Patents

Literature

30results about How to "Not easy to shift position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

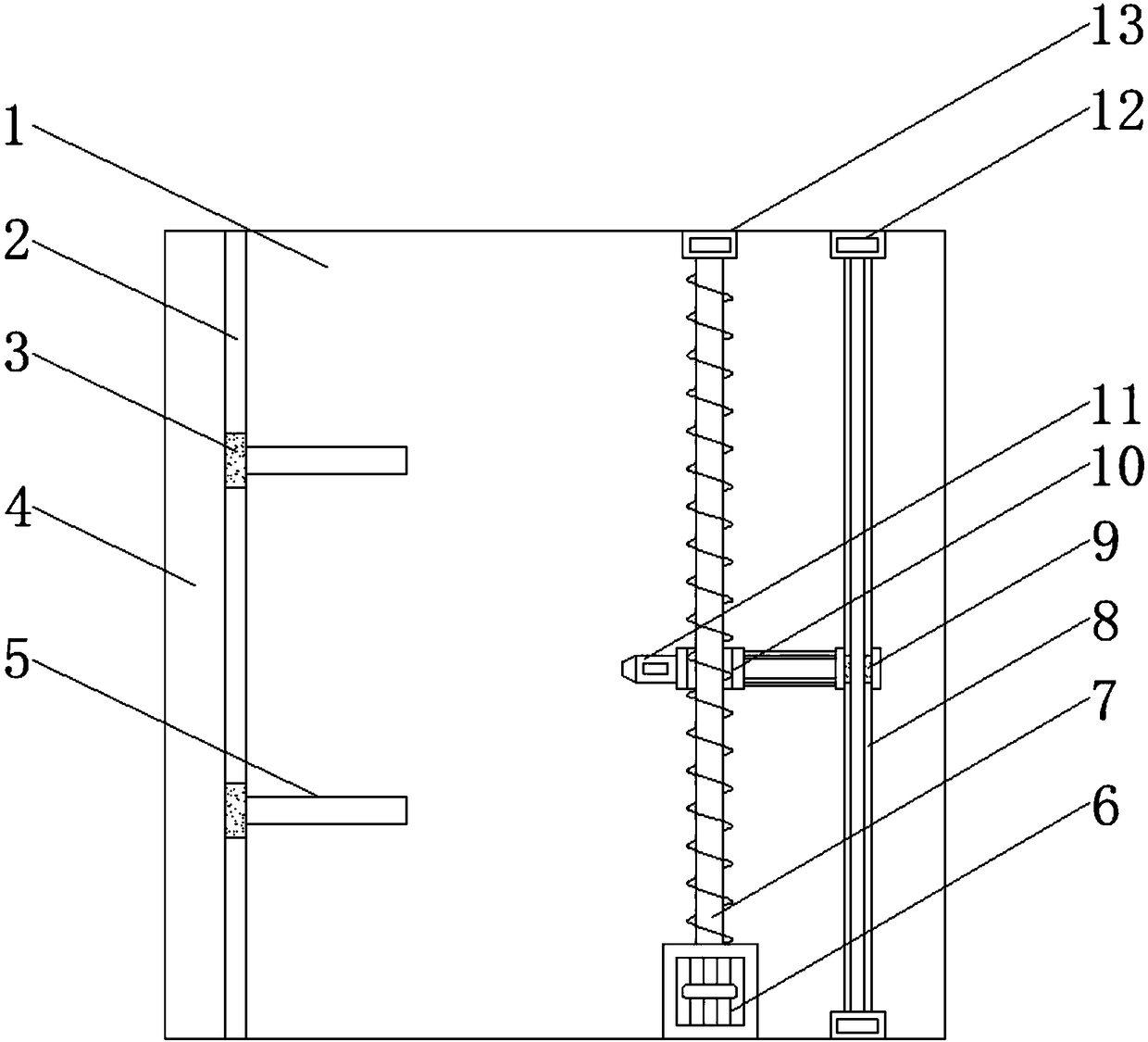

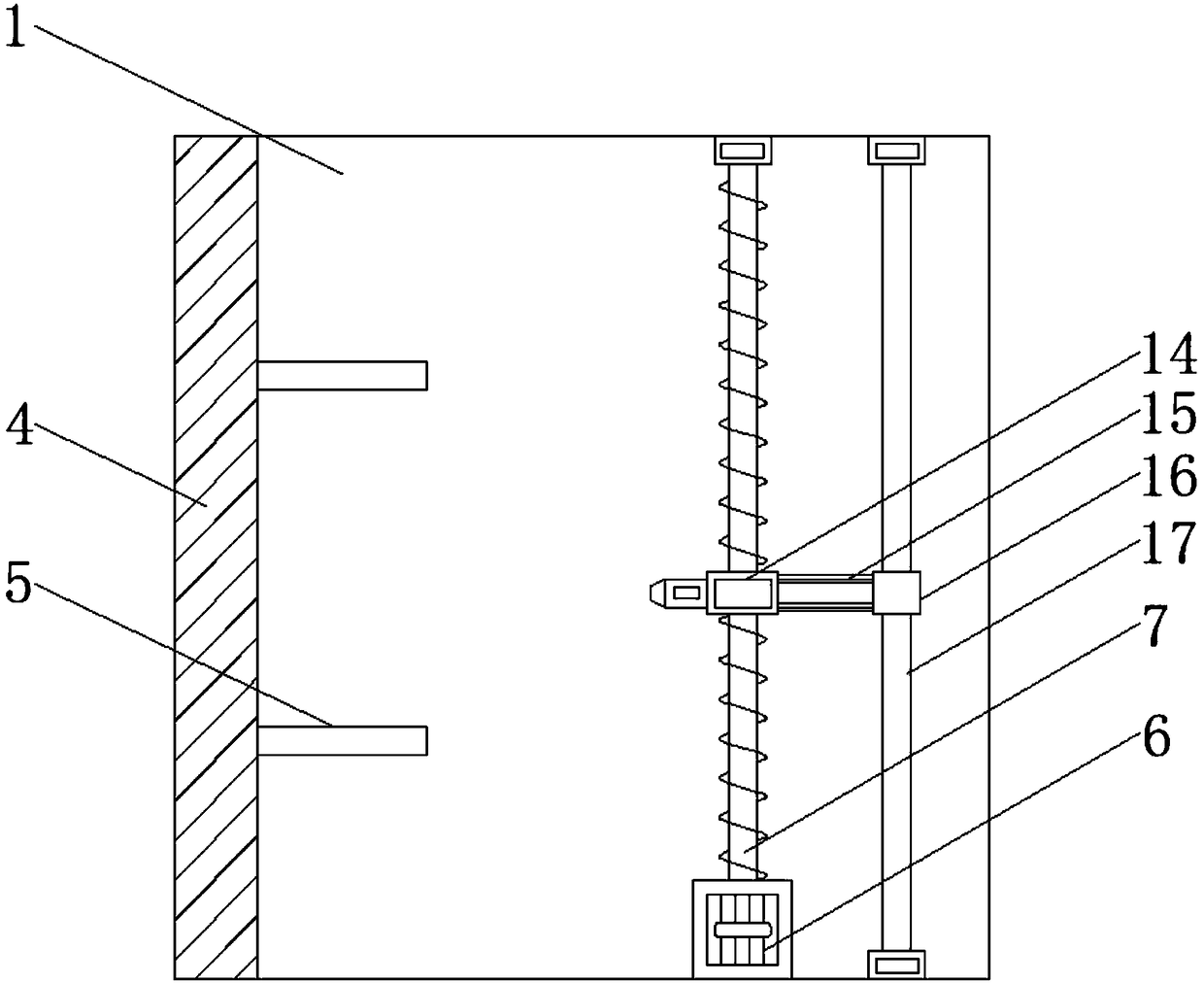

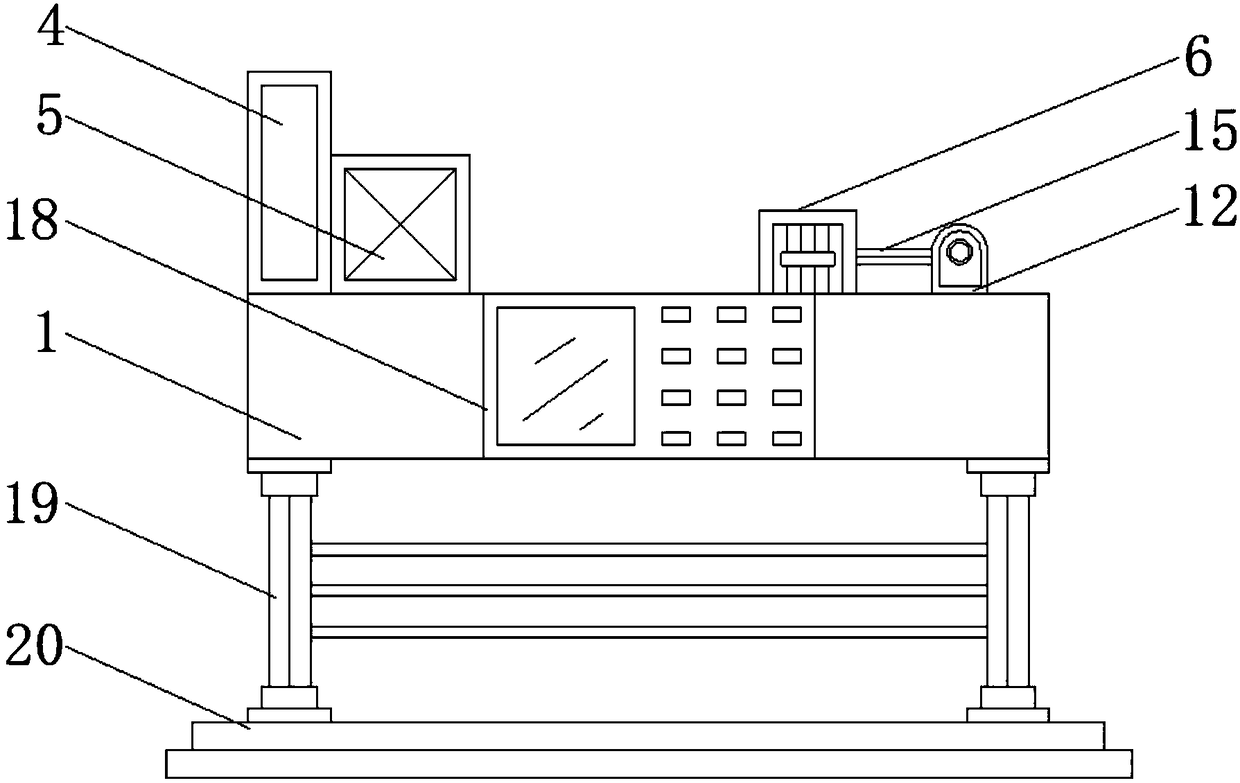

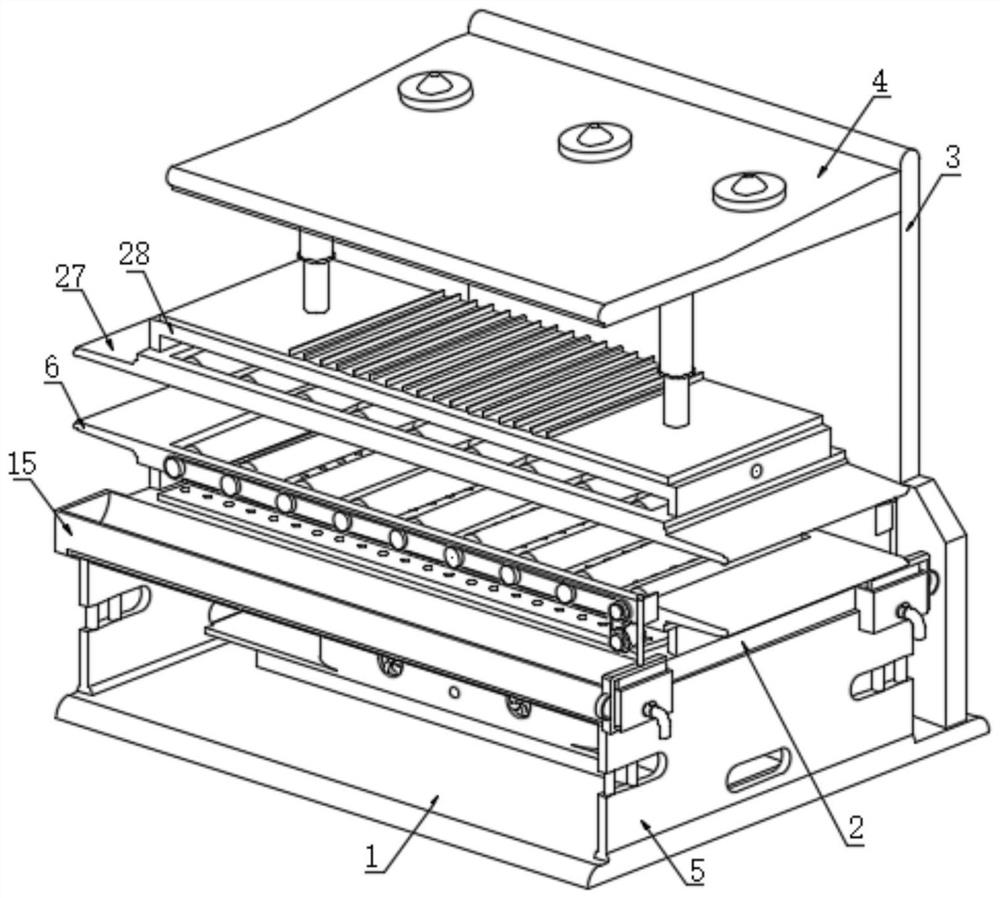

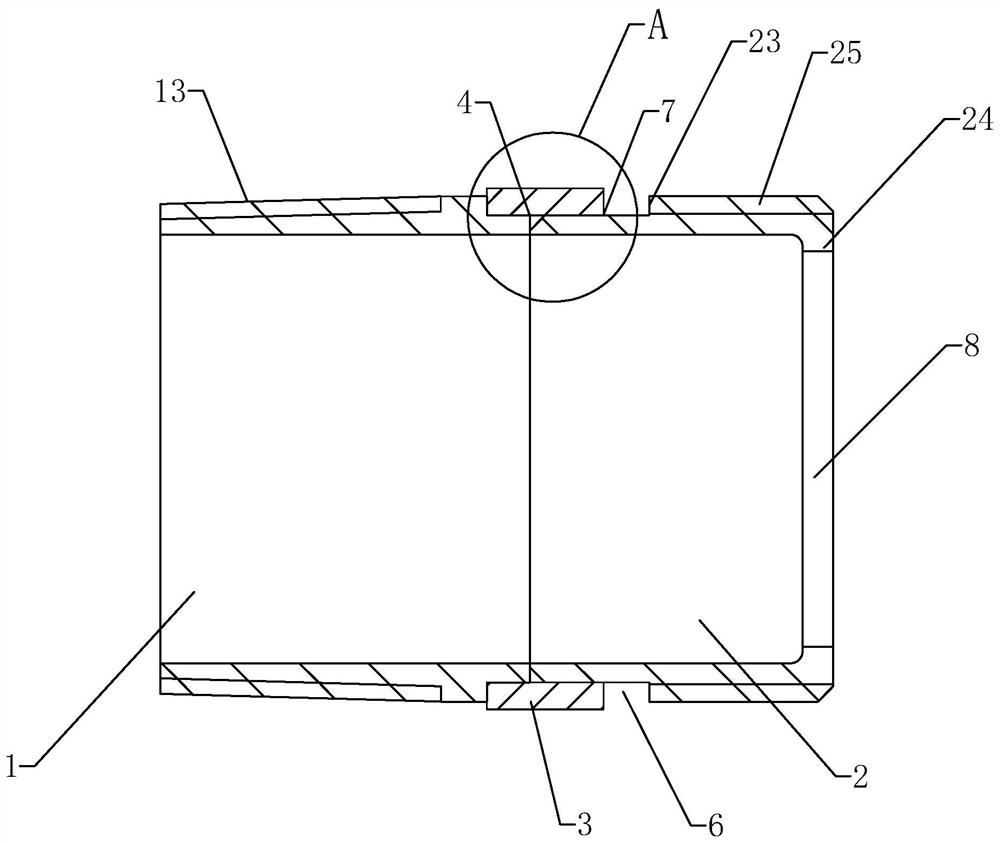

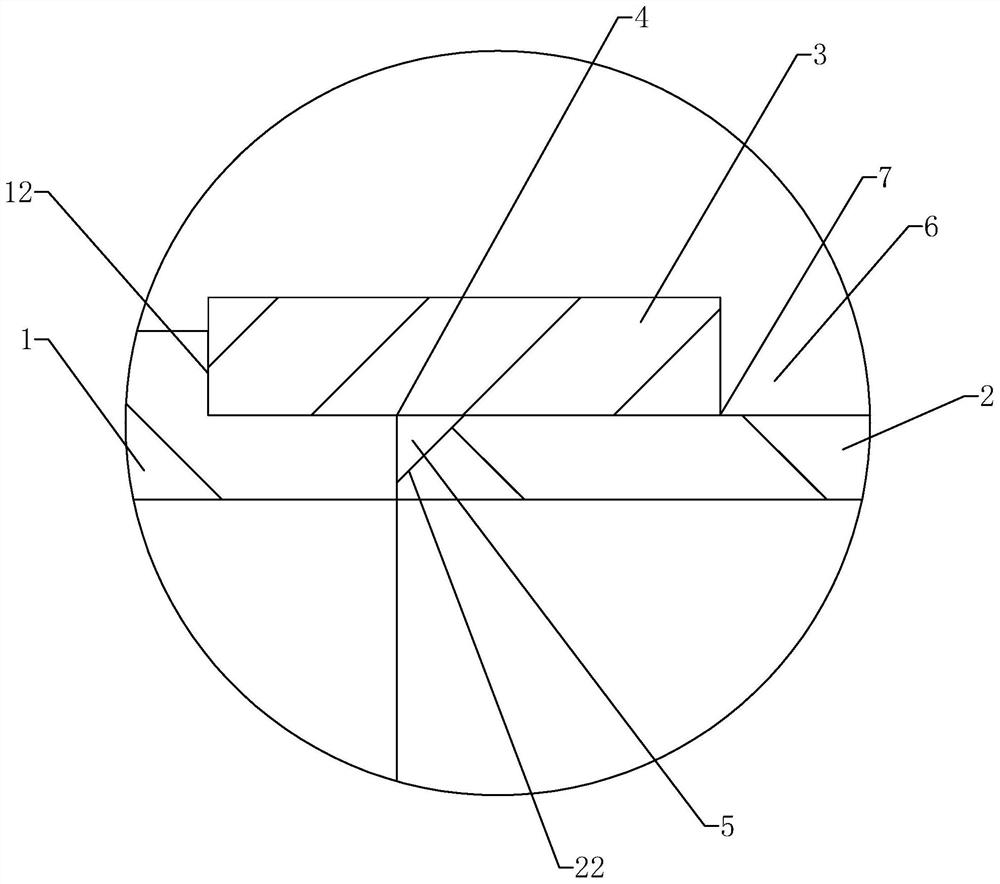

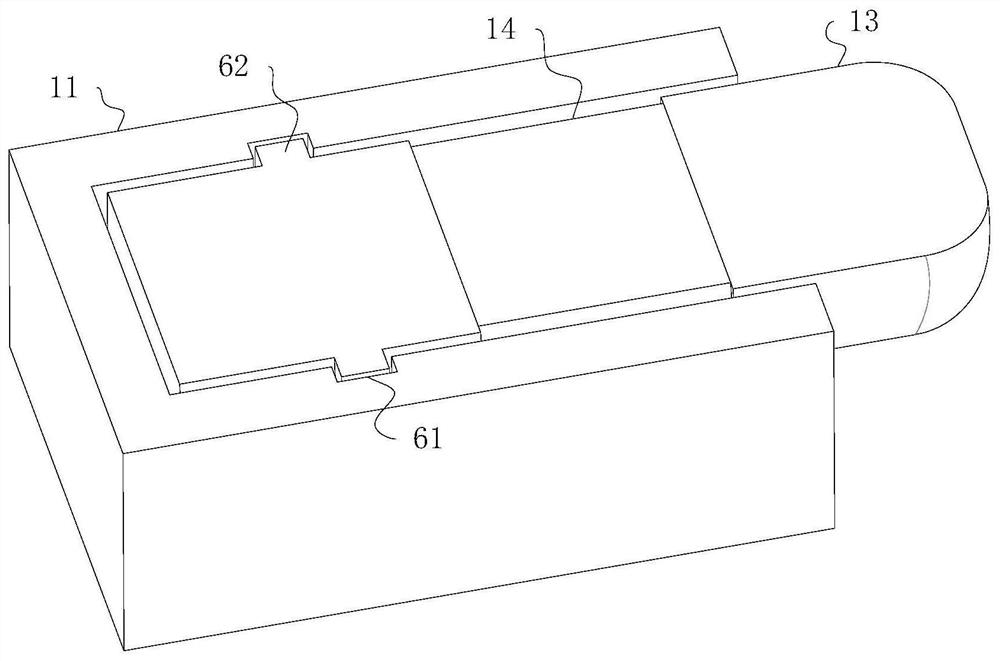

Device for detecting flatness of liquid crystal display screen frame

PendingCN108225221AThe fastening process is convenient and fastSimple structureUsing optical meansMotor driveLiquid-crystal display

The invention discloses a device for detecting the flatness of a liquid crystal display screen frame. The device comprises an operation platform, an electromagnetic slide rail, a fixed baffle, a motor, a screw rod, a slide rod, a controller and a fixed base and is characterized in that fixed rods are vertically mounted at the four corners of the top end of the fixed base, the operation platform istransversely mounted at the top ends of the fixed rods, the controller is mounted in the middle of one side of the operation platform, and the fixed baffle is vertically mounted on one side of the top end of the operation platform. The device has the advantages that the device is provided with the motor, the screw rod, a second bearing block, a threaded slide sleeve, a threaded slide sleeve shelland an infrared range finder, the motor drives the screw rod to rotate when the device is used, the threaded slide sleeve rotates to drive the threaded slide sleeve shell and the infrared range finder to move so as to measure the distance between the liquid crystal display screen frame and the infrared range finder to check whether the liquid crystal display screen frame is flat or not, and the device is simple in structure and convenient and efficient to operate.

Owner:苏州梅克兰检测服务有限公司

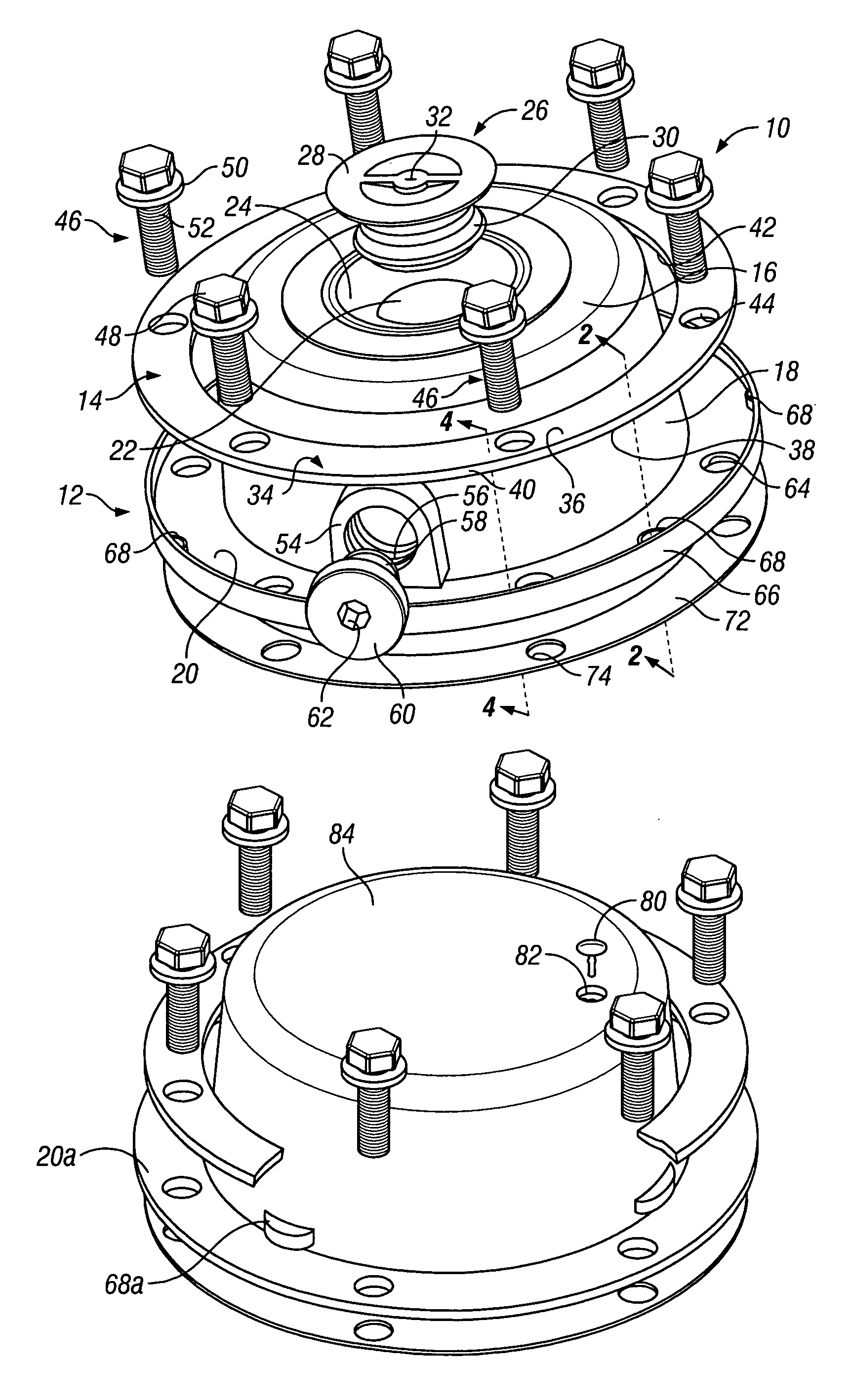

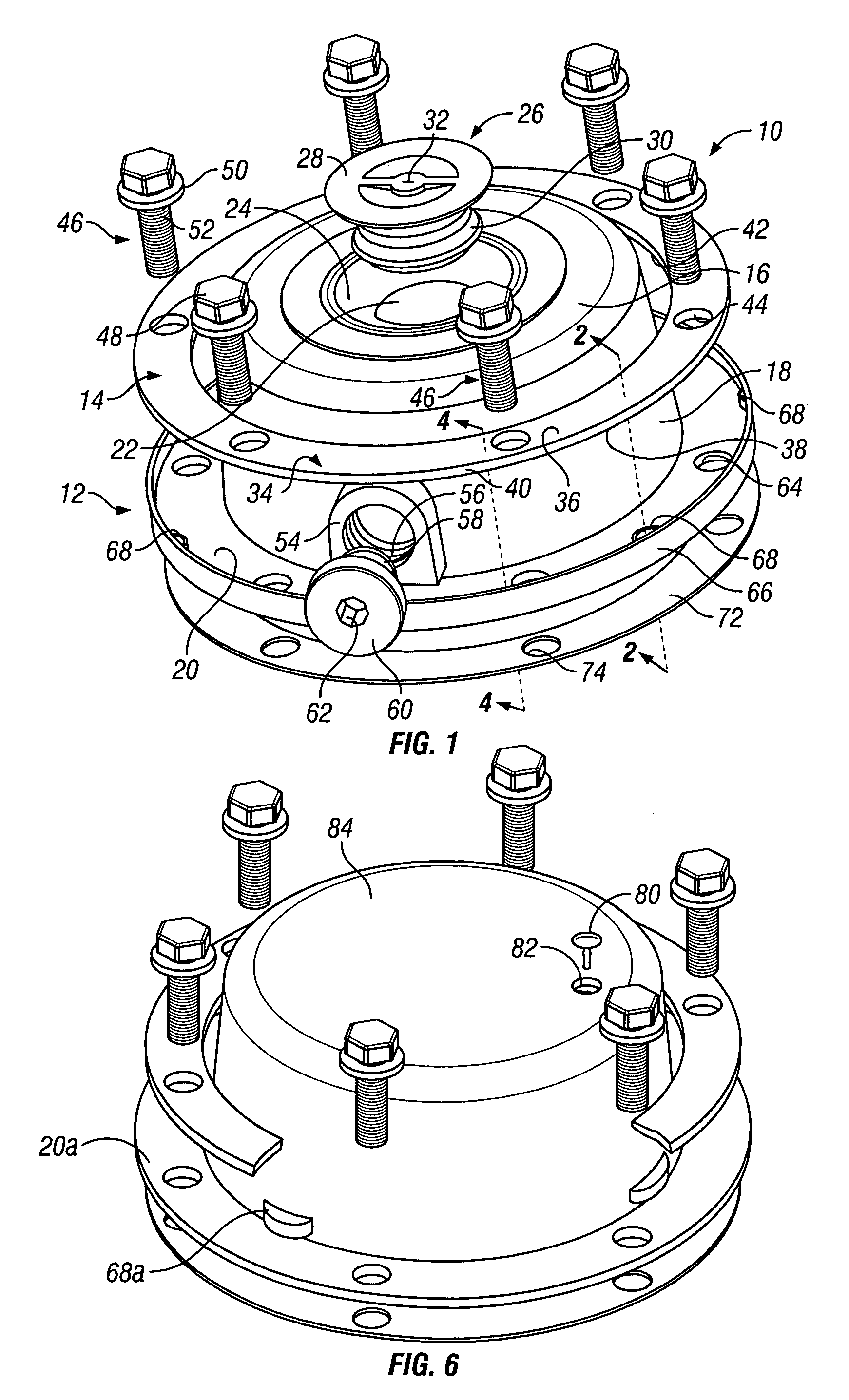

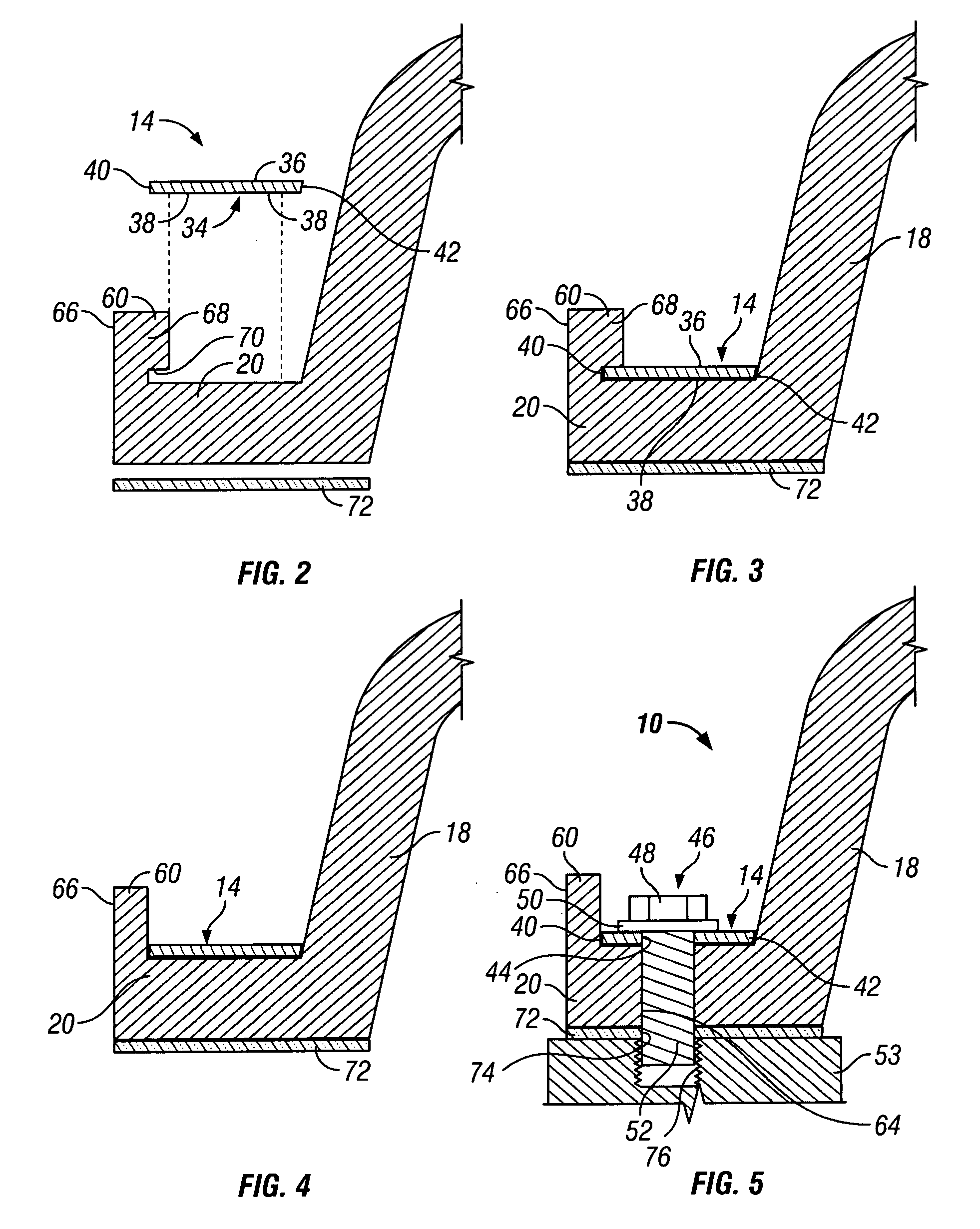

Low cost truck or like hubcaps

The hub cap has first end wall portion, a sidewall portion and a laterally extending mounting flange. There are plural fastener-receiving openings in the flange. A second endwall portion is integrally formed on the flange and is free from engagement with the hold-down ring. The second end wall portion has a plurality of integral retainers of reduced diameter with respect to the remainder of the wall. There is a hold down ring made from a stiff metal material, overlying the flange on the hub cap. The hold down ring has plural fastener-receiving openings therein, and the retainers snugly secure the hold-down ring in its installed position.

Owner:SKF USA INC

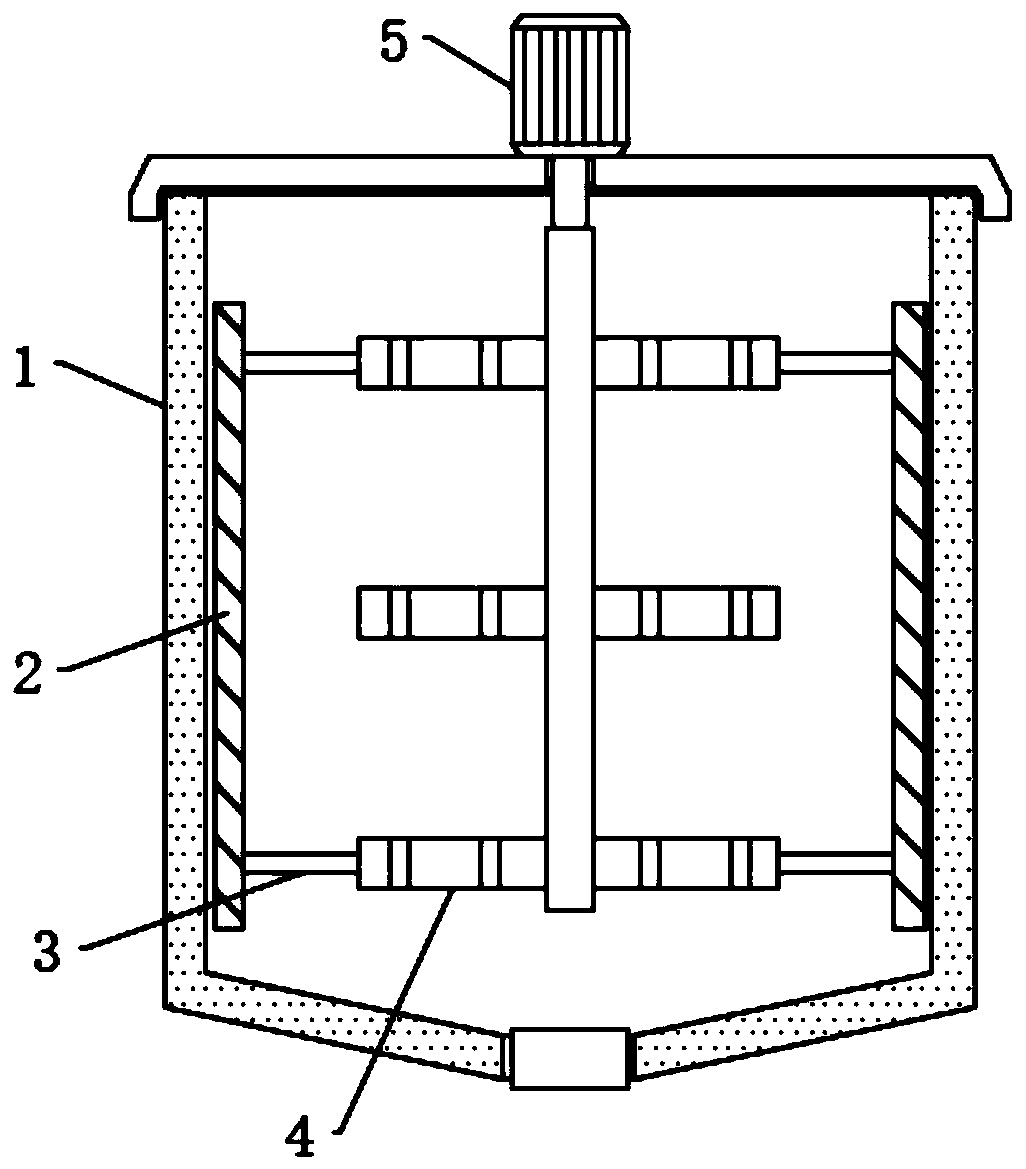

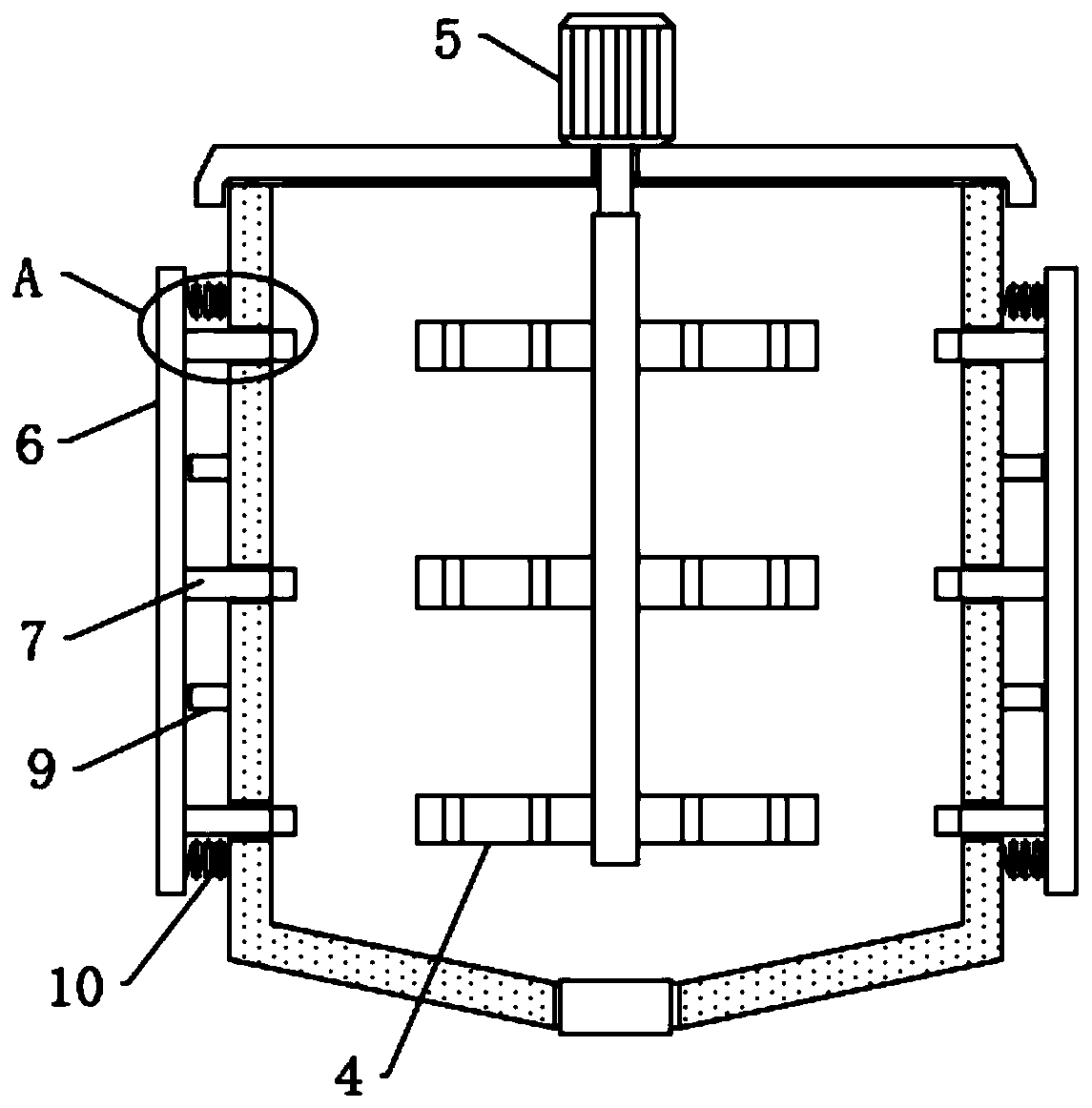

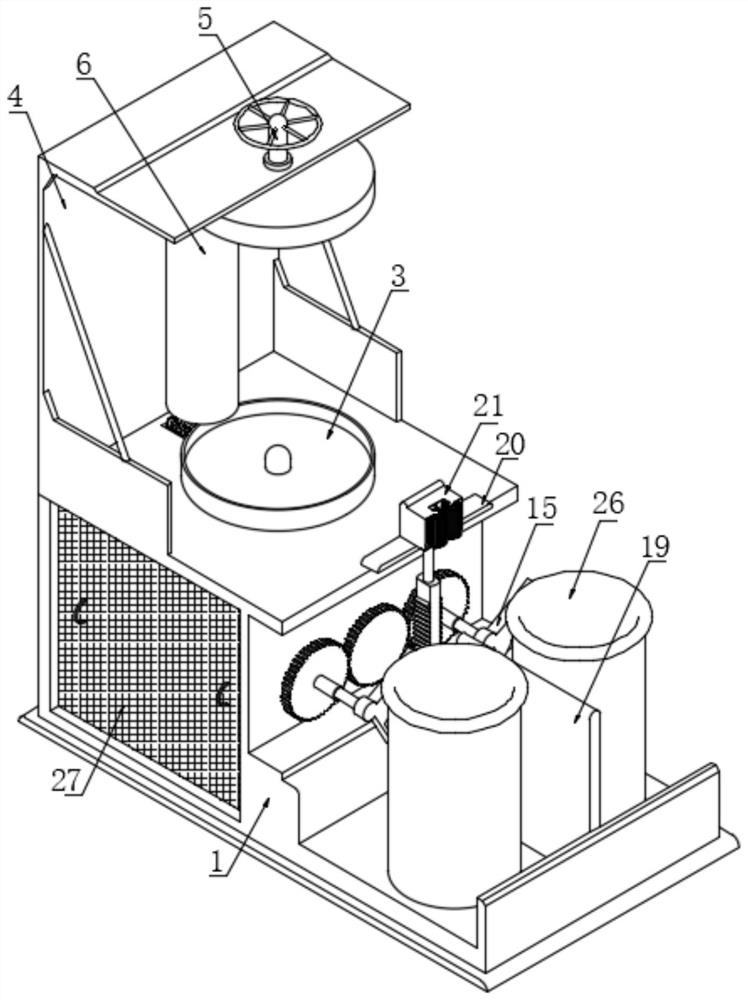

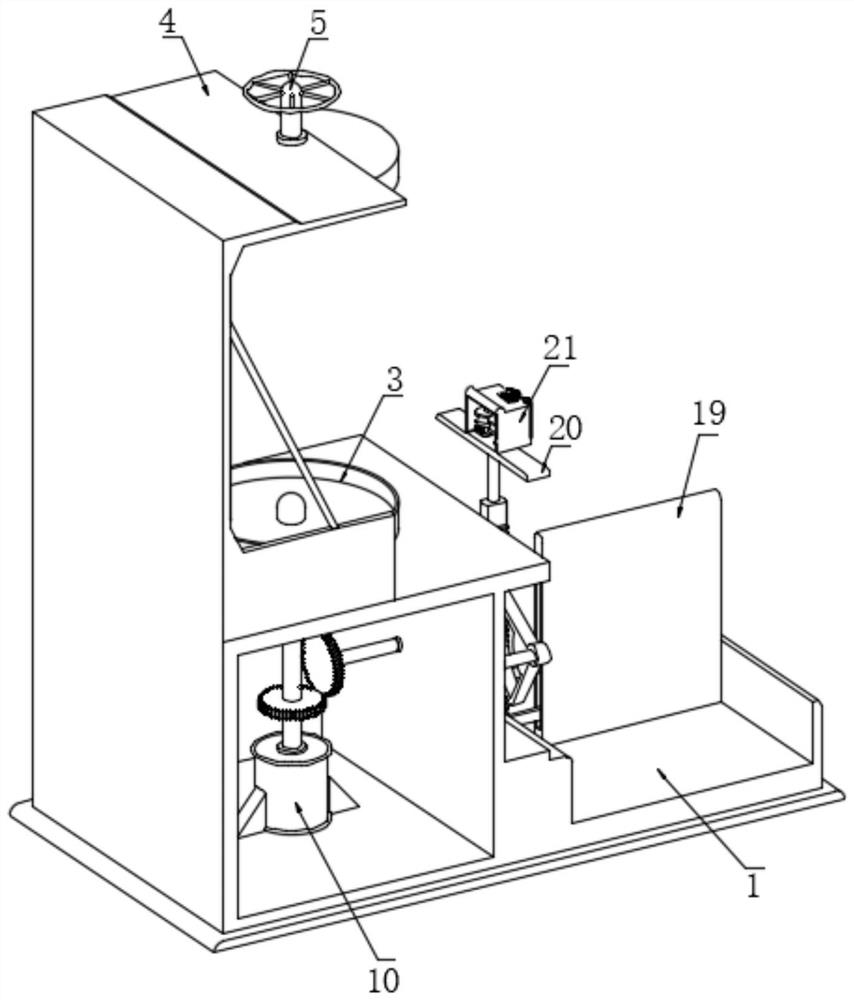

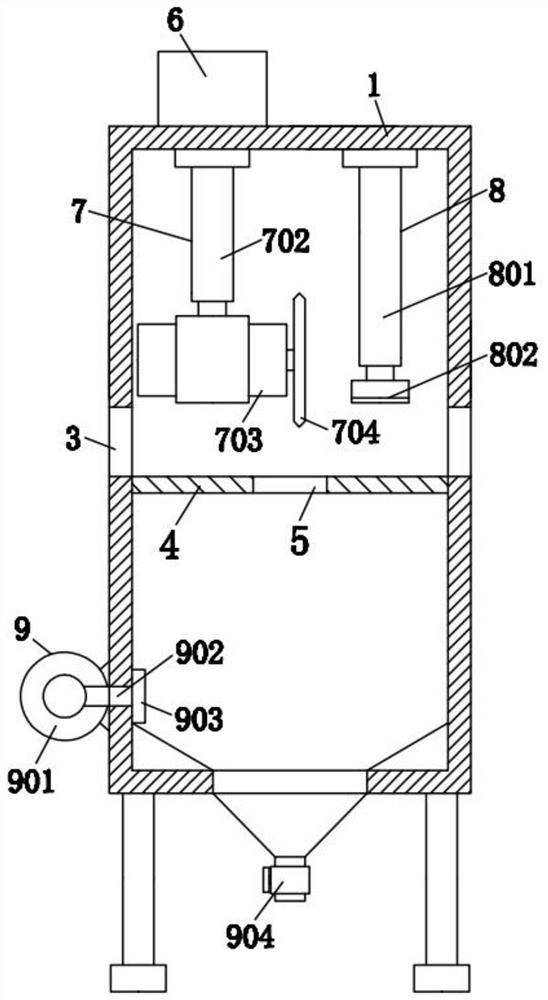

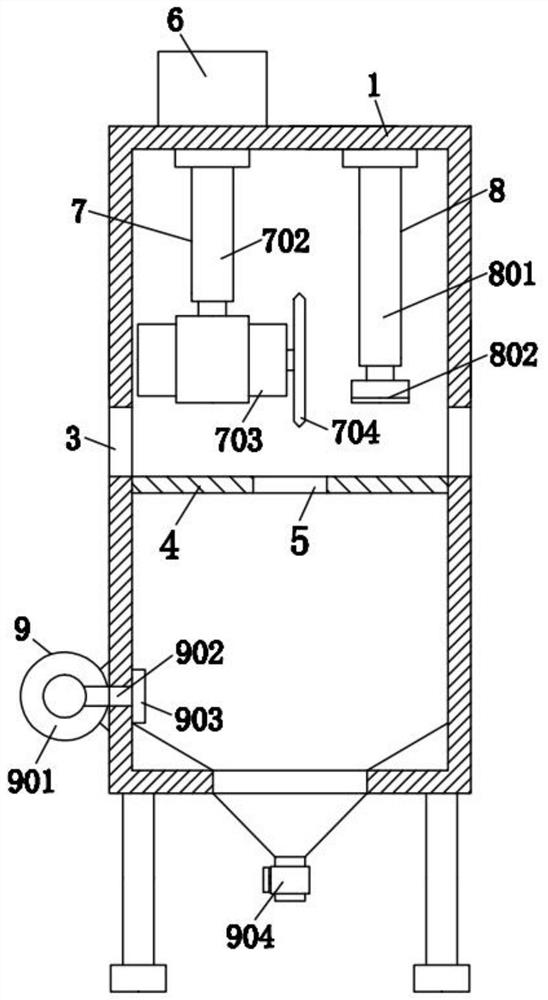

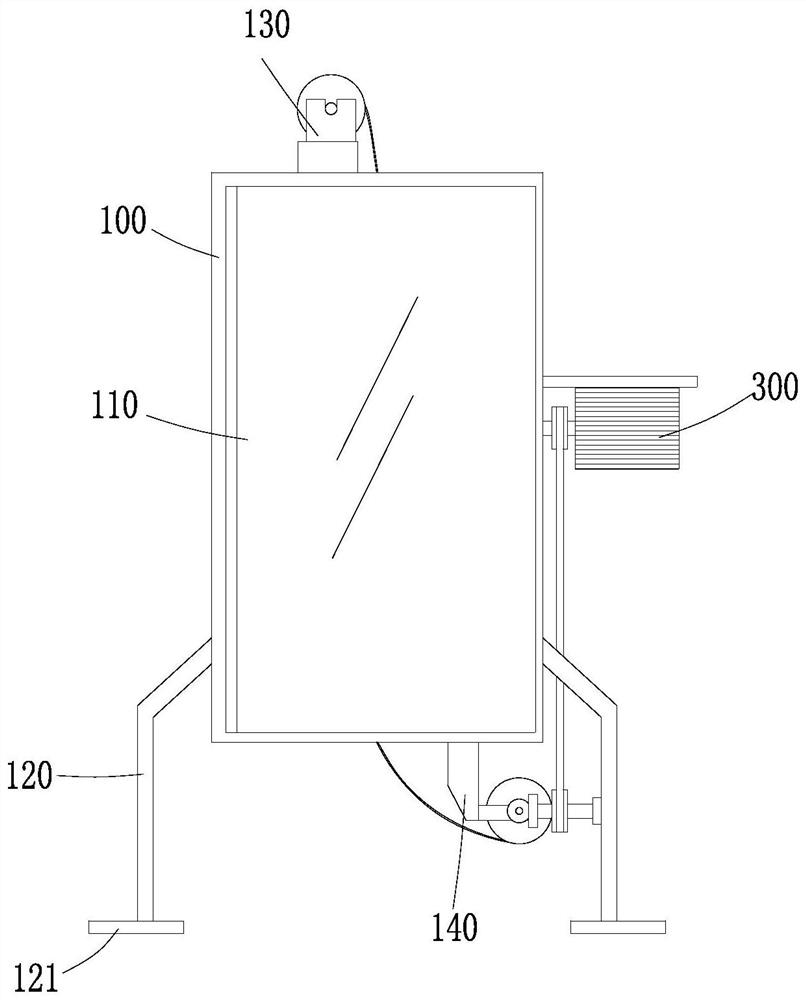

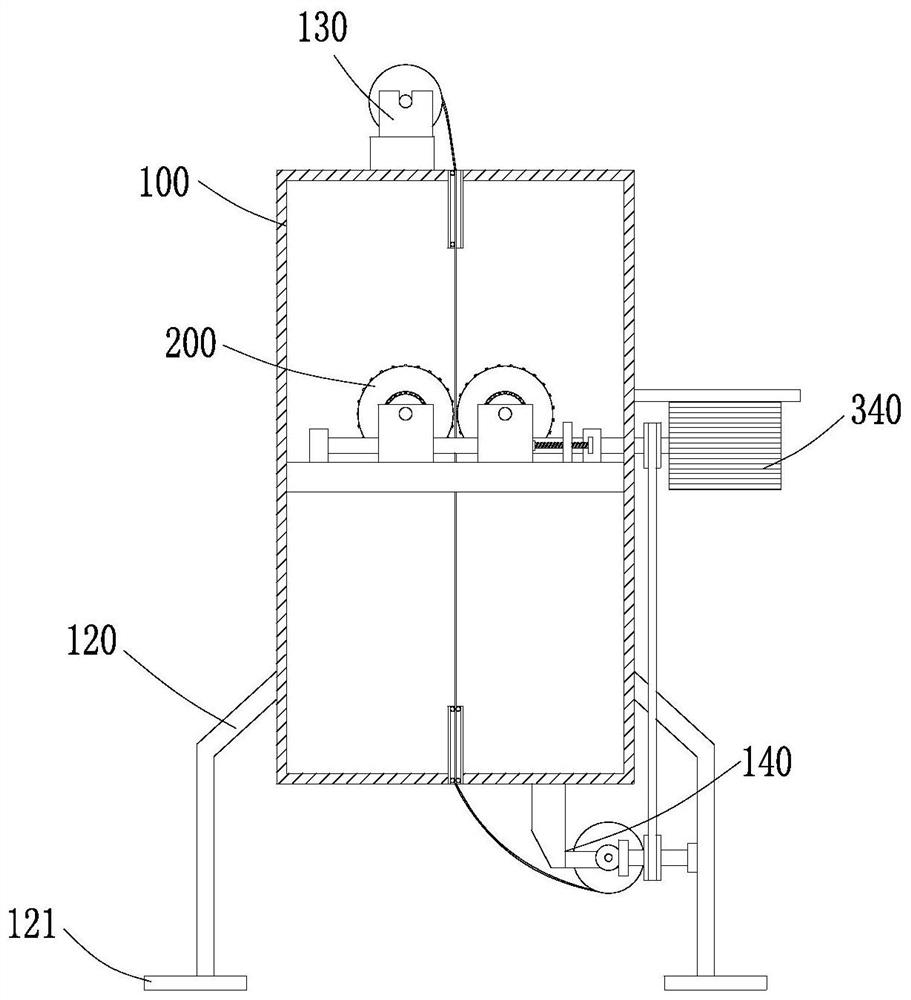

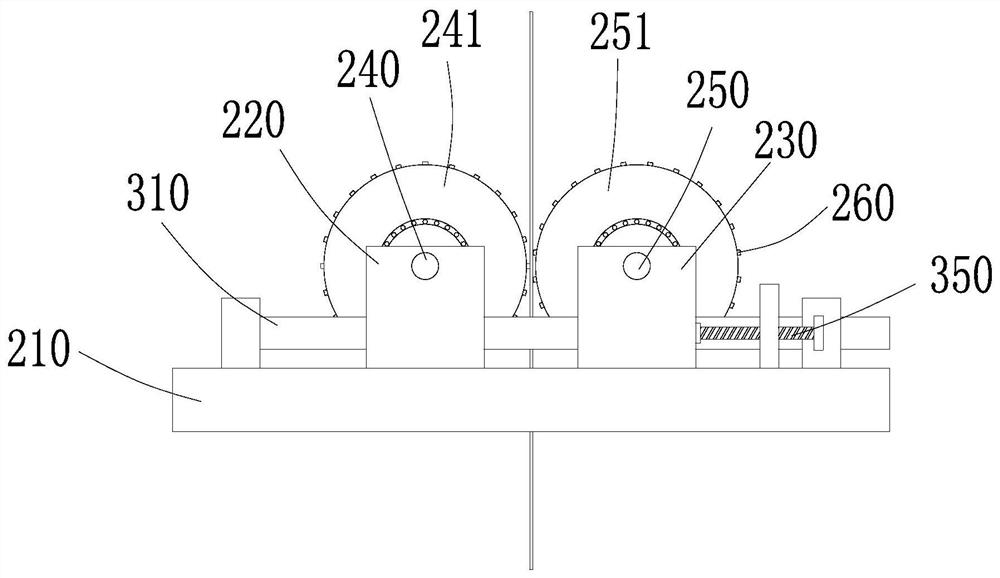

Efficient powder mixing equipment

InactiveCN111013460ASmooth Squeeze OperationStir wellShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringMechanical engineering

The invention discloses efficient powder mixing equipment, which belongs to the field of mixing equipment, the invention discloses the efficient powder mixing equipment, which comprises a mixing equipment body with an upper cover, wherein a stirring structure for uniformly mixing materials is arranged in the mixing equipment body; at least one group of scraping pieces for preventing materials frombeing easily attached to the inner wall of the mixing equipment body are also arranged in the mixing equipment body; the scraping piece is arranged, on one hand, materials attached to the inner wallof the mixing equipment body in the stirring process can be scraped off, on the other hand, a stirring area of the stirring rod can be further increased, material stirring is more sufficient, the stirring efficiency is improved, meanwhile, a vibration part is arranged; so that vibration is generated between the vibration part and the material mixing equipment body, the relative positions of part of materials can be changed while the materials splashed to the inner wall of the material mixing equipment body in the stirring process are shaken off, the materials are mixed more uniformly, the material mixing efficiency is improved in the process, and the production cost is saved.

Owner:杭州欣禾工程管理咨询有限公司

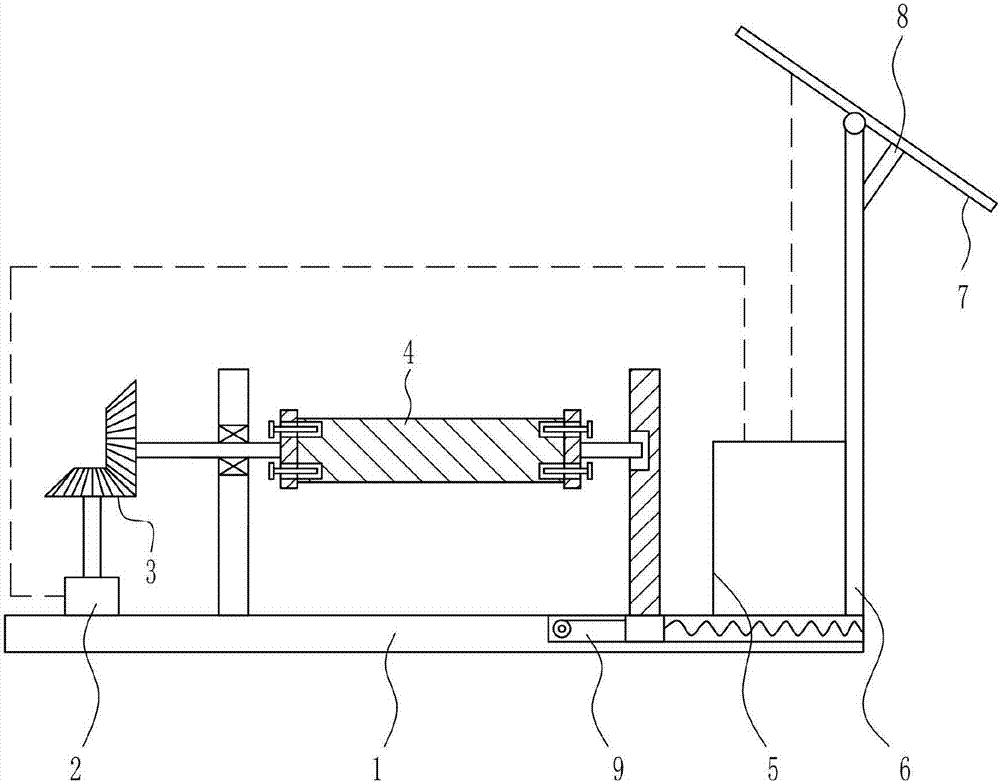

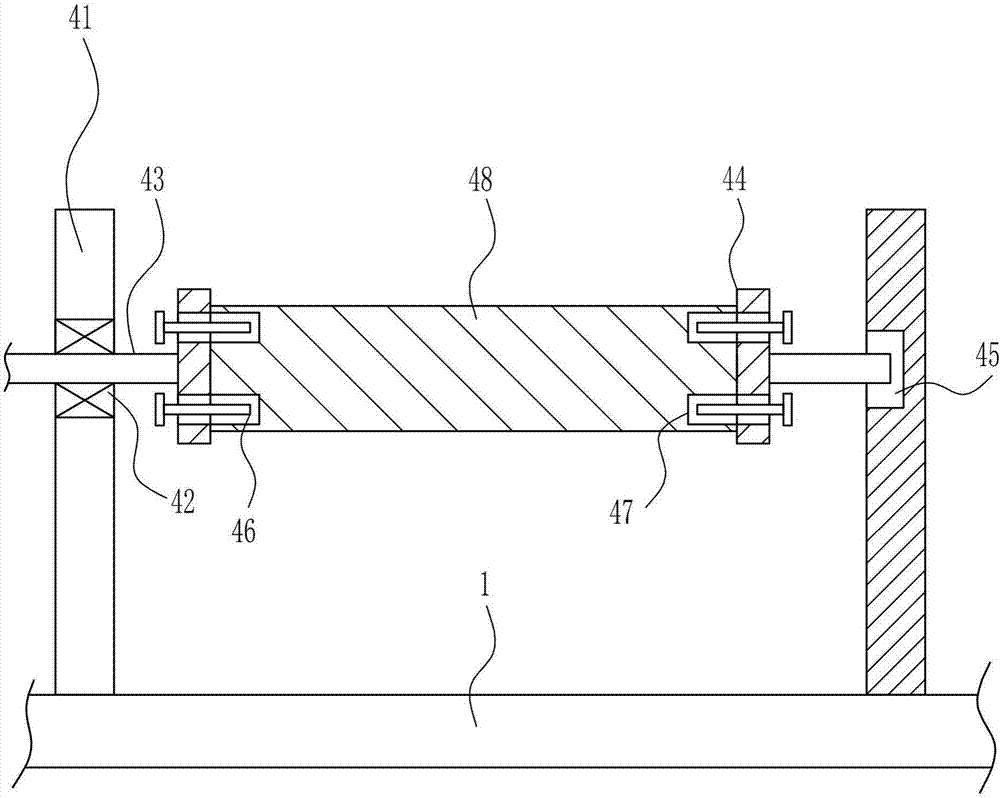

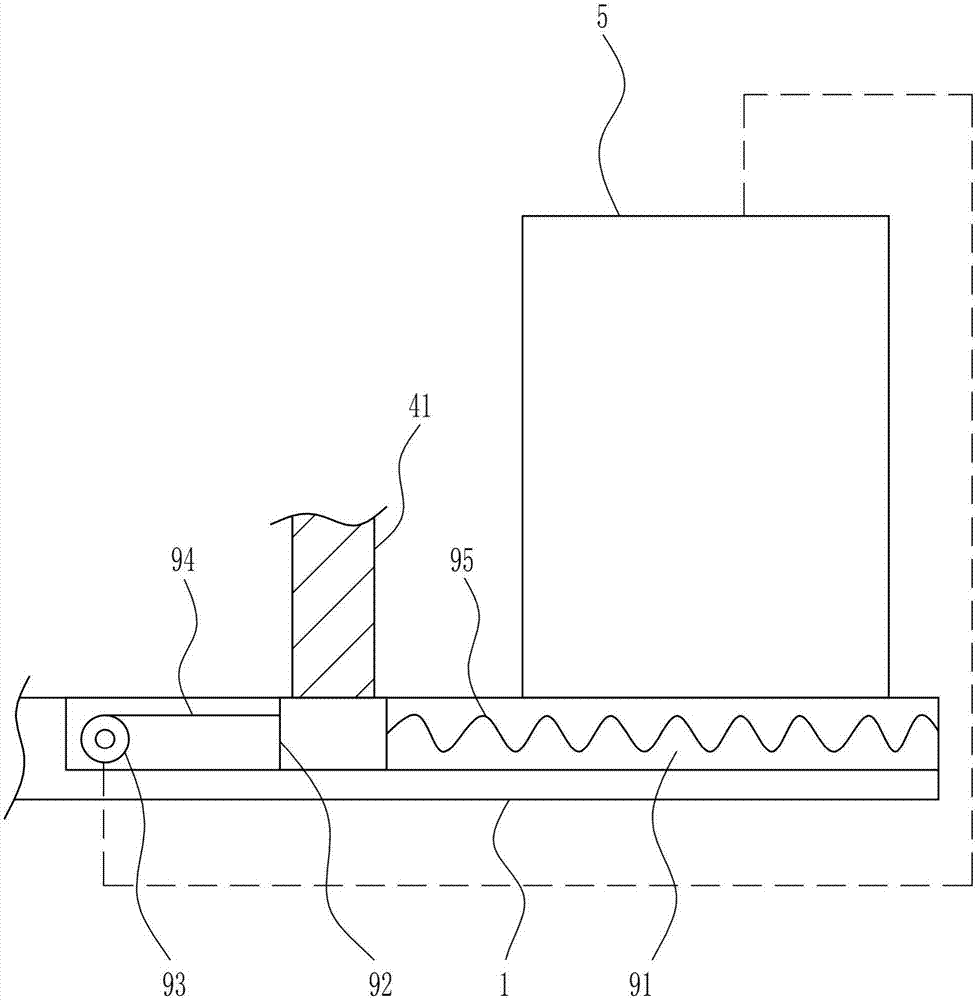

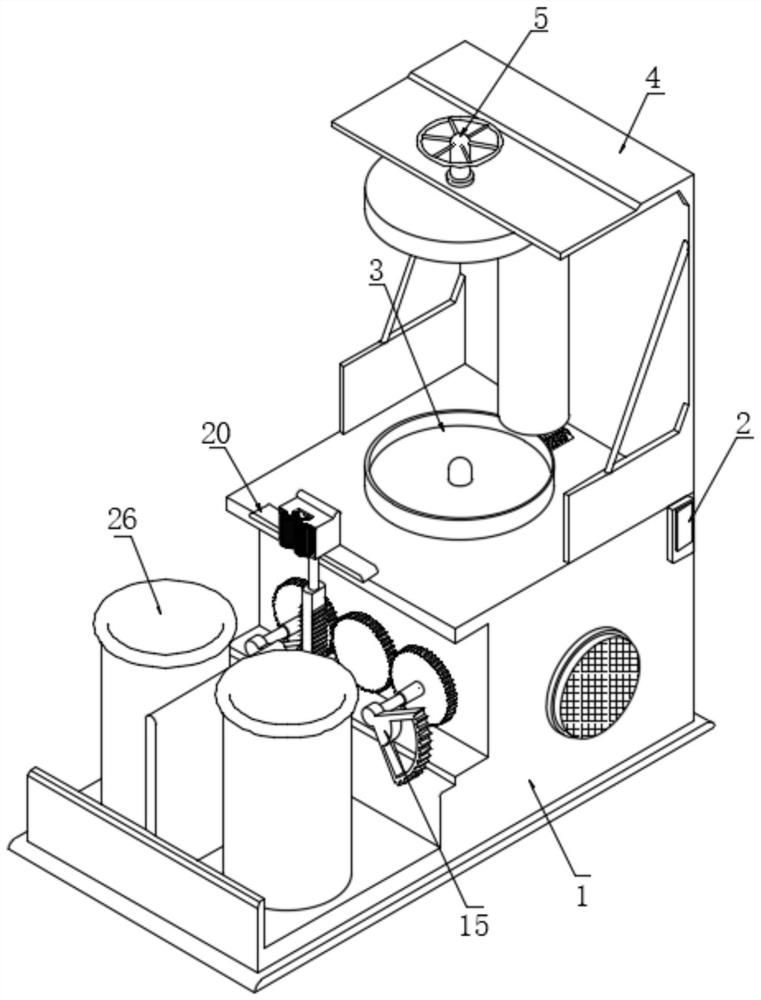

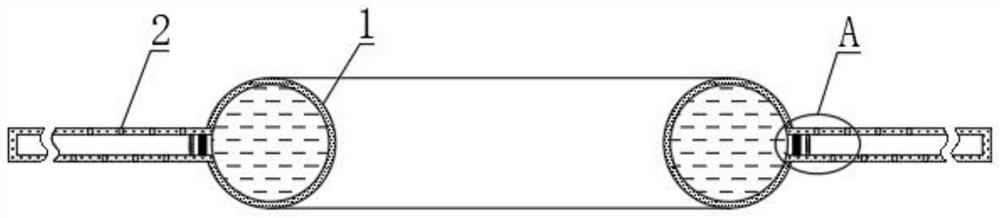

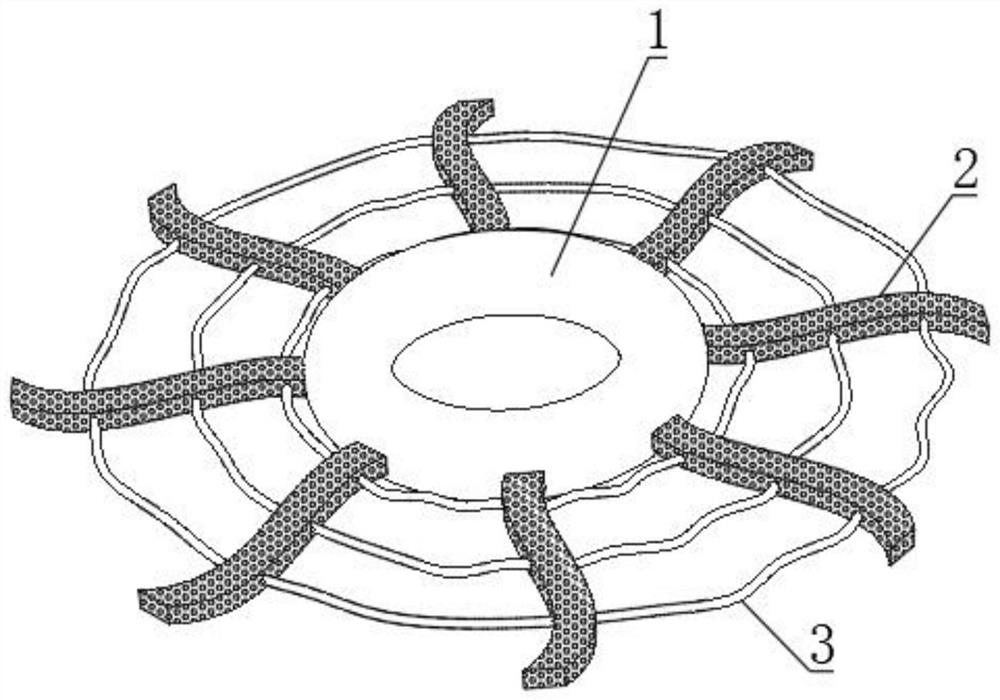

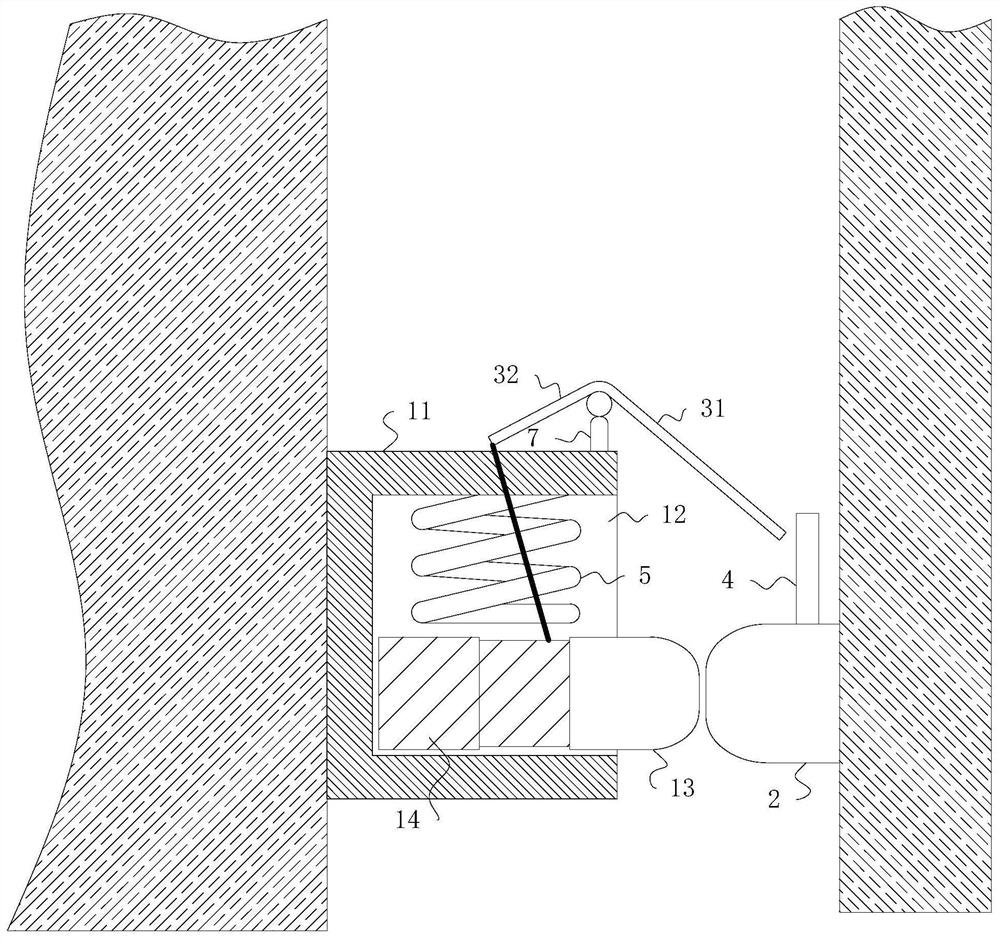

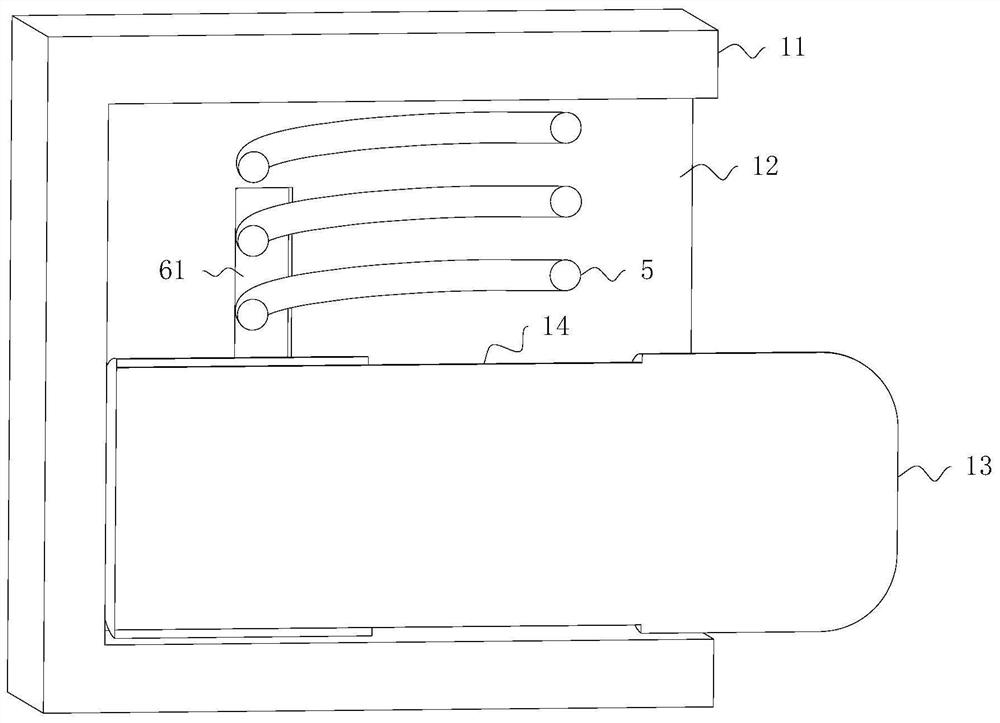

Photovoltaic panel assembly receiving and winding device for power transmission and distribution cable

ActiveCN106936108AImprove work efficiencyNot easy to shift positionFibre mechanical structuresArrangements using take-up reel/drumElectric power transmissionEngineering

The invention relates to a transmission and distribution cable receiving device, particularly to a photovoltaic panel assembly receiving and winding device for a power transmission and distribution cable. The photovoltaic panel assembly receiving and winding device is capable of carrying out receiving and winding by a photovoltaic panel assembly and adjusting the angle of the photovoltaic panel assembly to collect the sunlight. The photovoltaic panel assembly receiving and winding device comprises a bottom plate, a motor, a bevel gear, a receiving and winding mechanism, a storage battery, a connecting rod, and a photovoltaic panel assembly body and the like. The motor is installed at the left side of the top of the bottom plate; the bevel gear is connected to an output shaft of the motor; and the receiving and winding mechanism is arranged in the middle of the top of the bottom plate. With the receiving and winding mechanism and a moving mechanism, a cable can be received and wound compactly, thereby saving the space and taking down a receiving-winding cylinder with winding completion.

Owner:江苏众志达新能源科技有限公司

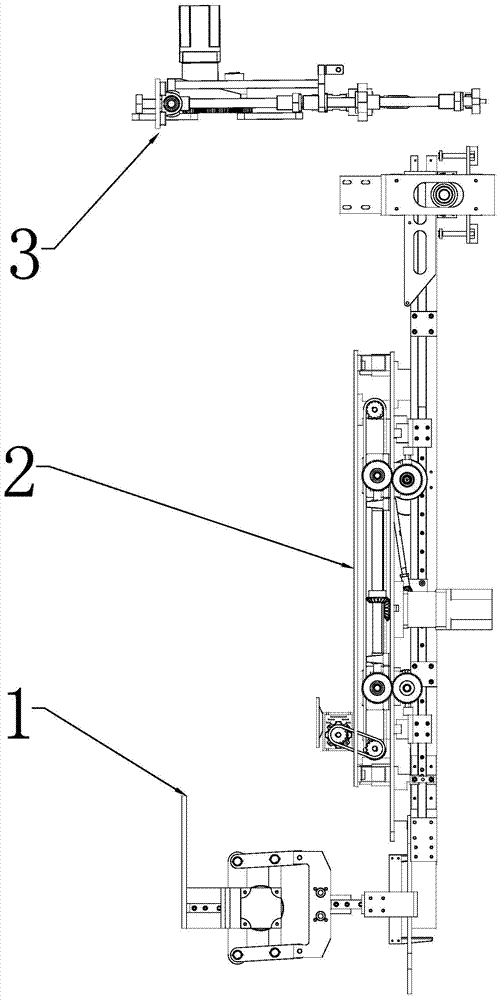

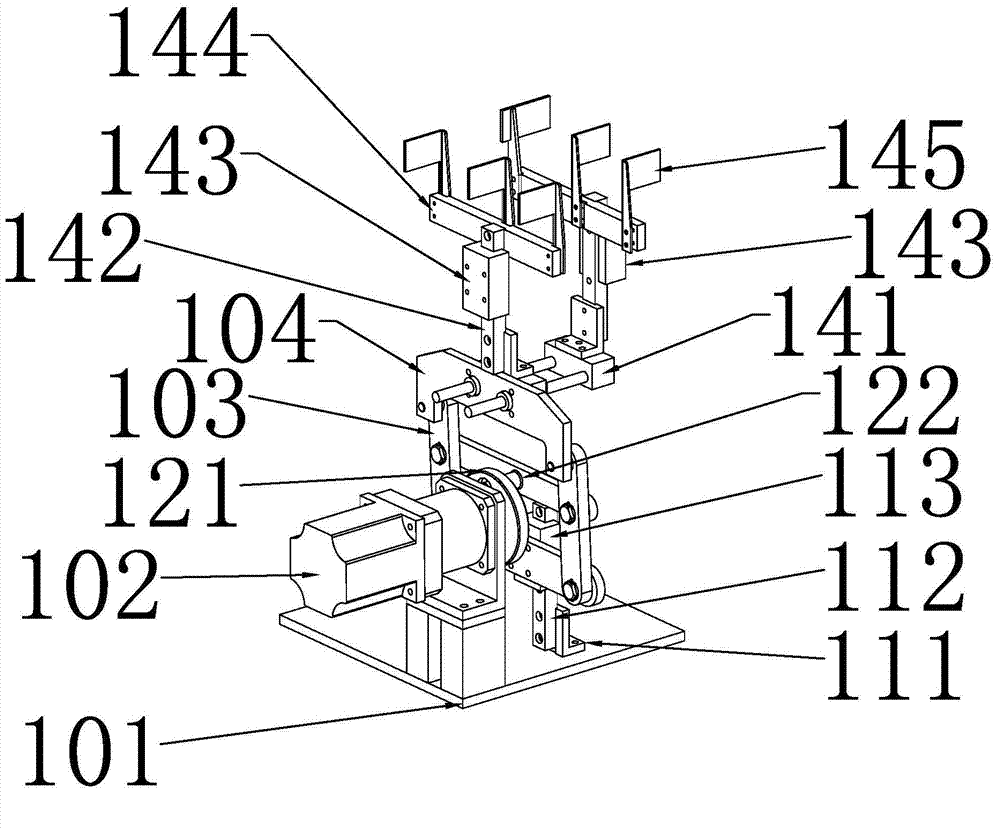

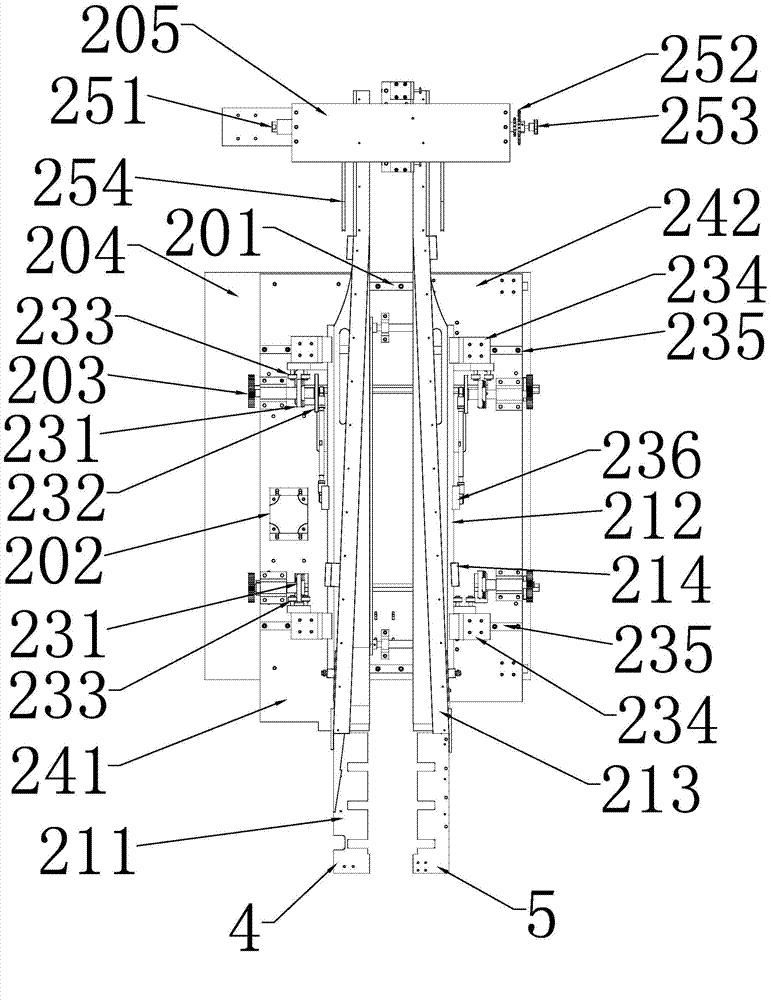

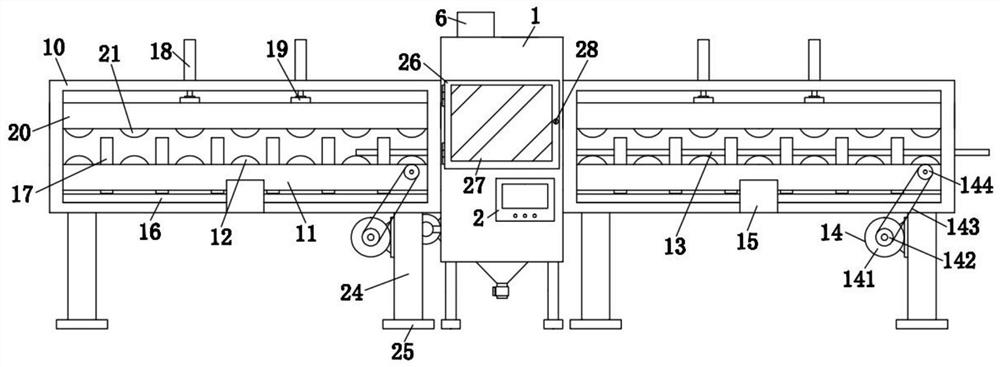

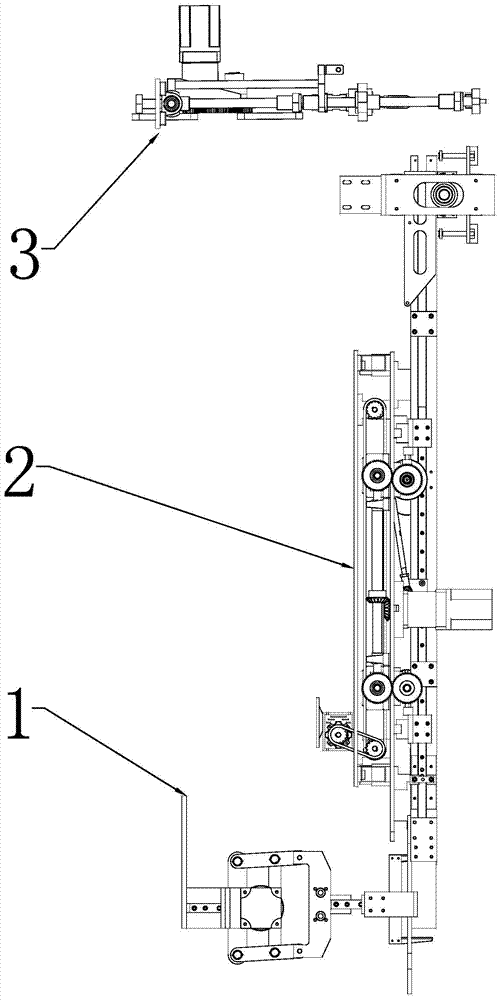

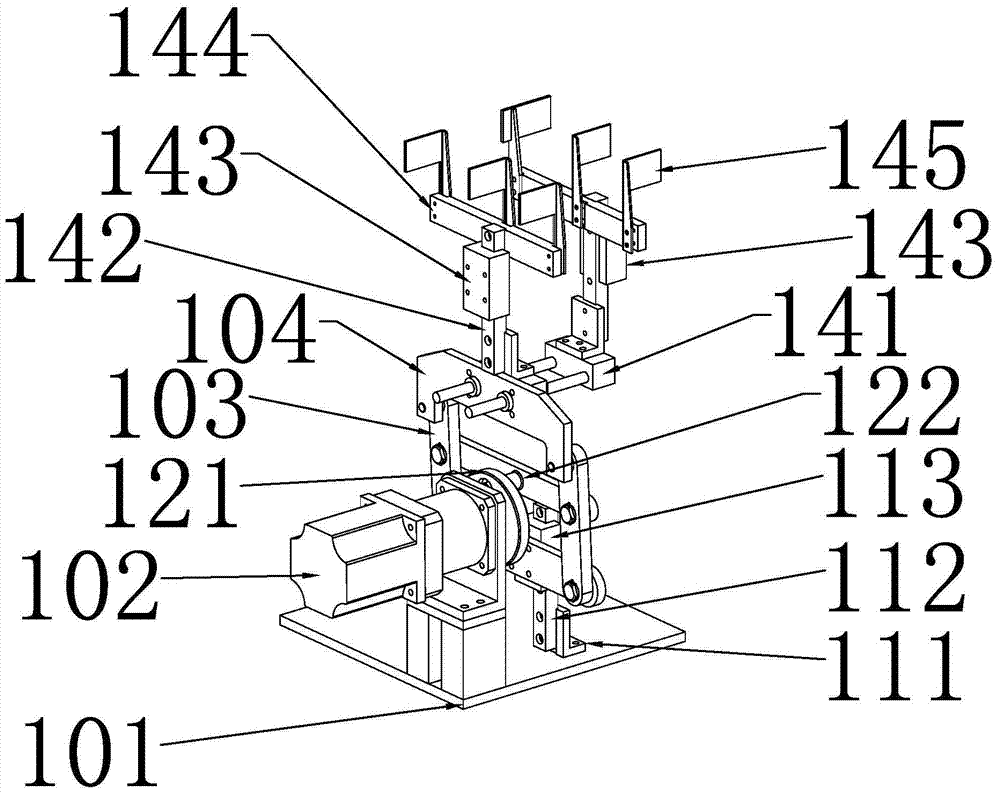

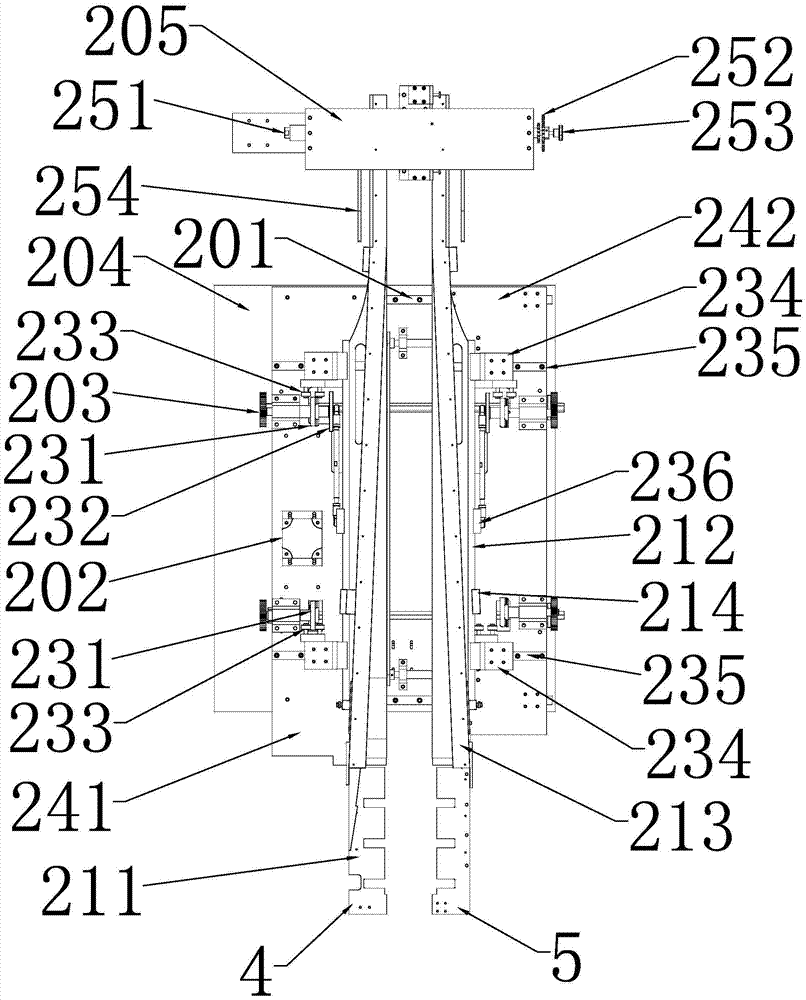

High-speed spring bagging machine

A high-speed spring bagging machine comprises a delivering mechanism, a conveying mechanism and a vertical welding mechanism. The high-speed spring bagging machine is characterized in that the conveying mechanism is provided with a left conveying arm and a right conveying arm, the delivering mechanism is arranged at the front end of the conveying mechanism, the vertical welding mechanism is arranged at the rear end of the conveying mechanism, spaces are reserved between the conveying mechanism and the delivering mechanism and between the conveying mechanism and the vertical welding mechanism, and the delivering mechanism, the conveying mechanism and the vertical welding mechanism are sequentially arranged and fixed to a rack. According to the conveying mechanism, a single motor is adopted for driving a transmission shaft, the welding width of non-woven fabric can be set, the manufacturing and the replacing of a non-woven fabric guiding mold are reduced, meanwhile, the speed for conveying springs is increased, and the yield of bagging the springs is improved. A parallel quadrangle double-crank mechanism is adopted for the delivering mechanism. More springs can be delivered in the spring bagging machine a short time. A single-motor is adopted in the vertical welding mechanism to drive a crank sliding block mechanism, the movement travel is effectively shortened, the design and packaging are simplified, electricity consumption is reduced when the spring bagging machine is used, noise is reduced, and the working environment is improved.

Owner:FOSHAN YULUN MACHINERY

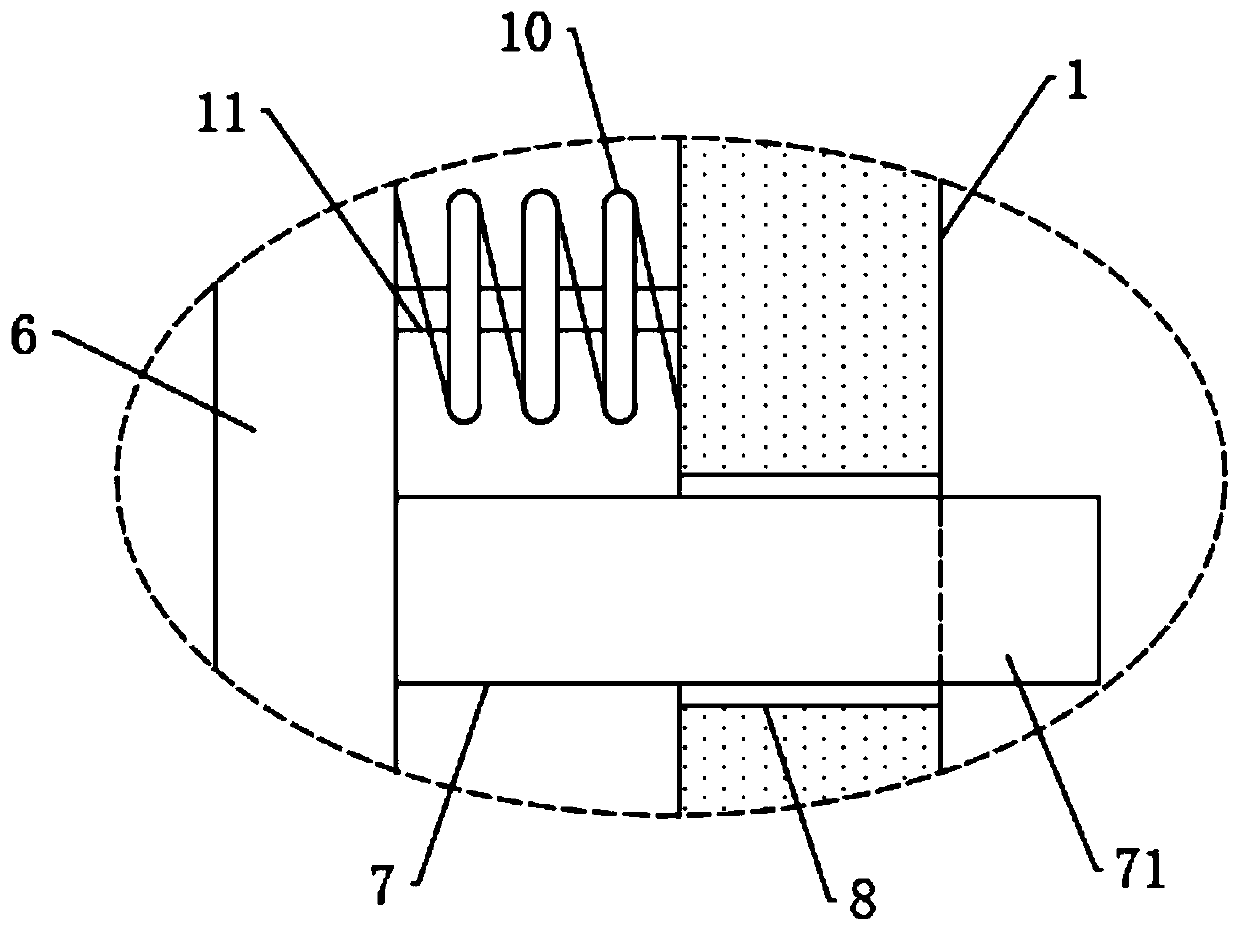

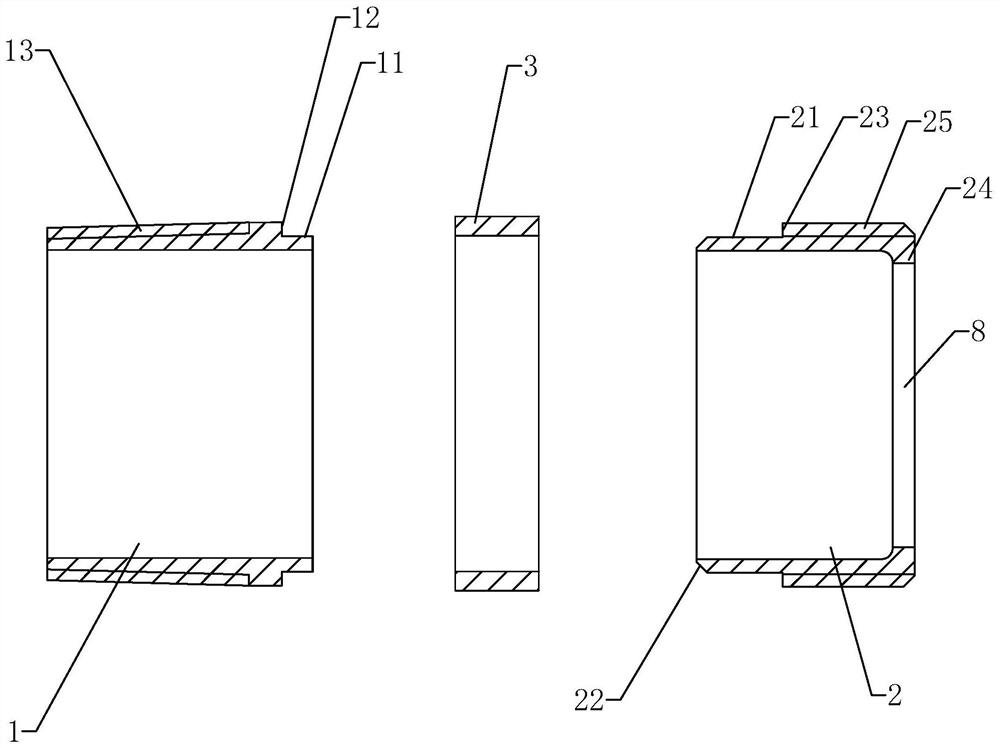

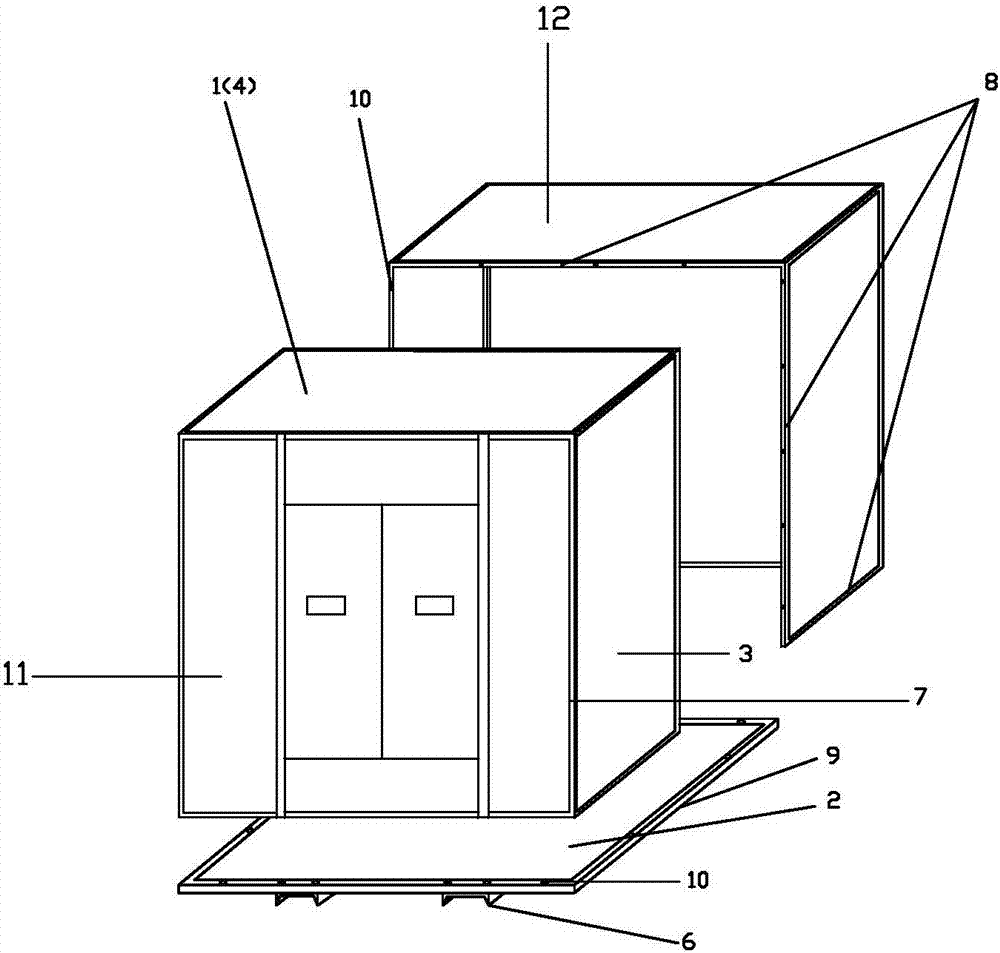

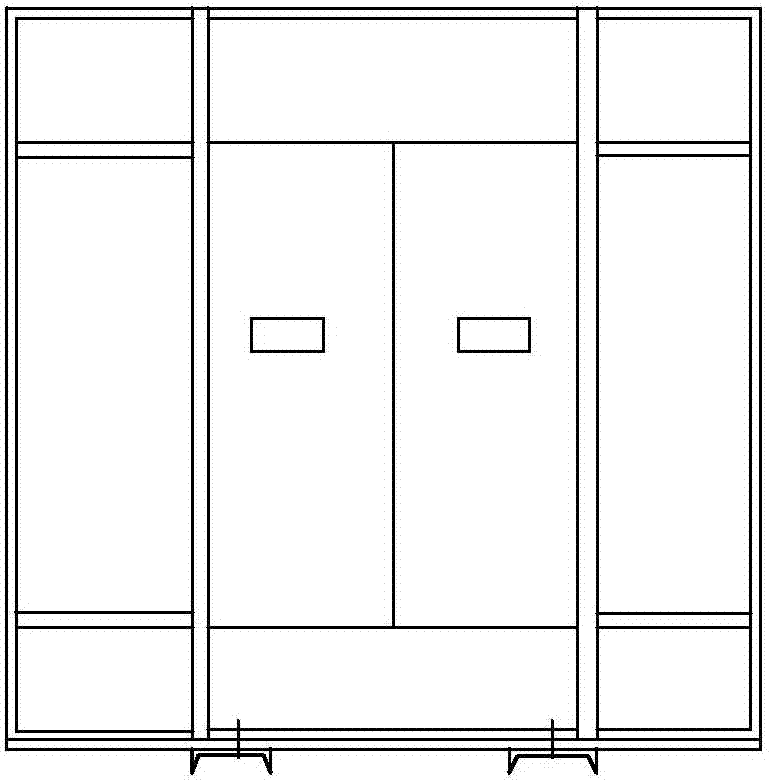

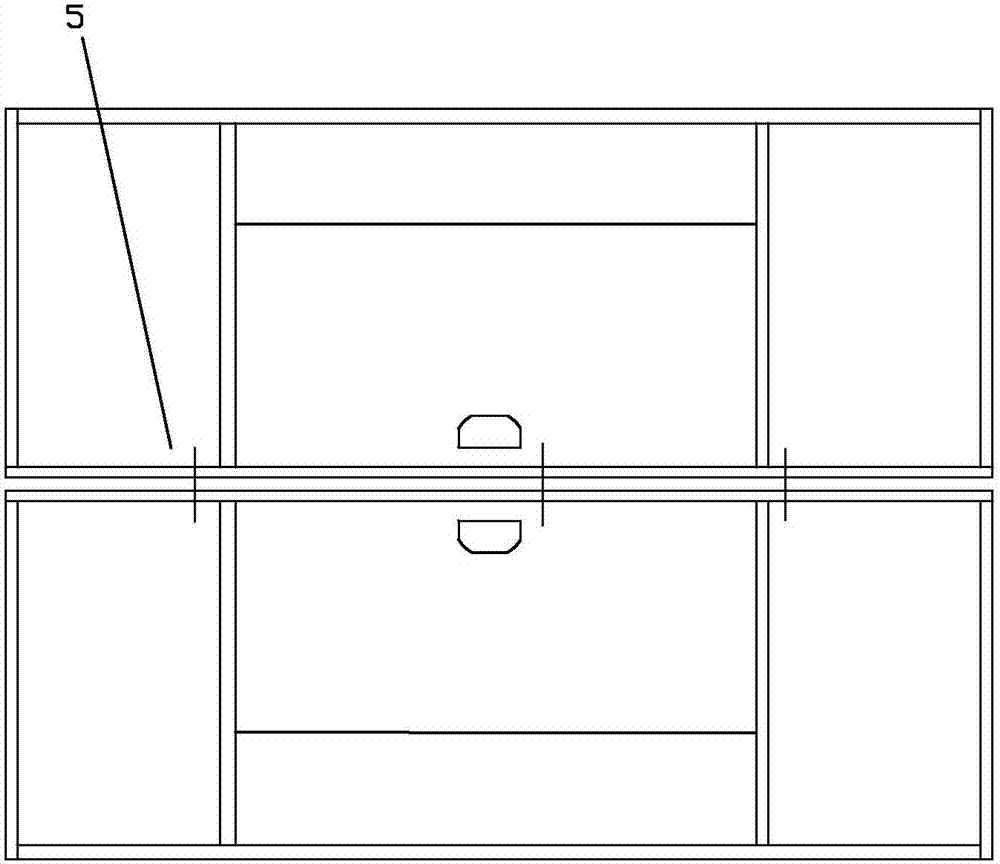

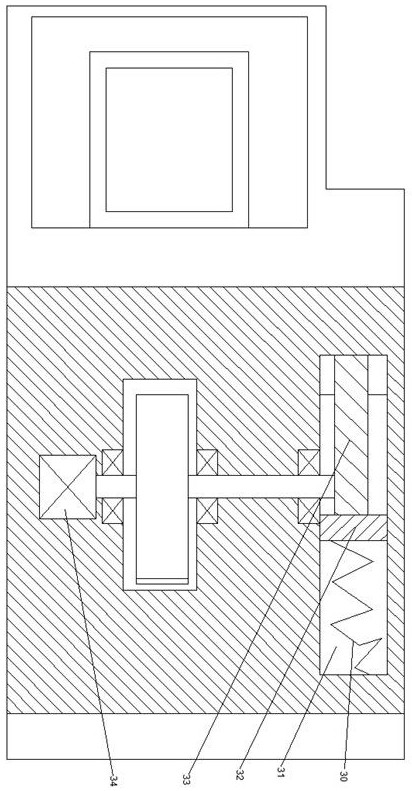

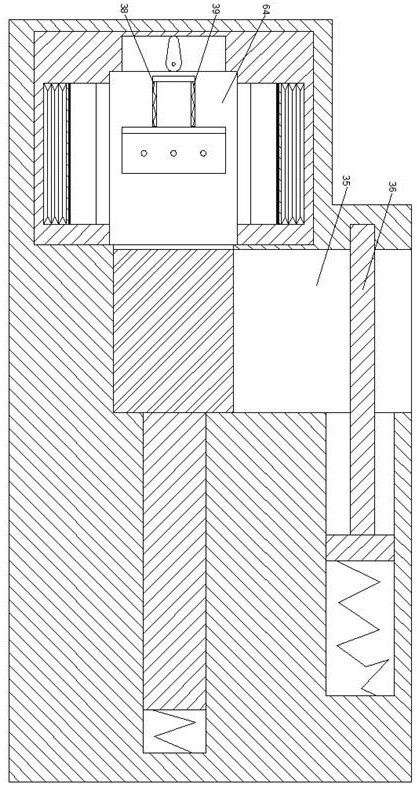

Anti-fracture dry-type transformer winding structure and using method thereof

InactiveCN113871168ANot easy to shift positionAvoid affecting useTransformers/inductances coils/windings/connectionsGear driveGear wheel

The invention discloses an anti-fracture dry-type transformer winding structure and a using method thereof, which belong to the technical field of dry-type transformers. The anti-fracture dry-type transformer winding structure comprises a rack, a controller is arranged on the back face of the rack, and the upper surface of the rack is fixedly connected with the lower surface of a top plate. According to the structure, the connecting shaft drives the fixing disc to rotate, the fixing disc drives the wire mold frame to rotate, meanwhile, the driving gear drives the driven gear to rotate, and after a single-layer wire is wound on the wire mold frame, the front sector tooth is separated from the toothed bar, and the rear sector tooth is meshed with the toothed bar, and thus, the rear sector teeth can drive the gear rod and the box body to move downward during rotation, in the same way, the box body and the two guide wheels sequentially move up and down in a reciprocating mode, the wire mold frame continuously rotates, compared with a traditional winding mode, the purpose of uniform winding is effectively achieved, the winding position can be automatically adjusted, a wire is not prone to deviating after being wound, the stability is improved, and the normal use of the dry-type transformer is prevented from being influenced.

Owner:连云港天威变压器有限公司

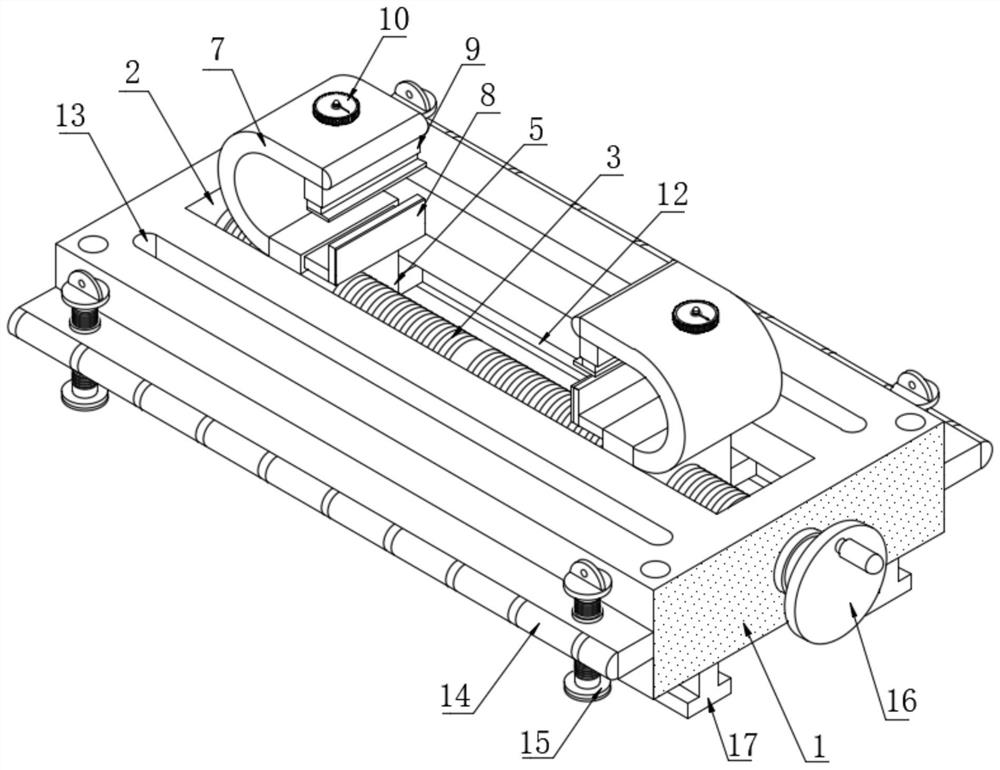

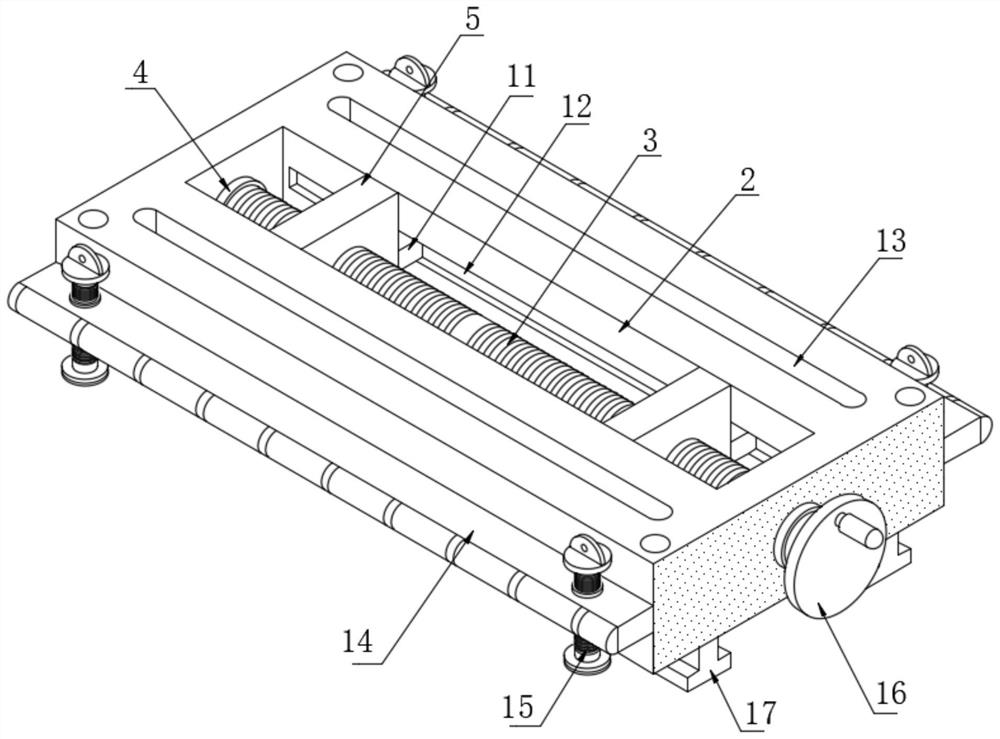

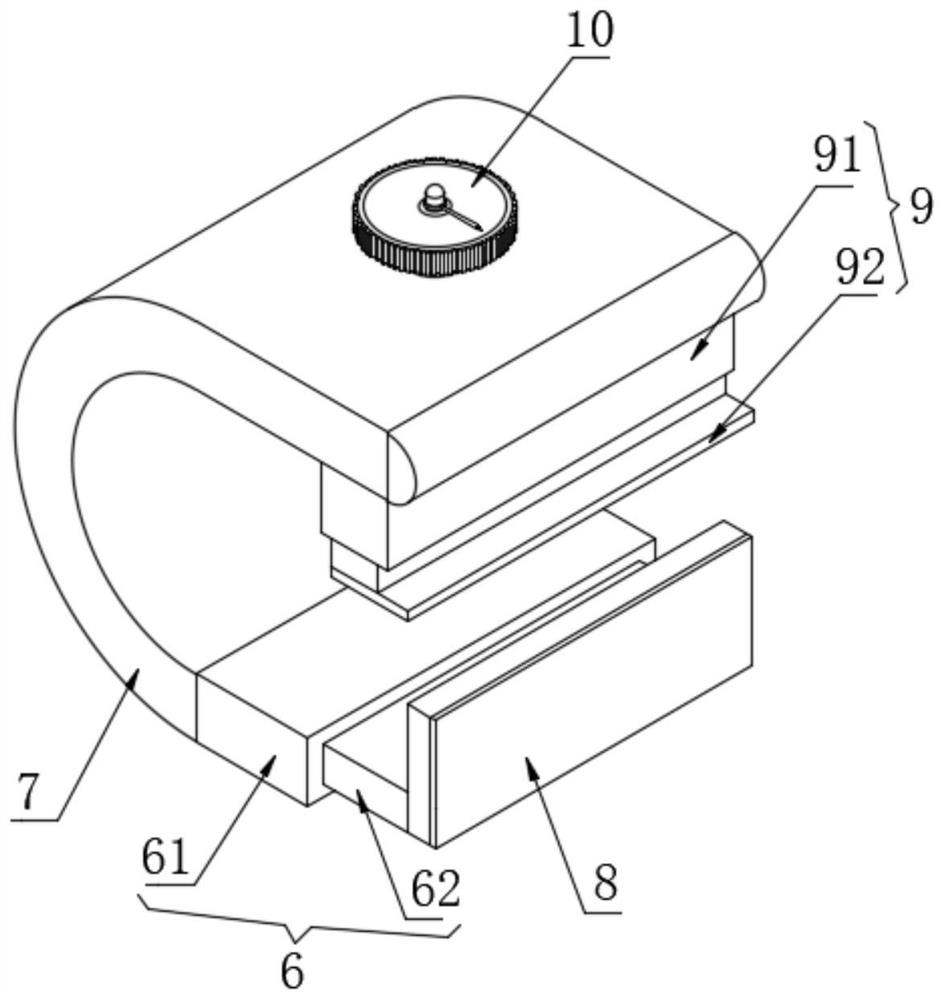

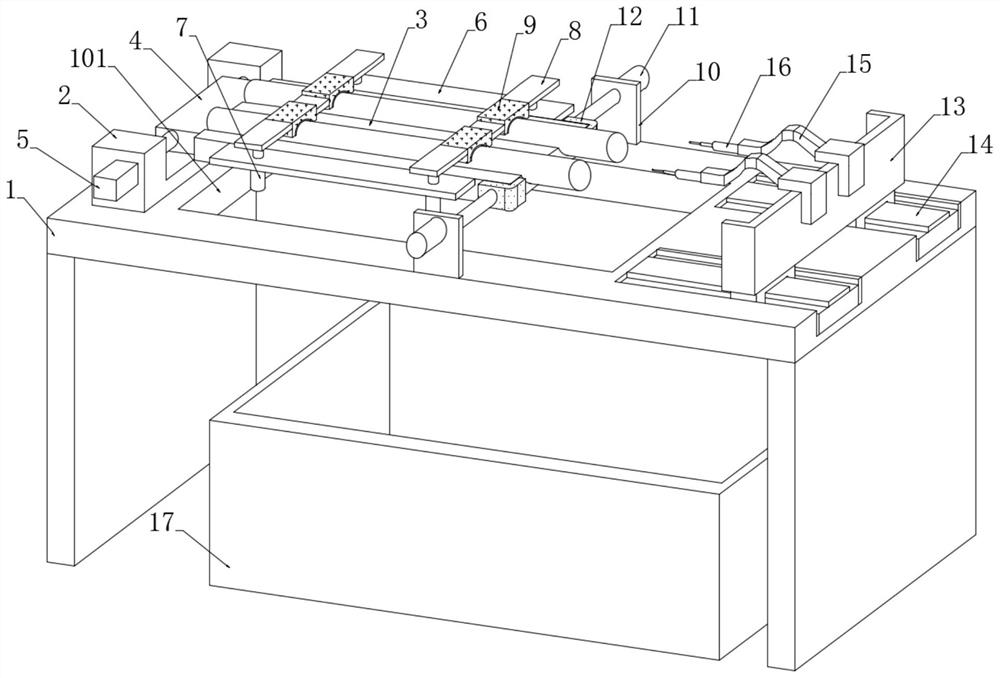

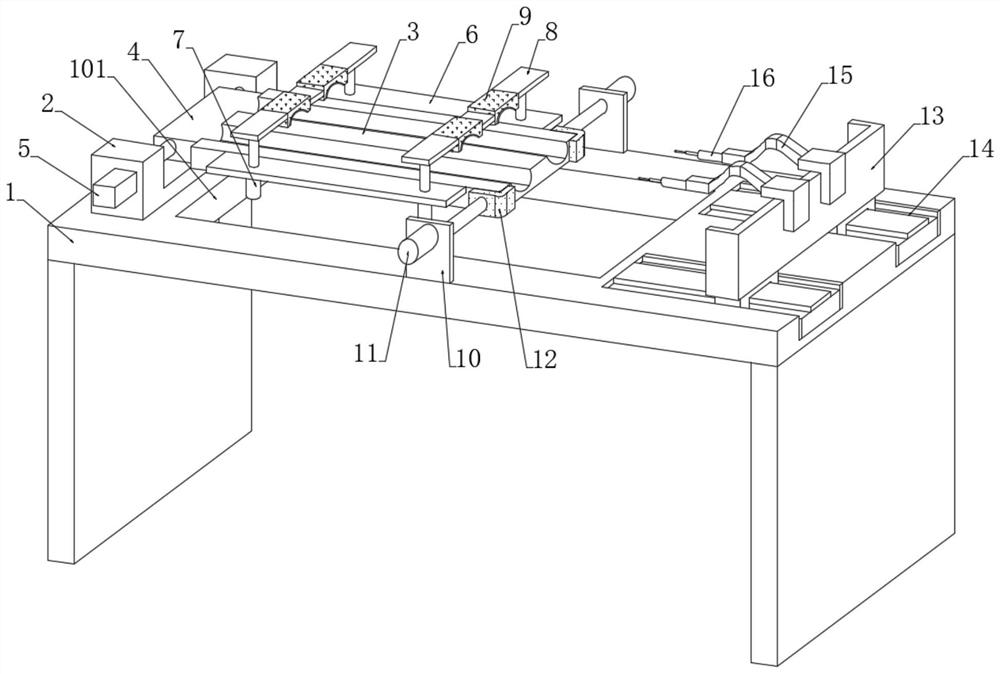

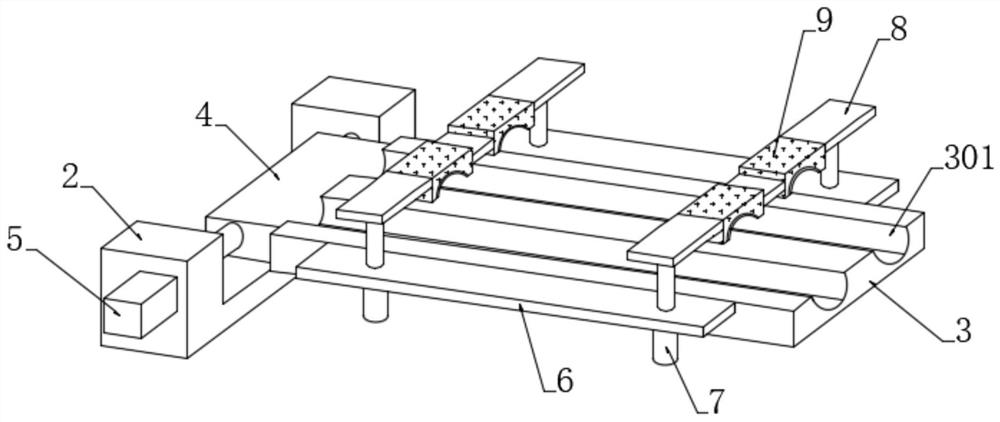

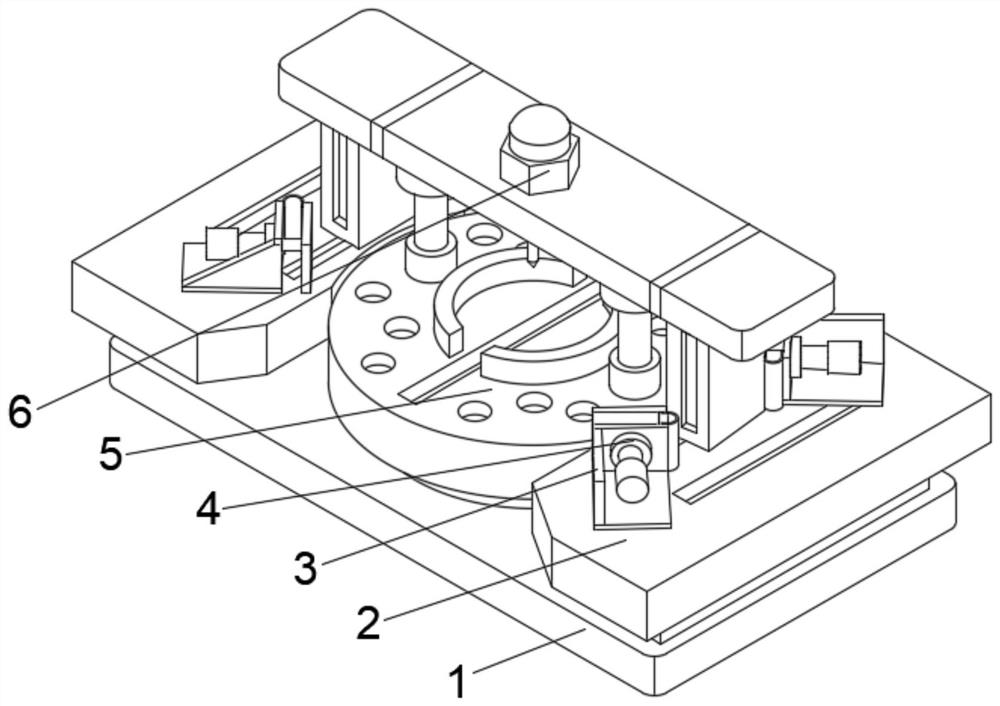

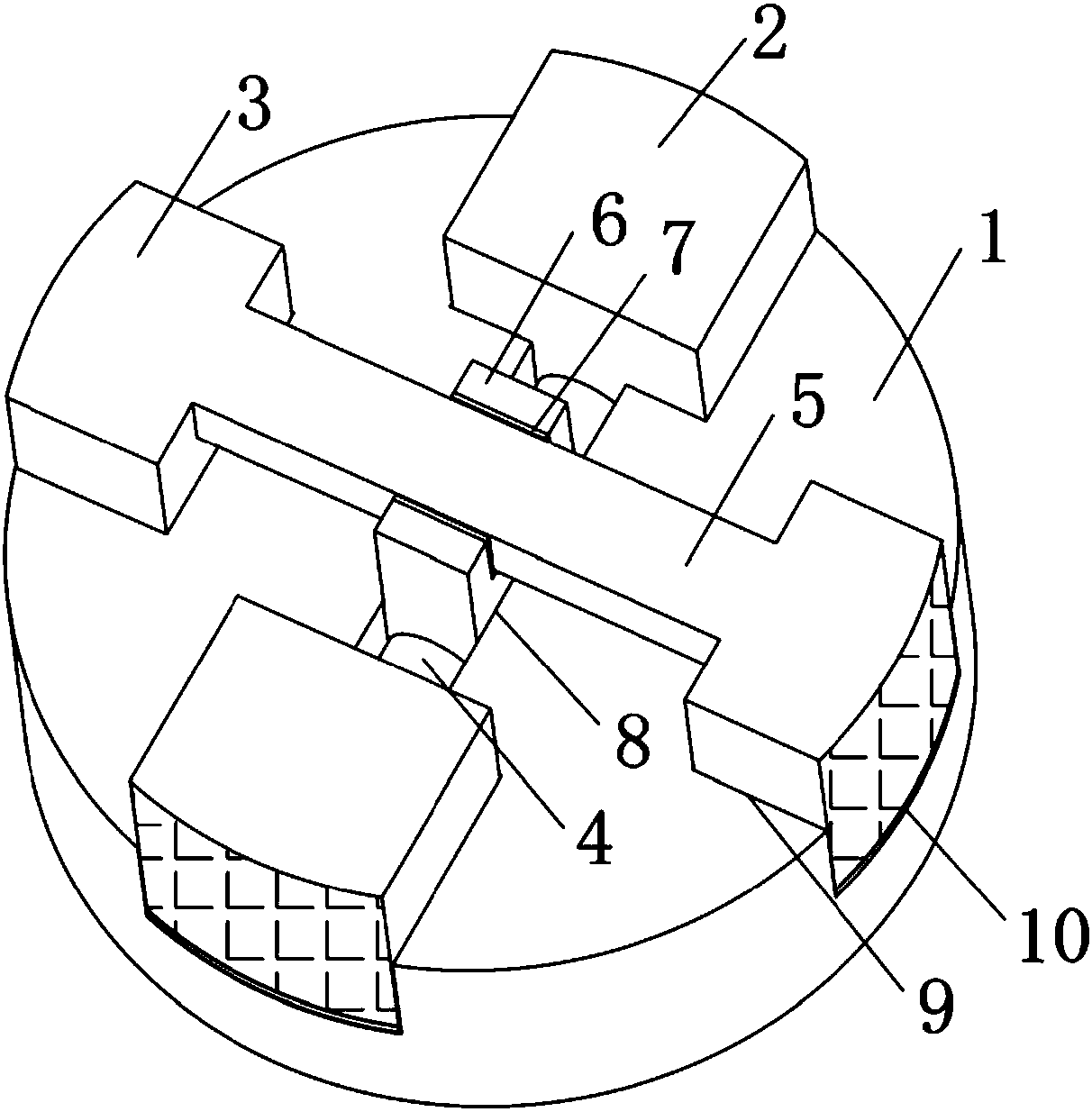

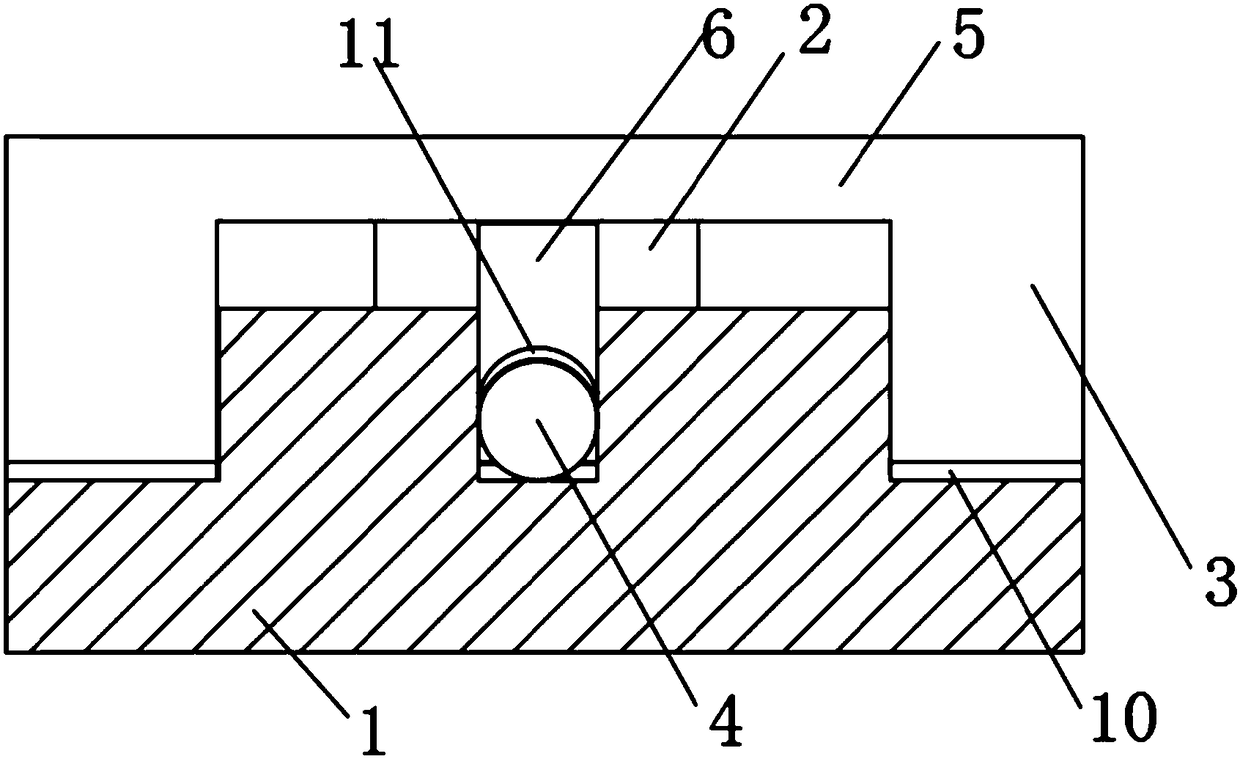

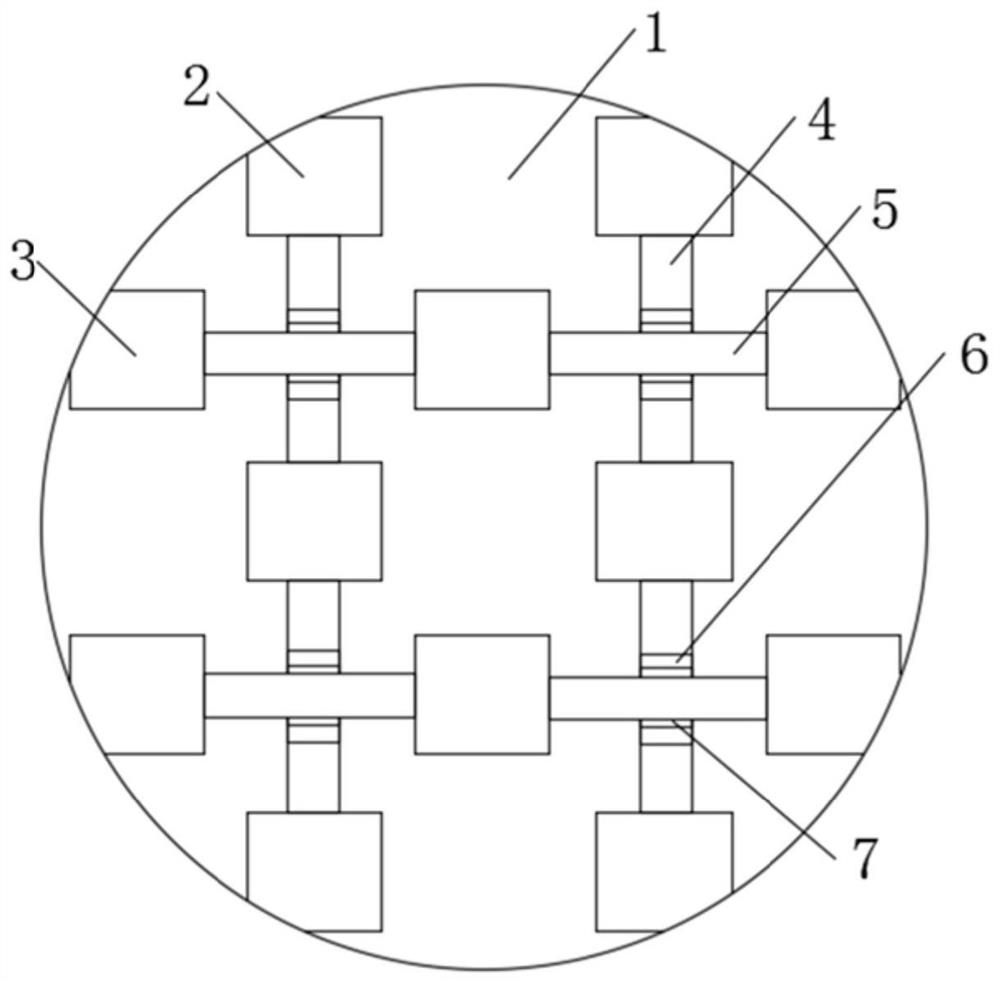

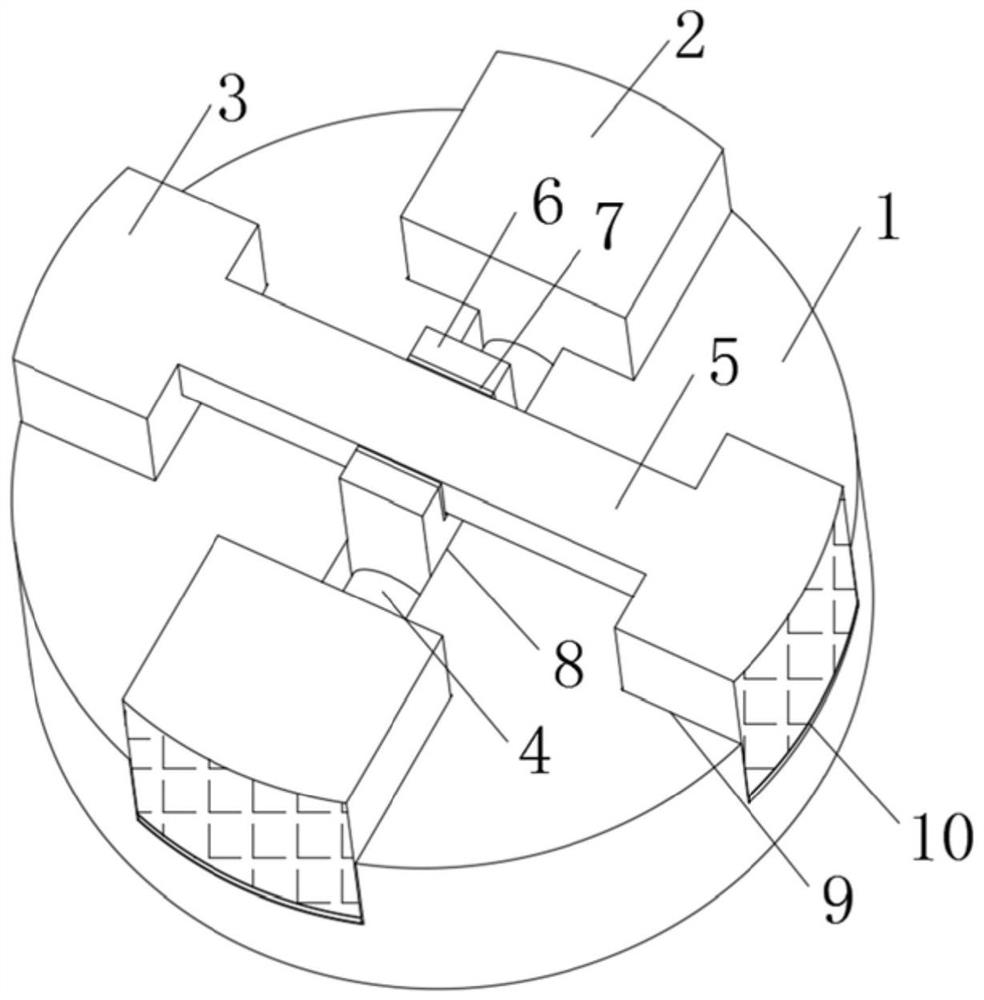

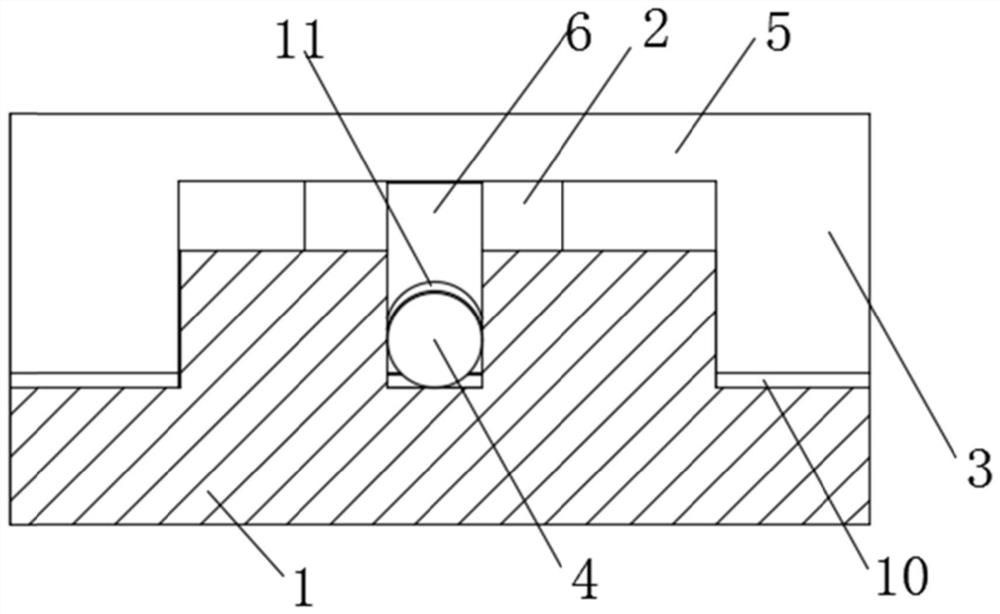

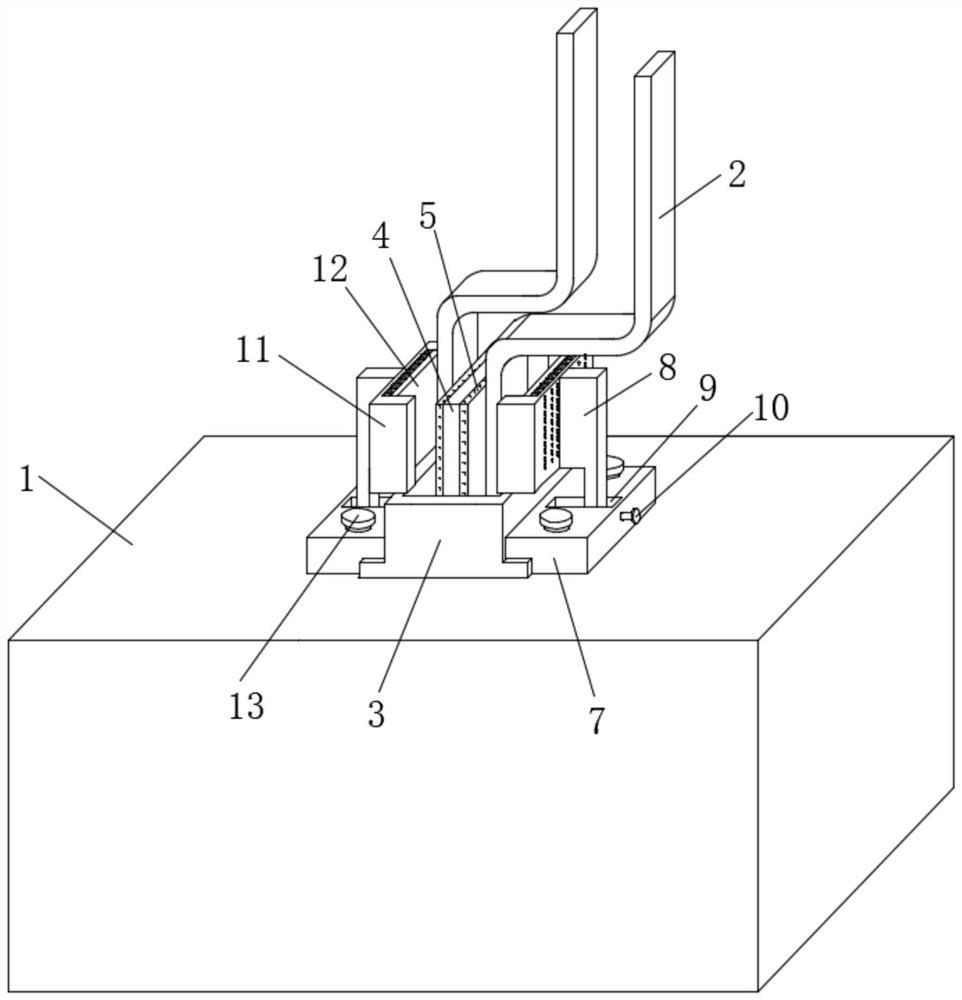

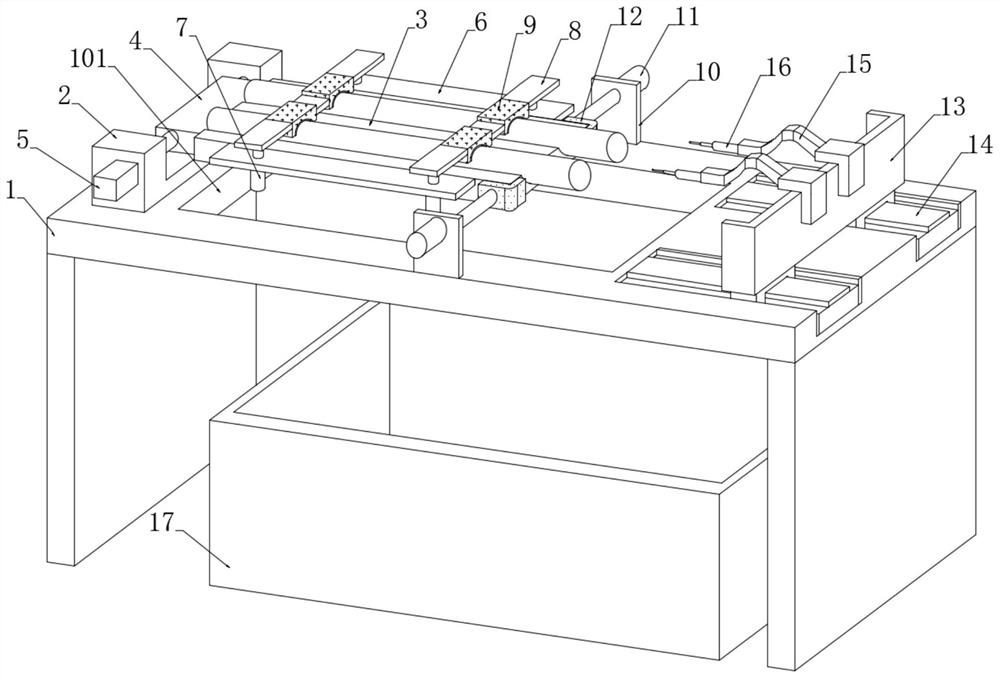

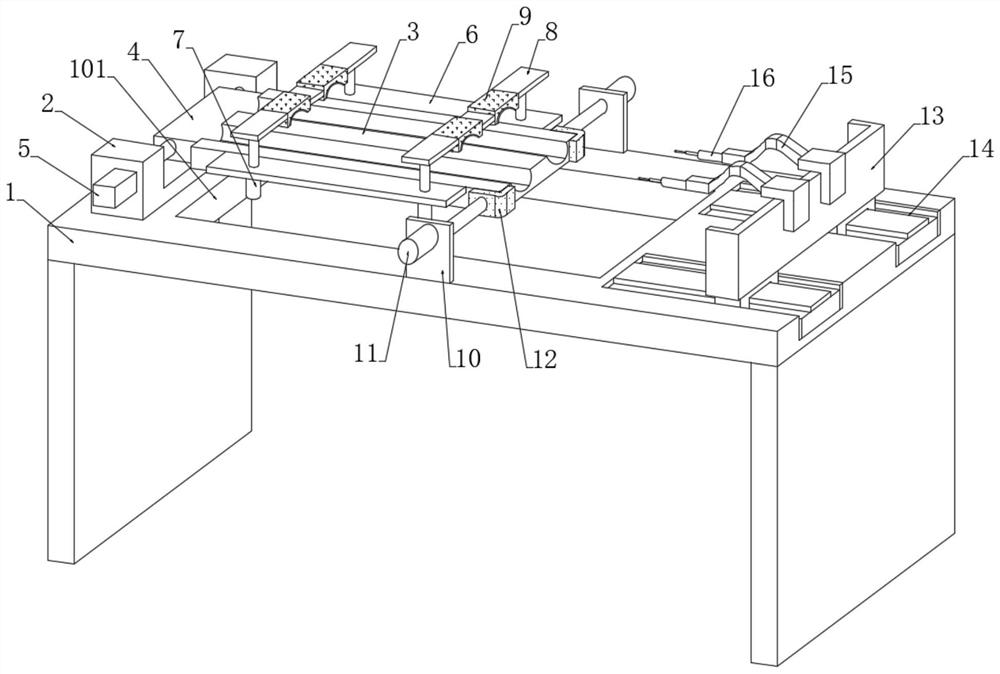

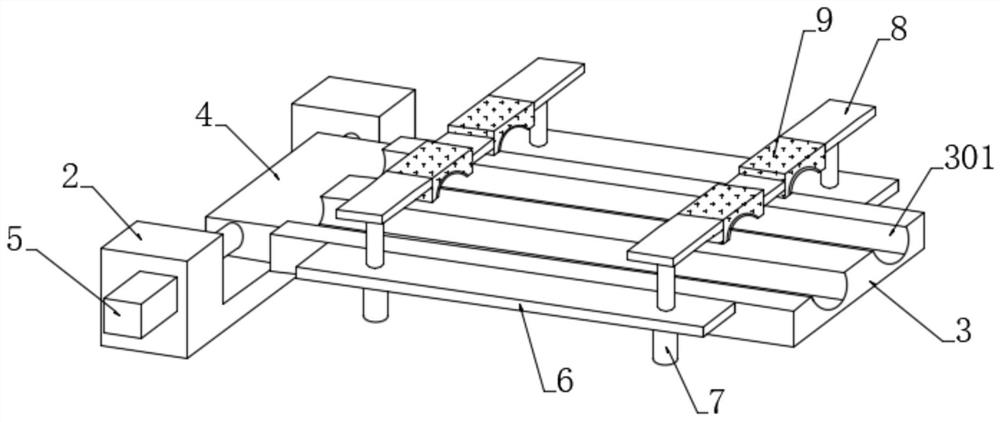

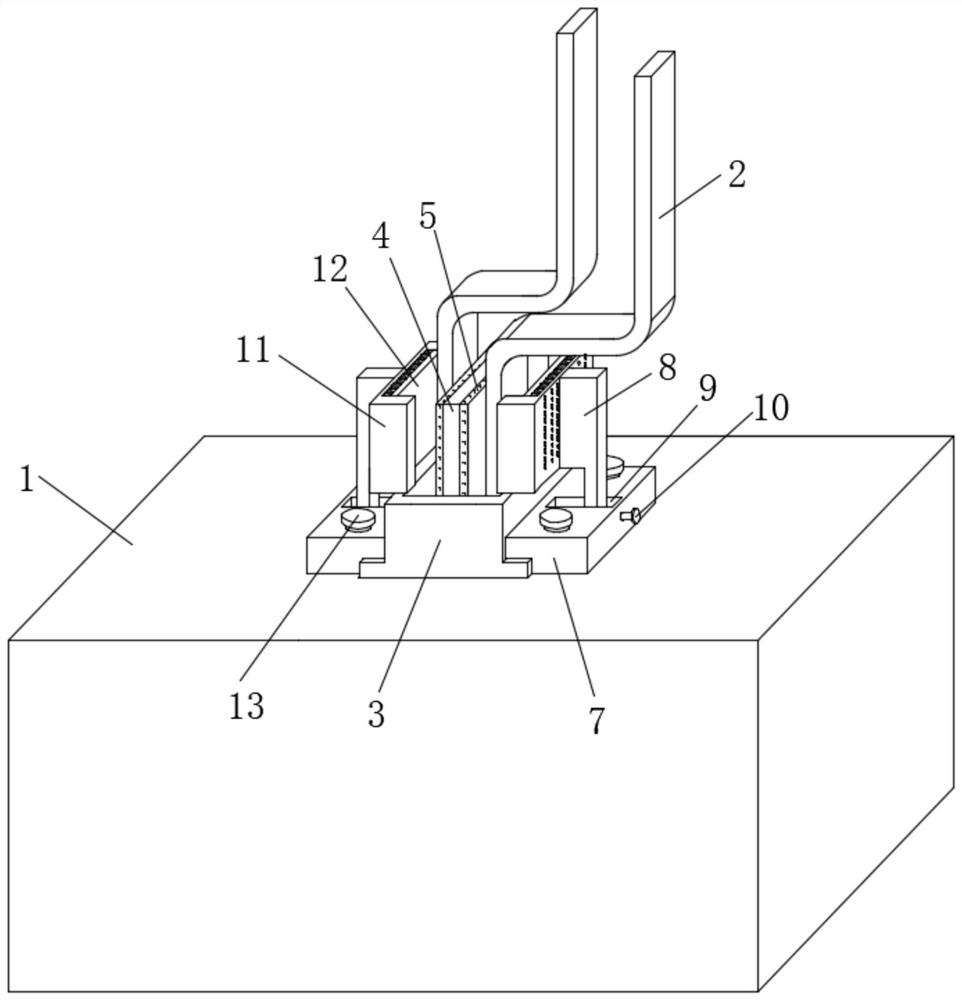

Workpiece multi-stage positioning device applied to numerical control milling machine

InactiveCN113182901ANot easy to shift positionHigh precisionPositioning apparatusMetal-working holdersNumerical controlMachine

The invention discloses a workpiece multi-stage positioning device applied to a numerical control milling machine, and belongs to the technical field of workpiece positioning. The workpiece multistage positioning device comprises a base, a through hole is formed in the upper surface of the base, a two-way threaded rod is arranged in the through hole, the two ends of the two-way threaded rod are rotatably connected to the two sides of the inner wall of the through hole through bearings, the outer surface of the two-way threaded rod is in threaded connection with two threaded caps, and the upper surfaces of the threaded caps are fixedly connected with the lower surface of a pushing and pressing assembly. According to the workpiece multi-stage positioning device applied to the numerical control milling machine, the threaded rod, the threaded caps, an air guide plate, a pressing plate, push plates, a first piston plate, a second piston plate and a pressure valve are arranged, the two push plates can limit the two sides of a workpiece, and compared with traditional repeated operation, by means of the scheme, the burden of workers is relieved, the purpose of multi-stage positioning of the workpiece is achieved, the workpiece is not prone to deviation in the machining process, and the machining precision of the workpiece is improved.

Owner:襄阳富德源机电有限公司

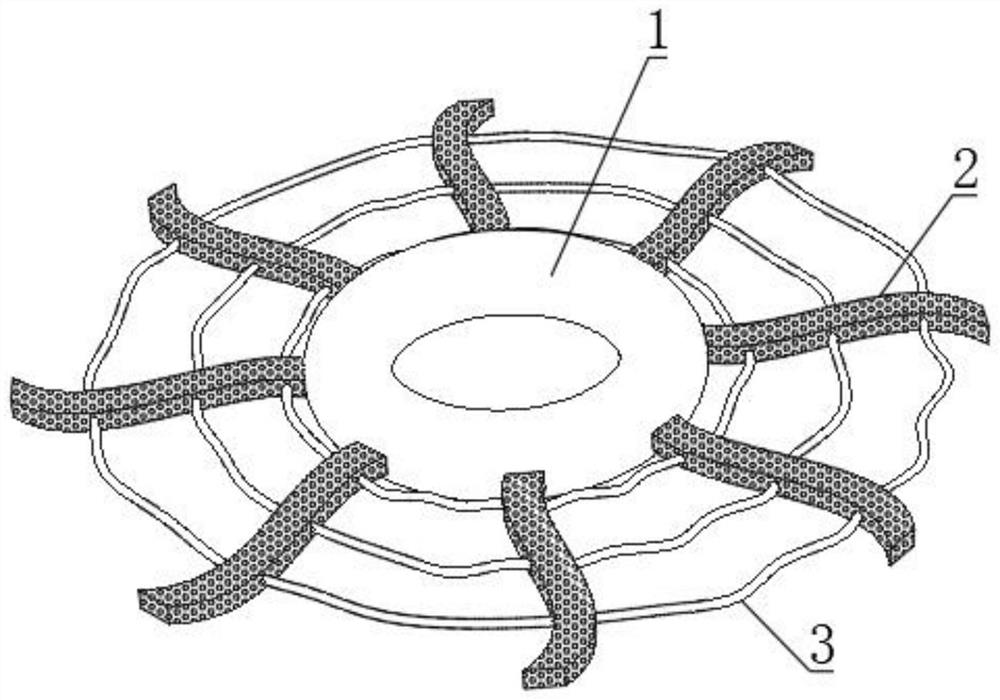

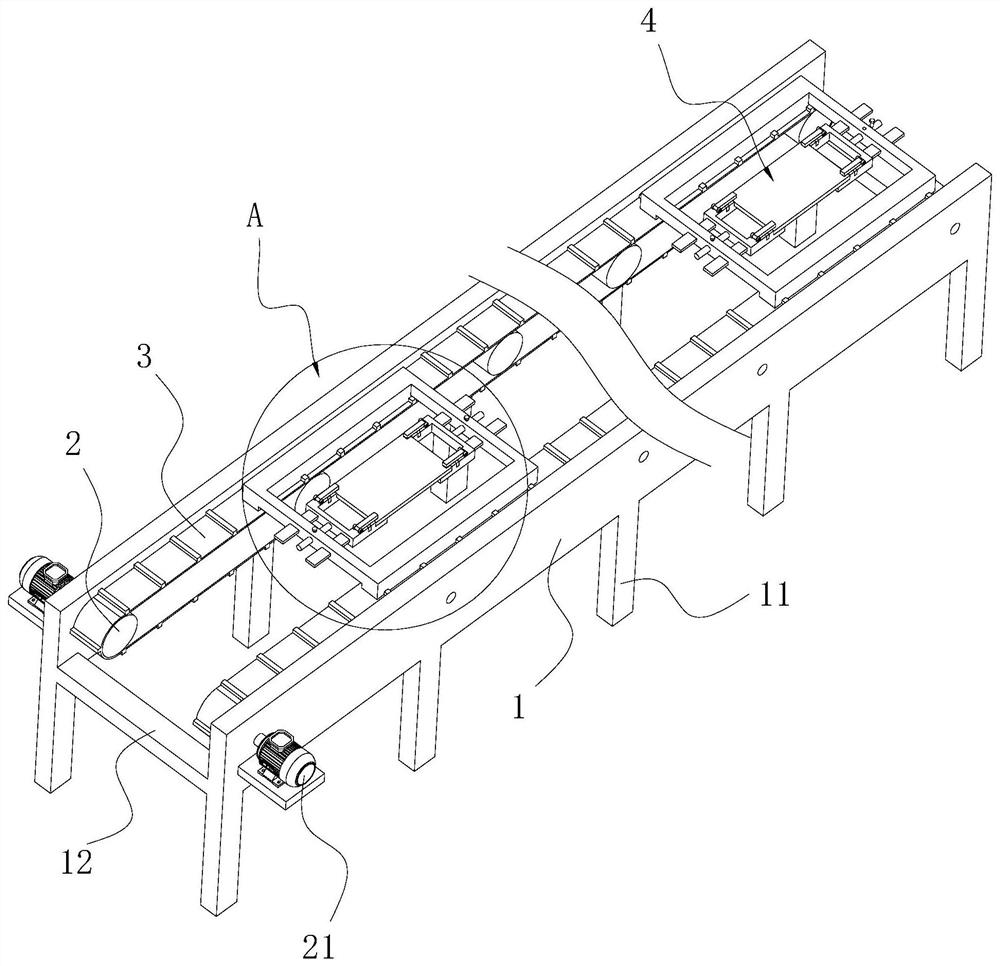

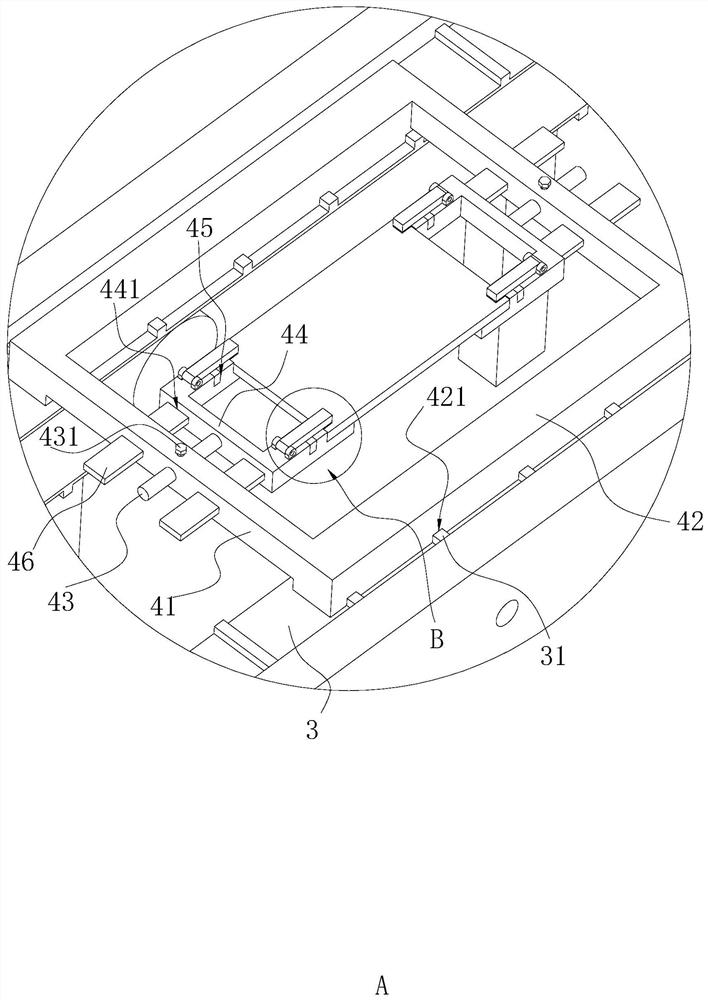

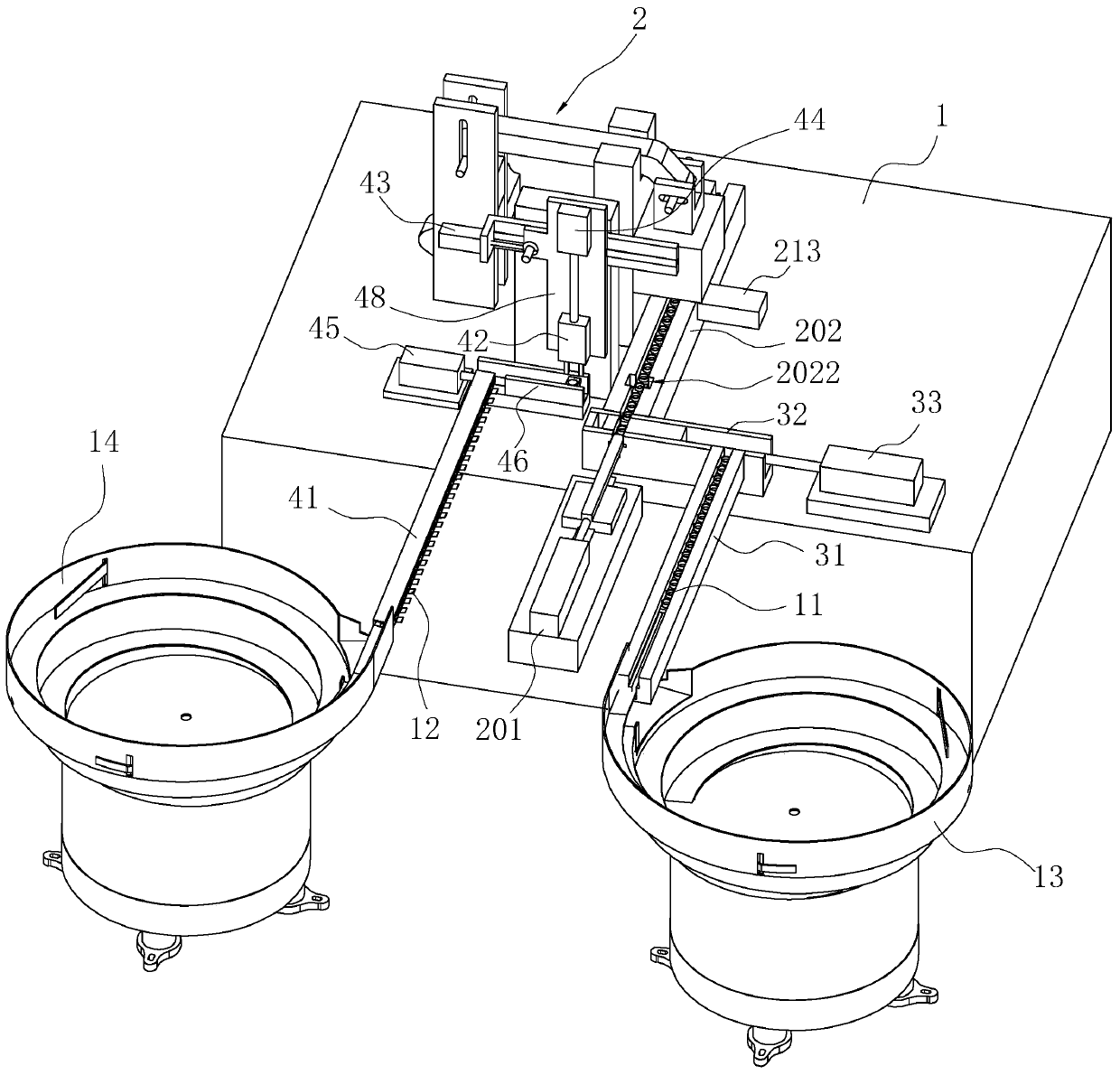

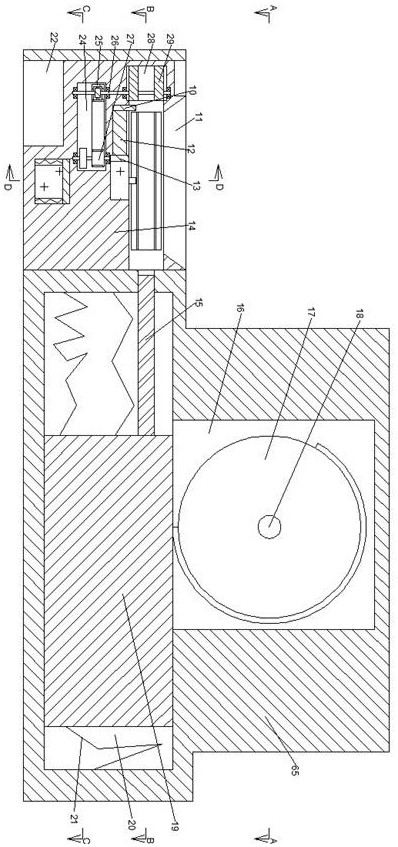

Ultra-thin wall metal filtering pipe fitting bottom drilling equipment

ActiveCN111687447AImprove the limit effectNot easy to shift positionMetal working apparatusPositioning apparatusAutomatic controlPipe fitting

The invention discloses ultra-thin wall metal filtering pipe fitting bottom drilling equipment, and belongs to the technical field of mechanical drilling. According to the ultra-thin wall metal filtering pipe fitting bottom drilling equipment, a plurality of arc-shaped positioning blocks capable of moving up and down are arranged on a pipe fitting positioning plate and matched with a plurality ofarc-shaped positioning cavities, and a plurality of pipe fittings to be drilled are positioned without manual positioning, so that the limiting effect is good, and the pipe fittings are not prone to position deviation caused by drilling in the drilling process; in addition, an electric drilling device at the driving end of a mechanical arm can flexibly drill the end parts of the pipe fittings withdifferent diameters and straight lengths through a movable seat electrically sliding on an operating platform, and the electric drilling device can densely drill the end surfaces of the pipe fittingsunder the automatic control of the mechanical arm; and after drilling the pipe fittings, the pipe fittings on a pipe fitting positioning plate is easy to fall into a receiving box through the rotaryinclined operation of the pipe fitting positioning plate without manual blanking, so that the working efficiency is effectively improved to a certain extent.

Owner:泰州鸿材科技有限公司

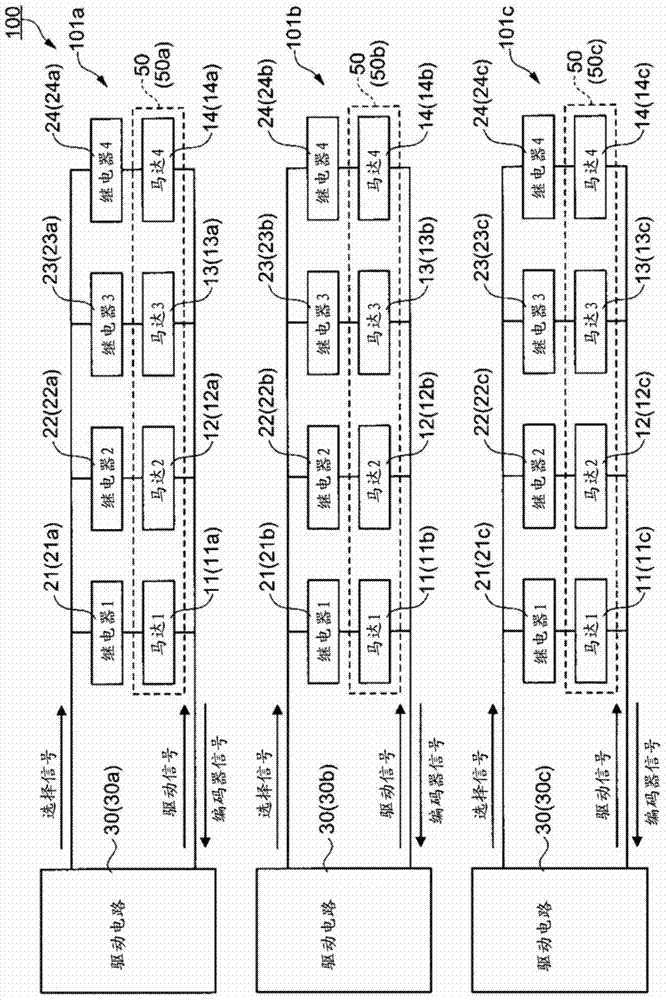

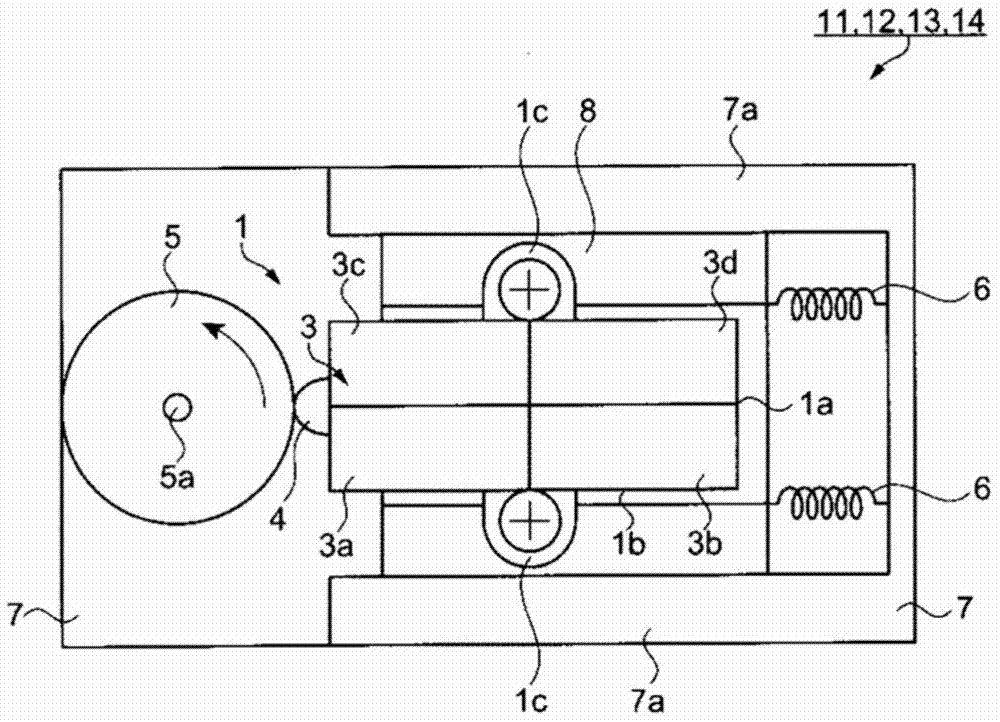

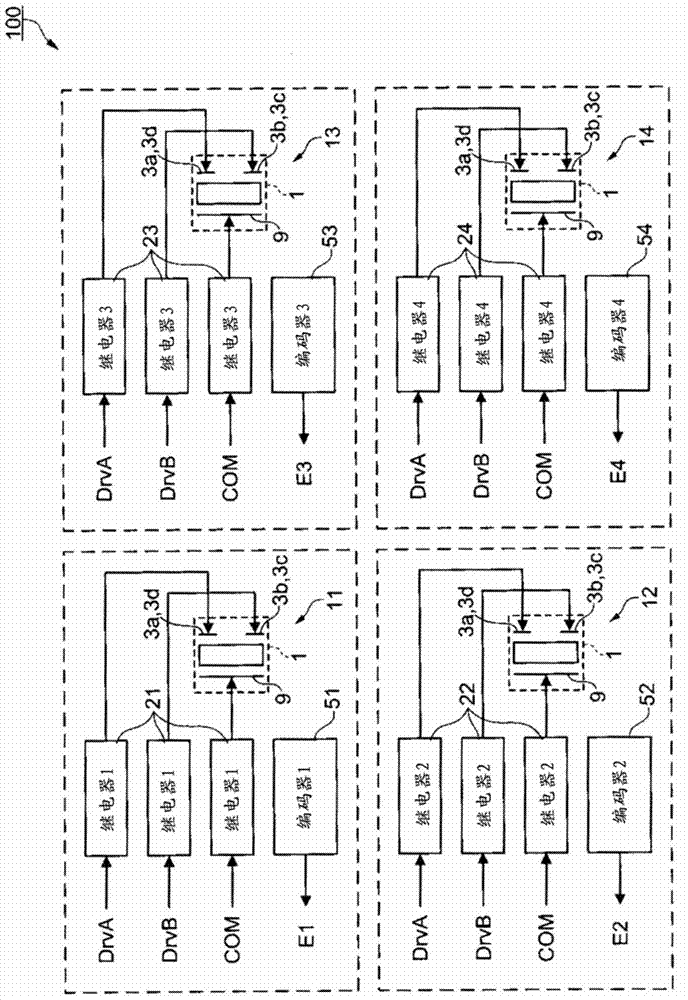

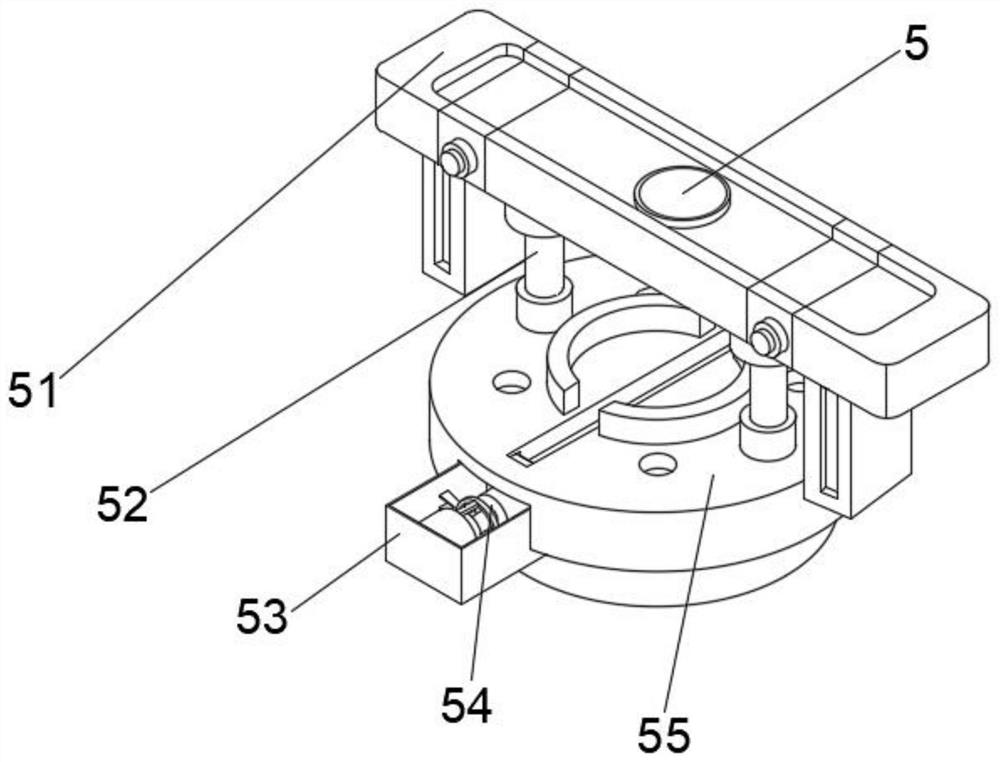

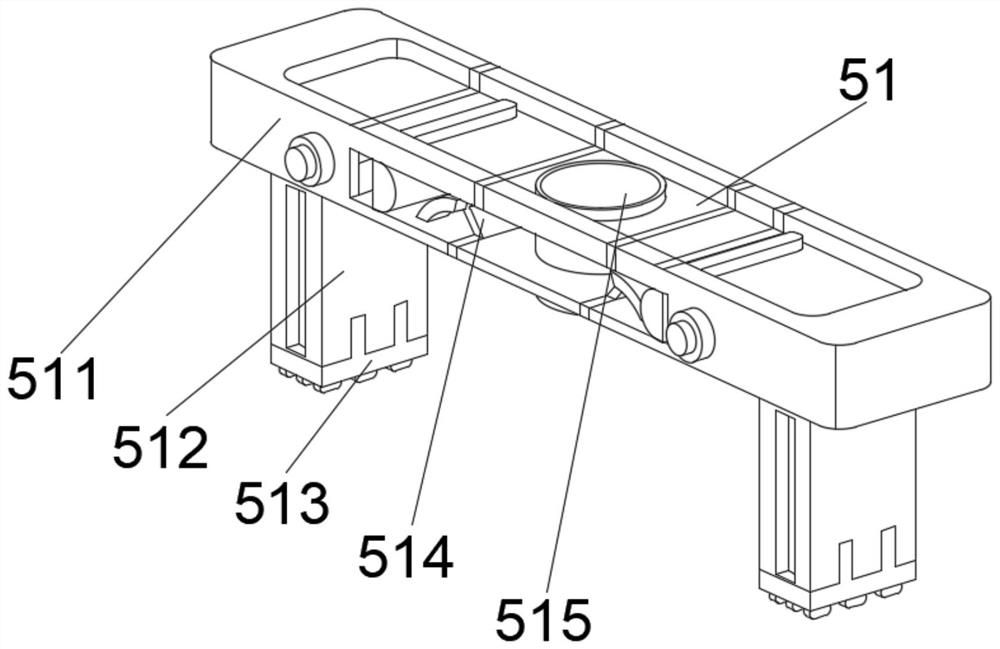

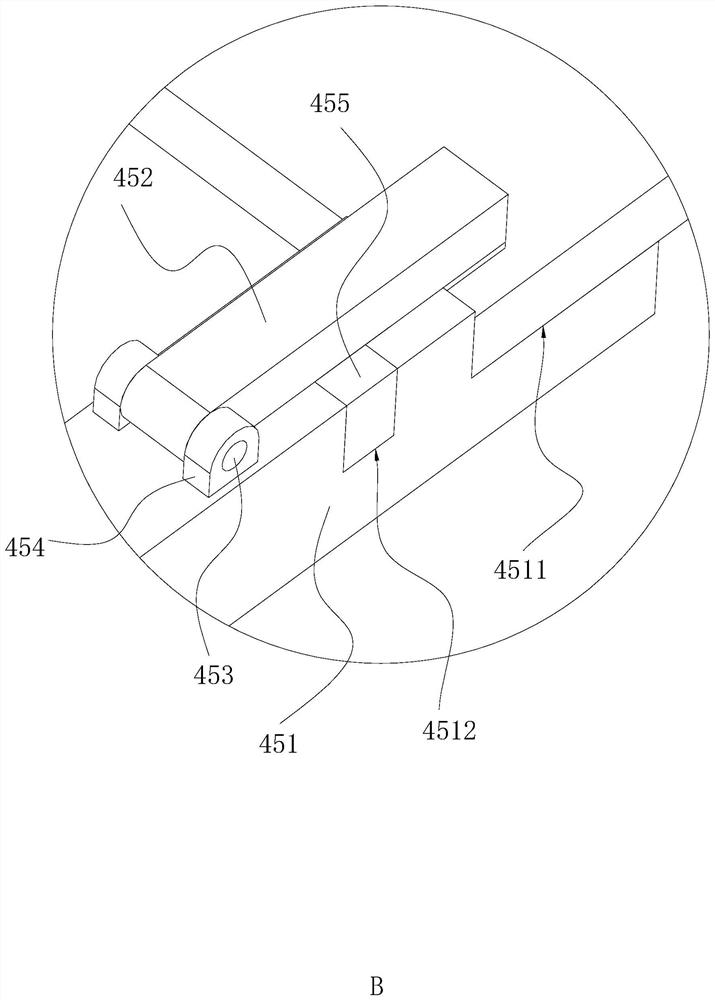

Drive device, electronic component carrying device, electronic component inspection device

InactiveCN104218844AHigh positioning accuracyConstant braking effectMechanical apparatusPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectronic component

Owner:SEIKO EPSON CORP

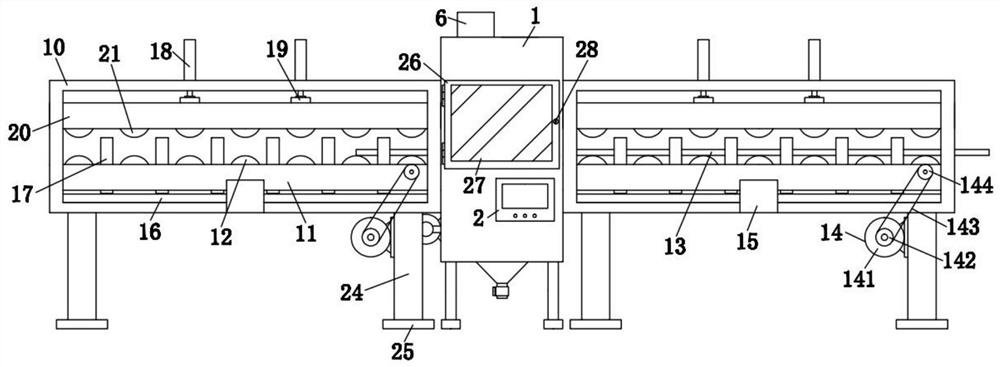

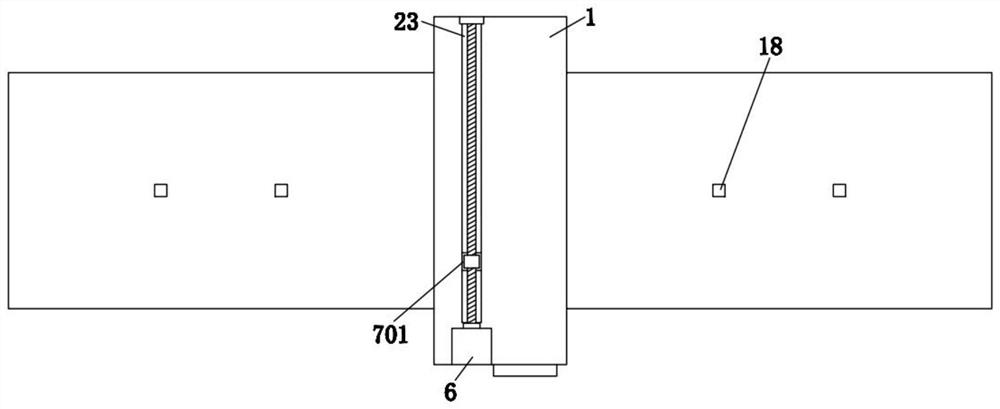

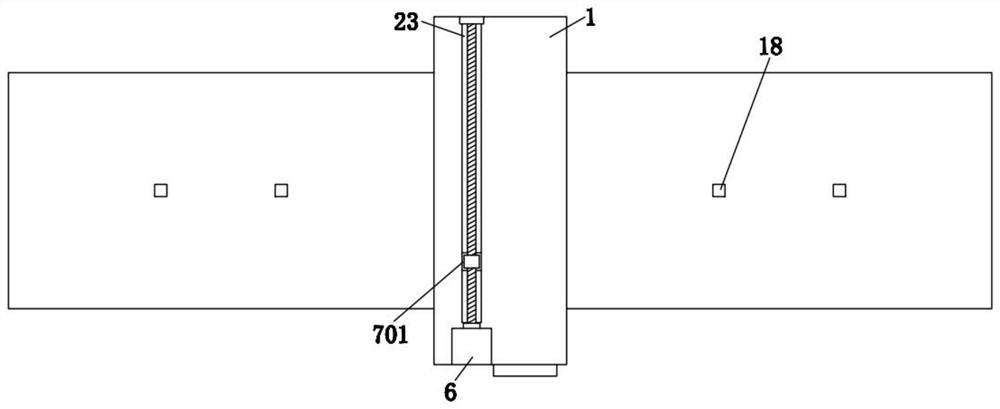

Graphite polyphenyl granule novel composite insulation board production line

PendingCN114030126ANot easy to shift positionImprove quality and production efficiencyCleaning using toolsProcess engineeringManufacturing line

The invention discloses a graphite polyphenyl granule novel composite insulation board production line, and belongs to the technical field of insulation board production, the graphite polyphenyl granule novel composite insulation board production line comprises a supporting bottom plate, the upper surface of the supporting bottom plate is fixedly connected with the lower surface of a supporting plate through supporting legs, and the rear portion of the upper surface of the supporting bottom plate is fixedly connected with the lower surface of a connecting baffle; and the front face of the connecting baffle is fixedly connected with the back face of a top plate. According to the device, by arranging a transmission roller, a pressing roller, a glue scraping assembly, a discharge valve and a handle, the handle can be held to move back and forth to clean materials overflowing from the heat preservation plate within the time period when the heat preservation plate is extruded, the materials can fall into an excess material collecting box after being scraped, and the movement of a scraper push plate can accumulate the material in the excess material collecting box to both sides and discharge it from the discharge valve; the purposes of cleaning and collecting the extruded and overflowed materials are effectively achieved, the production cost is reduced, meanwhile, the working environment is not prone to being polluted, and the efficient production and machining of the heat preservation plate are facilitated.

Owner:枣阳银达银通节能建材有限公司

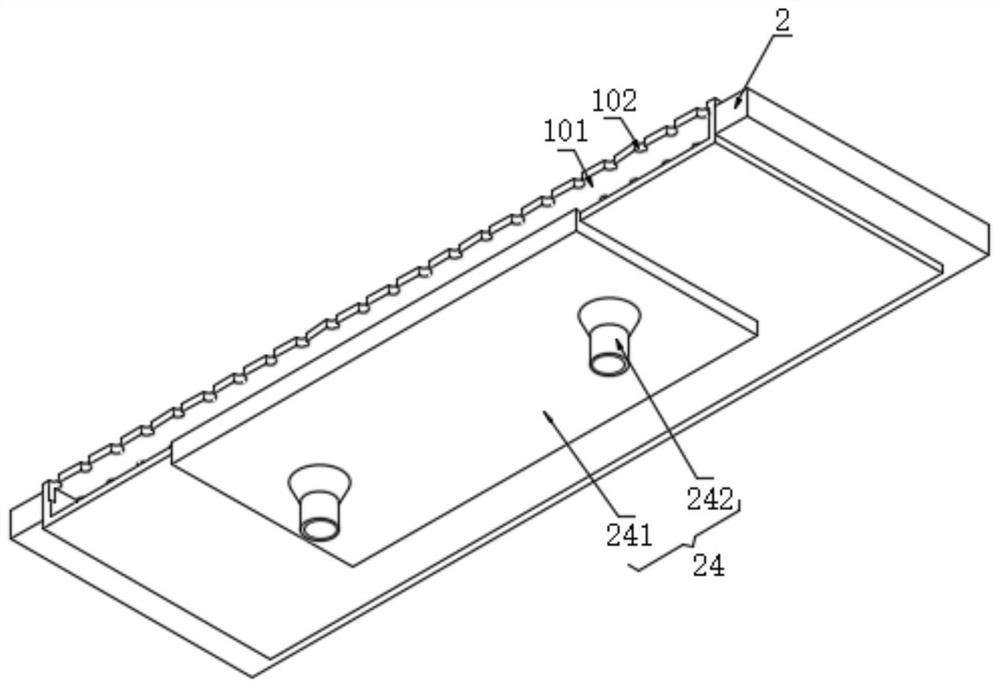

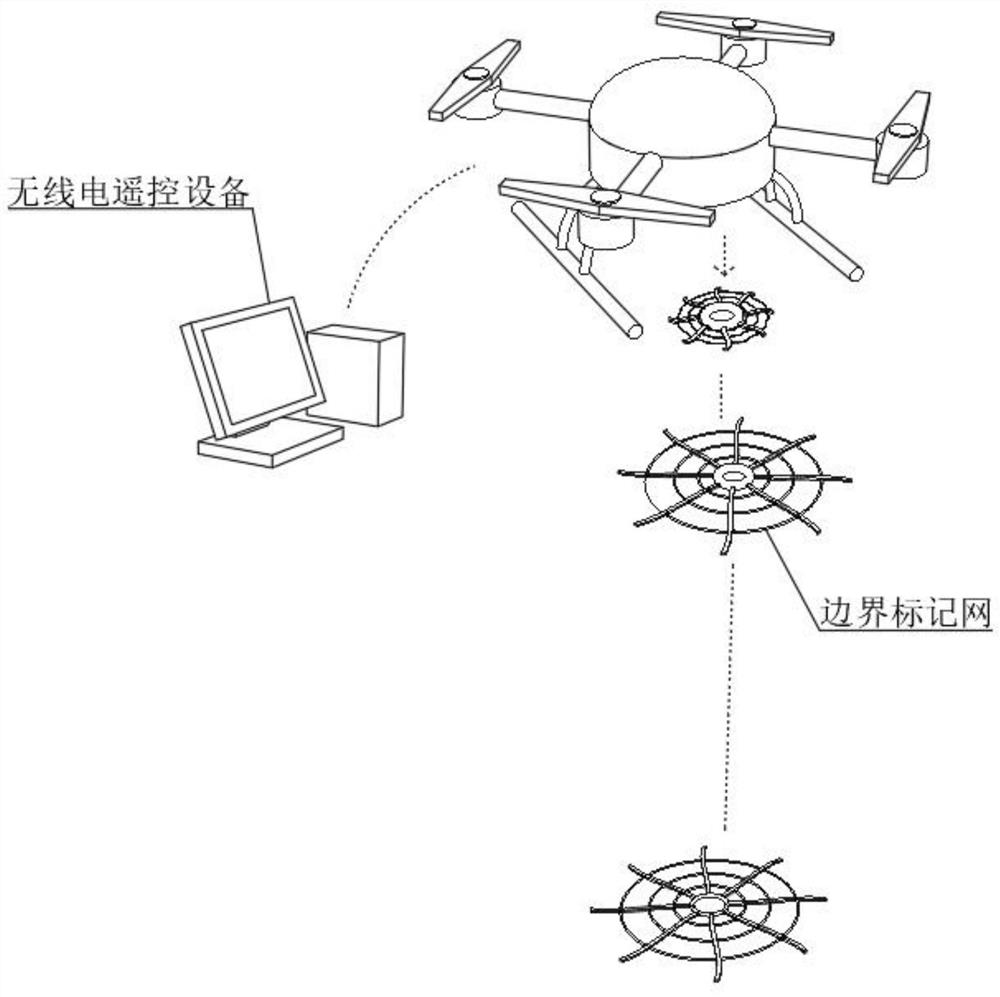

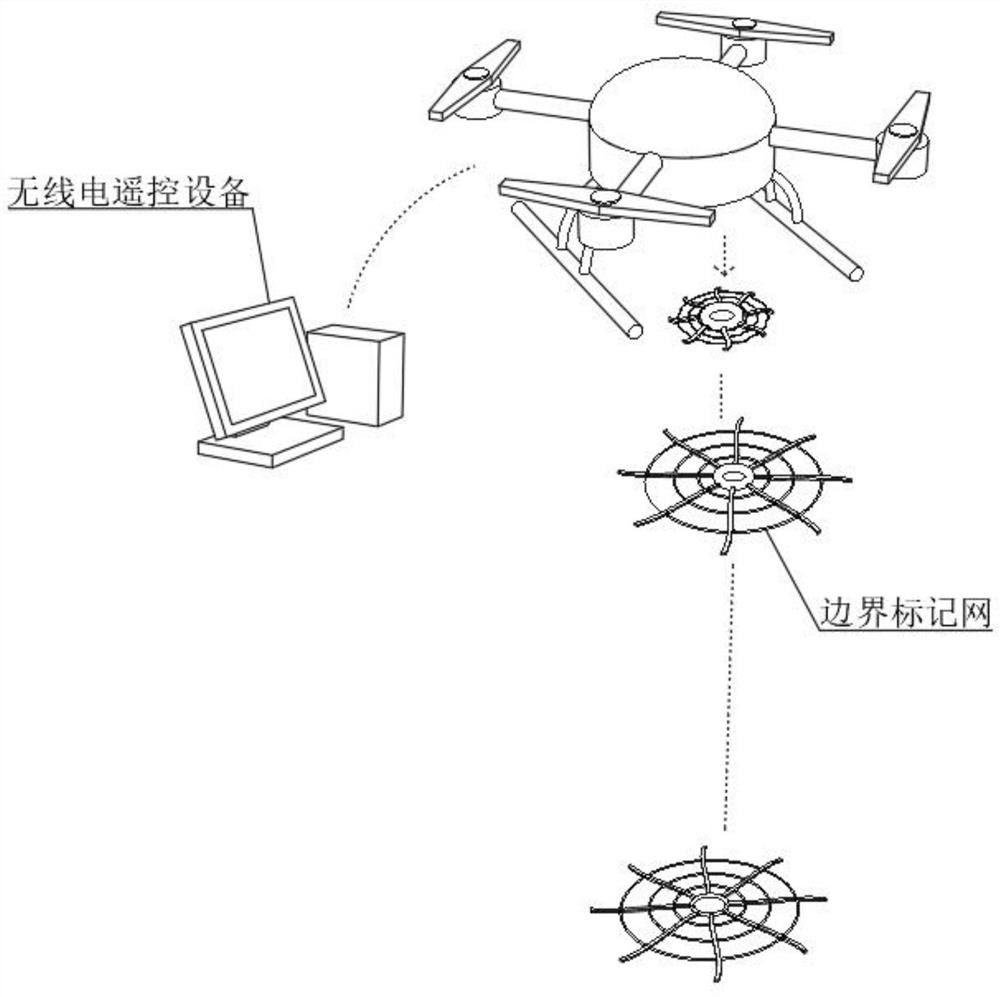

A fruit tree growth monitoring method based on UAV low-altitude remote sensing technology

ActiveCN112839207BRealize monitoringRealize analysisTransmission systemsRemote controlled aircraftFruit treeRemote control

The invention discloses a fruit tree growth monitoring method based on UAV low-altitude remote sensing technology, which belongs to the field of UAV monitoring technology. A fruit tree growth monitoring method based on UAV low-altitude remote sensing technology comprises the following steps: according to the distribution of orchard area Formulate the best aerial photography monitoring route and multiple spare aerial photography routes, and remotely control the drone to fly over the orchard through the radio remote control equipment terminal. Monitoring and analysis of the growth status, and during the monitoring process, by surrounding the abnormal growth area of the orchard, the boundary marking net is placed, and it is obviously and accurately covered on the upper end of the abnormal fruit tree without destroying the normal growth of the fruit tree, so as to quickly and accurately circle The abnormal growth area of fruit trees provides a visual range indication for artificially regulating the growth of fruit trees, so that people can quickly and accurately manage the growth of abnormal fruit trees.

Owner:河南瑞海科技发展集团有限公司

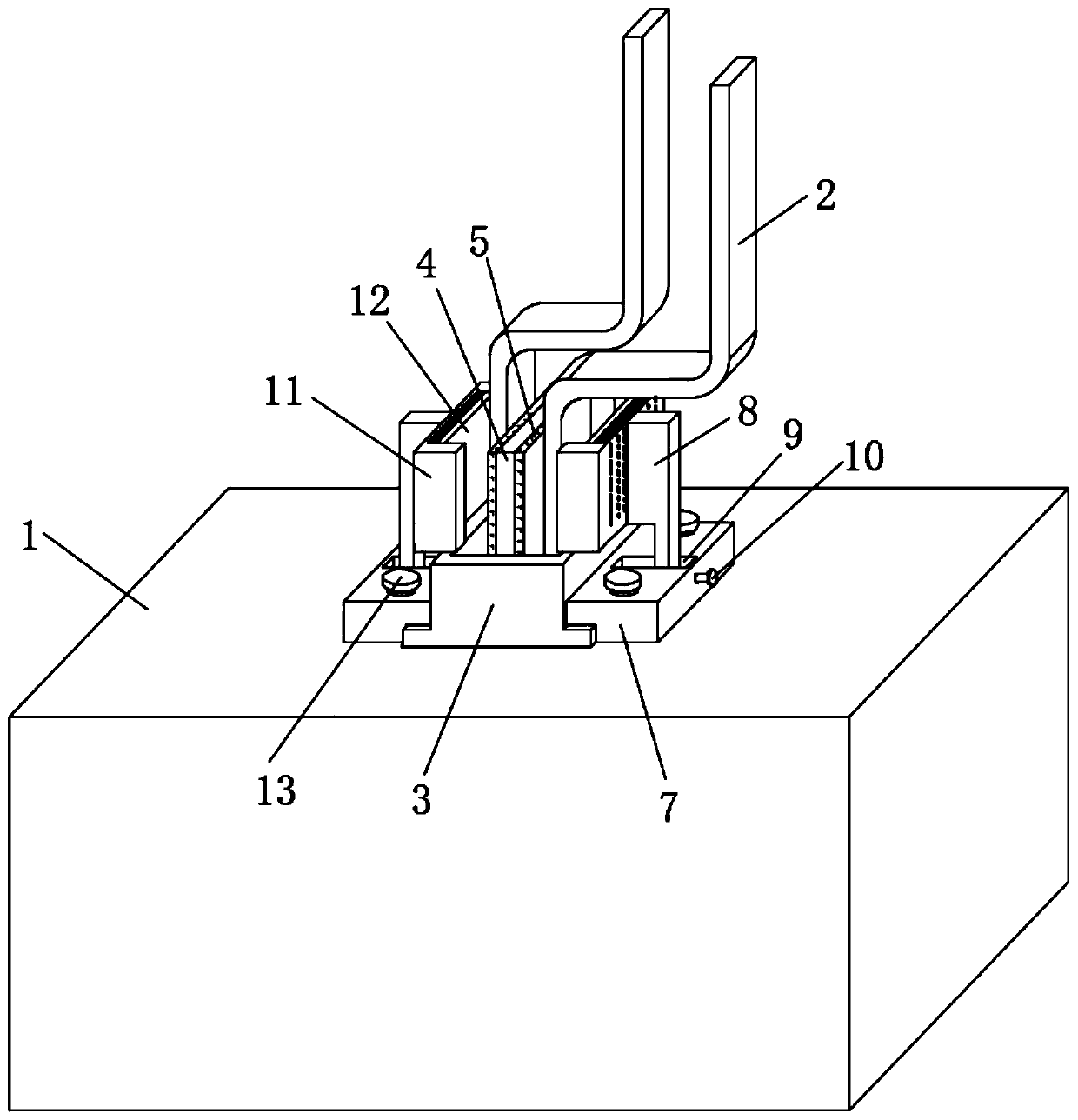

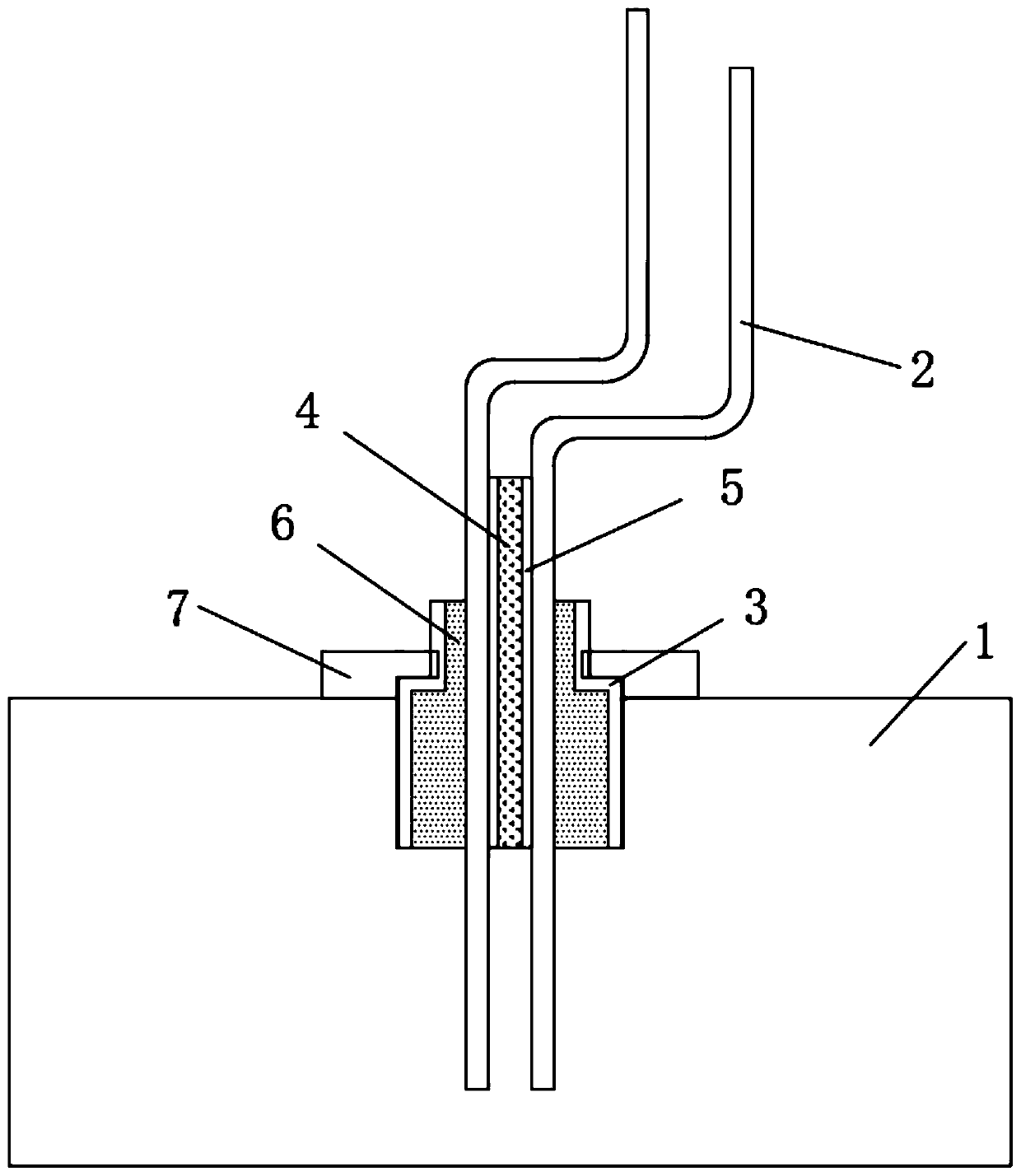

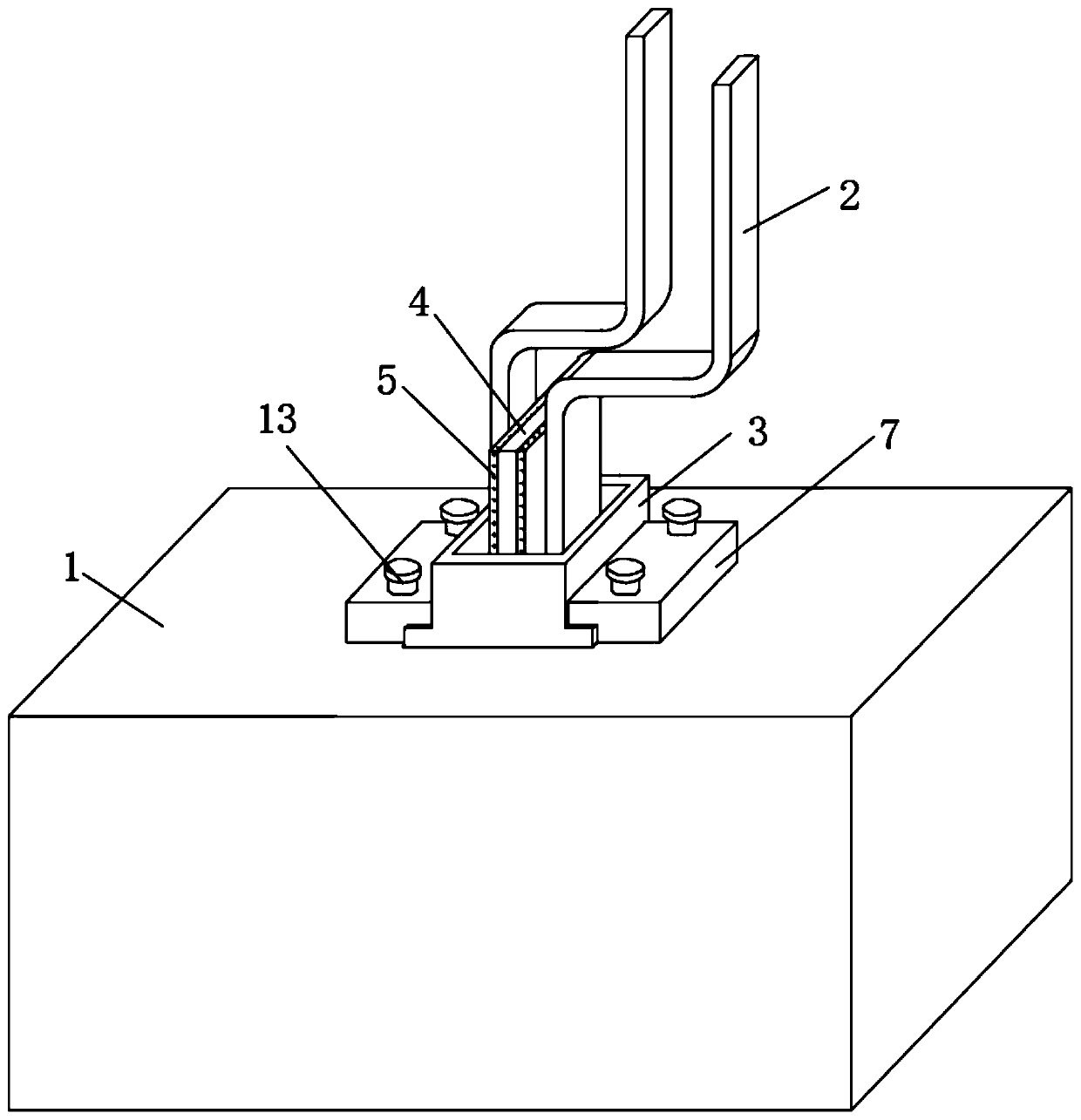

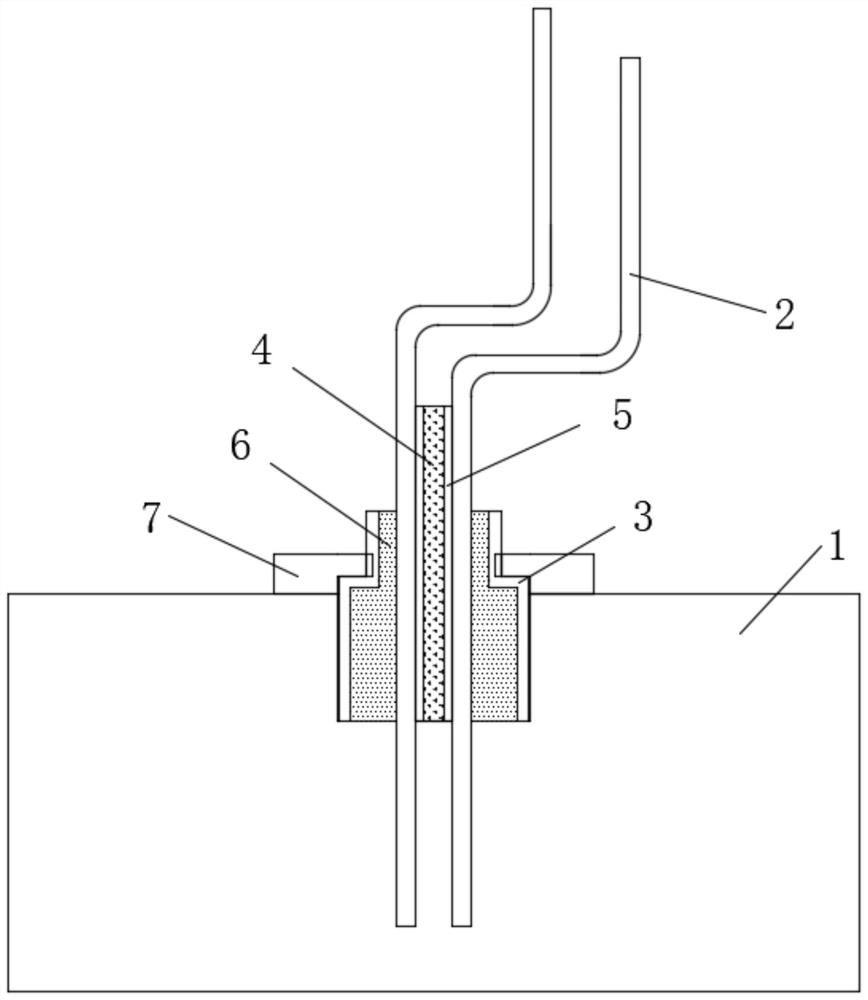

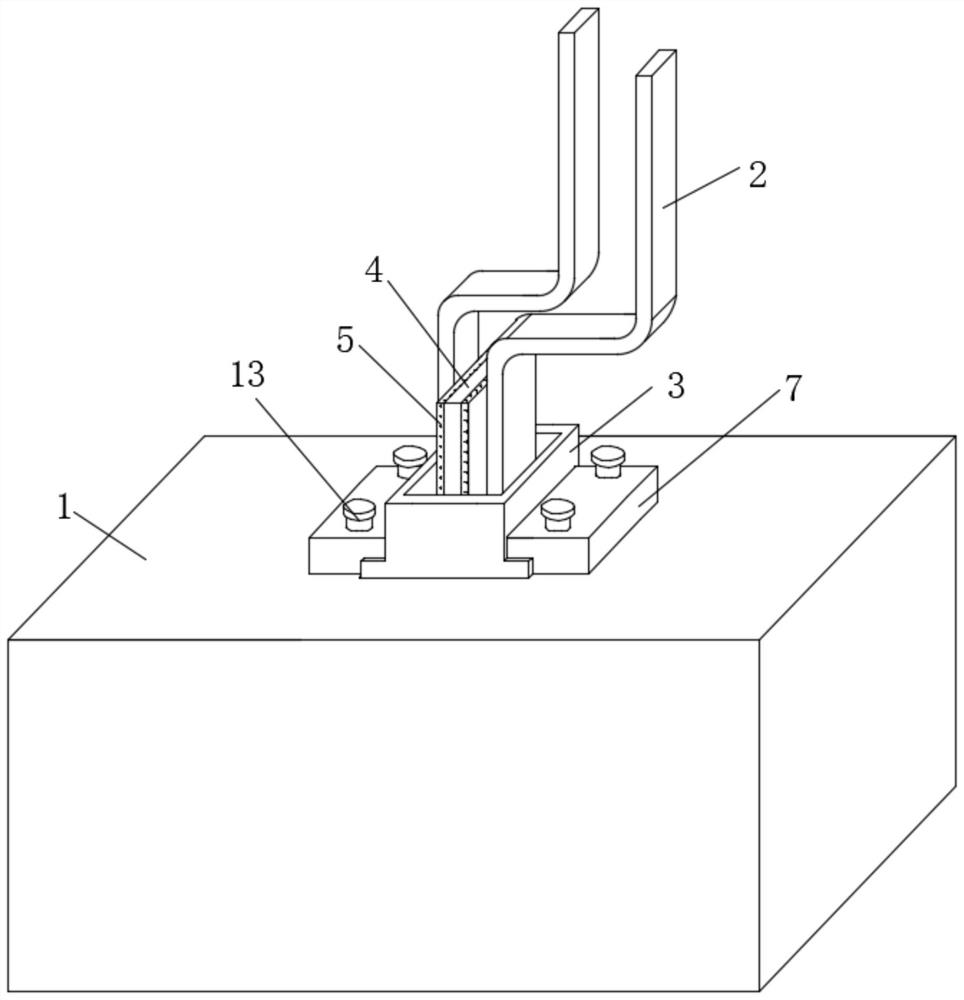

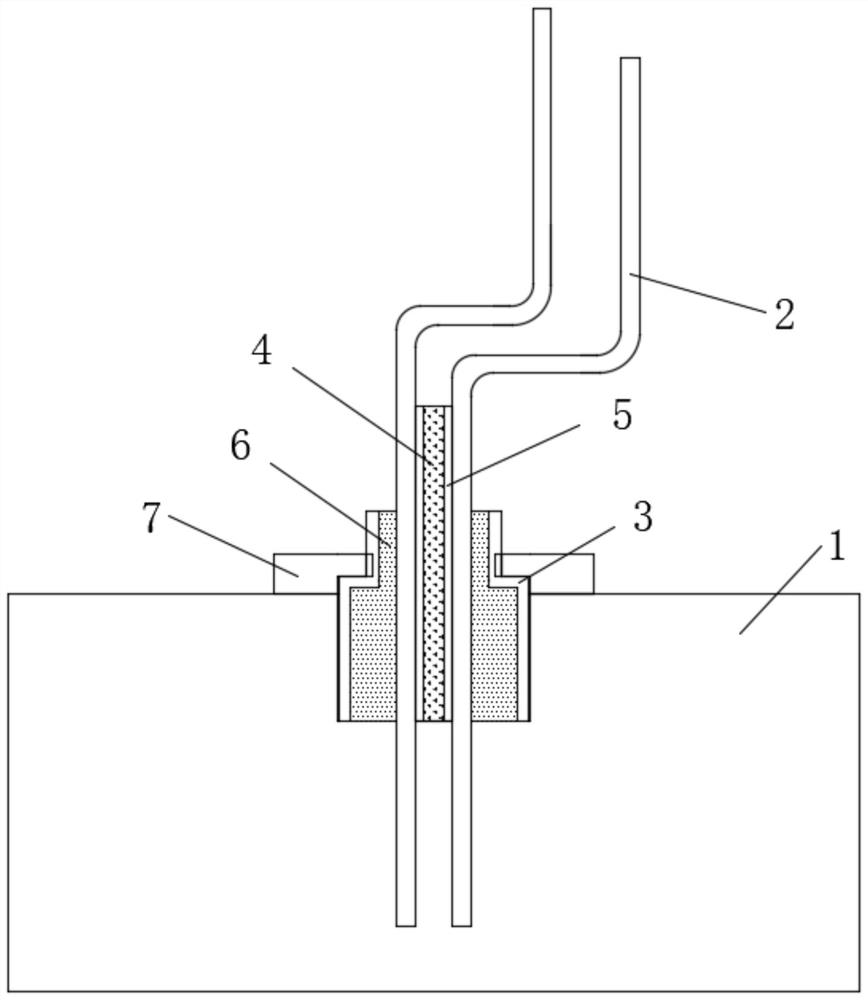

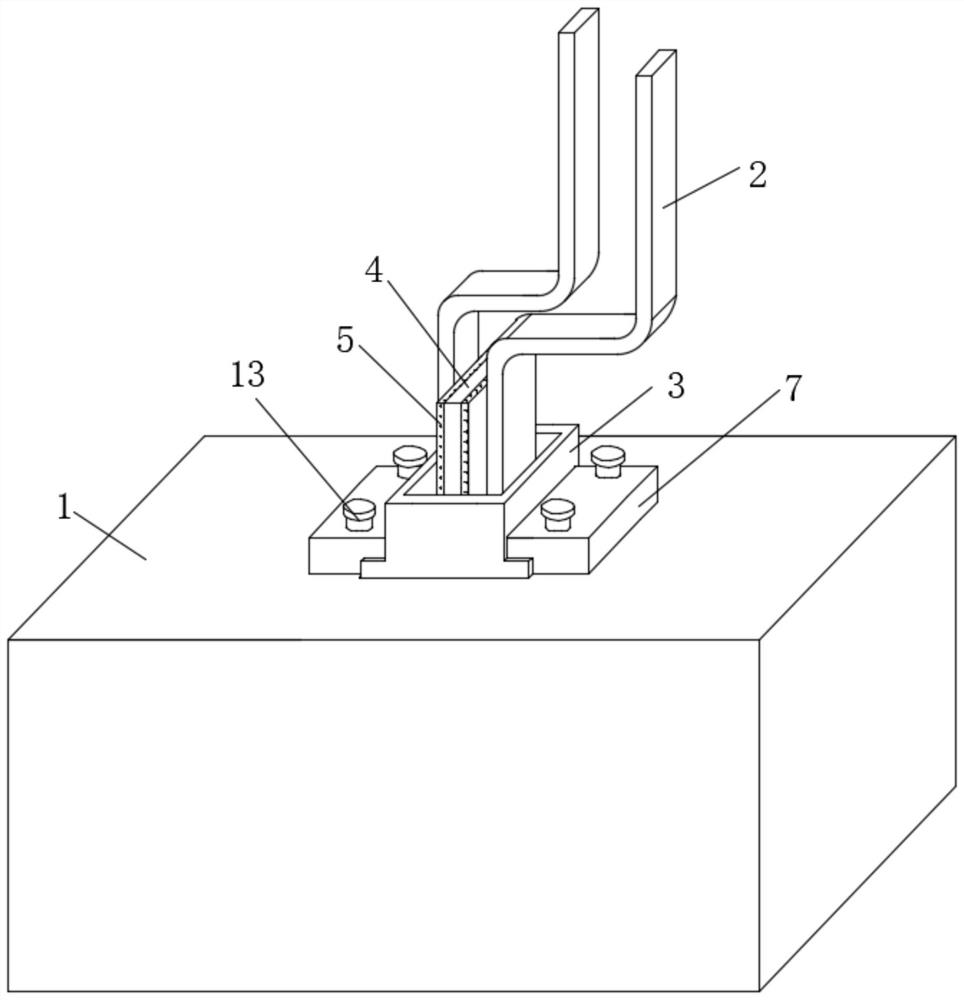

Fixing device for transformer outgoing copper bar and fixing method thereof

InactiveCN110797162AImprove connection stabilityAchieve movementTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a fixing device for a transformer outgoing copper bar and a fixing method thereof and belongs to the technical field of transformer outgoing copper bar fixing. The fixing device is characterized in that a convex mounting plate is matched with an insulating partition plate for use, the limiting and fixing effect on two copper bar bodies is achieved, the two copper bar bodiesare insulated, a limiting plate with a heat dissipation mechanism is installed on one side of the convex mounting plate through a fixing plate, and the fixing plate is installed on an outer side of the convex mounting plate in an embedded mode to further play a role in fixing the convex mounting plate and play a role in supporting the limiting plate with the heat dissipation mechanism. The fixingdevice is advantaged in that the horizontal position of the limiting plate is adjusted according to the thickness of the copper bar bodies, the limiting plate drives the heat dissipation mechanism toabut against outer side walls of the copper bar bodies, on one hand, the copper bar body fixing device is further suitable for fixing the copper bar bodies with different thicknesses, on the other hand, the copper bar bodies are cooled through contact connection of the heat dissipation mechanism.

Owner:玉环市梓鑫机械有限公司

A kind of galvanized sheet cutting method

ActiveCN111805291BRealize automatic pushStable deliveryMetal working apparatusMaintainance and safety accessoriesStructural engineeringMechanical engineering

The present invention relates to the field of galvanized sheet, specifically a galvanized sheet, including a box body, a control box is fixedly installed on the front side of the box body, and first rectangular openings are opened on the left and right sides of the box body, so that A support plate is fixedly installed between the inner wall of the box corresponding to the first rectangular opening, and a second rectangular opening is opened between the support plate and the upper surface of the box corresponding to the second rectangular opening. The first transmission screw body. The present invention automatically pushes the body of the galvanized sheet to achieve faster work efficiency, and at the same time reduces the labor intensity of workers, making it safer to use. The main body is transported stably and is not prone to collisions, and the galvanized sheet body is not easy to shift its position, so that the qualified rate of the galvanized sheet body size after cutting is higher, and the dust generated during the cutting process is conveniently collected by the dust collection mechanism, so that the work site Clean and tidy.

Owner:惠民万顺节能新材料有限公司

Efficient plasma cutting machine

PendingCN113828901AReduce wearExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesPhysicsPlasma cutting

The invention discloses an efficient plasma cutting machine and relates to the technical field of metal cutting. The efficient plasma cutting machine comprises a bottom plate, a cutting device is fixedly connected to the middle position of the top of the bottom plate, a plasma cutter is arranged in the middle position of the top of the cutting device, and bearing plates are fixedly connected to the positions, located on the two sides of the cutting device, of the top of the bottom plate. Supporting bases are fixedly connected to the positions, located on the two sides of the cutting device, of the top of the bearing plate, and positioning guiding pieces are arranged on the sides, close to the cutting device, of the supporting bases. According to the efficient plasma cutting machine, during moving, abrasion of the surface of a moving mechanism is effectively reduced, the service life of the device is further prolonged, vibration generated during cutting of the device is effectively reduced, position deviation of a metal piece in the cutting process is not prone to being caused by vibration, and the situation that chippings enter a driving piece to damage a power piece can be avoided, a stabilizing mechanism can rotate slowly, so that the cutting angle of the device is further increased.

Owner:任伟

Stainless steel water heating joint and production process thereof

PendingCN112128486AClosely connectedWill not polluteScrew threaded jointsStructural engineeringSS - Stainless steel

The invention discloses a stainless steel water heating joint and a production process thereof. The joint comprises a hexagonal shaft sleeve, a first connecting sleeve and a second connecting sleeve,wherein the first connecting sleeve and the second connecting sleeve are inserted in the hexagonal shaft sleeve, a first welding ring is formed between an outer ring of the end face of the first connecting sleeve and the inner wall of the hexagonal shaft sleeve through circumferential welding, and a chamfer is formed in the end face of the second connecting sleeve; and a second welding ring is formed between the outer wall of the second connecting sleeve and the end face, away from the first connecting sleeve, of the hexagonal shaft sleeve through circumferential welding, the first connectingsleeve abuts against the end face of the second connecting sleeve, and a containing space is formed between the chamfer and the end face of the first connecting sleeve and used for containing the first welding ring. The joint has the following advantages and effects that the scheme utilizes a new mechanical structure, and has the effects of environmental protection, simple technological process, high processing efficiency, low production cost and light finished product weight.

Owner:宁波宁水仪表有限公司

A dry-type transformer shell

ActiveCN106024278BStable structureAvoid deformationTransformers/inductances casingsSheet joiningTransformerEngineering

Owner:RONGZHONG ELECTRICAL EQUIP

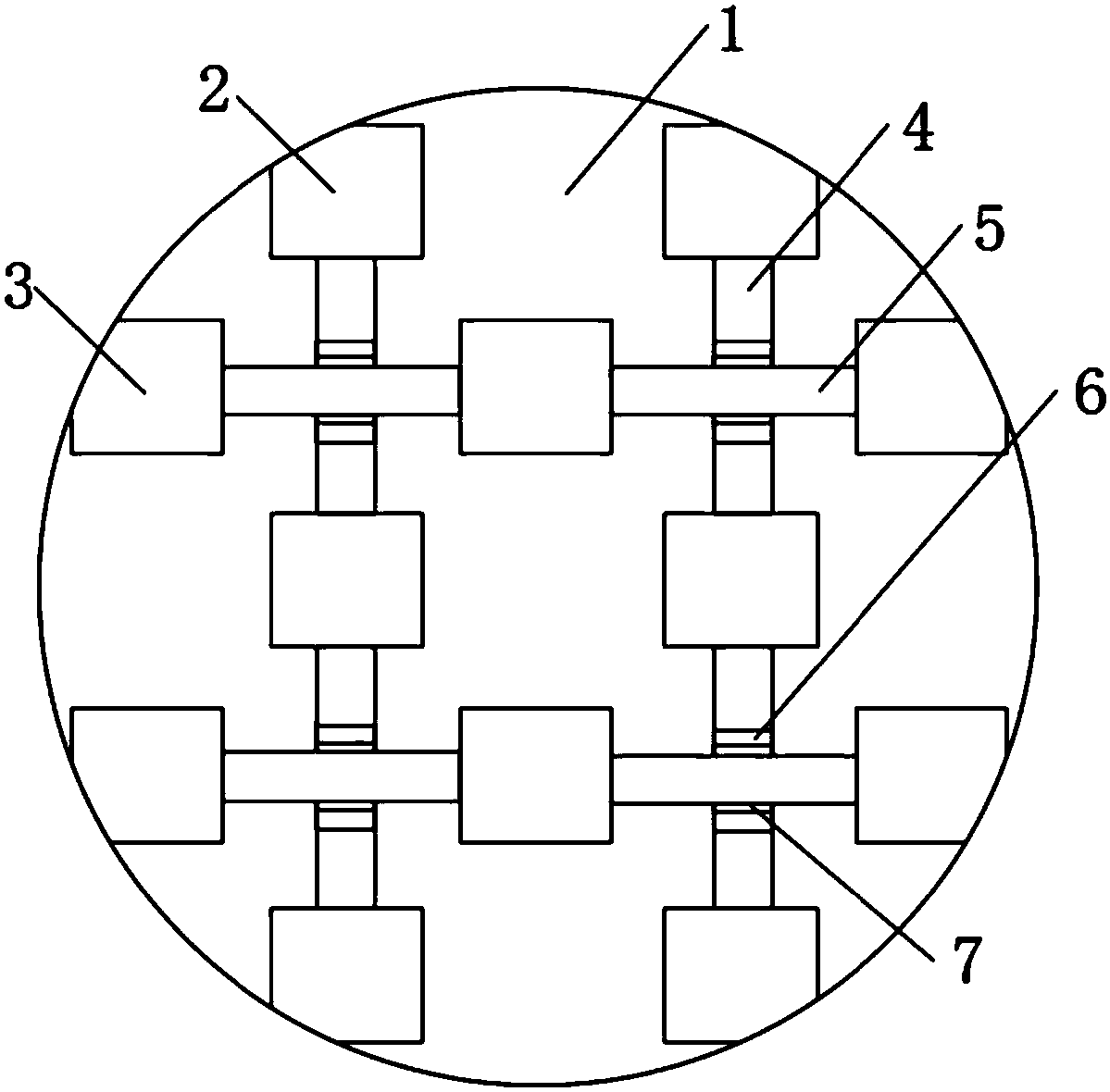

Touch induction electrode structure

ActiveCN108415594ANot easy to interfere with each otherHigh precisionInput/output processes for data processingMaterials scienceElectrode

The invention discloses a touch induction electrode structure. The structure comprises a substrate, first induction electrodes, second induction electrodes, a lead wire and an electric bridge, whereinthe surface of the substrate is inlaid with the first induction electrodes and the second induction electrodes; the adjacent first induction electrodes are connected through the lead wire; the adjacent second induction electrodes are connected through the electric bridge; the first induction electrodes and the second induction electrodes are clamped in fixing slots of the upper surface of the substrate; the first induction electrodes and the second induction electrodes are difficultly disturbed mutually, so that the control precision is improved; protective boards are laminated on the lower surfaces of the first induction electrodes and the second induction electrodes; the protective boards have the effects of protecting the induction electrodes, so that the wear between the substrate andthe induction electrodes is reduced and the service life is relatively long; and the lower ends of the first induction electrodes and the second induction electrodes are clamped in the fixing slots,so that the induction electrodes are difficultly shifted due to fall damage or other situations, the positions are relatively fixed, and the use is not influenced.

Owner:SHENZHEN ZHILING WEIYE TECH

Fruit tree growth monitoring method based on unmanned aerial vehicle low-altitude remote sensing technology

ActiveCN112839207ARealize monitoringRealize analysisTransmission systemsRemote controlled aircraftFruit treeAgricultural engineering

The invention discloses a fruit tree growth monitoring method based on an unmanned aerial vehicle low-altitude remote sensing technology, and belongs to the technical field of unmanned aerial vehicle monitoring, the fruit tree growth monitoring method based on the unmanned aerial vehicle low-altitude remote sensing technology comprises the following steps: formulating an optimal aerial photography monitoring route and a plurality of standby aerial photography routes according to orchard area distribution, the unmanned aerial vehicle is remotely controlled to sail over the orchard through the radio remote control equipment terminal, monitoring and data acquisition are performed on the growth state of the fruit tree in any period through the unmanned aerial vehicle, monitoring and analysis of the growth state of the fruit tree are achieved, and in the monitoring process, the boundary marking network is put in the abnormal growth area of the orchard in a surrounding mode, the device can obviously and accurately cover the upper end of the abnormal fruit tree without destroying the normal growth of the fruit tree, so that the abnormal growth area of the fruit tree is rapidly and accurately enclosed, visual range indication is provided for manual regulation and control of the growth of the fruit tree, and people can rapidly and accurately perform growth management on the abnormal fruit tree.

Owner:河南瑞海科技发展集团有限公司

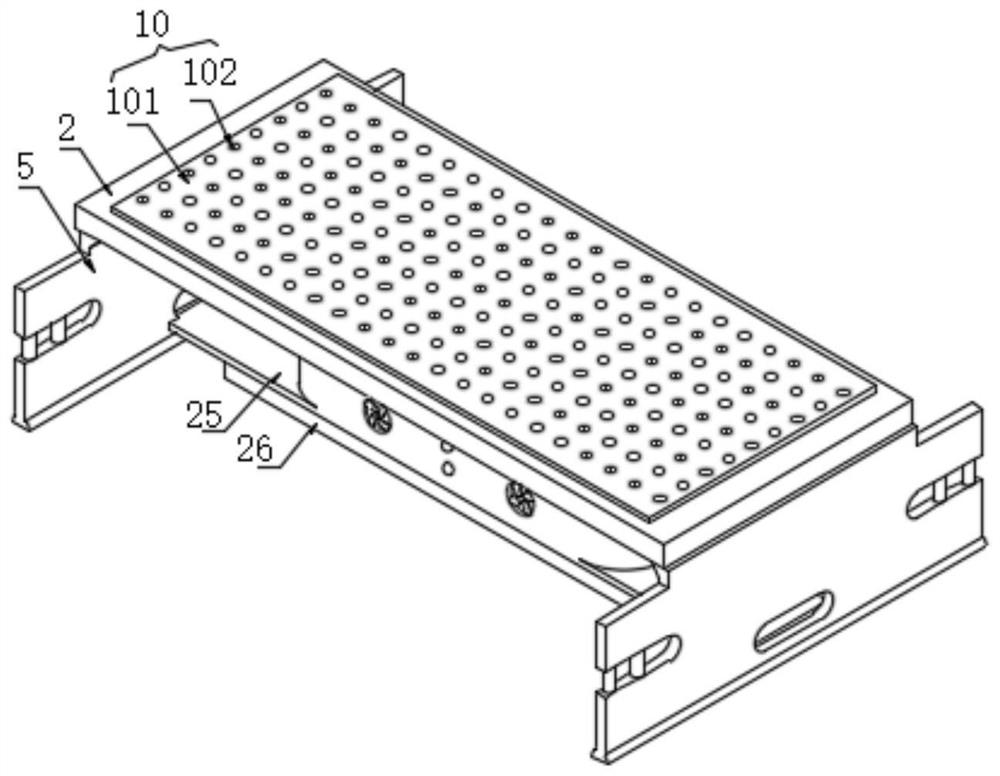

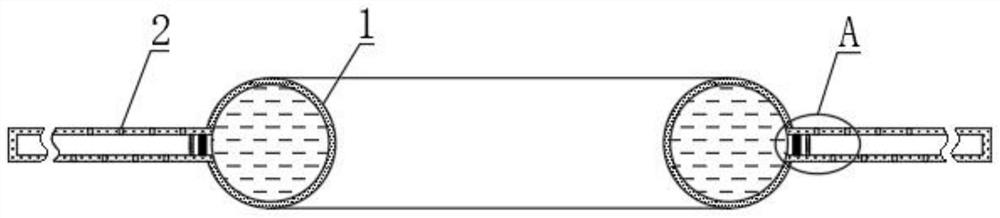

smt patch technology and conveying device applied to it

ActiveCN110775524BNot easy to shift positionEasy to operateConveyorsElectric machineryProcess engineering

The invention discloses an SMT patching process and a conveying device applied to the process, relates to the technical field of SMT patching, and solves the problem that the glue and components in the existing SMT patching process are prone to positional deviation when the PCB board is transferred The main point of the technical solution is that the conveying device includes two vertical plates, supporting legs, a number of rotating rollers rotatably connected to the sides of the two supporting plates close to each other, a motor fixedly connected to the supporting plates, and a conveyor belt sleeved on the rotating rollers. And the clamping mechanism supported on the two conveyor belts; the patch process includes: a. Fixed PCB board; b. Install the clamping mechanism; c. dispensing; d. check; e. Component placement; f. Reflow soldering; g. AOI test; h. Flip the patch, the conveyor belt transports the clamping mechanism, and passes through the dispenser, the placement machine and the reflow oven in turn, so that the PCB board can be kept flat during the transportation process, so that the glue and parts printed on the PCB board It is not easy to shift the position.

Owner:深圳市杰瑞佳科技有限公司

Touch Sensing Electrode Structure

ActiveCN108415594BNot easy to interfere with each otherHigh precisionInput/output processes for data processingTouch SensesEngineering

The invention discloses a touch induction electrode structure. The structure comprises a substrate, first induction electrodes, second induction electrodes, a lead wire and an electric bridge, whereinthe surface of the substrate is inlaid with the first induction electrodes and the second induction electrodes; the adjacent first induction electrodes are connected through the lead wire; the adjacent second induction electrodes are connected through the electric bridge; the first induction electrodes and the second induction electrodes are clamped in fixing slots of the upper surface of the substrate; the first induction electrodes and the second induction electrodes are difficultly disturbed mutually, so that the control precision is improved; protective boards are laminated on the lower surfaces of the first induction electrodes and the second induction electrodes; the protective boards have the effects of protecting the induction electrodes, so that the wear between the substrate andthe induction electrodes is reduced and the service life is relatively long; and the lower ends of the first induction electrodes and the second induction electrodes are clamped in the fixing slots,so that the induction electrodes are difficultly shifted due to fall damage or other situations, the positions are relatively fixed, and the use is not influenced.

Owner:SHENZHEN ZHILING WEIYE TECH

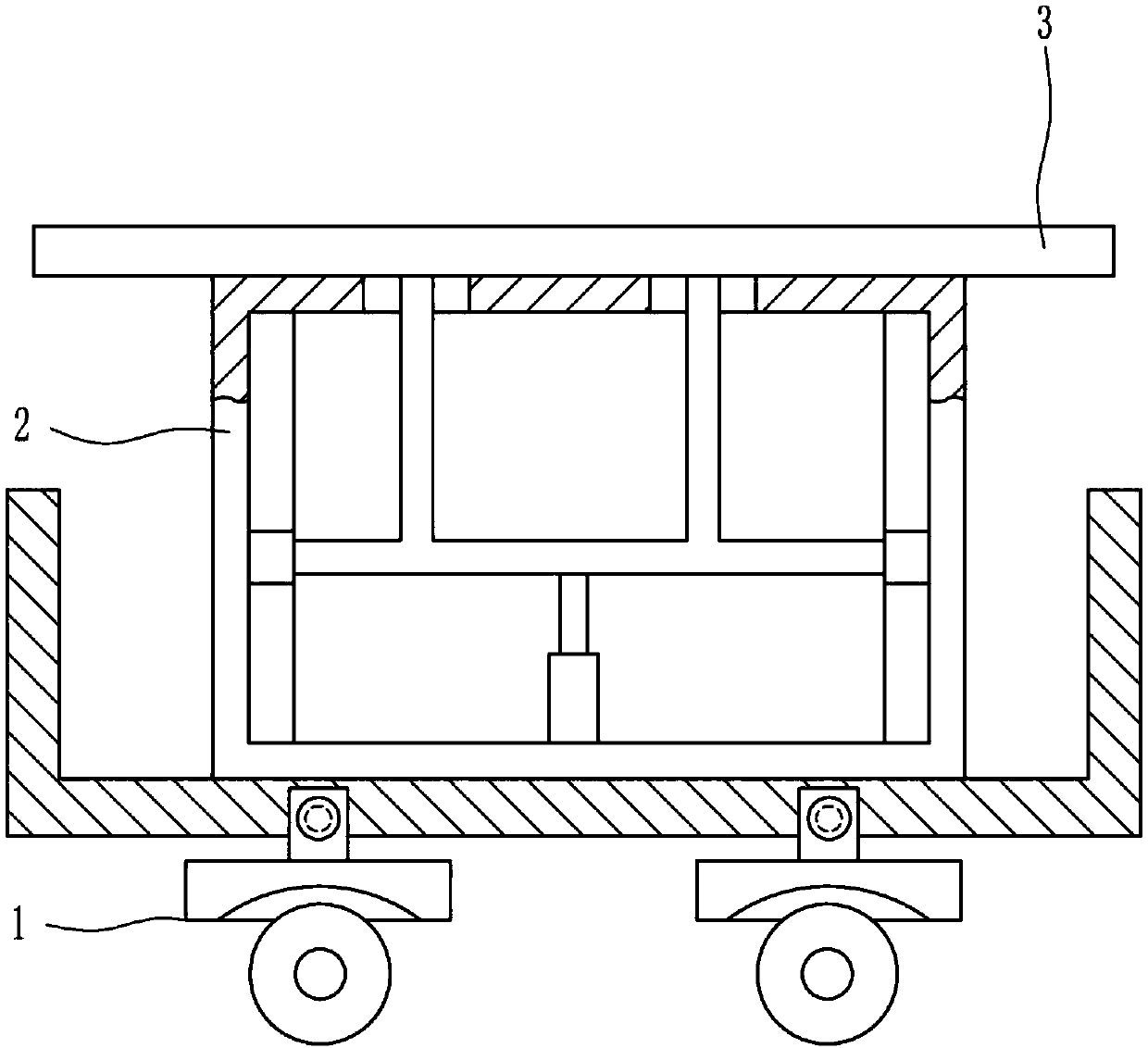

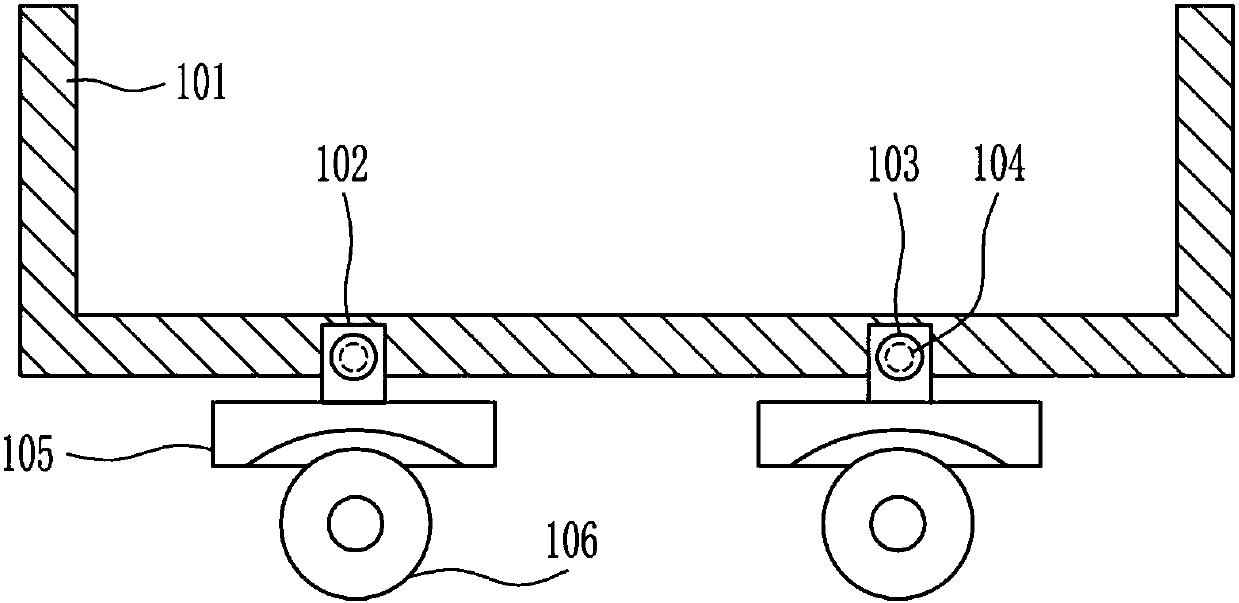

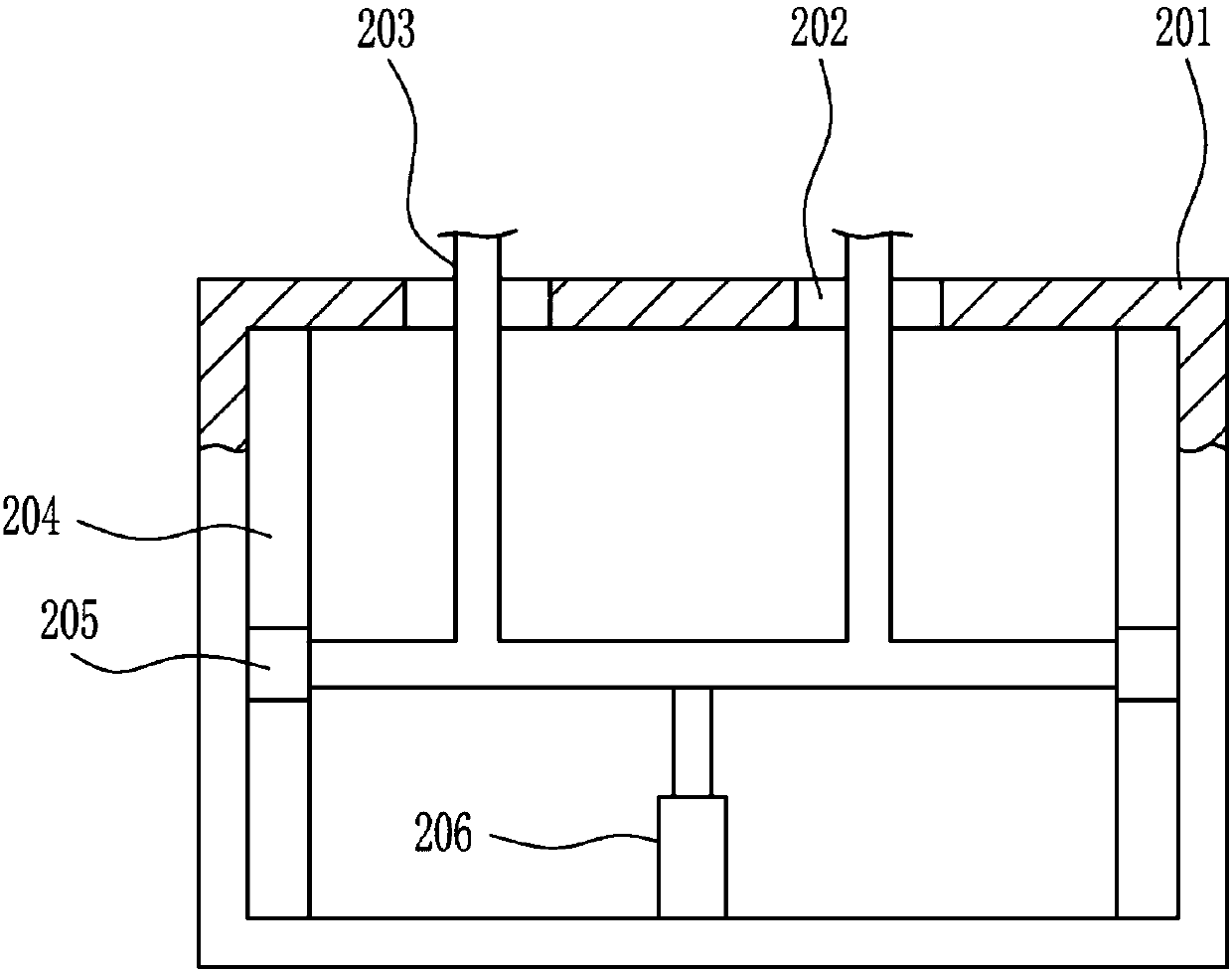

Dried fruit airing equipment for fruit processing

The invention relates to airing equipment, in particular to dried fruit airing equipment for fruit processing, and aims to solve the technical problem of providing the dried fruit airing equipment forthe fruit processing, which is convenient to move, which can adjust airing height, which can be discharged, exchanged and cleaned, and in which working articles are convenient to place and store. Inorder to solve the technical problems, the invention provides the dried fruit airing equipment for the fruit processing. The dried fruit airing equipment comprises a moving mechanism and the like, wherein a lifting mechanism is connected to the bottom end of an airing plate; and the moving mechanism is connected to the bottom of the lifting mechanism. According to the dried fruit airing equipmentdisclosed by the invention, the moving mechanism is arranged, so that the airing plate can arrive at an airing place through pushing a mounting frame, and the purpose of airing fruits is achieved; when universal wheels are not flexible and need maintenance or exchange, screws are screwed out, and the purpose of exchanging or maintaining the universal wheels can be realized; and the lifting mechanism is arranged, so that the purpose of performing airing through adjusting the height of the airing plate can be realized.

Owner:吴启航

A fixing device for transformer copper bars

InactiveCN110797162BAct as a limit fixationPlay a supporting roleTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses a fixing device for a transformer outgoing copper bar and a fixing method thereof and belongs to the technical field of transformer outgoing copper bar fixing. The fixing device is characterized in that a convex mounting plate is matched with an insulating partition plate for use, the limiting and fixing effect on two copper bar bodies is achieved, the two copper bar bodiesare insulated, a limiting plate with a heat dissipation mechanism is installed on one side of the convex mounting plate through a fixing plate, and the fixing plate is installed on an outer side of the convex mounting plate in an embedded mode to further play a role in fixing the convex mounting plate and play a role in supporting the limiting plate with the heat dissipation mechanism. The fixingdevice is advantaged in that the horizontal position of the limiting plate is adjusted according to the thickness of the copper bar bodies, the limiting plate drives the heat dissipation mechanism toabut against outer side walls of the copper bar bodies, on one hand, the copper bar body fixing device is further suitable for fixing the copper bar bodies with different thicknesses, on the other hand, the copper bar bodies are cooled through contact connection of the heat dissipation mechanism.

Owner:玉环市梓鑫机械有限公司

Easy-to-open door based on magnetic adsorption

InactiveCN112554682ASimple and labor-saving operationNot easy to shift positionWing fastenersPhysicsMagnet

The invention discloses an easy-to-open door based on magnetic adsorption, and belongs to the field of magnetic doors. The easy-to-open door based on magnetic adsorption comprises a magnetic adsorption structure, a second magnet, a lifting pulling structure, a pushing part, a compression spring, a limiting structure and a supporting part; the magnetic adsorption structure comprises a fixed part fixedly arranged on a wall surface, a containing cavity formed in the right end of the fixed part, a first magnet and an elastic extensible part; the first magnet and the elastic extensible part are arranged in the containing cavity; the first magnet and the elastic extensible part are of an integrated structure; the first magnet is located on the right side of the elastic extensible part; the fixedpart is located on a wall surface at the position close to the ground; the second magnet is arranged on the side, close to the wall surface, of a door body; the ends, close to each other, of the second magnet and the first magnet are opposite in magnetism; the supporting part is fixedly arranged on the upper end face, close to the right side, of the fixed part; and the lifting pulling structure is arranged between the supporting part and the elastic extensible part, so the adsorption effect between the door body and the wall surface can be easily relieved while adsorption fixation between thedoor body and the wall surface is achieved.

Owner:杭州甜蜜按钮科技有限公司

Galvanized plate

ActiveCN111805291ARealize automatic pushStable deliveryMetal working apparatusMaintainance and safety accessoriesEngineeringStructural engineering

The invention relates to the field of galvanized plates, in particular to a galvanized plate which comprises a box body. A control box is fixedly installed on the front side surface of the box body, first rectangular openings are formed in the left side surface and the right side surface of the box body, a supporting plate is fixedly installed between the inner walls, corresponding to the first rectangular openings, of the box body, a second rectangular opening is formed close to the middle of the supporting plate, and a first transmission lead screw body is fixedly installed on the upper surface of the portion, corresponding to the second rectangular opening, of the box body. A galvanized plate body is automatically pushed, the working efficiency is higher, the labor intensity of workersis reduced, the use is safer, the front side surface and the rear side surface of the galvanized plate body are limited through guide rollers, therefore, the galvanized plate body is stably conveyed and not likely to collide, the galvanized plate body is not likely to deviate, the qualified rate of the size of the galvanized plate body after cutting is higher, and dust generated in the cutting process is conveniently collected through a dust collection mechanism, and sanitation of a work site is achieved.

Owner:惠民万顺节能新材料有限公司

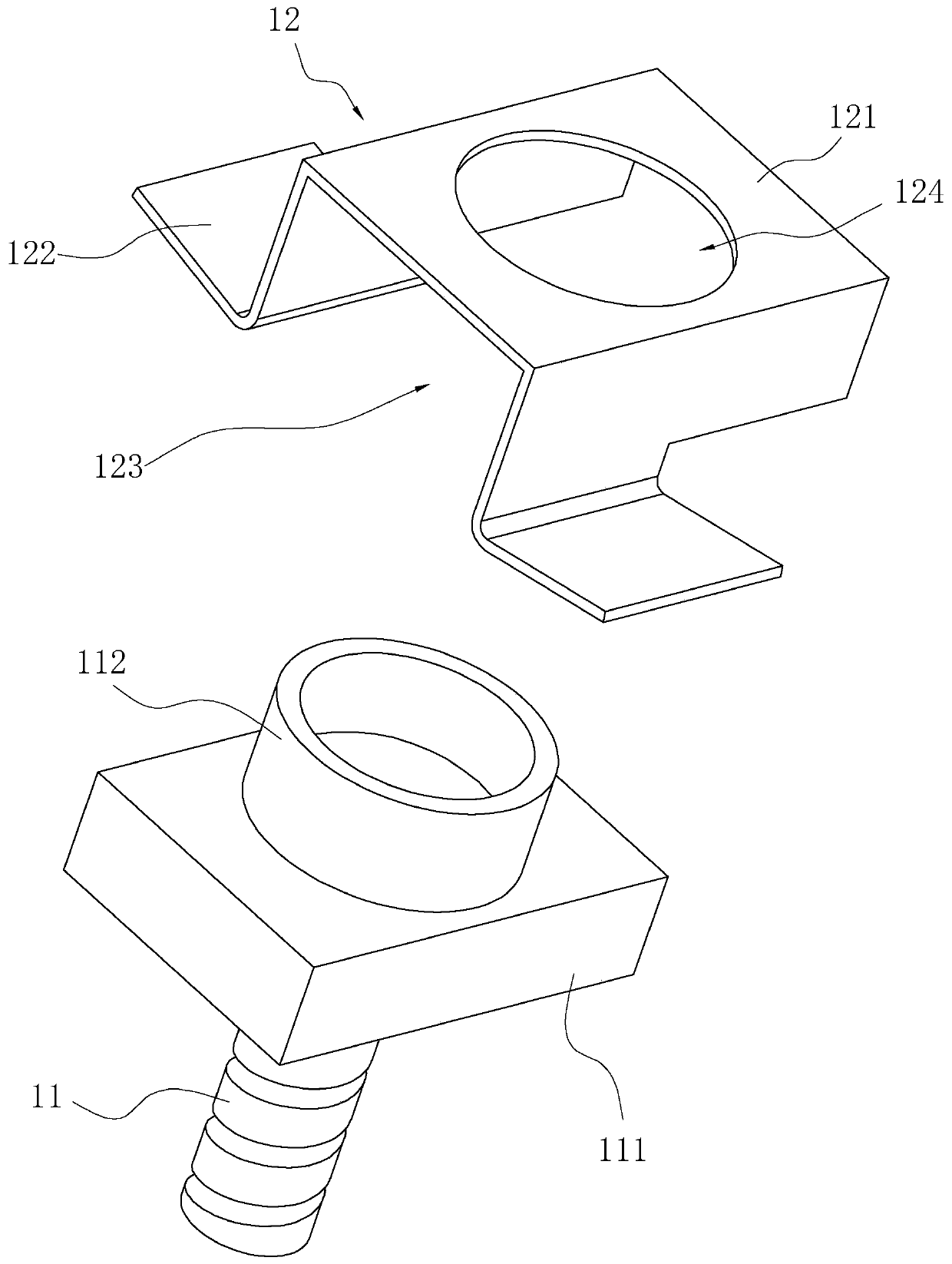

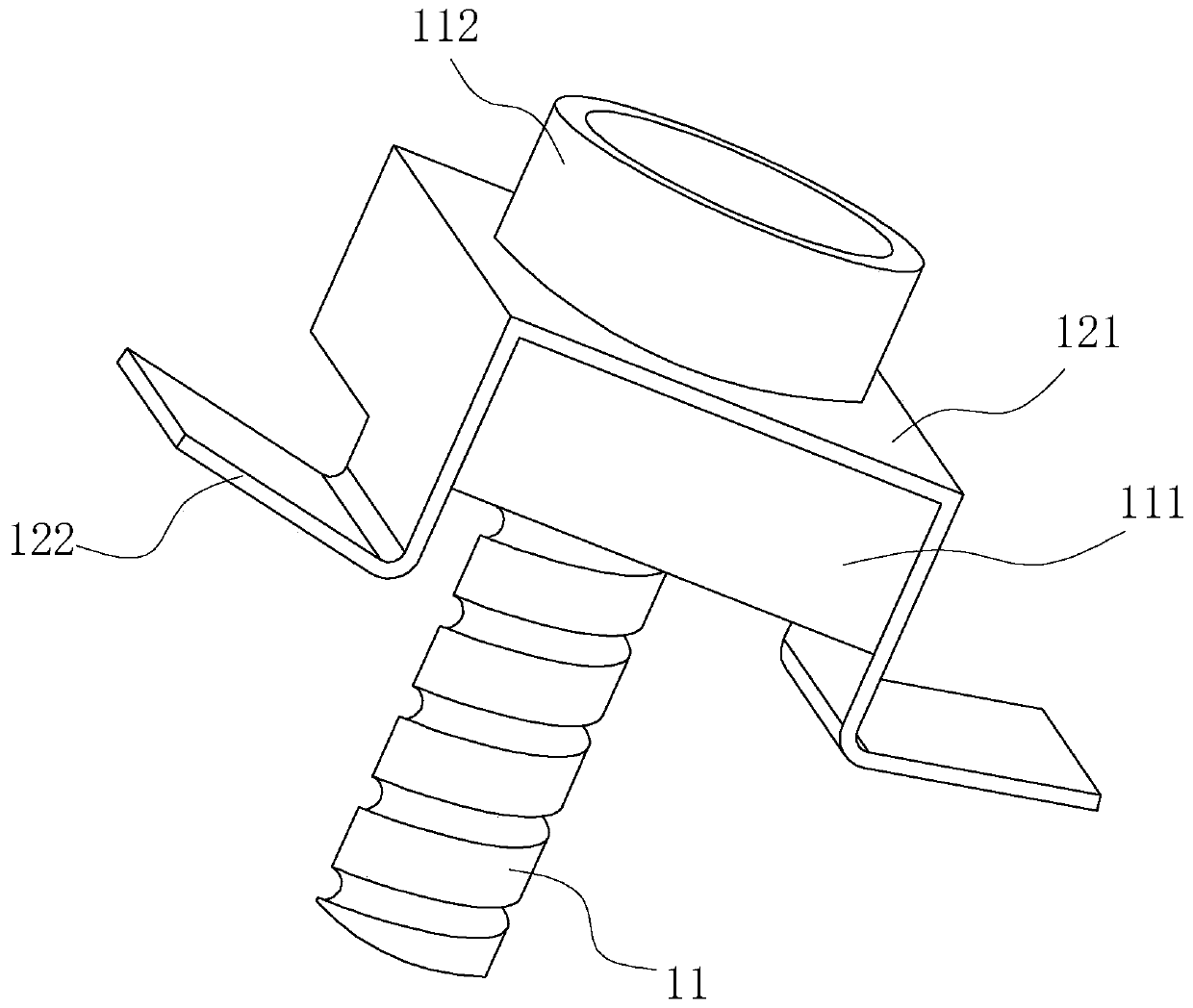

A clamp screw riveting device

Owner:东莞田心利达五金制品有限公司

A device for installing and fixing electronic tags

ActiveCN111486162BPrevent theftAvoid damageMaterial gluingStands/trestlesStructural engineeringMechanical engineering

Owner:JIAXING CHUANGMEI ELECTRIC APPLIANCE CO LTD

Bottom hole-making equipment for ultra-thin-walled metal filter pipe fittings

ActiveCN111687447BImprove the limit effectNot easy to shift positionMetal working apparatusPositioning apparatusAutomatic controlPipe fitting

The invention discloses a hole-making device at the bottom of an ultra-thin-walled metal filter pipe fitting, which belongs to the technical field of mechanical opening. It is a bottom-hole-making device for an ultra-thin-wall metal filter pipe fitting. The arc-shaped positioning block cooperates with multiple sets of arc-shaped positioning cavities to realize the positioning of multiple sets of pipe fittings to be drilled without manual positioning. In addition, the electric drill at the driving end of the mechanical arm can flexibly make holes for the ends of pipes with different diameters and lengths through the electric slide on the moving seat on the operating table, and under the automatic control of the mechanical arm , to realize the intensive drilling of the end face of the pipe fittings by the electric driller. After the pipe fittings are drilled, the pipe fittings on the pipe positioning plate can be rotated and tilted to make it easier for the pipe fittings on the pipe positioning plate to fall into the receiving box without manual cutting. To a certain extent, it can effectively improve work efficiency.

Owner:泰州鸿材科技有限公司

Metal film double-sided printing device

InactiveCN113787816ANot easy to shift positionHigh print alignment qualityRotary letterpress machinesWebs handlingComposite materialEngineering

The invention discloses a metal film double-sided printing device. The metal film double-sided printing device comprises a shell and a printing mechanism, wherein an opening is formed in the front side of the shell, a first fixing frame is arranged at the upper end of the shell and used for containing a film raw material barrel, and a second fixing frame is arranged at the lower end of the shell and used for containing a film winding barrel; the printing mechanism is arranged in the shell and comprises a transverse supporting plate arranged in the shell, a first vertical plate and a second vertical plate are arranged on the transverse supporting plate, a second rotating rod is rotationally arranged on the first vertical plate, a third rotating rod is rotationally arranged on the second vertical plate, and a first printing wheel is arranged at one end of the second rotating rod; and the first printing wheel is arranged at one end of the second rotating rod, a plurality of sets of printing protrusions are arranged on the outer ring of the first printing wheel and the outer ring of the second printing wheel correspondingly, a film raw material penetrates through the position between the first printing wheel and the second printing wheel to be subjected to double-face printing, and a driving mechanism is arranged on the transverse supporting plate. The metal film double-sided printing device realizes double-sided printing of the film raw material, and is good in printing effect and high in quality.

Owner:刘彪

A high-speed pocket spring machine

A high-speed pocket spring machine, including a transfer mechanism, a transfer mechanism, and a vertical welding mechanism, characterized in that: the transfer mechanism is provided with a left transfer arm and a right transfer arm, the front end of the transfer mechanism is provided with a transfer mechanism, and the rear There is a vertical welding mechanism at the end, and there is a space between each other, and the transmission mechanism, the transmission mechanism, and the vertical welding mechanism are arranged and fixed on the frame in sequence. The transmission mechanism of the present invention adopts a single motor to drive the transmission shaft and the welding width of the non-woven fabric can be set, which reduces the production and replacement of the non-woven fabric guiding mold, accelerates the speed of the spring transmission, and improves the output of the pocket spring. The transmission mechanism adopts a parallelogram double crank mechanism. Delivers more springs in a pocket spring machine in less time. The vertical welding mechanism adopts a crank slider mechanism driven by a single motor, which effectively shortens the movement stroke, simplifies design and installation, reduces power consumption when the pocket spring machine is used, reduces noise generation, and improves the working environment.

Owner:FOSHAN YULUN MACHINERY

Fixing device for transformer outlet copper bar and fixing method thereof

InactiveCN112466602AAct as a limit fixationPlay a supporting roleTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerMechanical engineering

The invention discloses a fixing device for a transformer outgoing copper bar and a fixing method thereof, belongs to the technical field of transformer outgoing copper bar fixing, and aims at achieving the limiting and fixing effects on two copper bar bodies and the fixing effect on the transformer outgoing copper bar bodies through cooperative use of a convex mounting plate and an insulating partition plate, and the insulation between the two copper bar bodies is achieved; the limiting plate with the heat dissipation mechanism is mounted on one side of the convex mounting plate through the fixed plate, and the fixed plate is mounted on the outer side of the convex mounting plate in an embedded mode, so that the fixed plate further plays a role in fixing the convex mounting plate and plays a role in supporting the limiting plate with the heat dissipation mechanism at the same time; the horizontal position of the limiting plate is adjusted according to the thickness of the copper bar body, the limiting plate drives the heat dissipation mechanism to abut against the outer side wall of the copper bar body, on one hand, the copper bar body fixing device is further suitable for fixingcopper bar bodies with different thicknesses, and on the other hand, the copper bar body is cooled through contact connection of the heat dissipation mechanism.

Owner:JIANGSU SHUOTU NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com