Plastic guardrail plate mould and plastic guardrail plate molding process adopting mould

A molding process and guardrail technology, which is applied in applications, household components, household appliances, etc., can solve the problems that the physical properties of plastic ribs are difficult to guarantee, and achieve the effects of reducing the difficulty of handling, ensuring safety, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

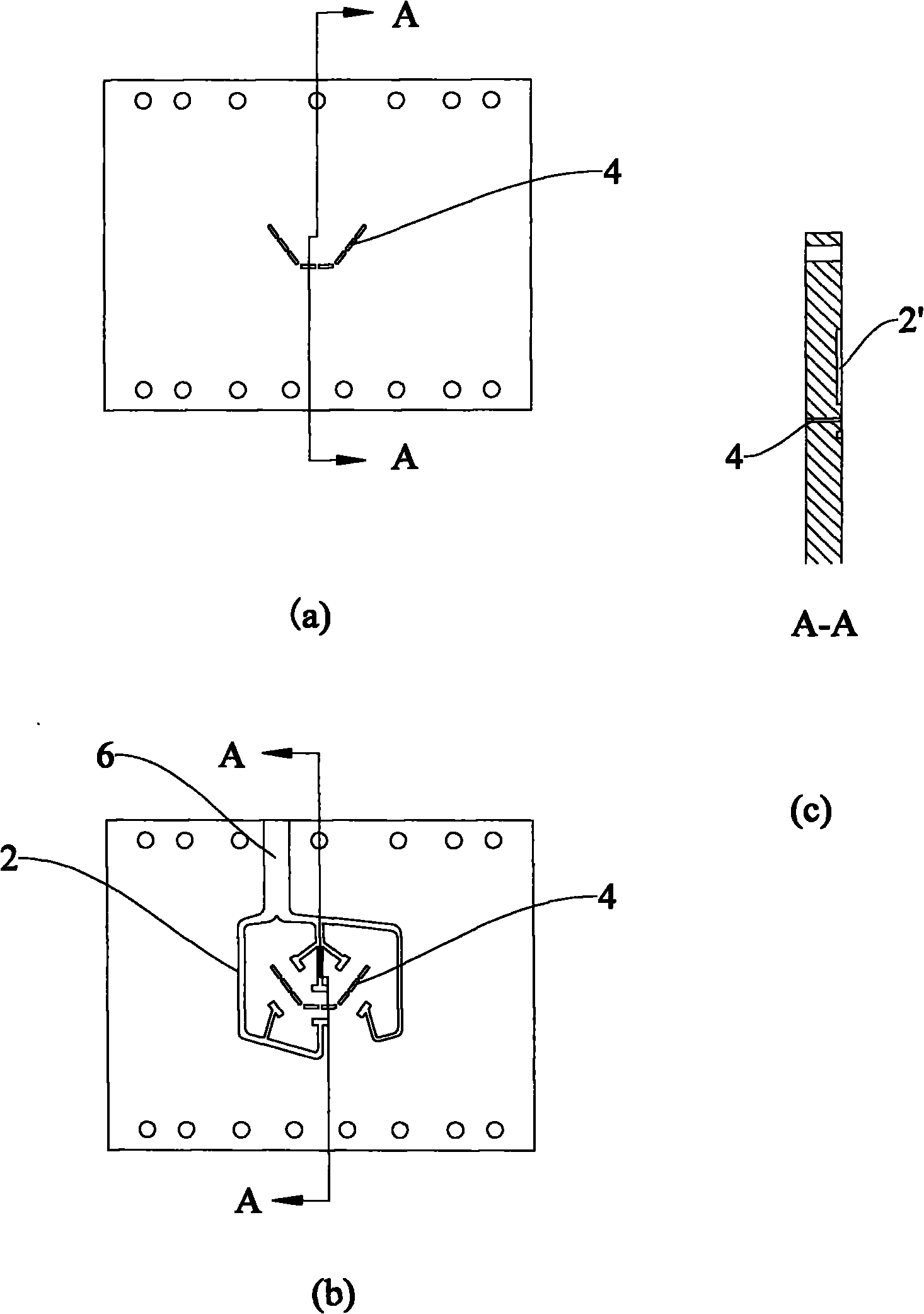

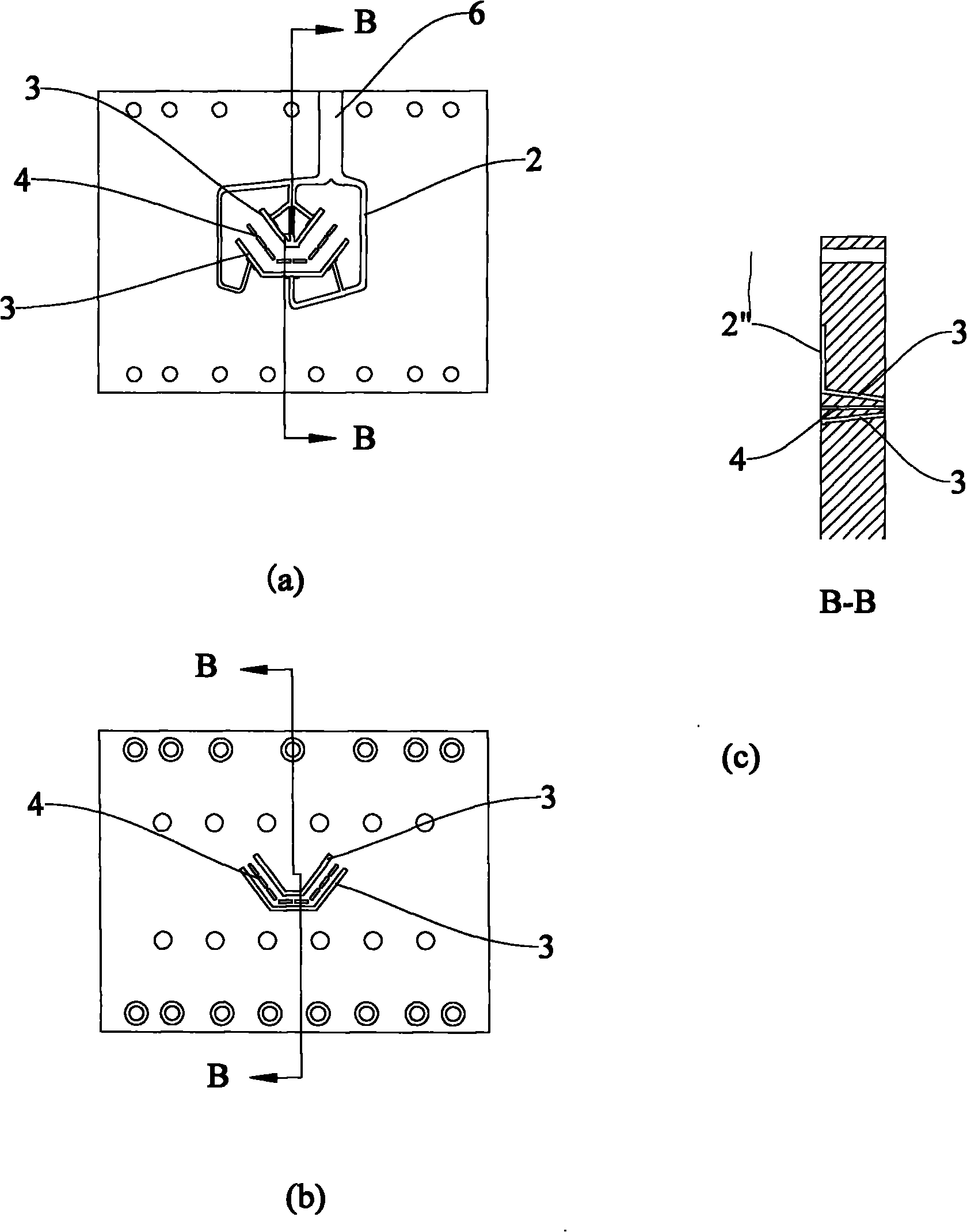

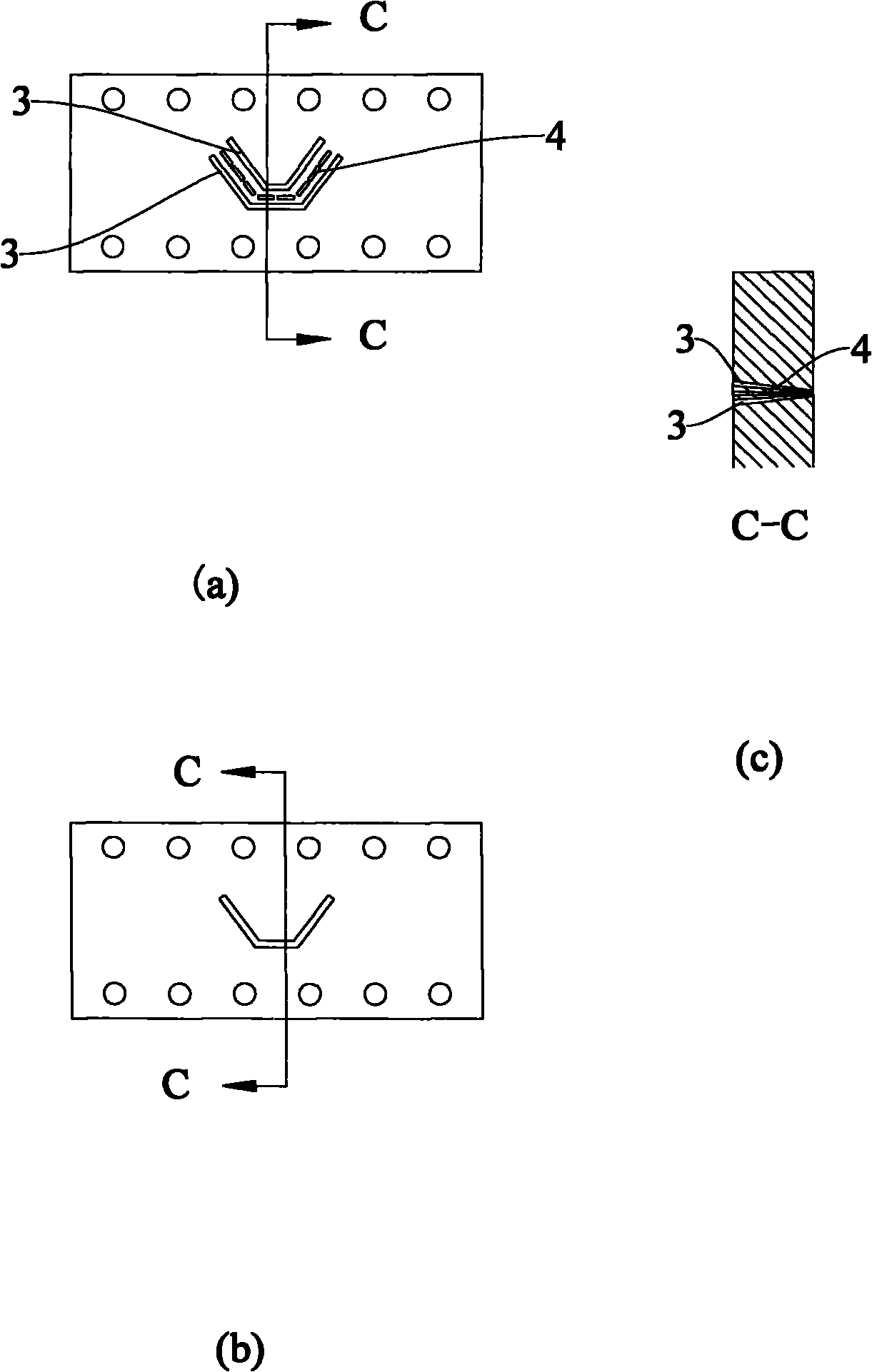

[0047] Such as Figure 1-5 The embodiment shown, the plastic guardrail mold of the present invention, comprises by Figure 1 to Figure 4 The mold body 1 composed of the submodules shown, wherein figure 1 The first submodule shown with figure 2 The second sub-module shown together forms the infusion mold part L of the mould, in the first sub-module figure 1 (b) The groove formed on the surface shown in the figure and the second sub-module figure 2 (a) The grooves formed on the surface shown in the figure together constitute the L of the plastic melt pouring channel 2 . Figure 4 The fourth sub-module shown is formed with a plastic guardrail molding channel 14, which becomes the molding die part N of the mould, Figure 4 (b) Figure shows the plastic guardrail forming outlet 5 of the plastic guardrail forming channel. Between the pouring mold part L and the forming mold part N, the figure 2 shown in the second submodule and image 3 The third sub-module shown is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com