Bifuntional combined steel plate shear wall

A steel plate shear wall, dual-function technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of limited bearing capacity, loss of steel plate protection, and poor economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

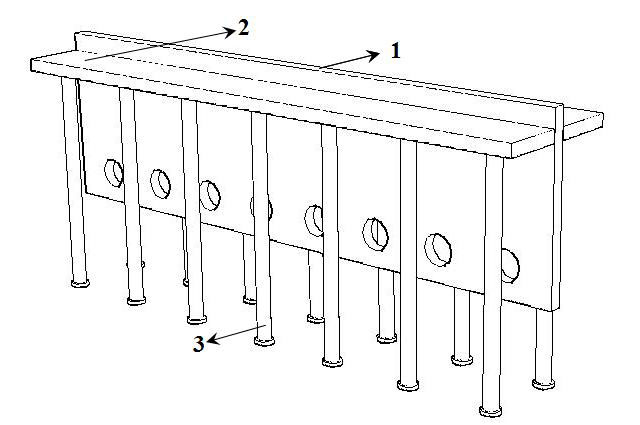

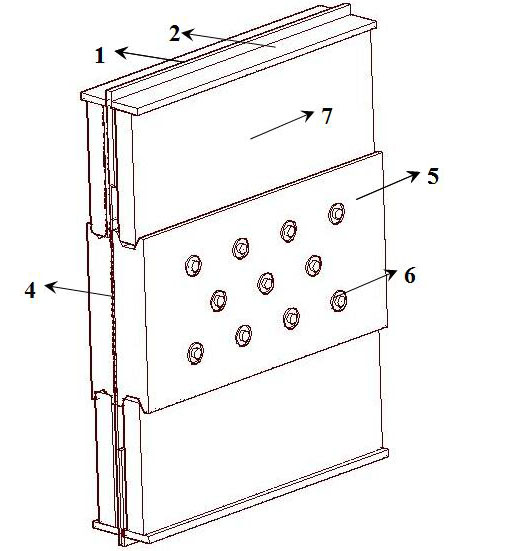

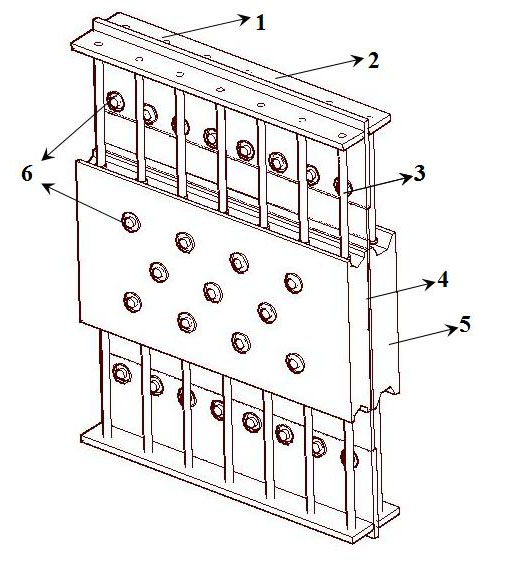

[0023] Such as figure 1 , as shown in 2, 3, and 4, the dual-function combined steel plate wall of the present invention consists of a T-shaped fish web 1, two wing plates 2, a shear connector 3, outsourcing lightweight concrete 7 and a traditional combined steel plate shear wall . The traditional combined steel plate shear wall includes built-in steel plate 4, external concrete plate 5 and high-strength bolts 6. The T-shaped fish web 1 at the upper and lower parts can be welded to the upper and lower beams and columns, the built-in steel plate 4 and the T-shaped fish web 1 are connected by high-strength bolts 6, and the external concrete plate 5 and the built-in steel plate 4 are connected by high-strength bolts 6. The shear connector 3 is spot-welded with the flange 2 located on both sides of the T-shaped fish web 1, and the length of the shear connector 3 should be partly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com