Aluminum plate or aluminum-plastic plate decoration plate with heat insulation function

A technology of aluminum-plastic panels and decorative panels, which is applied in covering/lining, construction, building construction, etc., can solve the problems of poor thermal insulation performance of aluminum panel curtain walls, difficulty in controlling construction quality, and difficult on-site operation, so as to facilitate popularization and implementation , light weight, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

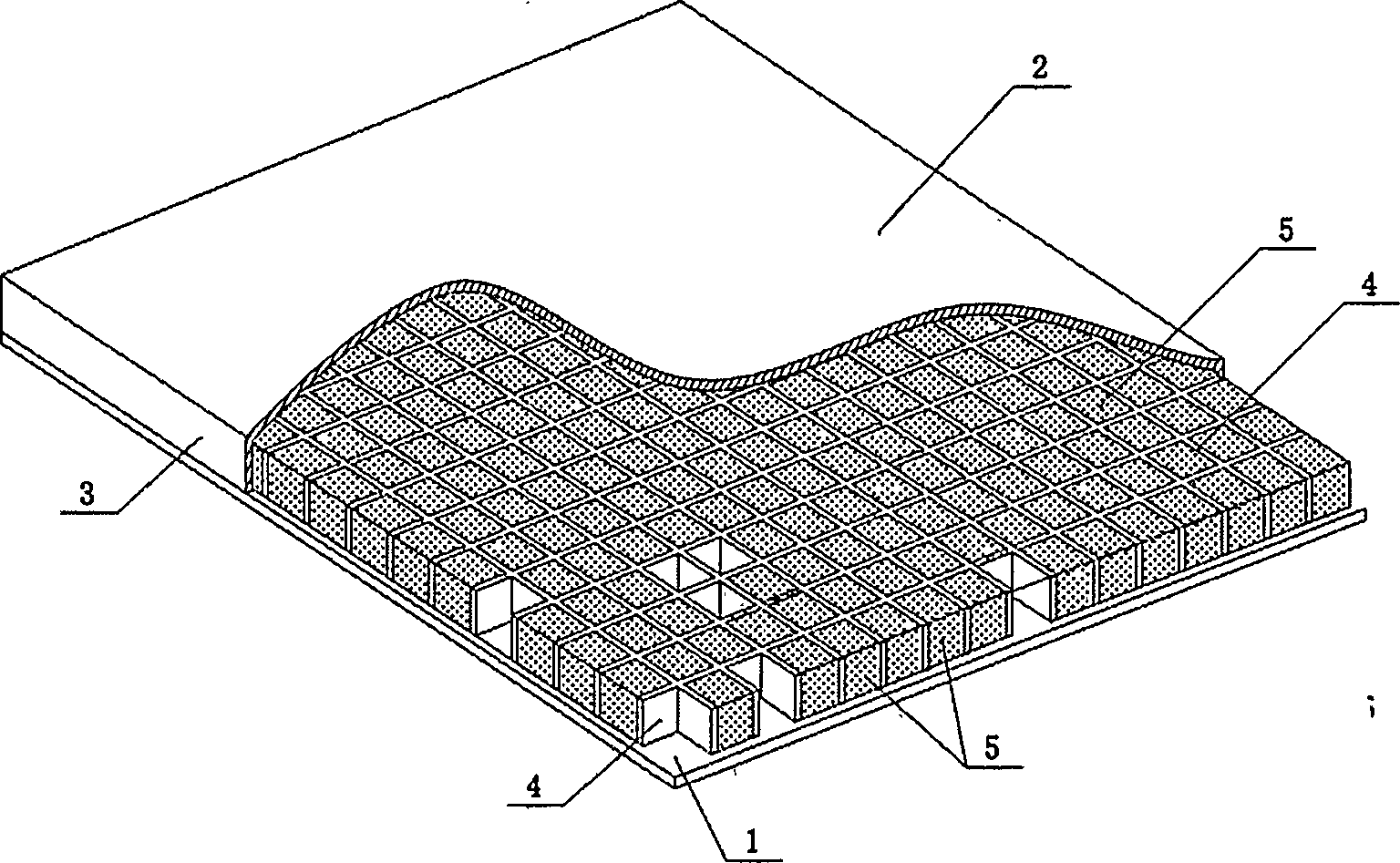

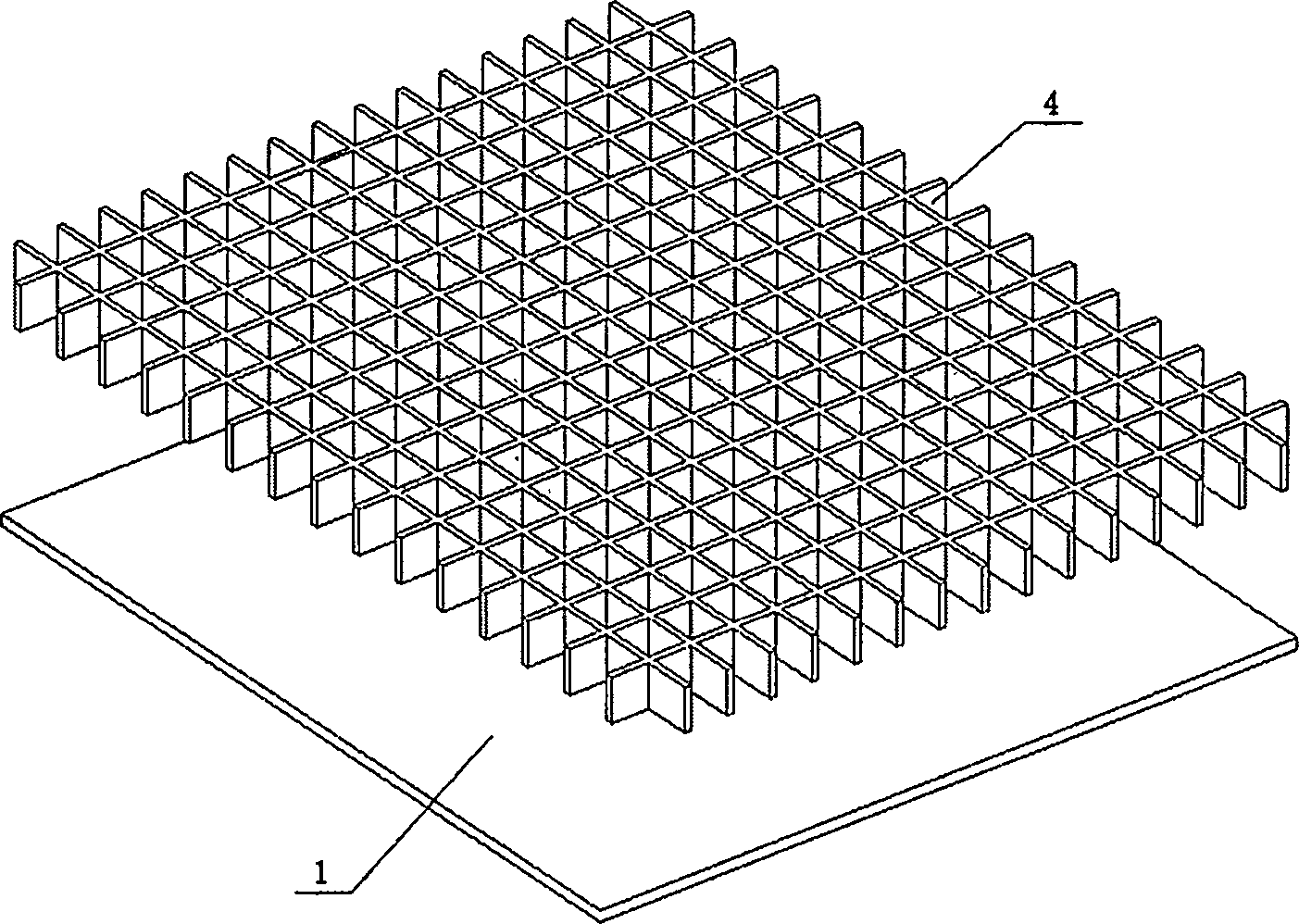

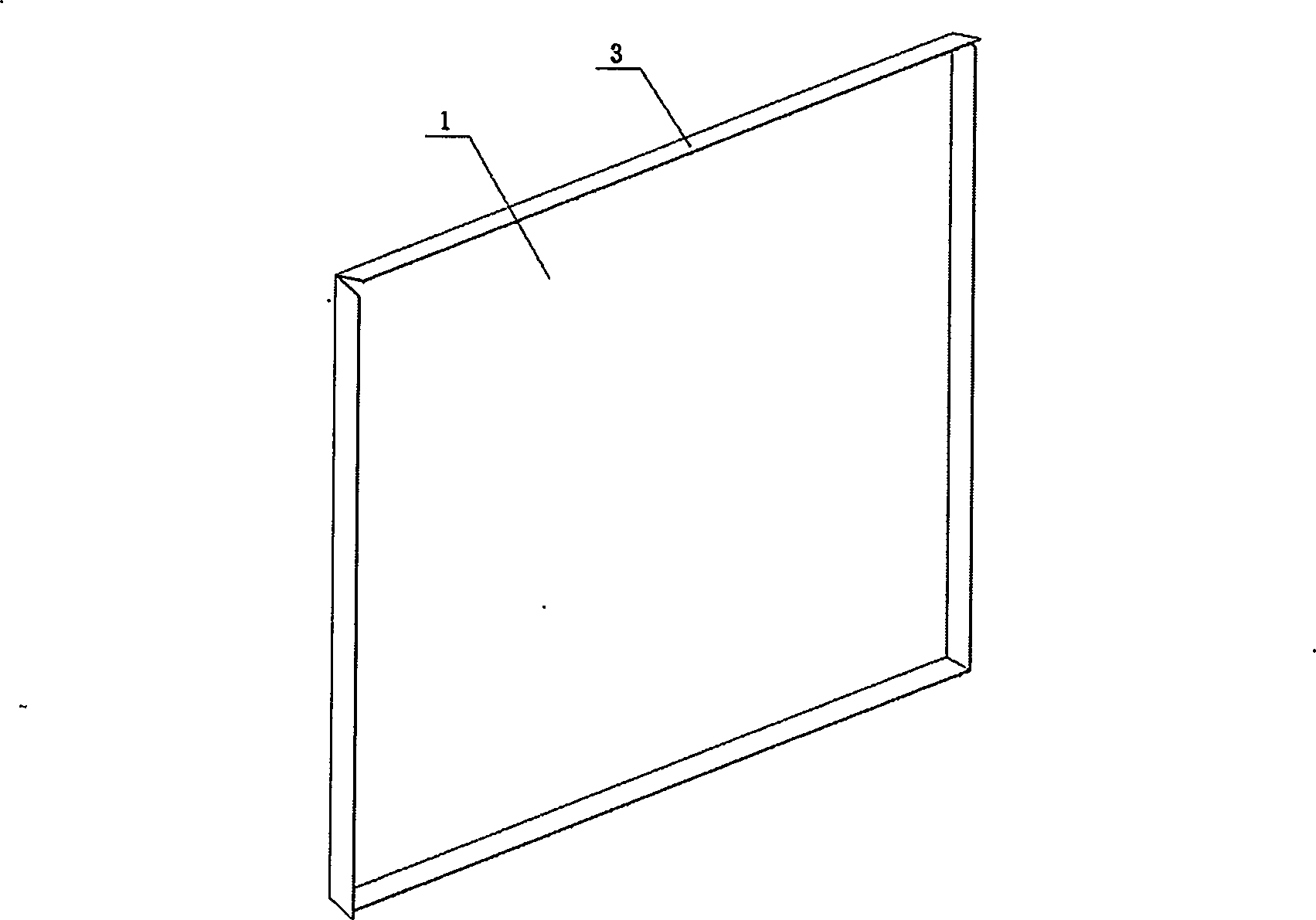

[0021] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , an aluminum plate or aluminum-plastic panel decorative panel with thermal insulation, comprising a surface veneer 1 and a back plate 2 of the aluminum plate or aluminum-plastic plate, the surface veneer 1 is folded around to form a flanged side panel 3, and the surface A layer of thermal insulation filling layer is provided in the cavity surrounded by decorative panel 1, flanged side panel 3 and back panel 2, and the thermal insulation filling layer includes a grid body 4 surrounded by a certain number of vertical and horizontal partitions. The body 4 is filled with thermal insulation filler 5 .

[0022] The filler 5 is polyisocyanurate PIR.

[0023] The backboard 2 is a high-strength calcium silicate board, or a cement board, or a fiber cement pressure board, or one of the autoclaved asbestos-free cellulose cement boards.

[0024] The thickness of the thermal insulation filling layer 5 is 25mm to 10...

Embodiment 2

[0027] Embodiment two: see figure 1 , figure 2 , image 3 , Figure 4 , the meaning is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that the filler 5 is polyurethane PU.

Embodiment 3

[0028] Embodiment three: see figure 1 , figure 2 , image 3 , Figure 4 , the meaning is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the lattice body 4 is made of PVC material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com