A yarn guiding device

A yarn guide and guide block technology, applied in textiles and papermaking, etc., can solve the problems of slow fiber twisting speed, slow air rotation speed, weak twist yarn, etc., to reduce the generation mechanism, increase twisting speed, The effect of increasing the breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

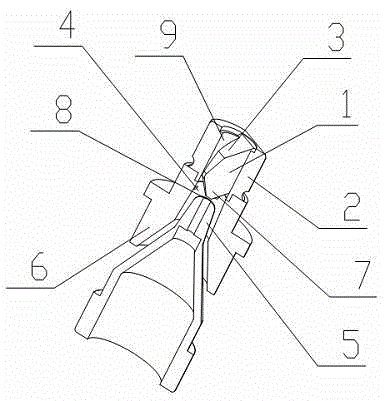

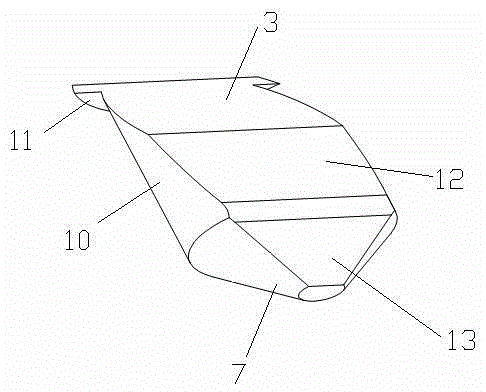

[0027] see figure 1 , figure 2 , a yarn guiding device of the present invention, which includes a guiding block 1, a casing 2 and a vortex tube 6, the guiding block 1 is arranged in the casing 2, and the guiding block 1 includes a cylindrical guiding block The base 10 and the conical boss 7, the conical boss 7 is arranged on the front end of the cylindrical guide block base 10, the rear end of the cylindrical guide block base 10 is provided with a positioning block 11, the The front end of the cylindrical guide block base 10 is cut to the middle to form the second guide surface 12, and the front of the cylindrical guide block base 10 to the rear end positioning block 11 is cut to form the first guide surface 3. The slope of the guide surface 3 is greater than that of the second guide surface 12. The front end of the cylindrical guide block base body 10 is cut off from the front end of the conical boss 7 to form a third guide surface 13. The second guide surface 12 It transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com