Automatic grass planting brick paving equipment for urban road

A technology of planting grass bricks and paving, applied in the direction of roads, roads, road repair, etc., can solve the problems of caulking, low work efficiency, low labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

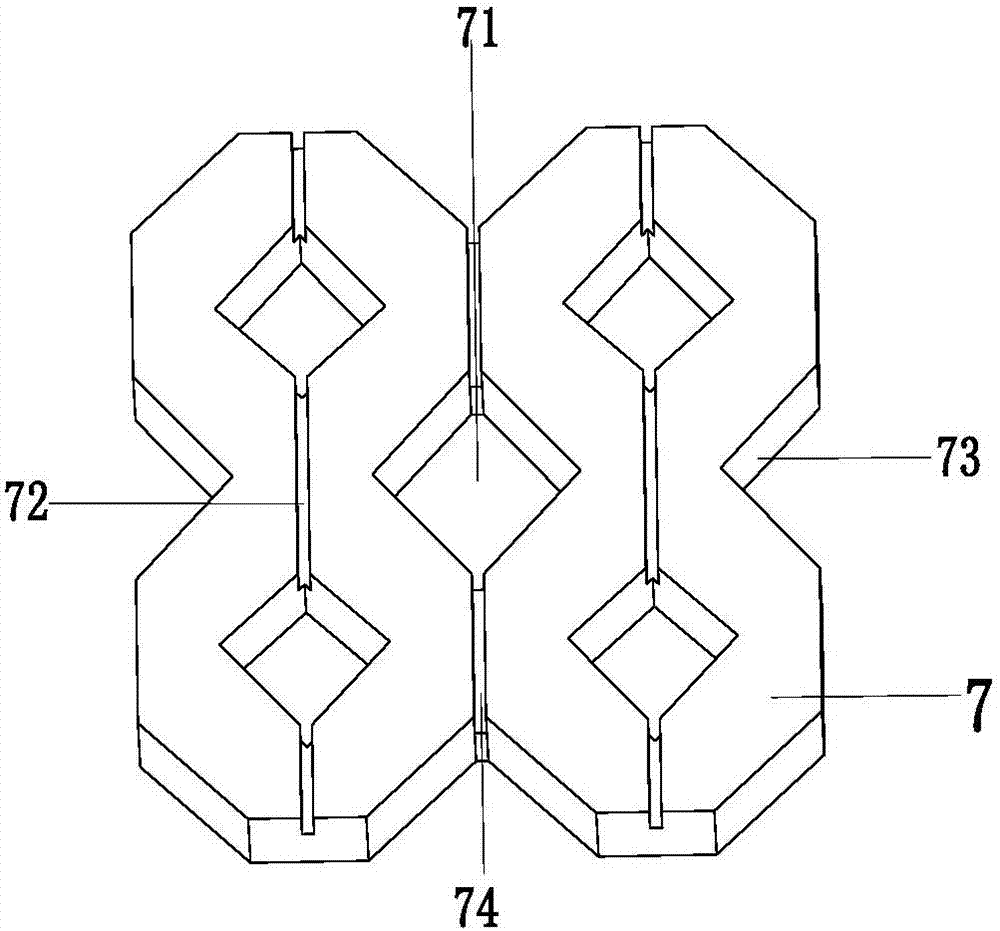

[0029] Such as figure 1 As shown, the existing grass planting brick 7 includes a grass planting brick middle hole 71, a grass planting brick brick body groove 72, a grass planting brick side recess 73, and a grass planting brick middle groove 74.

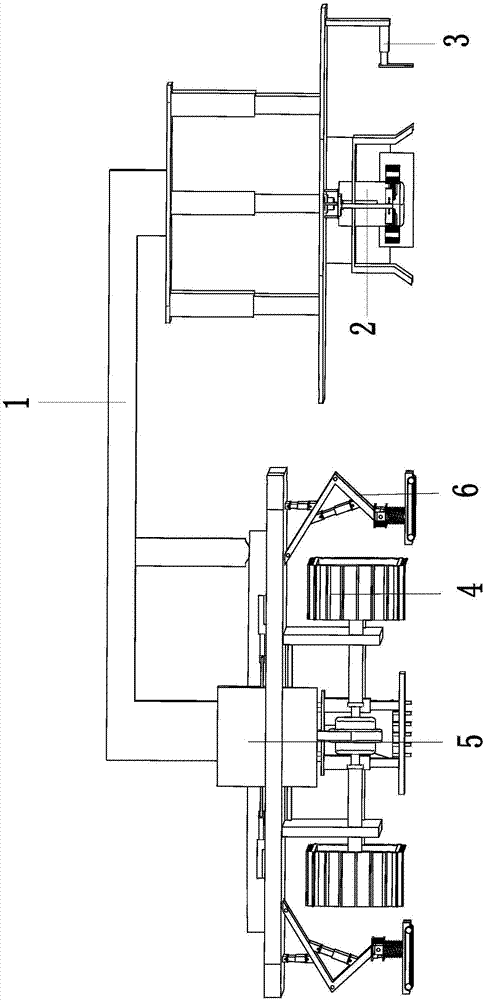

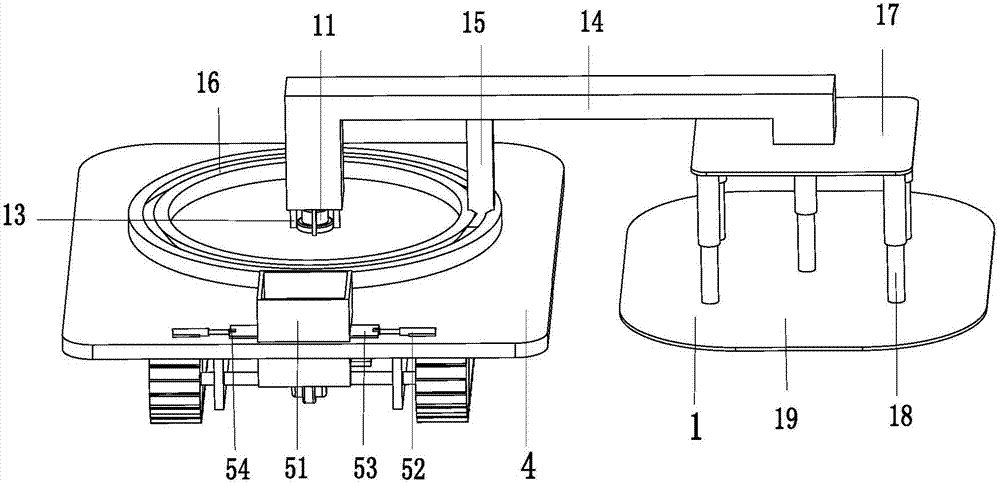

[0030] Such as Figure 2 to Figure 7 As shown, an urban road automatic paving grass-planting brick equipment includes a paving rotating device 1, a fixing device 2, a limit device 3, a walking support device 4, a pouring cleaning device 5 and four auxiliary moving devices 6, which are paving rotating The device 1 is installed on the fixed limit device 2, the fixing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com