Preparation method of polyborosiloxane modified rubber

A polyborosiloxane and modified rubber technology, which is applied in the field of polymer composite material preparation, can solve the unsolved problems of rubber material impact resistance and vibration damping performance, and achieve improved impact resistance and vibration damping performance, The effect of increased zero displacement resistance and increased equivalent damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

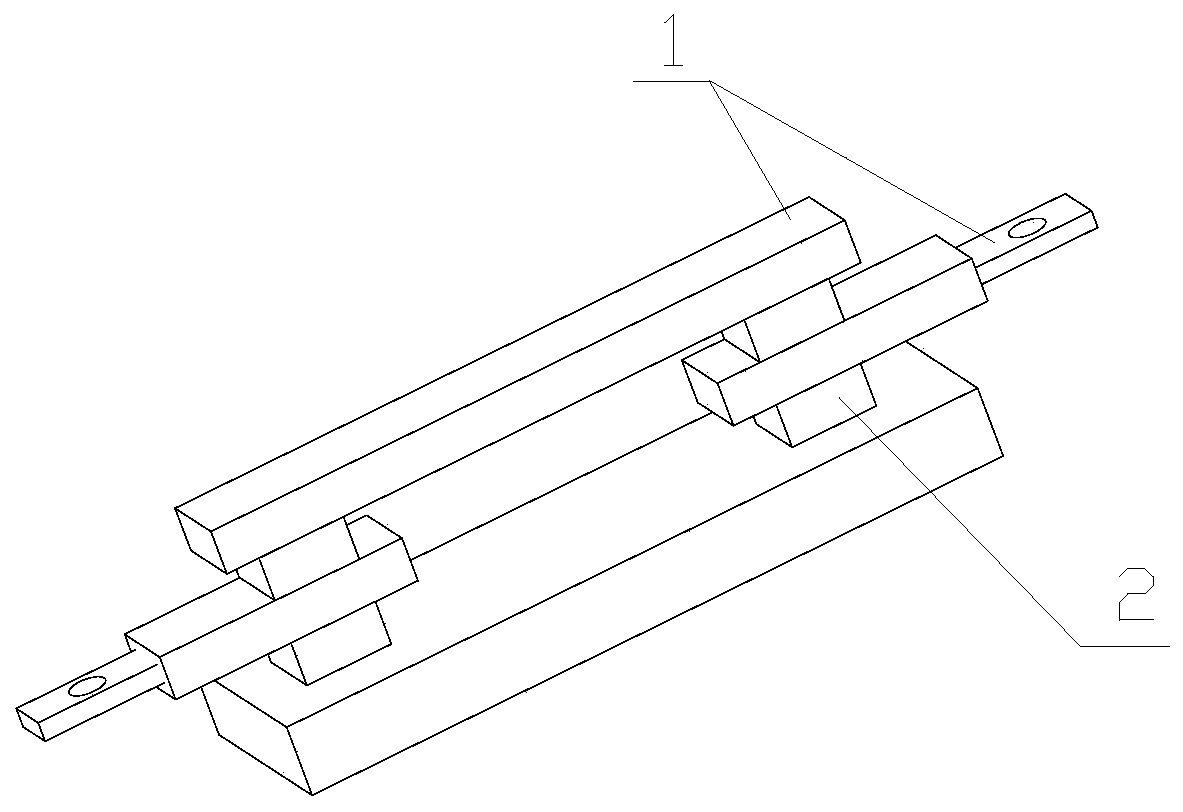

Image

Examples

preparation example Construction

[0032] A preparation method of polyborosiloxane modified rubber, by adding polyborosiloxane to rubber to improve the impact resistance and vibration damping performance of rubber, comprising the following steps:

[0033] Step 1: Put rubber (AxB1-x) and polyborosiloxane (PBDMS) into the internal mixer according to the proportion in turn, and then add a certain amount of carbon black, white carbon black, and metal oxides to it for dehydration and banburying. The temperature is 140°C-160°C, and the time is 10min-30min, so that various materials are mixed evenly. During the mixing process, the non-covalent bonds of polyborosiloxane (PBDMS) can be reversibly broken and regenerated, absorbing a large amount of external energy, and at the same time causing molecular chain movement to increase and internal friction to increase, thereby improving the damping performance. The ratio range of rubber (AxB1-x) to polyborosiloxane (PBDMS) is 100:20-88, and the rubber material obtained after ...

Embodiment 1

[0042] Step 1 Add butadiene rubber, EPDM rubber, polyborosiloxane, white carbon black and metal oxides into the internal mixer in the ratio of 60:20:10:15:5 in sequence, and banbury at 140°C for 10 minutes .

[0043] Step 2 Die-cut the material obtained in Step 1 into sheets of 1000mm×1000mm×6mm.

[0044] Step 3: vulcanize the sheet obtained in step 2 at a pressure of 10 MPa and a temperature of 150° C. for 10 minutes to obtain a vulcanized modified rubber material.

[0045] Step 4 Cut the vulcanized modified rubber material obtained in Step 3 into 25mm×25mm×6mm sheets to obtain sample a.

Embodiment 2

[0047] Step 1 Add styrene-butadiene rubber, EPDM rubber, polyborosiloxane, white carbon black and metal oxides to the internal mixer in the ratio of 60:40:40:15:8 in sequence, and banbury at 150°C for 15 minutes .

[0048] Step 2 Die-cut the material obtained in Step 1 into sheets of 1000mm×1000mm×6mm.

[0049] Step 3: vulcanize the sheet obtained in step 2 at a pressure of 13 MPa and a temperature of 140° C. for 10 minutes to obtain a vulcanized modified rubber material.

[0050] Step 4 Cut the vulcanized modified rubber material obtained in Step 3 into 25mm×25mm×6mm sheets to obtain sample b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com