Patents

Literature

54results about How to "Less prone to positional deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

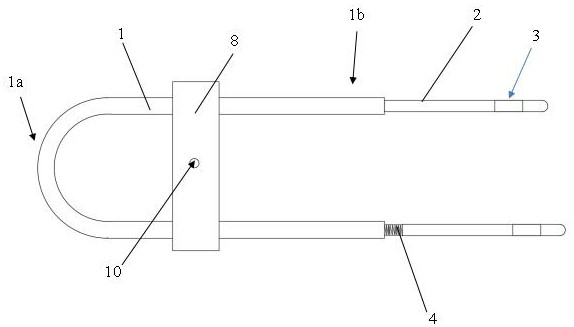

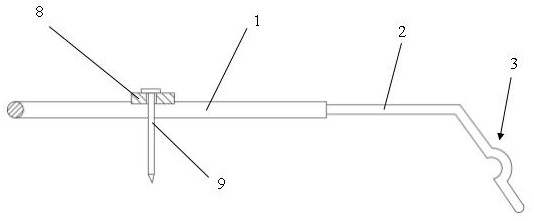

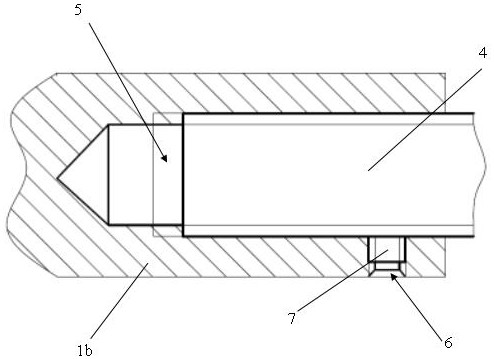

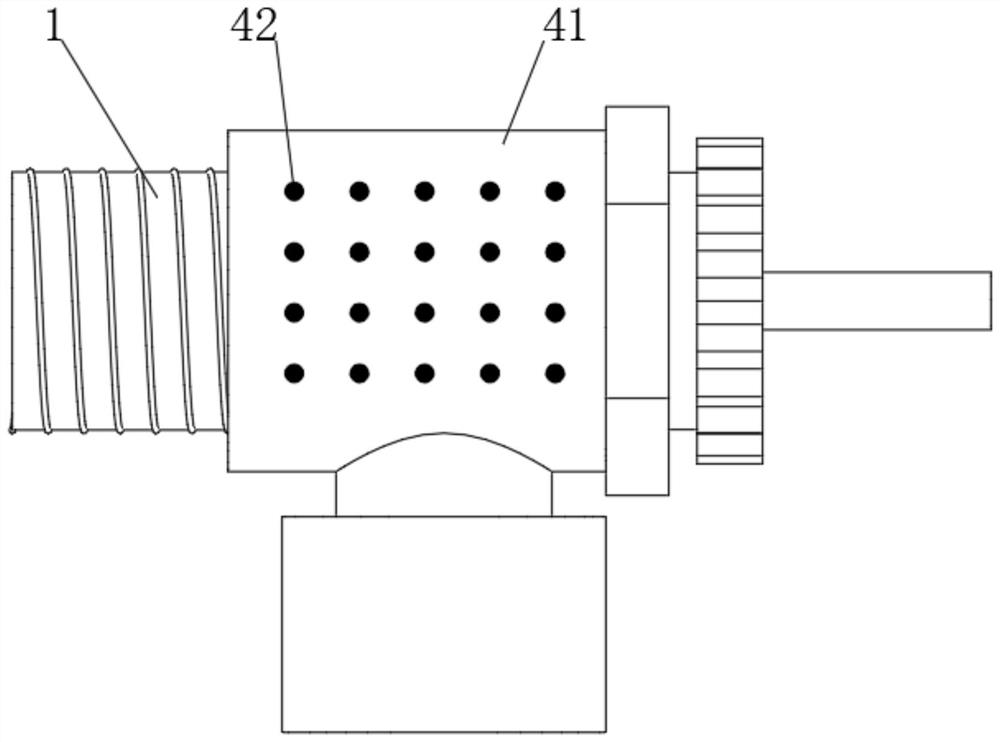

Optical fiber connector, method for manufacturing optical fiber connector, method for connecting optical fiber connector and optical fiber, and assembled body of optical fiber connector and optical fiber

InactiveCN104412139AEasy to carryLess prone to positional deviationCoupling light guidesOptical waveguide light guideFiberEngineering

Owner:RESONAC CORPORATION

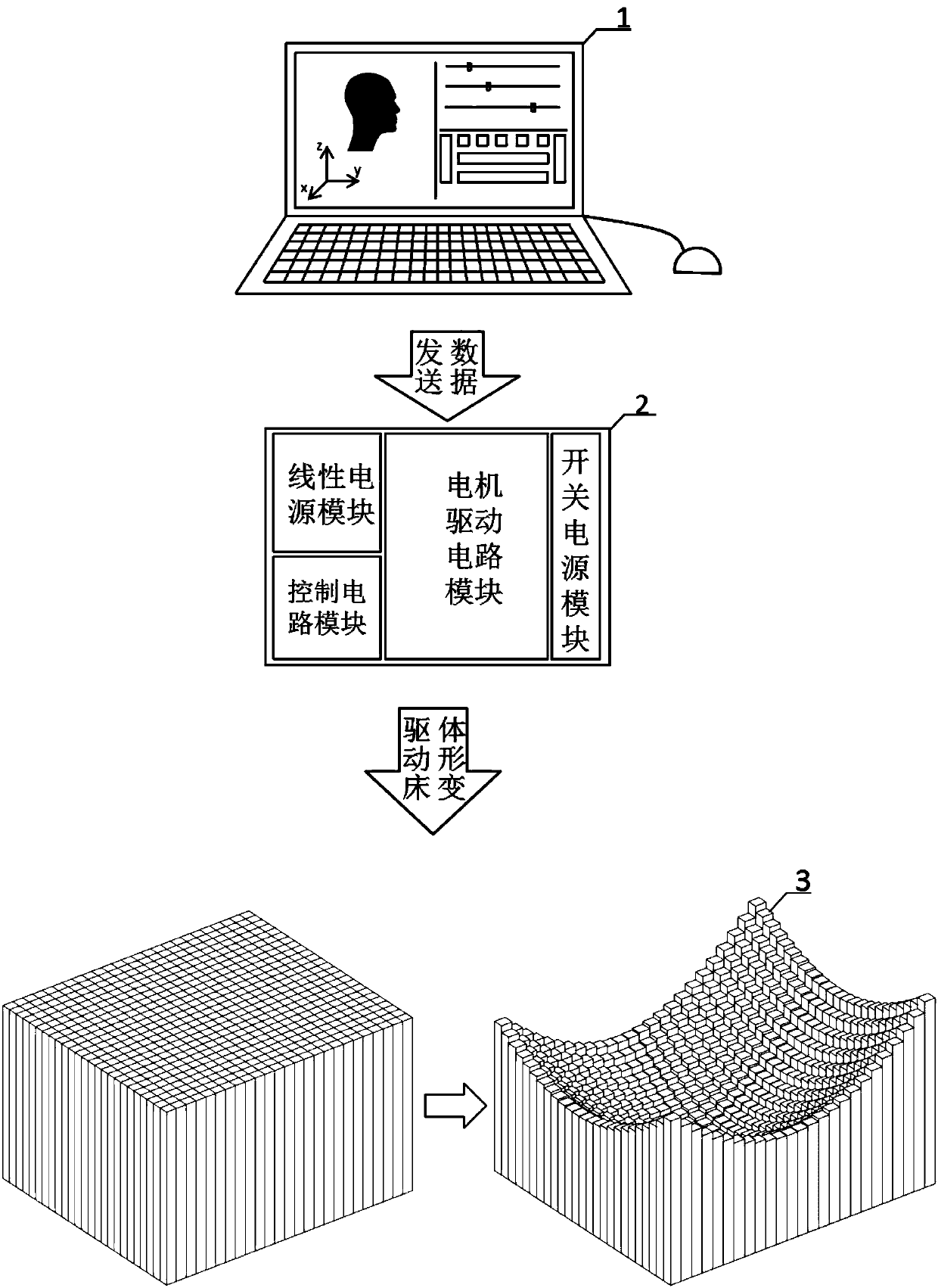

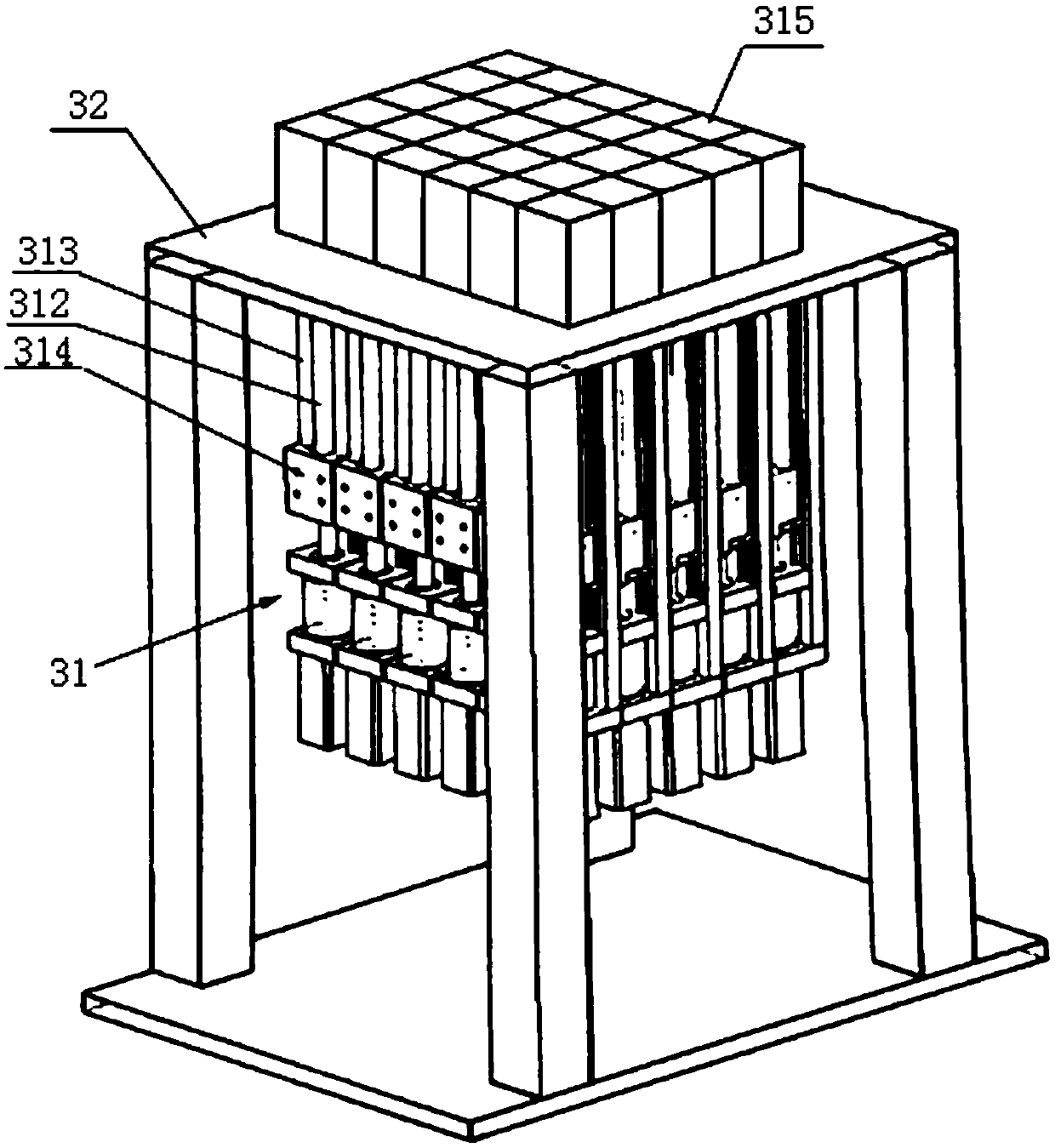

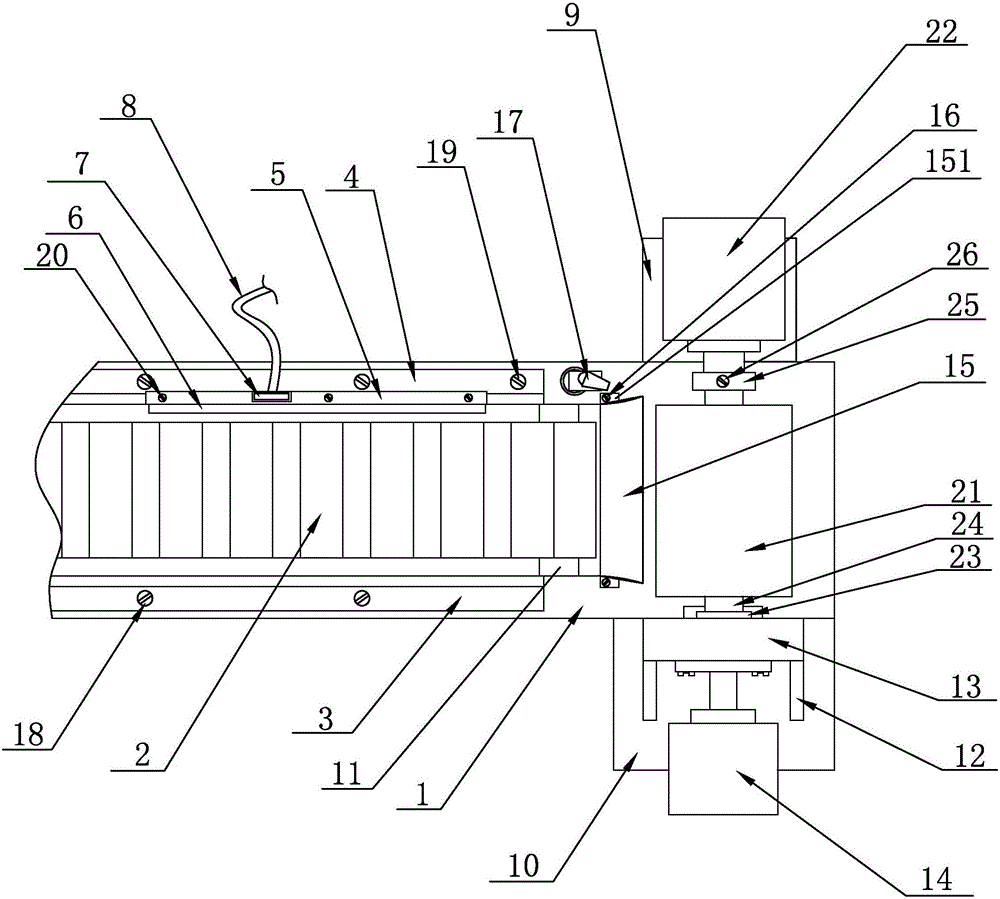

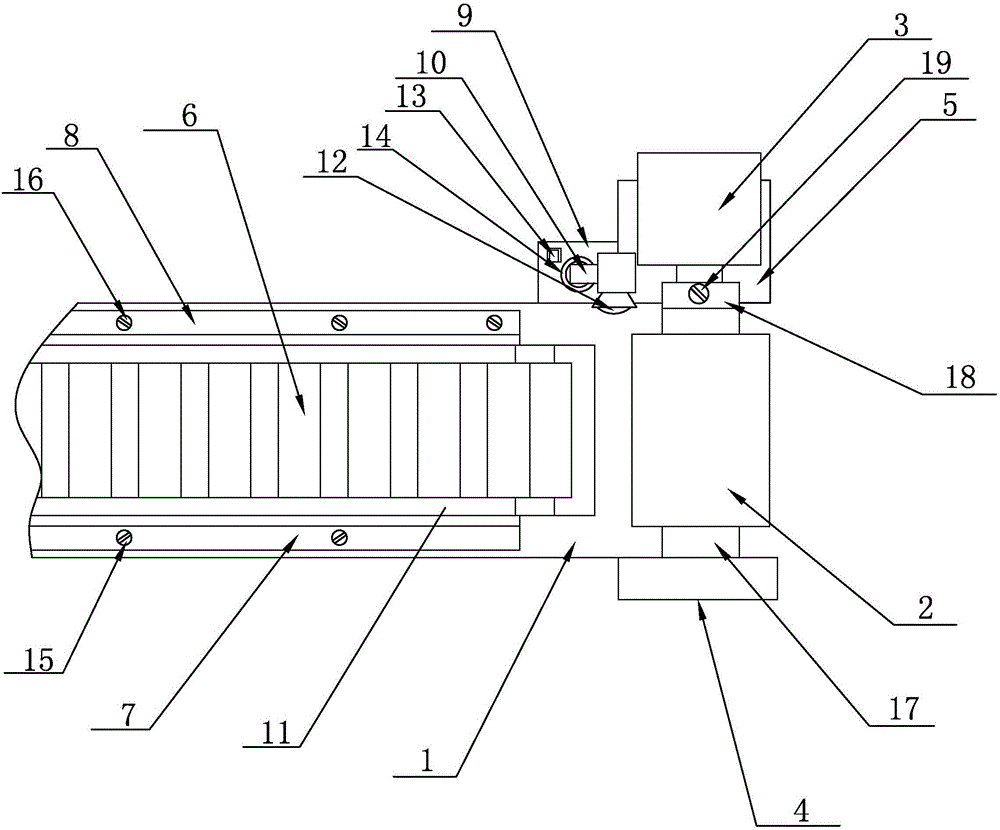

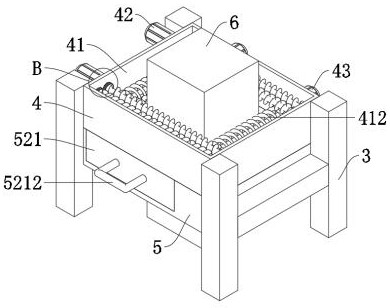

Arbitrary-hook-face radiotherapy bed system

ActiveCN109621234APositioning is accurateFixedX-ray/gamma-ray/particle-irradiation therapyToxicityEngineering

The invention discloses an arbitrary-hook-face radiotherapy bed system. The system comprises upper-computer software, a lower-computer control system and a therapy bed body, wherein the therapy bed body is a stereoscopic maneuvering device which is formed by splicing several lifting motor modules, after combined control of the upper-computer software and the lower-computer control system, an arbitrary hook face can be deformed at the top of the therapy bed body. The arbitrary-hook-face radiotherapy bed system is used for adjustment and stabilization of local posture of a curee during radiotherapy, and the posture which has the highest irradiation efficiency and the smallest radiation toxicity to normal tissue of the human body is adjusted.

Owner:SOUTH CHINA UNIV OF TECH

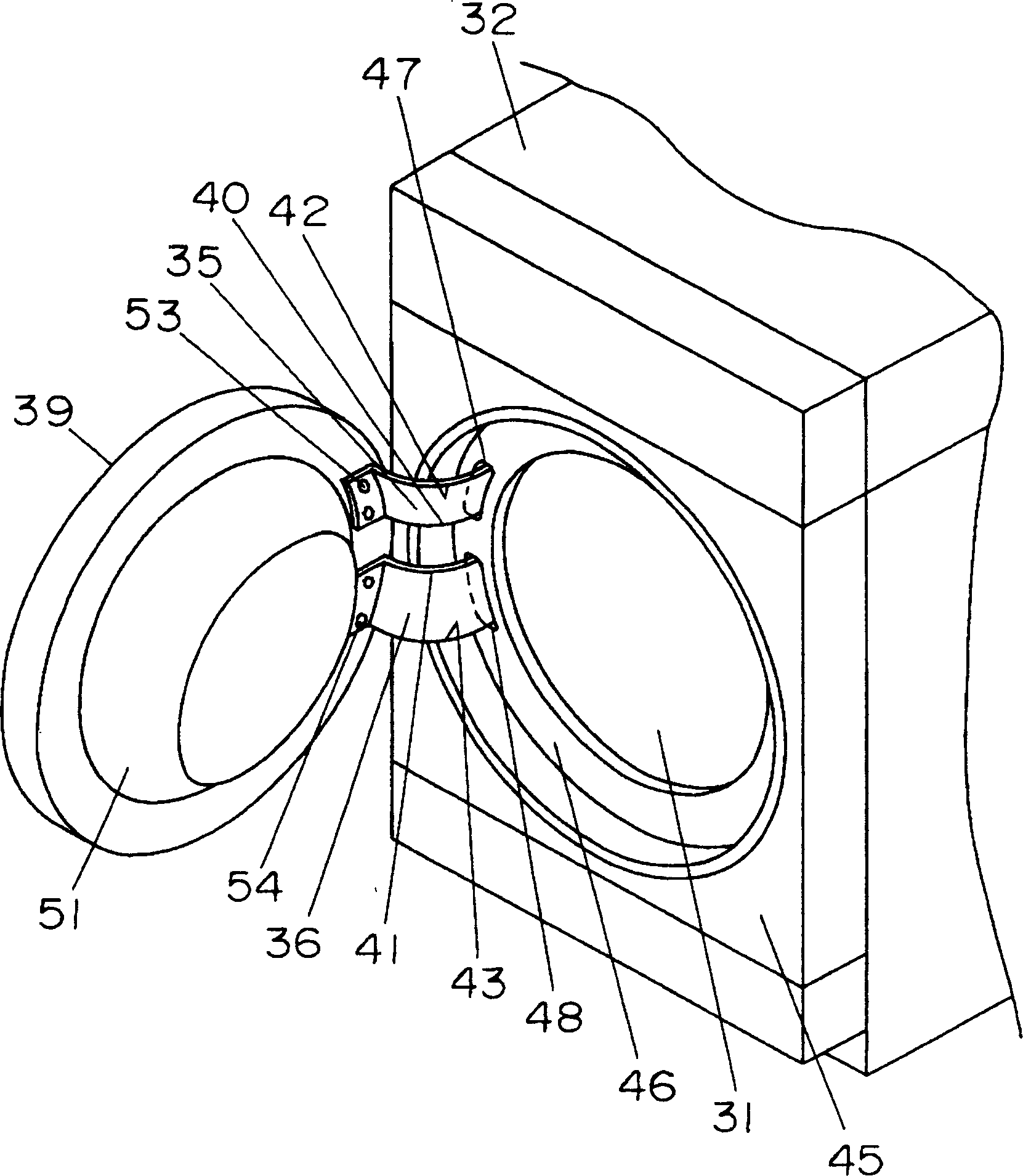

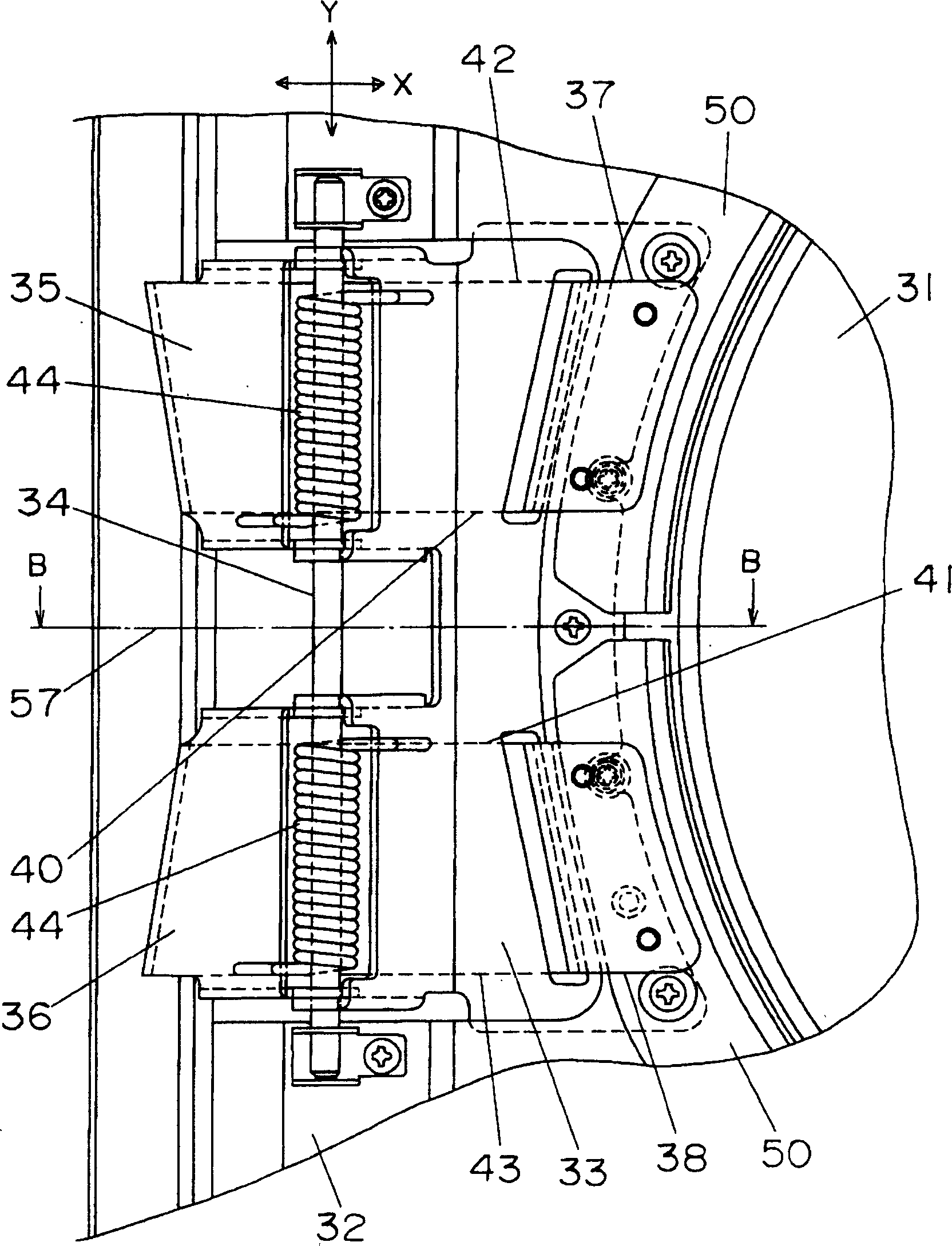

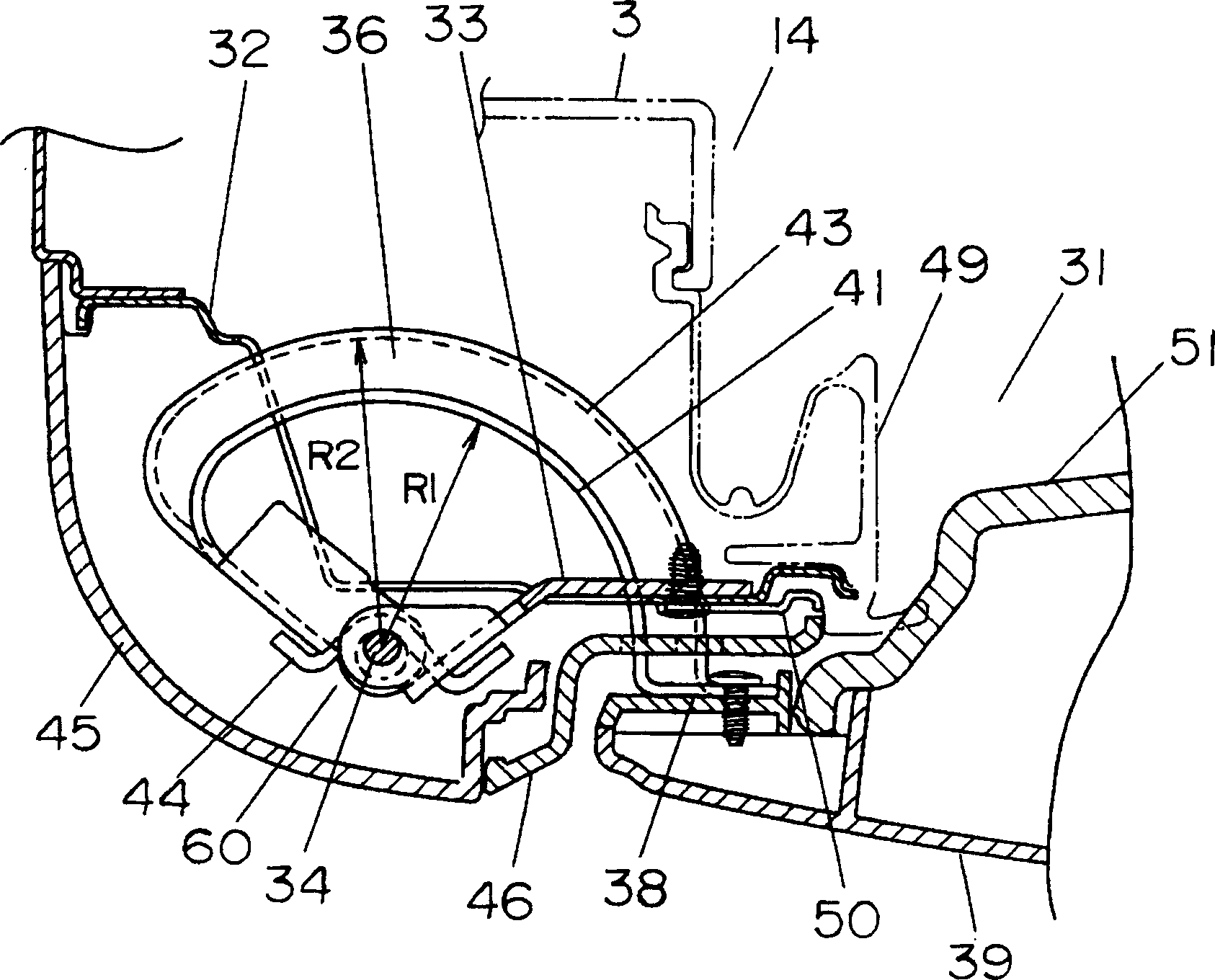

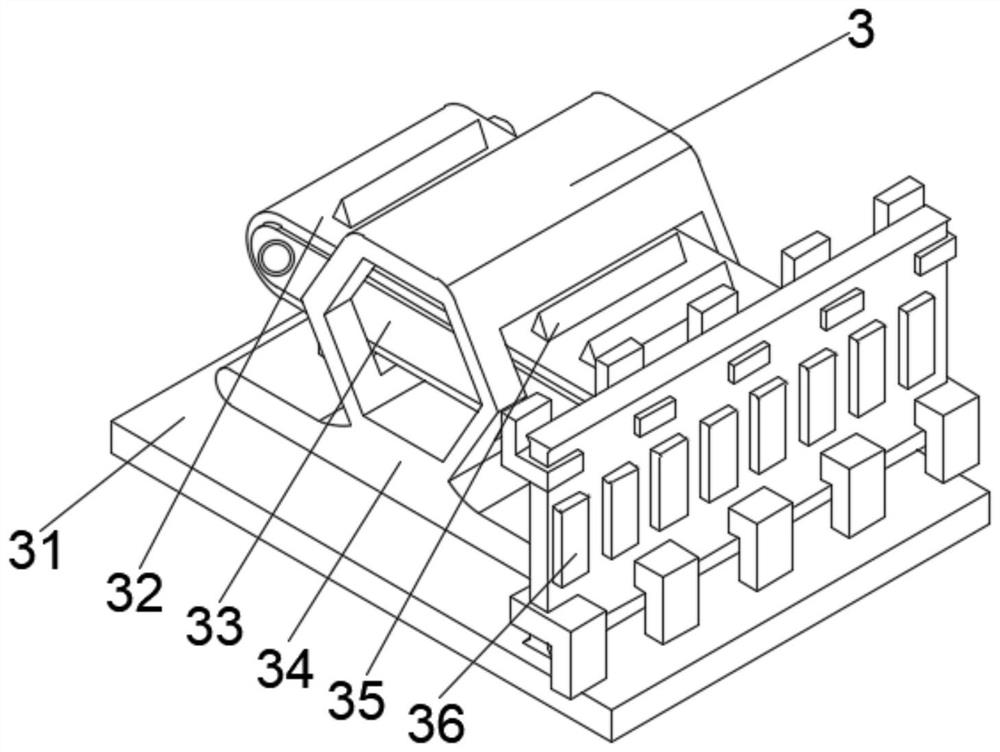

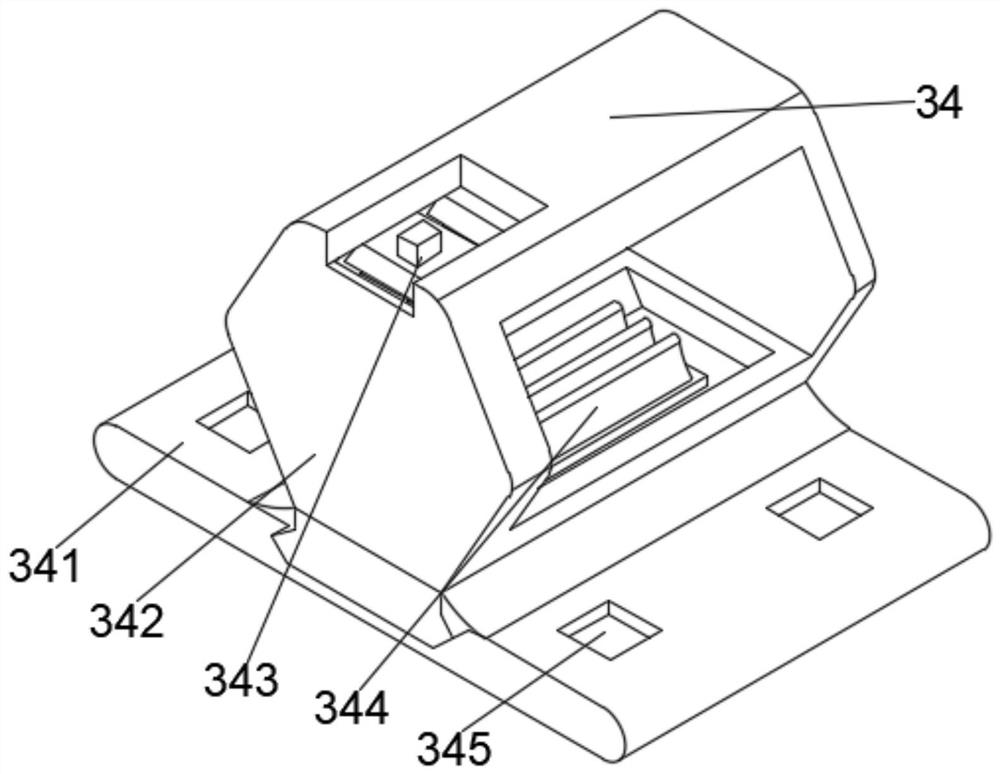

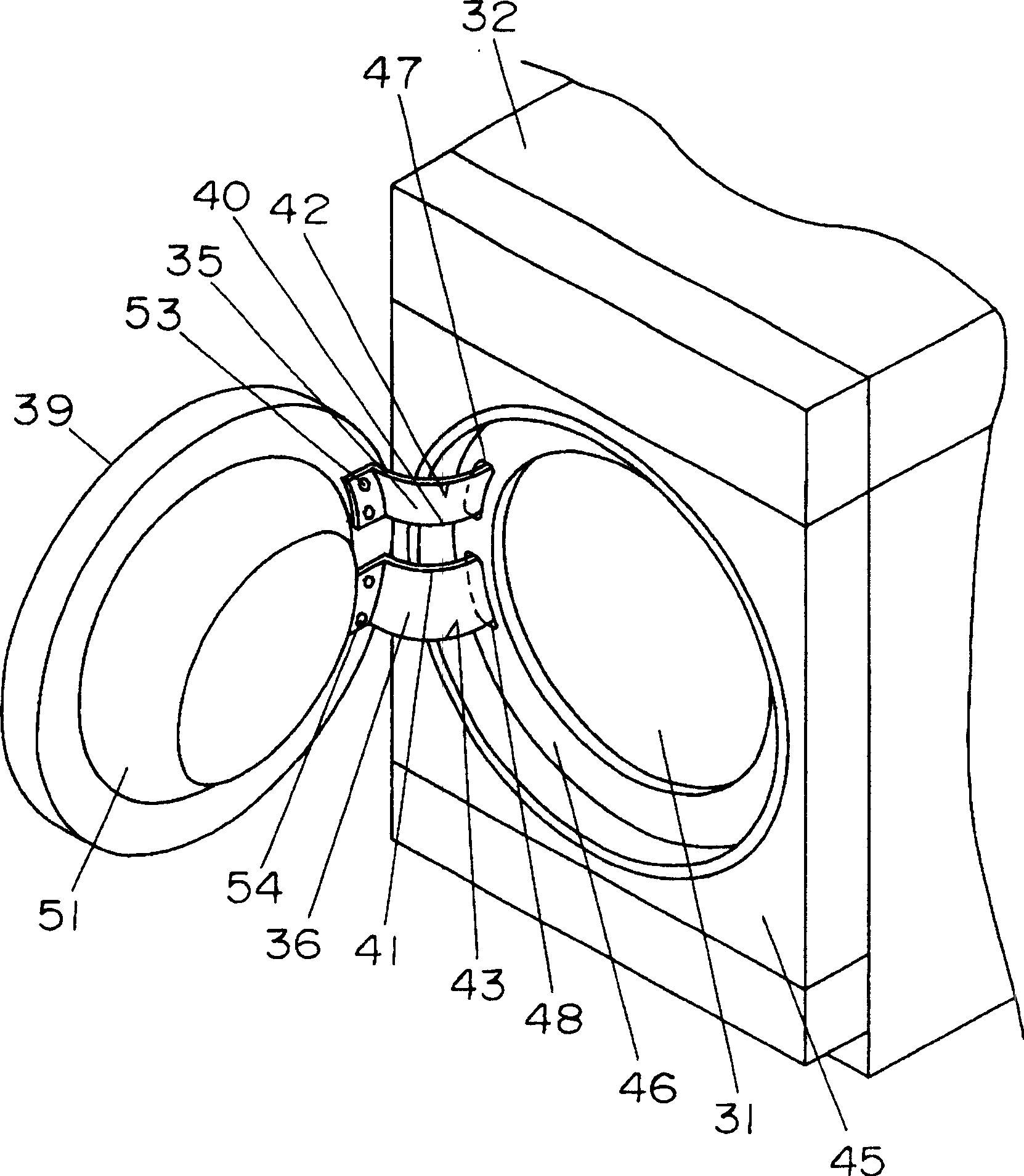

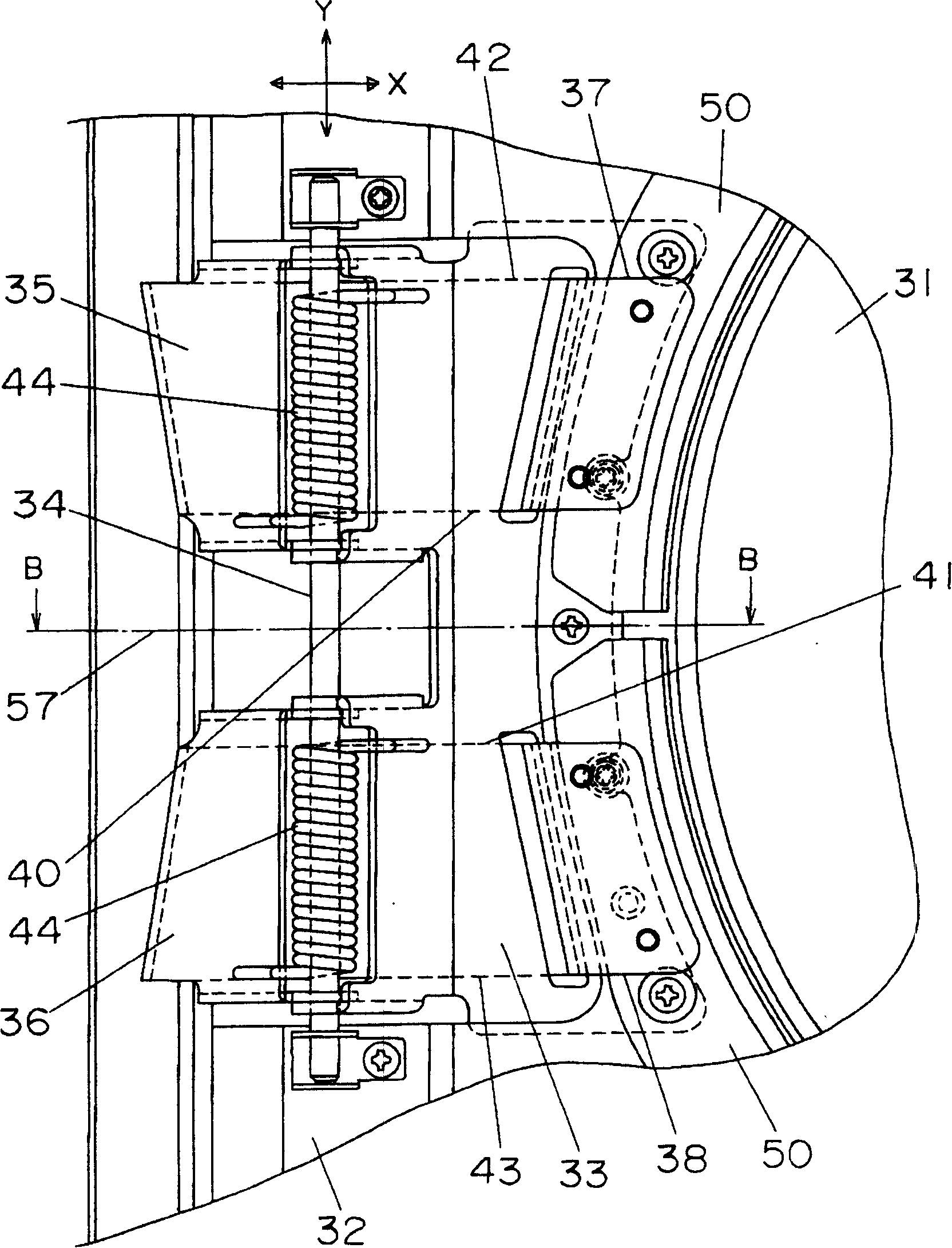

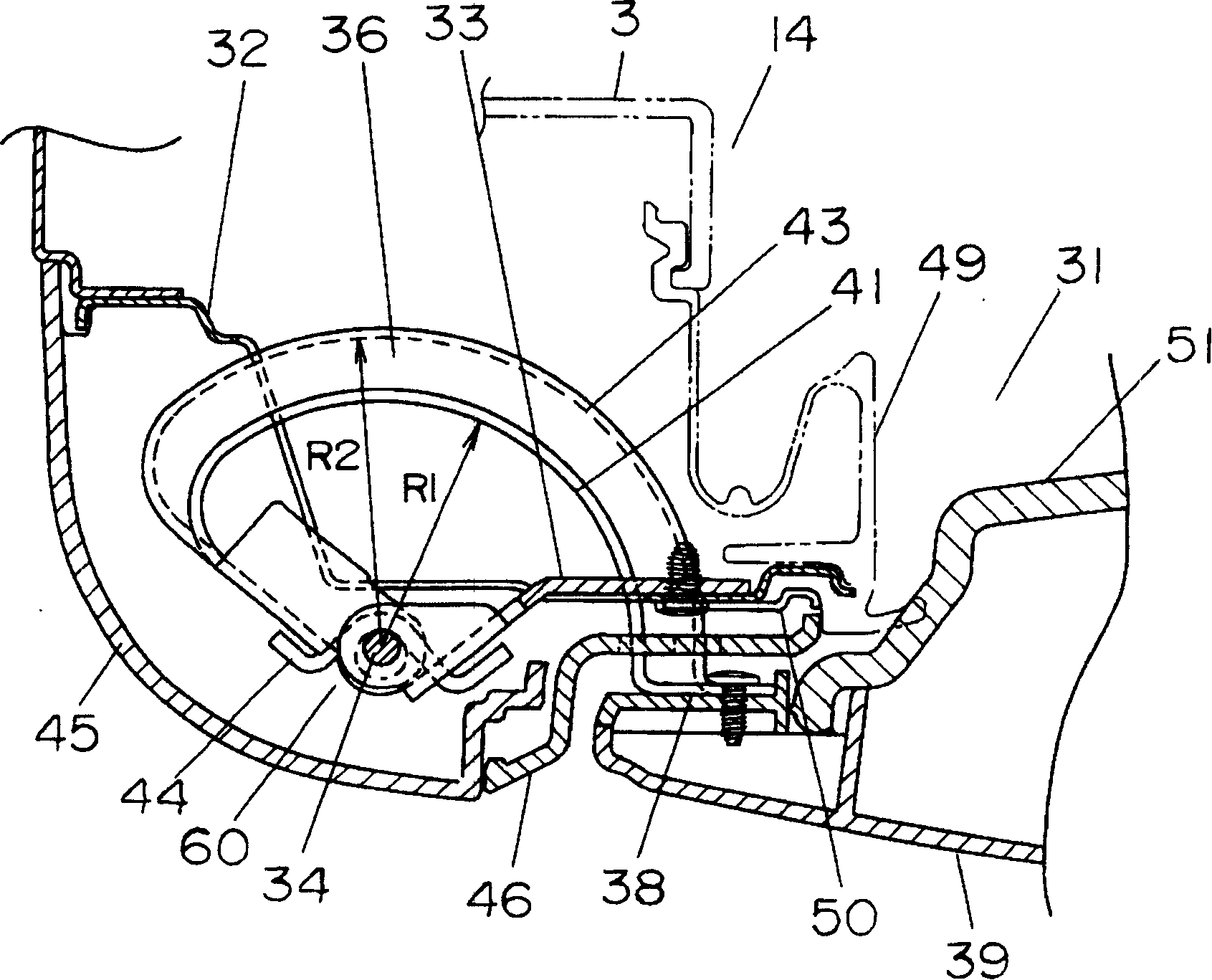

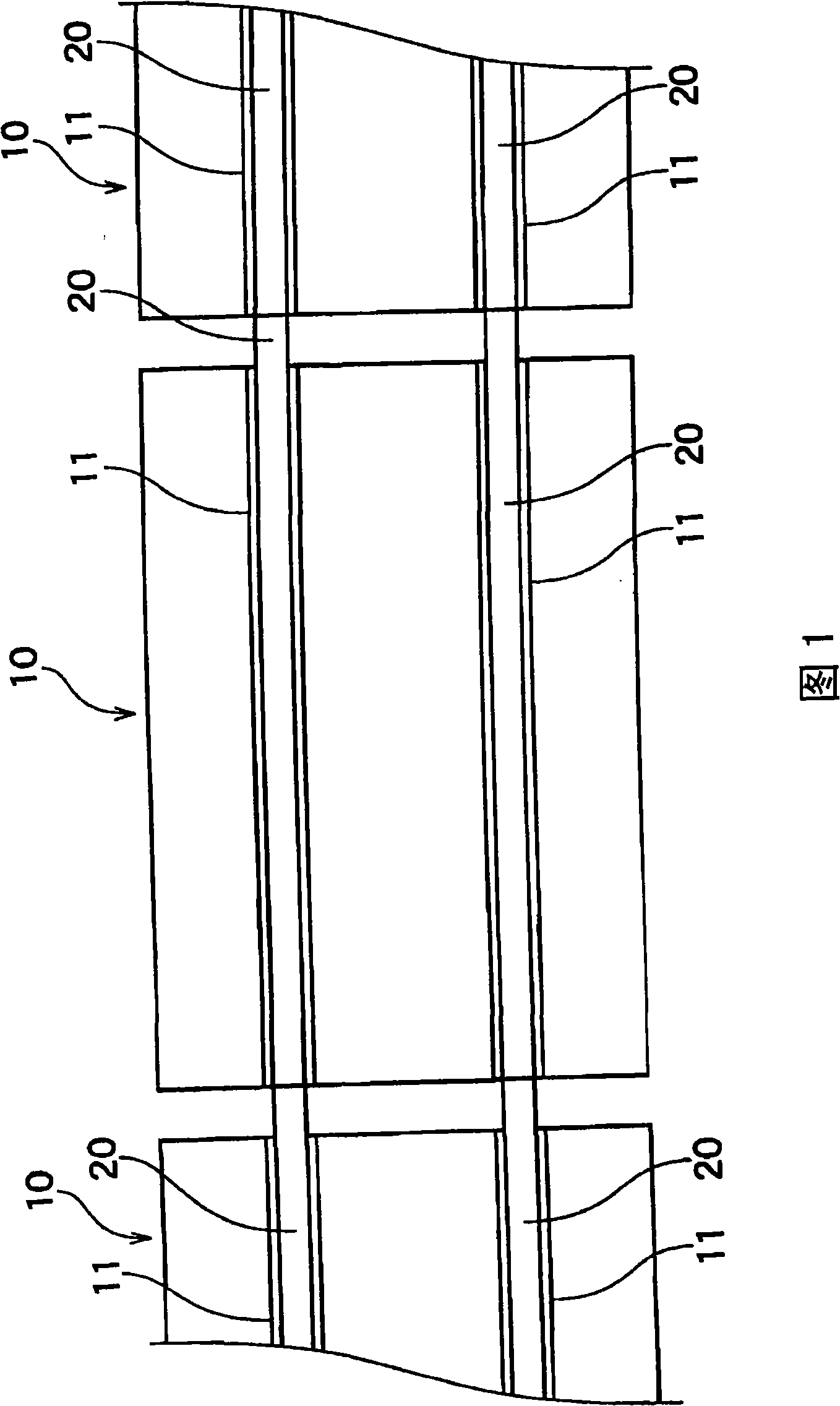

Drum washing machine

ActiveCN1584175AHigh strengthAvoid deformationOther washing machinesTextiles and paperLaundryEngineering

The present invention is a drum-type washing machine for washing clothes by rotating the drum, in which the strength of the connecting part connecting the body of the washing machine and the cover is improved, and the deformation that occurs when the cover is subjected to an excessive load can be prevented. , and at the same time, the position of the cover body is not easy to shift, and the watertight state when closed can also be kept stable. In the present invention, the front opening (31) of the washing machine body (32) is covered by a cover (39) in a freely openable and closed manner, and the washing machine body (32) is provided with a rotating shaft of the cover (39). The rotating shaft and the cover (39) are connected by two connecting members (35, 36). The two coupling members (35, 36) are substantially arc-shaped around the rotation shaft, and the radius of the arc-shaped portion becomes larger as the distance between them increases.

Owner:PANASONIC CORP

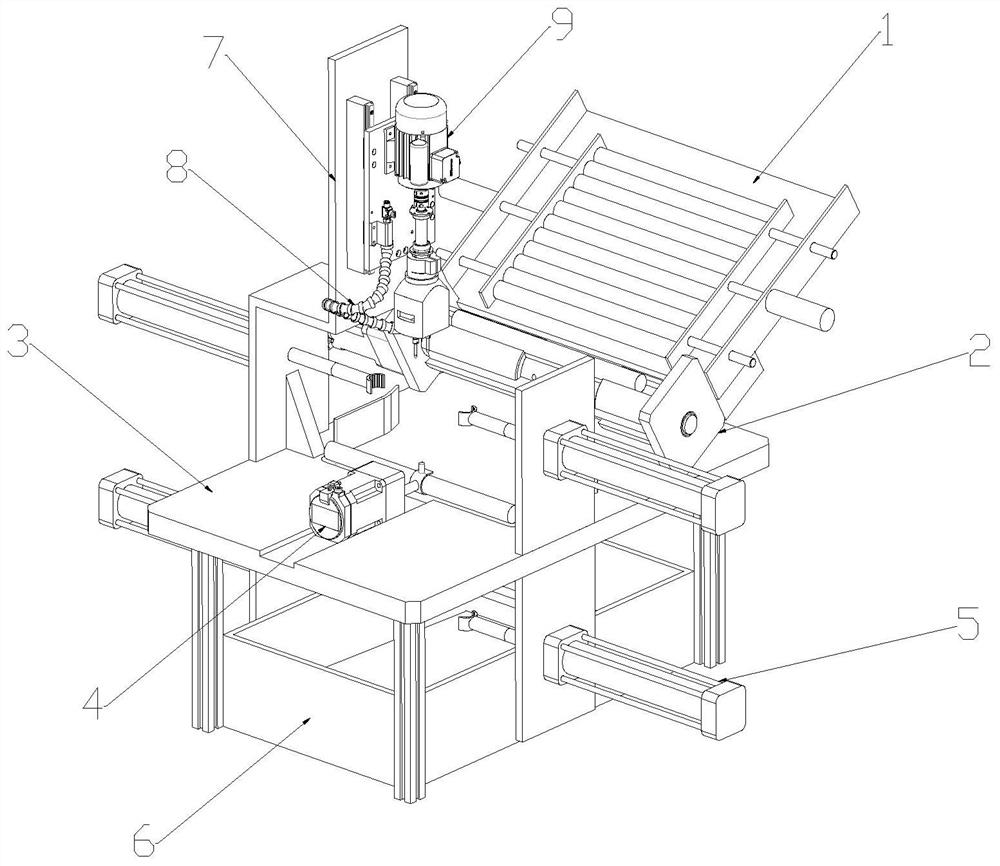

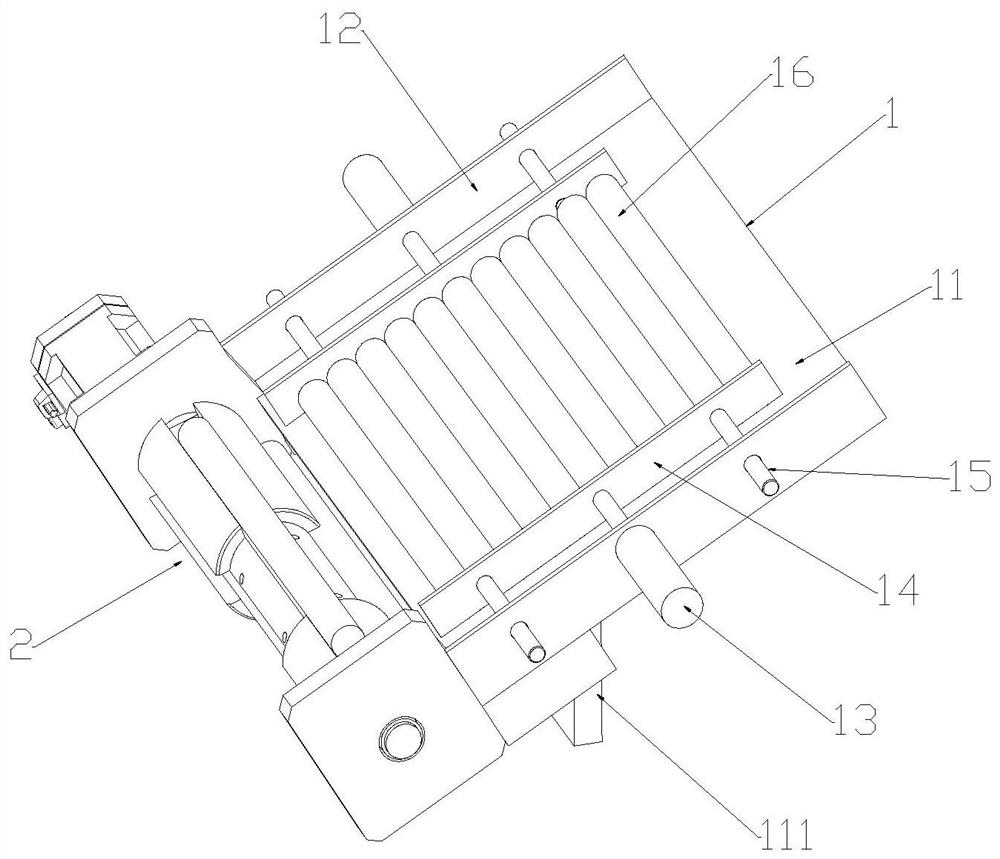

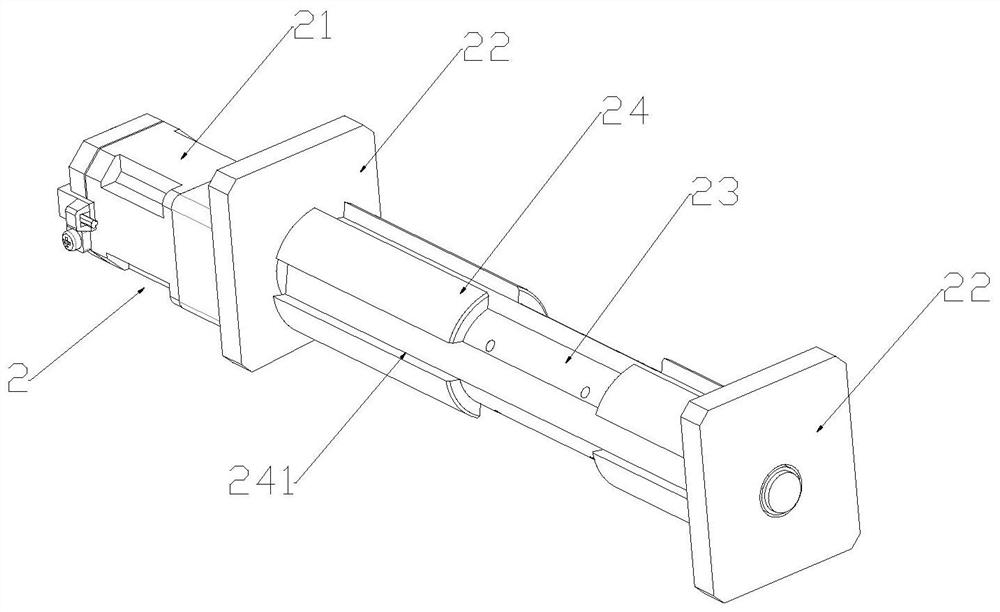

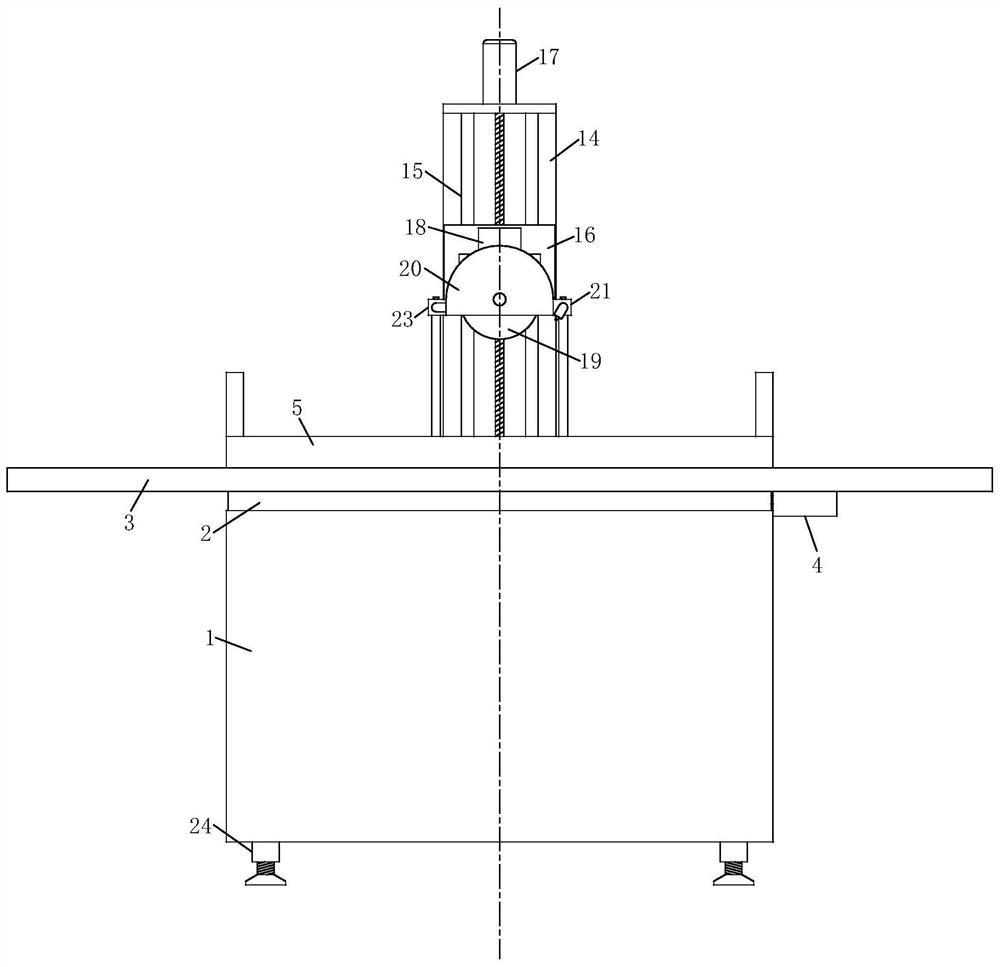

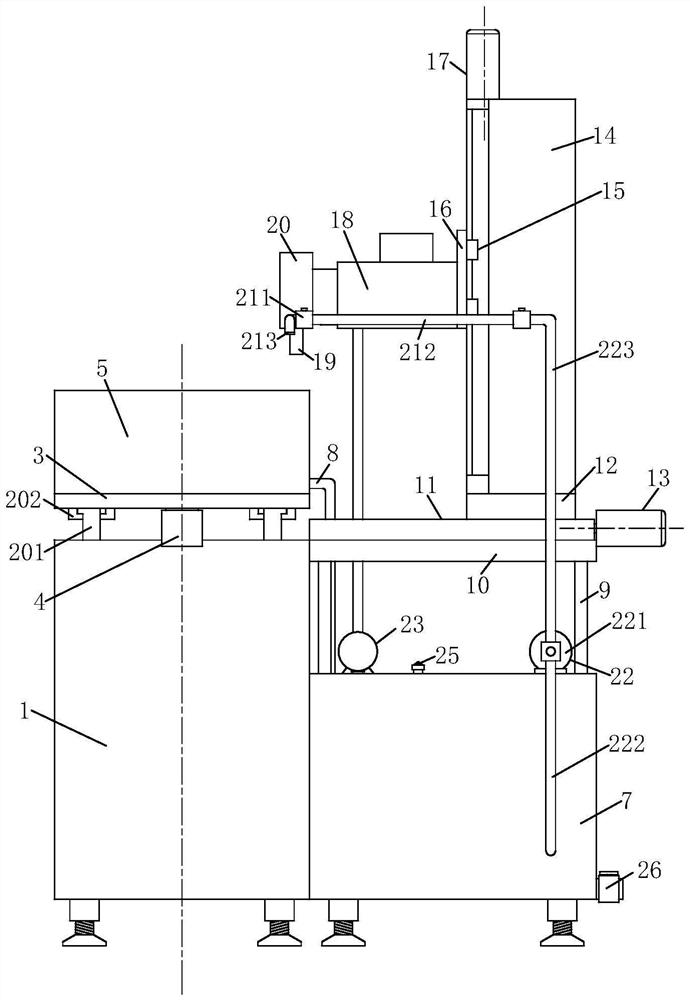

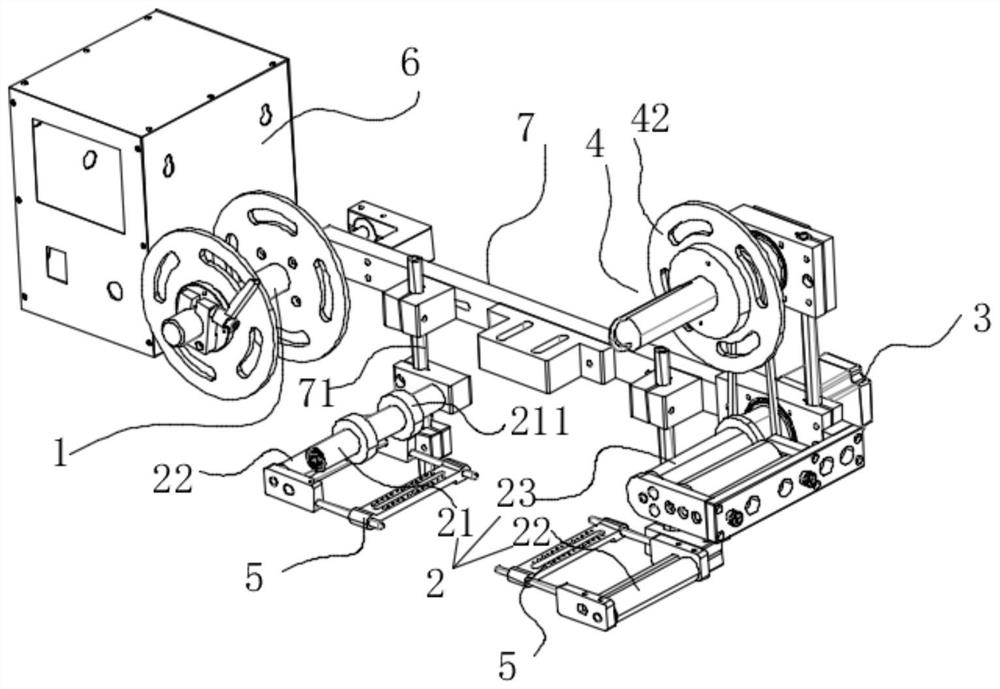

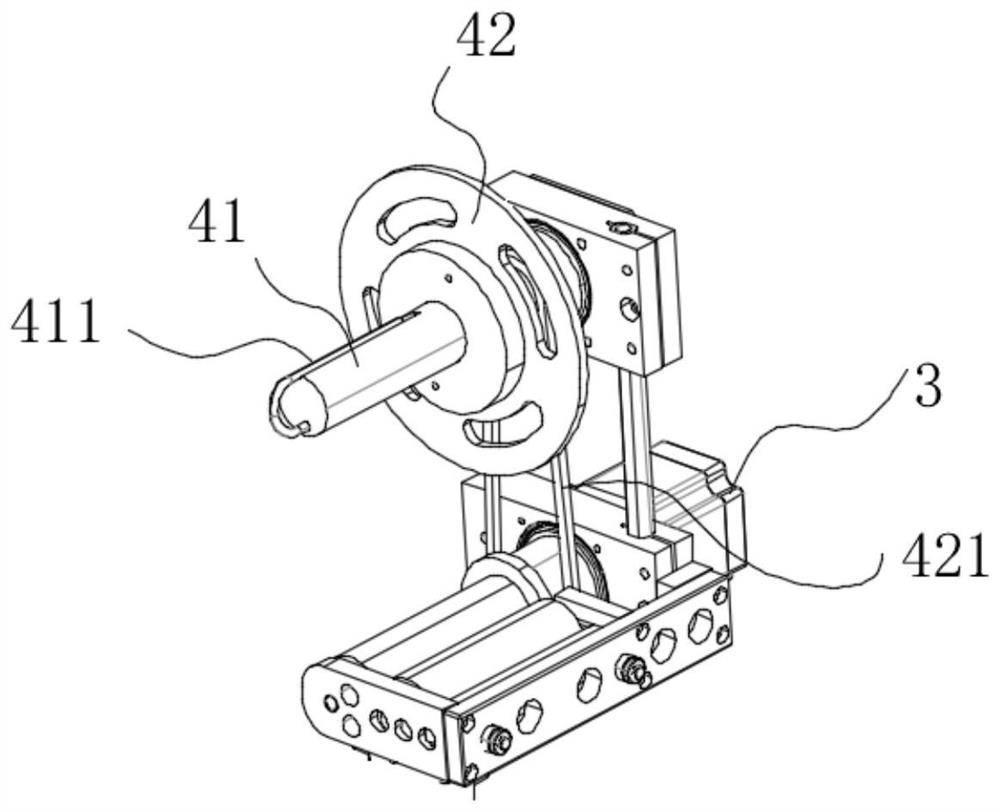

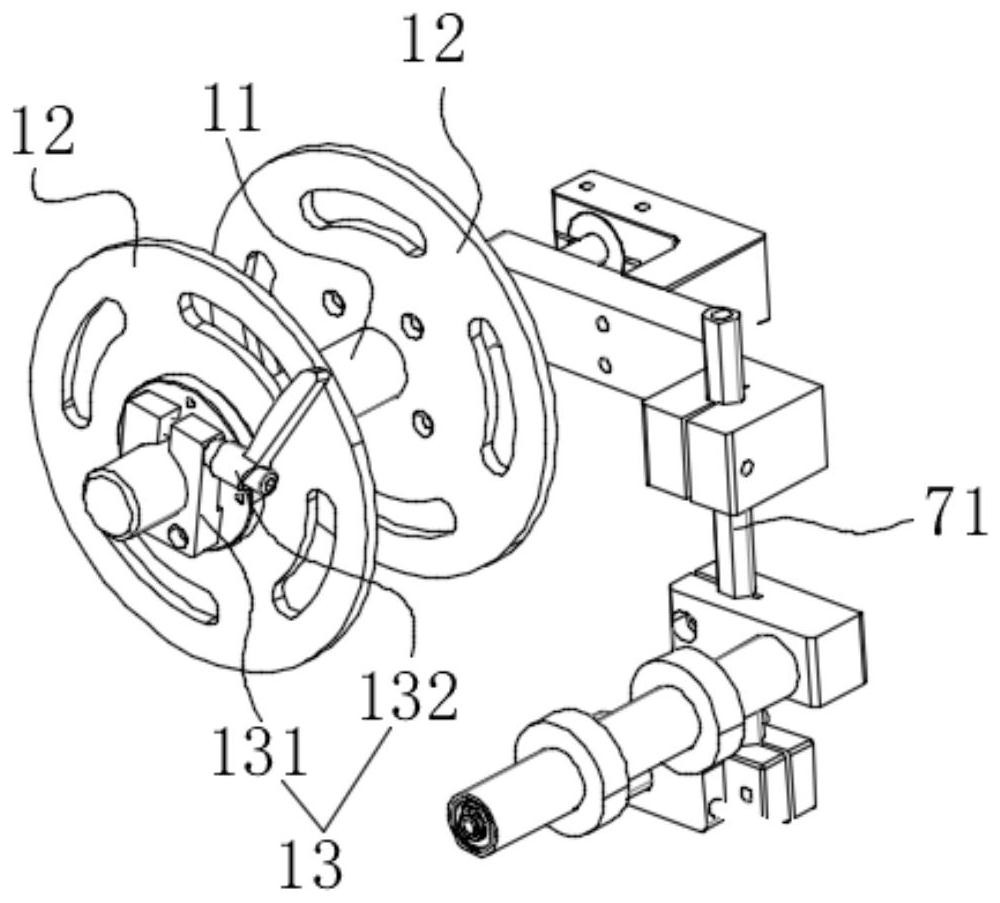

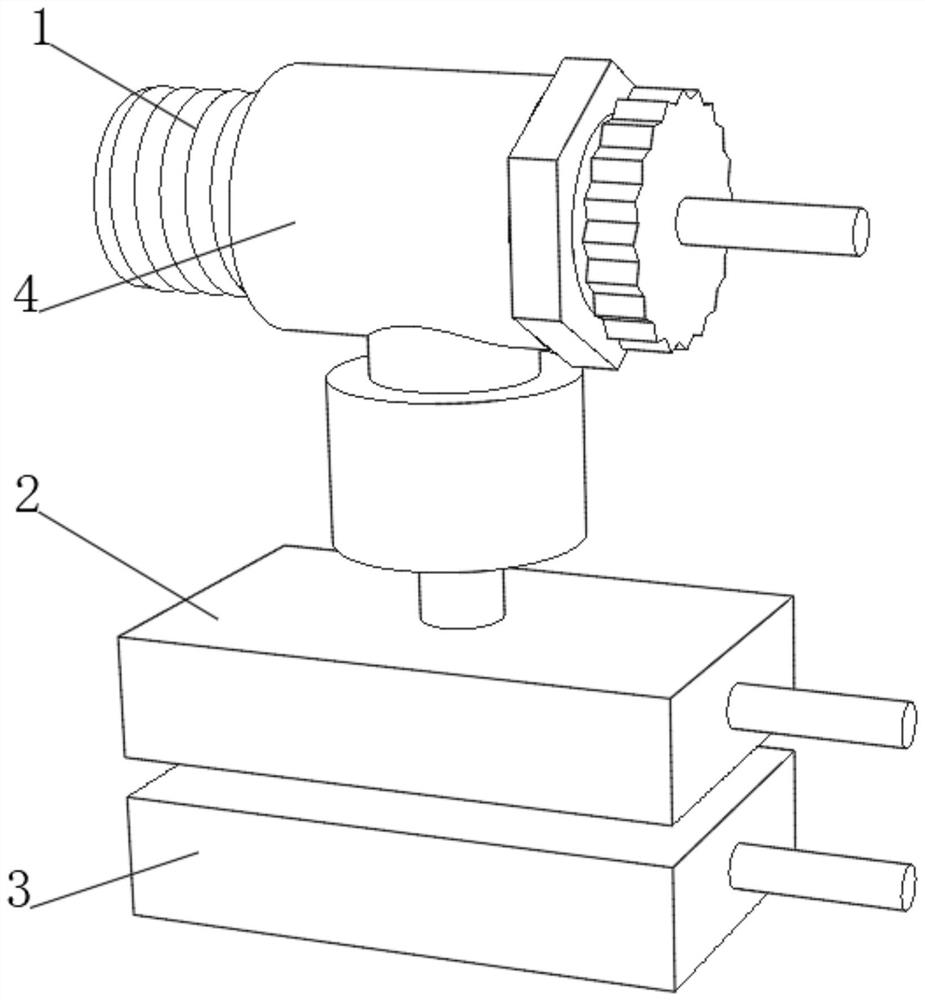

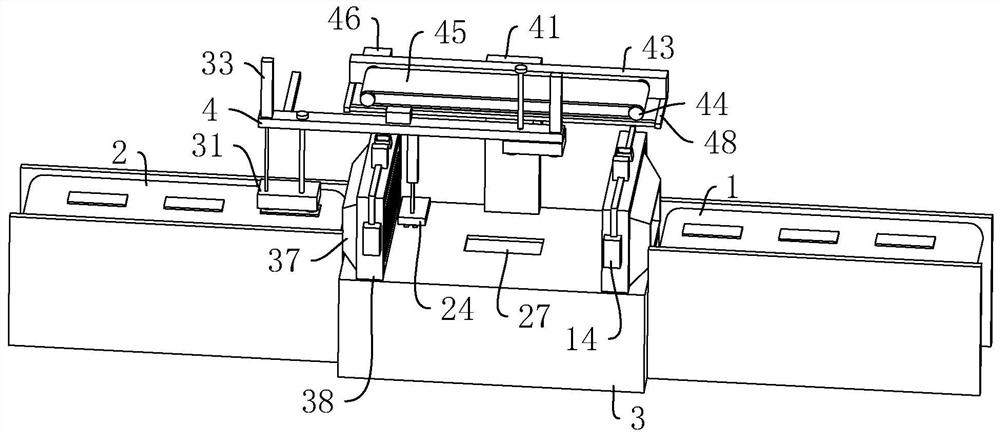

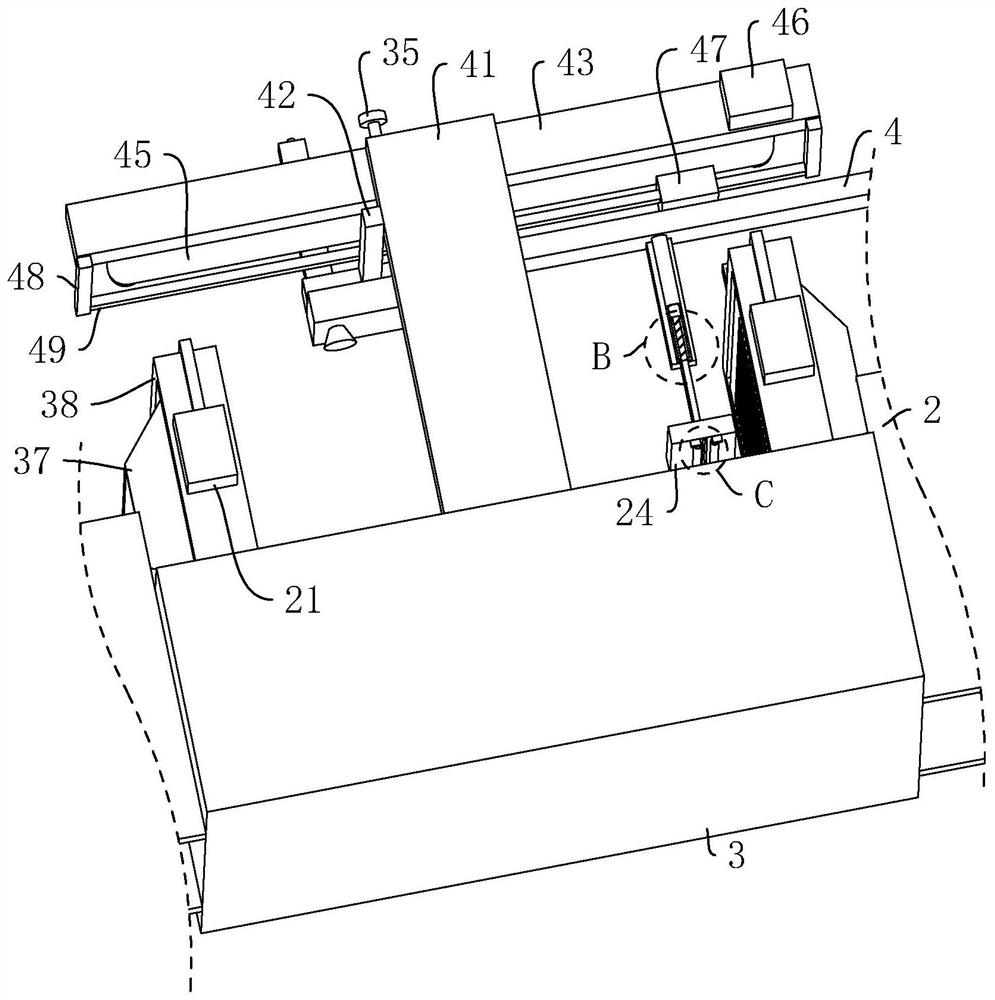

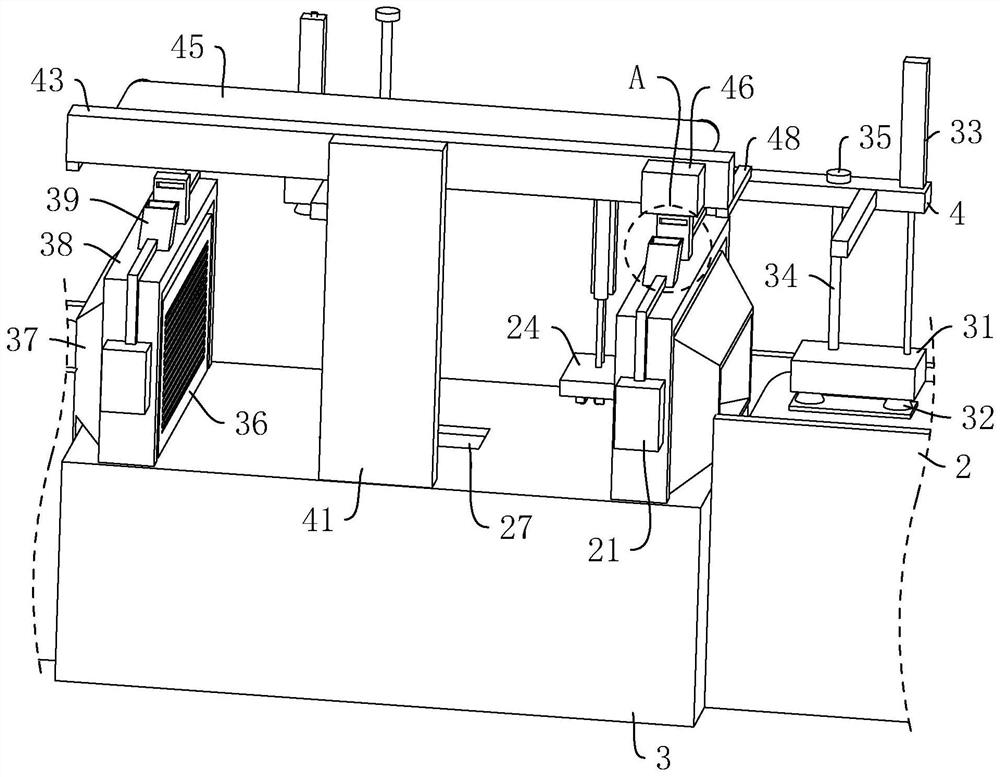

Automatic chamfering machining device for hardware shaft products

InactiveCN112846413ANo secondary clamping requiredImprove work efficiencyWork clamping meansPositioning apparatusMachiningPneumatic cylinder

The invention relates to the field of machining of shaft products, in particular to an automatic chamfering machining device for hardware shaft products. The automatic chamfering machining device comprises a worktable, wherein a feeding mechanism and a discharging mechanism are arranged above one side of the worktable, a rotating mechanism and a clamping mechanism are arranged at the upper end of the worktable, and a receiving box is arranged below the worktable; and a supporting mechanism is arranged above the worktable, and an air blowing mechanism and a chamfering mechanism are fixed to the side of the supporting mechanism. When the automatic chamfering machining device is used, firstly, a to-be-machined shaft is vertically fixed, a second pneumatic cylinder is driven to drive two chamfering cutters to move downwards, chamfering is achieved after a rotator rotates by half a circle, after chamfering of one end is completed, the chamfering cutters and a second arc-shaped ring retract, the to-be-machined shaft is enabled to rotate by 180 degrees, clamping and chamfering are repeated, secondary clamping is not needed, and the working efficiency is improved; and during clamping, due to the fact that clamping force is applied to the upper side and the lower side of the worktable, the clamping effect is better, by means of arrangement of an anti-skid gasket, a workpiece cannot move during chamfering, and the chamfering accuracy cannot be affected.

Owner:海宁超艺精密五金有限公司

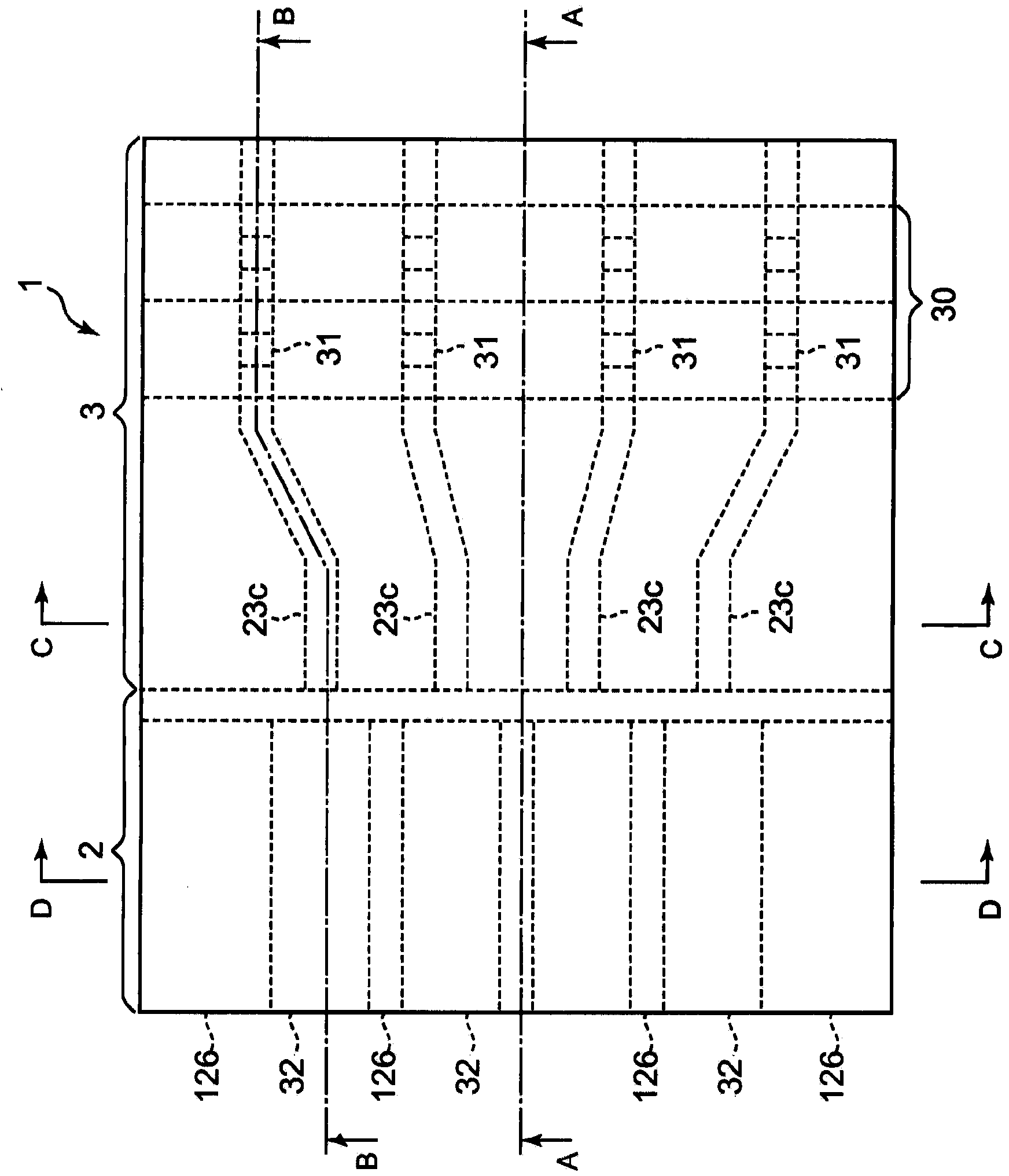

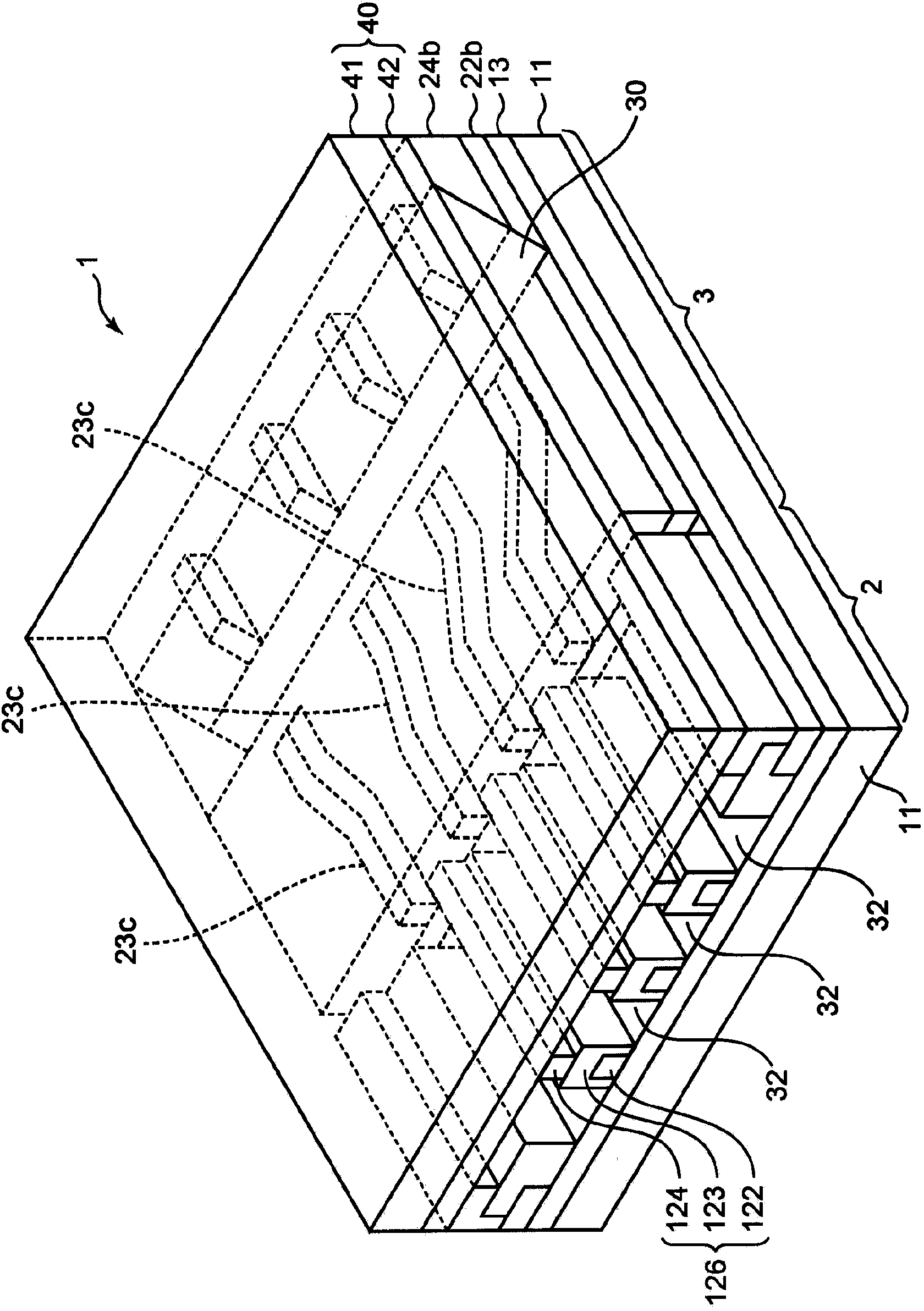

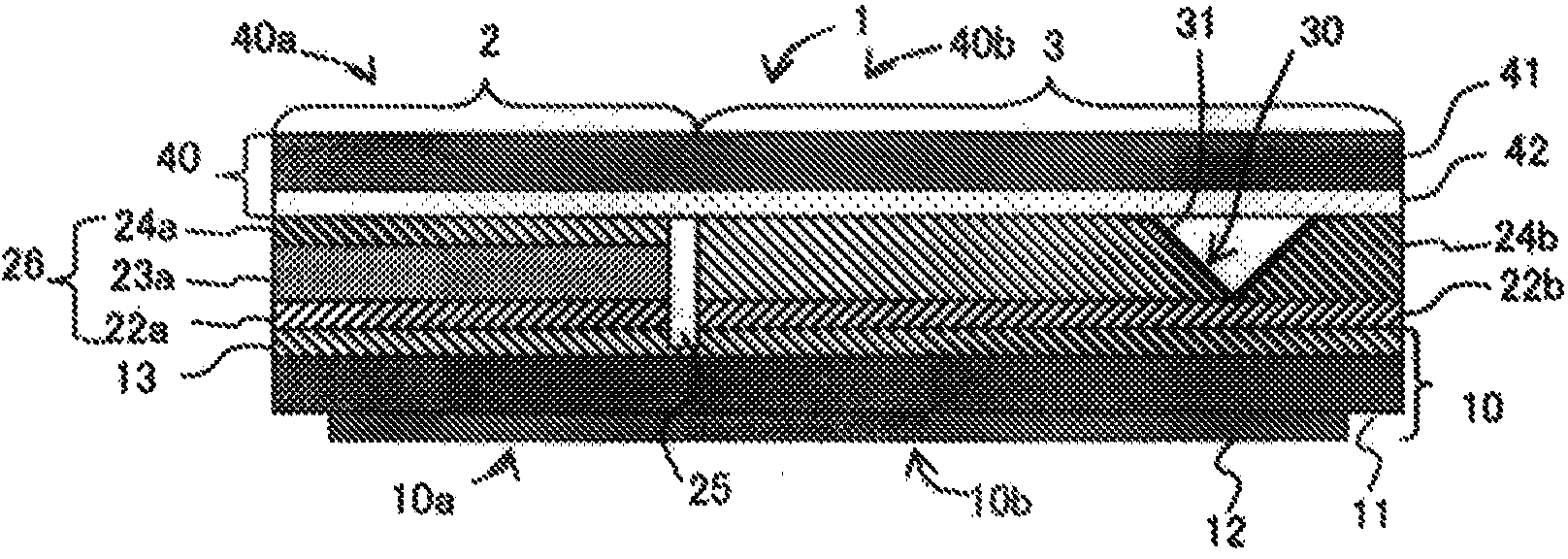

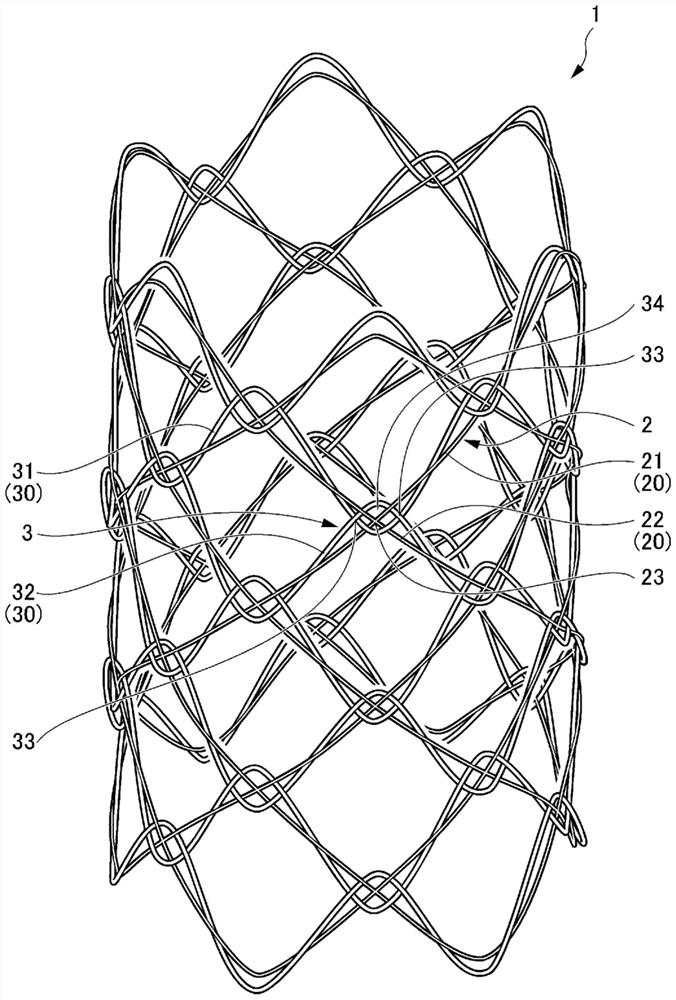

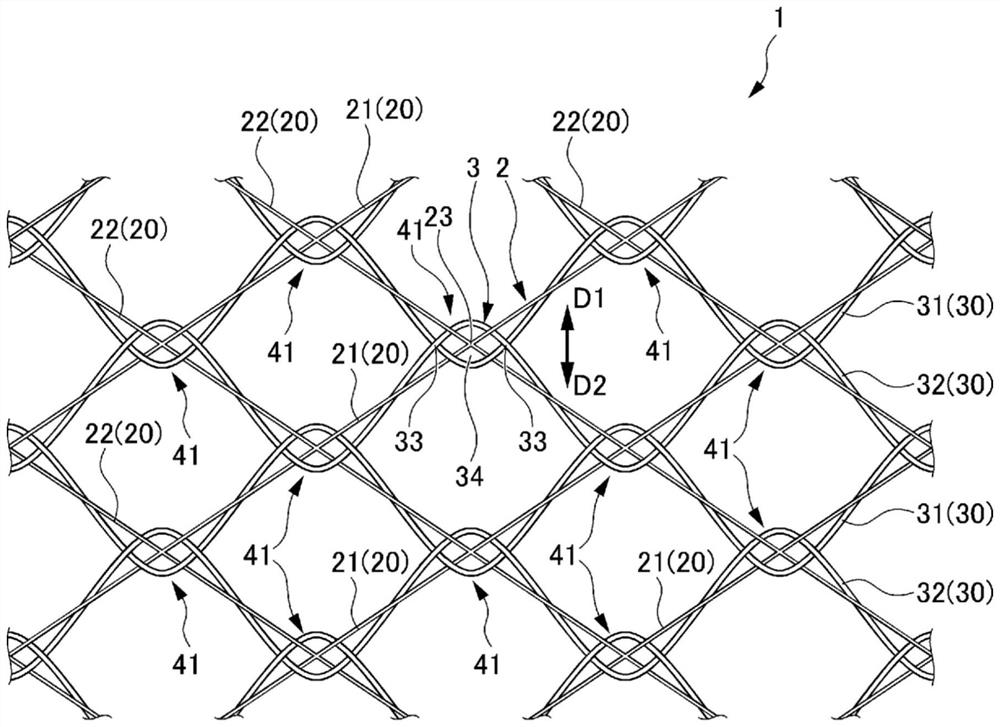

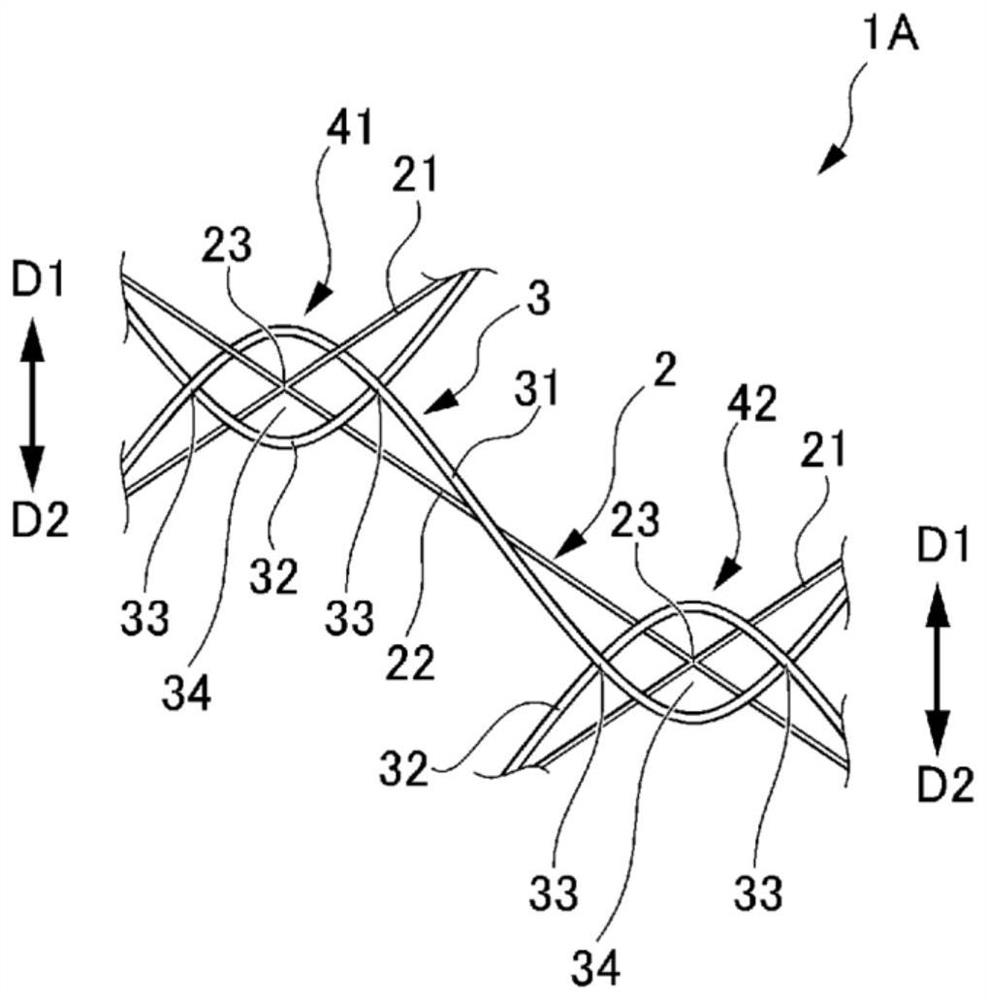

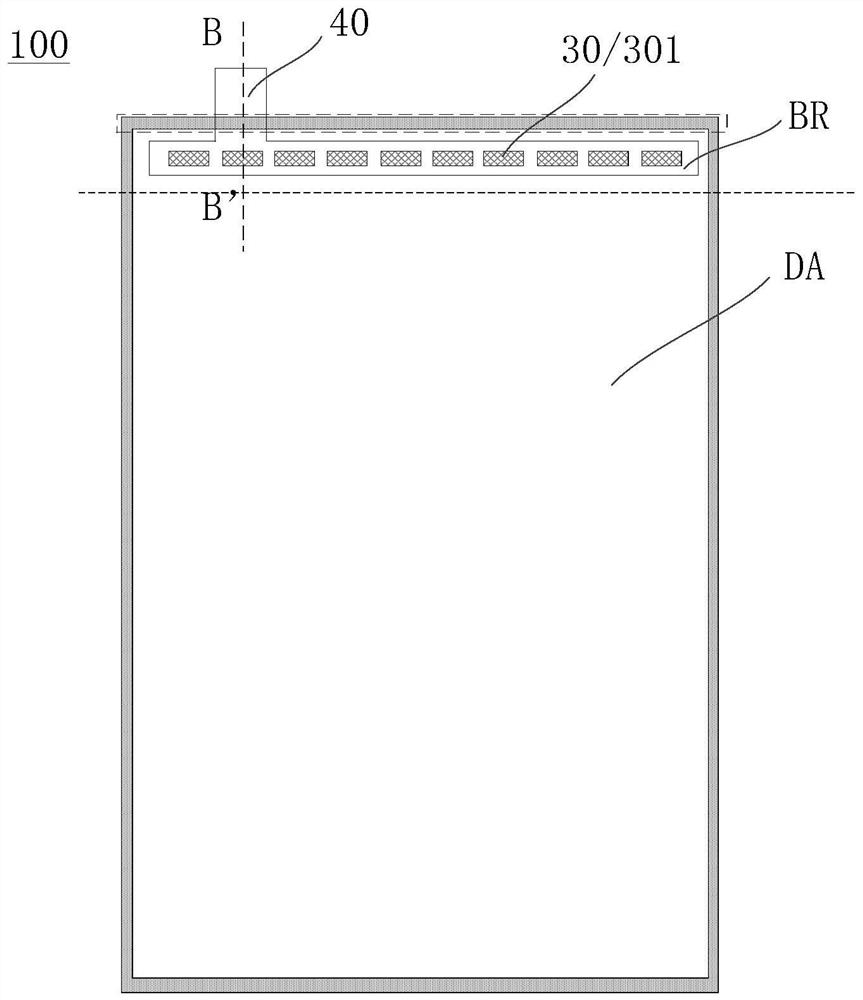

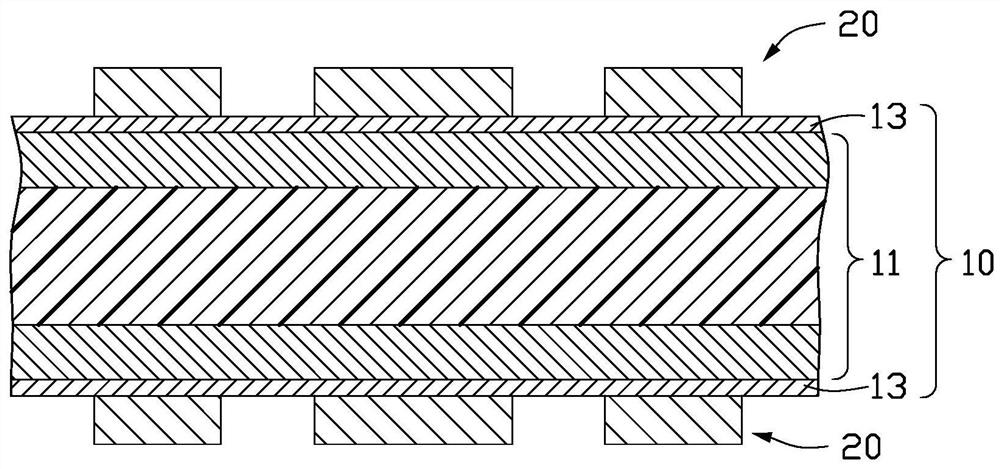

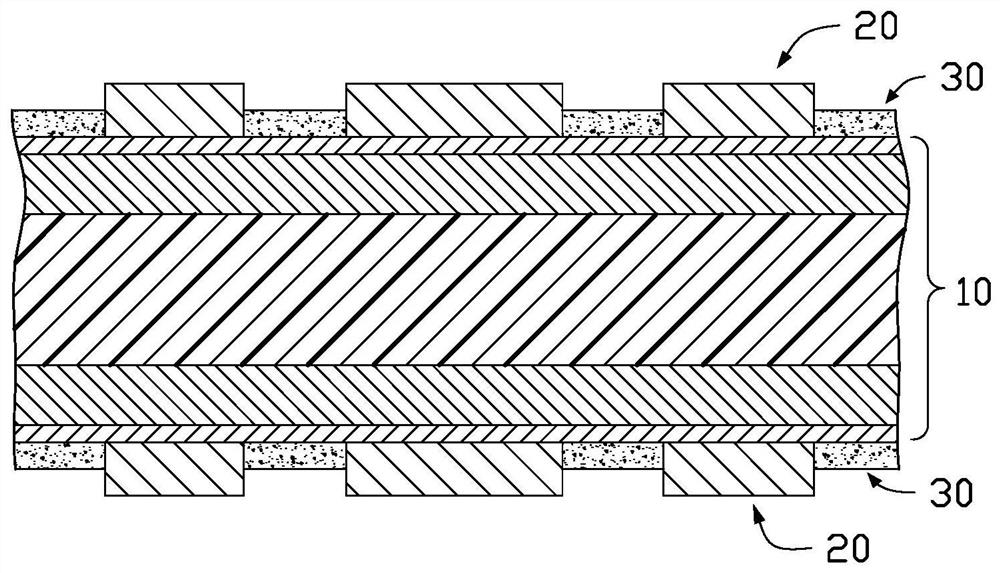

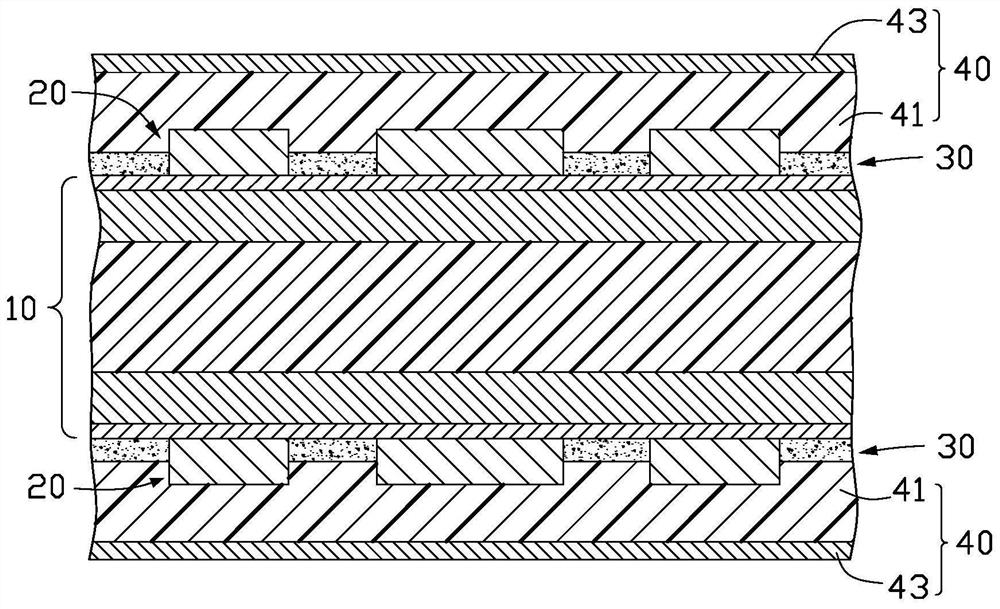

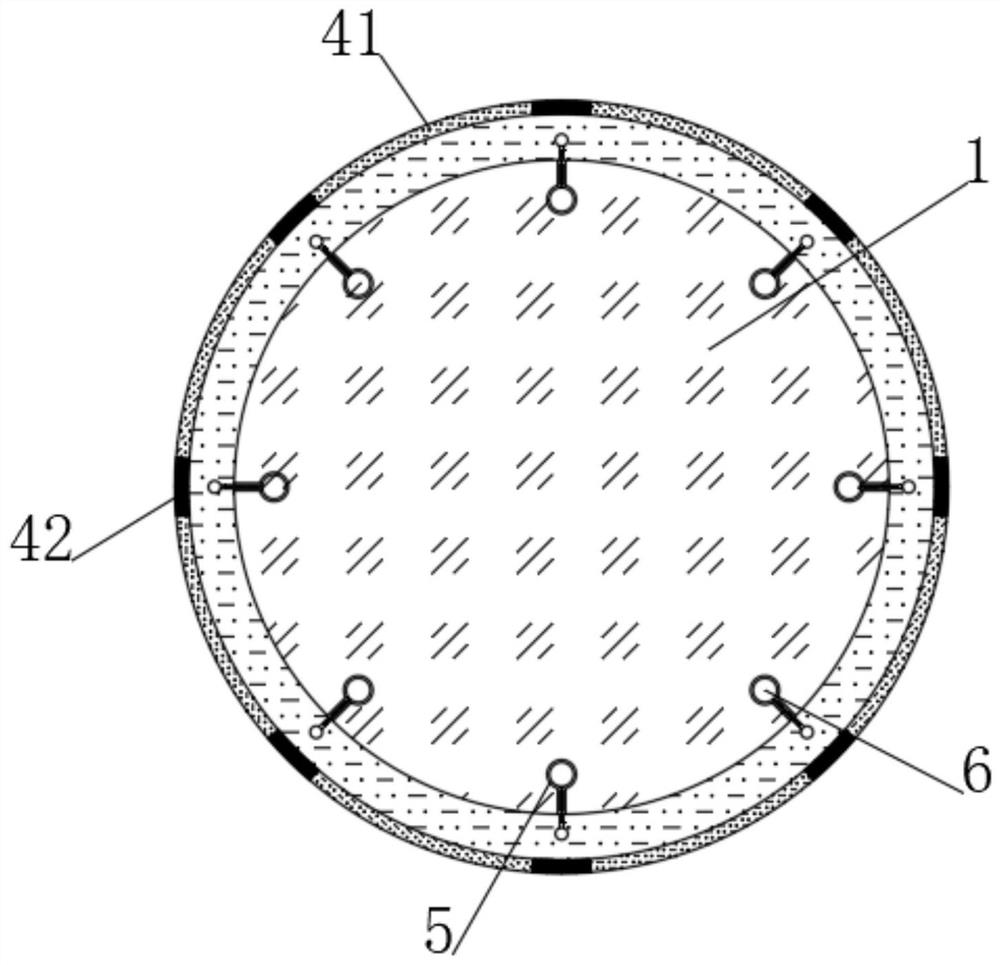

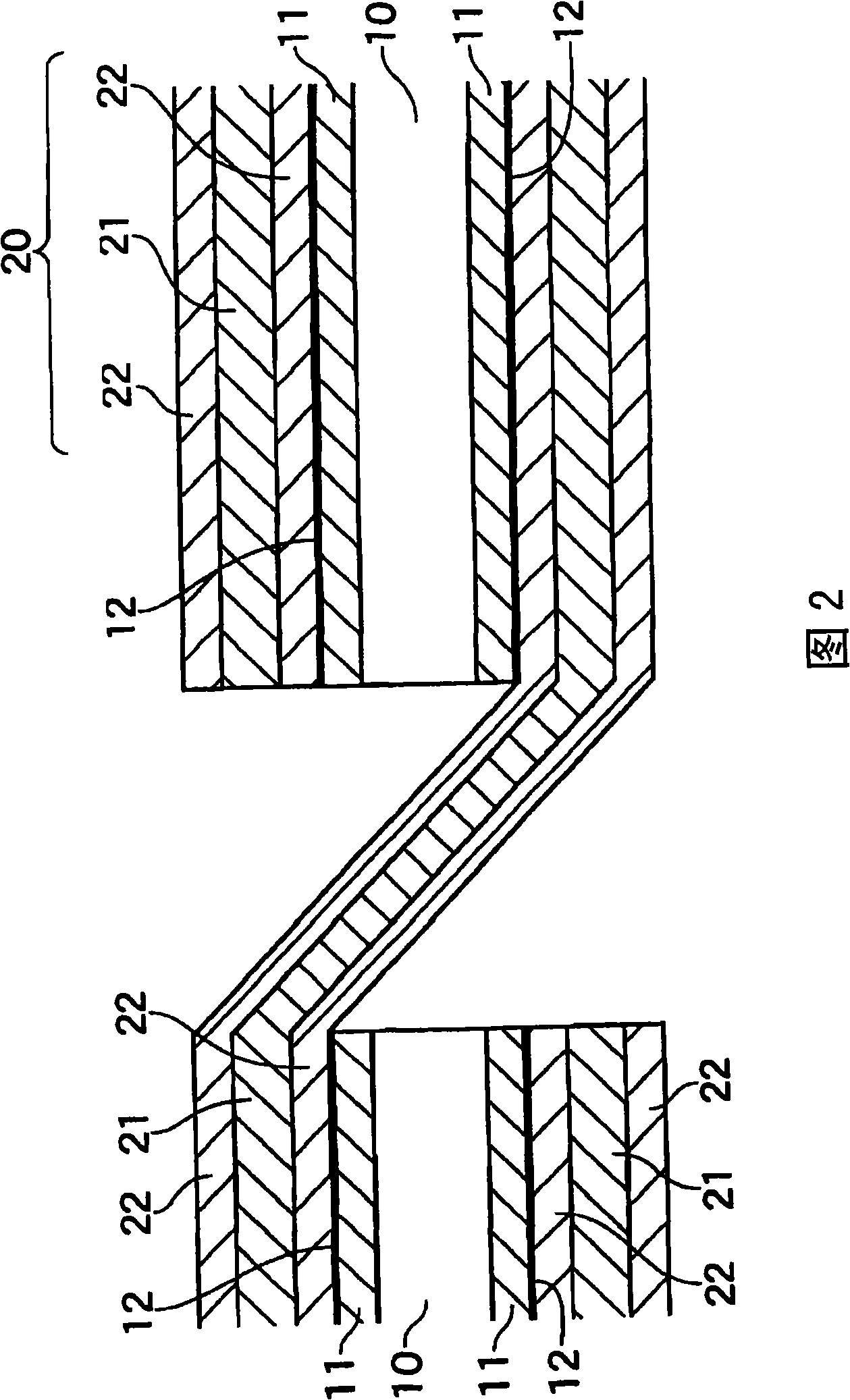

Synthetic resin stent

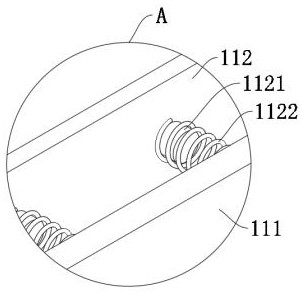

PendingCN113613601AEnsure storageLess prone to positional deviationStentsProsthesisFiberSynthetic resin

Provided is a stent which can ensure the storability in thin tubular members such as delivery systems and which is insusceptible to positional displacement after placement of the stent in an affected part of a bodily conduit. The synthetic resin stent 1 comprises a tubular first braid component 2 comprising a plurality of fibers that are braided into a net-like form, and a second braid component 3 comprising a plurality of fibers that are disposed braided into the first braid component 2 to form an annular shape. The first braid component 2 includes a plurality of first fibers 21, a plurality of second fibers 22, and a plurality of first intersections 23, and the second braid component 3 includes a plurality of wave-like third fibers 31 disposed separated in an axial direction and a plurality of wave-like fourth fibers 32 disposed separated in the axial direction. At least one of the first intersections 23 is disposed in an intersection region 34 surrounded by the third fiber 31 and the fourth fiber 32.

Owner:JMS CO LTD

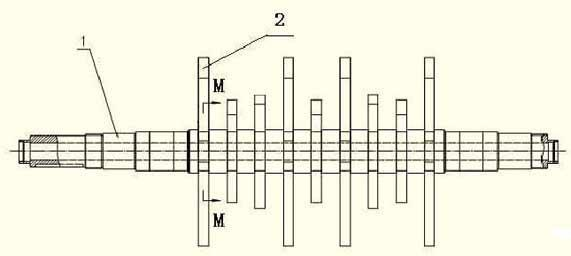

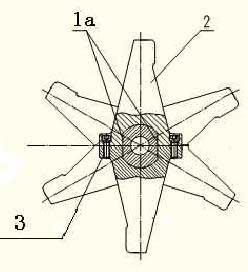

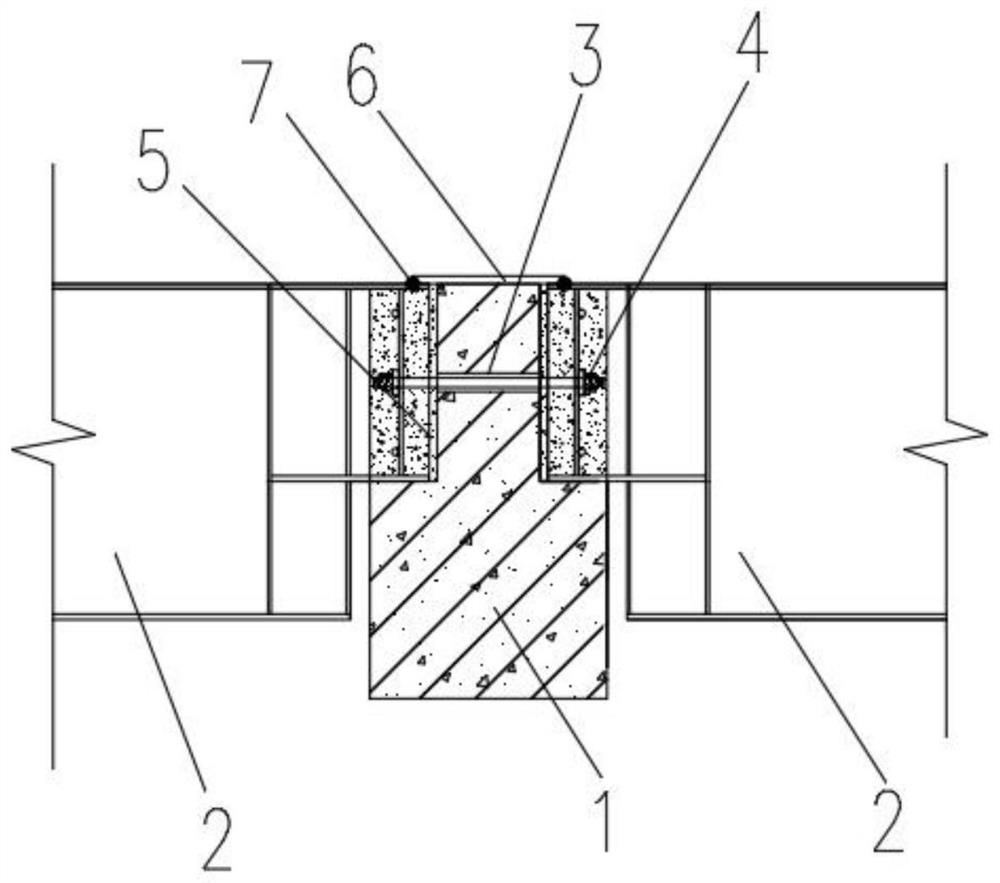

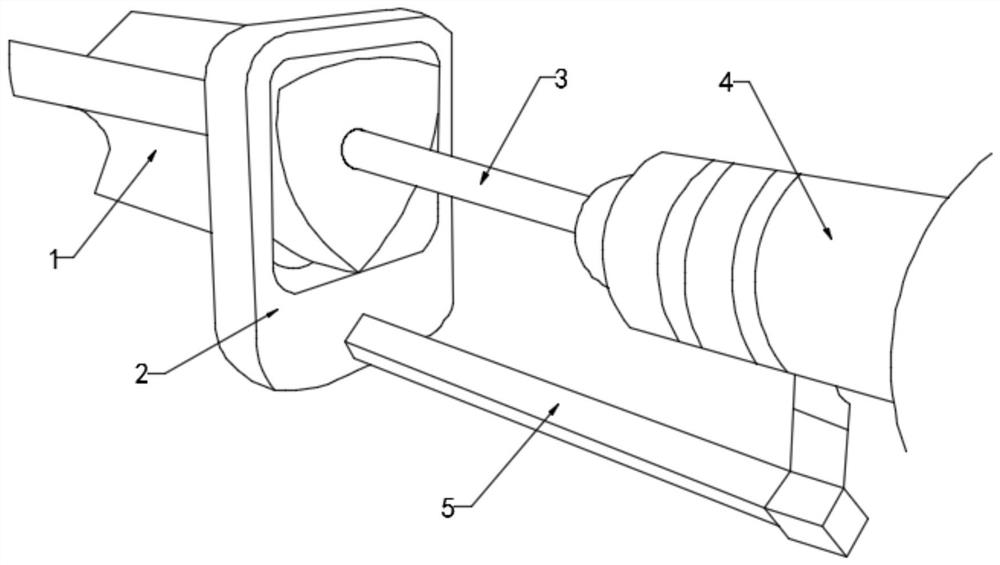

Blade and shaft connecting structure convenient for dismounting and manufacturing method thereof

A blade and shaft connecting structure convenient for dismounting and a manufacturing method thereof. The method comprises the following steps: first machining a shaft (1), milling bayonets for installation blades and carrying out finish machining on each bayonet surface (1a) to a required dimension; then manufacturing integral blades (2), machining a center aperture capable of assembling with the shaft (1) in the center of each blade, manufacturing ears at two sides of a middle part of each blade and machining installing holes on the ears; after manufacturing of the integral blade, cutting the integral blade into two halves transversely along the center, wherein each half blade, at center of the bottom, is provided with processed semicircle bottom recess (2a) capable of assembling with the shaft (1), and two sides of blade bottom are provided with ears (2b) processed with installing holes; splicing the two half blades and clamping in bayonets of the shaft and connecting the blades by coupling screws (3). The connecting structure of the invention can realize reliable connection of the blades and the shaft, is convenient for maintenance, dismounting and replacing, and can avoid shaft deformation and reduce vibration and noise during operation.

Owner:中国机械总院集团云南分院有限公司

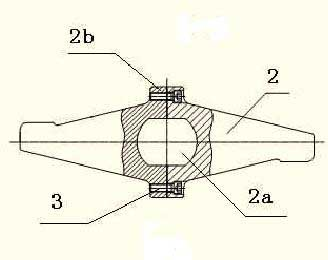

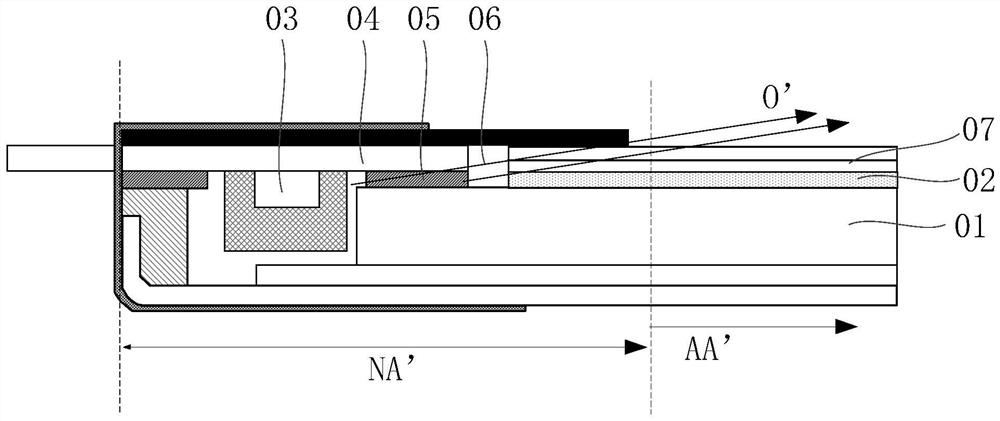

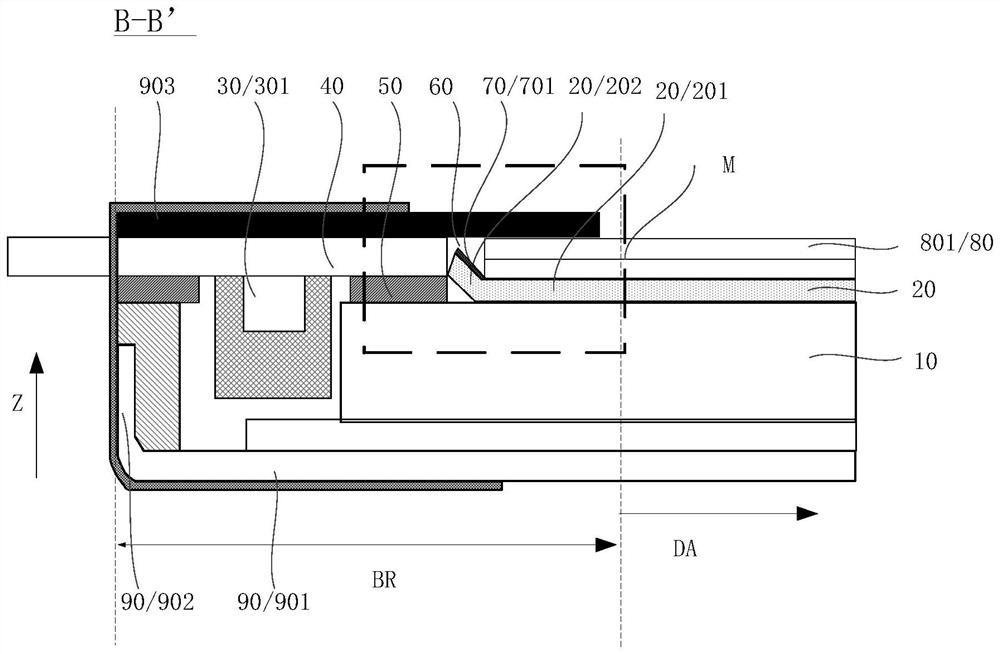

Backlight module and display device

PendingCN114019725AImprove Optical TasteReduce light leakageNon-linear opticsLight guideDisplay device

An embodiment of the invention provides a backlight module and a display device. The backlight module has a display area and a frame area surrounding the display area, and comprises: a light-emitting device and a circuit board electrically connected with the light-emitting device, wherein the circuit board is located on the side, facing the light-emitting direction of the backlight module, of the light-emitting device; a light guide plate located on the side, close to the display area, of the light-emitting device; lamp glue positioned between the light guide plate and the circuit board; a diffusion sheet which is located on the side, facing the light emitting direction of the backlight module, of the light guide plate and comprises a body part and a bent part connected with the body part, wherein the bent part is located on the side, close to the light-emitting device, of the body part, and the bent part is bent towards the side, away from the light guide plate, of the body part relative to the body part; and a shading film which comprises a first branch part, wherein the first branch part at least partially covers the bending part. According to the backlight module provided by the embodiment of the invention, the phenomena of light leakage and firefly of the backlight module can be improved, and the phenomena of light leakage or bright line of the display device caused by deviation of the diffusion sheet during assembly of the backlight module can be improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

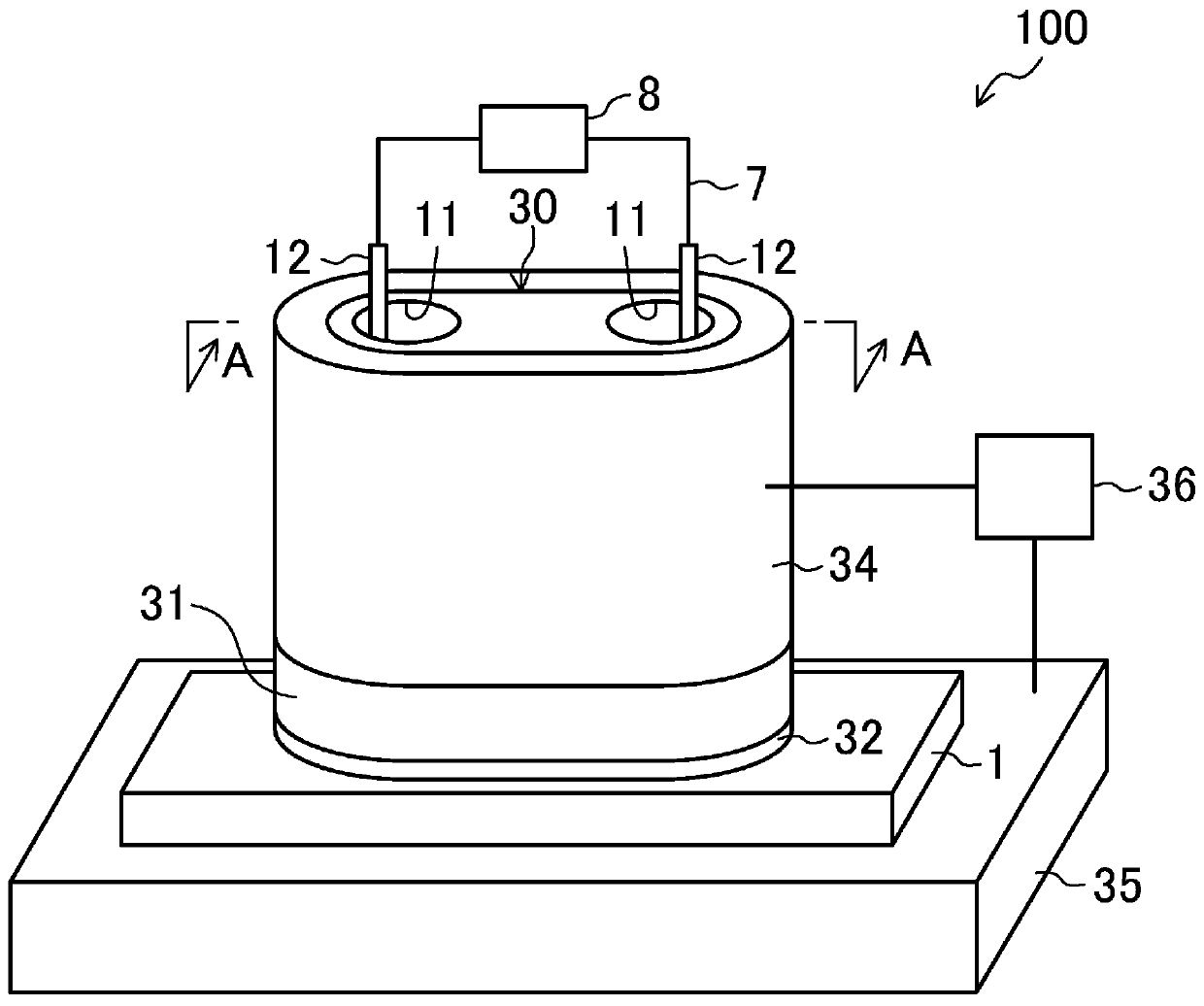

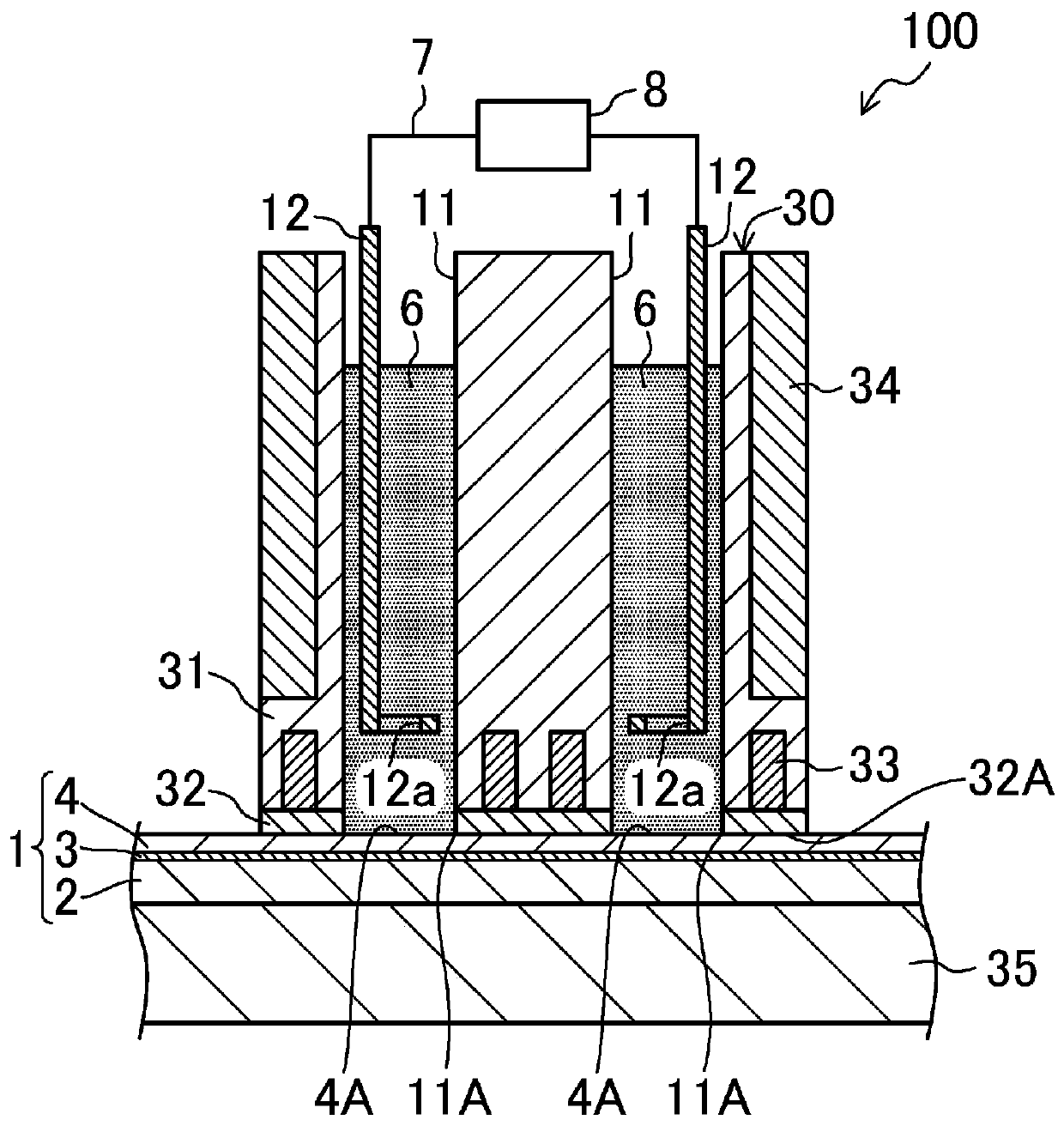

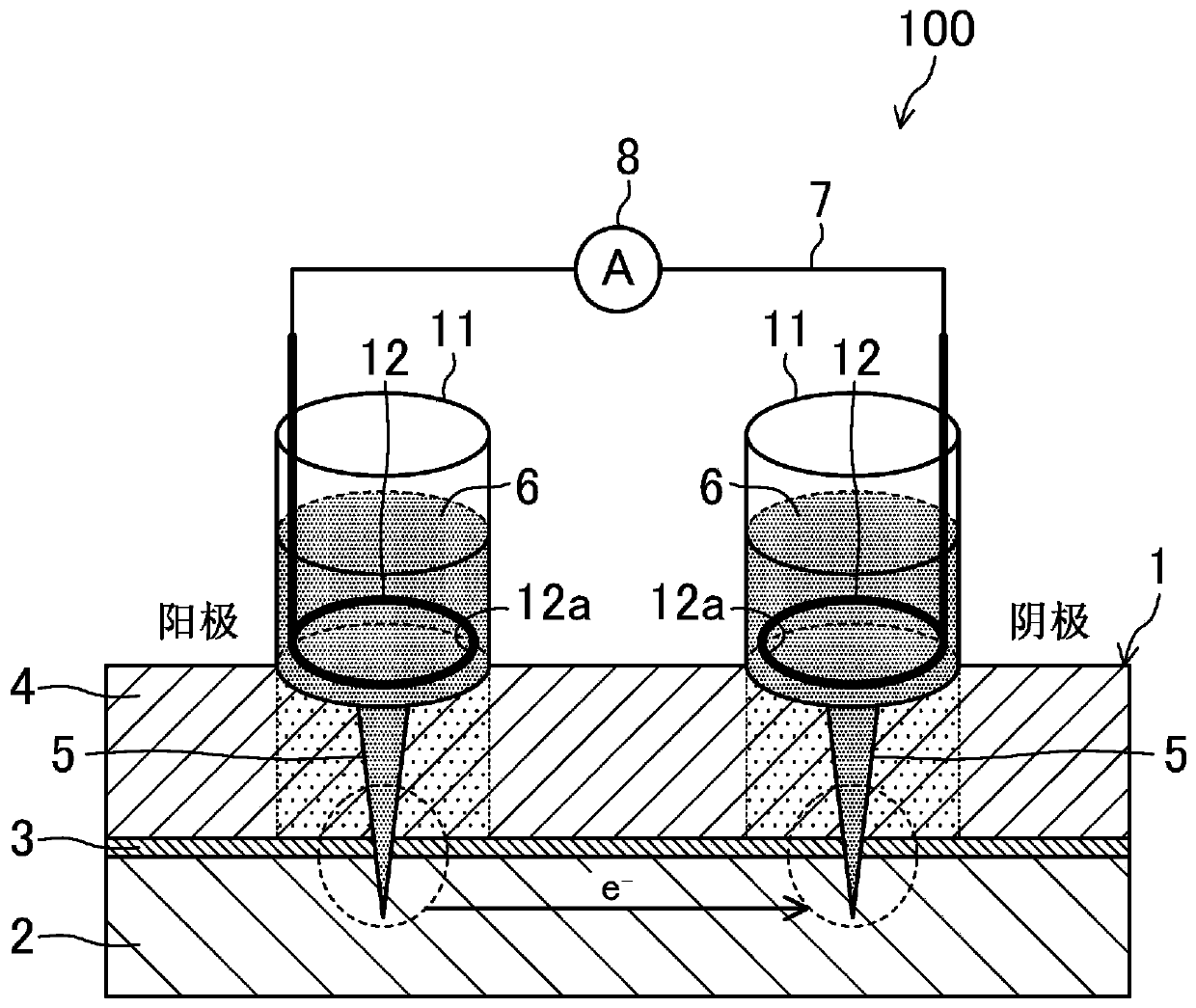

Corrosion resistance tester for coated metal material

ActiveCN111458287ALow costFit closelyWeather/light/corrosion resistanceMetallic materialsHemt circuits

The invention discloses a corrosion resistance tester for a coated metal material. The coated metal material is obtained by forming a surface treatment film on a metal substrate. The orrosion resistance tester includes: a container placed on the surface treatment film and including a plurality of water-containing electrolyte material holders that open through the bottom surface in contact with thesurface treatment film; the water-containing electrolyte material contained in each of the water-containing electrolyte material holders of the container, and being in contact with an associated oneof a plurality of separate measurement target portions of the surface treatment film; a plurality of electrodes being each in contact with the water-containing electrolyte material contained in an associated one of the water-containing electrolyte material holders; an external circuit connecting the electrodes together; and a conduction means configured to conduct electricity to the metal substrate through the electrodes and the external circuit.

Owner:MAZDA MOTOR CORP

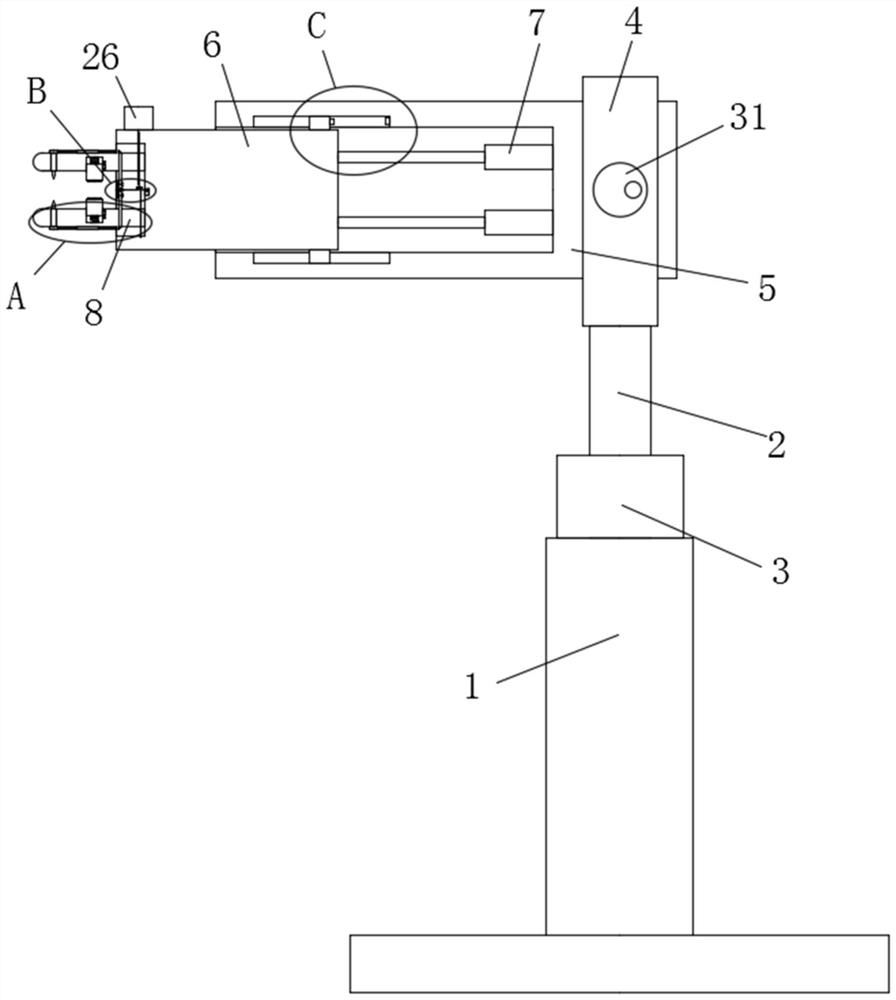

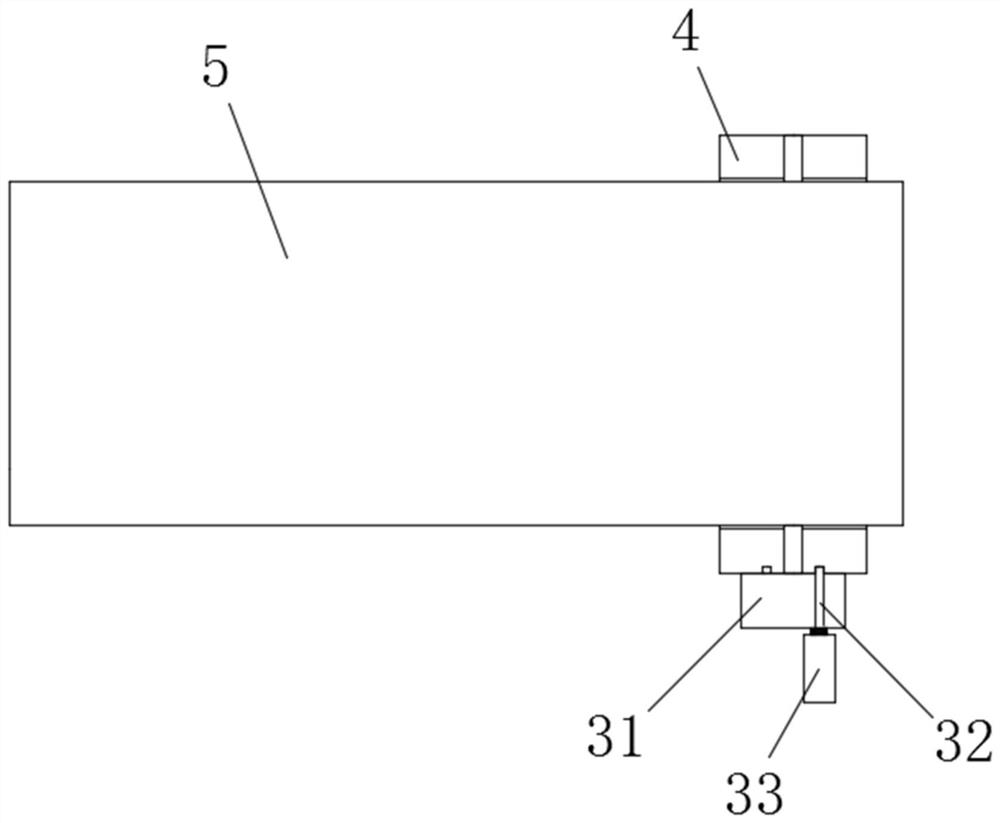

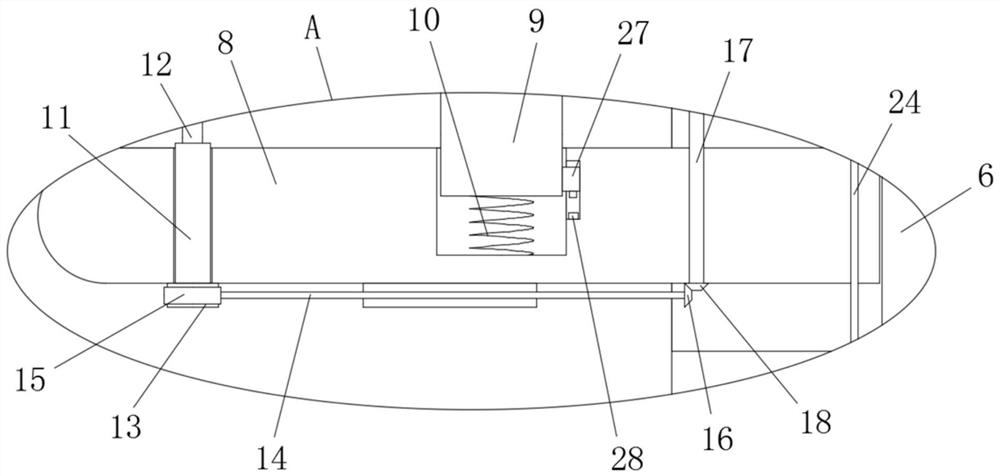

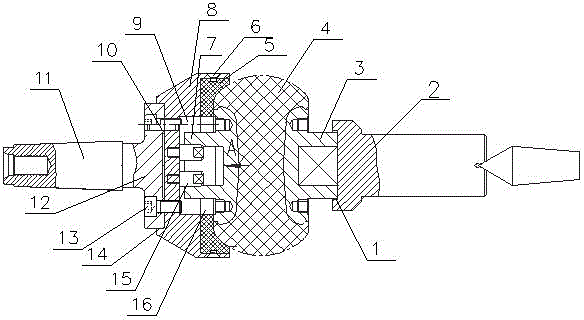

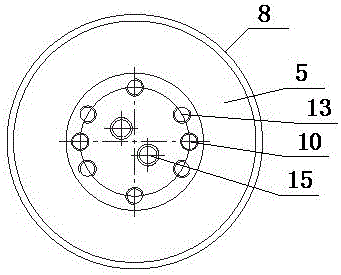

Metal pile nail removing device for dental restoration department

The invention belongs to the field of medical apparatus and instruments, and particularly relates to a metal pile nail removing device for the dental restoration department. Existing metal pile nail dismantling equipment needs to be operated manually, the position is not easy to stabilize, position deviation is easy to occur, and the harm to a patient is very large due to the fact that the equipment is manually held by hand for direct hard pulling. In order to solve said problems, the scheme provides that the device comprises a supporting frame; a fixing groove is formed in the top of the supporting frame, a threaded rod is slidably mounted in the fixing groove, a driving nut is mounted on the threaded rod in a threaded mode, a mounting plate is fixedly mounted at the top end of the threaded rod, an adjusting groove is formed in the top of the mounting plate, an adjusting column is rotatably mounted in the adjusting groove, a connecting groove is formed in one end of the adjusting column, and telescopic columns are slidably mounted in the connecting grooves. The invention is reasonable in structure and convenient to operate, the metal pile nail can be automatically removed through the removing device, the position can be well stabilized during removing, position deviation is not prone to occurring, and harm to a patient is small.

Owner:西安交通大学口腔医院

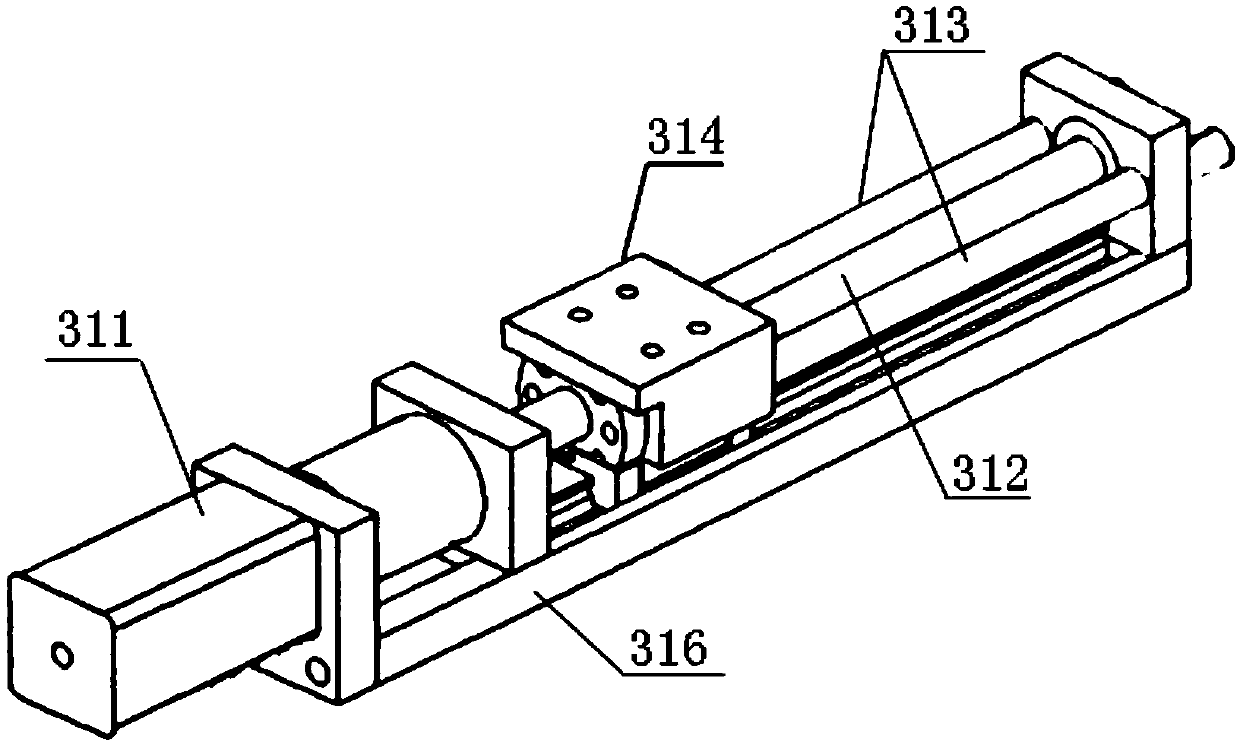

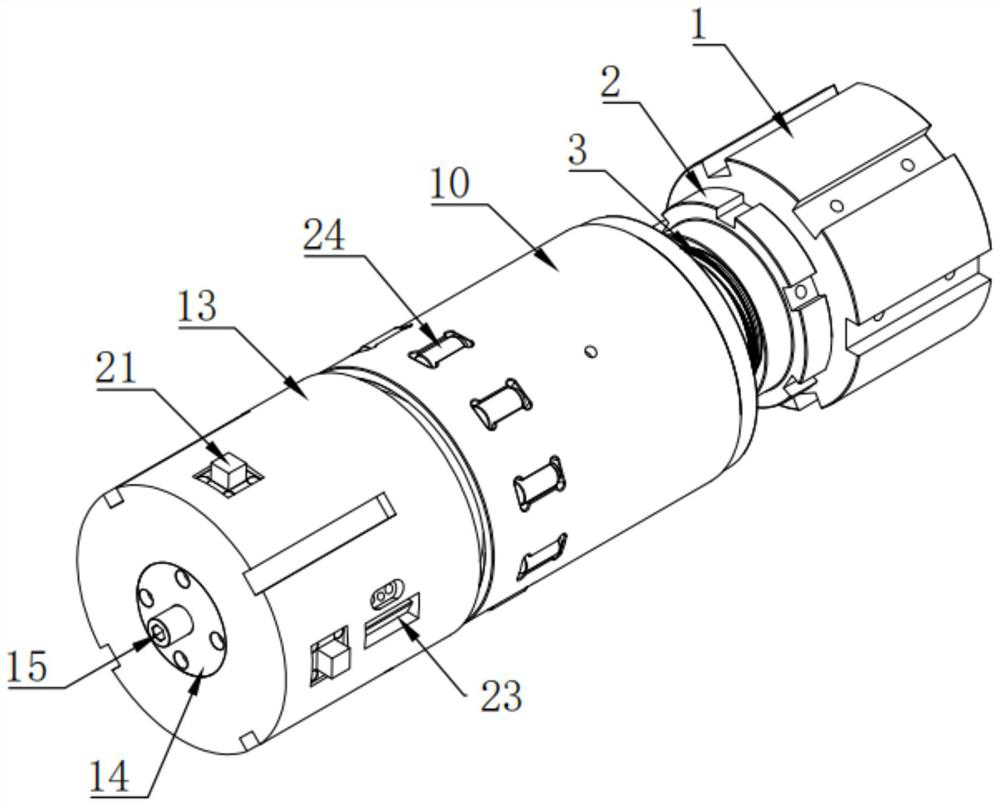

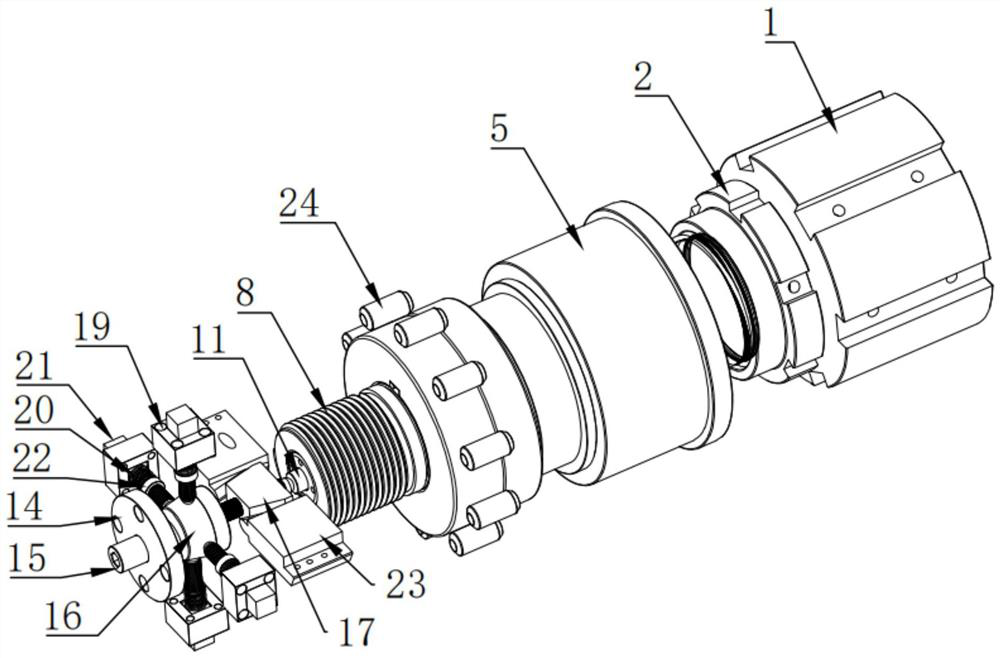

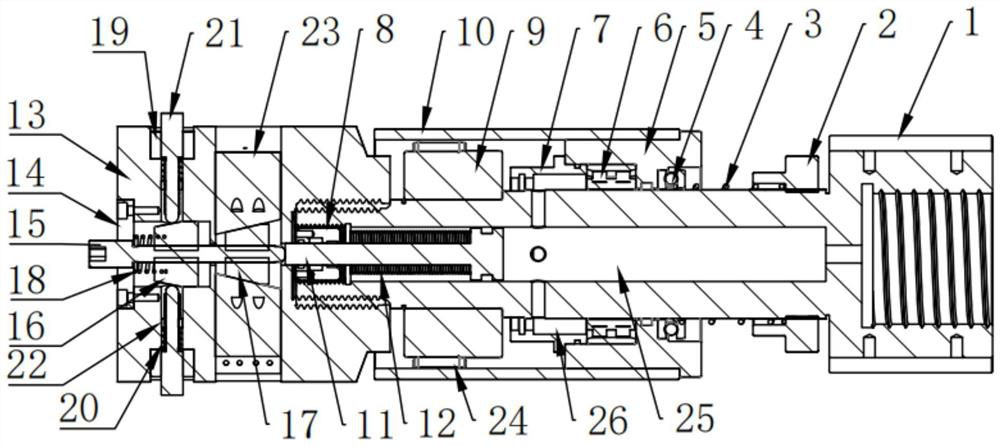

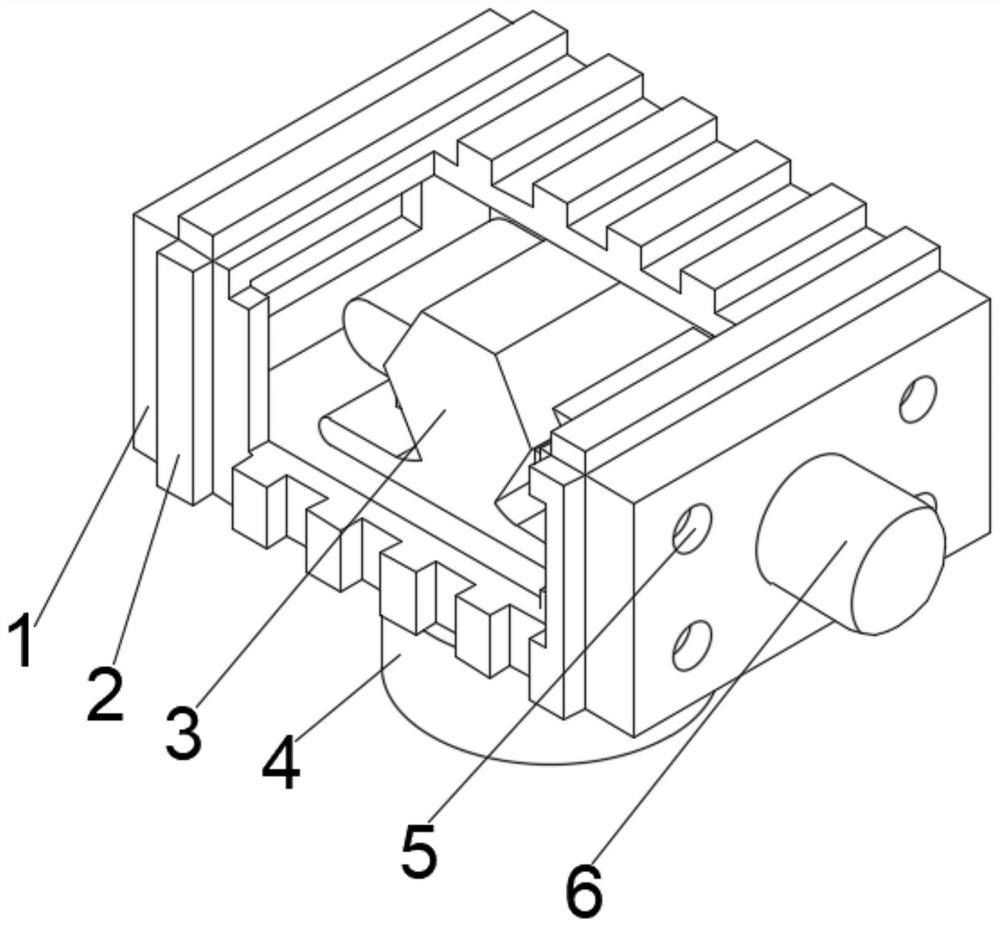

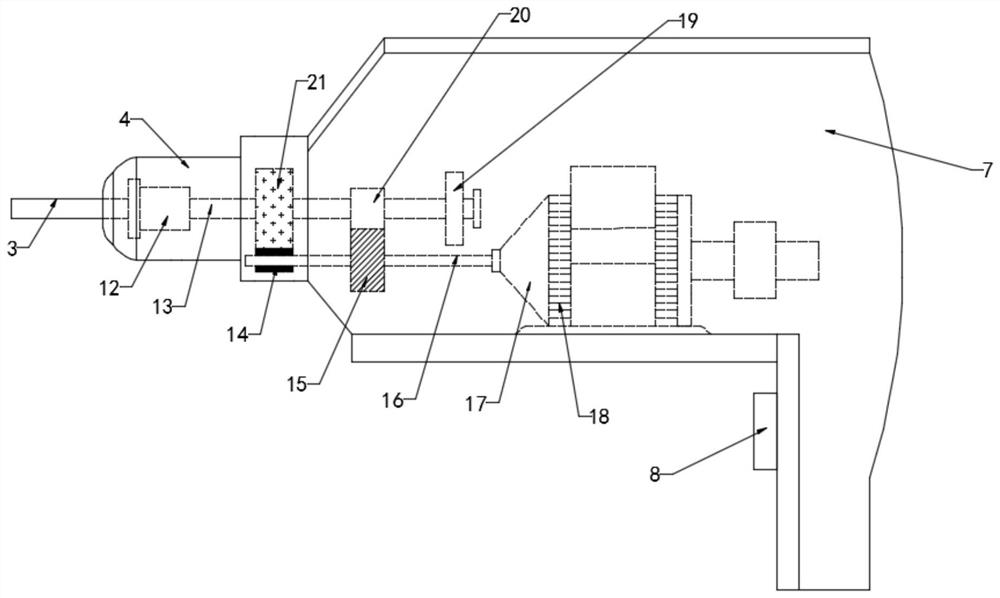

Adjustable combined boring head

PendingCN114346274ASimple processing technologyImprove processing qualityTransportation and packagingBoring headsScrew threadMachine tool

The invention belongs to the technical field of inner hole machining, and particularly discloses an adjustable combined boring head which comprises a boring head piston rod, a boring head body slidably connected to the outer side of the boring head piston rod in a sleeving mode and a push broach piston rod slidably connected to the inner side of the boring head piston rod in a sleeving mode. An adjusting screw rod is arranged at the axis of the end part of the boring head body, a rough boring adjusting expansion block and a fine boring adjusting expansion block which are matched with the rough boring cutter and the fine boring cutter are respectively in threaded connection with the adjusting screw rod, the expansion directions of the rough boring adjusting expansion block and the fine boring adjusting expansion block are the same, one end of the adjusting screw rod is in threaded connection with the boring head body, and the other end of the adjusting screw rod is in threaded connection with the boring head body. And the other end is propped against the output end of the push broach piston rod. The purposes of hydraulic automatic adjustment, improvement of operation safety of a machine tool and improvement of boring efficiency are achieved, the inner hole of the cylinder barrel is sequentially machined from rough boring to fine boring to tumbling, the electric charge expenditure is reduced, the abrasion rate of the machine tool is reduced, the labor intensity is reduced, and the working safety is guaranteed.

Owner:SHANDONG LAIWU COAL MINING MACHINERY

Circuit board and manufacturing method thereof

ActiveCN112105174AAvoid poor contactLess prone to positional deviationInsulating substrate metal adhesion improvementMultilayer circuit manufactureComposite materialElectrical and Electronics engineering

The invention relates to a manufacturing method of a circuit board. The method comprises the following steps of providing a bearing plate, and forming a first circuit layer on the surface of the bearing plate; arranging an adhesive layer in the area, exposed out of the first circuit layer, of the surface of the bearing plate, wherein the thickness of the adhesive layer is less than that of the first circuit layer; arranging wiring layers on the surfaces of the first circuit layer and the adhesive layer, wherein each wiring layer includes at least one dielectric layer and at least one second circuit layer which are arranged alternately, and the dielectric layer on the outermost side covers the first circuit layer and fills a gap, higher than the adhesive layer, of the first circuit layer; enabling the first circuit layer to be partially embedded into the dielectric layer on the outermost side; and removing the bearing plate and removing the adhesive layer so that a part of the first circuit layer convexly extends out of the surface of the dielectric layer on the outermost side. The invention further provides the circuit board.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

Multifunctional label paper collecting device

InactiveCN106629167ALess prone to positional deviationEasy to see the conveying situationWebs handlingPulp and paper industryConveyor belt

The invention discloses a multifunctional label paper collecting device, which comprises a device body, a collecting coil and an electromotor. The collecting coil is arranged on the right upper end of the device body, the electromotor drives the collecting coil to rotate, the middle of the upper end surface of the device body is provided with a conveyor belt mounting cavity, a conveyor belt is arranged in the conveyor belt mounting cavity, a front positioning baffle plate is arranged at the front end of the conveyor belt mounting cavity, a rear positioning baffle plate is arranged at the rear end of the conveyor belt mounting cavity, and the front positioning baffle plate and the rear positioning baffle plate are symmetrically arranged; the back positioning baffle plate is provided with a lamp holder, the lamp holder is provided with an LED lighting lamp and a button switch used to control ON / OFF of the LED lighting lamp, a support frame is arranged on two guide rails, a cylinder is arranged at the front end surface of the support frame, the cylinder is connected to the support frame by a piston rod, and the cylinder drives the support frame to move front and back along the two guide rails through the piston rod. According to the technical solution above, the structural design is reasonable, the structure is simple, multiple functions are realized, label paper is not easily deviated in a conveying process, and use is convenient.

Owner:嘉兴市耀华精密金属股份有限公司

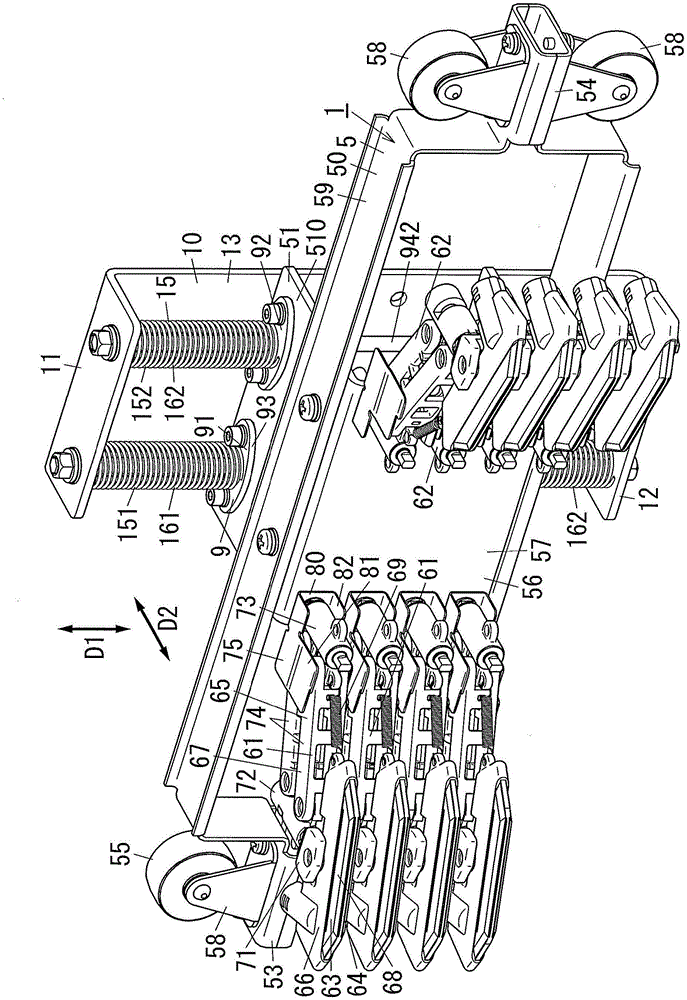

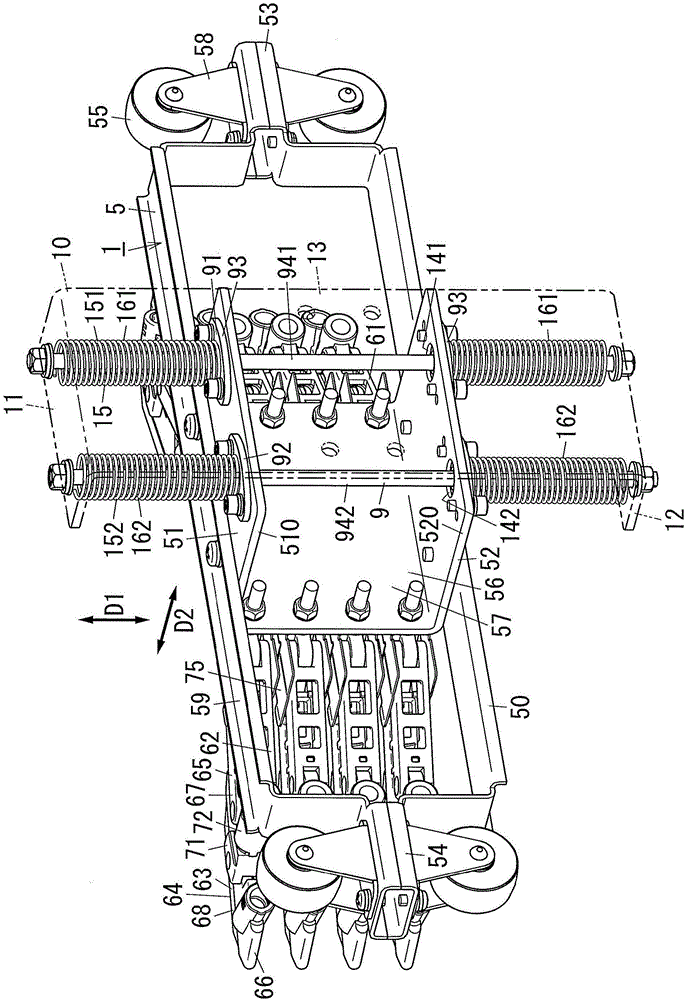

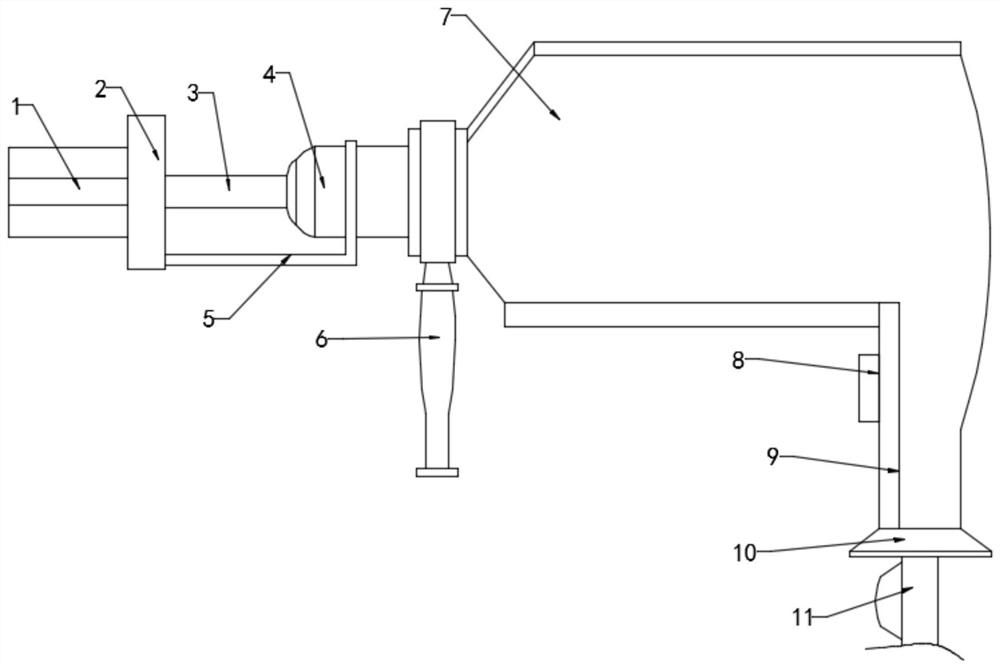

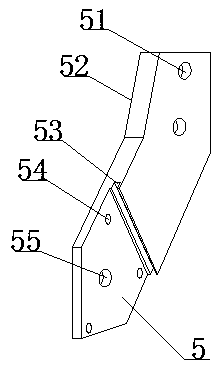

Current collection device and electric power transmission system

ActiveCN106476627ALess prone to positional deviationPoor contactPower current collectorsElectric power transmissionEngineering

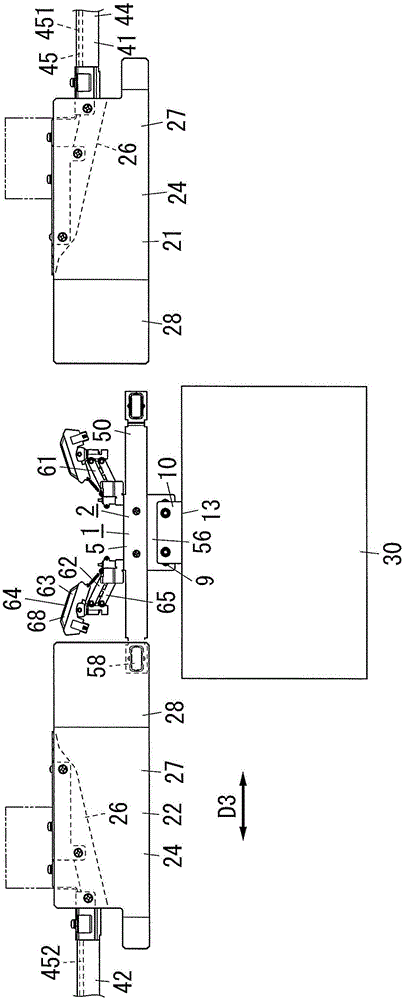

The topic of the invention provides a current collection device and an electric power transmission system. The collection device and the system have the advantages that position deflection of a current collector relative to a power supply circuit, and poor contact of the current collector relative to the power supply circuit do not take place easily. The current collection device (1) provided by the invention comprises current collection arms (61, 62), a movable component (5) and a displacement mechanism (9), wherein one end of an arm (65) of the current collection arms (61, 62) is used to hold a current collector (63), and the end part opposite to the current collector (63) side is held by the movable component (5); the movable component (5) can be connected to a connection component disposed on movable equipment (30) via the displacement mechanism (9); the displacement mechanism (9) can make the movable component (5) move relative to the connection component; and the displacement mechanism (9) can limit the displacement direction of the movable component (5) relative to the connection component to be opposite to the length direction of a power supply circuit (45).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Lifting device and semiconductor process equipment

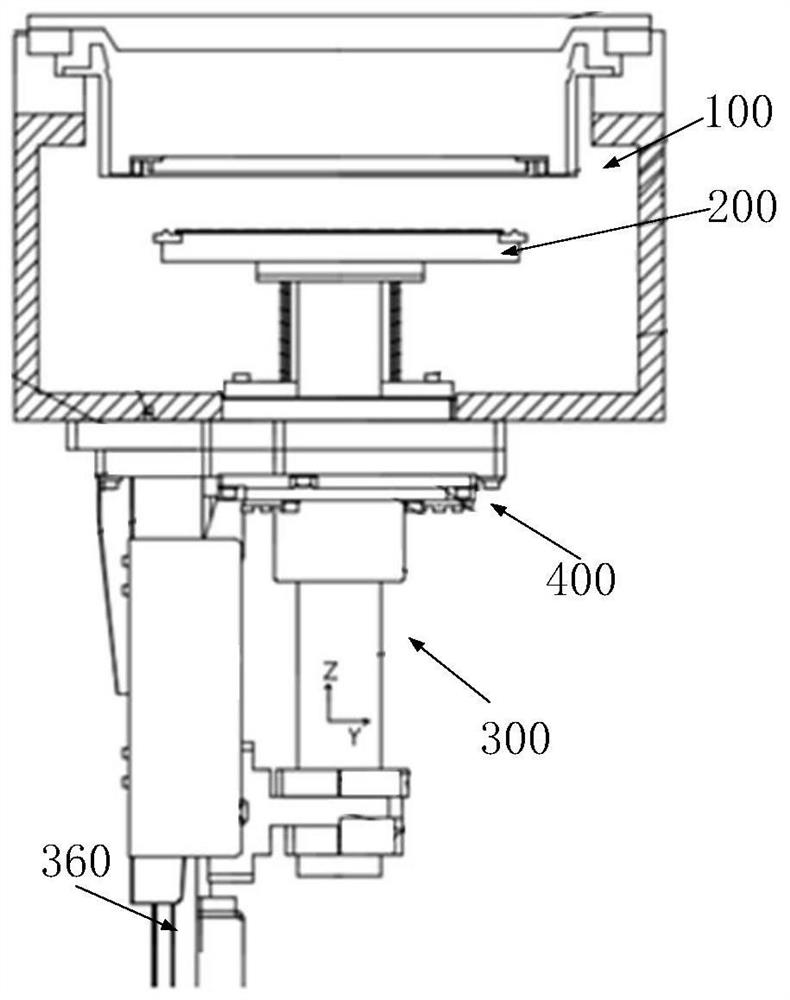

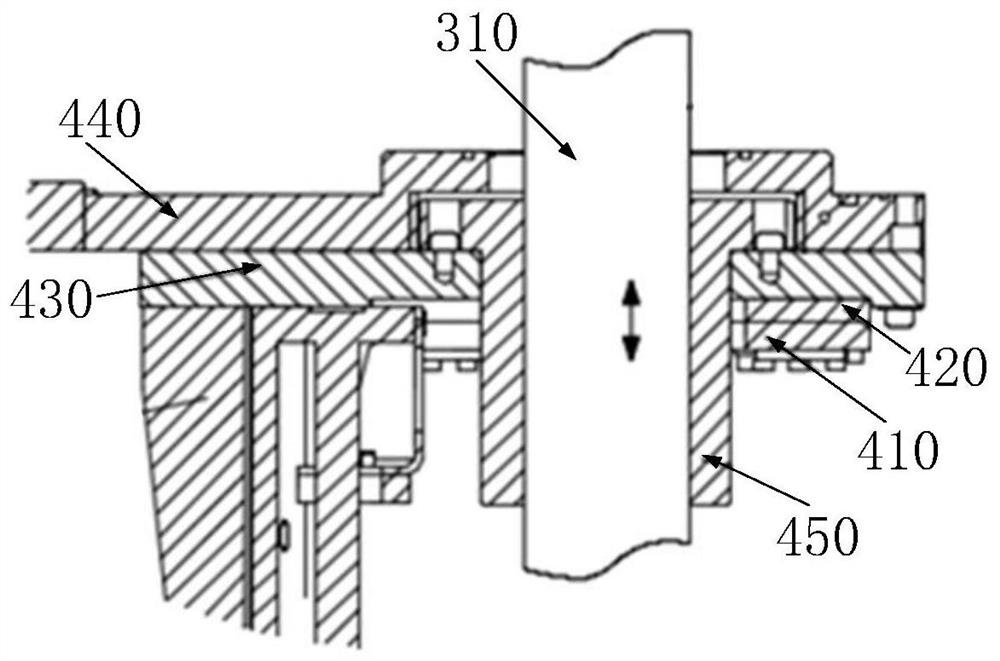

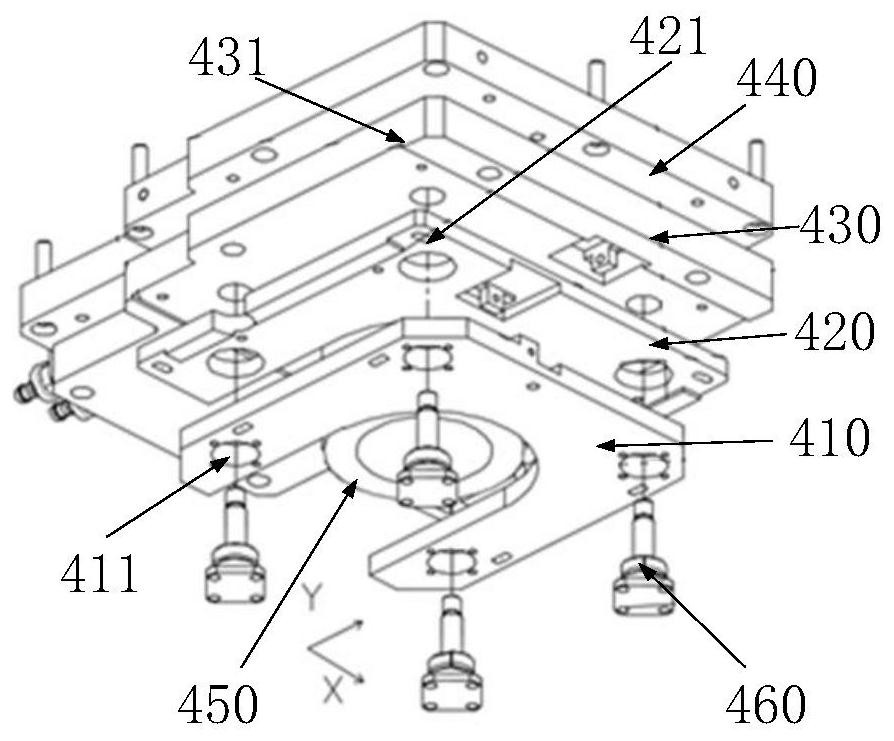

ActiveCN113061865AGuaranteed concentricityImprove the precision of the preparation processVacuum evaporation coatingSputtering coatingStructural engineeringManufacturing engineering

The invention discloses a lifting device and semiconductor process equipment, and relates to the field of semiconductor manufacturing. The lifting device is the lifting device of a base in the semiconductor process equipment, is used for driving the base to lift in a process chamber, and comprises a lifting mechanism and a translation mechanism. The translation mechanism comprises a supporting part, a first sliding plate, a second sliding plate and a mounting plate which are stacked, an adjusting assembly is connected with the supporting plate and the mounting plate, the mounting plate is fixed to the process chamber, the first sliding plate is slidably connected to the supporting plate in the first direction, and the second sliding plate is slidably connected to the first sliding plate in the second direction. A sliding sleeve extending in the third direction is arranged on the second sliding plate. The lifting mechanism comprises a lifting shaft, and the lifting shaft is arranged in the sliding sleeve in a sliding mode. The semiconductor process equipment comprises the lifting device. The device at least can relieve the problem of substrate position deviation.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

The positioning structure of the implant

Owner:CHUANG MEI DE MEDICAL DEVICE TIANJIN CO LTD

Coal mine electromechanical equipment for coal mining

PendingCN113417635AReduce contact areaNo wandering aroundMining devicesDust removalMining engineeringElectric machinery

The invention discloses coal mine electromechanical equipment for coal mining, and relates to the technical field of coal mine electromechanical equipment. The coal mine electromechanical equipment comprises a main body, a base is fixedly connected to the middle position of the bottom of the main body, a dustproof net is fixedly connected to the top of the main body, a motor is arranged in the middle of the outer wall of the right side of the main body, air holes are formed in the positions, located on the two sides of the motor, of the outer wall of the right side of the main body, and a working device is fixedly connected to the middle position of the bottom of an inner cavity of the main body. According to the coal mine electromechanical equipment for coal mining, the contact area between the equipment and the ground is reduced, a cleaning mechanism can clean the conveying belt in the working process of a conveying belt, the cleaning time of the equipment is saved, the working efficiency of the equipment is improved, dust generated in the conveying process is intercepted under cooperation of a separating mechanism, and therefore, the cleanness of circulating air is ensured, a blocking plate can ensure that materials cannot move during conveying, falling of the materials is avoided, the cleaning work of workers is relieved, and the situation that the dust floats everywhere is avoided while the device has stability.

Owner:杨正晖

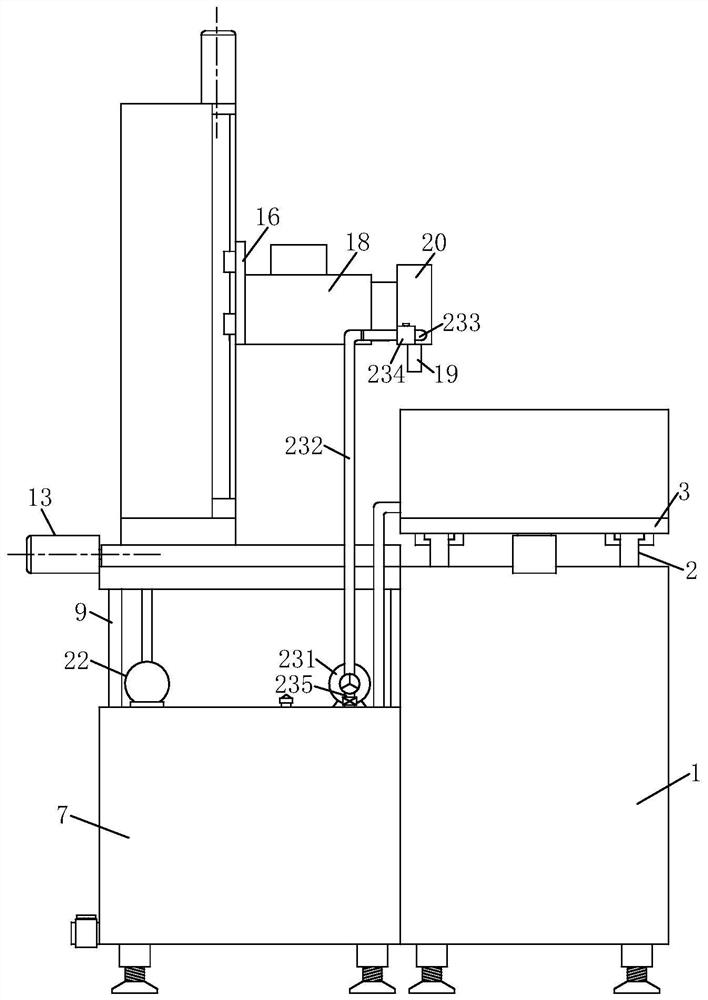

A fully automatic surface grinder

ActiveCN110640564BAchieve recyclingWork environment hygieneGrinding drivesGrinding work supportsEngineeringMachine

The present invention relates to the field of grinding machines, specifically a fully automatic surface grinder, comprising a bed body, the upper surface of the bed body is fixedly installed with a movable plate through a first sliding mechanism, and the upper surface of the bed body is fixedly installed near the middle There is a first screw group body, the first screw group body is fixedly connected to the upper surface of the movable plate, a working box is fixedly installed on the upper surface of the movable plate near the middle, and a placement mechanism is fixedly installed in the working box, so A filter box is fixedly installed on the rear side of the bed, and the filter box communicates with the working box through a conduit. The invention can recycle and filter the cooling liquid through the cooperation of the conduit and the filter box, and make it recycled through the conveying mechanism and the spraying mechanism, and then collect and filter the smoke and dust through the dust cover and the suction mechanism, so that the discharged gas is more efficient. Environmental protection, reducing the forward and backward movement of the placement mechanism, weakening the vibration of the placement mechanism and the workpiece on the upper surface, and making the fixing more firm.

Owner:江苏锋宝冶金设备有限公司

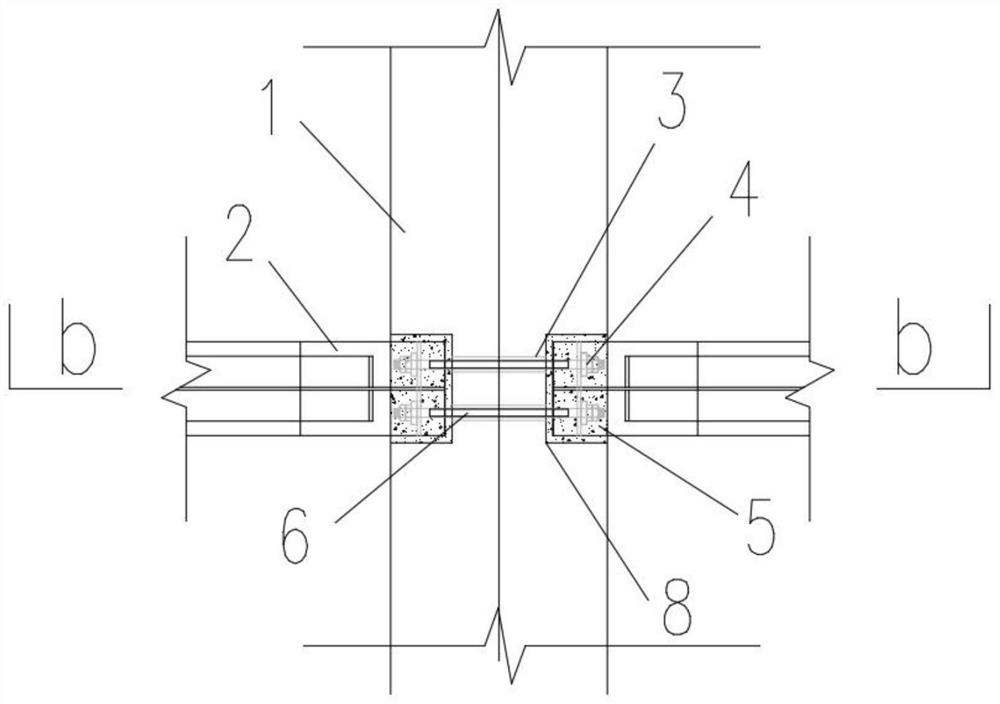

Connecting structure of concrete precast beam and steel beam and construction method of connecting structure

PendingCN114809296AHigh precisionLess prone to positional deviationGirdersJoistsStructural reliabilityRebar

The invention discloses a connecting structure of a concrete precast beam and a steel beam and a construction method of the connecting structure. The connecting structure comprises the concrete precast beam and the steel beam. Two grooves which are matched with the ends of the steel beam and are coaxial are reserved in the concrete precast beam, the two grooves are symmetrically formed in the two sides of the concrete precast beam, and a bolt hole for a split bolt to penetrate through is reserved between the two grooves. The ends of the two steel beams are arranged in the two grooves of the concrete precast beam, the split bolts penetrate through the bolt holes to fix the two steel beams, a fixing steel bar located on the upper sides of the steel beams is further arranged between the two steel beams, and the two ends of the fixing steel bar are welded and fixed to the two steel beams respectively. A gap at the joint of the concrete precast beam and the steel beam is filled with concrete. According to the connecting structure, the structural design is reasonable, the requirement for assembly precision is low, the steel beams are doubly fixed through the split bolts and the fixing steel bars, the gaps are filled with pouring concrete, and the connecting structure is good in reliability; the construction method is easy to operate and high in construction efficiency.

Owner:SHANGHAI BAOYE GRP CORP

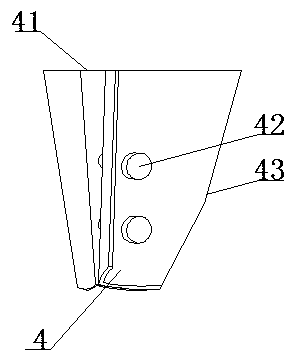

Small square hole electric drill

InactiveCN111659929ALess prone to positional deviationPowerfulPortable power-driven toolsPortable drilling machinesElectric machineryEngineering

The invention belongs to the field of small electronic equipment, and particularly relates to a small square hole electric drill. The small square hole electric drill comprises an electric drill body,wherein an end head is arranged at the front end of the electric drill body; a drilling assembly for drilling a square hole is installed at the front end of the end head; a driving assembly is arranged inside the electric drill body; the driving assembly drives the drilling assembly to operate; and then the square hole is drilled in a workpiece to be machined. The small square hole electric drillhas the following advantages that 1, the drilling assembly with the special structural design limits the movement range of a square hole drill bit through an arranged limiting frame, so that the square hole drill bit is not prone to position deviation and is not prone to breakage in the drilling process; and 2, the arranged driving assembly outputs the power of a motor through the combined actionof two different rotating shafts, compared with a traditional electric drill adopting a single motor and a single shaft to output power, the driving assembly with the structural design can ensure that the output power is not too high while the drilling operation is guaranteed, and the situation that the workpiece is damaged due to the fact that the drill bit which is operated strongly is caused by misoperation in the drilling operation is avoided.

Owner:蔡豪杰

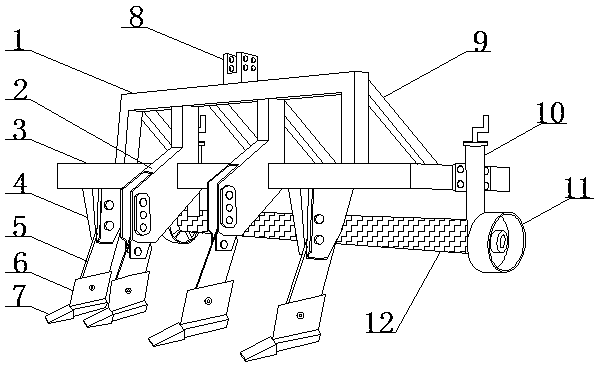

Agricultural device for agricultural soil improvement

PendingCN110754145AGood position fixationNot easy to fall offSoil lifting machinesSpadesAgricultural engineeringAgriculture

The invention discloses an agricultural device for agricultural soil improvement. The agricultural device comprises middle concave blocks and a metal base, and the middle concave blocks are fixedly mounted in the middle of the front end of the metal base. By mounting threaded holes in shaft outer shells of metal shafts, screws can be well mounted, and accordingly convenience in fixation is achieved; when metal ploughshares are mounted fixedly, the metal shanks well sleeve the metal ploughshares through fixing limiting grooves in middles of the shaft outer shells to play a great role in position fixation, so that top end position shifting is limited, and less proneness to outer side shedding is realized; further, convex columns of the metal ploughshares can be well fixed by the shank outershells through lower positioning grooves, so that a great fixing effect is achieved; then, reinforcing fixation can be performed by personnel through the external screws and the fixing threaded holes,and accordingly less proneness to position deviation in soil ploughing is realized.

Owner:田虎

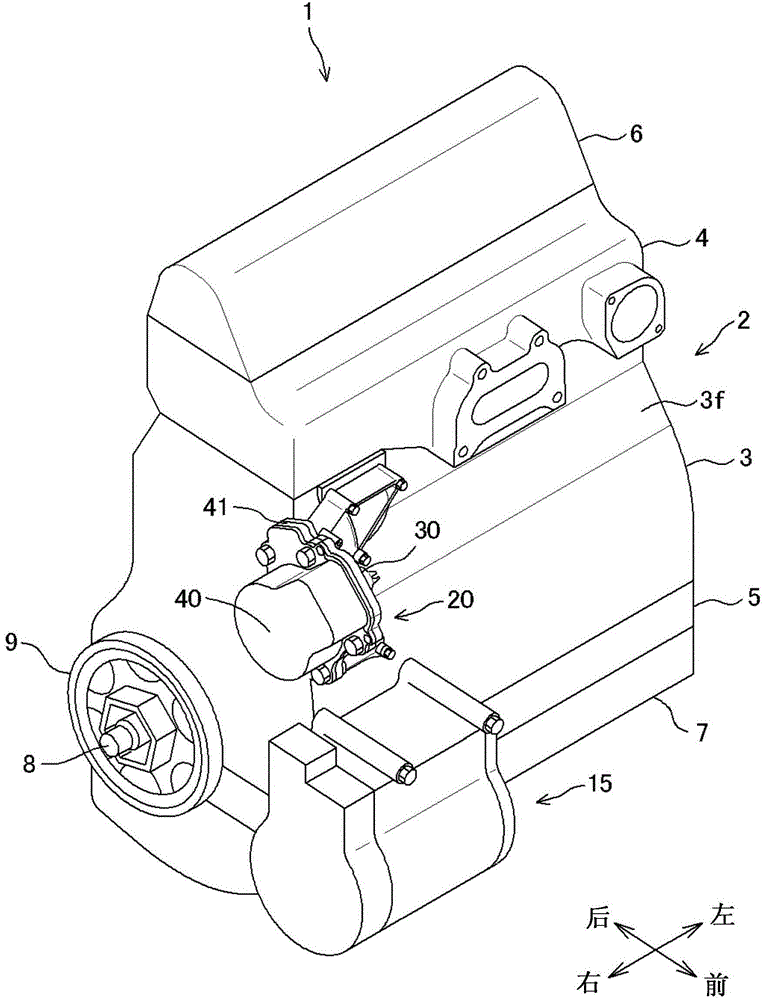

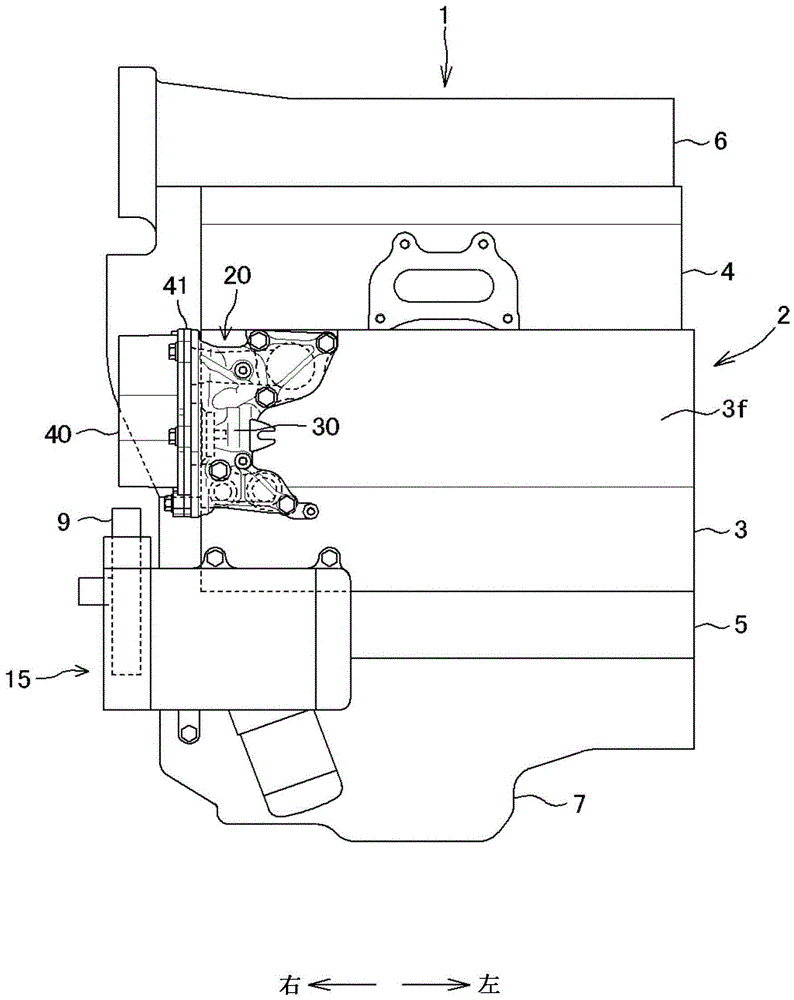

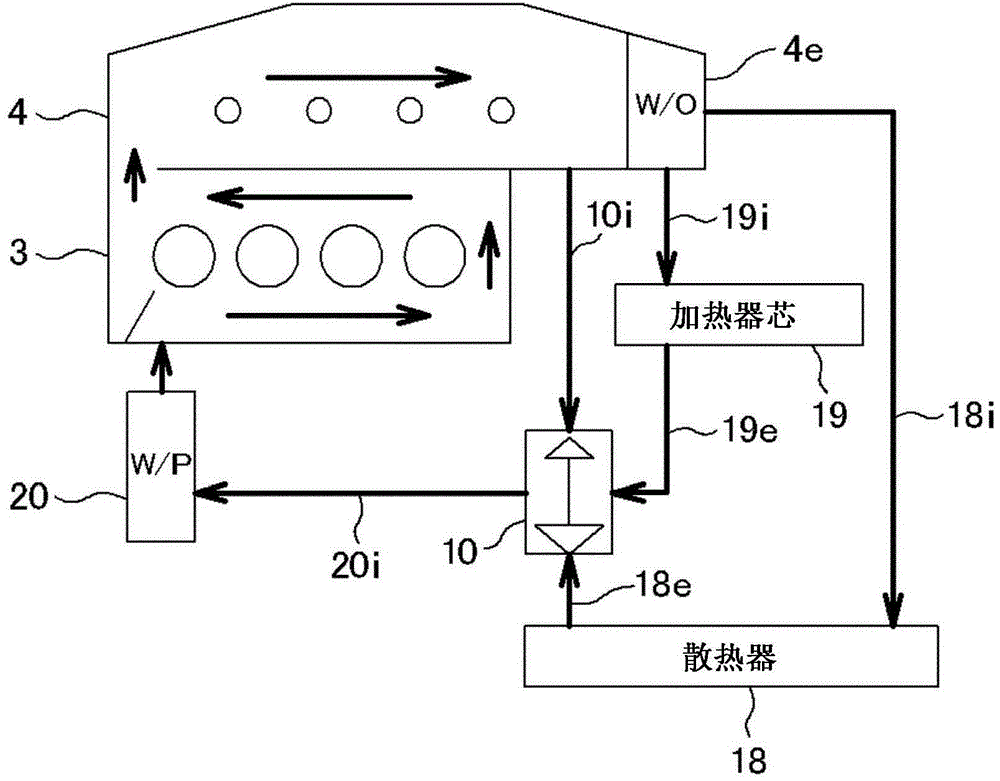

Water pump mounting structure in internal combustion engine

ActiveCN103122790BEffectively share and supportEasy to fixCasingsMachines/enginesDrive shaftEngineering

Owner:HONDA MOTOR CO LTD

Automatic rolled film tightening device

PendingCN114229548ARealize the tightening functionReduce labor intensityWebs handlingElectric machineryMotor drive

Owner:赛尔康(贵港)有限公司

Novel label paper winding device

The invention discloses a novel label paper winding device which comprises a device body, a winding reel, a motor and a bracket. The winding reel is arranged at the upper-right end of the device body. The bracket is fixedly arranged at the right end of the front end face of the device body. A motor base is fixedly arranged at the right end of the rear end face of the device body. The motor is mounted on the motor base and drives the winding reel to rotate. A conveyer belt mounting cavity is formed in the middle of the upper end face of the device body and internally provided with a conveyer belt device. A front positioning baffle is arranged at the front end of the conveyer belt mounting cavity, a rear positioning baffle is arranged at the rear end of the conveyer belt mounting cavity, and the front positioning baffle and the rear positioning baffle are symmetrically arranged. A lamp base is fixedly arranged at the front end of the motor base and provided with a lamp rack which is provided with an LED lamp. A button switch used for controlling on and off of the LED lamp is arranged on the upper end face of the lamp base. According to the technical scheme, the structure is reasonably designed and is simple, operation is easy, the positioning effect is good, using is convenient, and label paper is neatly wound.

Owner:嘉兴市耀华精密金属股份有限公司

Drum washing machine

InactiveCN1584175BHigh strengthAvoid deformationOther washing machinesTextiles and paperEngineeringMechanical engineering

The purpose of this invention is to stably secure a water sealing state while closed by improving the strength of a connecting member of connecting a cover with a washing machine main body so as to prevent deformation due to overloading to the cover and so as to hardly deviate the cover in a drum type washing machine which washes garments within a rotation drum. An opening part 31 in front of thewashing machine main body 32 is covered with the cover 39 in an openable and closable state. The rotary shaft part of the cover 39 is provided at the washing machine main body 32, and the rotary shaft part and the cover 39 are connected by a pair of connection members 35 and 36. The pair of connection members 35 and 36 are nearly circular with the rotary shaft part as a center, and the diameter of the nearly circular arc is increased with the separating distance between both of the connection members.

Owner:PANASONIC CORP

Power grid current limiting device and system

ActiveCN112399777AAvoid gatheringSpeed up distributionCooling/ventilation/heating modificationsCurrent limitingPower grid

The invention discloses a power grid current limiting device and system, and belongs to the electrical field. By arranging an outer heat removal shell, during long-time work, a large amount of heat isgathered at an air lift transfer rod, so that an air lift ejector rod is heated to jack up the air lift transfer rod outwards, and the air lift ejector rod continuously moves out of an embedded heatgathering groove until the end part contacts with a corresponding inward heat accumulation sheet, on one hand, the contact area of the air lift transfer rod and a heat removal liquid is increased, outward dissipation of heat gathered on the air lift transfer rod is accelerated, and on the other hand, the heat on a heat transfer ball is directly transferred to the outside of an outer heat removal shell through a heat conduction wire, so that the heat dissipation efficiency is further improved; and when the heat on the heat transfer ball is reduced to a certain extent, the air lift transfer rodretracts into the embedded heat accumulation groove, the air lift transfer rod moves inwards and outwards again along with the re-accumulation of the heat, and the process is repeated continuously, sothat the heat dissipation efficiency is improved, the accumulation of the heat on the current limiting device body is effectively avoided, and the normal operation of a power grid is effectively guaranteed.

Owner:TAIYUAN LONGWAY ELECTRONICS SCI & TECH

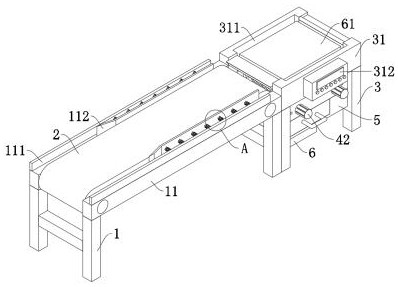

A fully automatic backlight laminating machine

ActiveCN113400772BLess prone to positional deviationReduce the possible impact on finished product qualityLamination ancillary operationsLaminationDust controlEngineering

This application relates to a full-automatic backlight lamination machine, including a brightness enhancement film conveyor belt used to transport the brightness enhancement film, a diffusion film conveyor belt used to transport the diffusion film, and a diffusion film conveyor belt located near the brightness enhancement film conveyor belt and the diffusion film conveyor belt. The lamination table for placing the bottom plate, the static electricity removal device installed on the lamination table to remove static electricity from the brightness enhancement film and the diffusion film, the dust removal device installed on the lamination table to remove dust from the brightness enhancement film and the diffusion film, and installed on the lamination film The moving rod above the stage, the diffusion film adsorption device arranged at the end of the moving rod and used to absorb the diffusion film, the brightness enhancement film adsorption device arranged at the end of the moving rod away from the diffusion film adsorption device and adsorbing the brightness enhancement film, and the film lamination table The table rod, the rod moving mechanism which is set on the table rod and drives the moving rod to move along the same linear direction where the diffusion film conveyor belt, the enhancement film conveyor belt, and the lamination table are located, is set at both ends of the moving rod and can be abutted The limit rod on the pole has the effect of reducing the possible impact on the quality of the assembled product.

Owner:深圳亿成光电科技有限公司

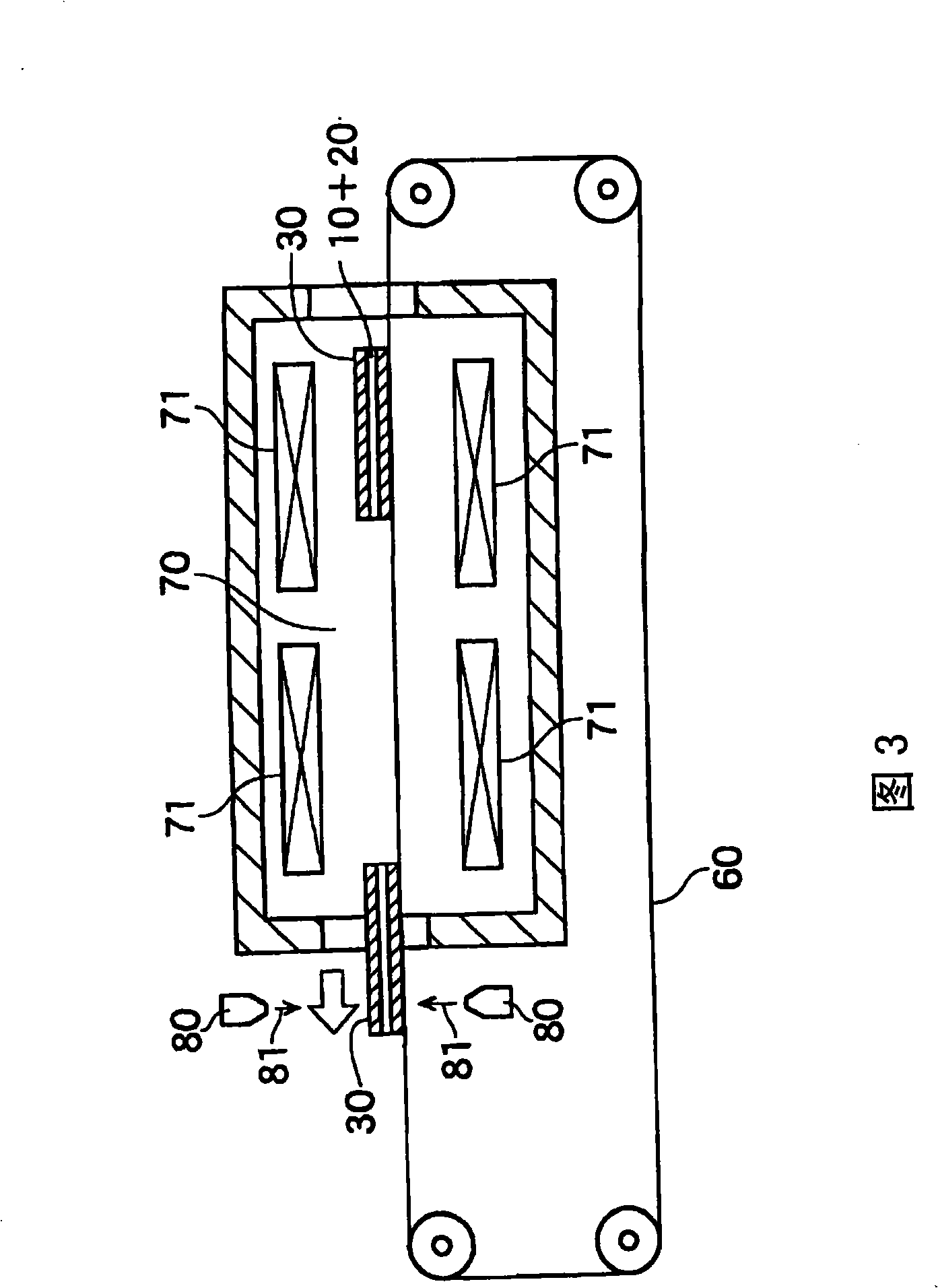

Method for soldering interconnectors to photovoltaic cells

InactiveCN101281937AReduce compressionReduce liftPhotovoltaic energy generationSemiconductor devicesInterconnectorEngineering

A method and apparatus for soldering interconnectors to photovoltaic cells that, after soldering, prevents bending of the photovoltaic cells due to heat warping caused by heat contraction of the lead wires. The interconnectors are positioned at predetermined positions on the photovoltaic cell, the interconnectors and the photovoltaic cells are held tightly together, and the solder is melted as the photovoltaic cells are heated, after which the photovoltaic cells are sequentially cooled in the long direction of the interconnectors with cold blasts from the end of the photovoltaic cells in the long direction of the interconnector.

Owner:NISSHINBO IND INC

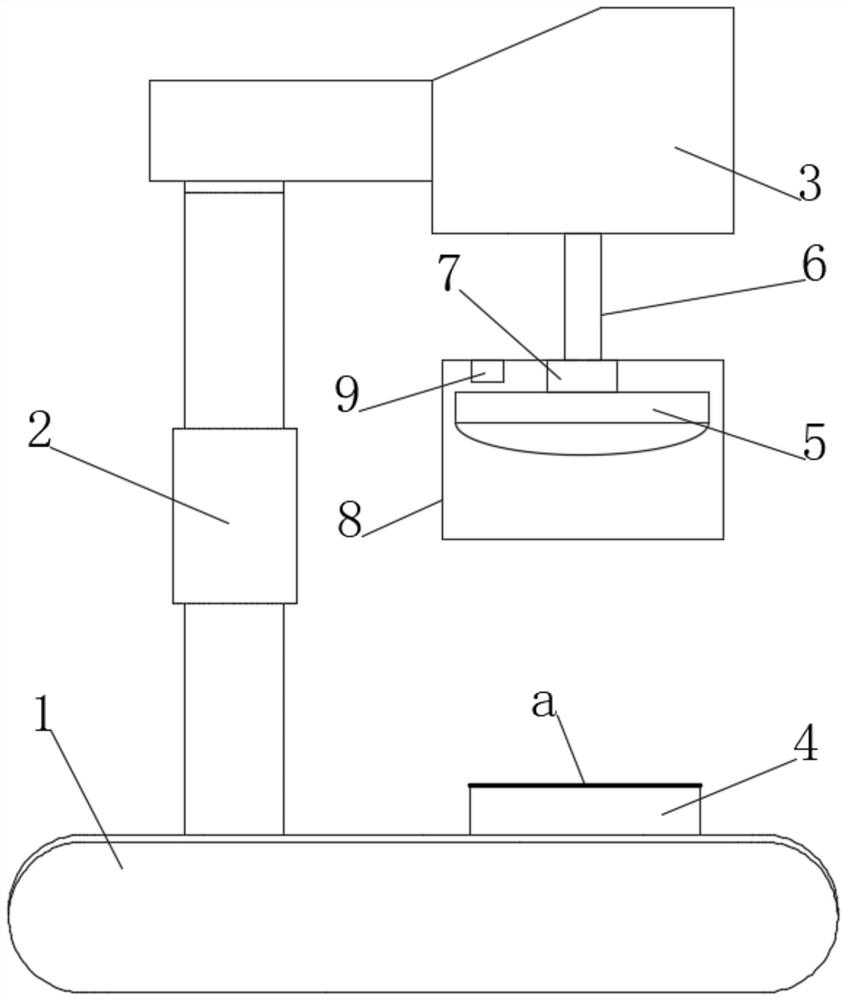

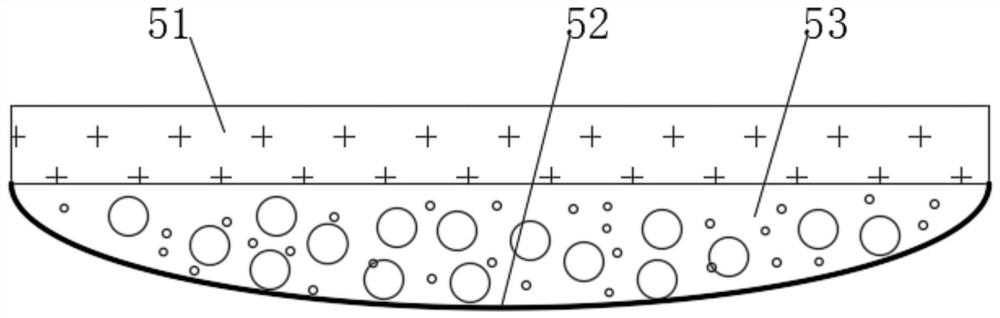

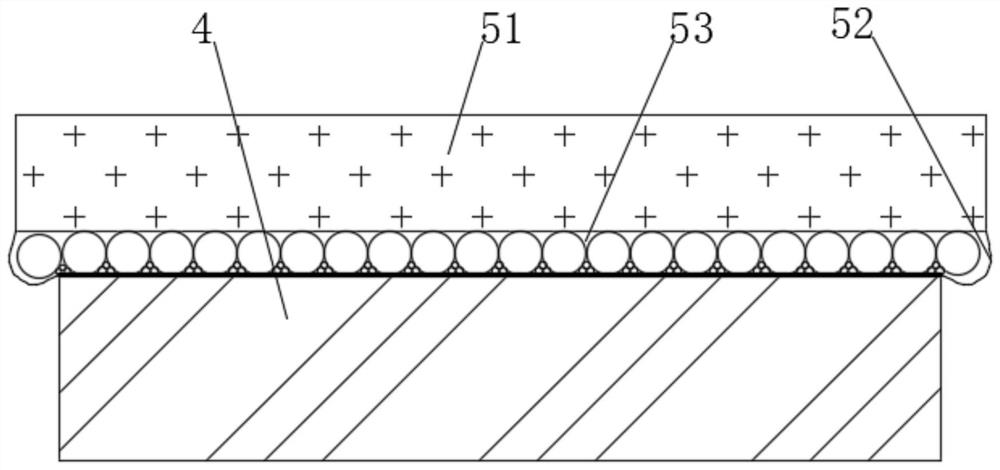

Novel mobile phone display screen pressure-bearing detector

ActiveCN111885249AHigh precisionImprove test accuracySubstation equipmentElectrical and Electronics engineeringMobile phone

The invention discloses a novel mobile phone display screen pressure-bearing detector, and belongs to the field of pressure-bearing detection equipment. The detector can convert the whole surface stress of a mobile phone display screen into multi-point stress during a pressure-bearing test through the arrangement of a force conversion bag, so as to enable the surface local bearing force of a cellphone display screen to be non-uniform; compared with whole-surface stress, multi-point stress detection is more suitable for the situation that the mobile phone display screen is broken due to unevenlocal stress in the using process, then the reference degree of the detection result for fragile improvement of the mobile phone display screen is higher, and in the testing process, a force conversion bag completely wraps the mobile phone display screen, the stability of the mobile phone display screen during stress is improved, the probability that the mobile phone display screen is broken in advance during testing is reduced, meanwhile, under the interaction of the multiple force conversion point balls and the inner limiting layer, the stability of multiple stress points on the mobile phonedisplay screen can be improved, and the probability that the mobile phone display screen lags behind to be broken during testing is reduced; and the precision of a test result is significantly improved.

Owner:深圳市宏瑞来科技有限公司

Production device for preparing composite thermal insulation material through doping with polylactic acid

InactiveCN112297296ALess prone to positional deviationReduce labor costsPlastic recyclingMechanical material recoveryThermal insulationEngineering

The invention discloses a production device for preparing a composite thermal insulation material through doping with polylactic acid. The production device comprises a first mounting frame and a second mounting frame which are symmetrically arranged, wherein first beams are fixedly connected to the top end of the first mounting frame, a conveying belt is arranged between the two first beams, sideplates are fixedly arranged on the edges of the sides, away from the conveying belt, of the top faces of the first beams, pressing plates are slidably arranged on the top faces of the first beams, aplurality of limiting blocks which are linearly distributed at equal intervals are fixedly arranged on the face, close to the pressing plate on the same side, of each side plate, and the outer sides of the limiting blocks are sleeved with springs. According to the production device, by slidably arranging the pressing plates on the top faces of the first beams, fixedly arranging the limiting blockswhich are linearly distributed at equal intervals on the face, close to the pressing plate on the same side, of each side plate and sleeving the outer sides of the limiting blocks with the springs, acomposite thermal insulation board is always located in the middle of the top face of the conveying belt in the process of moving towards a supporting plate, and position deviation is not likely to occur.

Owner:赵欠

A New Type Supporting Insulator Turning Fixture

InactiveCN104070376BLess prone to positional deviationSimple structureWork clamping meansPositioning apparatusEngineering

Owner:中发输配电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com