Patents

Literature

55results about How to "Increased shear stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

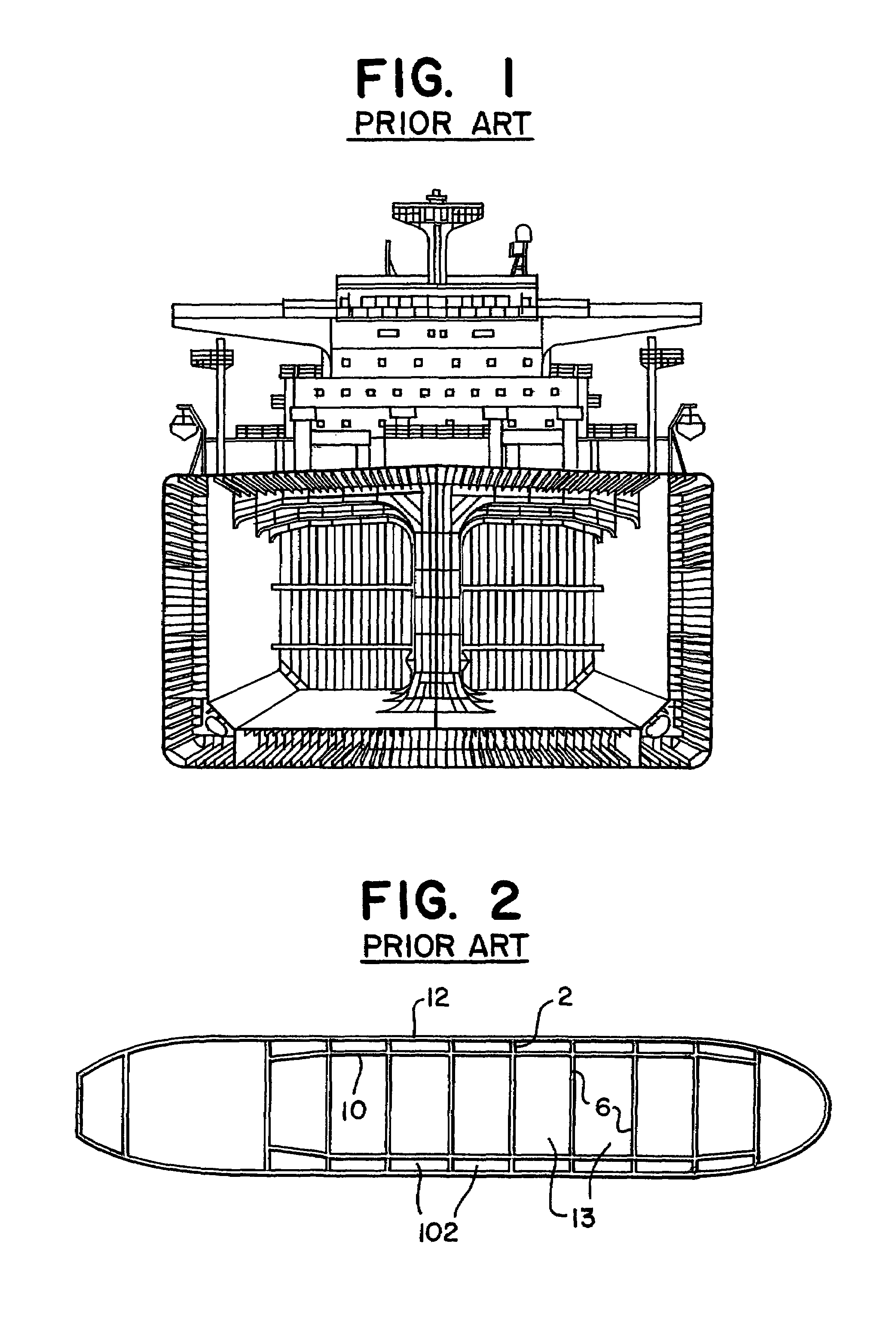

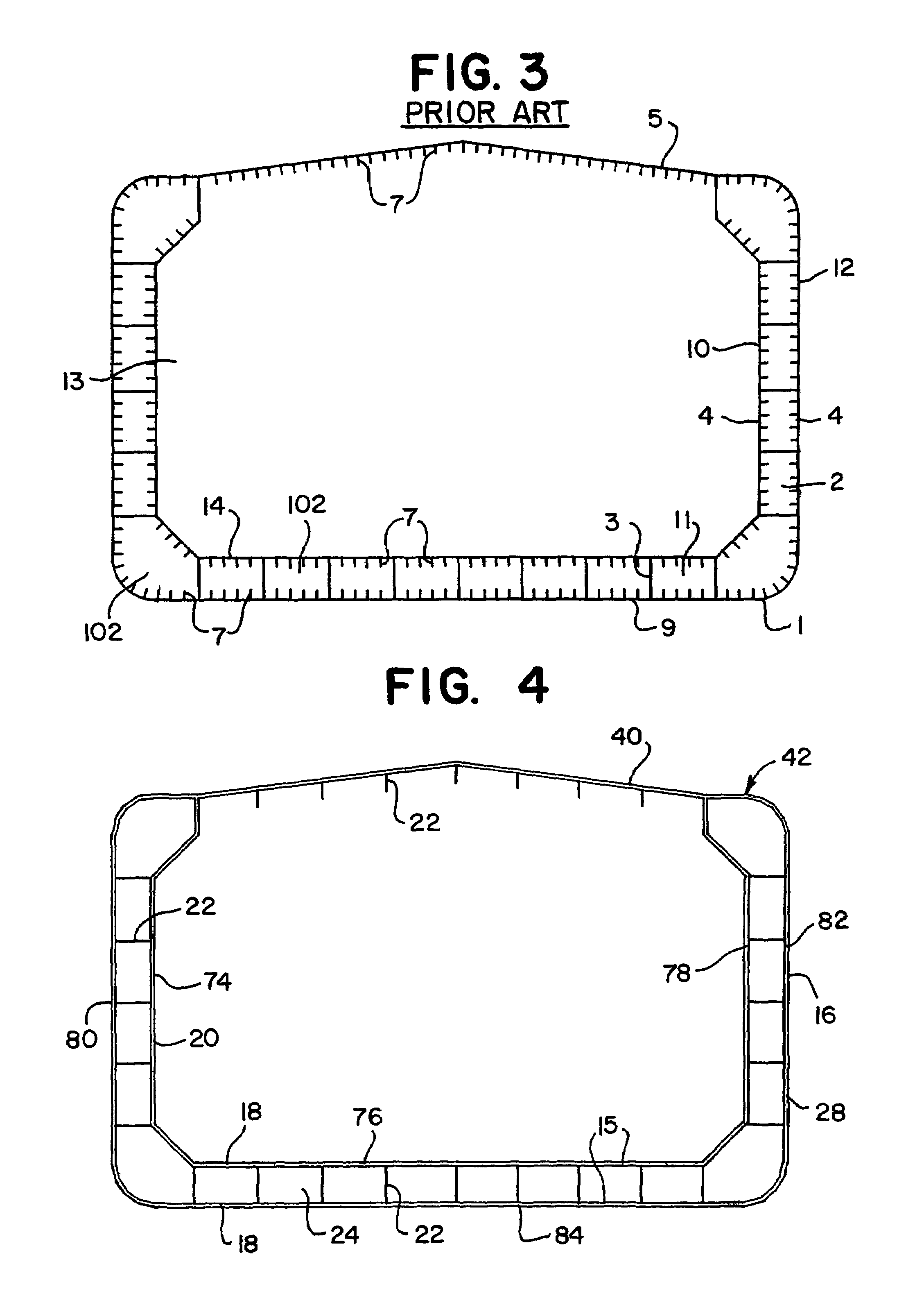

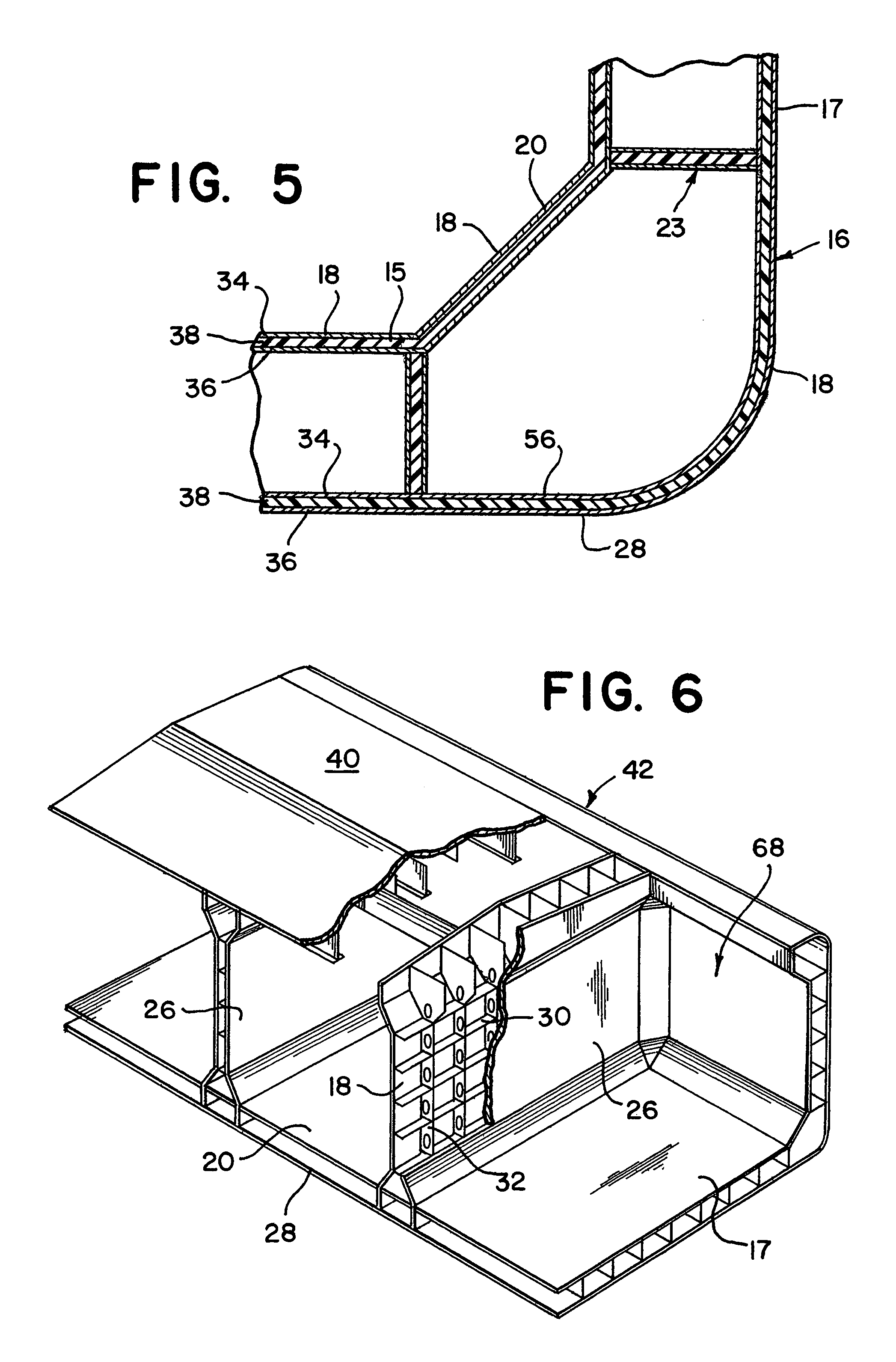

Composite steel structural plastic sandwich plate systems

InactiveUS6984452B2Solve the lack of ductilityReduce in quantityNon-magnetic metal hullsSynthetic resin layered productsStress concentrationComposite construction

Owner:INTELLIGENT ENG BAHAMAS

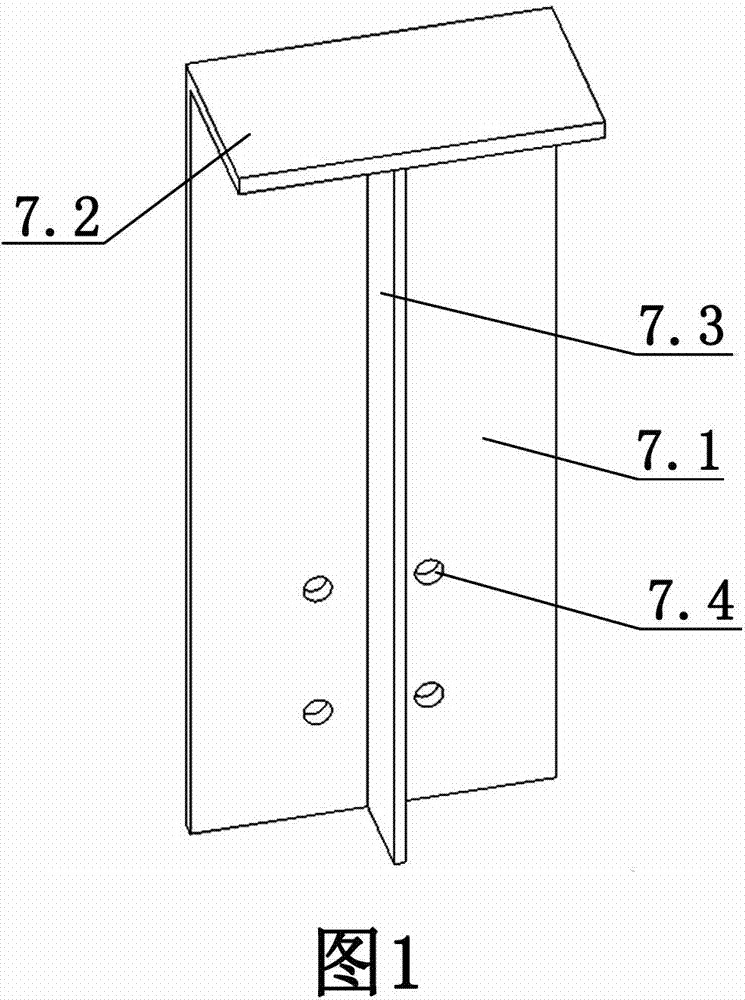

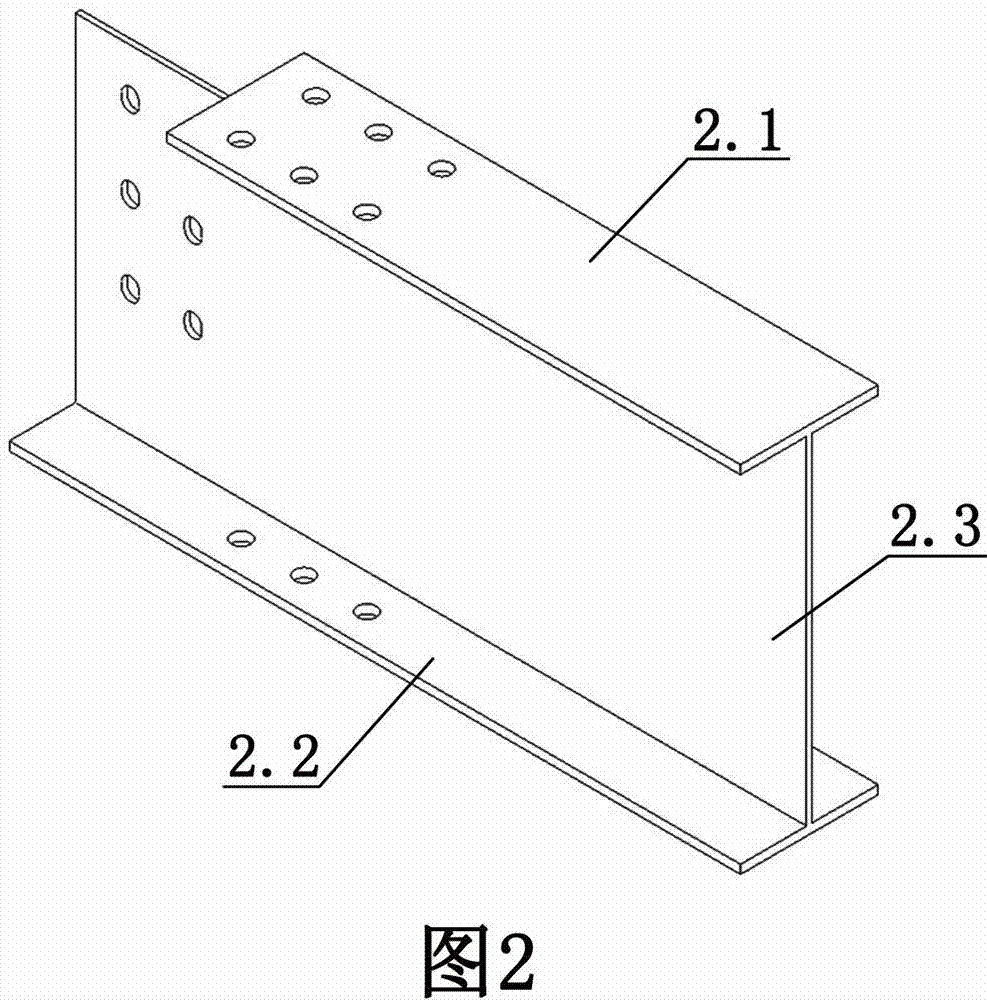

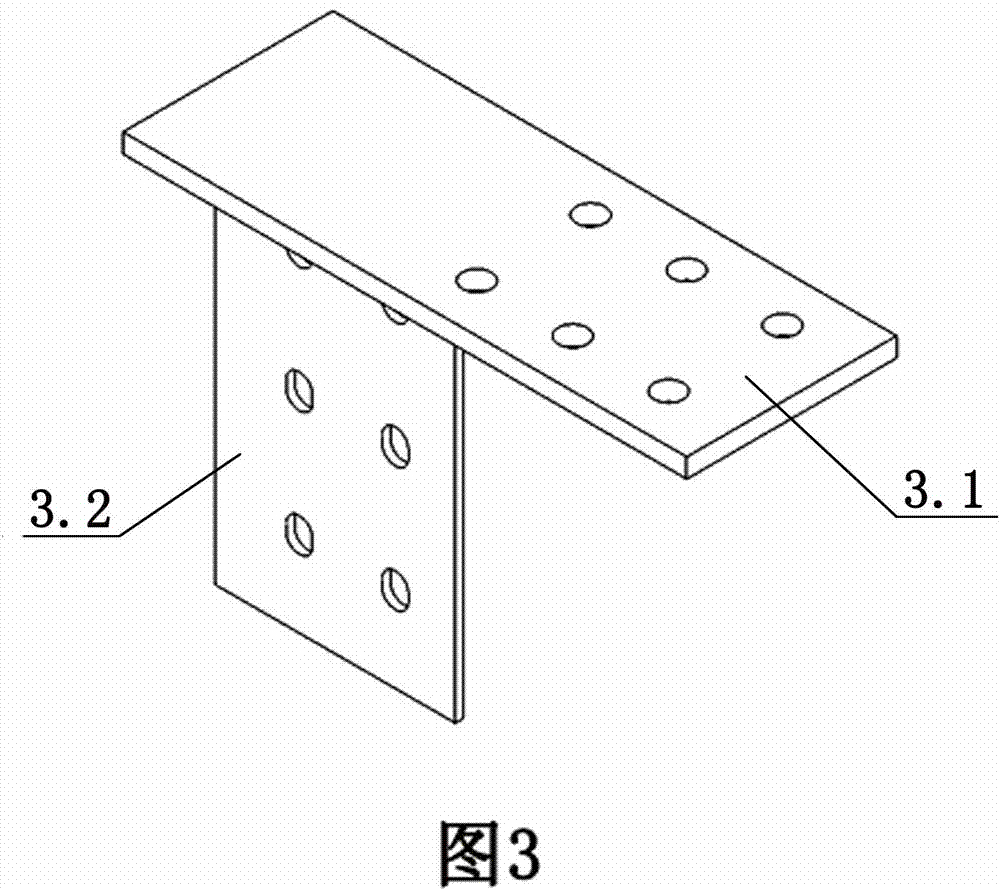

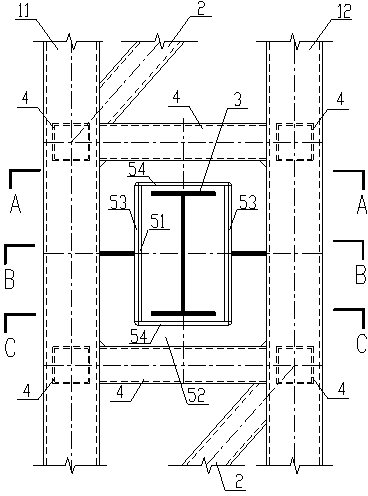

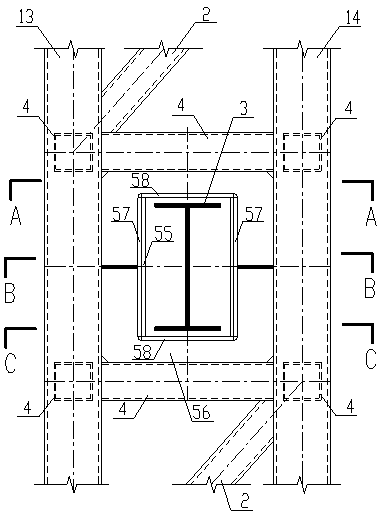

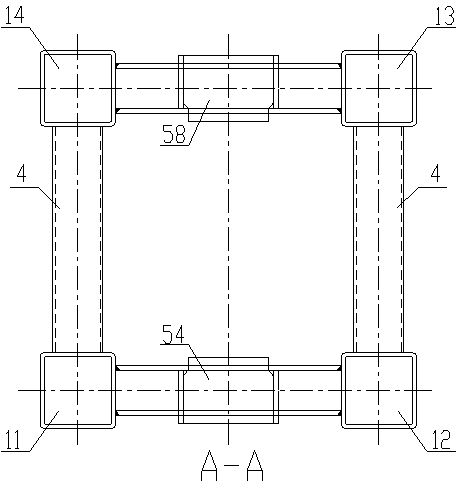

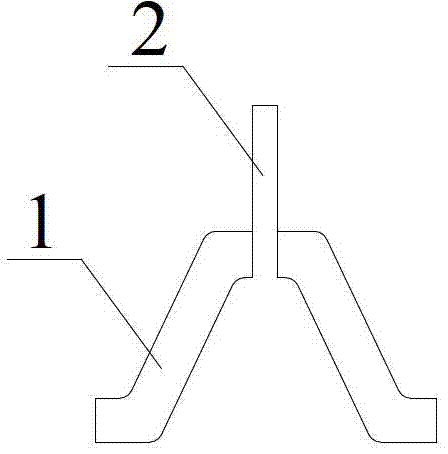

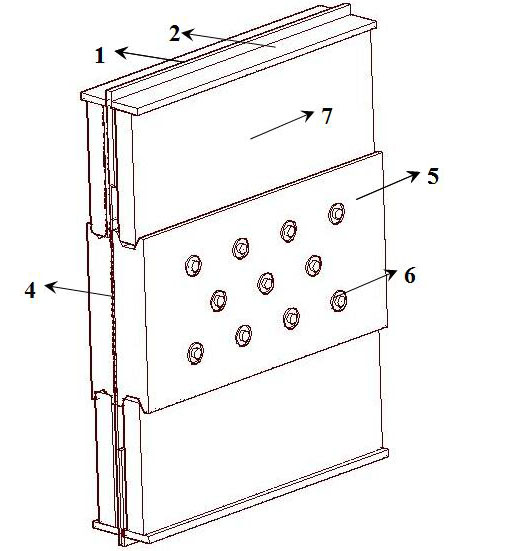

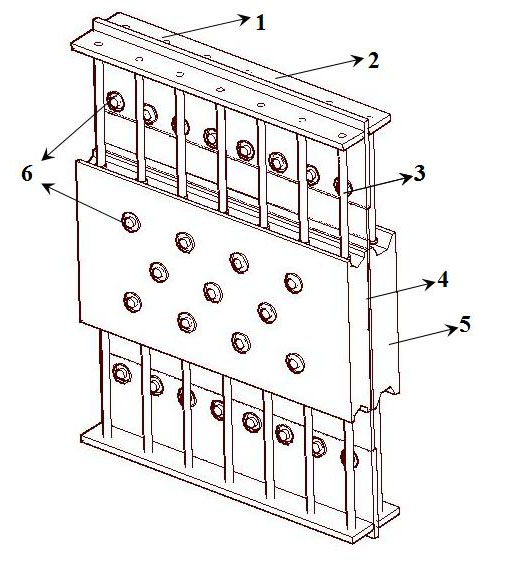

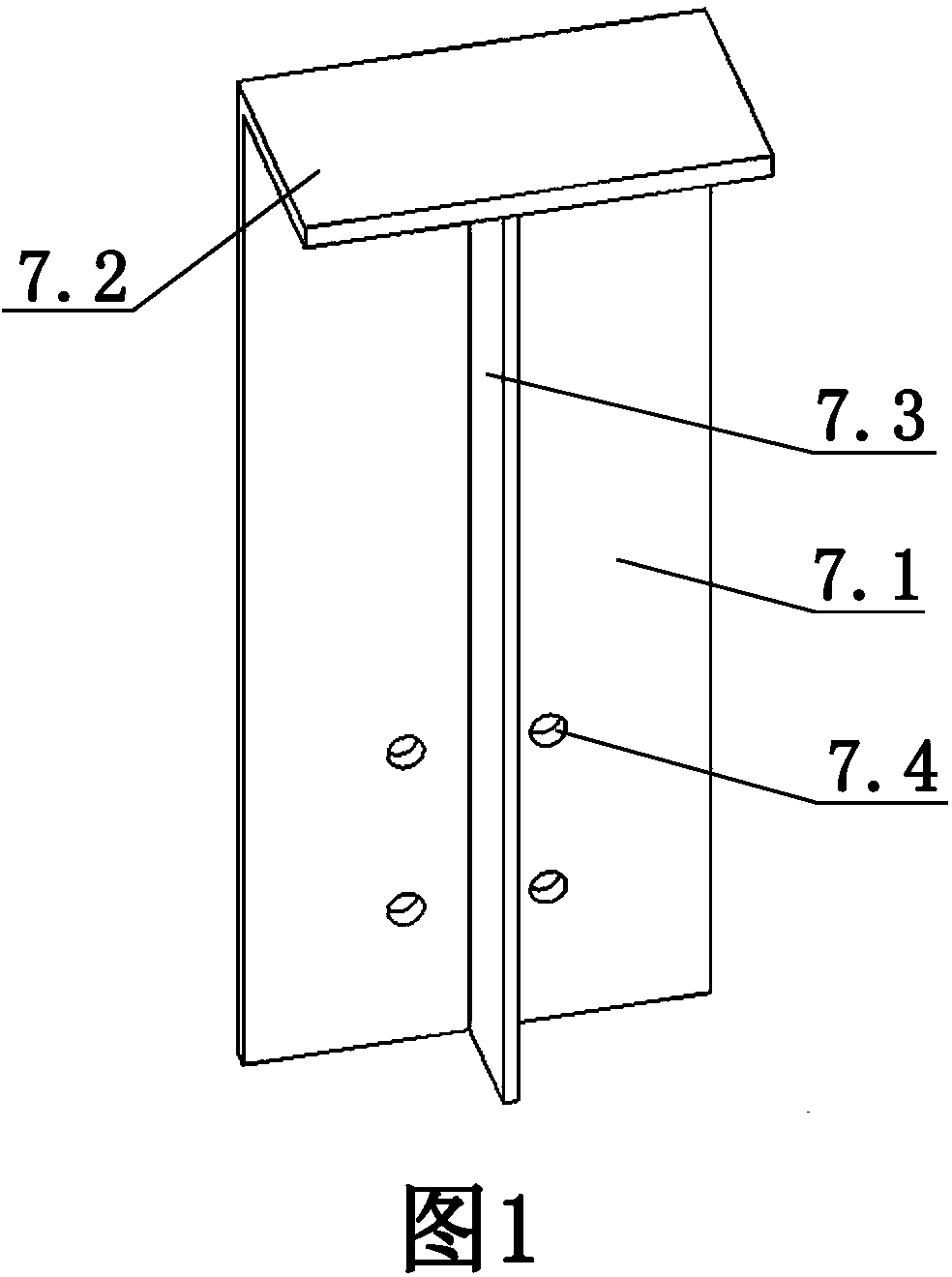

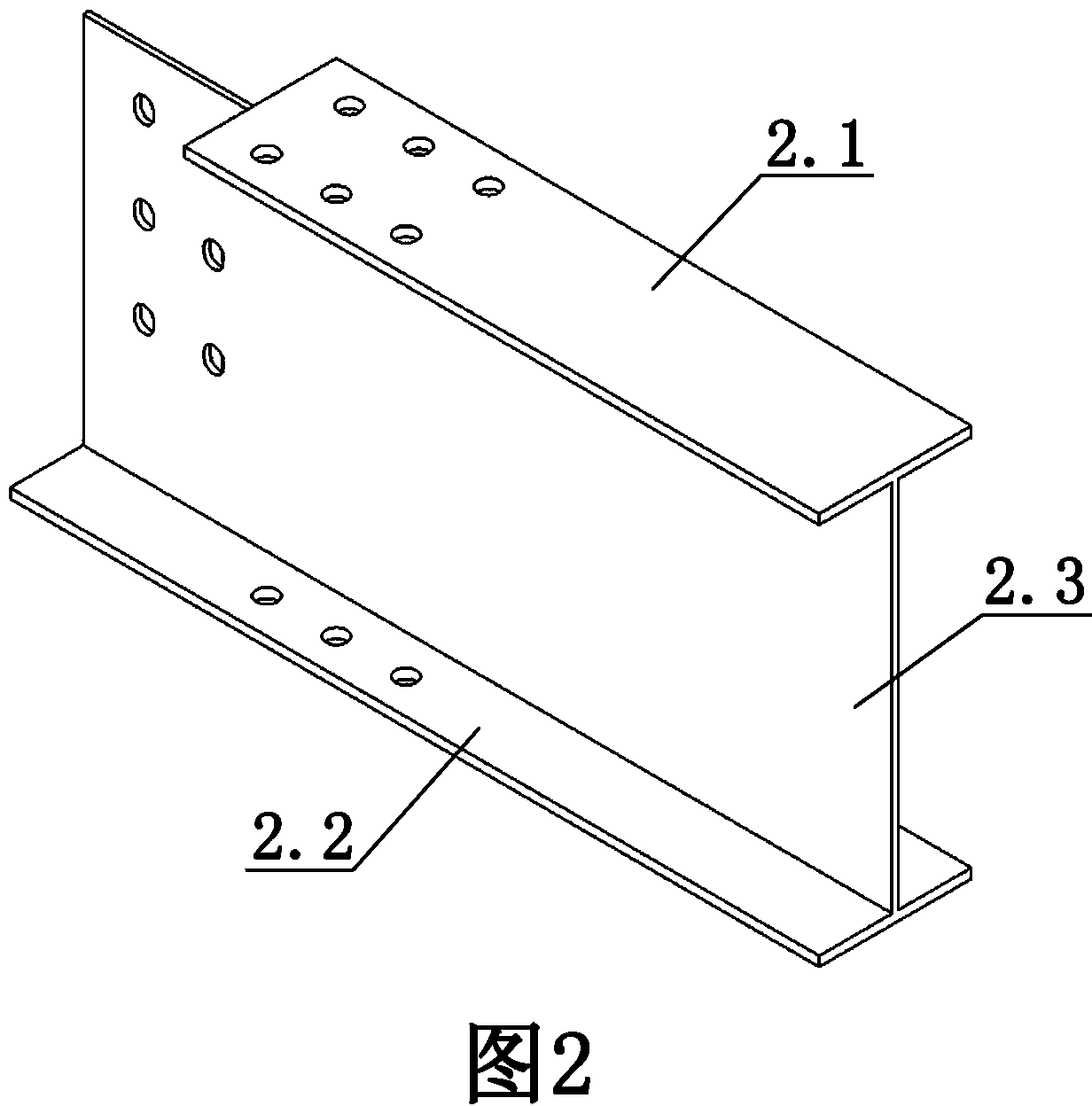

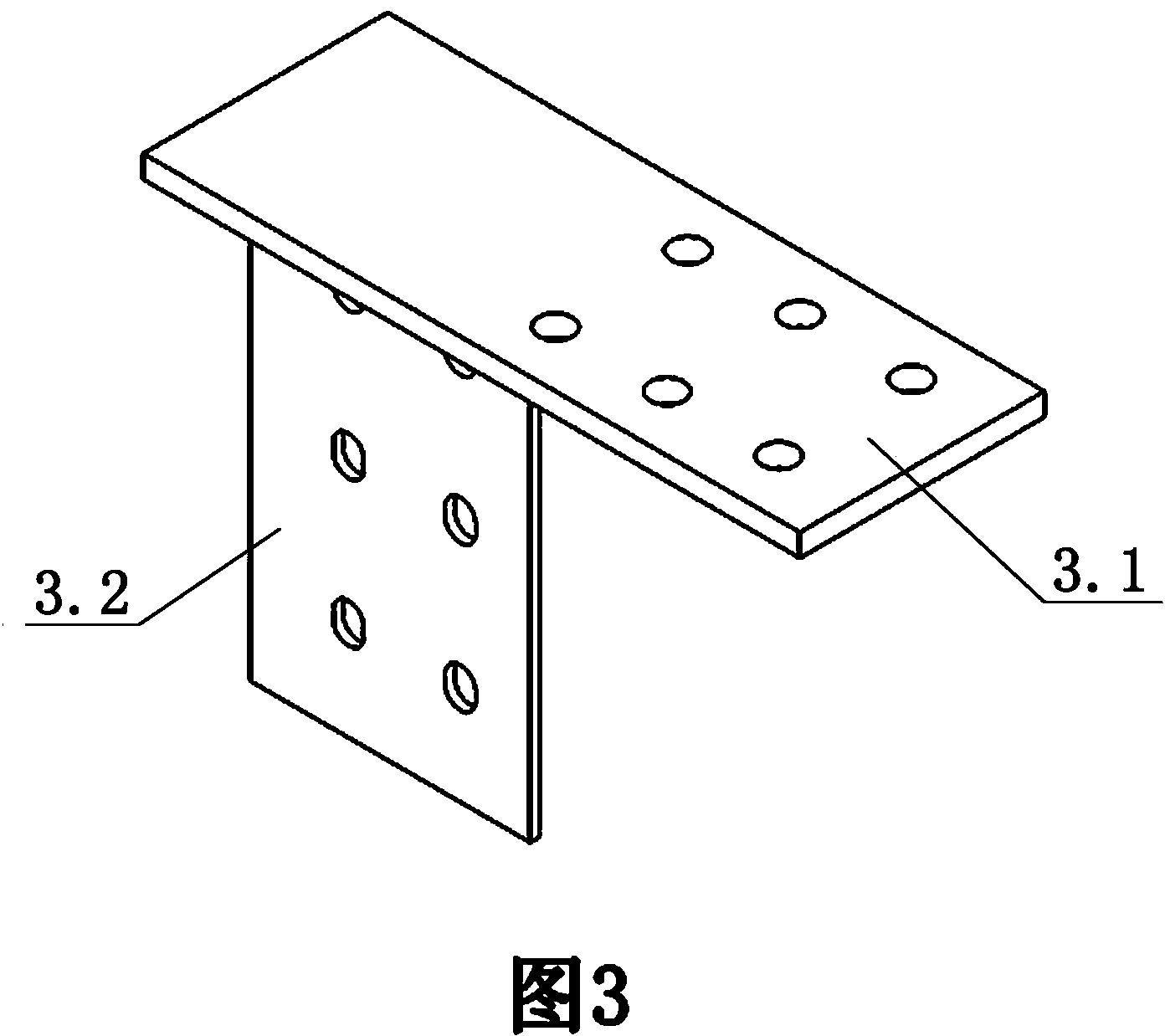

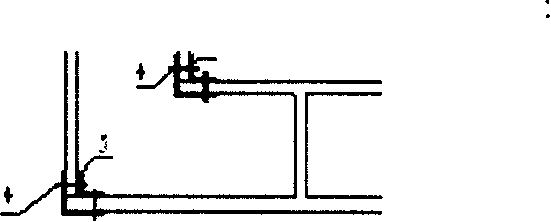

H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and construction method thereof

InactiveCN102733492AMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingSteel columnsMinor axis

The invention discloses an H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a column sealing piece, a T-shaped connection piece, an L-shaped connection piece and bolts. The column sealing piece consists of a column sealing plate, a beam upper flange stiffening rib and a column sealing plate stiffening rib; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

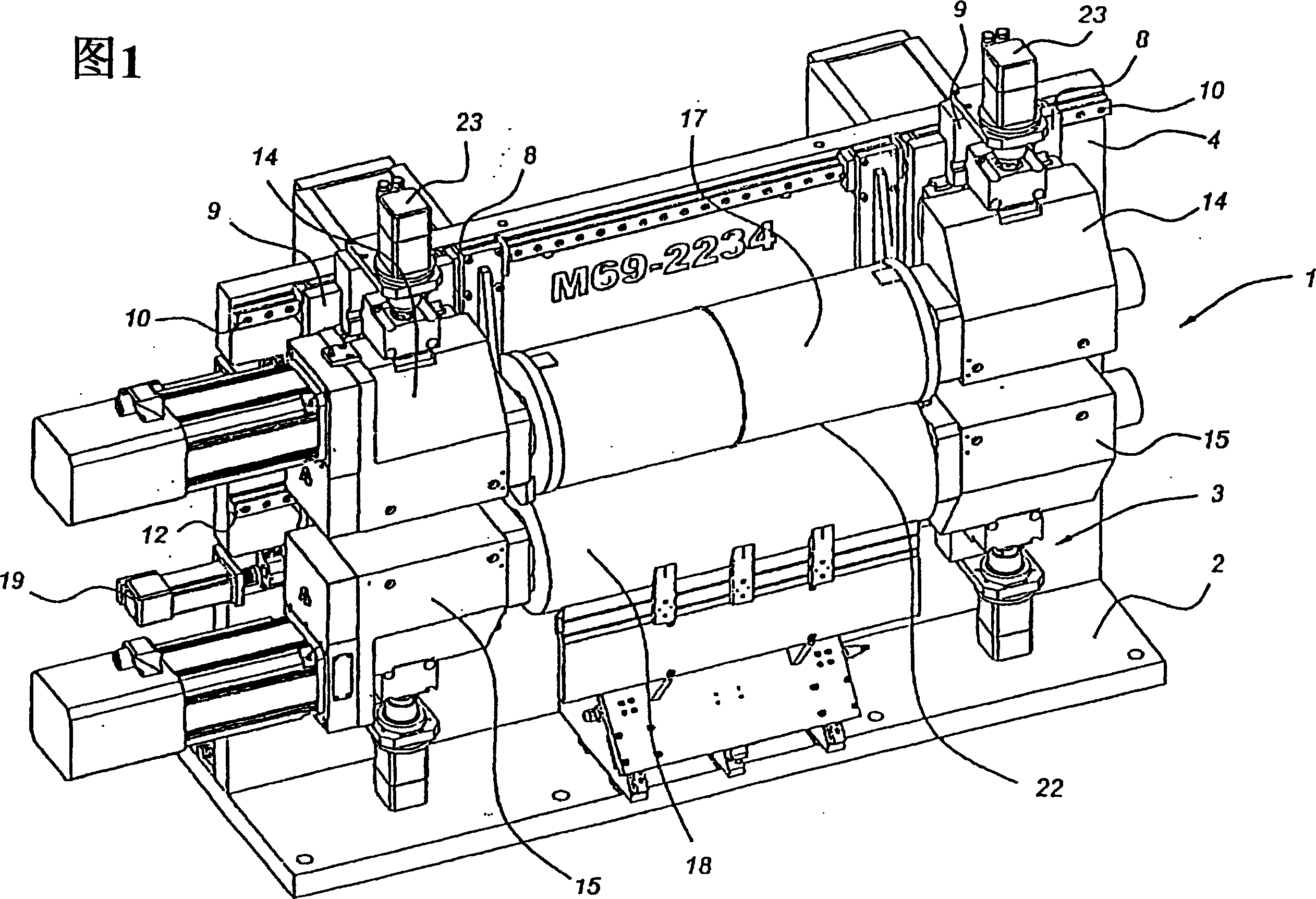

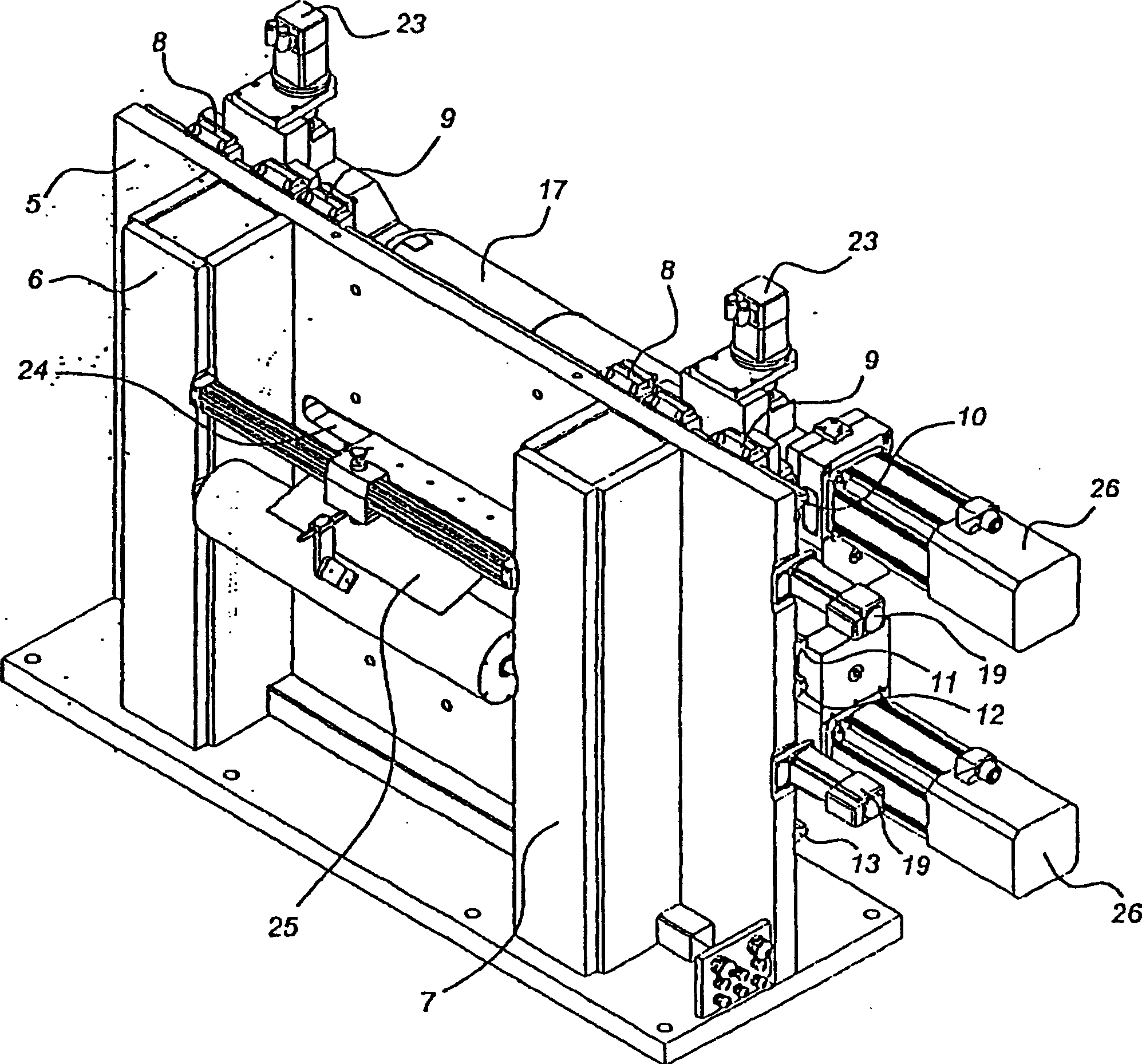

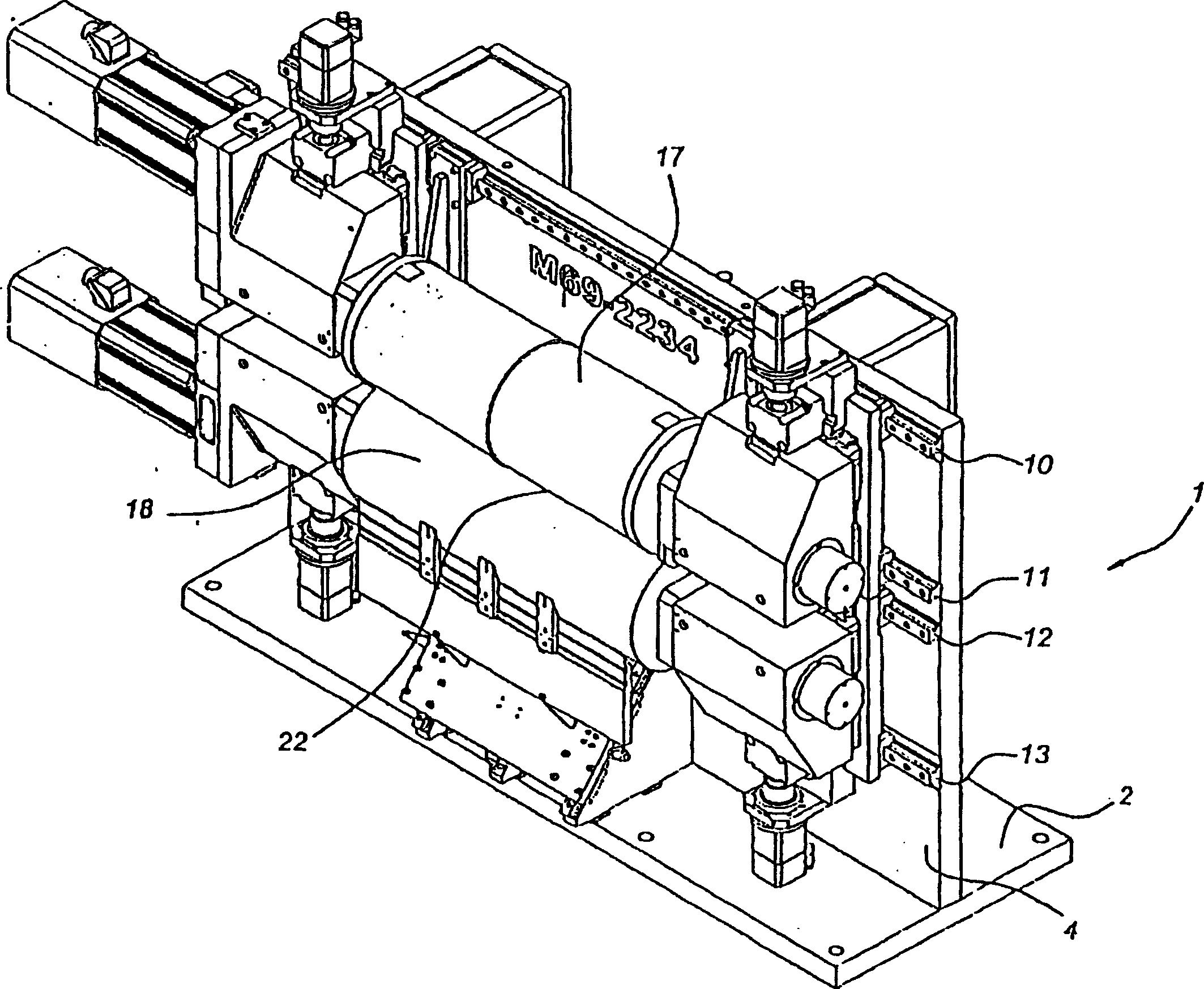

Rubber blanket sleeve for an offset printing machine and method of making

InactiveUS6382102B1Increased shear stiffnessImprove rigidityPrinting blanketsDomestic articlesElastomerEngineering

Rubber blanket sleeve for a channel-free rubber blanket cylinder of an offset printing machine and process of producing rubber blanket sleeve. The rubber blanket sleeve includes an inner, dimensionally stable support sleeve arranged as a supporting layer, and a microporous compressible elastomer layer having a compressibility within a range between about 7% and 15% with a load of 100 N / cm2. The elastomer layer includes a rubber matrix having a tensile stress of greater than about 2.2 N / mm2 and less than about 15 N / mm2 with 100% elongation. An outer covering rubber layer is arranged as a printing layer. All of the layers are composed of seamless, cylindrical bodies and are coupled to one another. The process includes arranging an inner, dimensionally stable support sleeve as a supporting layer, and positioning a microporous compressible elastomer layer having a compressibility within a range between about 7% and 15% with a load of 100 N / cm2 over the support sleeve. The elastomer layer includes a rubber matrix having a tensile stress of greater than about 2.2 N / mm2 and less than about 15 N / mm2 with 100% elongation. The process further includes arranging an outer covering rubber layer as a printing layer, such that all of the layers are composed of seamless, cylindrical bodies and are coupled to one another.

Owner:CONTITECH ELASTOMER BESCHICHTUNGEN

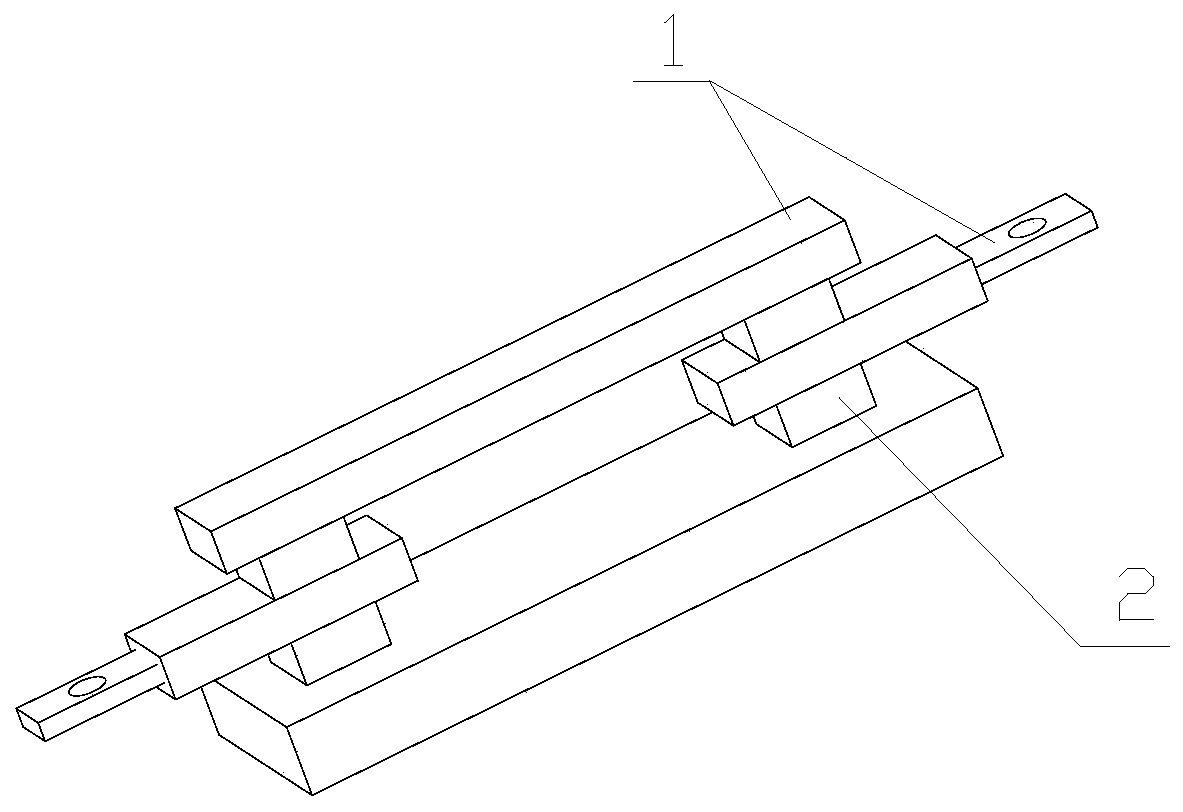

Installation for making a cut, crease and the like having a plate-shaped frame

InactiveCN1660551AHigh flexural rigidityIncreased shear stiffnessMechanical working/deformationMetal rolling stand detailsEngineeringMechanical engineering

Owner:吉恩亨利罗伯特马代恩

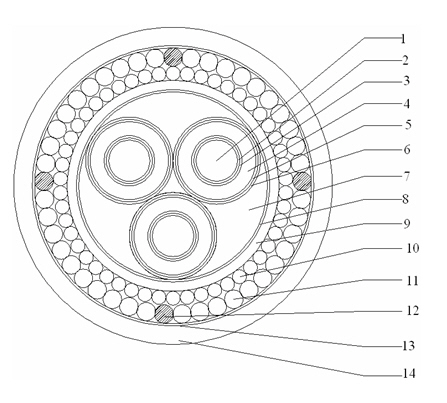

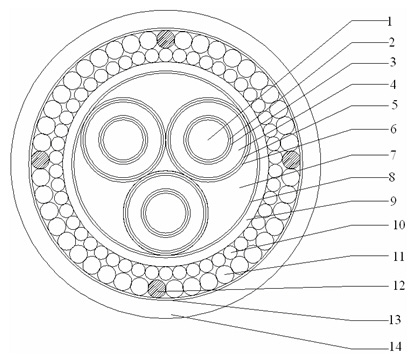

Seismic-resistant electrical cable

InactiveCN102157242AEven by forceLow elastic modulusPower cables with screens/conductive layersCopper conductorElastomer

The invention relates to a seismic-resistant electrical cable comprising a conductor, a semiconductive layer, a conductor shielding layer, an insulating layer, an insulating shielding layer, a copper strip shielding layer, an elastic body packing, a wrapping layer, an isolating sleeve, a thin round steel wire armoring layer, a thick round steel wire armoring layer, a copper conductor, an isolated layer and an outer sheath. The seismic-resistant electrical cable is characterized in that a semiconductive band layer is wrapped outside the conductor; insulating materials, packing materials, isolating sleeve materials and outer sheath materials are all elastic body polymers; and double-layer steel wire armoring is adopted for the armoring layers. The invention has higher shearing rigidity, bending rigidity and damping ratio, obvious effects of shear resistance, bending moment, axial force, torsion, and the like, and excellent seismic-resistant and seismic-proof capacity.

Owner:江苏天地龙电缆有限公司

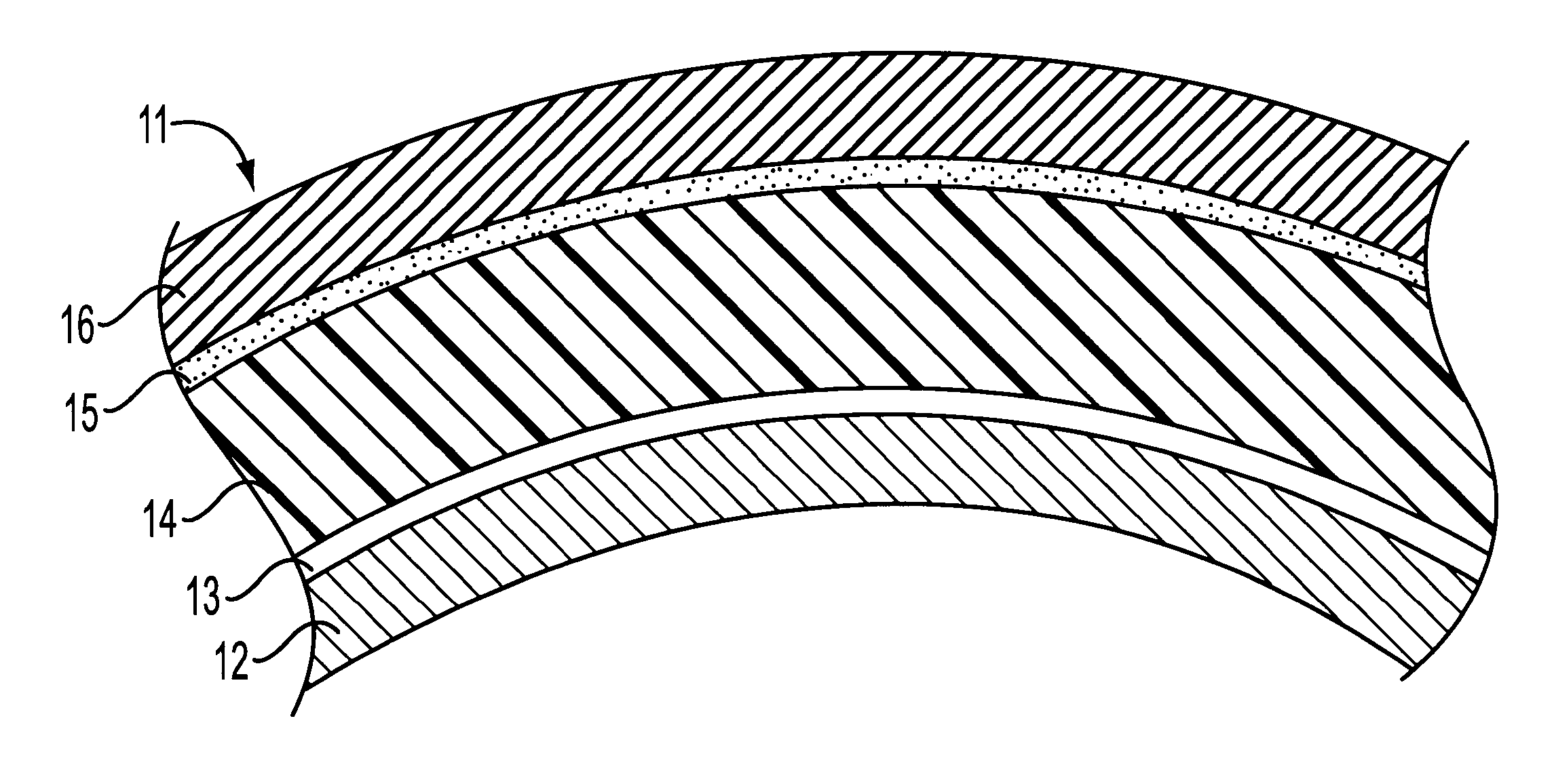

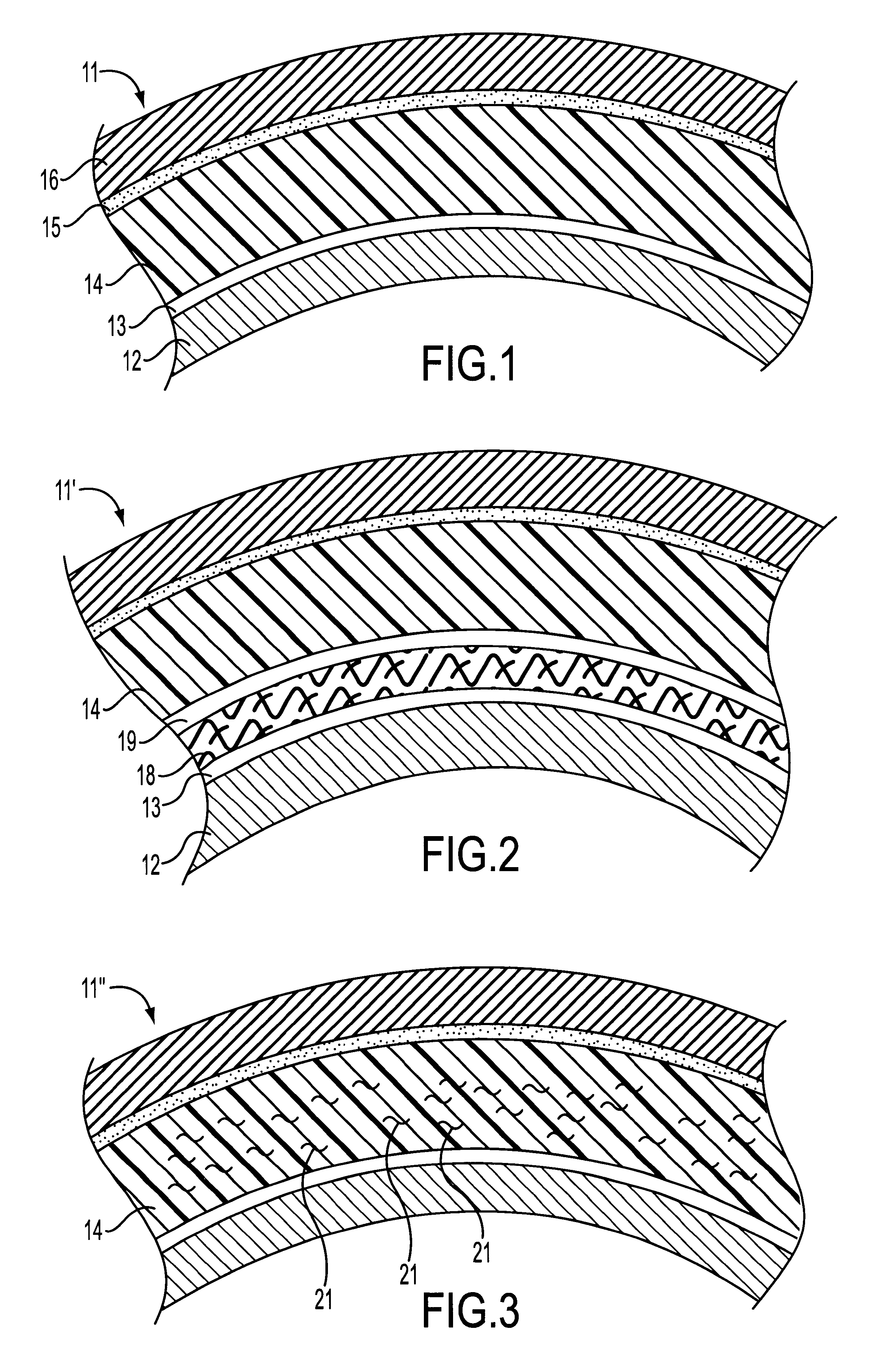

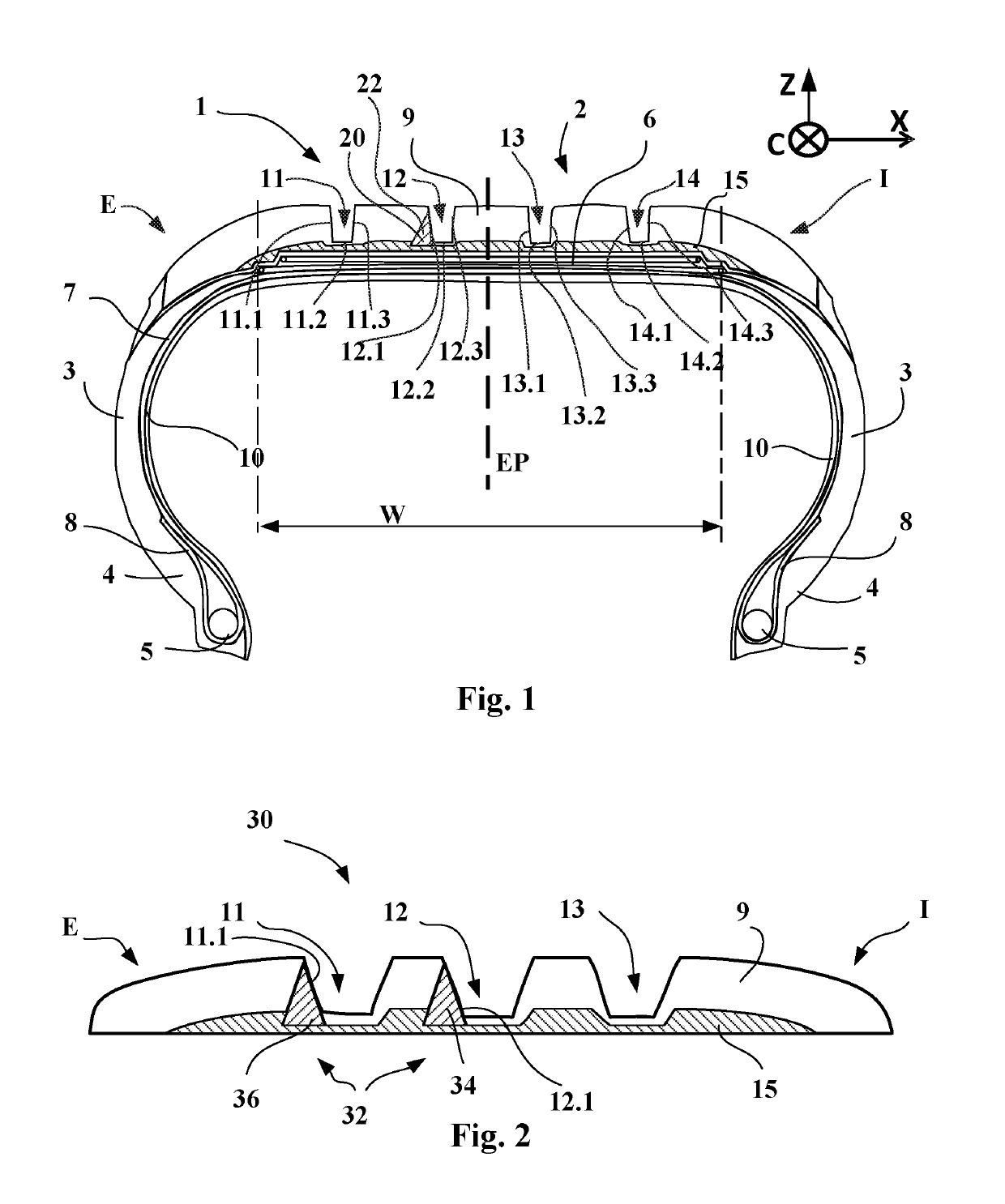

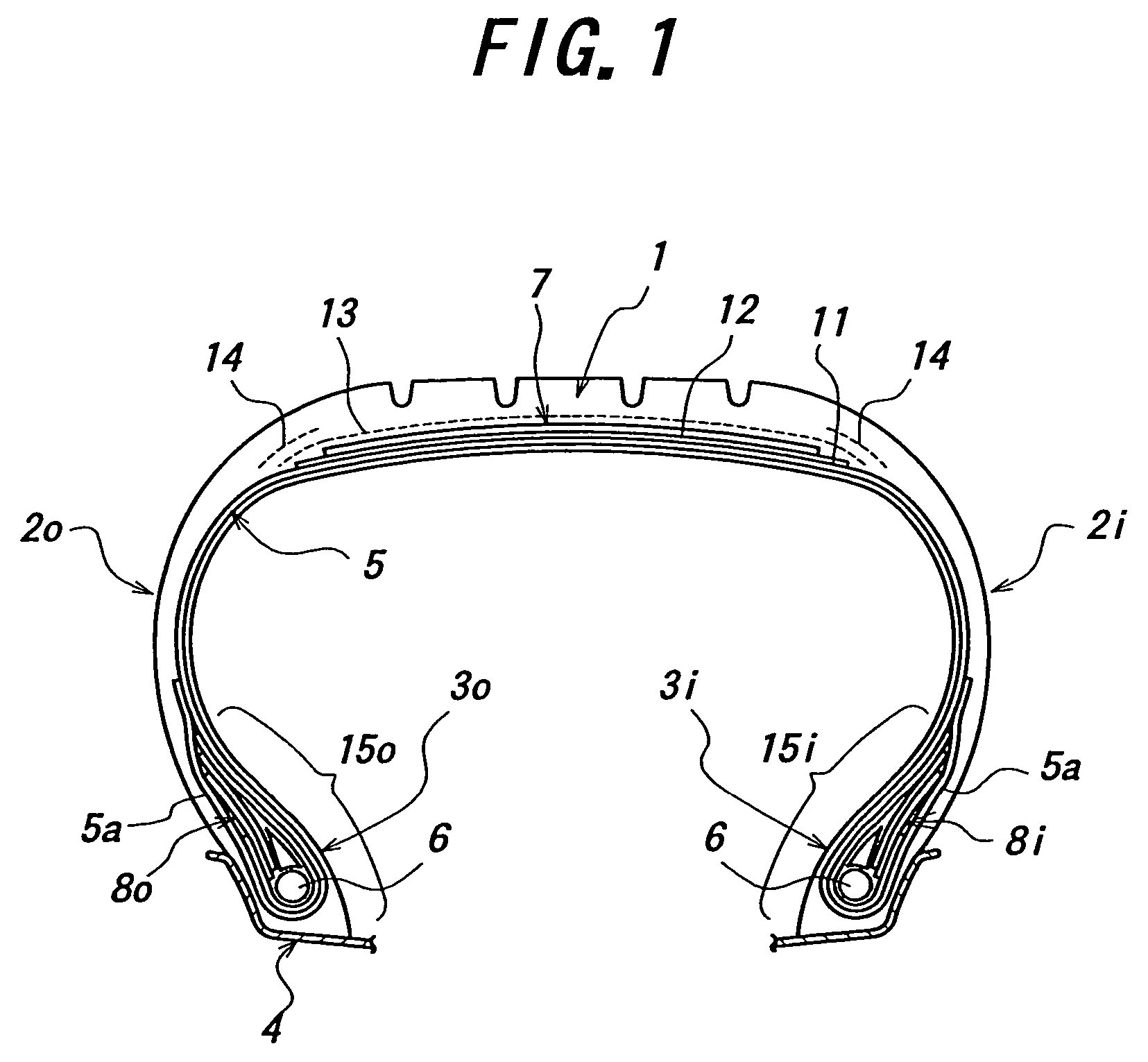

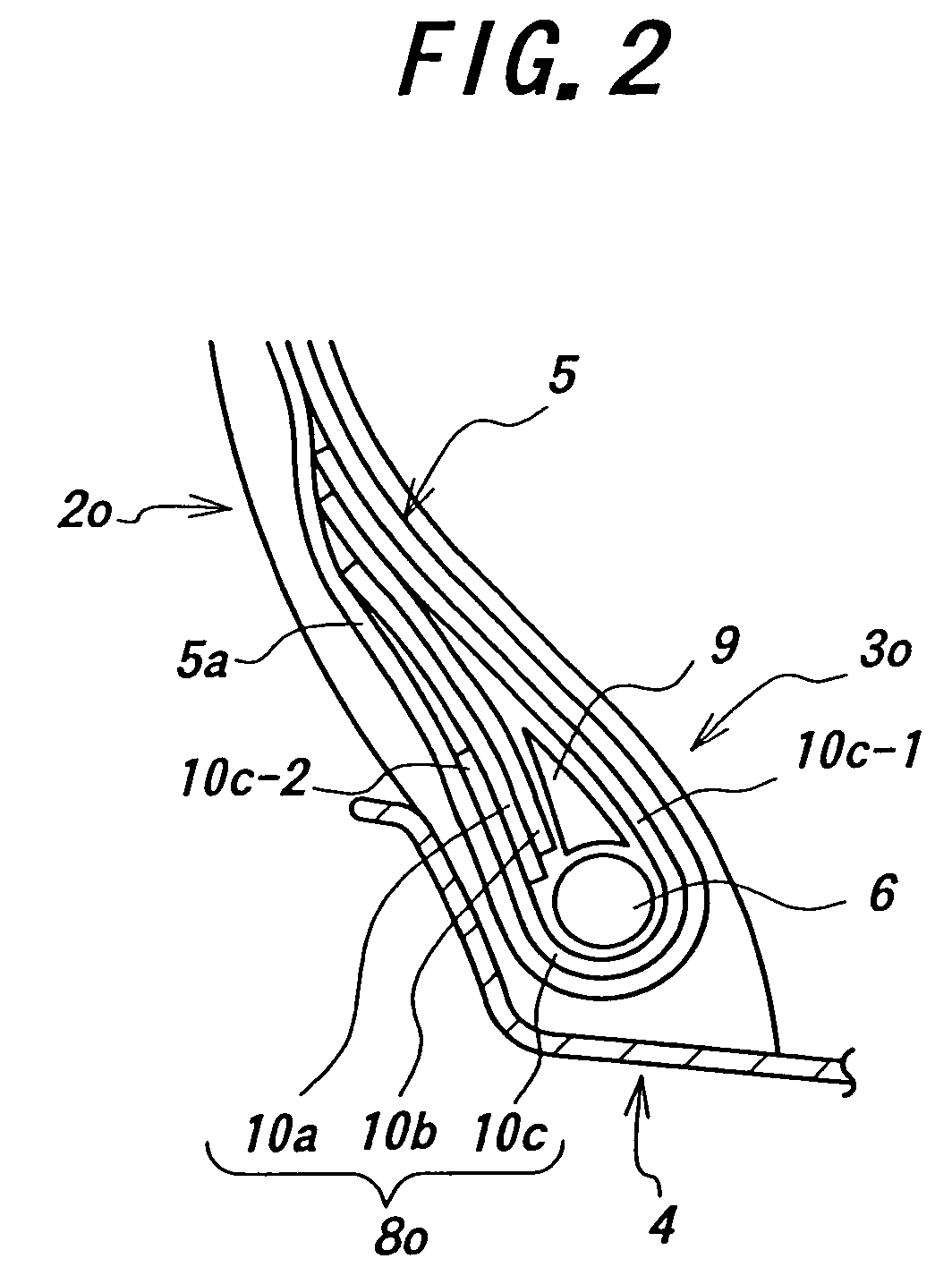

Tire comprising a tread containing reinforcing elements

ActiveUS20190255887A1Improve gripImprove efficiencyHeavy duty tyresHeavy duty vehicleBiomedical engineeringTread

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

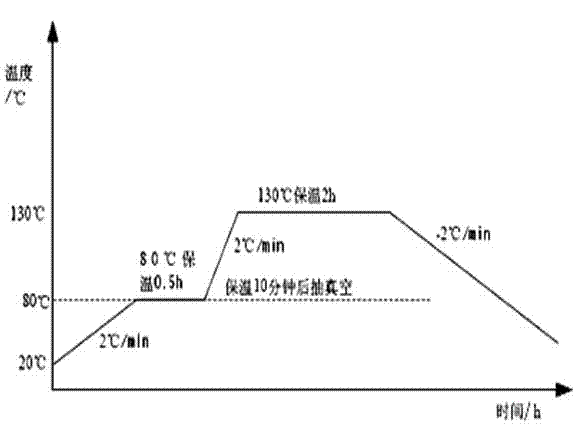

Preparation method of polyborosiloxane modified rubber

According to the preparation method of the polyborosiloxane modified rubber disclosed by the invention, polyborosiloxane is added into rubber to prepare the modified rubber material, so that the shearrigidity and the equivalent damping ratio of the modified rubber material are greatly improved, the zero displacement resistance is also increased, and the impact resistance and the vibration reduction performance of the prepared rubber material are obviously improved.

Owner:XI AN PEAK XUANKAI NEW MATERIAL CO LTD

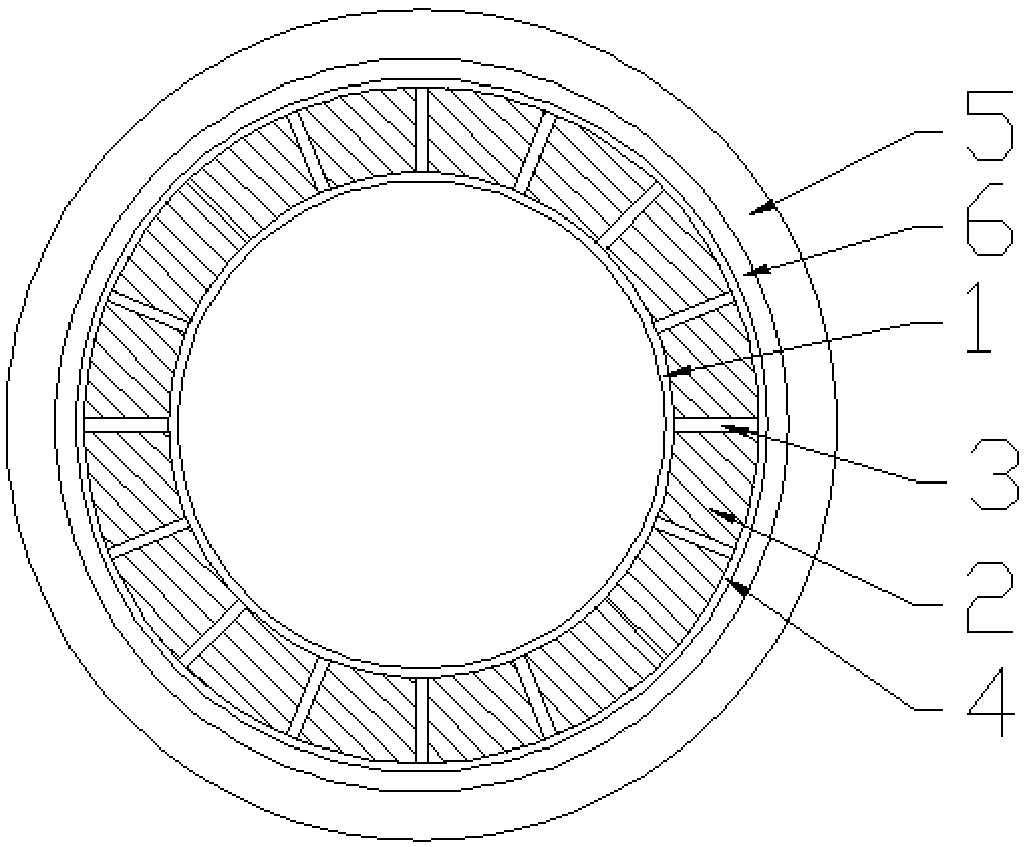

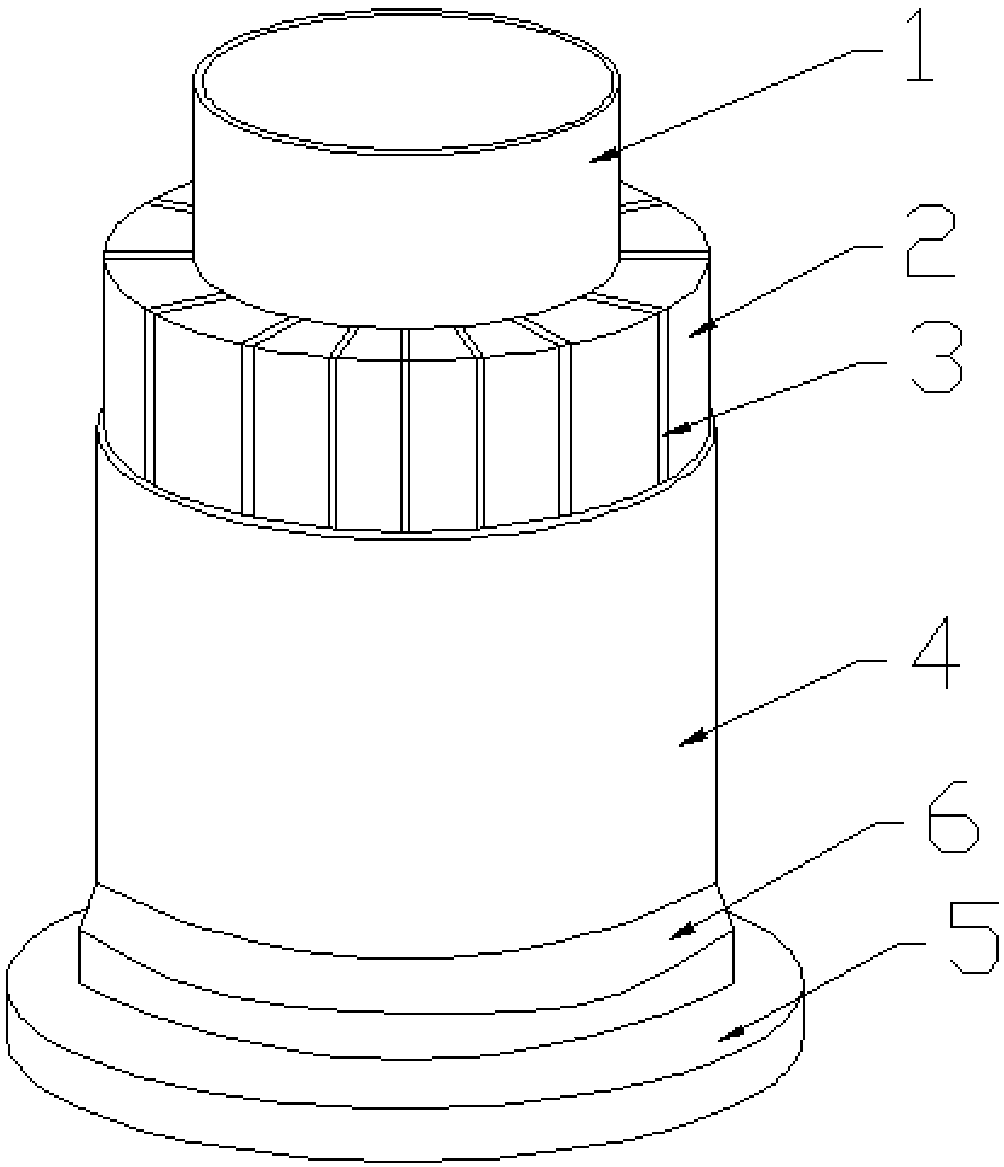

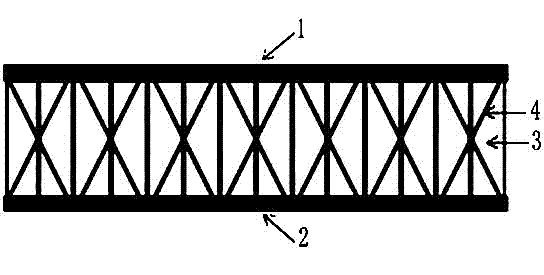

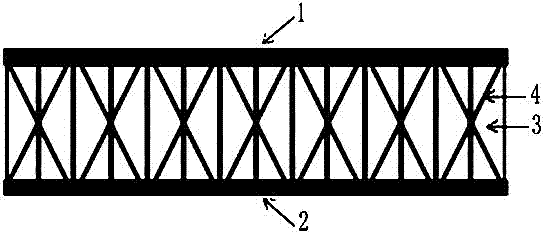

Lattice enhanced type composite material foam core sandwich supporting column and preparation method thereof

The invention discloses a lattice enhanced type composite material foam core sandwich supporting column and a preparation method thereof. A supporting column main body comprises a composite material inner skin and a composite material outer skin which are in cylindrical shapes, foam plate strips are arranged between the composite material inner skin and the composite material outer skin, compositematerial lattices are arranged between the foam plate strips, and the composite material lattices are distributed between the foam plate strips at equal intervals to connect the composite material inner skin with the composite material outer skin together. Supporting face connection flanges for being connected with a top structure or connected with another same supporting column are arranged at the two ends of the supporting column. End enhancing parts are arranged at the two ends of the outer skin of the supporting column. The lattice enhanced type composite material foam core sandwich supporting column can sharply improve the bearing efficiency under the precondition that the self weight of the structure is hardly increased, and meanwhile, the preparation method is low in cost and stable in property, and can prepare the lattice enhanced type composite material foam core sandwich supporting columns with large sizes.

Owner:ARMY ENG UNIV OF PLA

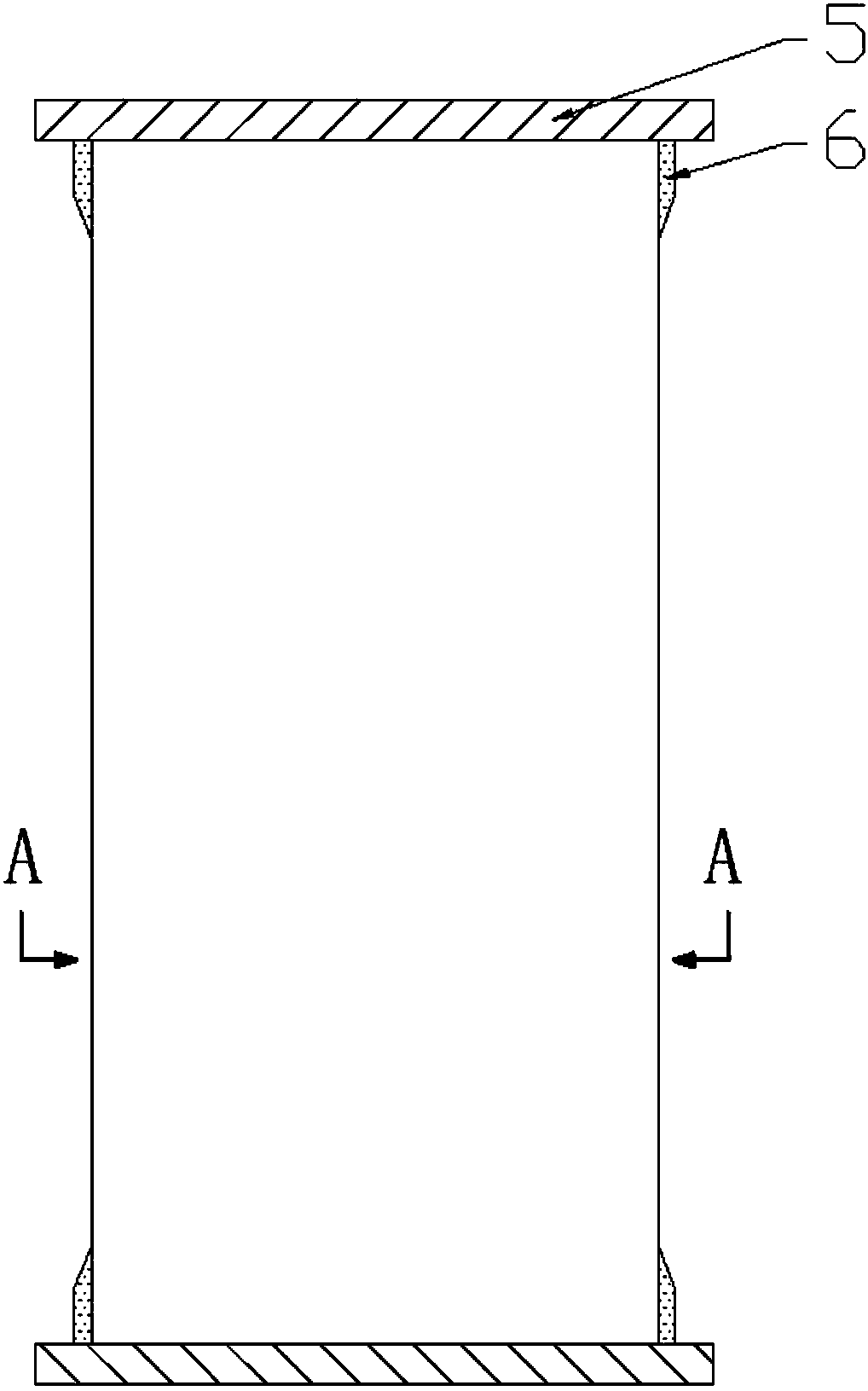

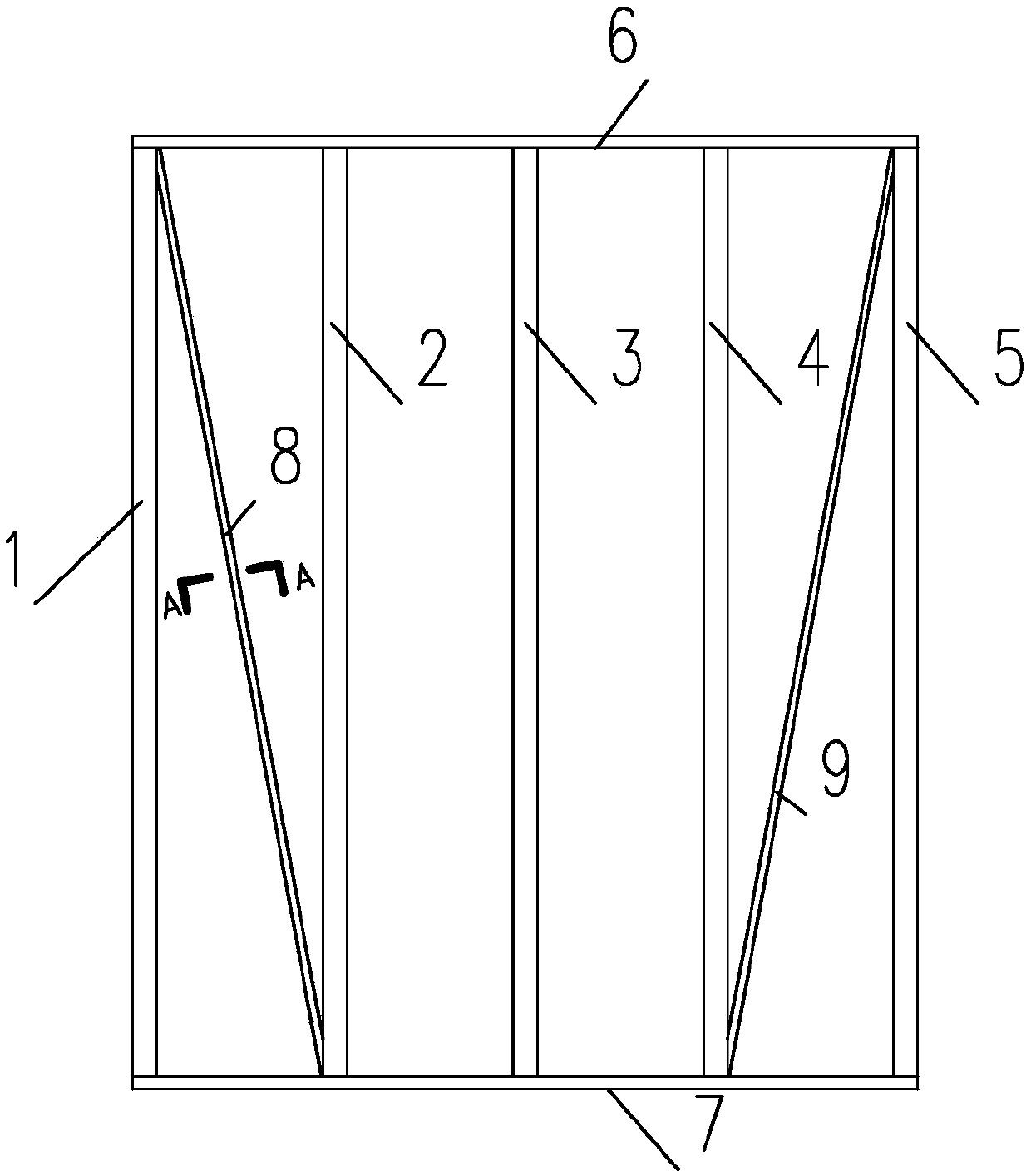

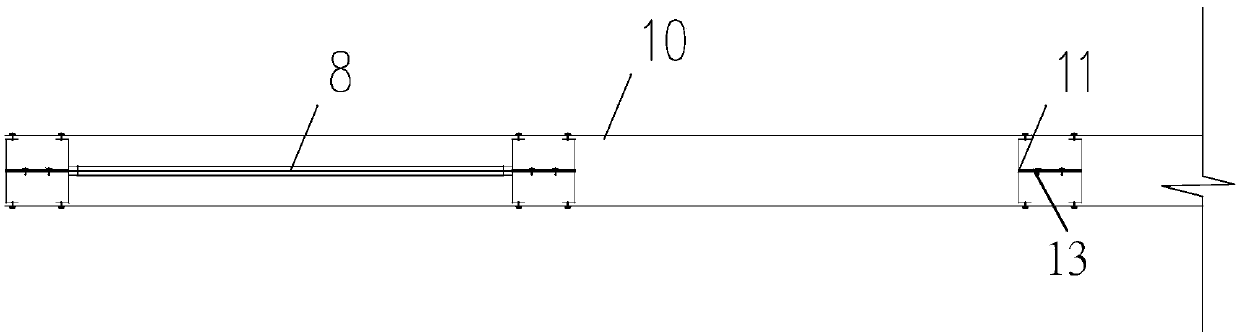

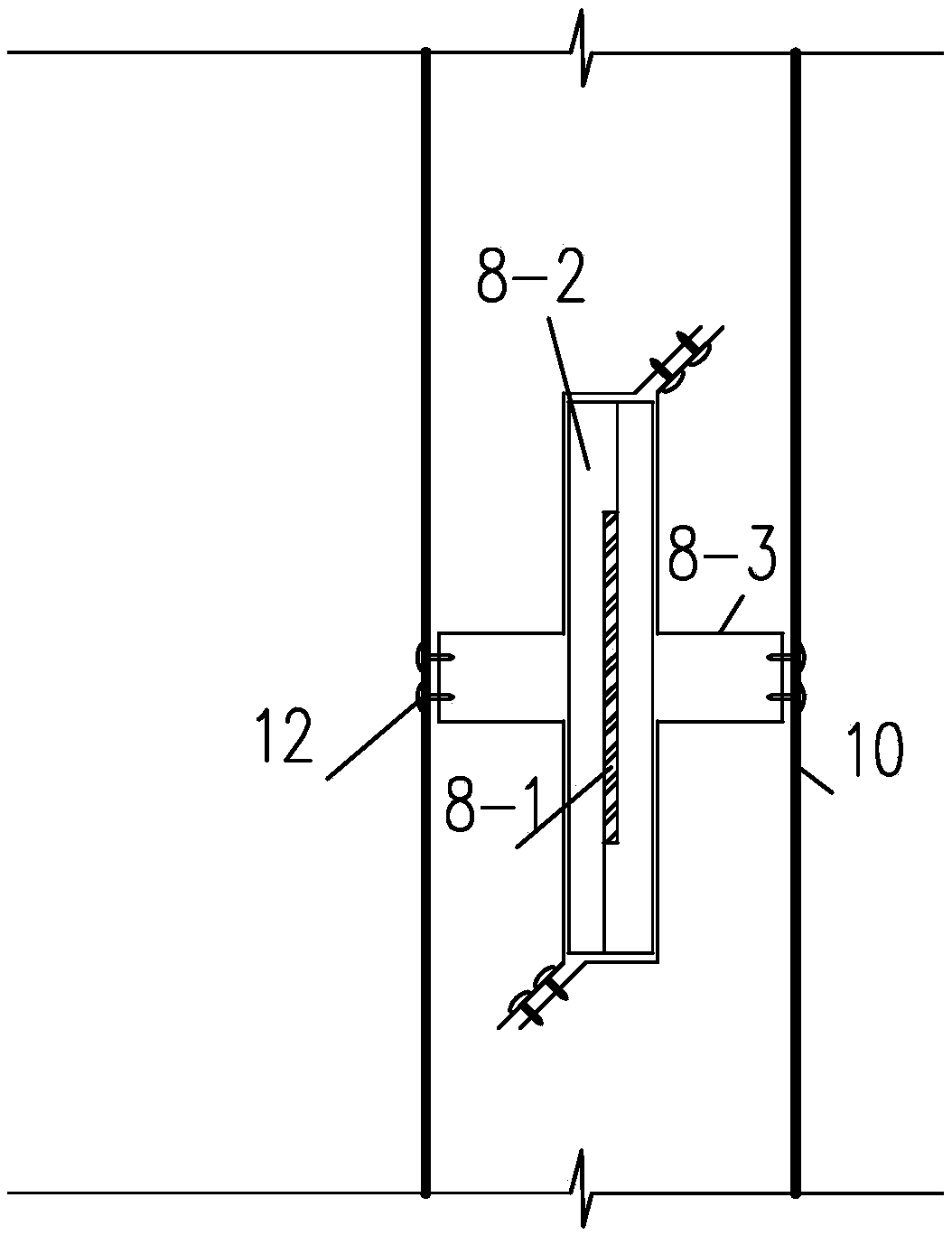

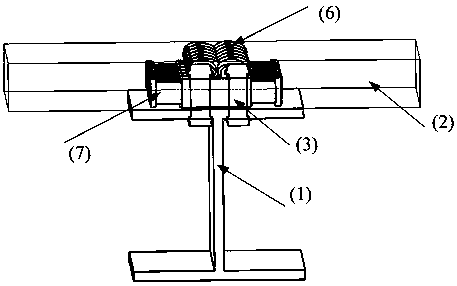

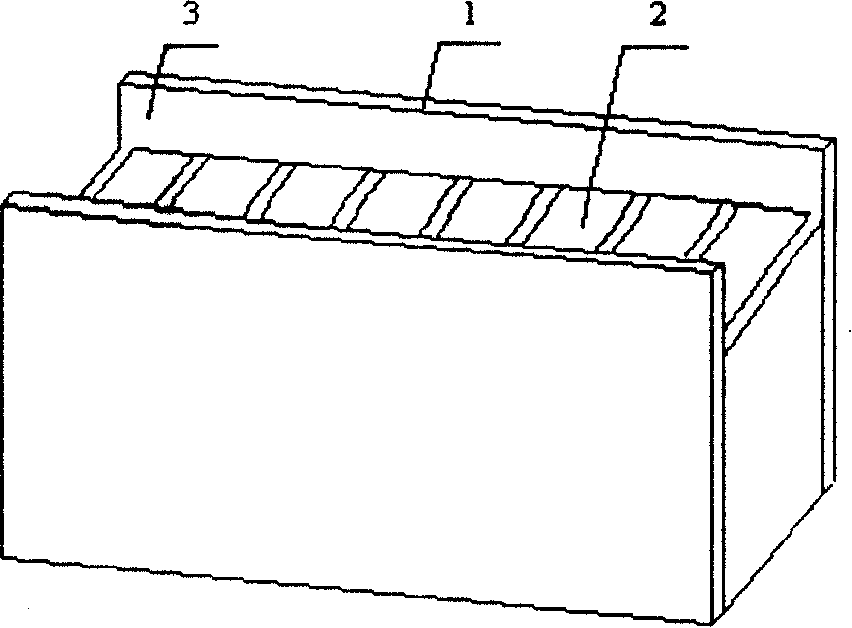

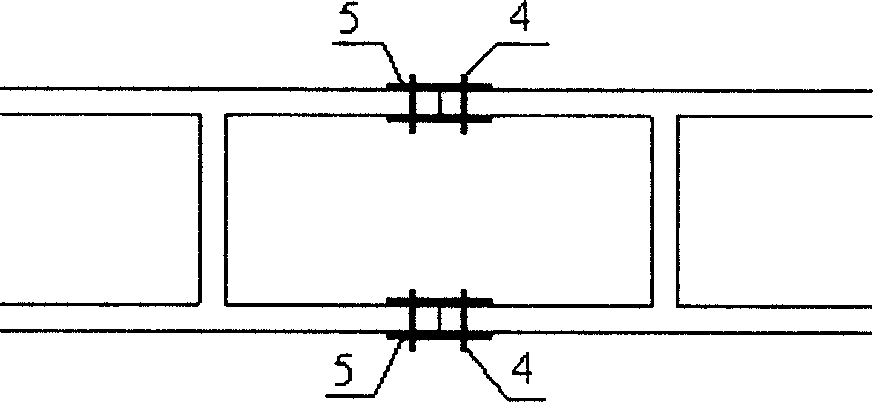

Reinforcing method for touched nodes of existing beam and lacing bar type lattice steel column

ActiveCN103806672AIncrease lateral stiffnessImprove economyBuilding repairsSystems designShear stiffness

The invention discloses a reinforcing method for touched nodes of an existing beam and a lacing bar type lattice steel column. The lacing bar type lattice steel column is composed of four square steel pipe columns and lacing bars, and the existing beam penetrates through the center of the lacing bar type lattice steel column. In order to enable the existing beam to smoothly penetrate through the center of the lacing bar type lattice steel column, the lacing bars are not arranged on the lacing bar type lattice steel column at the touched nodes, so the shear stiffness of the touched nodes is weakened to some extent. The shear stiffness and the rigidity of the lacing bar type lattice steel column at the touched nodes are enhanced by utilizing a box-shaped reinforcement structural system formed by reinforced steel plates and the square steel pipe columns of the lacing bar type lattice steel column. According to the reinforcing method, the shear resistance and the stress performance at the touched nodes of the lacing bar type lattice steel column and the existing beam can be effectively improved, in addition, power transmission system design of the nodes is clear, the stress is reasonable, and on-site construction is facilitated.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

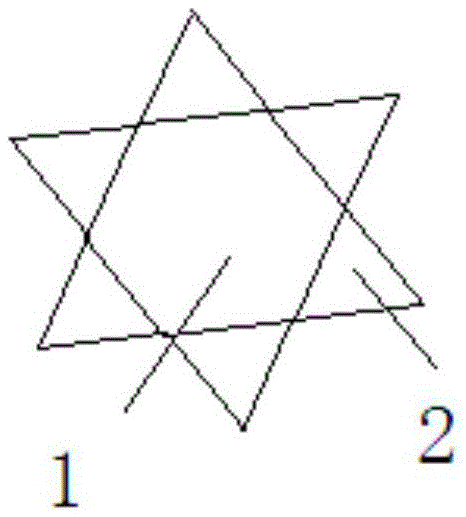

Foam interlayer structure compound material and preparation method thereof

ActiveCN102390129AIncreased shear stiffnessLight in massSynthetic resin layered productsLaminationShear stiffnessEngineering

The invention discloses a foam interlayer structure compound material and a preparation method thereof. A foam core material in the compound material is arranged between an upper skin and a lower skin, wherein one ends of one group of pultrusion rods in the foam core material are connected with the upper skin, the other ends of the group of pultrusion rods are connected with the lower skin to form a *-shaped structure, and pultrusion rods for connecting the upper skin and the lower skin are arranged between every two adjacent *-shaped structures. In the interlayer structure compound material, a plurality of pins are arranged in a foam matrix to form a space grid structure, thus the bonding force between the skins and the core material is improved, and because of geometrical features of the grid structure, the performances such as shearing resisting rigidity can be greatly improved. The foam interlayer structure compound material can be applied to aircraft members with high rigidity and weight requirements, such as wallboards, wing surfaces, tail beams and other main load-carrying structures.

Owner:句容市育达实业投资有限公司

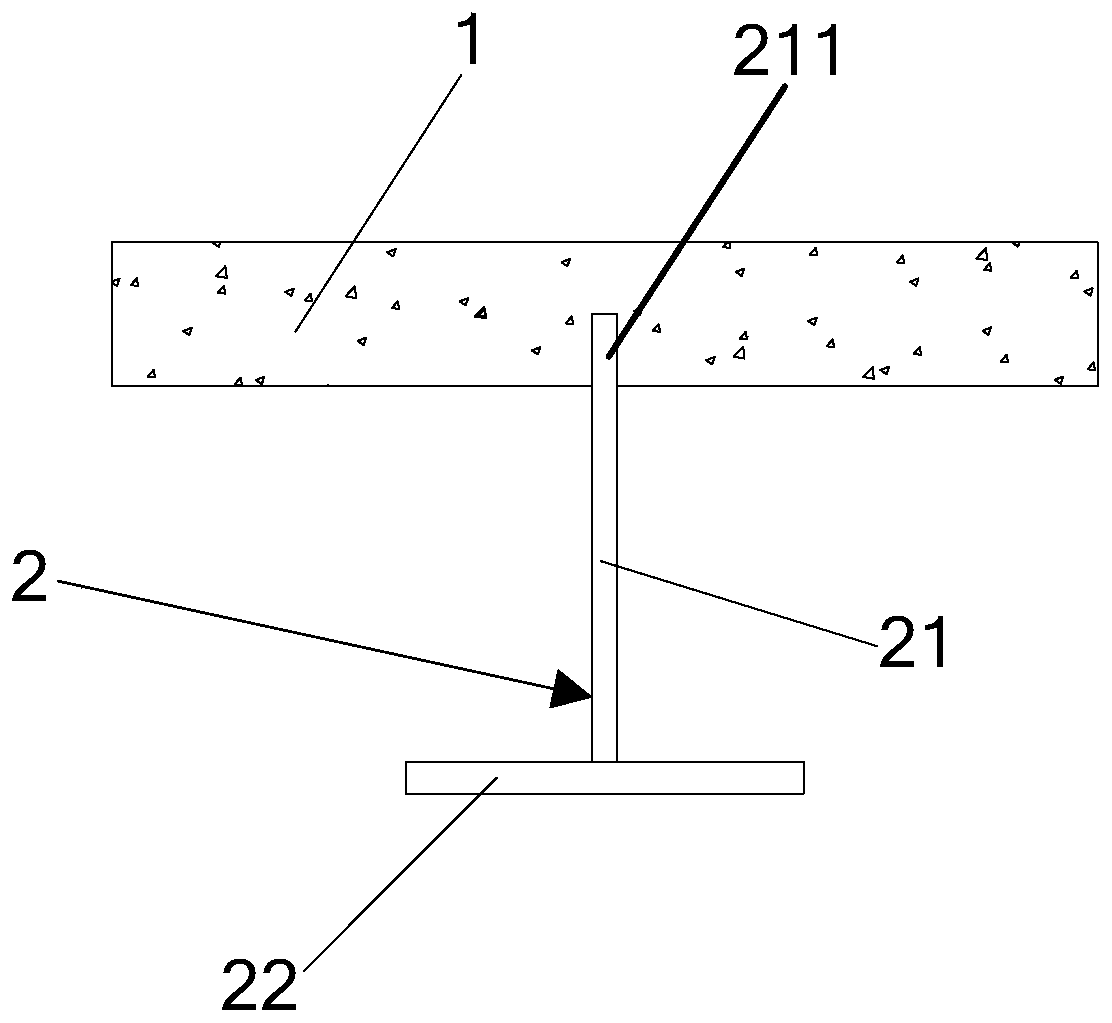

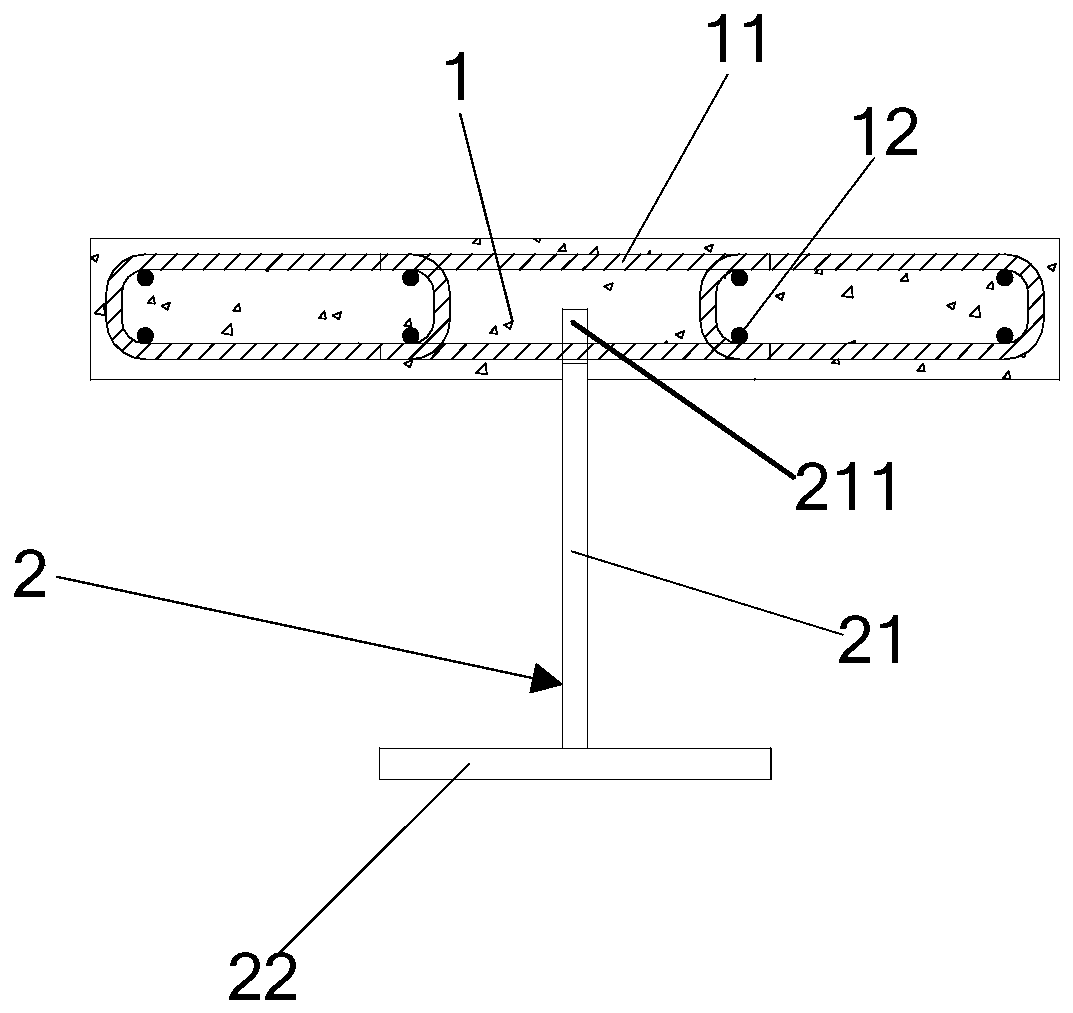

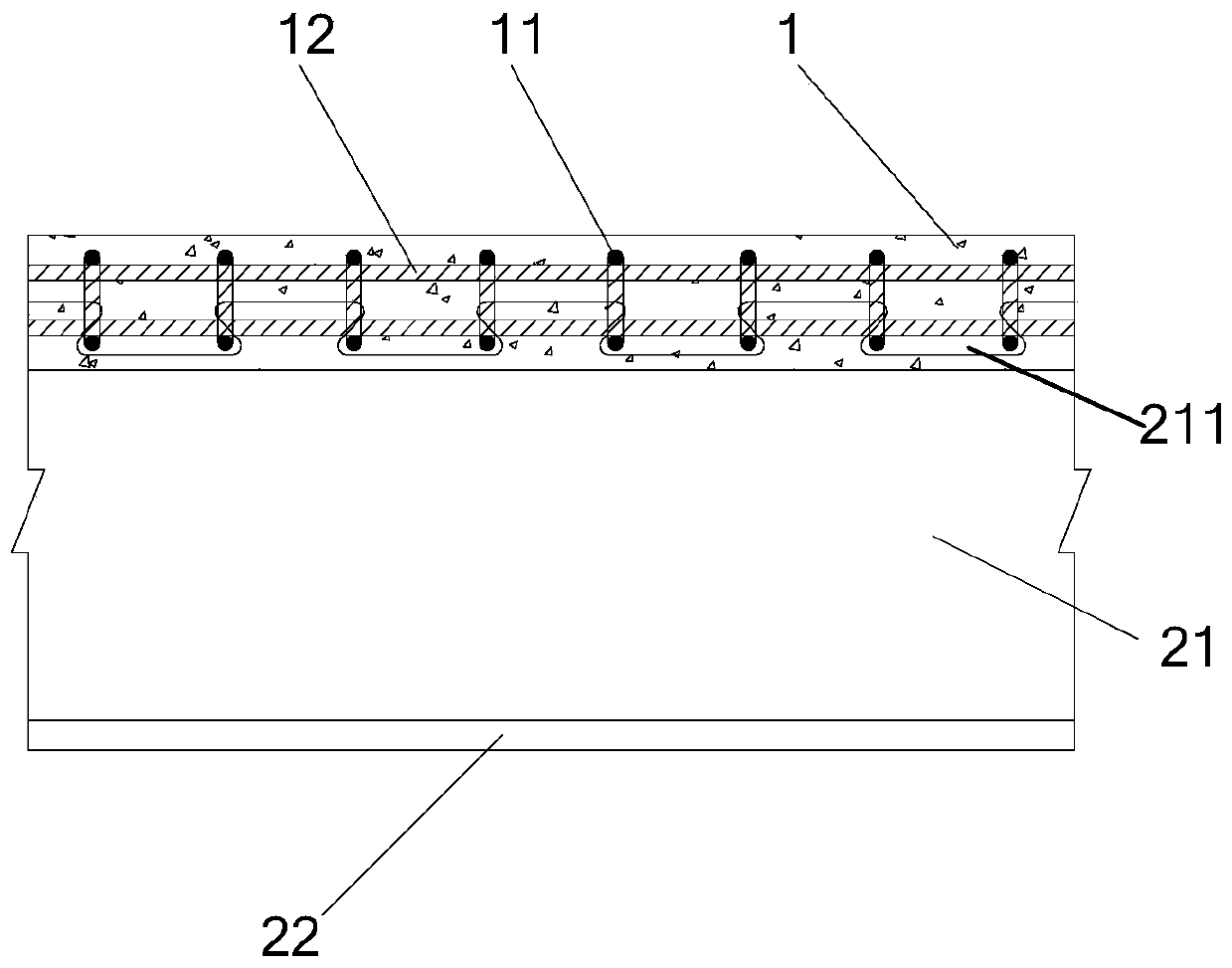

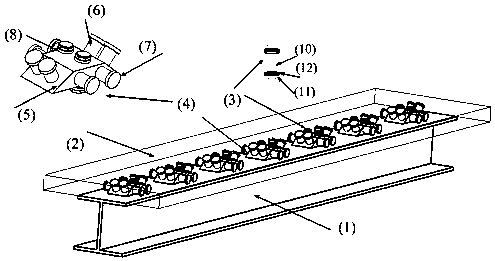

Combined beam and manufacturing method thereof

PendingCN110158447AImprove cracking strengthIncreased durabilityBridge structural detailsBridge erection/assemblyShear stiffnessEngineering

The invention relates to the field of bridge construction, and discloses a combined beam. The combined beam comprises a concrete plate, wherein transverse steel bars are arranged in the concrete plateat intervals. The combined beam further comprises an inverted T-shaped steel beam, the inverted T-shaped steel beam comprises a web plate and further comprises a wing plate, wherein a connecting partis arranged on one side of the web plate, the connecting part is arranged in the concrete plate, the web plate is connected with the transverse steel bars through the connecting part, and the wing plate is connected with the web plate in a perpendicular mode. The invention further discloses a manufacturing method of the combined beam. The mode that the connecting part is connected with the transverse steel bars in the concrete plate is adopted in the combined beam and is compared with the mode that shearing force nails are adopted to achieve the connection between a steel plate and a concreteplate, the advantages of being high in shear stiffness, high in bearing capacity, good in ductility and the like; and in addition, the combined beam is simple in structure, convenient and fast to construct, high in cracking strength and good in durability. According to the combined beam and the manufacturing method thereof, the defects that when the mode that the shearing force nails are adoptedto achieve the connection between the steel plate and the concrete plate is adopted, the shear resistance and the bearing capacity of a connecting piece are low, the shear stiffness is low, and the ductility is poor are overcome, and the problems that the concrete plate is prone to cracking, and the durability is poor are solved.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

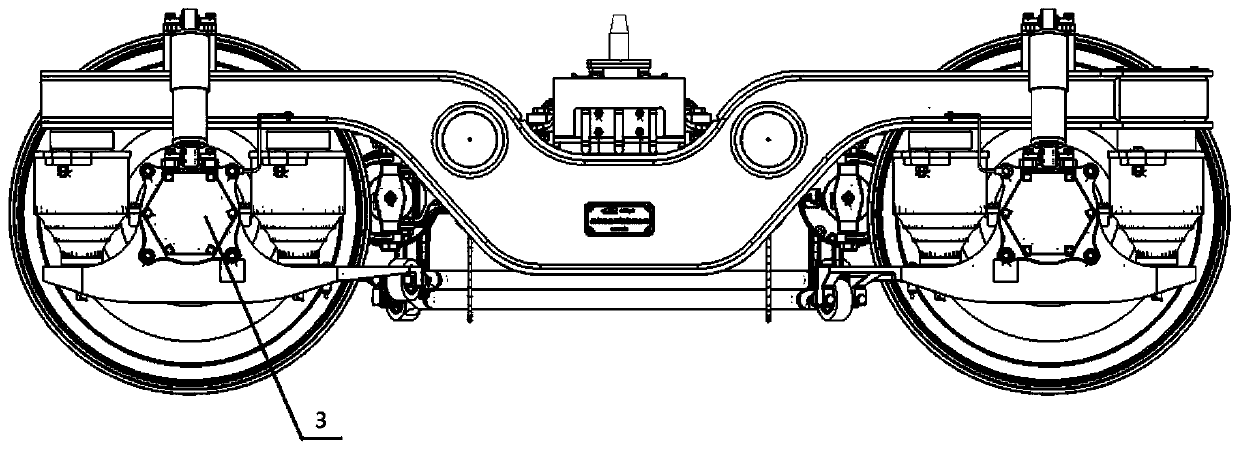

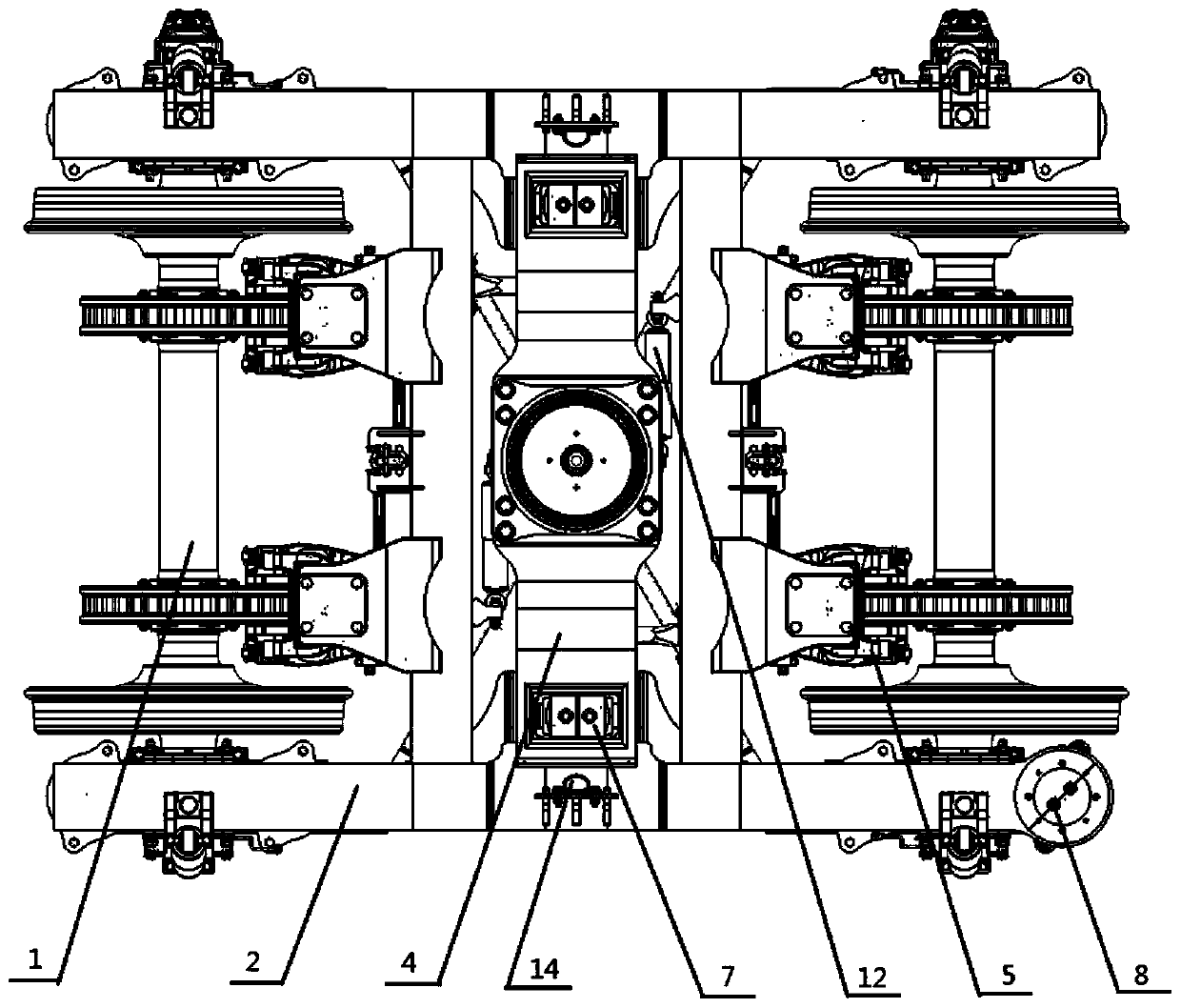

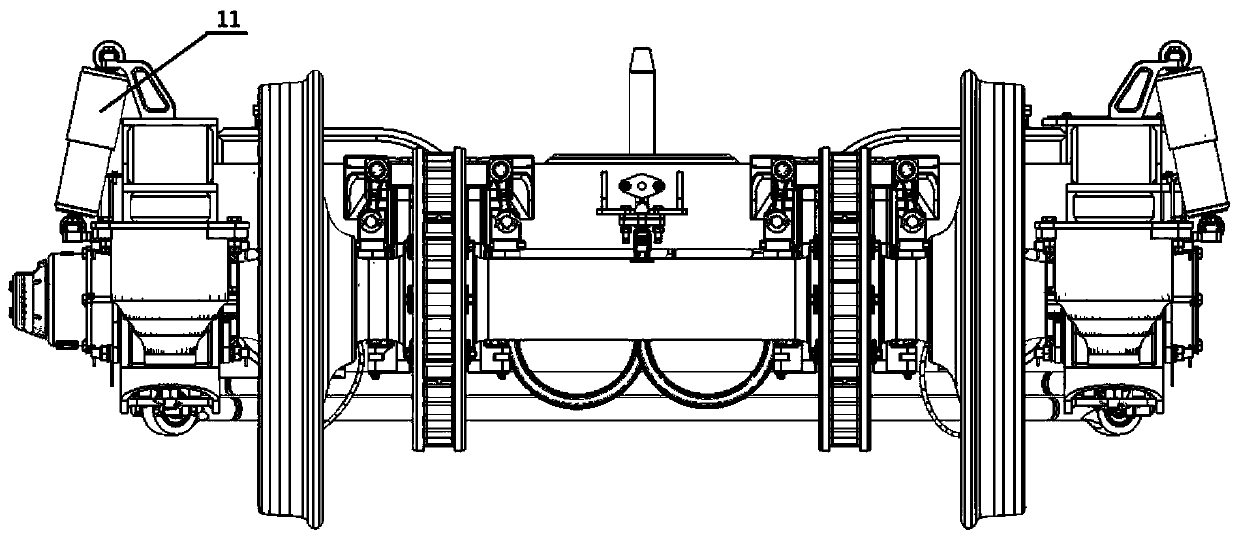

Axle box cross connection type express freight car bogie

PendingCN110920655AIncrease the critical speed of snaking instabilityReduce running noiseBogiesBogie-underframe connectionsBogieCross connection

The invention discloses an axle box cross connection type express freight car bogie. The bogie comprises an axle assembly, a framework, axle box suspension devices, a swing bolster, a foundation brakedevice, side bearings, an empty and load adjusting device and a central suspension device, the axle box suspension devices are installed at the two ends of the axle assembly respectively, the framework is located above the four axle box suspension devices, and the four axle box suspension devices are connected in a crossed mode through a crossed connection device; the cross connection device comprises two pull rods which are located below the swing bolster and arranged in a cross mode, and the two tail ends of each pull rod are hinged to an axle box suspension device of the bogie through elastic spherical hinges respectively. Constraint of the front wheel set and the rear wheel set is enhanced; the shearing rigidity between the wheel sets is increased, the snaking instability critical speed of the bogie is greatly increased, the axle box cross connection device can be suspended by adopting an axle box with soft rigidity, the operation stability is ensured, the head shaking constraintof the wheel sets can be released, the wheel rail acting force, wheel rail abrasion and operation noise are reduced, and the overall dynamic performance of the vehicle is improved.

Owner:CRRC MEISHAN

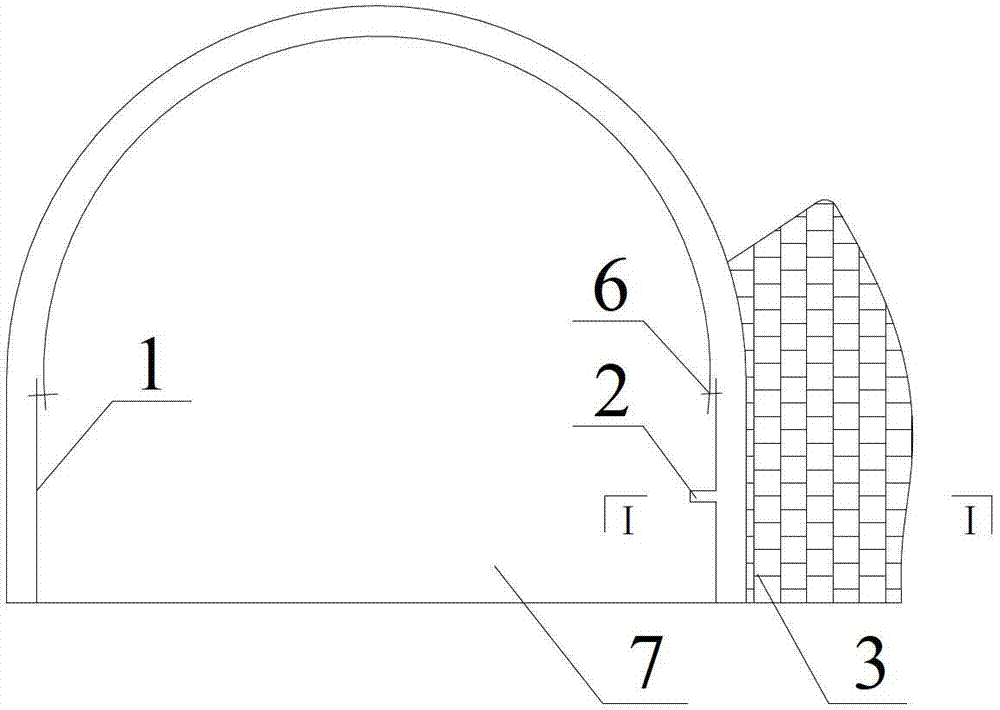

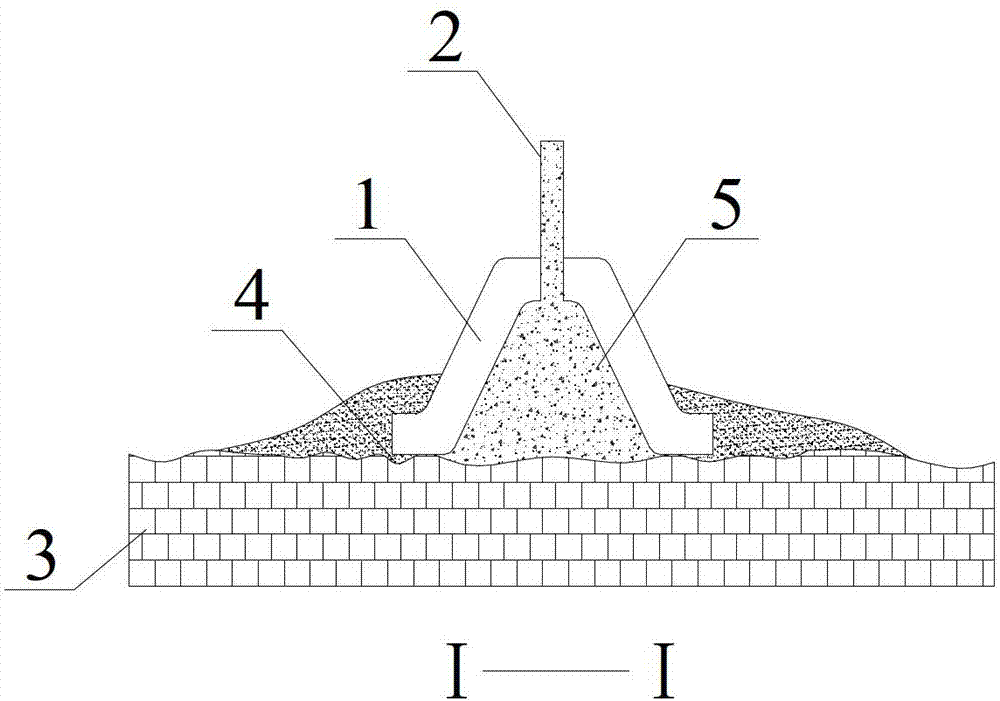

Backfilling U-shaped shed

InactiveCN102926766AAvoid point destructionIncrease the structural sectionUnderground chambersTunnel liningEnvironmental geology

The invention discloses a backfilling U-shaped shed and belongs to the field of underground supporting. The backfilling U-shaped shed comprises a U-shaped shed, wherein a grouting hole is reserved at the shed leg position of the U-shaped shed, a grouting pipe is welded outside the grouting hole, and the internal diameter of the grouting pipe is identical to the diameter of the grouting hole. A cavity behind a wall is subjected to grouting filling through the reserved grouting pipe, line contact of the U-shaped shed and the surface of roadway surrounding rock is converted to surface contact, and accordingly the supporting area is enlarged for more than five times. The U-shaped shed can be stressed timely and uniformly, the supporting performance is increased by more than three times, and point damage of the U-shaped shed caused by somewhere non-uniform force bearing is avoided. The structural section of the U-shaped shed is enlarged, and the bending resistance and shearing rigidity of the U-shaped shed are obviously improved. The U-shaped shed integral supporting performance is maximized, and long-term stability of broken soft-rock roadways is ensured.

Owner:SHANGHAI DATUN ENERGY

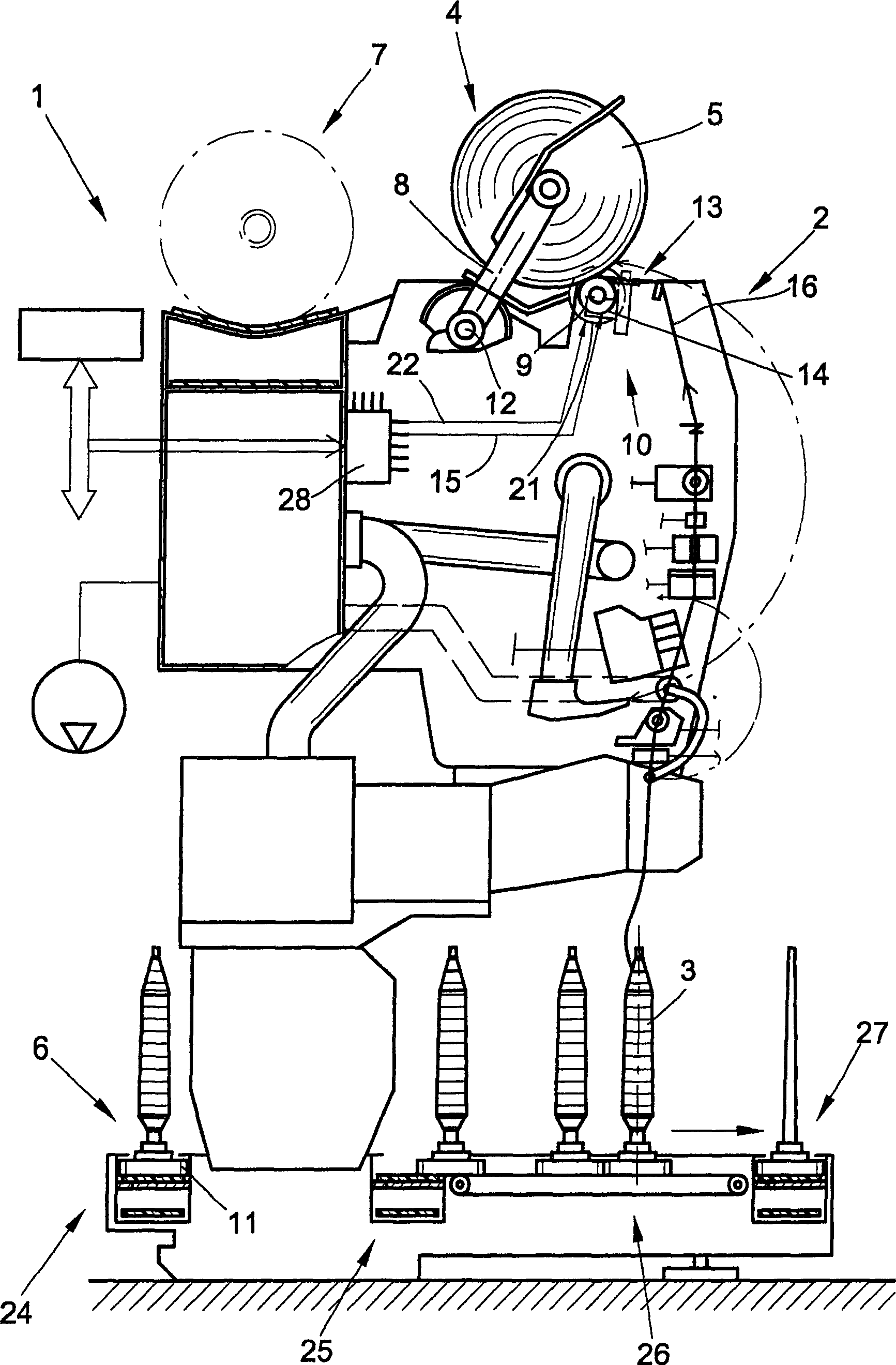

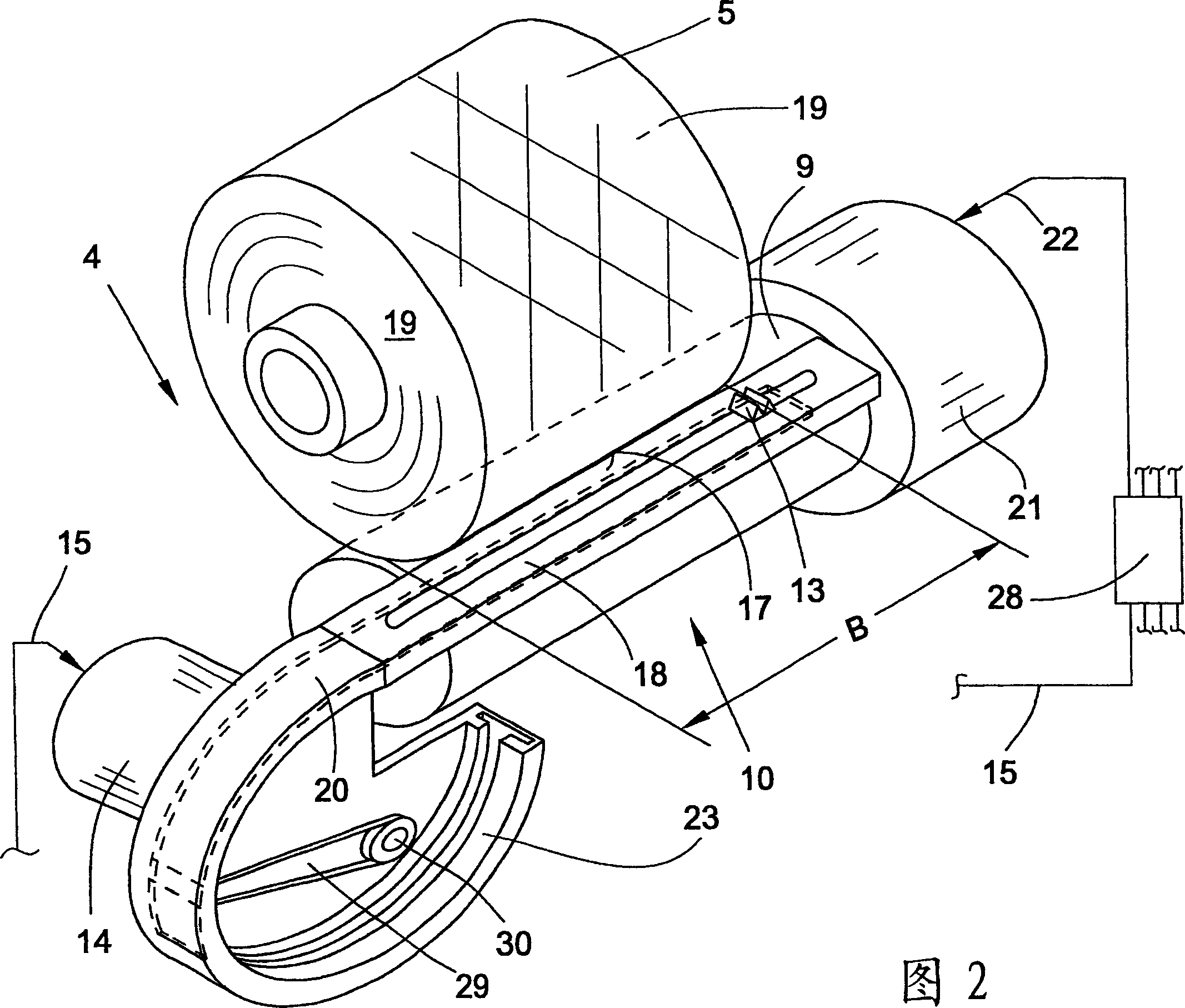

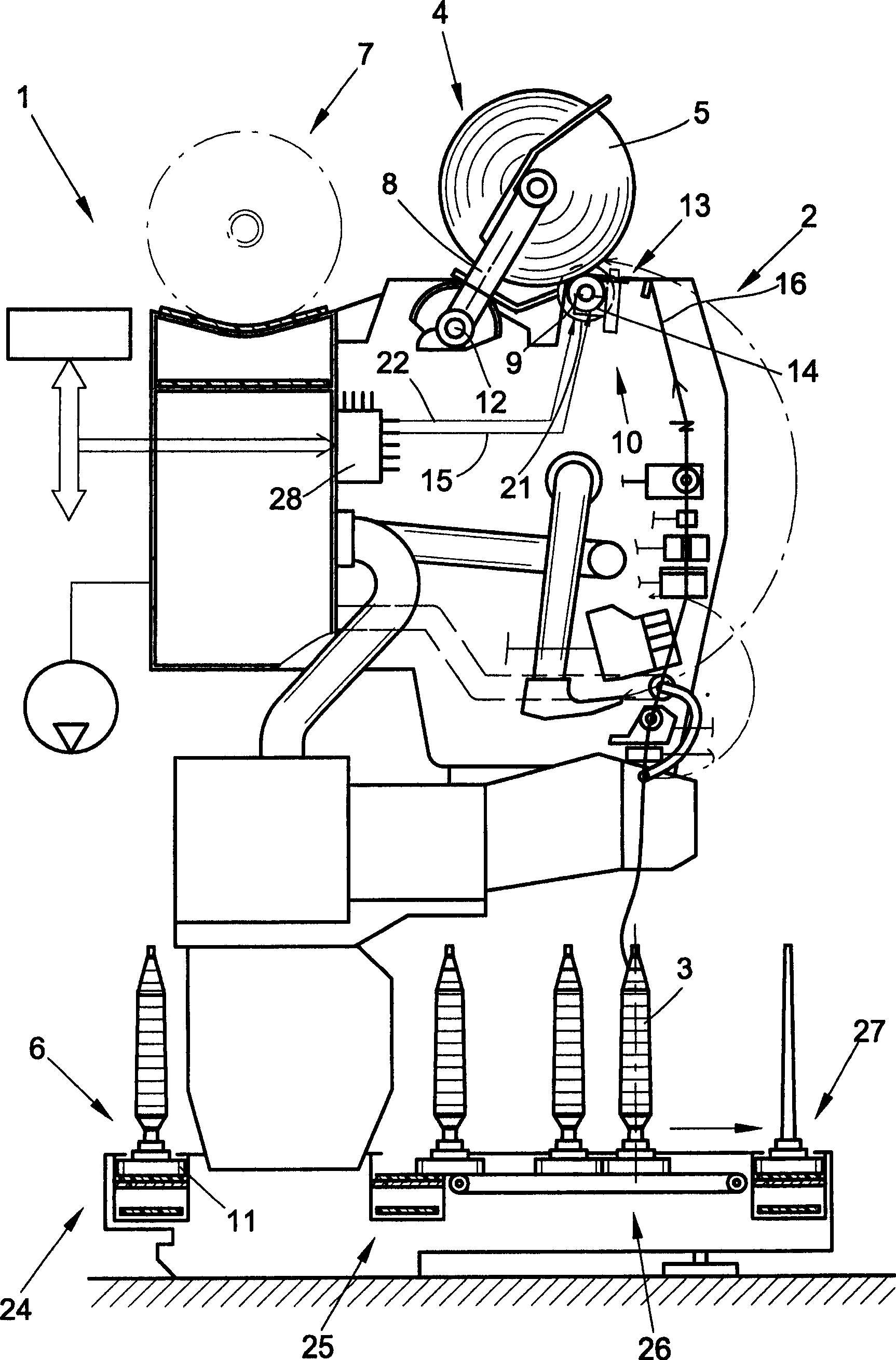

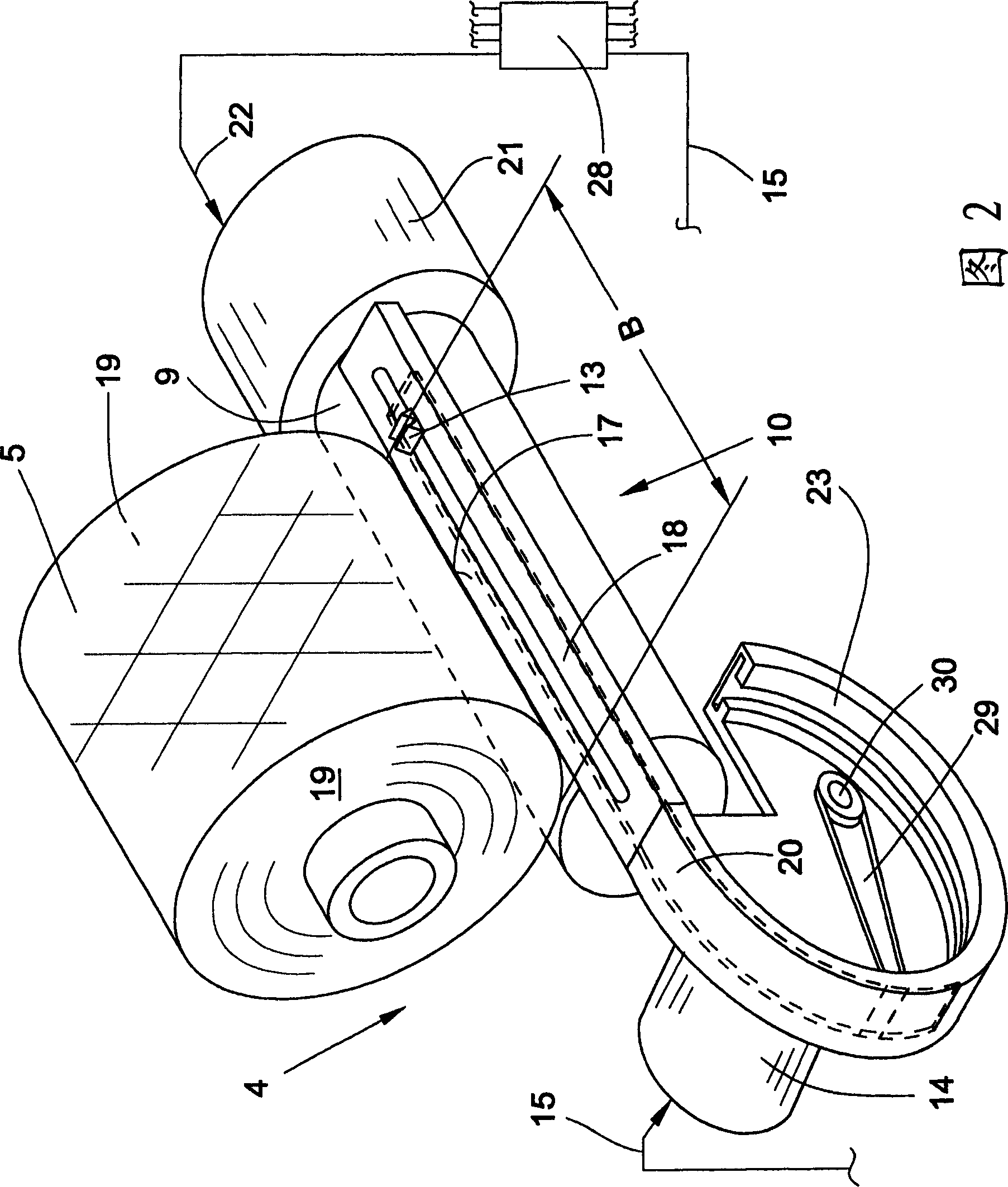

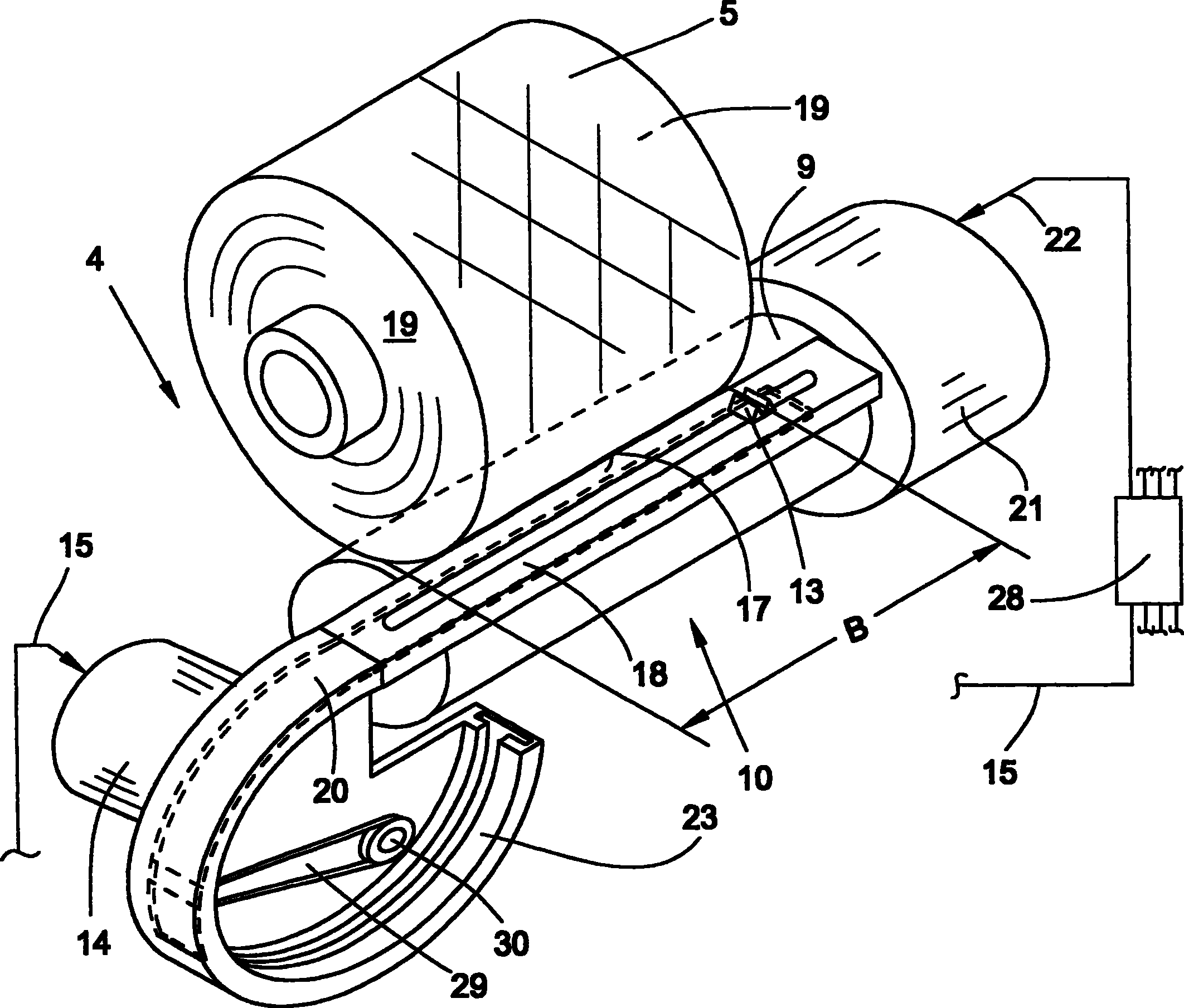

Yarn traversing device for a winding device of a textile machine producing cross-wound bobbins

The invention relates to a yarn traversing device for the winding mechanism of a textile machine for the production of cross-wound bobbins, the device having a yarn guide which is displaceable parallel to the surface of the winding bobbin and capable of Works by means of a reciprocating motorized single drive controllable in a defined manner. According to the invention, the yarn feeder (13) is arranged to be connected to an electric single drive (14) by means of a limited, flexible connecting means (20), which is configured to transmit tensile and compressive forces.

Owner:SAURER GERMANY GMBH & CO KG

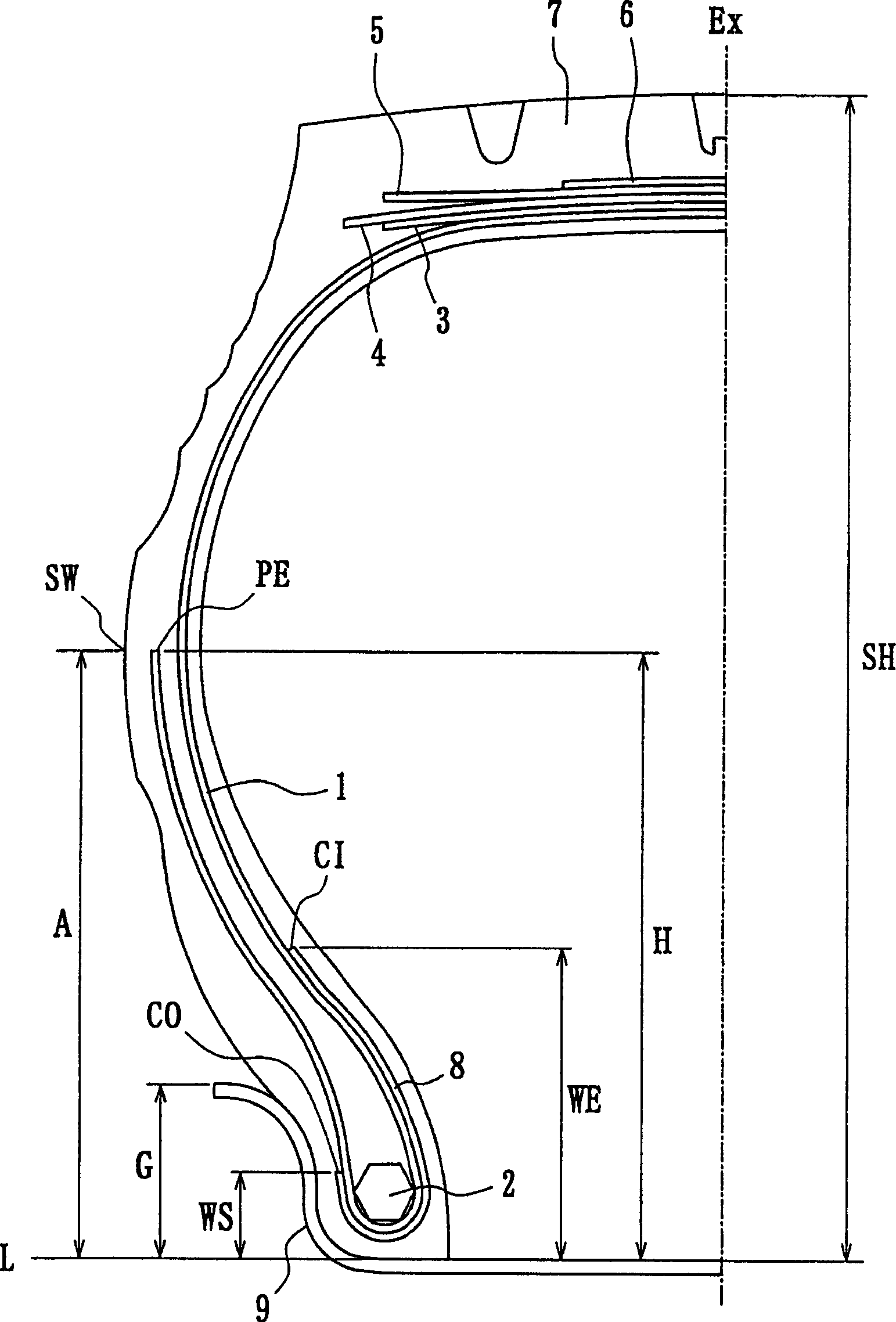

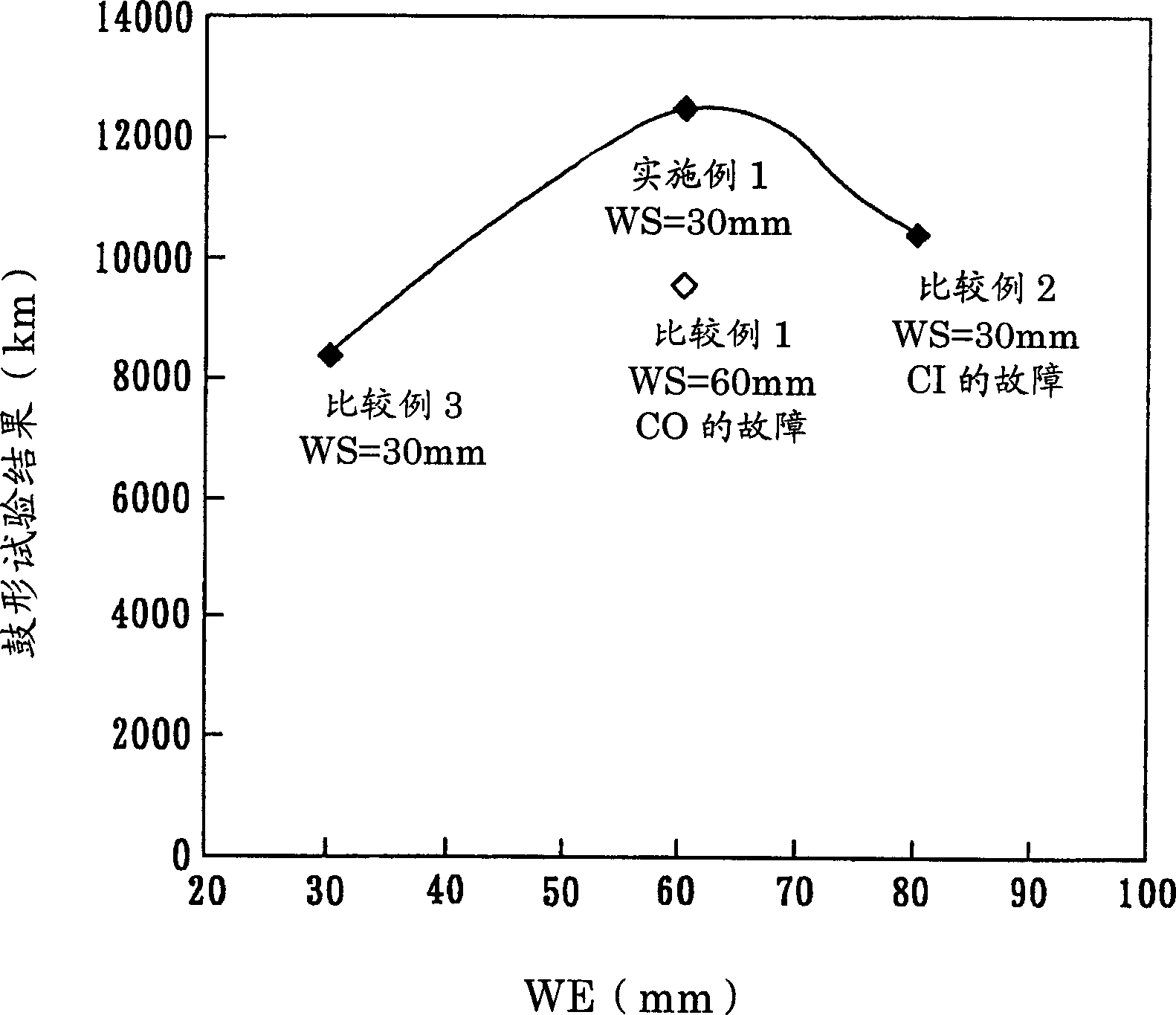

Air-inflation meridian tire for heavy load

InactiveCN1640696AIncreased durabilitySuppression of shear deformationTyre beadsRadial tireEngineering

The invention provides a pneumatic radial tire for a heavy load capable of optimizing a providing position of a rewinding end of a carcass ply or a wire chafer end, preventing a crack from beginning at the end part, and improving durability in the part and in the whole tire by suppressing collapse of a side wall part and a bead part.

Owner:BRIDGESTONE CORP

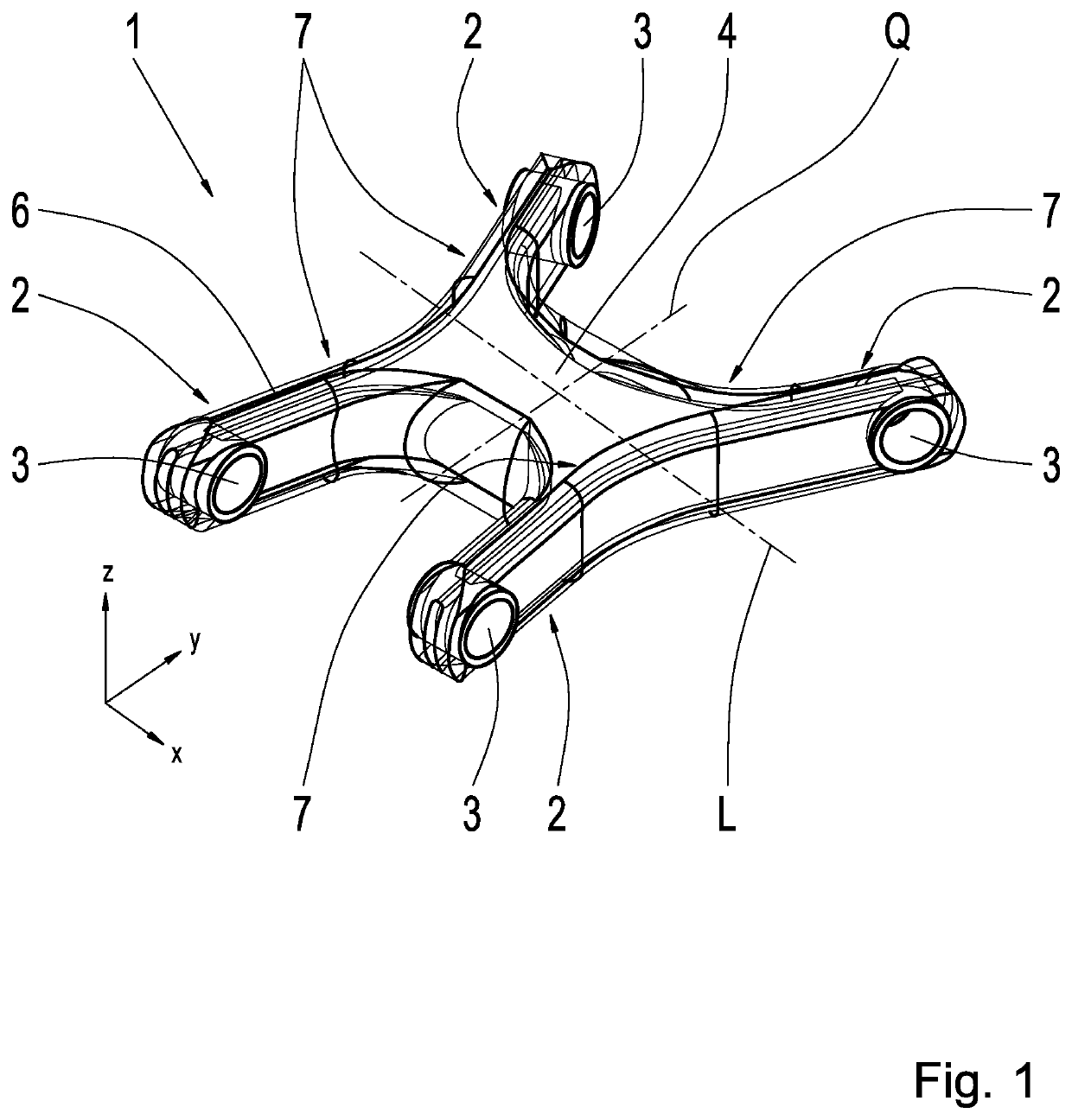

Method for producing a component, and component

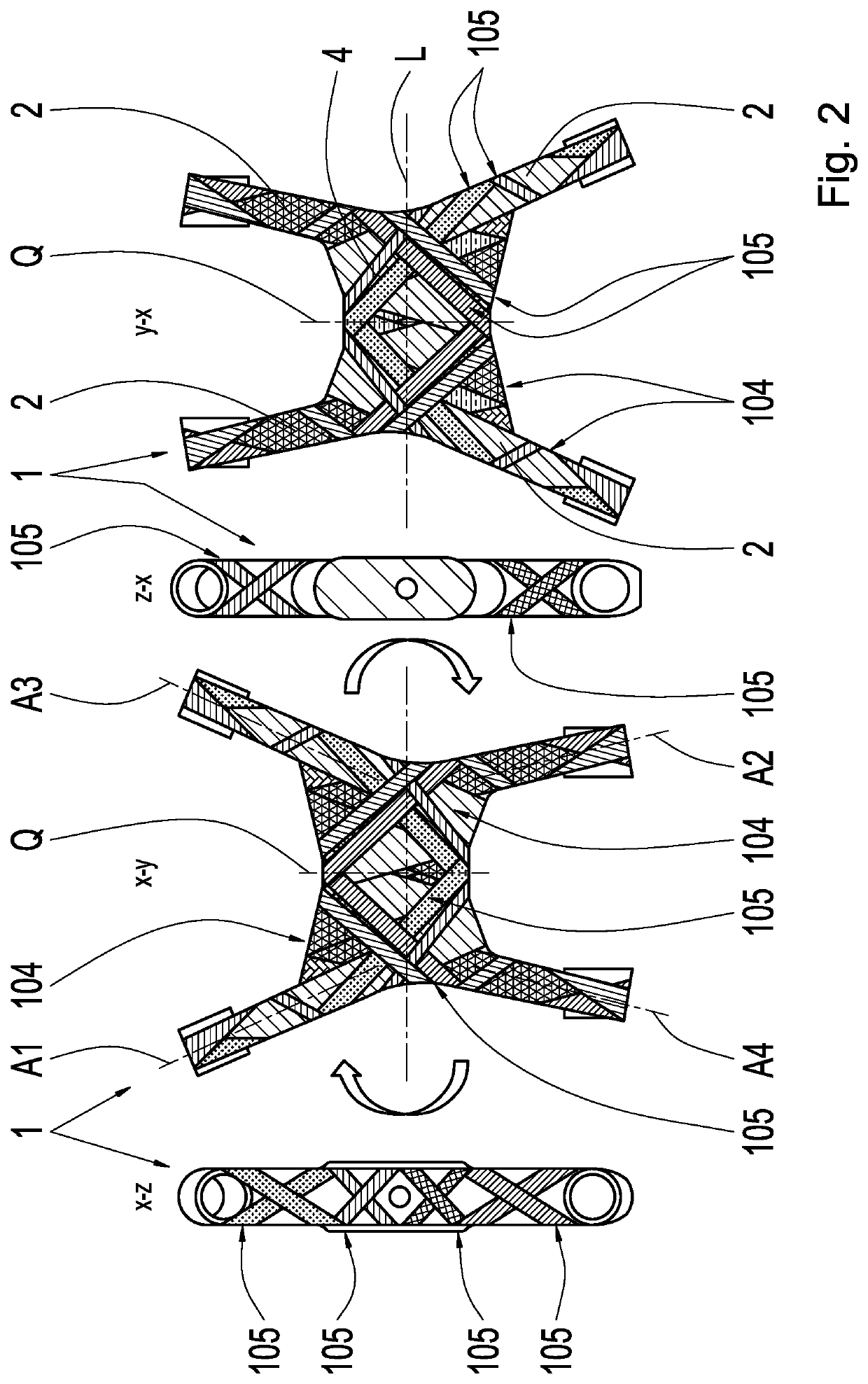

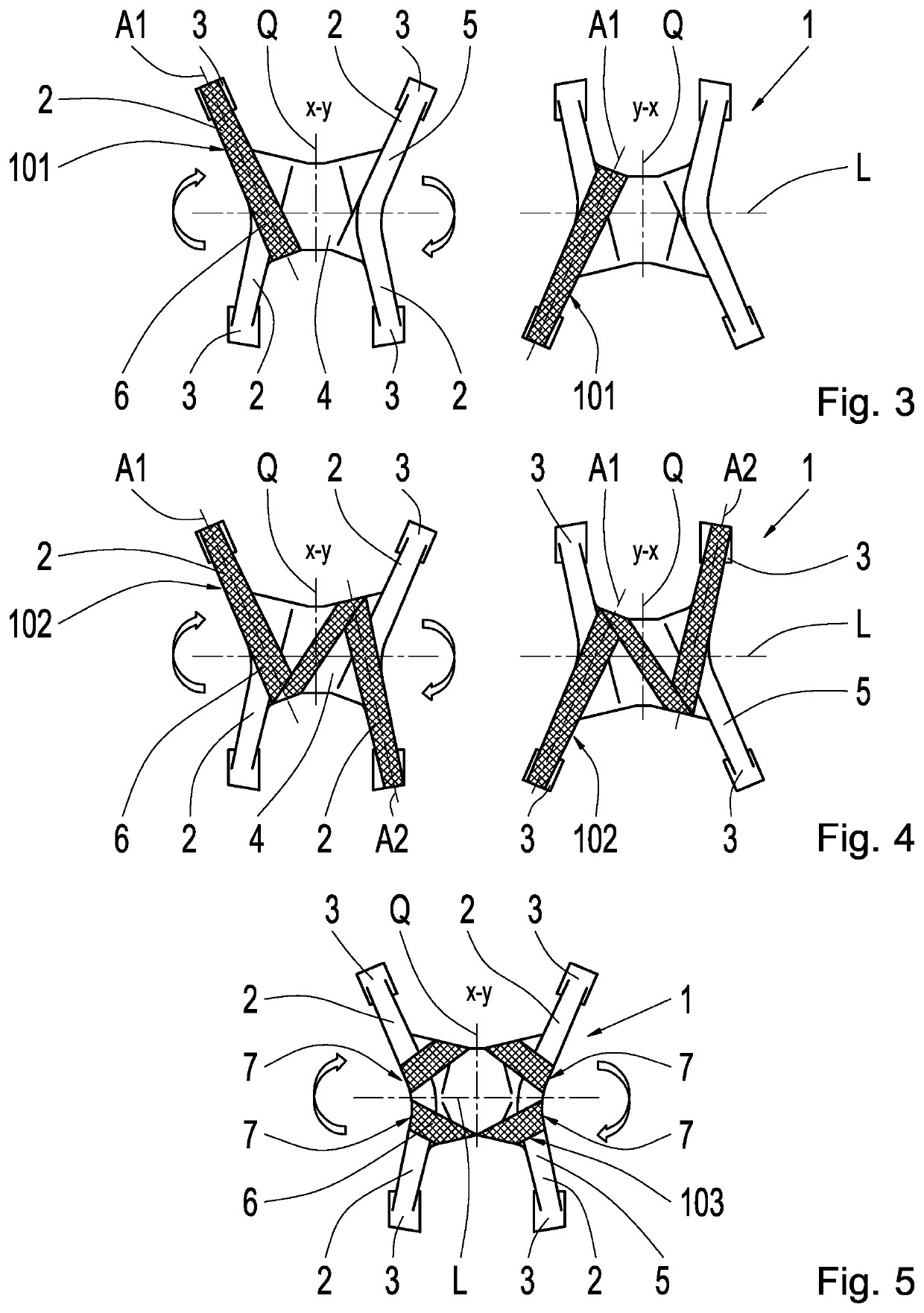

ActiveUS11440364B2Reduce tensionIncreased shear stiffnessConnecting rodsShaftsMechanical engineeringMaterial selection

A method for producing a component by a 3D winding method, a filament or a plurality of parallel filaments having a fiber-reinforced plastic composite material is or are laid down on a core in a combination of a plurality of different winding patterns. Every filament is preimpregnated. Every winding pattern influences at least one mechanical characteristic of the component. The mechanical characteristics of the component are selectively adjusted by the sequence, repetition, mixing, and material selection of the individual winding patterns.

Owner:ZF FRIEDRICHSHAFEN AG

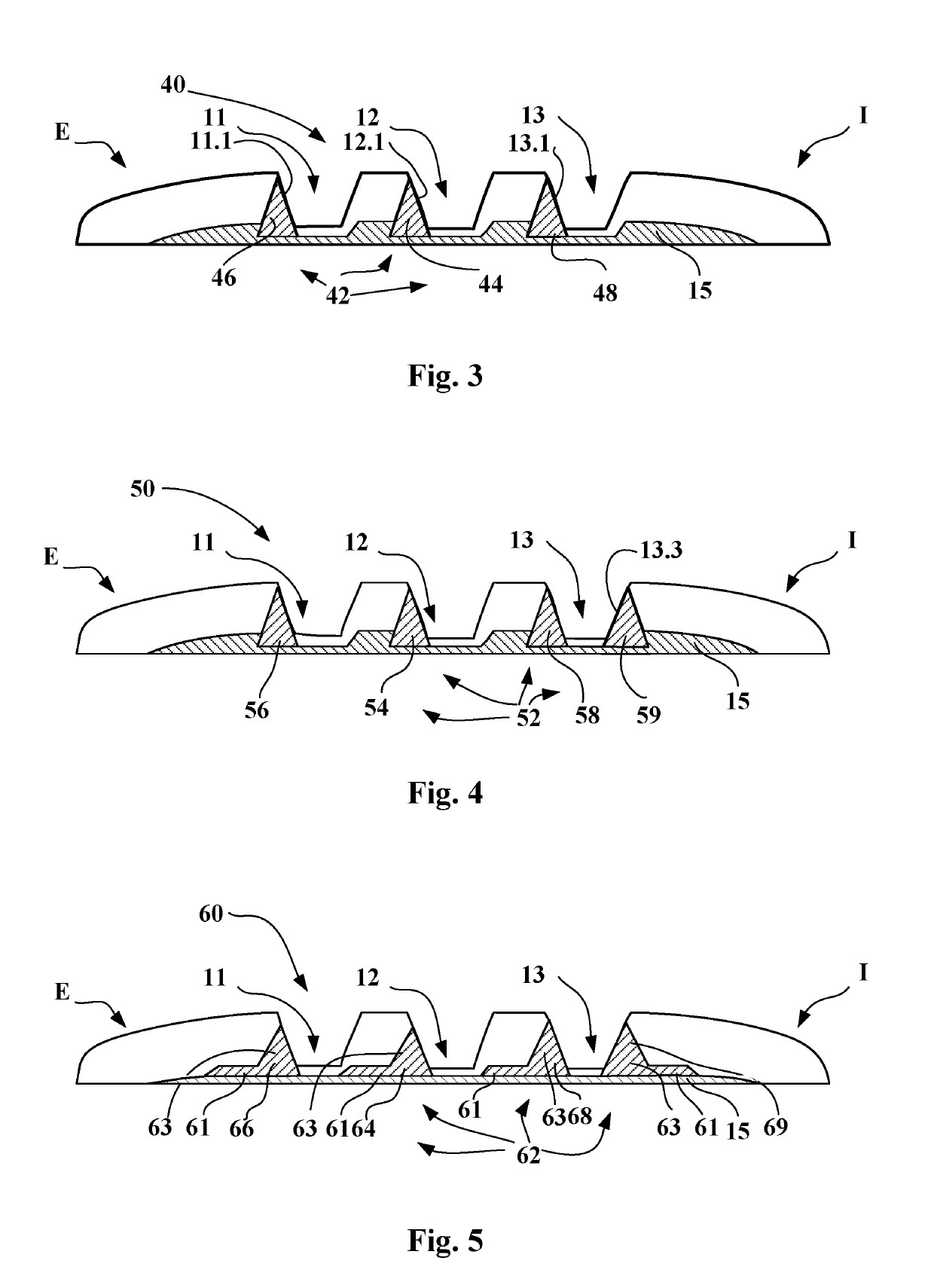

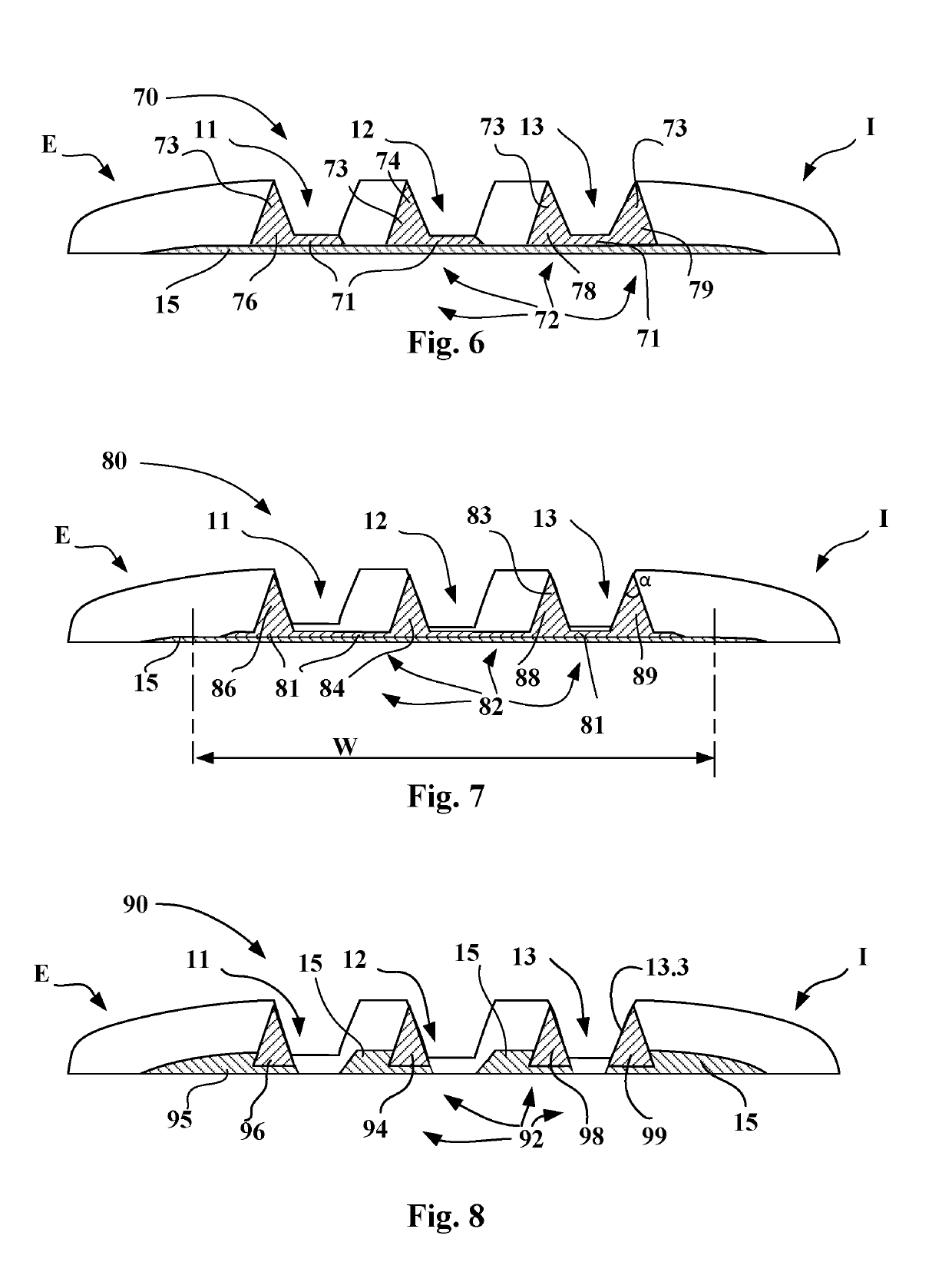

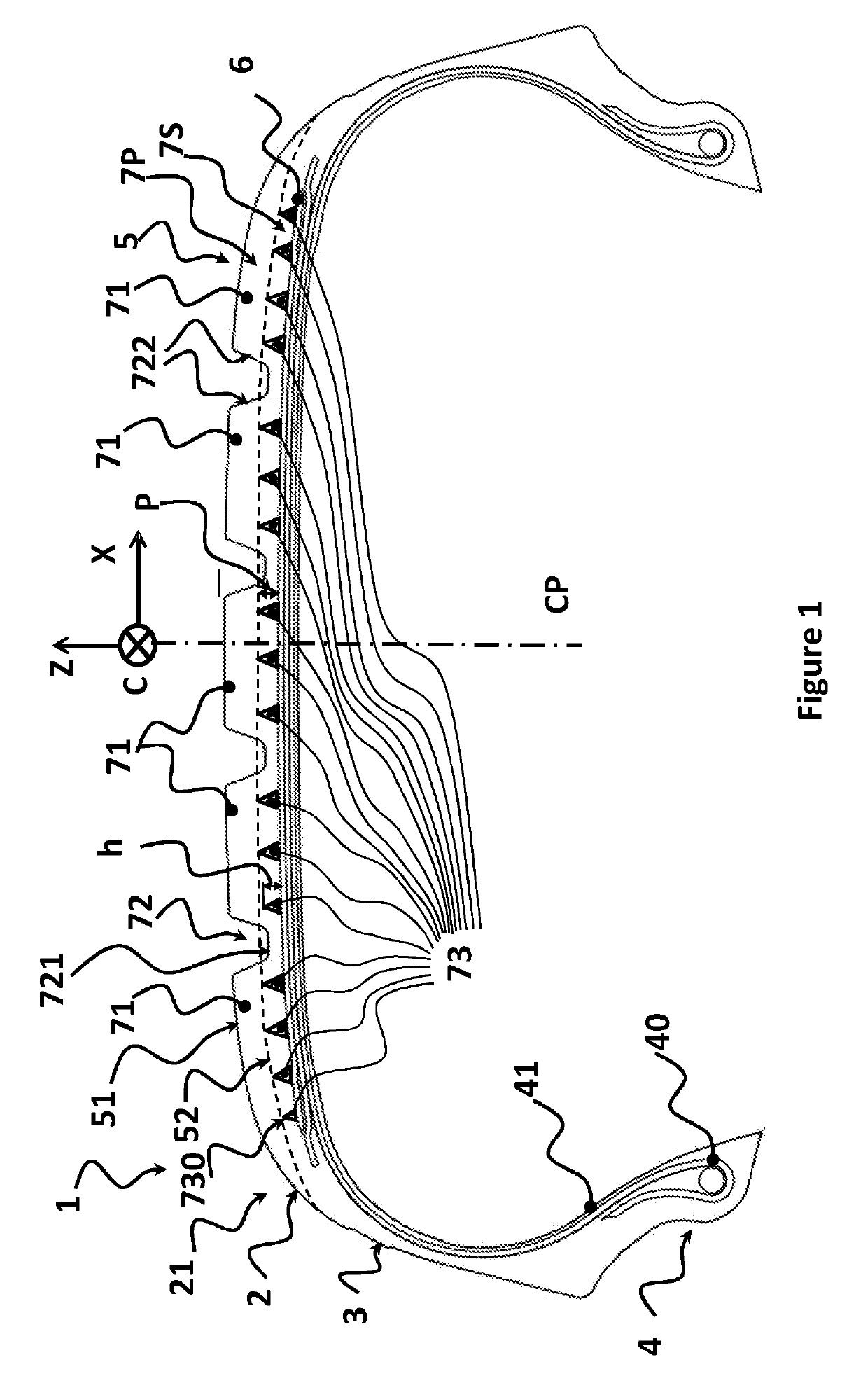

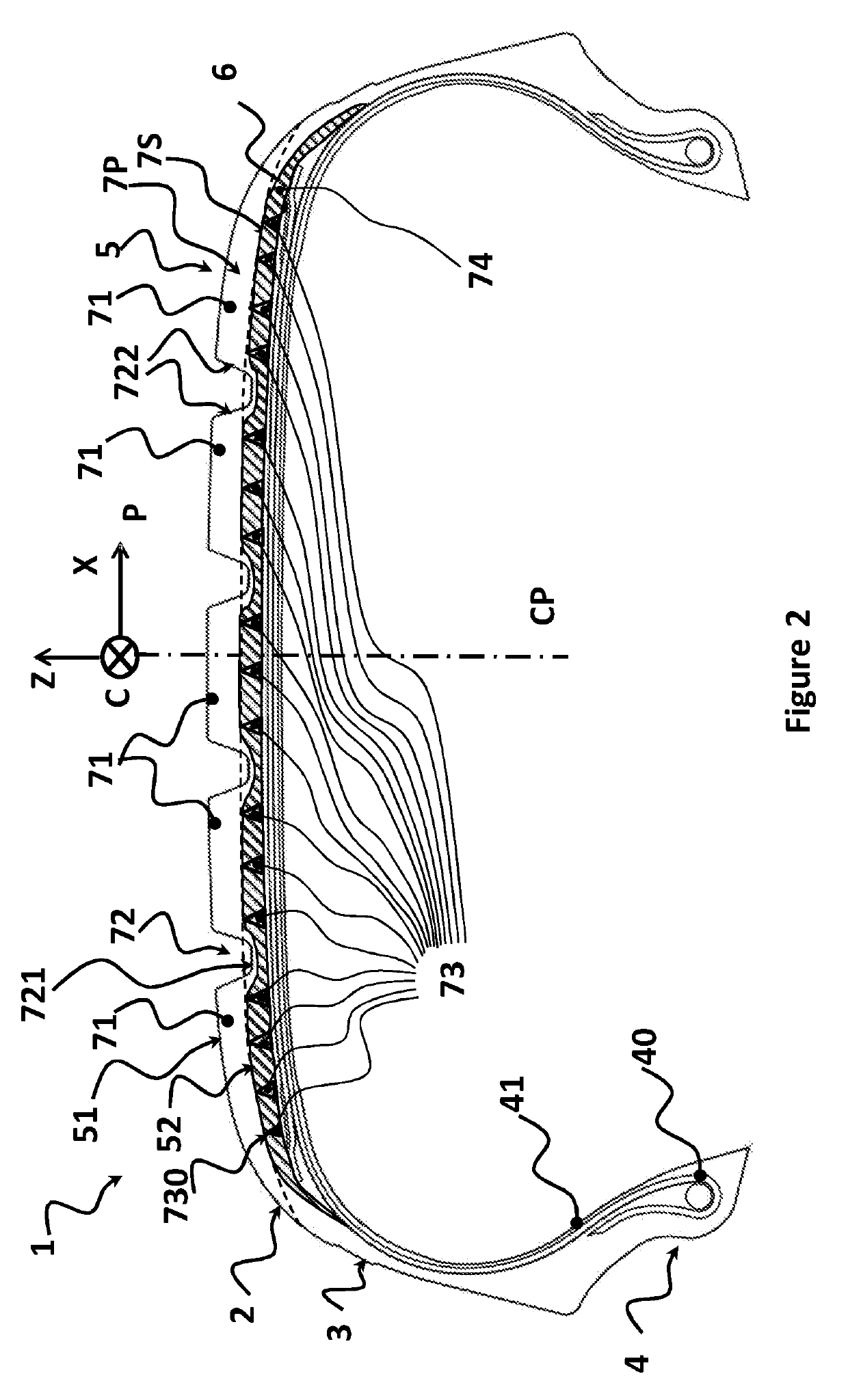

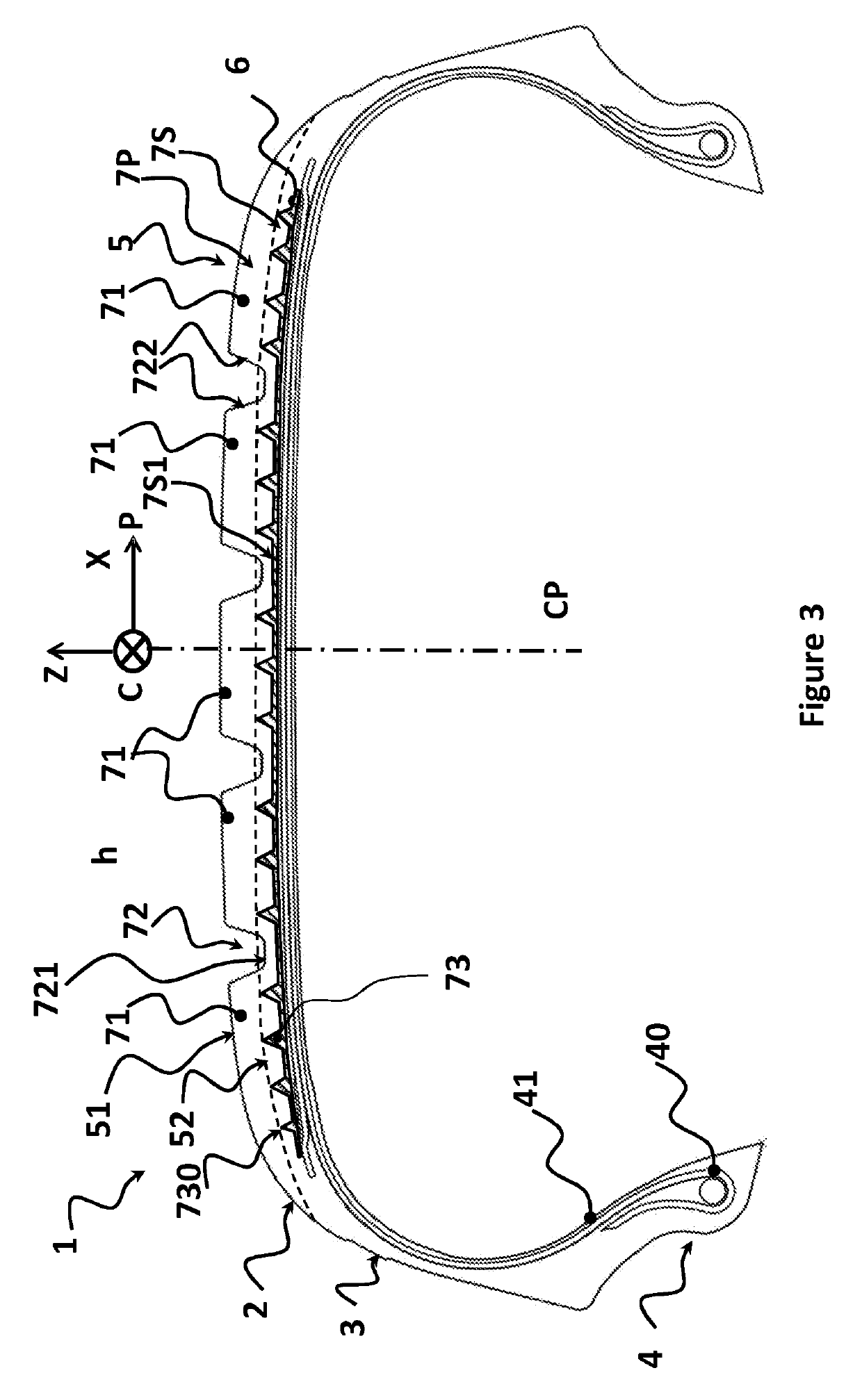

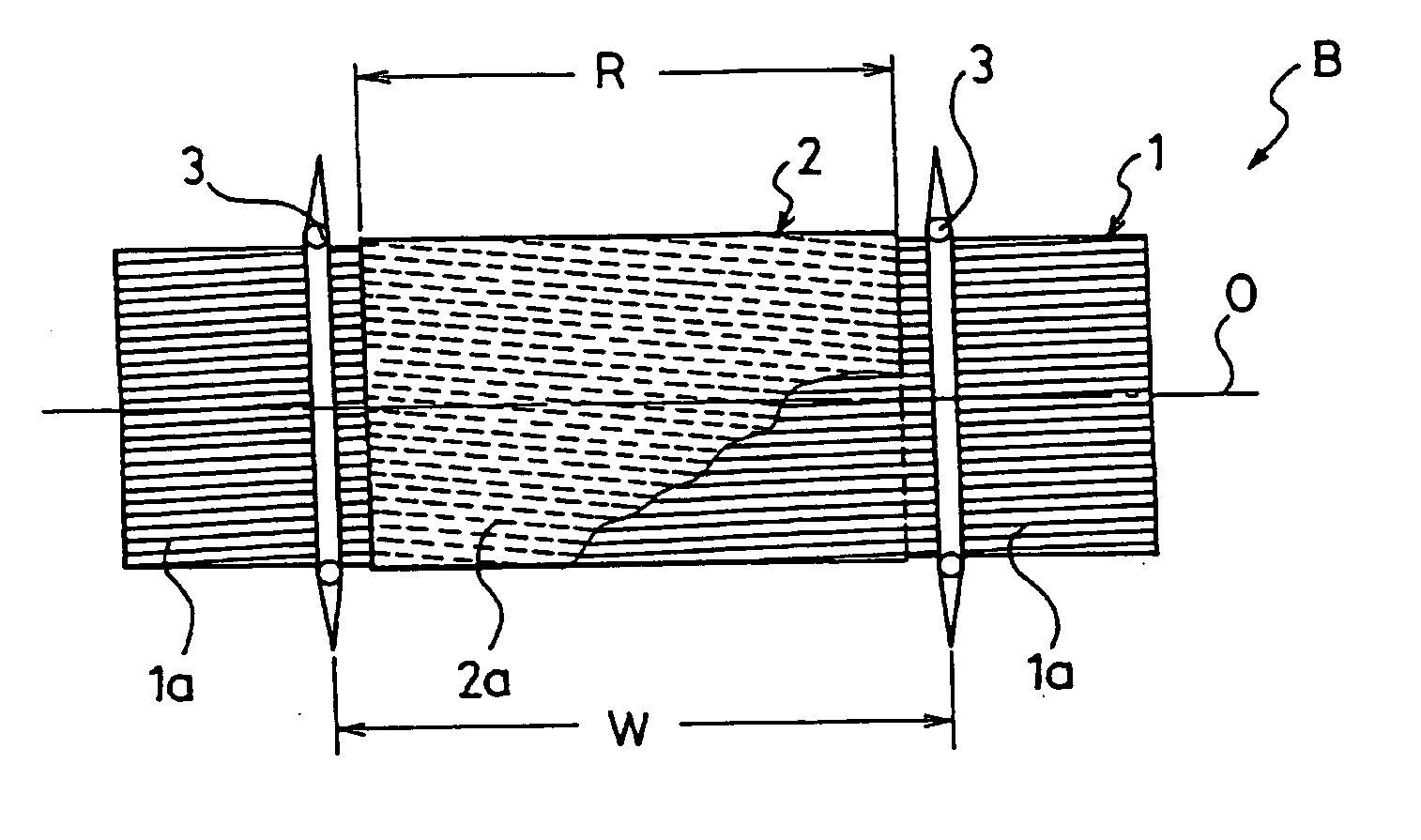

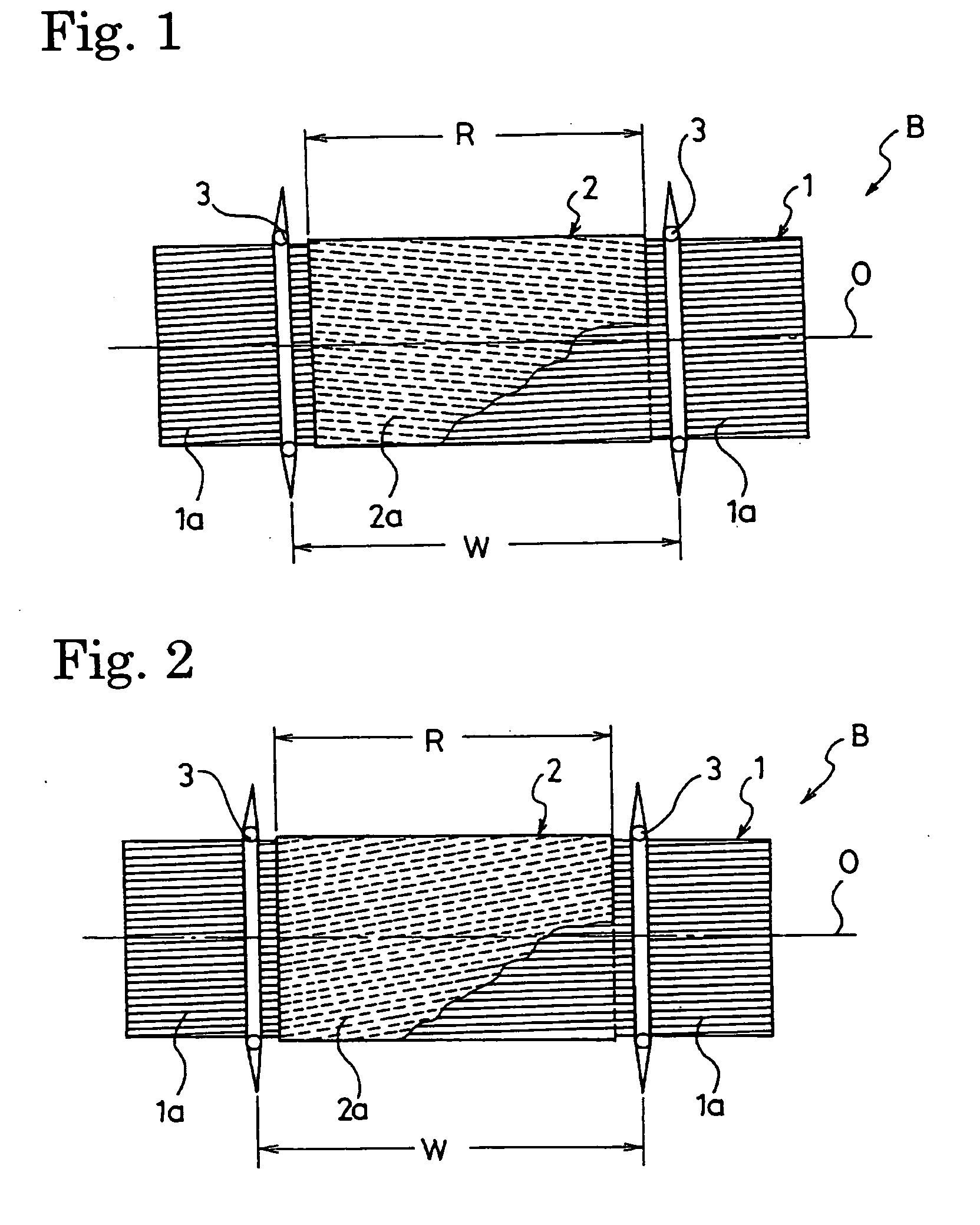

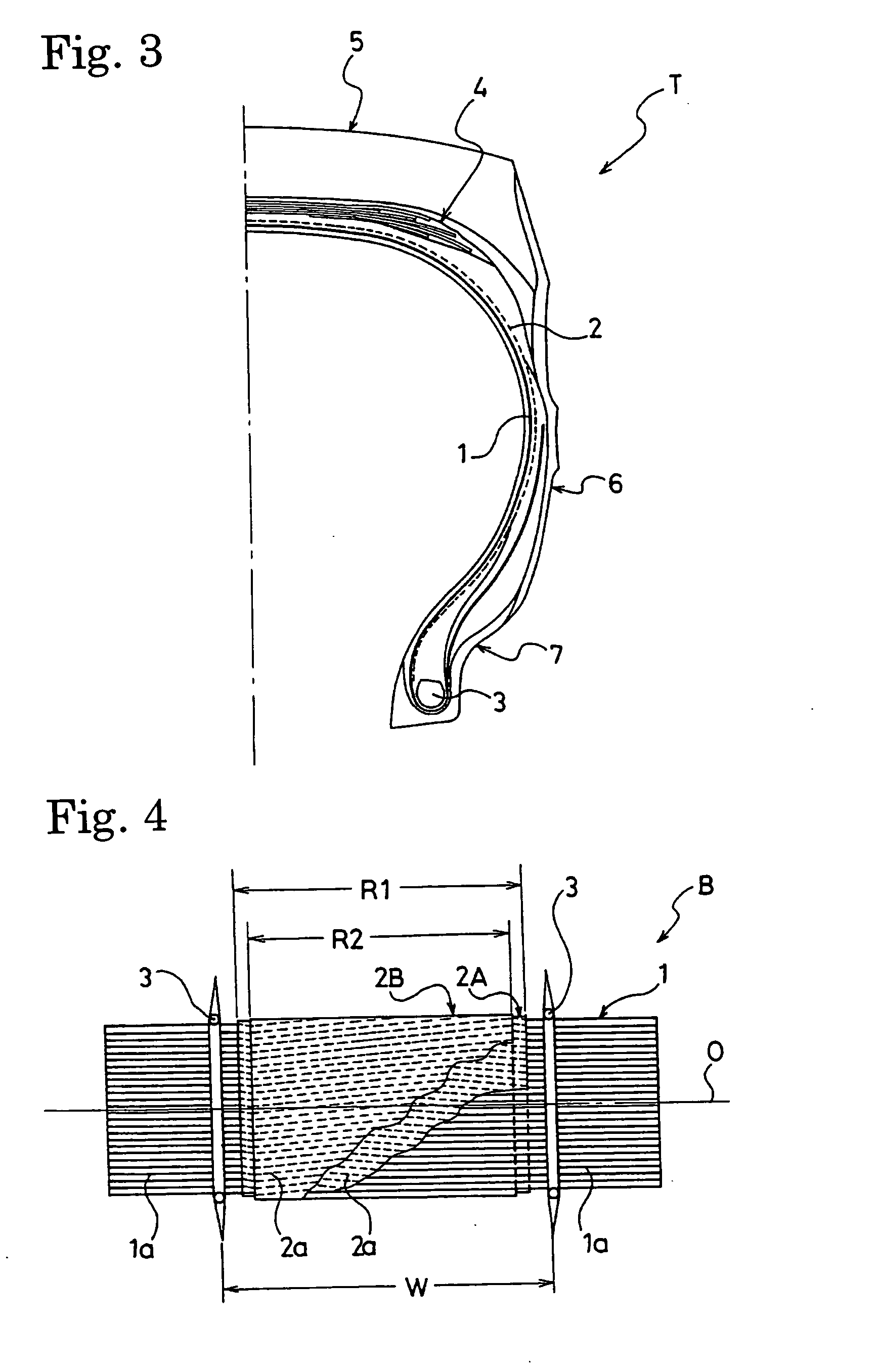

Tire comprising a tread containing circumferential reinforcing elements in the sublayer

A tire (1) comprises two beads (4), two sidewalls (3) connected to the beads and a crown (2) connected to the ends of the two sidewalls, the crown comprising a crown reinforcement (6) and a tread (5) radially outside the crown reinforcement (6), said tread (7) comprising a plurality of tread pattern blocks (71), at least two radially superposed layers: a sublayer (7S) covering the crown reinforcement (6), and a main layer (7P) radially above the crown reinforcement (6), the sublayer comprising a plurality of circumferential reinforcing elements (73) being formed of a rubber compound having greater stiffness than the stiffness of the rubber compound of the rest of the sublayer, the circumferential reinforcing elements (73) extending radially from the radially exterior surface of said crown reinforcement (6) in the direction of the interface between the sublayer (7S) and the main layer (7P), said circumferential reinforcing elements having an axial width which decreases gradually with increasing radial proximity to the outside.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

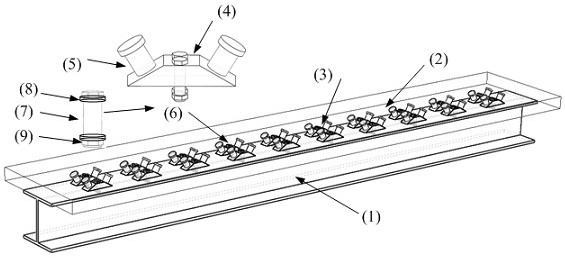

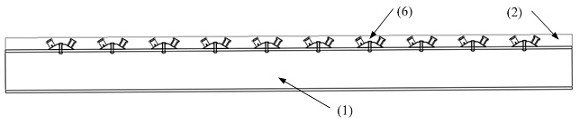

Cold-formed steel composite wall sandwiched with light-weight fabricated anti-buckling supports

PendingCN109555243APrevent slippingHave the effect of re-constrainingWallsProtective buildings/sheltersKeelSeismic resistance

The invention belongs to the field of building engineering, and particularly relates to a cold-formed steel composite wall sandwiched with anti-buckling supports, and wall surface plate material layers and cold-formed steel are used as constraining parts for the anti-buckling supports. The cold-formed steel composite wall includes upper and lower guide rails transversely arranged and vertically-and-oppositely-arranged keel columns, and the anti-buckling supports and outer cover wall panels are sandwiched between the vertically-and-oppositely-arranged keel columns. Steel strips are used as corematerials in the sandwiched supports, a wrap-around cross-section body composed of wall surface plate materials such as OSB plates and the cold-formed steel is used as a constraining member, and thewrap-around cross-section body in the constraining member are connected with the outer cover wall panels correspondingly by self-tapping screws. According to the cold-formed steel composite wall sandwiched with the anti-buckling supports, the side resistant ability of the cold-formed steel composite wall can be improved, the steel strips can be brought into full play under compression and tension,and the seismic resistance of the wall can be improved. The cold-formed steel composite wall includes the anti-buckling supports, wherein the anti-buckling supports are fabricated, no wet work exists, construction is simple, less labor is applied, and the requirements of green buildings and fabricated buildings are met.

Owner:SHENYANG JIANZHU UNIVERSITY

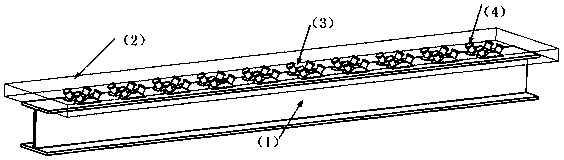

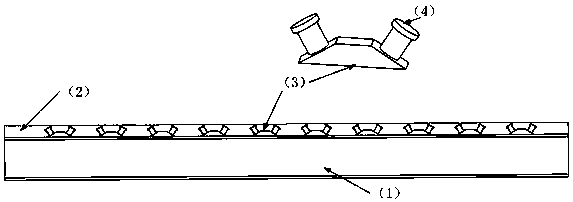

Steel plate bracket-cluster type inclined nail fast assembled steel-UHPC thin plate combined structural system

ActiveCN109736200AIncreased shear strengthImprove integrityBridge structural detailsBridge materialsIsosceles trapezoidSheet steel

The invention discloses a steel plate bracket-cluster type inclined nail fast assembled steel-UHPC thin plate combined structural system. The system comprises a steel beam, a UHPC thin plate, steel plate brackets and short nails; each steel plate bracket is of an isosceles trapezoid structure; connecting holes are formed in the steel plate brackets; high-strength friction type bolts penetrate through the connecting holes to be connected with the steel beam; the short nails are perpendicularly disposed on the inclined surfaces of the two sides, the front end surfaces and the rear end surfaces of the steel plate brackets, the UHPC thin plate is disposed above the steel beam; and combined bodies of the steel plate brackets and the short nails are uniformly distributed in the UHPC thin plate.UHPC is adopted and manufactured into ultra-thin bridge deck slabs, the self weight of the structure can be reduced, and the structure spanning capability is enhanced. Connection with the steel beam at an interface is achieved through the cluster type inclined nails of the plate brackets containing steel plates so as to form the combined structural system, the interface sliding amount is reduced by means of rigid connection of the steel plate brackets in a normal using stage, and in the ultimate limit state, the bolt-nail flexible connection part characteristic is adopted, and the defect thatthe ductility is insufficient if the steel plate brackets serve as rigid connection parts is overcome. Besides, the anti-shear property of the steel-UHPC interface can be enhanced by means of the bolts and nails which are laterally arranged.

Owner:SOUTHEAST UNIV

Bifuntional combined steel plate shear wall

ActiveCN101962974AIncrease the additional damping ratioAvoid damageConstruction materialWallsSheet steelLateral stiffness

The patent refers to the field of 'walls'. The invention relates to a bifuntional combined steel plate shear wall. A specially designed T-shaped fish-belly plate shear resisting system enhances the shear resisting stiffness in small earthquakes or in middle earthquakes, realizes stable transmission force, and augments the stiffness of the simply used steel shear wall; in large earthquakes, the shear resisting system quits operation, and partially provides the shear resisting stiffness; a plug-in concrete slab does not involve to share the horizontal effect, so as to lower the whole resist lateral stiffness; simultaneously the shear resisting system ensures the restraining effect of the concrete slab to the outer side of the steel plate, improves the energy consuming ability of the structure, augments the additional damping ratio of the structure, and decreases the damage effect of the structure in the earthquakes, thus achieving the effect of a fuse wire and a energy dissipater in large earthquakes. The bifuntional combined steel shear wall provided by the invention is a novel combined steel plate shear wall applied in high-rise building steel structures or other structures, has simple construction, convenient replacement, good economy, better vibration resistance and the like, and is a superior and practical side force resisting structural member.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Steel plate holder and skew spike combined interface connection steel and UHPC (ultrahigh performance concrete) thin slab combination structure system

ActiveCN109487699AIncreased shear strengthImprove integrityBridge structural detailsBridge erection/assemblySheet steelStructure system

The invention discloses a steel plate holder and skew spike combined interface connection steel and UHPC (ultrahigh performance concrete) thin slab combination structure system. According to the system, the ultra-thin deck slab is made from UHPC so that dead weight of the structure can be reduced while the bridge capacity of the structure can be improved; steel plate holder and skew spike combinedconnectors are used for interface connection at the interface, so that comprehensive advantages of the steel plates serving as the rigid connectors and the spikes serving as the flexible connectors can be achieved well, interface slippage can be reduced under action of rigid connection of the steel plate holders in the normal application state, and the defect in ductility of the steel plate holders which serve as the rigid connectors can be overcome according to characteristic of the spikes serving as the flexible connector in an ultimate state. The short skew spikes are in staggered arrangement to form the reinforcing truss web member of the UHPC slab, so that rigidity of the UHPC slab is increased and further the integral rigidity of the combined section is increased.

Owner:SOUTHEAST UNIV

Method of Manufacturing Radial Tire for Construction Vehicle

InactiveUS20070199639A1Avoid deformationIncreased shear stiffnessHeavy duty tyresTyresFiberArchitectural engineering

Disclosed is a method of manufacturing a radial tire for a construction vehicle, wherein when a cylindrical band is formed by using one layer of carcass layer formed of steel cords in a band making step, a shape retaining layer formed of at least one layer of organic fiber cords is wrapped on the outer peripheral surface of the carcass layer so that the organic fiber cords cross the steel cords of the carcass layer. The radial tire having excellent uniformity without any uneven widening between the steel cords can be provided without using a shape retaining auxiliary apparatus.

Owner:THE YOKOHAMA RUBBER CO LTD

Yarn traversing device for a winding device of a textile machine producing cross-wound bobbins

The device has a thread guide that is movable parallel to a surface of a bobbin. A drive is controllable by electric motors. The thread guide is attached to the electric motor controlled drive by a finite and flexible connecting unit (20) e.g. band. The connecting unit is designed such that the unit transfers both tractive and compressive forces, where the unit is supported by a stationary linearguide (18).

Owner:SAURER GERMANY GMBH & CO KG

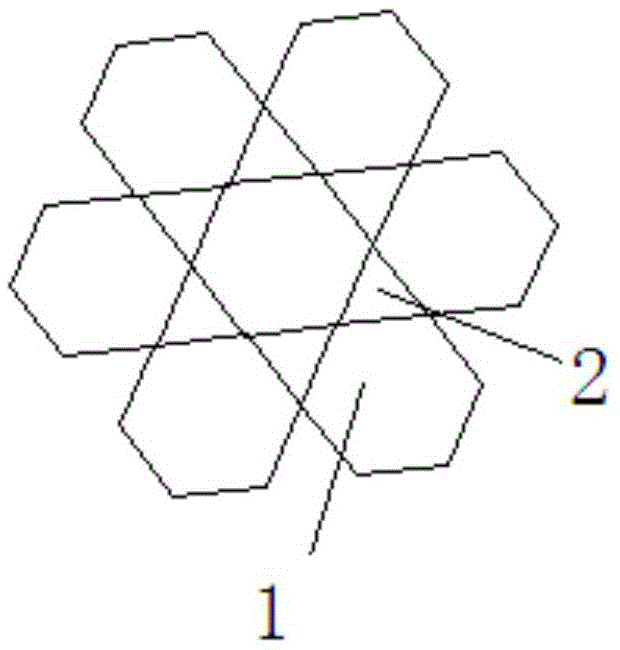

Little-odor and few-VOCs (volatile organic compounds) automotive paper honeycomb composite board and dry-method forming process thereof

ActiveCN105619997AUniform temperature distributionReduced differences in temperature gradientsNon-macromolecular adhesive additivesLaminationPhotoinitiatorWoven fabric

The invention discloses a little-odor and few-VOCs (volatile organic compounds) automotive paper honeycomb composite board, which comprises a paper honeycomb core layer, hot melt adhesive film layers, a non-woven fabric layer and a surface layer material, wherein the hot melt adhesive film layers are adhered to the upper surface and the lower surface of the paper honeycomb core layer; the non-woven fabric layer is adhered to the surface of a hot melt adhesive film; the surface layer material covers the non-woven fabric layer; the paper honeycomb core layer has a honeycomb-shaped structure consisting of hexagonal hole grids and triangular hole grids; a dentate adhering structure is formed between the surface layer material and the non-woven fabric layer; the hot melt adhesive film is prepared from the following raw materials of polyneopentylene-1,6-hexamethylene adipate glycol, a polyoxyethylene-polystyrene-polyoxyethylene triblock copolymer, polyethylene acrylate, pentaerythritol, neopentyl glycol, hexadecanoic acid, lauryl-L-glutamic acid-[alpha],[gamma]-dibutylamine, zinc ricinoleate, 2,5-dimethyl-2,5-di-(tert-butylperoxy)acetylene, a hydroxyketone photoinitiator and the like. The little-odor and few-VOCs automotive paper honeycomb composite board is little in odor; the VOCs are below a standard limit minimum.

Owner:贵阳渝冠技术服务中心

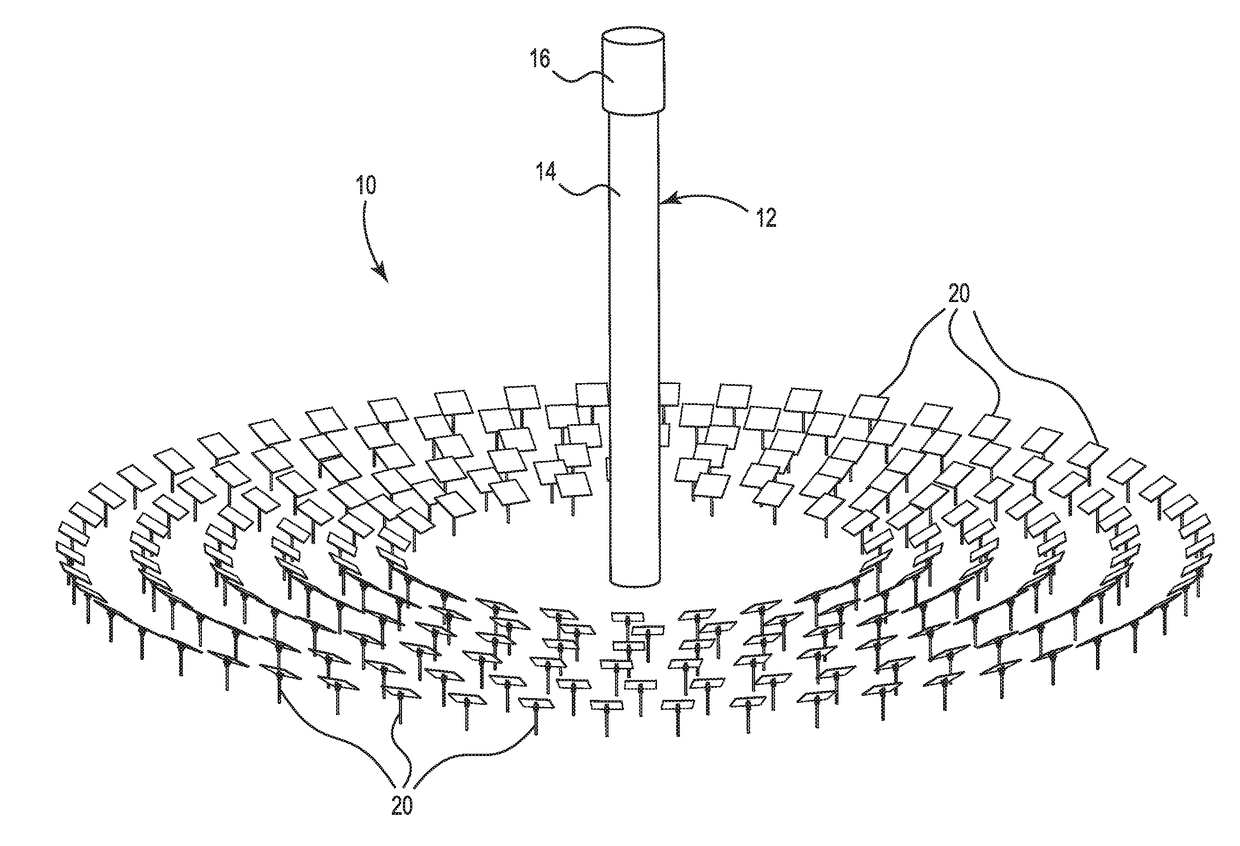

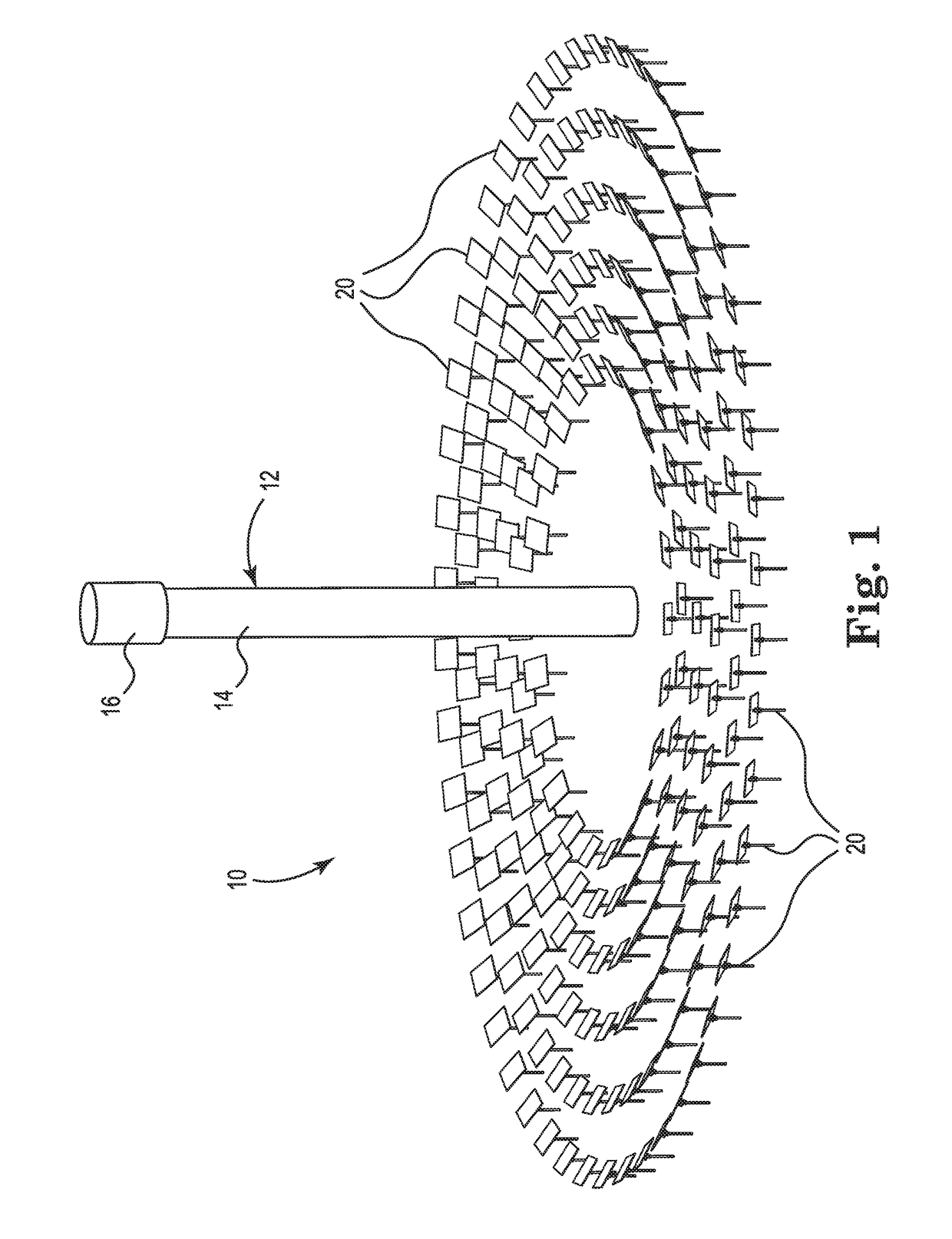

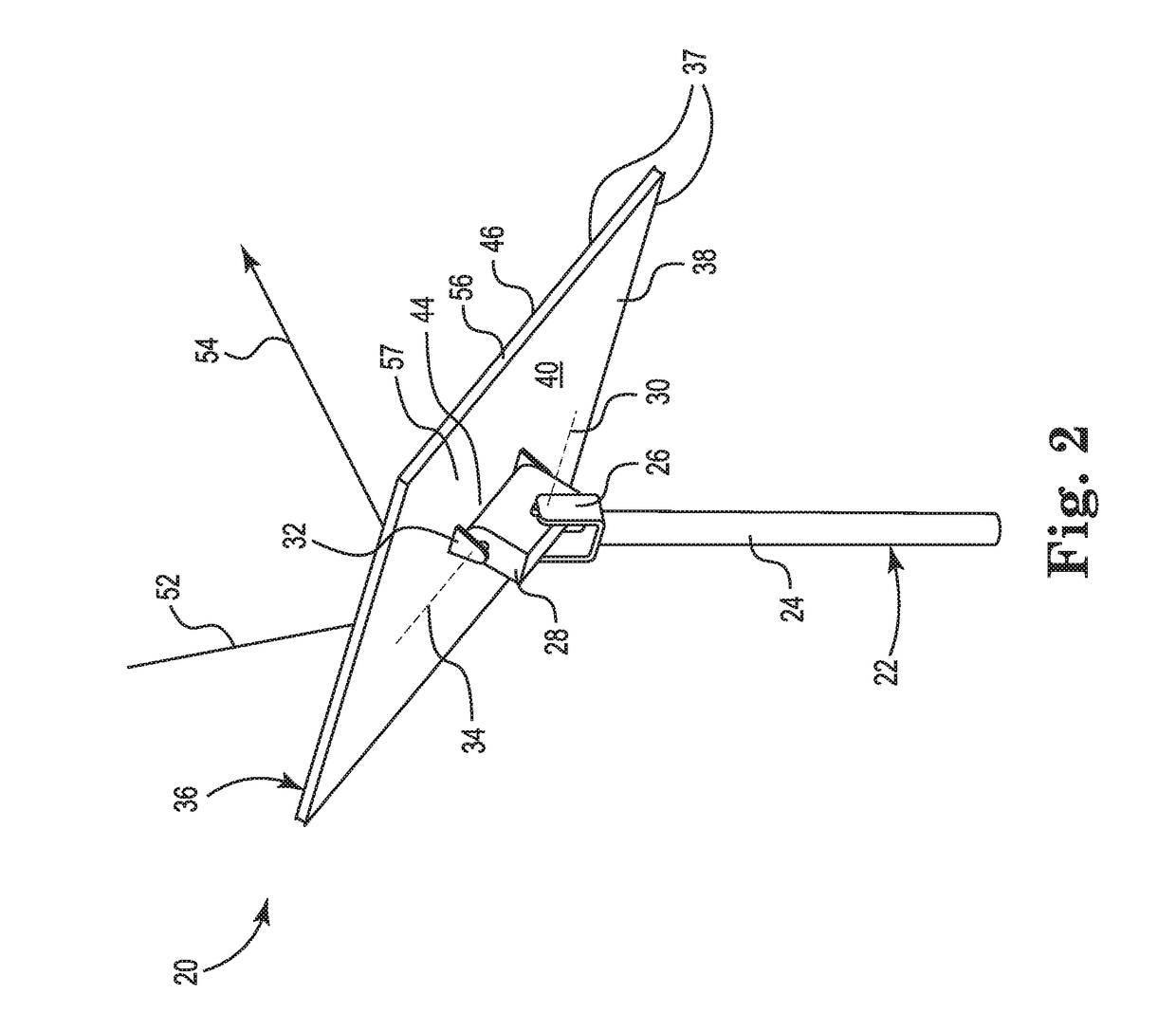

Composite sandwich mirror panel useful in concentrated solar power systems

The present invention provides strategies for mitigating the deleterious effects of differential thermal expansion in composite panel structures. The principles of the present invention are particularly useful in the field of concentrating solar power. The principles of the present invention can be used in CSP applications to make composite mirror panel structures with improved characteristics for accommodating differential thermal expansion between components of the composite. Significantly, the composite mirrors structures can still be securely attached to other heliostat components such as a drive mechanism while still having the ability to accommodate differential thermal expansion between the skins of a composite mirror panel helps to limit energy losses due to slope errors.

Owner:SOLARRESERVE TECH

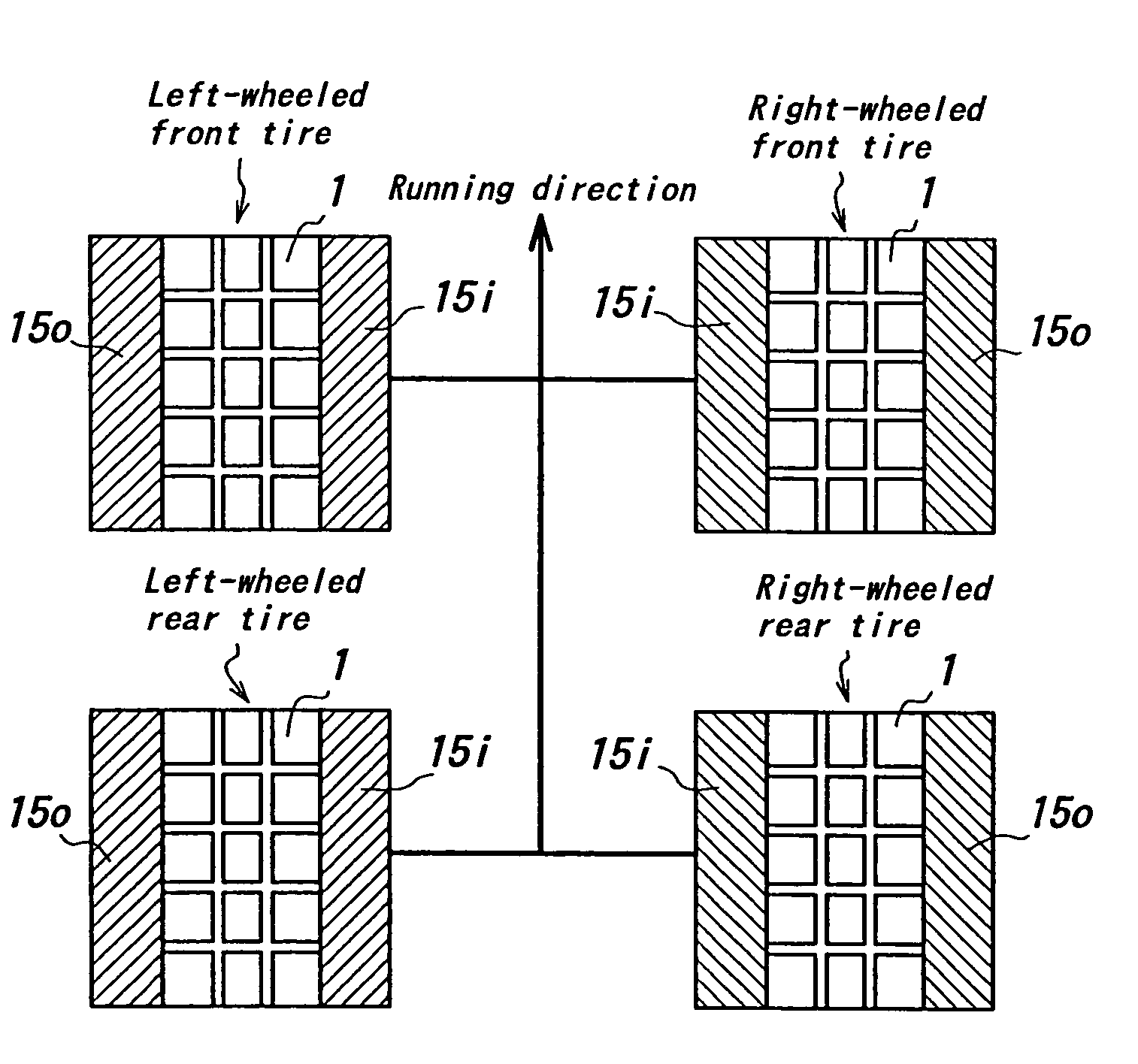

Pneumatic tire and a process for mounting the tire onto vehicle

InactiveUS7086439B2Improve vehicle performanceAvoid confusionWithout separate inflatable insertsSpecial tyresTreadAutomotive engineering

A pneumatic tire comprises a tread portion, a pair of sidewall portions, a pair of bead portions, a carcass, a belt, and a reinforcing member arranged in a tire zone including at least the sidewall portion, wherein a shearing rigidity in the circumferential direction of the reinforcing member is made larger at a first tire zone located at an outside of the vehicle than at a second tire zone located at an inside of the vehicle in the same tire at a posture of mounting the tire onto a vehicle.

Owner:BRIDGESTONE CORP

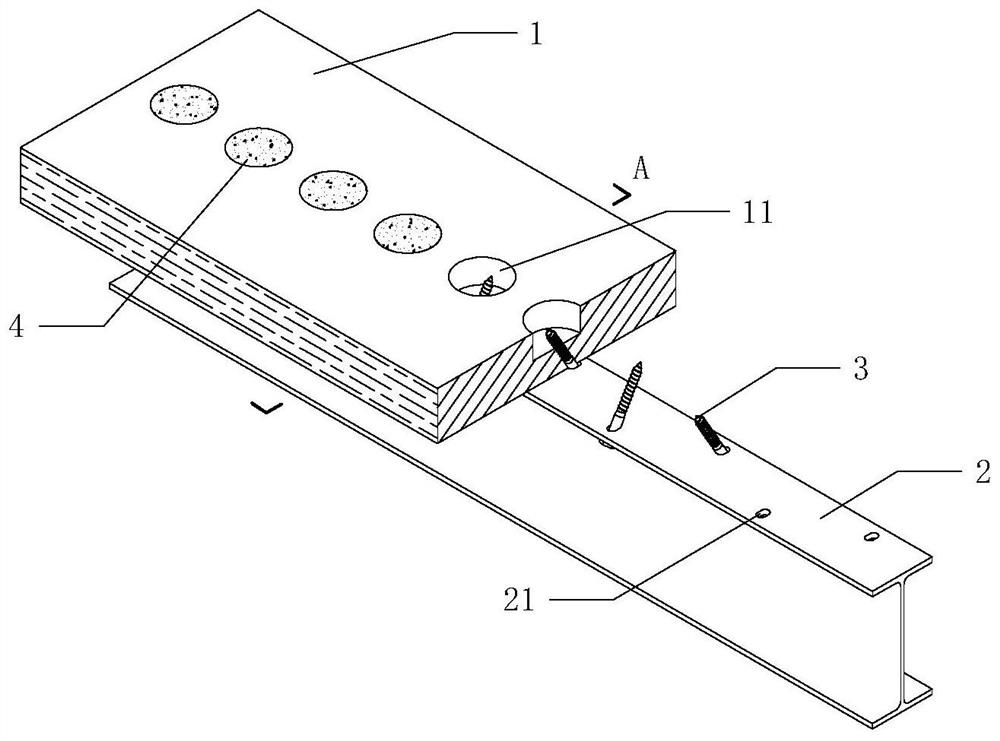

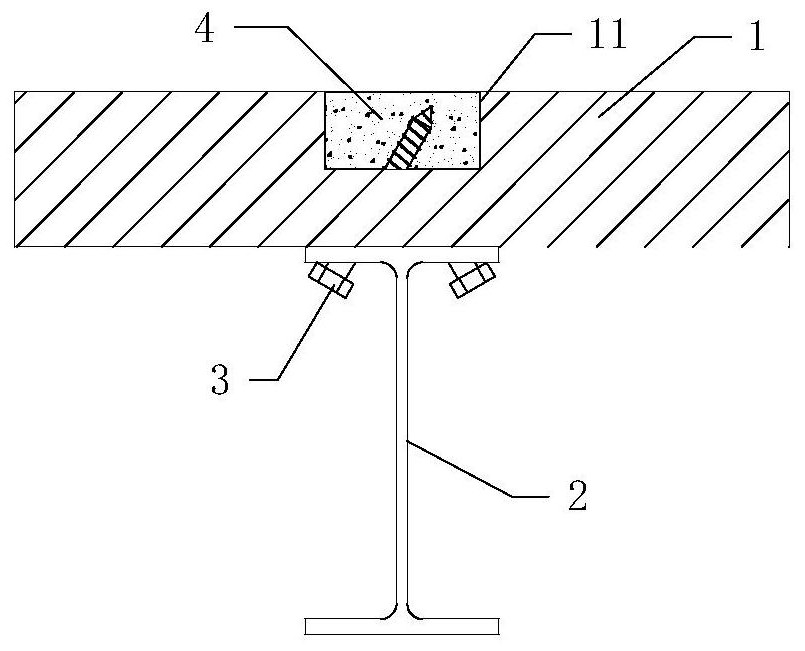

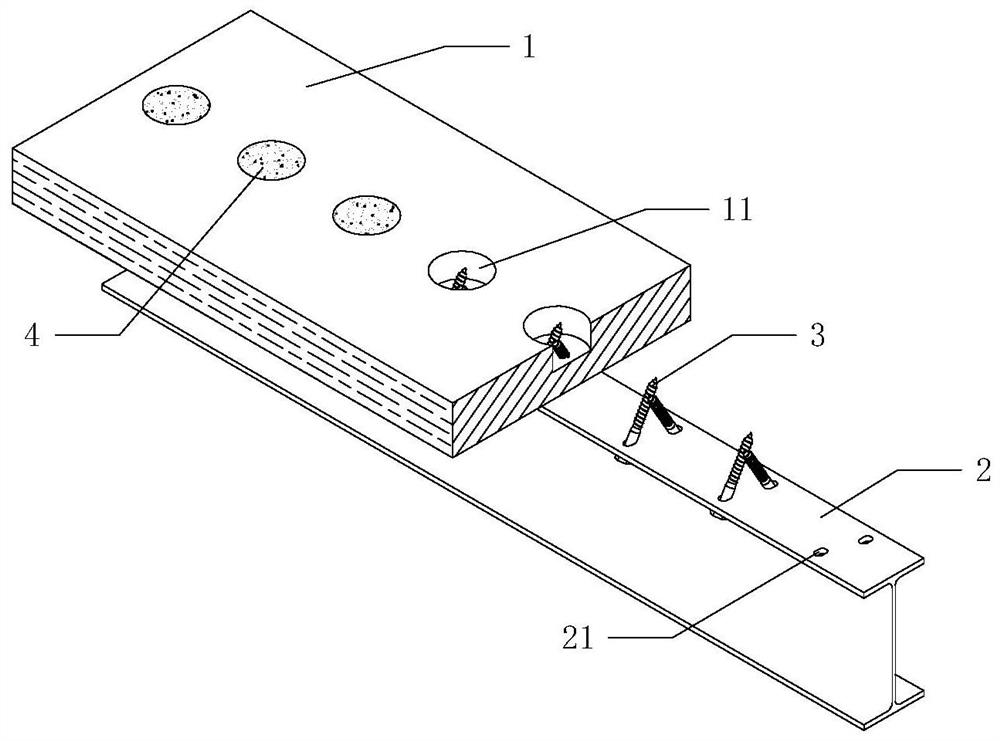

A steel-wood hybrid connection structure

ActiveCN110359569BAct as an end anchorImprove carrying capacityBuilding constructionsEngineeringWood plank

The invention discloses a steel-wood mixed connection structure, which comprises a wood board and a steel member. A slot hole is arranged on the side of the wood board different from the steel member. The depth of the slot hole is smaller than the thickness of the wood board. The tapping screw is anchored into the wood board through the reserved hole of the steel member, and the tail extends into the reserved slot hole of the wood board, and the slot hole is filled with mortar. The invention reserves a slot hole in the wood board, and the tail of the self-tapping screw extends into the reserved slot hole of the wood board, and pours mortar into it, which can play a kind of end anchoring effect on the screw, and improve the shear bearing capacity and rigidity of the screw connection. Prevent the screw from being pulled out due to excessive sliding deformation, and at the same time expand the stress area of the wood at the tip of the screw to prevent splitting and local crushing.

Owner:SOUTHEAST UNIV

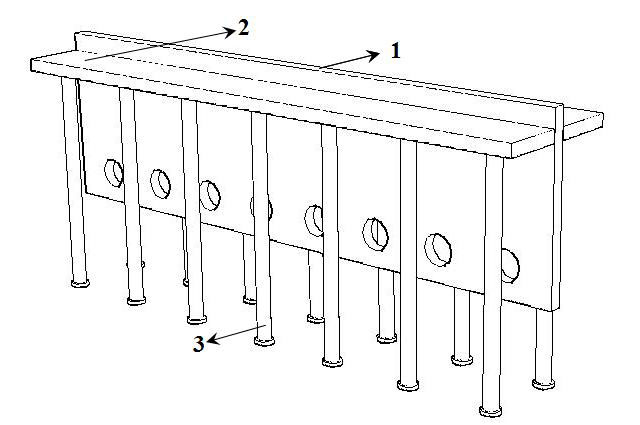

A steel plate support-diagonal nail combined quick-connect steel-uhpc combined structural system

ActiveCN109487698BIncreased shear strengthImprove integrityBridge structural detailsBridge erection/assemblyIsosceles trapezoidThin slab

The invention discloses a steel plate holder and skew spike combined rapid connecting steel and UHPC (ultrahigh performance concrete) combination structure system, comprising a steel beam, an UHPC thin slab, steel plate holders and short spikes; the steel plate holders are of isosceles-trapezoid structure, and are connected with the steel beam through high-strength bolts; the short spikes are vertically arranged on bevels of two sides of each steel plate holder; the UHPC thin slab is cast on the upper side of the steel beam; combinations of the steel plate holders and the short spikes are uniformly distributed inside the UHPC thin slab. As the deck slab is made of UHPC, dead weight of the structure can be reduced while bridge capacity of the structure can be improved; steel plate holder and skew spike combined connectors are used for interface connection at the interface, so that comprehensive advantages of the steel plates serving as the rigid connectors and the spikes serving as theflexible connectors can be achieved well, and interface slippage can be reduced under action of rigid connection of the steel plate holders in the normal application state; in the UHPC slab, the shortskew spikes are in staggered arrangement to form the reinforcing truss of the UHPC, and accordingly rigidity of the UHPC slab is increased and the integral rigidity of the combination section is increased.

Owner:SOUTHEAST UNIV

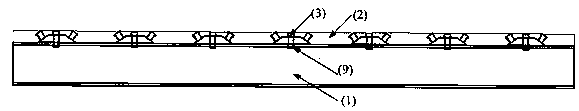

H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and construction method thereof

InactiveCN102733492BMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingEngineeringSteel columns

The invention discloses an H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a column sealing piece, a T-shaped connection piece, an L-shaped connection piece and bolts. The column sealing piece consists of a column sealing plate, a beam upper flange stiffening rib and a column sealing plate stiffening rib; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Ribbed grid-like reinforced concrete shear wall and making method thereof

The invention relates to a dense-rib network steel bar concrete shearing wall and relative producing method. It uses 2-6 bricks of hollow plates with vertical chamber and transverse groove to integrate a wall along the height direction of floor; and the vertical chamber and the transverse groove individually contain vertical steel bars and transverse steel bar while they are filled by concrete to form the dense-rib network shearing wall with better anti-shearing rigidity and anti-torsion property. The invention change the single-direction dense-rib plate into new dense-rib network shearing wall with better anti-torsion rigidity and high anti-shearing rigidity, while compared to present single-direction dense-rib wall, its anti-shearing rigidity is improved 15-20 times. It can apply small high floor and high floor constructions.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com