Ultra-thin wall metal filtering pipe fitting bottom drilling equipment

A metal filtration and ultra-thin-wall technology, which is applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as difficulty in high-efficiency production, lower product yield, and poor stability of pressing force. Achieve the effects of reducing manual labor, improving work efficiency, and improving the degree of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

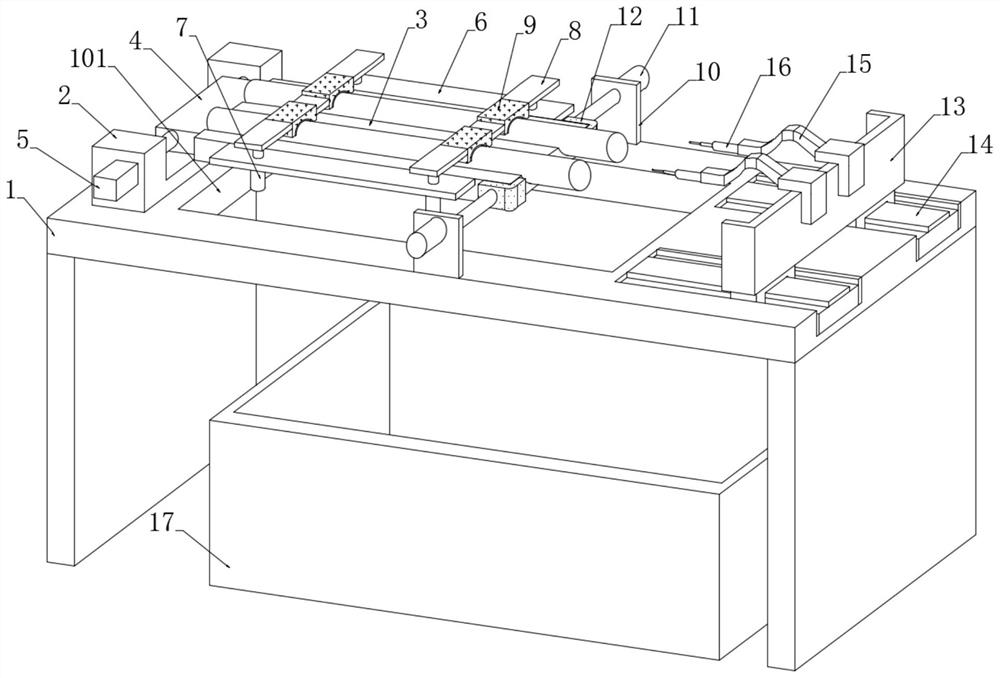

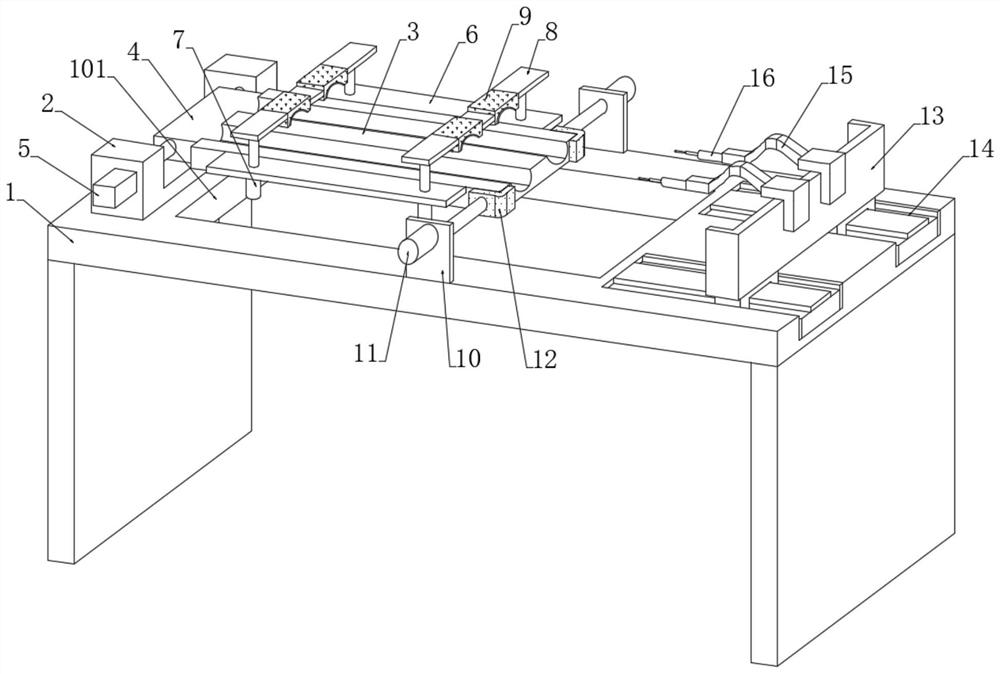

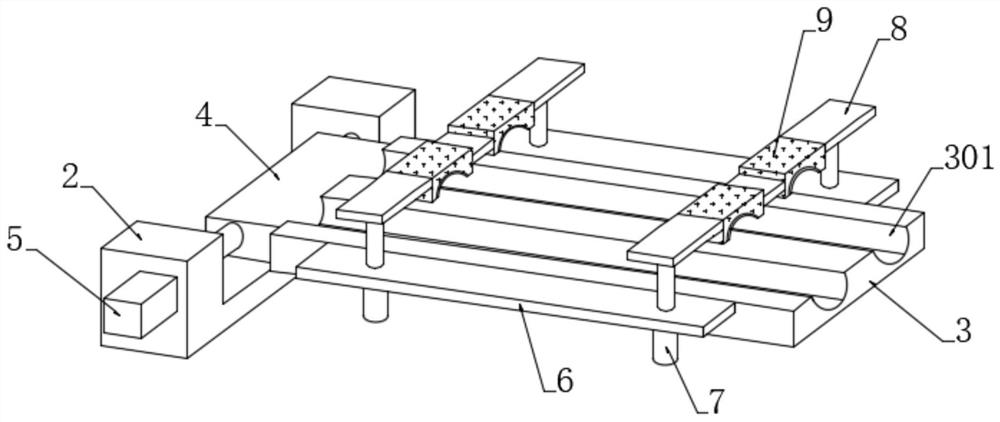

[0033] see figure 1, a bottom hole-making equipment for ultra-thin-walled metal filter pipes, comprising an operation table 1, a pipe positioning device installed on one end of the operation table 1, and a pipe hole-making device installed on the other end of the operation table 1, the pipe positioning device Carry out positioning, and then use the pipe fitting hole making device to make holes on the end surface of the pipe fitting to be holed. The pipe fitting positioning device includes a U-shaped frame 2 fixedly installed on one end of the console 1, and a pipe fitting positioning plate 3 is installed on the U-shaped frame 2 for rotation. The upper end of the console 1 is provided with a blanking chamber 101 corresponding to the position of the pipe fitting positioning plate 3, and the outer end of the U-shaped frame 2 is fixedly installed with a rotating motor 5 that drives the pipe fitting positioning plate 3, and the pipe fitting positioning plate 3 is close to the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com