Slot type and socket type combined connecting structure of prefabricated bridge substructure

A prefabricated assembly, combined connection technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of difficult matching of construction accuracy, uncontrollable grouting quality, unknown seismic performance, etc. The effect of increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

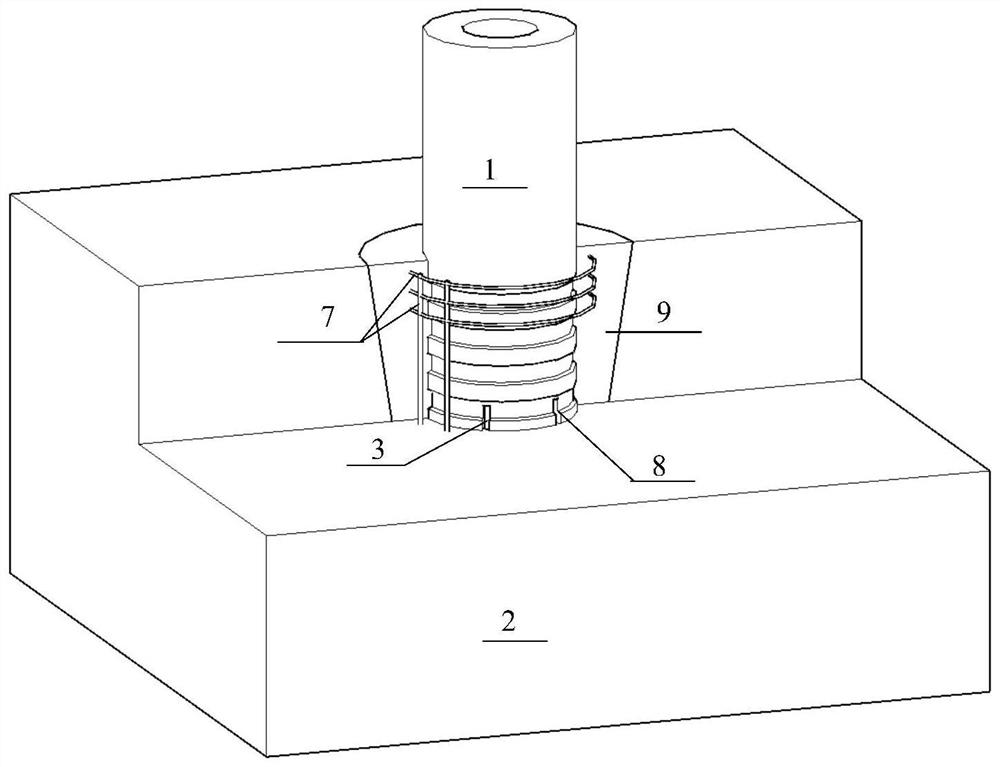

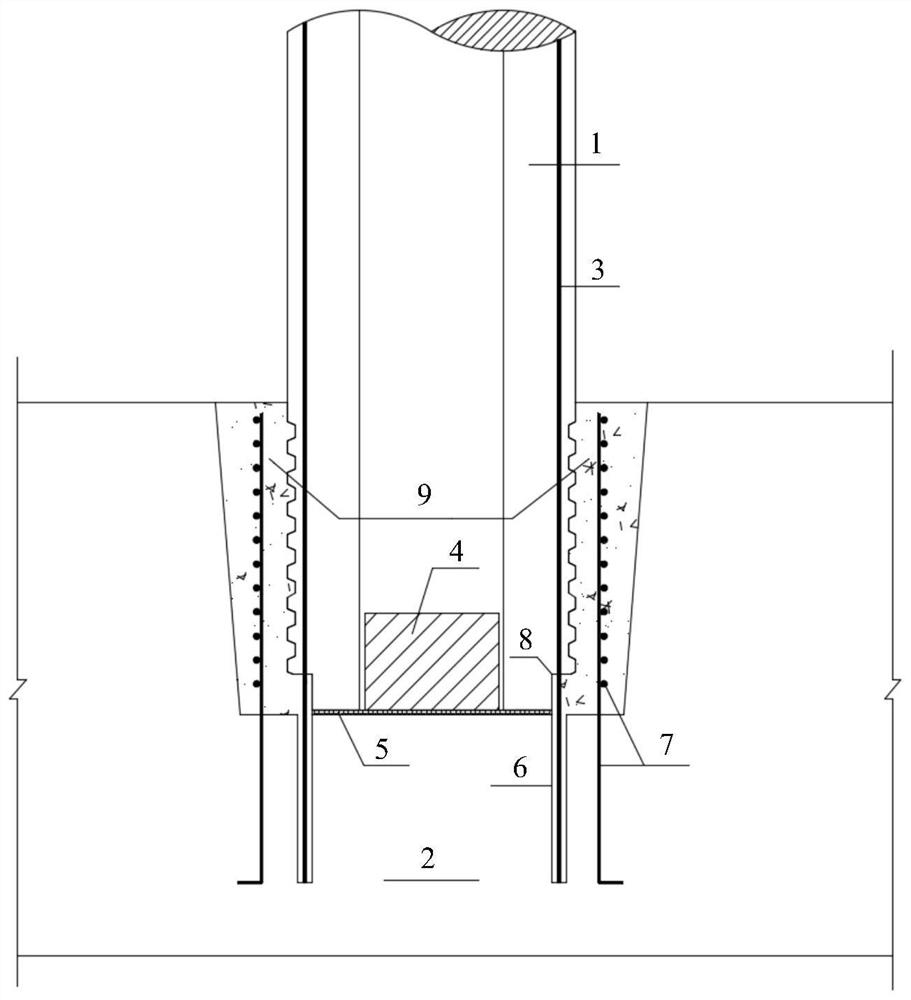

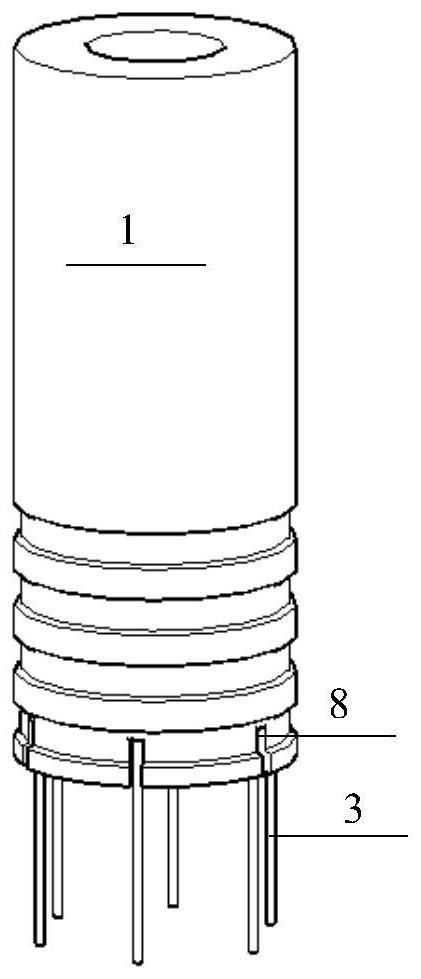

[0027] Example 1: See Figure 1~4 , a prefabricated assembled bridge substructure slot type and socket type combined connection structure, including prefabricated bridge pier 1, bearing platform 2, prefabricated bridge pier main reinforcement 3, positioning stopper 4, cushion layer 5, bellows 6, steel mesh 7 , steel formwork 8, rear pouring cup 9; the lower part of the prefabricated bridge pier 1 is made into a shear groove, and the surface is roughened before installation, and the lower part of the prefabricated bridge pier is embedded with a steel formwork 8, which is used for slotting the opening. The main reinforcements 3 of the prefabricated bridge piers are extended outwards, the caps 2 are provided with prefabricated bridge pier installation cups and positioning pads 4, pre-embedded steel mesh vertical reinforcement and bellows, the bottom surface of the prefabricated bridge piers and the caps are A mortar cushion layer 5 is arranged between the top surfaces of the cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com