Pipe hot medium internal pressure forming method based on molten glass

A technology of internal high pressure forming and molten state, which is applied in the field of internal pressure forming of pipe heat medium based on molten glass, can solve the problems of low heating rate, difficult sealing, low thermal conductivity, etc., achieve low compression rate, improve heating rate, The effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

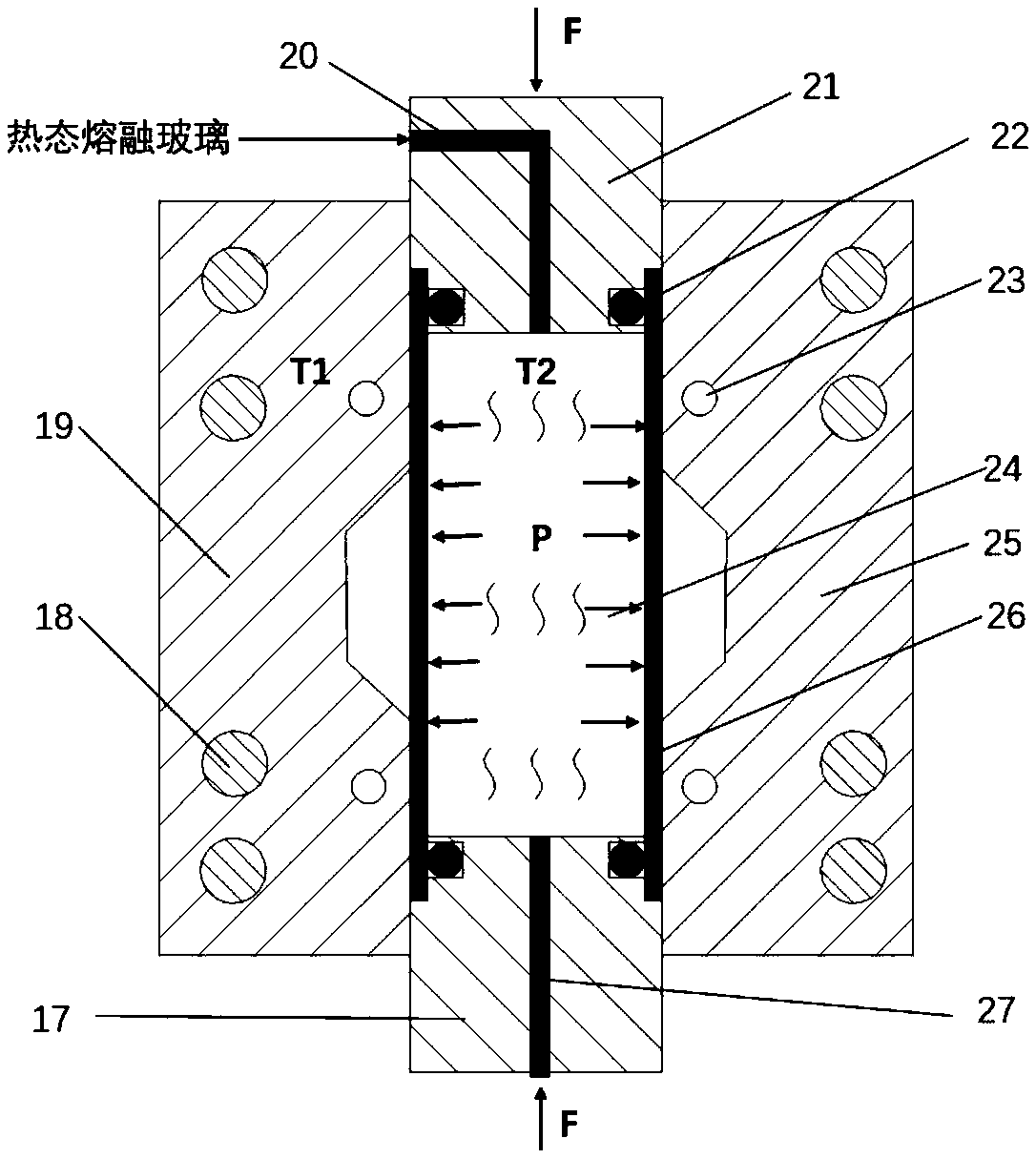

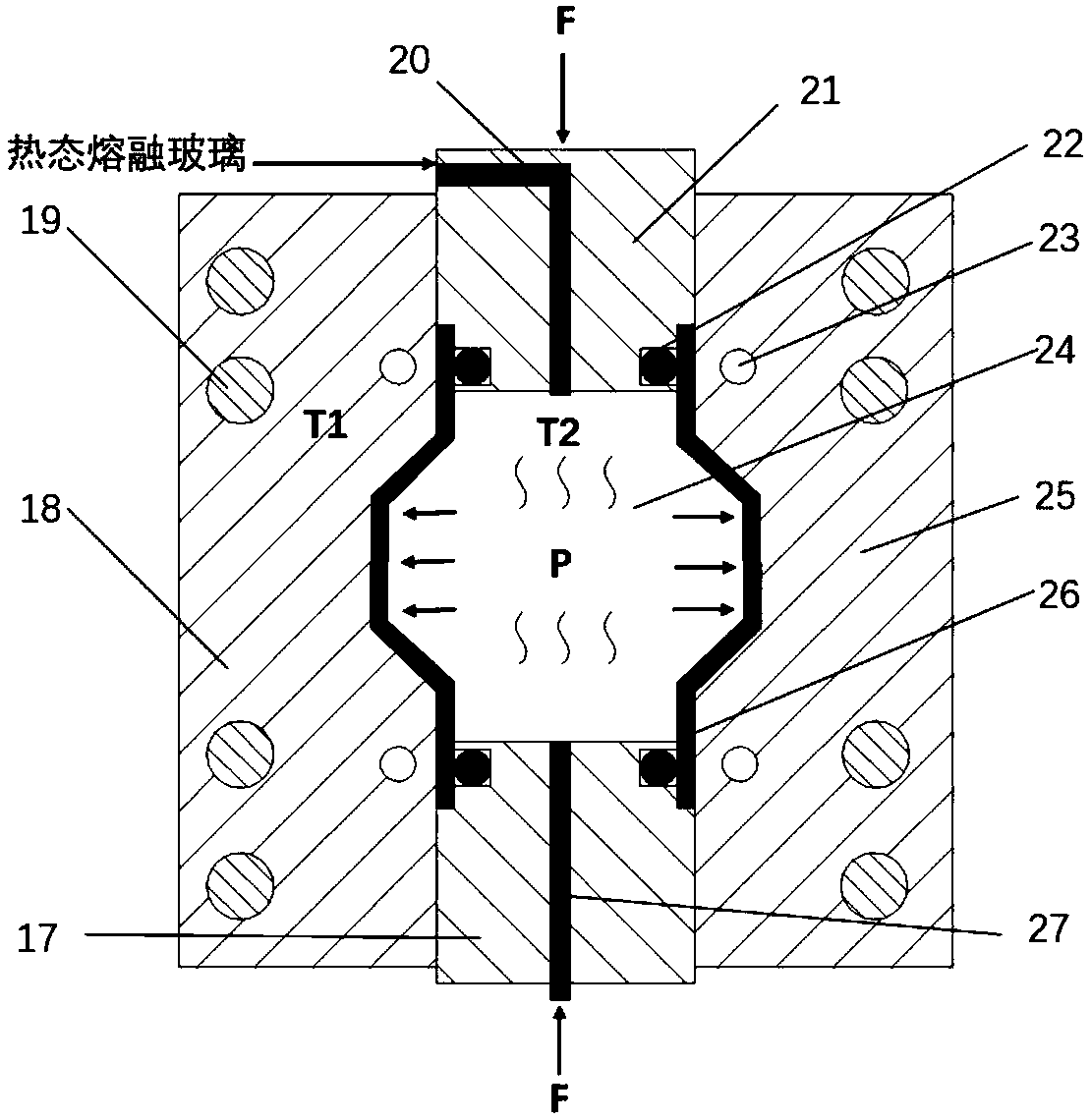

[0038] Specific implementation mode 1: This implementation mode is based on the molten glass-based internal pressure forming method of the pipe heat medium, including the following steps:

[0039] Step 1. Determine the high pressure forming temperature range in the pipe according to the type of pipe;

[0040] Step 2. Select the glass material according to the high pressure forming temperature in the pipe, so that the melting temperature of the glass material is the same as the high pressure forming temperature in the pipe;

[0041] Step 3: Place the pipe to be formed in an induction heater, and use induction heating to perform rapid preheating to obtain a pipe blank; wherein the preheating temperature is 100-300°C lower than the high-pressure forming temperature in the pipe;

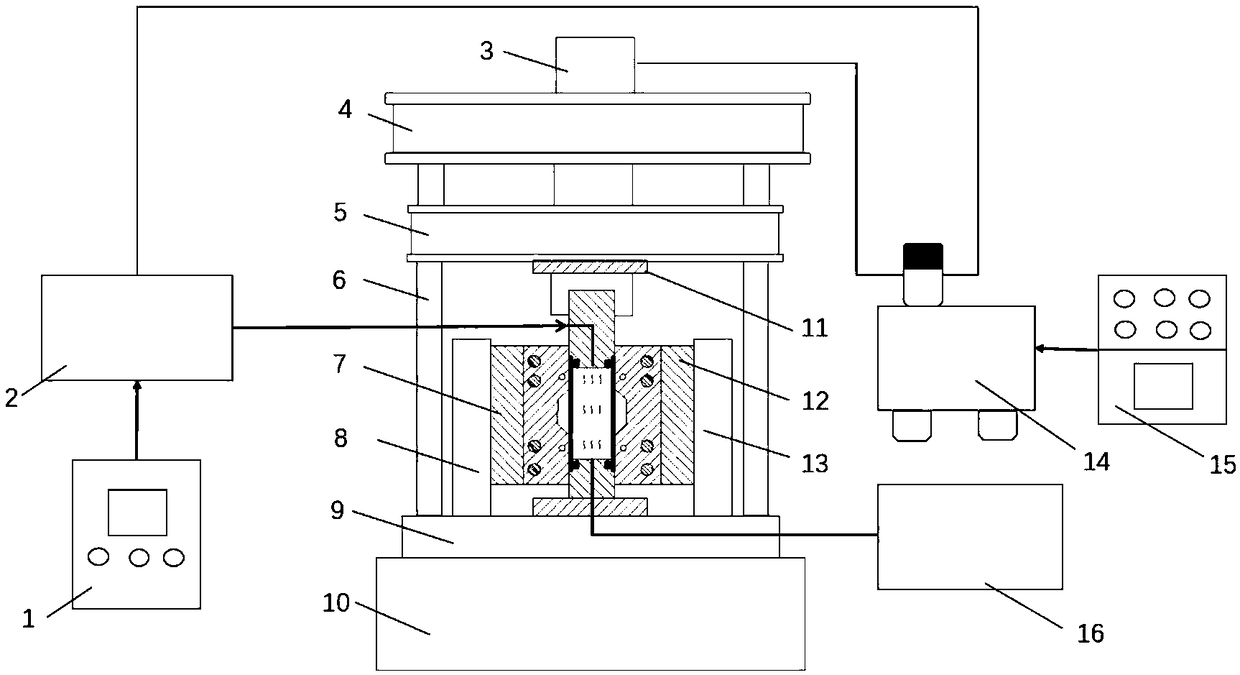

[0042] Step 4. The forming mold includes a left mold and a right mold. Put the left mold and the right mold into the left and right sides of the hydraulic cylinder of the hydraulic press in the hot inter...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pipe material in Step 1 is titanium alloy, aluminum-magnesium alloy or high-strength steel pipe. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the method for determining the high-pressure forming temperature range in the pipe according to the type of pipe is:

[0050] At different temperatures, tensile tests are carried out on the pipes to obtain the stress-strain curves at different temperatures, and the elongation of the pipes at different temperatures is obtained from the stress-strain curves, so as to determine the optimum forming temperature range. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com