Simple and convenient reinforcing steel bar straightening tool

A steel bar and straightening technology, applied in the field of tools, can solve the problems of small number of end wrenches, inconvenient use, affecting the quality and progress of the project, and achieve the effects of ensuring integrity and functionality, reducing engineering costs, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The simple steel bar straightening tool of the present invention comprises a straightening head, a handle and a sleeve.

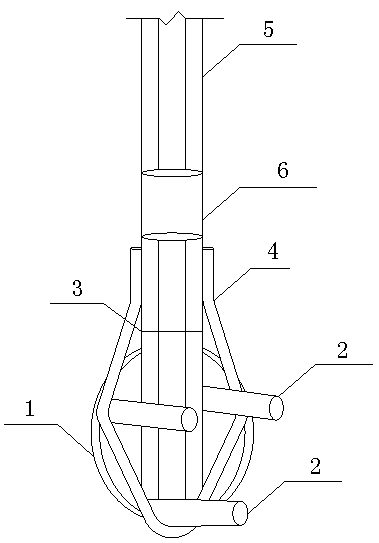

[0028] see now figure 1 , figure 1 It is a structural schematic diagram of a steel bar straightening tool according to an embodiment of the present invention. As shown in the figure, the straightening head includes a circular plate 1, three straightening rods 2, a connecting rod 3, and a hoop 4. The circular plate is a circular steel plate with a diameter ≥ 140 mm and a thickness ≥ 12 mm; the three straightening rods are three Short steel bars, each short steel bar has a diameter of 25mm and a length of 100mm, and the three short steel bars are arranged in an isosceles triangle on the surface of the circular steel plate. The distance between the three straightening rods should be greater than 60mm, and each short steel bar is perpendicular to the circular plate; A number of steel bars are bundled and welded together to form the first steel tendon. ...

Embodiment 2

[0032] Simple steel bar straightening tool using method of the present invention:

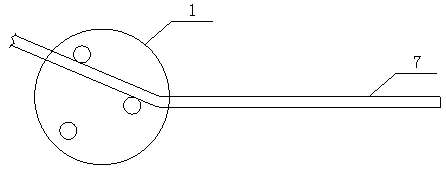

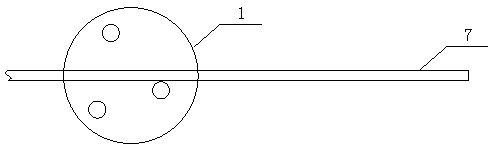

[0033] When the steel bar is straightened, the on-site operator holds the handle with both hands, clamps any two of the straightening rods on both sides of the bent part of the steel bar, pushes the handle to the adjustment direction required by the steel bar, and repeats fine-tuning until the The straight state required by the steel bar to achieve the straightening effect of the steel bar. figure 2 It is a schematic diagram of the use state of the steel bar straightening tool of the embodiment of the present invention, image 3 It is a schematic diagram of straightening the steel bar 7 to be straightened according to the embodiment of the present invention.

[0034] The present invention has substantive features and significant technical progress. The simple steel bar straightening tool of the present invention can effectively straighten bent and deformed steel bars while maintaining quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com