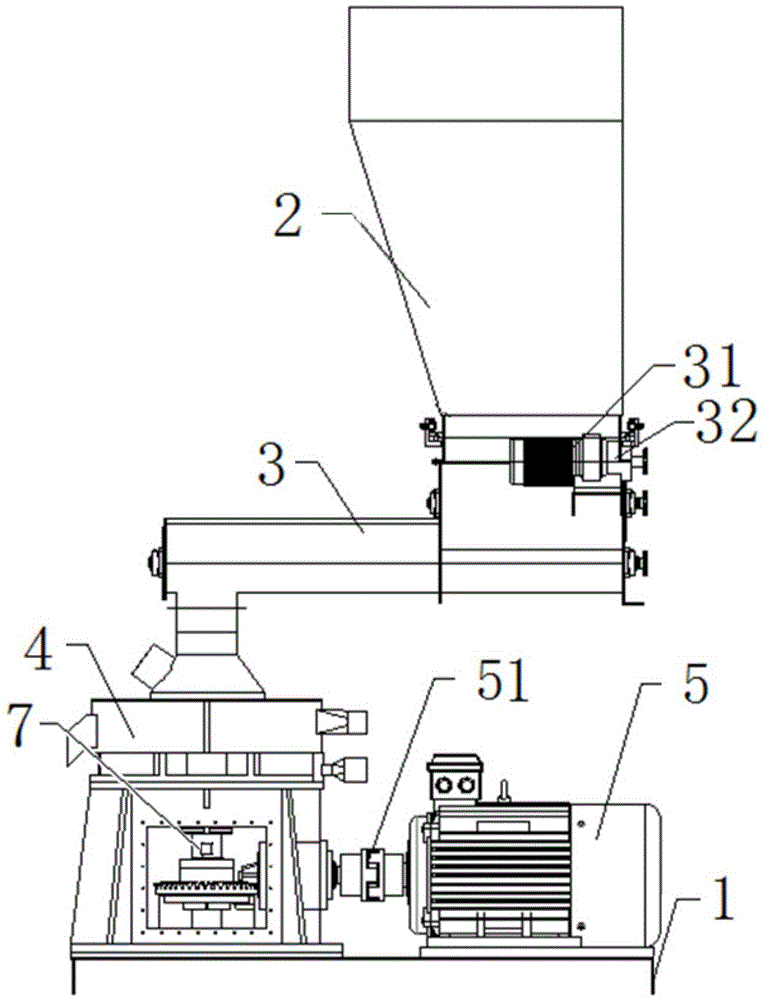

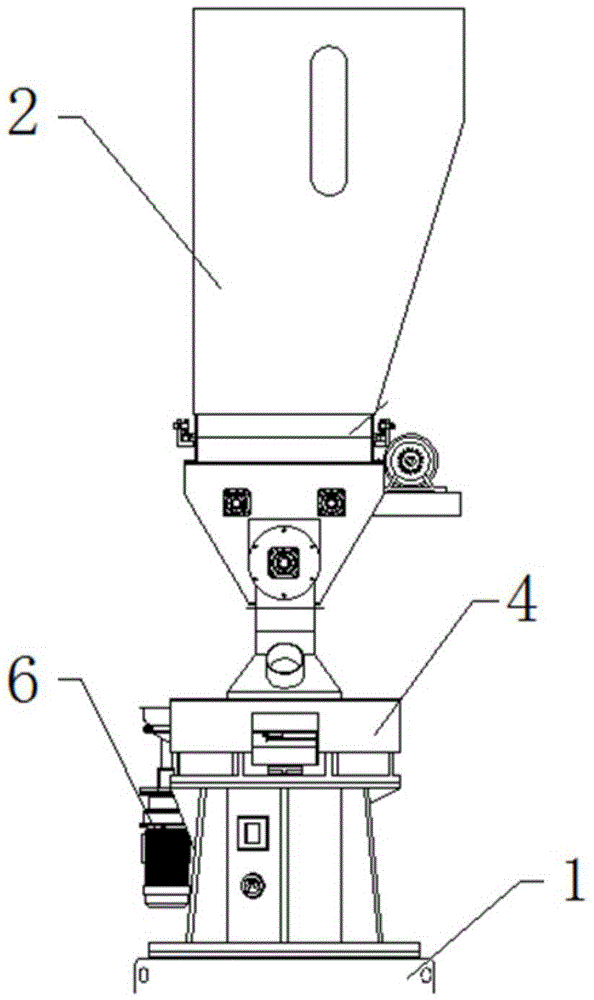

[0027] Such as figure 1 and figure 2 Shown is a pellet machine that can produce high-strength biomass pellets. It includes a bracket 1, a bin to be granulated 2, a feeder 3, a pressing device 4, a main motor 5, a material distribution motor 6 and a pressure self-regulating device 7.

[0028] The bracket 1 is made of ABS+20% GF high-hardness plastic material.

[0029] The bin 2 to be granulated is funnel-shaped.

[0030] The feeder 3 includes a variable frequency speed regulating motor 31, a reducer 32, an auger cylinder and an auger shaft, and the frequency conversion motor is directly connected with the reducer and then connected with the auger shaft; The shaft is fixed inside the cylinder of the auger through the front and rear end covers, and a bearing is arranged at the connection point between the shaft and the cylinder of the auger. A hand hole cover and a cleaning door are arranged on the side wall of the cylinder body of the auger.

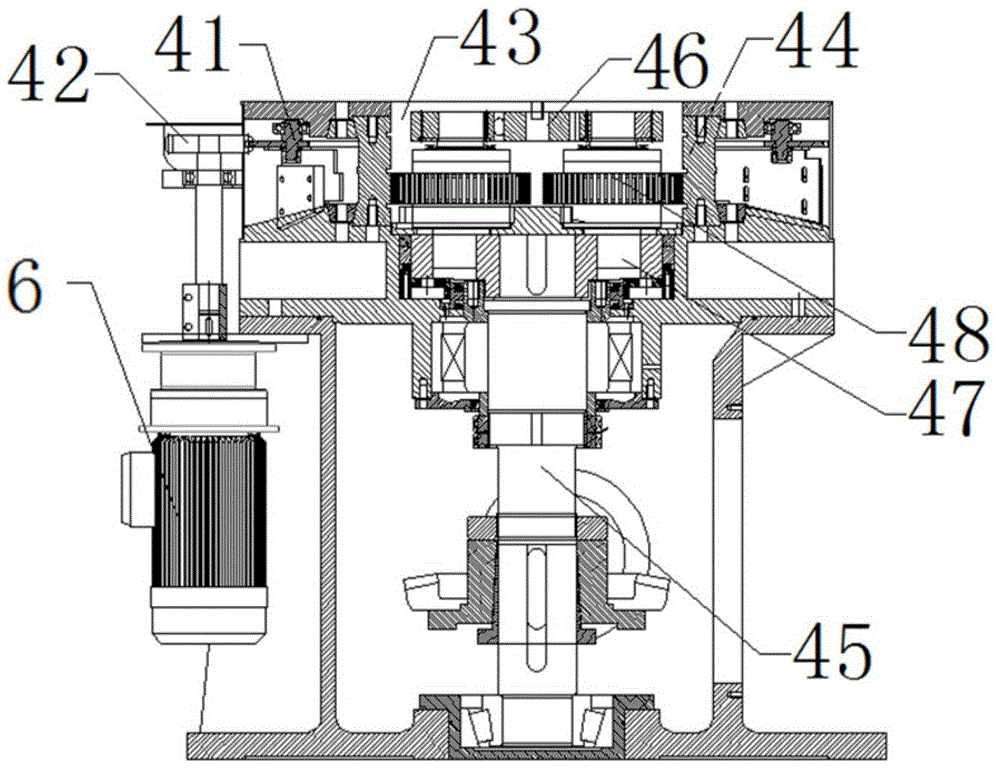

[0031] Such as image 3 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com