Patents

Literature

38results about How to "Low construction precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

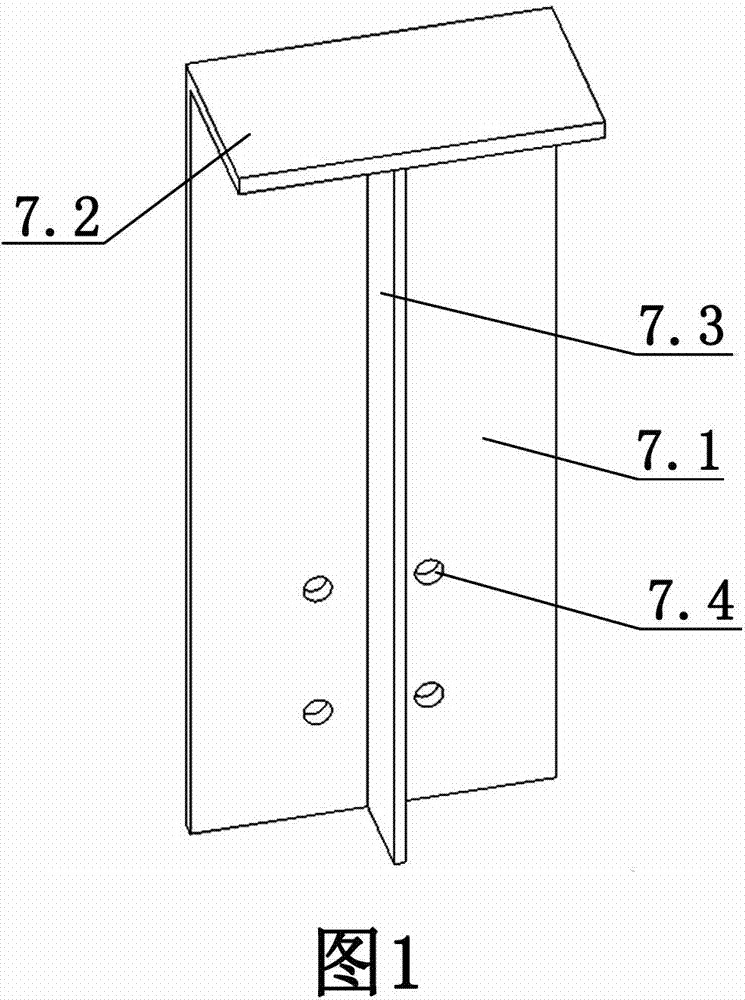

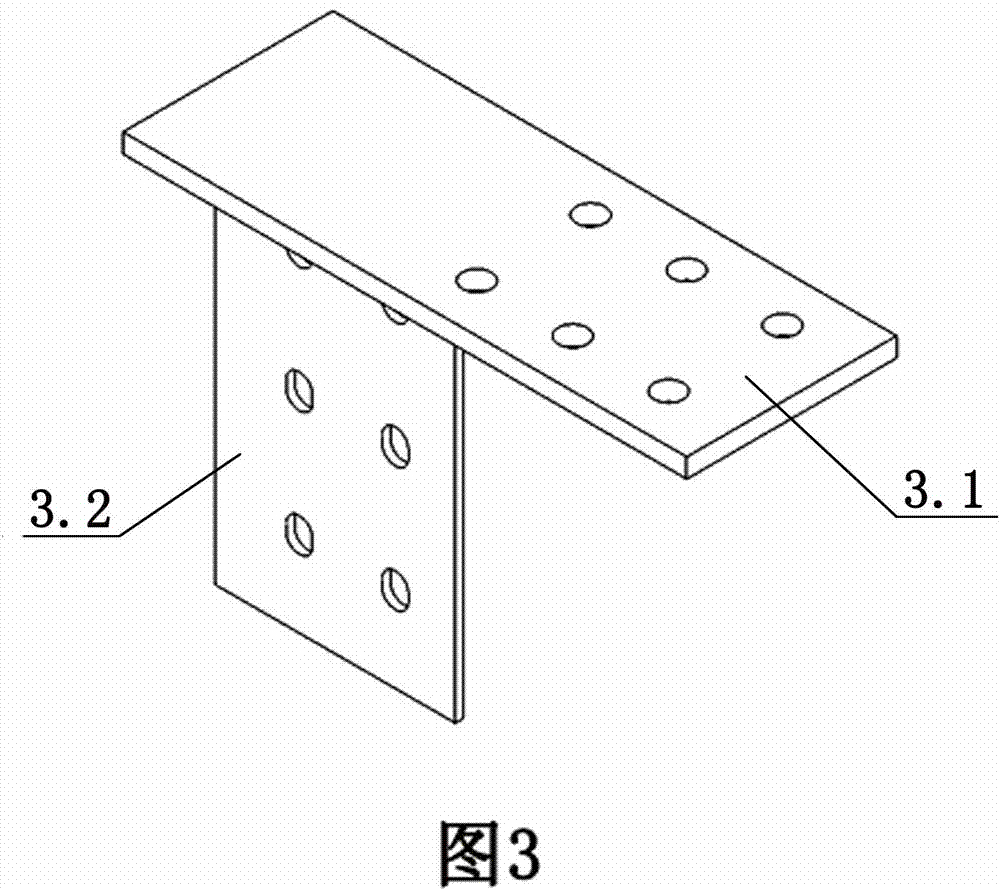

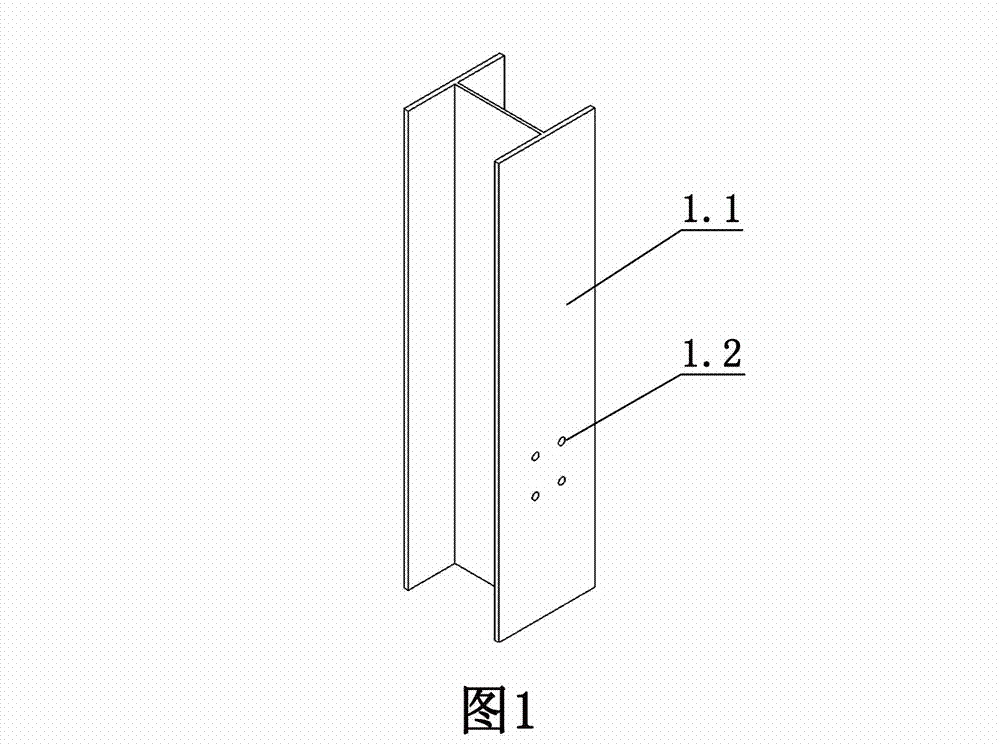

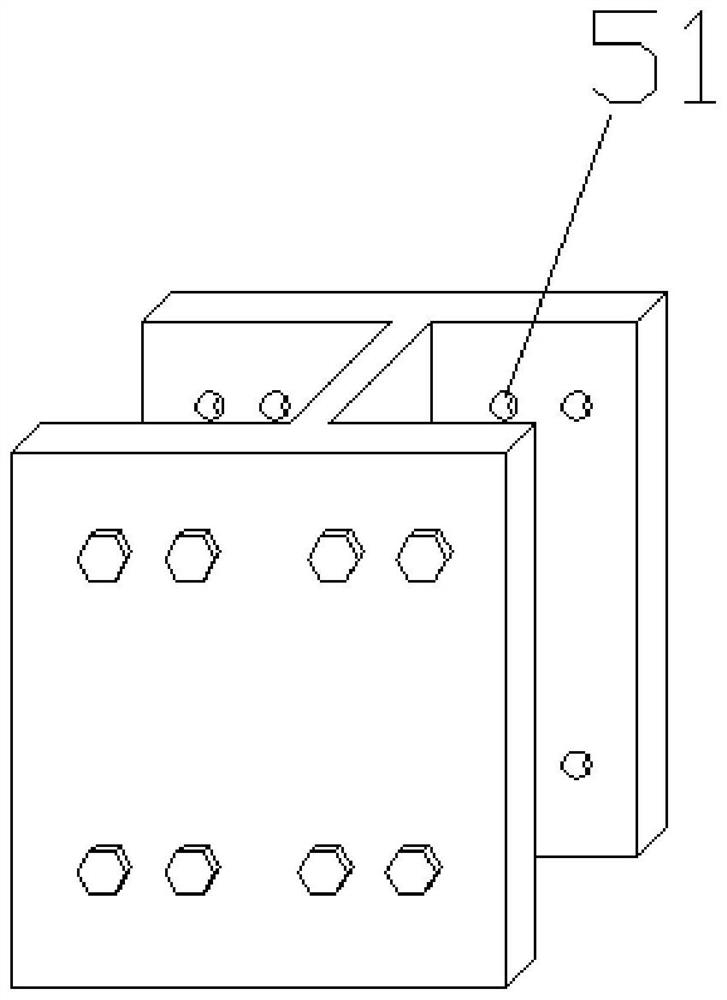

H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and construction method thereof

InactiveCN102733492AMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingSteel columnsMinor axis

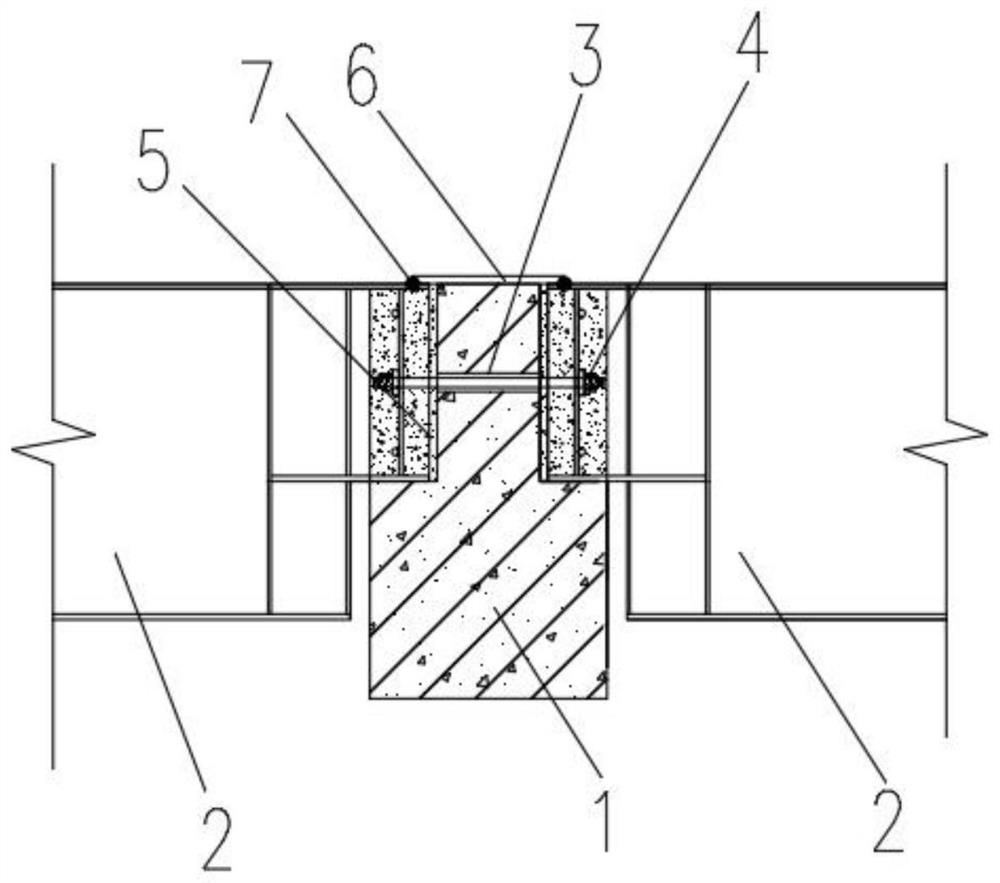

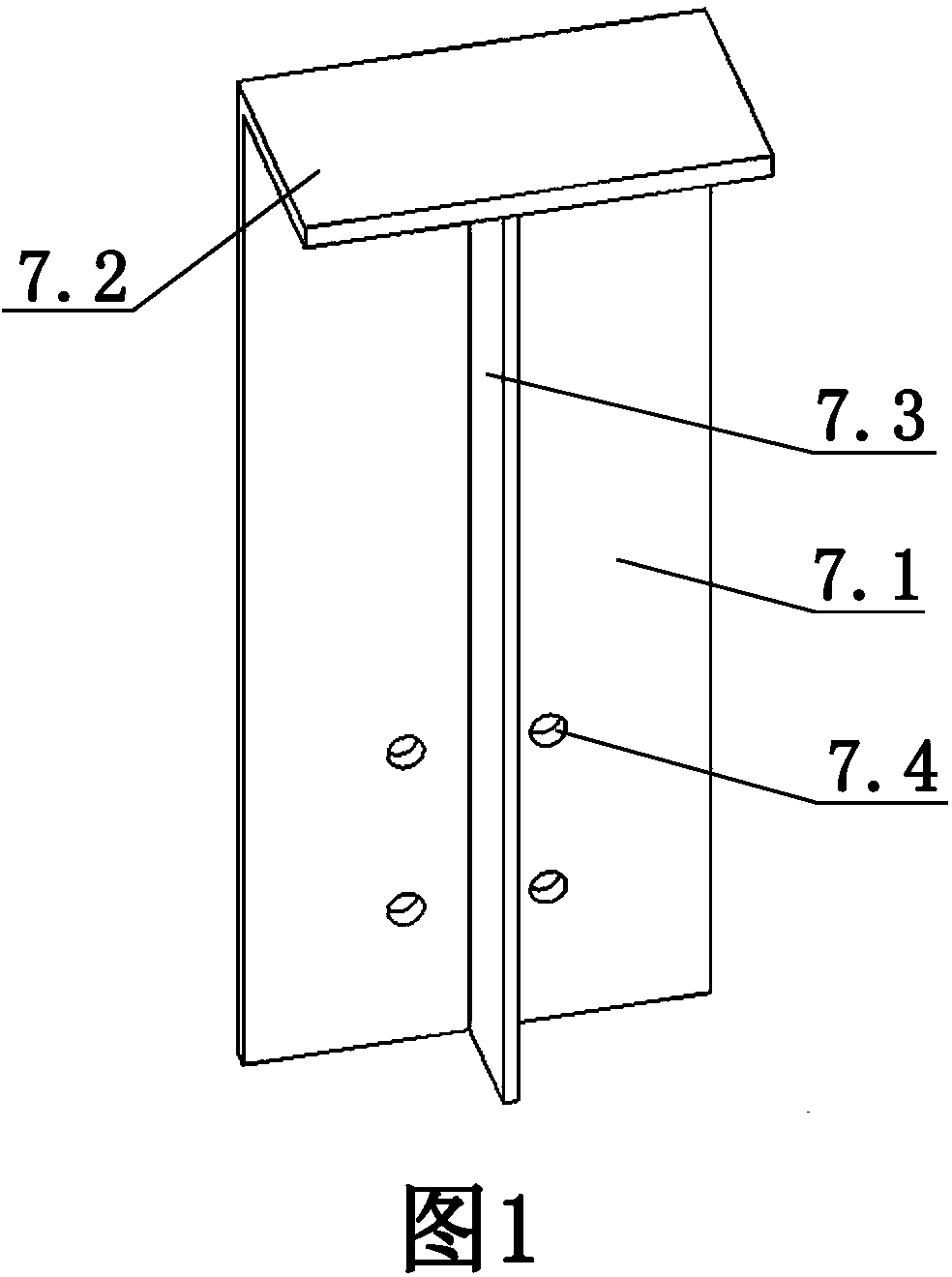

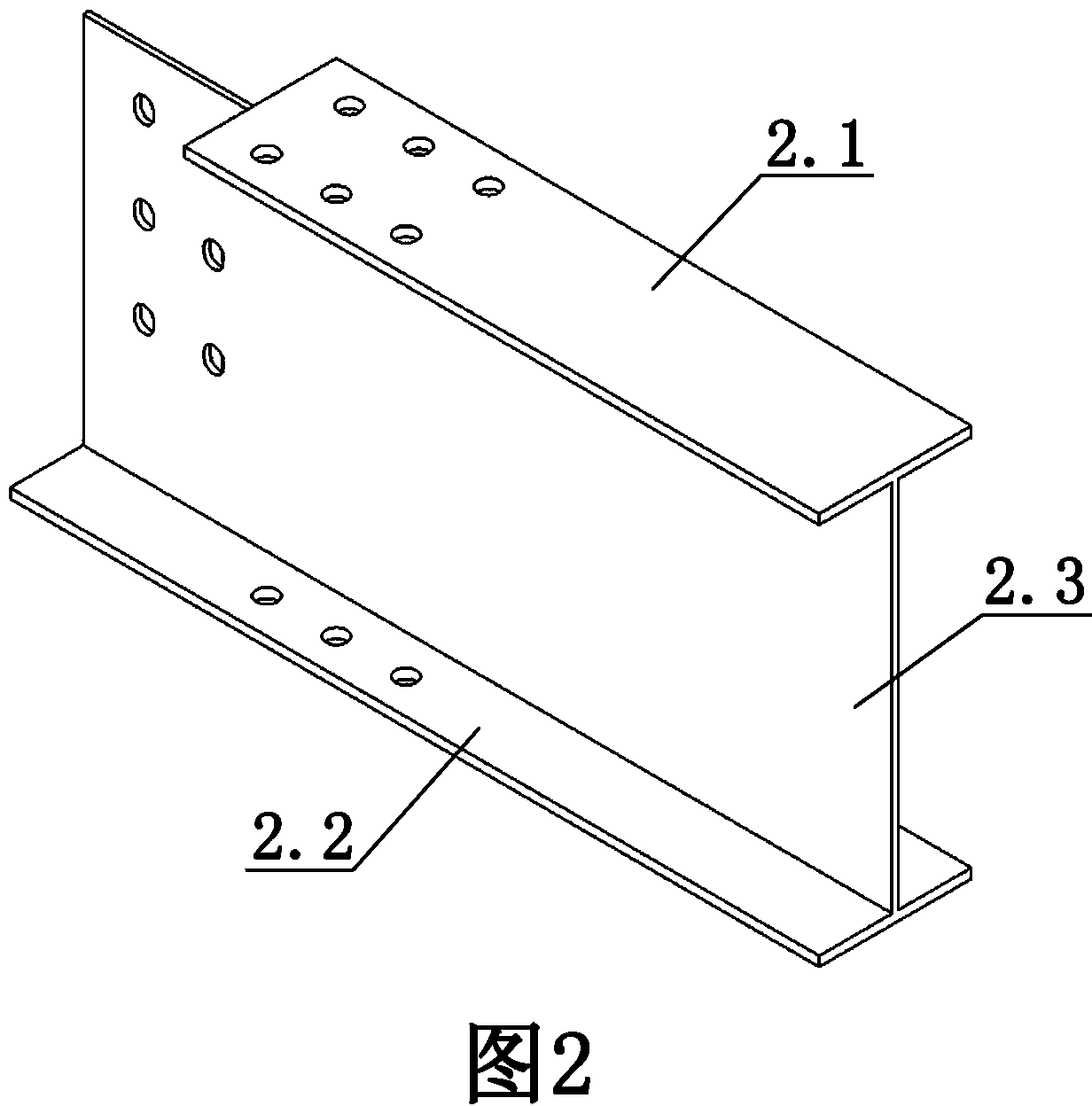

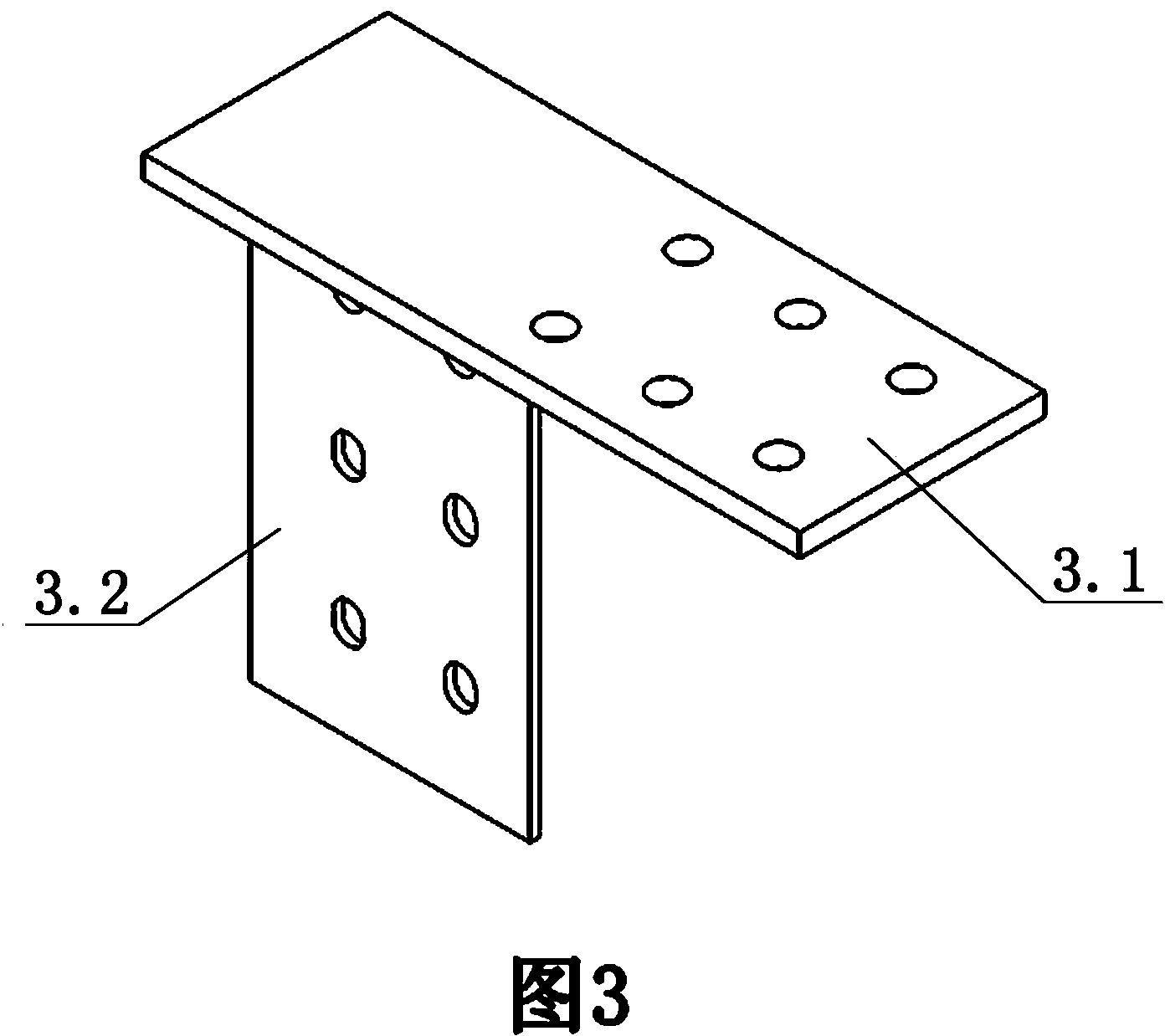

The invention discloses an H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a column sealing piece, a T-shaped connection piece, an L-shaped connection piece and bolts. The column sealing piece consists of a column sealing plate, a beam upper flange stiffening rib and a column sealing plate stiffening rib; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

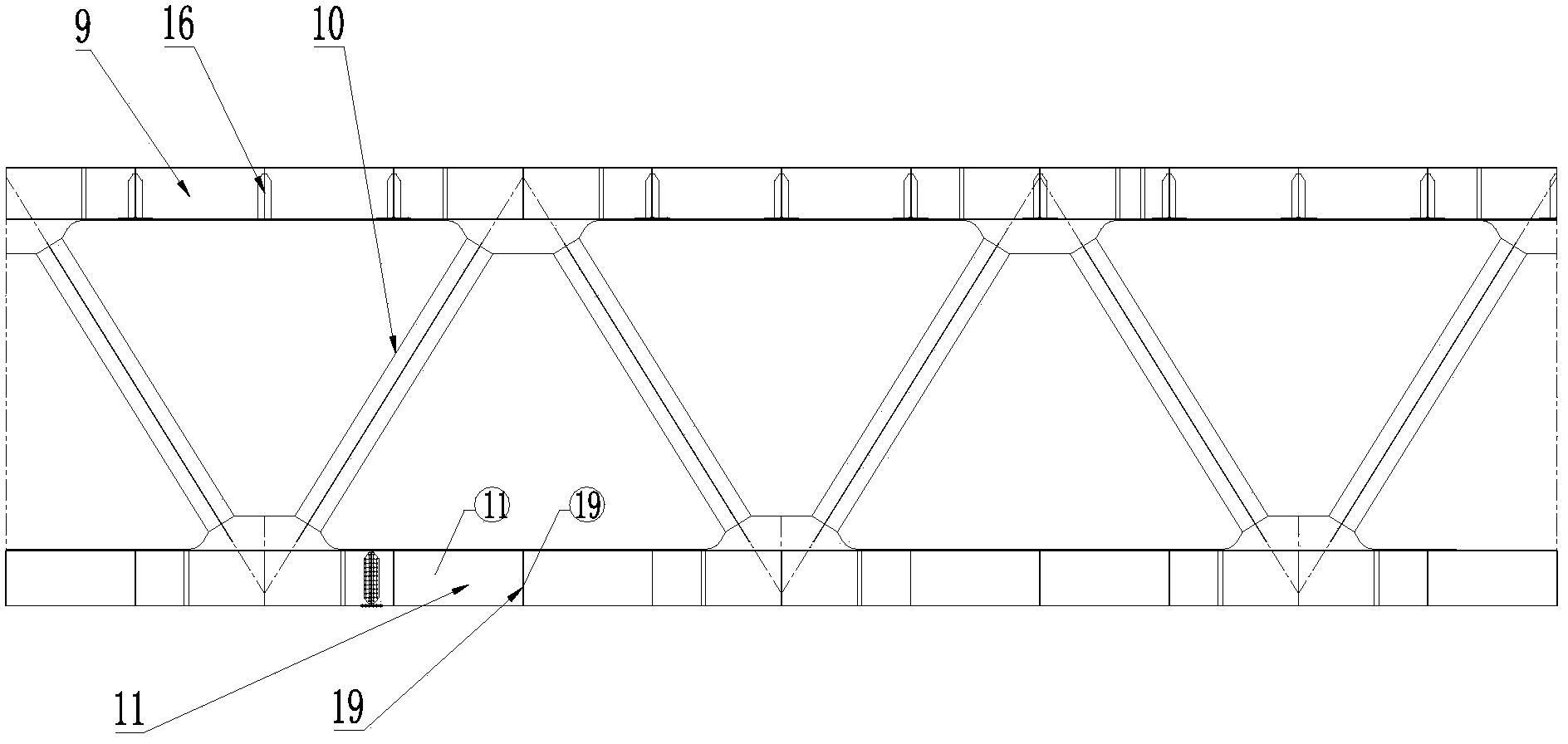

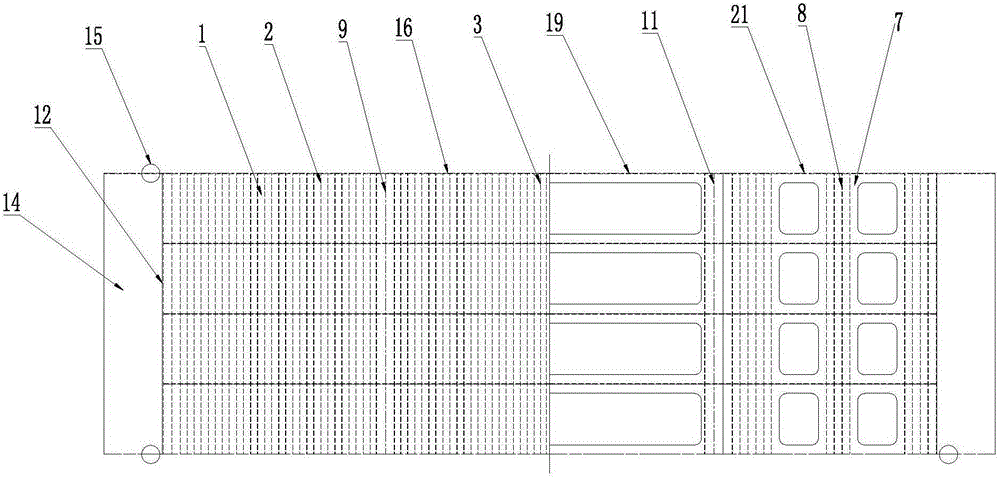

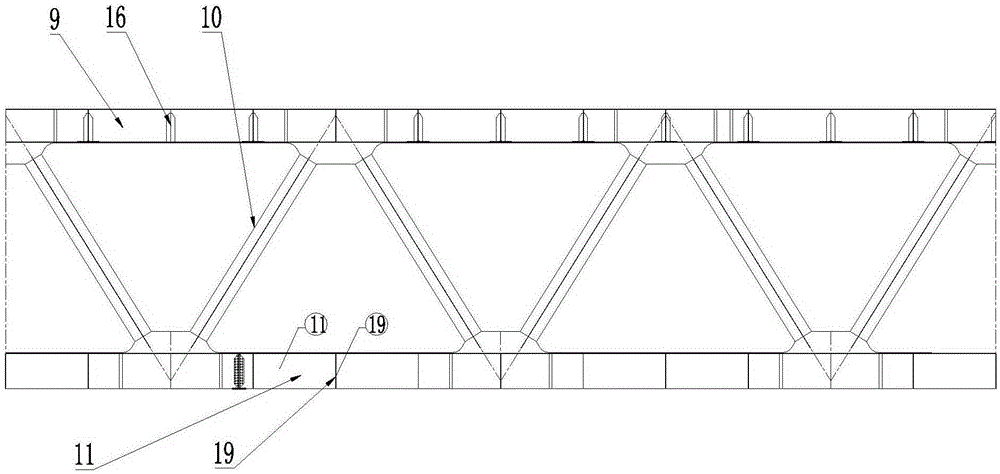

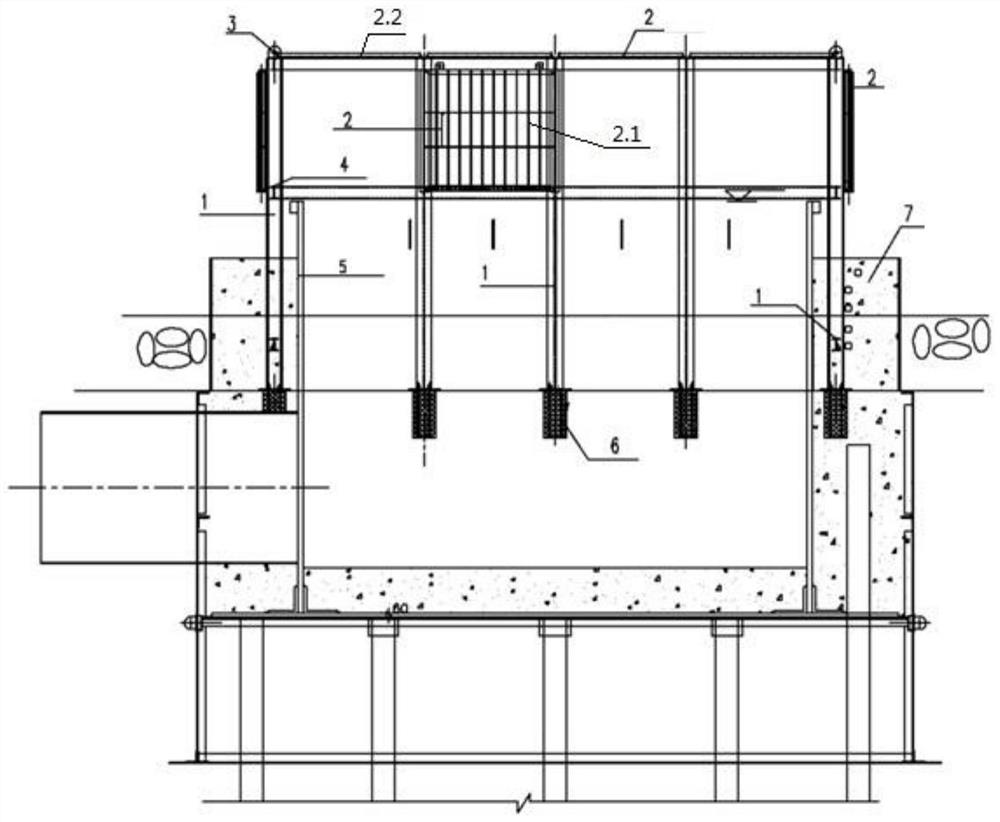

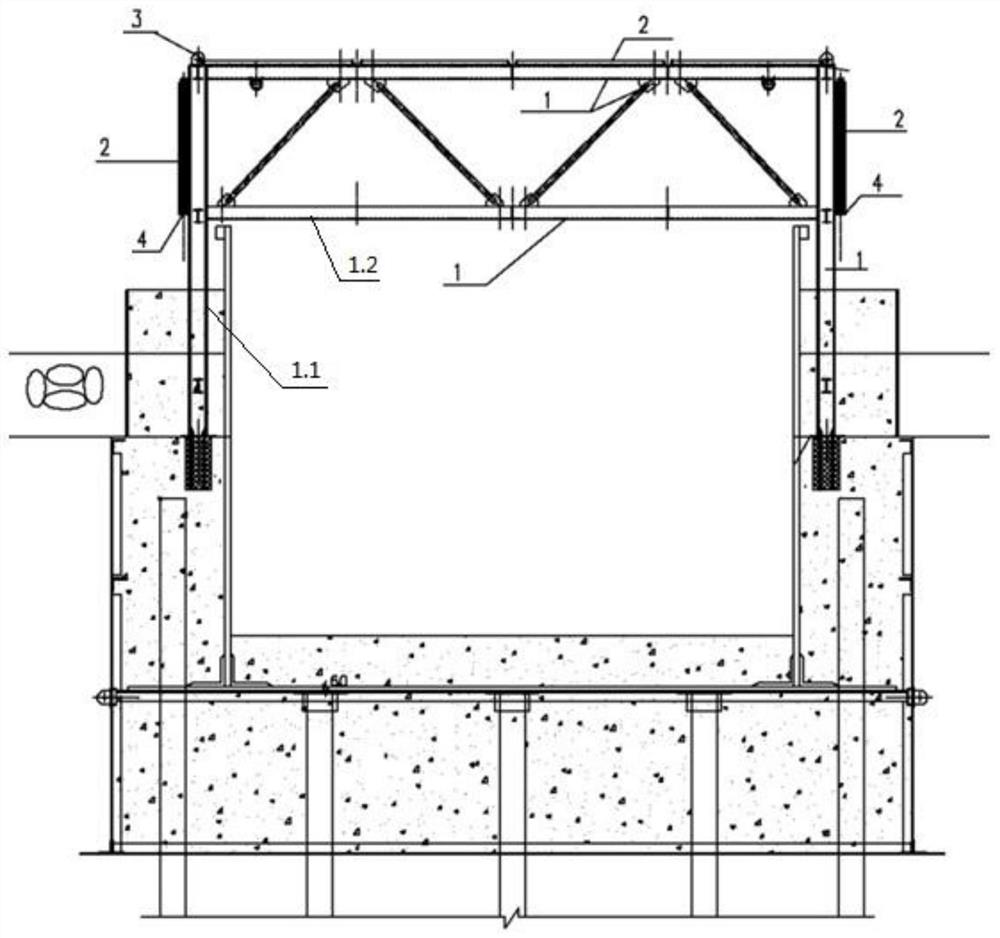

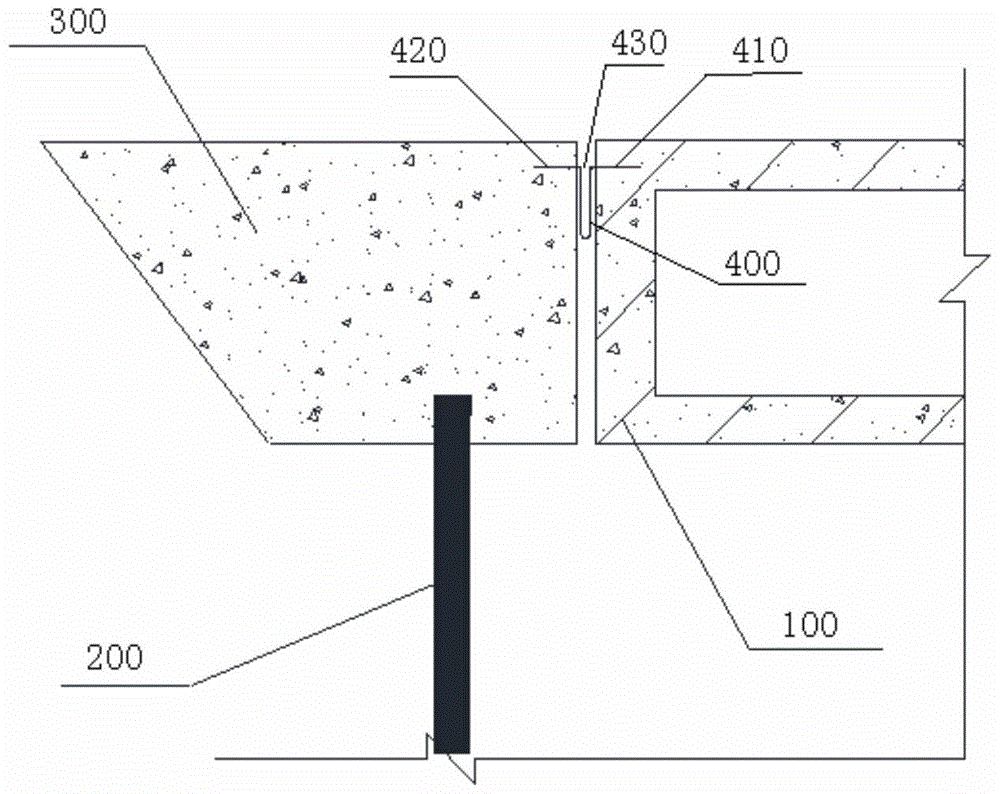

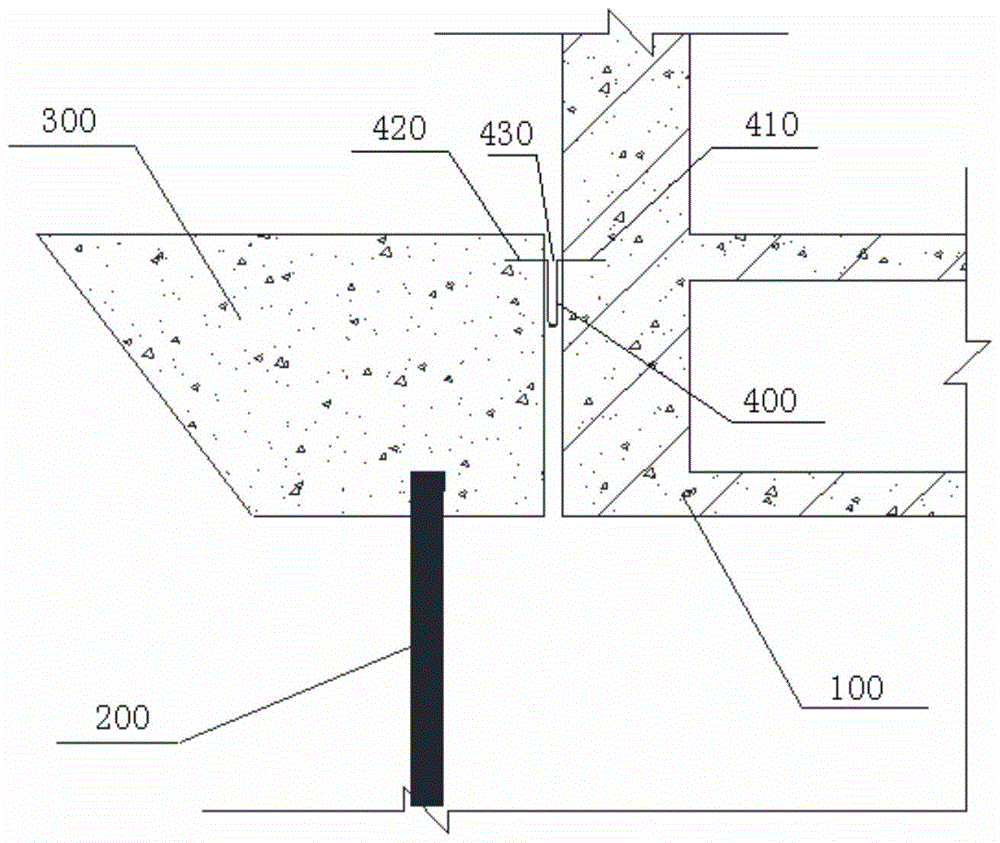

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

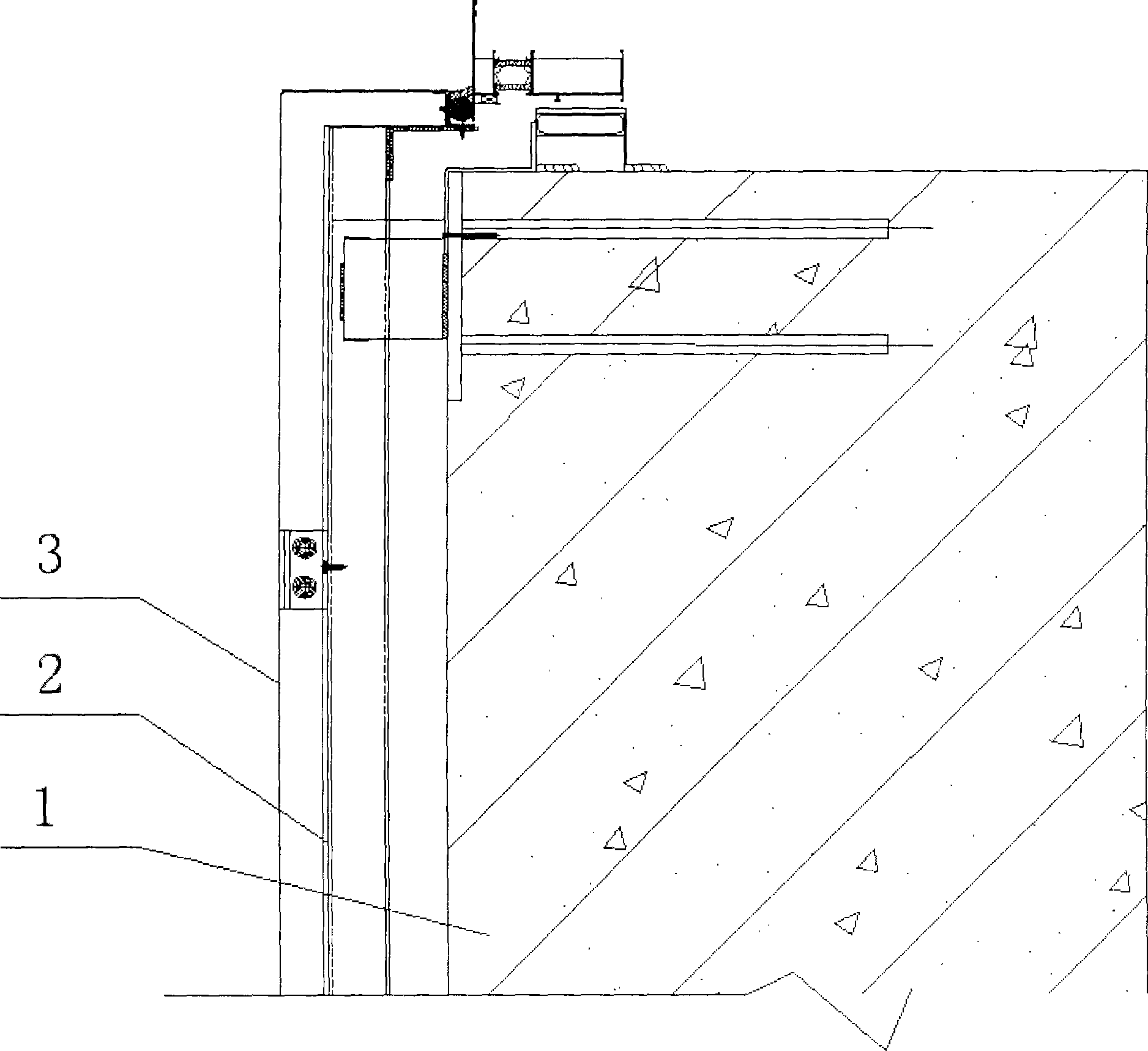

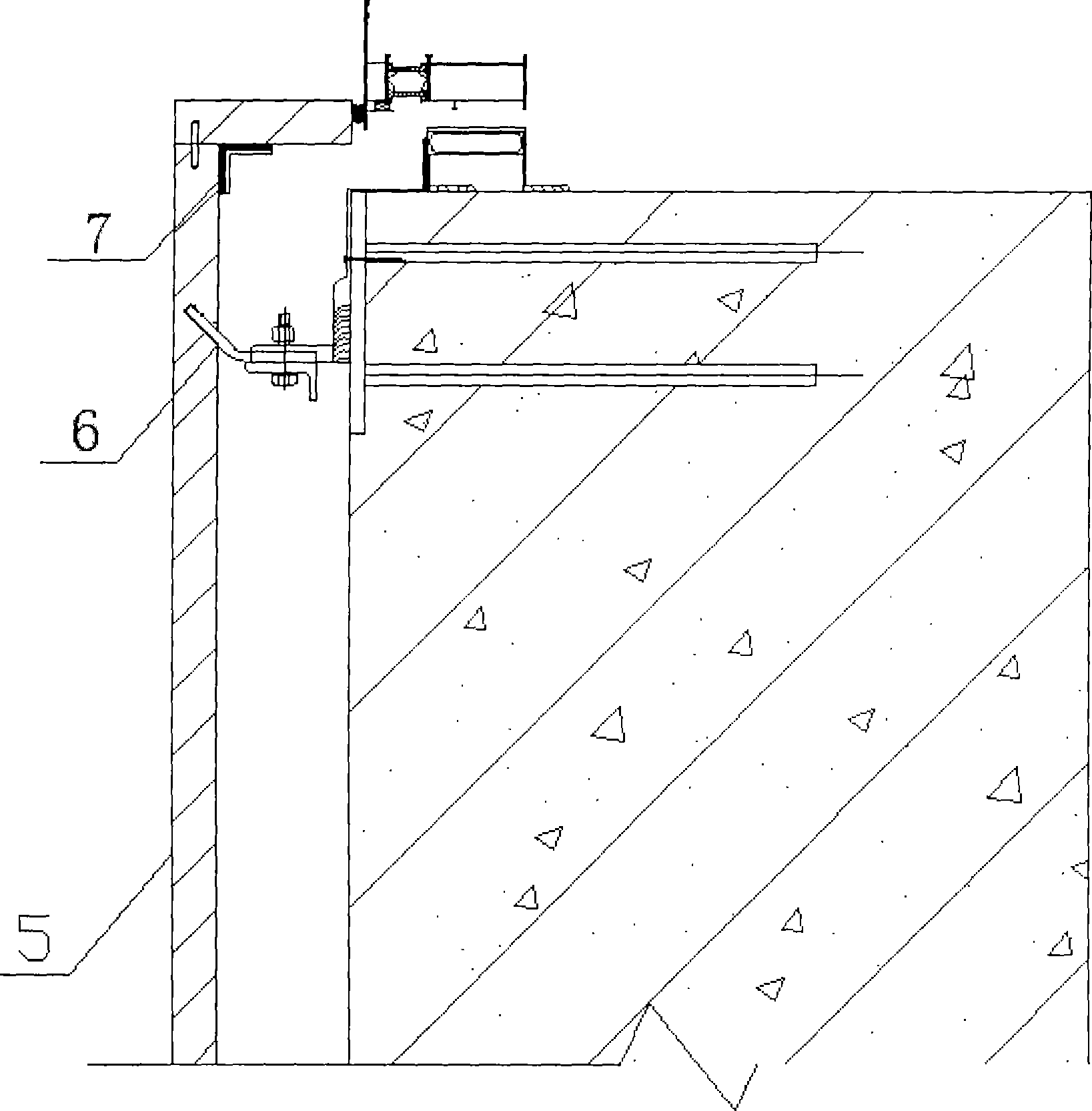

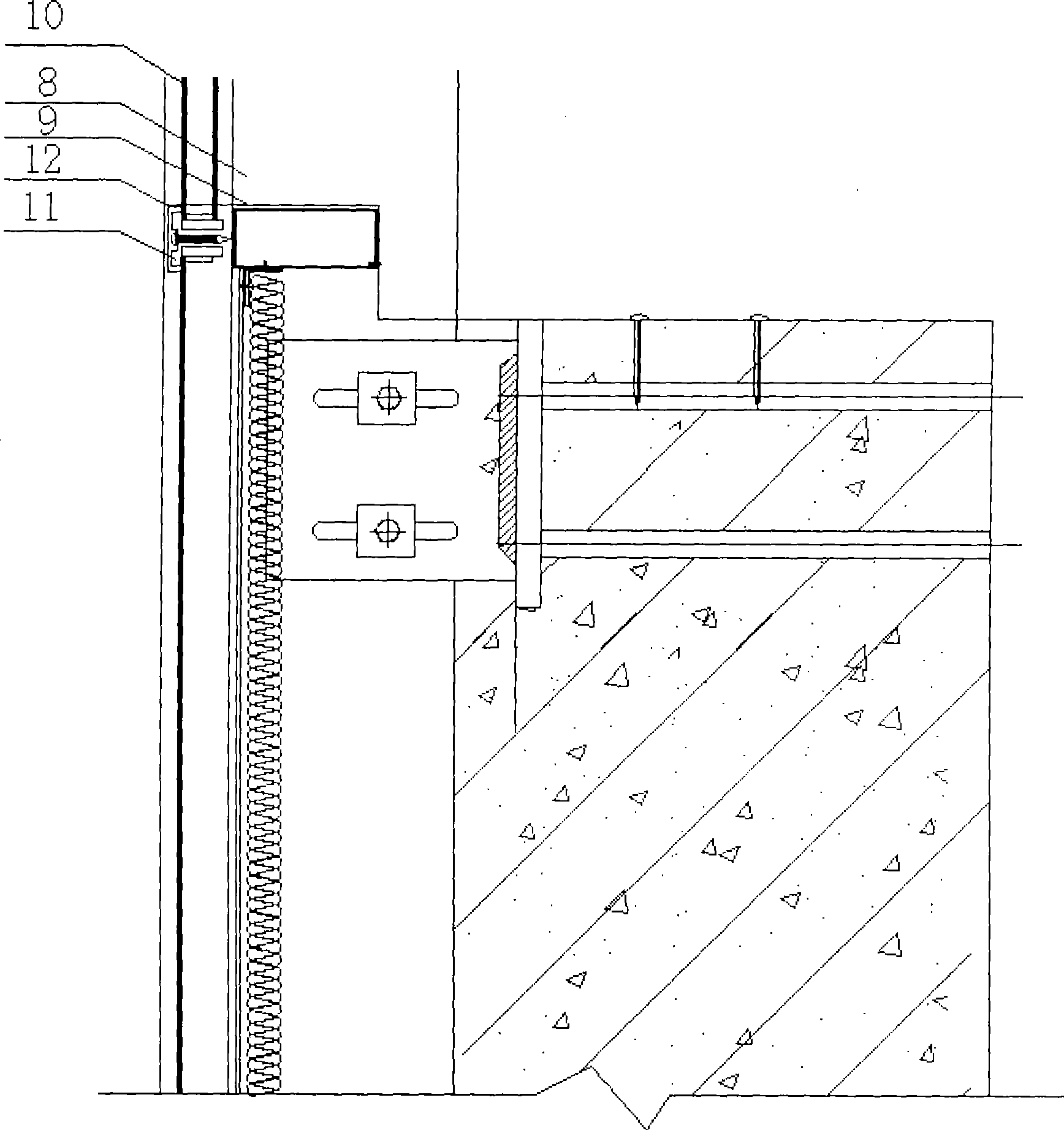

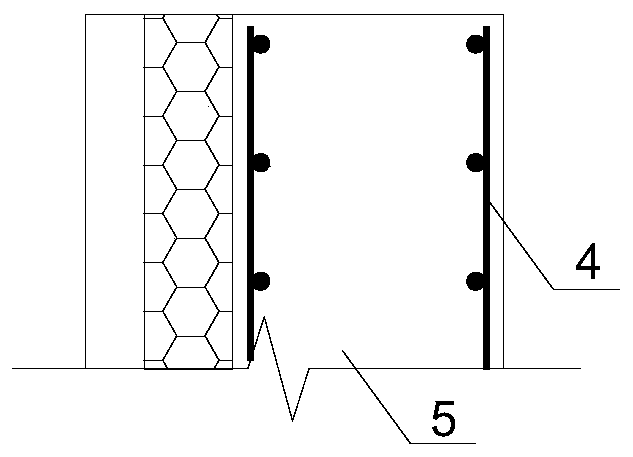

Combined curtain wall

The invention relates to a combined curtain wall which is characterized by comprising an aluminum single veneer curtain wall, a heat-insulated transparent frame glass curtain wall, a stone curtain wall, a steel plate structure and aluminum alloy doors and windows. The aluminum single veneer curtain wall is positioned at the aluminum plate part between a porch and the windows and a large area of shearing wall parts; the stone curtain wall is positioned on a solid wall on the lower part; and the rest part of the combined curtain wall is the heat-insulated transparent frame glass curtain wall. The combined curtain wall can effectively prevent the electric erosion and the earthquake while strengthening the viewing effect, reduce the precision requirement of the construction and better achieve the effects of heat preservation and insulation.

Owner:葛汉明

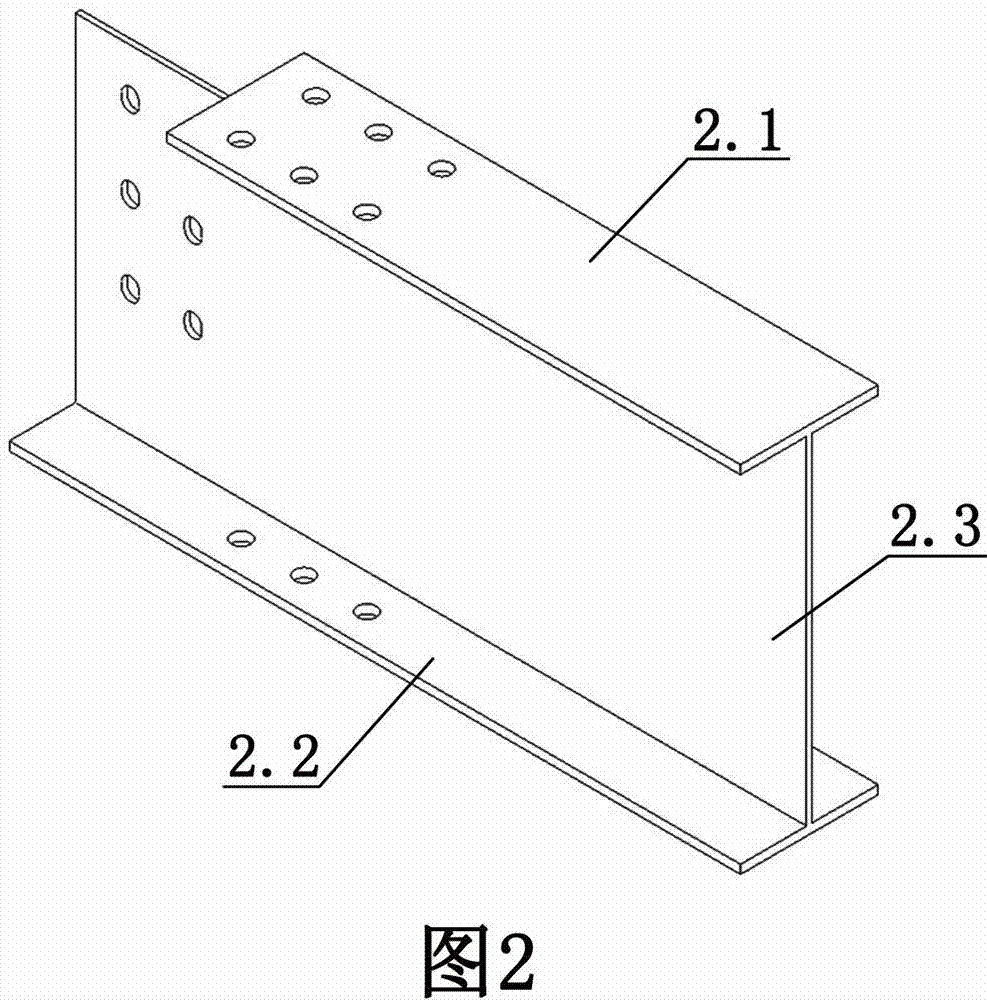

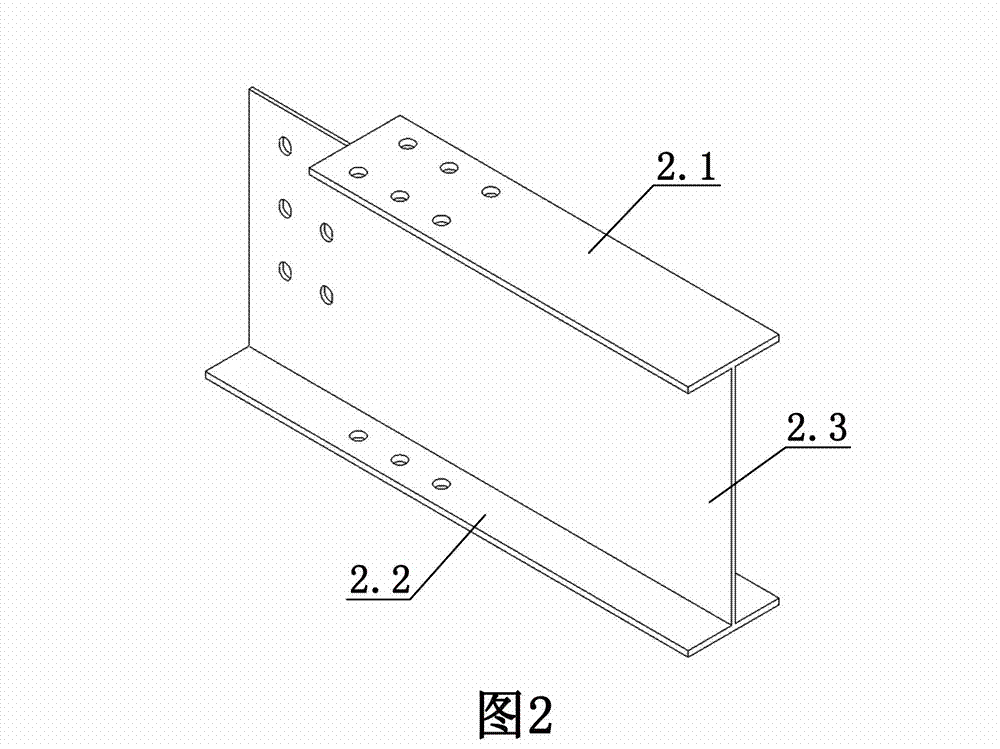

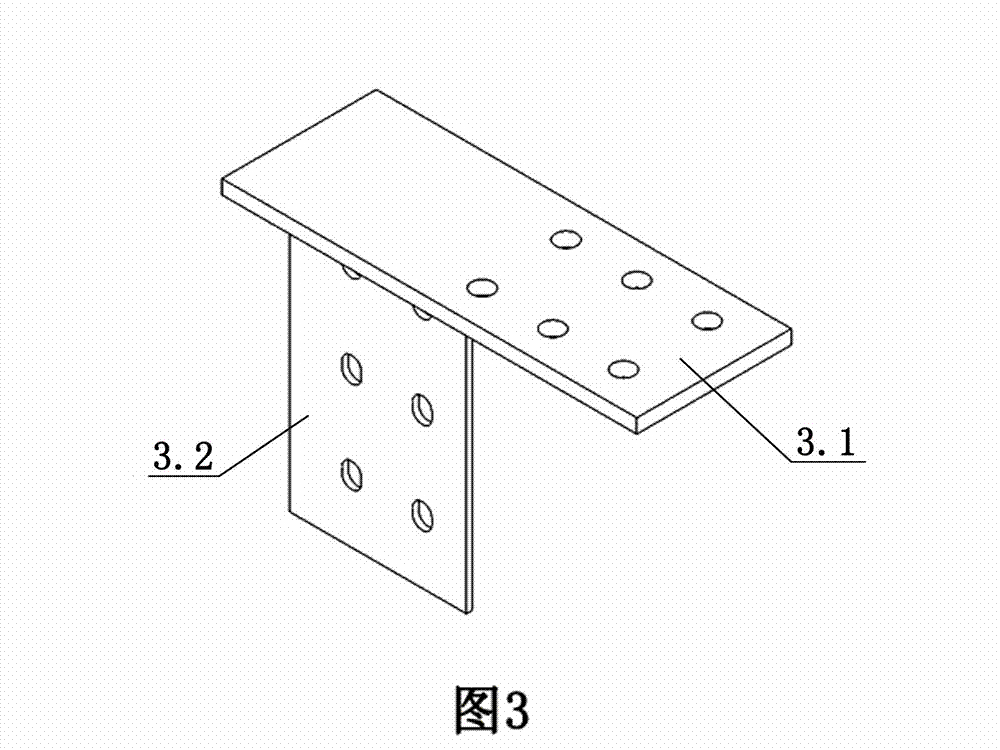

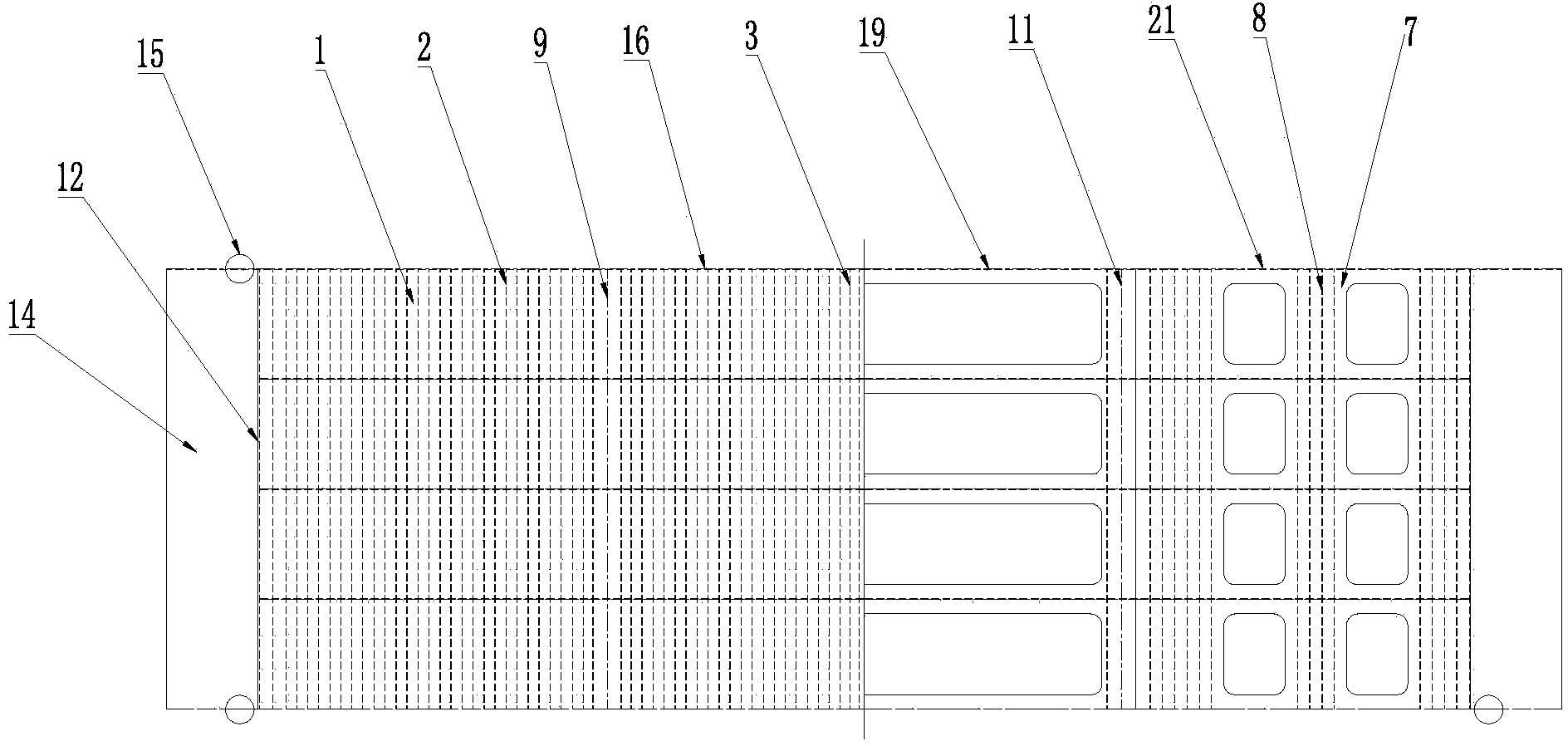

H-shaped steel beam and H-shaped steel column strong-axis variable-beam height fabricated node and construction method thereof

InactiveCN102733489AMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingSteel columnsFlange

The invention discloses an H-shaped steel beam and H-shaped steel column strong-axis variable-beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a T-shaped connection piece, an L-shaped connection piece and bolts; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally, and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the upper flange plate connection plate is connected with an upper flange plate through the bolts; the web connection plate is connected with a web through the bolts; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward; the lower flange plate connection plate is connected with a lower flange plate through the bolts; and the column connection plate is connected with a column flange plate of the H-shaped steel column through the bolts. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

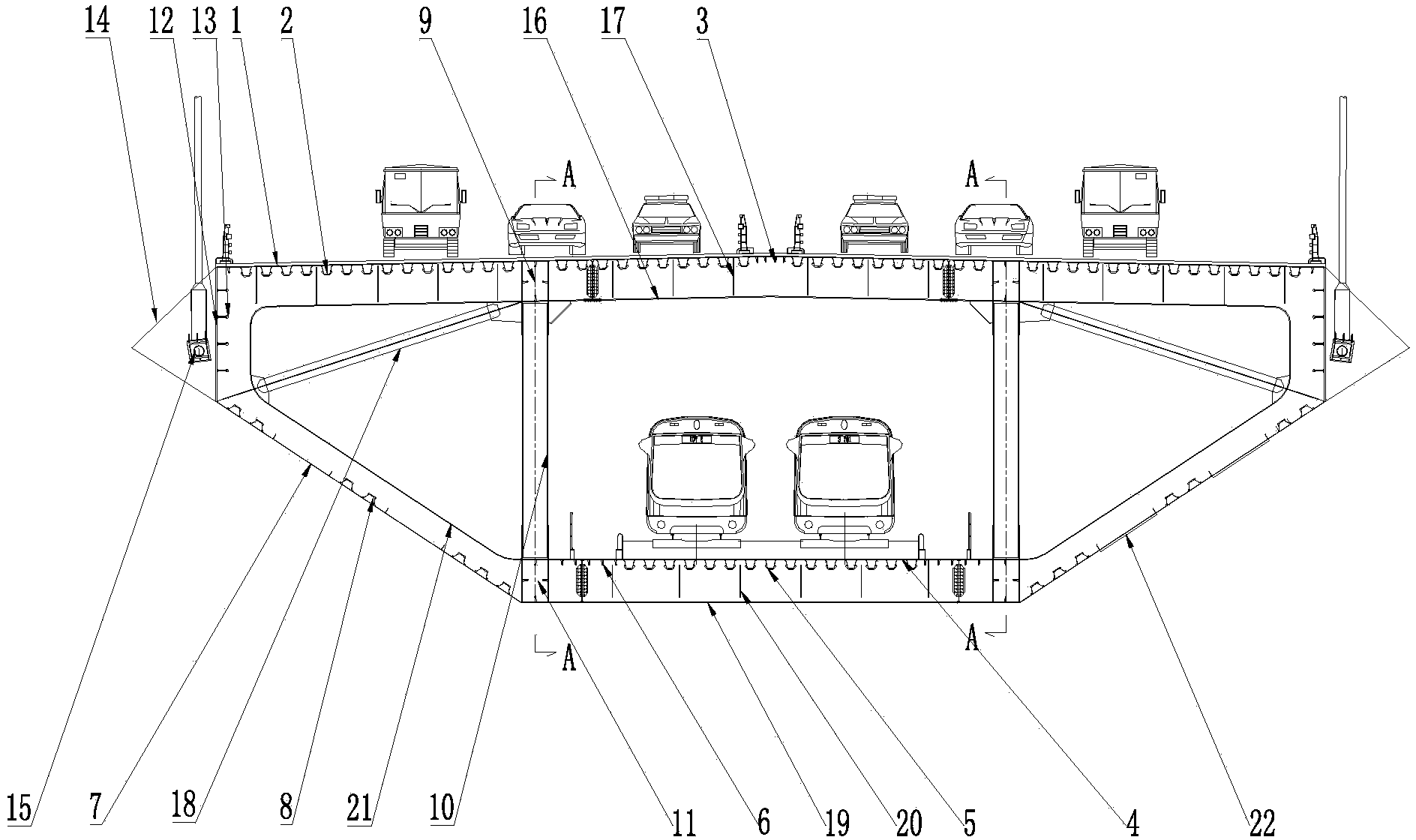

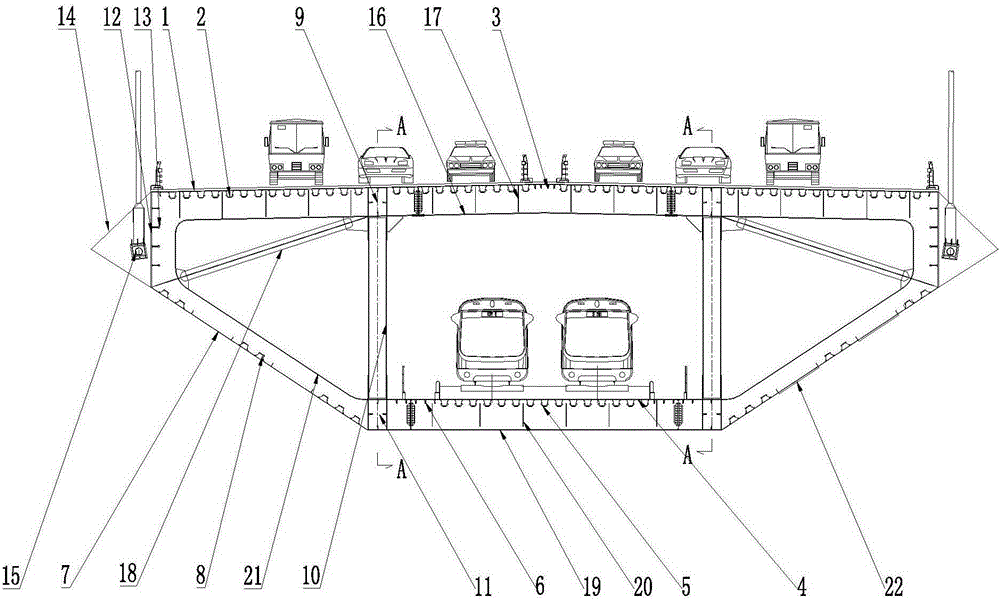

Highway and railway layered steel box beam

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Connecting structure and construction method for assembly type bridge pier column and bearing platform

InactiveCN110863427AFirmly connectedEasy constructionBridge structural detailsFoundation engineeringArchitectural engineeringEngineering

The invention provides a construction method for an assembly type bridge pier column and a bearing platform, and relates to the technical field of assembly type bridge construction. The method comprises the steps: 1, prefabricating the pier column; 2, manufacturing the bearing platform with a bearing platform reserved slot hole on the upper end face; 3, installing the pier column into the bearingplatform reserved slot hole; 4, pressing grouting materials into the bearing platform reserved slot hole; wherein step 1 comprises the substeps of prefabricating a first part and a second part of thepier column, wherein the outer diameter of the first part is smaller than that of the second part, and connecting the first part to the lower end surface of the second part; the step 1 further comprises the substep of arranging a transverse anchoring head and a vertical anchoring head; and in the step 3, the first part of the pier column is installed into the bearing platform reserved slot hole until the lower end face of the second part is not higher than the opening depth of the bearing platform reserved slot hole. The construction method is convenient and fast to construct, can enable the connection of the pier column and the bearing platform to be stable, and is suitable for wide-range popularization.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

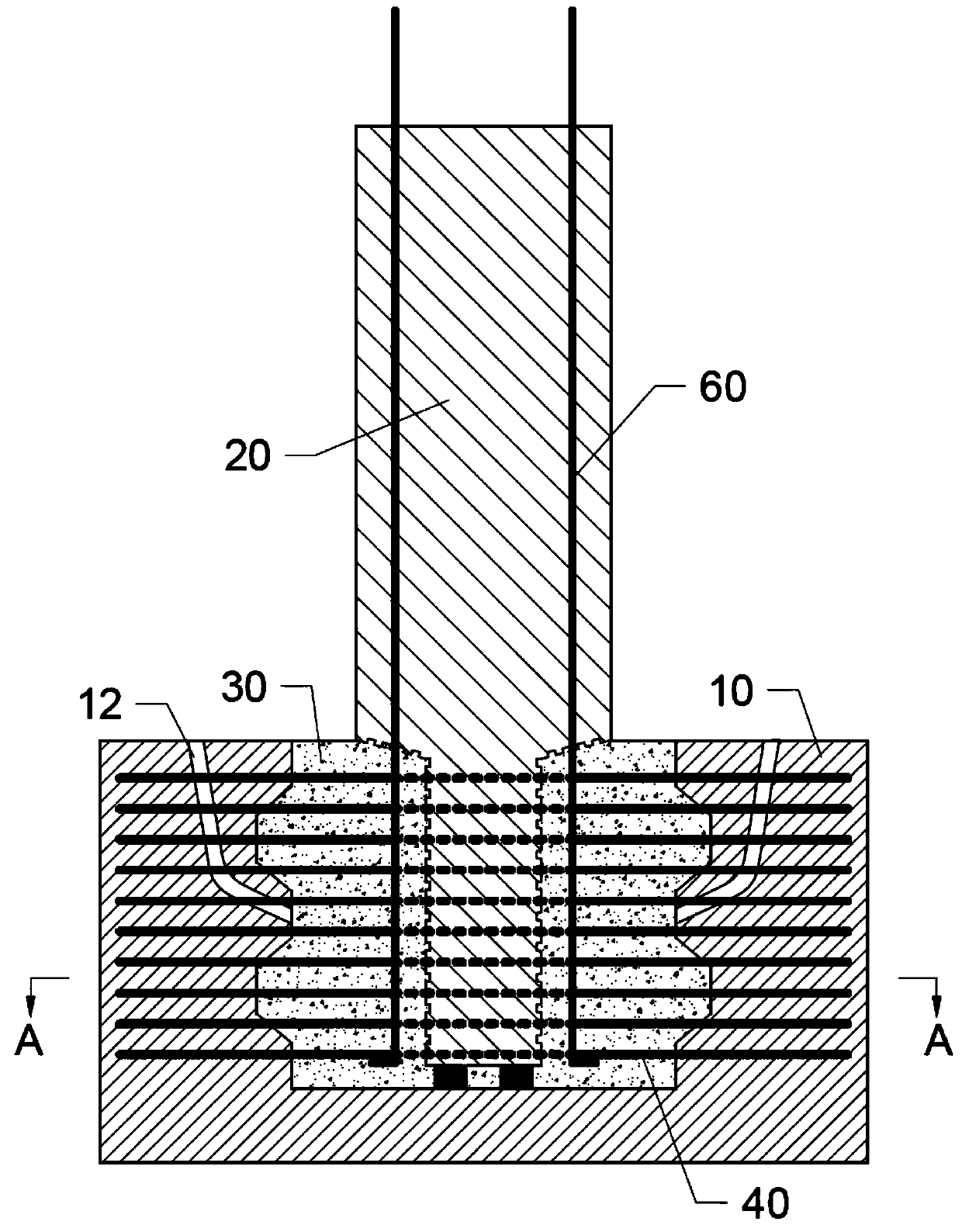

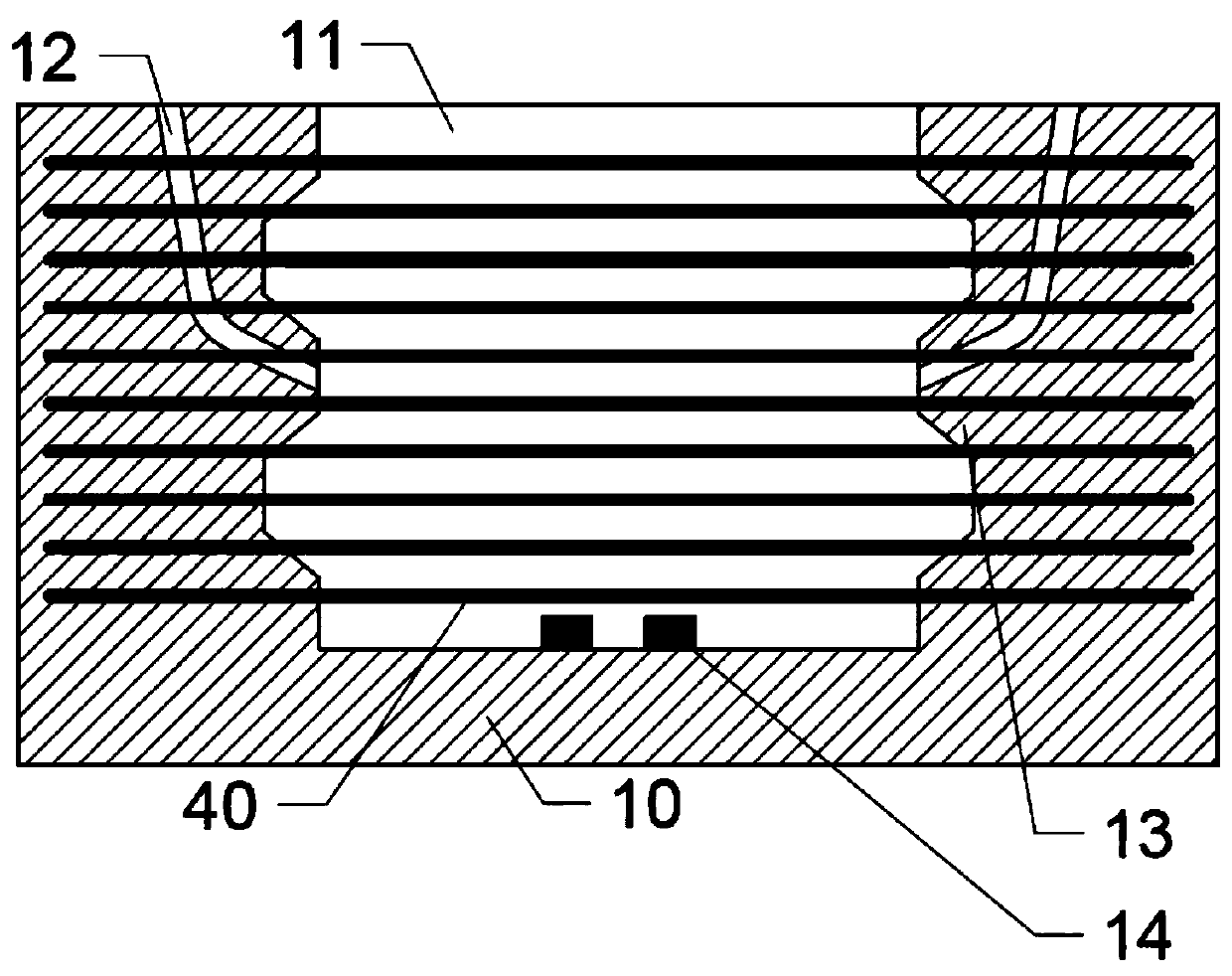

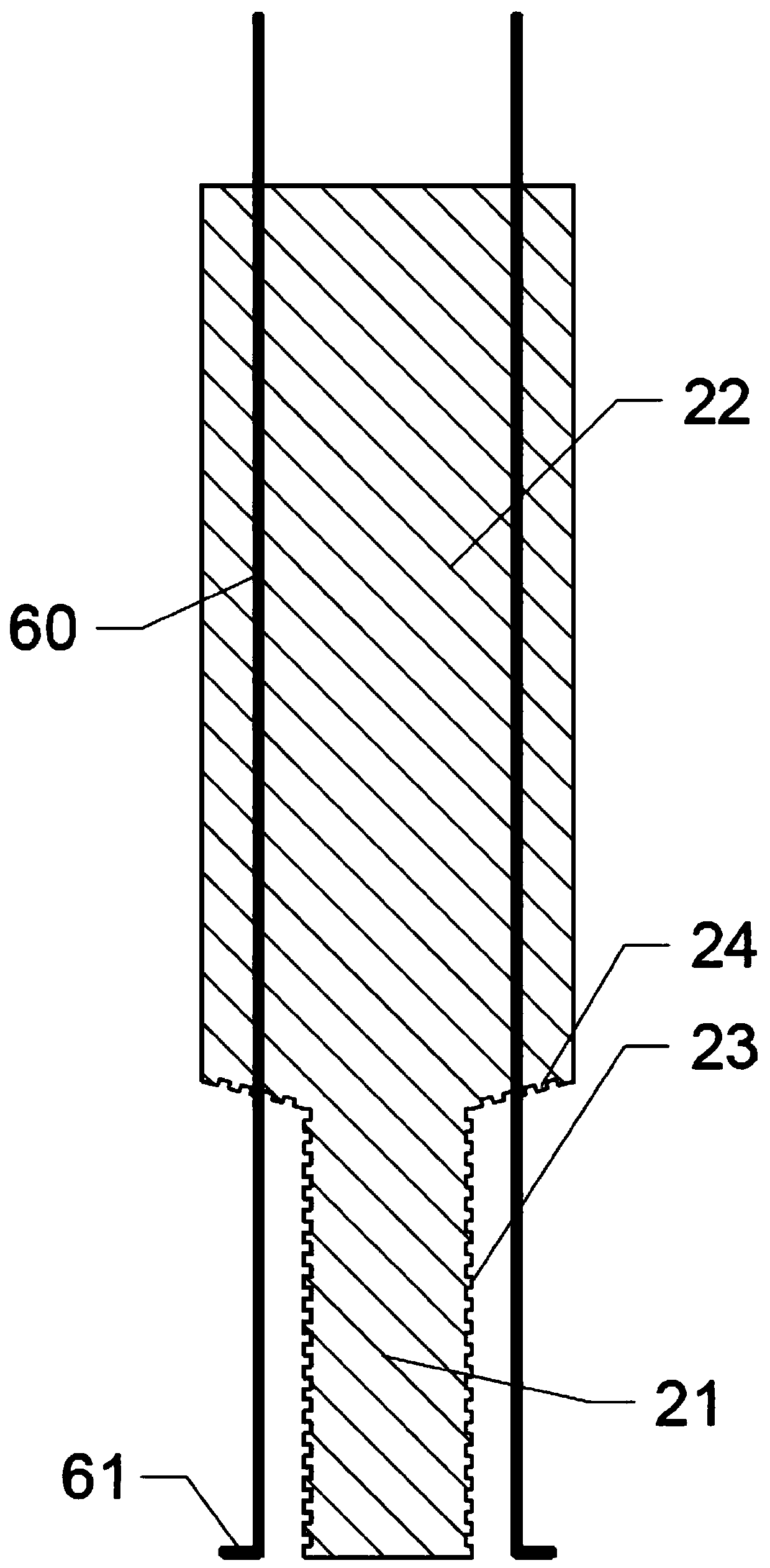

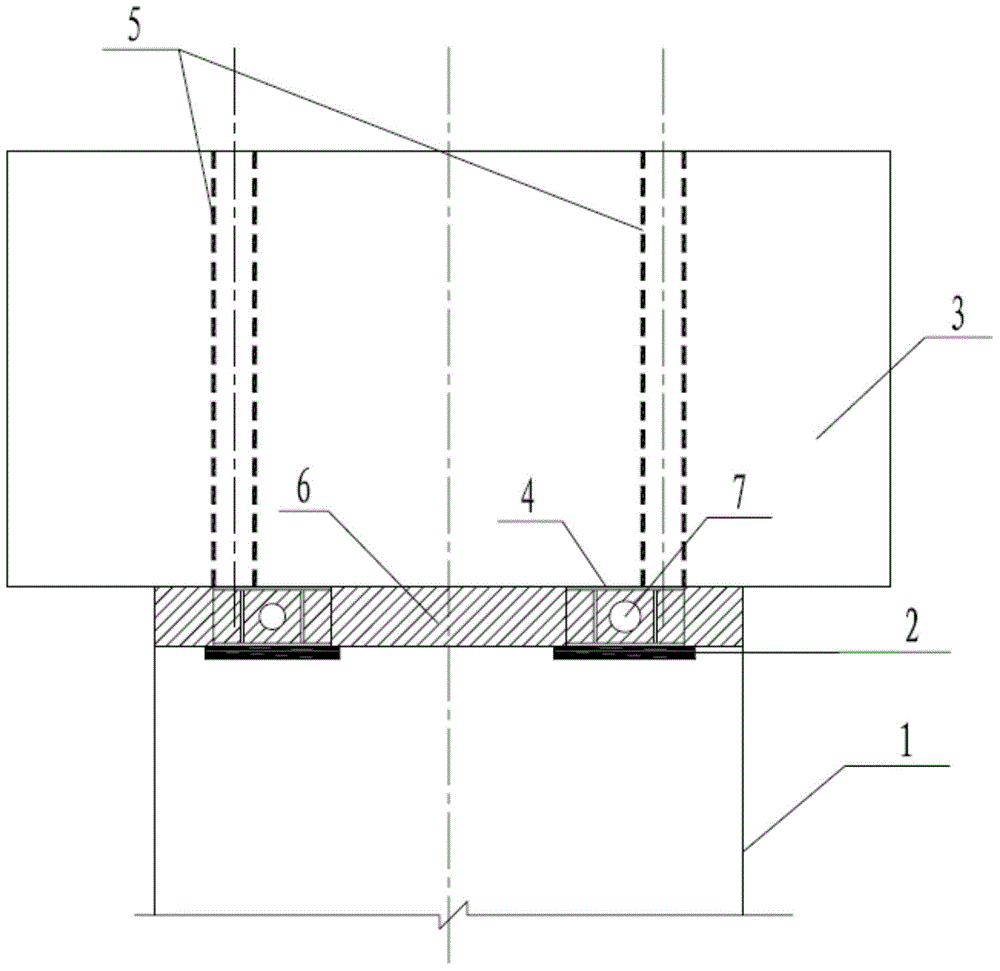

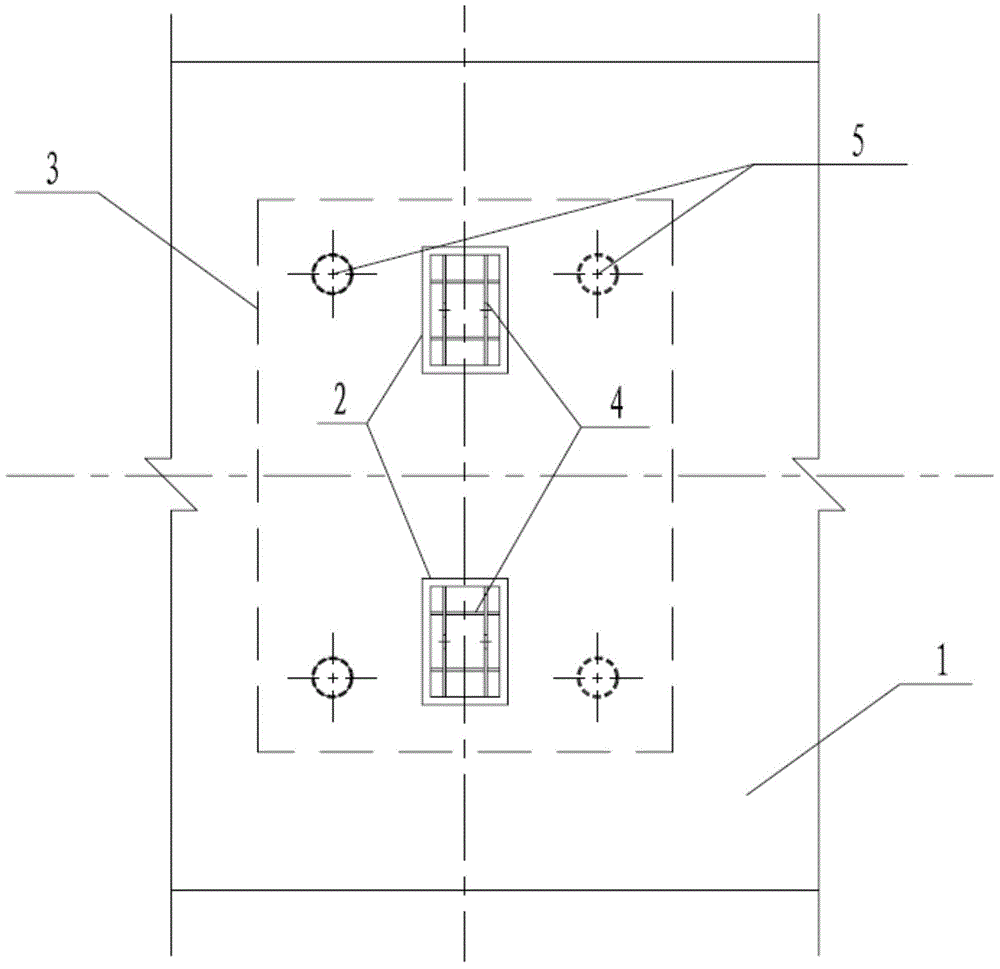

Slot type and socket type combined connecting structure of prefabricated bridge substructure

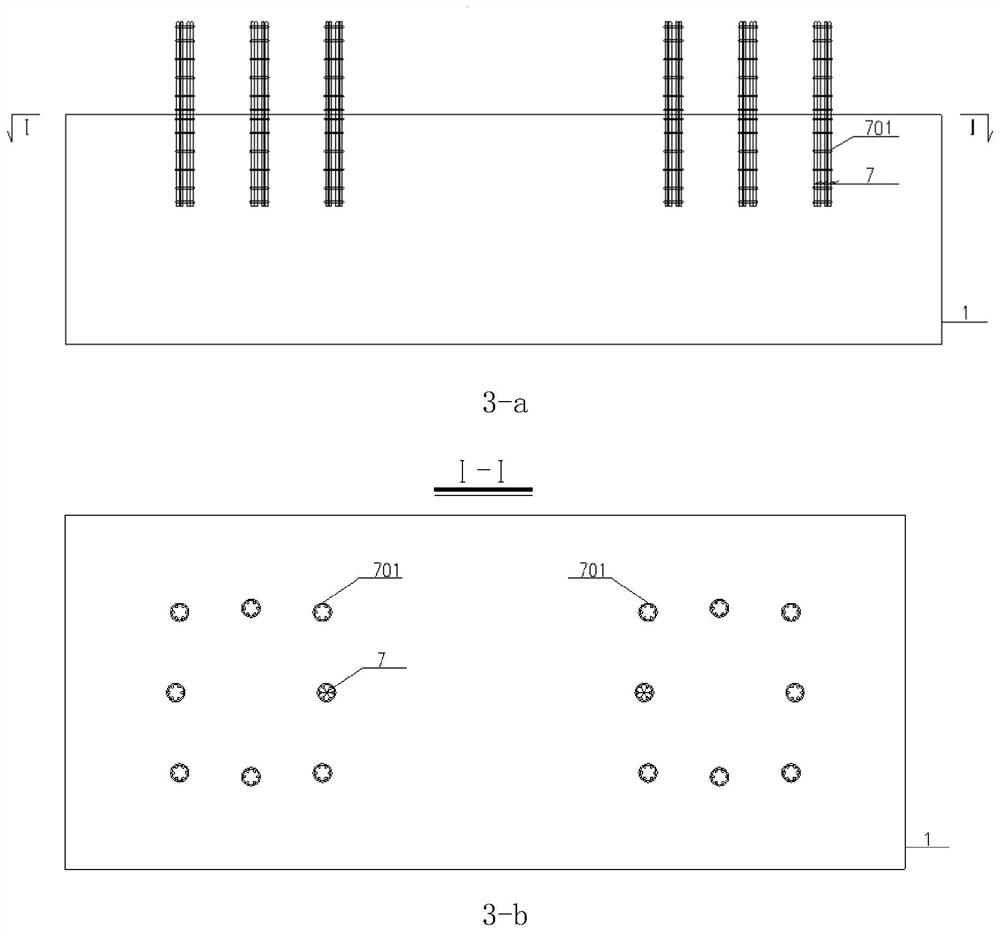

PendingCN112502030ASimple structureLow construction precision requirementsBridge structural detailsFoundation engineeringArchitectural engineeringMesh reinforcement

The invention discloses a slot type and socket type combined connecting structure of a prefabricated bridge substructure. The slot type and socket type combined connecting structure comprises a prefabricated pier, a prefabricated pier main rib, a bearing platform, a positioning cushion block, a cushion layer, a corrugated pipe, a reinforcing mesh, a steel formwork and a post-pouring cup opening. Asteel formwork is embedded in the lower portion of the prefabricated pier, a mortar cushion layer is arranged between the bottom face of the prefabricated pier and the top face of the cup opening ofthe bearing platform, the corrugated pipes are embedded in the bearing platform, and the number and positions of the corrugated pipes need to be matched with those of the notches and the prefabricatedpier main ribs so that the prefabricated pier main ribs can be inserted into the corrugated pipes of the bearing platform. The reinforcing mesh is arranged in a post-pouring cup opening of the bearing platform, and the prefabricated pier and the bearing platform are connected into a whole through post-pouring concrete. The method is simple and convenient in construction, controllable in quality,easy to control, safe and reliable; by extending the prefabricated pier main reinforcements outwards and arranging the post-pouring cup openings, the bearing capacity is greatly improved, the strengthis high, the ductility is good, and the connecting structure can be used for connecting prefabricated bridge lower structures in high earthquake areas and is wide in application range.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST +1

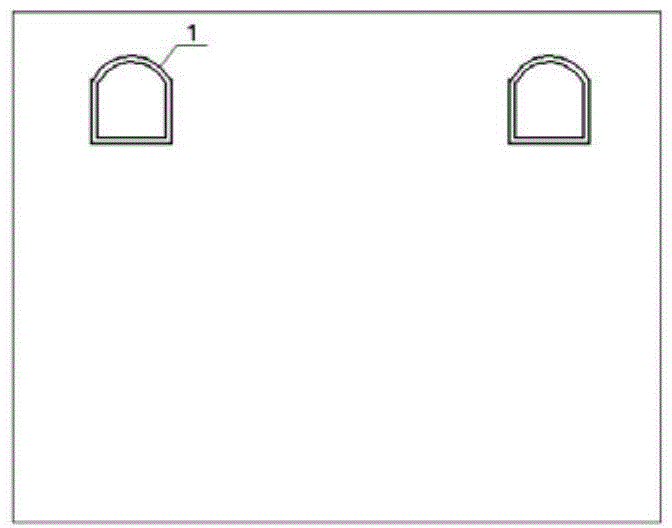

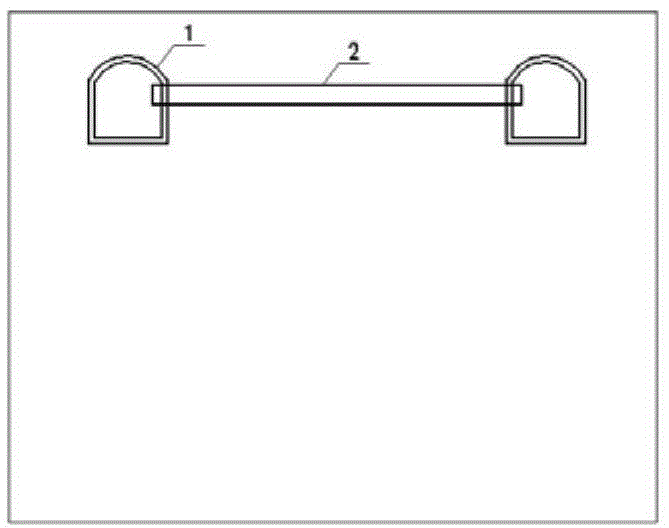

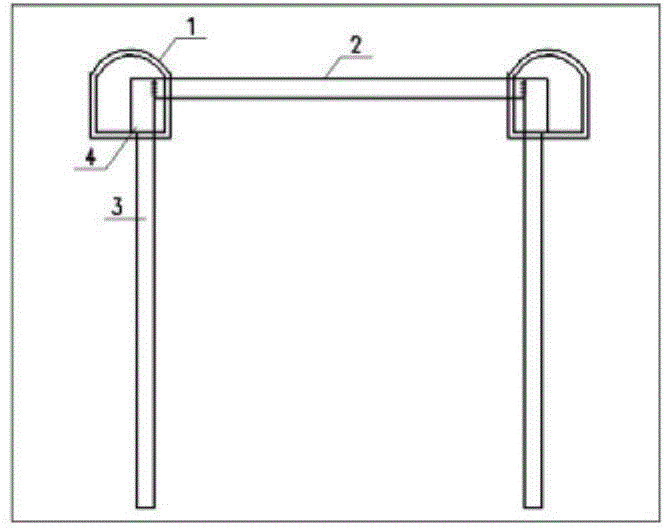

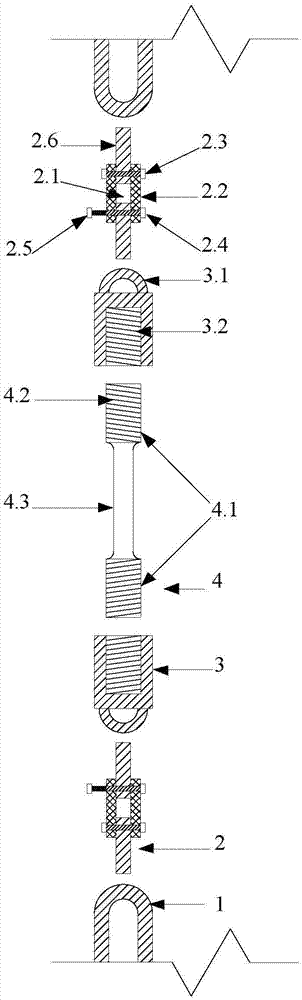

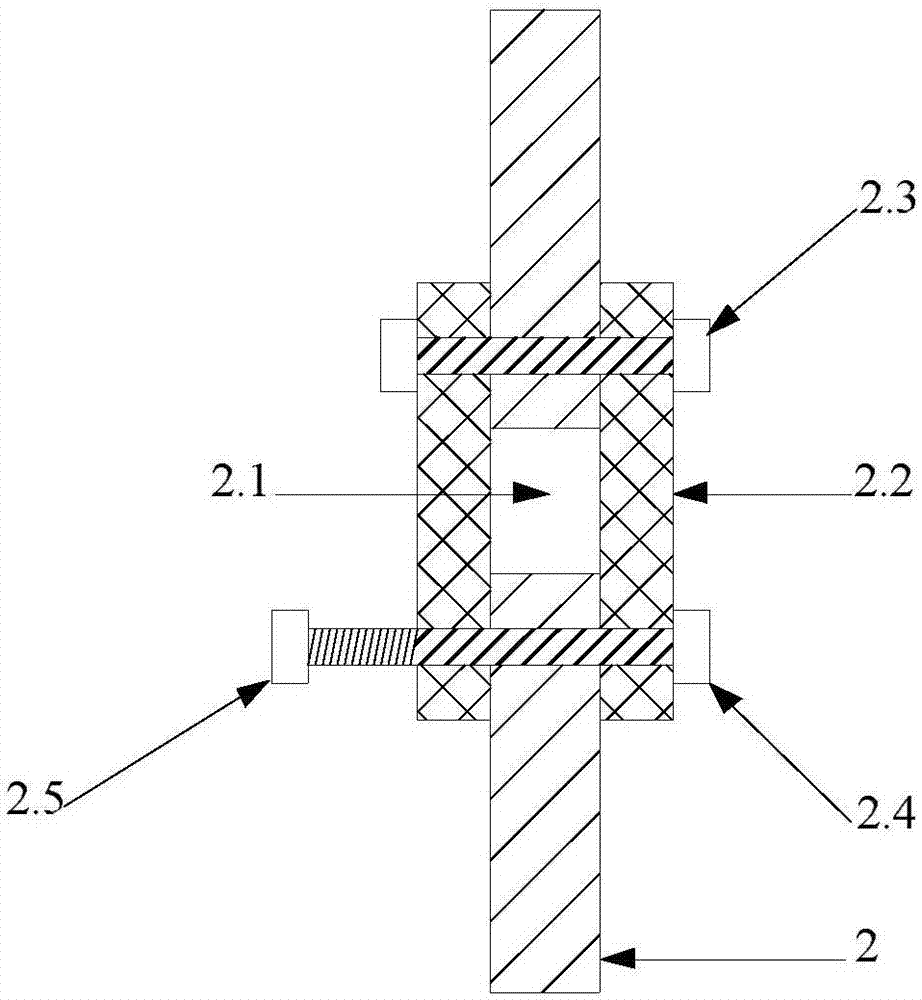

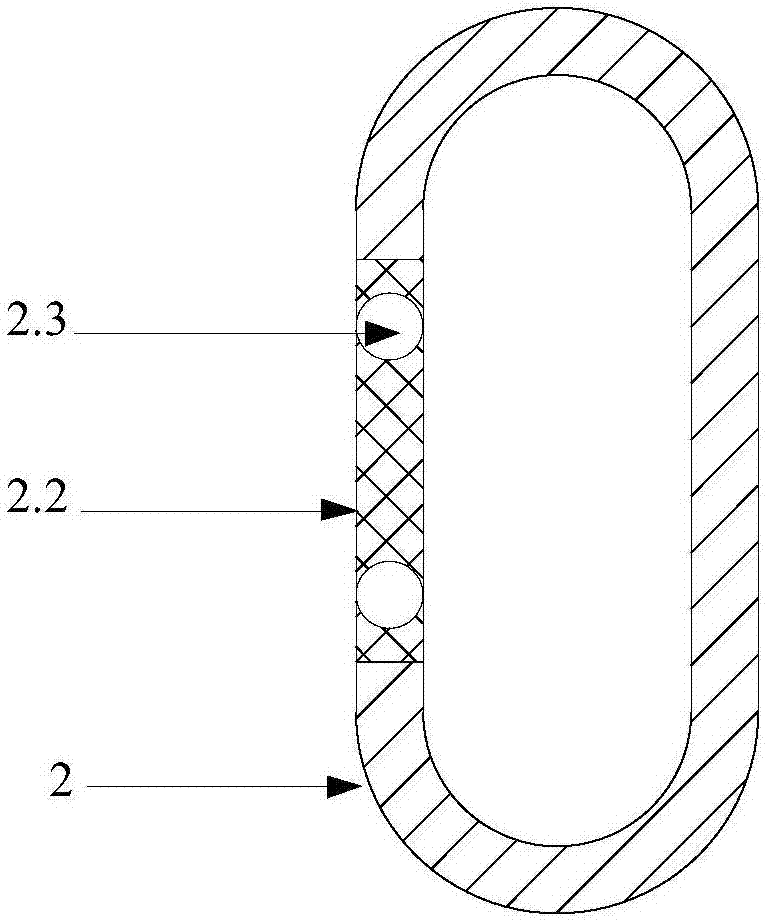

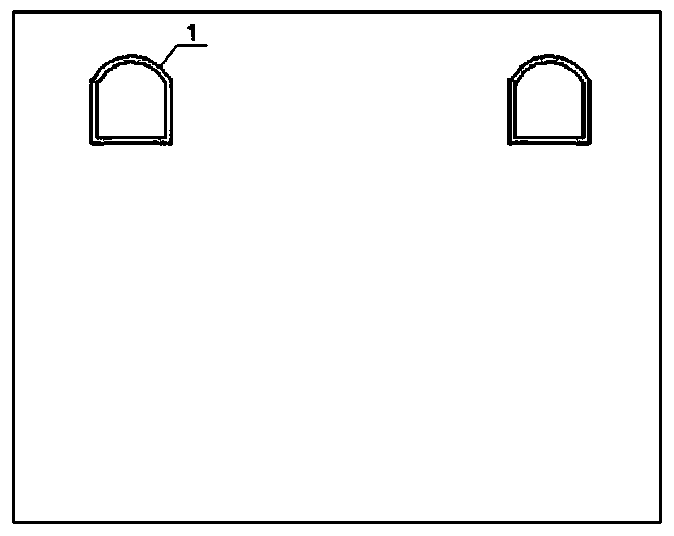

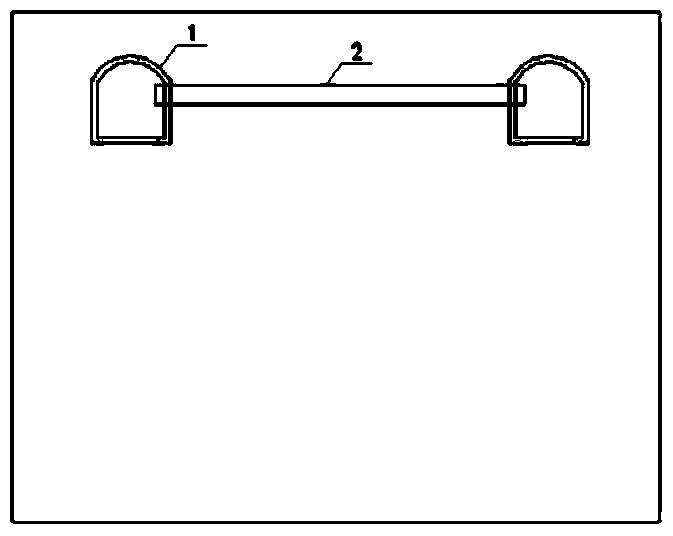

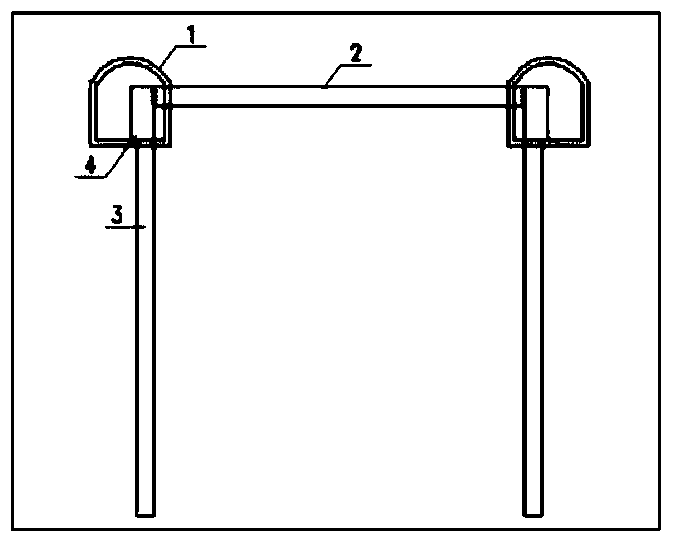

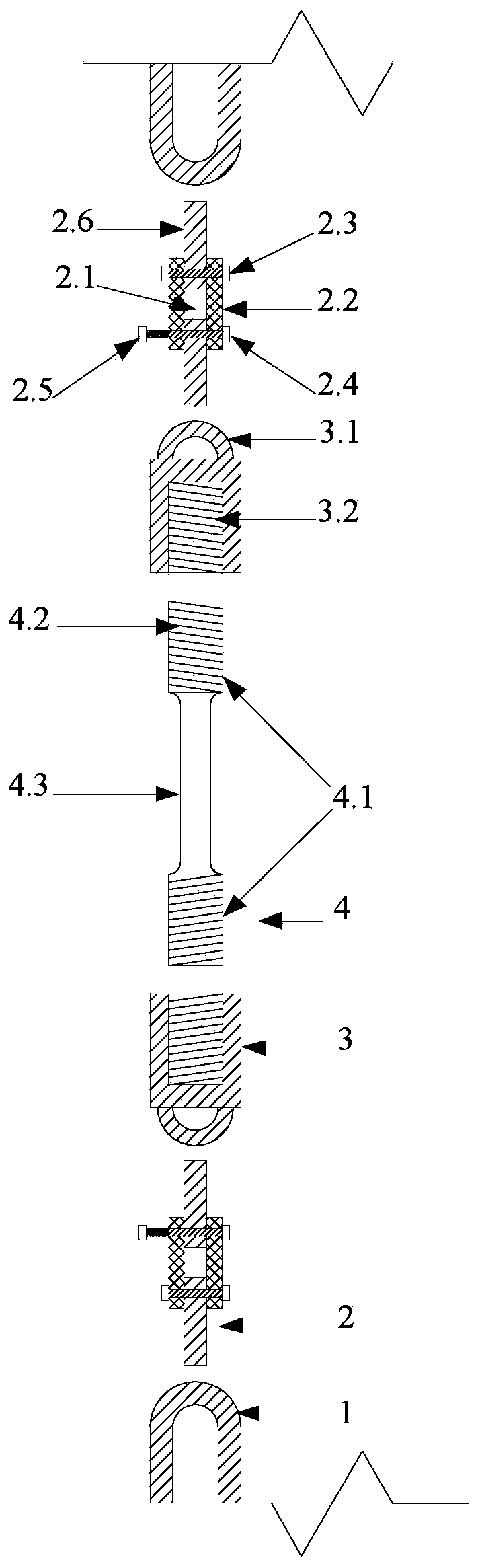

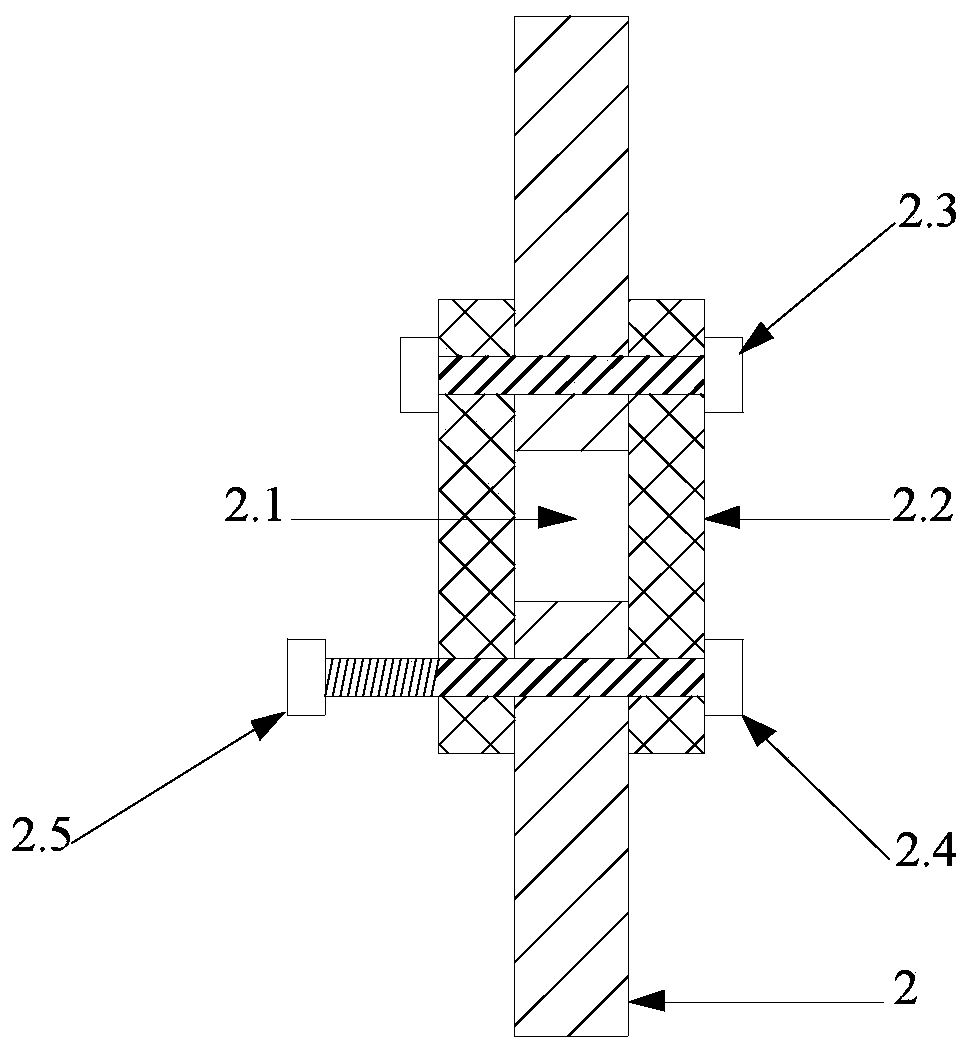

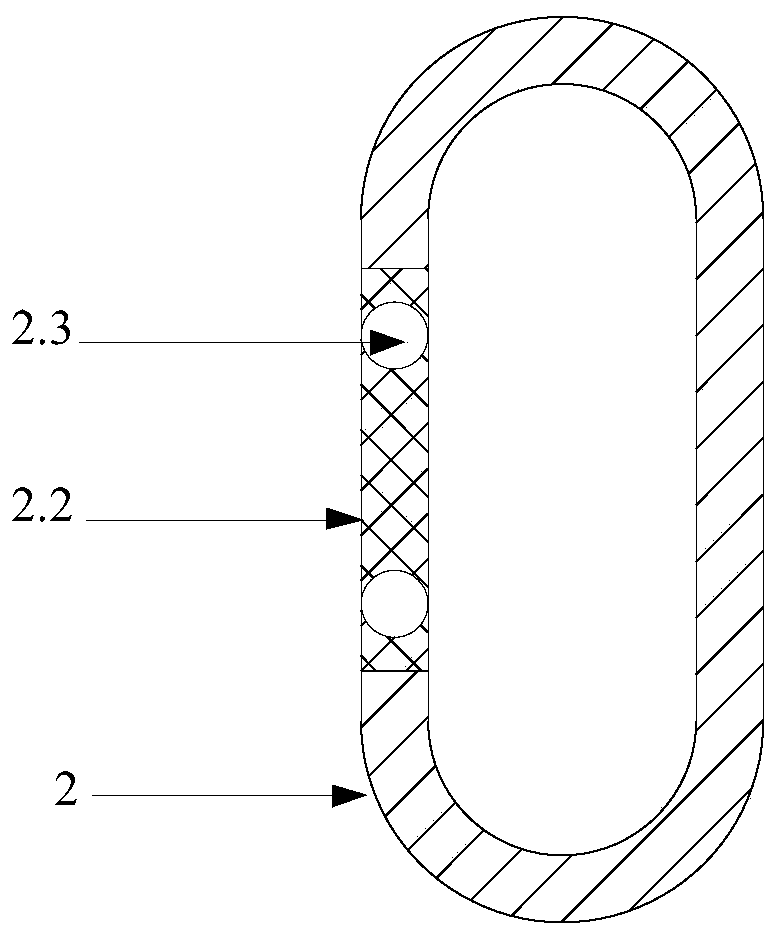

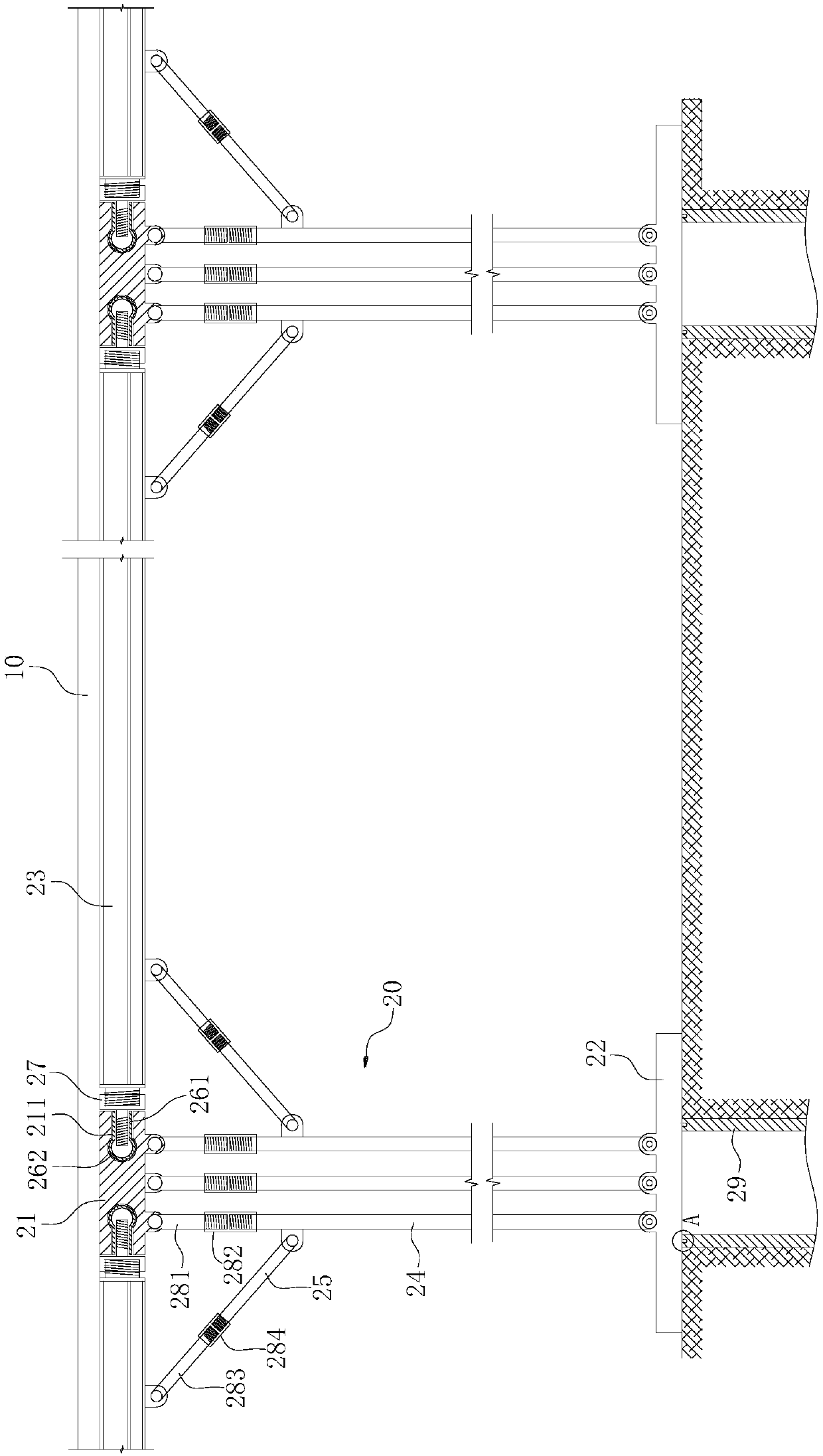

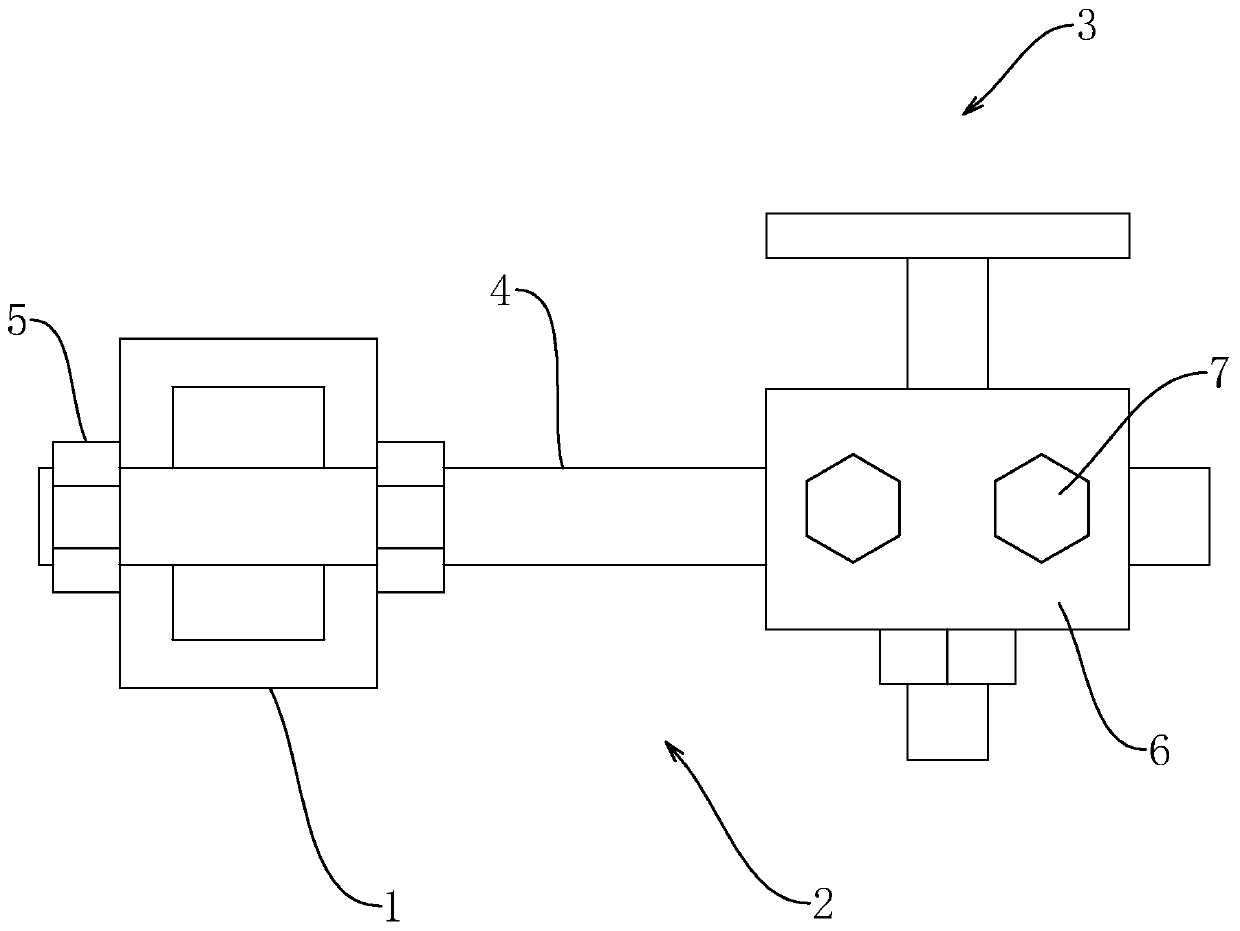

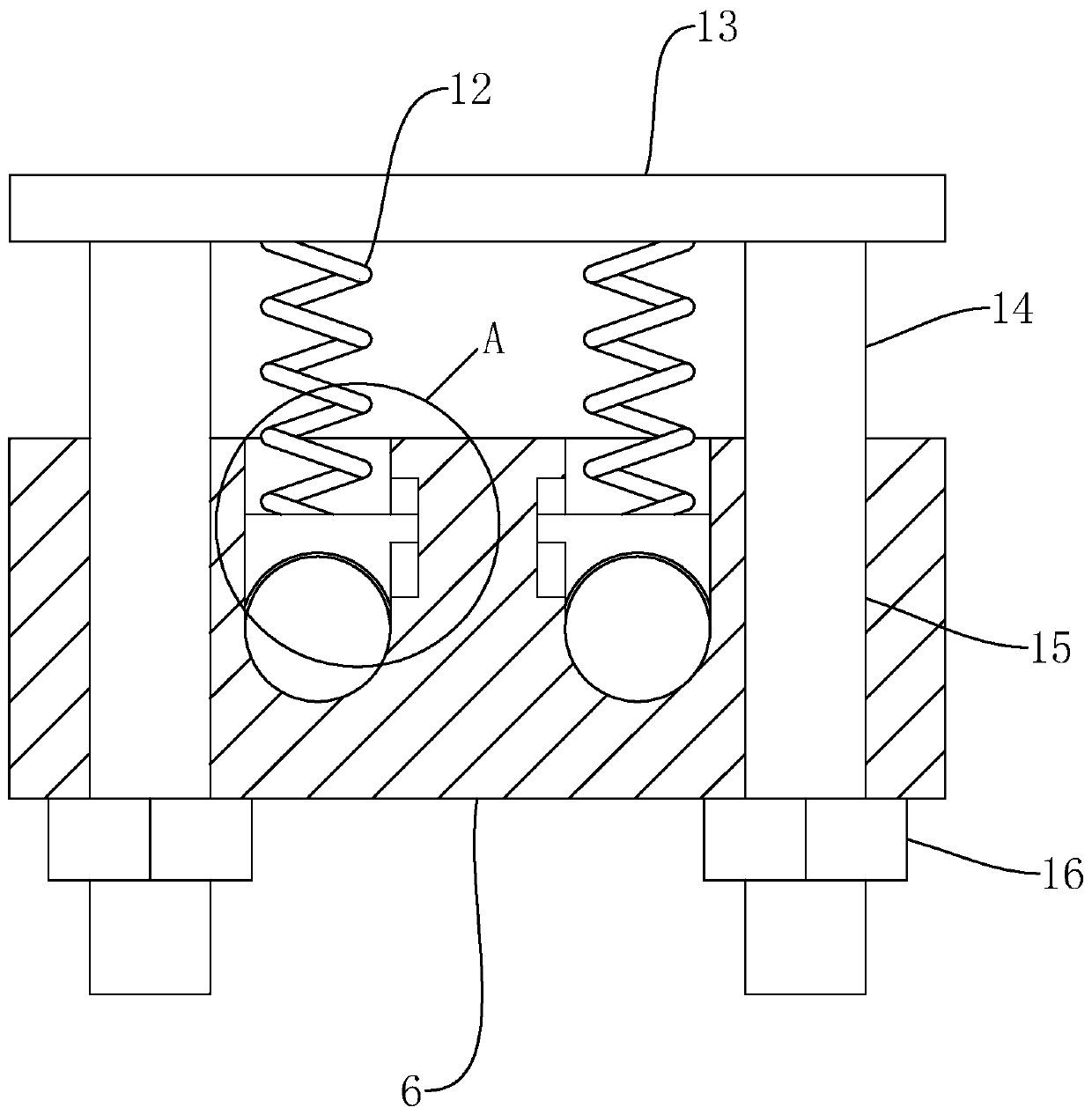

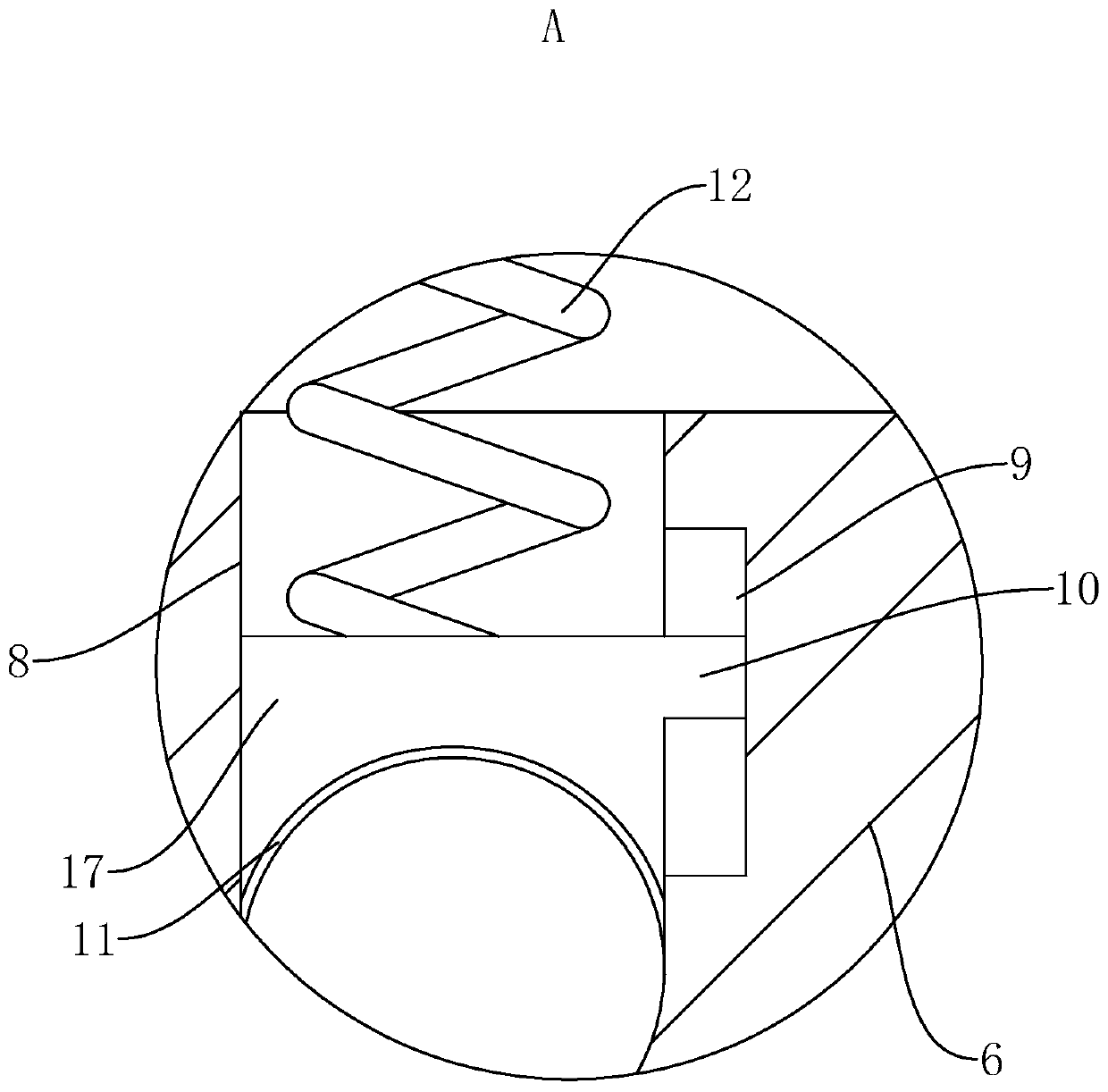

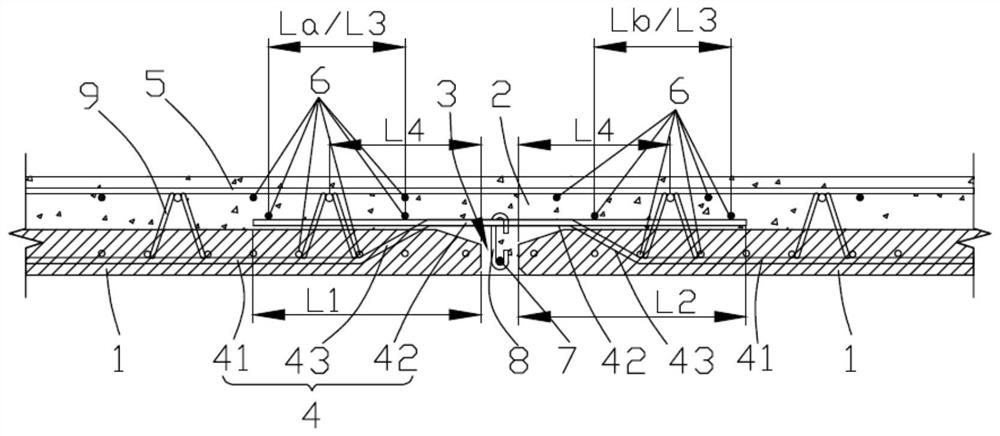

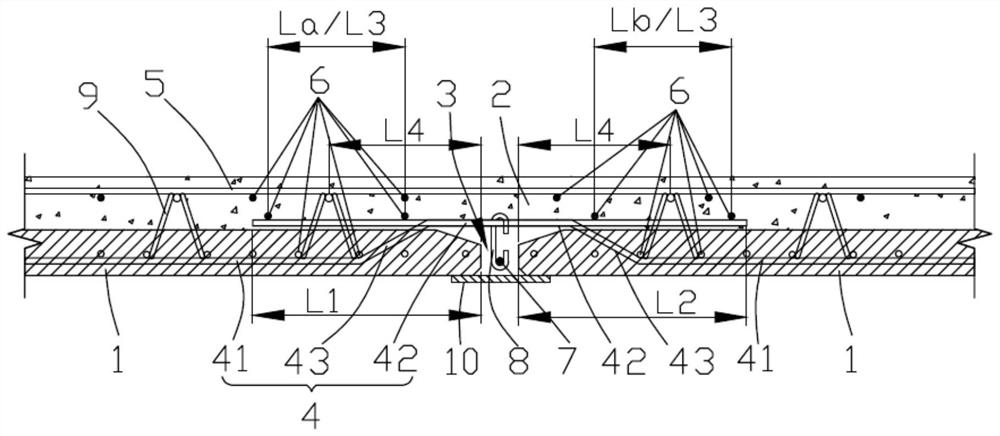

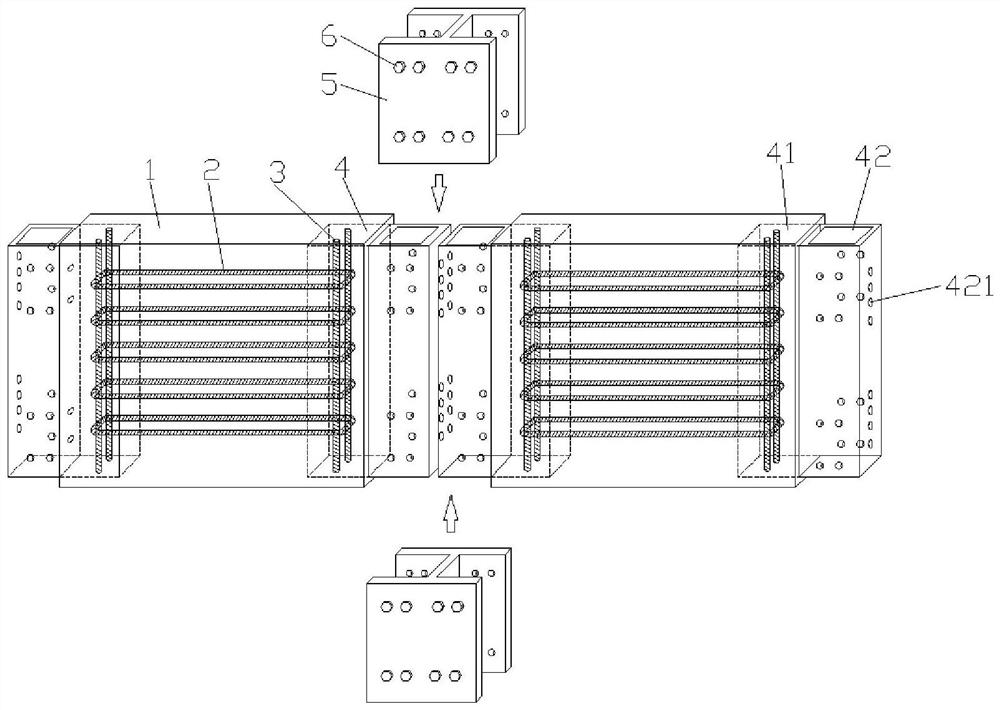

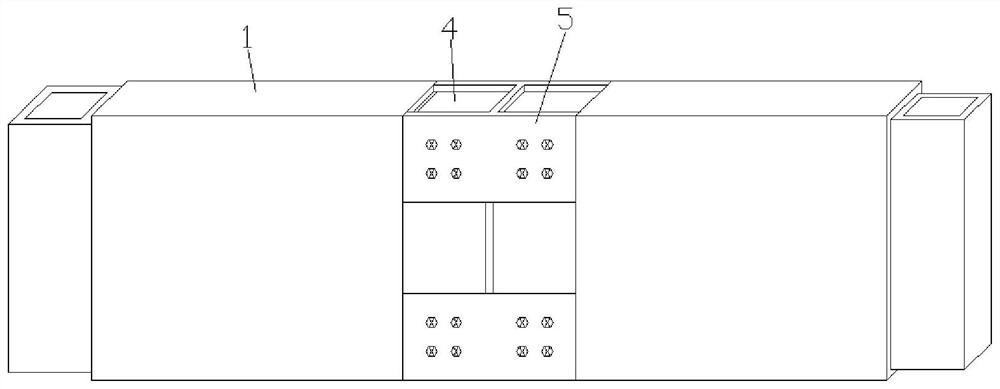

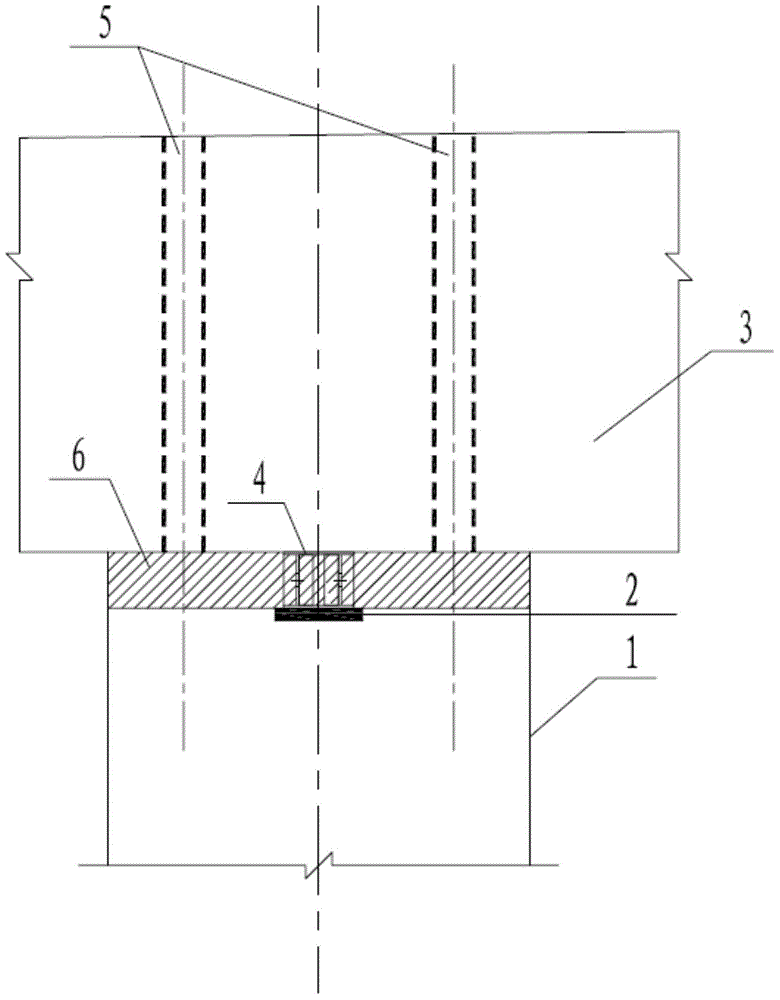

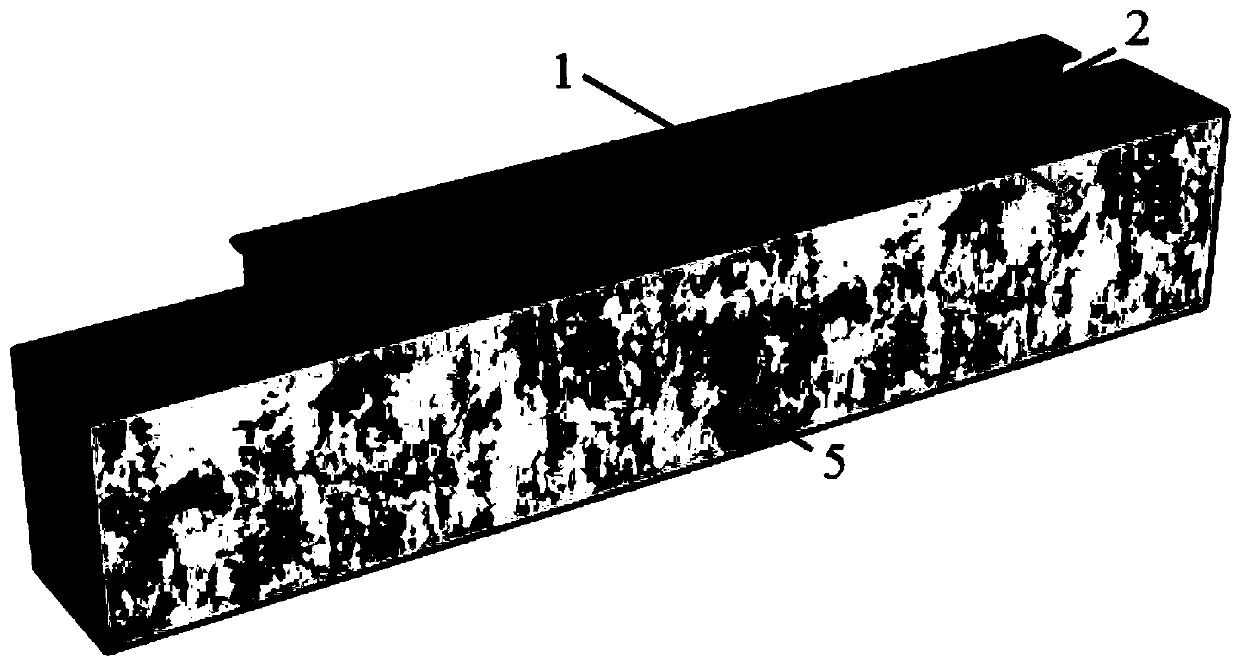

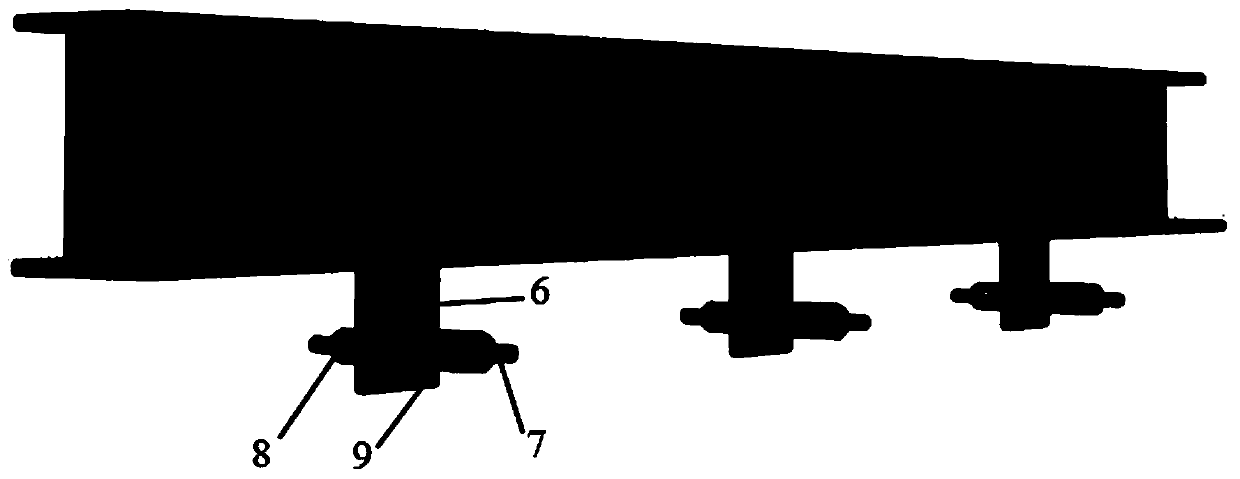

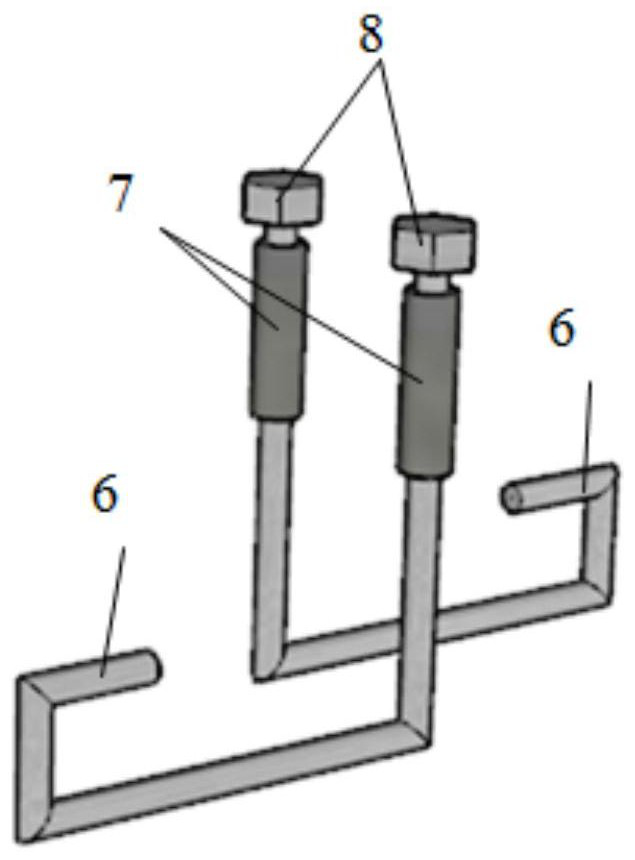

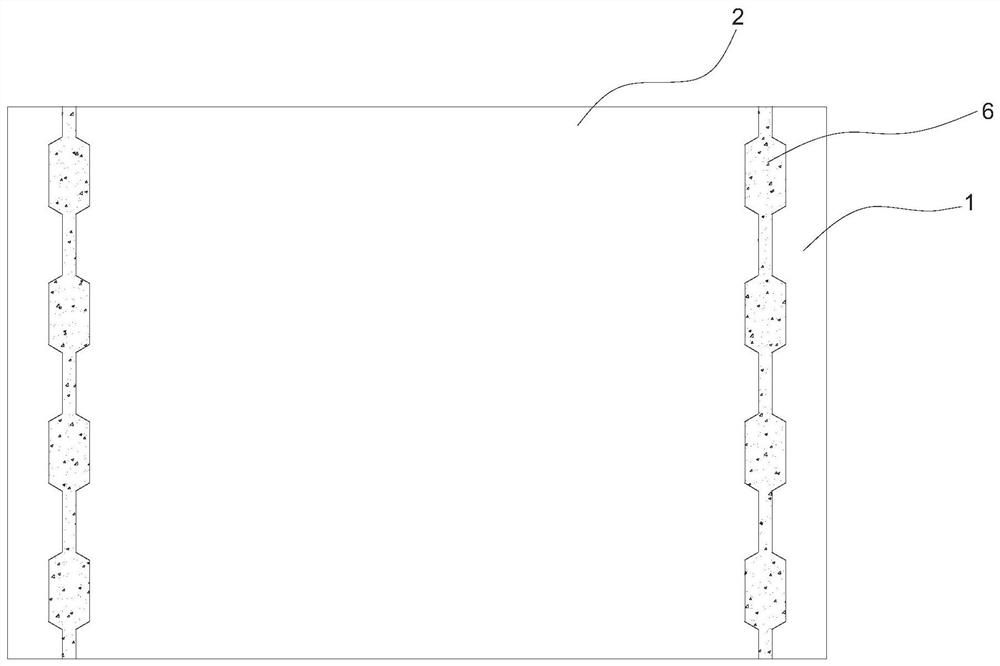

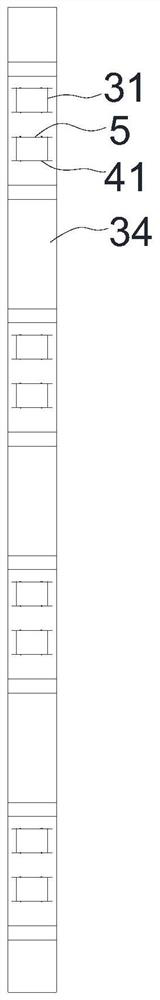

Lock chain type earthquake damage replaceable energy dissipation device

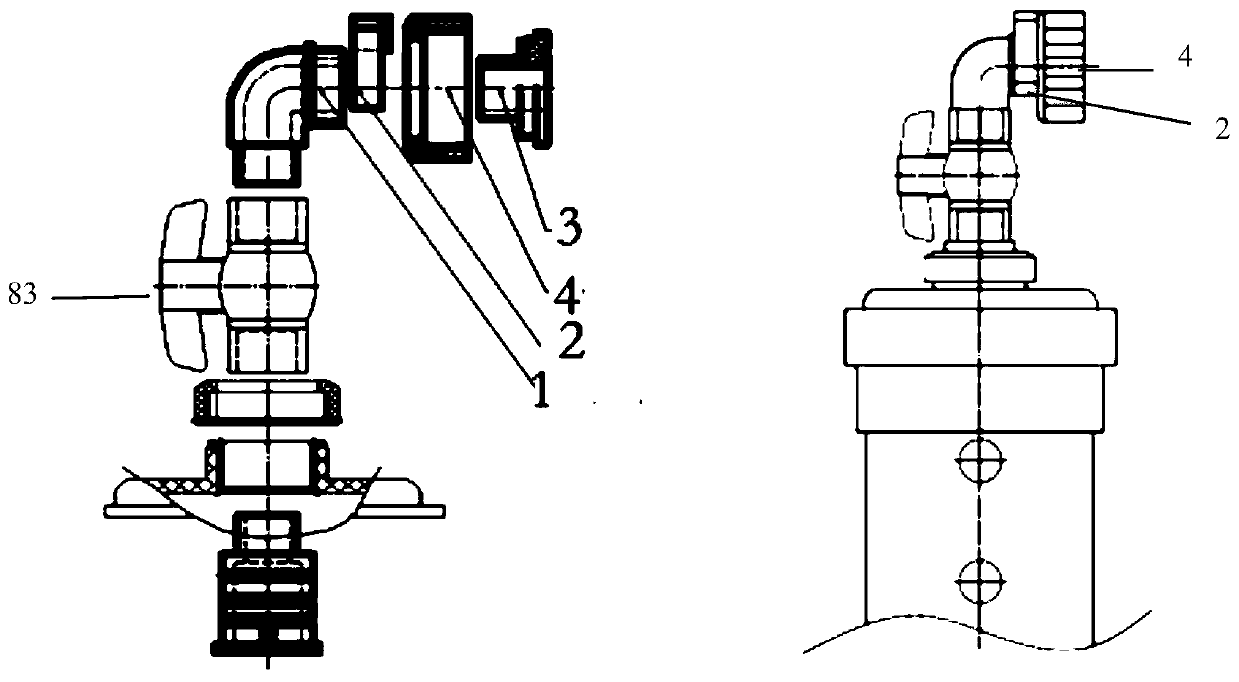

ActiveCN107338735AEasy to centerLow construction precision requirementsBridge erection/assemblyBridge strengtheningChain typeRebar

The invention discloses a lock chain type earthquake damage replaceable energy dissipation device. The lock chain type earthquake damage replaceable energy dissipation device comprises a U-shaped pre-embedded joint (1), a lock chain type button (2) with a switch, a reinforcing rib sleeve (3), top end of which is connected with a circular ring, and an energy dissipation steel rod (4). The device is used in a dry joint section splicing pier; the U-shaped pre-embedded joint (1) is separately pre-embedded into the top of a bearing table and the bottom of a bottom second section; the U-shaped pre-embedded joint (1) is connected to the reinforcing rib sleeve (3), top end of which is connected with the circular ring through the lock chain type button (2) with the switch; and connecting heads (4.1) at the two ends of the energy dissipation steel rod (4) are connected with the reinforcing rib sleeve (3), top end of which is connected with the circular ring. The dry joint section splicing pier using the lock chain type earthquake damage replaceable energy dissipation device has good self-turn capacity and energy dissipation capacity; and moreover, the lock chain type earthquake damage replaceable energy dissipation device is replaced after an earthquake, so that rapid repair for the pier after the earthquake is realized.

Owner:SOUTHEAST UNIV

Public iron layered steel box girder

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

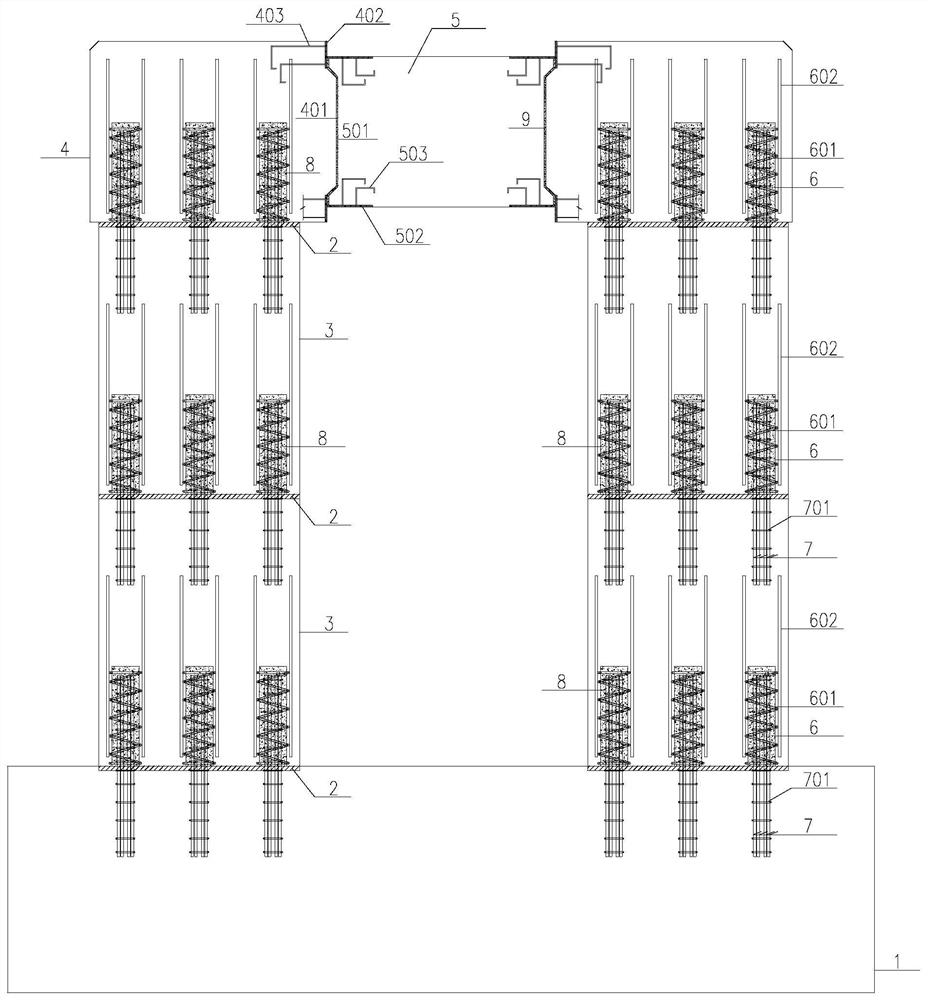

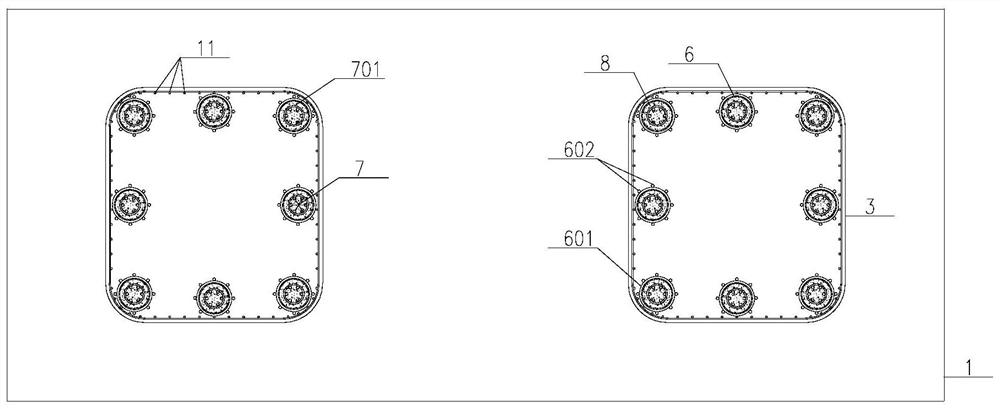

A Construction Method for Shallow Burying and Undercover Excavation of Large-Scale Underground Space - Horizontal Hole Covering Method

ActiveCN104863597BMany working surfacesLow construction precision requirementsUnderground chambersTunnel liningSpatial structureSystem construction

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

Chain-type vibration loss replaceable energy dissipation device

ActiveCN107338735BEasy to centerLow construction precision requirementsBridge erection/assemblyBridge strengtheningChain typeRebar

The invention discloses a lock chain type earthquake damage replaceable energy dissipation device. The lock chain type earthquake damage replaceable energy dissipation device comprises a U-shaped pre-embedded joint (1), a lock chain type button (2) with a switch, a reinforcing rib sleeve (3), top end of which is connected with a circular ring, and an energy dissipation steel rod (4). The device is used in a dry joint section splicing pier; the U-shaped pre-embedded joint (1) is separately pre-embedded into the top of a bearing table and the bottom of a bottom second section; the U-shaped pre-embedded joint (1) is connected to the reinforcing rib sleeve (3), top end of which is connected with the circular ring through the lock chain type button (2) with the switch; and connecting heads (4.1) at the two ends of the energy dissipation steel rod (4) are connected with the reinforcing rib sleeve (3), top end of which is connected with the circular ring. The dry joint section splicing pier using the lock chain type earthquake damage replaceable energy dissipation device has good self-turn capacity and energy dissipation capacity; and moreover, the lock chain type earthquake damage replaceable energy dissipation device is replaced after an earthquake, so that rapid repair for the pier after the earthquake is realized.

Owner:SOUTHEAST UNIV

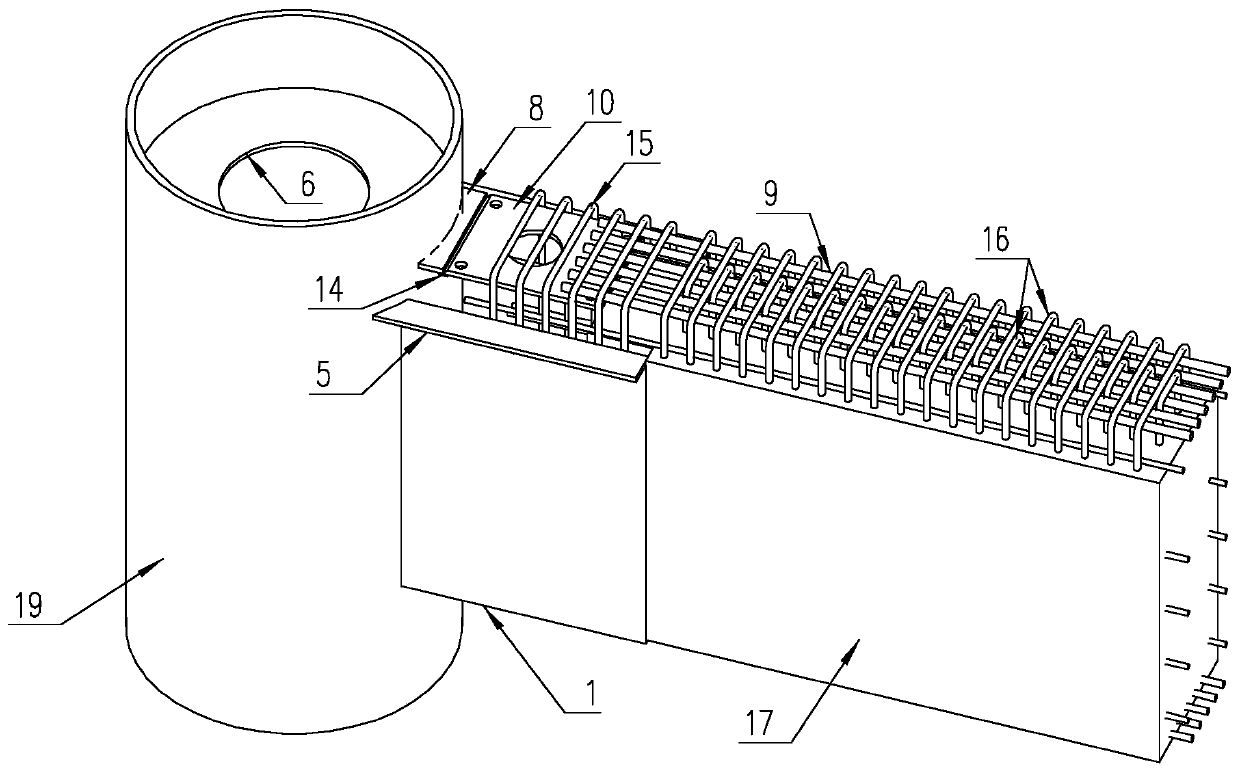

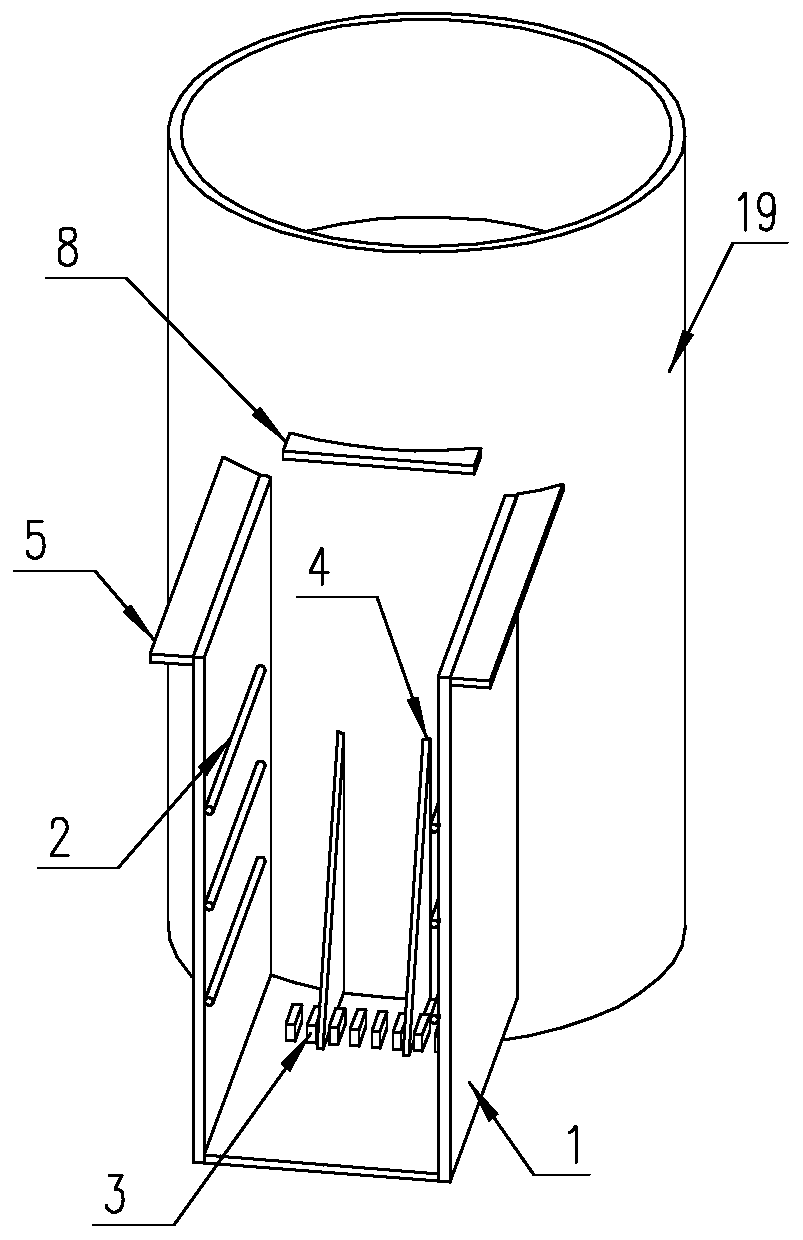

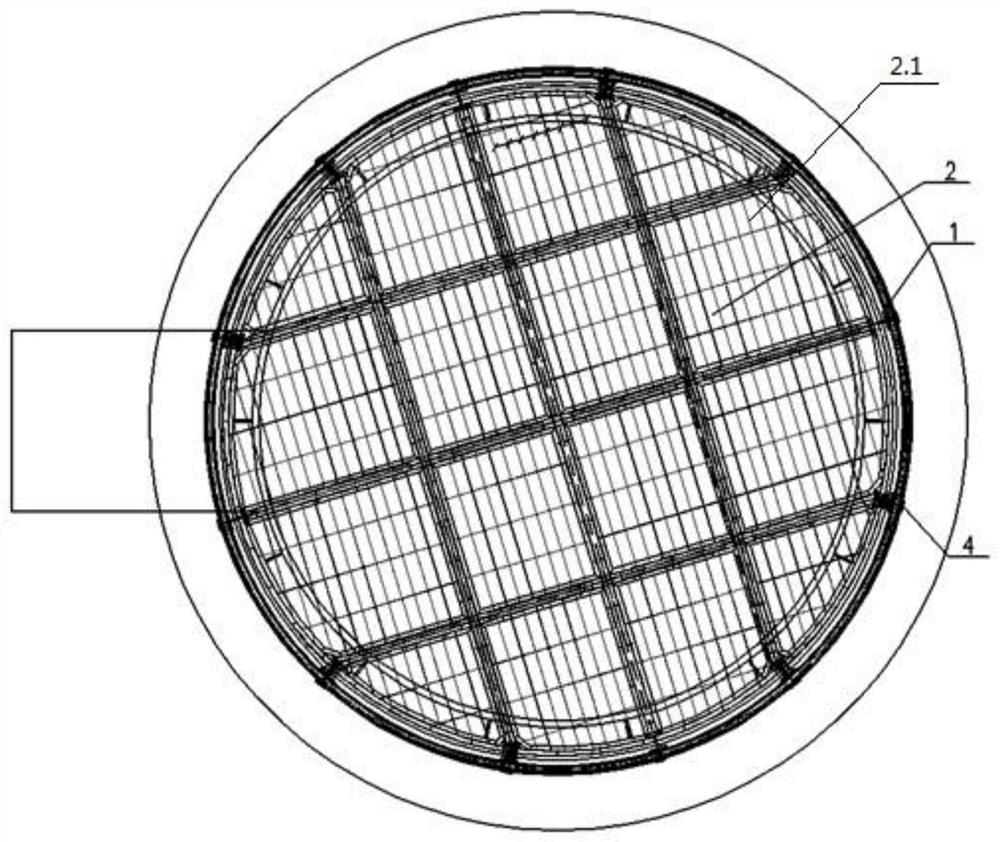

Method for repairing top cover of large-diameter water taking head

ActiveCN112796368ARecovery functionReduce repair costsHydro energy generationArtificial water canalsSteel frameFresh water

The invention discloses a method for repairing a top cover of a large-diameter water taking head. The method comprises the following steps: prefabricating an externally-wrapped steel frame and a water inlet steel grating. Concrete is poured at the original foundation position of the underwater water taking head, a lower foundation of the newly-manufactured top cover is formed, and connecting bolts are pre-buried in the lower foundation. The prefabricated steel frame is transported to the position above the lower foundation in a hoisting mode, and the steel frame is connected with the lower foundation through pre-buried connecting bolts. After the steel frame is installed, the frame part, below the water inlet window, on the steel frame is poured in an underwater concrete pouring mode, and the steel frame and the lower foundation form a whole. The prefabricated steel grating is installed on the top of the steel frame, and then the top cover of the water taking head is repaired. The method can be suitable for repairing the top cover of the water taking head under various conditions, including fresh water and seawater conditions, can also be suitable for water taking heads with various shapes, can meet the service life after repairing, and has relatively low construction cost and higher construction speed.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

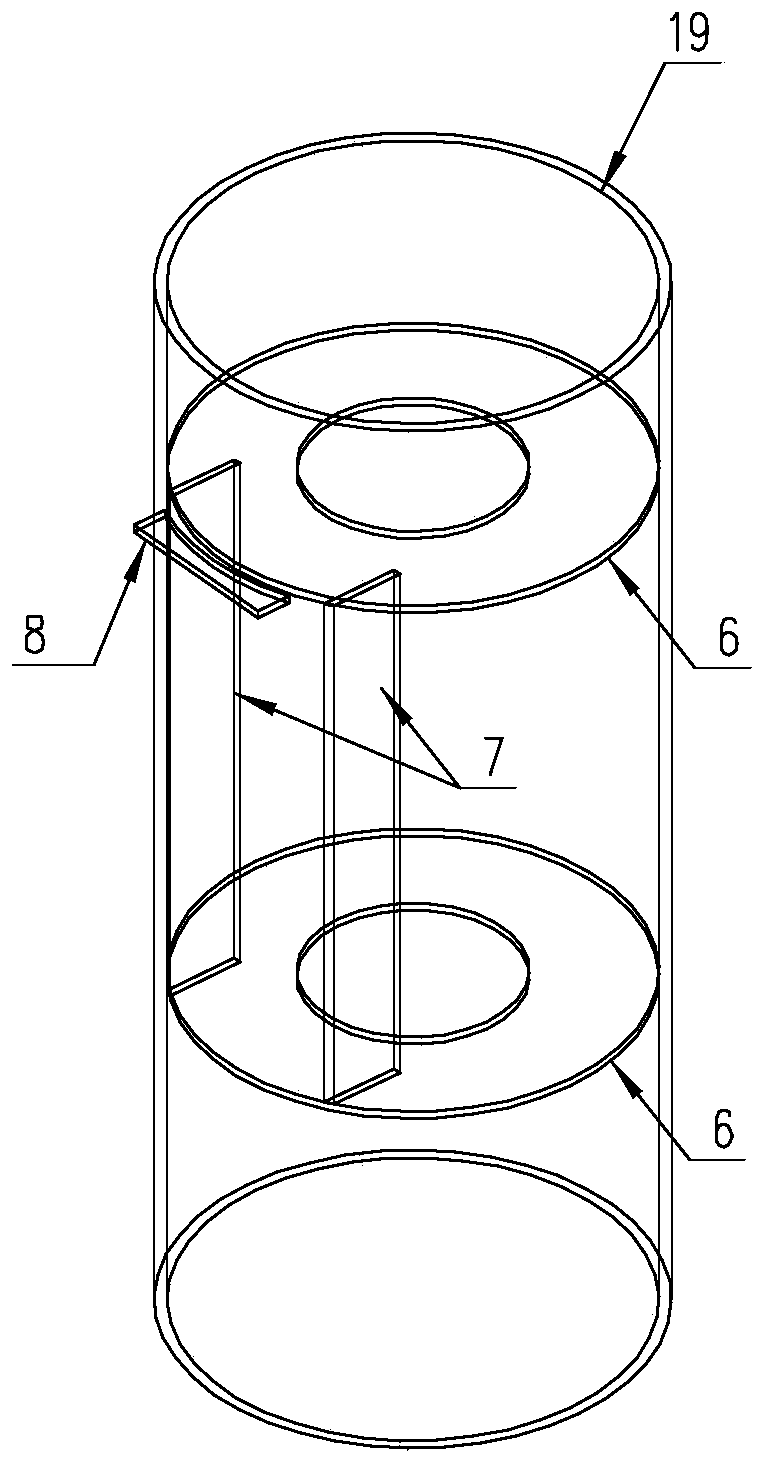

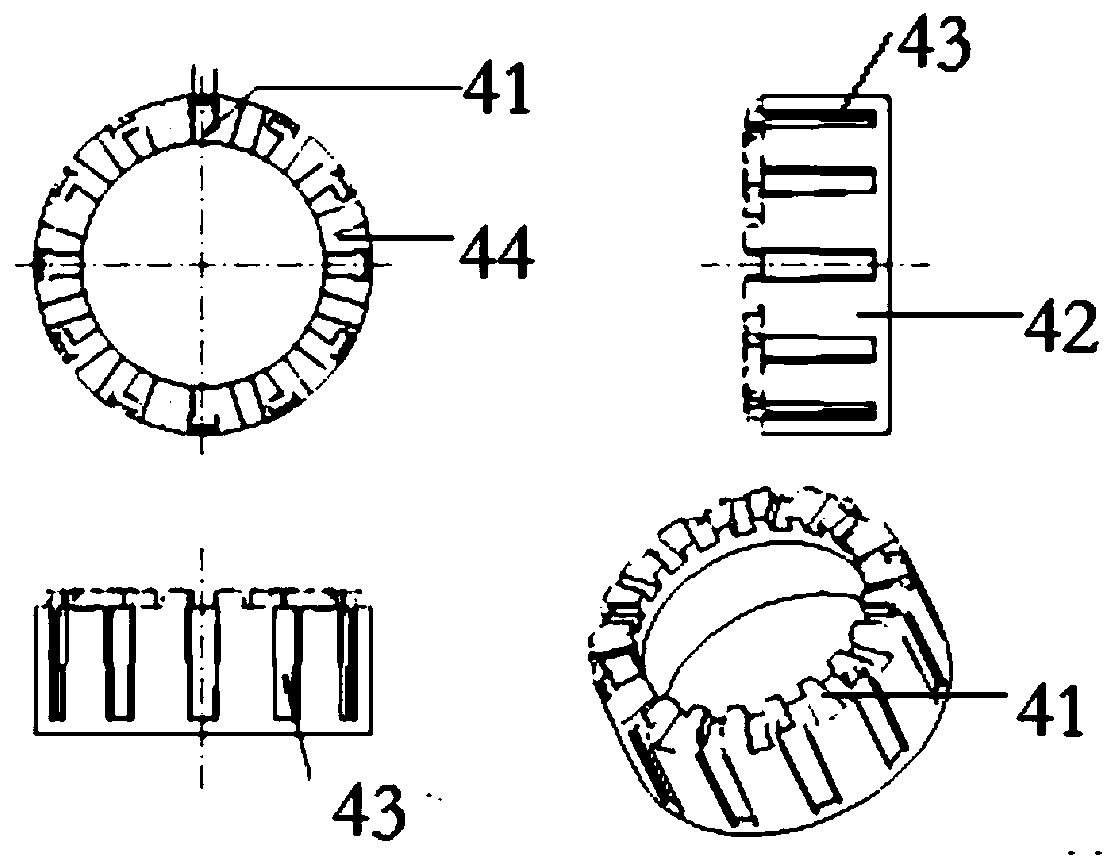

Template table with integrated installation of beam columns

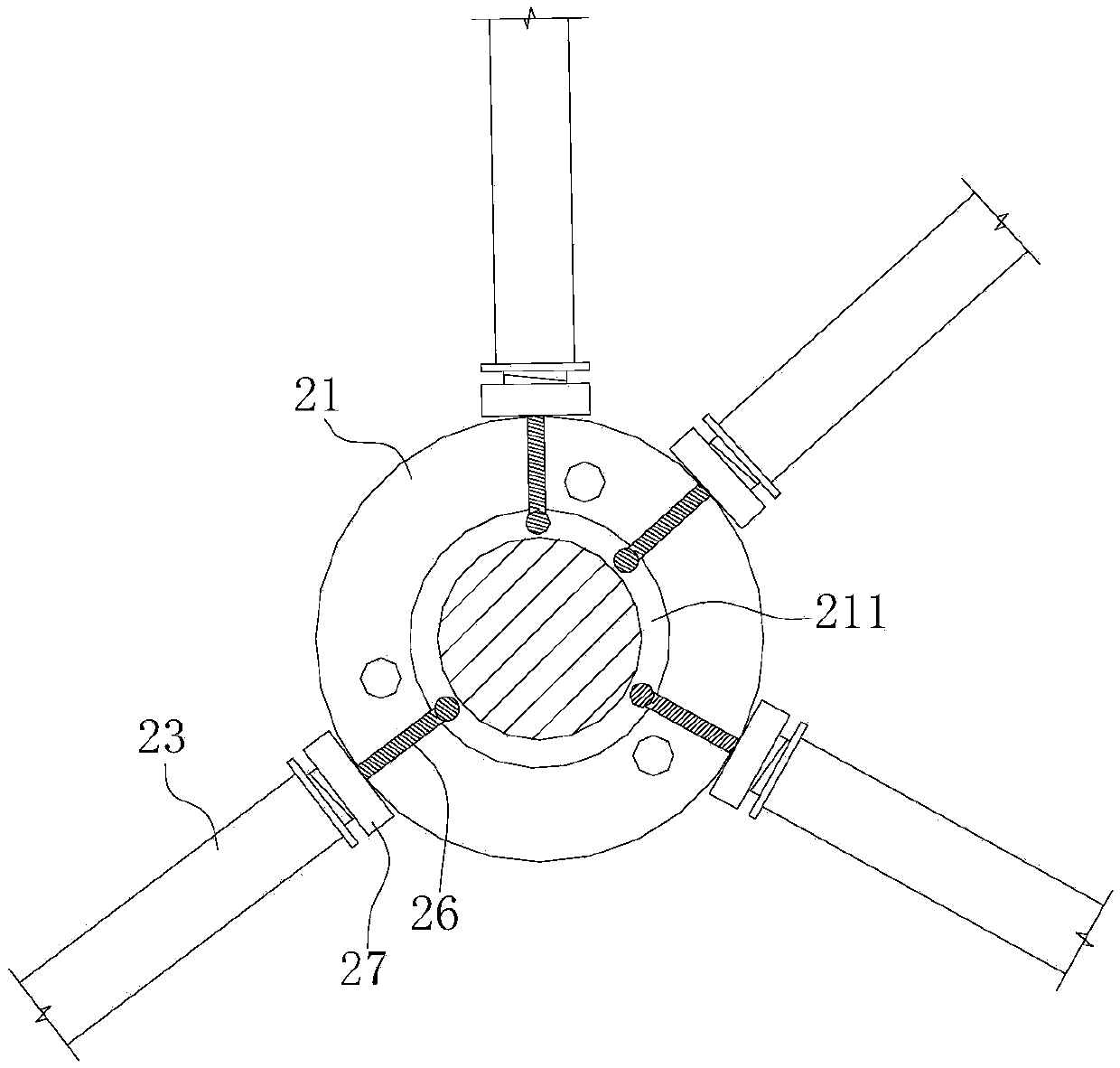

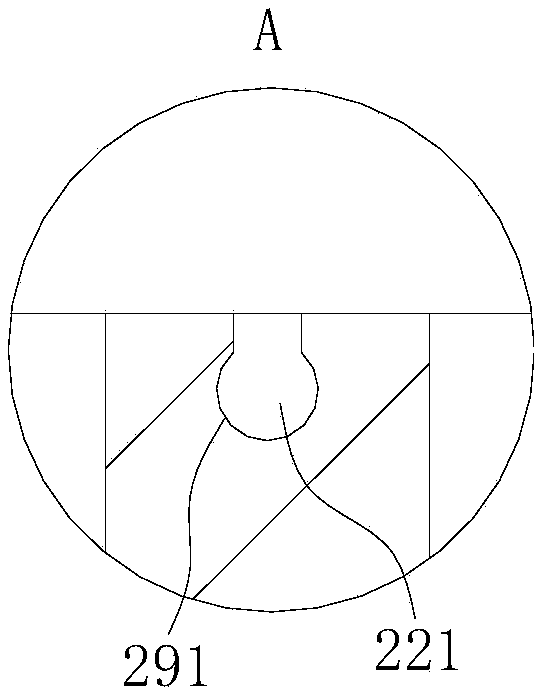

PendingCN109667418AStable supportLow installation requirementsForms/shuttering/falseworksUniversal jointBeam column

The invention discloses a template table with the integrated installation of beam columns. The template table comprises a template, and two or more pairs of integrated beam columns arranged at the bottom part of the template, wherein each integrated beam column comprises a support plate, an installation plate, two or more horizontal support beams, vertical support rods with the quantity being thesame as the quantity of the two or more horizontal support beams, and inclined support rods with the quantity being the same as the quantity of the two or more horizontal support beams; the support plates are in circular shapes; annular guide rail slots extending along the circumferential directions of the support plates are formed in the outer circumferential walls of the support plates; and universal joints are connected to one ends of the horizontal support beams, are slidably arranged in the annular guide rail slots, and can rotate in the annular guide rail slots around own axes.

Owner:HEFEI DESIGN & RES INST LLC OF COAL IND

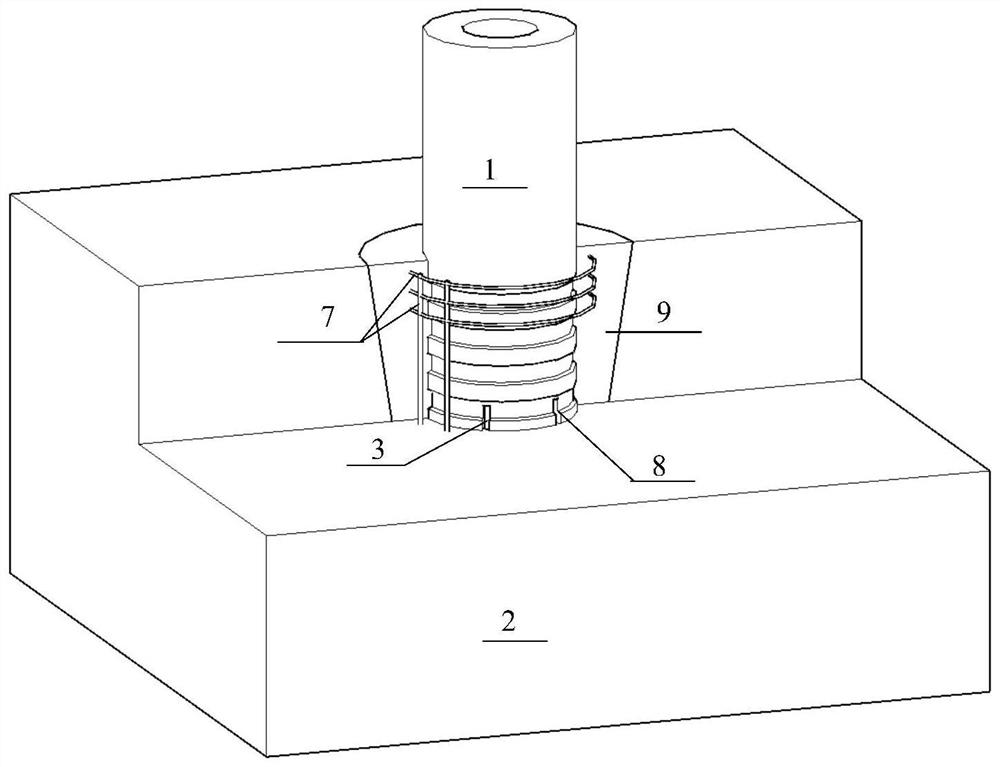

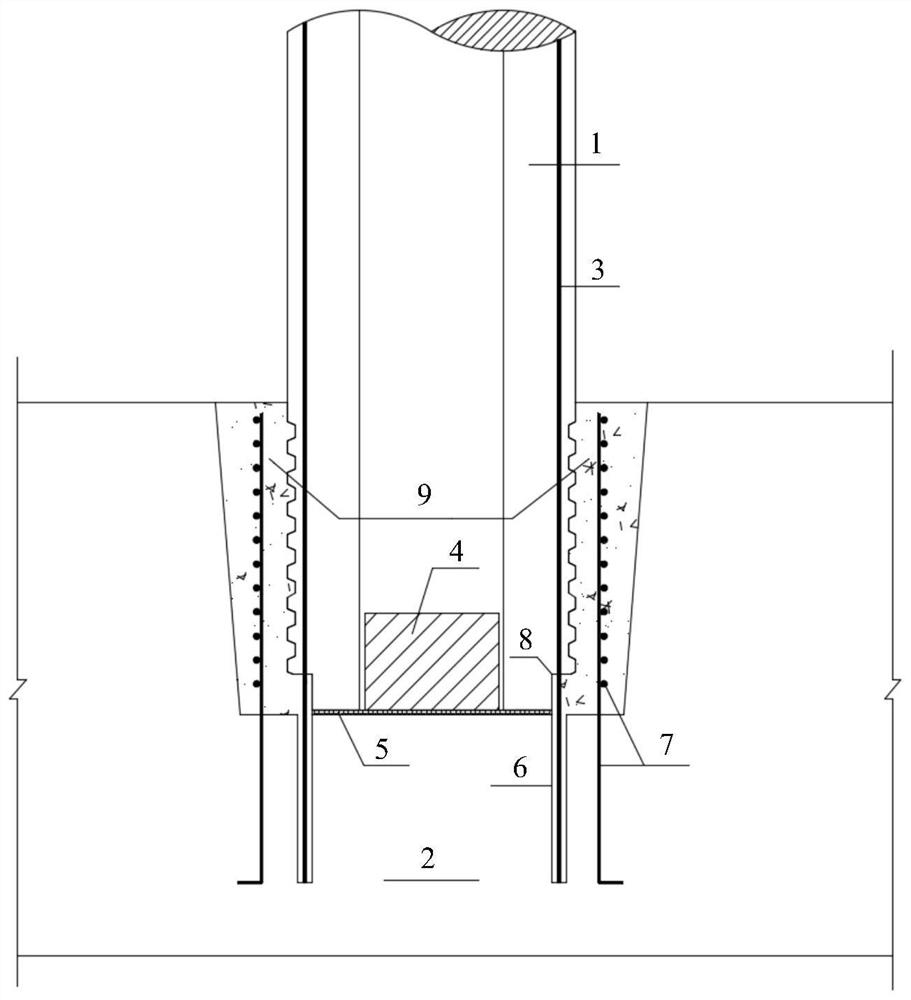

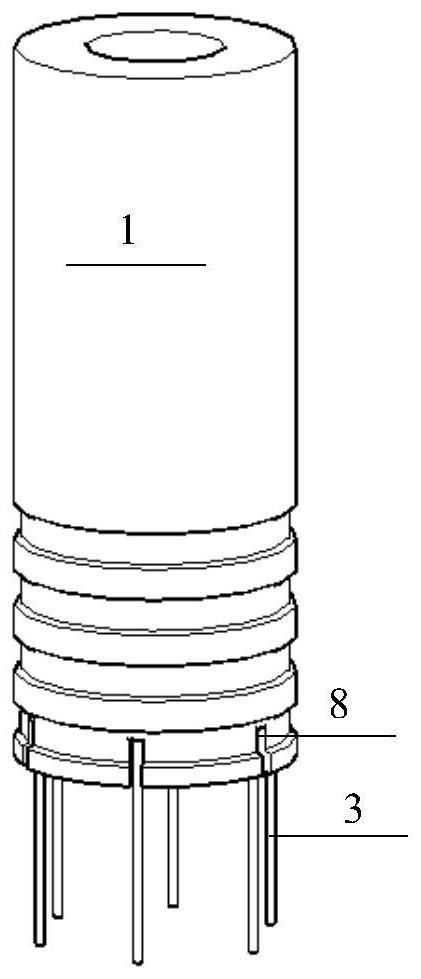

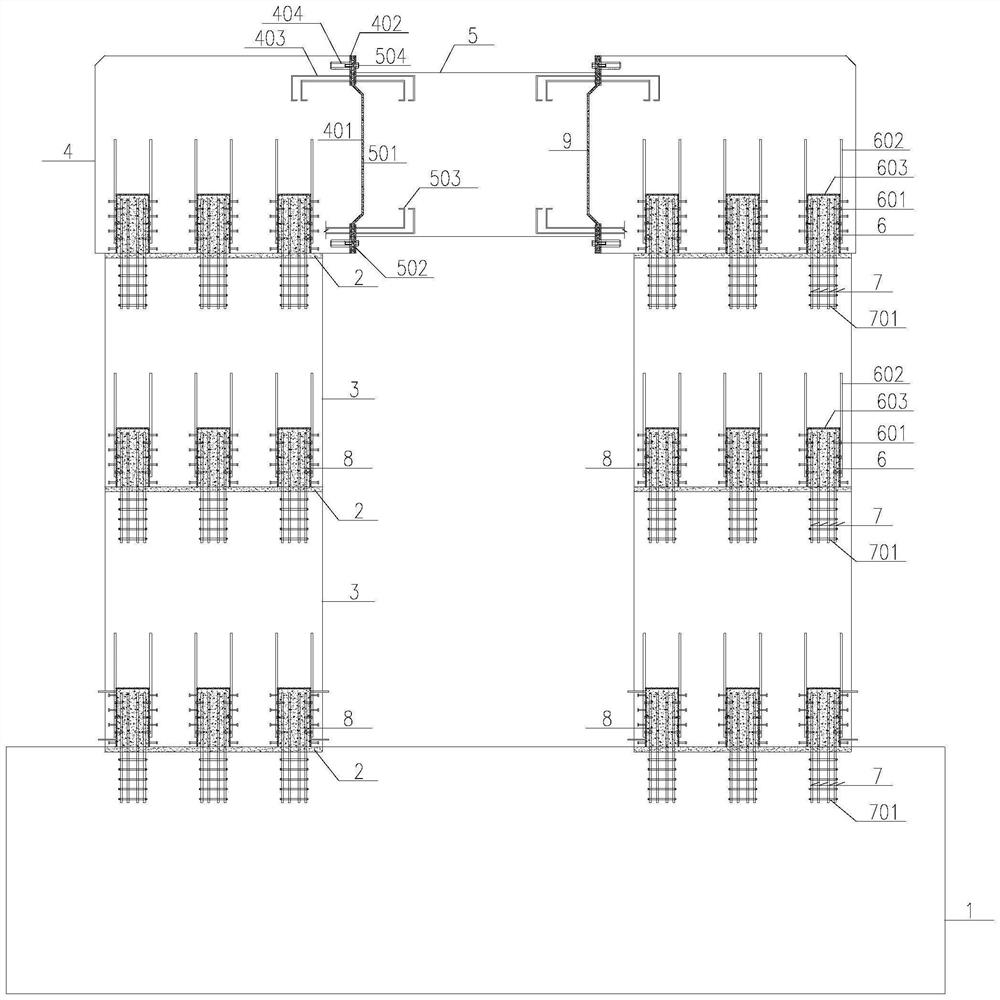

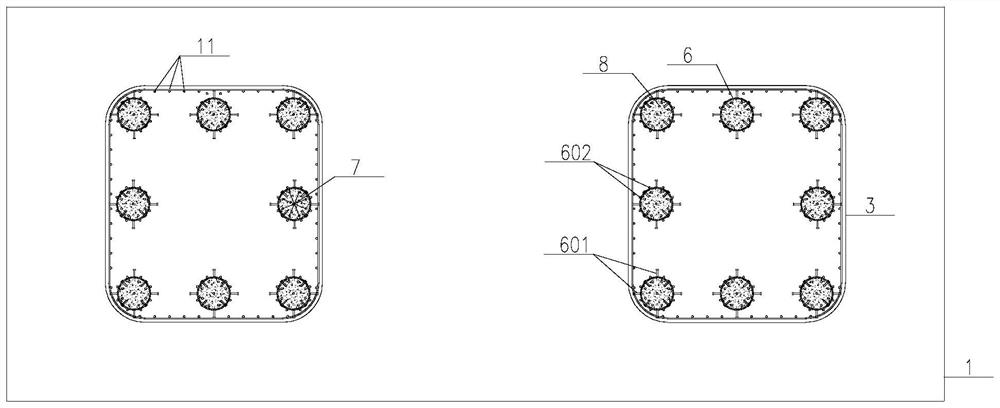

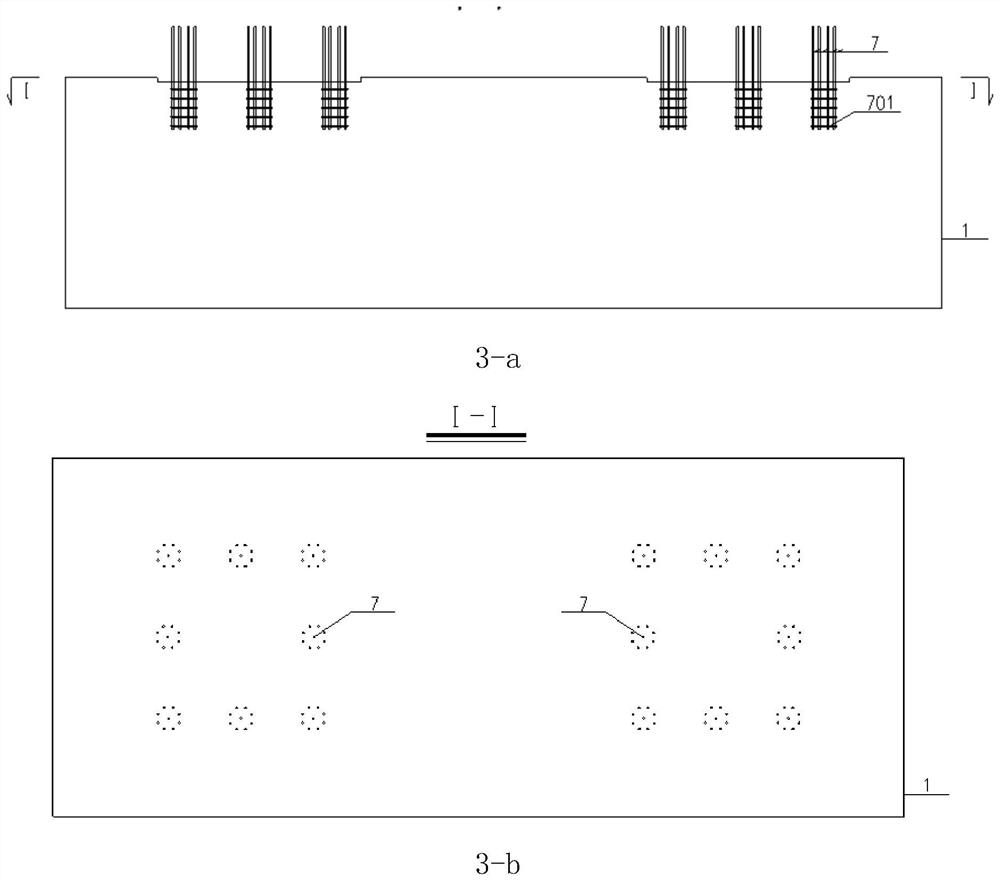

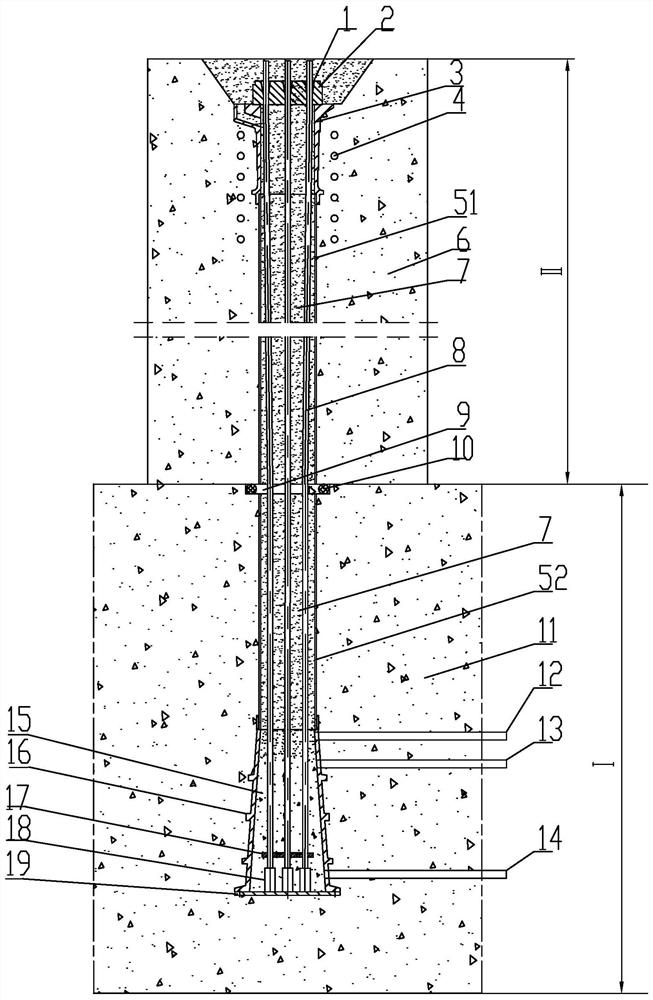

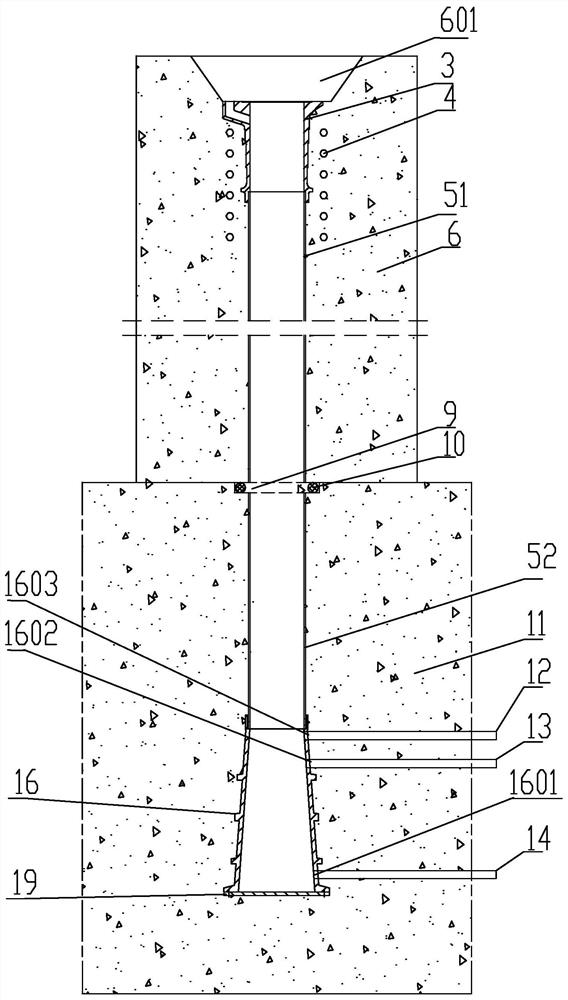

Cluster grouting corrugated pipe assembled pier connected with prefabricated bearing platform and construction method

PendingCN111827094AReduce the numberLarge construction toleranceBridge structural detailsFoundation engineeringPre stressArchitectural engineering

The invention provides a cluster grouting corrugated pipe assembled pier connected with a prefabricated bearing platform and a construction method. The assembled pier comprises a foundation, pier column sections and top cap sections. The foundation is formed by connecting foundation prefabricated sections through foundation connecting seams, connecting steel bars are pre-buried in the top surfacesof the foundation prefabricated sections and the prefabricated pier column sections, bundling connecting corrugated pipes are pre-buried in the bottom surfaces of the corresponding prefabricated piercolumn sections and the prefabricated top cap sections, the pre-buried connecting steel bars penetrate into the bundling connecting corrugated pipes, and then a high-strength grouting materials are poured; the top cap connecting sections and the top cap sections are connected through top cap splicing seams, and then the connecting steel plates are connected in a welded mode; and steel strands penetrate through the pre-buried corrugated pipes pre-buried in all the sections and are arranged in a U shape, the steel strands are tensioned at the top of the top cap, then foundation connecting joints are constructed, and then concrete is poured to complete splicing. The spliced pier connecting steel bars are arranged in a bundled mode, a construction tolerance is large, a construction precisionrequirement is low, splicing difficulty is small, grouting efficiency is high, the top cap sections are quickly spliced, prestress installation is convenient and fast, and cost is low.

Owner:CHINA RAILWAYS CORPORATION +1

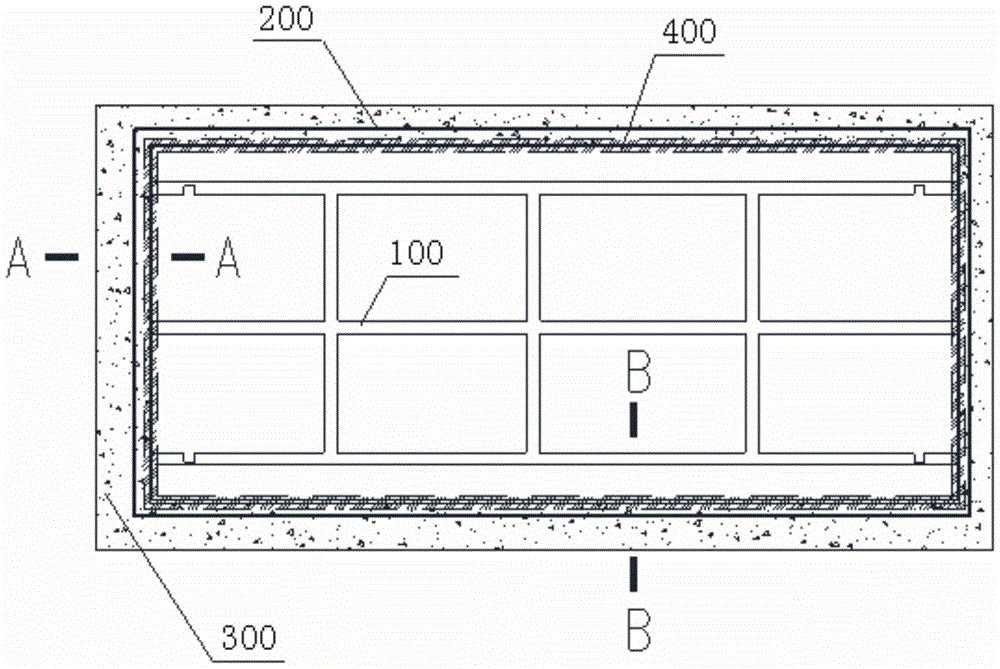

Immersed ultrafiltration membrane equipment with high integration level

PendingCN111135723ALow construction precision requirementsAvoid unqualifiedMembranesUltrafiltrationProcess engineeringUltrafiltration

The invention belongs to the field of membrane assemblies, and particularly relates to high-integration-level immersed ultrafiltration membrane equipment, which comprises a bracket and a plurality ofultrafiltration membrane assemblies symmetrically arranged in two rows, wherein the ultrafiltration membrane assembly comprises a shell and a membrane tow arranged in the shell, one end of the membrane tow is a water production end, the other end of the membrane tow is a closed end, a water production box is arranged at the water production end, an aeration box is arranged at the closed end, a fixing resin is arranged in the water production box and is used for fixing the membrane tow, a water production port communicated with the water production box is formed in the top of the water production box, the water production port is connected with a connecting elbow through a valve, a water production elbow is connected with a water production main pipe through an anti-loose joint, an aerationpipe groove matched with an aeration branch pipe is formed in the aeration box, and the aeration branch pipe can be inserted into the aeration pipe groove to position the ultrafiltration membrane assembly. Due to the fact that the aeration branch pipe below the single ultrafiltration membrane assembly is connected with the ultrafiltration membrane assembly in a pluggable mode, when the ultrafiltration membrane assembly is replaced and maintained, the requirements for in-situ replacement and after-sales repair of the membrane assembly can be met after the liquid level is lowered.

Owner:TIANJIN MOTIMO MEMBRANE TECH

Glass pedal connecting device and its installation method

ActiveCN109763612BLow construction precision requirementsEasy to installTreadsToughened glassSupport plane

Owner:深圳市极尚建设集团股份有限公司

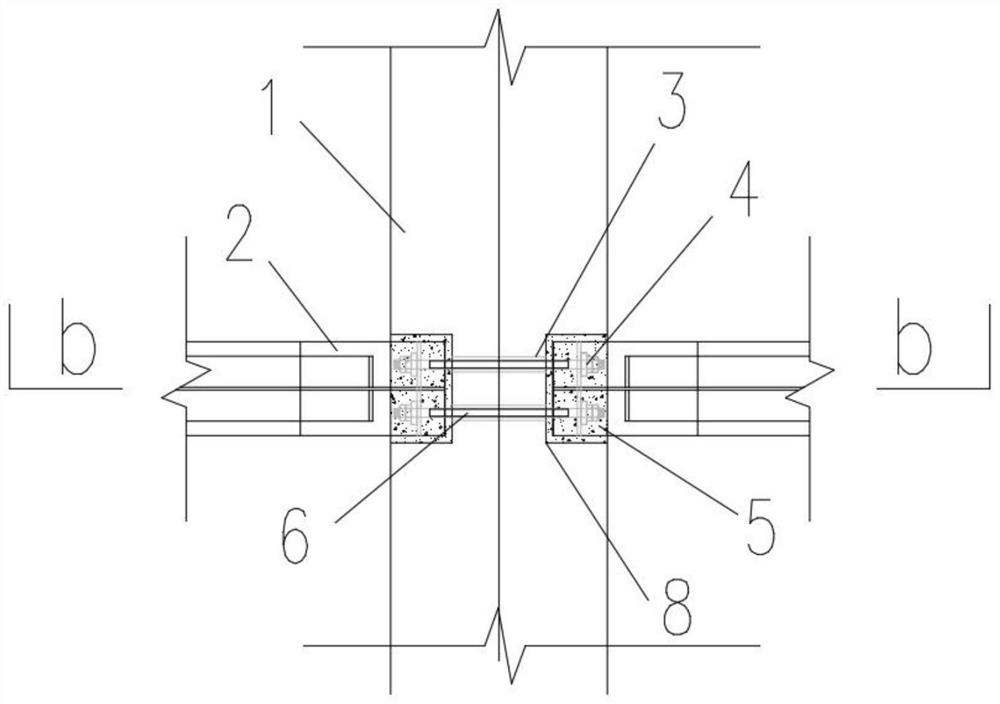

Connecting structure of concrete precast beam and steel beam and construction method of connecting structure

PendingCN114809296AHigh precisionLess prone to positional deviationGirdersJoistsStructural reliabilityRebar

The invention discloses a connecting structure of a concrete precast beam and a steel beam and a construction method of the connecting structure. The connecting structure comprises the concrete precast beam and the steel beam. Two grooves which are matched with the ends of the steel beam and are coaxial are reserved in the concrete precast beam, the two grooves are symmetrically formed in the two sides of the concrete precast beam, and a bolt hole for a split bolt to penetrate through is reserved between the two grooves. The ends of the two steel beams are arranged in the two grooves of the concrete precast beam, the split bolts penetrate through the bolt holes to fix the two steel beams, a fixing steel bar located on the upper sides of the steel beams is further arranged between the two steel beams, and the two ends of the fixing steel bar are welded and fixed to the two steel beams respectively. A gap at the joint of the concrete precast beam and the steel beam is filled with concrete. According to the connecting structure, the structural design is reasonable, the requirement for assembly precision is low, the steel beams are doubly fixed through the split bolts and the fixing steel bars, the gaps are filled with pouring concrete, and the connecting structure is good in reliability; the construction method is easy to operate and high in construction efficiency.

Owner:SHANGHAI BAOYE GRP CORP

H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and construction method thereof

InactiveCN102733492BMeet the requirements of prefabricated constructionHigh node stiffnessBuilding material handlingEngineeringSteel columns

The invention discloses an H-shaped steel beam and H-shaped steel column minor axis variable beam height fabricated node and a construction method thereof. The node comprises an H-shaped steel column, an H-shaped steel beam, a column sealing piece, a T-shaped connection piece, an L-shaped connection piece and bolts. The column sealing piece consists of a column sealing plate, a beam upper flange stiffening rib and a column sealing plate stiffening rib; the T-shaped connection piece consists of an upper flange plate connection plate which is arranged horizontally and a web connection plate which is perpendicular to the bottom surface of the upper flange plate connection plate; the L-shaped connection piece consists of a lower flange plate connection plate which is arranged horizontally and a column connection plate which is perpendicular to the lower flange plate connection plate downward. All accessories required by the node are prefabricated in a factory, the requirement of equal-strength connection in the process of changing the section of the H-shaped steel beam in a certain range can be met, high-strength bolts are adopted by a construction field node so as to realize the fabricated connection, and the node is high in rigidity and high in connection speed, and can meet the requirement of the fabricated construction of a steel structure.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Bidirectional laminated slab prefabricated bottom plate abutted seam structure and construction method thereof

PendingCN114457948ALow costReduce amortizationFloorsBuilding reinforcementsArchitectural engineeringRebar

The invention provides a two-way laminated slab prefabricated bottom plate abutted seam structure and a construction method of the two-way laminated slab prefabricated bottom plate abutted seam structure. The two-way laminated slab prefabricated bottom plate abutted seam structure comprises prefabricated bottom plates, a cast-in-place layer, a bent steel bar assembly, reinforcing bars and a plurality of distribution bars, abutted seams are formed between the prefabricated bottom plates, the reinforcing bars are arranged in the cast-in-place layer, and the distribution bars are evenly distributed in the prefabricated bottom plates and the cast-in-place layer. The bent reinforcing steel bar assemblies convexly extend from the abutted seam of the prefabricated bottom plate to the cast-in-place layer, and the bent reinforcing steel bar assemblies are vertically connected with the distribution reinforcing steel bars; and the reinforcing bars and the distribution bars are vertically connected with each other. Compared with the prior art, the two-way laminated slab prefabricated bottom slab abutted seam structure does not need die holing, the production efficiency is improved, die amortization is reduced, and the laminated slab cost is reduced.

Owner:内蒙古中朵远大建筑工业有限公司

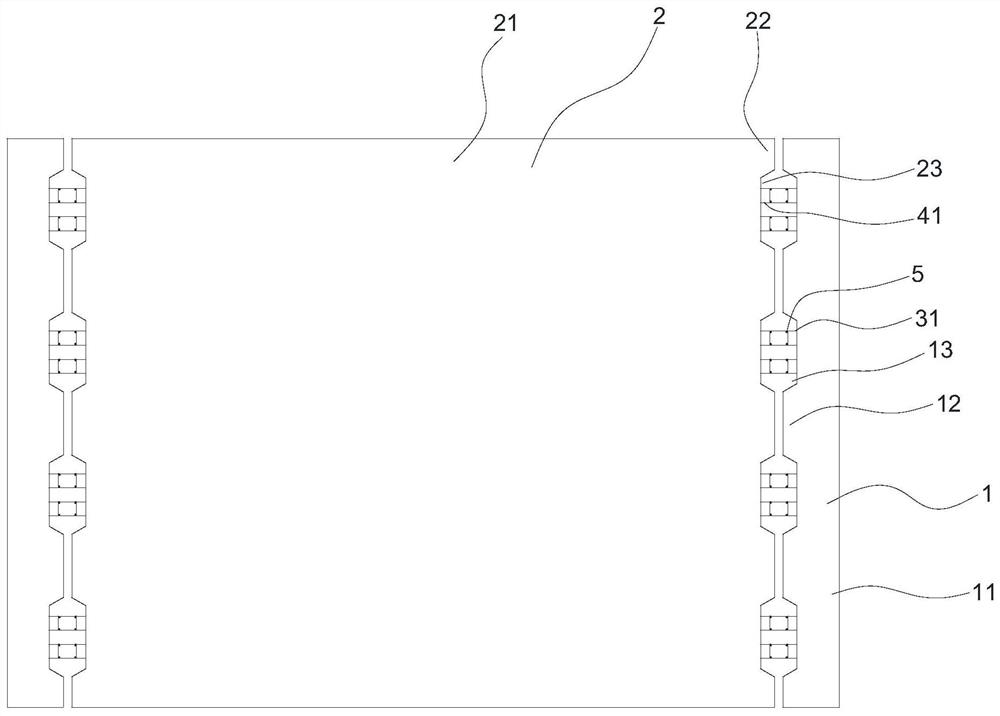

Novel prefabricated assembly type shear wall horizontal joint structure and construction method

PendingCN114718217ALow construction precision requirementsImprove the interface dimensionWallsWind energy generationSocial benefitsArchitectural engineering

The invention discloses a novel prefabricated assembly type shear wall horizontal joint structure and a construction method, and relates to the technical field of building structure engineering. The four high-strength ribbed longitudinal bars are evenly arranged on the two sides of the prefabricated shear wall, the five hoop-shaped high-strength ribbed steel bars evenly and horizontally surround the four high-strength ribbed longitudinal bars and are perpendicularly distributed in the prefabricated shear wall, and the hoop-shaped high-strength ribbed steel bars and the high-strength ribbed longitudinal bars are connected in a binding mode through binding wires. Inner cavities in the two sides of the prefabricated shear wall are fixedly connected with the square steel tube bundles, H-shaped steel connecting pieces are installed between the upper ends and the lower ends of every two adjacent square steel tube bundles, and the H-shaped steel connecting pieces and the square steel tube bundles are fixed through high-strength bolts. And meanwhile, the safety of the structure can be guaranteed, the building period is shortened, and the connecting mode has great social benefits and economic benefits.

Owner:XINYU UNIV

Wet joint construction for the connection between prefabricated bridge pier columns and cover beams

ActiveCN104018422BMeet the stiffnessImprove performanceBridge structural detailsStructural stressPrefabrication

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

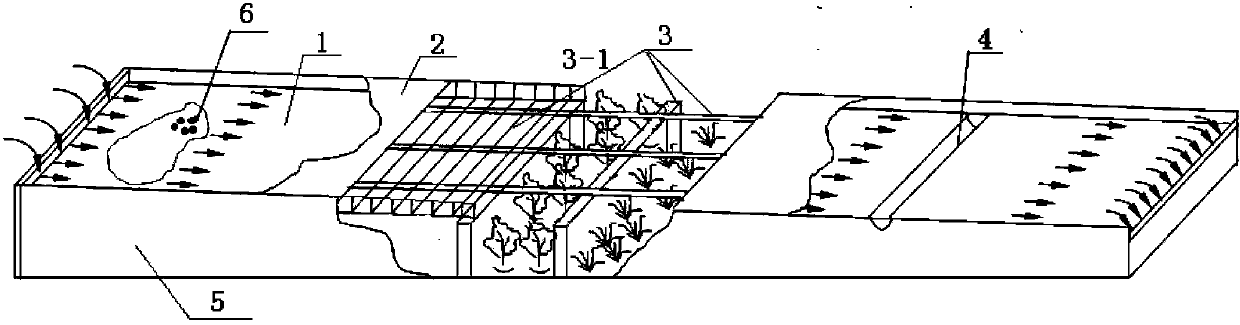

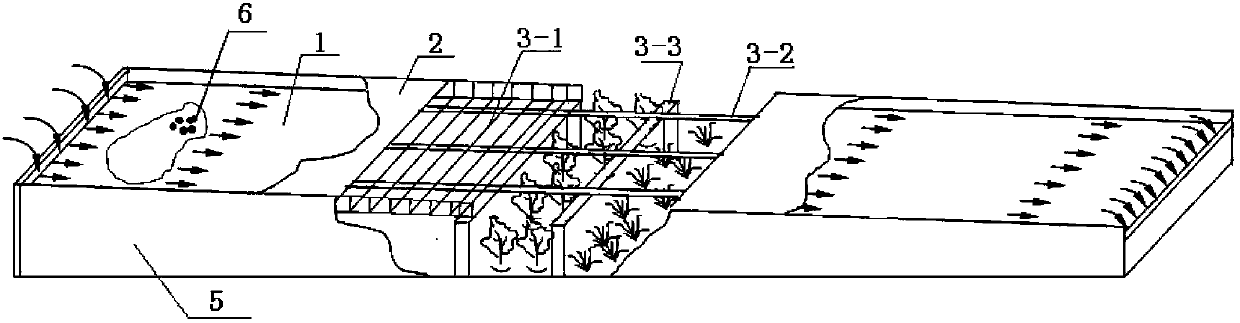

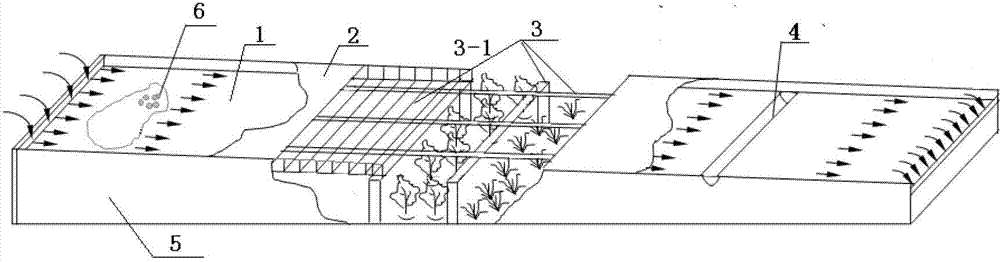

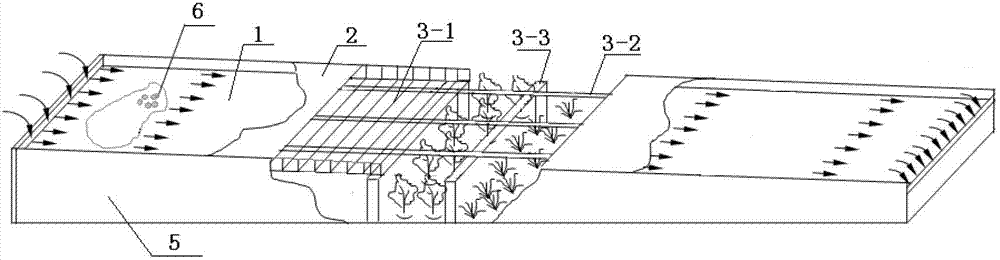

Thin-layer breeding multiple production system

ActiveCN103361259ARealize three-dimensionalRealize resource utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseClosed loop

The invention relates to a thin-layer breeding multiple production system. The multiple production system comprises a thin-layer breeding system and a greenhouse system, wherein the thin-layer breeding system comprises a breeding device and a circulatory system; the breeding device comprises a bottom surface and a corresponding support frame; the breeding device is in a closed loop connection with the circulatory system; and the greenhouse system is disposed below the breeding device. The support frame of the thin-layer breeding system, as a main structure body of the greenhouse system, combines the thin-layer breeding system and the greenhouse system, so that plant and animal breeding can be developed while carrying on microalgae breeding, thereby realizing stereoscopic and resourceful utilization of land and providing novel mode for developing ecology energy and ecological agriculture.

Owner:ENN SCI & TECH DEV

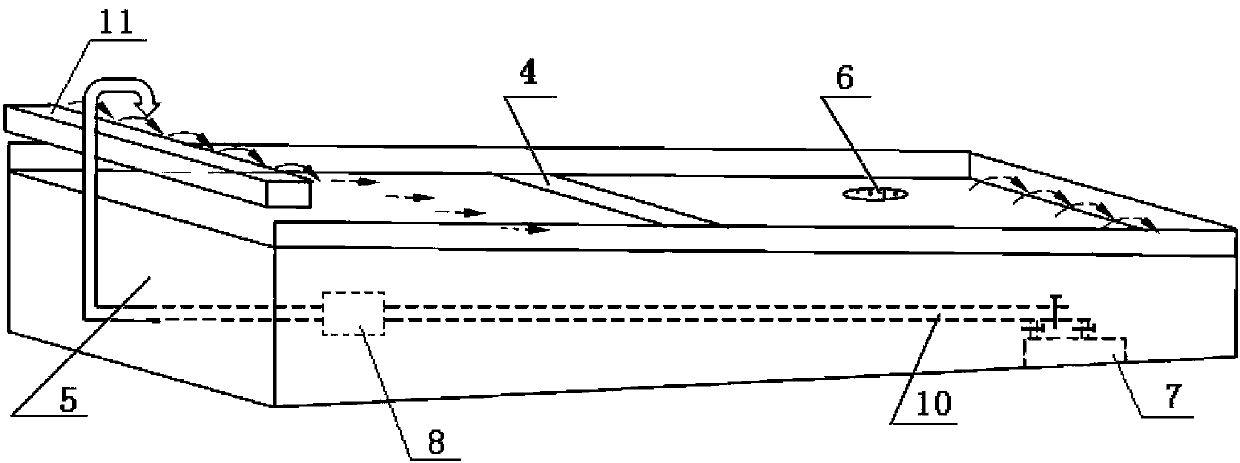

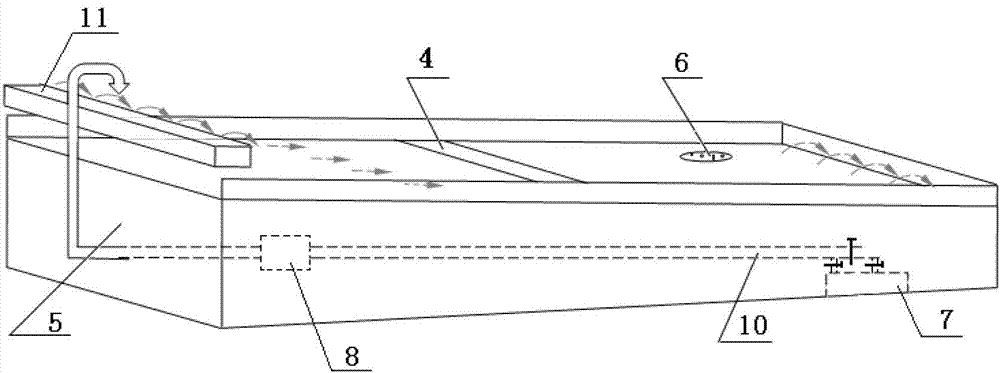

An anti-seepage and anti-liquefaction floating sluice foundation and its construction method

ActiveCN104727337BImprove stabilityLow construction precision requirementsFoundation engineeringEngineeringStructural engineering

The invention discloses a seepage-proofing and anti-liquefaction floating transportation sluice foundation. The floating transportation sluice foundation comprises a vacant box sluice bottom board arranged on the foundation, continuous closing sheet piles which are arranged around the vacant box sluice bottom board and submerged into the foundation, a concrete floor which is arranged around the vacant box sluice bottom board and connected with the pile tops of the continuous closing sheet piles, and a flexible sealing structure which is arranged between the vacant box sluice bottom board and the concrete floor so as to achieve flexible sealing closing between the vacant box sluice bottom board and the concrete floor. The invention further discloses a construction method of the seepage-proofing and anti-liquefaction floating transportation sluice foundation. The seepage-proofing and anti-liquefaction floating transportation sluice foundation and the construction method thereof have the advantage that the seepage problem of a floating transportation sluice and the liquefaction problem of the foundation can be solved at the same time through the prefabricated vacant box sluice bottom board, the concrete floor arranged around the vacant box sluice bottom board, the flexible sealing structure arranged between the vacant box sluice bottom board and the concrete floor, and the continuous closing sheet piles.

Owner:SHANGHAI WATER ENG DESIGN & RES INST

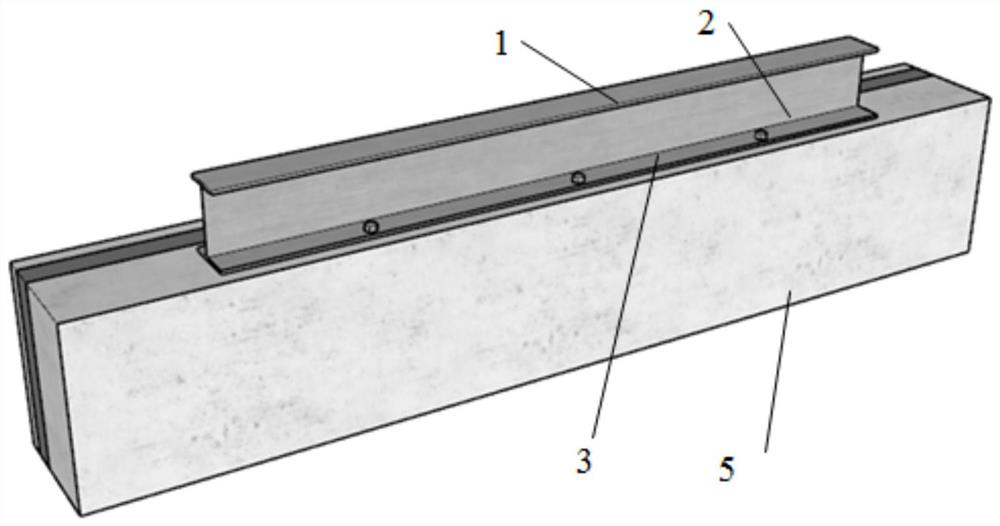

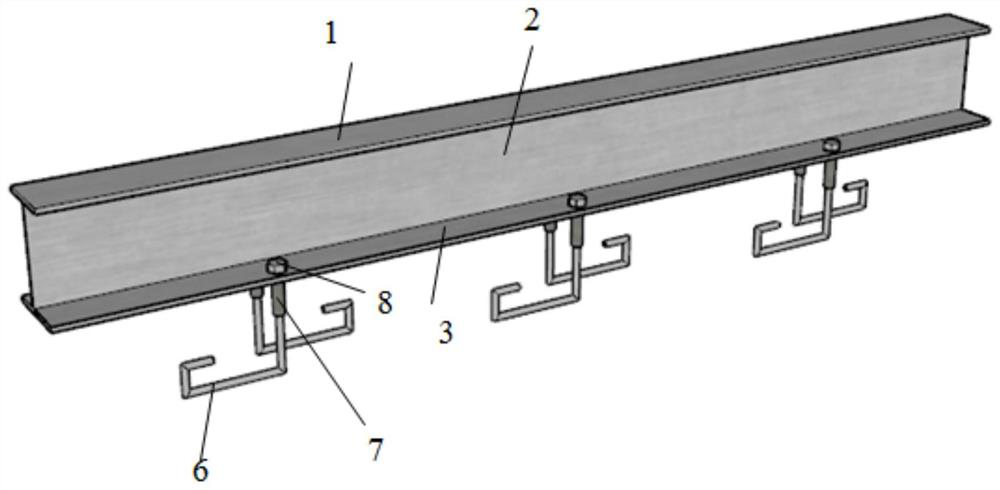

Slidable connection node of wallboard and H-shaped steel beam and construction method of node

The invention provides a slidable connection node of a wallboard and an H-shaped steel beam and a construction method of the node. The connection node comprises the H-shaped steel beam, the wallboardand a connector, the H-shaped steel beam comprises an upper flange, a web and a lower flange, and the connector comprises a connection plate, a bolt, a first sleeve and a second sleeve; the connectionplate is vertically fixed to the bottom of the lower flange and is parallel to the web, the connection plate is provided with a long circular hole, and the bolt penetrates through the first sleeve, the long circular hole in the connection plate and the second sleeve in sequence; the first sleeve and the second sleeve are in threaded connection with the bolt, and the bolt, the first sleeve and thesecond sleeve are embedded in the wallboard. According to the slidable connection node, when a building is subjected to a horizontal load, the overall wallboard slides in the length direction of thesteel beam, and the situation is avoided that the wallboard with high rigidity participates in resisting the horizontal load; it is guaranteed that the stress mode of the structure is matched with thedesign intention, and the demand for the lateral resisting property of parts, such as beams and columns, connected with the wallboard is lowered.

Owner:HARBIN INST OF TECH

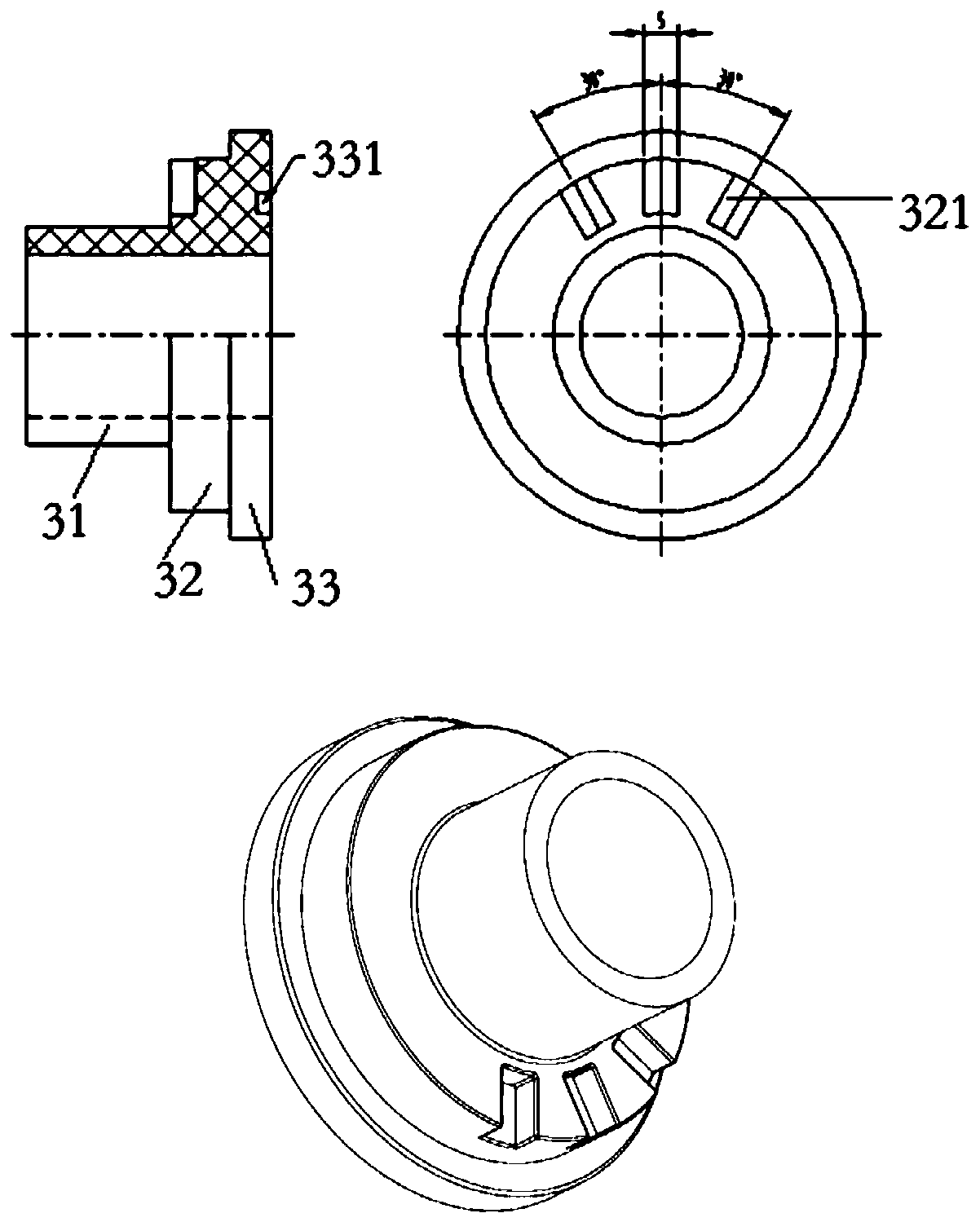

Cluster grouting sleeve assembling pier connected with prefabricated bearing platform and construction method

PendingCN111827093AReduce the numberLarge construction toleranceBridge structural detailsFoundation engineeringPre stressArchitectural engineering

The invention provides a cluster grouting sleeve assembled pier connected with a prefabricated bearing platform and a construction method. The pier comprises a foundation, a pier column section and atop cap section. The foundation is formed by connecting foundation prefabricated sections through foundation connecting seams, connecting steel bars are pre-buried in the top surfaces of the foundation prefabricated sections and the prefabricated pier column sections, bundling connecting sleeves are pre-buried in the bottom surfaces of the corresponding prefabricated pier column sections and the prefabricated top cap sections, the pre-buried connecting steel bars penetrate into the bundling connecting sleeves, and then high-strength grouting materials are poured into the bundling connecting sleeves. The top cap connecting sections and the top cap section are connected through top cap splicing seams, and then the connecting bolts are connected with the connecting sleeves; steel strands penetrate through pre-buried corrugated pipes pre-buried in the top cap sections, pier column sections and foundation prefabricated sections to be pre-embedded with corrugated pipes., the corrugated pipesare embedded in the top cap sections, the pier column sections and the foundation prefabricated sections, the steel strands are tensioned at the top of the top cap and in the foundation, then foundation connecting joints are constructed, and then concrete is poured to complete splicing. The spliced pier connecting steel bars are arranged in a bundled mode, the construction tolerance is large, theconstruction precision requirement is low, the splicing difficulty is small, the grouting efficiency is high, the top cap sections are quickly spliced, and prestress installation is convenient and fast.

Owner:CHINA RAILWAYS CORPORATION +1

A slidable connection node structure between wall panels and steel beams and its construction method

The invention provides a slidable connection node structure between a wall panel and a steel beam and a construction method thereof. The connection node structure includes a steel beam, a wall panel and a connector, the steel beam includes an upper flange, a web and a lower flange, and the connector It includes two L-shaped embedded parts. One end of the L-shaped embedded part is a free end, and the other end is a connecting end. The connecting ends of the two L-shaped embedded parts are connected to one end of a sleeve. The other end is connected with a bolt passing through the lower flange. The two bolts are symmetrically arranged on both sides of the web, and the connection between the bolt and the lower flange is a long round hole. Two L-shaped embedded parts and corresponding sleeves All are pre-buried in the wall panel, and the wall panel is connected with the lower flange of the steel beam by bolts passing through the oblong hole on the lower flange and connecting with the corresponding sleeve. In the present invention, when the building is subjected to a horizontal load, the entire wall panel slides in the length direction of the steel beam, avoiding the participation of the rigid wall panel in resisting the horizontal load, and ensuring that the stress mode of the structure matches the design intention.

Owner:HARBIN INST OF TECH

Connecting structure for prefabricated concrete wall and concrete edge columns and construction method

PendingCN112376703AImprove integrityReduced cast-in-place operationsStrutsWallsArchitectural engineeringStirrup

Owner:SOUTH CHINA UNIV OF TECH +1

Prestressed anchoring structure system for pier assembly and pier assembly construction method

InactiveCN113605239AReliable anchoringLow pre-embedded construction requirementsBridge structural detailsBridge erection/assemblyArchitectural engineeringAssembly (construction)

The invention discloses a prestressed anchoring structure system for pier assembly and a pier assembly construction method. The prestressed anchoring structure system comprises a bonding type fixed end anchorage device located in a base, a clamping piece type tensioning end anchorage device located at the top of a pier column, a steel strand cable and an embedded pipe. The embedded pipe is divided into two sections; the embedded pipe section I is arranged in the pier column, the upper end of the embedded pipe section I is hermetically connected with an anchor bearing plate, and the lower end of the embedded pipe section I is positioned at the bottom of a pier column; the embedded pipe section II is arranged in the base, the upper end of the embedded pipe section II is positioned at a splicing surface sealing notch in the top surface of the base, and the lower end of the embedded pipe section II is hermetically connected with the top of the horn-shaped anchor bearing plate; a splicing surface sealing ring is mounted at the splicing surface sealing notch in the top surface of the base; in the assembly state, in an inner cavity of the horn-shaped anchor bearing plate, a steel strand bundle containing the extrusion head and poured high-strength mortar are bonded and anchored, and force is transmitted into the base through the horn-shaped anchor bearing plate; and the bottom of the horn-shaped anchor bearing plate is hermetically connected with the end cover plate. The fixed end of the prestressed anchoring structure system is reliably anchored, and the requirement for pre-embedded construction is low; and the structure is simple and the cost is low.

Owner:LIUZHOU OVM MASCH CO LTD

A thin-layer culture polygeneration system

ActiveCN103361259BRealize three-dimensionalRealize resource utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseClosed loop

The invention relates to a thin-layer breeding multiple production system. The multiple production system comprises a thin-layer breeding system and a greenhouse system, wherein the thin-layer breeding system comprises a breeding device and a circulatory system; the breeding device comprises a bottom surface and a corresponding support frame; the breeding device is in a closed loop connection with the circulatory system; and the greenhouse system is disposed below the breeding device. The support frame of the thin-layer breeding system, as a main structure body of the greenhouse system, combines the thin-layer breeding system and the greenhouse system, so that plant and animal breeding can be developed while carrying on microalgae breeding, thereby realizing stereoscopic and resourceful utilization of land and providing novel mode for developing ecology energy and ecological agriculture.

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com