Installation for making a cut, crease and the like having a plate-shaped frame

A technology of equipment and incision, applied in the direction of cutting tools for shearing machines, driving devices for metal rolling mills, metal processing equipment, etc., can solve problems such as difficulty in accessing bottom rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

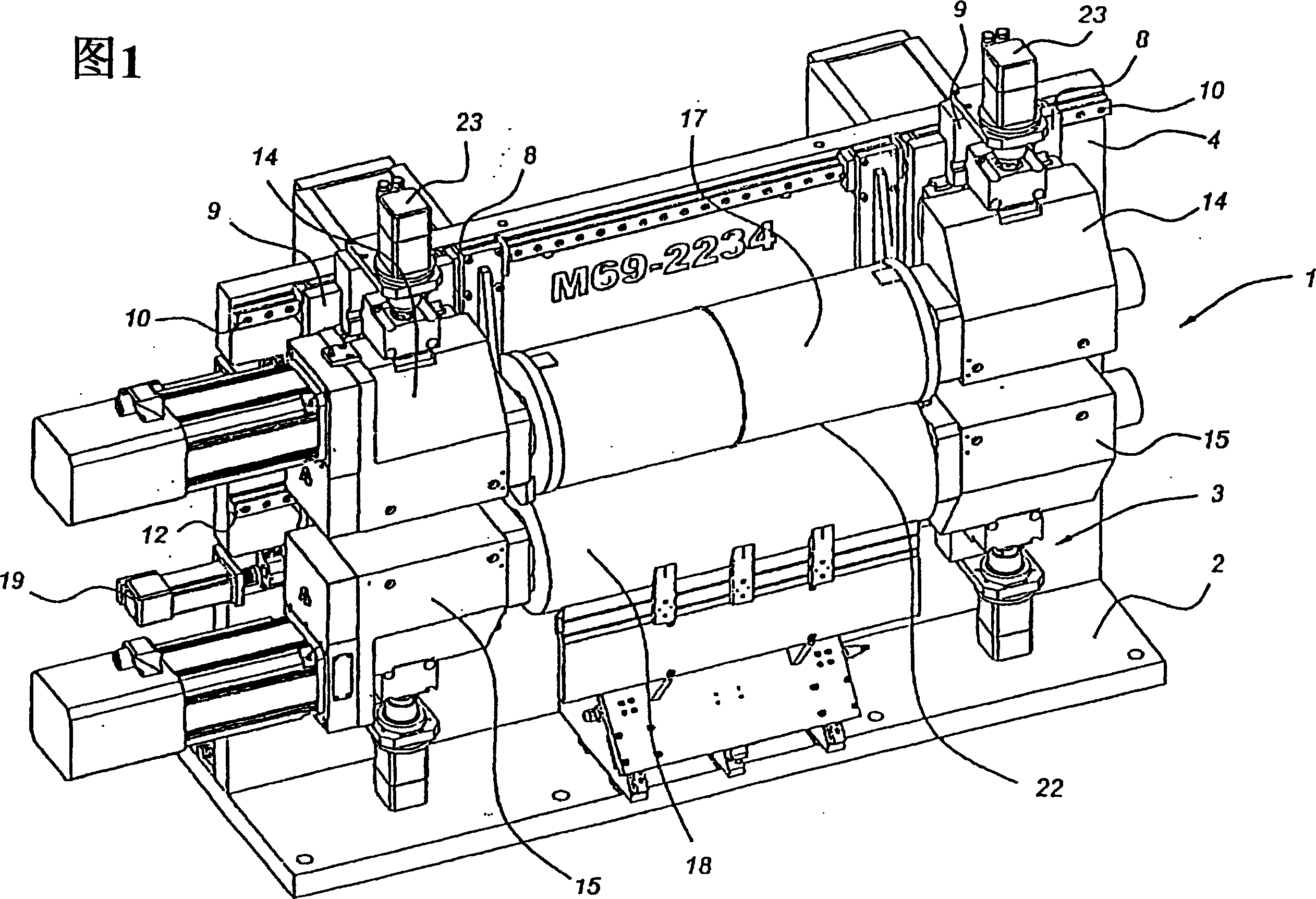

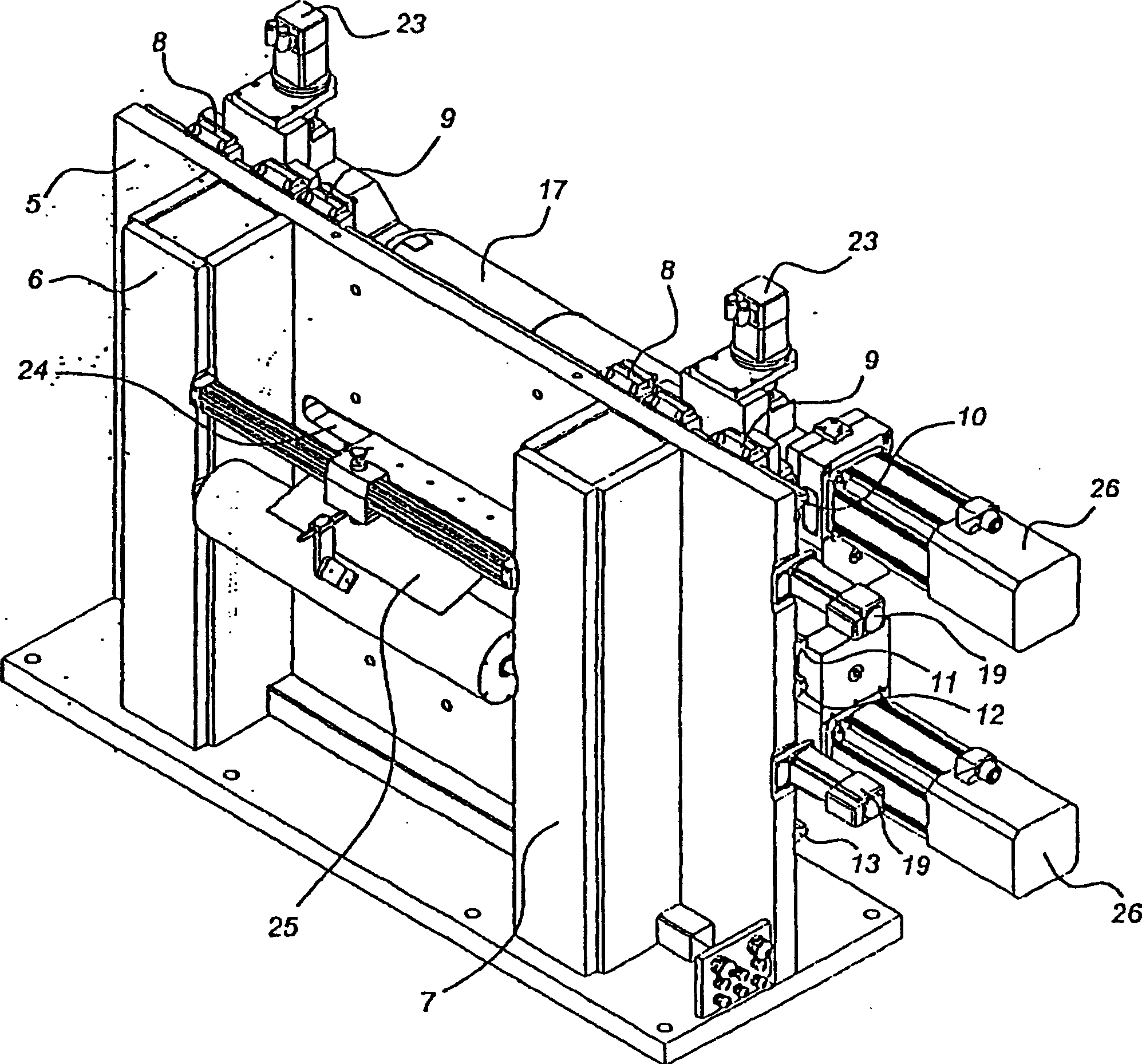

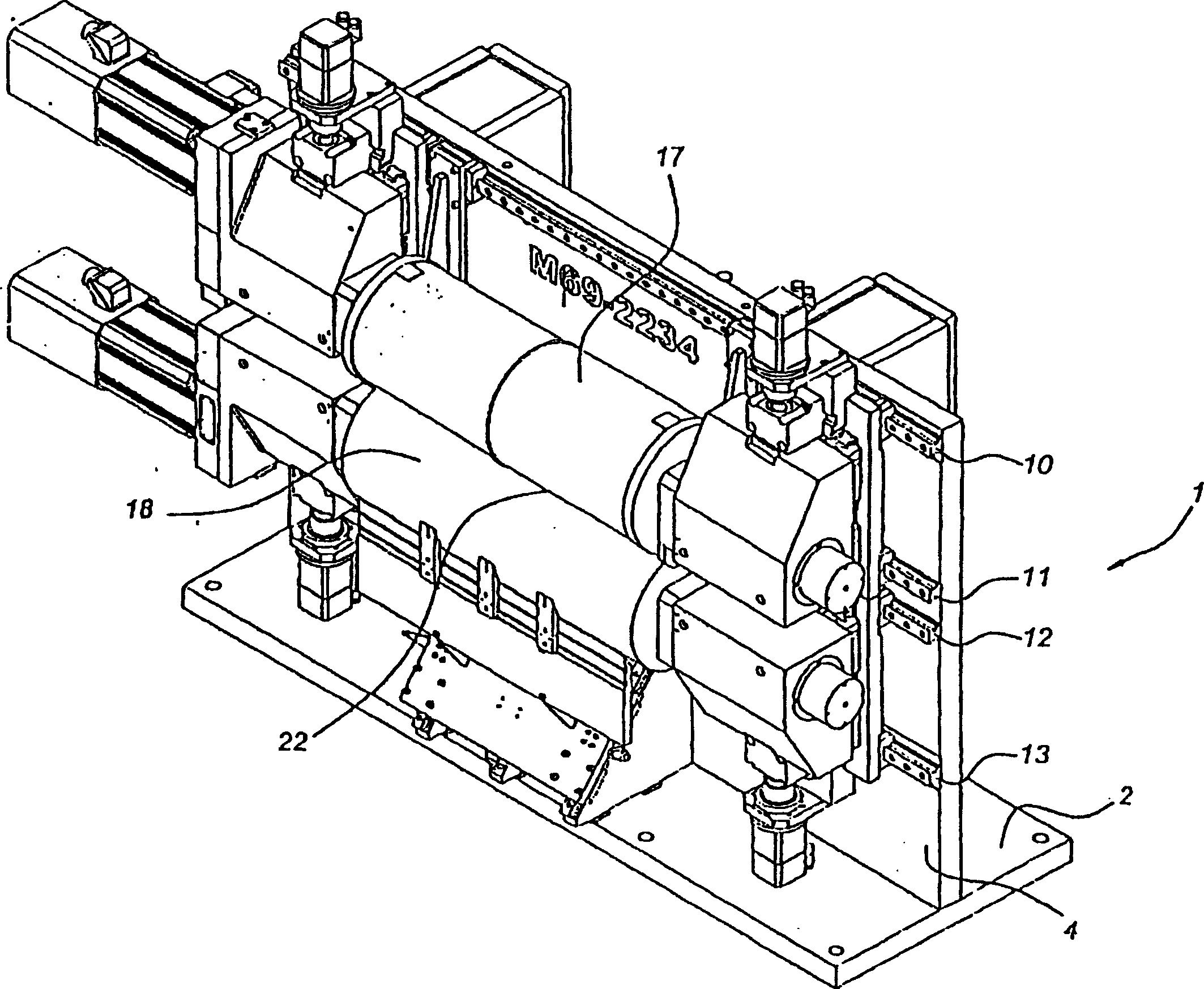

[0031] The rotary device shown in FIGS. 1 to 4 has a frame generally indicated by 1 which mainly includes a base 2 and a plate 3 . Tablet 3 has a flat front 4 and a flat rear 5 . Reinforcing columns 6 , 7 extending to the base 2 are secured to the flat back 5 .

[0032] On the front 4 of the plate 3 are mounted two pairs of vertical rails 8 , 9 . The rails 8, 9 in each pair are connected to each other and are supported on horizontal rails 10-13 so that they can move.

[0033] Two heads 14, 15 are fitted on each pair of vertical rails. A stub shaft 16 is rotatably supported in each head. As can be seen in FIG. 4 , the minor axis 16 has the shape of a frustum of a cone. In each case, the rollers 17 , 18 are supported on two short shafts 16 placed opposite each other, as shown in FIG. 1 .

[0034] With regard to mounting and respectively removing the rollers, the heads 14 , 15 are removed by moving the associated pair of guide rails 8 , 9 apart using linear actuators 19 . R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com