Patents

Literature

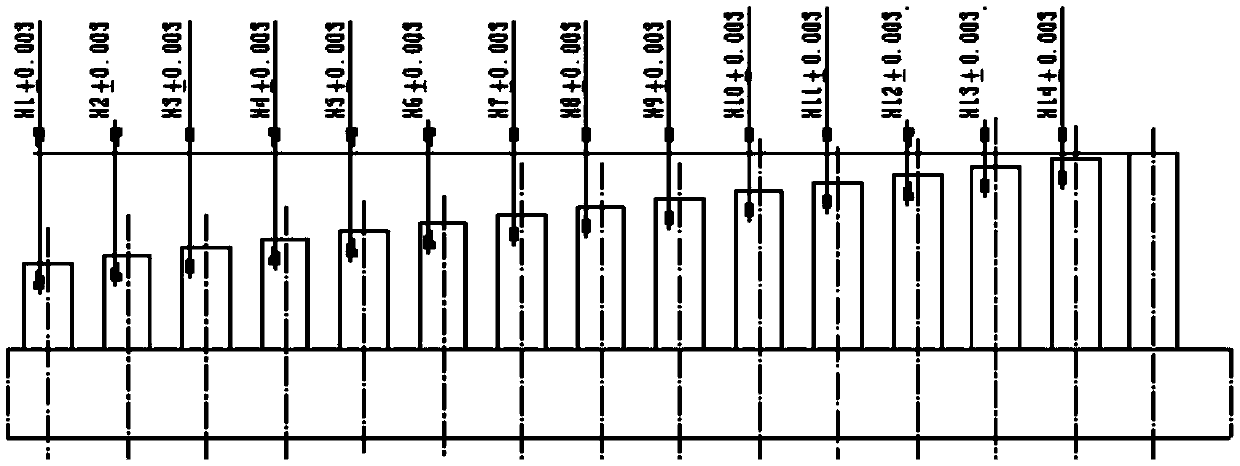

31results about How to "Accurate flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

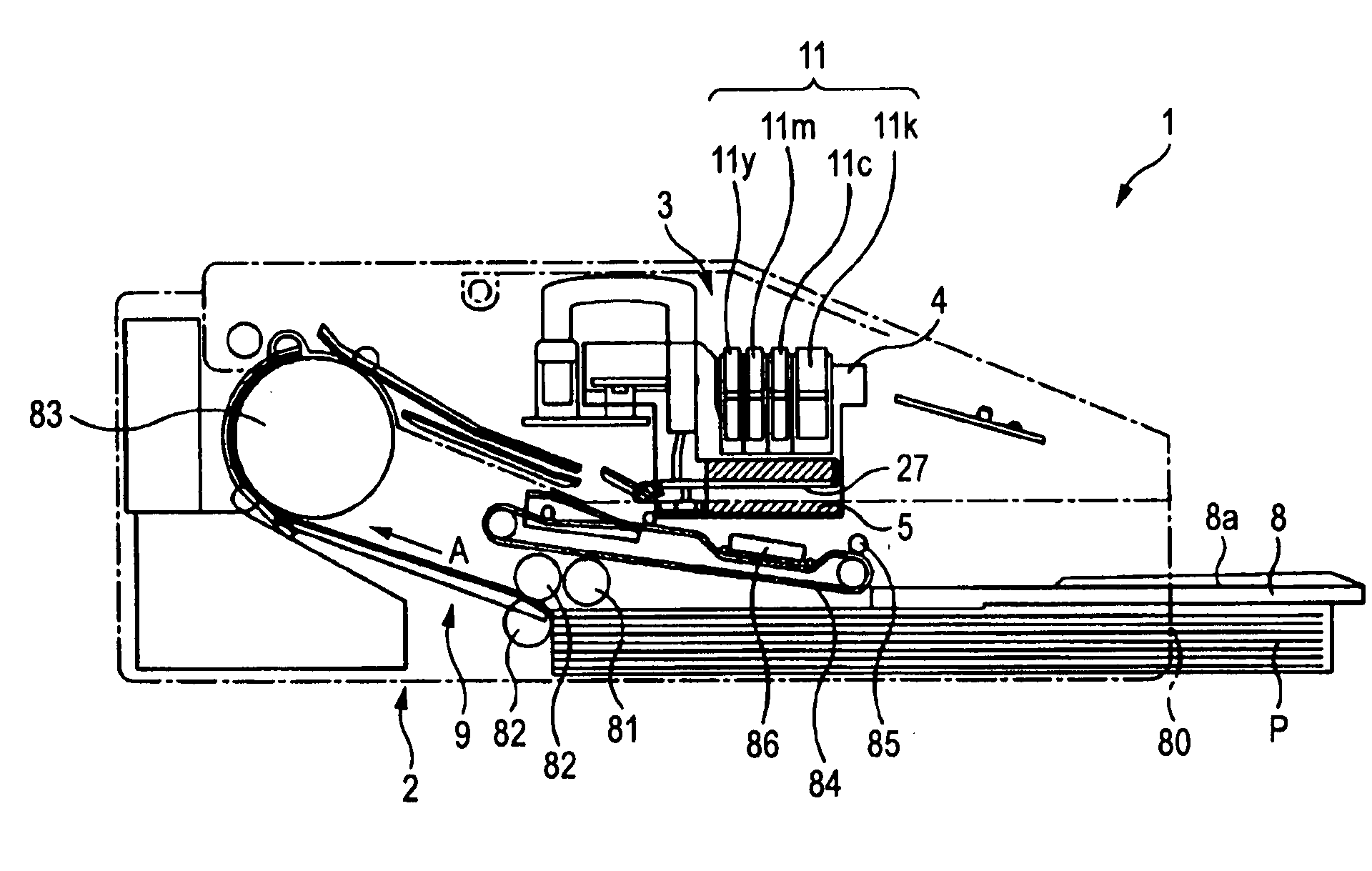

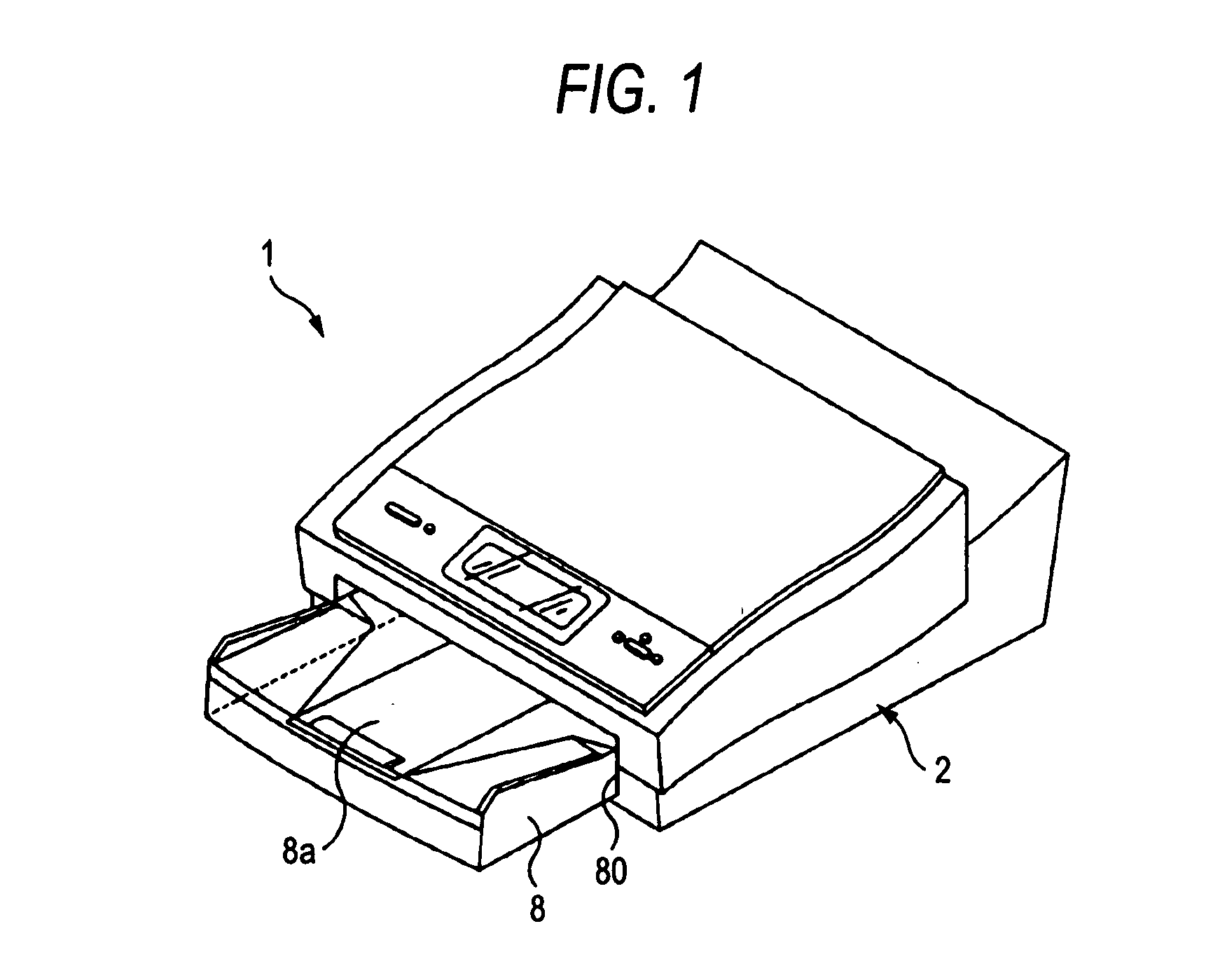

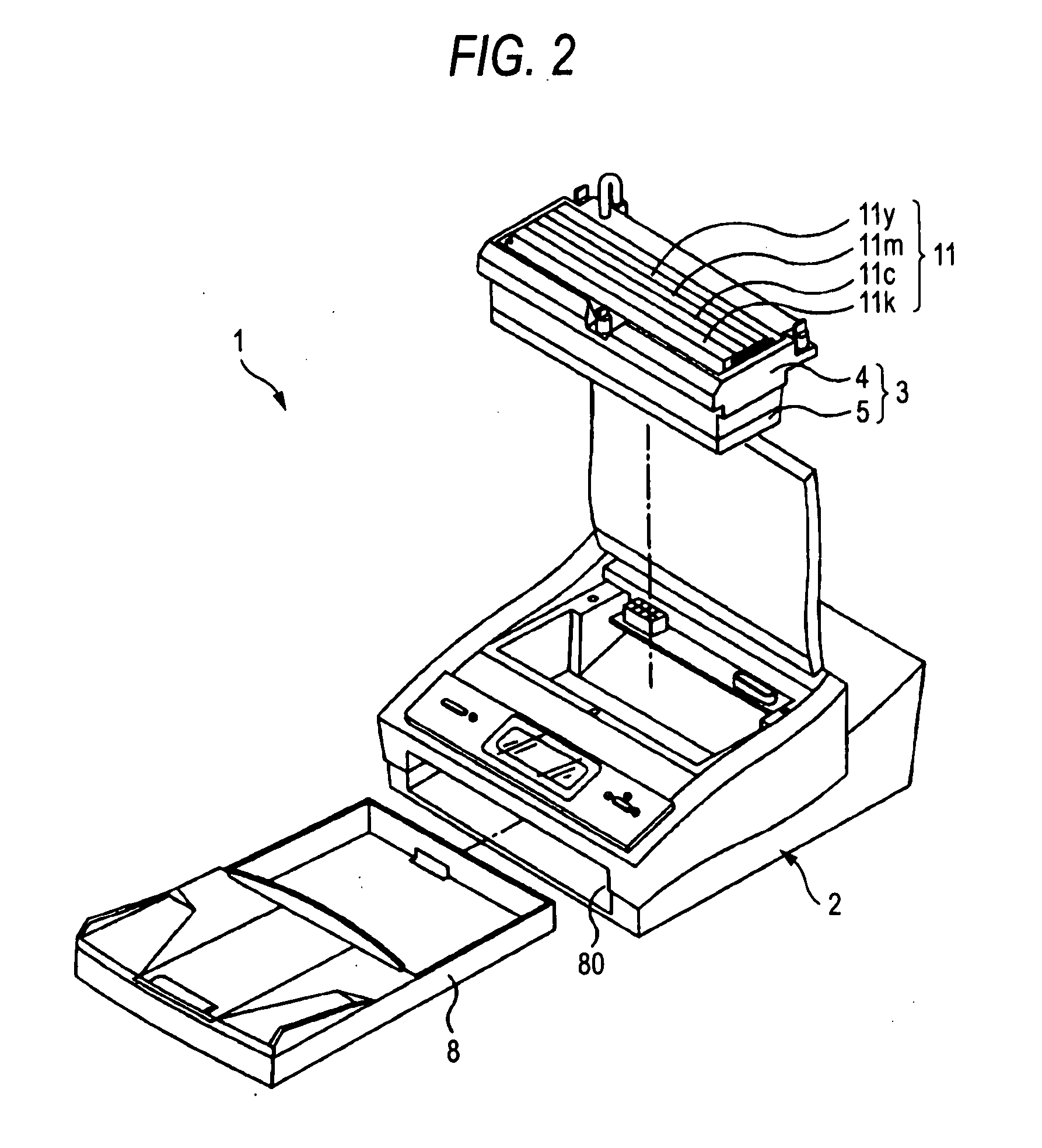

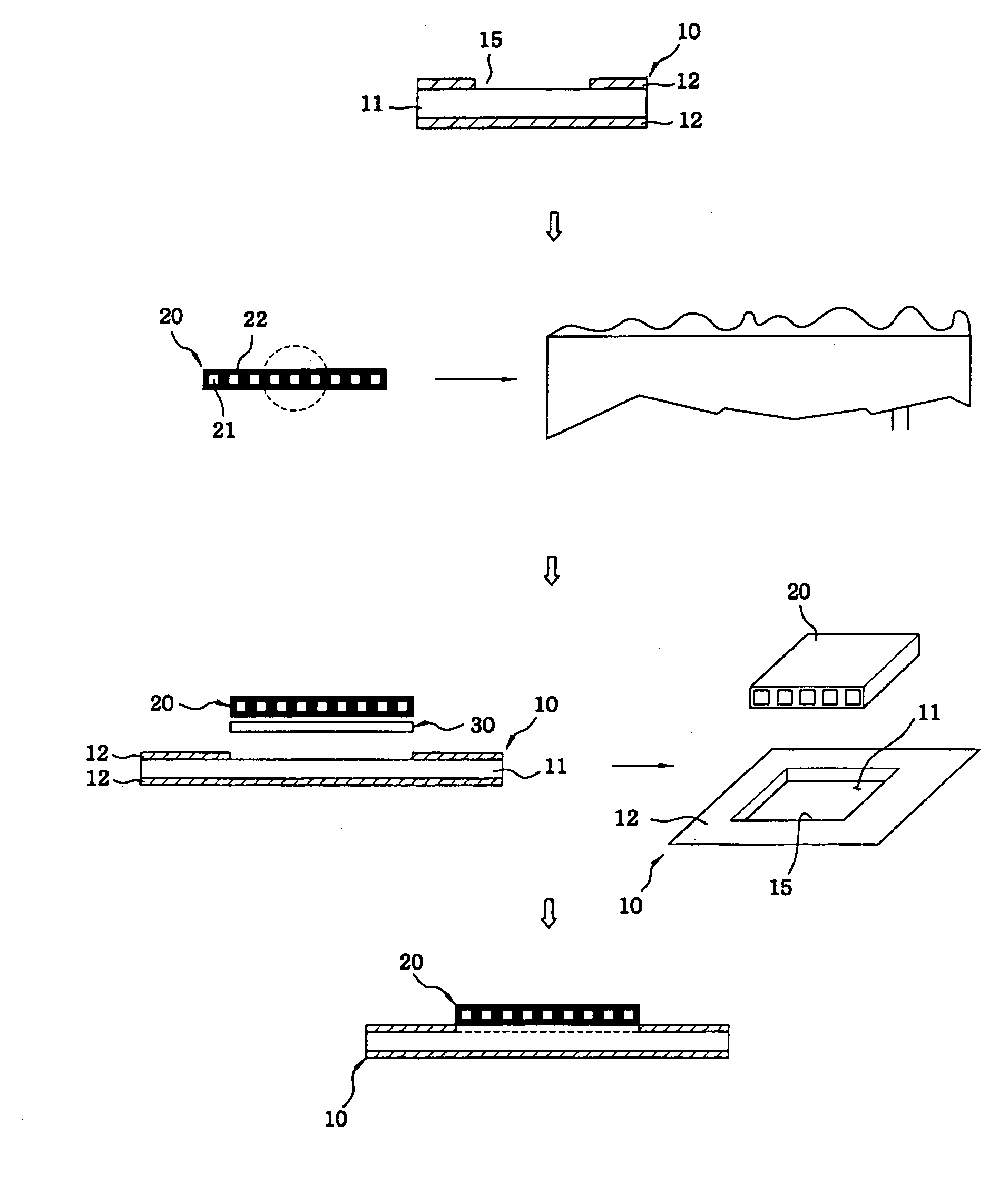

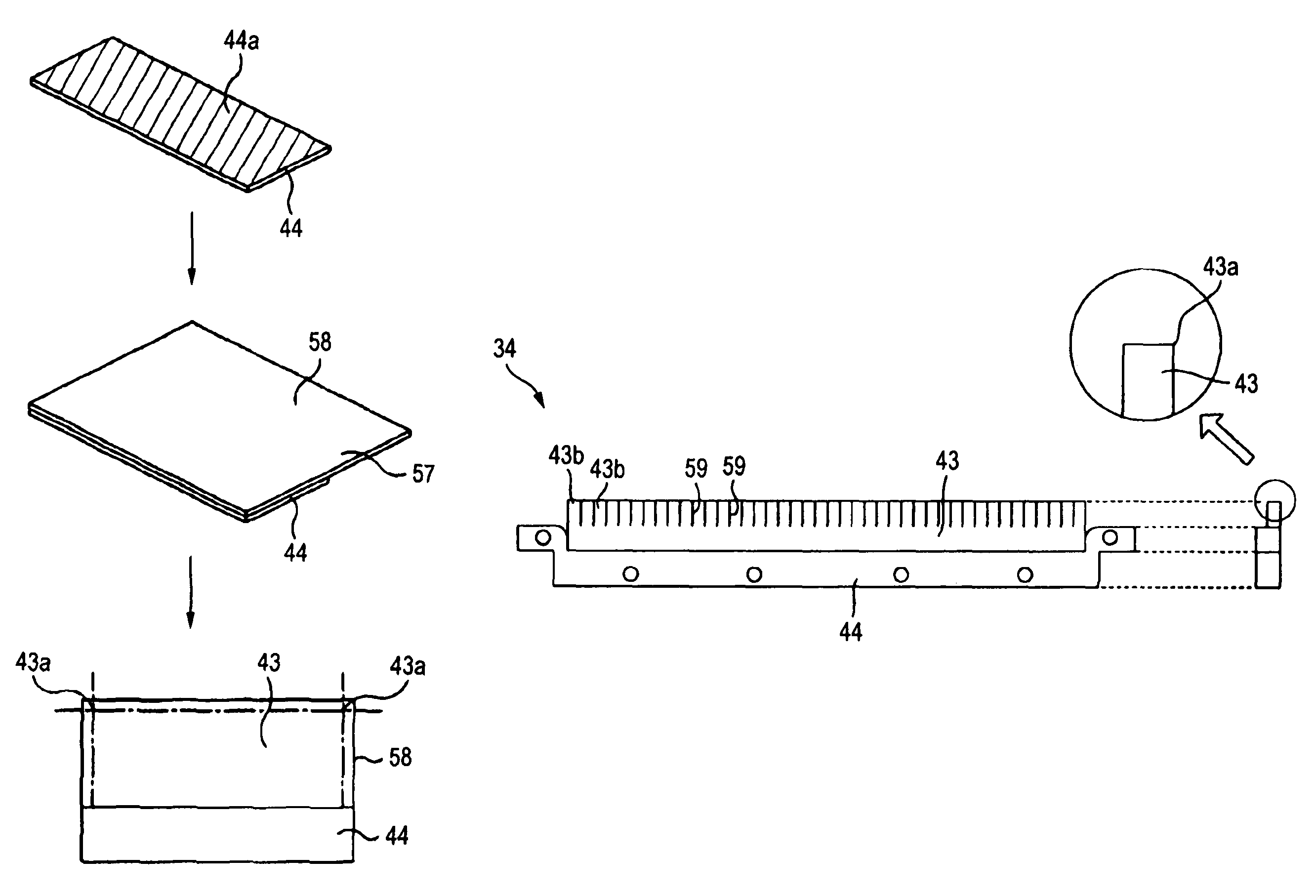

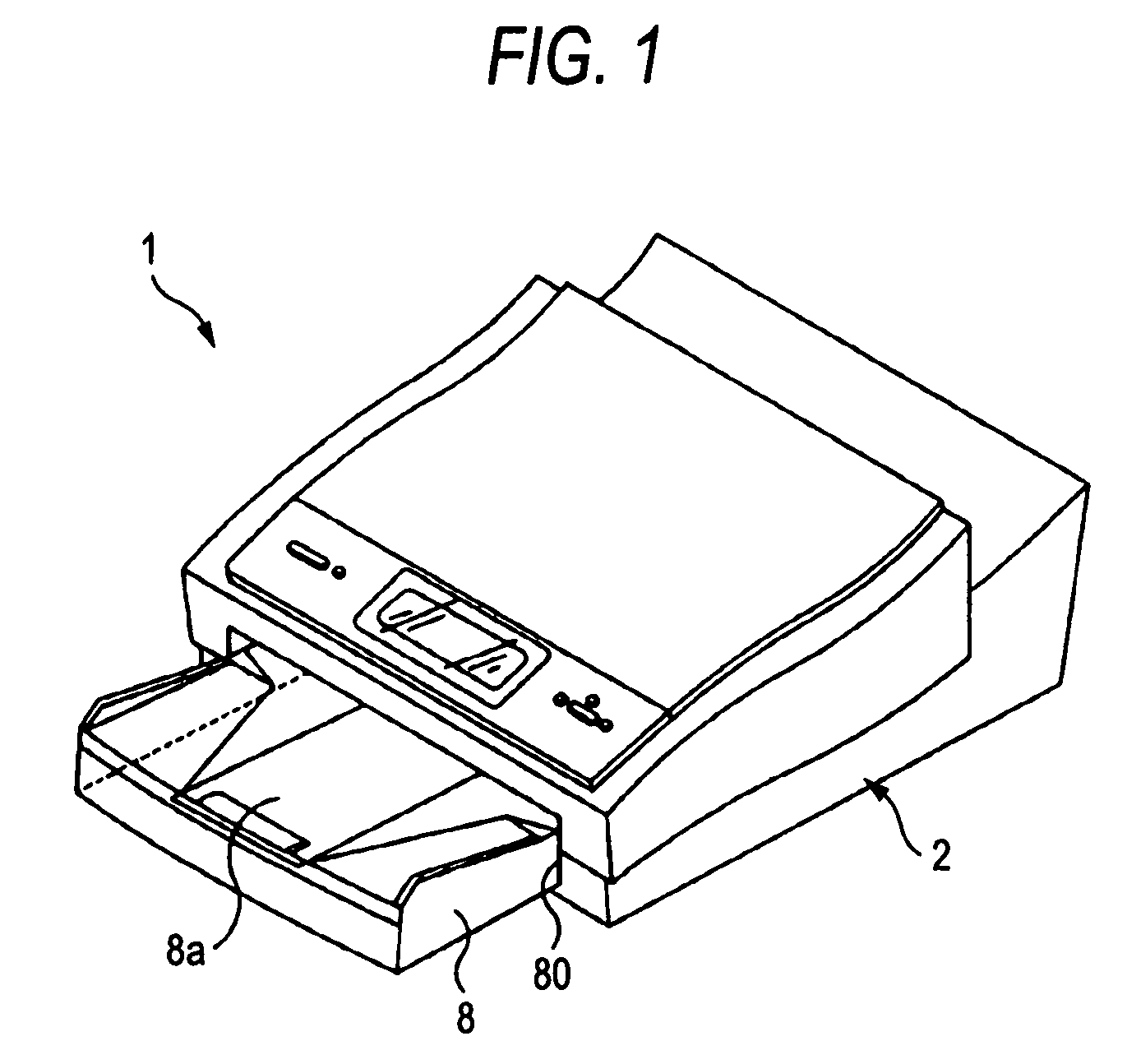

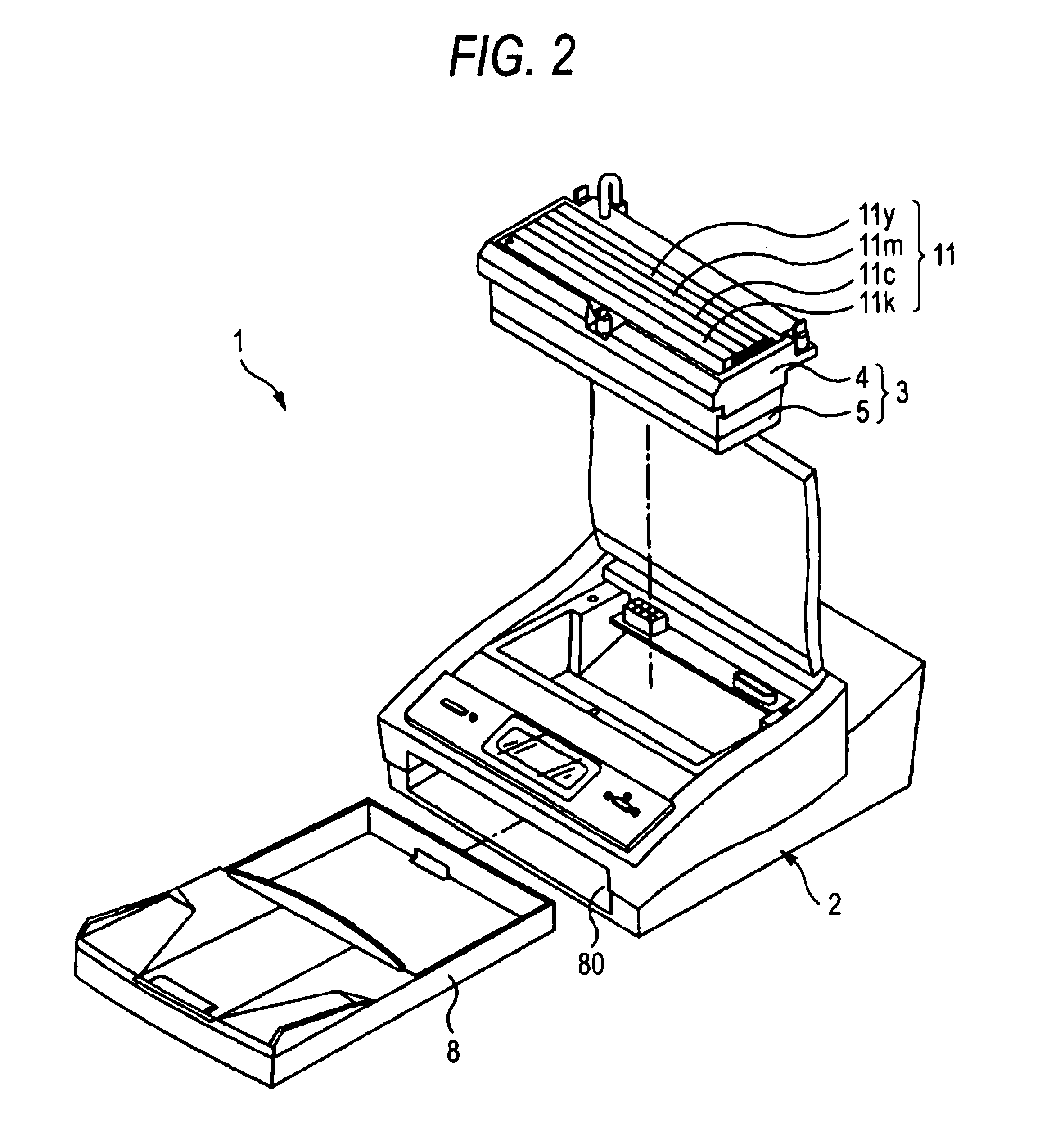

Cleaning blade, method fabricating cleaning blade, and cleaning apparatus for liquid discharge head

A cleaning blade which wipes a liquid discharge area by being moved relatively with respect to the liquid discharge area of a liquid discharge head having the liquid discharge area in which liquid discharge nozzles are arranged to discharge a liquid is disclosed. The cleaning blade includes: a supporting plate which has an adhesive agent layer on its front surface; and a wipe part which is slid and contacted with the liquid discharge area, the wipe part formed in which an elastic part formed of a synthetic resin is formed in one piece on the adhesive agent layer, and a tip end thereof is cut in a predetermined shape.

Owner:SONY CORP

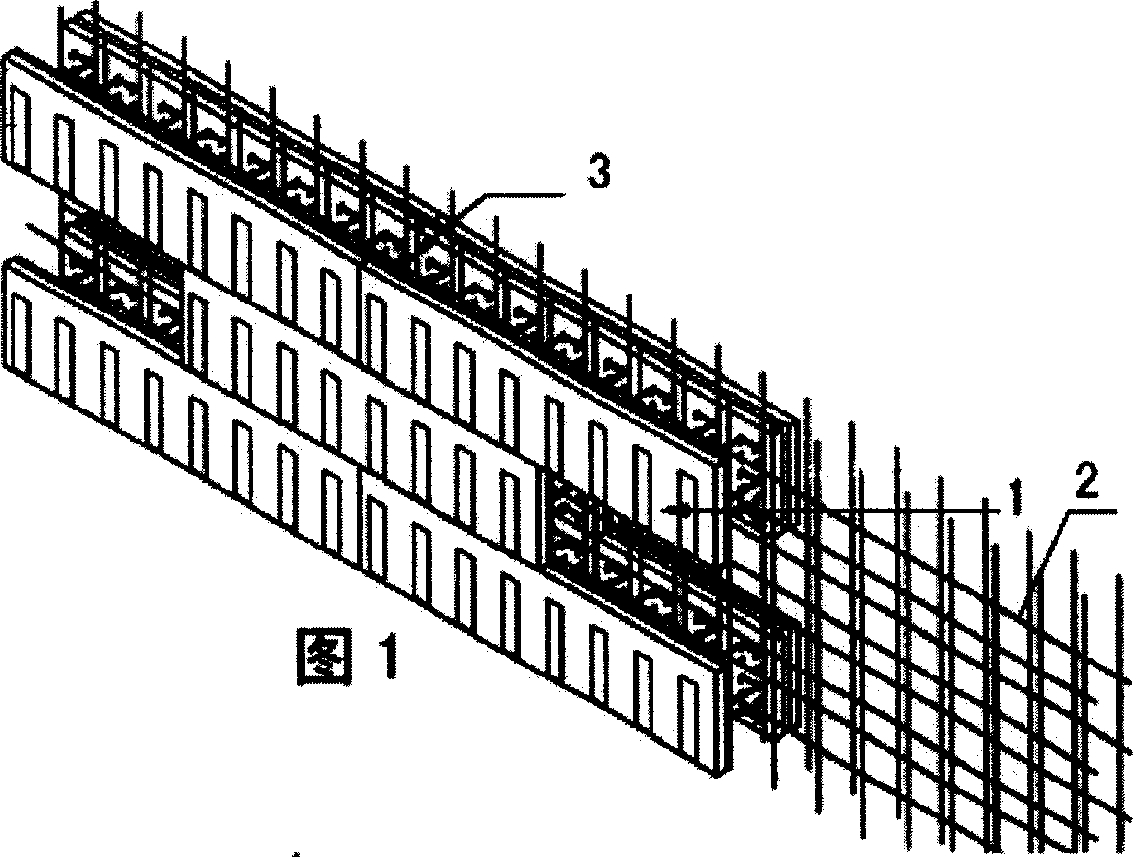

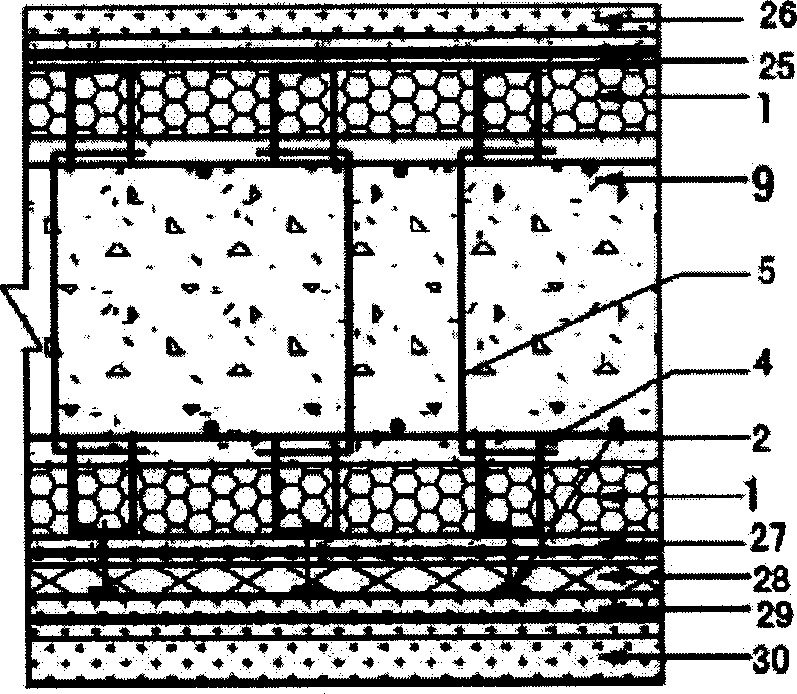

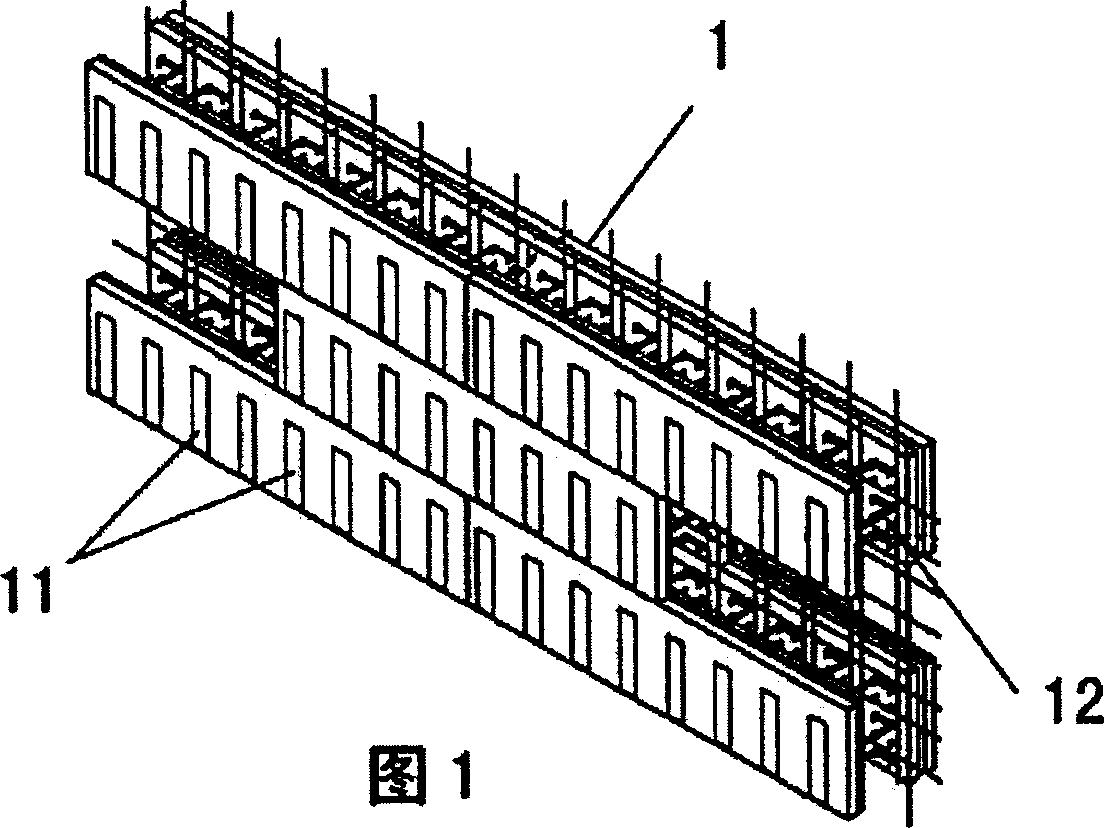

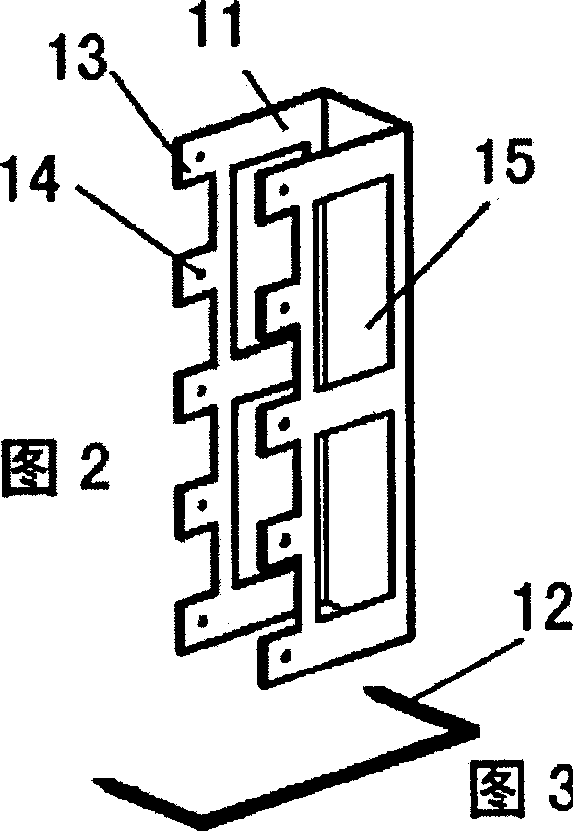

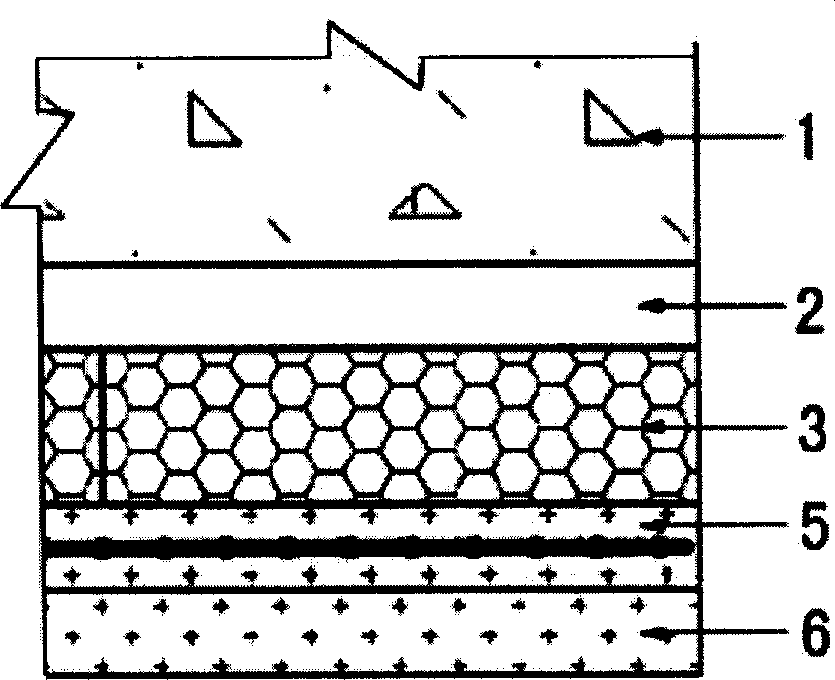

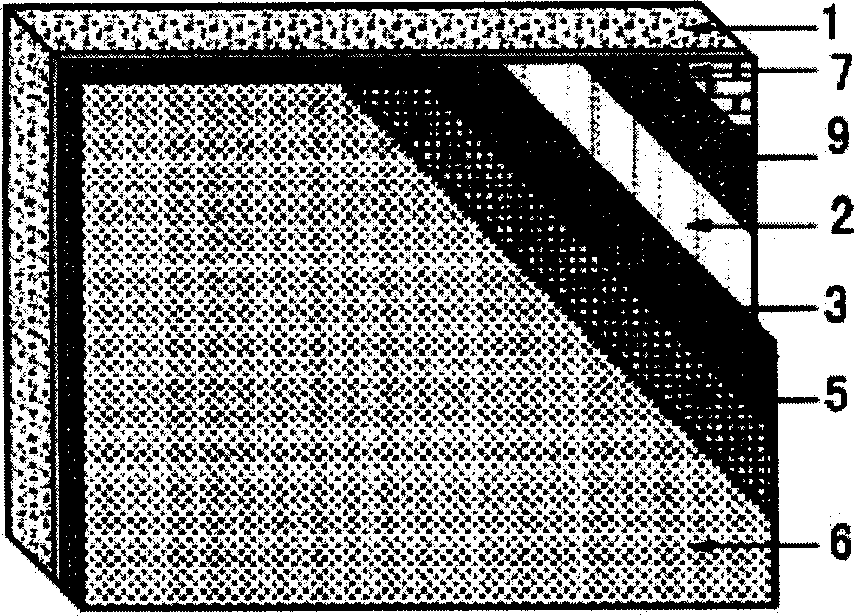

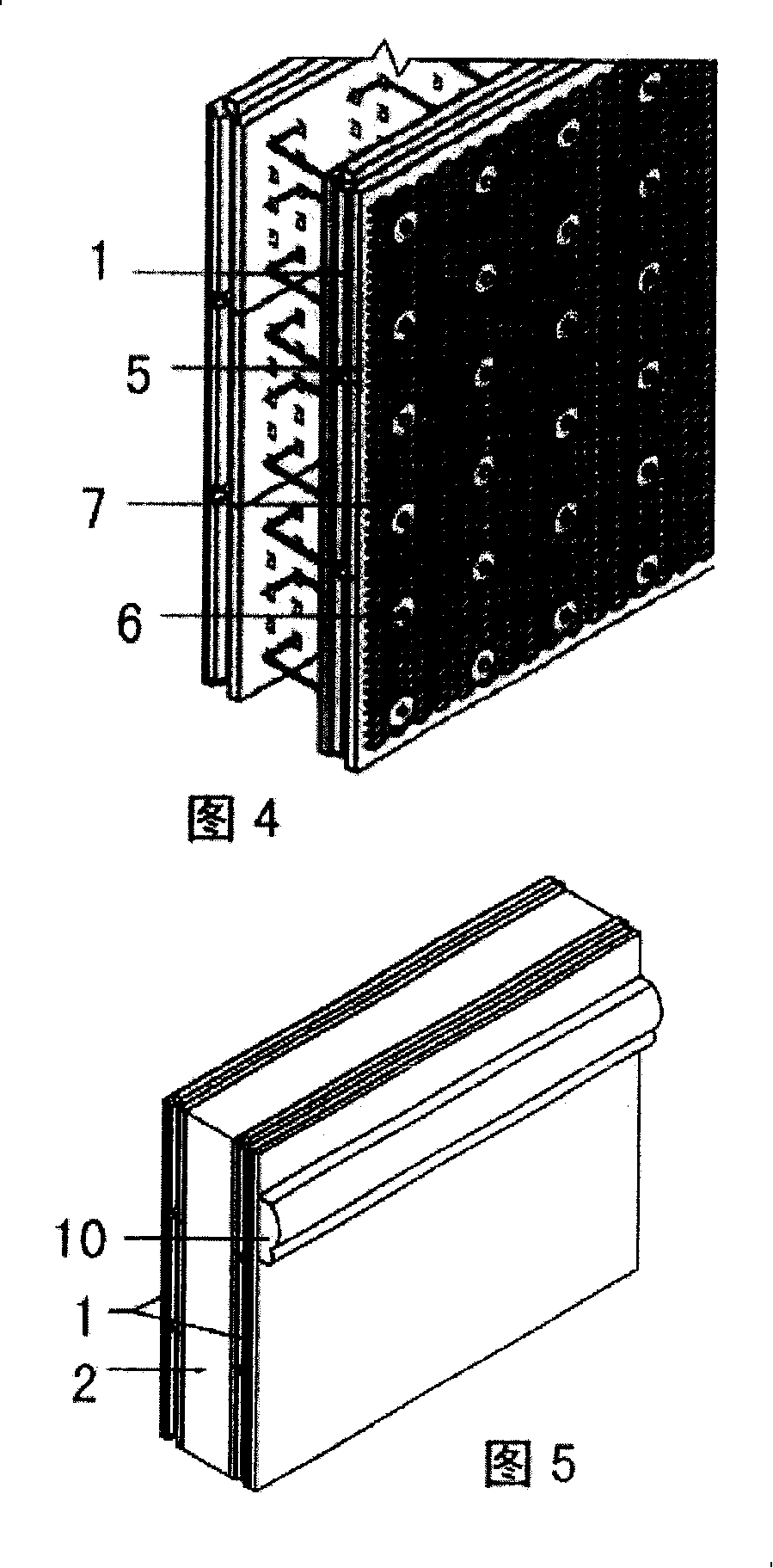

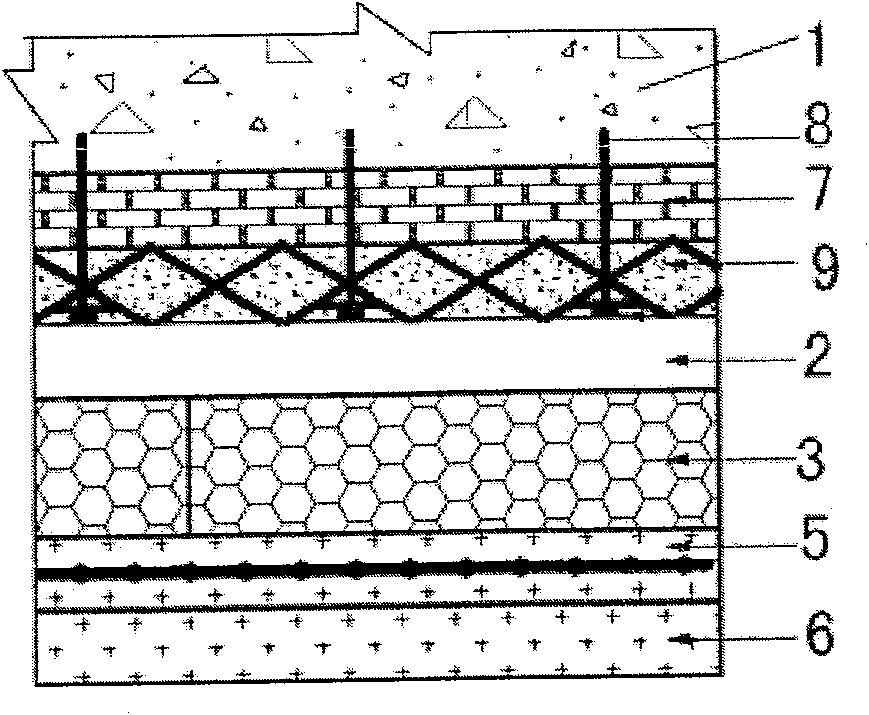

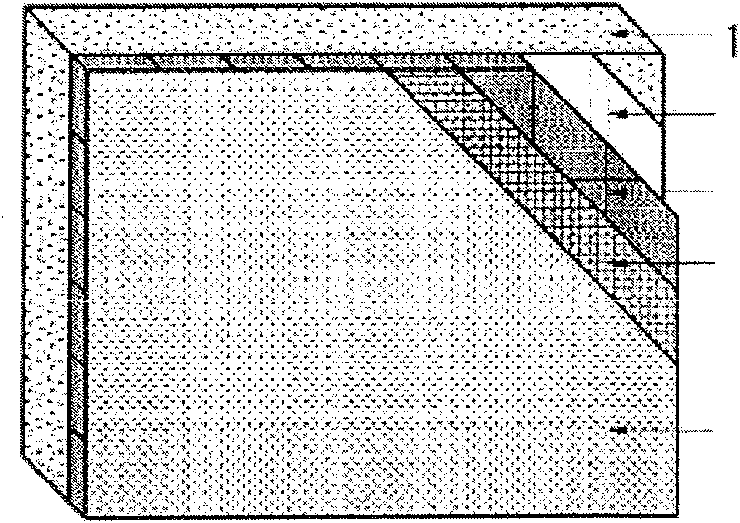

Concrete building combined with heat insulating framework and its construction method

InactiveCN1693609AHigh strengthAvoid BloatingHeat proofingForming/stuttering elementsGlass fiberFiberglass mesh

This invention is built-up plate heat preservation and insulation concrete building and its construction method. The heat preservation and insulation layer is also used as wall framework, concrete wall body base course is placed in wall framework, wall framework is consisted by two pieces of parallel set polystyrene foam plastic side plate, inner fixed billet is set in the plate, steel bar junction piece and welded mesh is set between the billet. PVC baffles are pasted on four walls of door and window mouth depth part, glass fiber grid layer is pasted on PVC baffles, inner and outer surface of wall heat protection plate is enclosed by glass fiber grid layer. Expanded metal is fixed on the layer, and it enclosures the outer surface of the heat protection plate, cement mortar is filled in mesh of the expanded metal, the thickness of the mortar is same to the expanded metal, concrete drowned orifice is opened on down table that at door and window mouth. The bottom layer of polystyrene heat protecting floor slab is floor slab plate that made of flute type polystyrene foam plastic pre-buried steel, rib joist steel is set in the flute, and it is placed with top layer as one body.

Owner:朱秦江

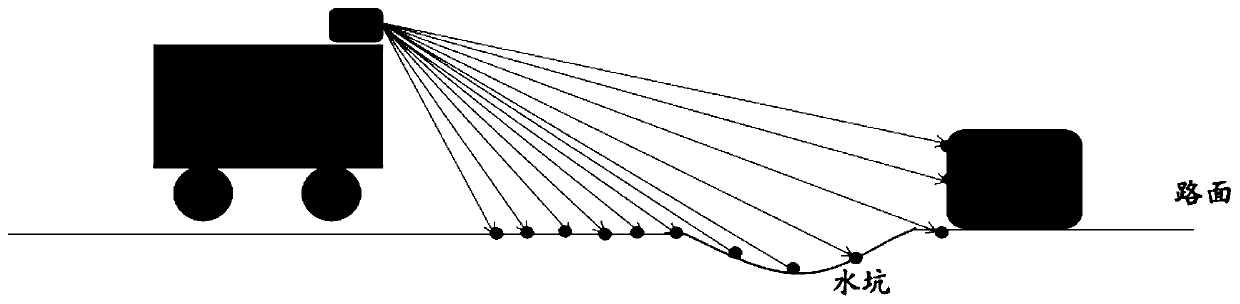

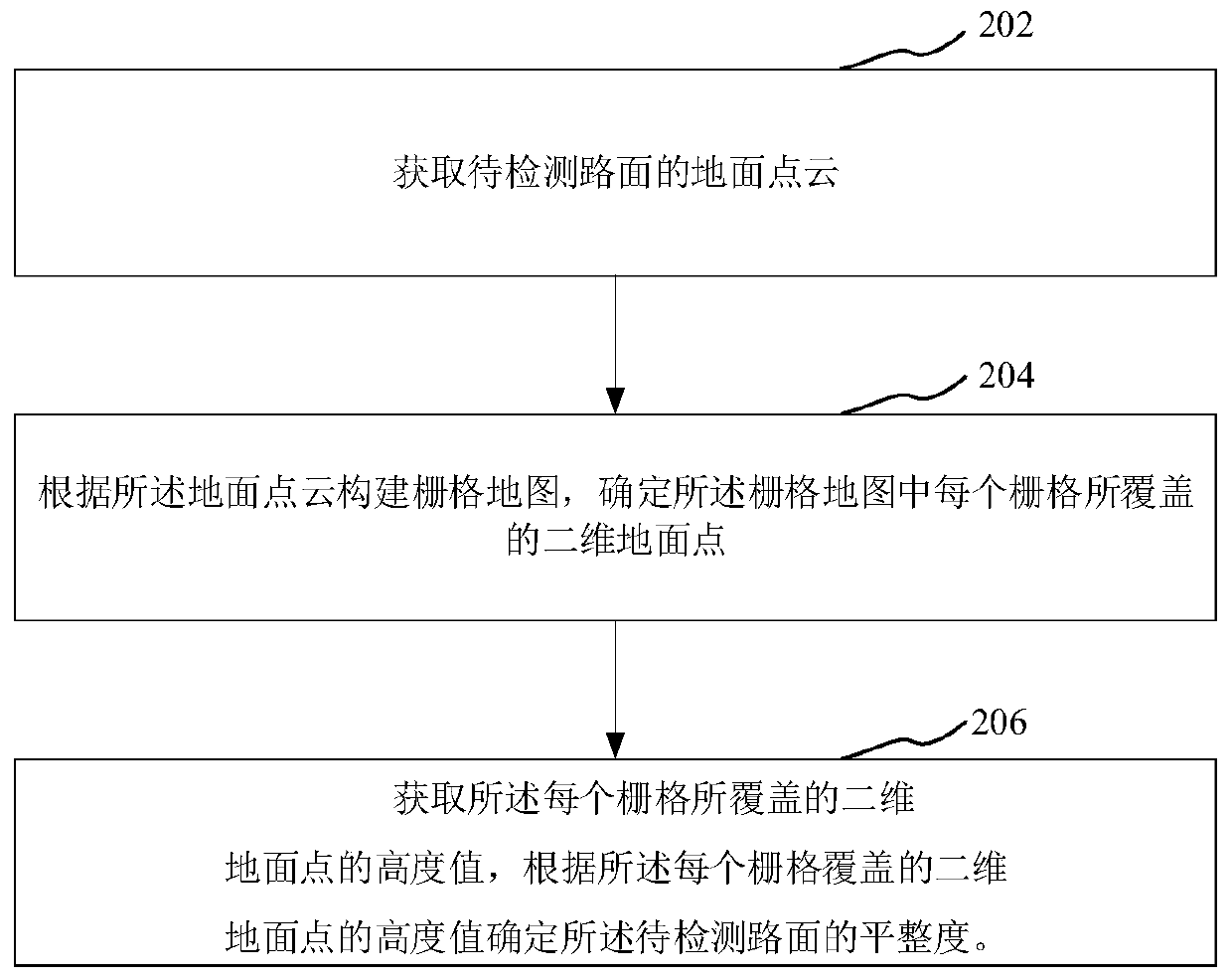

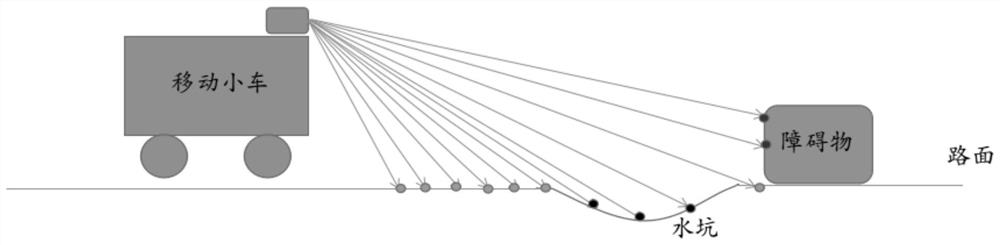

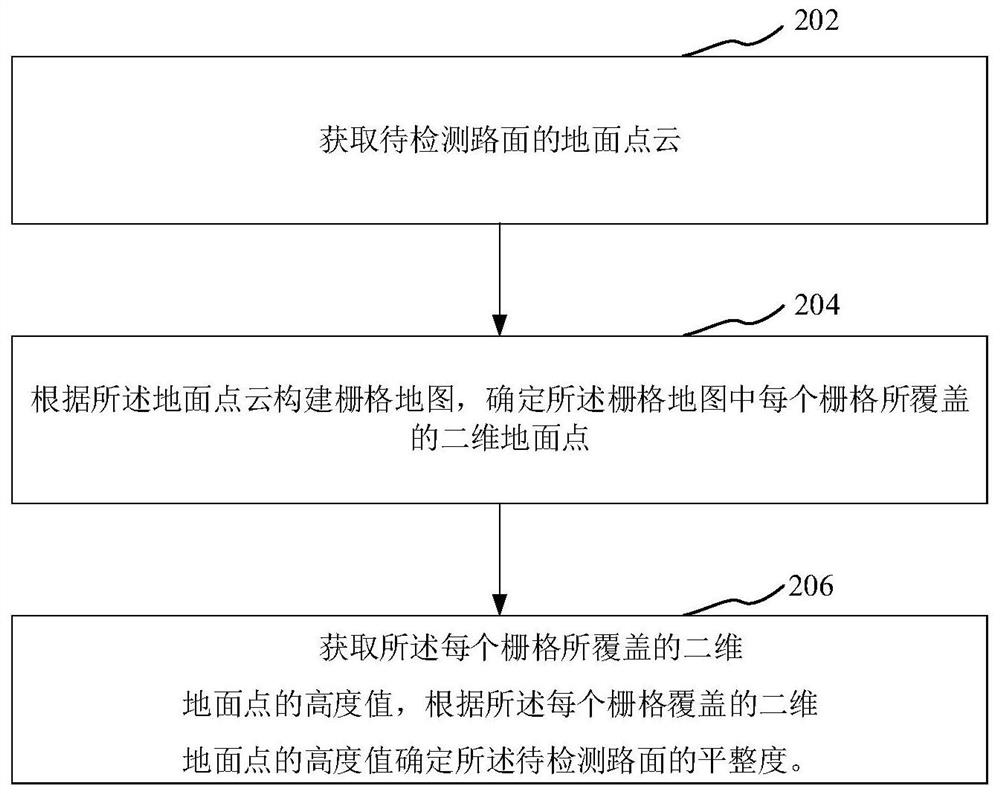

Road surface detection method and device, computer equipment and storage medium

ActiveCN110084116AHigh precisionHigh flatness precisionImage analysisThree-dimensional object recognitionPoint cloudRoad surface

The invention relates to a road surface detection method and device, computer equipment and a storage medium. The method comprises the steps of acquiring ground point cloud of a to-be-detected road surface; constructing a grid map according to the ground point cloud, and determining two-dimensional ground points covered by each grid in the grid map; and obtaining the height value of the two-dimensional ground point covered by each grid, and determining the flatness of the pavement to be detected according to the height value of the two-dimensional ground point covered by each grid. By the adoption of the method, pavement detection with higher precision can be achieved.

Owner:SUTENG INNOVATION TECH CO LTD

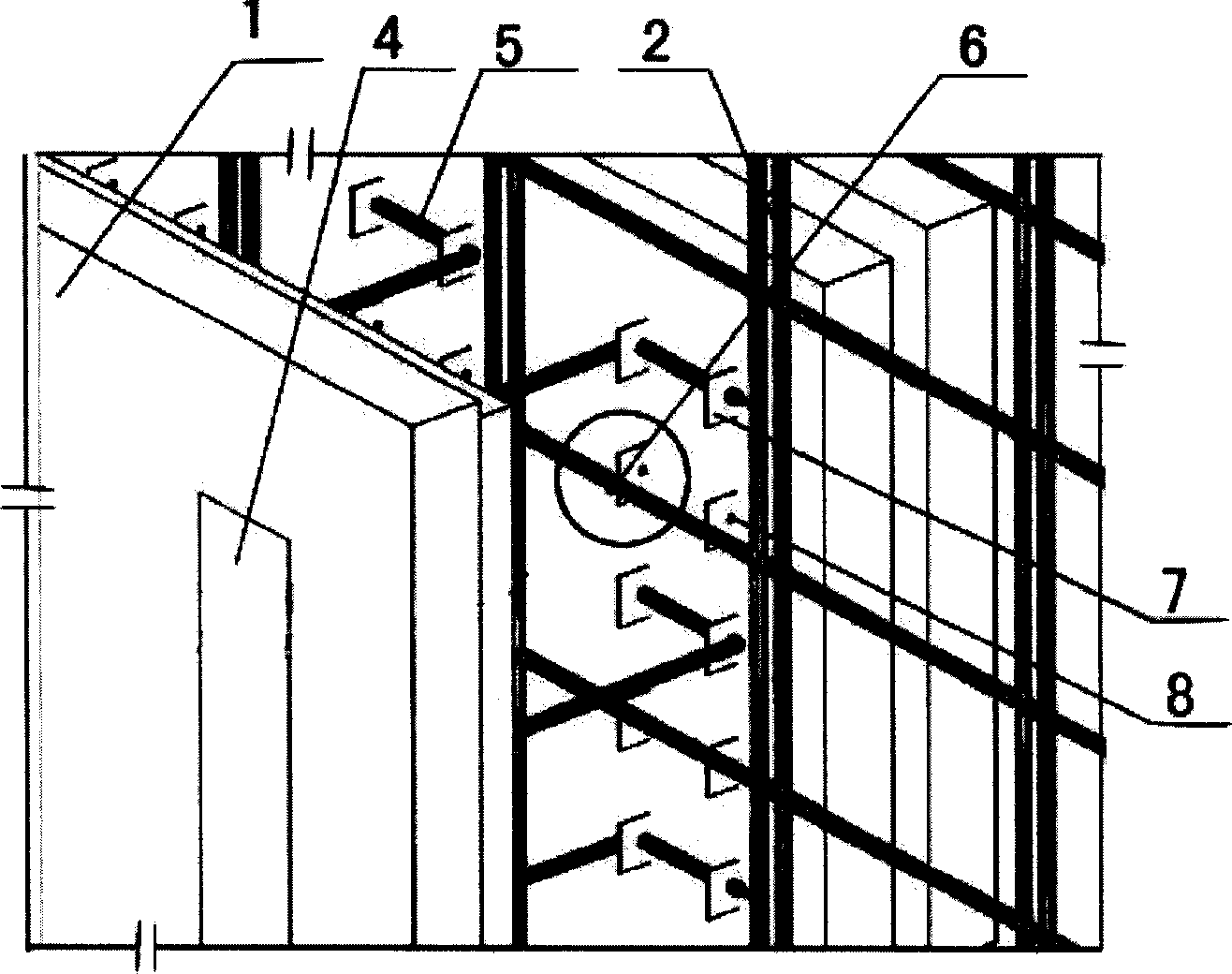

Composite heat insulation concrete wall and its construction method

The invention relates to a composite thermal insulation concrete wall and relative constructing method, wherein, the thermal insulation layer is used as wall module, inside which the concrete wall base is irrigated; the wall module is formed by two sheets of polystyrene foam plastic side modules, while the modules contain two rows of steel sheets whose edge has teeth with through holes; said teeth and through holes extend out from the polystyrene foam plastic side modules and the two ends of connection reinforced bar is through the holes; outside the wall module, it arranges glass fiber network cloth adhered by polymer cement slurry, steel sheet network anchored on said internal steel sheet, and second glass fiber network cloth and ornament layer while the grid of steel sheet network is filled with the cement slurry in the same thickness of steel sheet network. The invention can effectively improve the strength of polystyrene thermal insulation wall module, avoid the breakage of external wall, apply the ornament and avoid the oxidation of module caused by ultraviolet radiation.

Owner:朱秦江

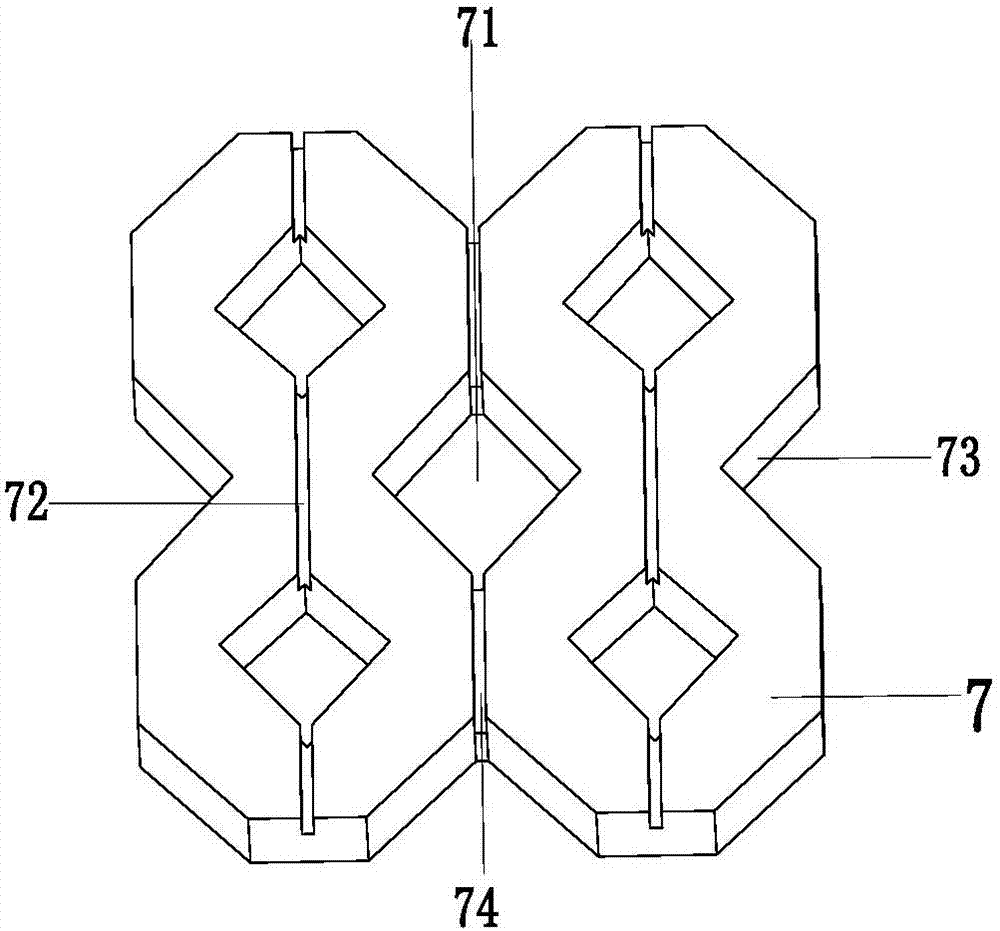

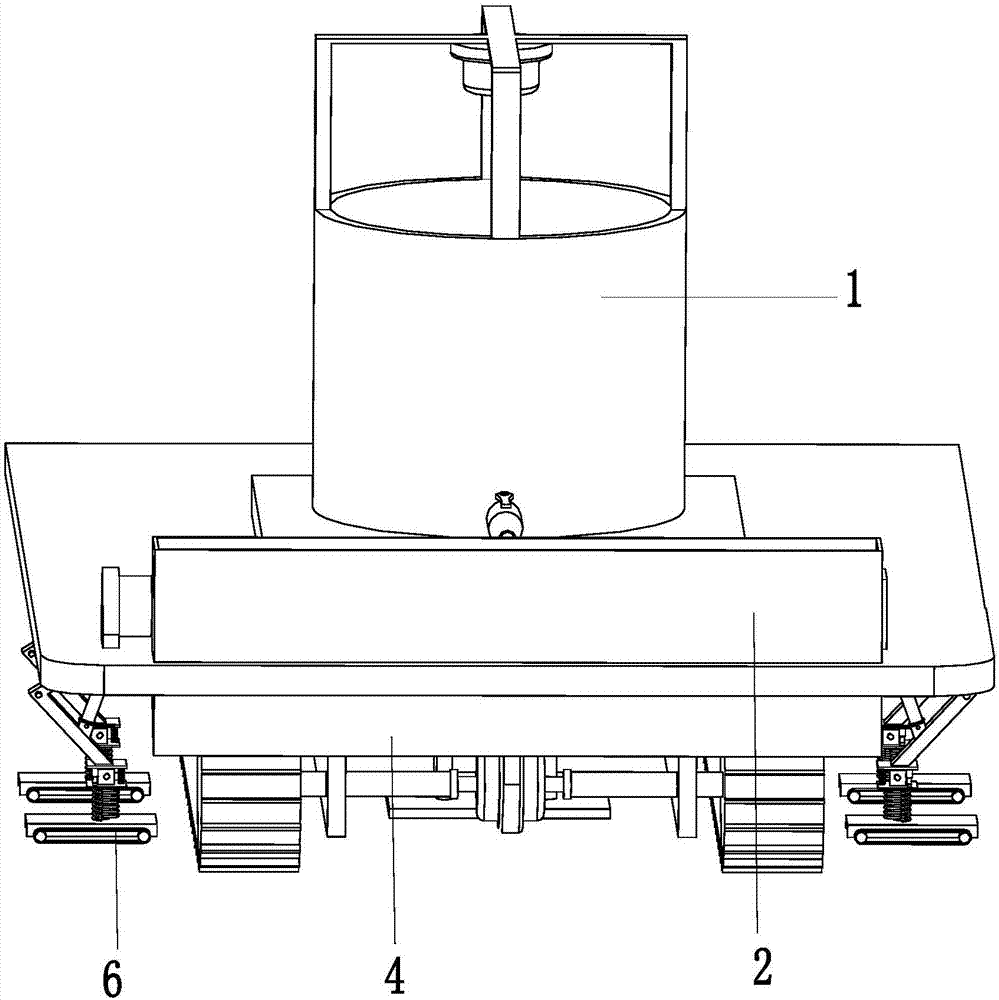

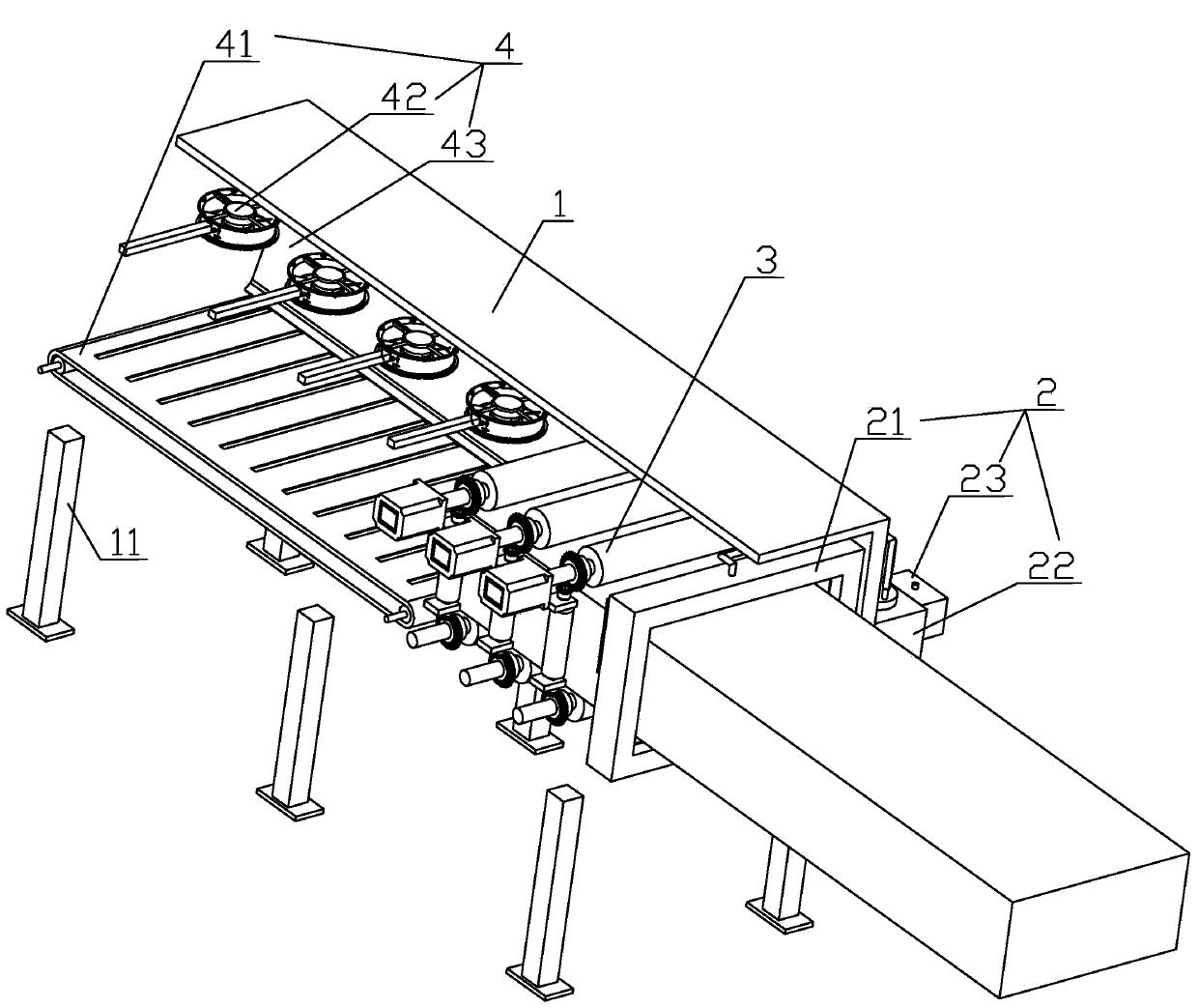

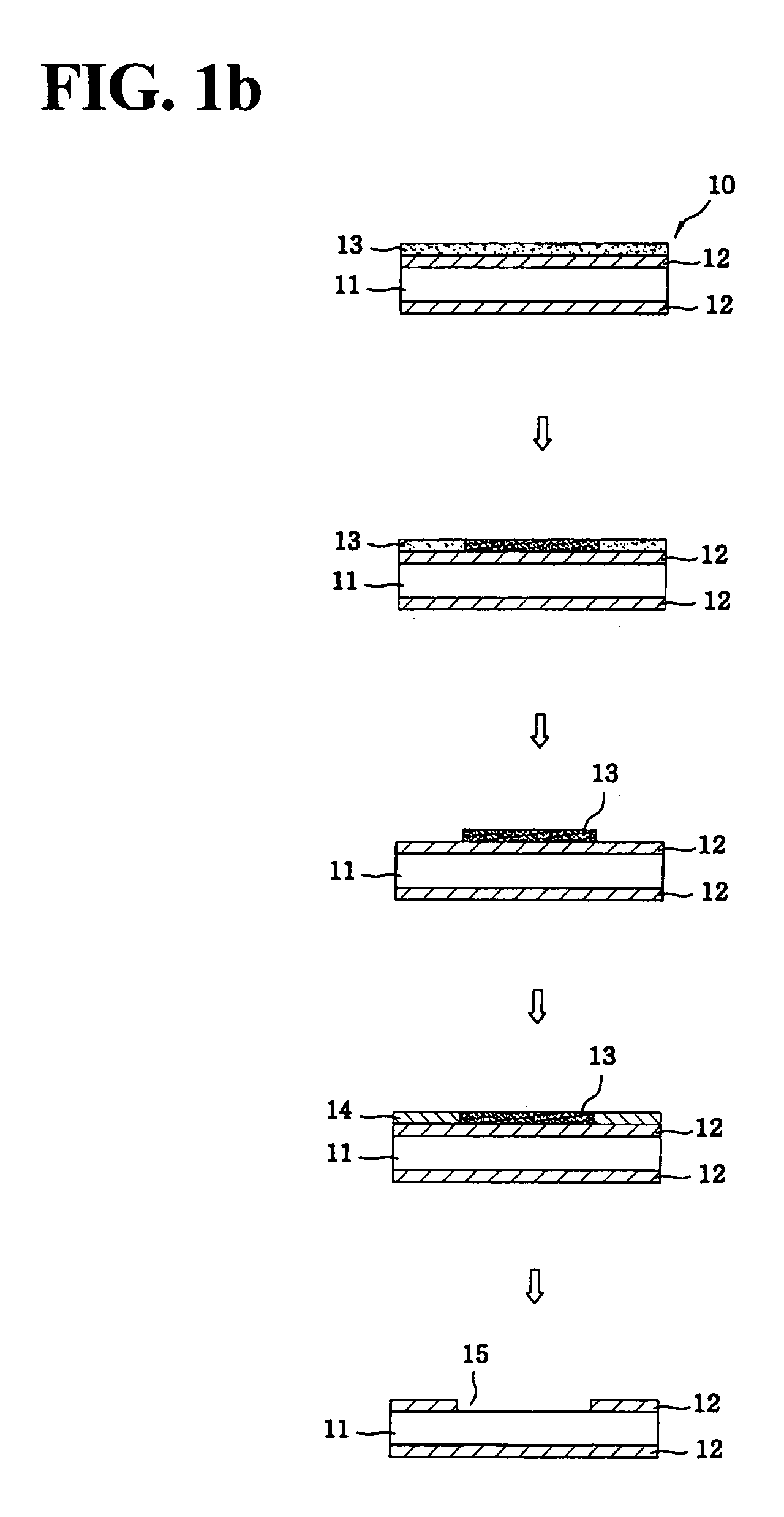

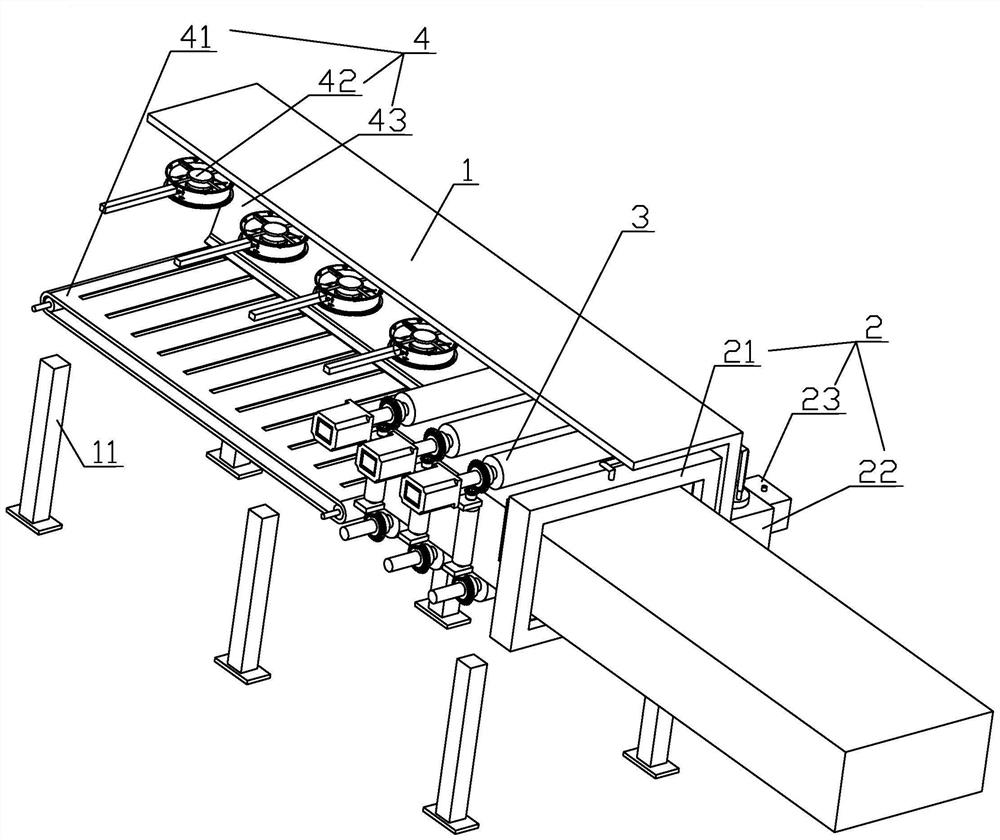

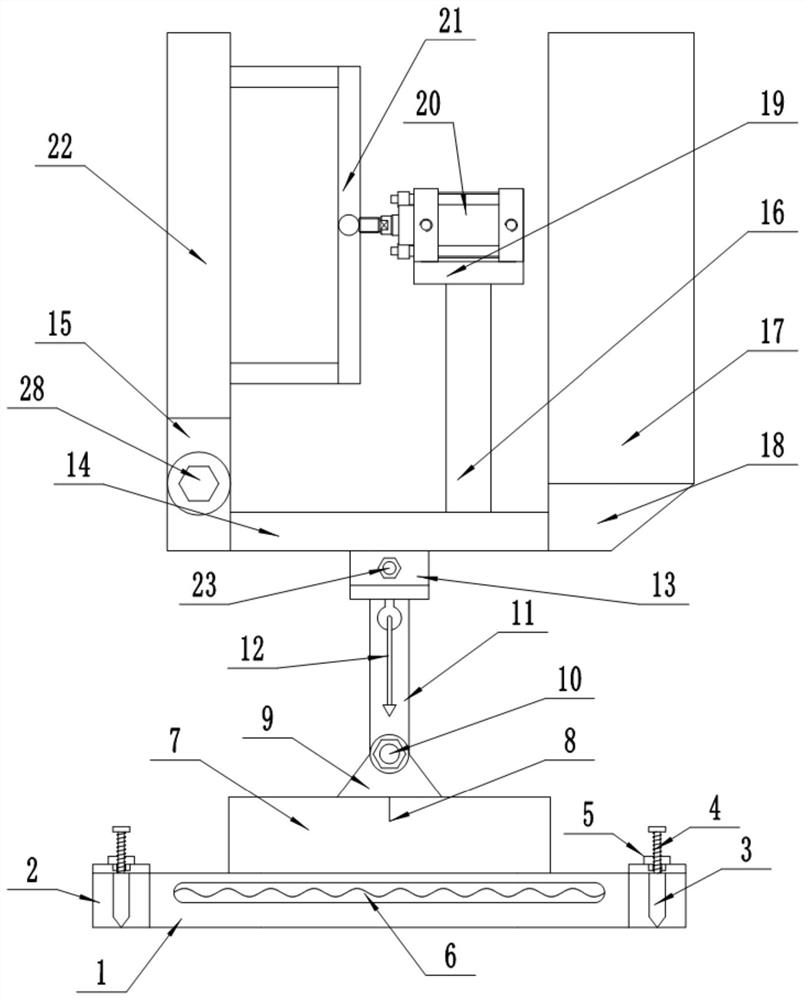

Automatic grass planting brick paving equipment for urban road

InactiveCN107338710AReduce labor intensityImprove gripTemporary pavingsRoads maintainenceBrickEngineering

The invention relates to an automatic paving and planting brick equipment for urban roads, which includes a paving rotating device, a fixing device, a limit device, a walking support device, a pouring and cleaning device and four auxiliary moving devices. The paving rotating device is installed on On the fixed limit device, the fixed device is installed on the bottom of the pavement rotating device, the limit device is installed on the bottom of the pavement rotating device, and the bottom of the walking support device is symmetrically installed with four auxiliary moving devices, the pouring cleaning device and the walking support device connected. The invention can solve the problems of low work efficiency, manual handling of grass planting bricks, and easy deviation when manually correcting the position of grass planting bricks in the existing manual laying of grass planting bricks; it can realize different types of grass planting bricks Perform functions of stable grabbing, positioning and laying, automatic caulking, and stable movement.

Owner:俞樑兵

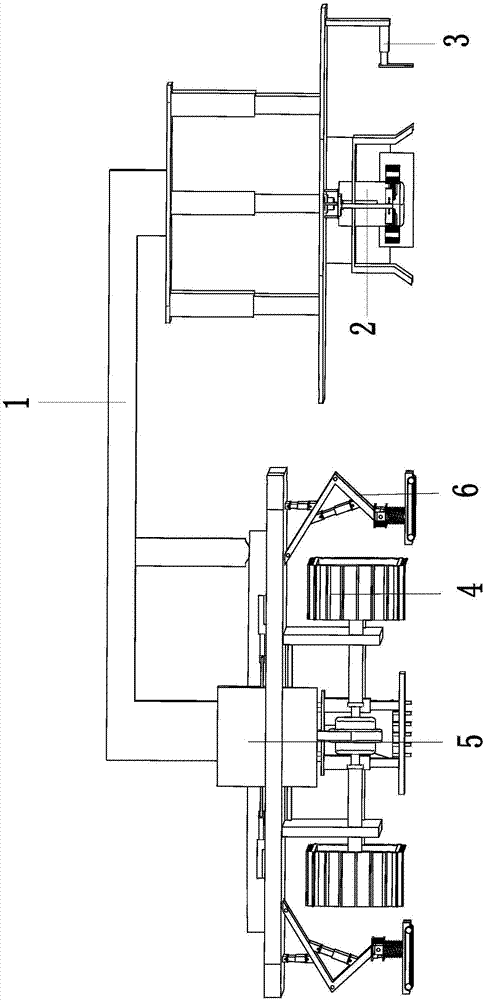

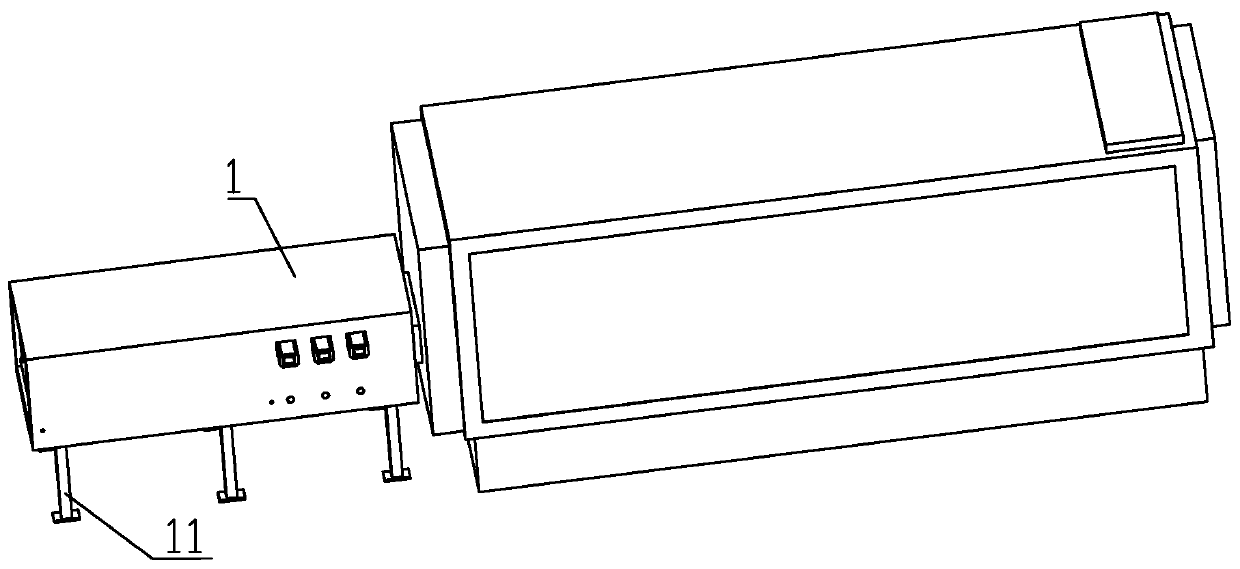

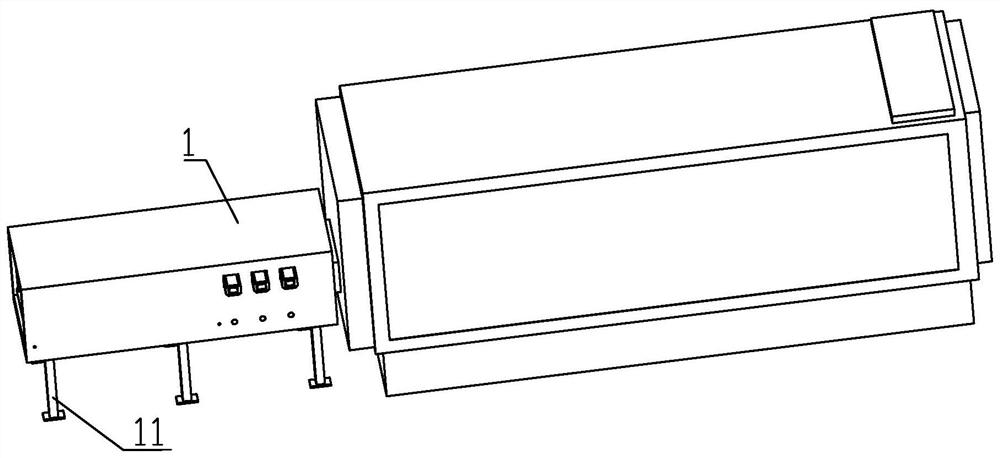

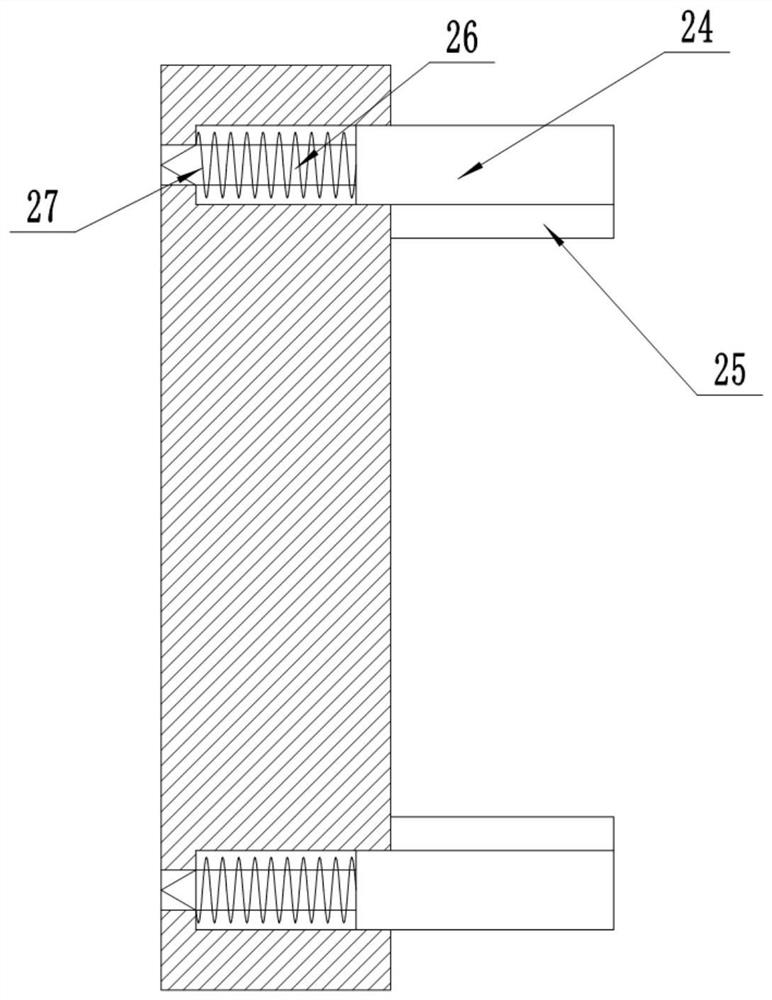

Automatic joint filling equipment for grass-planting brick road paving of building of green city

The invention relates to an automatic caulking device for road pavement with grass-planting bricks for green city construction, which includes a stirring device, a feeding device, a cleaning device, a walking support device and four auxiliary moving devices. The stirring device is installed on the walking support On the device, the unloading device is installed on the walking support device, the cleaning device is connected with the walking support device, and four auxiliary moving devices are symmetrically installed on the bottom of the walking support device. The present invention can solve the problems of low work efficiency, high labor intensity, manual mixing and handling of cement mortar, excessive workload of manual filling of grass-planting bricks, and manual filling of grass-planting bricks. Problems such as uneven filling; realized the function of automatic filling of different types of grass-planting bricks, with mechanized mixing of cement mortar and automatic slurry, mechanized filling of grass-planting bricks without manual operation, mechanized filling of grass-planting bricks evenly Etc.

Owner:俞樑兵

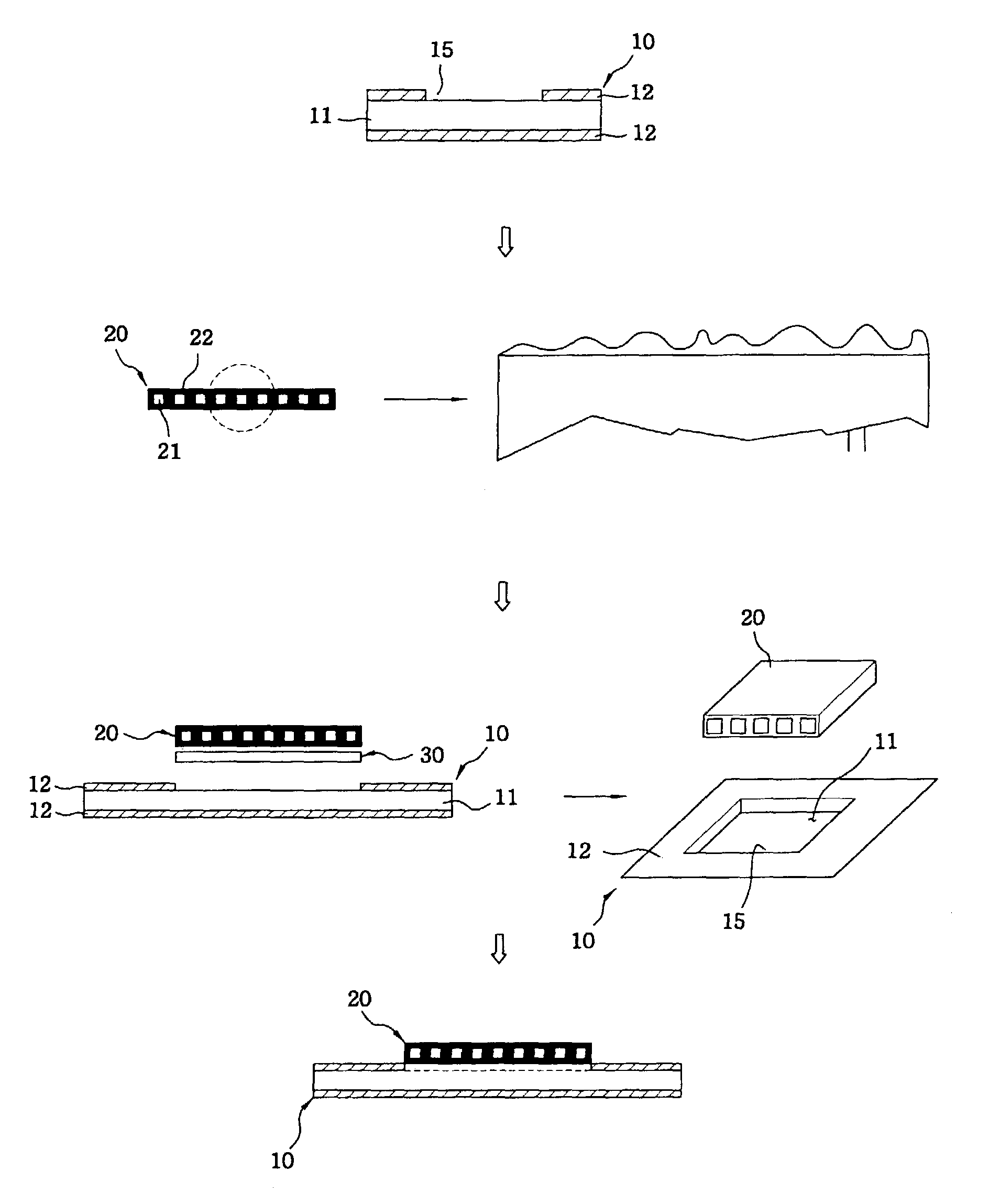

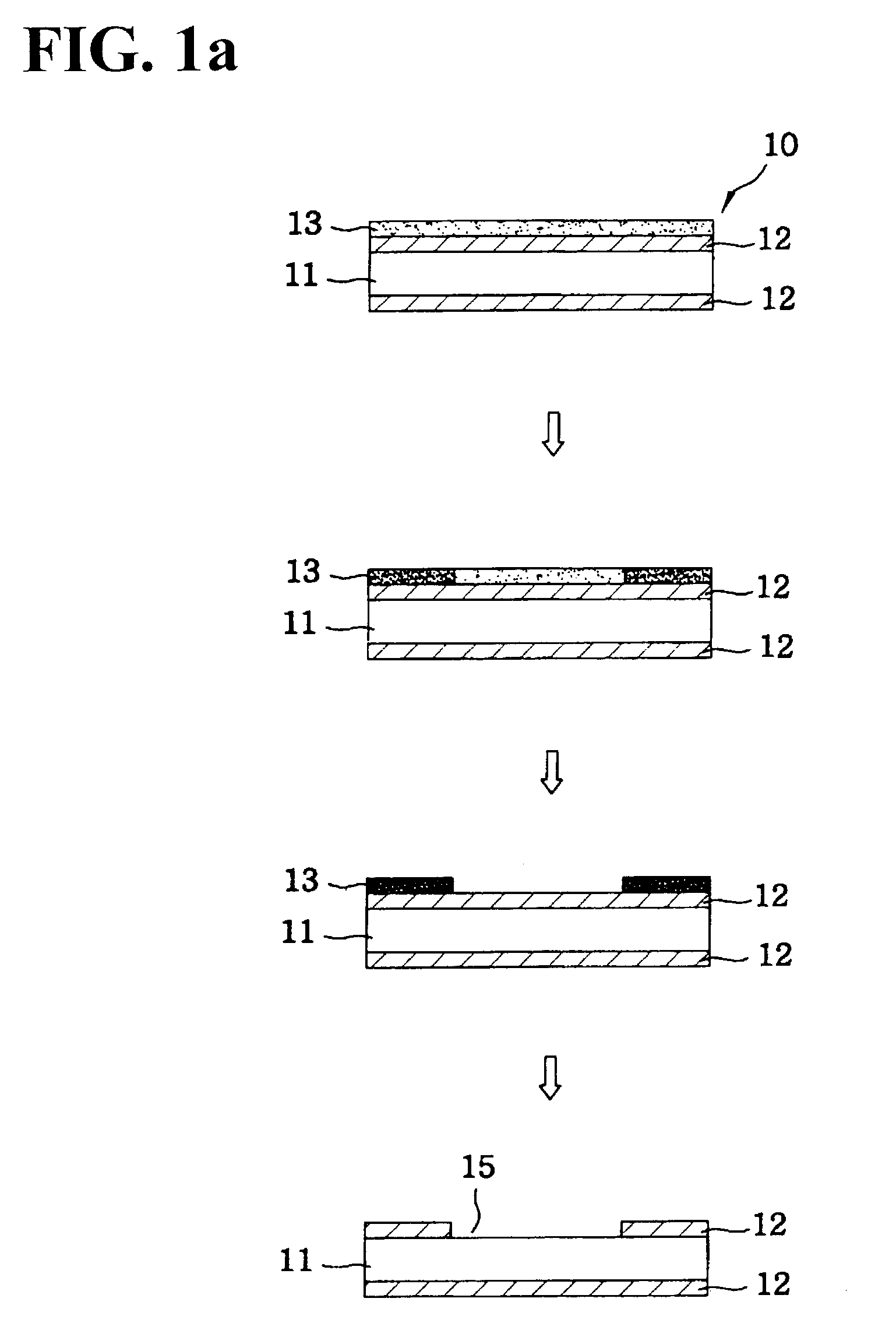

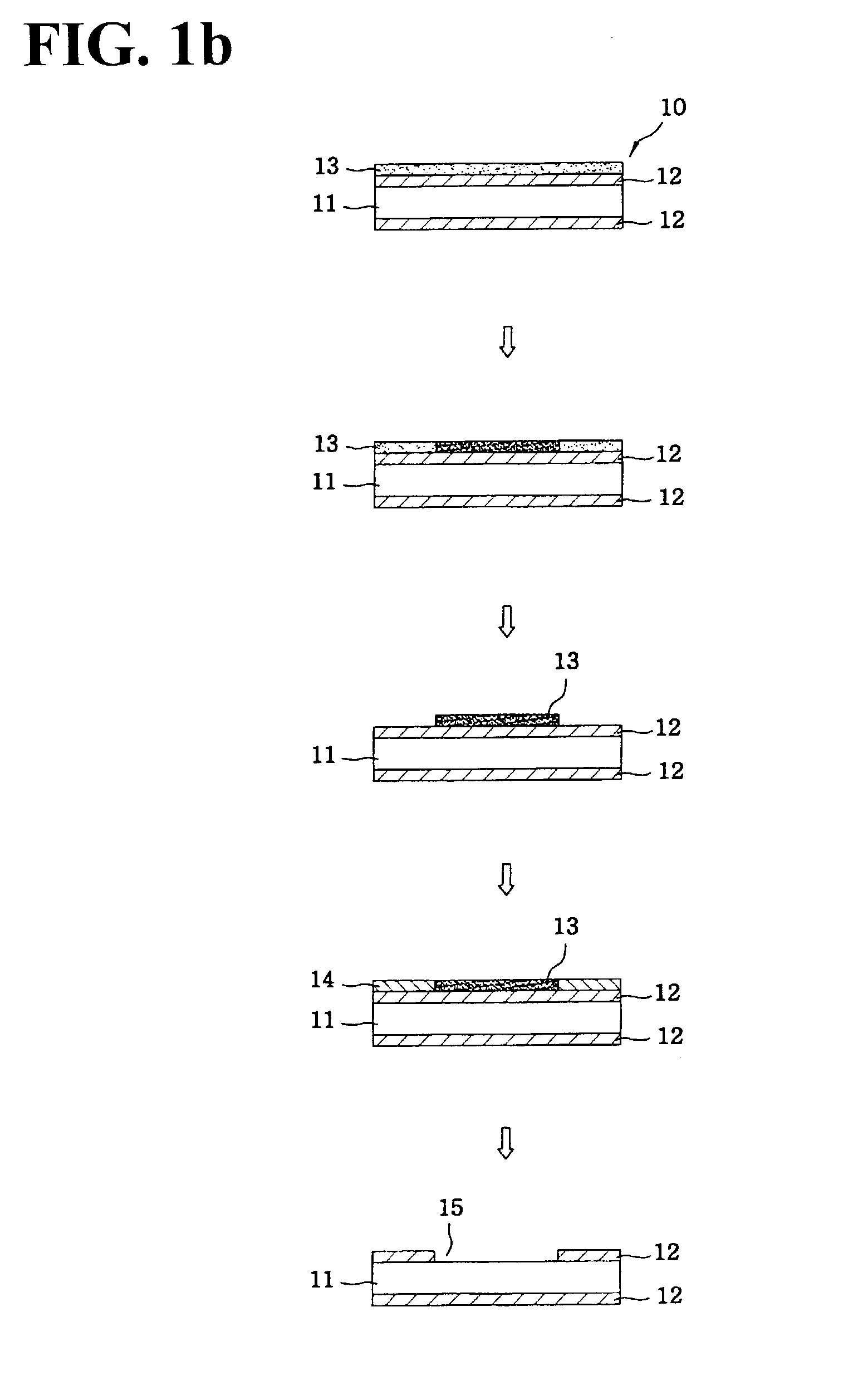

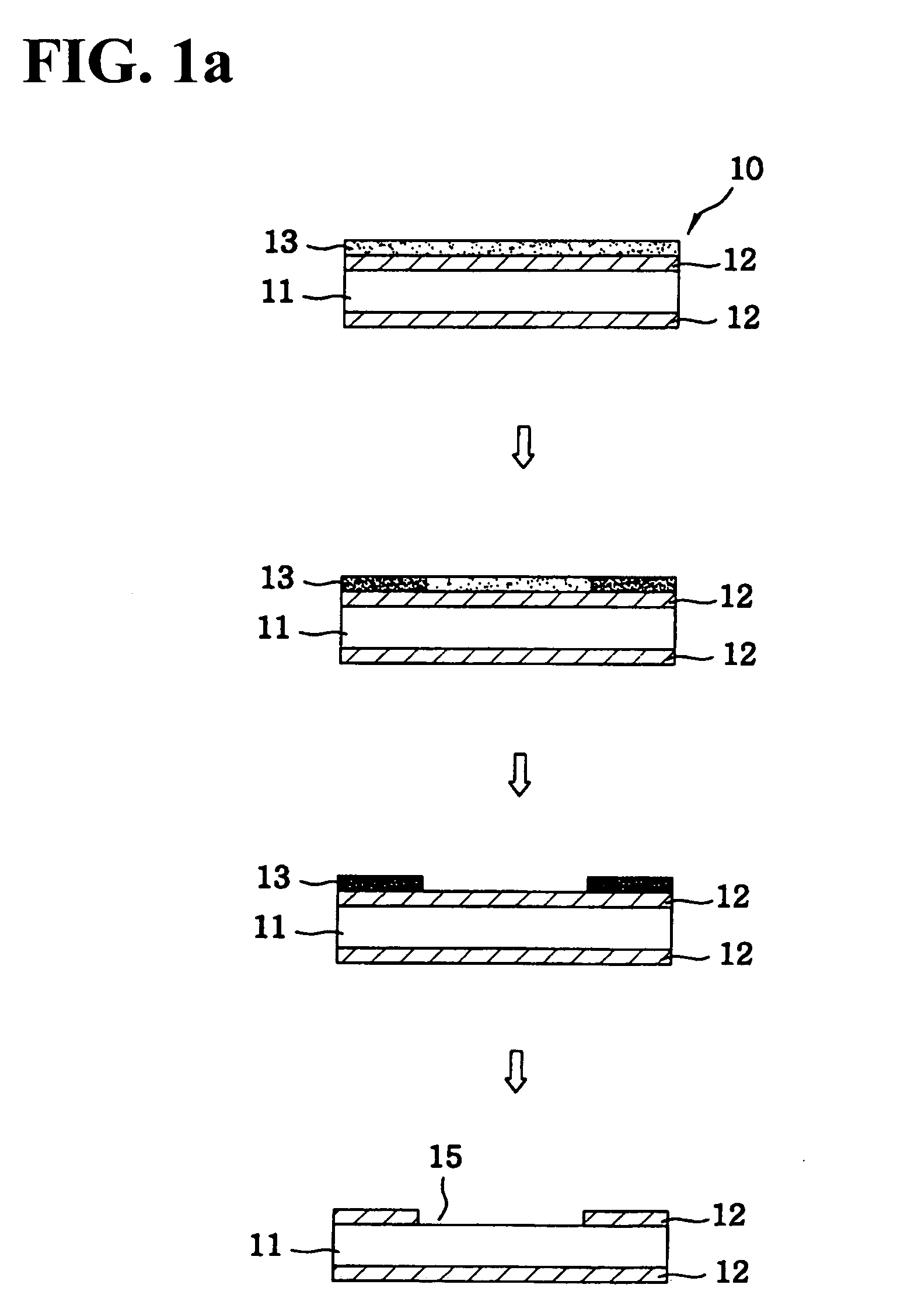

Method of attaching optical waveguide component to printed circuit board

InactiveUS7025849B2Precise of componentAccurate flatnessPrinted circuit assemblingLamination ancillary operationsPresent methodSurface roughness

Disclosed is a method of attaching an optical waveguide component to a printed circuit board, which is a double-sided or a multilayer printed circuit board, through pre-bonding and main-bonding by use of an adhesive tape. Prior to being attached to the printed circuit board, the optical waveguide component is preferably subjected to a plasma surface treatment to give a surface roughness thereto. The present method is advantageous in that the optical waveguide component can be attached to the printed circuit board with improved flatness and precise alignment without causing chemical or thermal damage to the optical waveguide component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Production process for aluminum alloy window sectional material

ActiveCN110665986AEffective straighteningAccurate flatnessShaping toolsExtrusion control devicesIngotWater cooling

The invention discloses a production process for an aluminum alloy window sectional material. The production process for the aluminum alloy window sectional material comprises the following steps: A1,cast ingot preparation; A2, soaking; A3, raw material preheating; A4, extrusion forming: an aluminum alloy cast ingot is extruded through an extruder, the aluminum alloy cast ingot is extruded by theextruder, so that the aluminum alloy cast ingot in an extrusion barrel is enabled to extrude towards an extrusion die and extruded out from a die hole of the extrusion die, and in the process, the temperature of the extrusion die is controlled to be 380 DEG C; A5, preliminary cooling: water cooling is adopted, and the extruded aluminum alloy section material is cooled to be 250-300 DEG C; A6, rolling straightening: the surface of the aluminum alloy section material is rolled through a straightening machine, so that the surface of the aluminum alloy section material is straight; A7, aftercooling: air cooling is adopted, and the aluminum alloy section material is cooled to be 200 DEG C and below; A8, heat treatment; and A9, surface treatment. The production process for the aluminum alloy window sectional material has the following advantage and effect: due to the production process, the accuracy of the straightness and the surface planeness of the aluminum alloy section material is increased, so that a guarantee on the installation dimensions of an aluminum alloy window prepared from the aluminum alloy sectional material is benefited.

Owner:无锡辰浩建筑节能科技有限公司

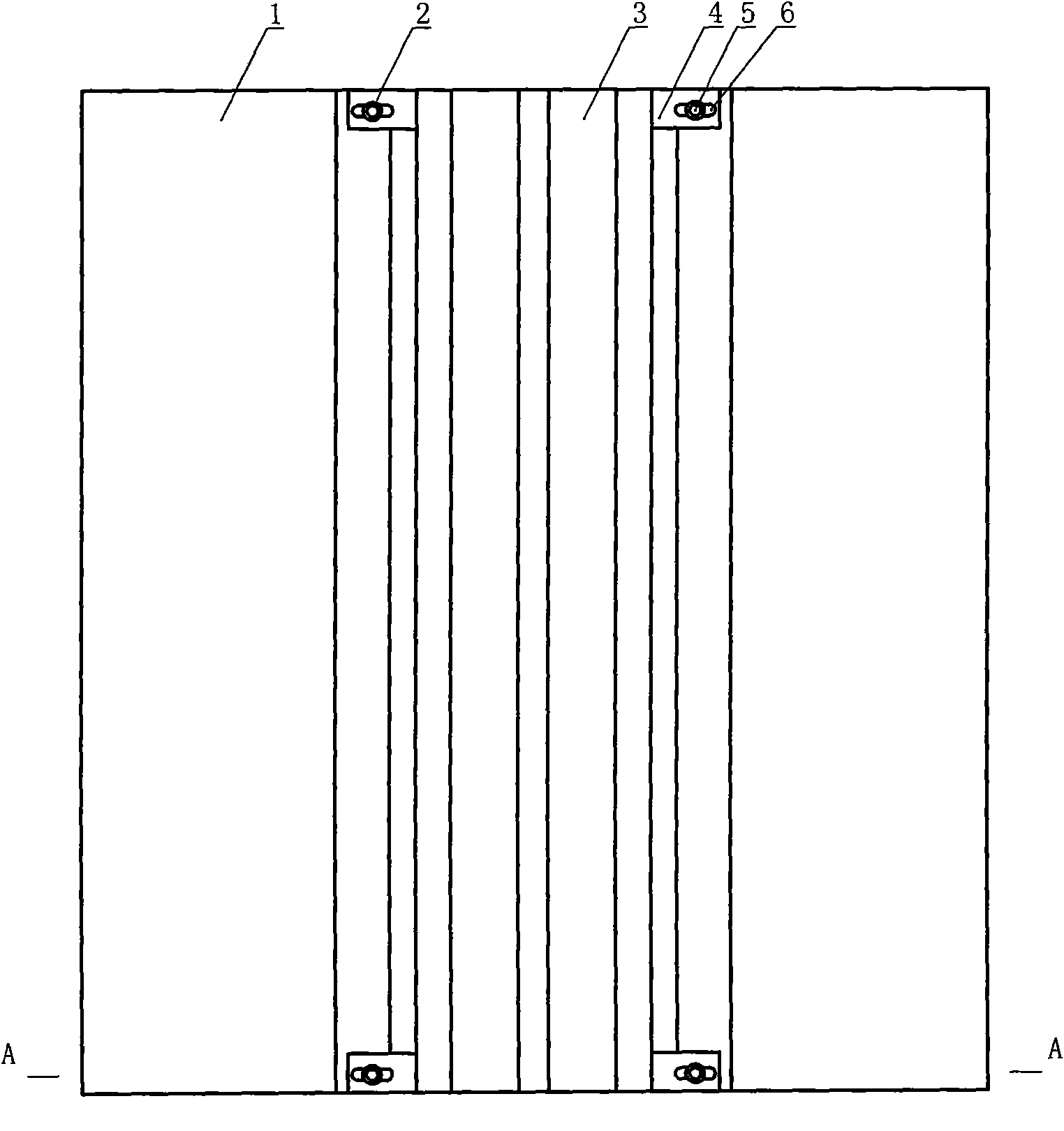

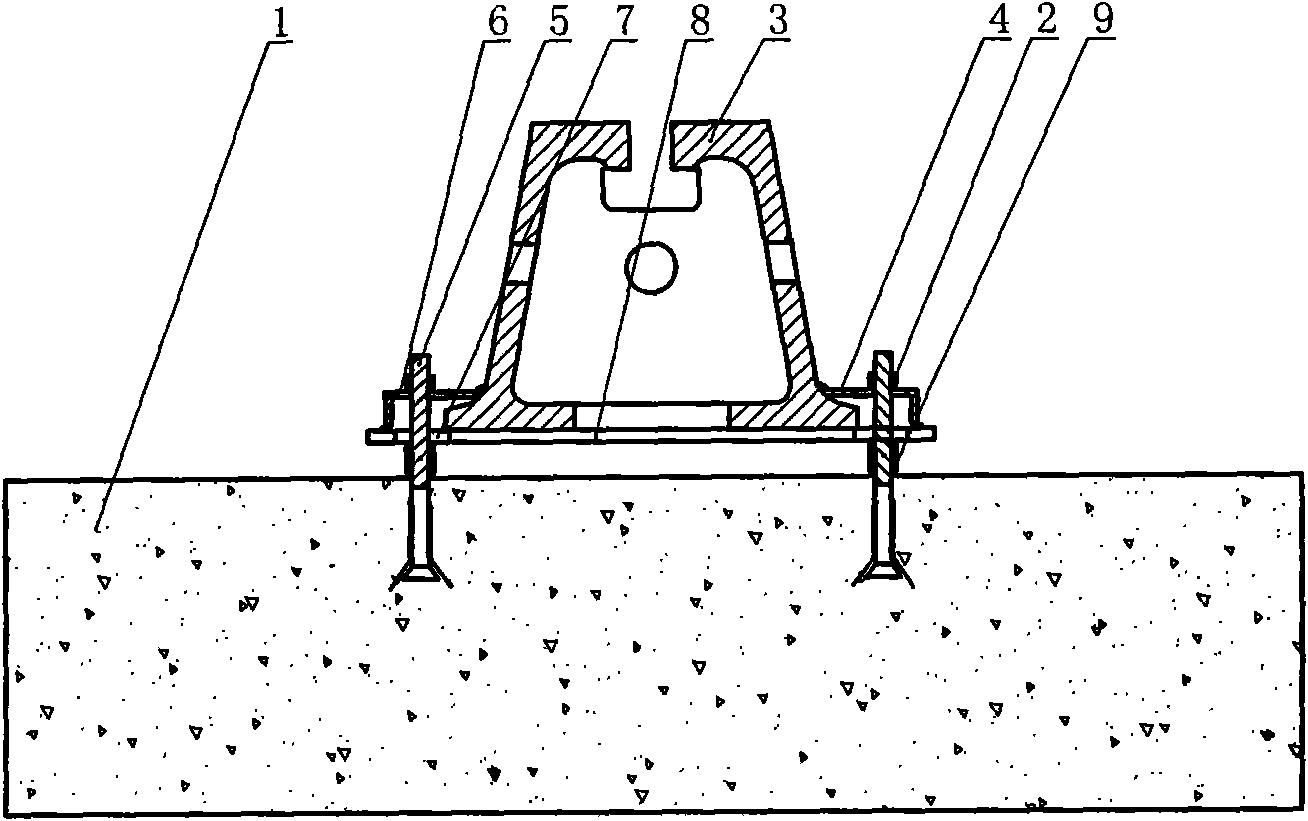

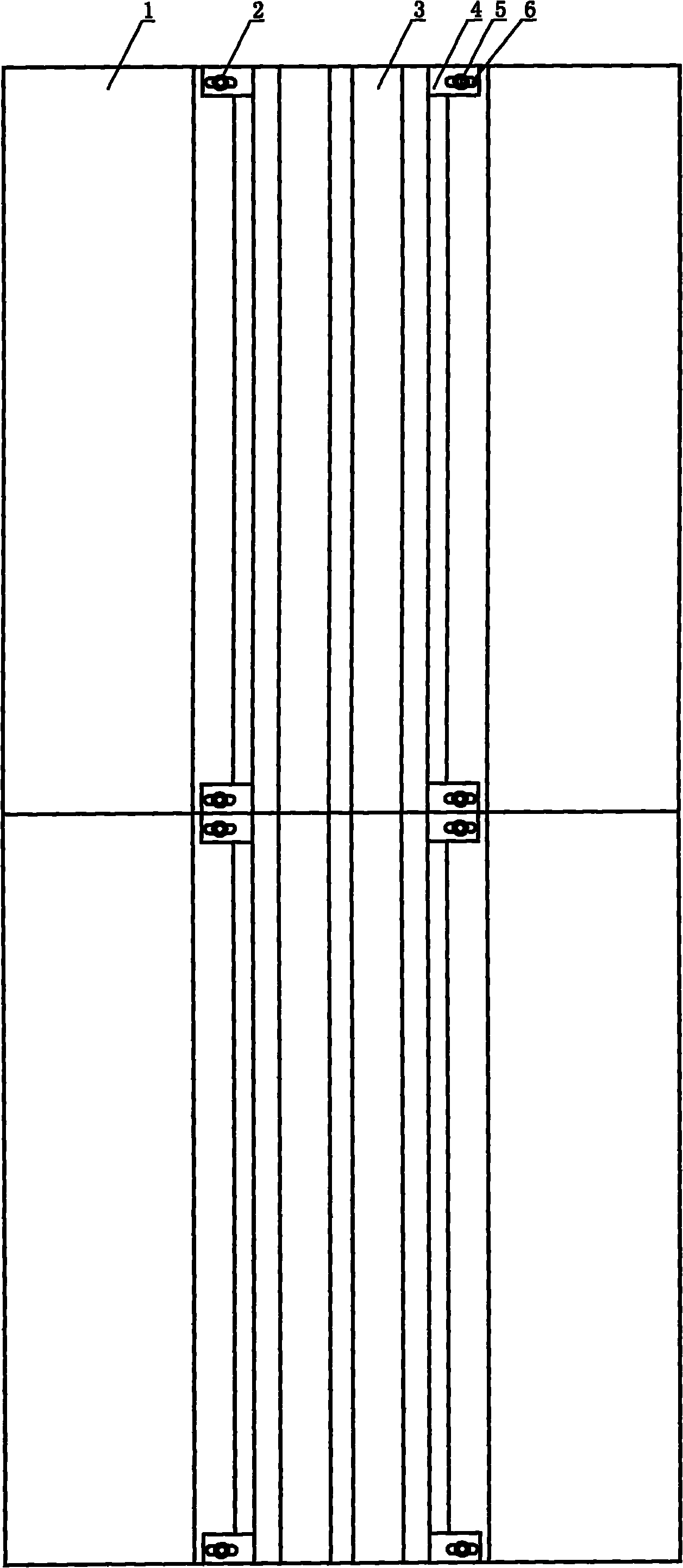

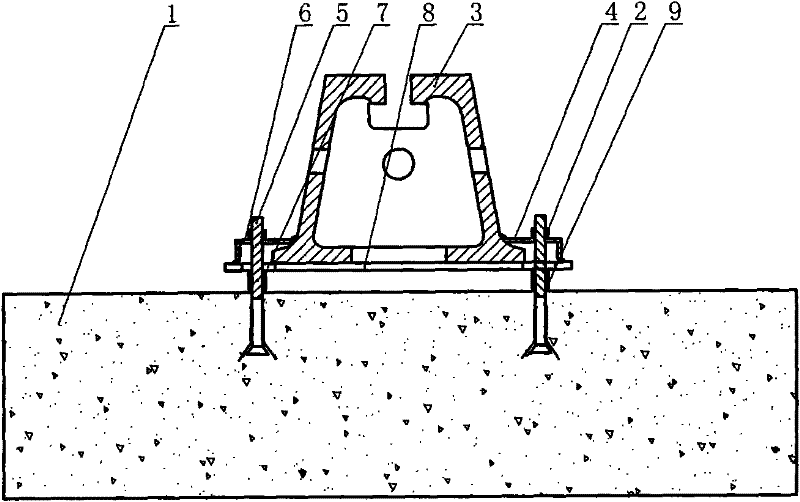

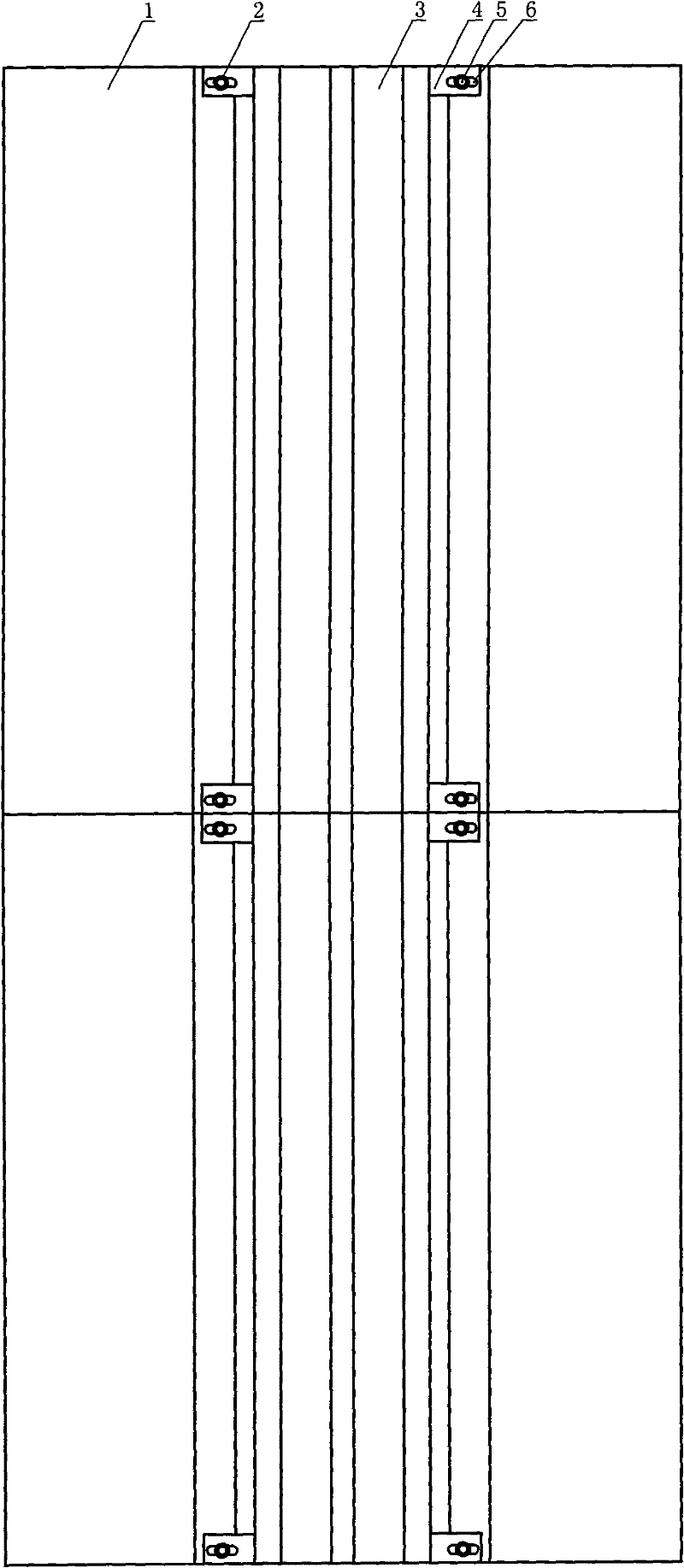

Evenness adjusting methods for industrial factory building T-shaped groove and platform thereof

The invention relates to evenness adjusting methods for an industrial factory building T-shaped groove and a platform thereof. The evenness adjusting method for the T-shaped groove comprises the following steps of: (1) measuring and confirming the position of the T-shaped groove and drilling a positioning hole; (2) installing an expansion bolt with an adjusting nut into the positioning hole and placing a tray on the adjusting nut of the expansion bolt; (3) adjusting the evenness of a support plate by a leveling instrument and a theodolite through the adjusting nut on the expansion bolt and placing the T-shaped groove on the corresponding position of the support plate; (4) adjusting the evenness of the support plate again by the leveling instrument and the theodolite through the adjusting nut on the expansion bolt and fixing the T-shaped groove by a compression bolt and angle iron with an opening so as to finish the evenness adjustment of the T-shaped groove. The invention has the advantages of simplicity and easiness for operation, easiness for precision control, shorter adjusting time, higher working efficiency, lower construction cost, high integral appearance quality and time and labor saving. The evenness adjusting methods for the industrial factory building T-shaped groove and the platform thereof have higher precision.

Owner:MCC TIANGONG GROUP

Method of attaching optical waveguide component to printed circuit board

InactiveUS20050205201A1Precise of componentAccurate flatnessPrinted circuit assemblingLamination ancillary operationsPresent methodSurface roughness

Disclosed is a method of attaching an optical waveguide component to a printed circuit board, which is a double-sided or a multilayer printed circuit board, through pre-bonding and main-bonding by use of an adhesive tape. Prior to being attached to the printed circuit board, the optical waveguide component is preferably subjected to a plasma surface treatment to give a surface roughness thereto. The present method is advantageous in that the optical waveguide component can be attached to the printed circuit board with improved flatness and precise alignment without causing chemical or thermal damage to the optical waveguide component.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

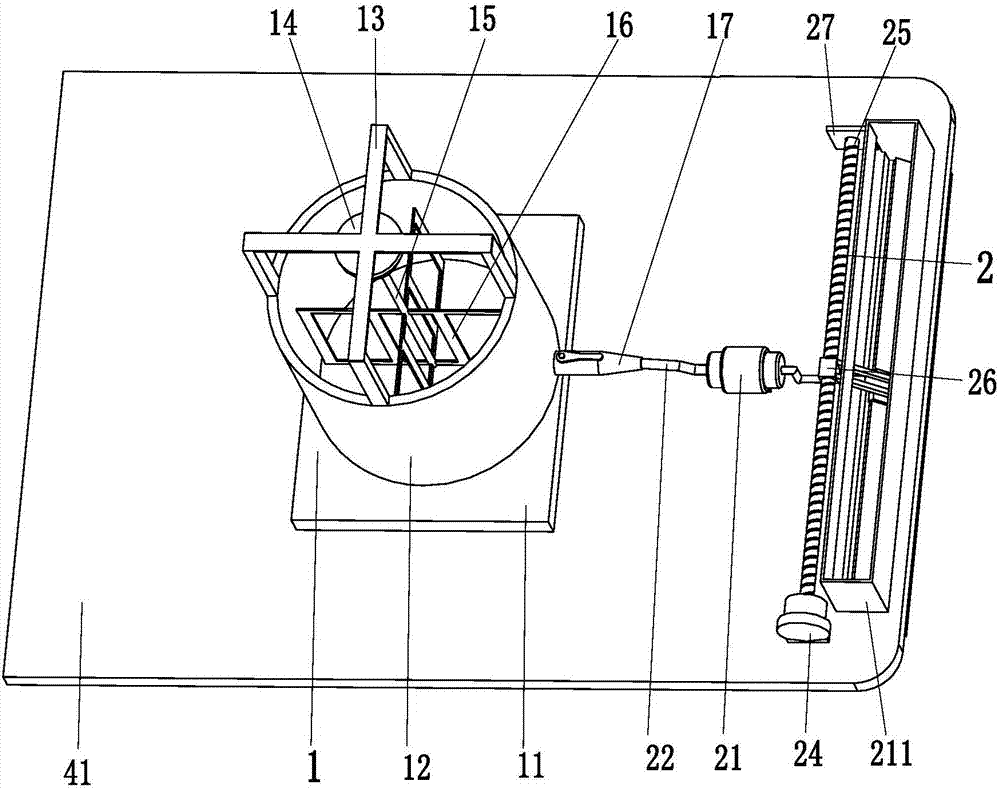

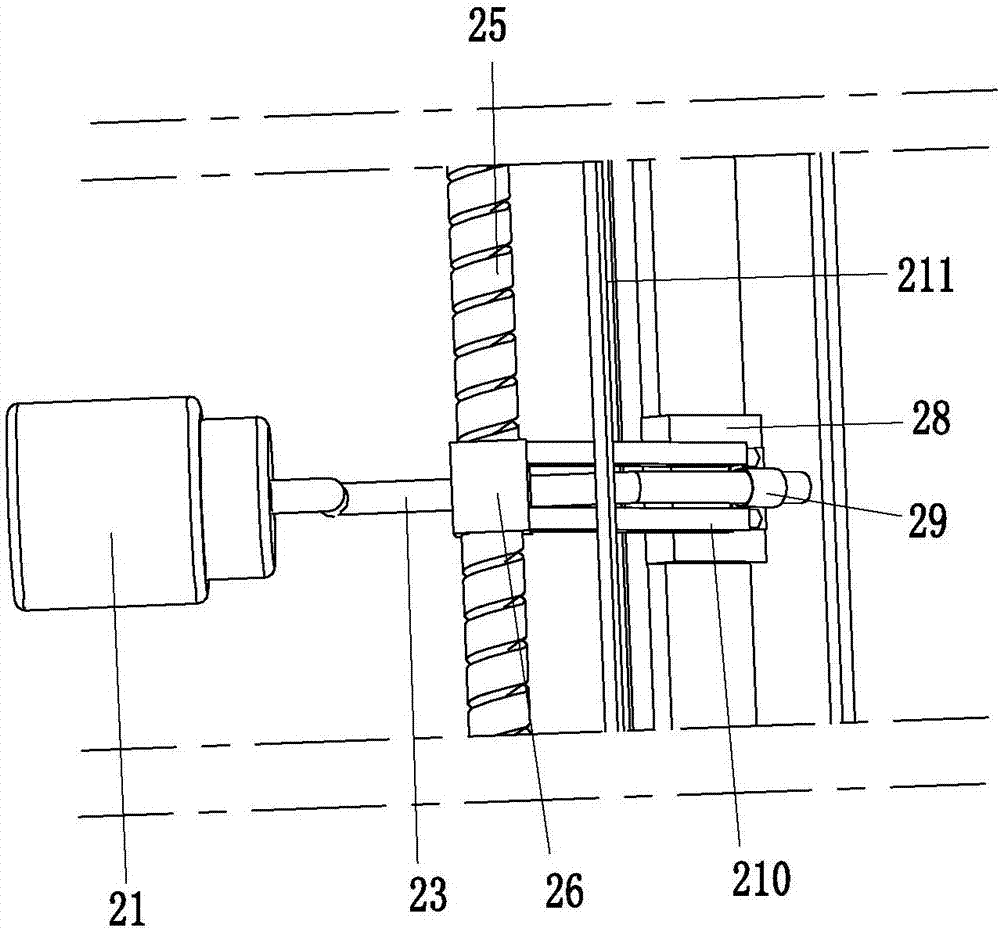

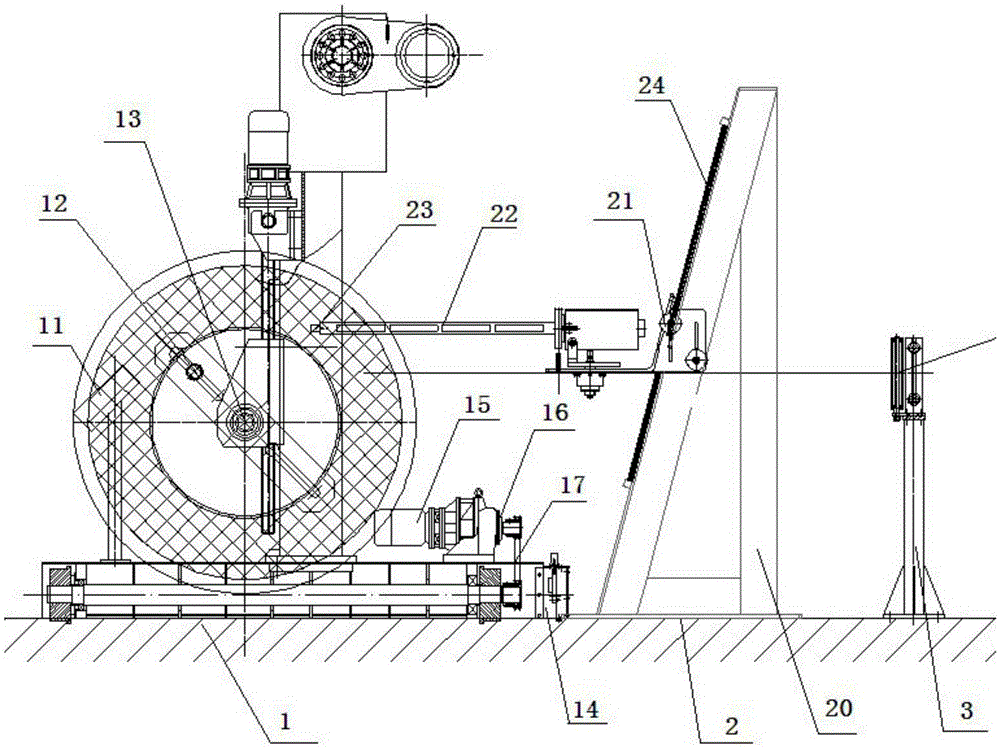

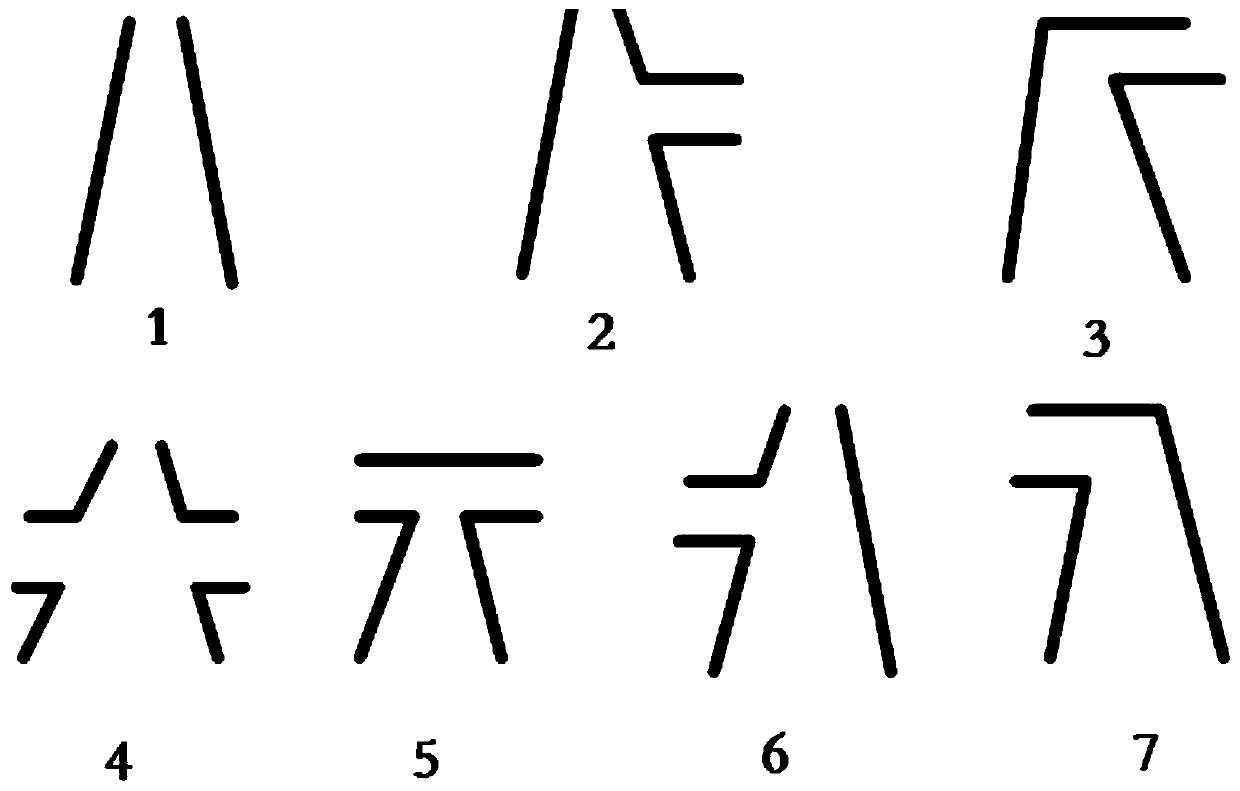

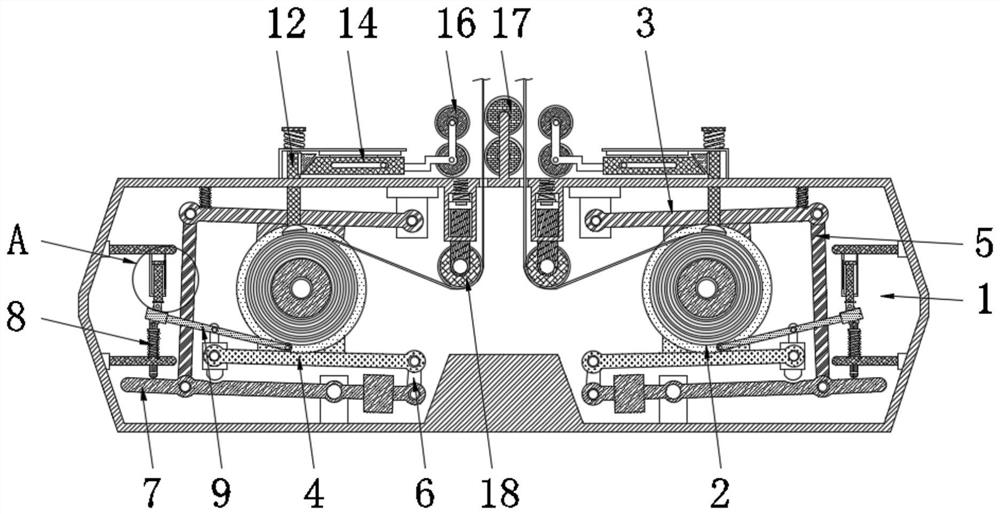

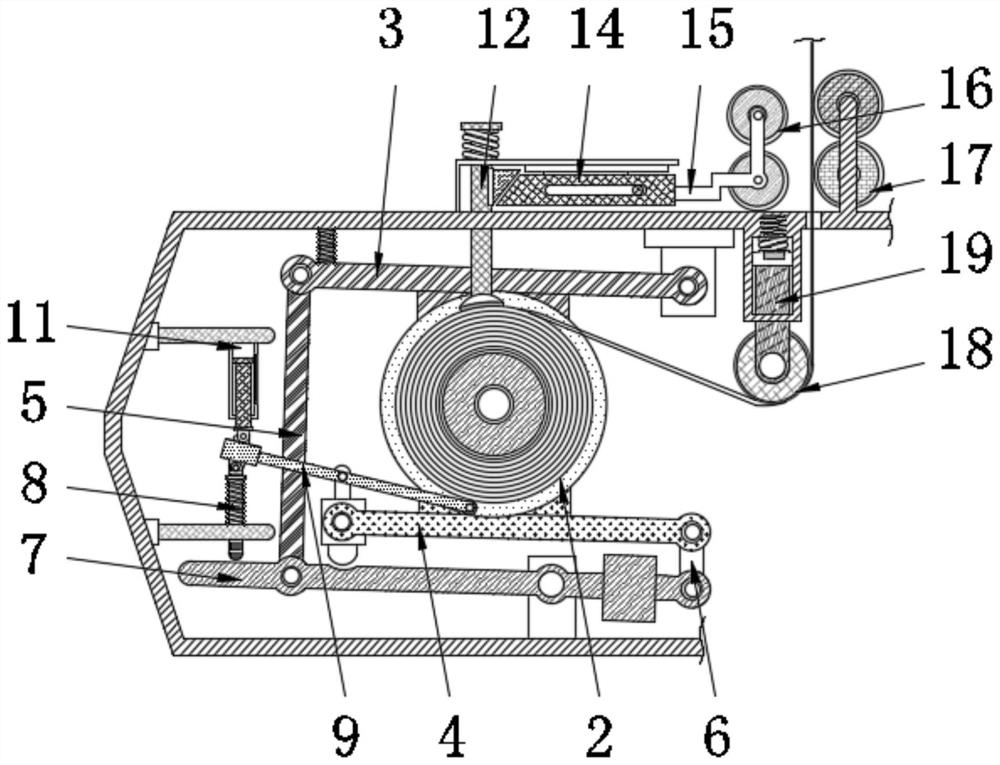

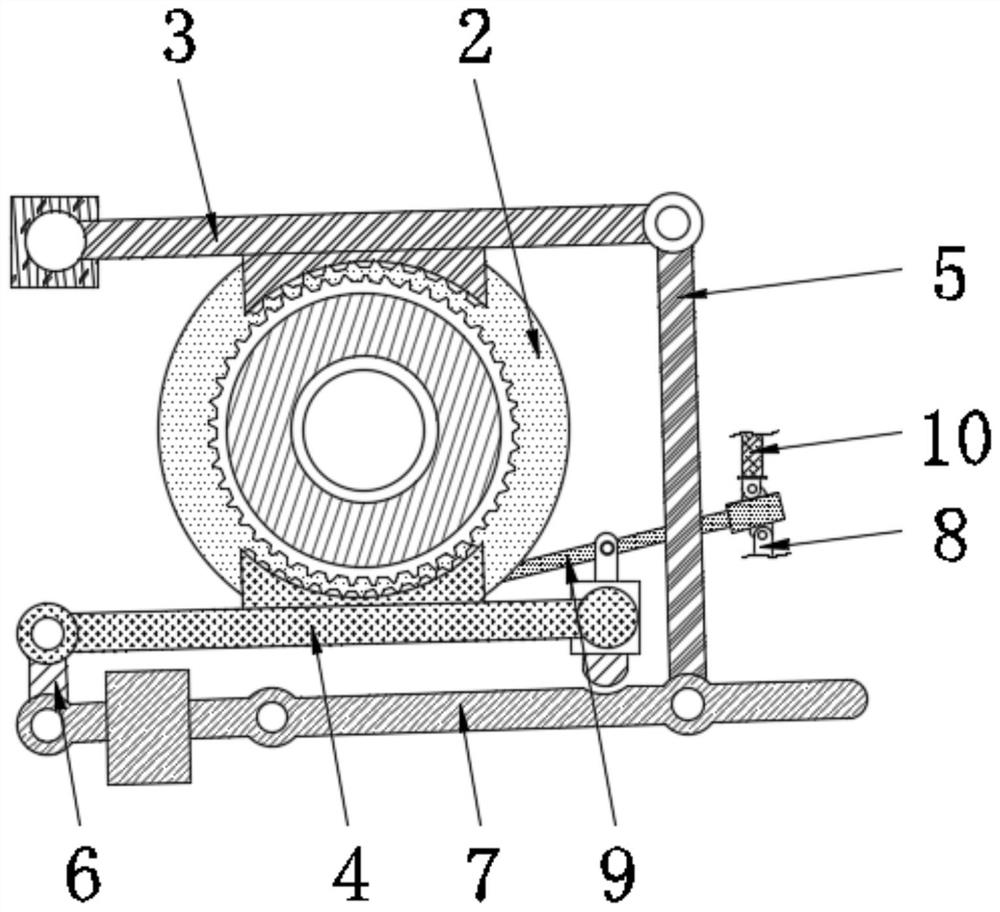

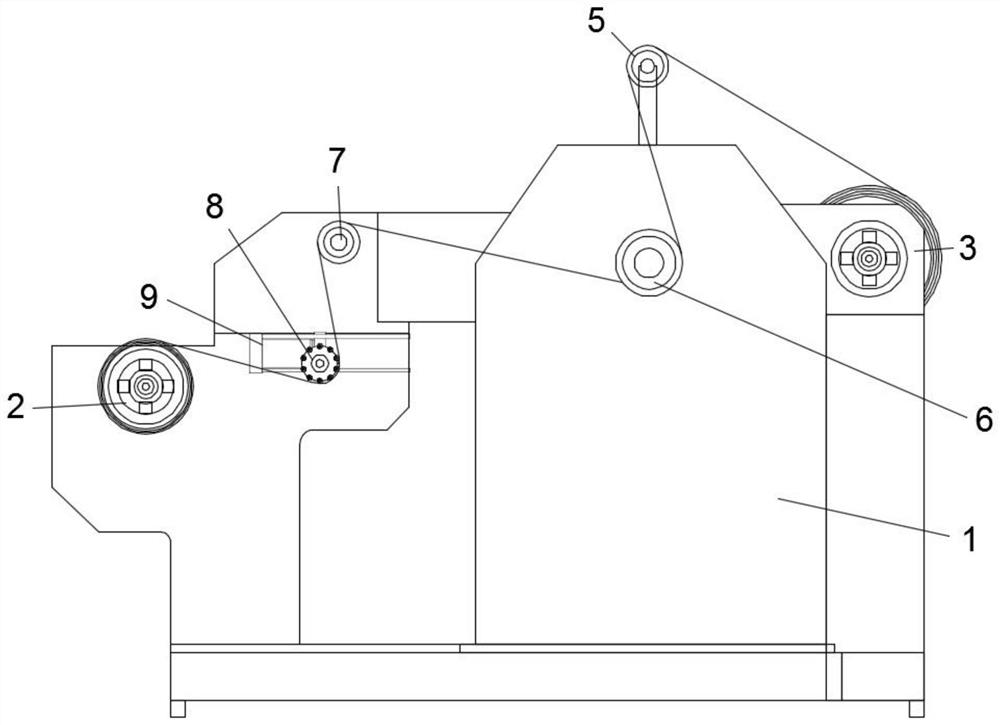

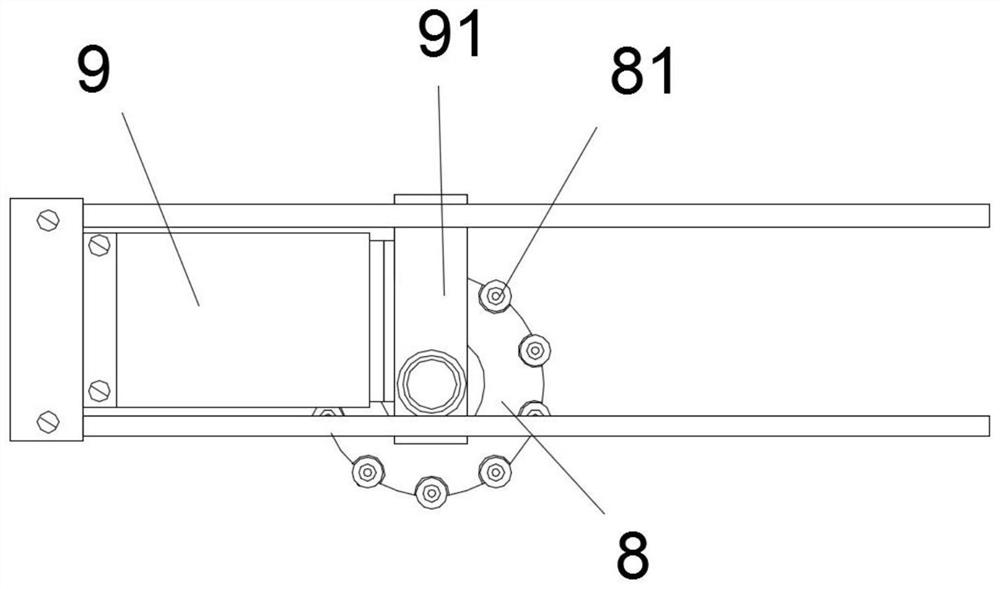

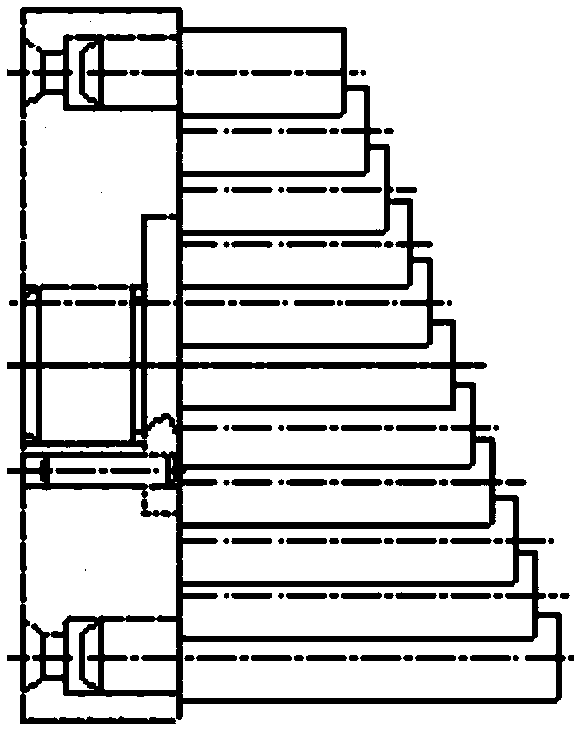

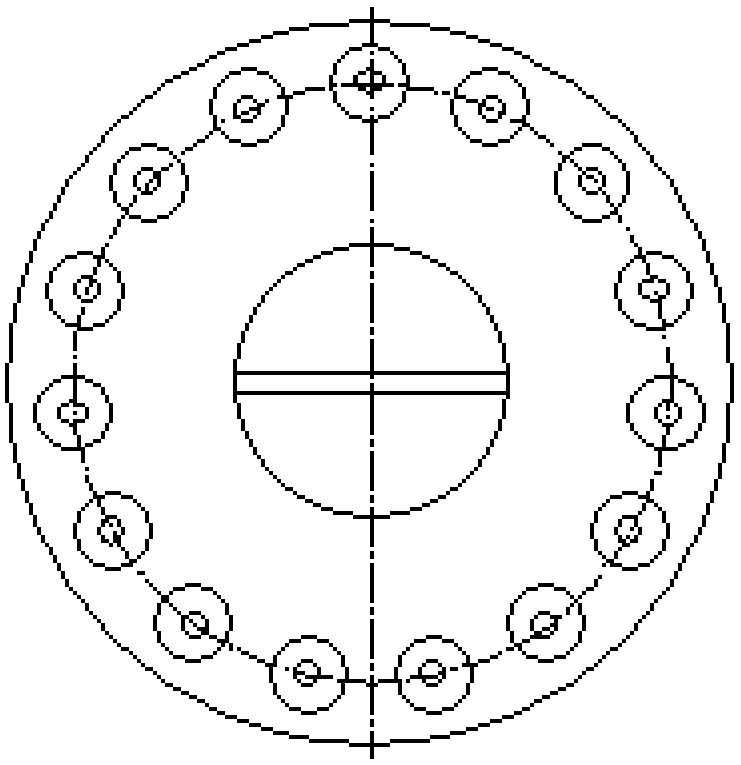

Take-up device for cable arrangement system

The invention relates to a take-up device for a cable arrangement system. The take-up device comprises a take-up assembly, an automatic cable guiding assembly and a frame shaped like a Chinese character 'jing'. A conveyed cable is supported by the frame shaped like the Chinese character 'jing' and guided into the take-up assembly through the automatic cable guiding assembly to be taken up. The take-up assembly comprises a cable arrangement reel, a first motor driving the cable arrangement reel, and a take-up frame matched with the cable arrangement reel to arrange and take up the cable. The take-up frame is arranged on one side of the cable arrangement reel and driven by a second motor to linearly move in a reciprocating mode. The linear reciprocating moving route of the take-up frame is parallel to the tangent line in the rotating circumferential direction of the cable arrangement reel. The take-up device is reasonable in design and simple in structure; in the take-up working process, when the cable arrangement reel rotates, the take-up frame moves left and right regularly, the cable can be arranged on the cable arrangement reel in order, and the production quality of the cable is guaranteed.

Owner:江苏亨芯石英科技有限公司

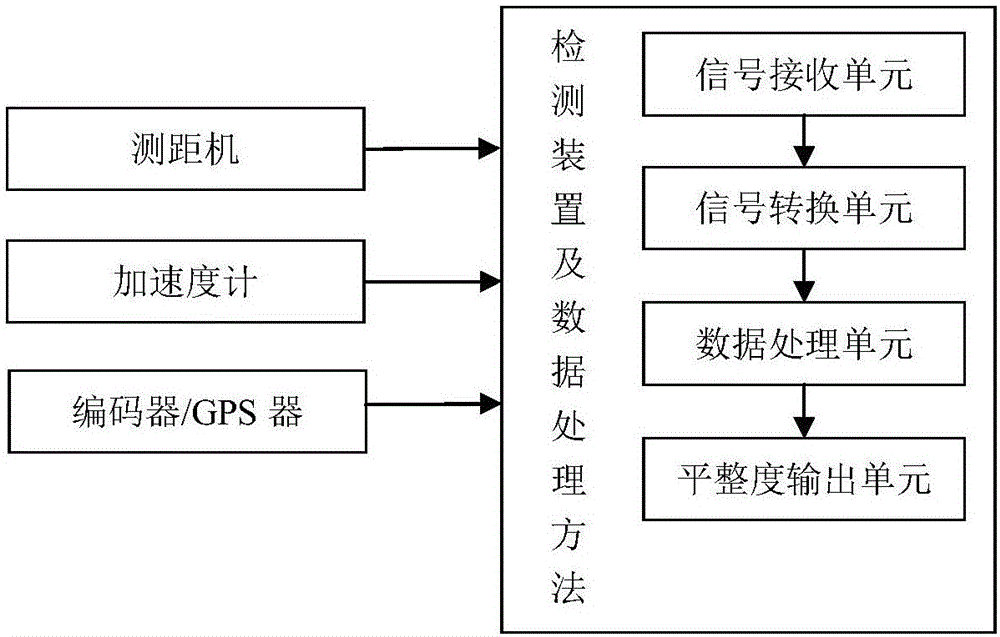

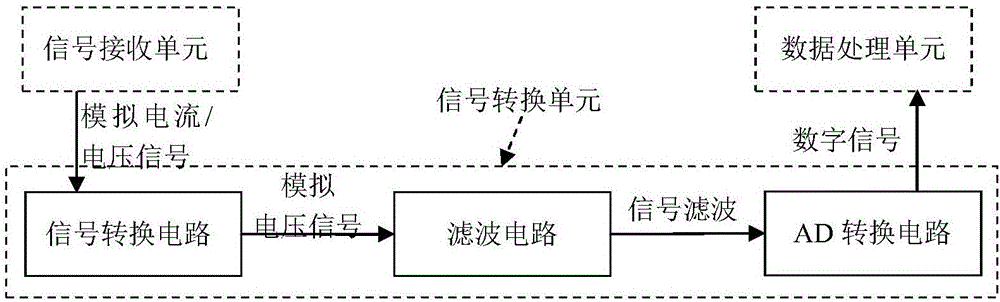

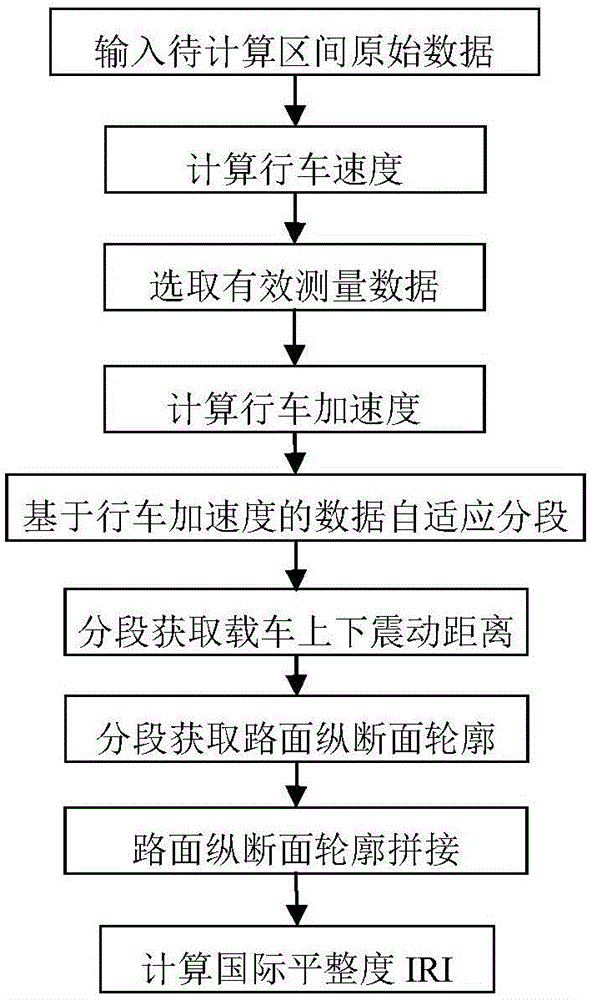

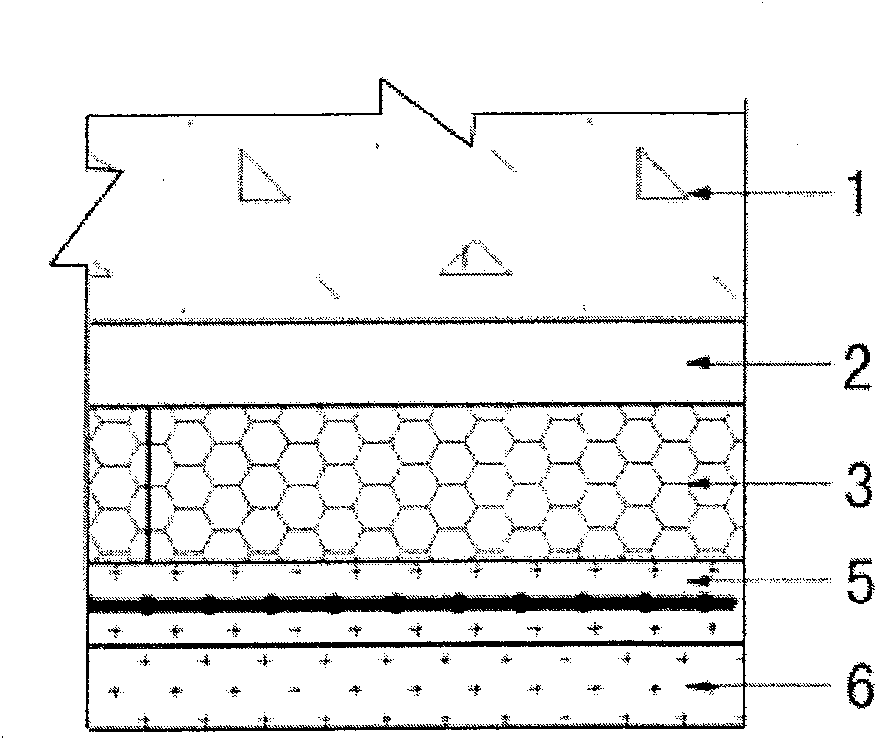

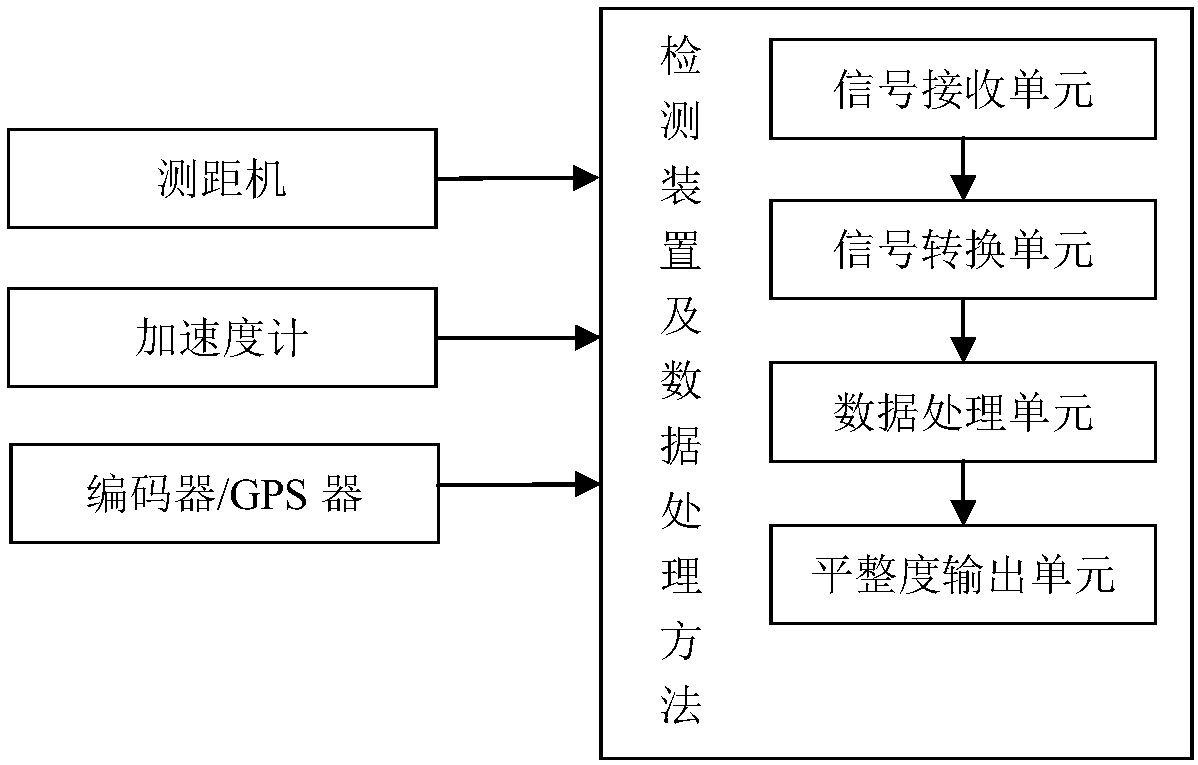

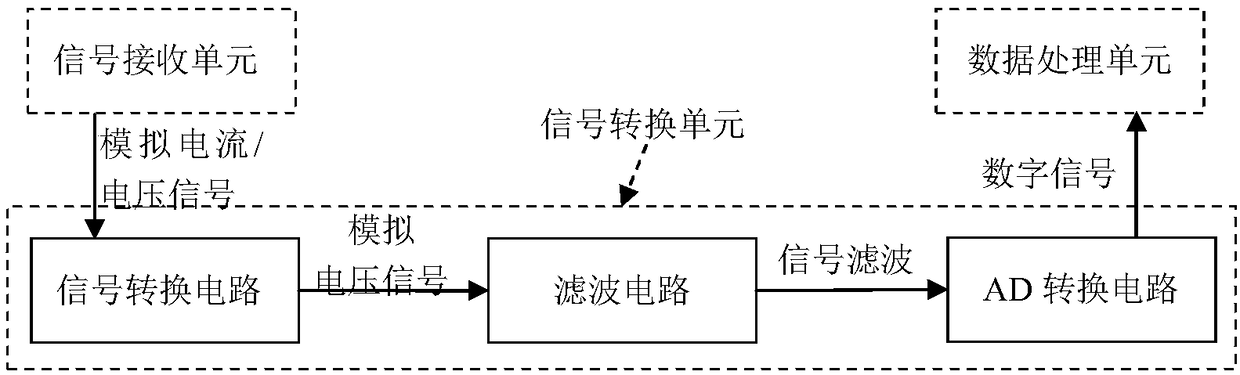

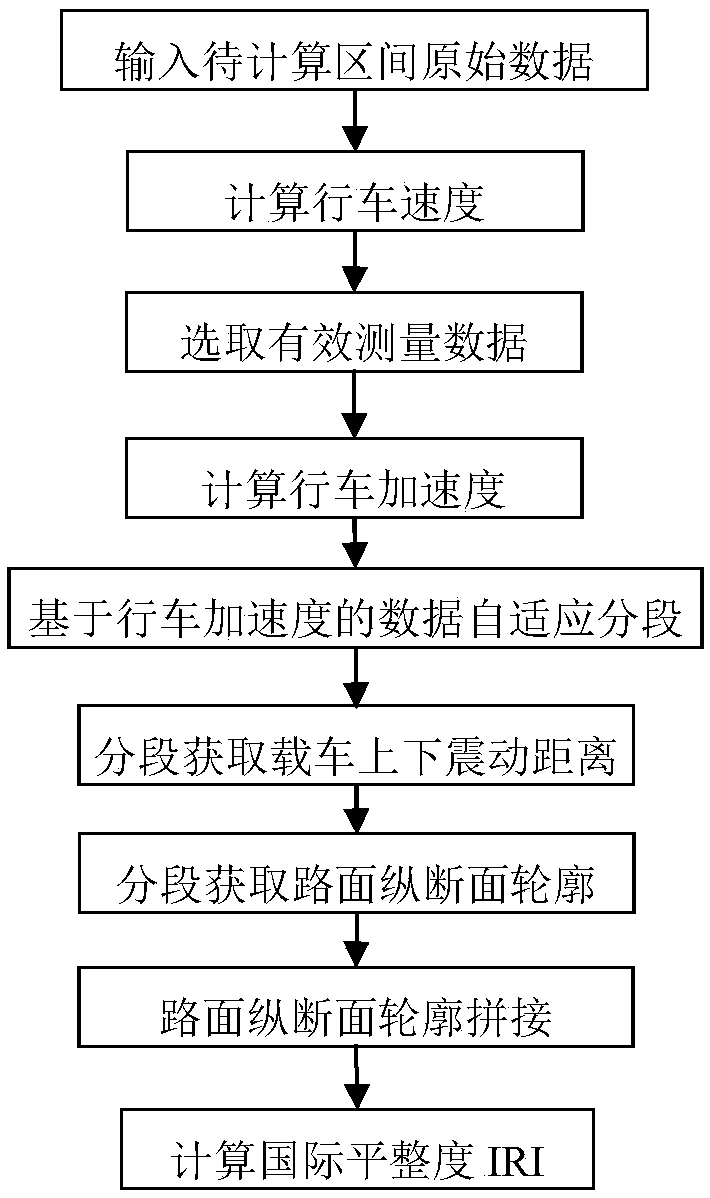

Flatness detecting device and method adapting to low-speed and variable-speed measurement

ActiveCN106638242AImprove maintainabilityStrong reliabilityRoads maintainenceAccelerometer dataLow speed

The invention discloses a flatness detecting device and method adapting to low-speed and variable-speed measurement. The device comprises a signal receiving unit, a signal converting unit, a data processing unit and a flatness output unit. The position offset errors produced by a large amount of accelerometer data second integral of a low-speed measurement interval are effectively decreased by selecting part of effective data, namely removing part of ultra-low-speed redundant data. In the low-speed measurement interval, the existing accumulative error influence of a carrier vehicle shaking distance in a follow-up normal measurement interval is calculated according to the shaking speed obtained based on integrated acceleration. The influence of the low-speed measurement interval on the follow-up normal measurement interval is greatly reduced by utilizing data self-adaptive segmentation of running vehicle acceleration, the data gap phenomenon caused by data segmentation processing is effectively eliminated by splicing segmented road surface longitudinal section outlines, accordingly a relative real outline of a road surface is effectively obtained, and further rapid and accurate flatness measurement at different speeds is achieved.

Owner:WUHAN WUDA ZOYON SCI & TECH

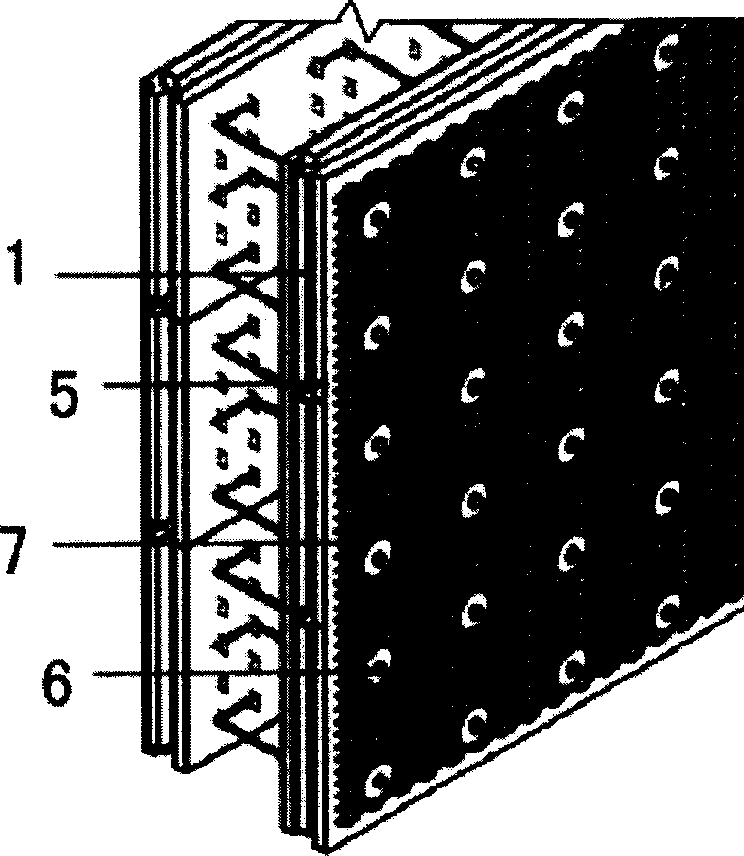

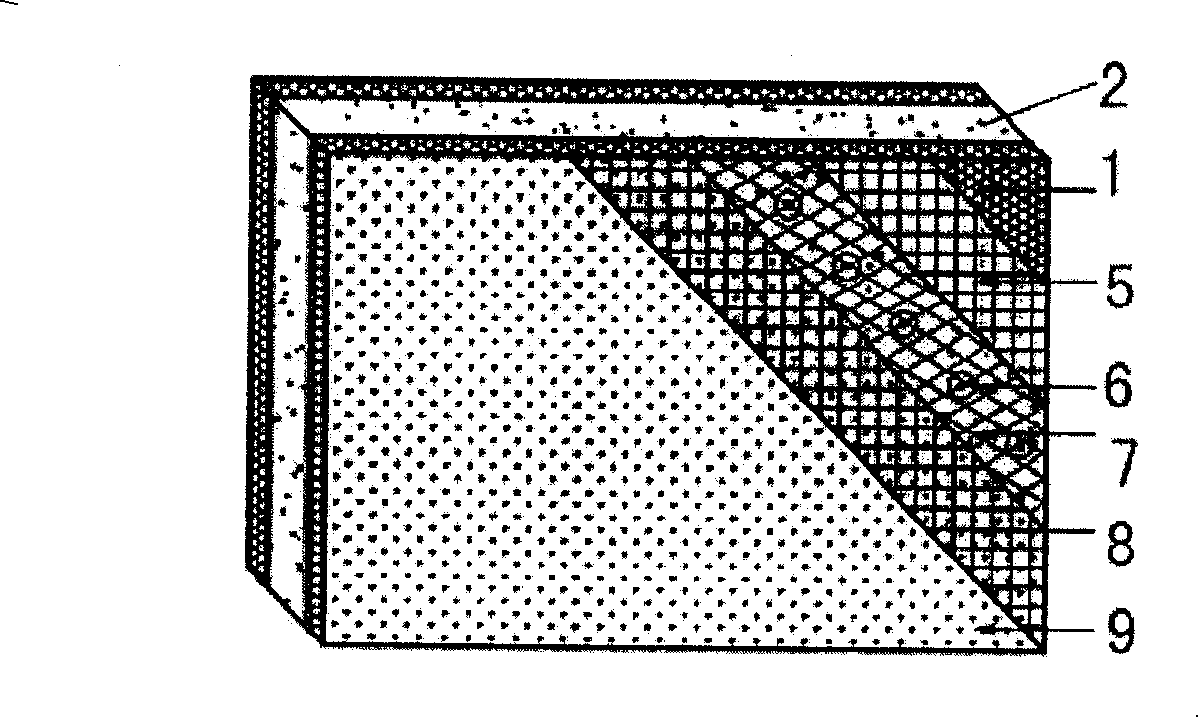

Composite lead-bearing type external heat insulating wall and its construction method

This invention discloses a composite load-bearing type external heat insulating wall, light weight load-bearing type heat insulating wall brick is pasted on wall. The wall brick is that polystyrene foam plastic rectangular block external surface is enwrapped by a layer of glass fiber grid fibric pasted by polymer cement sand bed, decorating layer is pasted on its surface. steel wire mesh is needed to fixed on wall face of old building. Building wall heat insulating and load-bearing effect are revealed in this invention, the advantages are good and precise flatness, high bond strength, wall crack and drop-out can be effectively prevented, it is easy to be made for multiple wall decorating. This invention is propitious to building energy saving and loss reduction, it ca be used to all kinds of new built concrete heat protection wall body, and heat insulating and modification to old buildings.

Owner:朱秦江

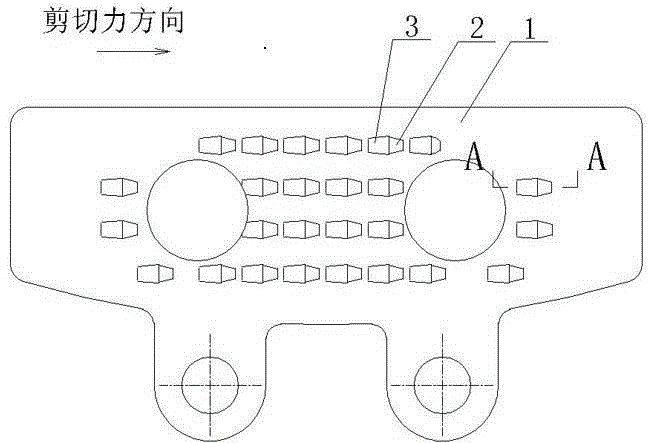

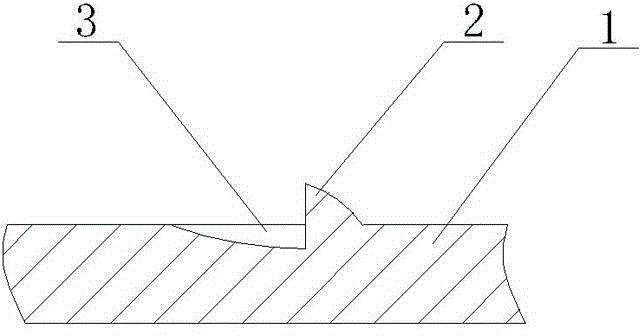

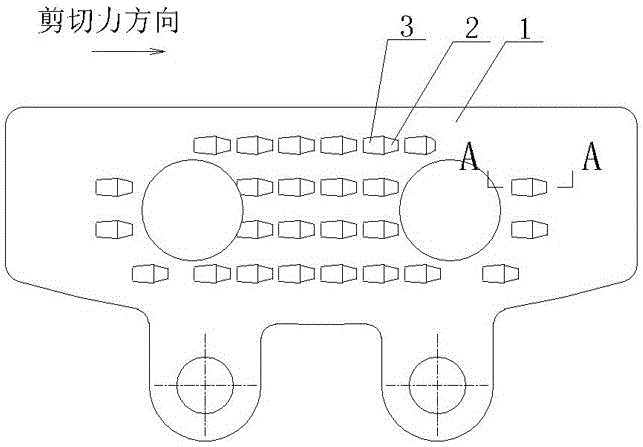

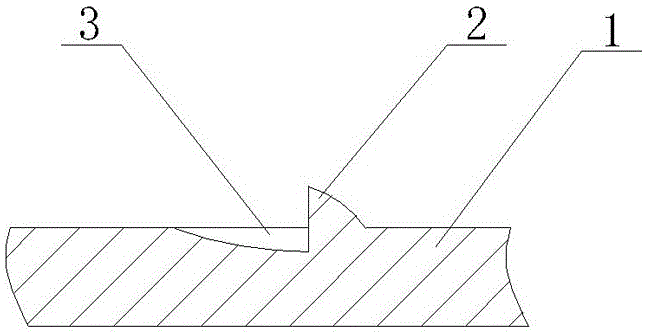

Cold pressing manufacturing process of brake block

ActiveCN104482084AHigh strengthImprove wear resistanceOther chemical processesFriction liningPorosityProcess engineering

The invention discloses a cold pressing manufacturing process of a brake block. The process is characterized by comprising the steps of 1, preparing a steel back; 2, preparing a gasket material; 3, performing cold pressing and forming for the brake block; 4, shaping and brake block; 5, thermally processing the brake block. Compared with the traditional cold-pressed brake block, the cold-pressed brake block manufactured by the process has the advantages of being high in surface porosity factor, high in high-temperature declining performance, high in shearing resistance, stable in quality, and long in service life.

Owner:浙江耐磨达科技有限公司

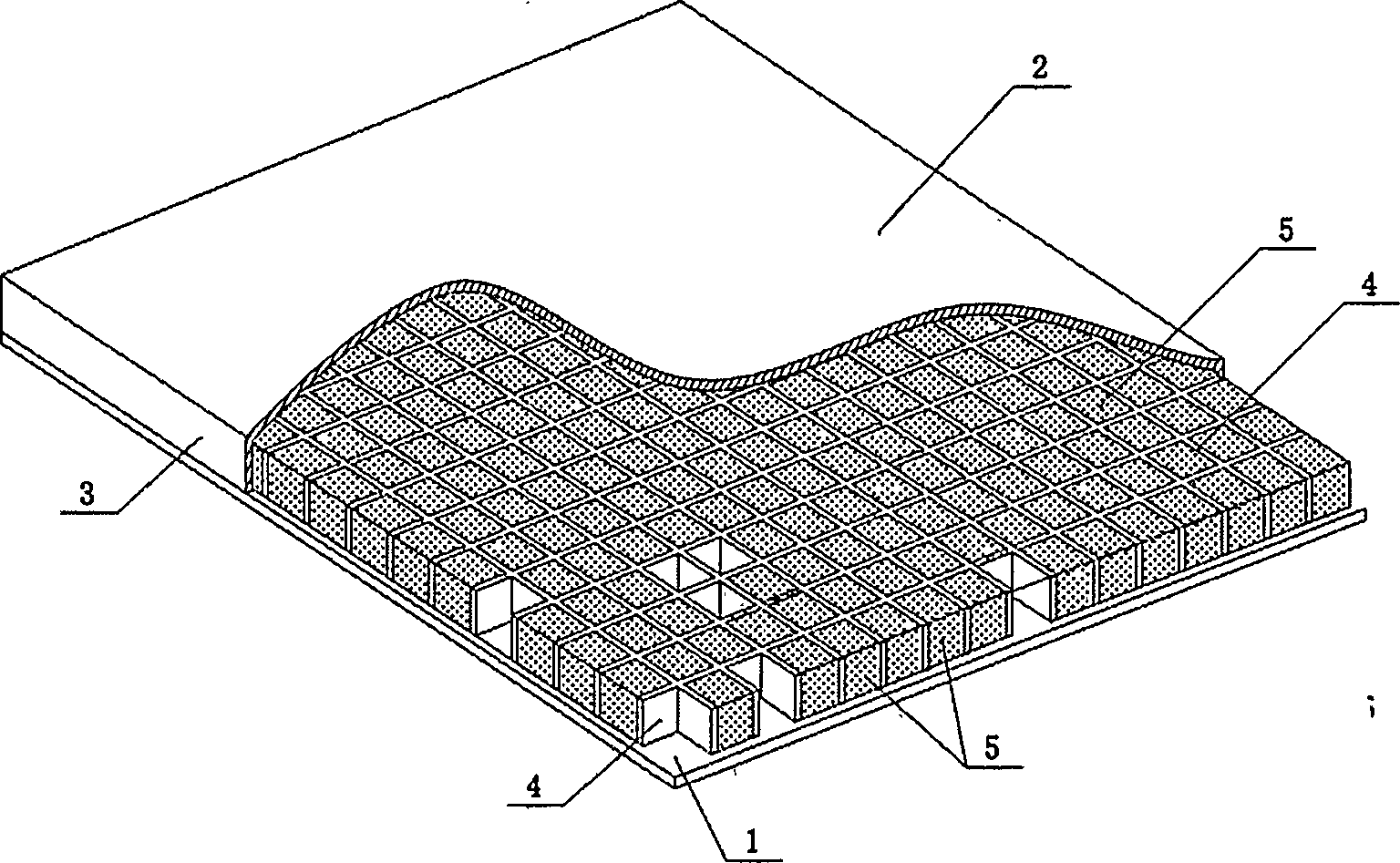

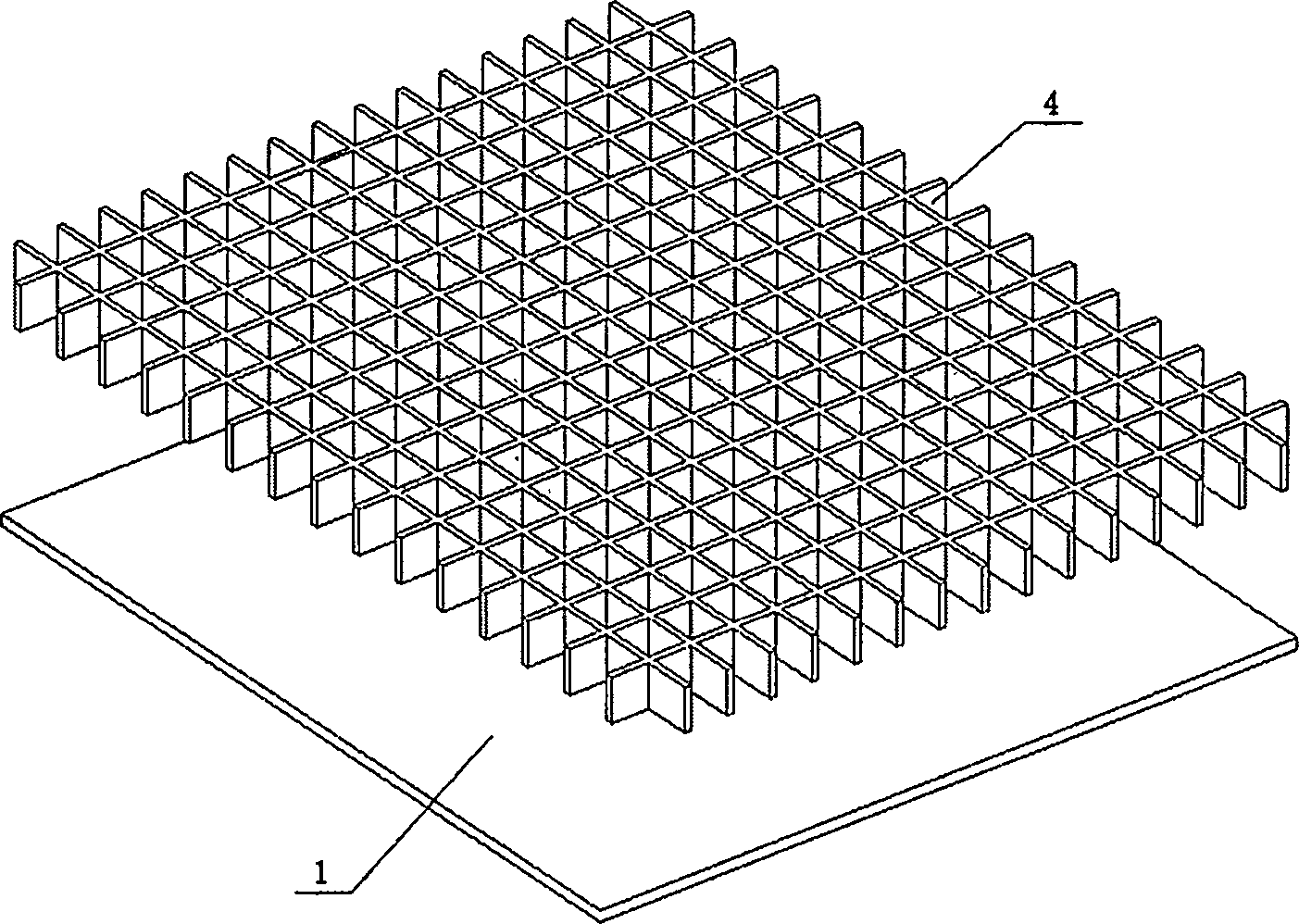

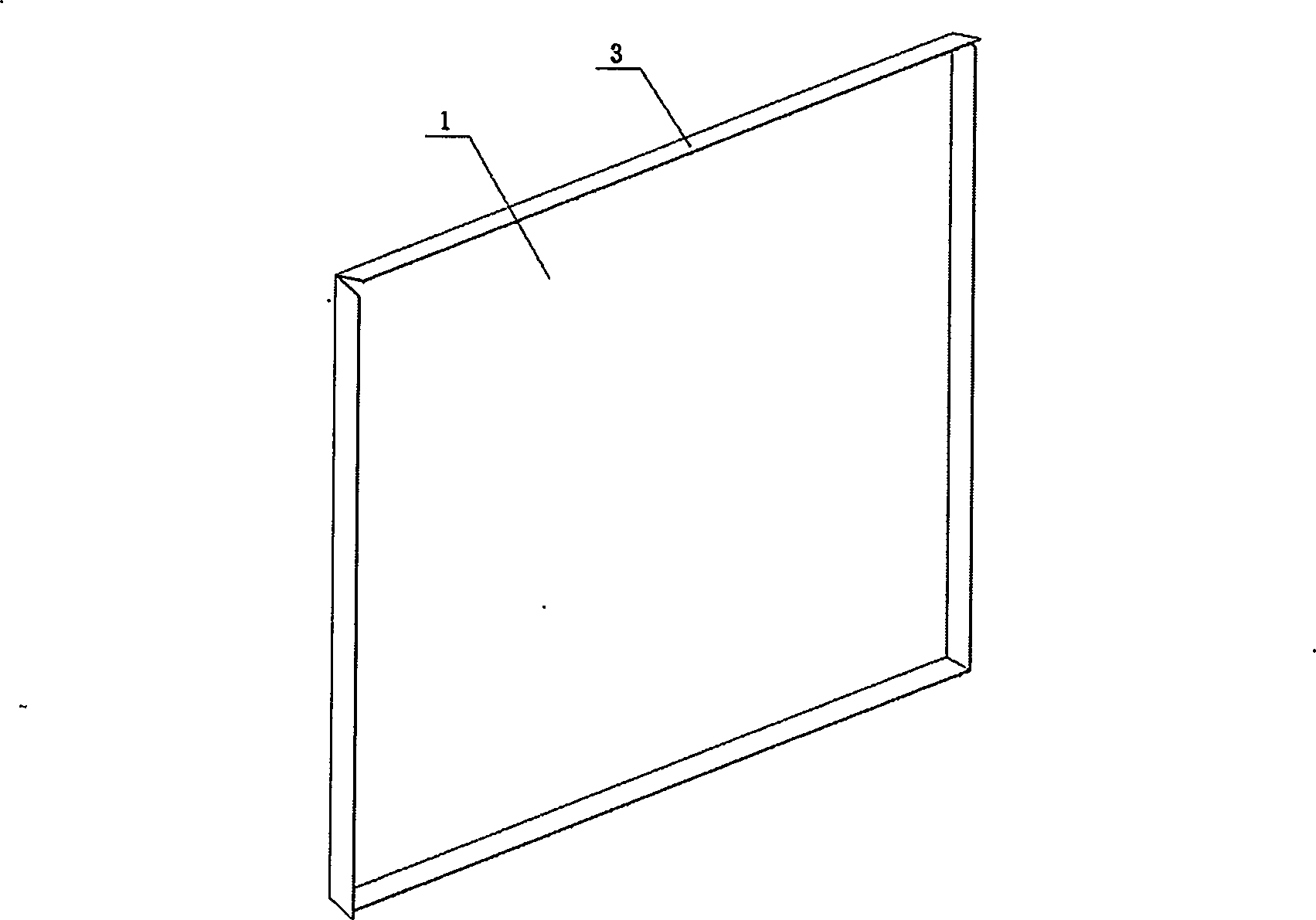

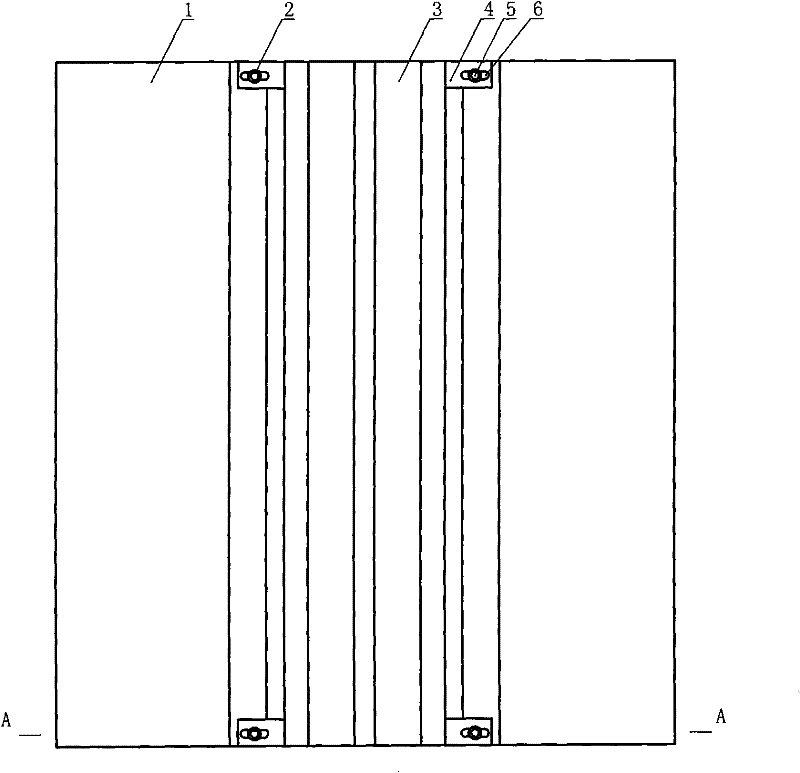

Aluminum plate or aluminum-plastic plate decoration plate with heat insulation function

The invention relates to an aluminum plate or aluminum-plastic plate decoration plate with a heat insulation function. The aluminum plate or aluminum-plastic plate decoration plate comprises a surface decoration plate and a back plate of an aluminum plate or aluminum-plastic plate, the periphery of the surface decoration plate forms flanging side plates through turning and folding, a heat insulation filling layer is arranged in a cavity defined by the surface decoration plate, the flanging side plates and the back plate, the heat insulation layer comprises a certain number of lattice combined bodies defined by longitudinal and transverse separating strips, and heat insulation filling materials are filled in the lattice combined bodies. The aluminum plate or aluminum-plastic plate decoration plate has the advantages that the manufacturing process is greatly improved, and both the dry hanging and the wet pasting can be realized; dual functions of heat insulation and decoration are realized, both the materials and the time consumed by construction are greatly reduced, and the aluminum plate or aluminum-plastic plate decoration plate is more applicable to scale production; the requirements on outer wall heat insulation and energy saving by the nation and all ministries and commissions are completely met, the construction can be carried out in different construction situations, and the aluminum plate or aluminum-plastic plate decoration plate is very favorable for popularization and implementation.

Owner:周瑞山

Composite heat insulation concrete wall and its construction method

The invention relates to a composite thermal insulation concrete wall and relative constructing method, wherein, the thermal insulation layer is used as wall module, inside which the concrete wall base is irrigated; the wall module is formed by two sheets of polystyrene foam plastic side modules, while the modules contain two rows of steel sheets whose edge has teeth with through holes; said teeth and through holes extend out from the polystyrene foam plastic side modules and the two ends of connection reinforced bar is through the holes; outside the wall module, it arranges glass fiber network cloth adhered by polymer cement slurry, steel sheet network anchored on said internal steel sheet, and second glass fiber network cloth and ornament layer while the grid of steel sheet network is filled with the cement slurry in the same thickness of steel sheet network. The invention can effectively improve the strength of polystyrene thermal insulation wall module, avoid the breakage of external wall, apply the ornament and avoid the oxidation of module caused by ultraviolet radiation.

Owner:朱秦江

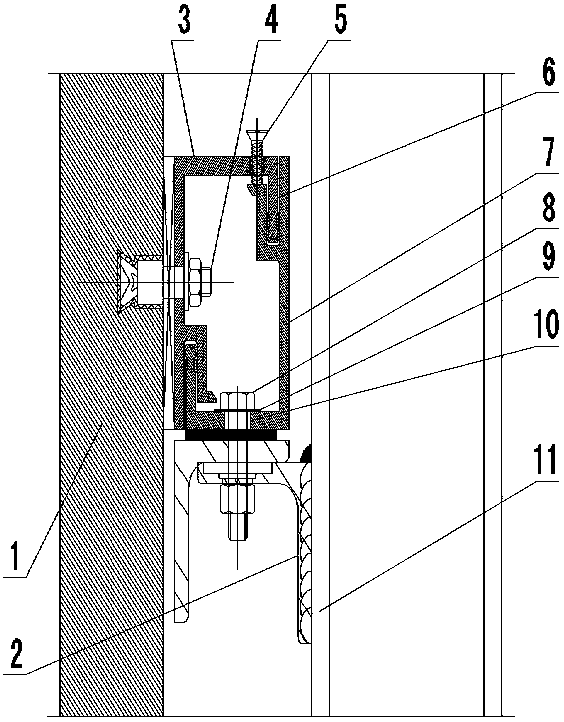

Installation structure and installation method of external wall back-bolt type dry hanging stone

InactiveCN108179853ATwo-way adjustment of horizontal seam straightnessFlatness two-way adjustmentCovering/liningsBuilding material handlingKeel

The invention relates to an installation structure and installation method of outer wall back-bolt type dry hanging stone. The installation structure comprises stone, a back bolt, hangings, and a metal keel, the metal keel is fixed on an outer wall, the stone is connected with the hangings through the back bolt, a sub-hanging and a mother hanging are connected through a slot mode to form a double-card sub-mother hanging, an adjusting screw is added to the top of the mother hanging, the adjusting screw is used to adjust the flatness of horizontal seams of the stone, and the mother hanging is fixed on the upper end of metal keel; and the bottom of the master hanging is provided with a bolt hole for adjusting the flatness of the stone panel and the straightness of flat-fell seams of the stone, by the adjusting bolt to adjust the flatness of the stone panel and the straightness of the flat-fell seams of the stone, the bi-directional adjustment of the flatness of the stone panel and the flatness of the horizontal seams of the stone is realized. According to the installation structure and installation method of the outer wall back-bolt type dry hanging stone, the size deviation of the outer wall of the stone can be controlled effectively, so that the flatness of the horizontal seams of the outer wall dry hanging stone, the flatness of the stone panel, the straightness of splicing ofthe stone are more accurate, thus the quality of the whole appearance of the outer wall dry hanging stone is improved.

Owner:HEBEI SCI & ENG CONSTR ENG GRP CO LTD

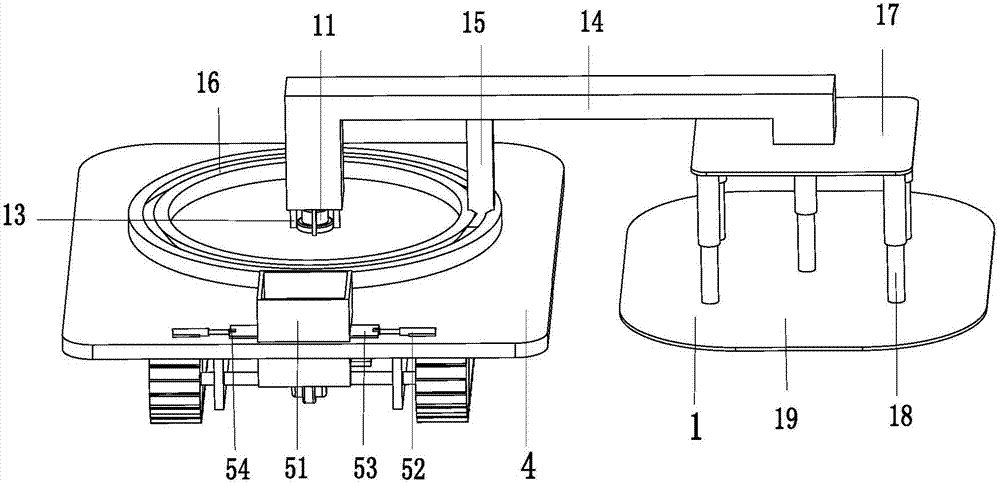

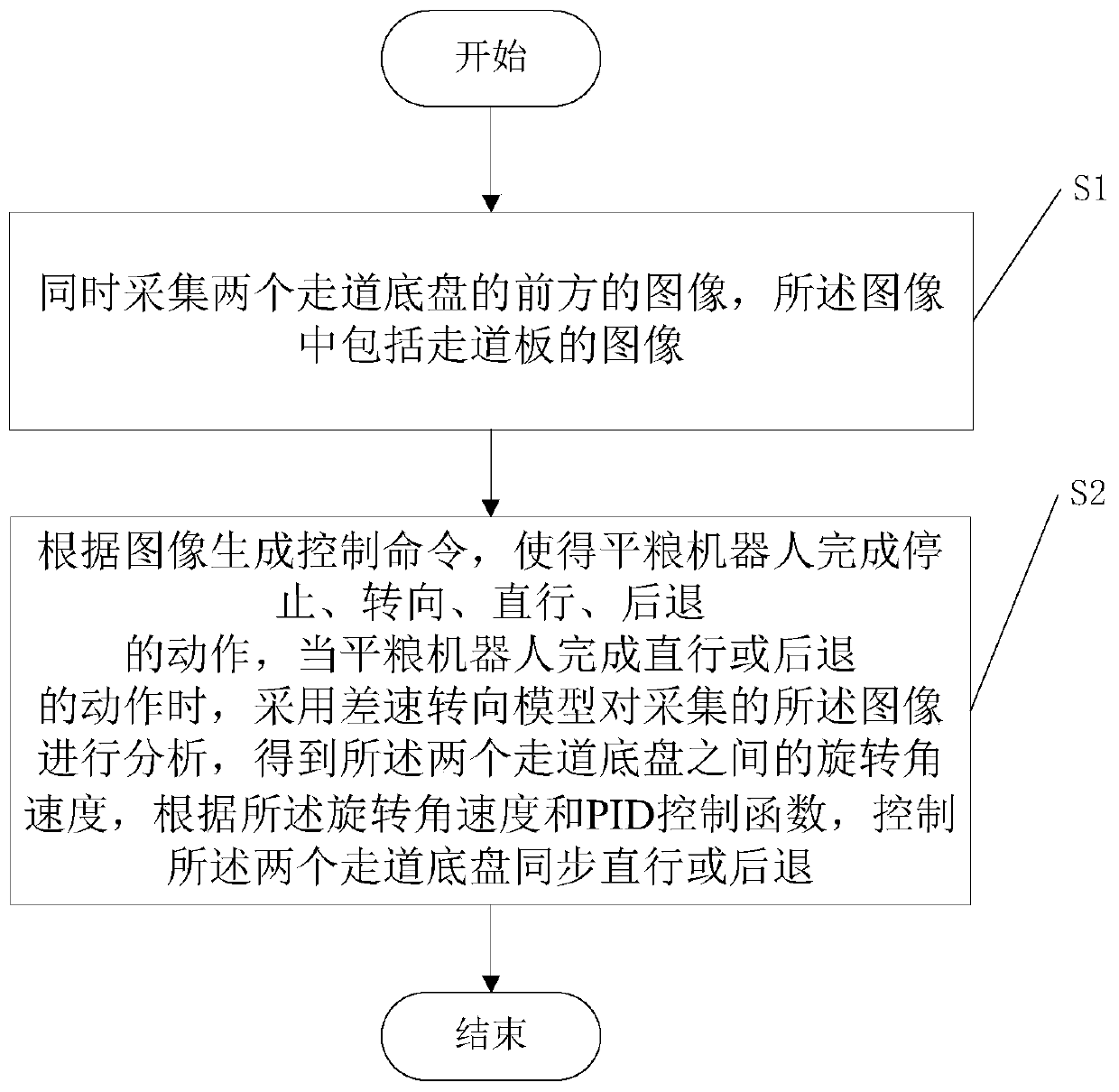

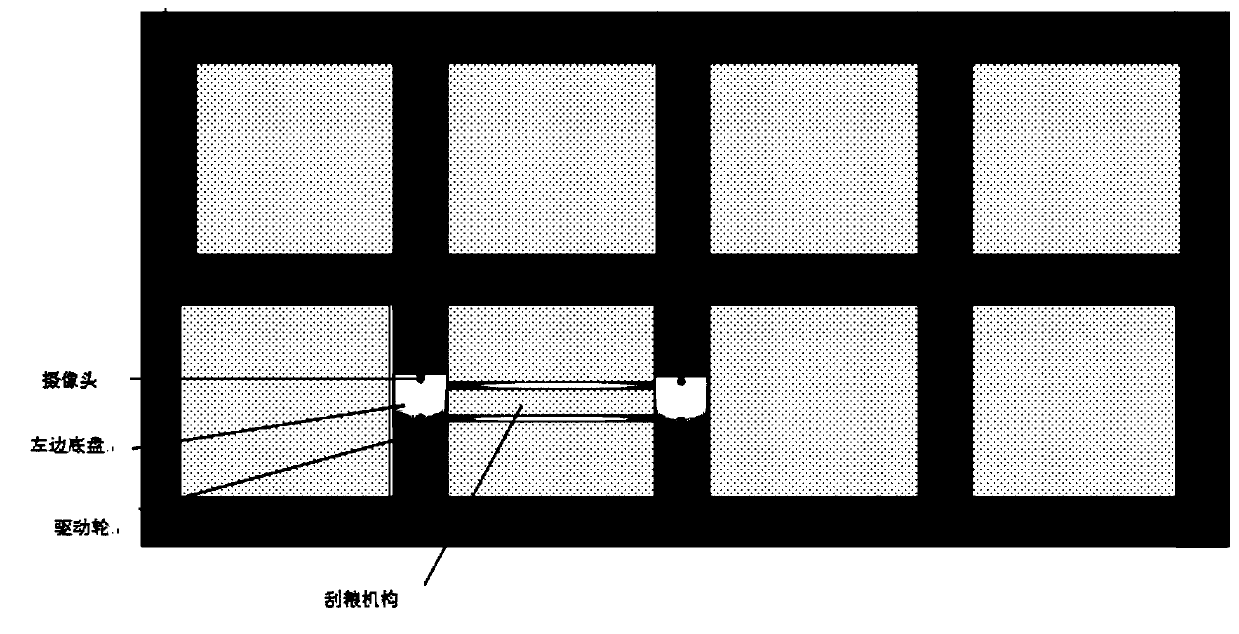

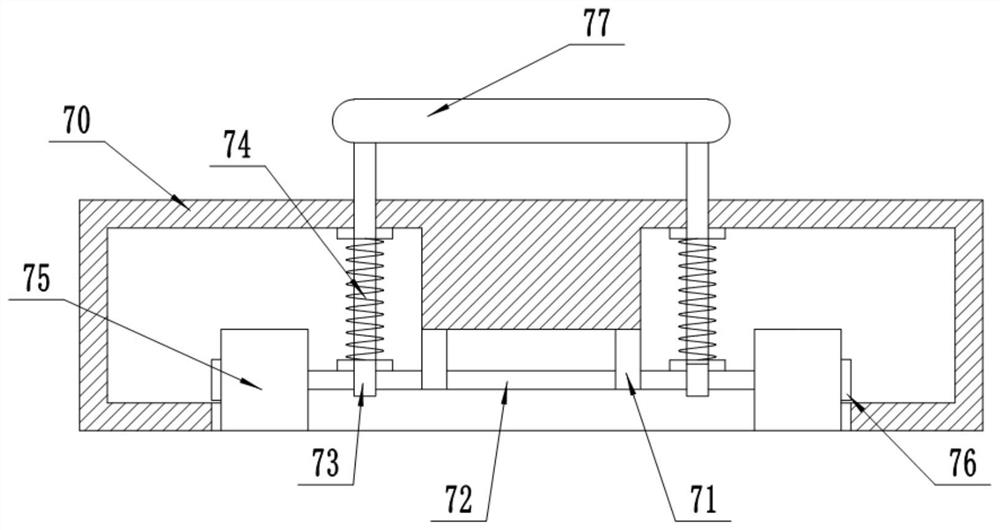

Control method and system of grain leveling robot

ActiveCN110531772AImprove stabilityImprove synchronicityControl using feedbackControllers with particular characteristicsGrain storageSynchronism

The invention discloses a control method and system of a grain leveling robot in the technical field of grain storage. The method comprises the steps: 1) images in front of two aisle chassises are collected at the same time; 2) according to an image generation control command, the grain leveling robot is allowed to finish the actions of stopping, steering and going straight, when the grain leveling robot goes straight, a differential steering model is adopted to analyze the collected images to obtain rotating angular speed between the two aisle chassises, and the two aisle chassises are controlled to go forward synchronously according to the rotating angular speed and a PID control function. The system comprises the two aisle chassises and one grain scraping mechanism. The two ends of thegrain scraping mechanism are fixed to the two aisle chassises respectively, so that the two aisle chassises have the same deflection direction and deflection angle when going straight; and through thesystem and method, stability and synchronism of robot operation are improved, and the grain scraping effect is good.

Owner:SICHUAN ARTIGENT ROBOTICS EQUIP

A production process of aluminum alloy window profiles

ActiveCN110665986BEffective straighteningAccurate flatnessShaping toolsExtrusion control devicesIngotWater cooling

Owner:无锡辰浩建筑节能科技有限公司

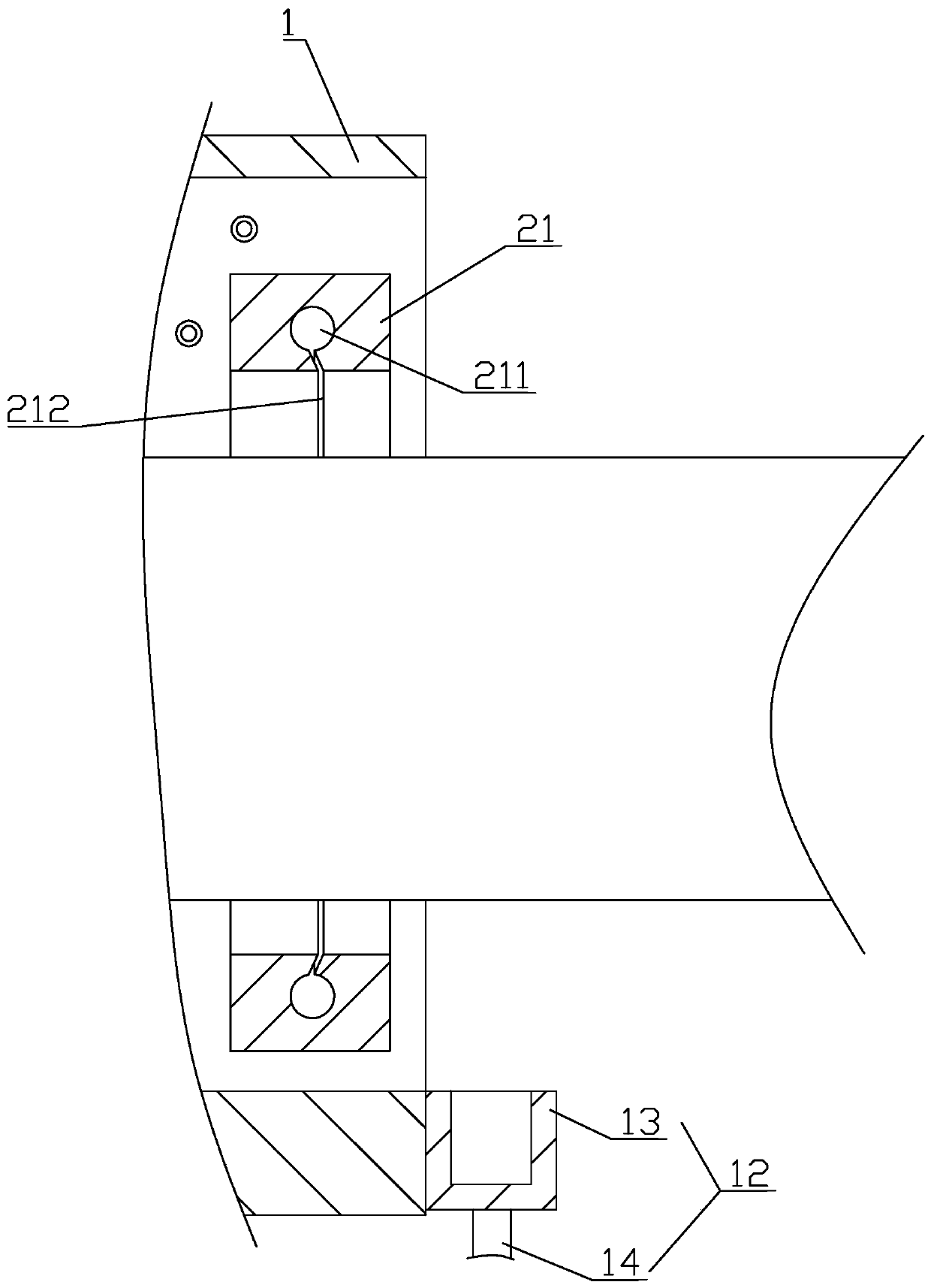

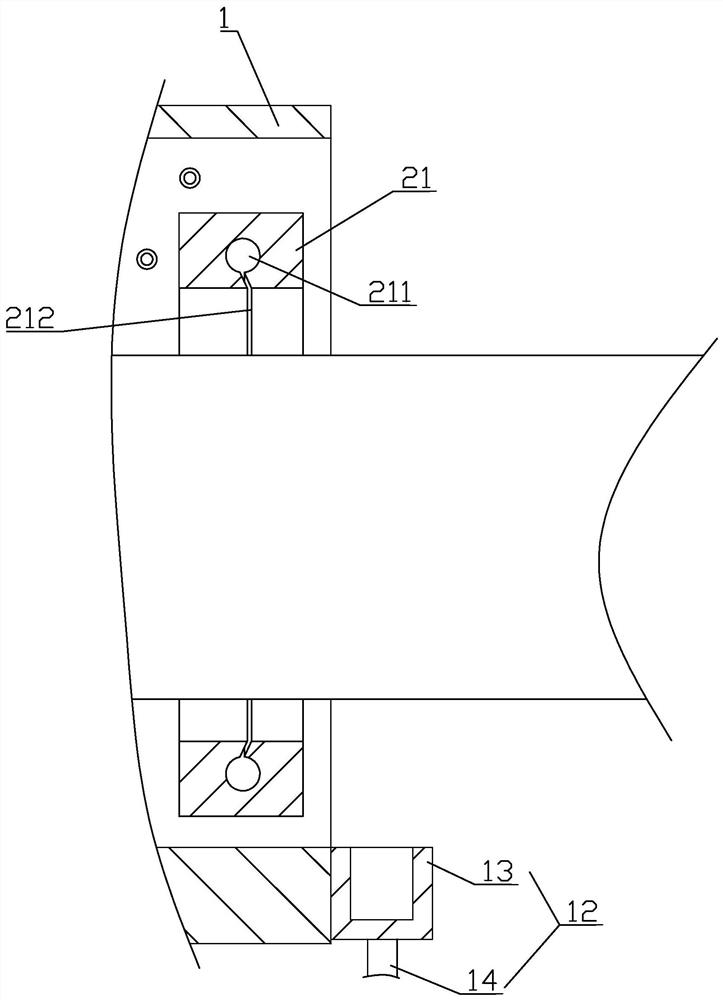

Wall flatness detection device for civil engineering

PendingCN113251904AEasy to measureAccurate measurementCarpet cleanersFloor cleanersStructural engineeringWorkbench

The invention discloses a wall flatness detection device for civil engineering. The wall flatness detection device comprises a horizontal bottom plate, an adjusting block, an adjusting needle, an adjusting bolt, a locking nut, horizontal liquid, a moving device, a calibration line, a support, a first locking valve, a supporting column, a calibration needle, a rotating sleeve, a workbench and the like. The device is reasonable and simple in structure, low in production cost, convenient to install and complete in function, the horizontal bottom plate is arranged and placed on the ground in front of a wall needing to be measured, and whether horizontal liquid in the horizontal bottom plate is inclined or not is observed after the horizontal bottom plate is placed; the adjusting bolt is rotated to enable the adjusting needle to heighten the needed face so that the horizontal liquid can be in a parallel face, the matched locking nut is locked after adjustment is completed, and after locking is completed, the device above the supporting column is installed on the support and fixed by rotating the first locking valve. Firstly, the flatness of the ground is corrected, so that the measured flatness of the wall is more accurate, and the authenticity of a measured value is greatly improved.

Owner:谷皋

Cleaning blade, method of fabricating cleaning blade, and cleaning apparatus for liquid discharge head

A cleaning blade which wipes a liquid discharge area by being moved relatively with respect to the liquid discharge area of a liquid discharge head having the liquid discharge area in which liquid discharge nozzles are arranged to discharge a liquid is disclosed. The cleaning blade includes: a supporting plate which has an adhesive agent layer on its front surface; and a wipe part which is slid and contacted with the liquid discharge area, the wipe part formed in which an elastic part formed of a synthetic resin is formed in one piece on the adhesive agent layer, and a tip end thereof is cut in a predetermined shape.

Owner:SONY CORP

Composite bearing type external heat insulating wall and its construction method

This invention discloses a composite load-bearing type external heat insulating wall, light weight load-bearing type heat insulating wall brick is pasted on wall. The wall brick is that polystyrene foam plastic rectangular block external surface is enwrapped by a layer of glass fiber grid fibric pasted by polymer cement sand bed, decorating layer is pasted on its surface. steel wire mesh is needed to fixed on wall face of old building. Building wall heat insulating and load-bearing effect are revealed in this invention, the advantages are good and precise flatness, high bond strength, wall crack and drop-out can be effectively prevented, it is easy to be made for multiple wall decorating. This invention is propitious to building energy saving and loss reduction, it ca be used to all kindsof new built concrete heat protection wall body, and heat insulating and modification to old buildings.

Owner:朱秦江

A flatness detection device and method suitable for low-speed and variable-speed measurement

ActiveCN106638242BImprove maintainabilityStrong reliabilityRoads maintainenceAccelerometer dataLow speed

The invention discloses a flatness detecting device and method adapting to low-speed and variable-speed measurement. The device comprises a signal receiving unit, a signal converting unit, a data processing unit and a flatness output unit. The position offset errors produced by a large amount of accelerometer data second integral of a low-speed measurement interval are effectively decreased by selecting part of effective data, namely removing part of ultra-low-speed redundant data. In the low-speed measurement interval, the existing accumulative error influence of a carrier vehicle shaking distance in a follow-up normal measurement interval is calculated according to the shaking speed obtained based on integrated acceleration. The influence of the low-speed measurement interval on the follow-up normal measurement interval is greatly reduced by utilizing data self-adaptive segmentation of running vehicle acceleration, the data gap phenomenon caused by data segmentation processing is effectively eliminated by splicing segmented road surface longitudinal section outlines, accordingly a relative real outline of a road surface is effectively obtained, and further rapid and accurate flatness measurement at different speeds is achieved.

Owner:WUHAN WUDA ZOYON SCI & TECH

Brake Pad Cold Press Manufacturing Process

ActiveCN104482084BHigh strengthImprove wear resistanceOther chemical processesFriction liningPorosityProcess engineering

The invention discloses a cold pressing manufacturing process of a brake block. The process is characterized by comprising the steps of 1, preparing a steel back; 2, preparing a gasket material; 3, performing cold pressing and forming for the brake block; 4, shaping and brake block; 5, thermally processing the brake block. Compared with the traditional cold-pressed brake block, the cold-pressed brake block manufactured by the process has the advantages of being high in surface porosity factor, high in high-temperature declining performance, high in shearing resistance, stable in quality, and long in service life.

Owner:浙江耐磨达科技有限公司

Evenness adjusting methods for industrial factory building T-shaped groove and platform thereof

The invention relates to evenness adjusting methods for an industrial factory building T-shaped groove and a platform thereof. The evenness adjusting method for the T-shaped groove comprises the following steps of: (1) measuring and confirming the position of the T-shaped groove and drilling a positioning hole; (2) installing an expansion bolt with an adjusting nut into the positioning hole and placing a tray on the adjusting nut of the expansion bolt; (3) adjusting the evenness of a support plate by a leveling instrument and a theodolite through the adjusting nut on the expansion bolt and placing the T-shaped groove on the corresponding position of the support plate; (4) adjusting the evenness of the support plate again by the leveling instrument and the theodolite through the adjusting nut on the expansion bolt and fixing the T-shaped groove by a compression bolt and angle iron with an opening so as to finish the evenness adjustment of the T-shaped groove. The invention has the advantages of simplicity and easiness for operation, easiness for precision control, shorter adjusting time, higher working efficiency, lower construction cost, high integral appearance quality and time and labor saving. The evenness adjusting methods for the industrial factory building T-shaped groove and the platform thereof have higher precision.

Owner:MCC TIANGONG GROUP

Road surface detection method, device, computer equipment and storage medium

ActiveCN110084116BHigh precisionHigh flatness precisionImage analysisThree-dimensional object recognitionPoint cloudSimulation

The present application relates to a road surface detection method, device, computer equipment and storage medium. The method includes: acquiring a ground point cloud of the road surface to be detected; constructing a grid map according to the ground point cloud, determining the two-dimensional ground points covered by each grid in the grid map; acquiring the ground point cloud of each grid The height value of the two-dimensional ground points covered by each grid, and the flatness of the road surface to be detected is determined according to the height value of the two-dimensional ground points covered by each grid. By adopting the method, road surface detection with higher precision can be realized.

Owner:SUTENG INNOVATION TECH CO LTD

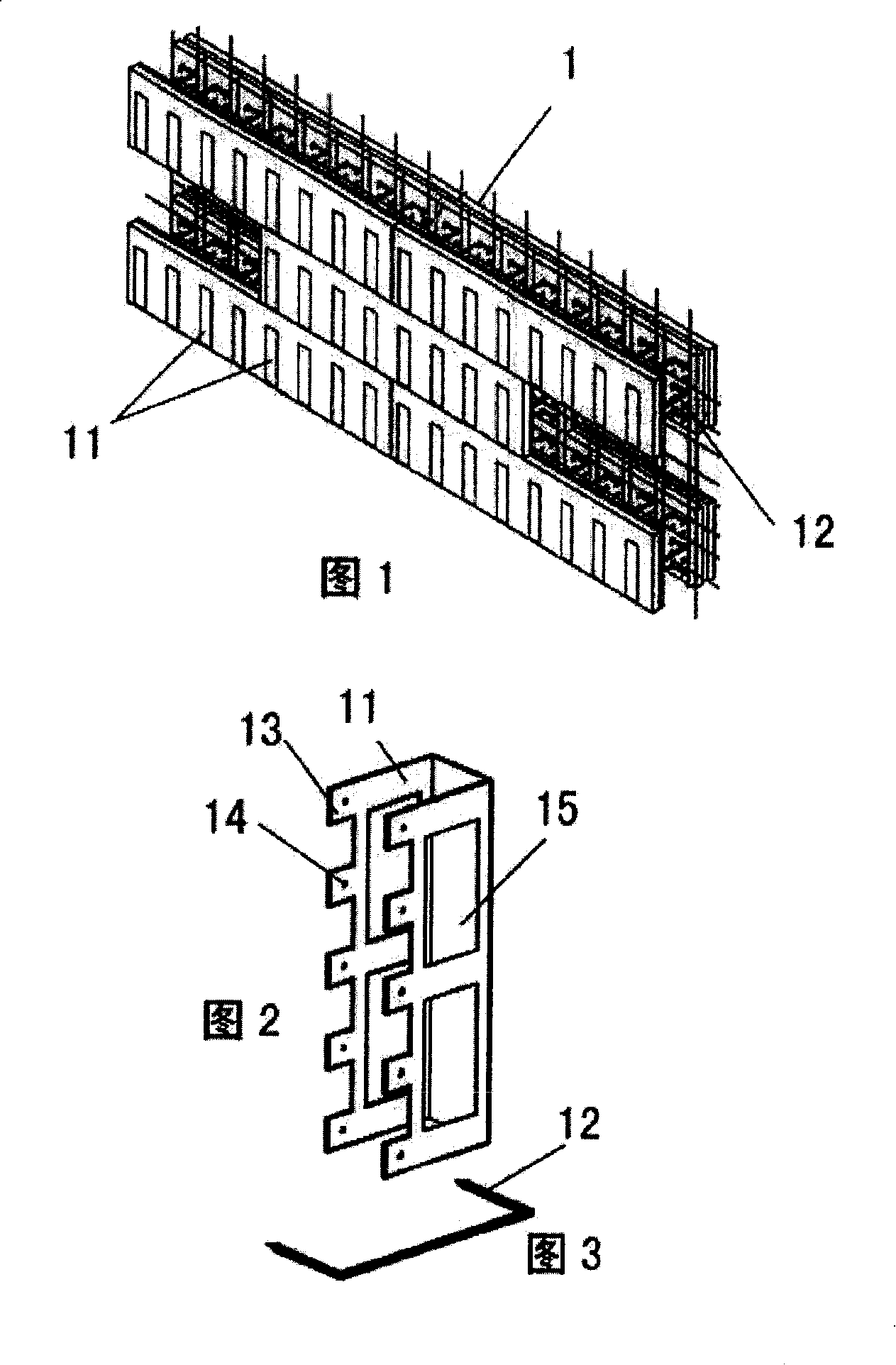

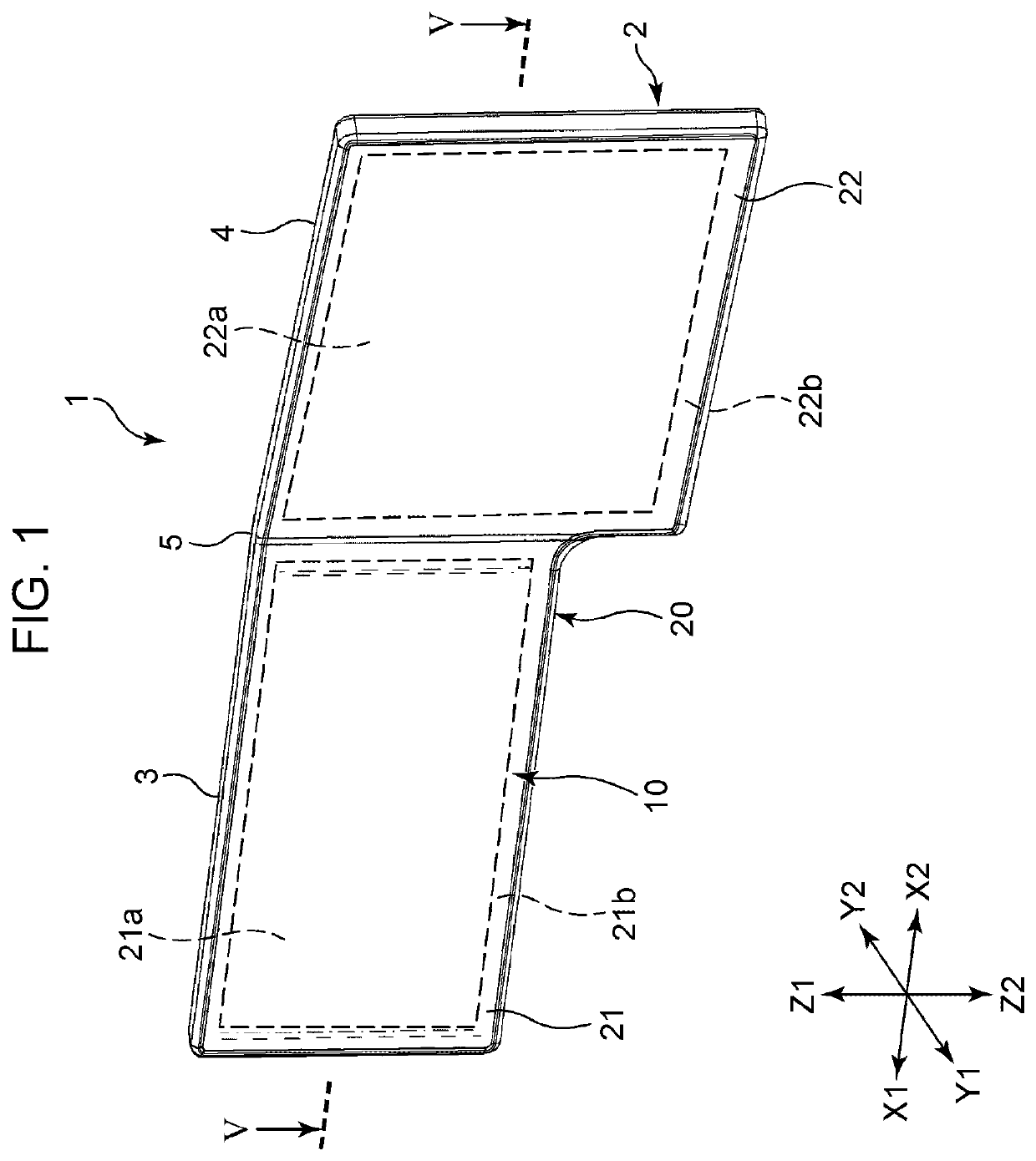

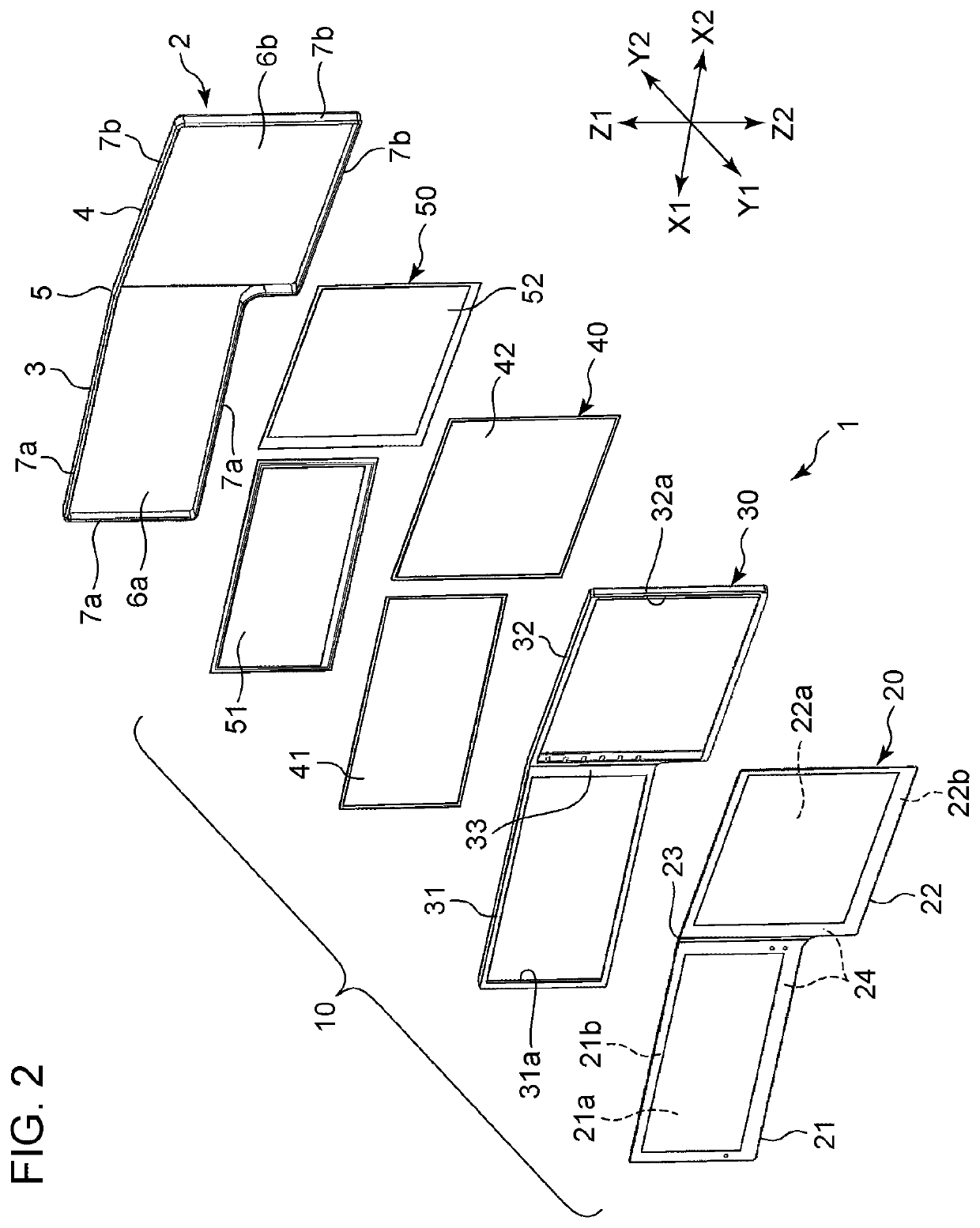

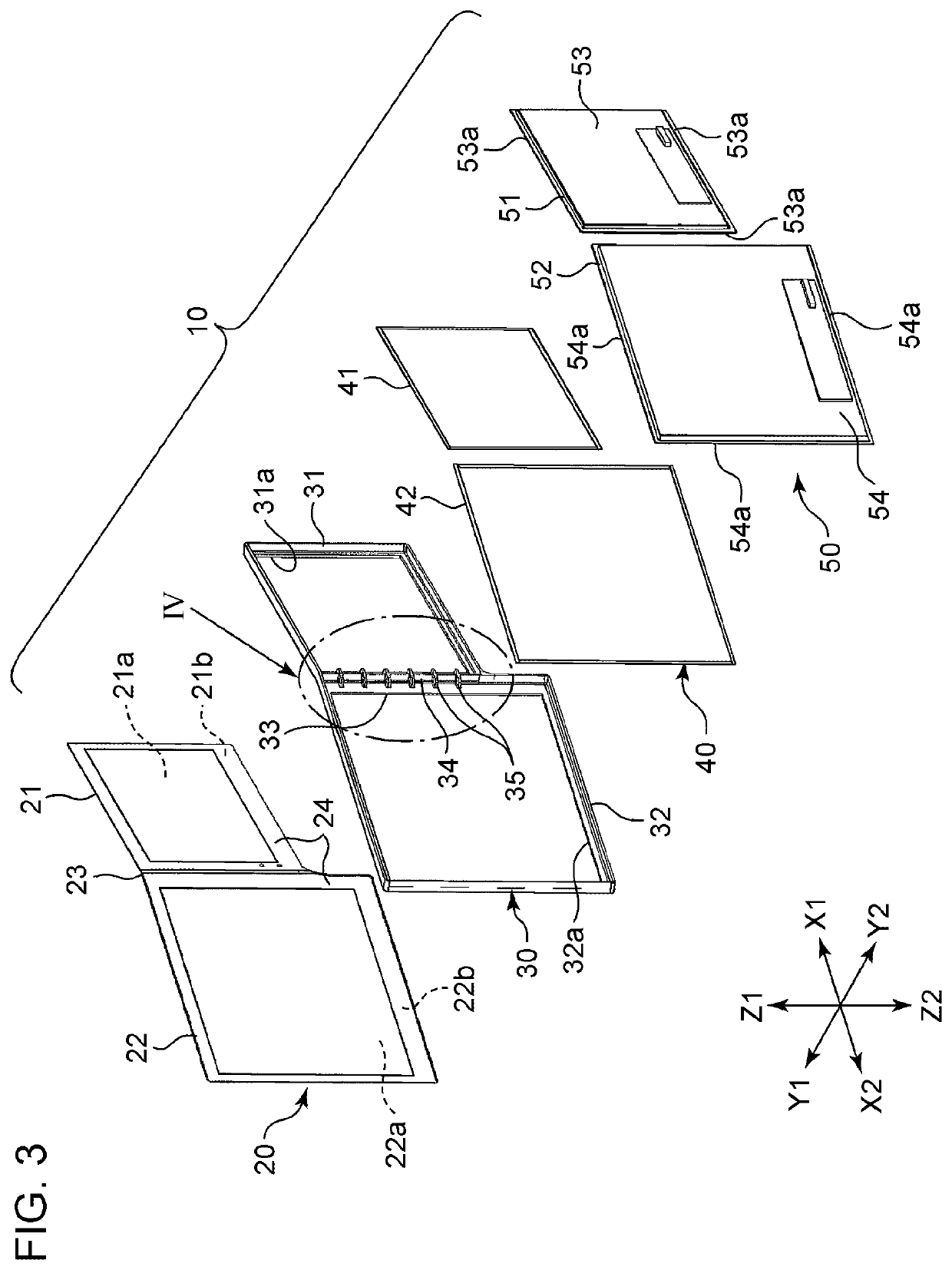

Display apparatus and method for assembling the same

A frame-shaped reinforcement member is bonded and fixed to a rear surface of a cover panel, such as a glass plate. The reinforcement member has a rigidity higher than that of the cover panel. Since the reinforcement member is provided, the flatness of flat portions of the cover panel can be maintained at a high level. The reinforcement member is bonded and fixed to a rear support member after display cell elements are bonded to the flat portions and backlights are fixed to the reinforcement member.

Owner:ALPINE ELECTRONICS INC

Improved steel coil decoiler capable of improving leveling precision

InactiveCN112108534AGuaranteed tensionImprove work efficiencyClassical mechanicsStructural engineering

The invention provides an improved steel coil decoiler capable of improving leveling precision. A bottom roller is fixedly installed between every two adjacent flattening rollers and on the upper surface of a machine bin, fixing rods are installed on the portions, on the inner wall of the machine bin, of the lower surfaces of the flattening rollers in a sliding mode, pressing wheels are rotatablyinstalled at the tail ends of the fixing rods, magnets are arranged in the top ends of the fixing rods, and a corresponding coil is arranged above the magnets and inside the machine bin. In the leveling process of the surface of a steel coil base, the diameter is smaller and smaller, the left end of a supporting rod attached to the surface of a steel coil is gradually downward, therefore a slidingrod is driven to move in a sleeve to adjust the positions of a metal sheet and a variable resistor, current in the coil connected with the variable resistor in series is adjusted, it is guaranteed that a magnetic field generated by the coil pushes the magnets, the fixing rods are pushed to drive the pressing wheels to move downwards, the tensioning state of the steel coil in the leveling processis automatically adjusted according to the diameter change of the steel coil in the leveling process, and the working efficiency is improved.

Owner:徐金良

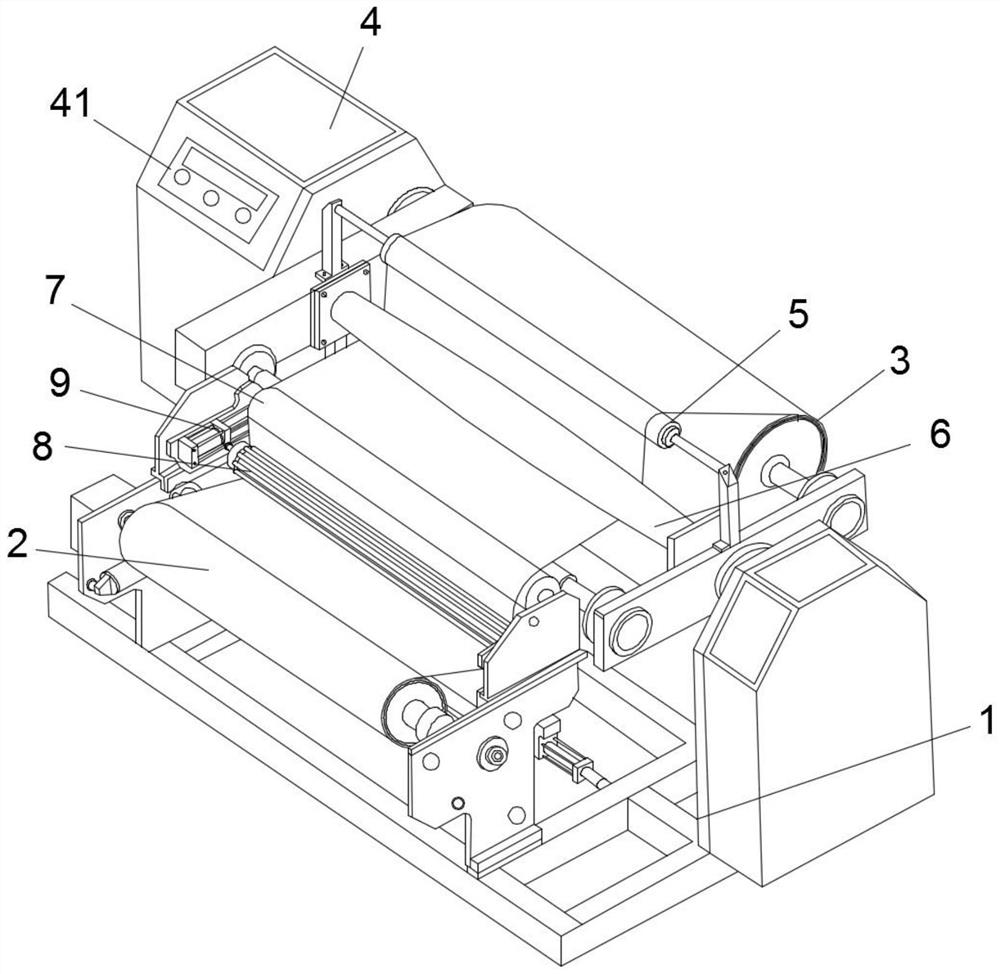

Cloth flattening and rolling equipment

The invention relates to the technical field of cloth rolling, in particular to cloth flattening and rolling equipment which structurally comprises a rack, wherein the front side and the rear side ofthe rack are rotatably connected to a front roller and a winding up roller separately, a driving box is arranged on one side of the rack, the driving box is arranged on one side of the winding up roller, the driving box comprises a driving motor, the driving motor is in shaft connection to one end of the winding up roller and is used for driving the winding up roller to rotate to roll cloth, a first upper abutting roller, an arc-shaped lower abutting roller, a second upper abutting roller and an adjustable abutting roller are arranged between the winding up roller and the front roller, the arc-shaped lower abutting roller is arranged below the first upper abutting roller, the adjustable abutting roller is arranged below the second upper abutting roller in a front-back adjustable displacement manner, two ends of the first upper abutting roller, the arc-shaped lower abutting roller and the second upper abutting roller are rotatably connected to the rack, the arranged adjustable abuttingroller can adjust tension of cloth on all cloth rollers, so that it is guaranteed that textile cloth is not too loose in a conveying process, and wrinkles of the textile cloth are reduced.

Owner:杨智琼

Machining method for Z-directional multi-axis parts with height differences

ActiveCN109648416APrecise controlAccurate flatnessGrinding work supportsPlane surface grinding machinesEngineeringMulti axis

The invention belongs to the field of mechanical manufacturing, and relates to a machining method for Z-directional multi-axis parts with height differences. The machining method comprises the following steps: 1) the bottom surface of a mounting base is grinded as a positioning reference surface; 2) a part with the smallest height is mounted on the mounting surface, and the axial direction of thepart with the smallest height is perpendicular to the line surface of the positioning reference surface; 3) the upper end surface of the part with the smallest height is grinded, so that the height isqualified; 4) a part with the second smallest height is mounted on the mounting surface, and the axial direction of the part with the second smallest height is perpendicular to the line surface of the positioning reference surface; and 5) with the upper end surface of the part with the smallest height as the reference surface, the upper end surface of the part with the second smallest height is grinded to achieve the qualified height. The machining method for the Z-directional multi-axis parts with height differences can accurately control the planeness, the verticality and the surface roughness, can realize quick machining, and effectively guarantees the pass percent.

Owner:XIAN AERO ENGINE CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com