Little-odor and few-VOCs (volatile organic compounds) automotive paper honeycomb composite board and dry-method forming process thereof

A technology of paper honeycomb and composite board, applied in paper/cardboard layered products, vehicle parts, adhesive additives, etc., can solve the problems of affecting the driver's sight, occupant's physical injury, dry cough and allergies, and improve the heat transfer efficiency and Cross-section diameter, improvement of load carrying capacity, effect of improvement of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

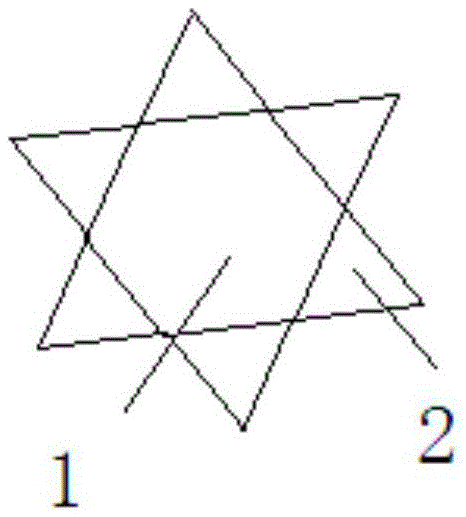

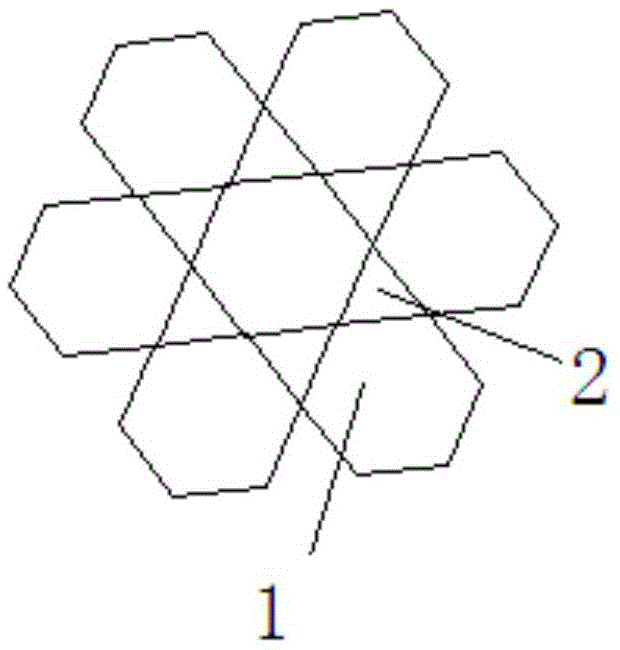

[0028] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot melt adhesive film includes the following components by weight: 10 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 5 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 5 parts of polyethylene acrylate, 3 parts of pentaerythritol, 2 parts of neopentyl glycol, 1 part of hexadecanoic aci...

Embodiment 2

[0034] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot-melt adhesive film includes the following components by weight: 20 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 10 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 10 parts of polyethylene acrylate, 7 parts of pentaerythritol, 6 parts of neopentyl glycol, 3 parts of hexadecanoic ...

Embodiment 3

[0040] The low-odor and low-VOC automobile paper honeycomb composite board of the present embodiment, the composite board comprises a paper honeycomb core layer, a hot-melt adhesive film layer bonded to the upper and lower surfaces of the paper honeycomb core layer, and a hot-melt adhesive film bonded to the The non-woven fabric layer on the surface and the surface layer material covered on the non-woven fabric layer, the paper honeycomb core layer is a honeycomb structure composed of hexagonal cells and triangular cells, the surface layer material and the non-woven There is a tooth-like bonding structure between the cloth layers, and the raw material of the hot-melt adhesive film includes the following components by weight: 10 parts of polyneopentyl adipate-1,6-hexanediol ester diol, polyoxygen 10 parts of ethylene-polystyrene-polyoxyethylene triblock copolymer, 5 parts of polyethylene acrylate, 7 parts of pentaerythritol, 2 parts of neopentyl glycol, 3 parts of hexadecanoic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com