Low-temperature co-firing ceramic wave-absorbing material and preparation method thereof

A technology of low-temperature co-fired ceramics and wave-absorbing materials, applied in reactors, nuclear engineering, shielding, etc., can solve problems such as damage shape, difficulty in film formation, poor effect of sheet-shaped wave-absorbing materials, etc., and achieve good wave-absorbing performance and process Simple, Widely Applicable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

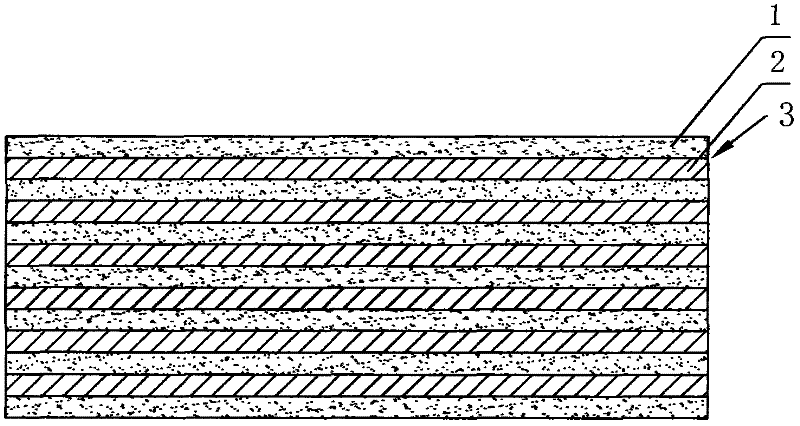

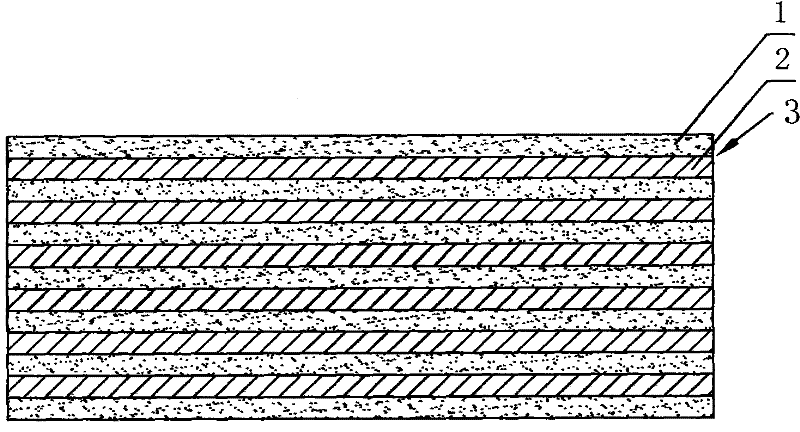

Image

Examples

Embodiment 1

[0028] Firstly, the low temperature co-fired ceramic nanopowder raw material is dispersed in a solvent to prepare a ceramic slurry.

[0029] The solvent is water, so that the prepared ceramic slurry has a certain viscosity and fluidity, so that it can be removed in the subsequent low-temperature sintering process without affecting the performance of the finished product.

[0030] The ceramic nanopowder adopts low-temperature co-fired glass ceramics that can be sintered in an inert atmosphere filled with nitrogen.

[0031] Then, the ceramic slurry is cast into a film on the glass fiber cloth sheet-like wave-absorbing material mixed with carbon fibers through a waterfall casting process. The waterfall casting process is to store the ceramic slurry in a container at a high place, and a slit is opened at the lower end of the container, and the ceramic slurry passes through the slit at a certain speed due to gravity or extrusion from above to form a casting waterfall; A conveyor b...

Embodiment 2

[0036] Firstly, the low temperature co-fired ceramic nanopowder raw material is dispersed in a solvent to prepare a ceramic slurry.

[0037] Various organic solvents can be used as the solvent, so that the prepared ceramic slurry has a certain viscosity and fluidity. It is advisable to use a mixed organic solvent that can be removed in the subsequent low-temperature sintering process without affecting the performance of the finished product.

[0038] Ceramic nanopowder adopts low-temperature co-fired ceramic nanopowder mixed with absorbing fiber or metal, and low-temperature co-fired glass ceramics that can be sintered in a reducing atmosphere filled with hydrogen.

[0039] Then, the ceramic slurry is cast into a film on the glass fiber cloth sheet-like wave-absorbing material mixed with carbon fibers through a waterfall casting process. The waterfall casting process is to store the ceramic slurry in a container at a high place, and a slit is opened at the lower end of the con...

Embodiment 3

[0044] Firstly, the low temperature co-fired ceramic nanopowder raw material is dispersed in a solvent to prepare a ceramic slurry.

[0045] An organic solvent is used as the solvent, so that the prepared ceramic slurry has a certain viscosity and fluidity, and it is advisable to use a mixed organic solvent that can be removed in the subsequent low-temperature sintering process without affecting the performance of the finished product.

[0046] Ceramic nanopowder adopts low-temperature co-fired ceramic nanopowder mixed with oxide powder, preferably low-temperature co-fired glass ceramics that can be sintered in a reducing atmosphere, to further optimize the absorbing performance.

[0047] Then, the ceramic slurry is cast into a film on the glass fiber cloth sheet-like wave-absorbing material mixed with carbon fibers through a waterfall casting process. The waterfall casting process is to store the ceramic slurry in a container at a high place, and a slit is opened at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com