Backfilling U-shaped shed

A backfilling, U-shaped technology, which is used in the field of surrounding rock support of mine roadways, U-shaped sheds, and rock mass engineering, can solve the problems of high labor intensity, slow construction speed, easy blocking, etc., and achieve increased shear stiffness. , to ensure long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation of the present invention will be further described below in conjunction with the accompanying drawings

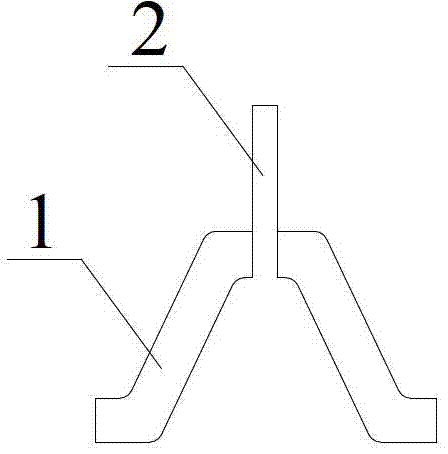

[0013] Such as figure 1 As shown, a U-shaped shed that can be filled behind the wall, a grouting hole is left at the leg of the U-shaped shed 1, and the diameter of the grouting hole is 20mm. Weld a grouting pipe 2 outside the hole, the length of the grouting pipe is 150 mm, the wall thickness is 1.8 mm, and the inner diameter of the grouting pipe is the same as the diameter of the grouting hole.

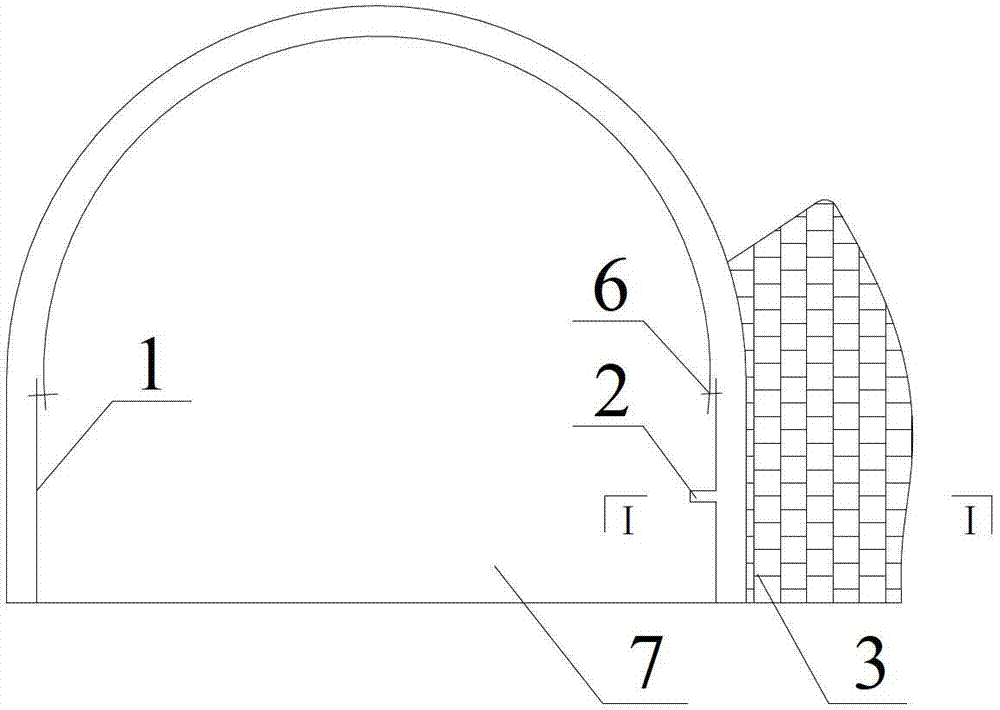

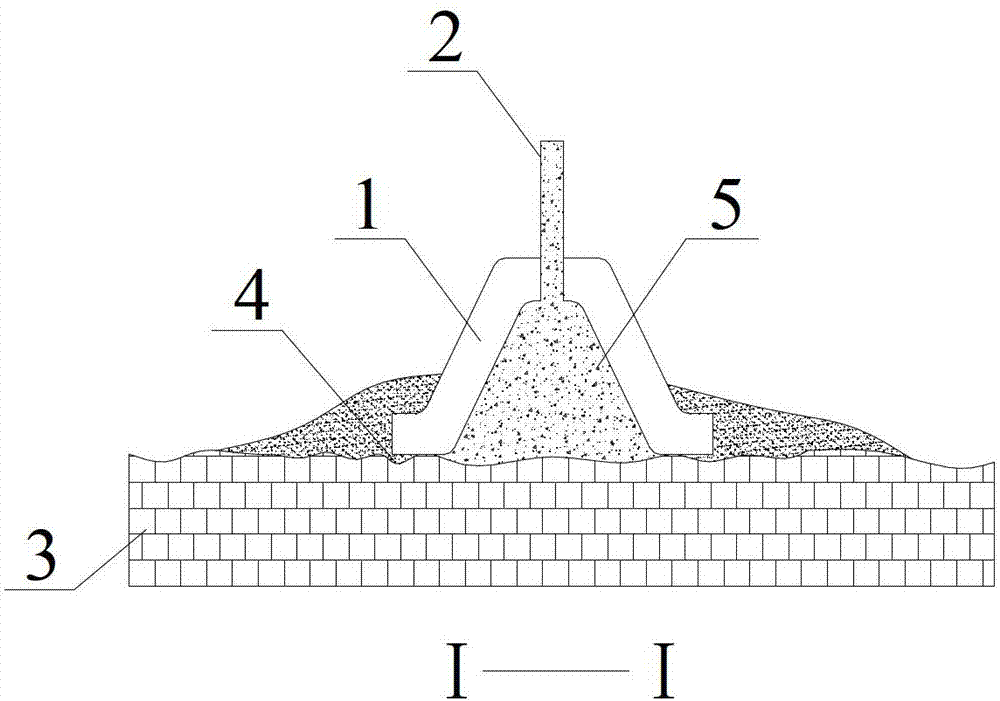

[0014] Such as figure 2 and image 3 As shown, when in use, the U-shaped shed 1 is first erected at 3 places on the surface of the surrounding rock of the roadway 7 that needs to be supported, and the surface of the roadway is sprayed to seal the gap 4 and U between the U-shaped shed 1 and the surface of the surrounding rock of the roadway. The gap 6 at the interface of the U-shaped shed, and then use the grouting pipe 2 left by the legs of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com