Air-inflation meridian tire for heavy load

A technology for radial tires and heavy loads, applied to the field of pneumatic radial tires for heavy loads, to achieve the effect of improving durability and suppressing shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention will be described based on the drawings.

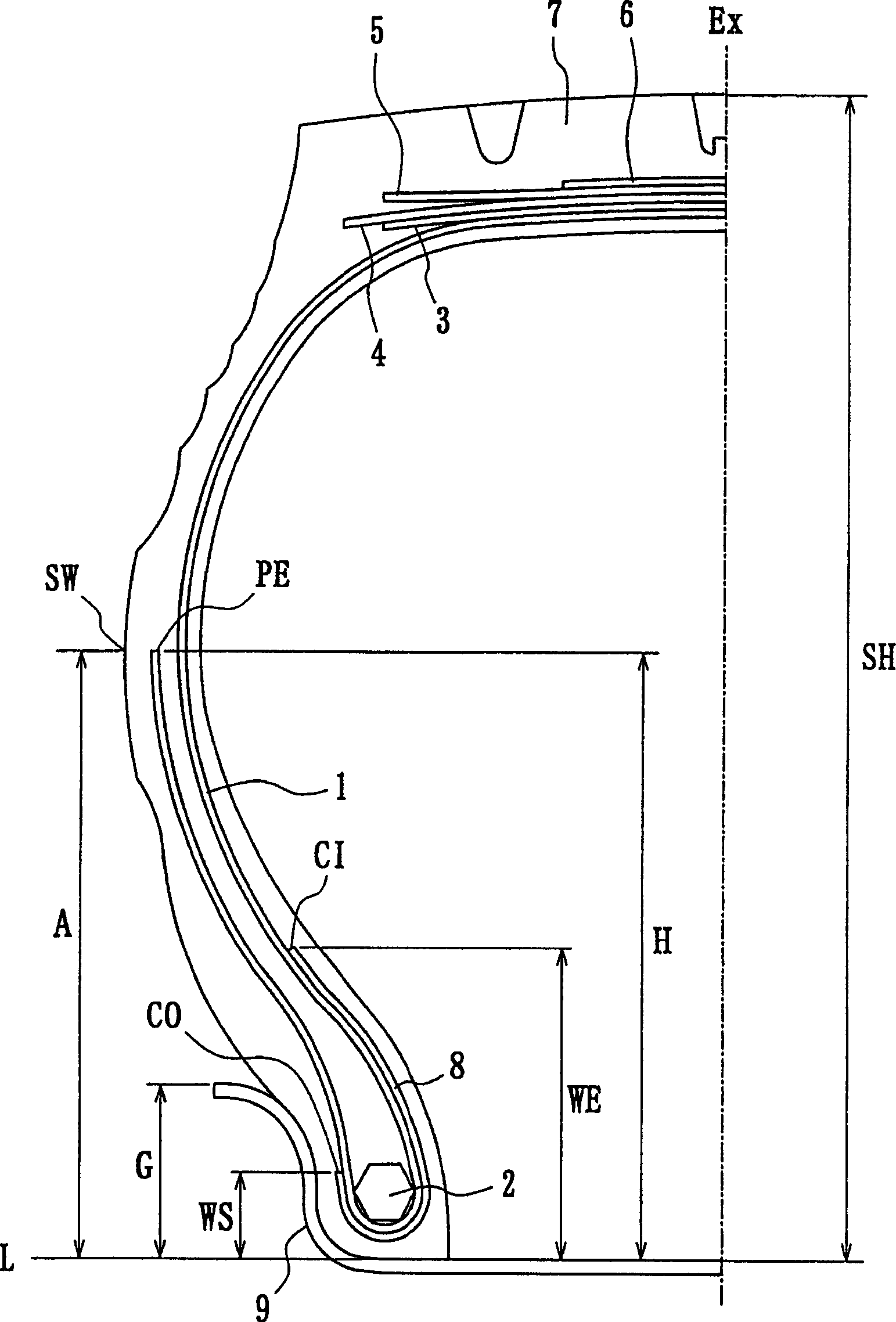

[0020] figure 1 It is a cross-sectional view showing the tread portion of the left half of the tire in the width direction when the tire according to one embodiment of the present invention is mounted on an applicable rim and filled with a predetermined air pressure. The right half is symmetrical to the left half with the central line Ex as the axis.

[0021] In the figure, 1 denotes a carcass layer, which is developed in a ring shape between bead cores 2, and its side parts are wound around each bead core 2 from the inner side to the outer side of the tire. On the outer peripheral side of the top of the carcass layer 1 , four belt layers 3 , 4 , 5 , 6 are arranged, and a tread rubber 7 is arranged on the outer peripheral side of the belt layer 6 . Further, a wire chafer 8 as a carcass reinforcement is wound around the bead core 2 along the outer side of the carcass layer 1 wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com