Lattice enhanced type composite material foam core sandwich supporting column and preparation method thereof

A technology of composite materials and reinforcement materials, which is applied in the field preparation of building components, pillars, building structures, etc., and can solve problems such as easy debonding of the skin and the core layer, no lifting of the structure's self-weight, and low shear resistance , to achieve superior surface-core bonding strength, improve overall stability, and high surface-core bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

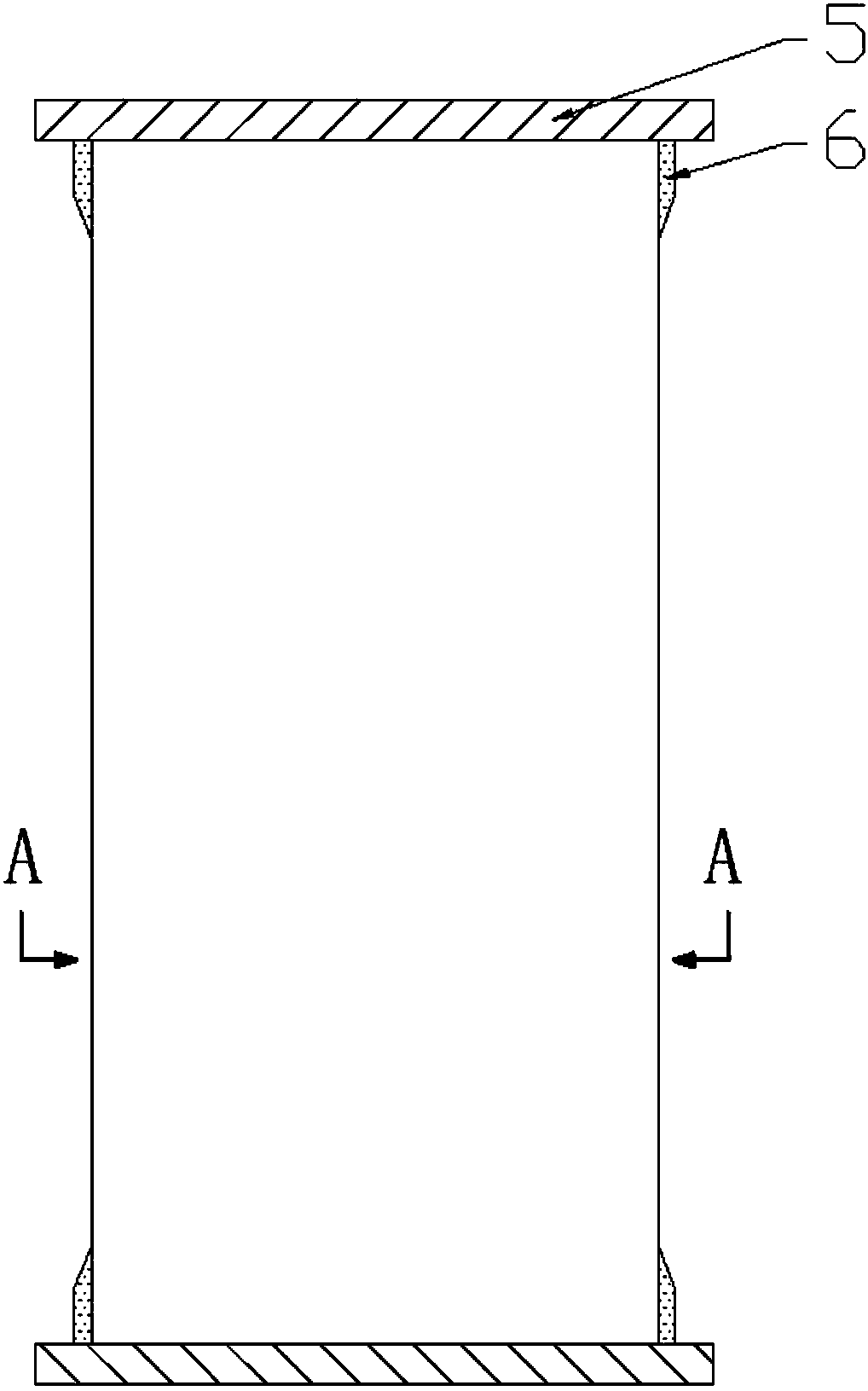

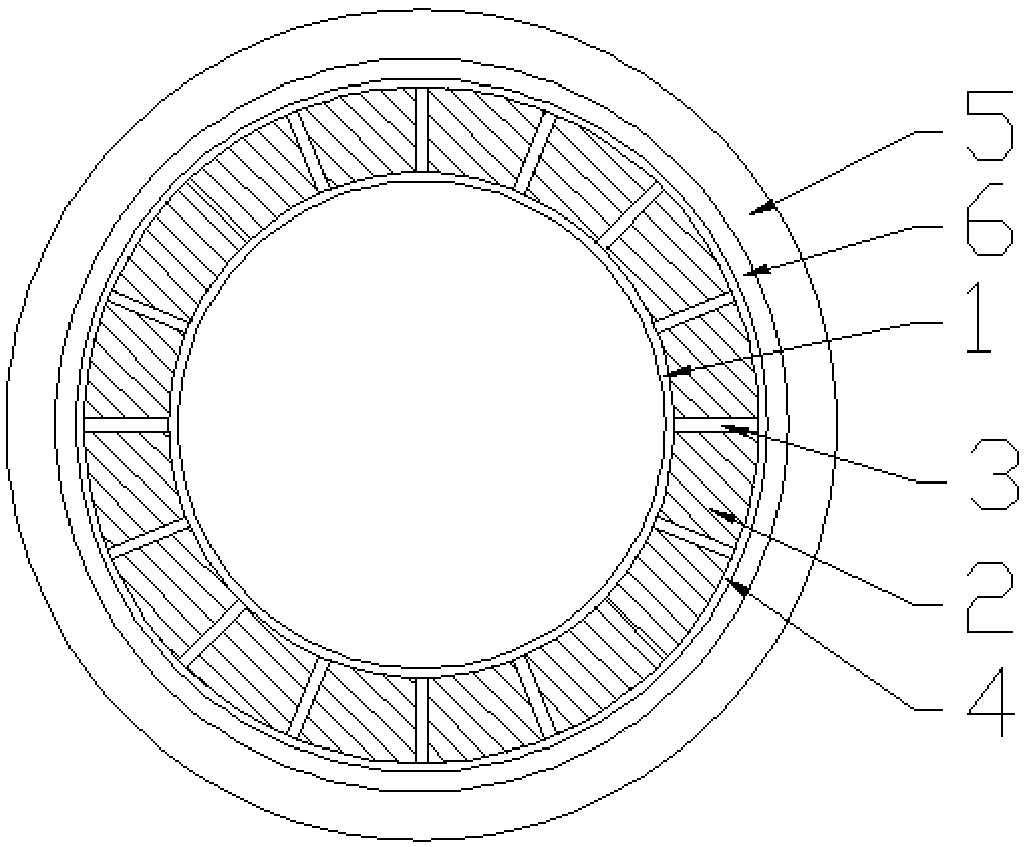

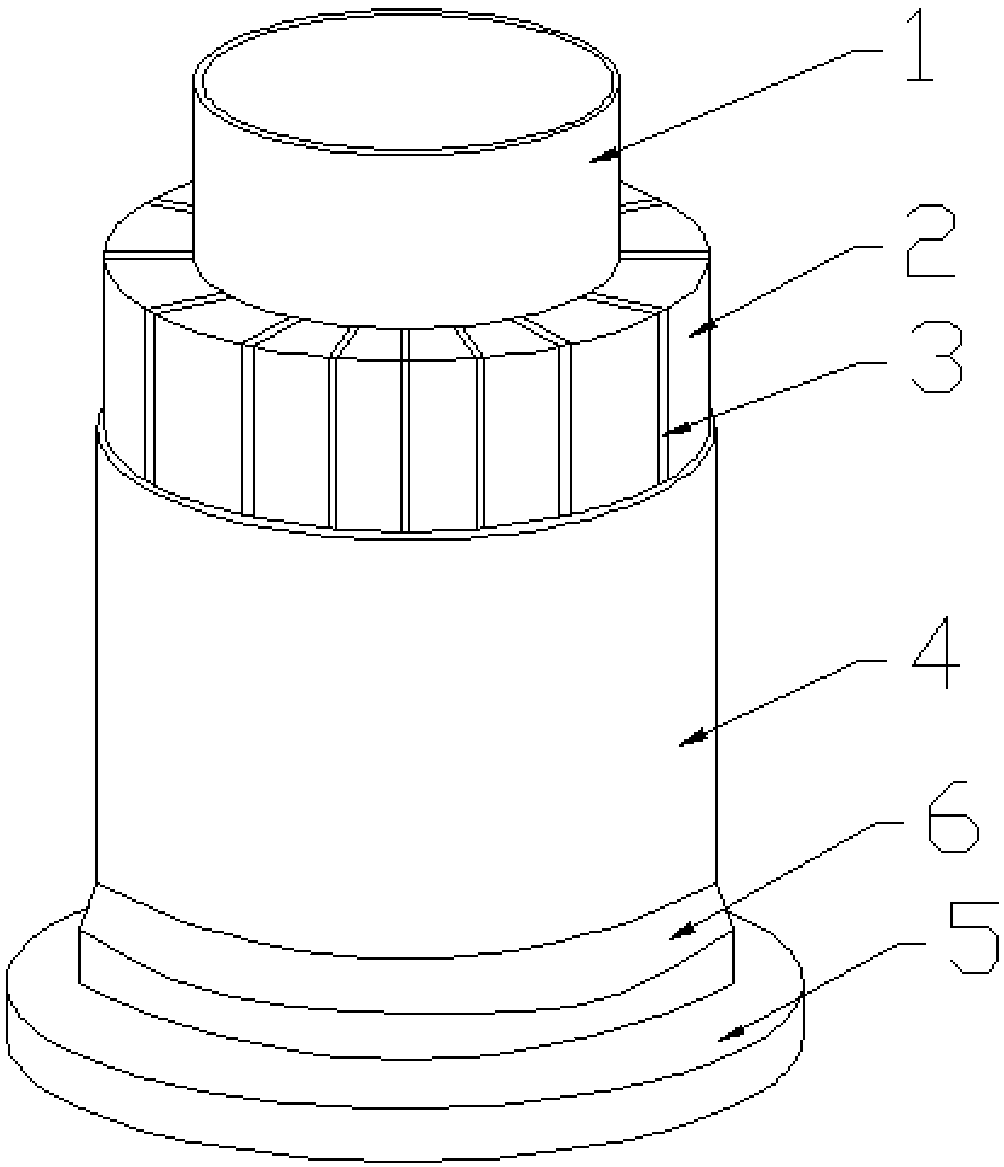

[0030] This embodiment provides a lattice-reinforced composite foam sandwich support column, such as figure 1 As shown, including support column body, support surface connection flange and end wrap reinforcement, such as figure 2 , image 3 As shown, the main body of the support column includes a cylindrical composite material inner skin 1 and a composite material outer skin 4, and a foam slat 2 is arranged between the composite material inner skin 1 and the composite material outer skin 4, and the foam slat 2 The outer side is wrapped with composite material, and the composite material along the wall thickness direction connects the composite material inner skin 1 and the composite material outer skin 4 to form a composite material lattice 3, that is, a composite material lattice is arranged between the foam slats 2 3. Composite material lattices 3 are equally spaced between the foam slats 2, and the composite material inner skin 1 and the composite material outer skin 4 ar...

Embodiment 2

[0037] This embodiment provides a method for preparing a lattice-reinforced composite foam sandwich support column, which includes the following specific steps:

[0038] (1) Preparation of foam slats: According to the design requirements of the component size, the foam slabs are cut into foam slats with a trapezoidal cross section in advance. According to the requirements, 32 isosceles trapezoidal cross-section foam slats 2 are cut, with a length of 2000mm and a thickness of 40mm. Upper bottom 37mm, lower bottom 44mm, spare;

[0039] (2) Fiber cloth wrapping foam slats: Wrap fiber cloth on the outside of foam slats and fix them with fiber filaments; cut the glass fiber plain weave cloth with a thickness of 0.5mm into 2000mm long strips with a width of 330mm, totaling 32 pieces. Then the foam slat 2 that is cut is wrapped up with glass fiber plain weave cloth, and is fixed with fiber silk, and the fiber cloth thickness on every foam slat 2 is 1.5mm at this moment, is dried for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com