Patents

Literature

73results about How to "Effective straightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

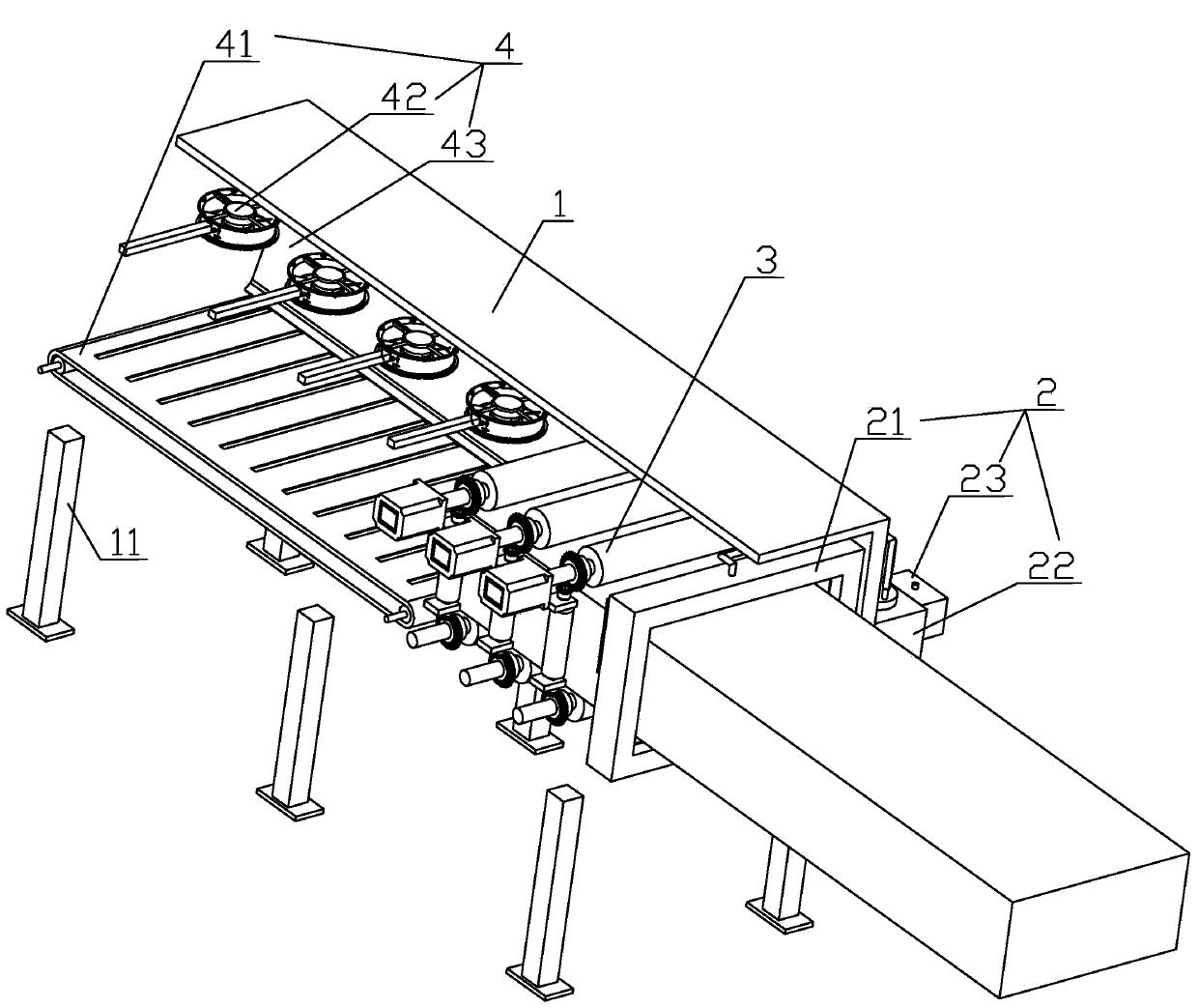

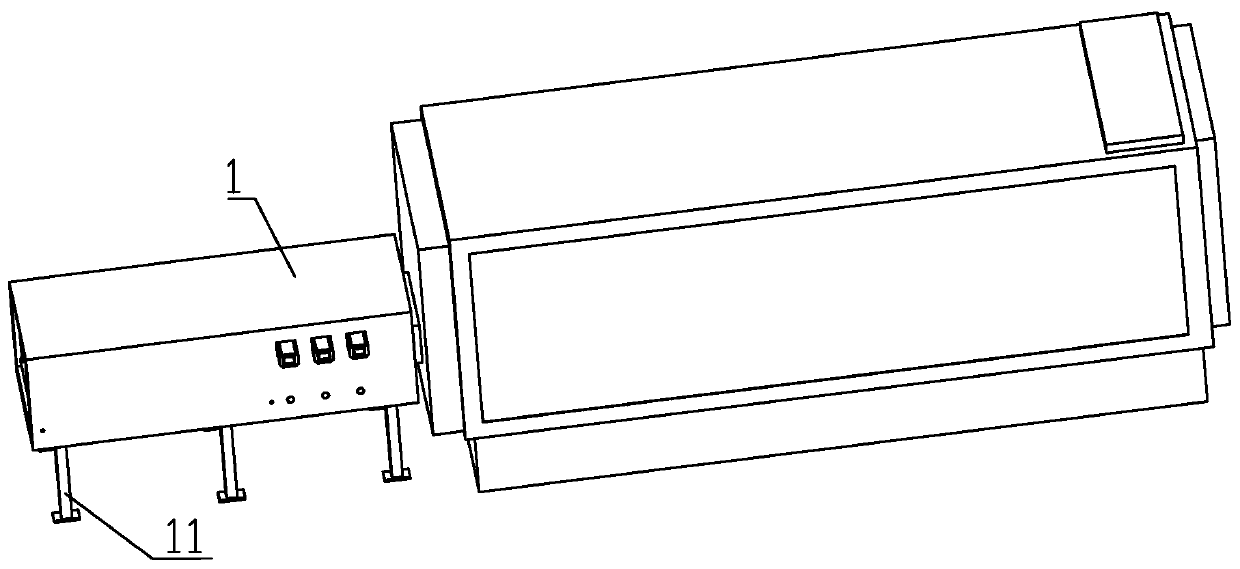

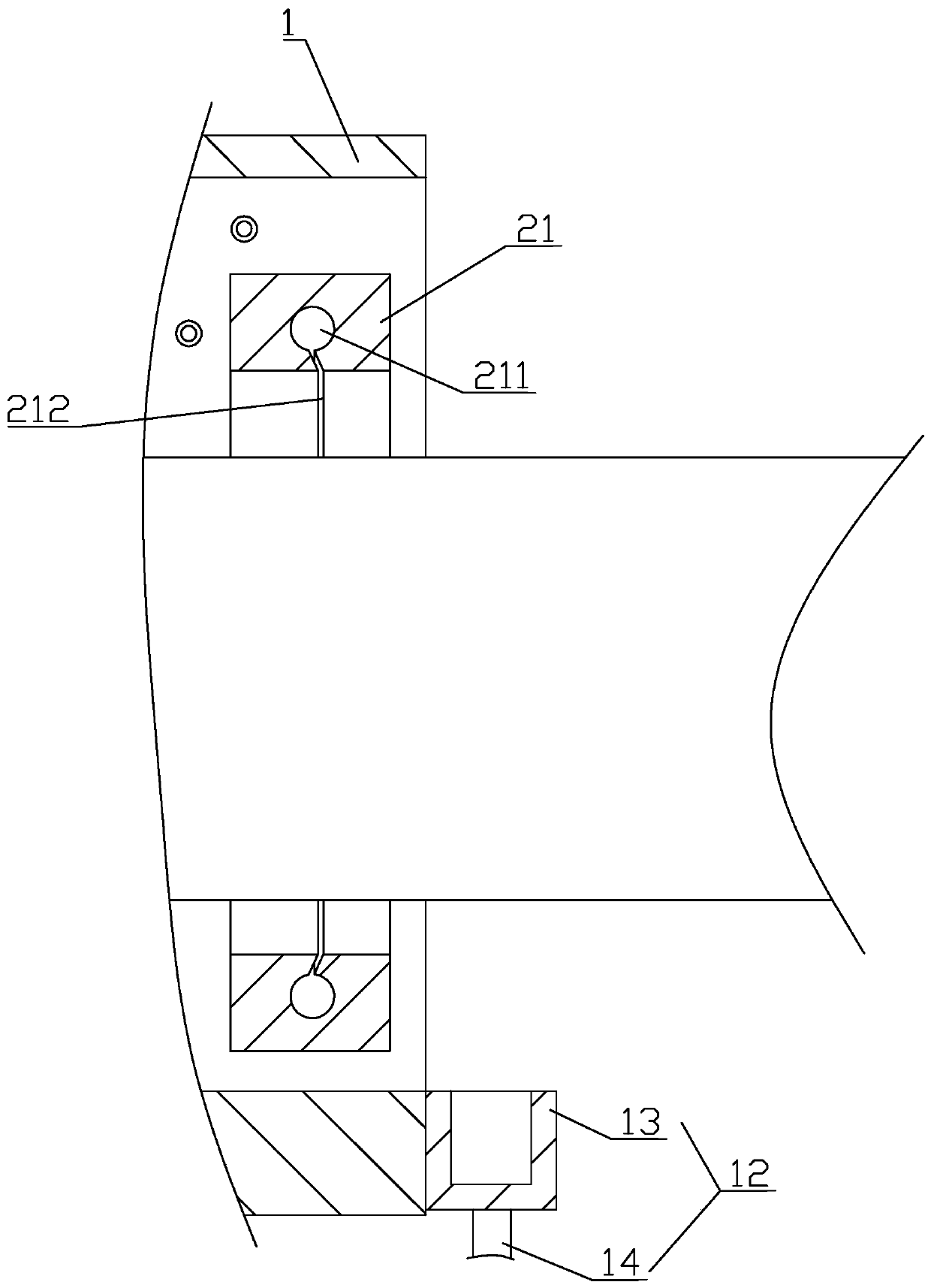

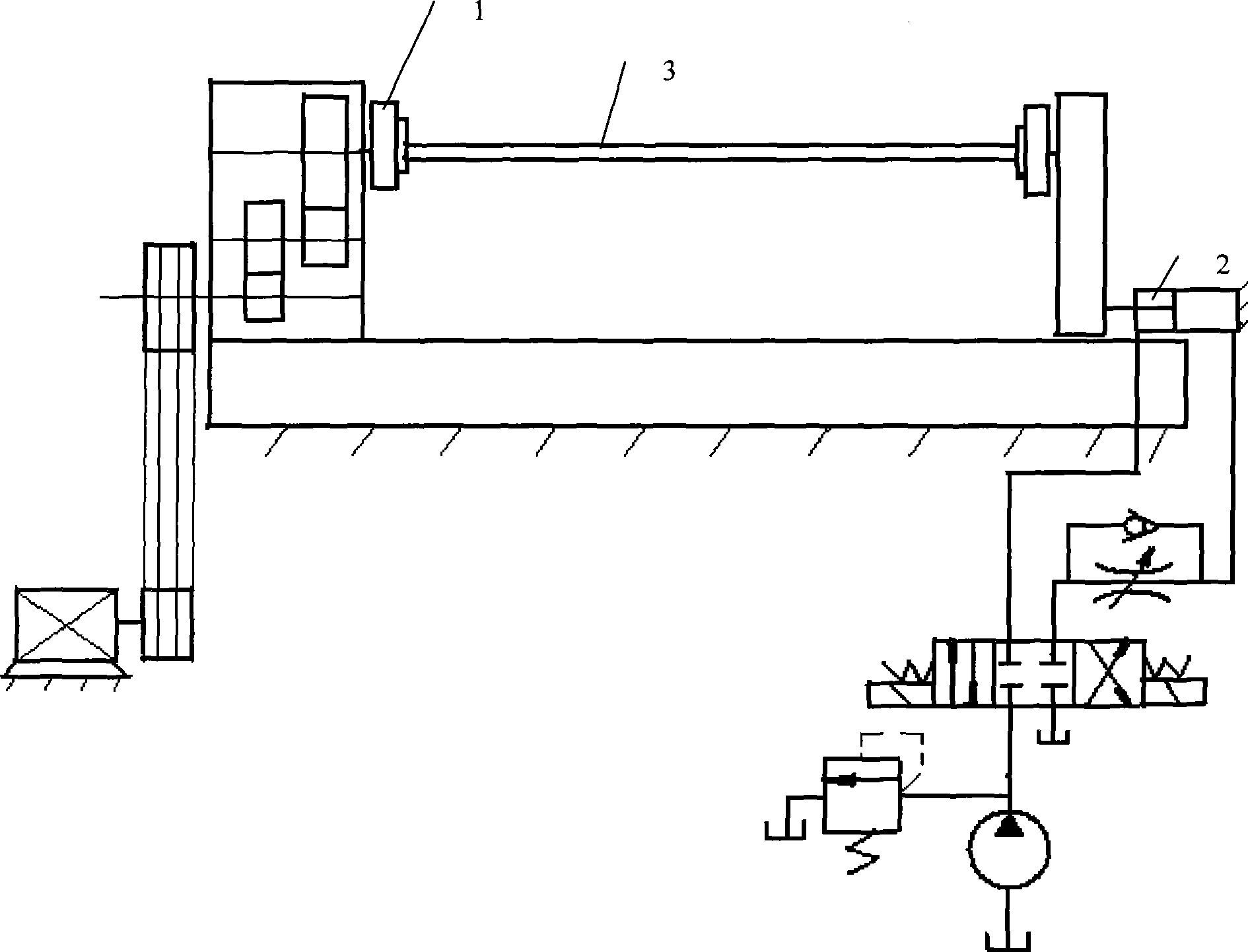

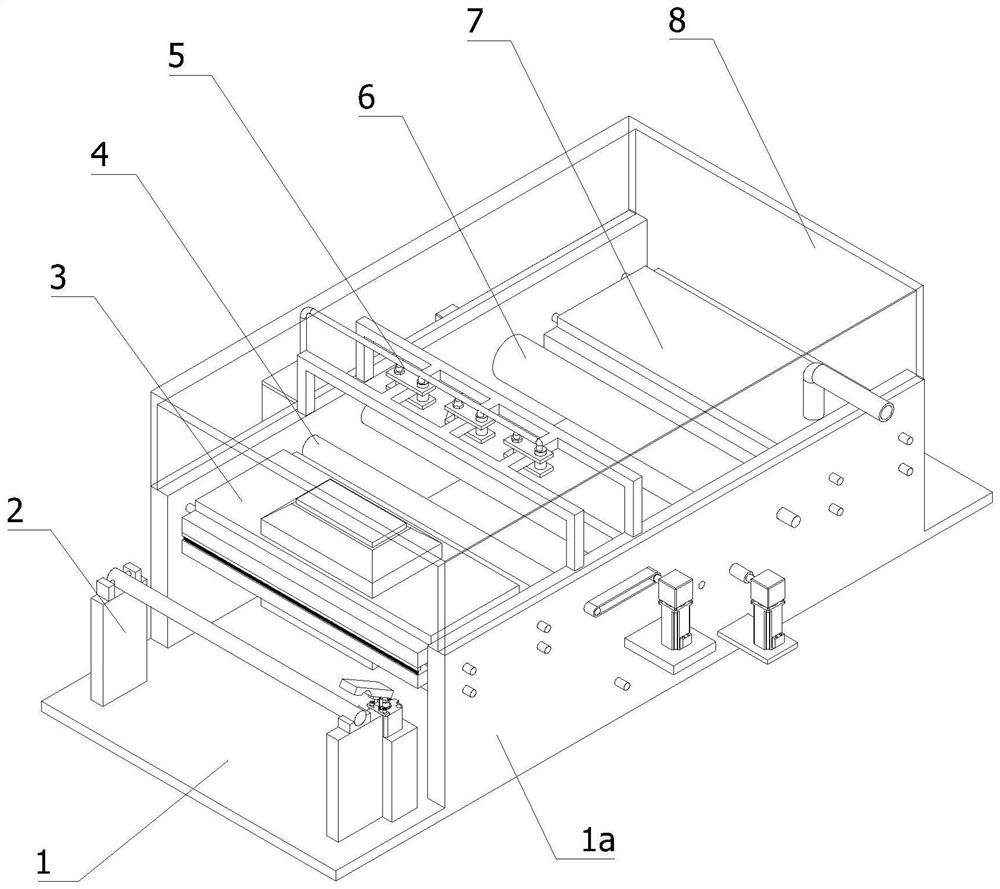

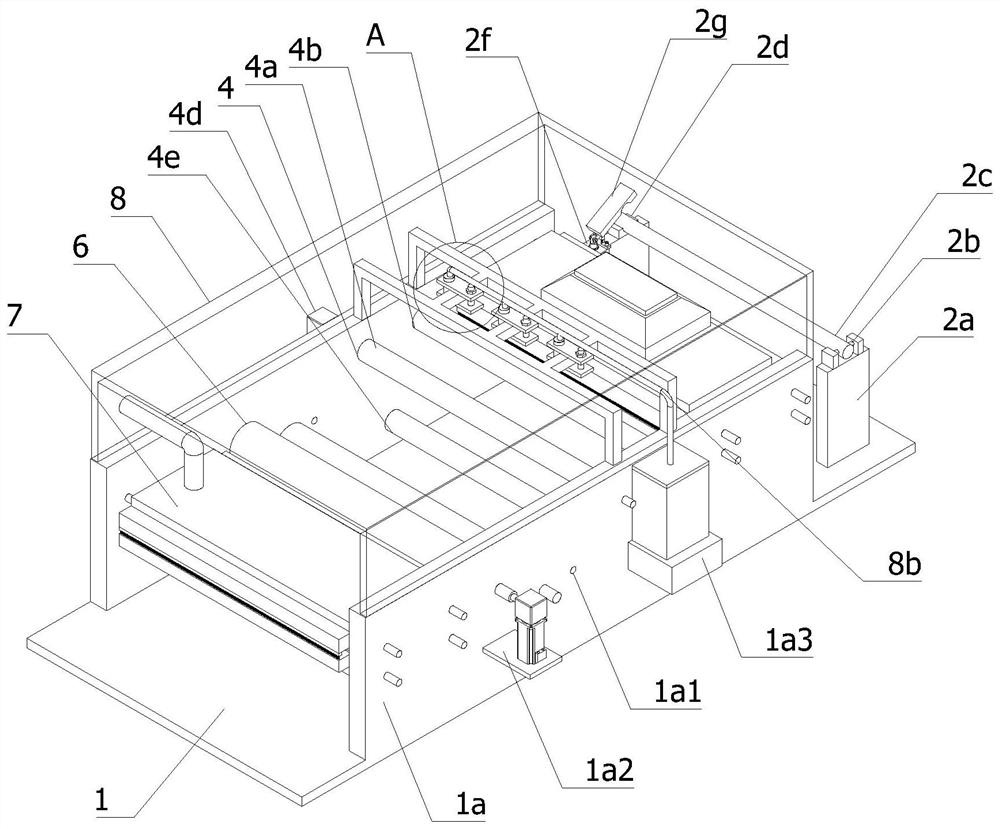

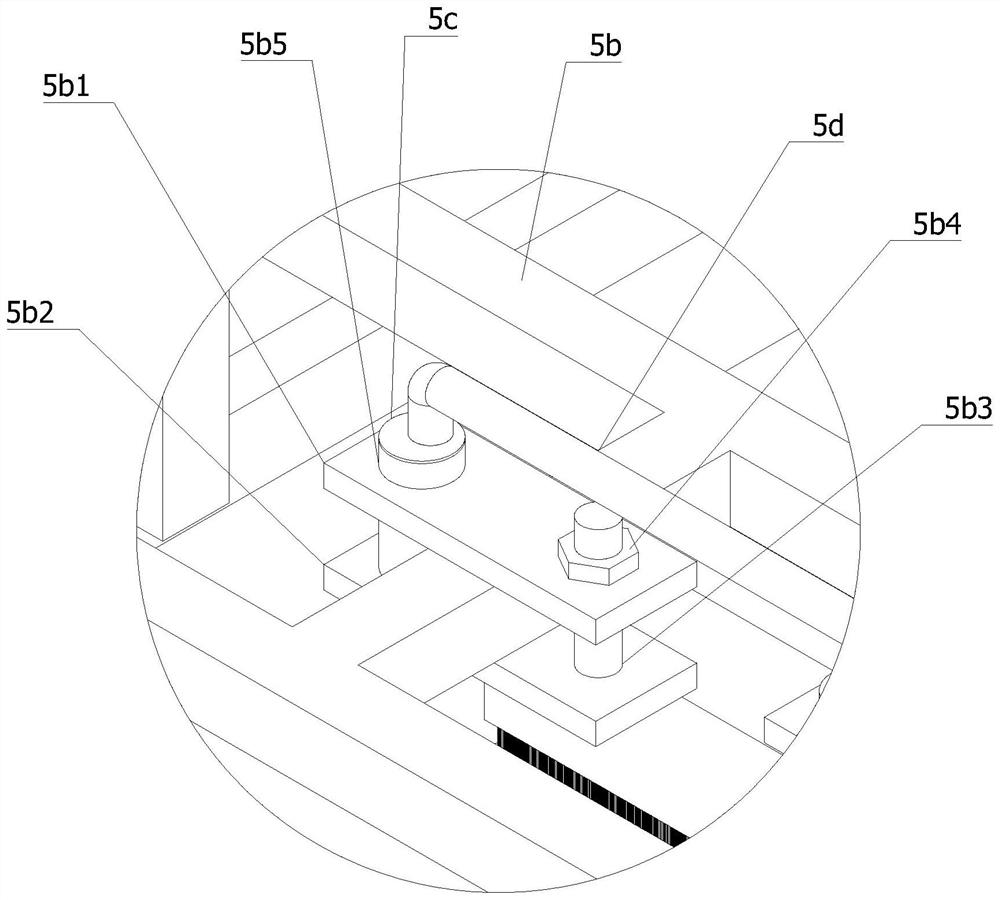

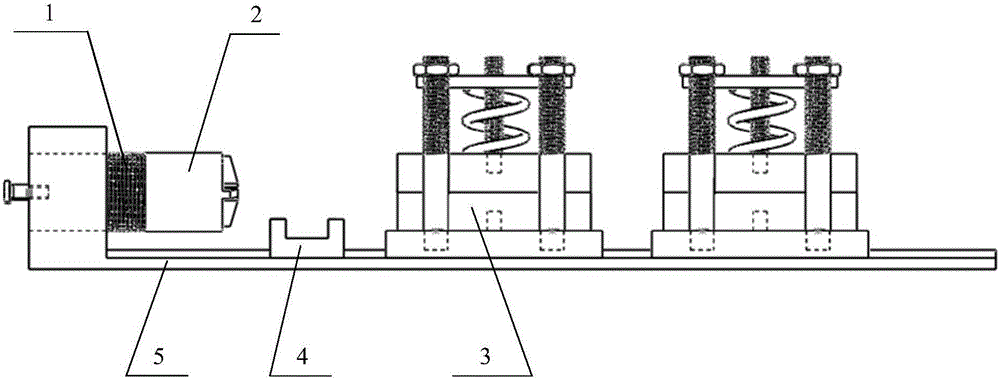

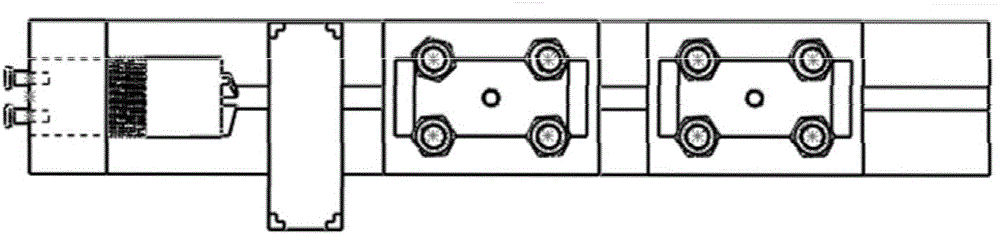

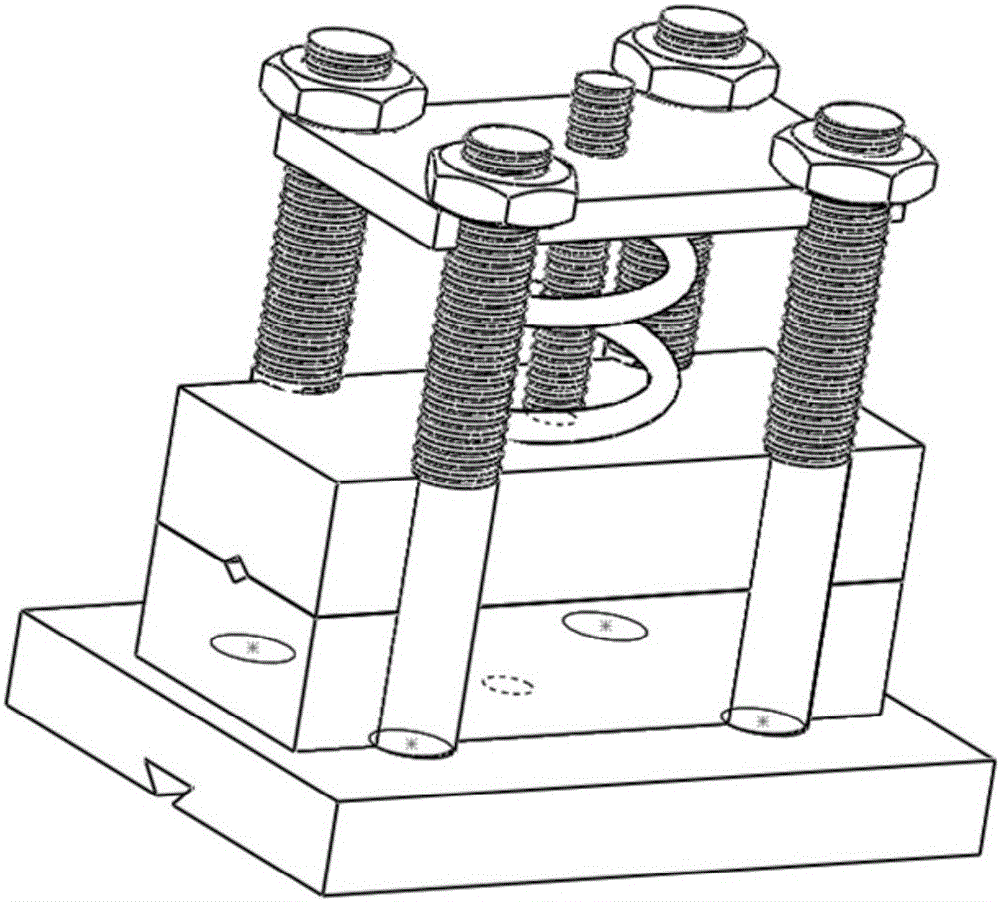

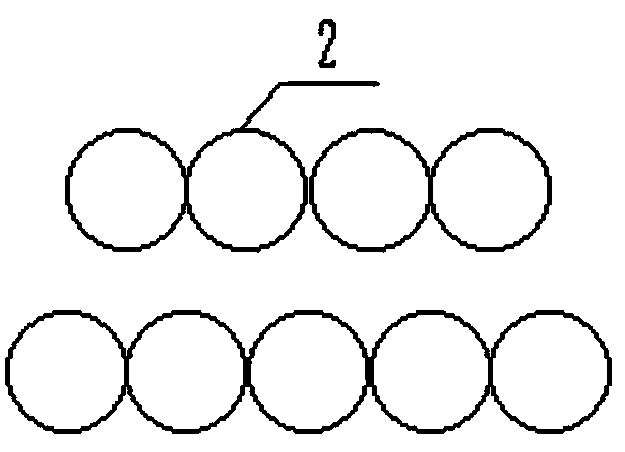

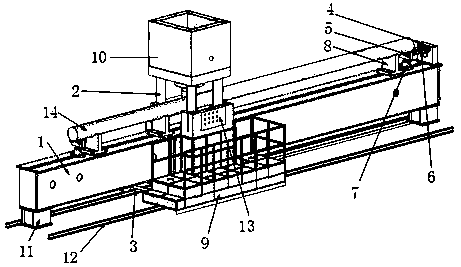

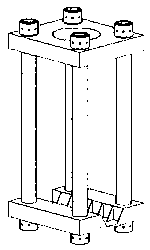

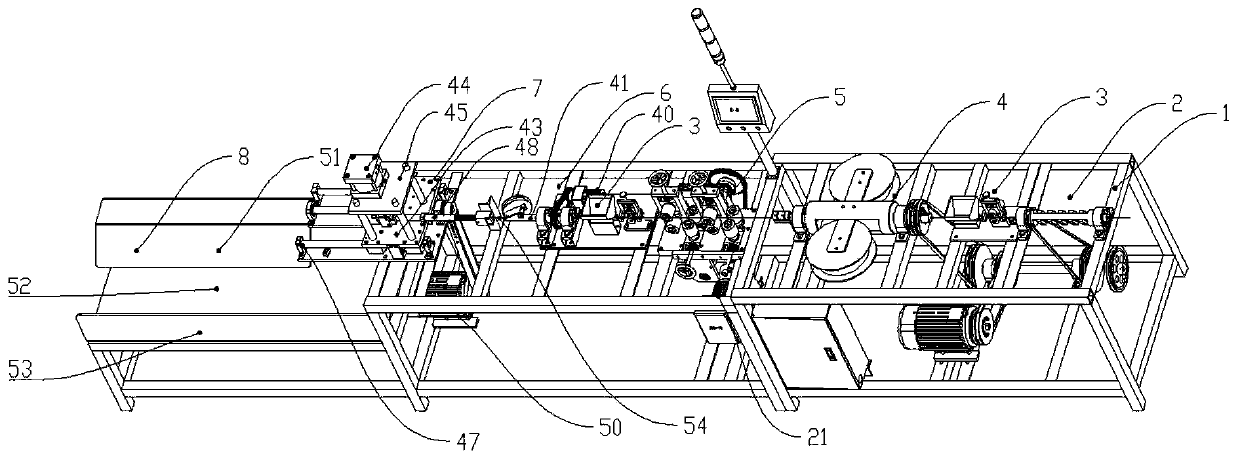

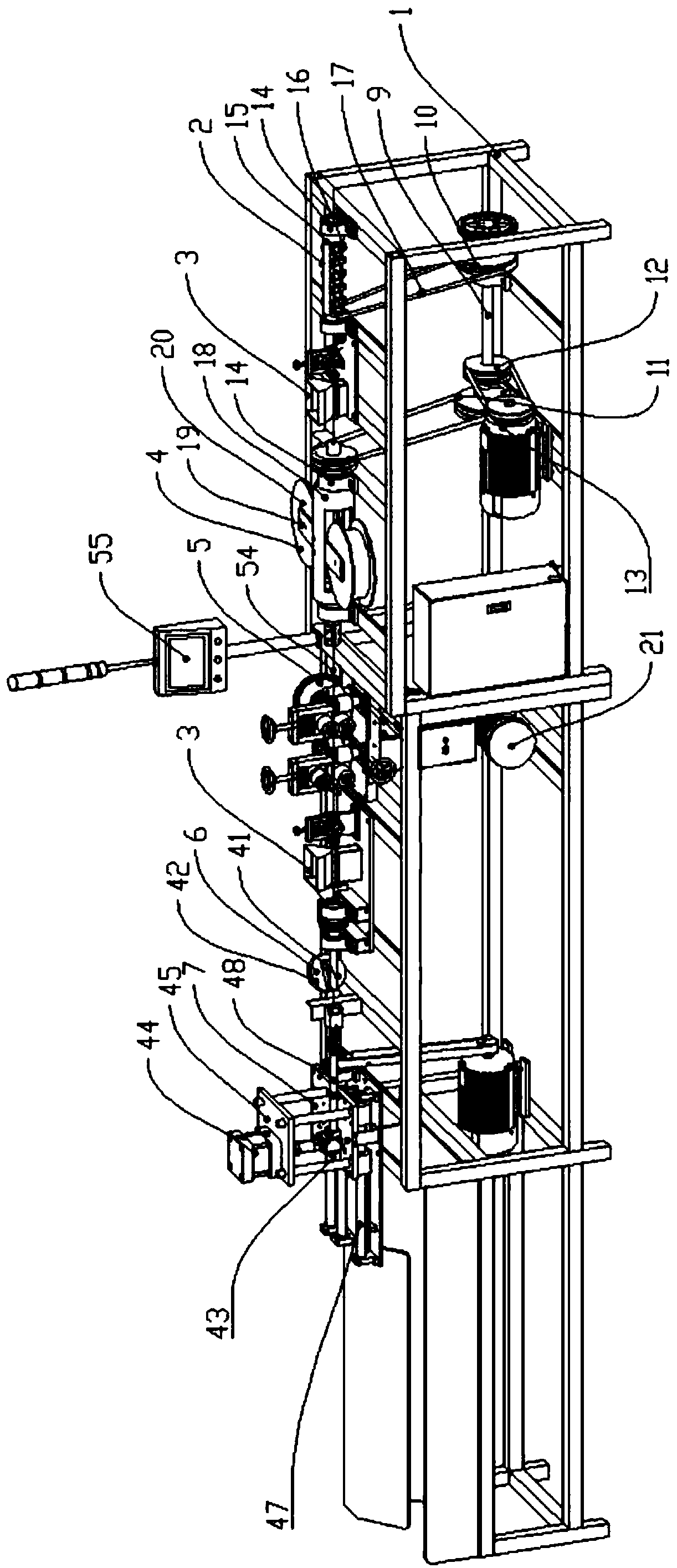

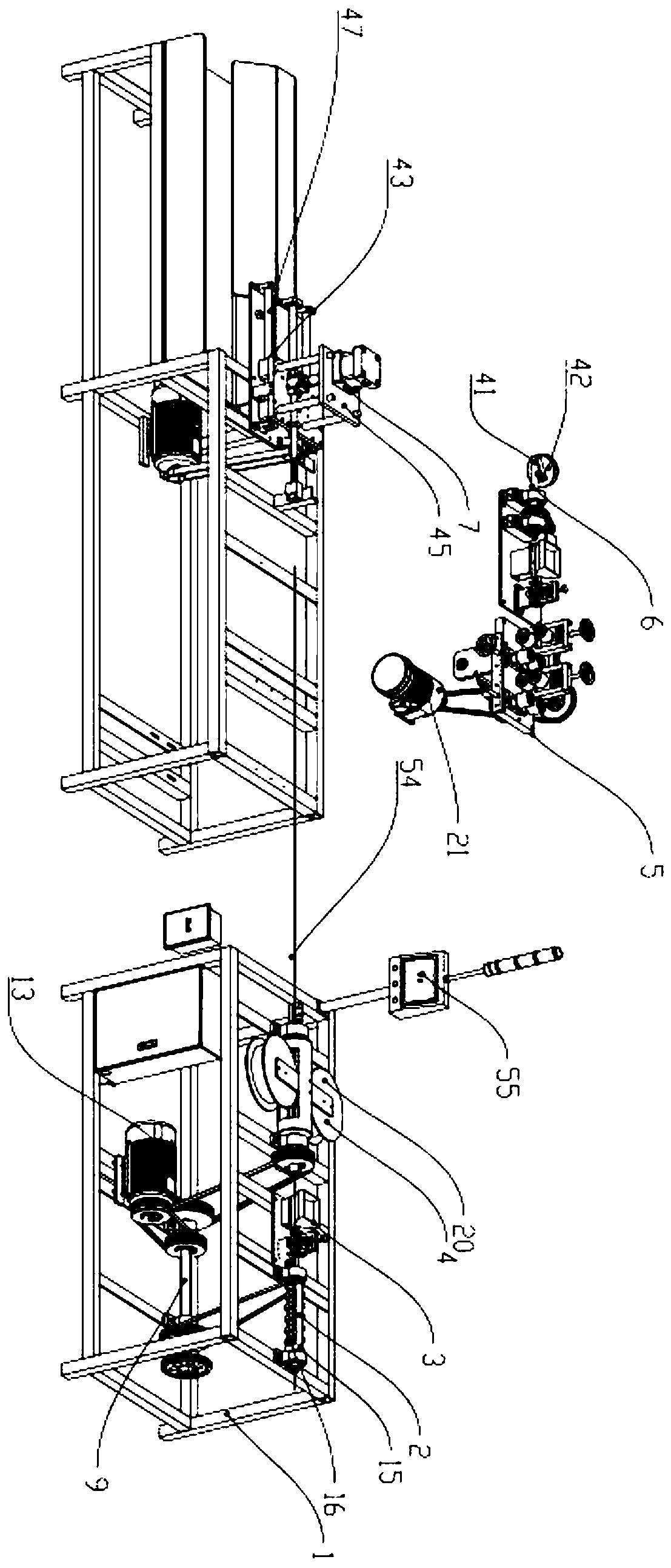

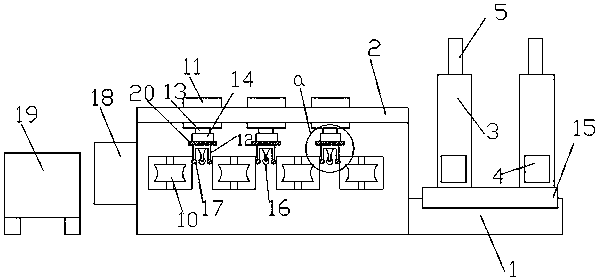

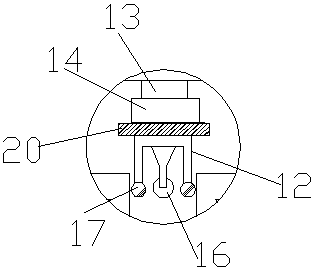

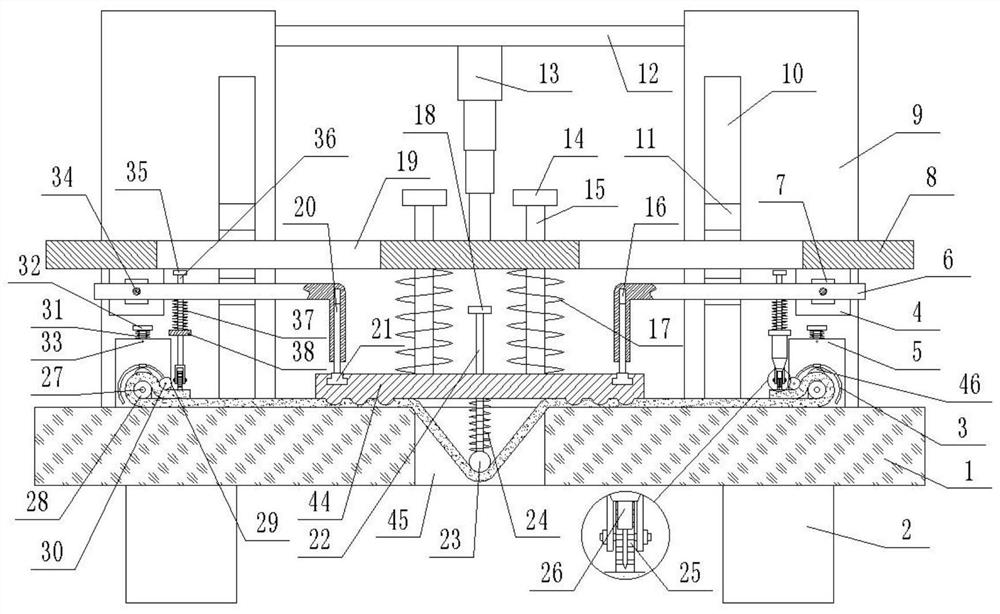

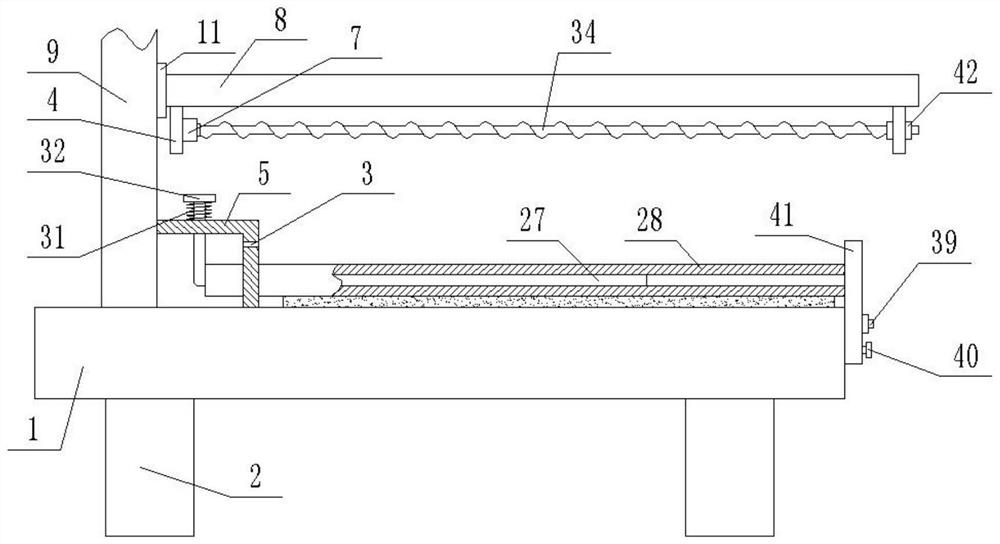

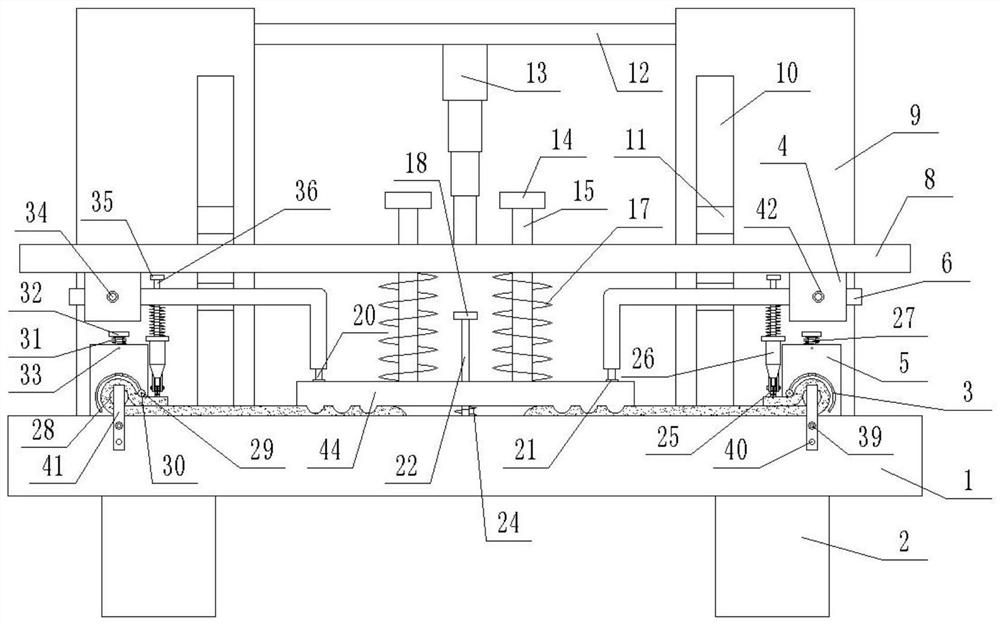

Metal wire rod precision alignment cutting device and method

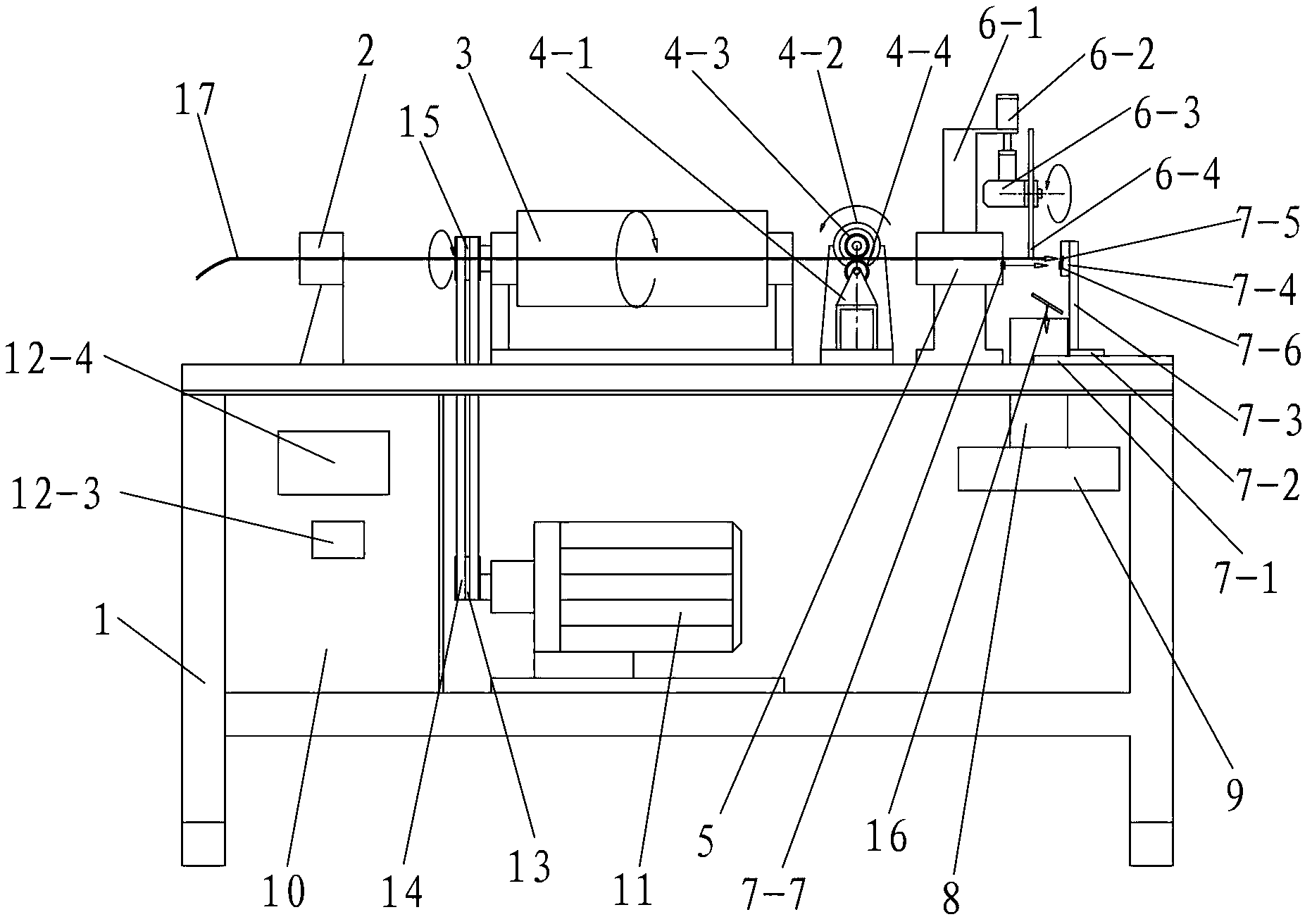

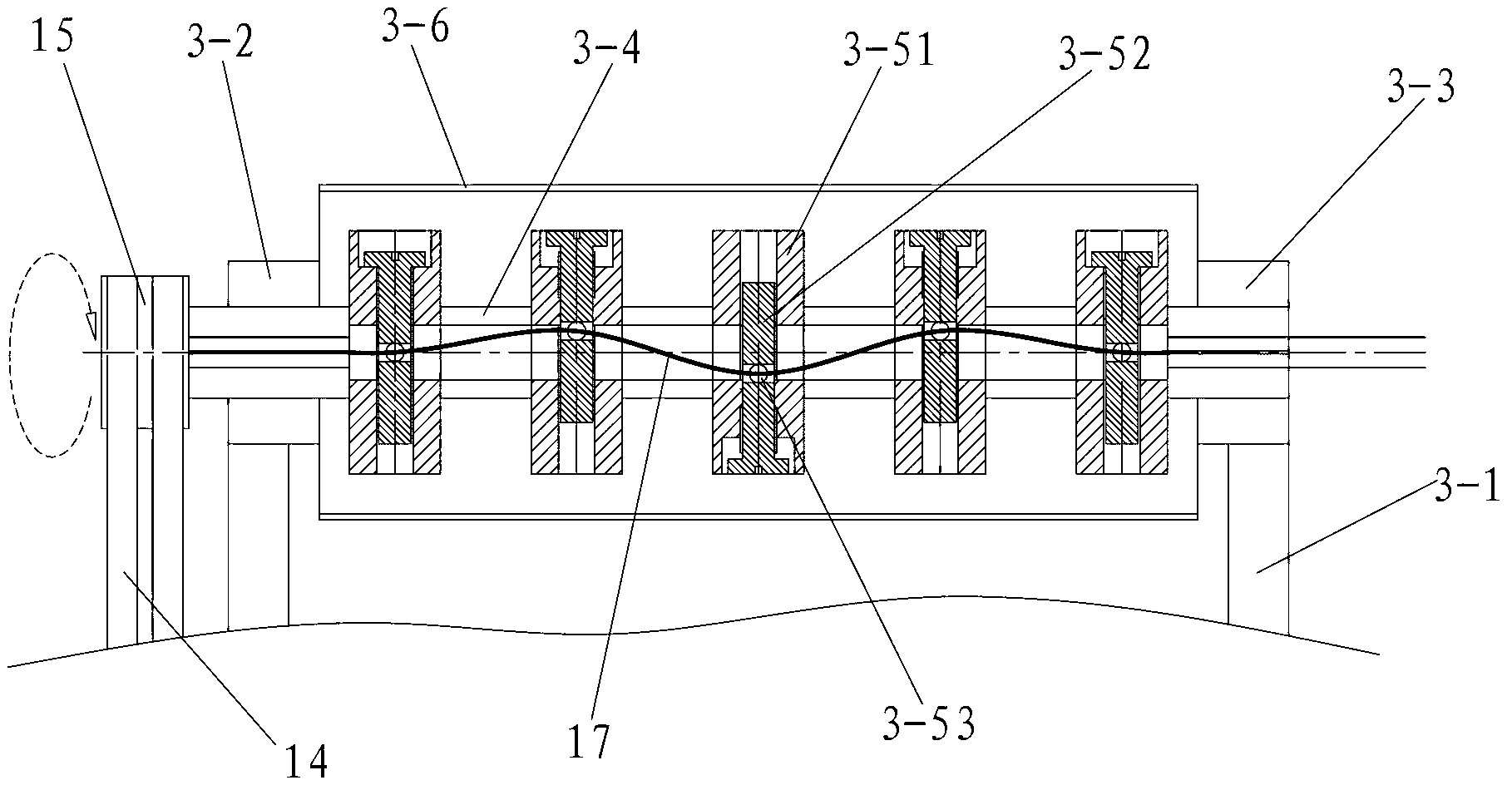

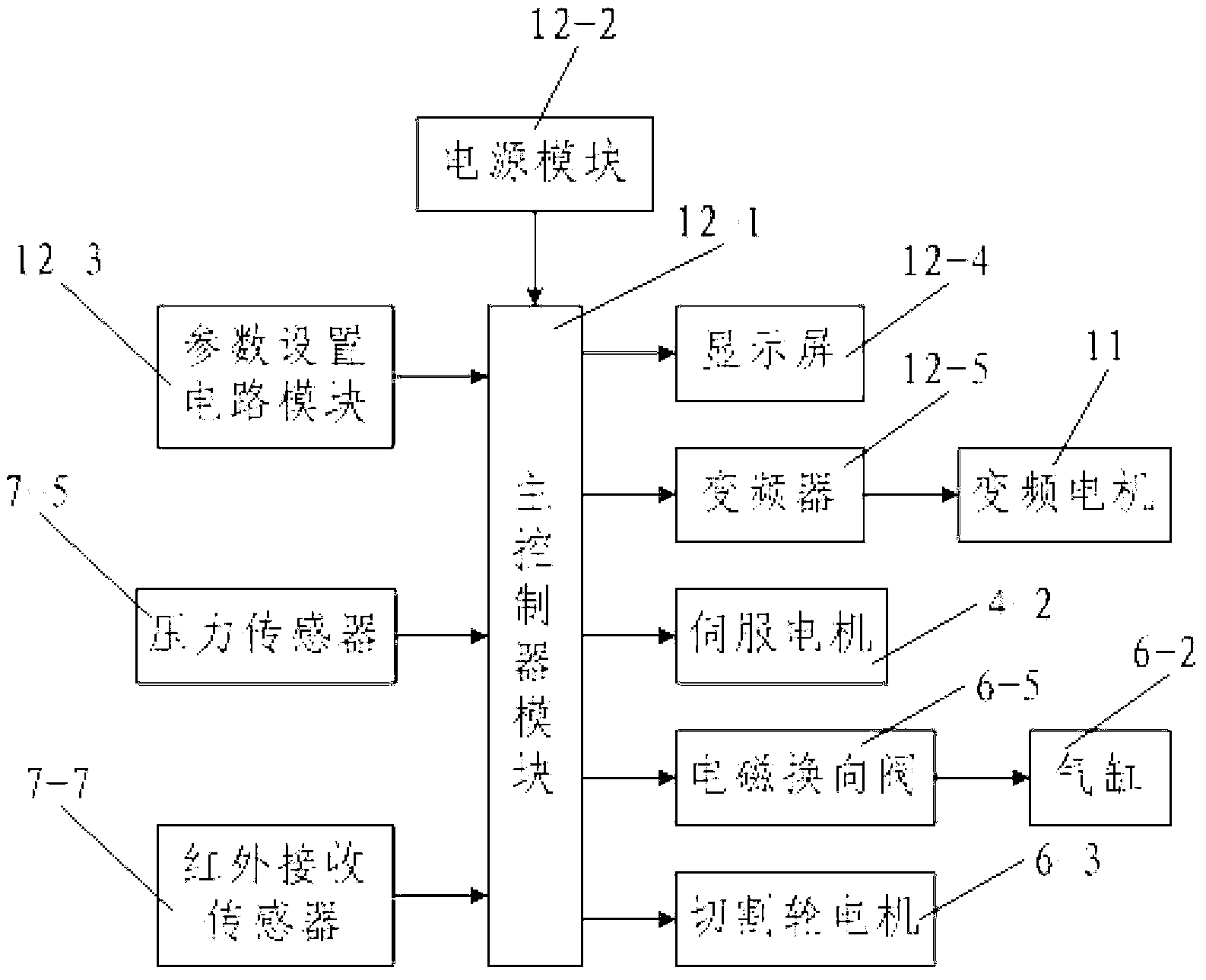

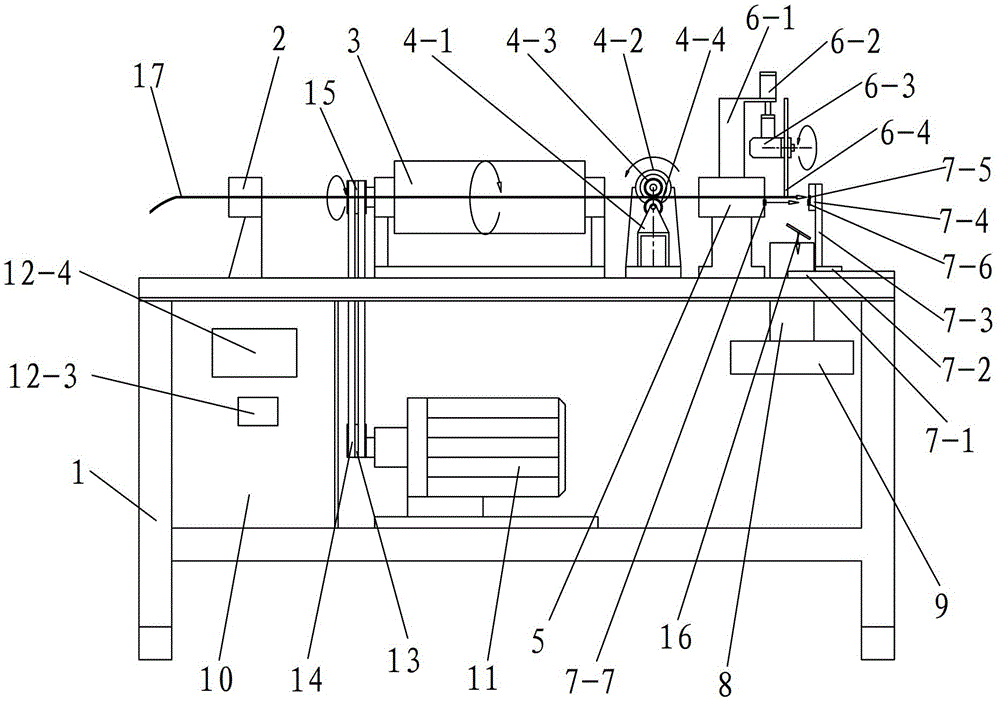

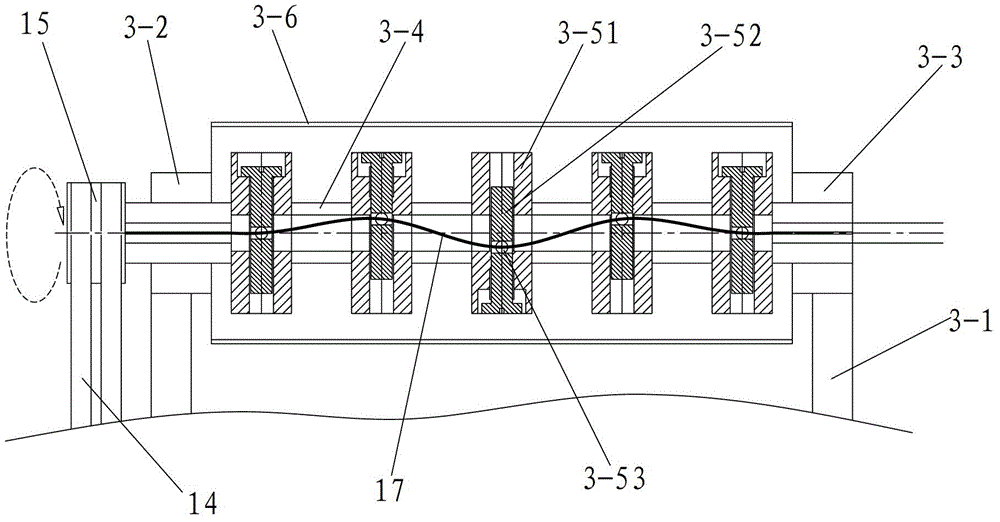

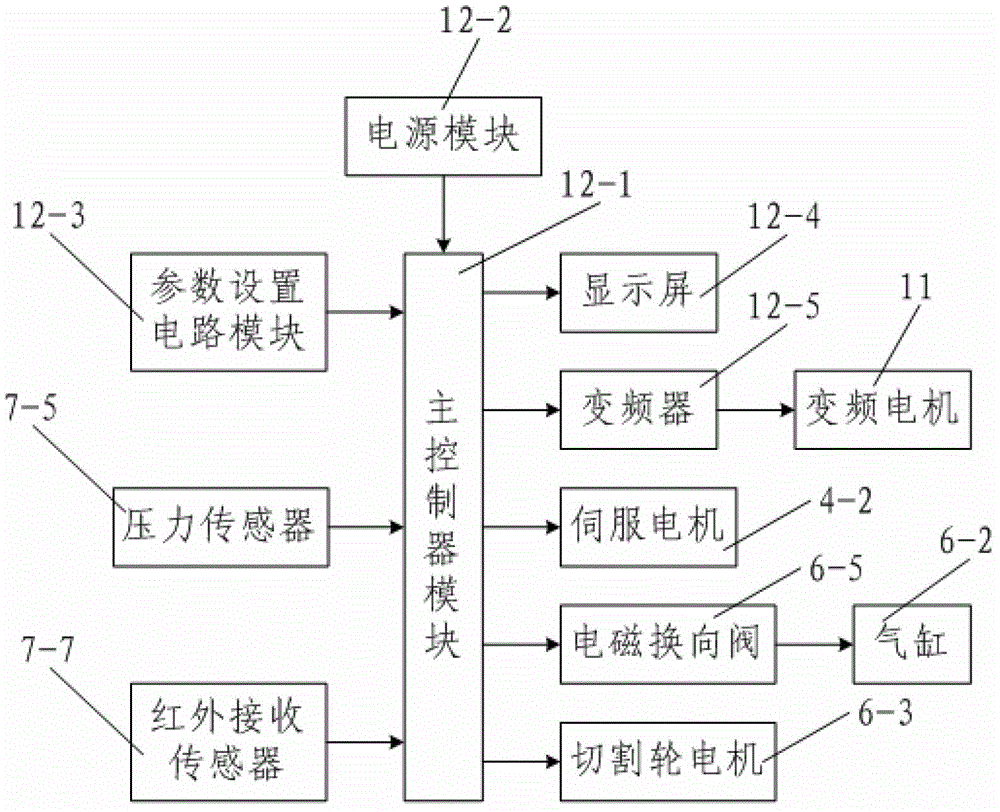

The invention discloses a metal wire rod precision alignment cutting device and a method. The device comprises a double-layer machine frame. A front end guiding tank, a revolving alignment tank, a traction mechanism, a back end guiding tank, a cutting mechanism and a machinery sizing mechanism are arranged on the top portion of the double-layer machine frame. The revolving alignment tank comprises a revolving alignment straight tank support seat, an alignment guiding tank, a plurality of alignment modules and a protection cover. The traction mechanism comprises a traction mechanism support seat, a servo motor, a driving friction wheel and a driven friction wheel. The cutting mechanism comprises a cutting wheel support frame, an air cylinder, a cutting wheel motor and a slice-shaped cutting wheel. The machinery sizing mechanism comprises a horizontal scale plate, a pressure sensor, an infrared transmitting sensor and an infrared receiving sensor. The method includes the steps that the metal wire rod enters the revolving alignment tank through a front end guiding rank. The metal wire rod is alignmented, tracted, cut and prepared and enters the next working circulation. The metal wire rod precision alignment cutting device and the method is high in automatic degree. The shape of the cut metal line segment and the size precision are high. The cutting opening is smooth, free of deckle edge and free of splitting off. The metal wire rod precision alignment cutting device and the method are strong in practicality.

Owner:JINDUICHENG MOLYBDENUM CO LTD

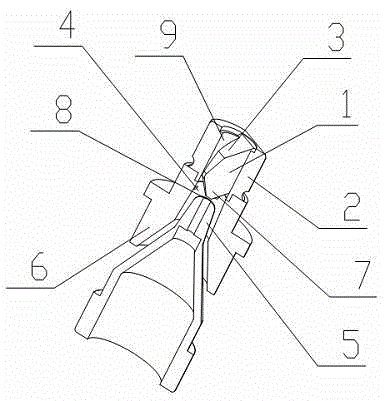

Vibrating micromechanical sensor of angular velocity

ActiveUS8104343B2Reliable measurementImprove performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCouplingAngular velocity

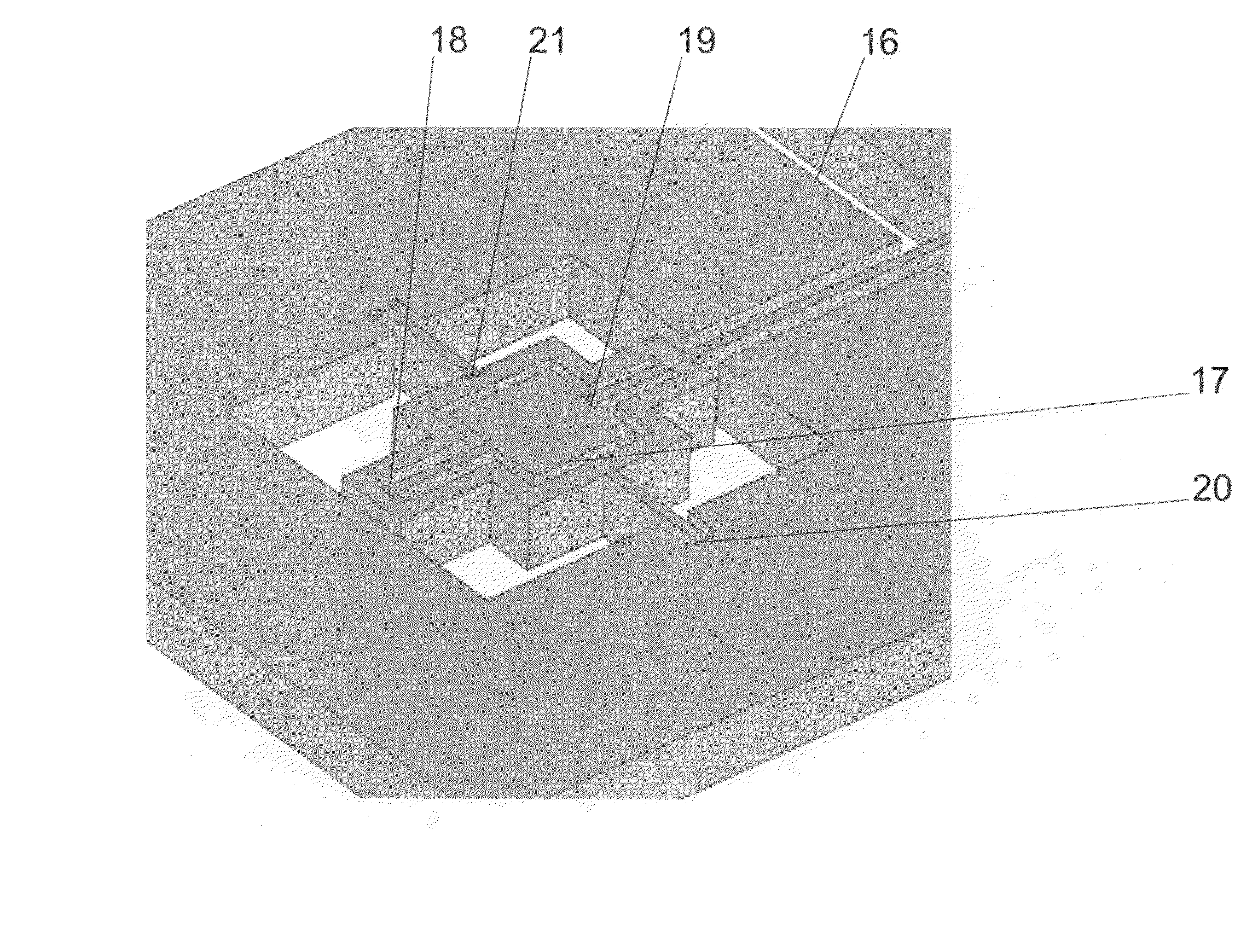

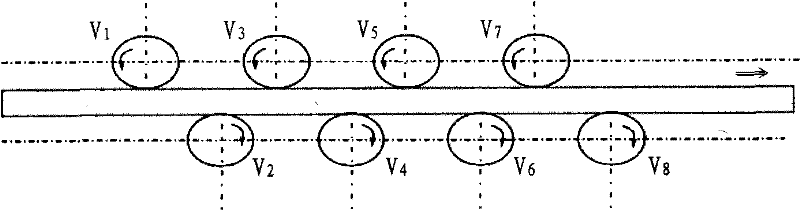

The invention relates to measuring devices to be used in the measuring of angular velocity and, more precisely, to vibrating micromechanical sensors of angular velocity. In a sensor of angular velocity according to the invention, a mass is supported to the frame of the sensor component by means of an asymmetrical spring structure (1), (2), (3), (4), (22), (24) in such a way, that the coupling from one mode of motion to another, conveyed by the spring (1), (2), (3), (4), (22), (24), cancels or alleviates the coupling caused by the non-ideality due to the skewness in the springs or in their support. The structure of the sensor of angular velocity according to the invention enables reliable measuring with good performance, particularly in small vibrating micromechanical solutions for sensors of angular velocity.

Owner:MURATA MFG CO LTD

Vibrating micromechanical sensor of angular velocity

ActiveUS20090165553A1Reliable measurementImprove performanceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCouplingAngular velocity

The invention relates to measuring devices to be used in the measuring of angular velocity and, more precisely, to vibrating micromechanical sensors of angular velocity. In a sensor of angular velocity according to the invention, a mass is supported to the frame of the sensor component by means of an asymmetrical spring structure (1), (2), (3), (4), (22), (24) in such a way, that the coupling from one mode of motion to another, conveyed by the spring (1), (2), (3), (4), (22), (24), cancels or alleviates the coupling caused by the non-ideality due to the skewness in the springs or in their support. The structure of the sensor of angular velocity according to the invention enables reliable measuring with good performance, particularly in small vibrating micromechanical solutions for sensors of angular velocity.

Owner:MURATA MFG CO LTD

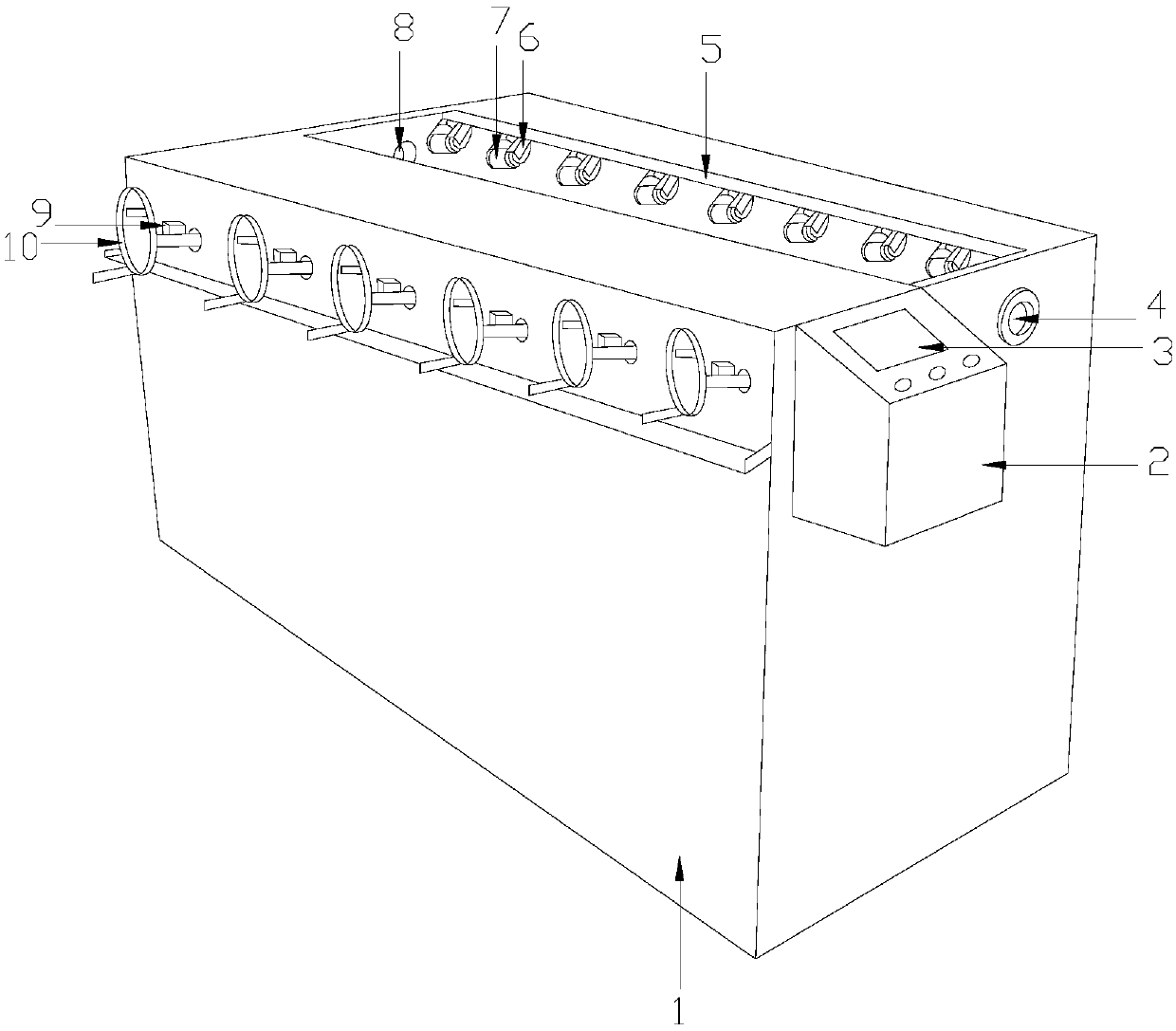

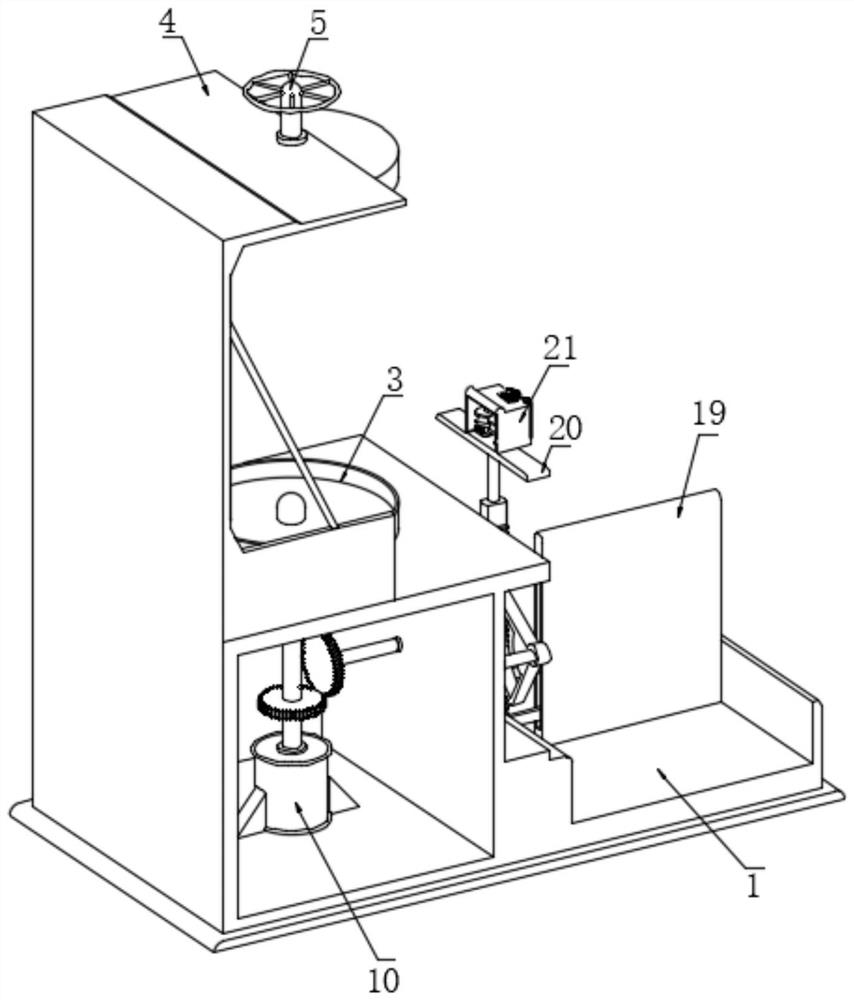

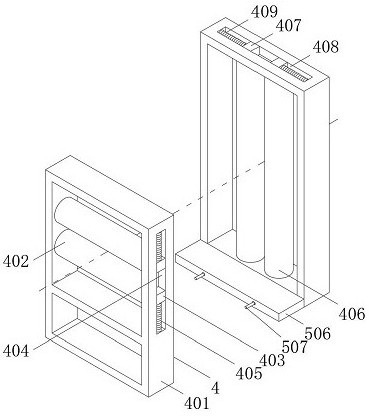

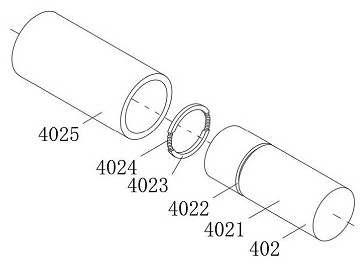

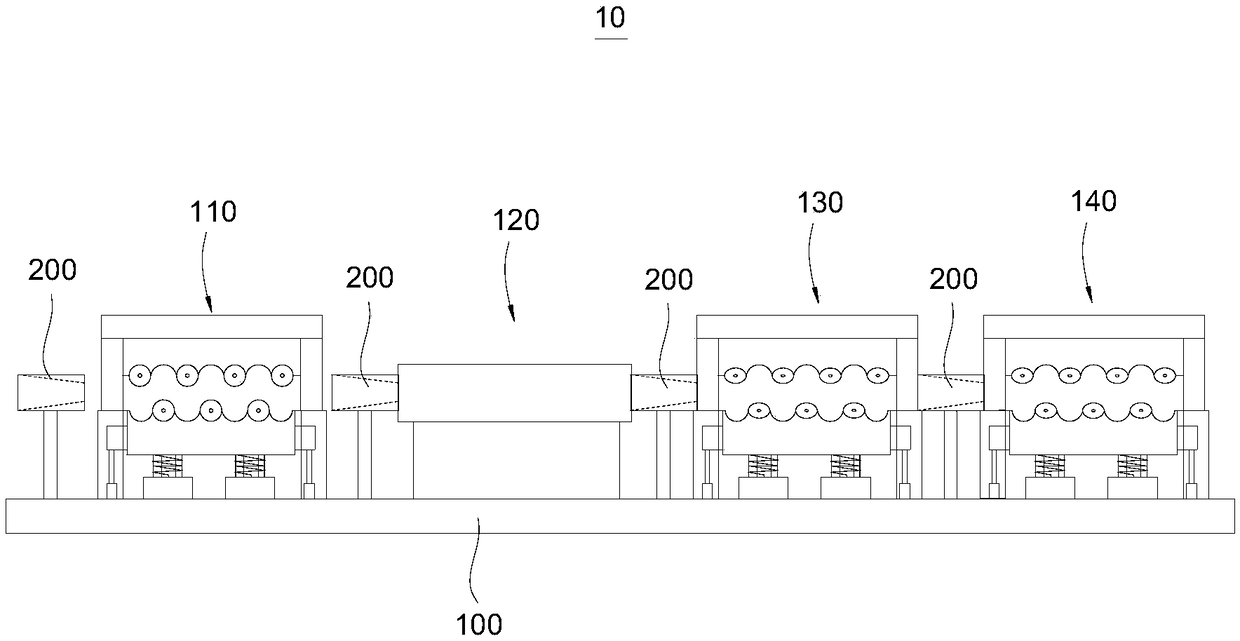

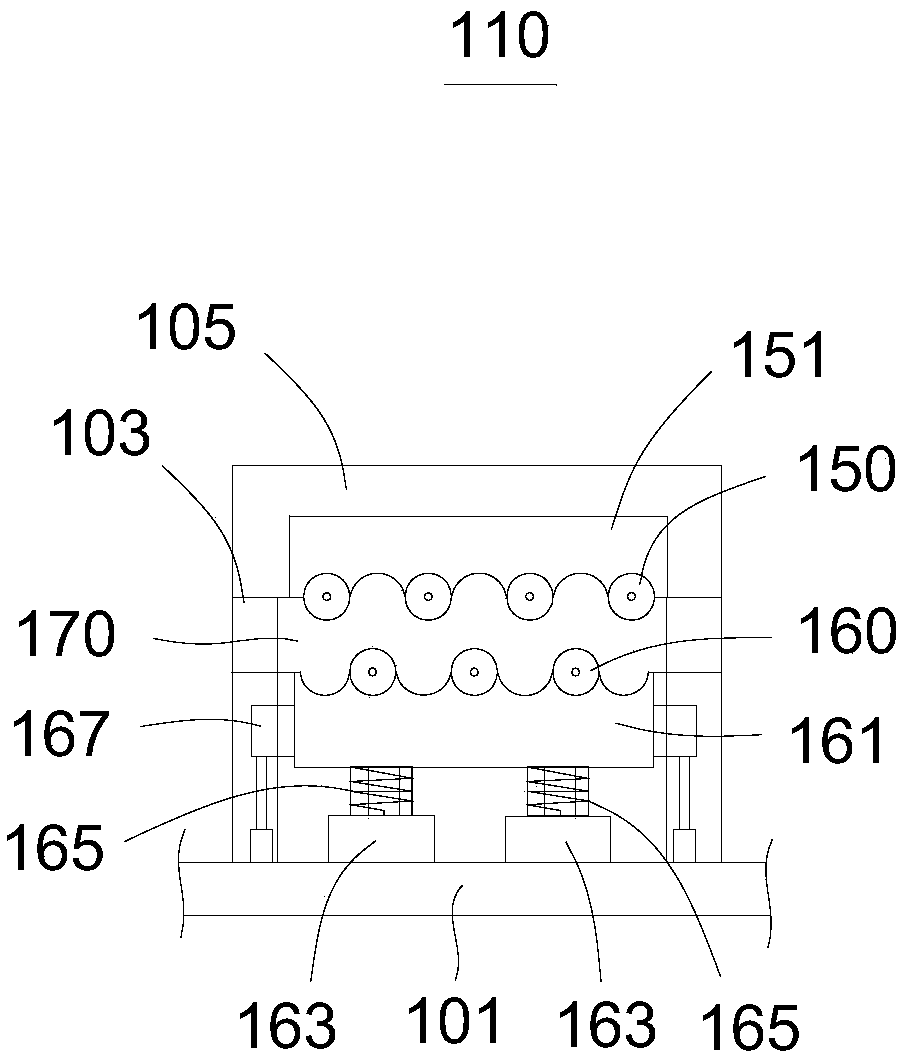

Novel aluminum profile straightening machine

InactiveCN108672525AEffective straighteningEasy to straighten and processShaping toolsMetal-working feeding devicesElectric machineryEngineering

The invention discloses a novel aluminum profile straightening machine. The novel aluminum profile straightening machine comprises an automatic straightening mechanism, an accumulator, a control panel, a discharge port, a fixed shaft, roller bases, rollers, a feed port, an accuracy table and an adjusting wheel. The novel aluminum profile straightening machine can effectively straighten aluminum profiles deformed or rolled on a rolling drum, and is high in working efficiency and practicability; due to lower pressing rollers on telescopic support rods, the distance from upper pressing rollers tothe lower pressing roller scan be adjusted according to the thicknesses of aluminum profiles, the aluminum profiles with different thicknesses are straightened, and the problems can be effectively solved; a driving feeding wheel is driven by a driving motor; aluminum plate raw materials are fed into a movable frame through the feed port; aluminum plates are conveyed by the driving feeding wheel and a first bearing roller; the position of a straightening steel plate at the bottom side is induced through a linear sensor; and a hydraulic transmission rod is adjusted by the control panel to adjust surface positions of the straightening steel plate and a straightening roller mechanism.

Owner:SINOPOL ELECTRONICS TECH

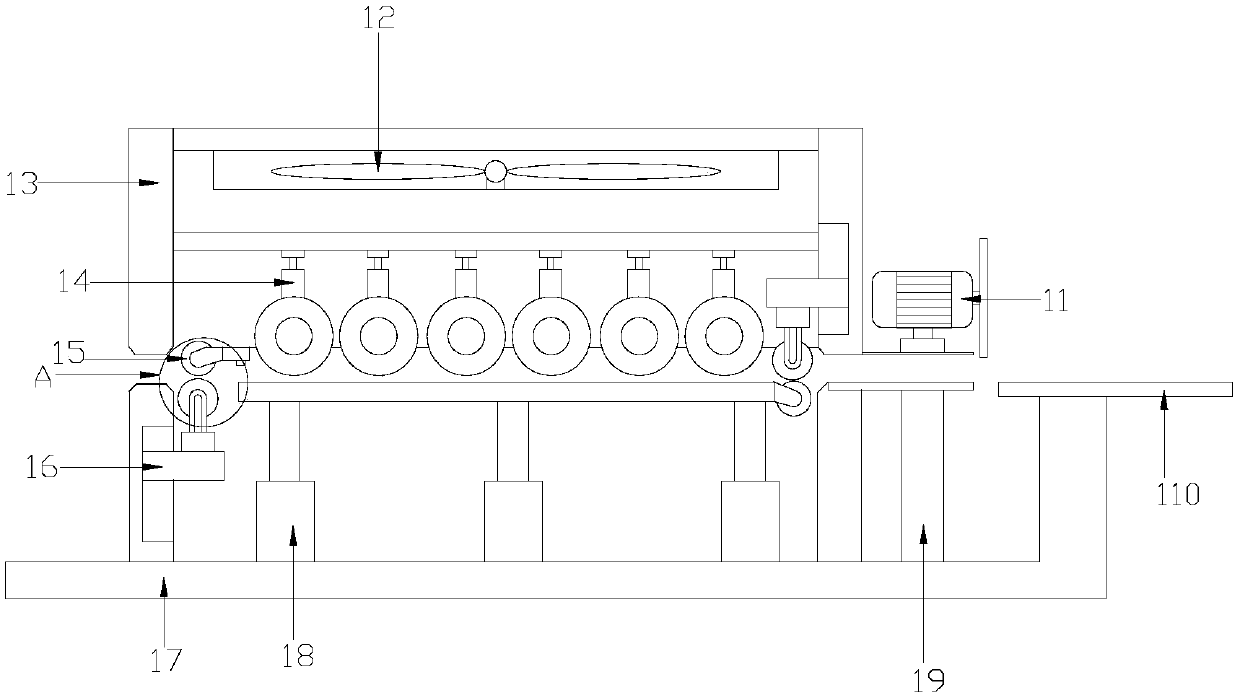

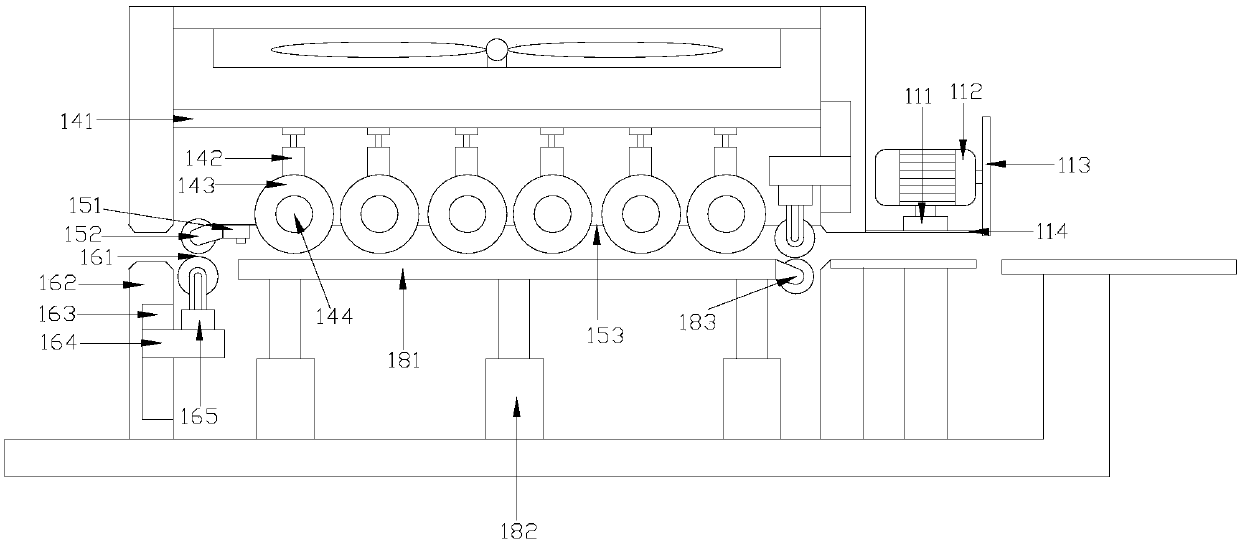

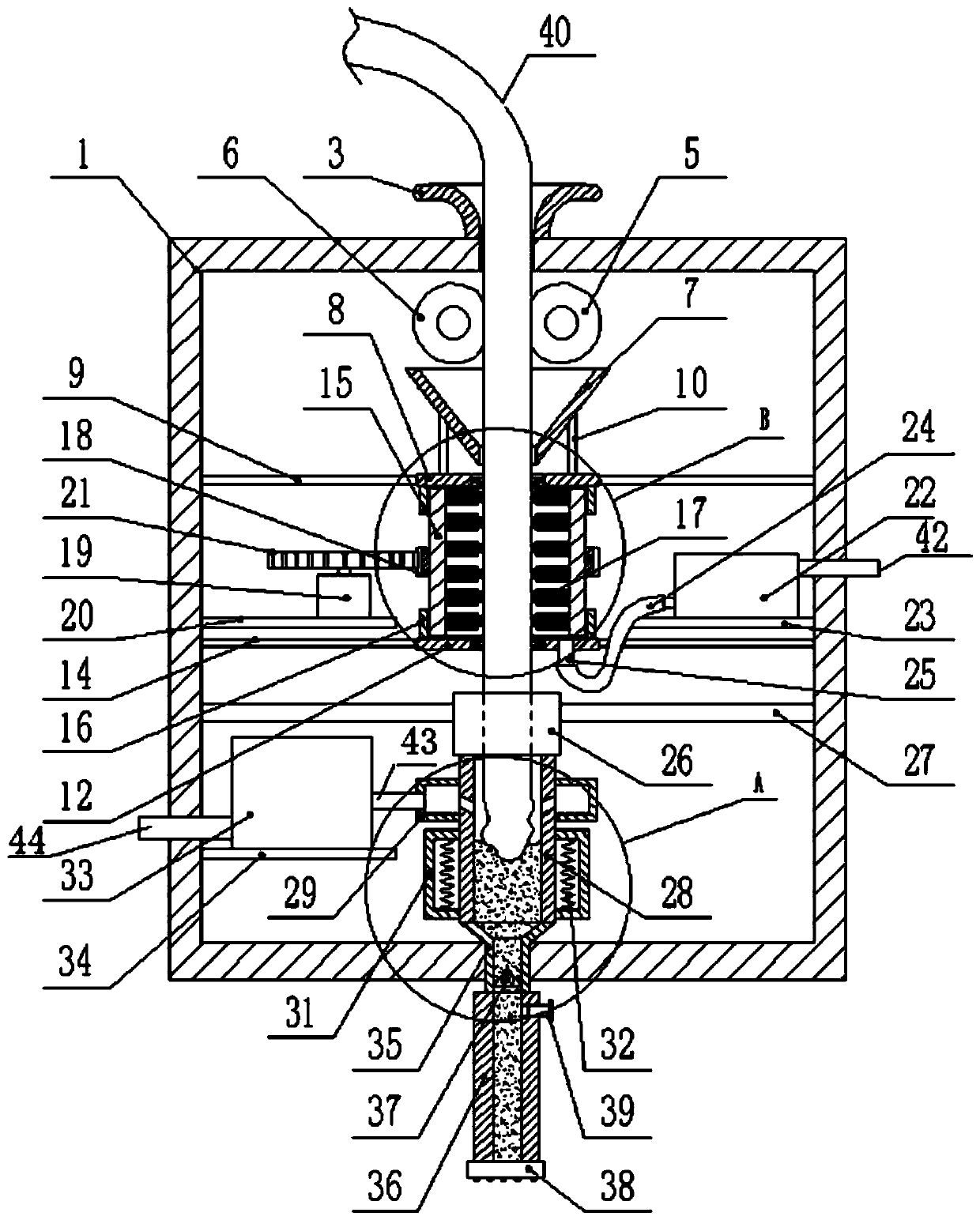

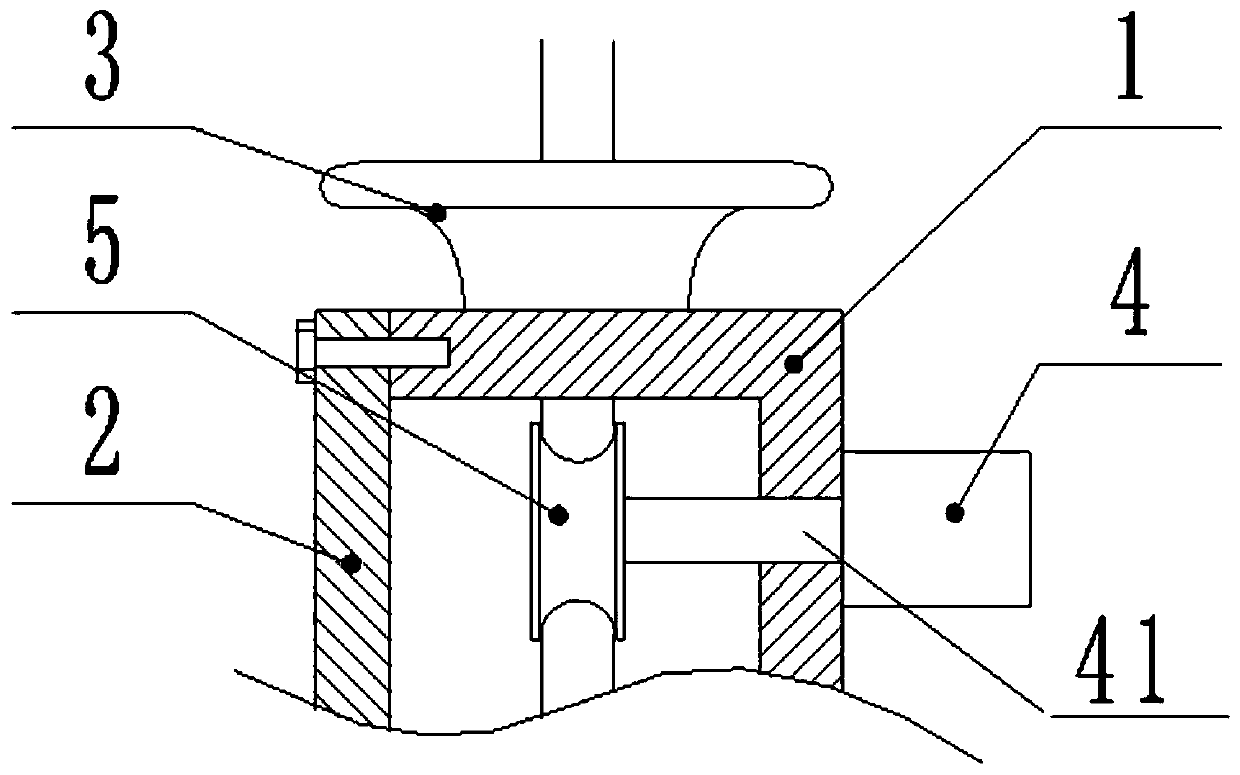

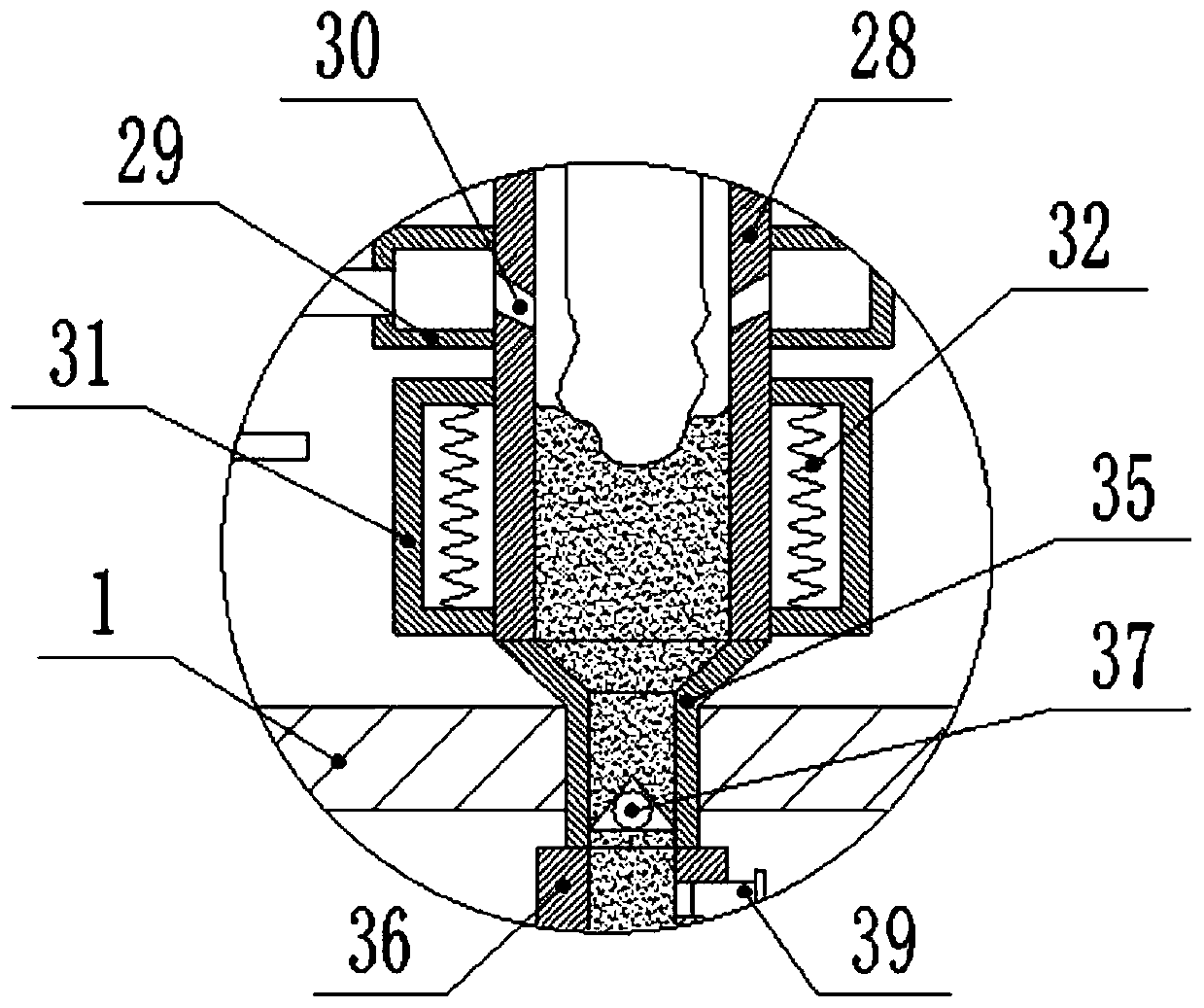

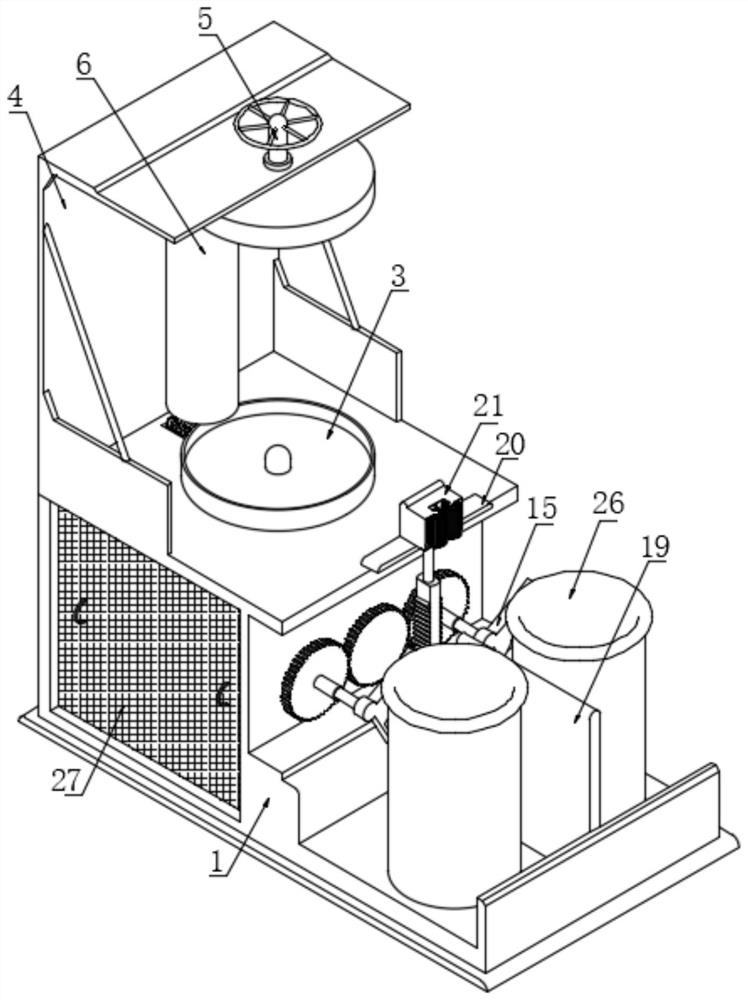

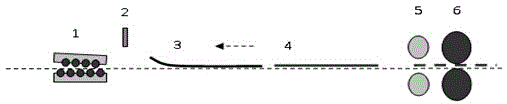

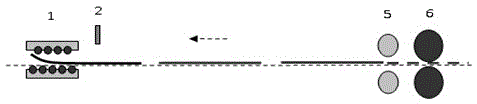

Wire extruding device for 3D printing machine

ActiveCN109927295AEffective straighteningEffective warm-upAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a wire extruding device for a 3D printing machine. The wire extruding device comprises a shell (1), a guiding mechanism, a cleaning mechanism, a heating mechanism and a discharging mechanism; a cavity is formed in the shell (1); the guiding mechanism, the cleaning mechanism, the heating mechanism and the discharging mechanism are arranged in sequence; a wire channel (40) isformed from the guiding mechanism to at least a part of the heating mechanism; a box door (2) is arranged on the shell; a through hole penetrating to the cavity is formed in the upper surface of theshell; the guiding mechanism comprises a group of pulley units; a gap is formed between each group of pulley units; the cleaning mechanism comprises a roller (15); a plurality of brushes (17) are arranged on the inside wall of the roller; the heating mechanism comprises a passing cylinder (26) and a melting cylinder (28); a preheating unit and a heating unit are sequentially arranged on the outersurface of the melting cylinder in the vertical direction; and the discharging mechanism communicates with the melting cylinder. The wire extruding device achieves the effects that the straightness ofa wire in the extruding process is effectively improved, no impurities exist basically, the melting effect is good, the product quality is effectively improved, and the product cost is reduced.

Owner:WUHU INST OF TECH

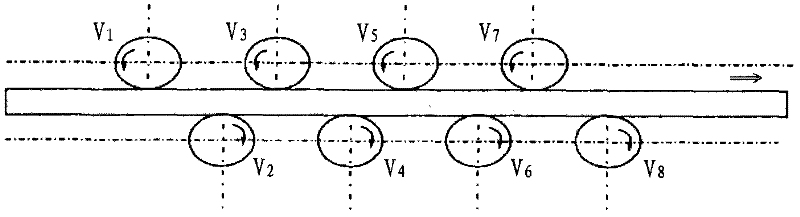

Micro-tension equal-torque metal material straightening method

InactiveCN102172680ANo compressive stressAvoid abnormal wear and tearMetallic materialsInternal stress

The invention provides a micro-tension equal-torque metal material straightening method. In the method, by regulating the linear speeds of all straightening rollers, the liner speeds of the straightening rollers increase gradually in the feeding direction of a metal material under a condition that a metal material straightening process is carried out normally and the torques of the straightening rollers are equal. When the micro-tension equal-torque metal material straightening method provided by the invention is used, the micro-tension and equal-torque straightening of metal materials is realized; therefore, the sudden changes of the torques of the straightening rollers are avoided and the pressure stress and internal stress of the metal materials are avoided, the quality of the metal material is improved, the service life of straightening equipment is prolonged, and the straightening efficiency is improved.

Owner:PANGANG GRP ENG TECH +2

Production process for aluminum alloy window sectional material

ActiveCN110665986AEffective straighteningAccurate flatnessShaping toolsExtrusion control devicesIngotWater cooling

The invention discloses a production process for an aluminum alloy window sectional material. The production process for the aluminum alloy window sectional material comprises the following steps: A1,cast ingot preparation; A2, soaking; A3, raw material preheating; A4, extrusion forming: an aluminum alloy cast ingot is extruded through an extruder, the aluminum alloy cast ingot is extruded by theextruder, so that the aluminum alloy cast ingot in an extrusion barrel is enabled to extrude towards an extrusion die and extruded out from a die hole of the extrusion die, and in the process, the temperature of the extrusion die is controlled to be 380 DEG C; A5, preliminary cooling: water cooling is adopted, and the extruded aluminum alloy section material is cooled to be 250-300 DEG C; A6, rolling straightening: the surface of the aluminum alloy section material is rolled through a straightening machine, so that the surface of the aluminum alloy section material is straight; A7, aftercooling: air cooling is adopted, and the aluminum alloy section material is cooled to be 200 DEG C and below; A8, heat treatment; and A9, surface treatment. The production process for the aluminum alloy window sectional material has the following advantage and effect: due to the production process, the accuracy of the straightness and the surface planeness of the aluminum alloy section material is increased, so that a guarantee on the installation dimensions of an aluminum alloy window prepared from the aluminum alloy sectional material is benefited.

Owner:无锡辰浩建筑节能科技有限公司

Rotating and straightening method using metal pipe tension

The invention relates to the straightening of the bending deformation generated during the manufacturing, processing, storing and transporting of a metal pipe. The method is to rotationally straightening with a tensile force of the metal pipe and comprises: a clipping device clips both ends of the metal pipe to enable the tensile force of the metal pipe material reach a yield limit; at the same time, the clipping device drives the metal pipe to rotate together at a proper speed. In the method, only both ends of the metal pipe are clipped so as to bend the metal pipe and enable the metal pipe material to generate a tensile force of the yield limit; at the same time, the metal pipe also rotates continuously to equalize moment all parts, without causing deformation of the metal pipe; therefore, the straightening method straightens the metal pipe effectively, without scraping the surface of the metal pipe.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

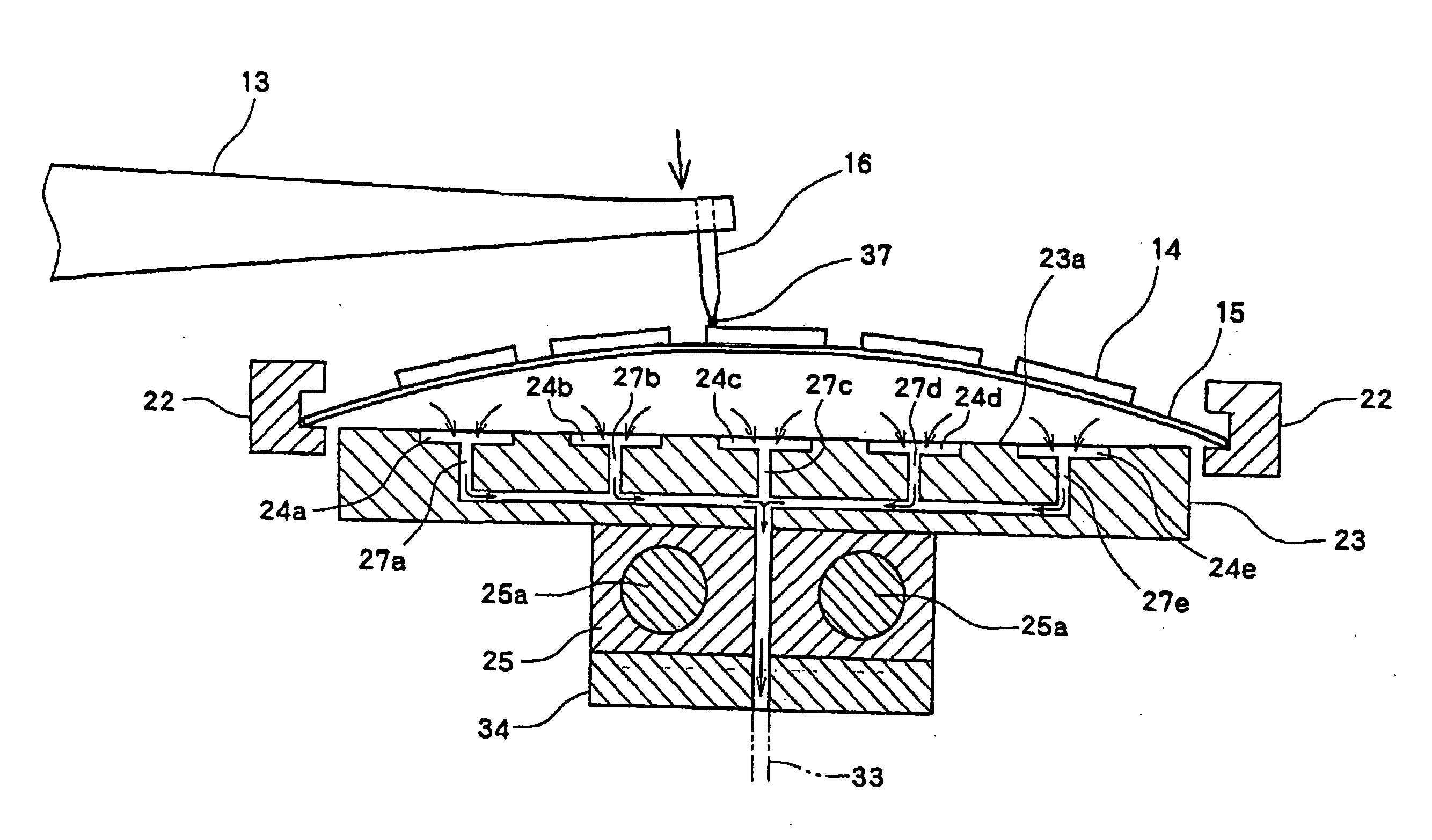

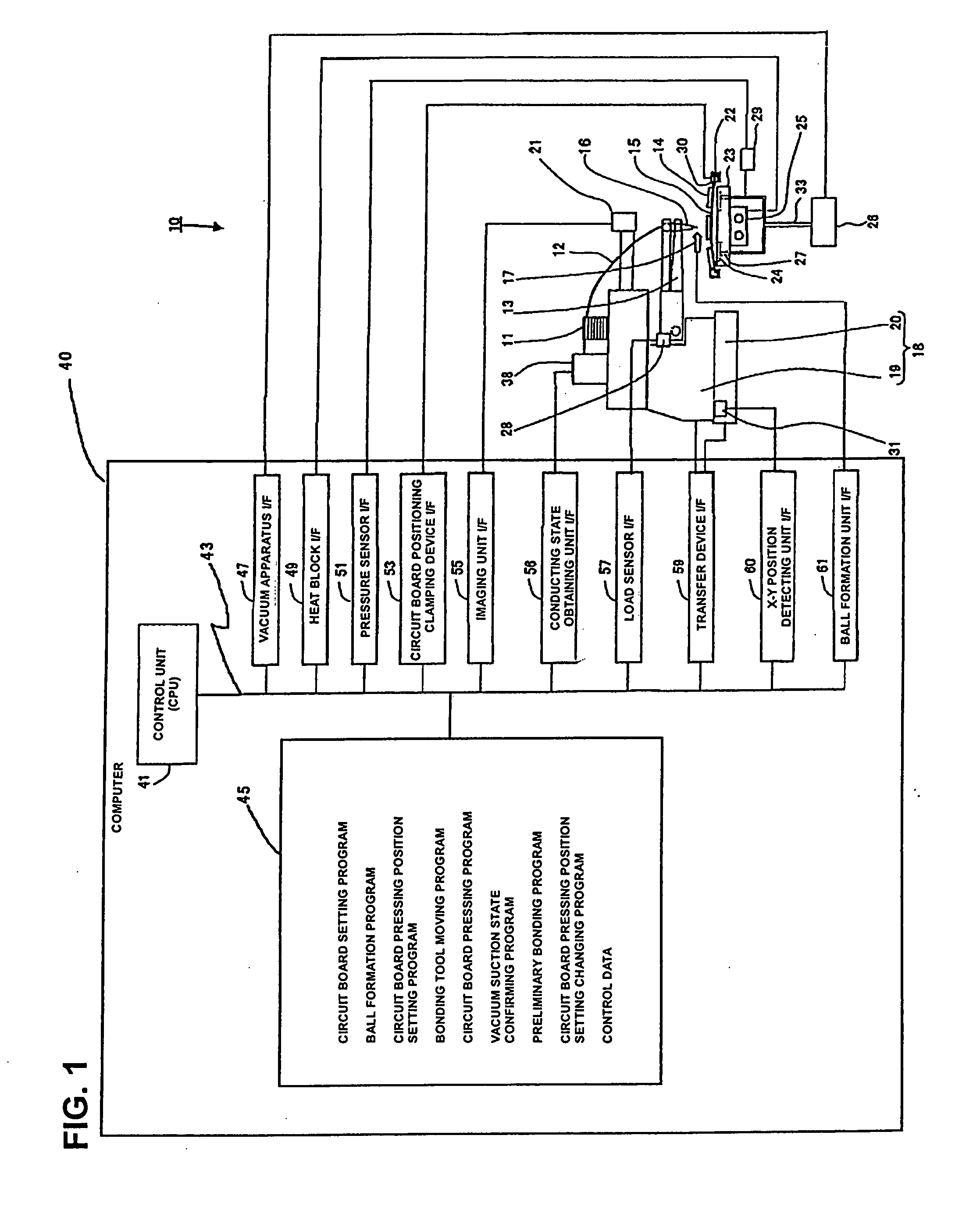

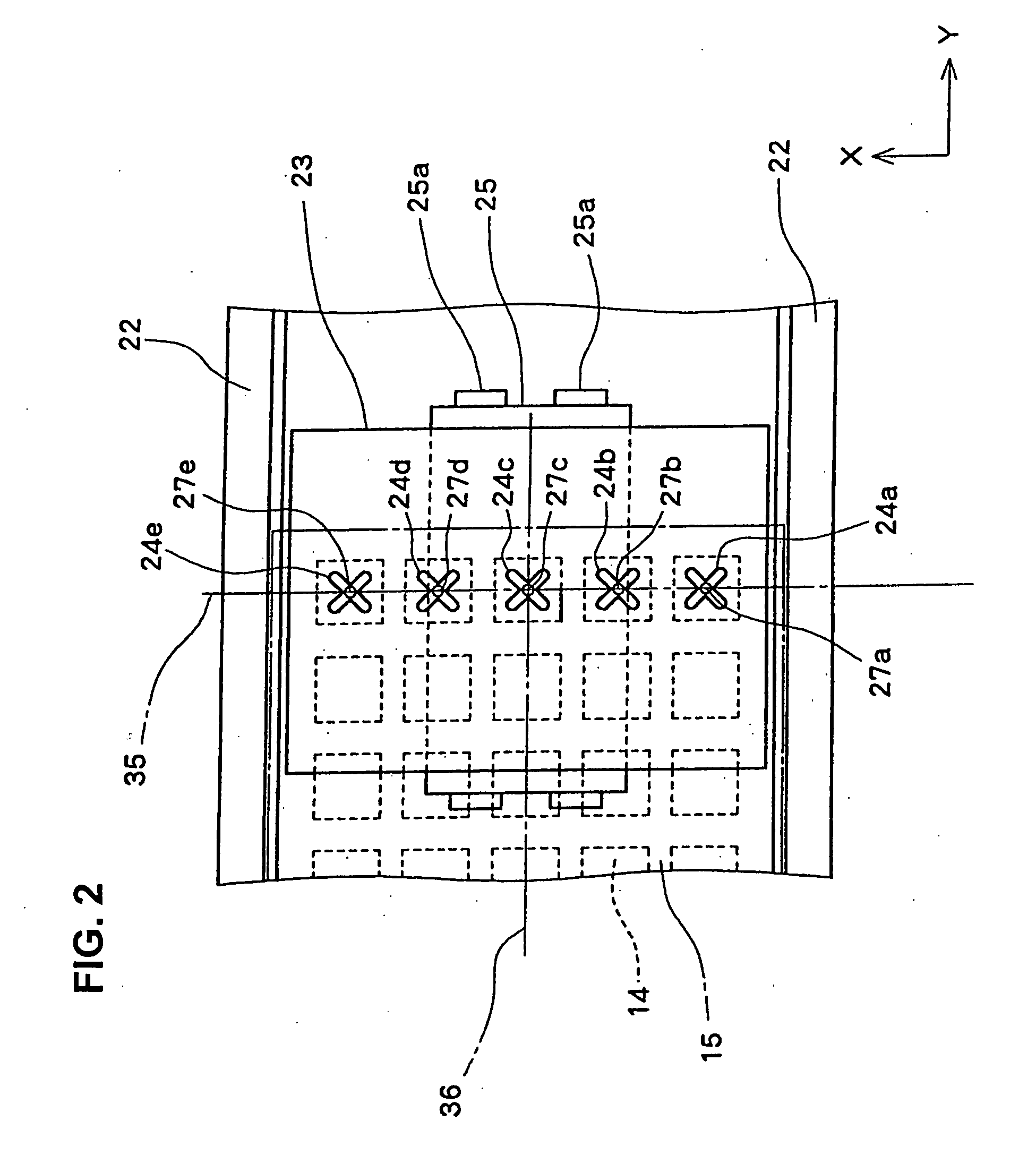

Method of fixing curved circuit board and wire bonding apparatus

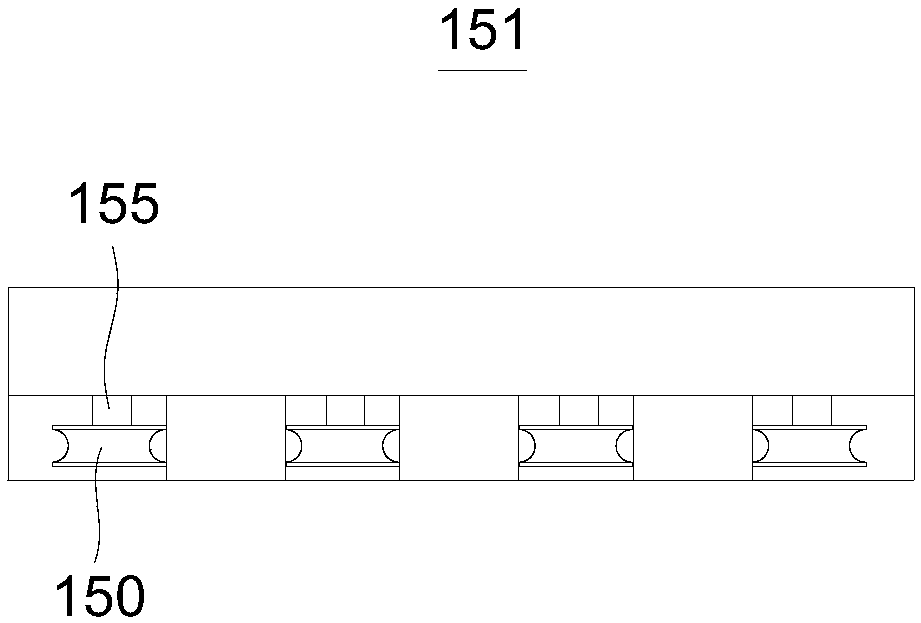

InactiveUS20070287222A1Effective straighteningEffectively fixedPrinted circuit assemblingSolid-state devicesLead bondingPrinted circuit board

A method of holding a curved circuit board in a flat fashion and a wire bonding apparatus thereof, including suction cavities provided in a suction stage to which a curved circuit board is suctioned. While evacuating air from the vacuum suction cavities, a capillary attached to the tip end of a bonding arm is lowered to press a part of the curved circuit board down thus having at least one of the vacuum suction cavities sealed by the circuit board, allowing the remaining vacuum suction cavities to be sealed successively so that the curved circuit board is straightened to be flat and suction-held on the suction stage. The vacuum suction cavities are sealed with by straightened circuit board, and the circuit board is held on the suction stage in place.

Owner:SHINKAWA CO LTD

Plate stacking straightening method for centre wave buckling of thin-specification high-strength plate

ActiveCN105081010AEffective straighteningStraightening process to achieve effective straighteningSheet steelChinese characters

Owner:NANJING IRON & STEEL CO LTD

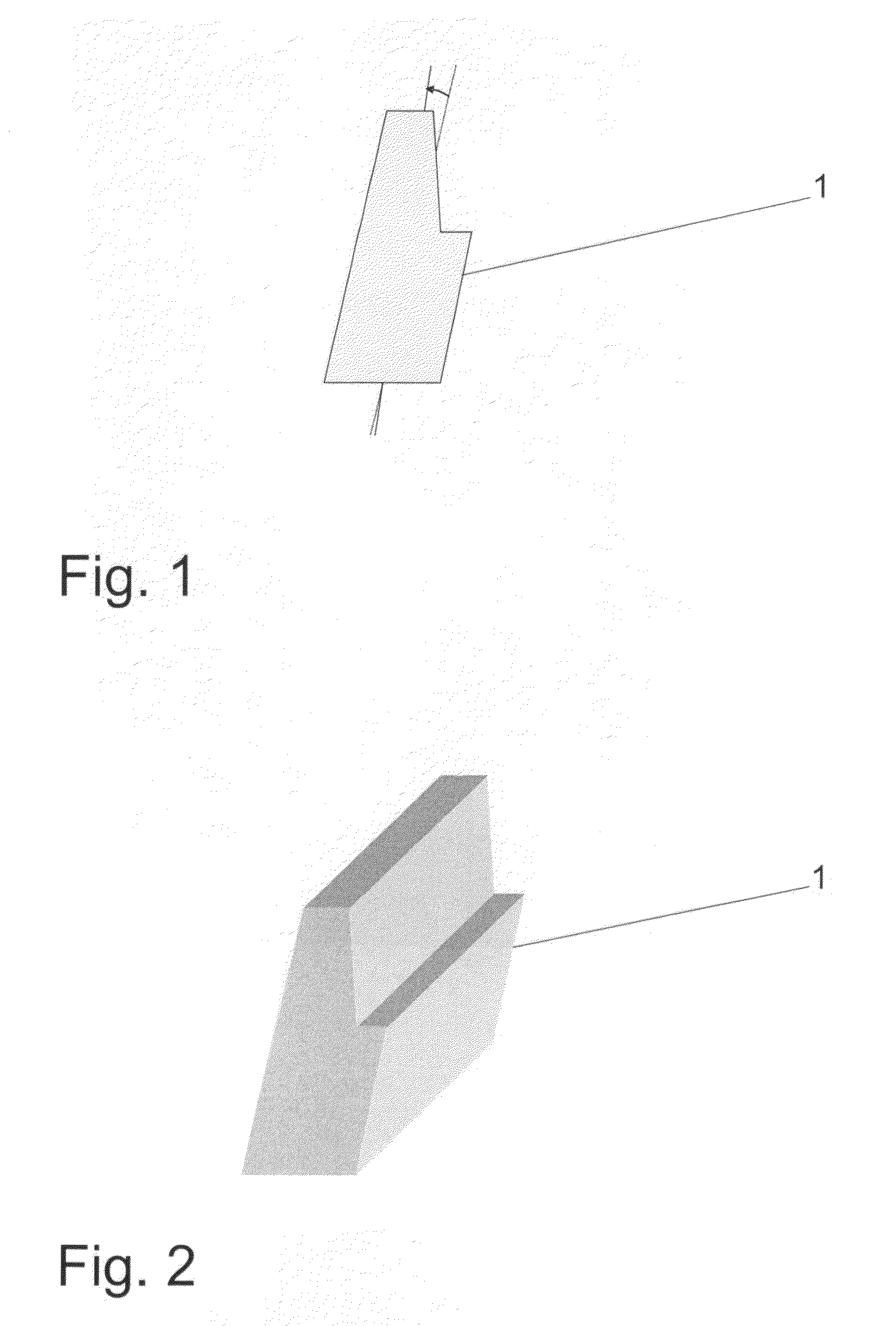

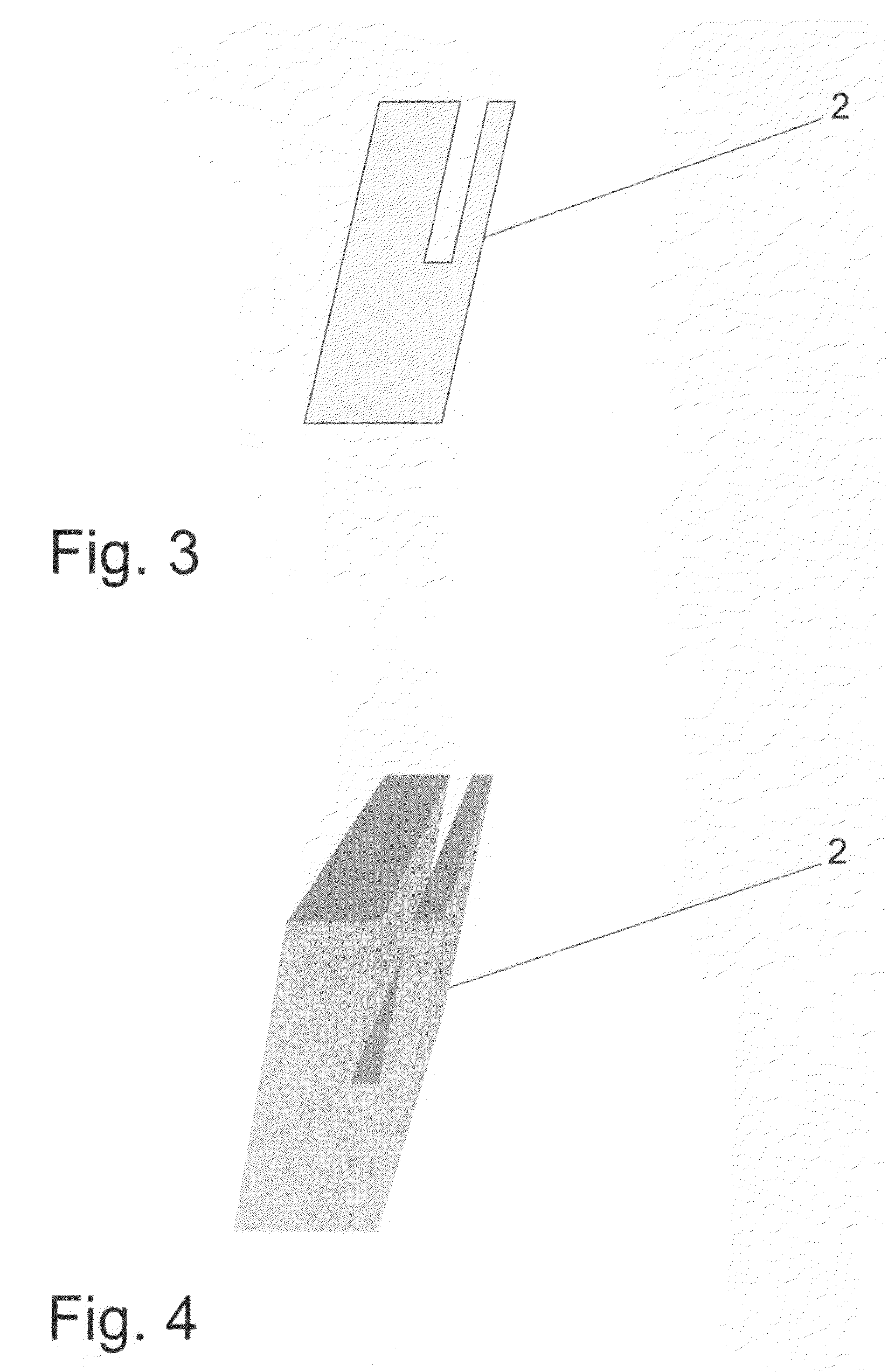

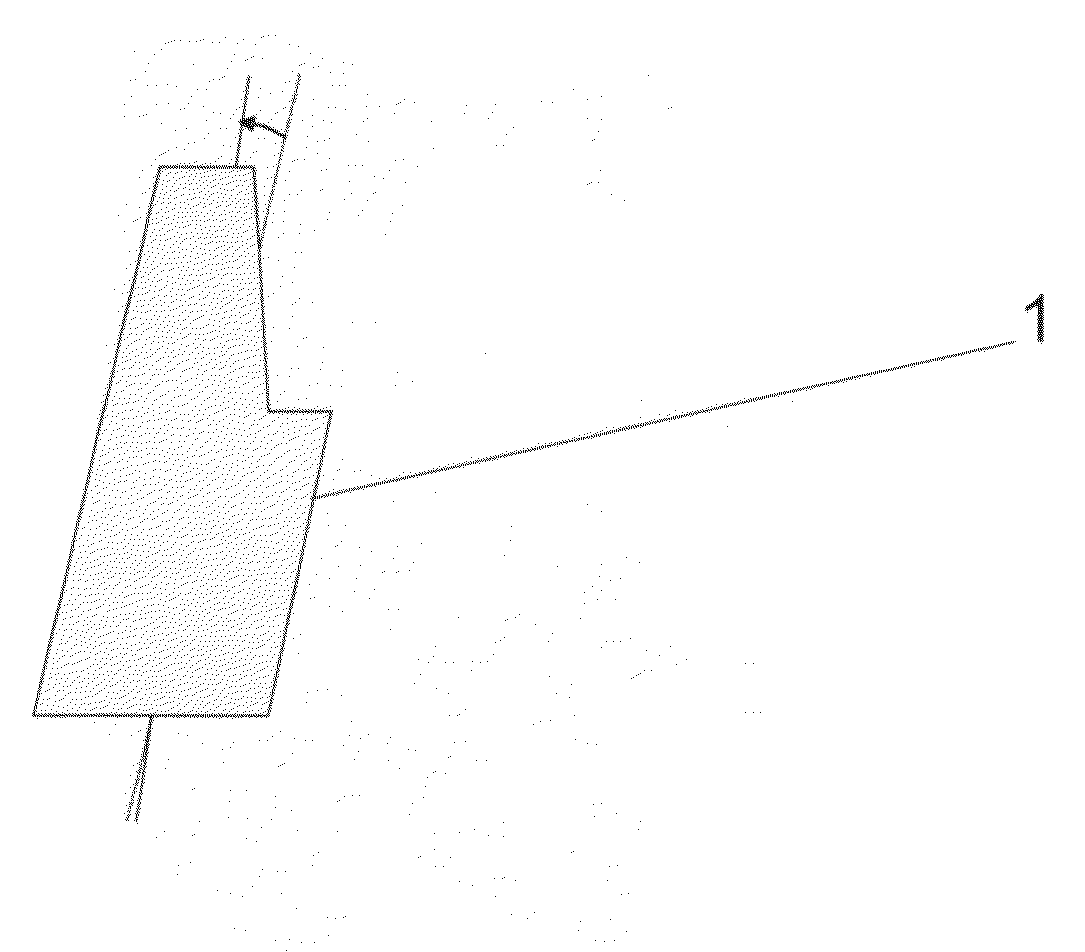

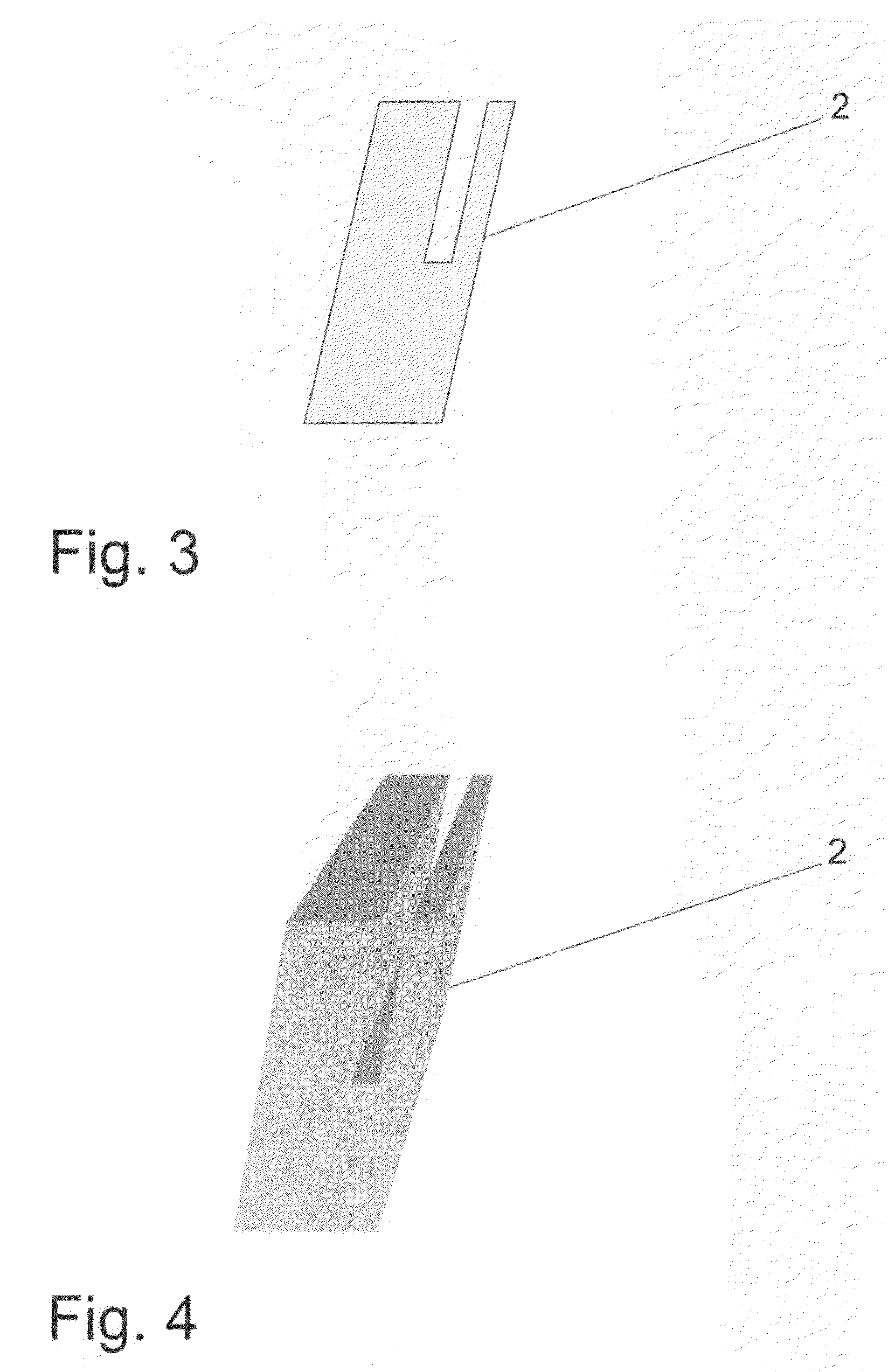

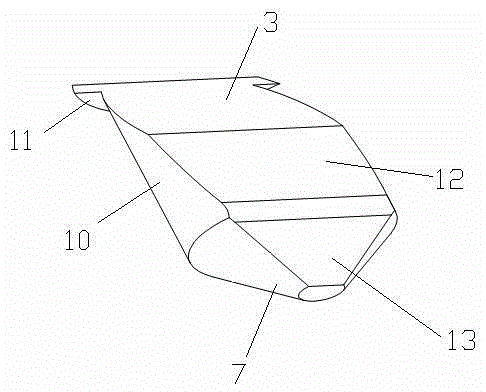

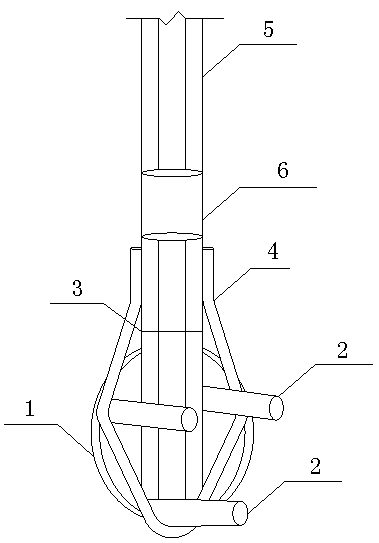

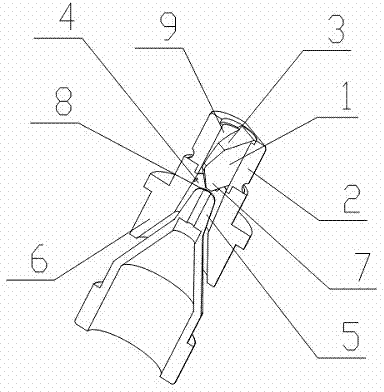

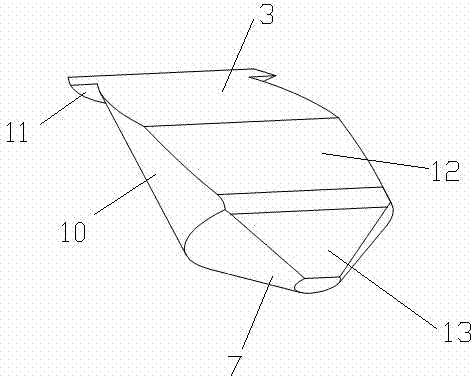

A yarn guiding device

ActiveCN103924333BIncrease the vortex speedIncrease twisting speedTextiles and paperBreaking strengthYarn

The invention relates to a yarn guiding device, and belongs to the technical field of textile machinery. The yarn guiding device comprises a guiding block (1), a shell (2) and a vortex tube (6), wherein the guiding block (1) is arranged in the shell (2), the guiding block (1) comprises a cylindrical guiding block base body (10) and a conical boss (7), a positioning block (11) is arranged at the rear end of the cylindrical guiding block base body (10), the front side of the portion, from the front end to the middle, of the cylindrical guiding block base body (10) is cut off to form a second guiding face (12), the front side of the portion, from the middle to the positioning block (11) at the rear end, of the cylindrical guiding block base body (10) is cut off to form a first guiding face (3), and the front side of the portion from the front end of the cylindrical guiding block base body (10) to the front end of the conical boss (7) is cut off to form a third guiding face (13). According to the yarn guiding device, the rotational speed of air flow inside a swirl chamber can be increased, the twisting speed of yarn is high, the yield of the final yarn is increased, and the breaking strength of the final yarn is improved.

Owner:江阴市华方新技术科研有限公司

Dust removal and ironing device for textile fabric

ActiveCN113279235ADoes not affect rotationSave human effortMechanical cleaningPressure cleaningTextile technologyDust control

The invention relates to the technical field of textile, in particular to a dust removal and ironing device for a textile fabric. The dust removal and ironing device comprises a workbench; mounting plates are vertically mounted on the two sides of the workbench; a feeding frame is fixedly mounted at one end of the workbench; a dust removal device is fixedly mounted between the mounting plates on the two sides of the workbench; a fabric transmission device is arranged on one side of the discharging end of the dust removal device; the working end of a humidifying device faces the working end of the fabric transmission device; an ironing device is arranged on one side of the discharging end of the fabric transmission device; the feeding end of a cooling device and the discharging end of the ironing device are kept horizontal; and dustproof covers are arranged above the mounting plates on the two sides of the workbench. According to the invention, the purposes of ironing and cooling the textile fabric after dust and sundries on the upper surface and the lower surface of the textile fabric can be automatically removed are achieved, and the technical problems that the fabric quality is poor due to the fact that the fabric surface is stained with the dust, manual ironing wastes time and labor, and a long-term working environment harms human bodies are solved.

Owner:江西怡生服装有限公司

Cutting and bending straightening device for metal pipe

ActiveCN105817896AFlat cutGuaranteed performanceOther manufacturing equipments/toolsMetalArchitectural engineering

The invention discloses a cutting and bending straightening device for a metal pipe. The cutting and bending straightening device comprises an installation seat, a chuck threaded connector, a chuck, a metal pipe cutting tool sleeve and metal pipe straighteners. An inner threaded hole is formed in the position, at one end of the installation seat, of a seat body. The chuck threaded connector is fixedly connected with the chuck. The chuck threaded connector and the chuck serve as an assembly with a threaded section and a non-threaded section to be installed in the inner threaded hole, and in addition, the assembly can be adjusted so that the threaded section or the non-threaded section of the assembly can be located in the inner threaded hole. The metal pipe straighteners and the chuck are oppositely installed on the installation seat. The metal pipe cutting tool sleeve is installed between the chuck and the metal pipe straighteners. Each metal pipe straightener is provided with a metal pipe clamp with adjustable clamping pressure. By means of the cutting and bending straightening device for the metal pipe, the metal pipe can be effectively straightened, a flat communicating end face is cut, and the use performance of the metal pipe is effectively ensured.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

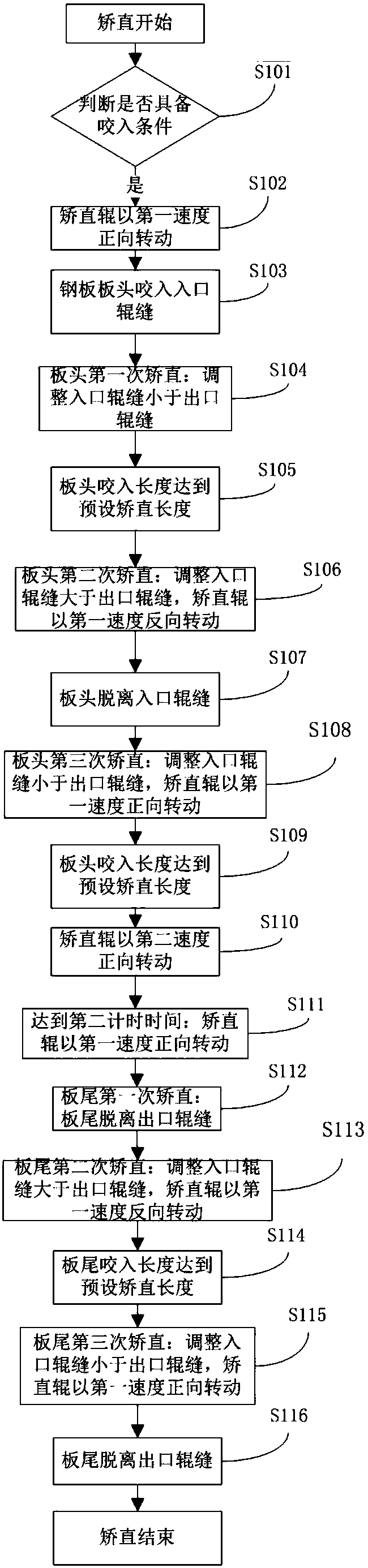

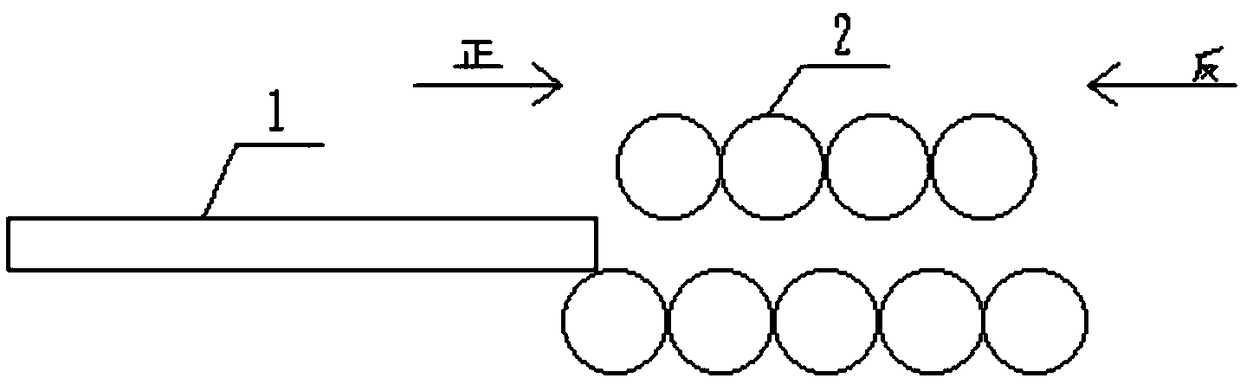

Straightening control method of steel plate

ActiveCN108089466AShorten straightening timeImprove straightening efficiencyProgramme control in sequence/logic controllersSheet steelSteel plates

The application discloses a straightening control method of a steel plate. The method comprises: if a straightening machine has a biting condition, a controller controls a straightening roller rotateforwardly at a first speed and the head of a to-be-straightened steel plate is bitten into an entrance roller slit of the straightening roller; whether the biting length of the head of the to-be-straightened steel plate reaches a preset straightening length is detected; if so, first straightening of the head of the steel plate is completed and the straightening roller is controlled to rotate reversely at a first speed, so that the straightening roller completes second straightening of the plate head along an opposite direction; and if the head of the to-be-straightened steel plate is separatedfrom the entrance roller slit, the straightening roller is controlled to rotate forwardly at a first speed. Therefore, the straightening time of the steel plate is shortened effectively, so that thestraightening efficiency of the steel plate is improved effectively.

Owner:SHANXIN SOFTWARE CO LTD

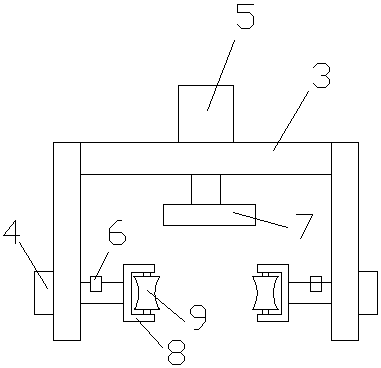

Hydraulic straightening machine with movable type pressure head

The invention provides a hydraulic straightening machine with a movable type pressure head. The hydraulic straightening machine with the movable type pressure head is composed of a lathe bed, a gantrymechanism, a gantry driving base, a rolling adjustment device, a gantry hydraulic driving mechanism, a control panel and a moving walking board. Two ends of the lathe bed are connected with bed legs,the gantry mechanism is of a gantry sealing type structure and spans the lathe bed, the gantry driving base is arranged at the bottom of the gantry mechanism, and four rollers are mounted on the gantry driving base. The rolling adjustment device comprises a rotary driving mechanism, a V-shaped roller bracket, a universal transmission section and a lifting oil cylinder. The gantry hydraulic driving mechanism is composed of a pressure oil pump, a main oil cylinder, an oil tank, an oil circuit integrated block and a hydraulic valve. The moving walking board is arranged on one side of the lathe bed, and the control panel is mounted on the moving walking board. The hydraulic straightening machine with the movable type pressure head can be widely applied to steel-making plants and large-scale steel markets and used for straightening thin and long shaft type part workblanks or straightening circular steel materials or steel pipes, so that the allowance for machining of straightened workpieces is uniform, the allowance for machining is reduced, and the hydraulic straightening machine with the movable type pressure head has the advantages of reasonable design, convenient use and high-efficiency straightening.

Owner:SHANDONG HUAYU UNIV OF TECH

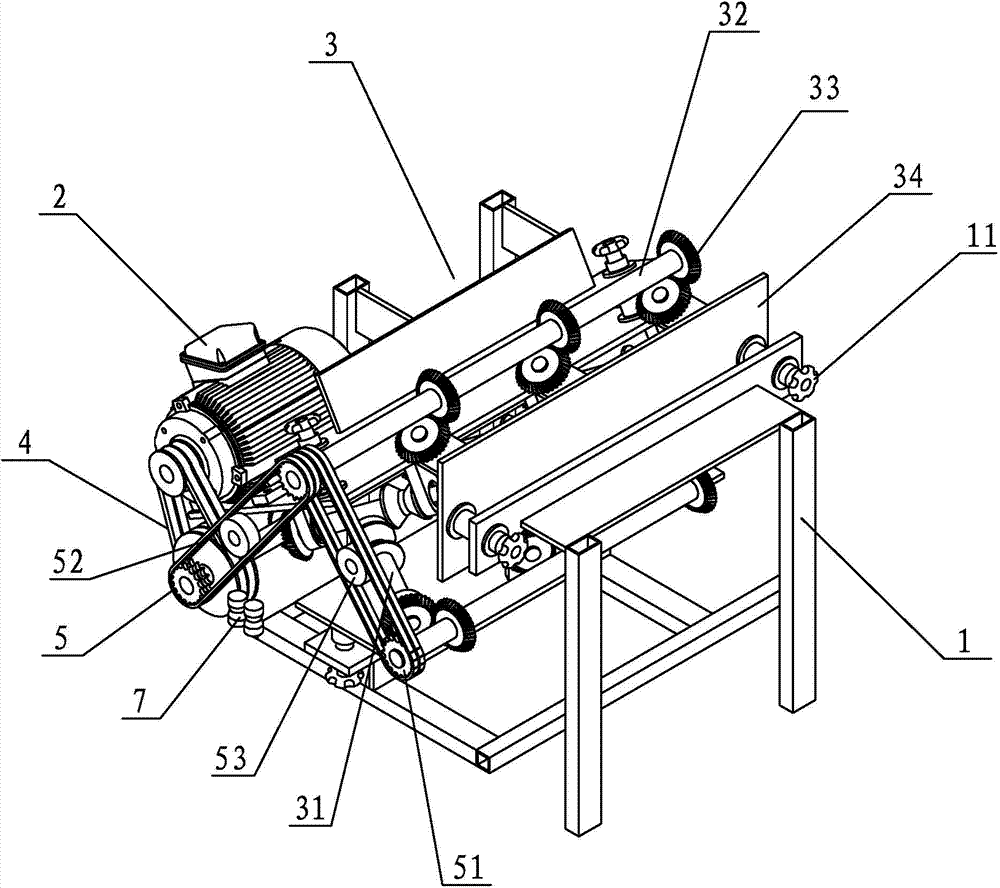

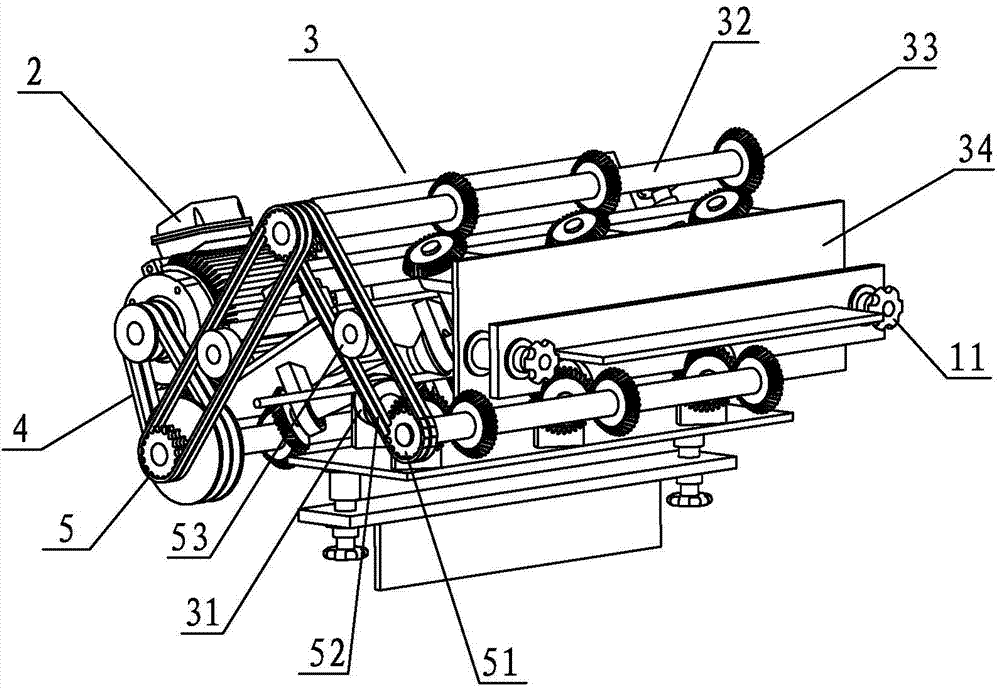

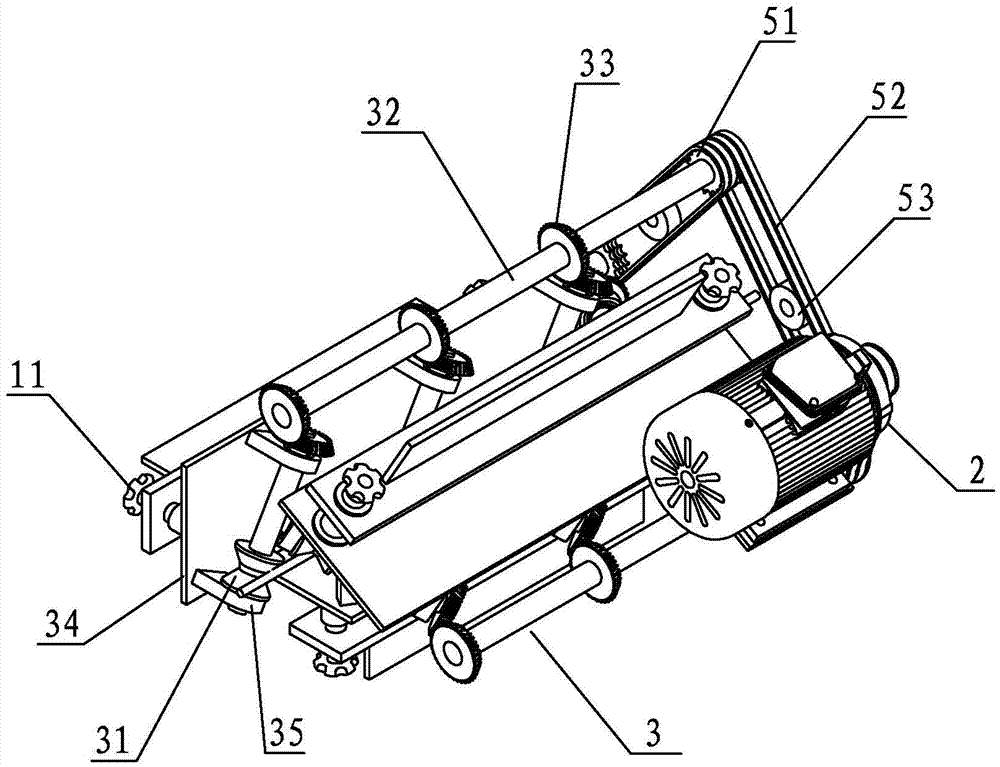

Spinning type reinforcing steel bar automatic straightening machine

The invention discloses a spinning type reinforcing steel bar automatic straightening machine. The spinning type reinforcing steel bar automatic straightening machine comprises a machine frame and a drive device, wherein a straightening mechanism driven by the drive device is arranged on the machine frame, the straightening mechanism comprises at least one set of inclined rotating idler wheels, each set of inclined rotating idler wheels are composed of a plurality of inclined rotating idler wheels making contact with a reinforcing steel bar, the inclined rotating idler wheels are sequentially arranged in the axial direction of the reinforcing steel bar, the inclined rotating idler wheels in the same set are evenly distributed on the radial periphery of the reinforcing steel bar in the circumferential direction, the inclined rotating idler wheels incline relative to the axial direction of the reinforcing steel bar, and the drive device drives the inclined rotating idler wheels to rotate and to straighten and convey the reinforcing steel bar. The spinning type reinforcing steel bar automatic straightening machine is reasonable in structure, capable of effectively straightening and automatically conveying the reinforcing steel bar at the same time, and good in straightening effect.

Owner:冯广建

Anti-fracture dry-type transformer winding structure and using method thereof

InactiveCN113871168ANot easy to shift positionAvoid affecting useTransformers/inductances coils/windings/connectionsGear driveGear wheel

The invention discloses an anti-fracture dry-type transformer winding structure and a using method thereof, which belong to the technical field of dry-type transformers. The anti-fracture dry-type transformer winding structure comprises a rack, a controller is arranged on the back face of the rack, and the upper surface of the rack is fixedly connected with the lower surface of a top plate. According to the structure, the connecting shaft drives the fixing disc to rotate, the fixing disc drives the wire mold frame to rotate, meanwhile, the driving gear drives the driven gear to rotate, and after a single-layer wire is wound on the wire mold frame, the front sector tooth is separated from the toothed bar, and the rear sector tooth is meshed with the toothed bar, and thus, the rear sector teeth can drive the gear rod and the box body to move downward during rotation, in the same way, the box body and the two guide wheels sequentially move up and down in a reciprocating mode, the wire mold frame continuously rotates, compared with a traditional winding mode, the purpose of uniform winding is effectively achieved, the winding position can be automatically adjusted, a wire is not prone to deviating after being wound, the stability is improved, and the normal use of the dry-type transformer is prevented from being influenced.

Owner:连云港天威变压器有限公司

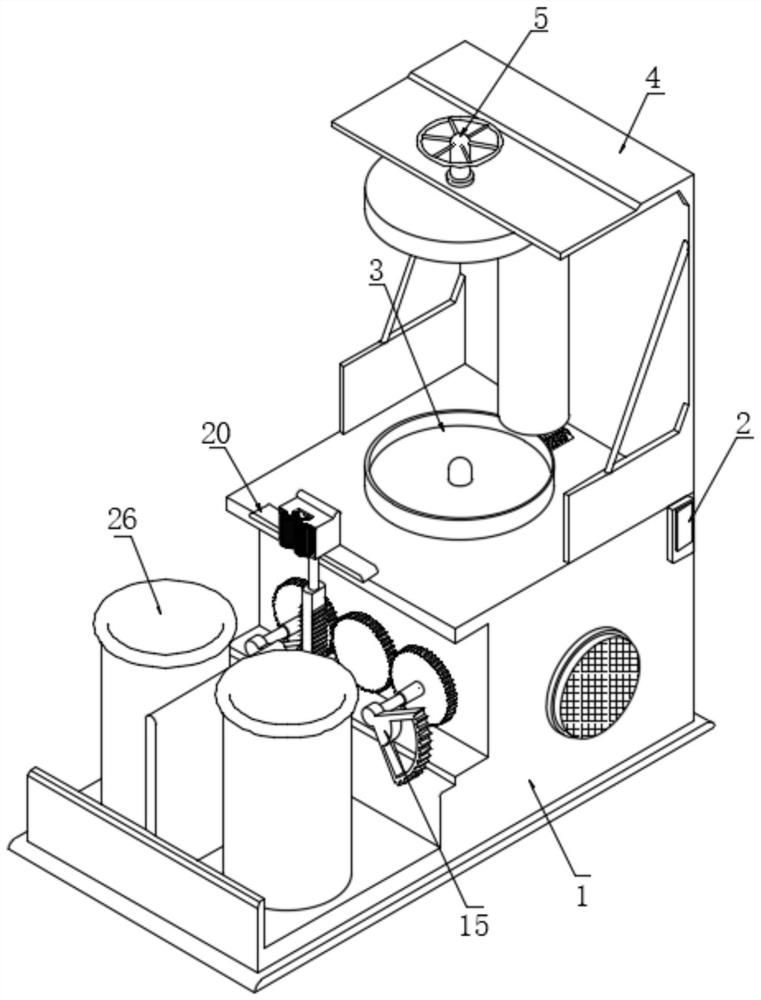

Iron wire winding and shearing device used during production of artificial flowers

ActiveCN110403281AEffective straighteningMeet needsArtificial flowers and garlandsRolling paperPulp and paper industry

The invention relates to the technical field of production of artificial flowers, and in particular relates to an iron wire winding and shearing device used during production of artificial flowers. The device comprises a rack, and an iron wire aligning mechanism, a support and glue adhering mechanism, a roll paper mechanism, a conveying mechanism, a face paper mechanism and a breaking mechanism are fixed on the rack in the sequence from right to left, wherein a support and glue adhering mechanism is also fixed between the conveying mechanism and the face paper mechanism. Through the device provided by the invention, the purpose that a layer of roll paper wraps the surface of the iron wire and a layer of face paper winds the surface of the roll paper can be effectively realized, meanwhile,the iron wire wrapped by the roll paper and the face paper can be effectively cut to have the same length, and the cut iron wires are pushed into a collecting device.

Owner:赣州东峰自动化设备有限公司

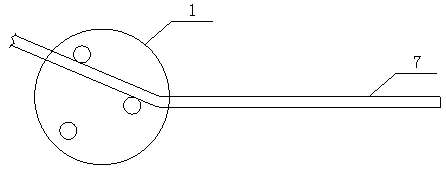

Simple and convenient reinforcing steel bar straightening tool

The invention discloses a simple and convenient reinforcing steel bar straightening tool. The simple and convenient reinforcing steel bar straightening tool comprises a straightening head, a handle and a sleeve, and is characterized in that the straightening head comprises a circular plate, three straightening rods, a connecting rod and a holding hoop; the circular plate is a circular steel platewith the diameter of greater than or equal to 140 mm and the thickness of greater than or equal to 12 mm; the three straightening rods are three short reinforcing steel bars; the handle is a second reinforcing steel bar bundle which is formed by bundling, fixing and welding a plurality of reinforcing steel bars together; the reinforcing steel bar location of the second reinforcing steel bar bundleis the same as that of a first reinforcing steel bar bundle; the length of the second reinforcing steel bar bundle is greater than or equal to 1,500 mm; screw threads are formed in one end of the second reinforcing steel bar bundle; the sleeve is a straight threaded reinforcing steel bar sleeve; and the sleeve is connected between the first reinforcing steel bar bundle and the second reinforcingsteel bar bundle through the screw threads. The simple and convenient reinforcing steel bar straightening tool disclosed by the invention has the advantages that the tool is simple in structure and convenient to manufacture; a bent and deformed reinforcing steel bar can be effectively straightened with guaranteed quality and quantity when a reserved reinforcing steel bar is collided so as to ensure the integrity and the functionality of reinforcing steel bar engineering; the straightening tool can be recycled; materials are saved; and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

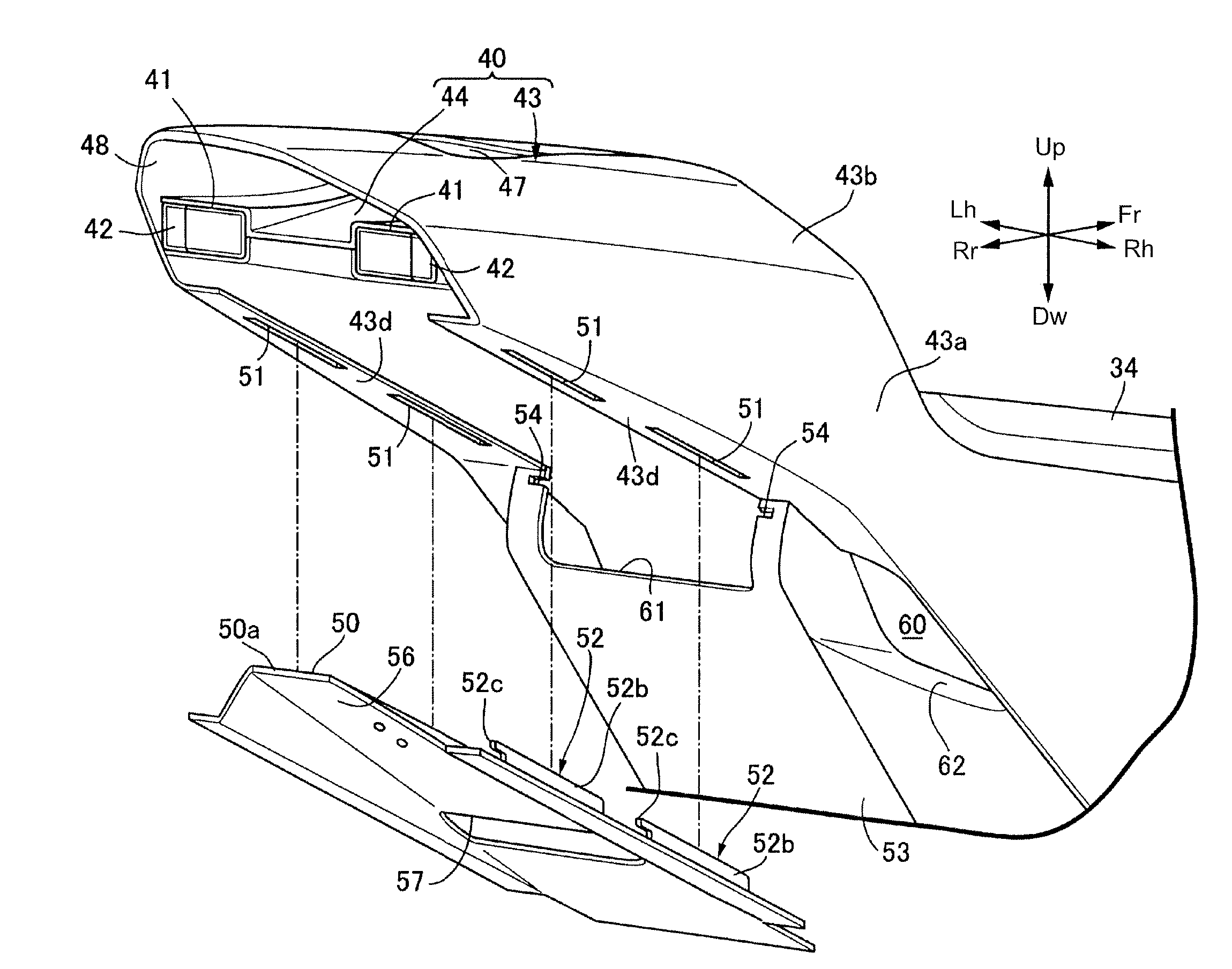

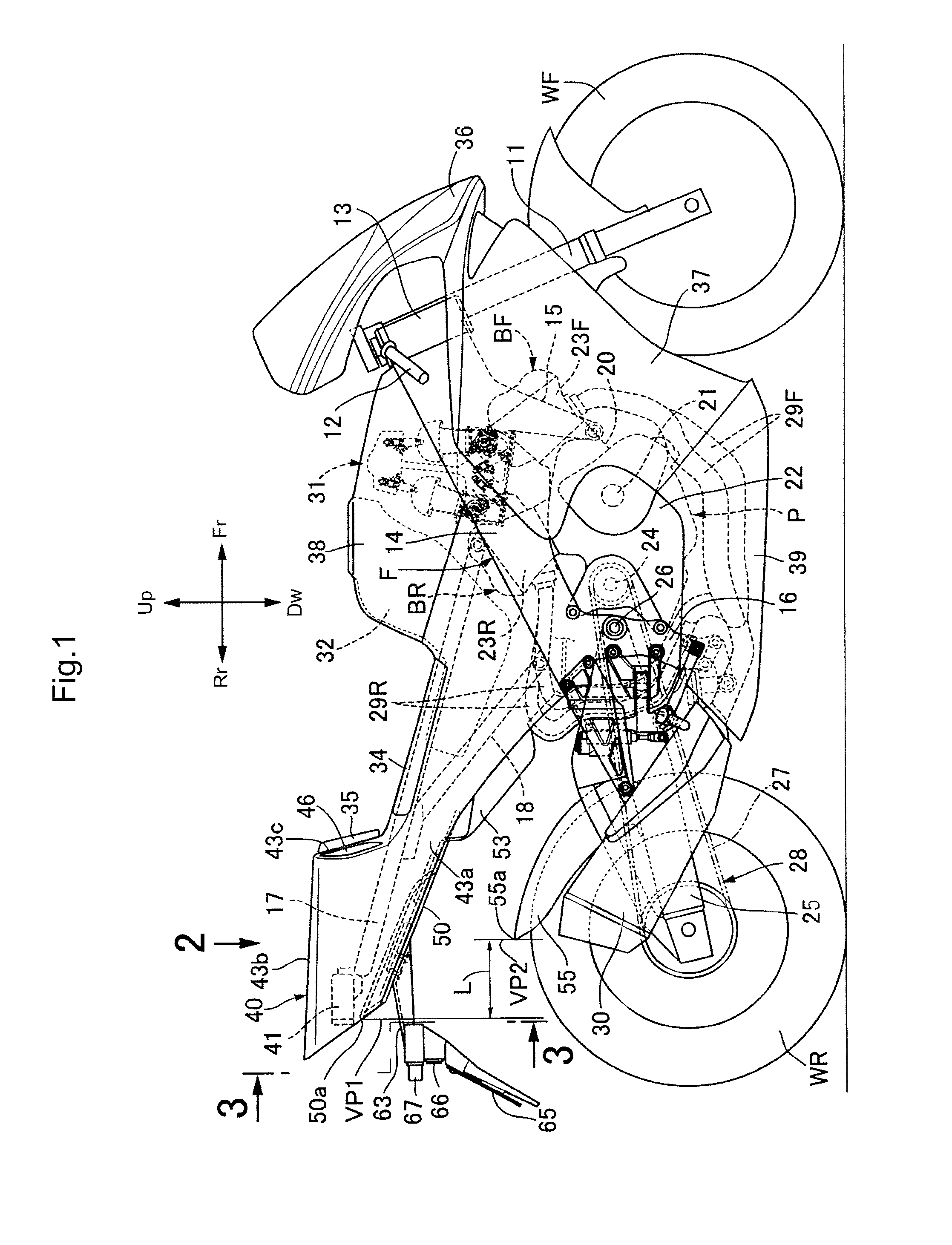

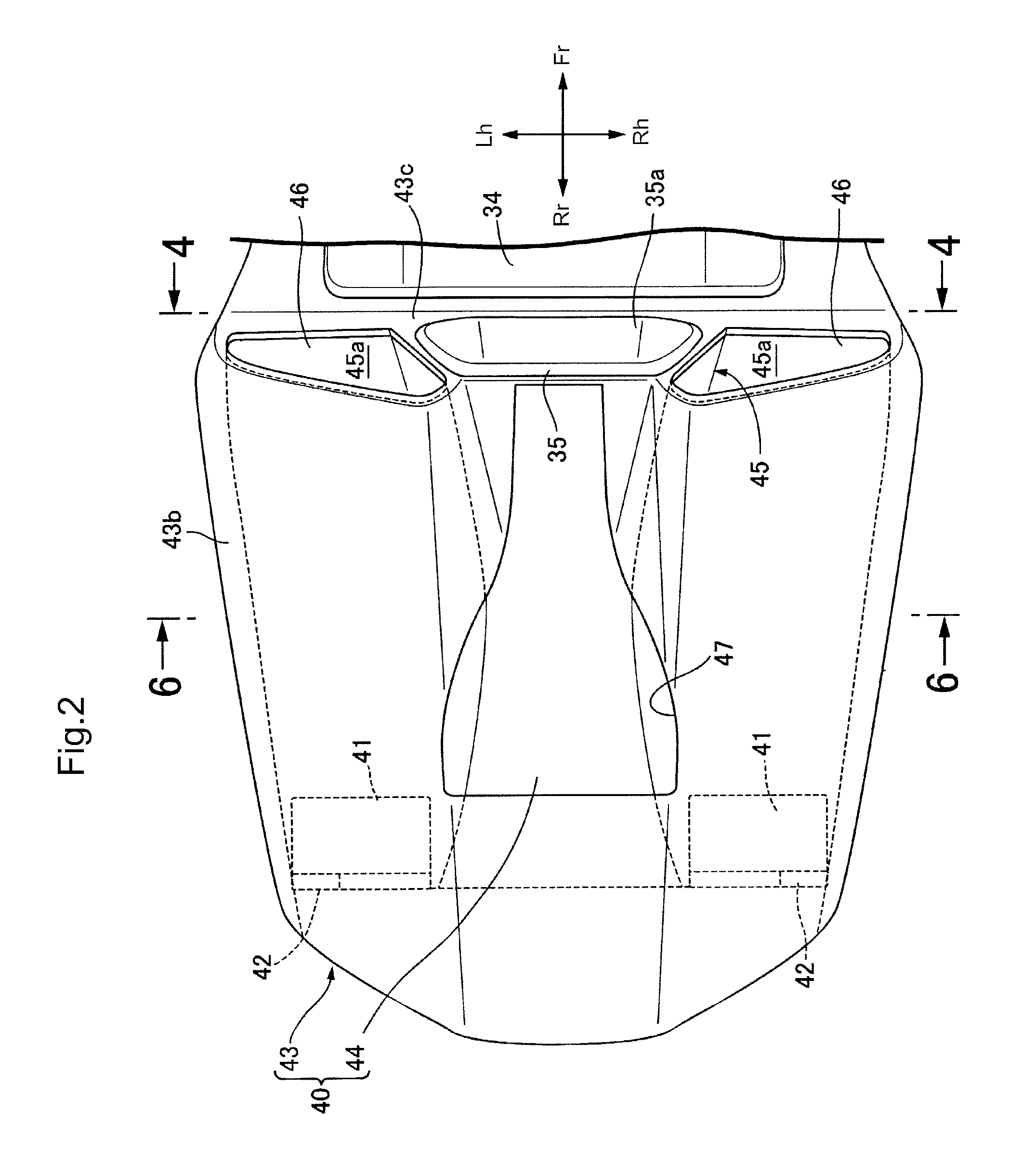

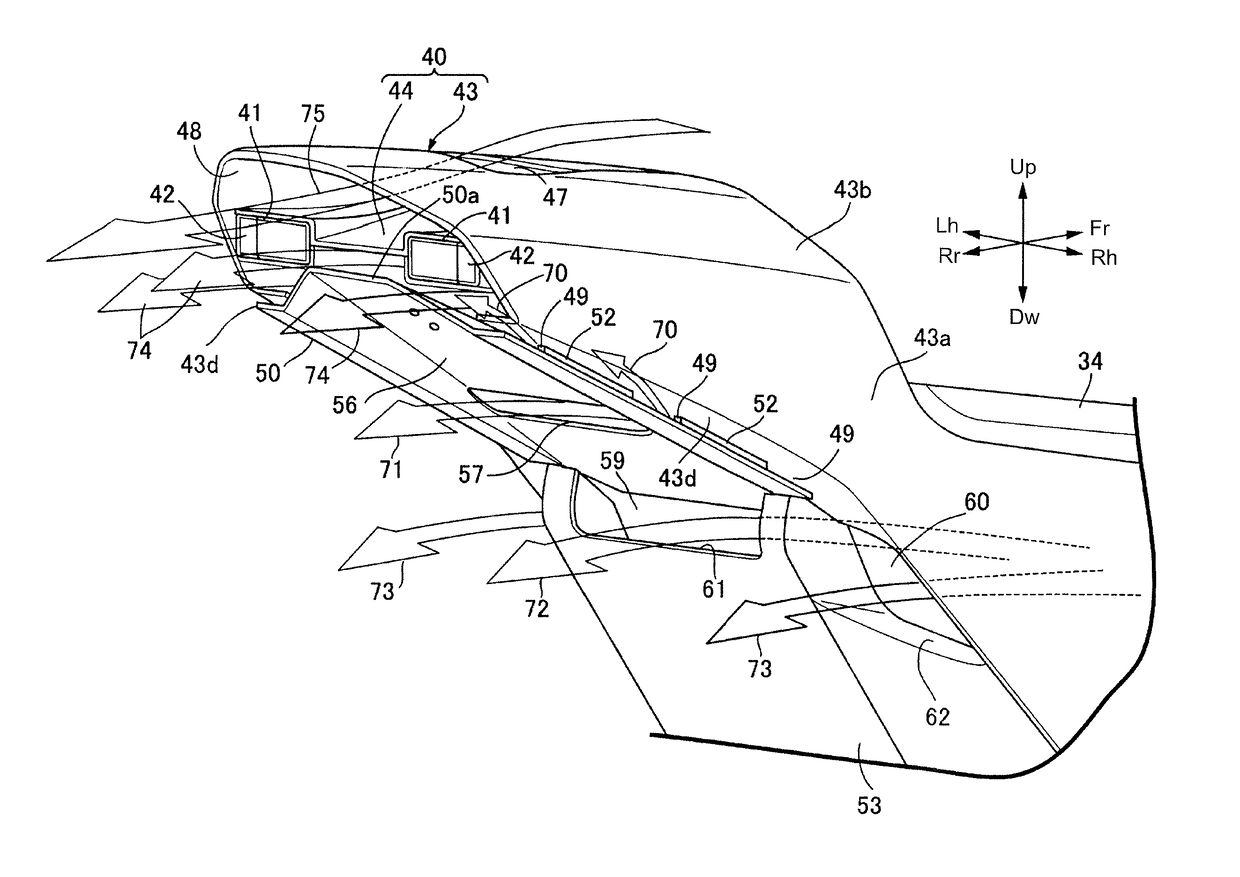

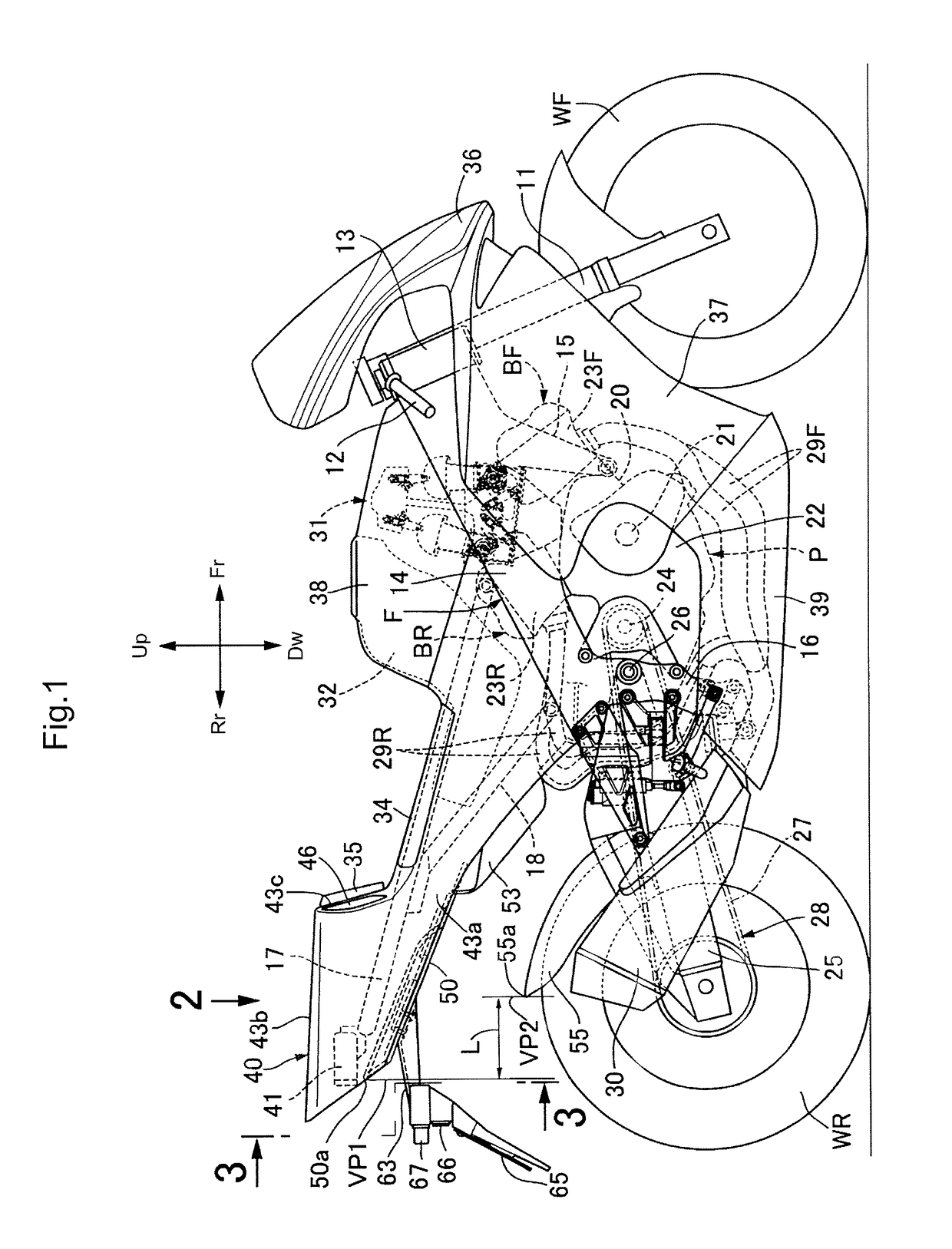

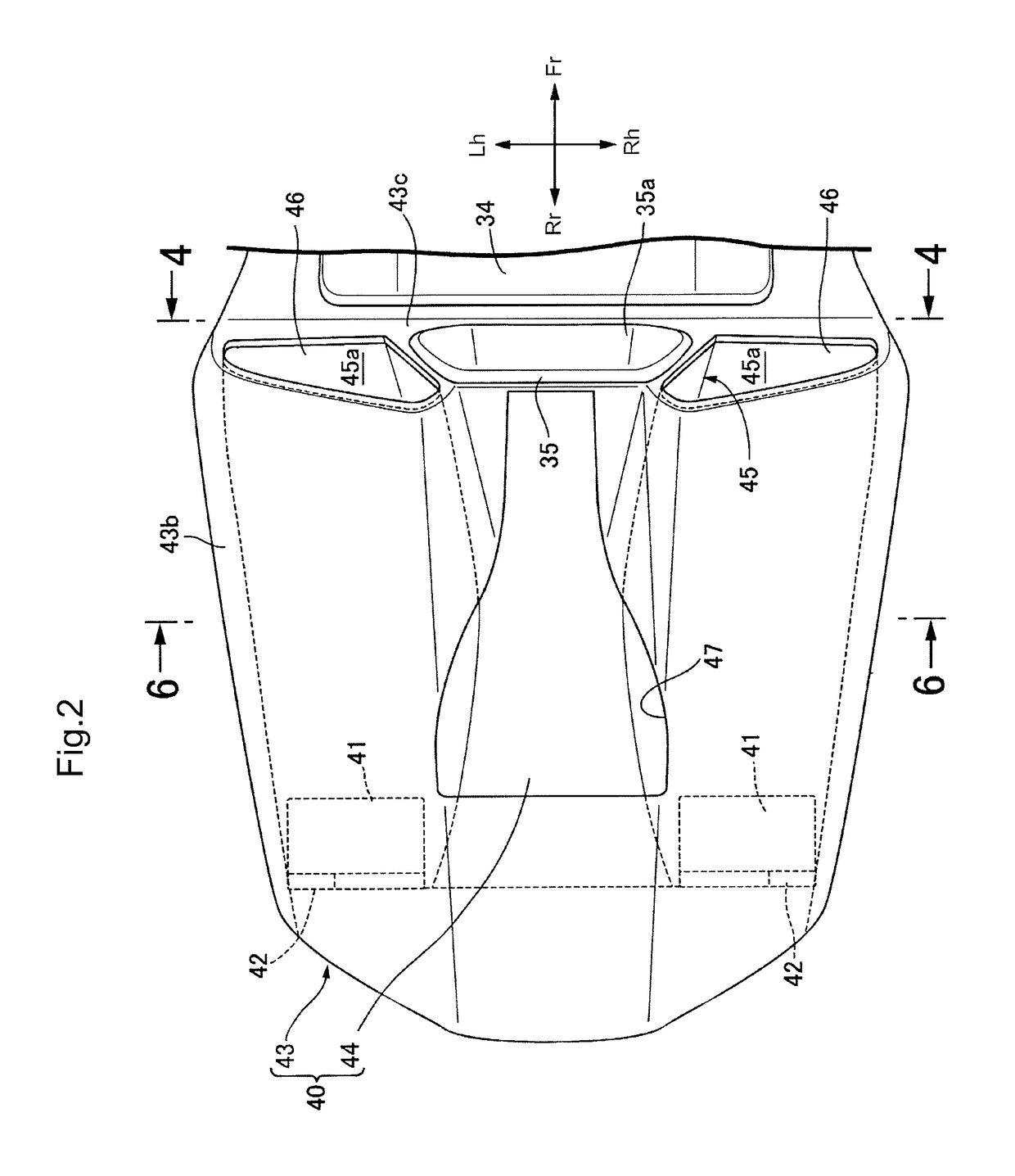

Rear structure of motorcycle

ActiveUS20170036711A1Reduce resistanceMore air flowVehicle body stabilisationOptical signalVisibilityPower unit

A motorcycle with a power unit for reducing the running resistance of a flow of air by effectively straightening the flow of air while ensuring the visibility of a tail light unit. The tail light unit emits light toward the rear of the vehicle and is arranged in a rear cowl which covers a rear part of the body frame at least behind an operator's seat. A straightening plate covers a rear part of a body frame F from below while allowing air flowing from a power unit to the rear to be straightened and discharged to the rear of the vehicle. The straightening plate is fixedly arranged below a rear cowl, which covers the rear part of the body frame from the side and above, behind an operator's seat.

Owner:HONDA MOTOR CO LTD

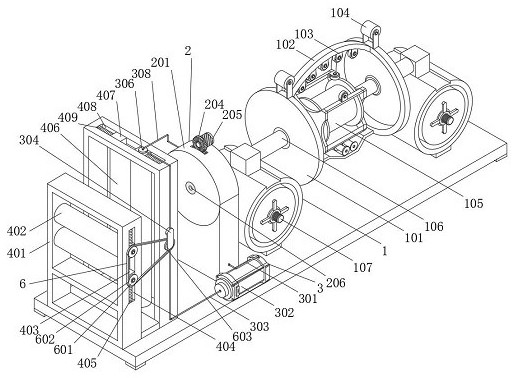

Titanium pipe straightening device

InactiveCN109894497AEffective straighteningStress reliefMetal-working feeding devicesHollow article cleaningHydraulic cylinderEngineering

The invention provides a titanium pipe straightening device. The titanium pipe straightening device comprises a feeding and conveying table and a straightening machine, wherein a plurality of door frames are sequentially arranged on the feeding and conveying table; first air cylinders are arranged at the left end and the right end of each door frame, and the top ends of the door frames are connected and fixed to hydraulic cylinders; infrared sensors are fixed to the first air cylinders, and hydraulic shafts of the hydraulic cylinders are connected and fixed to upper auxiliary rollers; cylindershafts of the first air cylinders are connected and fixed to fixed frames; feeding wheels are arranged in the fixed frames; a plurality of straightening assemblies are sequentially arranged on the straightening machine; blending assemblies are arranged between every two straightening assemblies; each blending assembly comprises a blending motor and a blending frame; the blending motors are connected and fixed to rotating shafts; the ends of the rotating shafts are sequentially connected with sleeves and the blending frames; and universal wheels are arranged in the blending frames, and cleaning wheels are connected to claw arms at the ends of the blending frames. The titanium pipe straightening device can effectively straighten and eliminate stress, reach a balance point and improve the safety and reliability of operation.

Owner:江苏天工科技股份有限公司

Cable pair twister with multi-direction cable production technology

ActiveCN113643860AQuick straighteningGuaranteed straightening accuracyCable/conductor manufactureStructural engineeringElectric cables

The invention discloses a cable pair twister with a multi-direction cable production technology, belonging to the technical field of cable production equipment. The cable pair twister comprises a pair twisting mechanism, wherein a burr cleaning mechanism is arranged on one side, corresponding to a cable core conveying direction, of the pair twisting mechanism. Through mutual cooperation of a designed straightening assembly, a self-debugging assembly, a linkage assembly, a drainage assembly, the burr cleaning mechanism and other structures, a quick torsion-free straightening function of a reel cable core is achieved; particularly, a disc-shaped copper-aluminum cable core can be effectively and quickly straightened, and on the basis of ensuring high efficiency, the straightening precision of a first straightening roll and a second straightening roll on a cable inner core can be guaranteed, flexible strain capacity is high, and straightening work can be conducted on cable inner cores of different models; and acting force acting on the cable inner core can be automatically kept along with the abrasion degree of the surfaces of the first straightening roll and the second straightening roll, and the quality of a processed cable is prevented from being influenced by too large pressure or too small action.

Owner:江苏昕讯光电科技有限公司

Hot-straightening process for thin-gauge coiling rolling plate

InactiveCN104998926AFix for not being able to bite into the levelerEffective straighteningEngineeringMechanical engineering

The invention discloses a hot-straightening process for a thin-gauge coiling rolling plate. When a straightener operator finds the head part of the coiling rolling plate is warped, and the steel plate cannot be normally gripped into the straightener, a roll container fast lifting button is pressed immediately, so that a straightener roll container is fast lifted to a preset position, and meanwhile, a first stage calculates and tracks the position of the head part of the steel plate by utilizing a heat detector in front of the straightener, the roll speed and time; when the head part of the steel plate penetrates out of the straightener, the steel plate is kept in a moving state, so that subsequent steel plates are prevented from being laminated; the first stage automatically sets the straightening roll seam to a target value according to the straightening process of an operating console, and the straightening roll seam is kept unchanged, thus all the subsequent steel plates are straightened until the straightening is finished. By adopting the hot-straightening process disclosed by the invention, the problem that the head-warped thin-gauge coiling rolling plate cannot be subjected to hot-straightening is successfully solved, and the hot-straightening qualification rate of the thin-gauge coiling rolling plates is improved.

Owner:NANJING IRON & STEEL CO LTD

Metal wire rod precision alignment cutting device and method

Owner:JINDUICHENG MOLYBDENUM CO LTD

Garment edge folding and locking device

InactiveCN113584743AEffective straighteningOperation time savingWork-feeding meansElectric machineryStructural engineering

The invention discloses a garment edge folding and locking device. The device comprises a workbench, and supporting legs are fixedly connected to the four corners of the workbench. Firstly, a fabric is laid on the workbench, the two ends of the fabric cover two rollers respectively, and other redundant fabric is placed in a second through hole; the two ends of the fabric are folded and the folded fabric is pressed tightly through cooperative use of L-shaped sliding rods, sleeves, the rollers and L-shaped fixed rods; then a transverse plate descends through operation of an electric telescopic rod; in the descending process, through cooperative use of a second sliding rod, a round rod and a second spring, the stacked fabric is effectively stretched straight; then the fabric is pressed and fixed through cooperative use of first sliding rods, first springs and a pressing plate, and meanwhile, a pressing wheel descends to press the folded fabric; and then motors are started to operate, the L-shaped rods in threaded connection with threaded rods drive a hemming mechanism to move towards one side, and meanwhile, the hemming mechanism operates to carry out edge locking operation on the folded fabric.

Owner:福建泉州爱格乐制衣有限公司

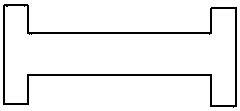

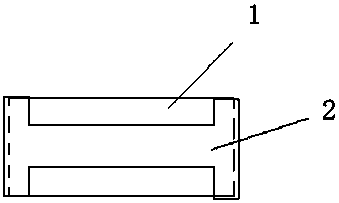

Plate overlapping straightening process for waved surfaces on two sides of ultra-thin middle-thick plate

ActiveCN105080969AEffective straighteningLarge amount of elastic deformationMetal rolling arrangementsThick plateSheet steel

The invention discloses a plate overlapping straightening process for waved surfaces on two sides of an ultra-thin middle-thick plate. An I-shaped lining plate is overlapped on the plate to be straightened so as to be straightened together with the plate to be straightened. Tension is generated in the middle area in the width direction of the steel plate in the straightening process. The elastic deformation amount of a middle thick layer of the middle area in the width direction of the steel plate is increased. The waved surfaces on the two sides of the ultra-thin middle-thick plate are effectively straightened. The plate overlapping straightening process includes the steps that the lining plate is manufactured, and the I-shaped liming plate is aligned with the plate to be straightened; a first time of straightening is carried out, and the plastic deformation amount is 80%; a second time of straightening is carried out, and the plastic deformation amount is 80%. According to the plate overlapping straightening process, the -shaped lining plate is overlapped on the plate to be straightened so as to be straightened together with the plate to be straightened, tension is generated in the middle area in the width direction of the steel plate in the straightening process, and the elastic deformation amount of a middle thick layer of the middle area in the width direction of the steel plate is increased. Finally, the waved surfaces on the two sides of the ultra-thin middle-thick plate are effectively straightened.

Owner:NANJING IRON & STEEL CO LTD

Cable linearity keeping device and equipment

PendingCN109277485AImprove straight line holding performanceEffective straighteningOblique angleLinearity

The invention discloses a cable linearity keeping device and equipment, and relates to the field of straightening devices. Particularly, the cable linearity keeping device comprises a first straightening assembly used for straightening a cable in the horizontal direction, a second straightening assembly used for straightening the cable in the vertical direction, and a third straightening assemblyused for straightening the cable in the oblique angle direction. The multiple straightening assemblies can press the cable in the vertical direction, horizontal direction and oblique angle direction,the cable is continuously straightened through the multiple straightening assemblies, convex portions can be effectively pressed and straightened, and the cable linearity keeping performance is improved.

Owner:NINGXIA RUIYIN NONFERROUS METAL TECH CO LTD

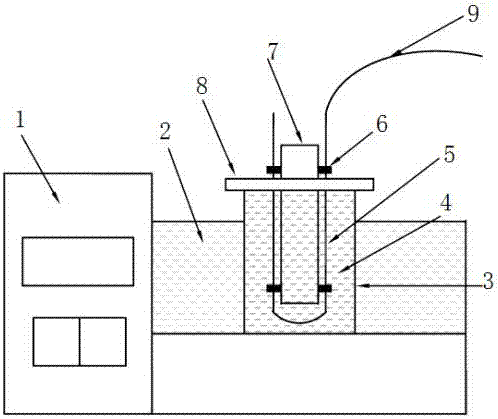

Fiber bragg grating surface metallization device

InactiveCN108004528AIncrease stressEffective straighteningLiquid/solution decomposition chemical coatingWater bathsFiber

The invention discloses a fiber bragg grating surface metallization device comprising a water bath kettle. Water is contained in the water bath kettle, a beaker is further supported in the water bathkettle, and the water surrounds the beaker and is used for heating the beaker. A supporting plate is arranged at the top of the beaker, a plating solution for chemical plating is contained in the beaker, and a fixing frame is vertically arranged on the supporting plate and inserted into the plating solution. A fiber bragg grating is bonded to the fixing frame through a glue bonding piece, a to-be-plated part of the fiber bragg grating is arranged in the plating solution in the beaker and is in a straightened state under the effect of the fixing frame and the glue bonding piece. The fiber bragggrating surface metallization device has the beneficial effects that according to the fiber bragg grating surface metallization device, in the chemical plating process, the to-be-plated part of the fiber bragg grating can be effectively straightened, and thus stress of the fiber bragg grating subjected to film plating is prevented from being over large.

Owner:苏州协同创新智能制造科技有限公司

Yarn guiding device

The invention relates to a yarn guiding device, and belongs to the technical field of textile machinery. The yarn guiding device comprises a guiding block (1), a shell (2) and a vortex tube (6), wherein the guiding block (1) is arranged in the shell (2), the guiding block (1) comprises a cylindrical guiding block base body (10) and a conical boss (7), a positioning block (11) is arranged at the rear end of the cylindrical guiding block base body (10), the front side of the portion, from the front end to the middle, of the cylindrical guiding block base body (10) is cut off to form a second guiding face (12), the front side of the portion, from the middle to the positioning block (11) at the rear end, of the cylindrical guiding block base body (10) is cut off to form a first guiding face (3), and the front side of the portion from the front end of the cylindrical guiding block base body (10) to the front end of the conical boss (7) is cut off to form a third guiding face (13). According to the yarn guiding device, the rotational speed of air flow inside a swirl chamber can be increased, the twisting speed of yarn is high, the yield of the final yarn is increased, and the breaking strength of the final yarn is improved.

Owner:江阴市华方新技术科研有限公司

Rear structure of motorcycle

ActiveUS9975586B2Reduce resistanceMore air flowVehicle body stabilisationOptical signalVisibilityPower unit

A motorcycle with a power unit for reducing the running resistance of a flow of air by effectively straightening the flow of air while ensuring the visibility of a tail light unit. The tail light unit emits light toward the rear of the vehicle and is arranged in a rear cowl which covers a rear part of the body frame at least behind an operator's seat. A straightening plate covers a rear part of a body frame F from below while allowing air flowing from a power unit to the rear to be straightened and discharged to the rear of the vehicle. The straightening plate is fixedly arranged below a rear cowl, which covers the rear part of the body frame from the side and above, behind an operator's seat.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com