Eccentric locking pin for electrophoresis sledge

An eccentric locking and electrophoresis skid technology, which is applied in the direction of electrophoretic plating, electrolytic coating, electrolytic process, etc., can solve the problem of the difficulty in ensuring the height before and after the rotation of the hook pin, the difficult locking state of the eccentric rotation pin, and the unsafe locking method by gravity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

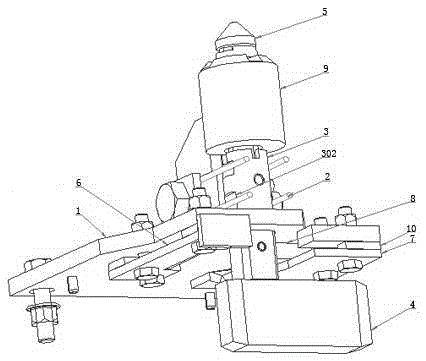

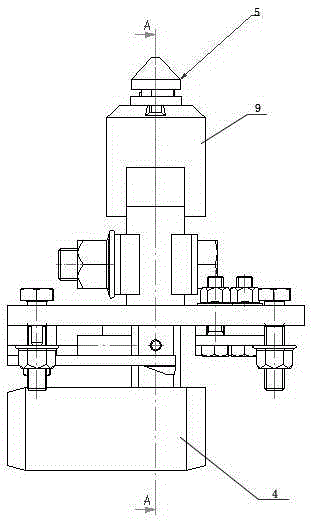

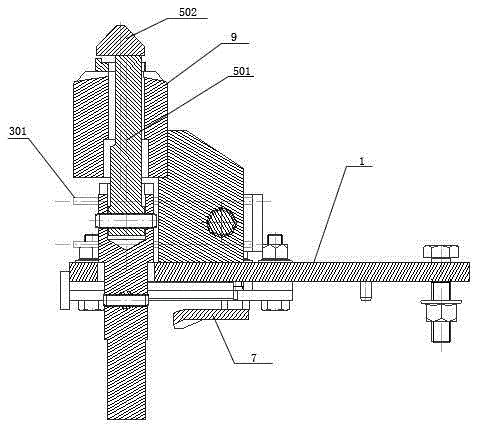

[0020] An eccentric locking pin for an electrophoresis sled, comprising a base plate, an elastic limiting device, a rotating shaft, a rotary dial, an eccentric detent, a height limiting plate in the unscrewed state of the detent, a height limiting plate in the revolving state of the detent, and an eccentric pin The height position guide rod is provided with an elastic limit device on the end surface of the base plate, and a height limit plate in the unscrewed state and a height limit plate in the unrotated state are arranged on the lower end surface of the base plate, and the rotation shaft passes through the base plate. The top of the rotating shaft above the base plate is connected with an eccentric pin, and the rotation of the rotating shaft is elastically limited by the elastic limit device. The limit of the elastic limit device is to ensure that the rotating shaft will not rotate when it is not subjected to external force. The rotating shaft can be rotated when it is subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com