Anti-fracture dry-type transformer winding structure and using method thereof

A dry-type transformer and winding structure technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problem of affecting the normal use of dry-type transformers, the inability to automatically adjust the winding position, uneven wiring on the outer wall of the wire formwork, etc. Problems, to achieve the effect of automatically adjusting the winding position, improving the winding density, and not easy to shift the position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

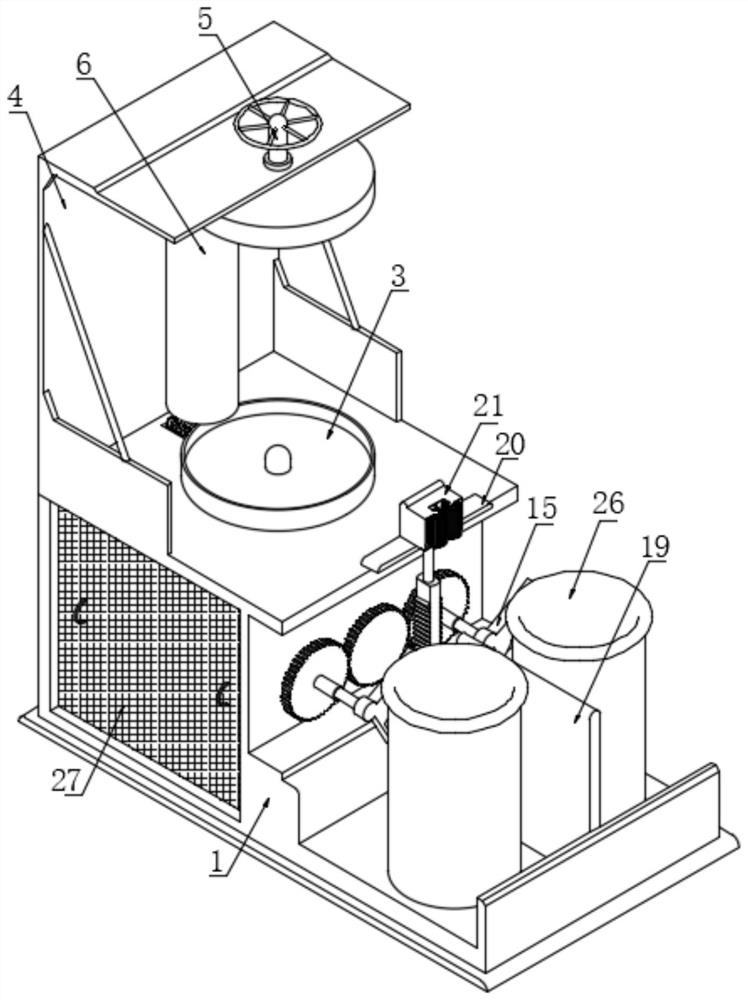

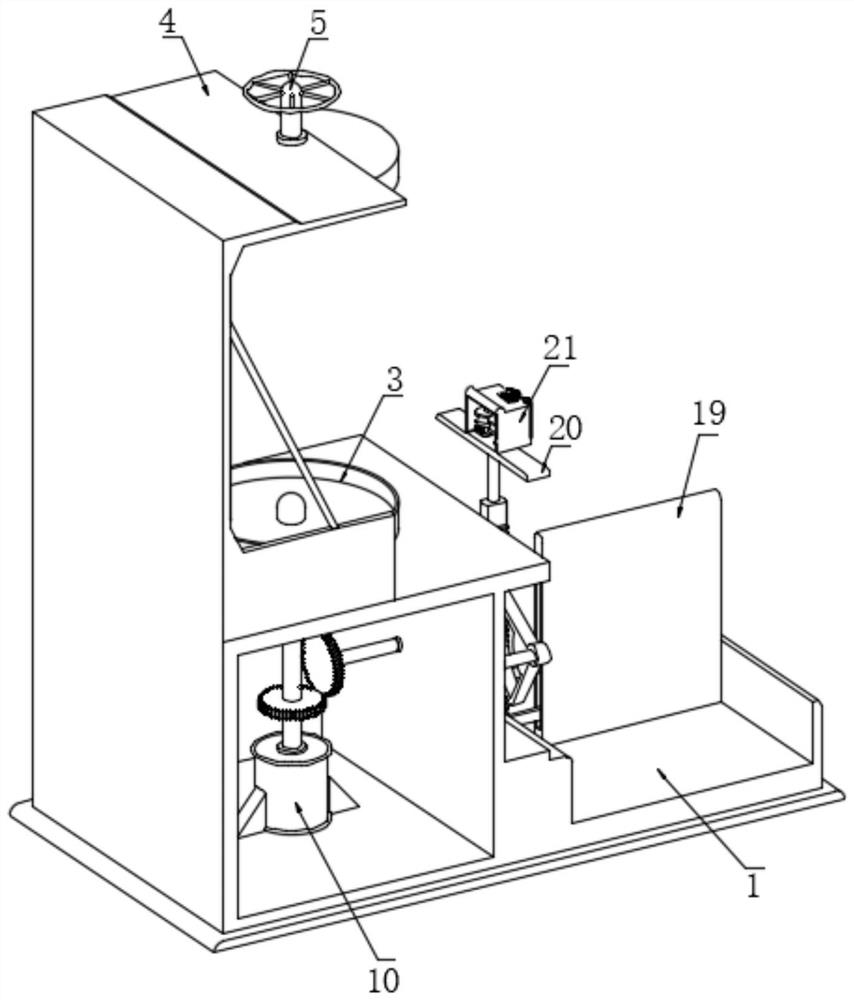

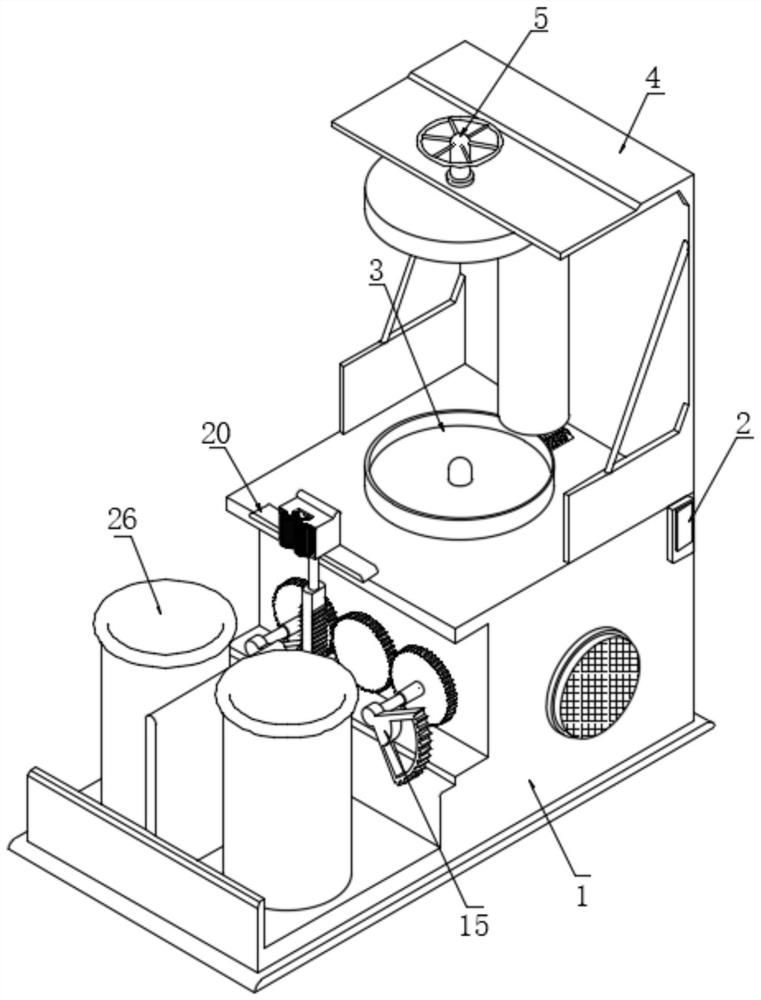

[0040] Such as Figure 1-8 As shown, the present invention provides a technical solution: a breakage-proof dry-type transformer winding structure, including a frame 1, a controller 2 is arranged on the back of the frame 1, the upper surface of the frame 1 and the lower surface of the top plate 4 The surface is fixedly connected, the upper surface of the inner wall of the top plate 4 and the upper surface of the frame 1 are provided with a fixed plate 3, and the left side of the two fixed plates 3 is provided with the same pressure roller 6, and the top and bottom ends of the pressure roller 6 are fixed. The support assembly 8 is connected, and the support assembly 8 is arranged in the chute 7, and the two chute 7 are set on the upper surface of the inner wall of the top plate 4 and the upper surface of the frame 1 respectively, and the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com