Optical fiber connector, method for manufacturing optical fiber connector, method for connecting optical fiber connector and optical fiber, and assembled body of optical fiber connector and optical fiber

A technology of optical fiber connector and optical fiber, applied in the direction of optical waveguide light guide, coupling of optical waveguide, light guide, etc., can solve the problems of complexity, light loss, and many processes, and achieve the effect of not being easy to shift position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0086] (Structure of fiber optic connector)

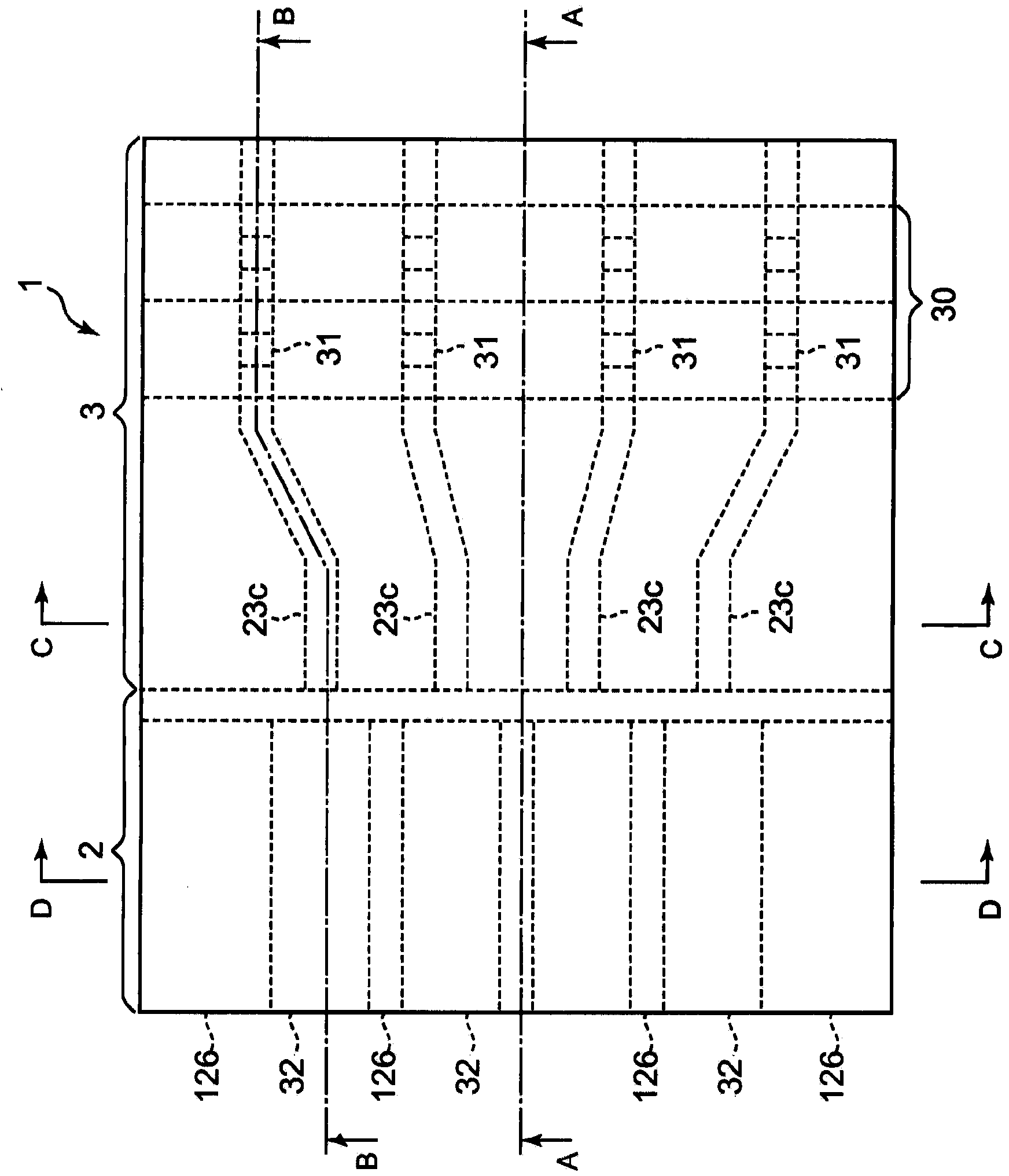

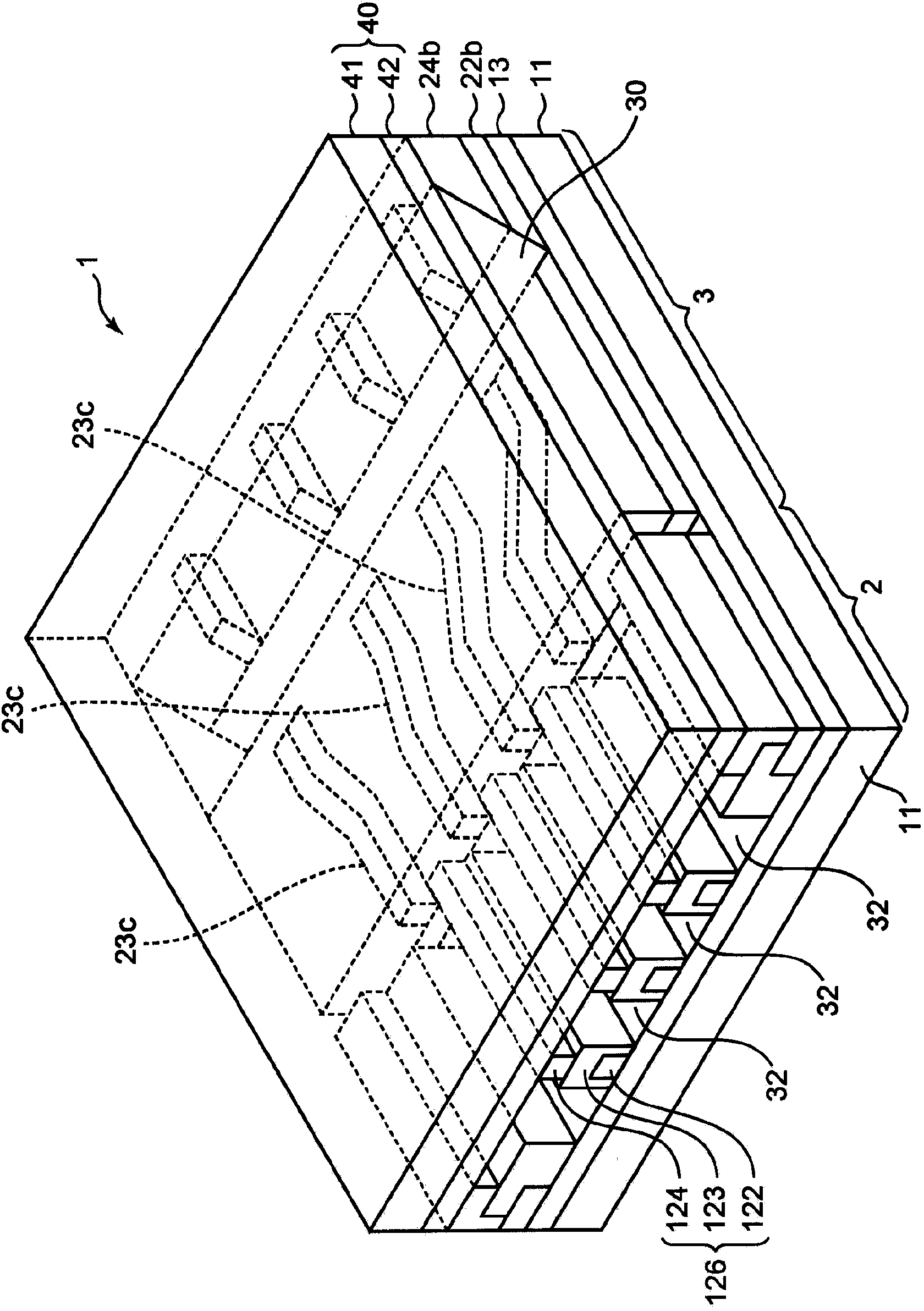

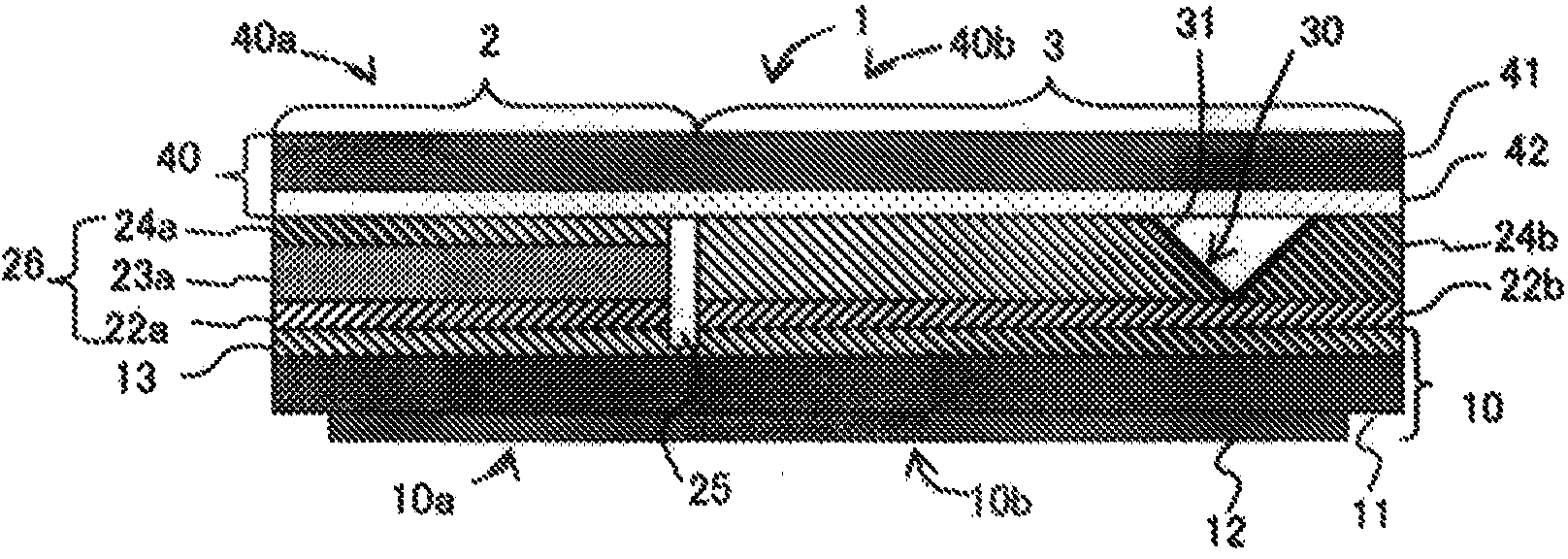

[0087] Hereinafter, the optical fiber connector 1 according to the first embodiment will be described with reference to the drawings. figure 1 It is a plan view showing the optical fiber connector 1 of the first embodiment, figure 2 It is a perspective view showing the optical fiber connector of the first embodiment, image 3 for along figure 1 The end view of the A-A line, Figure 4 for along figure 1 The end view of the B-B line, Figure 5 for along figure 1 The end view of the C-C line, Figure 6 for along figure 1 End view of the D-D line.

[0088] The optical fiber connector 1 of the first embodiment is an optical fiber connector in which an optical fiber guide member 2 and an optical waveguide 3 are arranged side by side.

[0089] The fiber guide member 2 is composed of a part constituting the substrate 10 ( image 3 The fiber guide side substrate part 10a on the left side in the middle), the fiber guide pattern 26...

no. 2 Embodiment approach

[0191] (Structure of fiber optic connector)

[0192] In the optical fiber connector of the second embodiment, in the optical fiber connector of the first embodiment, instead of the slit groove 25 or together with the slit groove 25, there is an adhesive introduction that communicates with the outside of the optical fiber guide member 2 and the fiber guide groove 32. Slit fiber optic connectors.

[0193] In the optical fiber connector of the second embodiment, the fiber guide groove 32 communicates with the outside through the fiber insertion port of the fiber guide groove 32 and communicates with the outside through the adhesive introduction slit. Therefore, when the adhesive is introduced from one of the optical fiber insertion port and the adhesive introduction slit, the air in the fiber guide groove 32 flows out from the other of the optical fiber insertion port and the adhesive introduction slit. Thus, the adhesive can be easily introduced into the fiber guide groove 32 ....

Embodiment 1

[0279] [Production of Optical Fiber Connector 1A]

[0280] (1st process)

[0281] The 20 μm thick lower cladding layer-forming resin film obtained above was cut into a size of 100×100 μm, the protective film was peeled off, and laminated on the second lower cladding layer side by a vacuum laminator under the same conditions as above. Irradiate 250mJ / cm from the carrier film side through a negative photomask with 95μm x 3.0mm x 4 non-exposed parts using an ultraviolet exposure machine (manufactured by ORC Seisakusho, Ltd., EXM-1172). 2 Ultraviolet light (wavelength 365nm). Then, the carrier film was peeled off, and the first lower cladding layer was etched with a developer solution (1% potassium carbonate aqueous solution). Next, it was washed with water, dried and cured by heating at 170° C. for 1 hour, and an opening of 95 μm×3.0 mm was formed in the portion where the fiber guide groove was formed. As a result, the optical waveguide side first lower cladding layer 22b is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com