Patents

Literature

452results about How to "Reduce seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

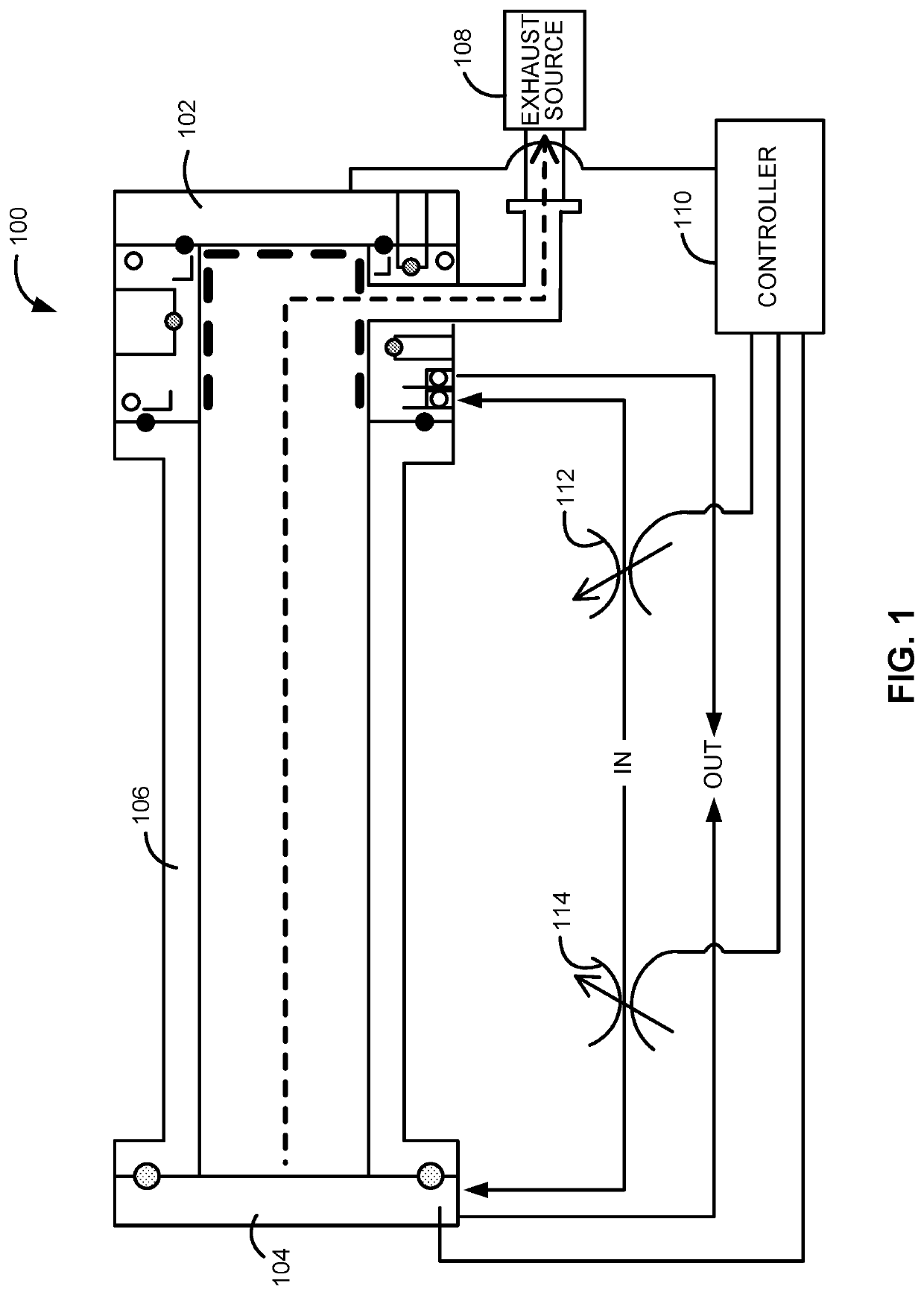

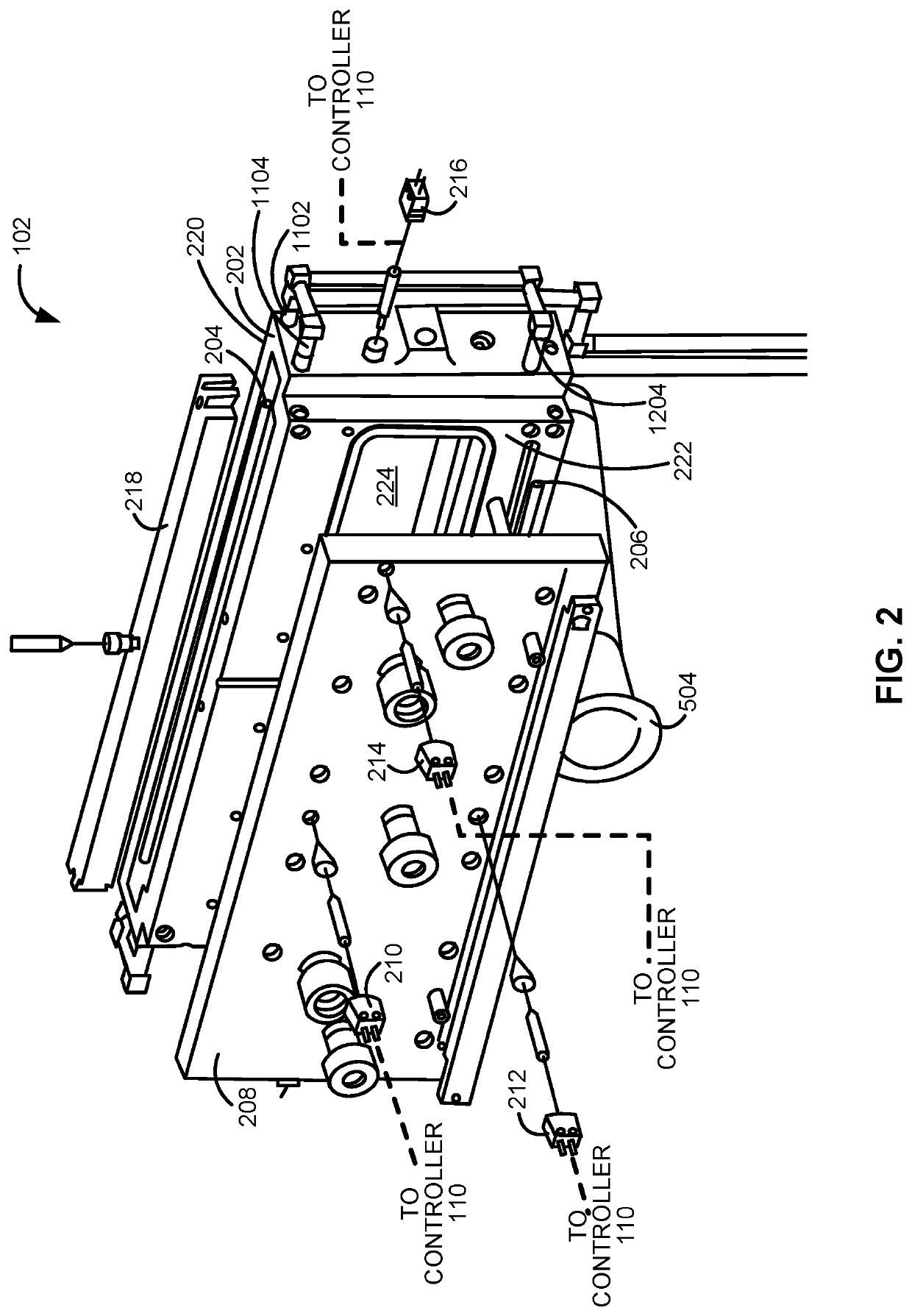

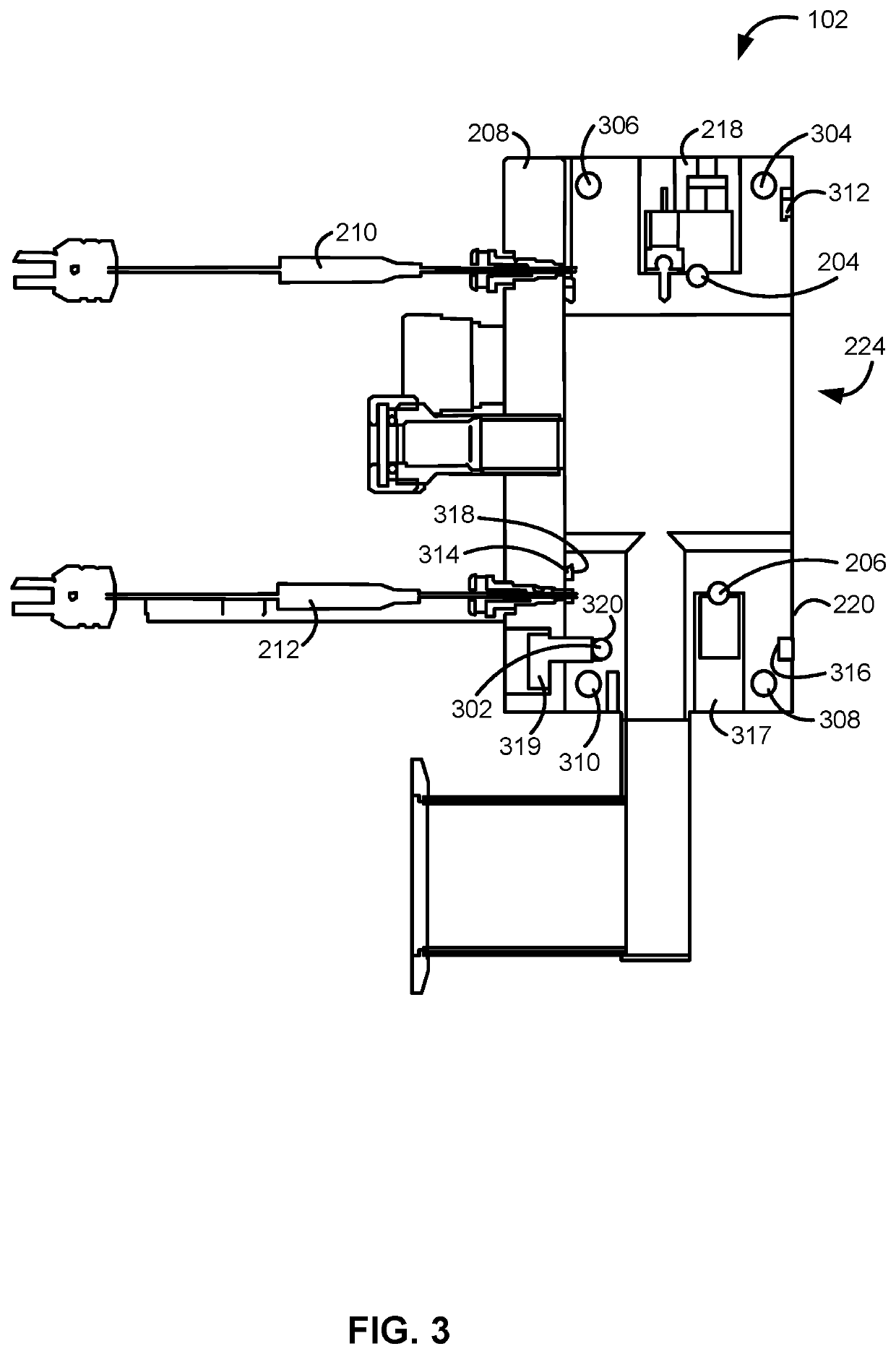

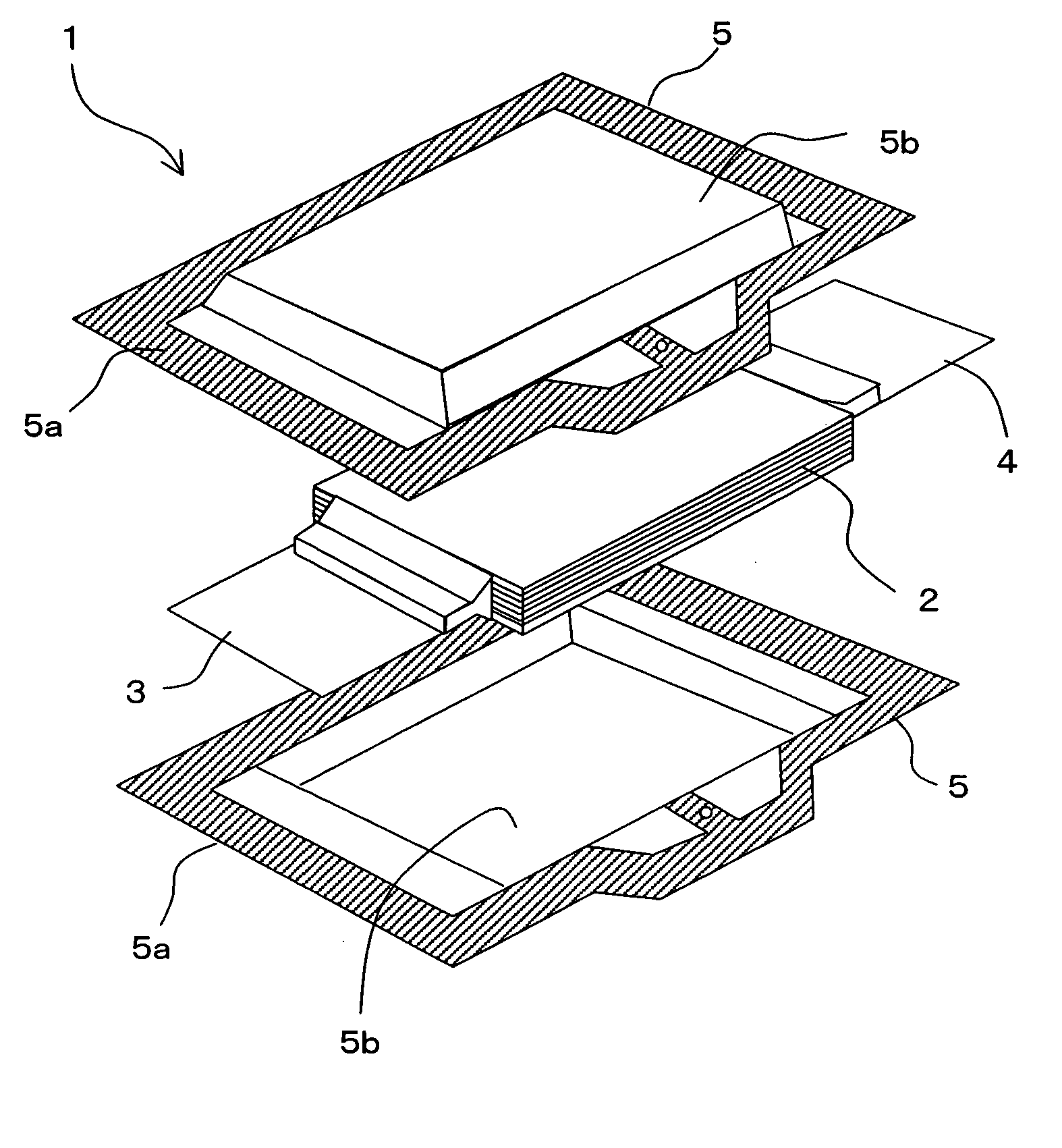

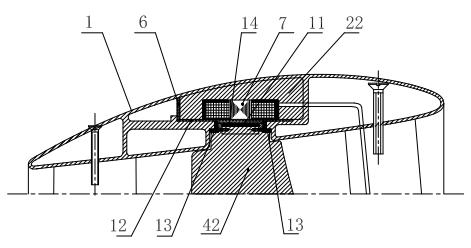

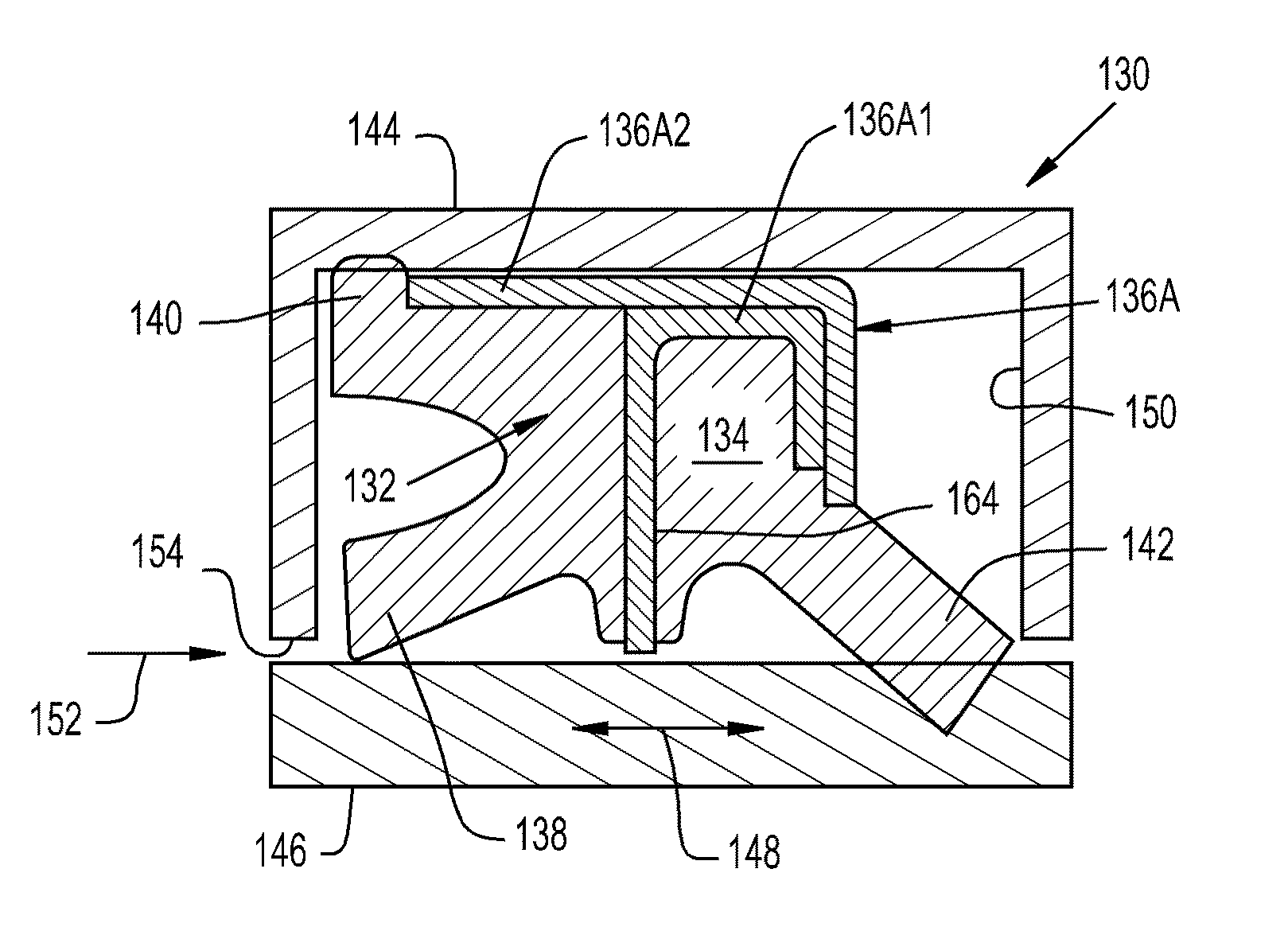

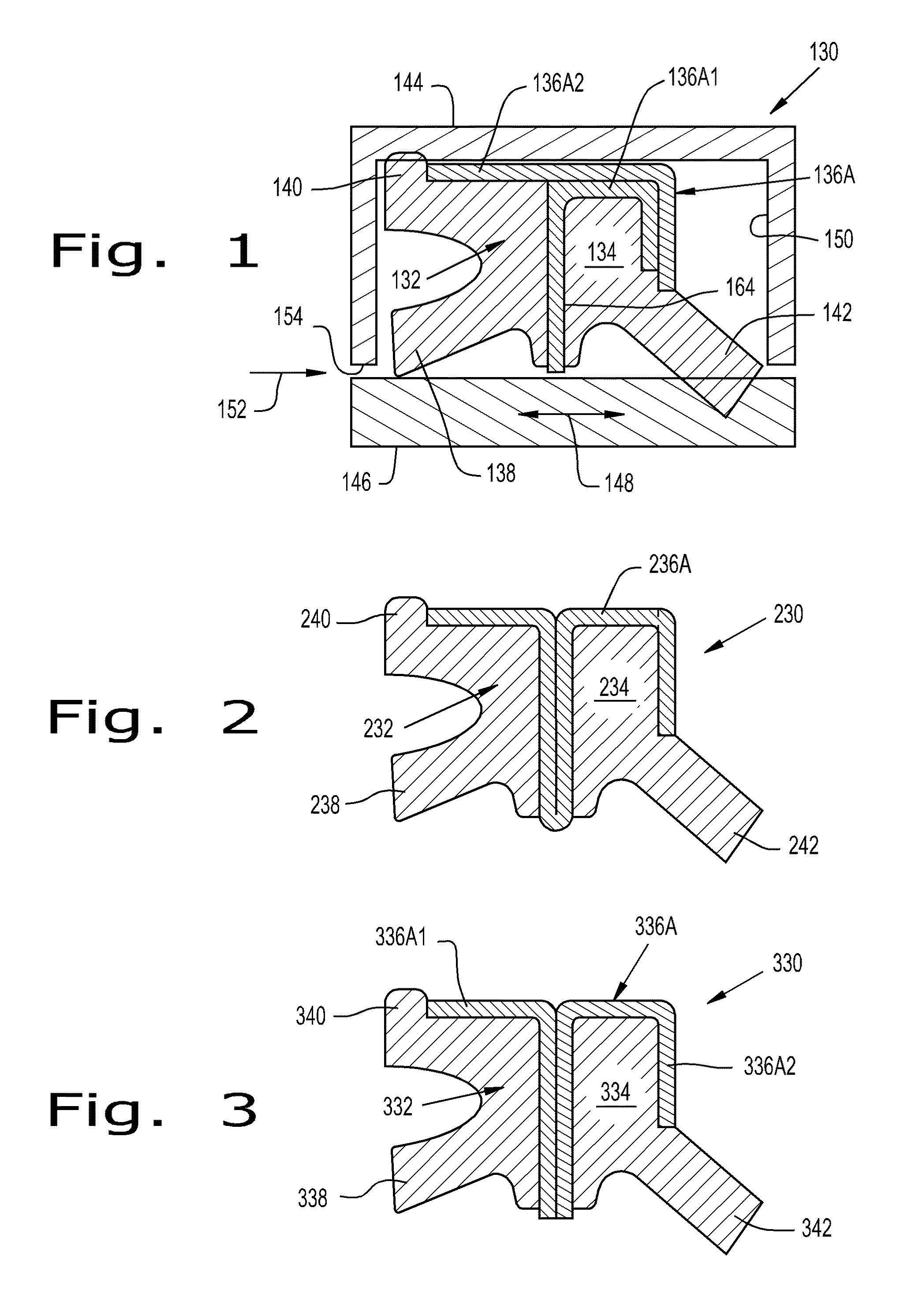

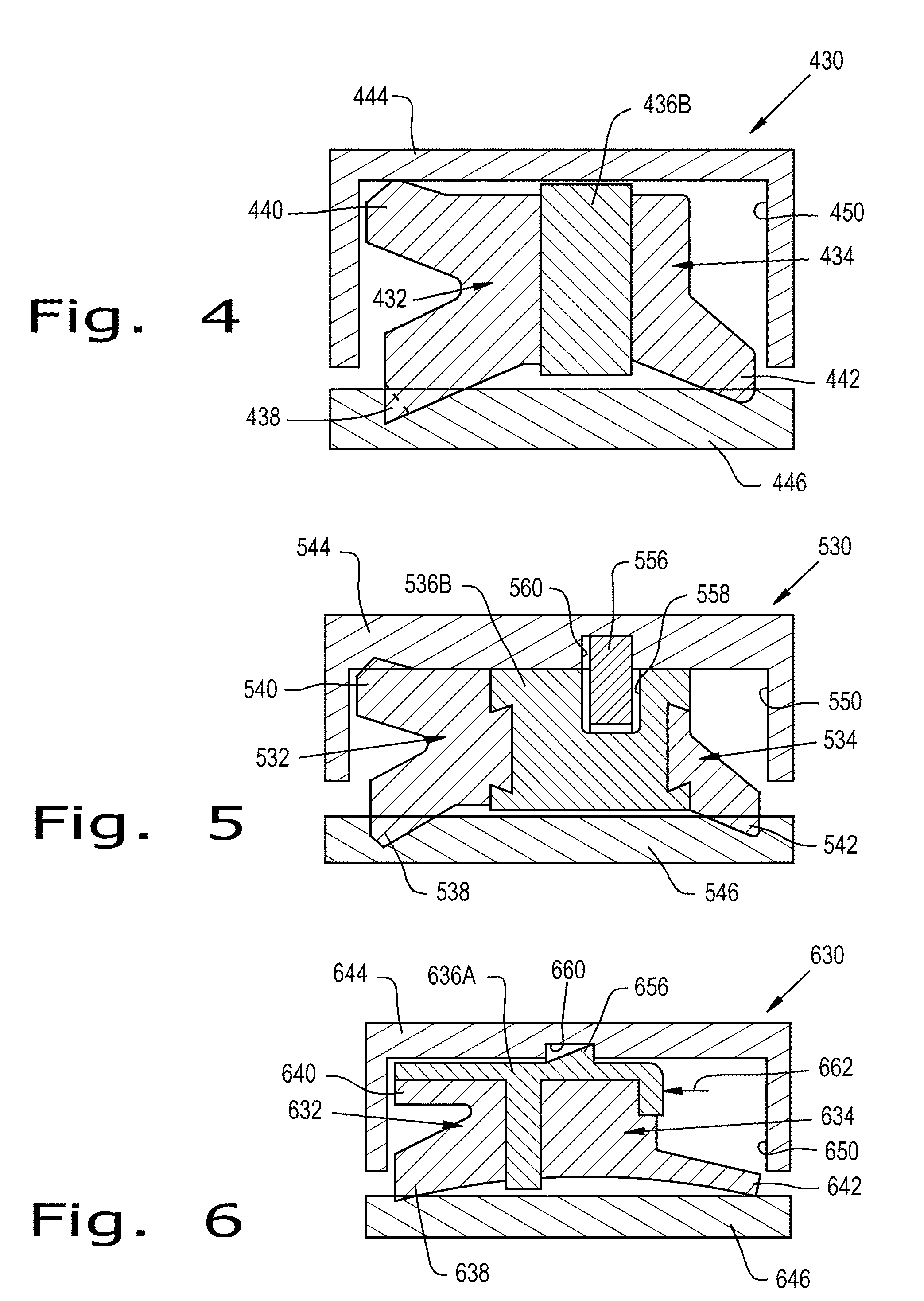

Temperature-controlled flange and reactor system including same

ActiveUS20200002811A1Reduce sealReduce condensationElectric discharge tubesVacuum evaporation coatingReactor systemMechanical engineering

A flange, flange assembly, and reactor system including the flange and flange assembly are disclosed. An exemplary flange assembly includes heated and cooled sections to independently control temperatures of sections of the flange. Methods of using the flange, flange assembly and reactor system are also disclosed.

Owner:ASM IP HLDG BV

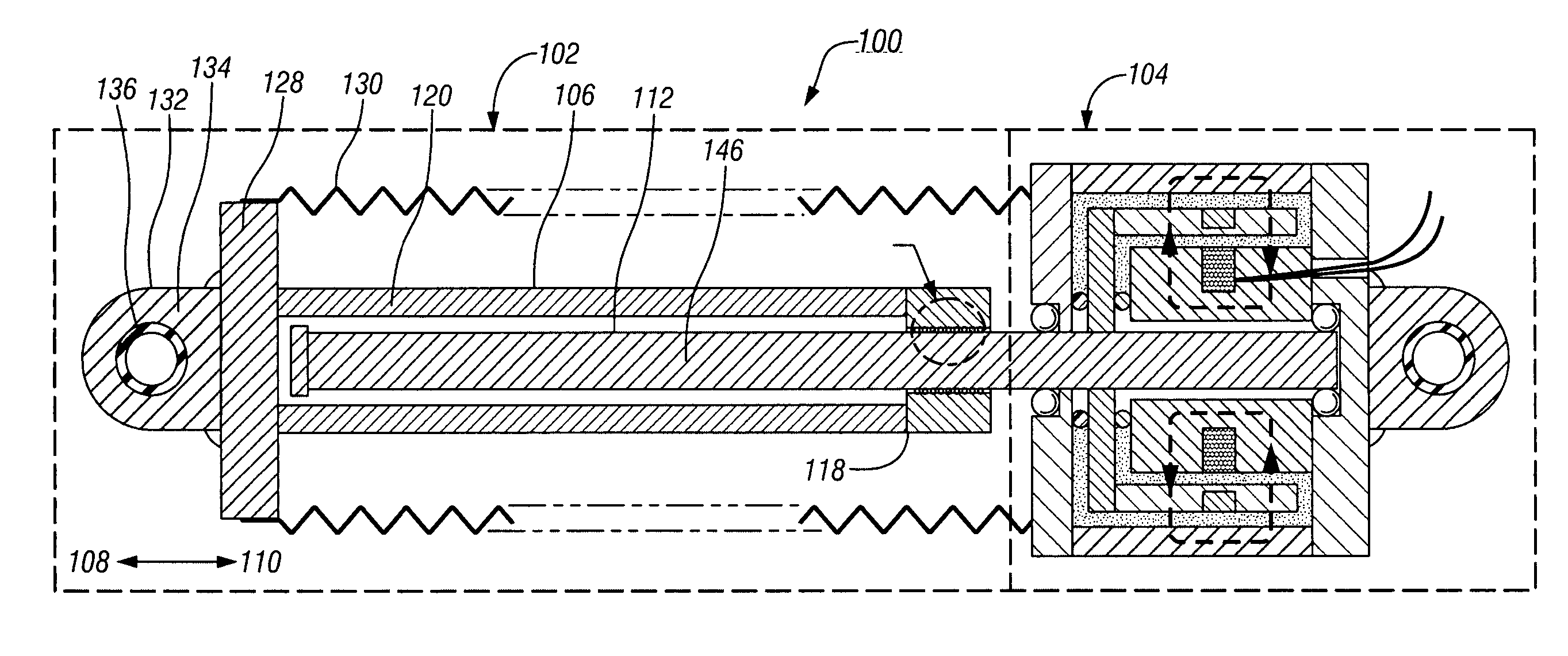

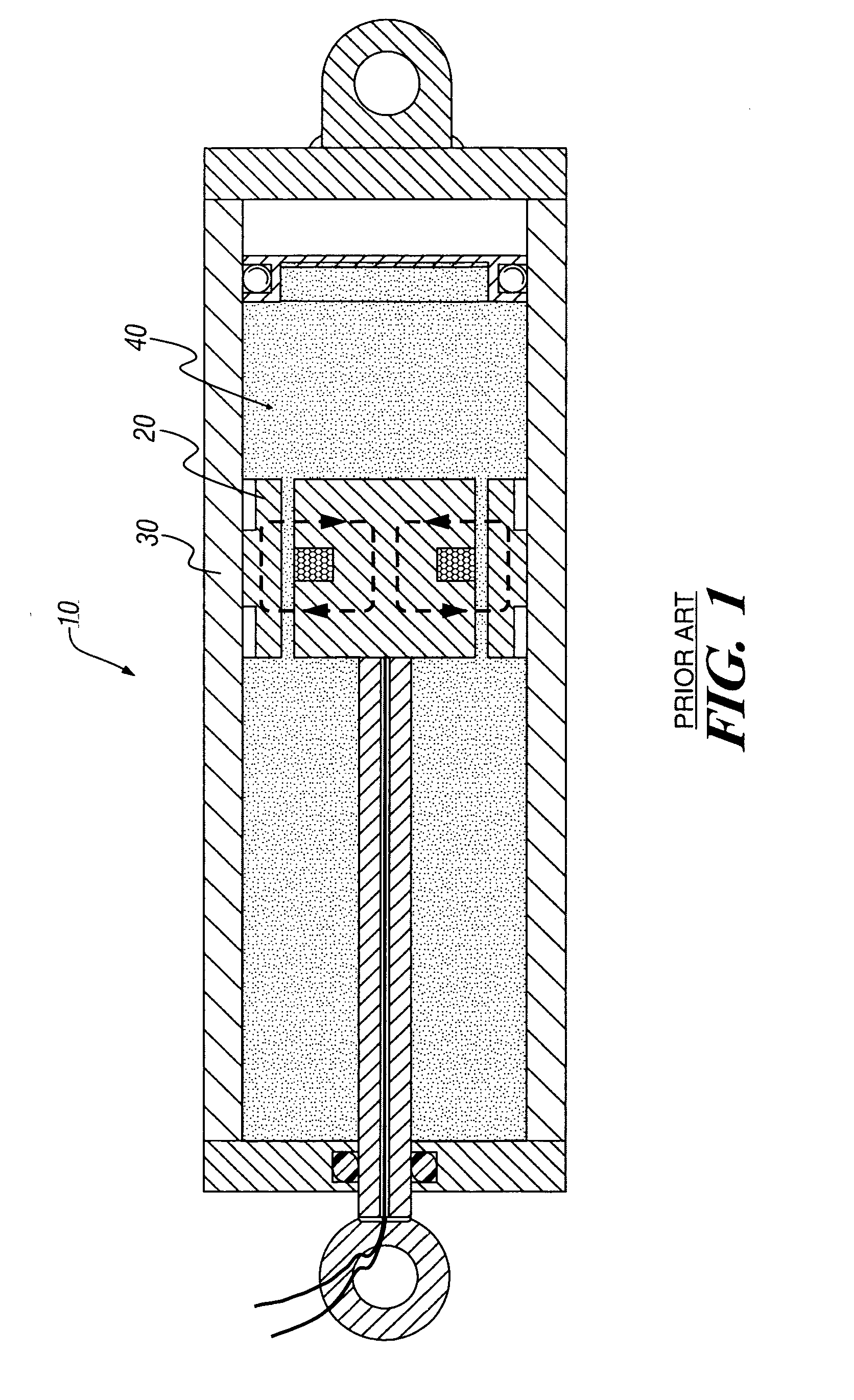

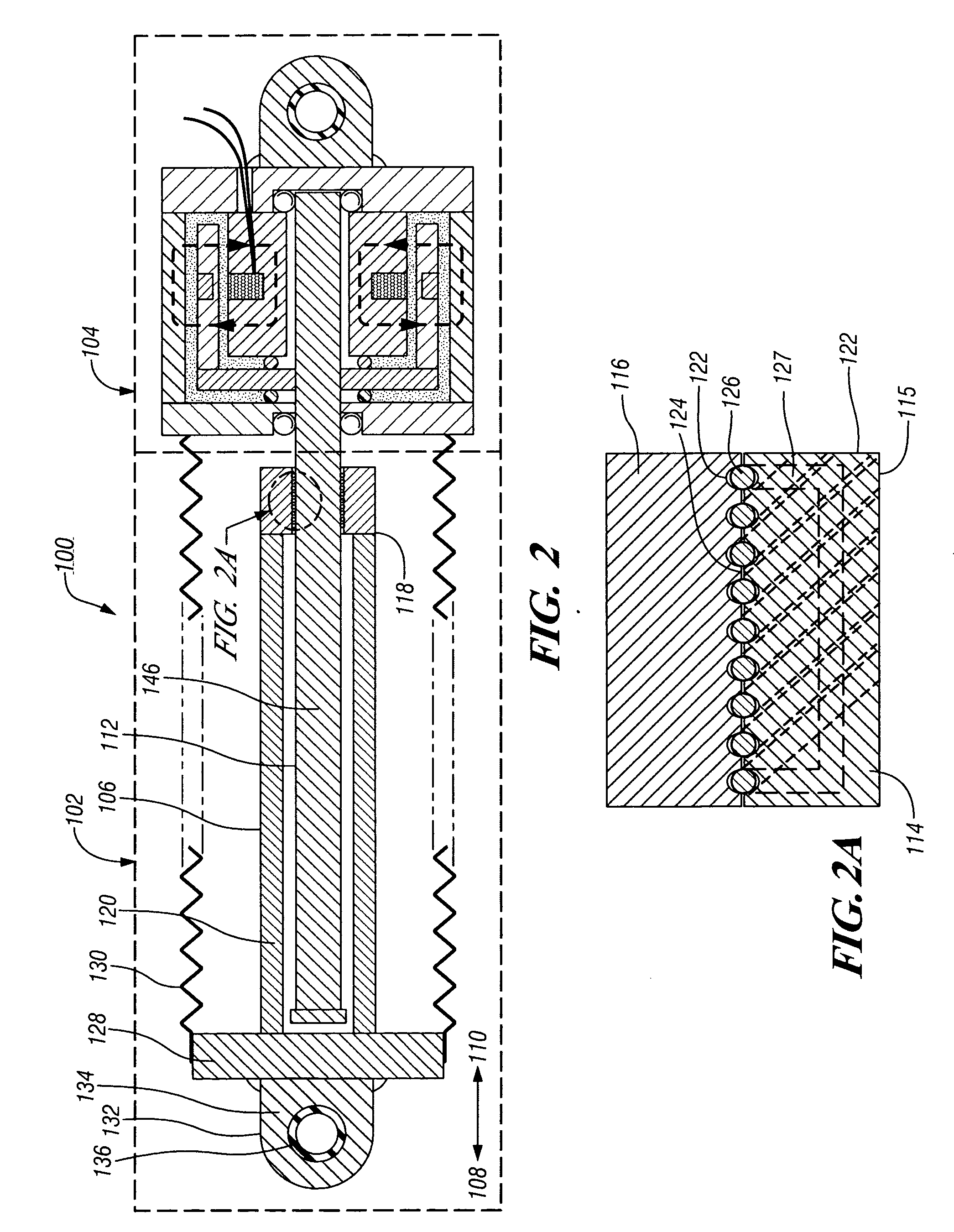

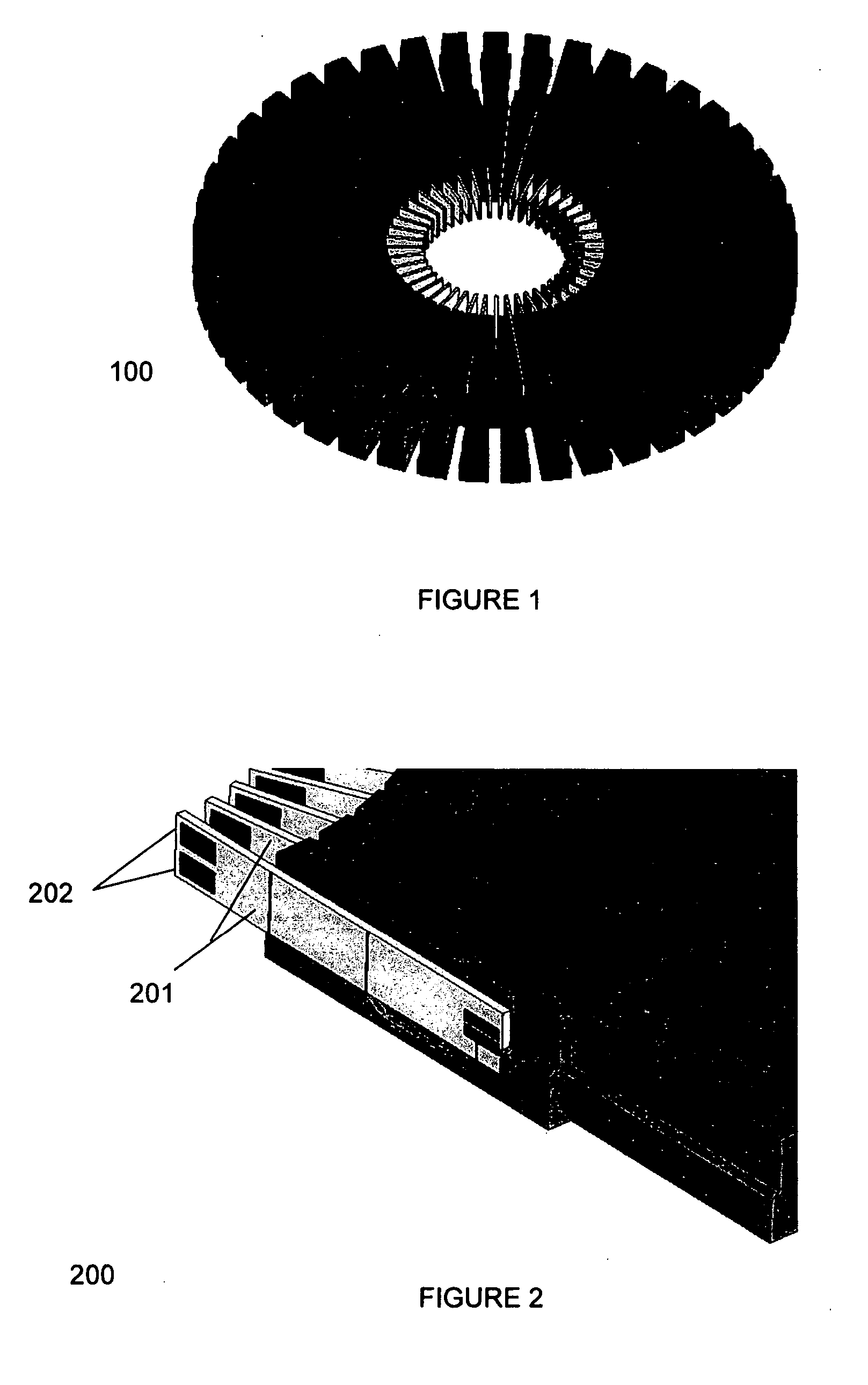

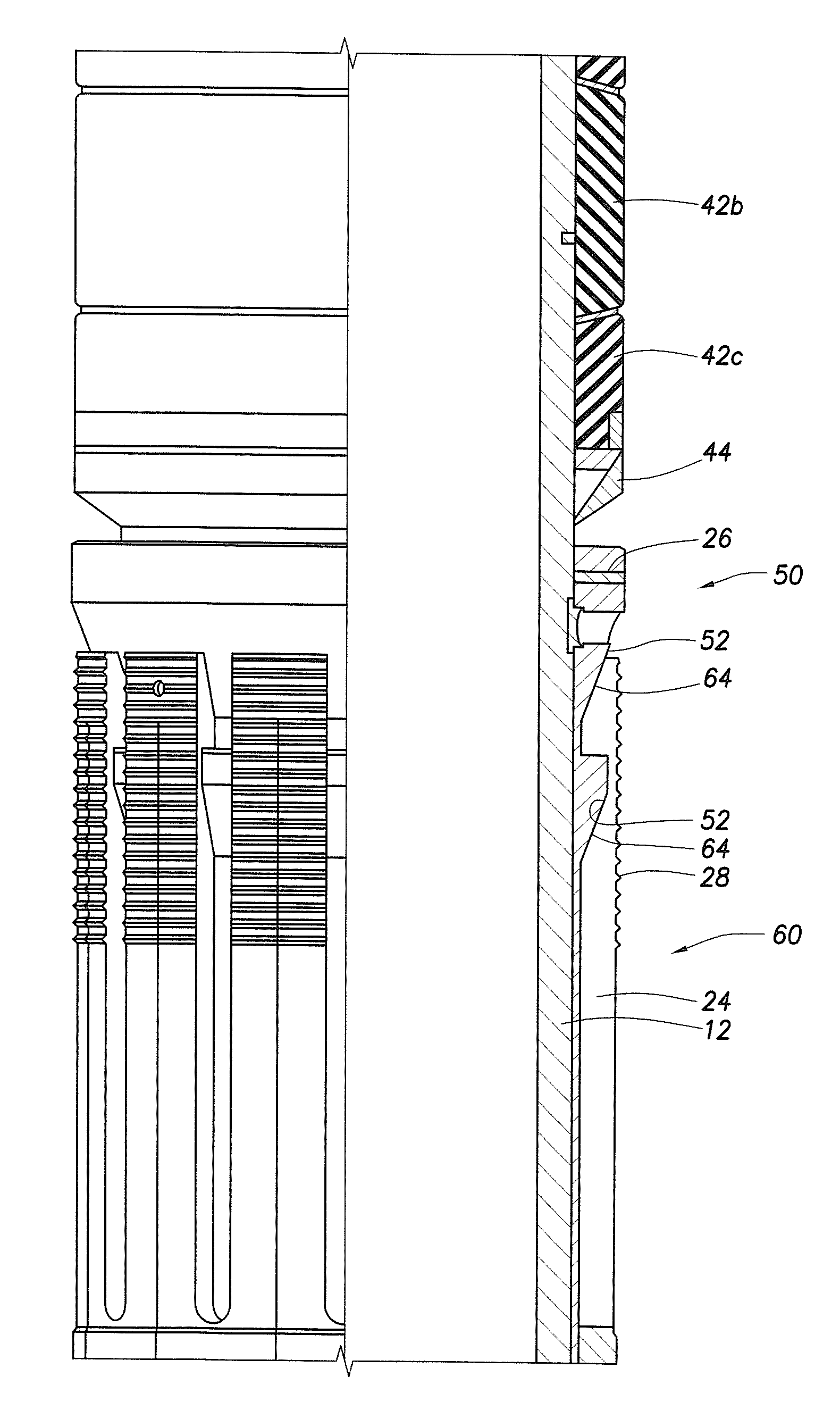

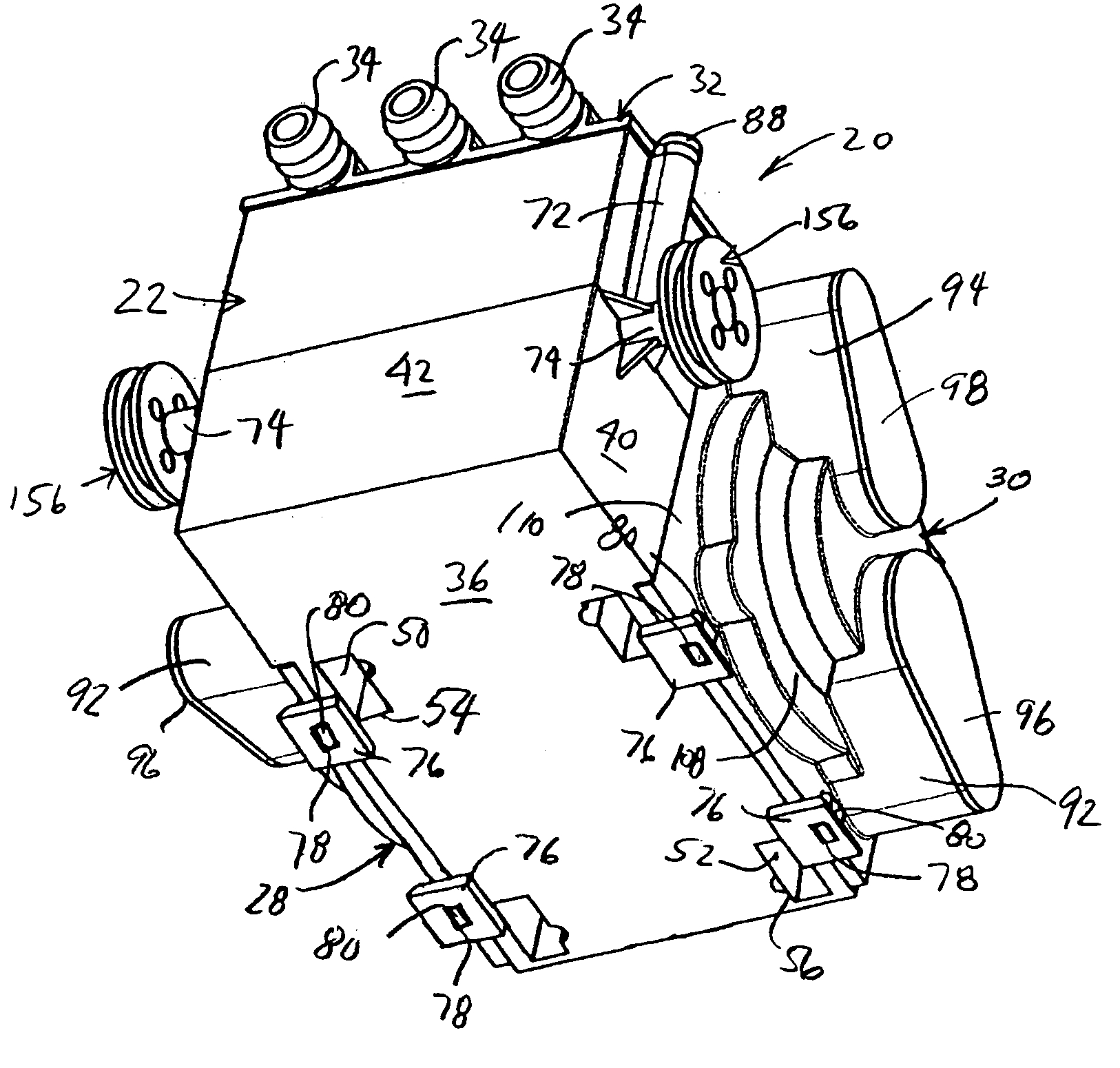

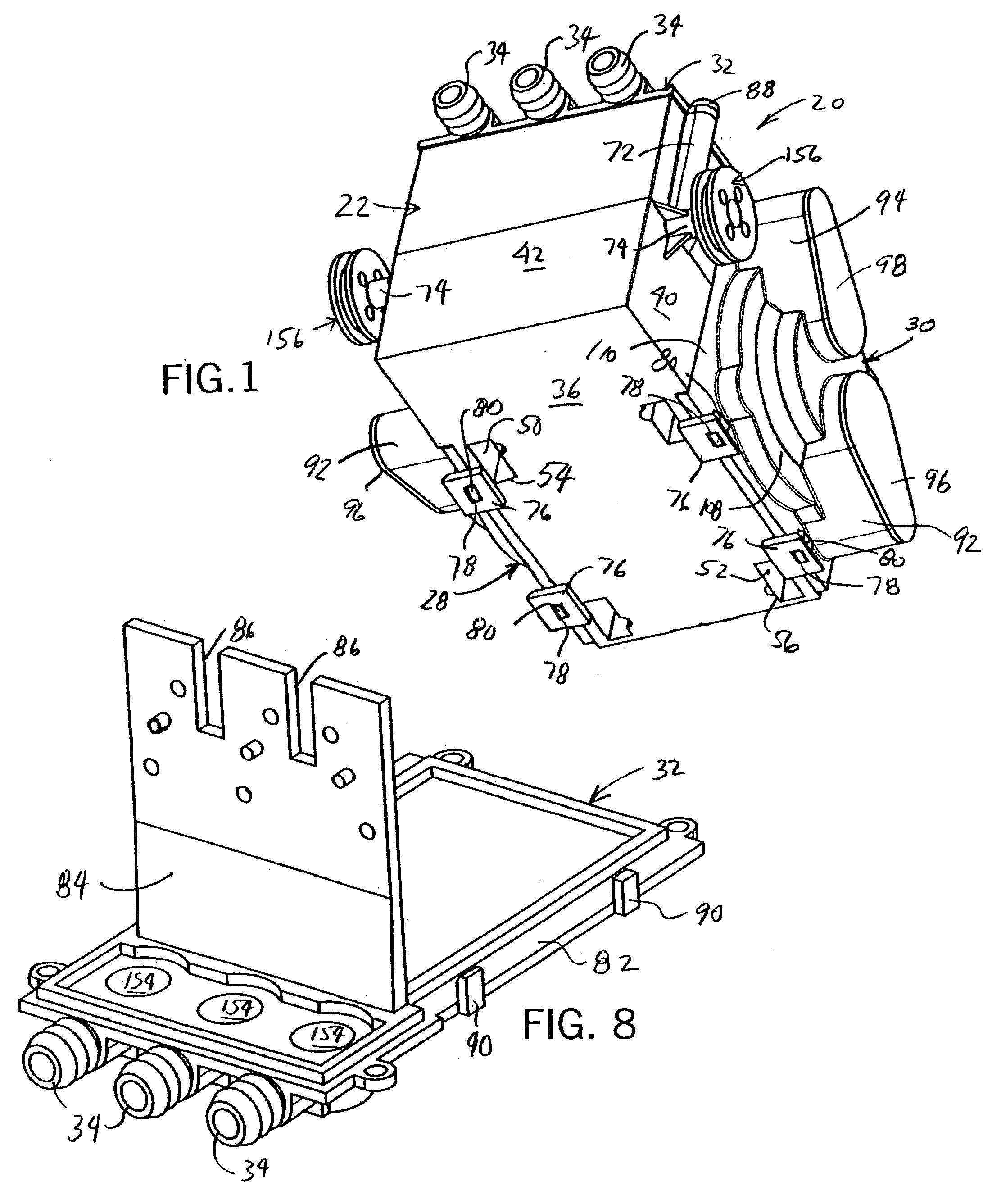

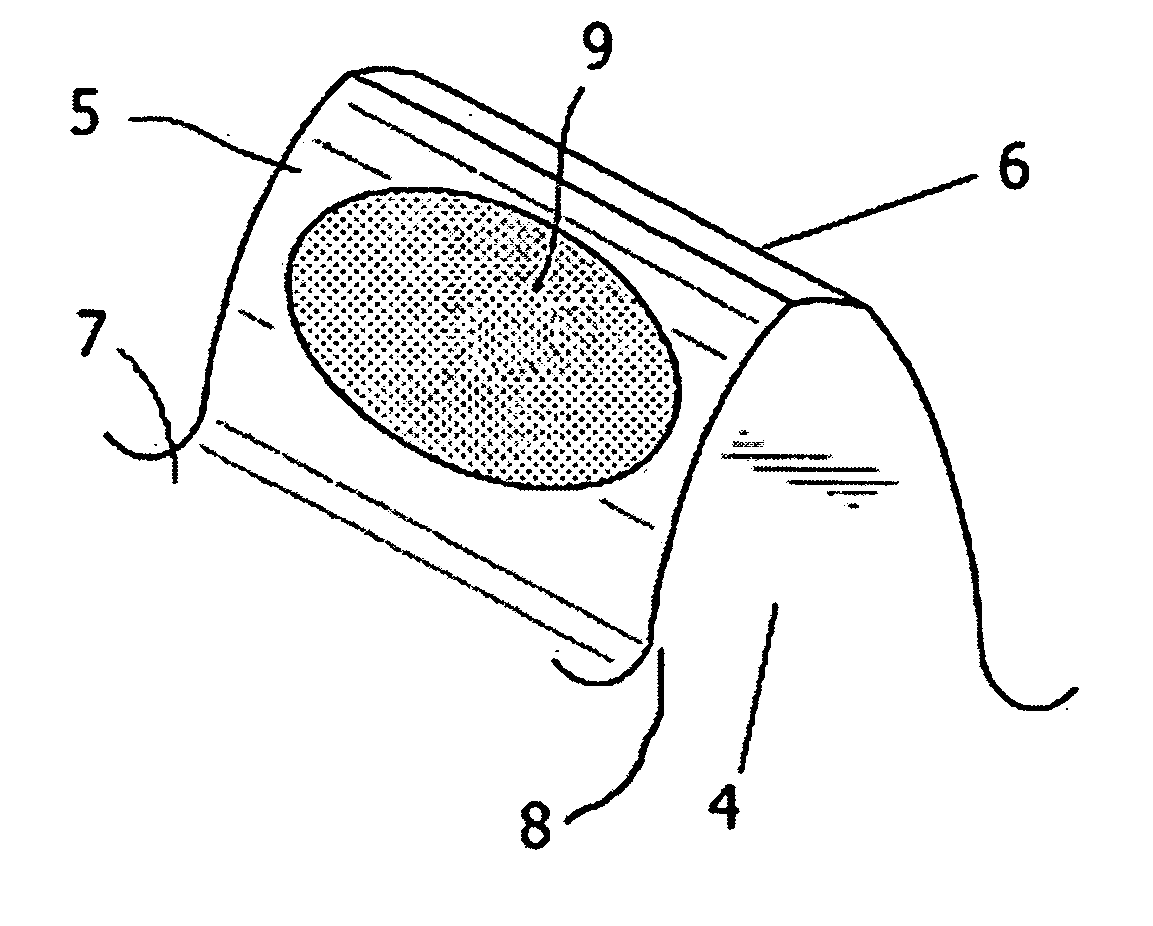

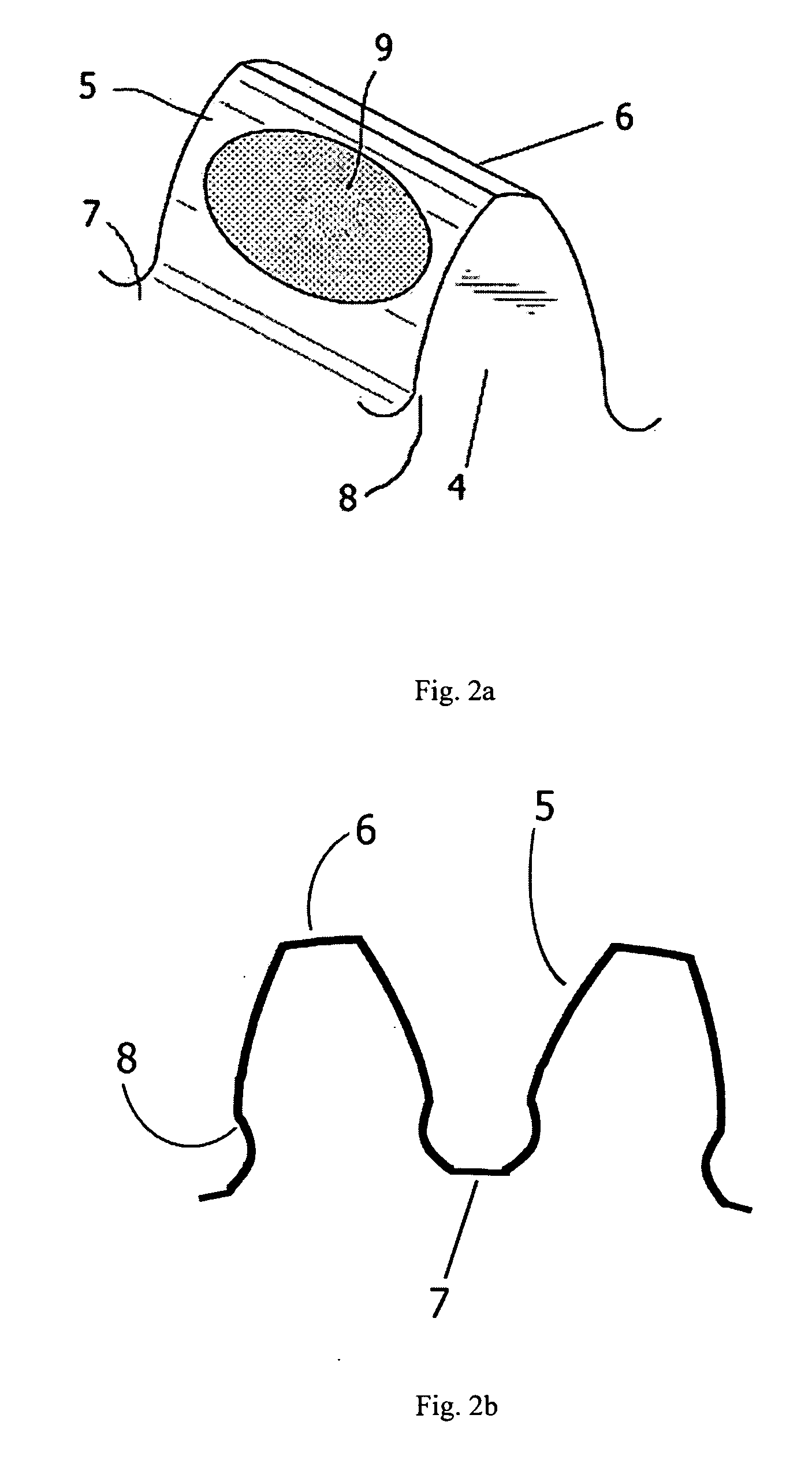

Fluid damper having continuously variable damping response

ActiveUS20050121269A1Reduce manufacturing costLower the volumeSpringsNon-rotating vibration suppressionMagnetorheological fluidEngineering

An improved damping apparatus that utilizes a fluid having a viscosity that may be varied by the application of an electromagnetic field, such as a magnetorheological fluid or an electrorheological fluid, to provide the damping response. The damping apparatus includes a linear to rotary conversion mechanism which comprises a translatable member that is adapted for linear translation in a forward and a reverse direction and a rotatable member comprising a rotatable shaft that is rotatably coupled to the translatable member; wherein translation of the translatable member in one of the forward or the reverse directions produces a forward or a reverse rotation of the rotatable member and shaft, respectively. The damping apparatus also includes a damping mechanism which comprises a hub that is fixed to the shaft, a means for generating a variable electromagnetic field in response to an applied electrical signal that may be continuously varied in response to an input signal that is representative of a desired damping force and a fluid having a viscosity that may be continuously varied by application of the electromagnetic field that is in touching contact with the hub. Application of the variable electromagnetic field to the fluid produces changes in the viscosity of the fluid that in turn provides variable resistance to rotation of the hub and resistance to translation of the translatable member, thereby providing a damping apparatus with a continuously variable damping response.

Owner:GM GLOBAL TECH OPERATIONS LLC

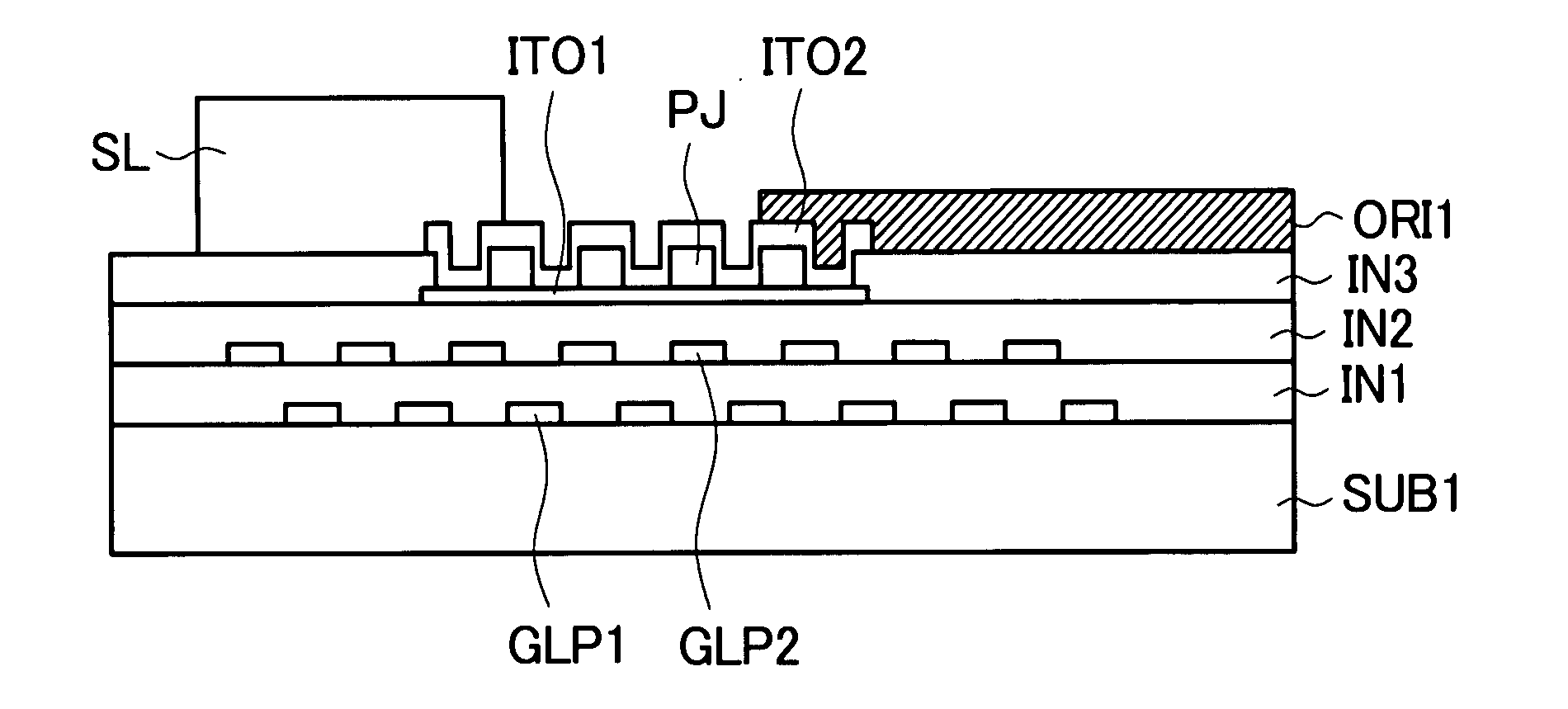

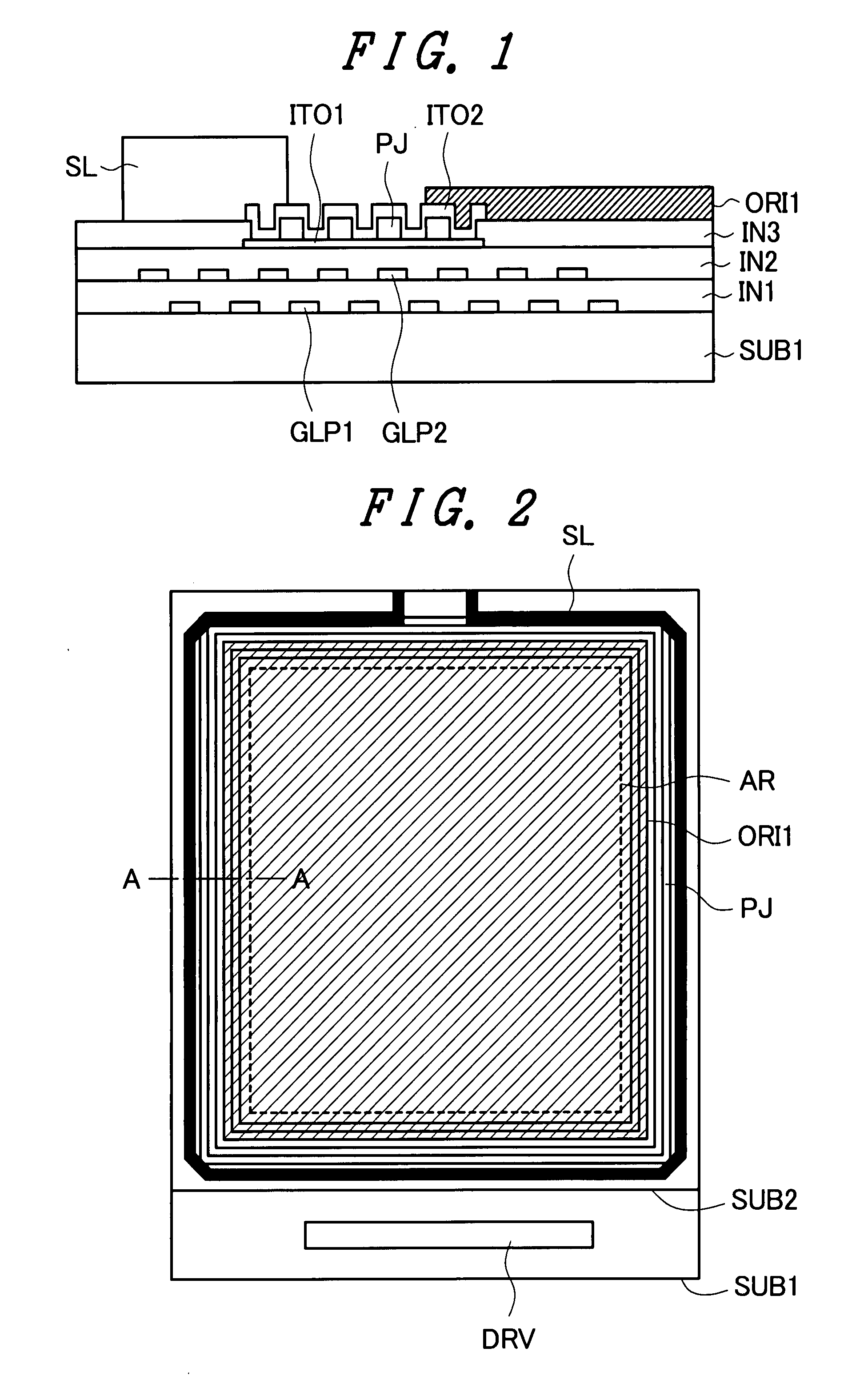

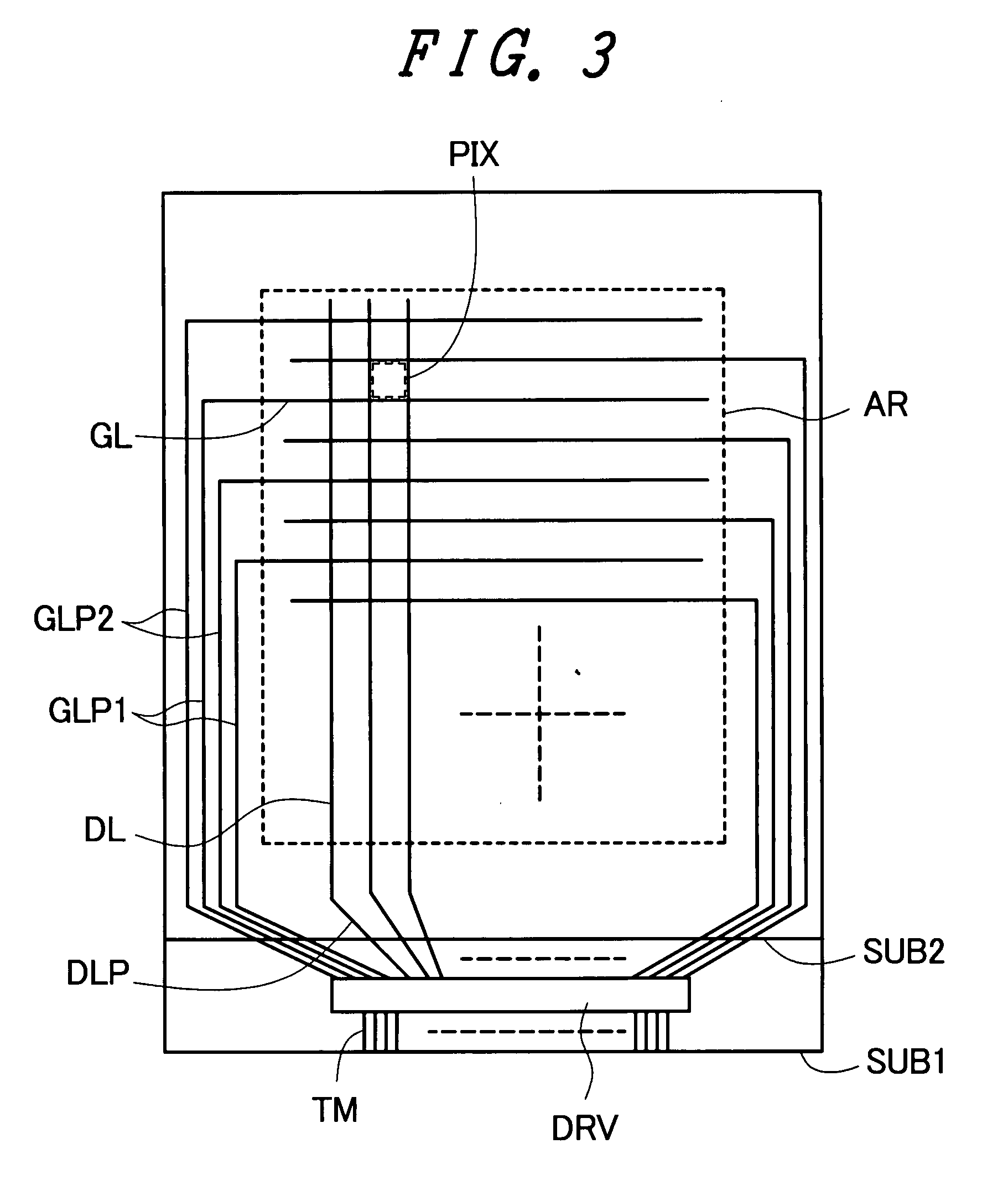

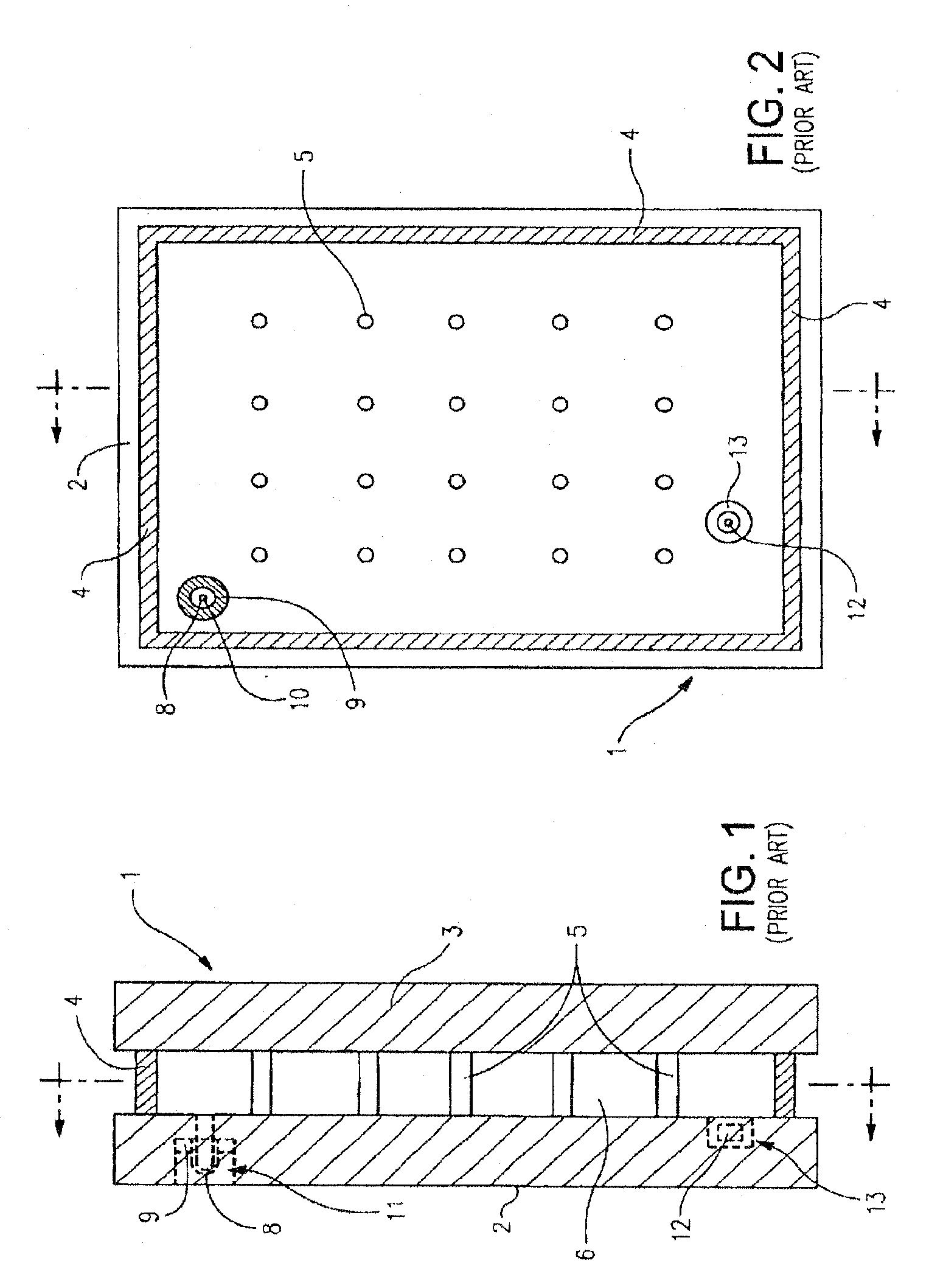

Liquid crystal display device

ActiveUS20080137022A1Reduce sealing defectSuppressing spreadingNon-linear opticsLiquid-crystal displayElectrical and Electronics engineering

The present invention provides a liquid crystal display device with a narrow picture frame which reduces a sealing defect by suppressing spreading of an orientation film. In a region inside a sealing material and outside a display region, an uneven surface for suppressing spreading of the orientation film is formed. It is preferable that the uneven surface is formed using an insulation film and, at the same time, an etching stopper layer is formed below the insulation film which forms the uneven surface. It is more preferable that the uneven surface and the stopper layer are simultaneously formed with a layer used for forming pixels in a step for forming such a layer thus preventing the increase of manufacturing steps.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

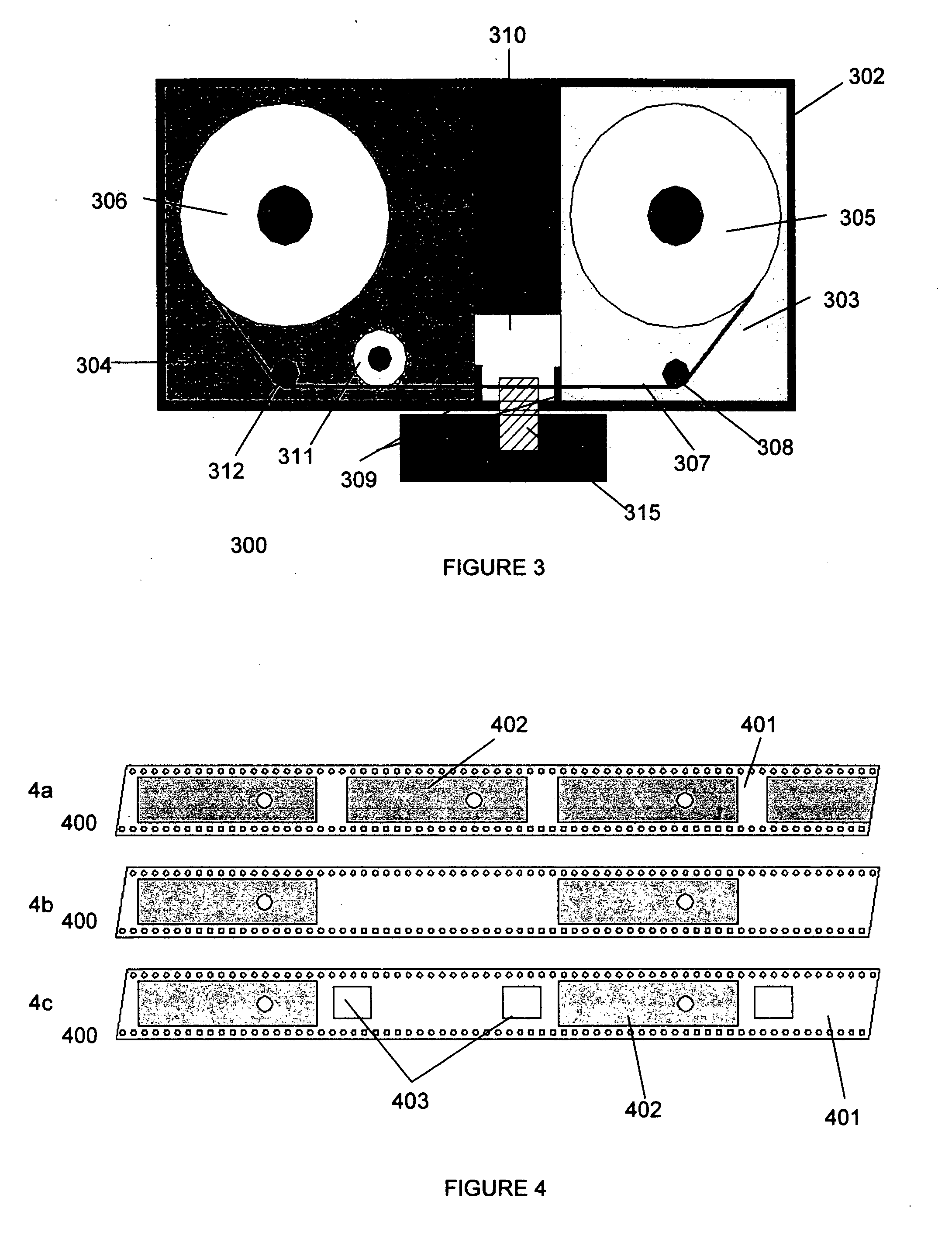

Test substrate handling apparatus

InactiveUS20070119710A1Precise positioningReduce pollutionImmobilised enzymesBioreactor/fermenter combinationsAnalyteIntegration testing

The present invention is an integrated, test substrate handling apparatus for the measurement and analysis of blood analytes and blood parameters. The test substrate handling apparatus includes multiple test substrate components combined in a single unit. It advances a test substrate for measurement of blood parameters via programmed, periodic blood sampling or via operator input.

Owner:GLUCON

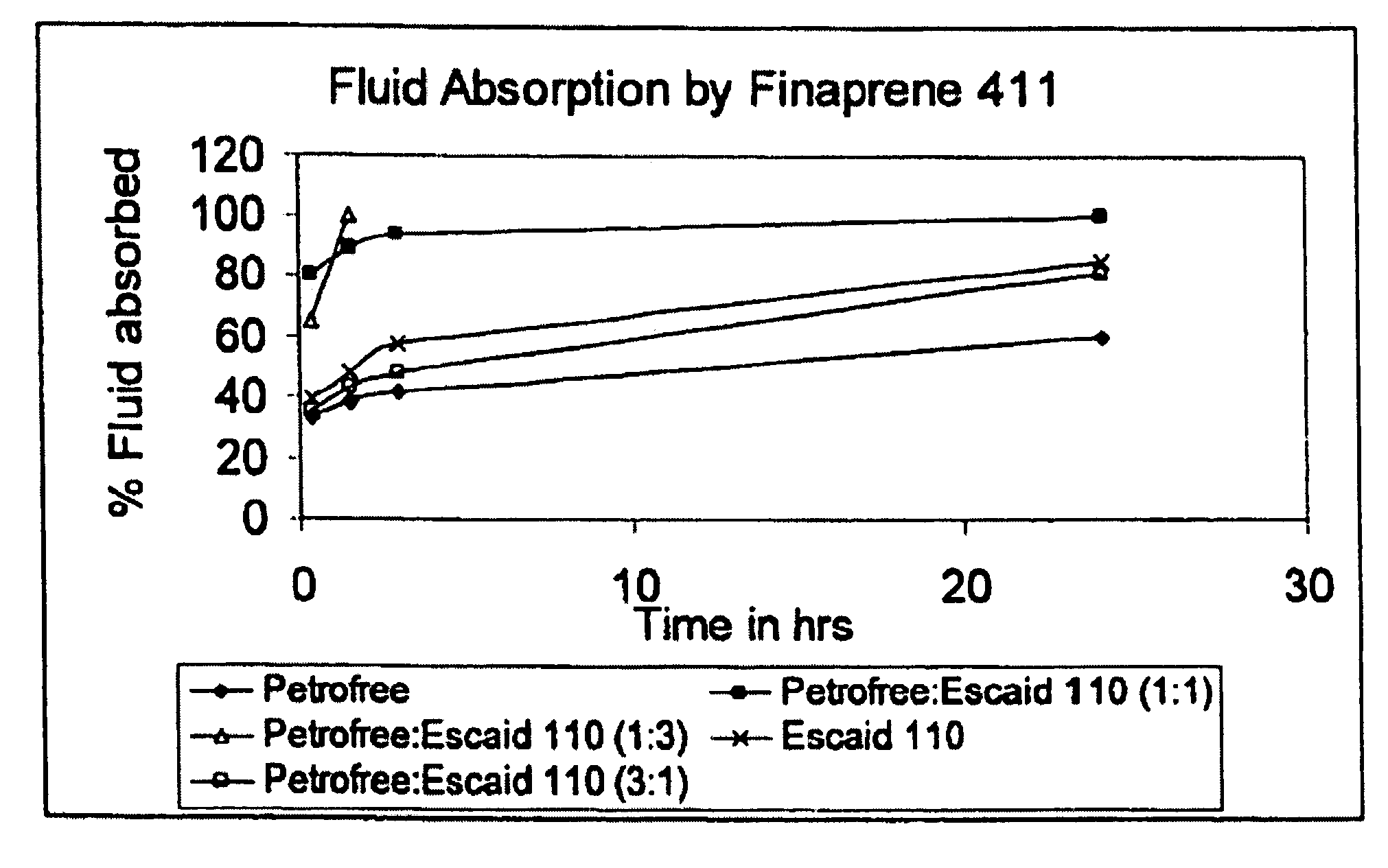

Methods for wellbore strengthening and controlling fluid circulation loss

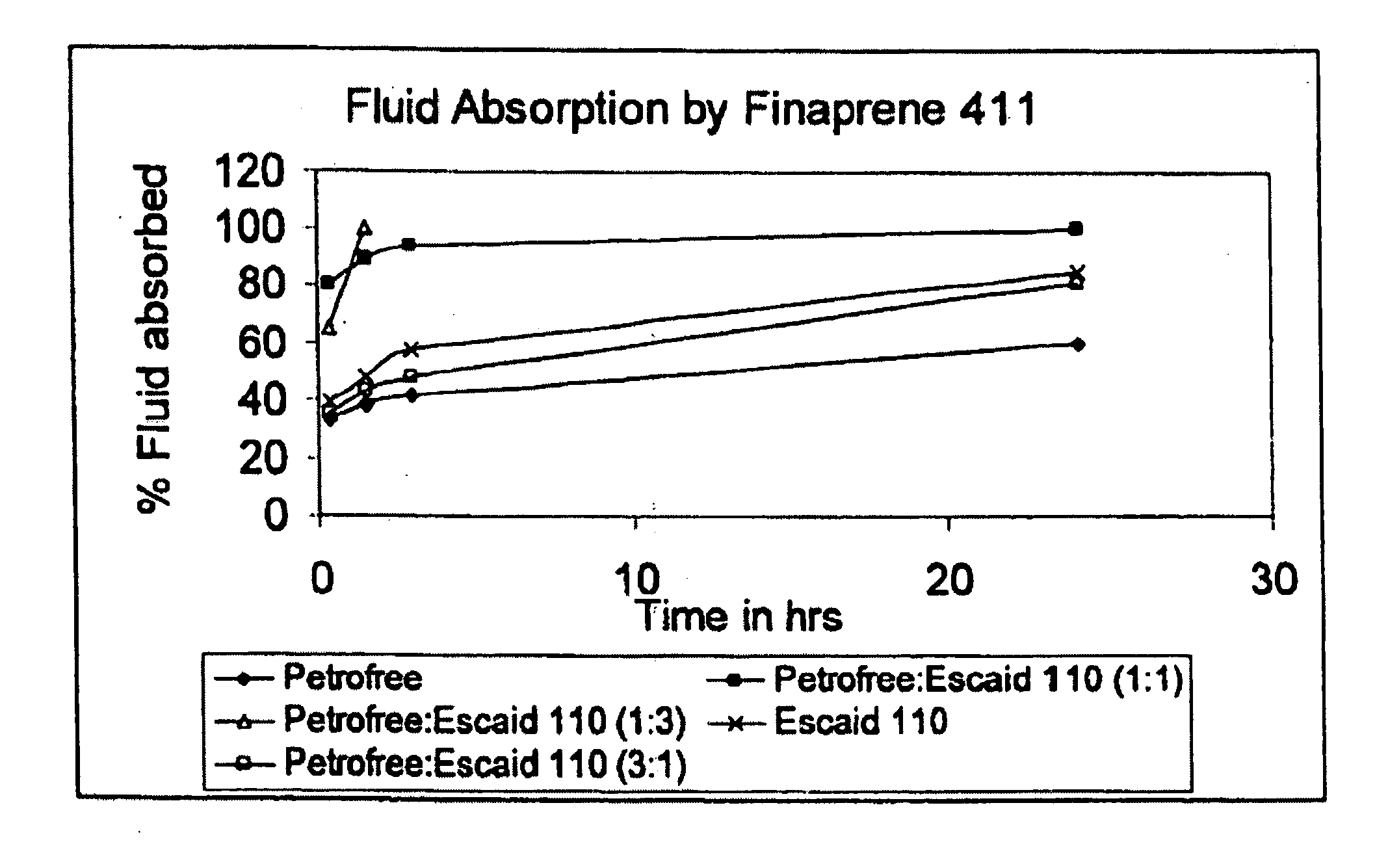

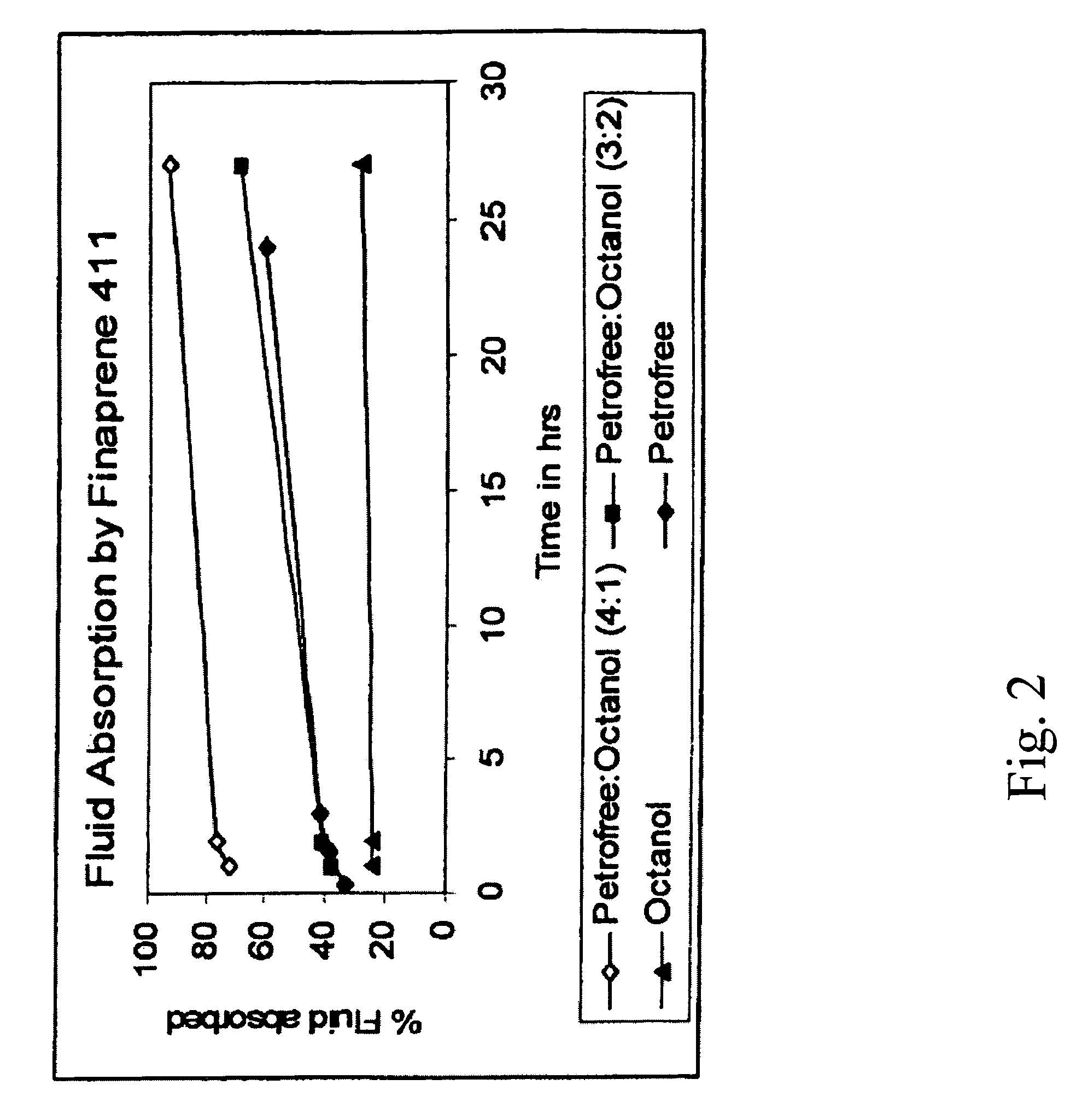

ActiveUS20070017676A1Reduce sealReduce lossesLiquid/gas jet drillingFluid removalCarrier fluidSealant

A sealant composition and methods for using the same are disclosed. In an embodiment, a method of servicing a wellbore in contact with a subterranean formation is disclosed. The method comprises placing a sealing agent and a nonaqueous carrier fluid in the wellbore. The method further comprises placing a nonaqueous activating fluid in the wellbore. In addition, the method comprises contacting the sealing agent with the nonaqueous activating fluid to form a sealant composition.

Owner:HALLIBURTON ENERGY SERVICES INC

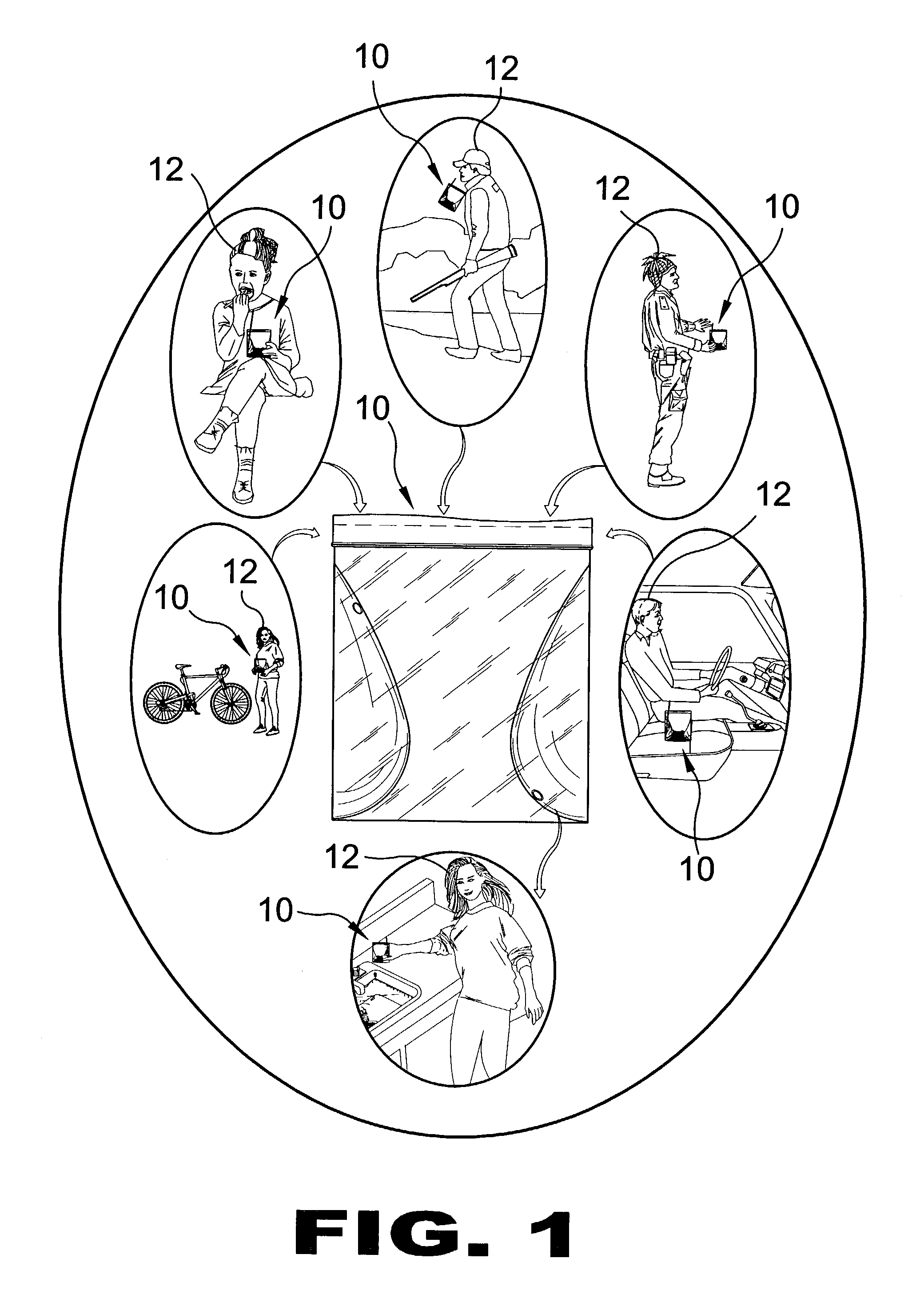

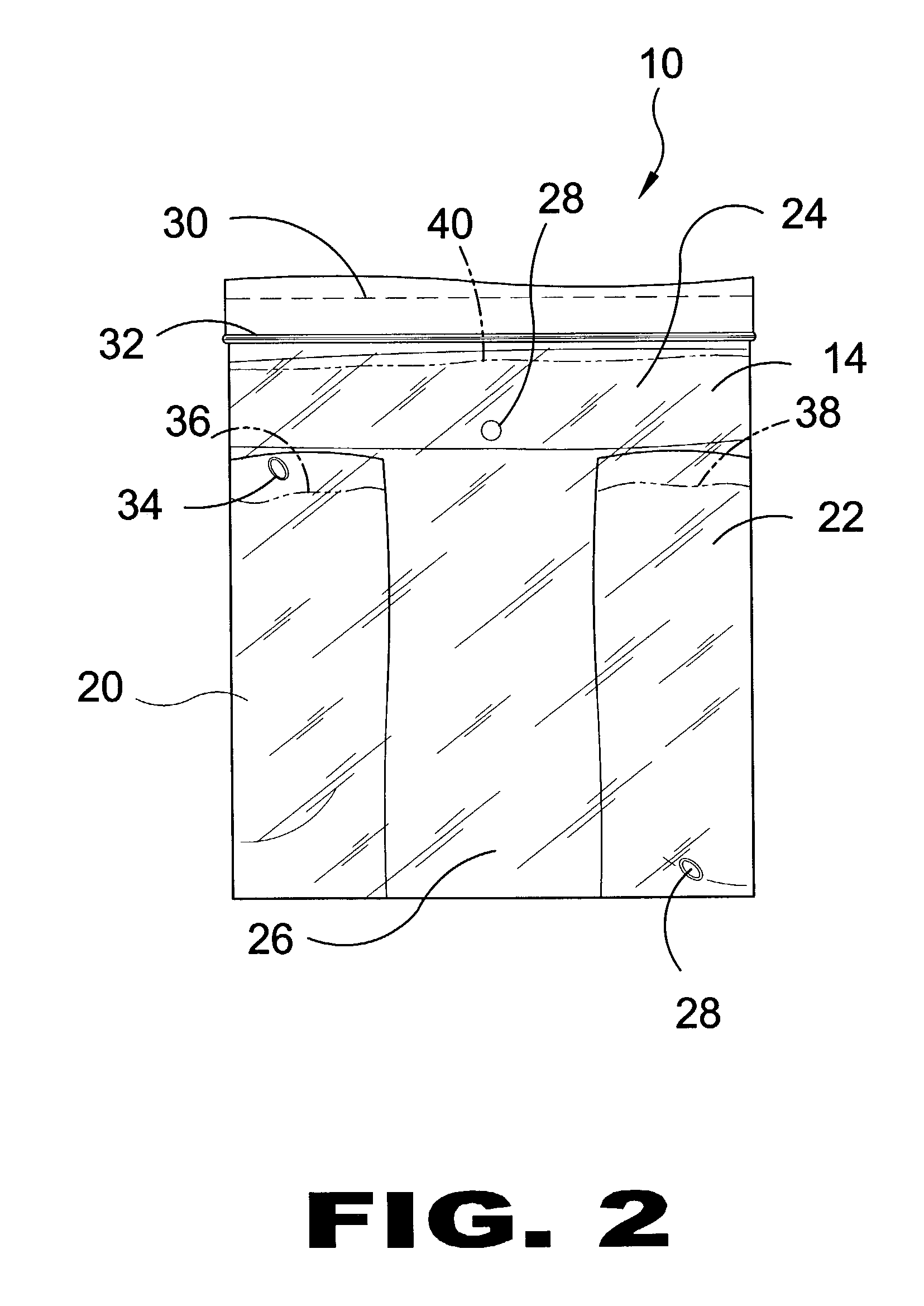

Flexible mixing pouch with aseptic burstable internal chambers

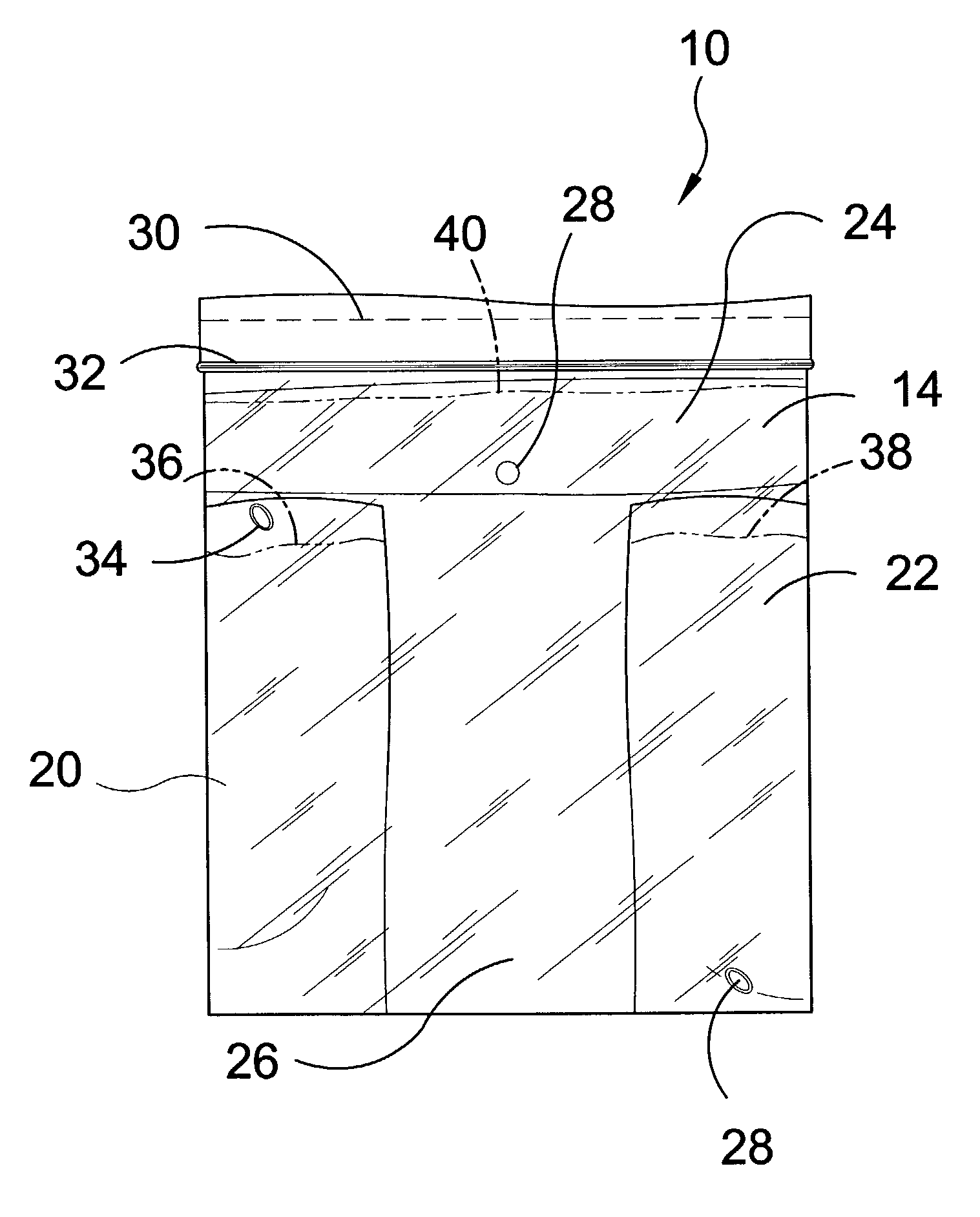

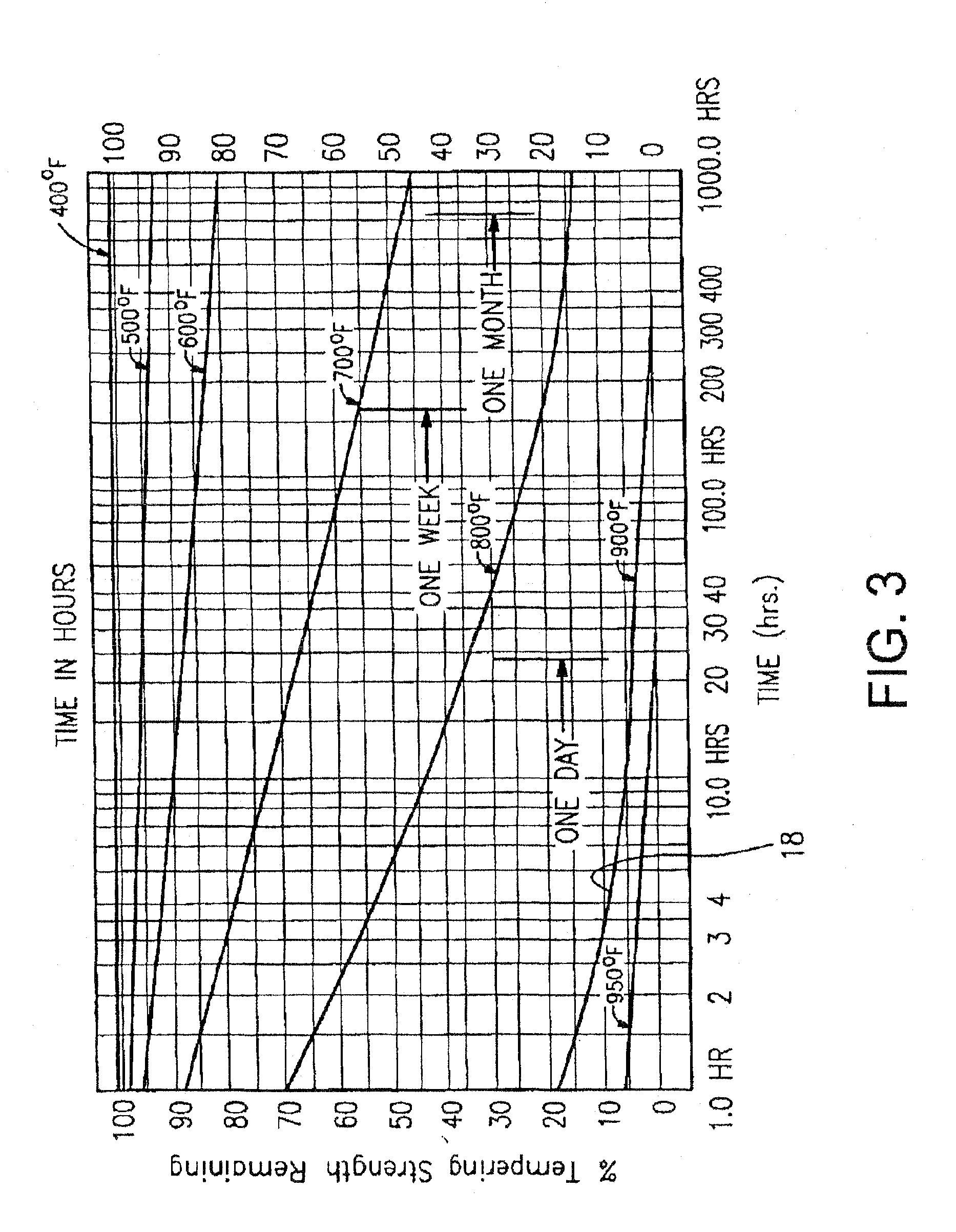

InactiveUS6935492B1Amount be controlReduced strengthRigid containersContainers with multiple articlesInternal pressureHermetic seal

A flexible mixing pouch with aseptic burstable internal chambers for storing a plurality of substances in isolated, hermetically sealed aseptic chambers therein in order to maintain the freshness and integrity of each pre-measured substance until ready for combining into a desired solution. The interior pocket of the outer pouch contains one or more internal storage chambers adjacent a mixing chamber. Impermeable sheets bonded to the outer pouch define the sealed storage chambers and include a frangible portion thereon forming burst ports. The user squeezes the desired storage chamber and the pressure applied thereto creates a disparity between the internal pressure against the impermeable sheet and the external pressure in said mixing chamber and compromises the integrity of the associated burst port causing it to rupture and discharge the contained substance into the mixing chamber where it is combined with the contained substance to create the desired solution having a precise, predefined ratio of the first substance to the second substance.

Owner:LOEB BARRY ALAN

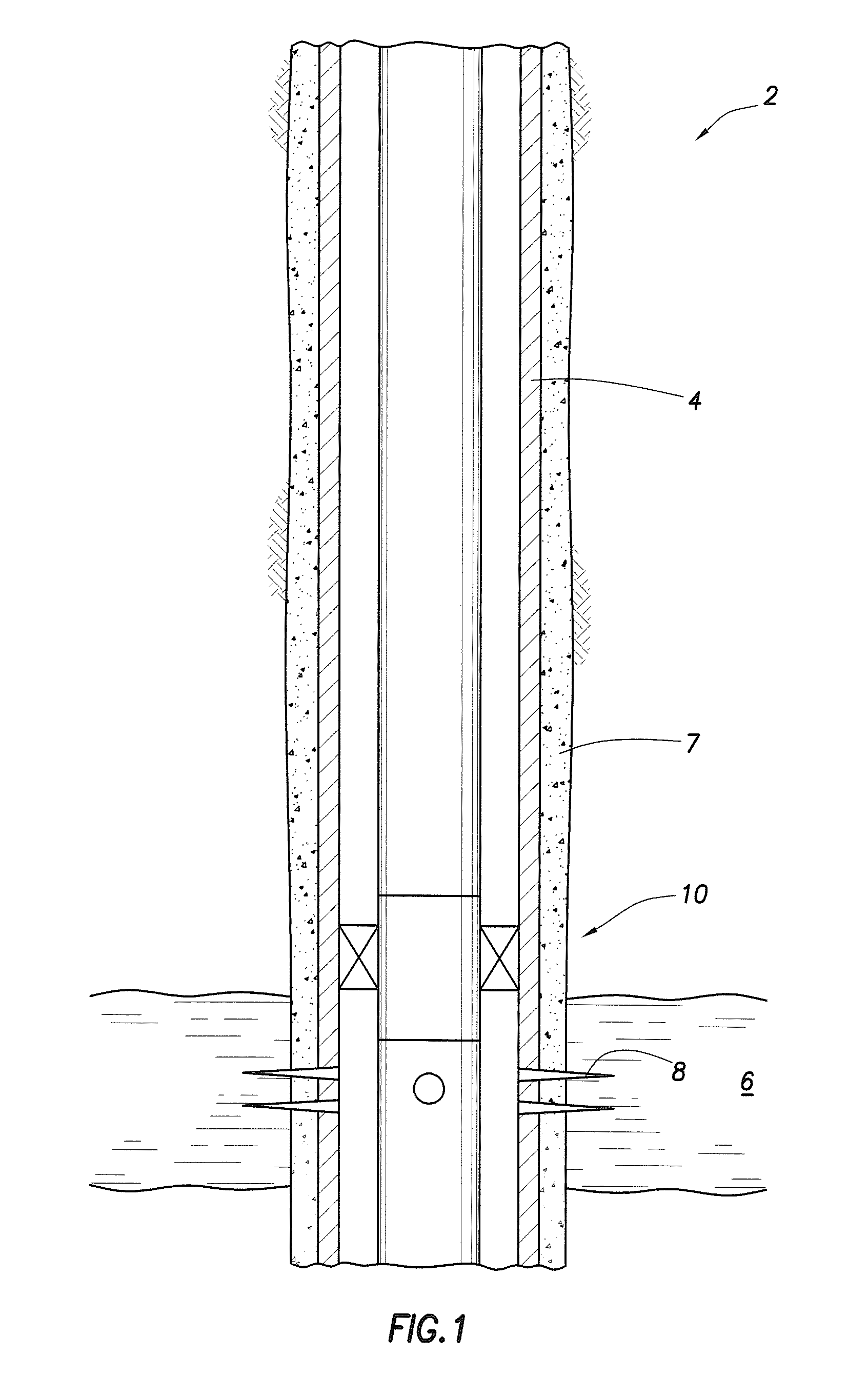

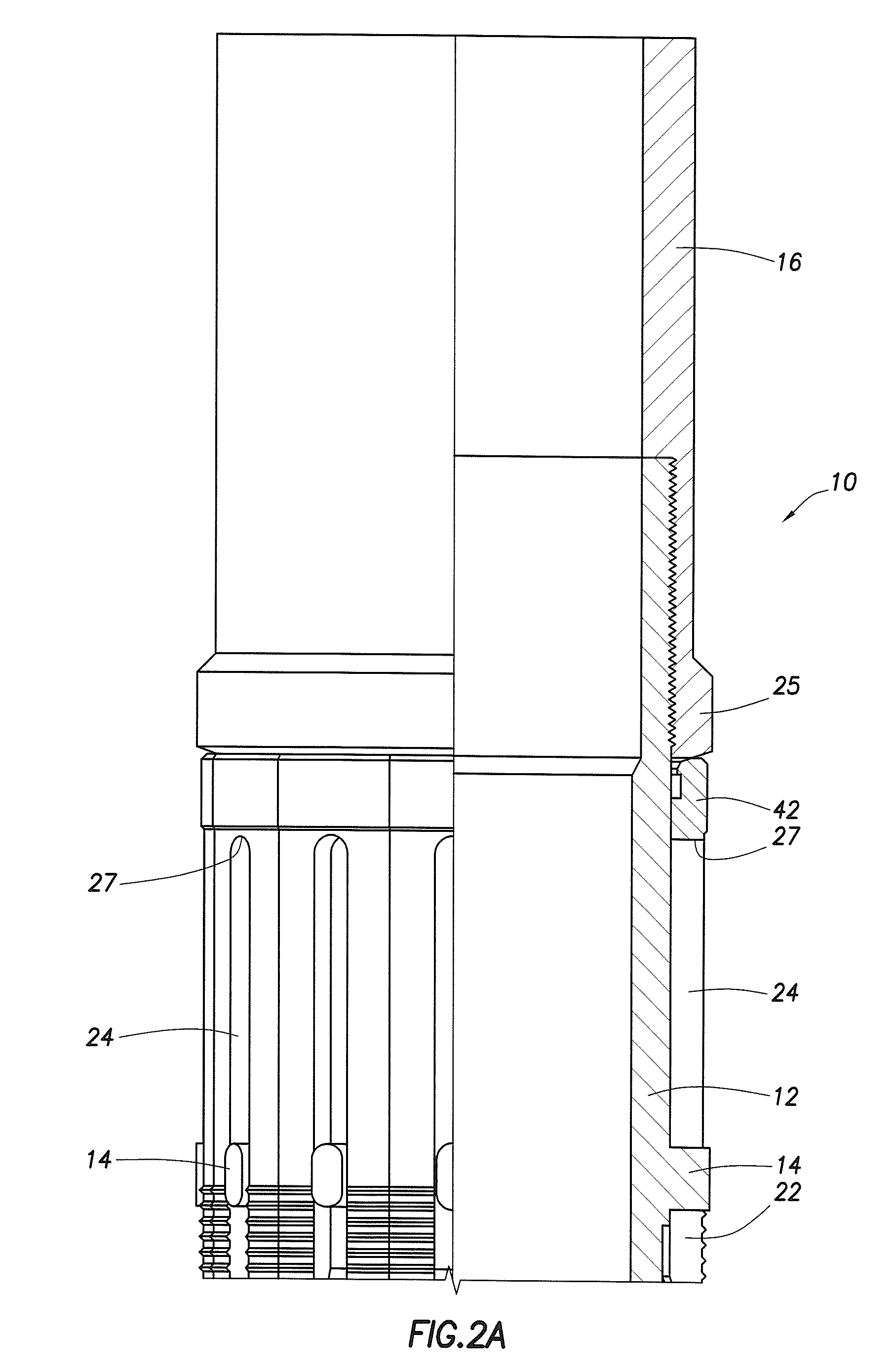

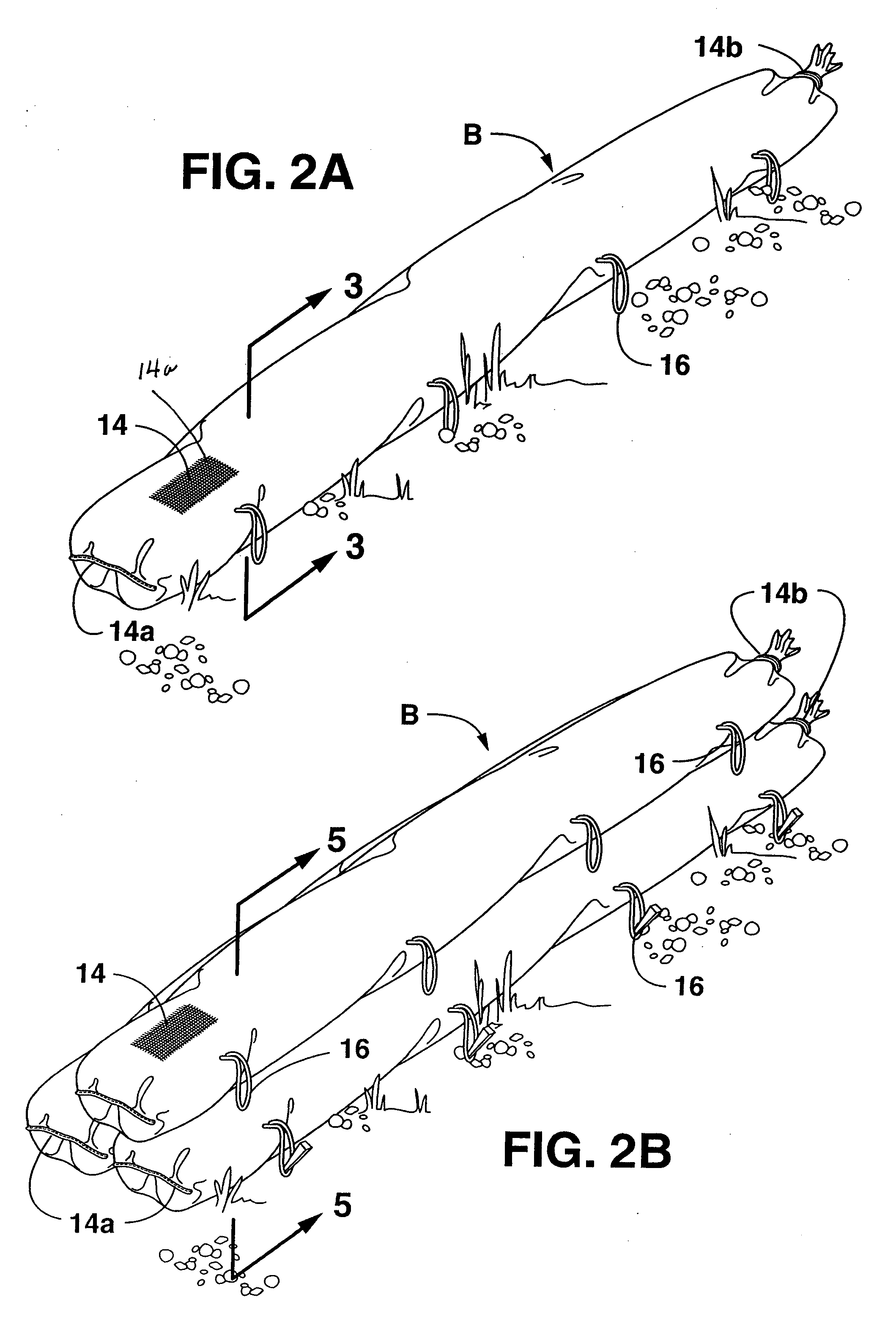

Retrieval Method For Opposed Slip Type Packers

ActiveUS20110147013A1Reduce compressionReduce sealFluid removalSealing/packingEngineeringMechanical engineering

A method is provided which releases and retrieves an opposed slip downhole tool by reducing the compressive forces on the sealing elements prior to unsetting the slip assemblies. Further, the method does so without damaging the slip assemblies. The method provides for the retrieval of the entire downhole tool including all of its component parts, requiring but a single trip within the wellbore. When the tool is to be retrieved, the sealing element is disengaged from the casing by relaxing the compression forces on the sealing element. Then the slip assemblies are disengaged from the casing such that the slip assemblies are no longer in gripping engagement with the casing. The tool is then retrieved from the wellbore. The step of disengaging the sealing assembly can be performed by radially contracting the sealing element with or without longitudinally expanding the sealing element.

Owner:HALLIBURTON ENERGY SERVICES INC

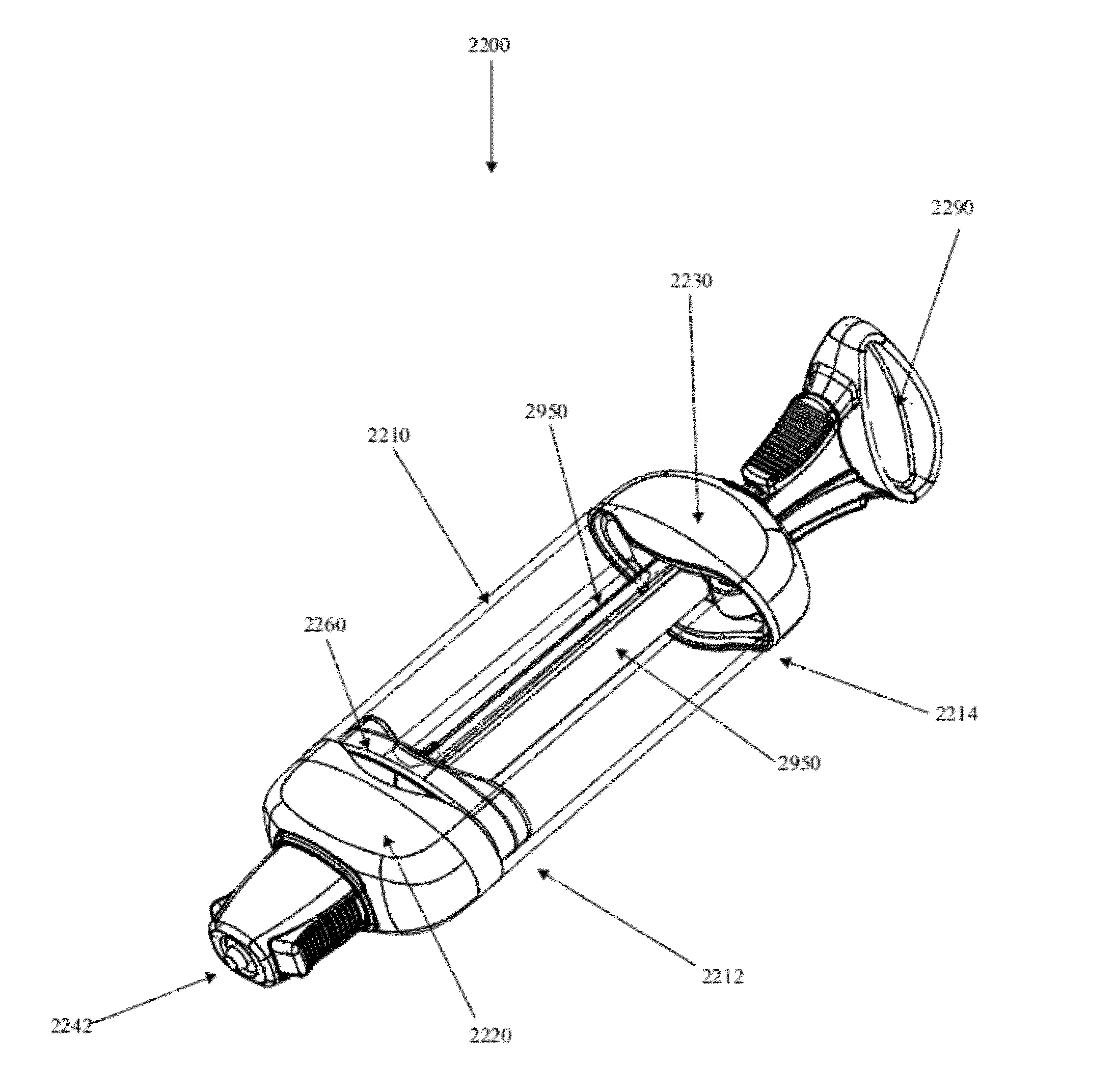

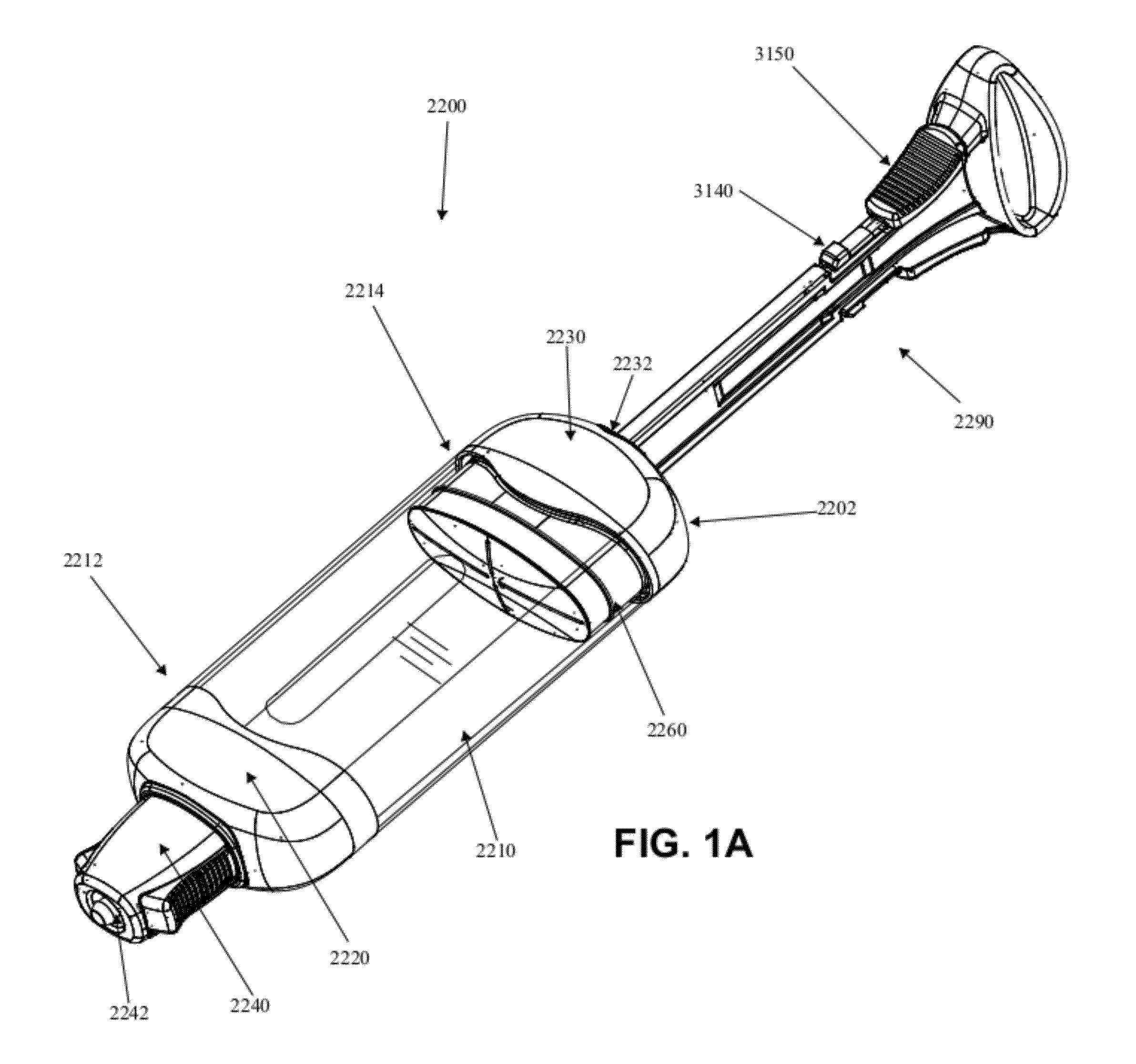

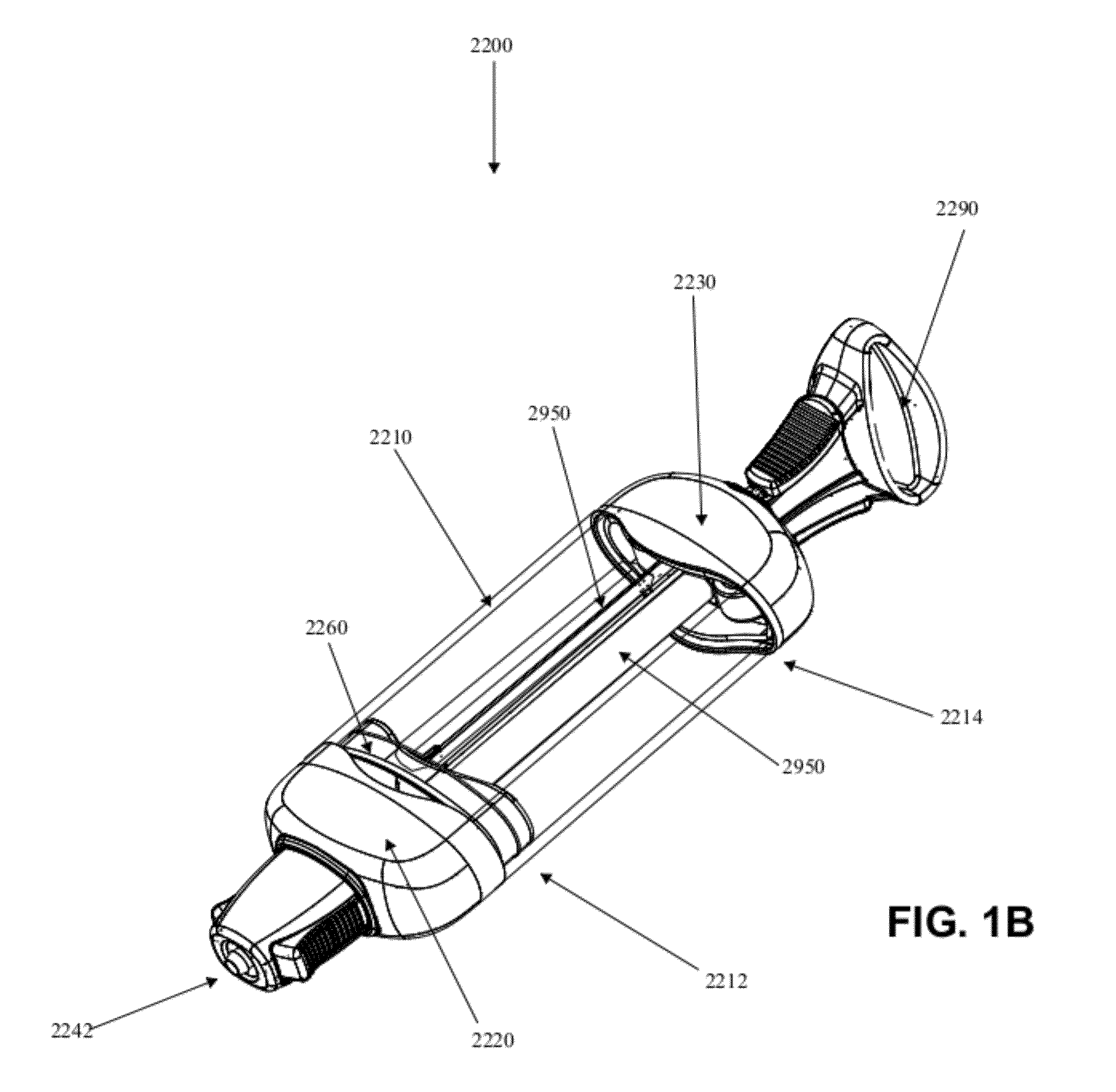

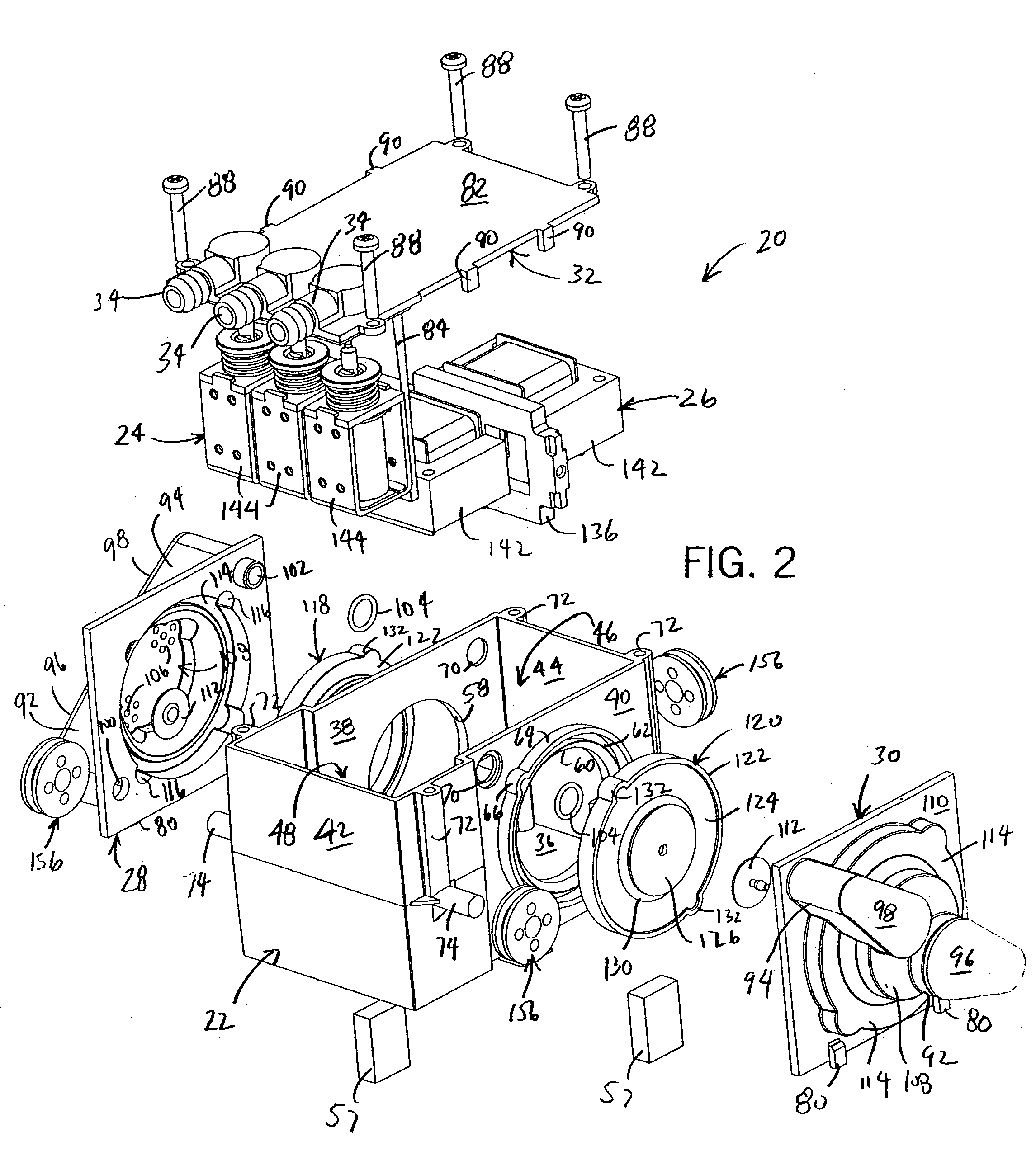

Controlled negative pressure apparatus and absorbency mechanism

ActiveUS20120071845A1Reduce pressureReduce frictionMedical devicesIntravenous devicesDamages tissuePhysical therapy

Methods and devices for treatment of damaged tissue are disclosed, including treatment of wounds by employing non-electrically powered, reduced pressure therapy devices. The devices are capable of generating a substantially constant reduced pressure with low tolerance for pressure fluctuations. Also disclosed herein are reduced pressure therapy systems that comprise an alarm system to detect the depleted state of the suction device and provide an alert to the patient and / or practitioner.

Owner:KCI LICENSING INC

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

ActiveUS20120213954A1Improve sealingReduce sealClimate change adaptationWindows/door improvementMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

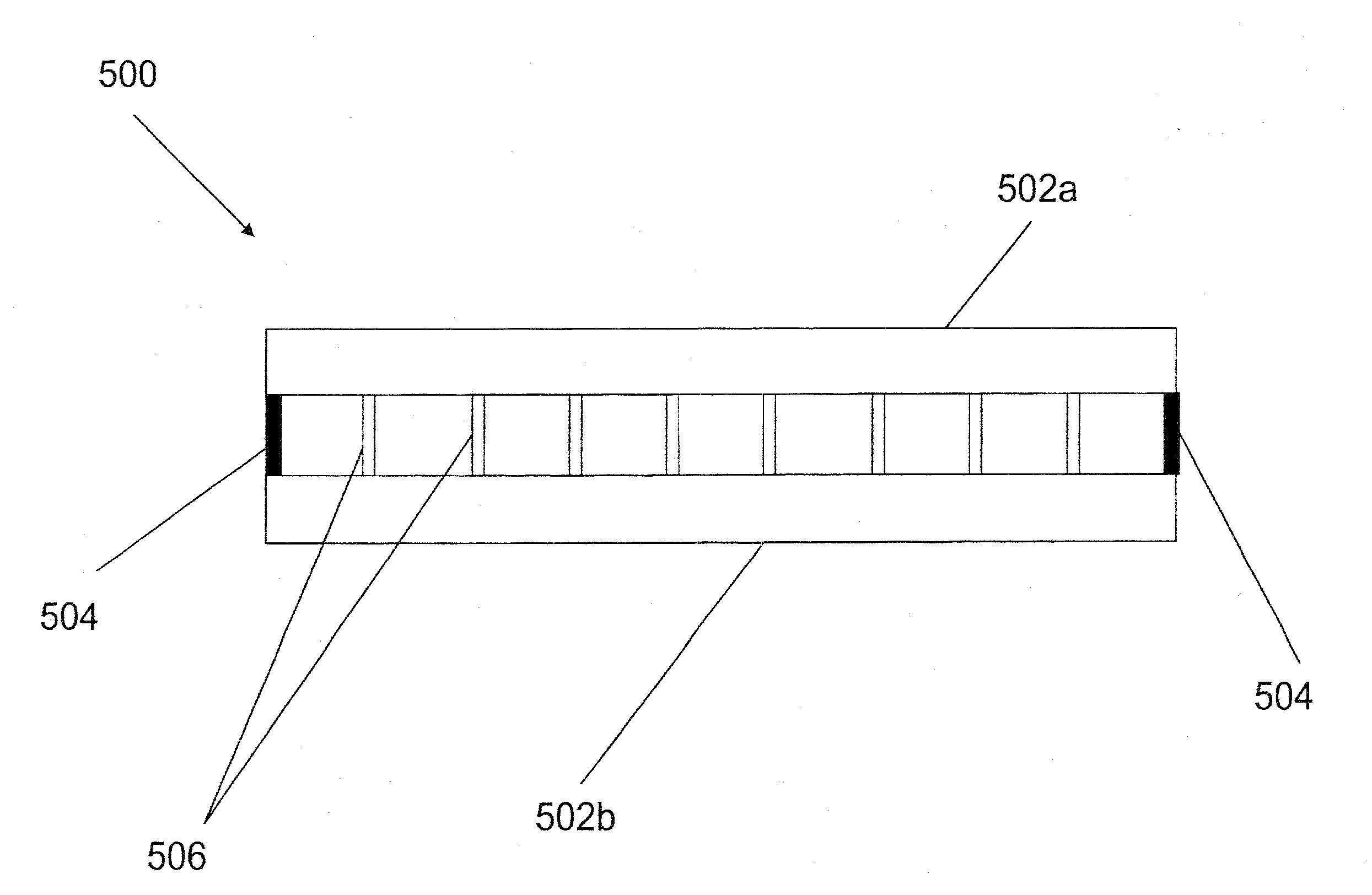

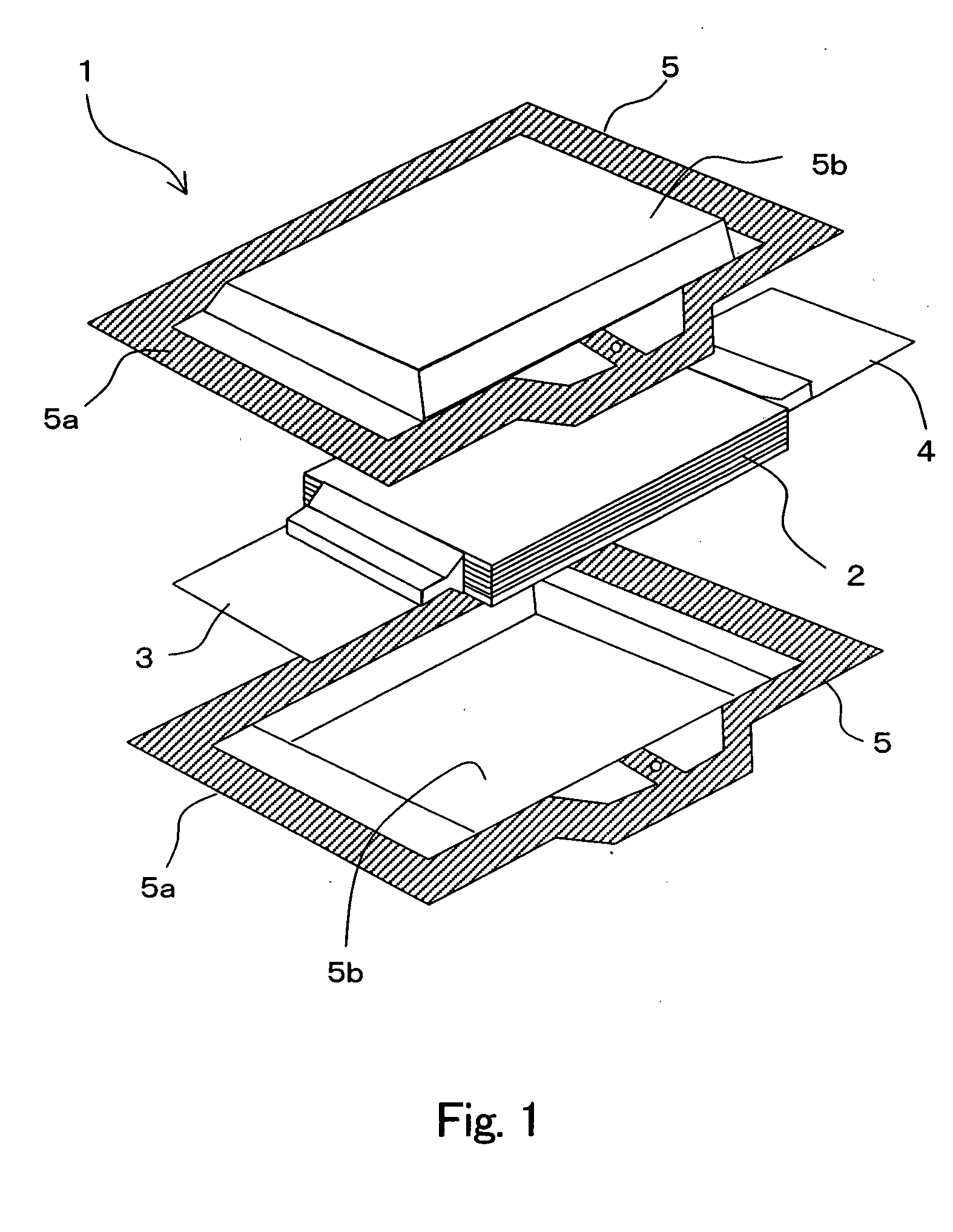

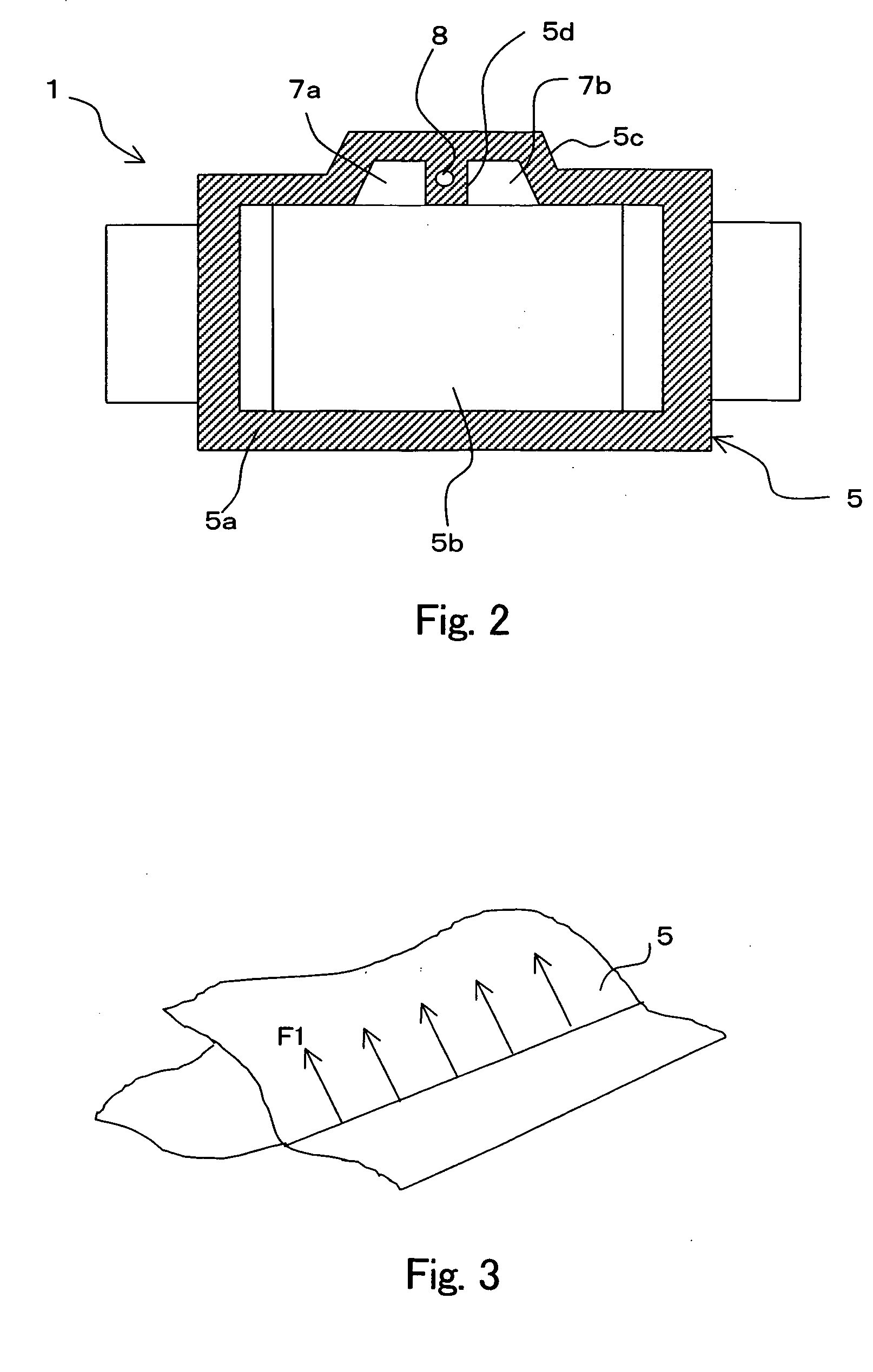

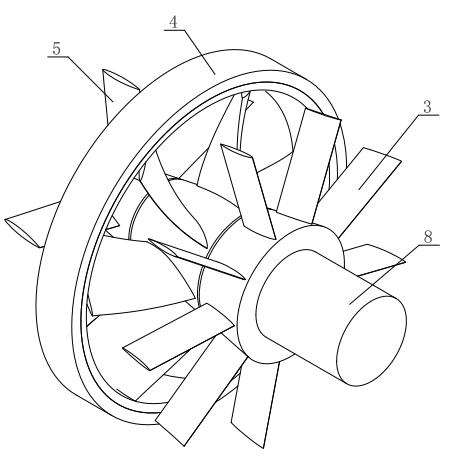

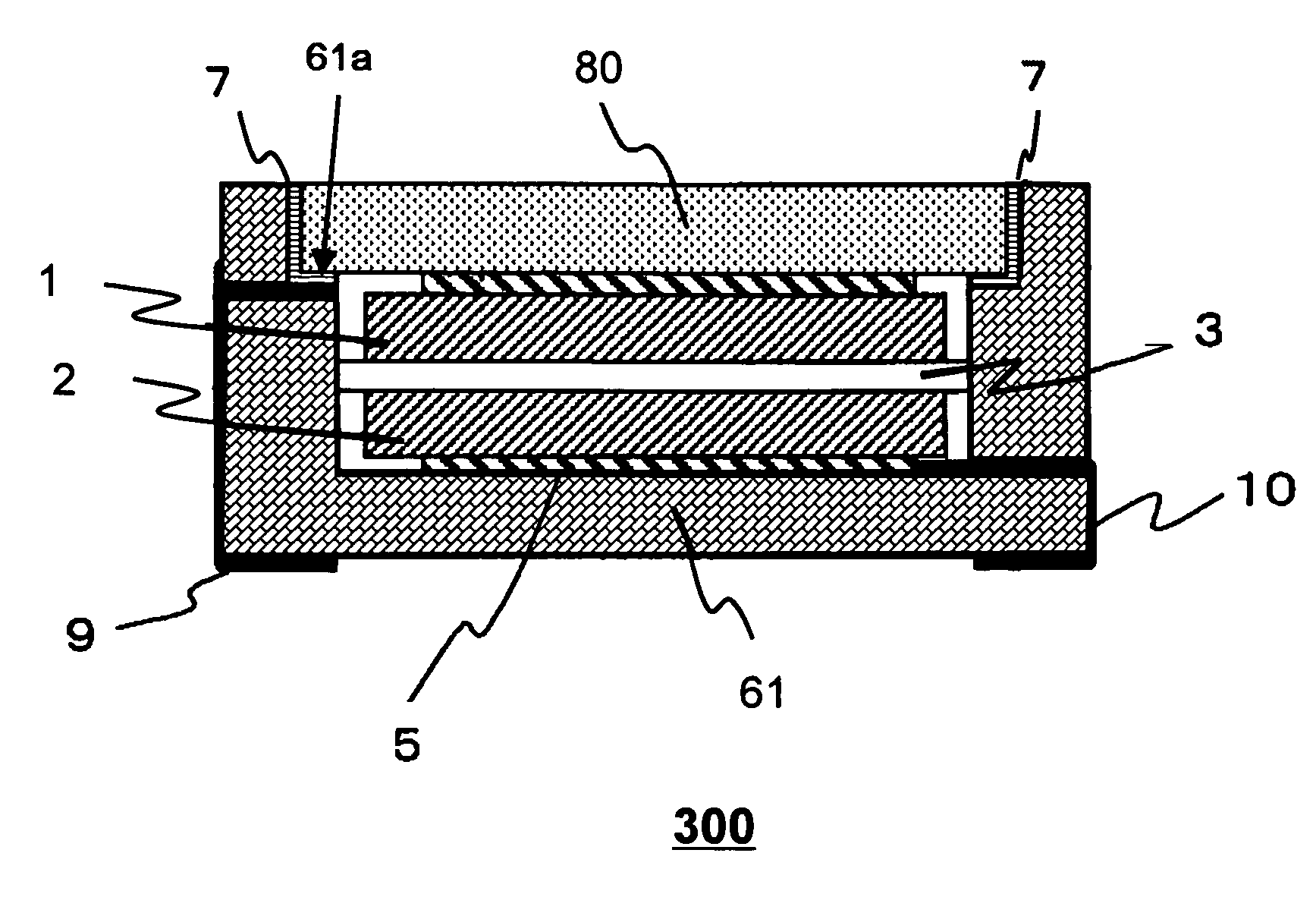

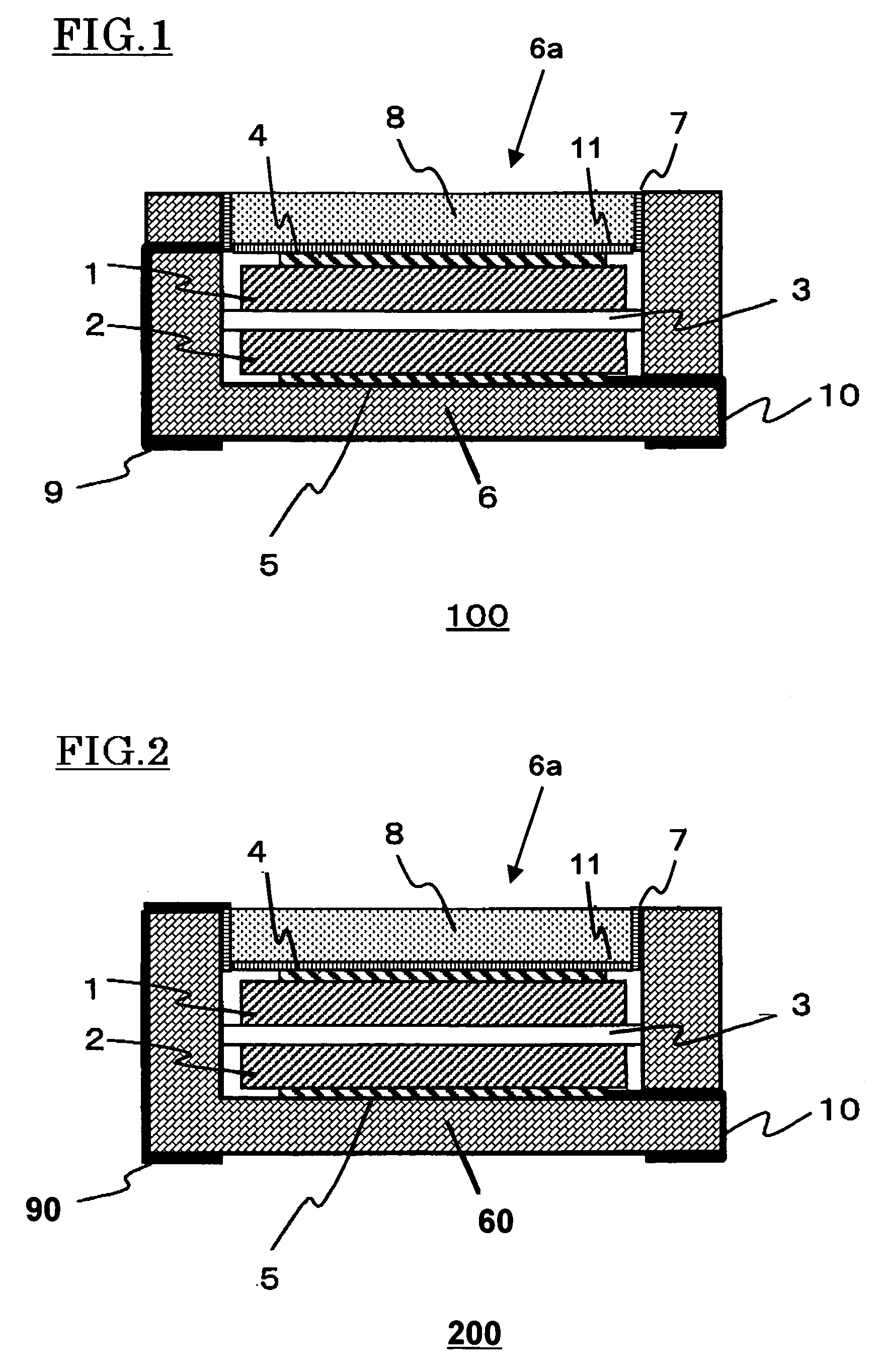

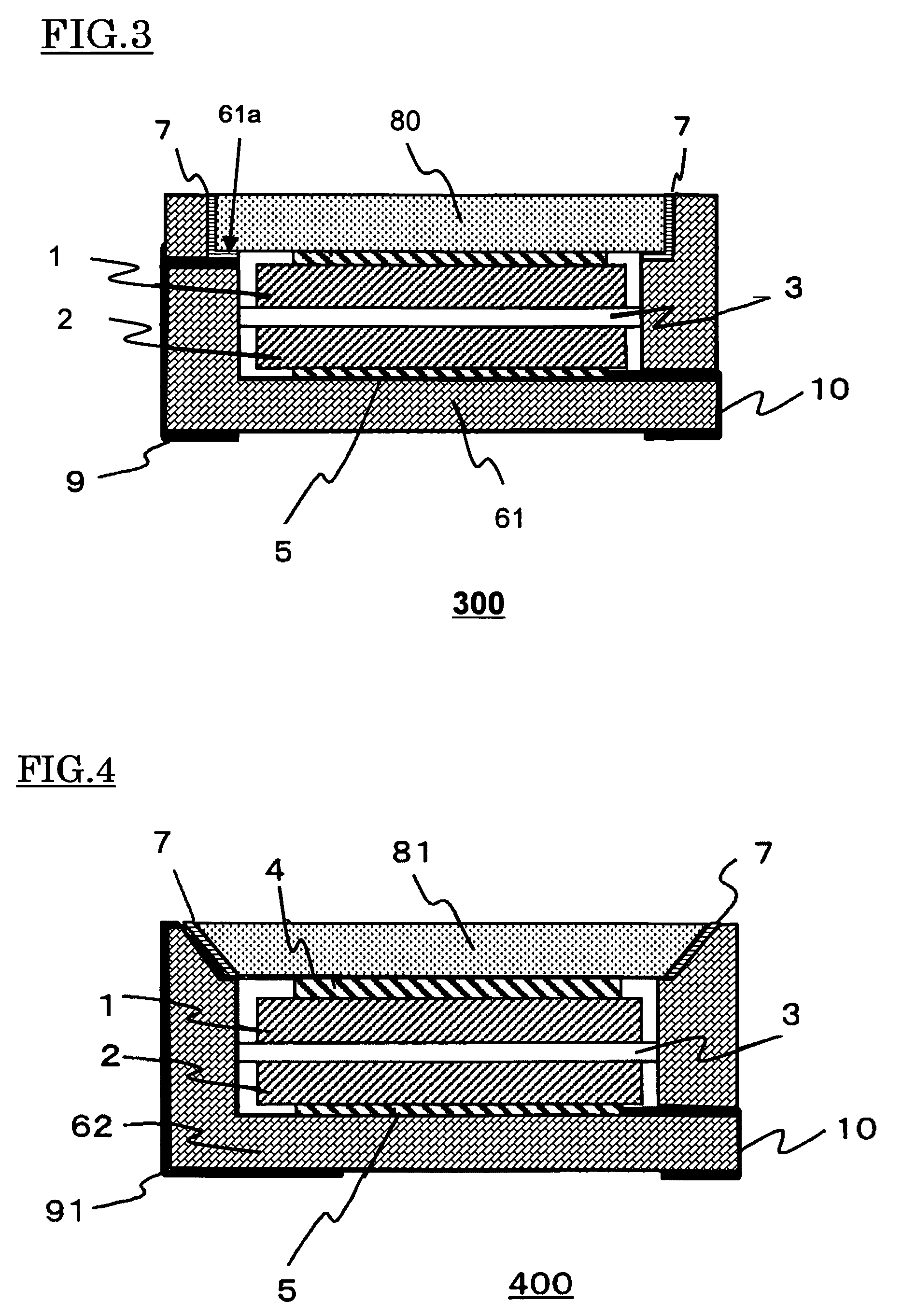

Film-covered electric device having pressure release opening

ActiveUS20050158622A1Reduce sealEasy to set upClosuresFixed capacitor housing/encapsulationStress concentrationElectrical devices

A film-covered electric device has an electric device element and casing films. The casing films include a sealing area formed by thermally fusing the facing surfaces of the casing films together around the periphery of the electric device element, an electric device element receiving part encapsulating the electric device element inside the sealing area, and unfused portions formed in the shape of cove communicating with the electric device element receiving part. The casing films further include a stress concentrating portion touching the unfused portions for concentrating thereon the peeling stress of the casing films generated at the sealing area by the expansion of the electric device element receiving part, and a pressure releasing part is formed in the stress concentrating portion.

Owner:NEC CORP

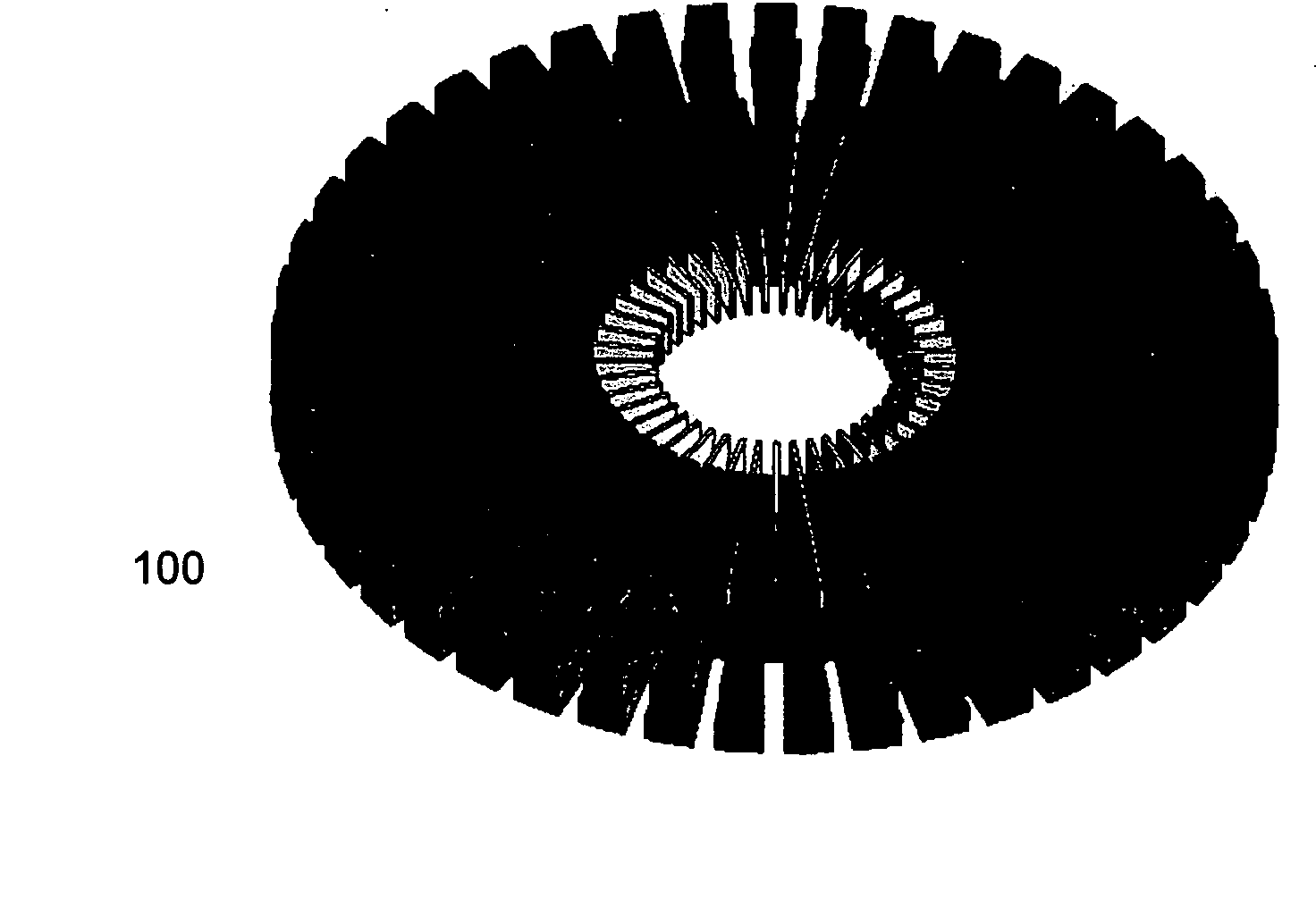

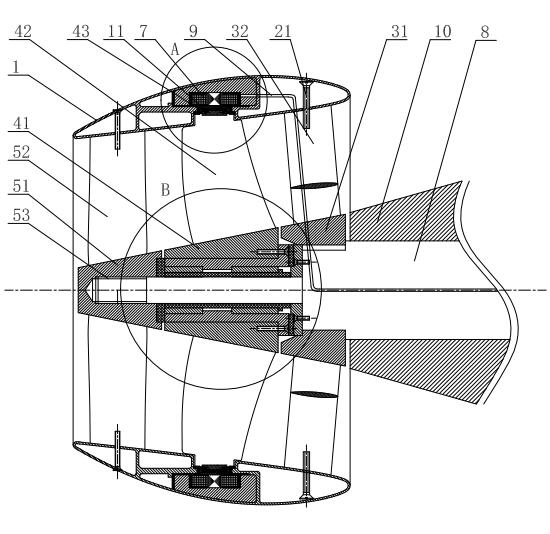

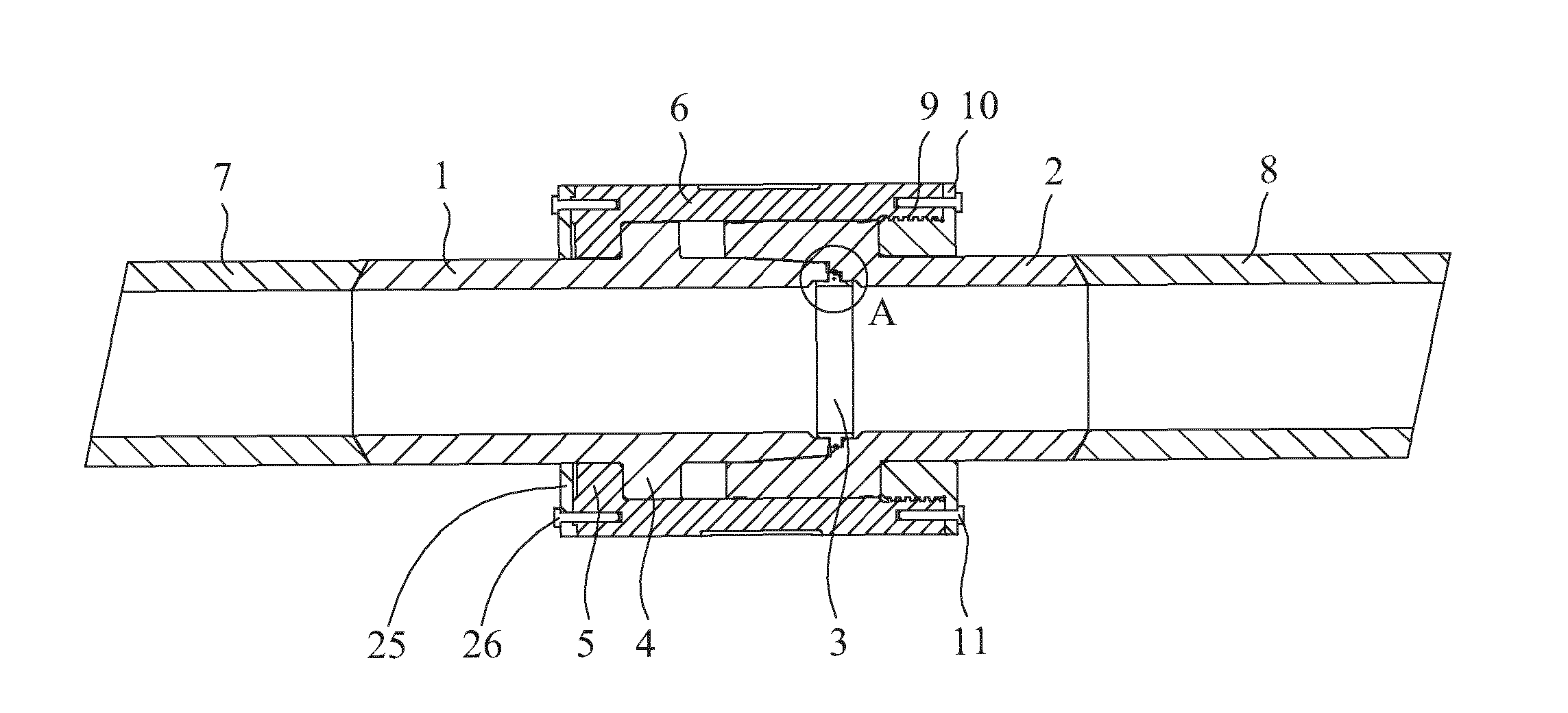

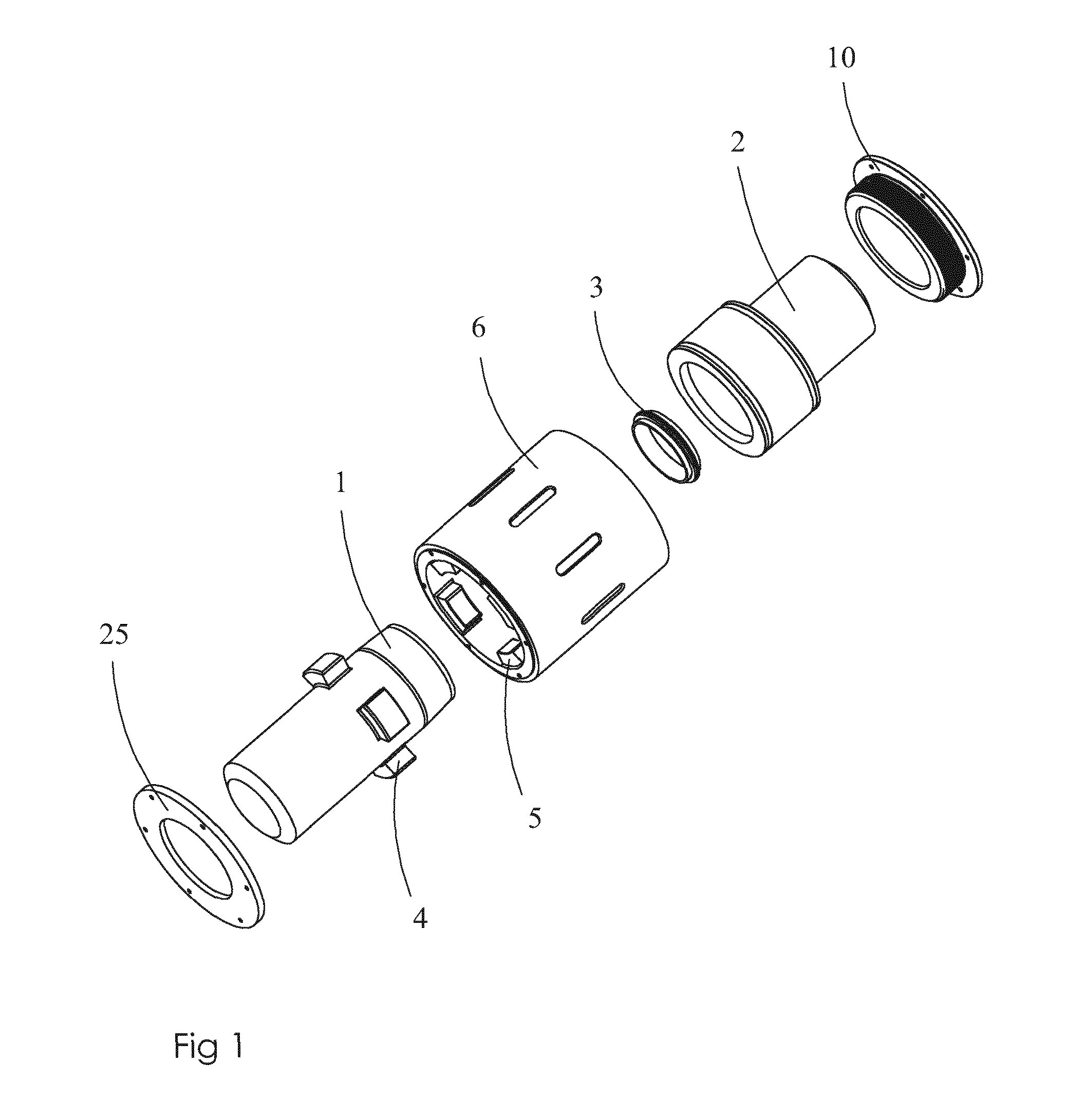

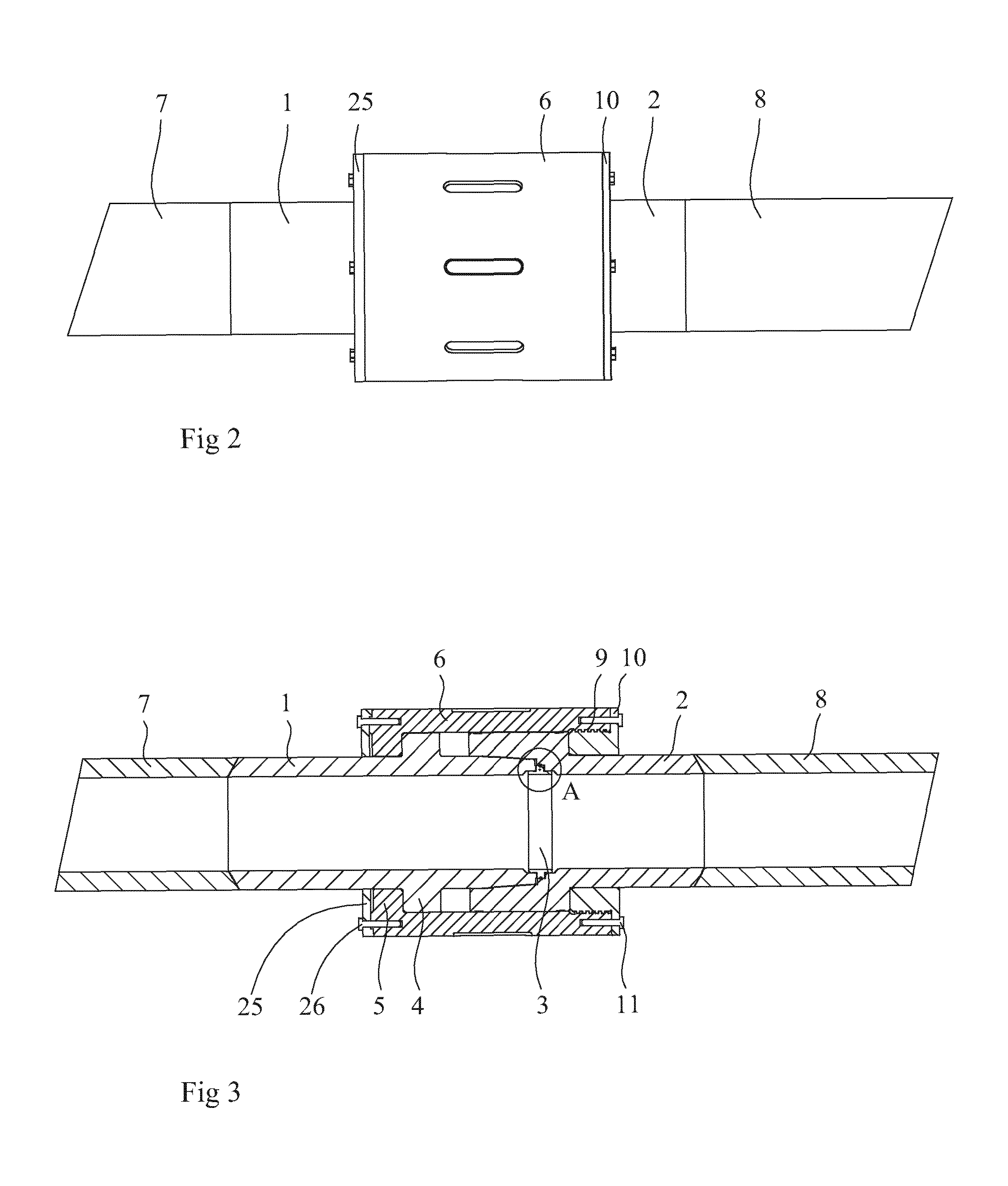

Shaftless driven type integrated motor propeller

InactiveCN102632982ALarge diameterIncrease output torqueRotary propellersPropulsive transmission driveCavitationPropeller

The invention discloses a shaftless driven type integrated motor propeller which is arranged on the tail part of a boat body of a water vehicle or underwater vehicle and comprises a front stator, a rotor propeller and a rear stator which are serially arranged on a solid non-rotating shaft, wherein the periphery of the propeller is connected with the circumferential rim of the annular propeller, a rotor permanent magnet is embedded in the circumferential rim of the propeller, a stator winding is arranged in the inner cavity of a guide pipe, the rotor permanent magnet and the stator winding are sealed by adopting water, and a gap is arranged between the rotor permanent magnet and the stator winding to form an annular motor. The rotor permanent magnet and the stator winding as well as the guide pipe are organically combined to form a modular unit, thus the shaftless driven type integrated motor propeller can be easily installed on a water platform or underwater platform, is suitable for large-power main propelling of a water boat or underwater submergible device, and has the advantages of reasonable structure, high propelling efficiency, low hydrodynamic force radiation noise, excellent cavitation property, safety and reliability.

Owner:中国船舶重工集团公司第七〇二研究所

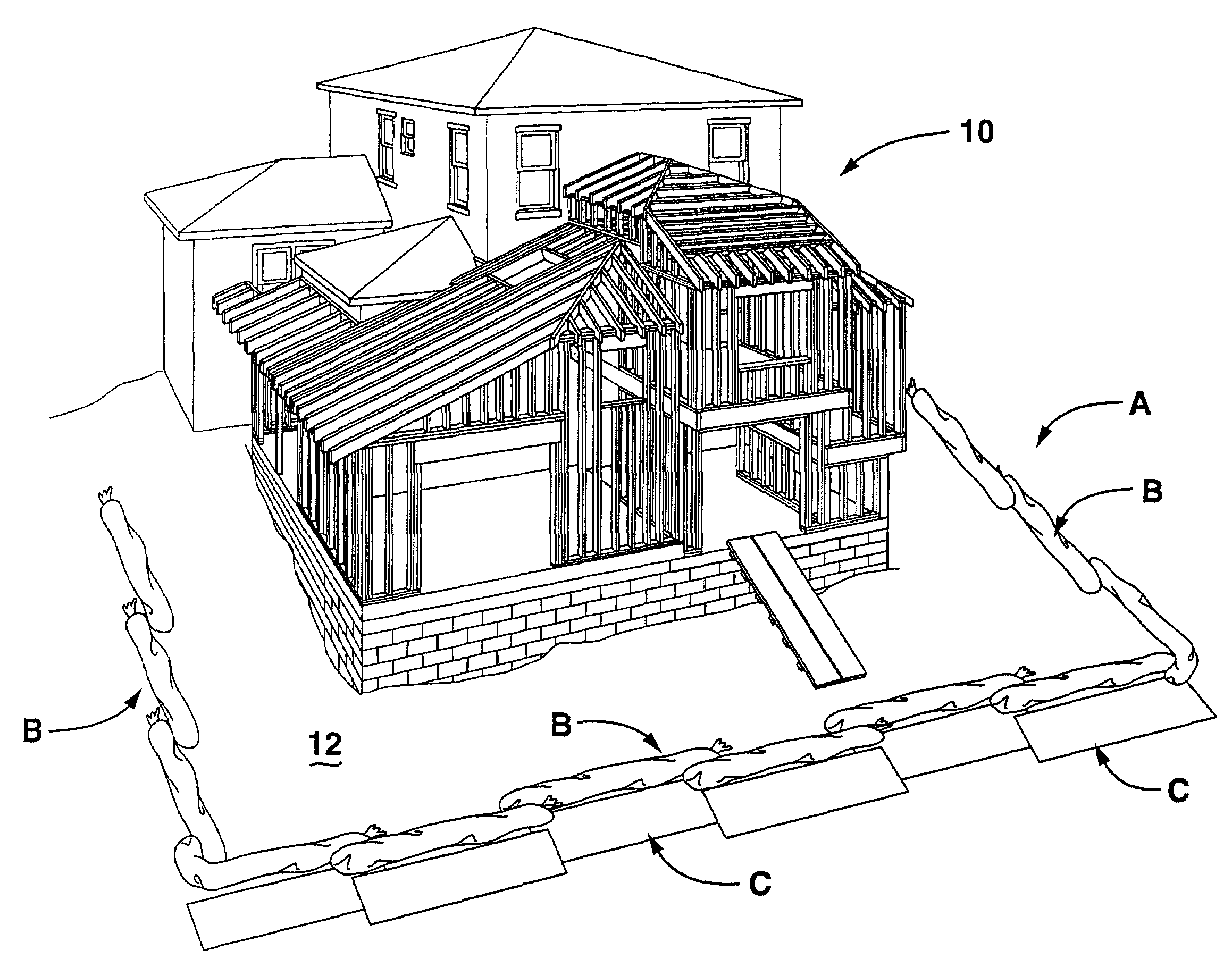

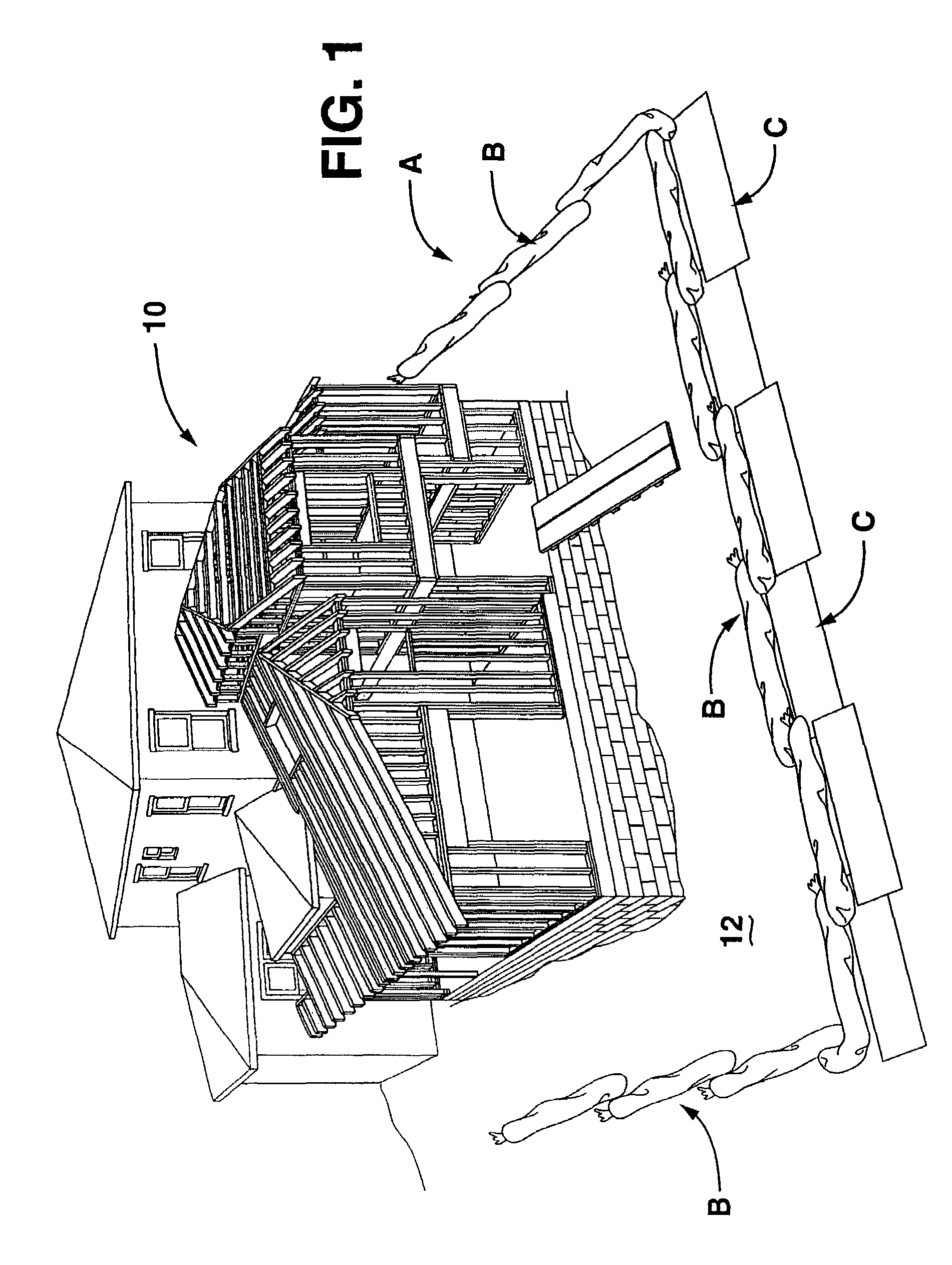

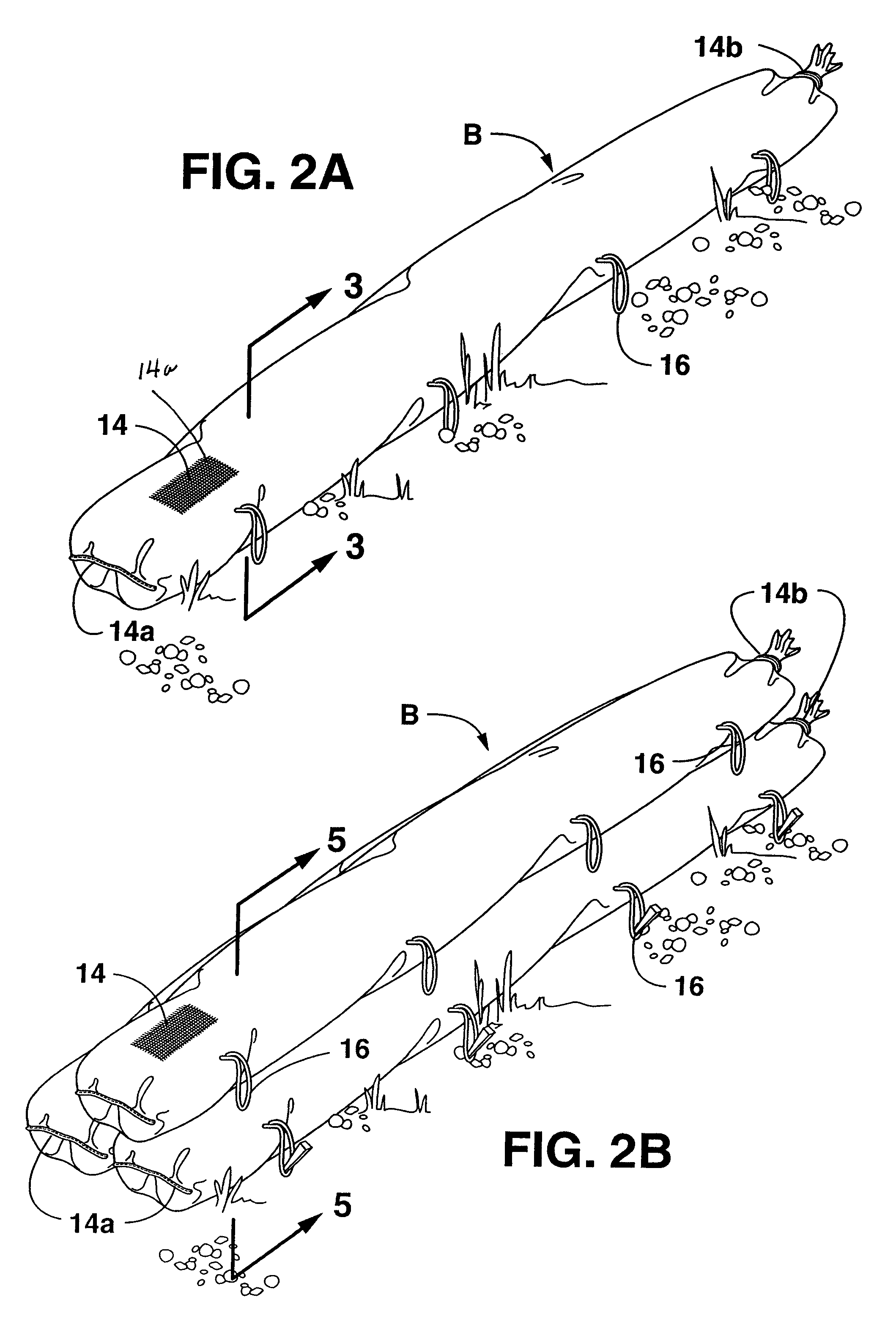

Water filtration and erosion control system

ActiveUS7449105B2Useful in erosion controlErosion minimizationLoose filtering material filtersCartridge filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

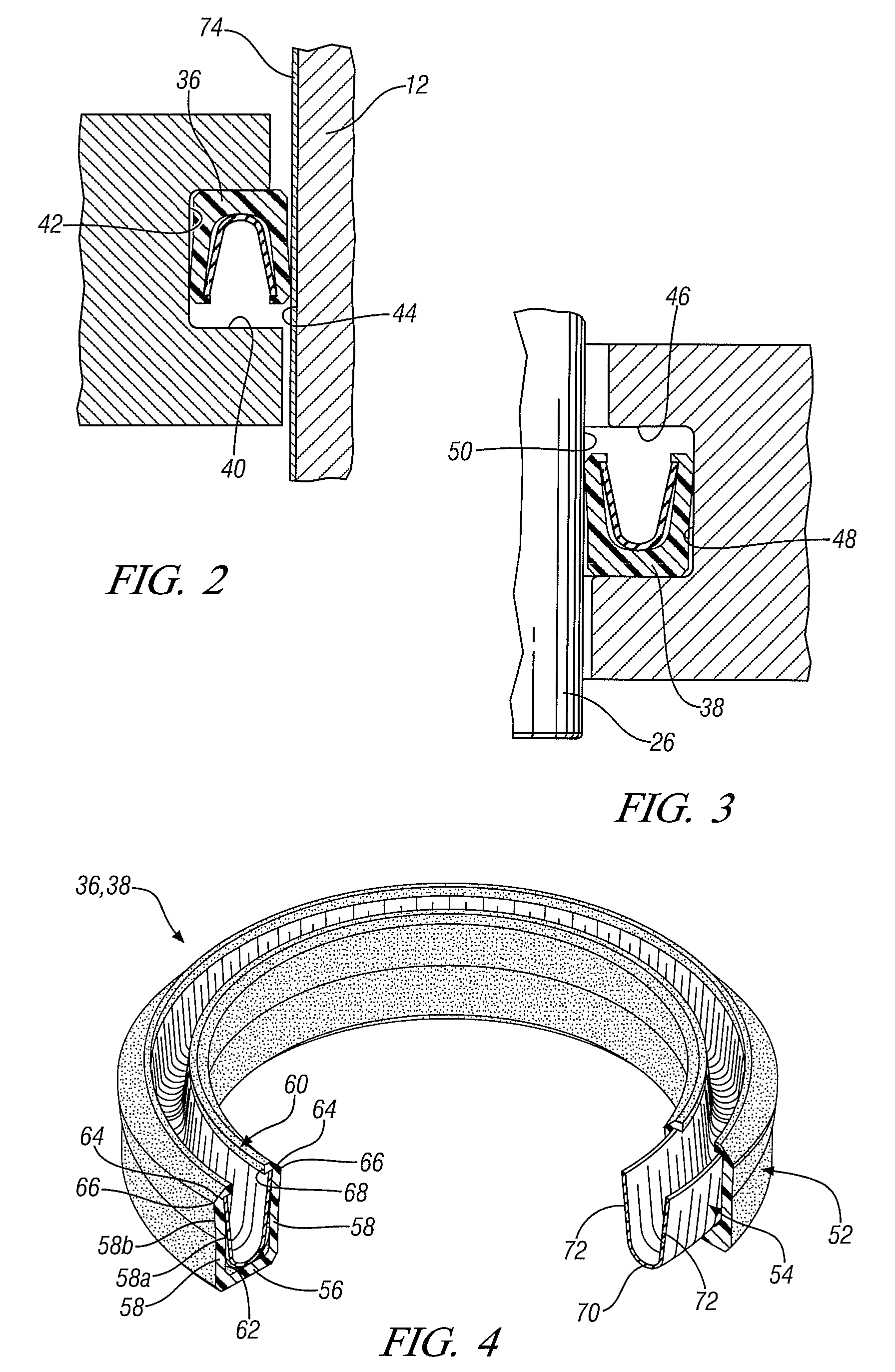

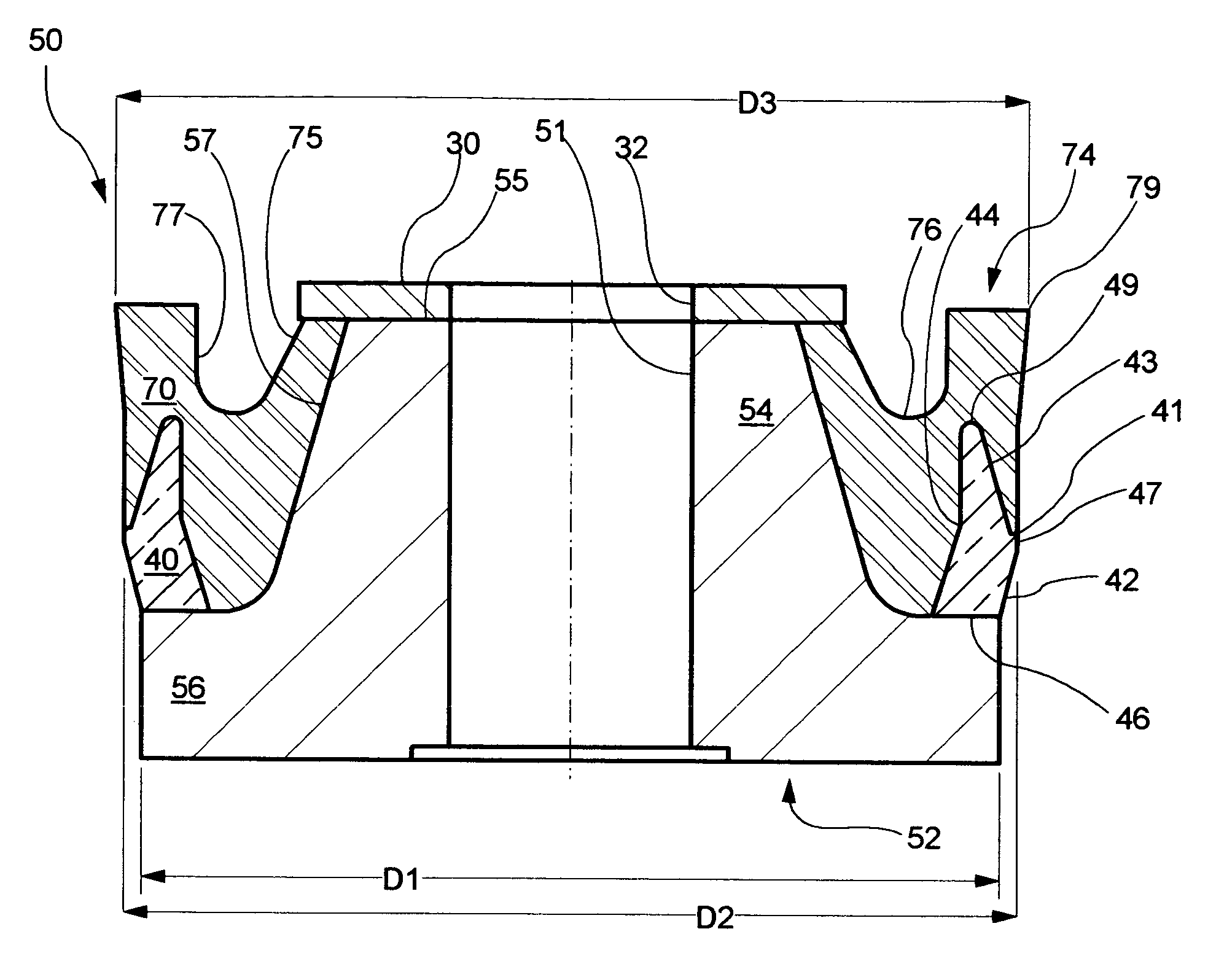

Seal assembly

A seal assembly, includes a seal element including at least one seal lip, a wiper element including a wiper lip, and a structural element attached to the seal element and the wiper element, the seal assembly being configured for functioning under pressure in an amount greater than 500 pounds per square inch.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

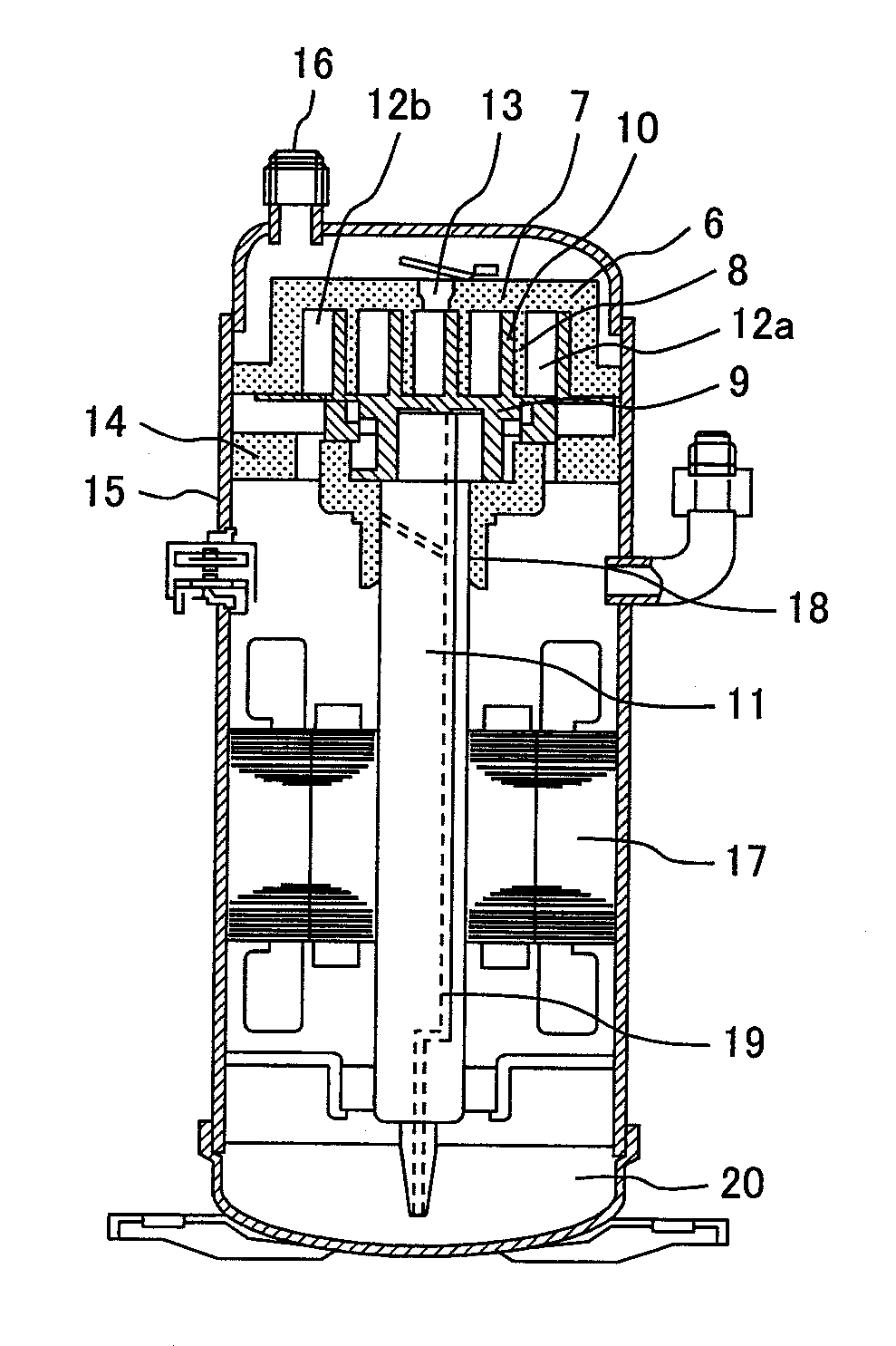

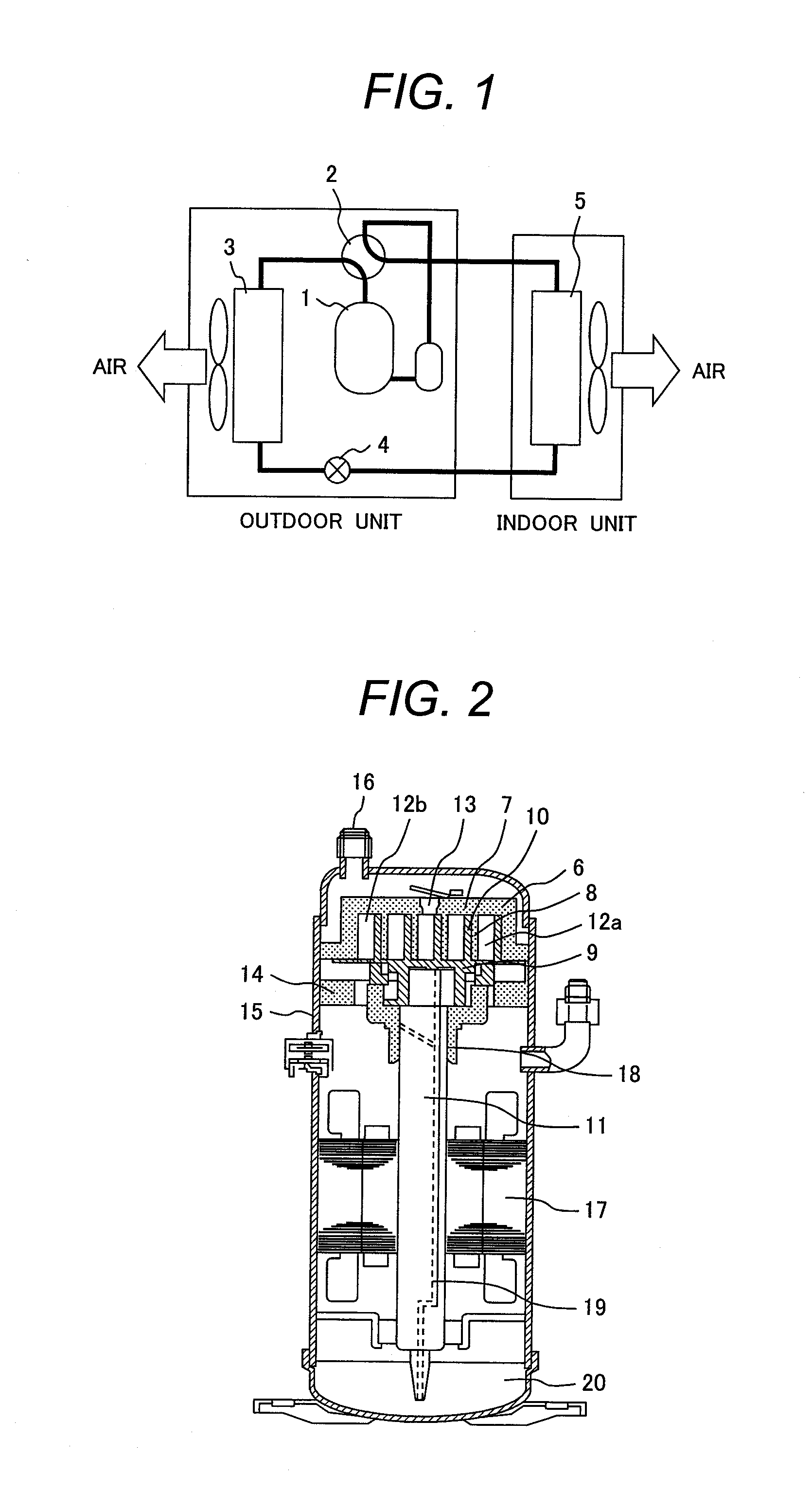

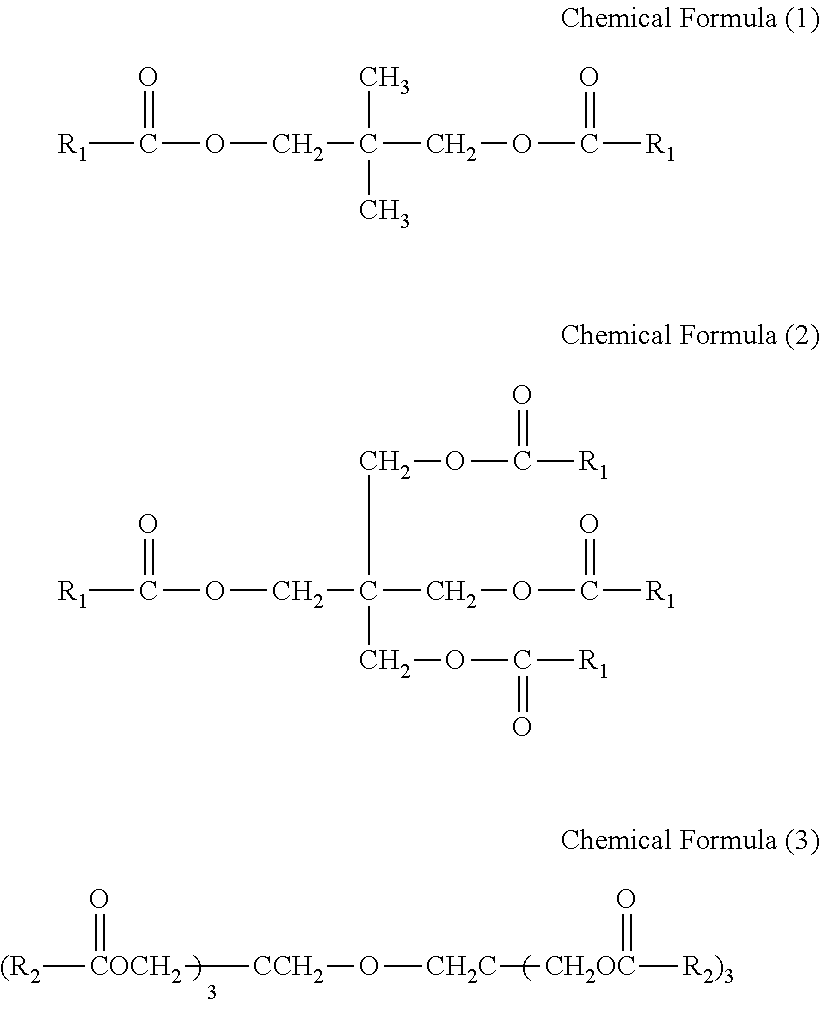

Compressor for refrigeration and air-conditioning and refrigerating and air-conditioning apparatus

InactiveUS20120024007A1Improve performanceGood miscibilityPositive displacement pump componentsCompression machines with non-reversible cyclePolyolPolyolester

A refrigerating machine oil including a refrigerating machine oil basis such as polyol ester oil and an additive polyol ester oil is mixed to a refrigerant including 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene or the like. A compressor for refrigeration and air-conditioning including the mixture charged therein is used. The composition of the additive polyol ester oil is 1 to 30 wt %.The wear resistance of the compressor is improved, and the efficiency of a refrigerating and air-conditioning apparatus using the compressor is enhanced.

Owner:HITACHI APPLIANCES INC

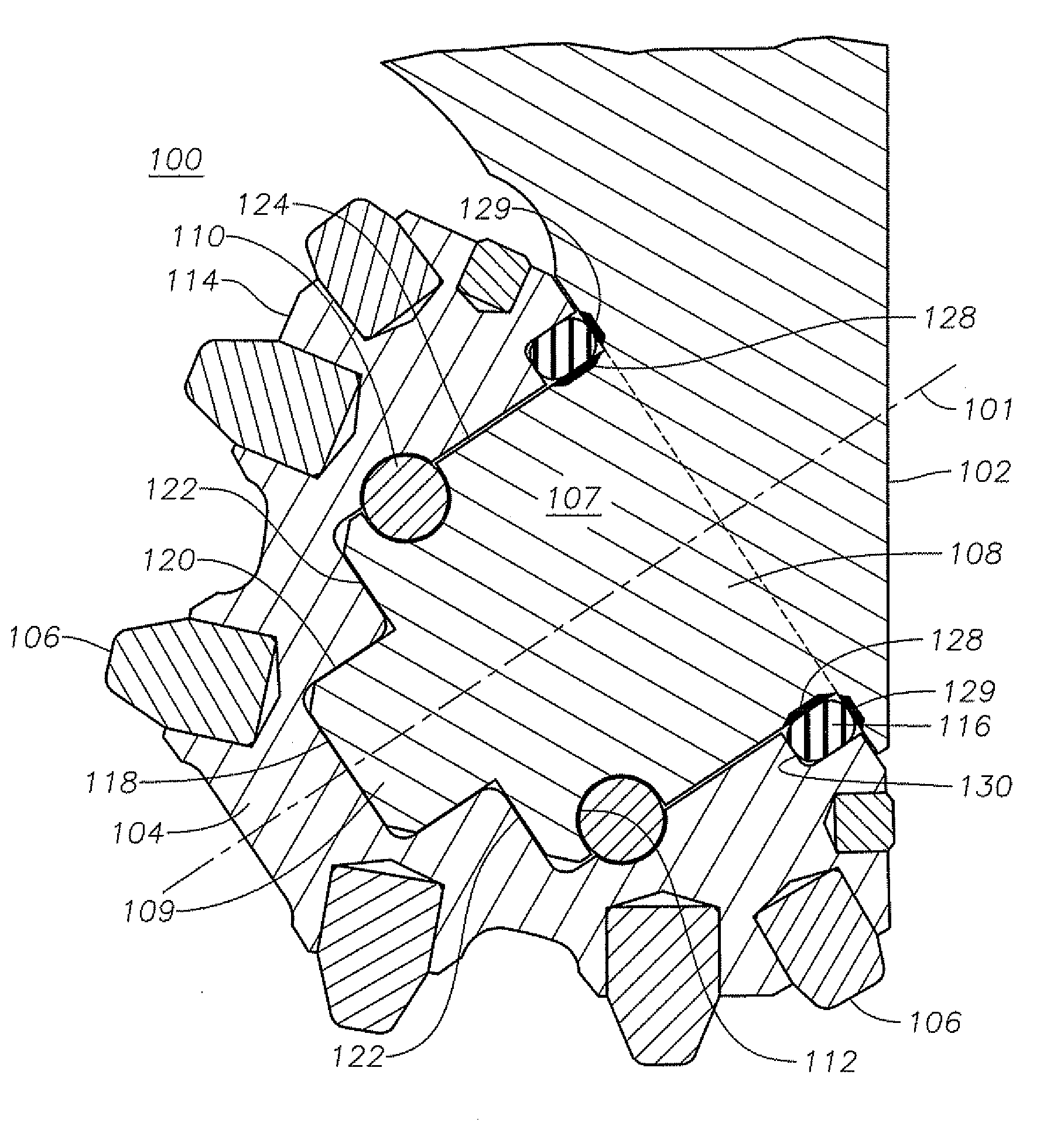

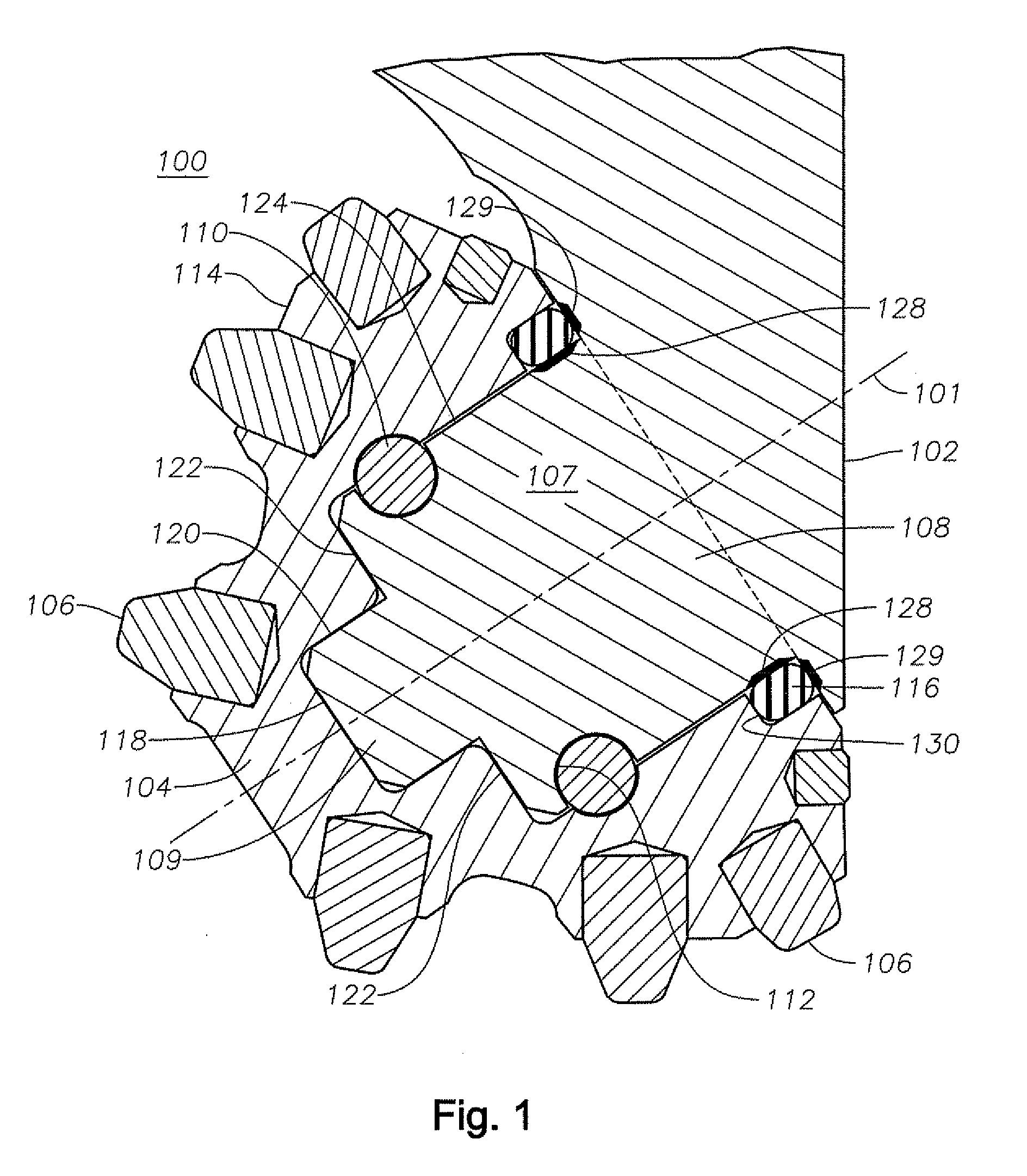

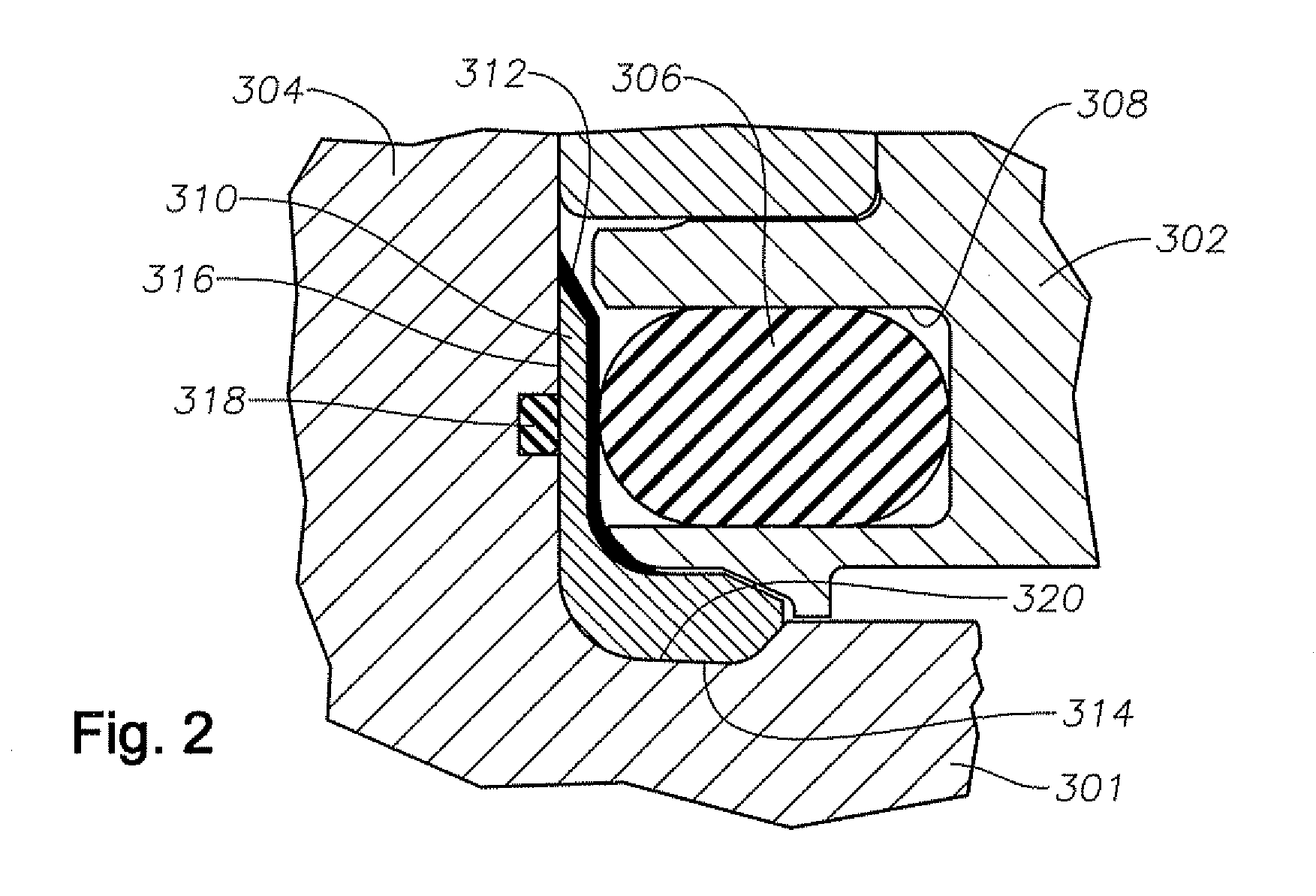

Earth Boring Bit with DLC Coated Bearing and Seal

A roller cone bit is provided that includes a wear resistant diamond-like carbon coating applied to a bearing shaft, where it is in sliding contact with the bearing seal. The wear resistant diamond-like carbon coating reduces wear and corrosion of the head bearing shaft sealing surface and provides extended life to the bearing seal.

Owner:BAKER HUGHES INC

Compositions and methods for treating lacerations, abrasions, avulsions, burns, ulcers, and cases of excessive bleeding

InactiveUS20090148502A1Reducing and ameliorating excessive bleedingReduce controlAntibacterial agentsPowder deliveryExcessive BleedingMedicine

Described herein are compositions and methods related to wound treatment. Compositions are multi-components admixed in amounts and ratios to meet specific objectives for optimally treating various types of wound injury.

Owner:HEMO NANOSCI

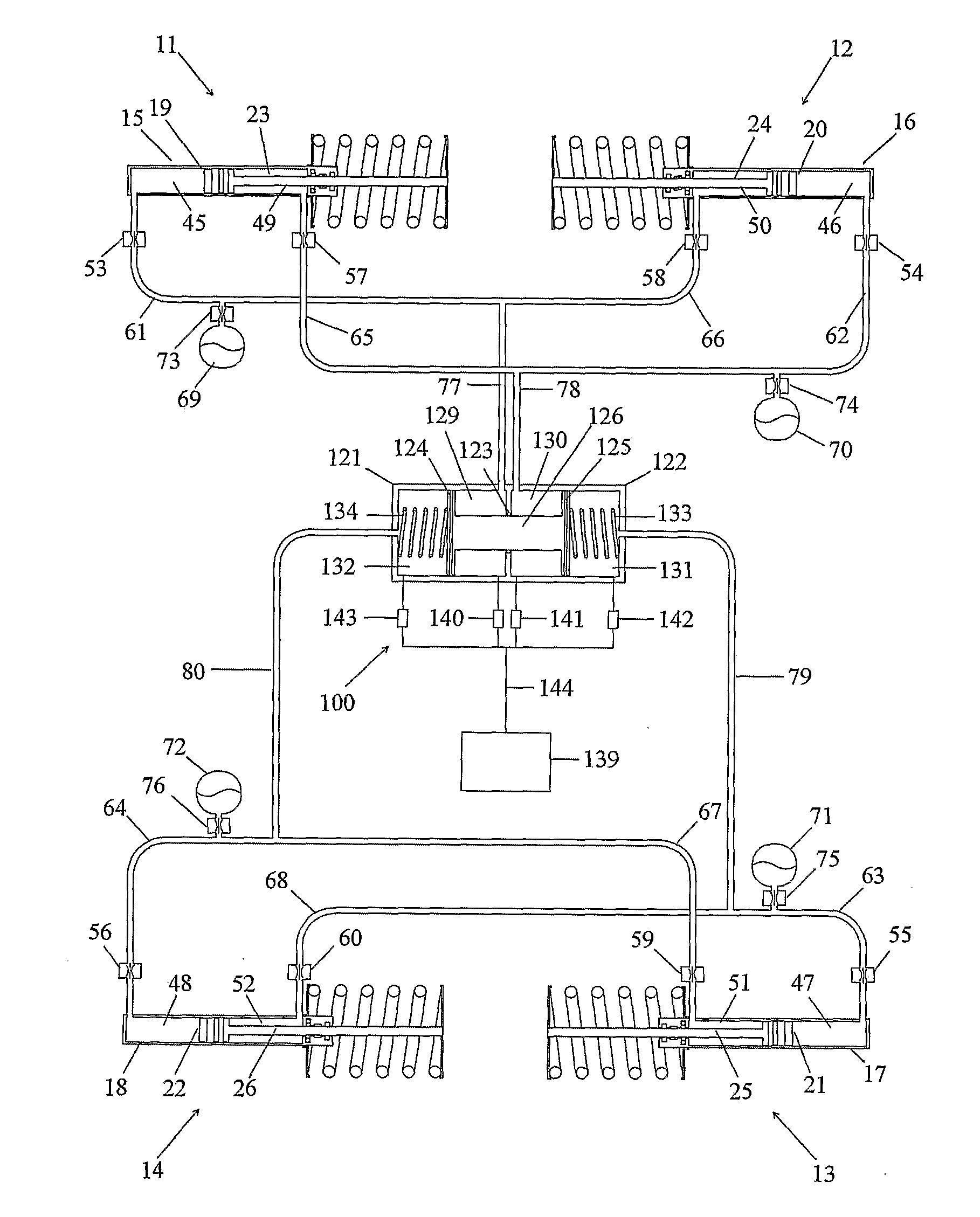

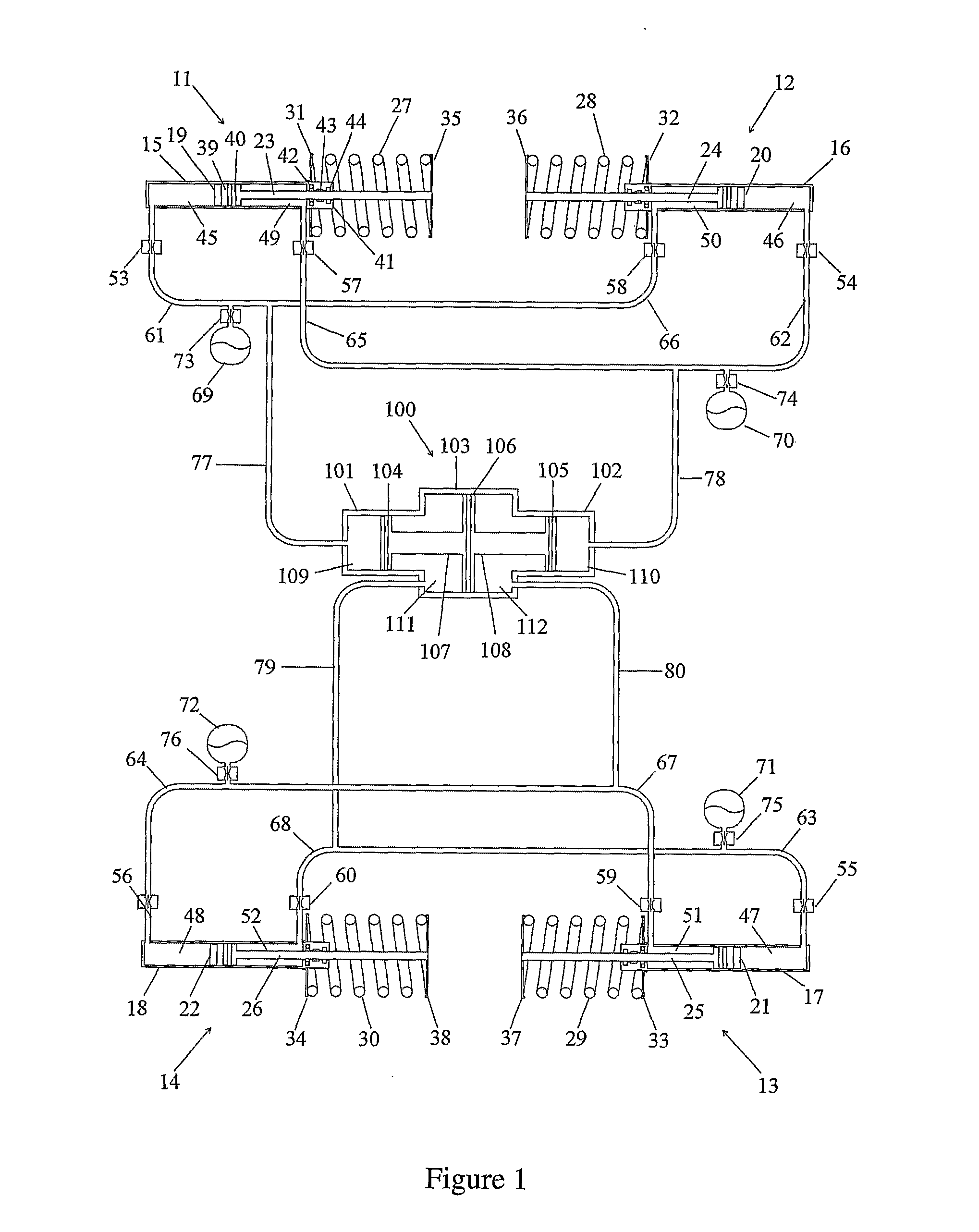

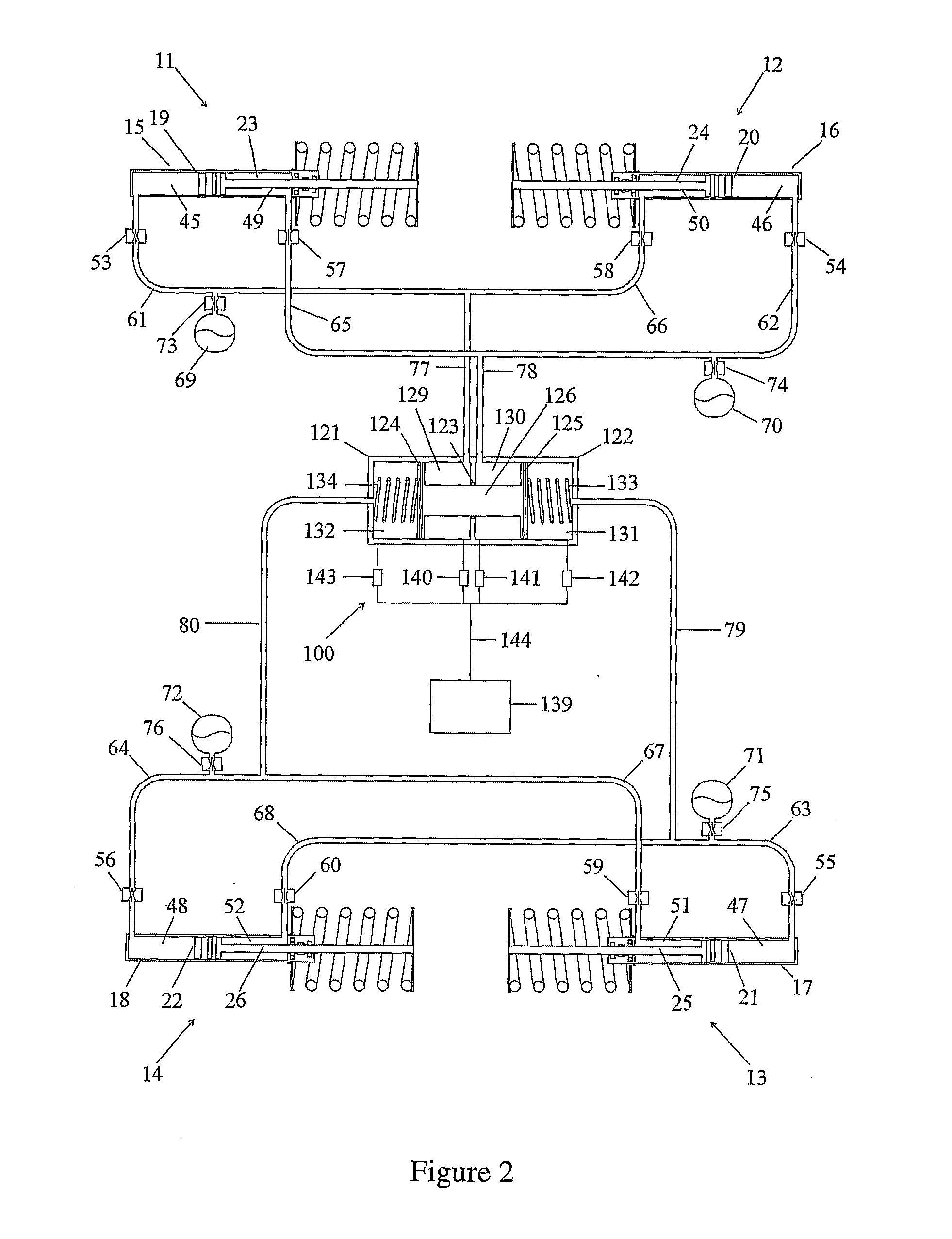

Hydraulic System for a Vehicle Suspension

ActiveUS20080272561A1Reduce system pressureReduce frictionInterconnection systemsResilient suspensionsPiston rodHydraulic pressure

A vehicle hydraulic suspension system has front left (15), front right (16), rear left (18) and rear right (17) wheel ram. There is a mode decoupling device (100) with first (129), second (130), third (132) and fourth (131) balance chambers formed by a cylinder / piston rod assembly (124,125,126). The compression chamber (45) of the front left wheel ram (15) is in fluid communication with the first balance chamber (129), the compression chamber (46) of the front right wheel ram (16) is in fluid communication with the second balance chamber (130), the compression chamber (48) of the rear left wheel ram (18) is in fluid communication with the third balance chamber (132), and the compression chamber (47) of the rear right wheel ram (17) is in fluid communication with the fourth balance chamber (131). There are also front and rear resilient vehicle support means between vehicle body and the wheel assemblies.

Owner:KINEHTIK PTI LTD

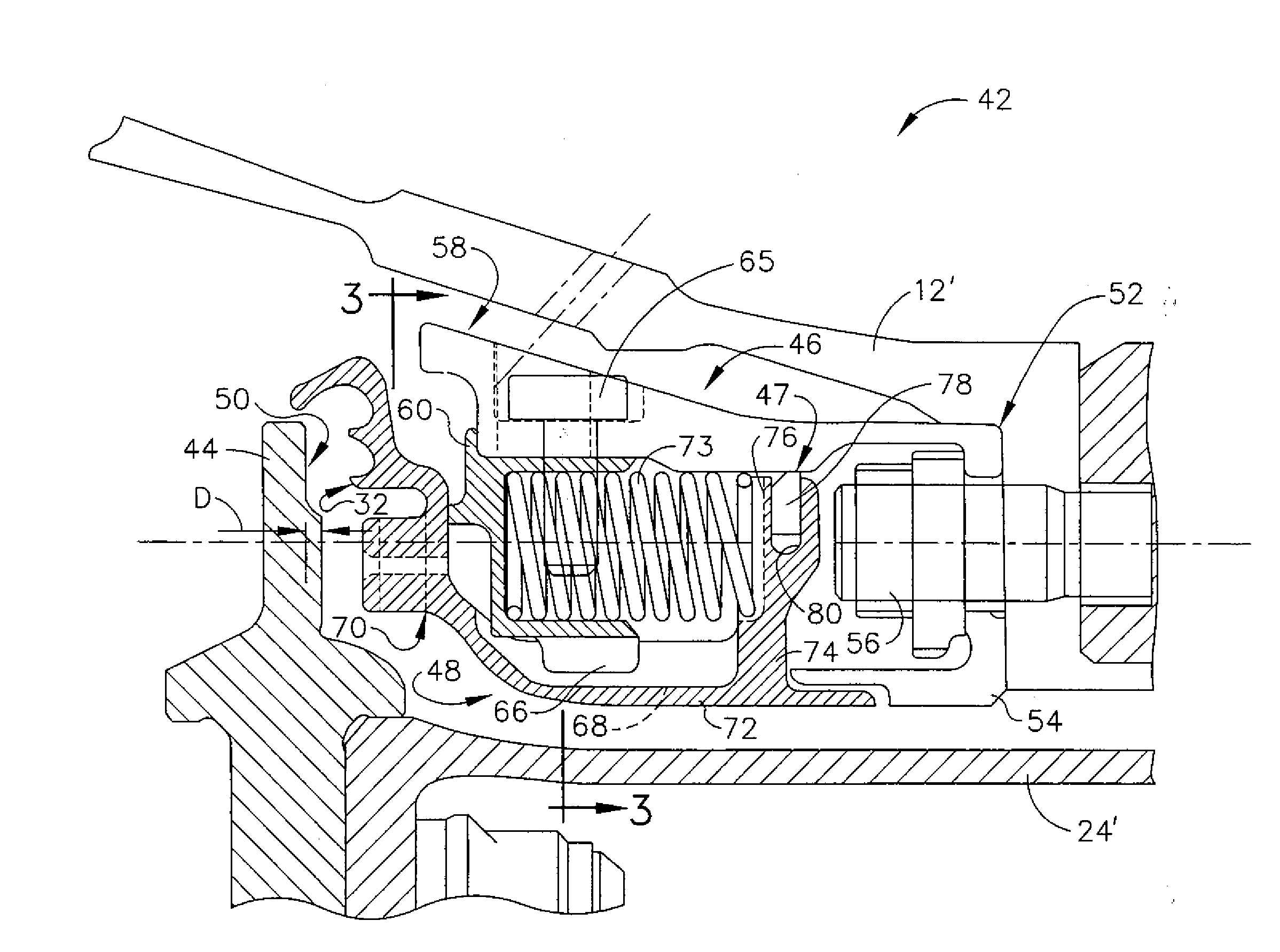

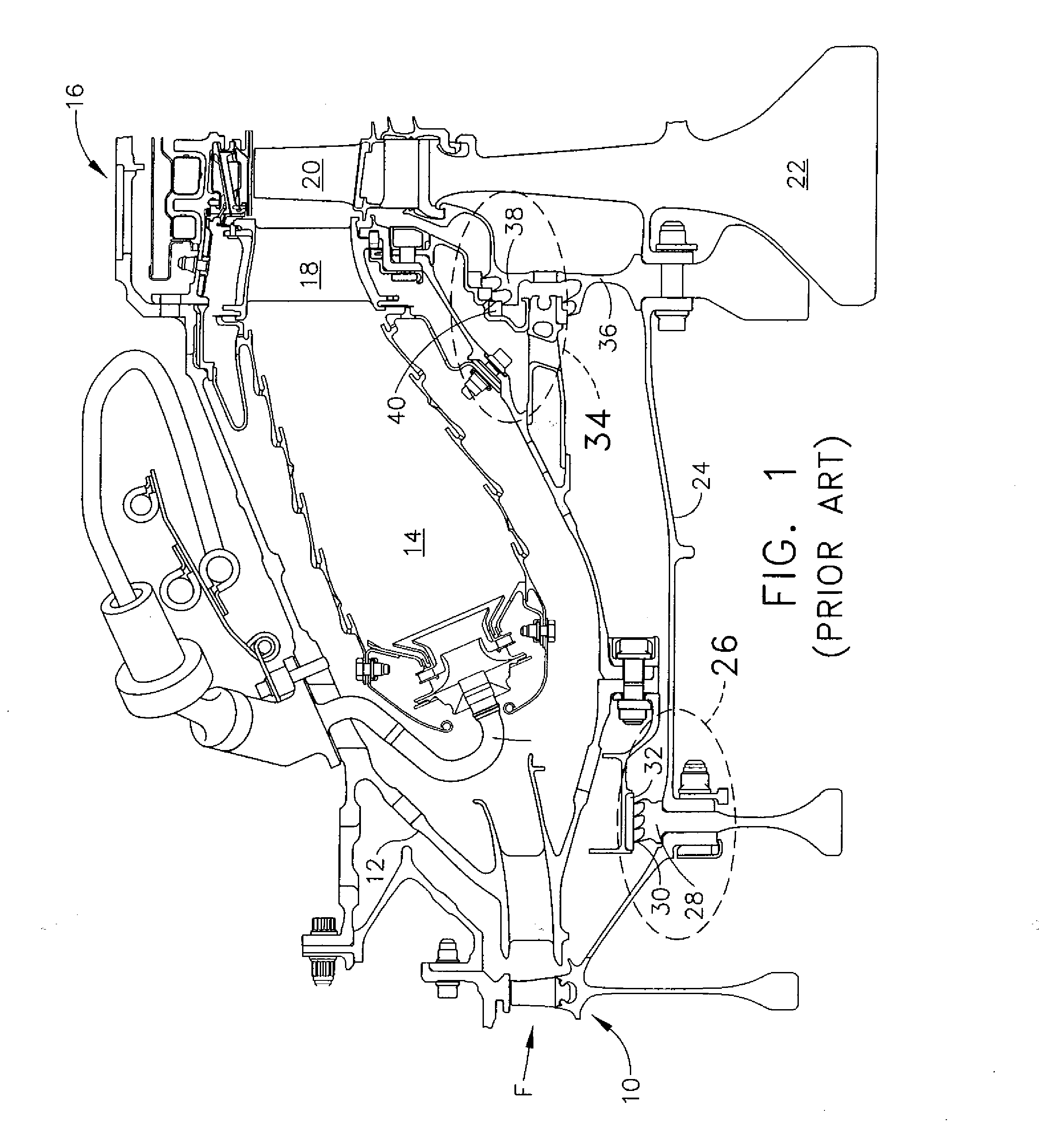

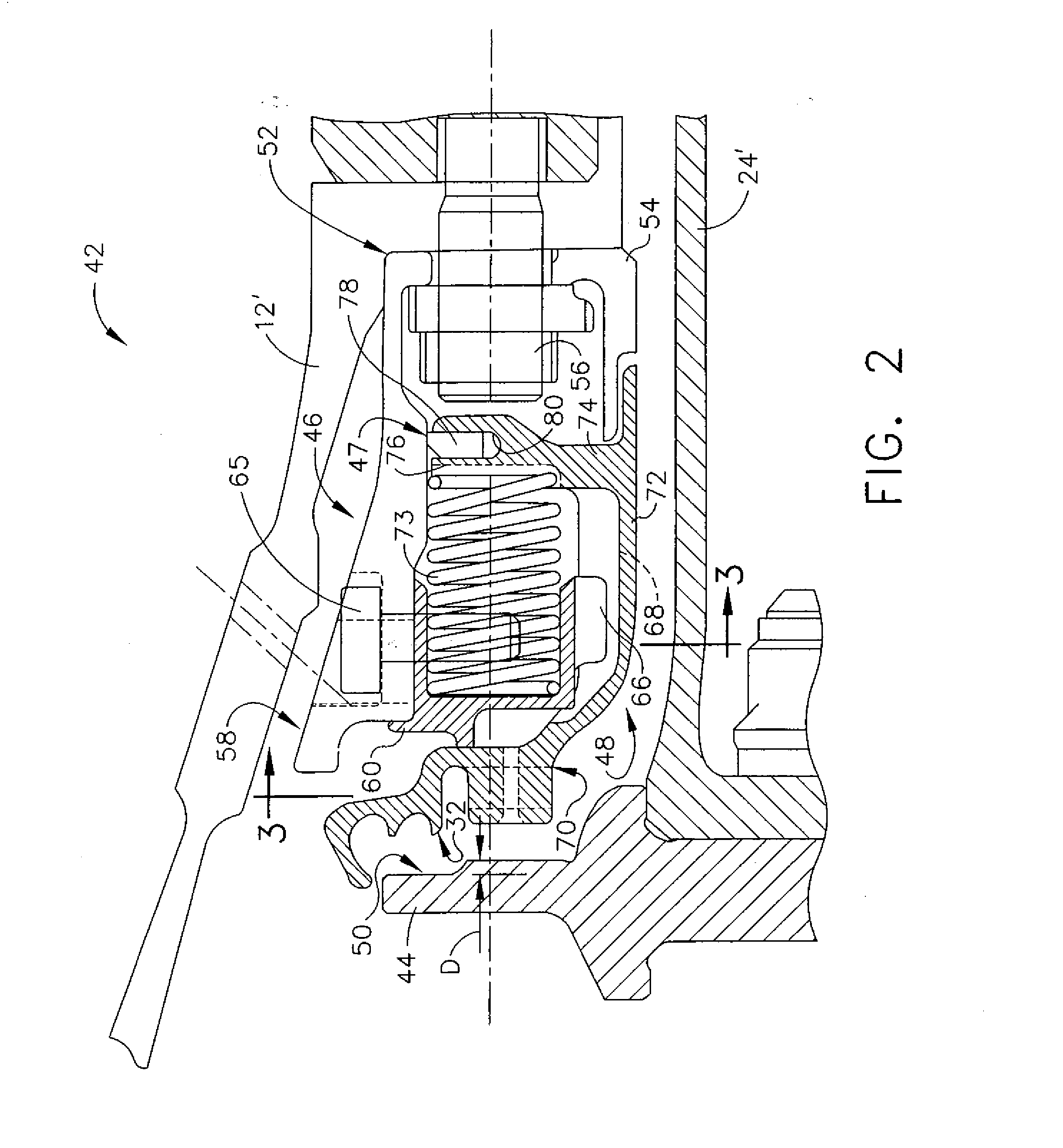

Aspirating labyrinth seal

InactiveUS20080018054A1Reduce leakageLow leakageEngine sealsEngine manufactureEngineeringMechanical engineering

Owner:GENERAL ELECTRIC CO

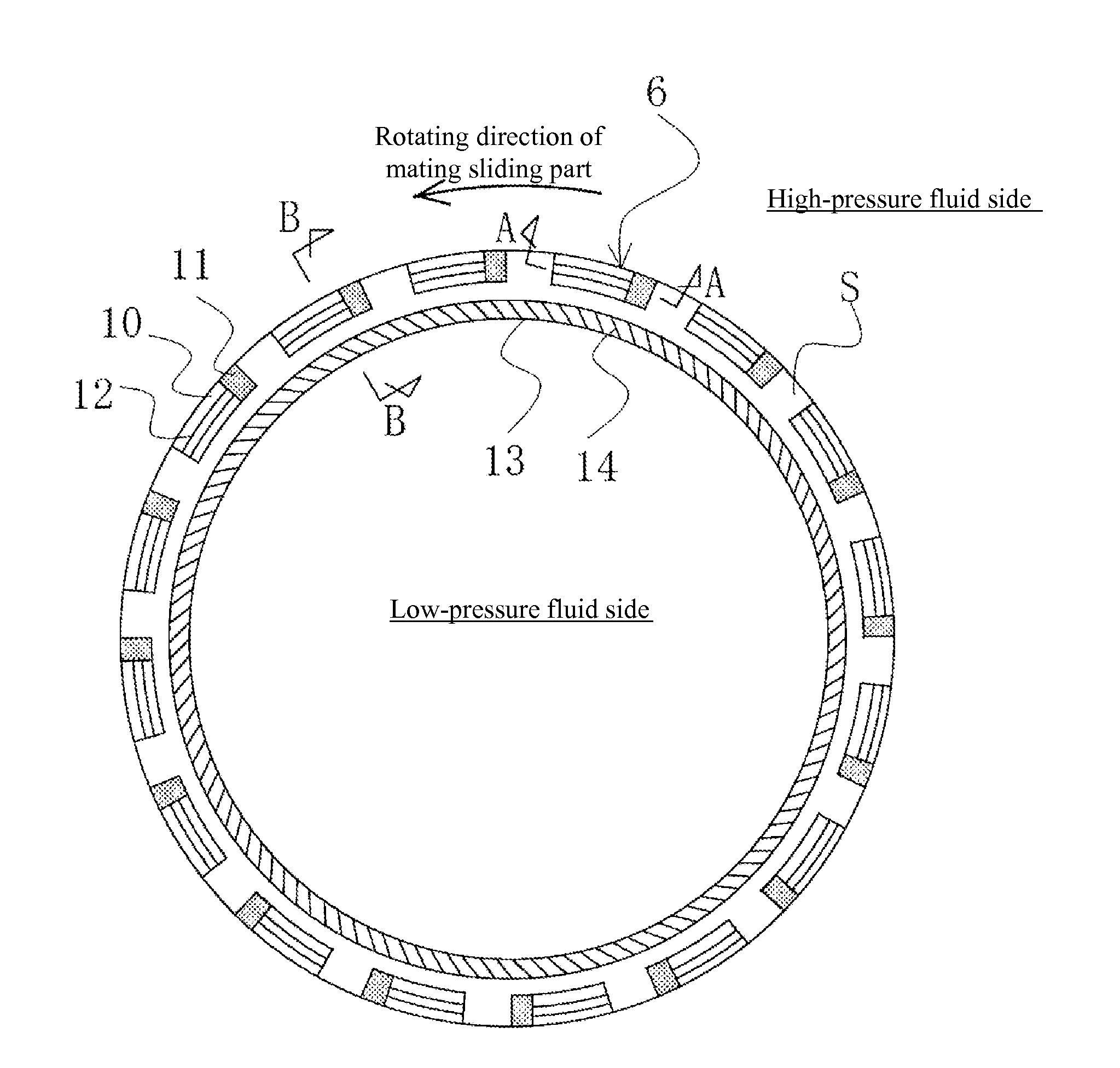

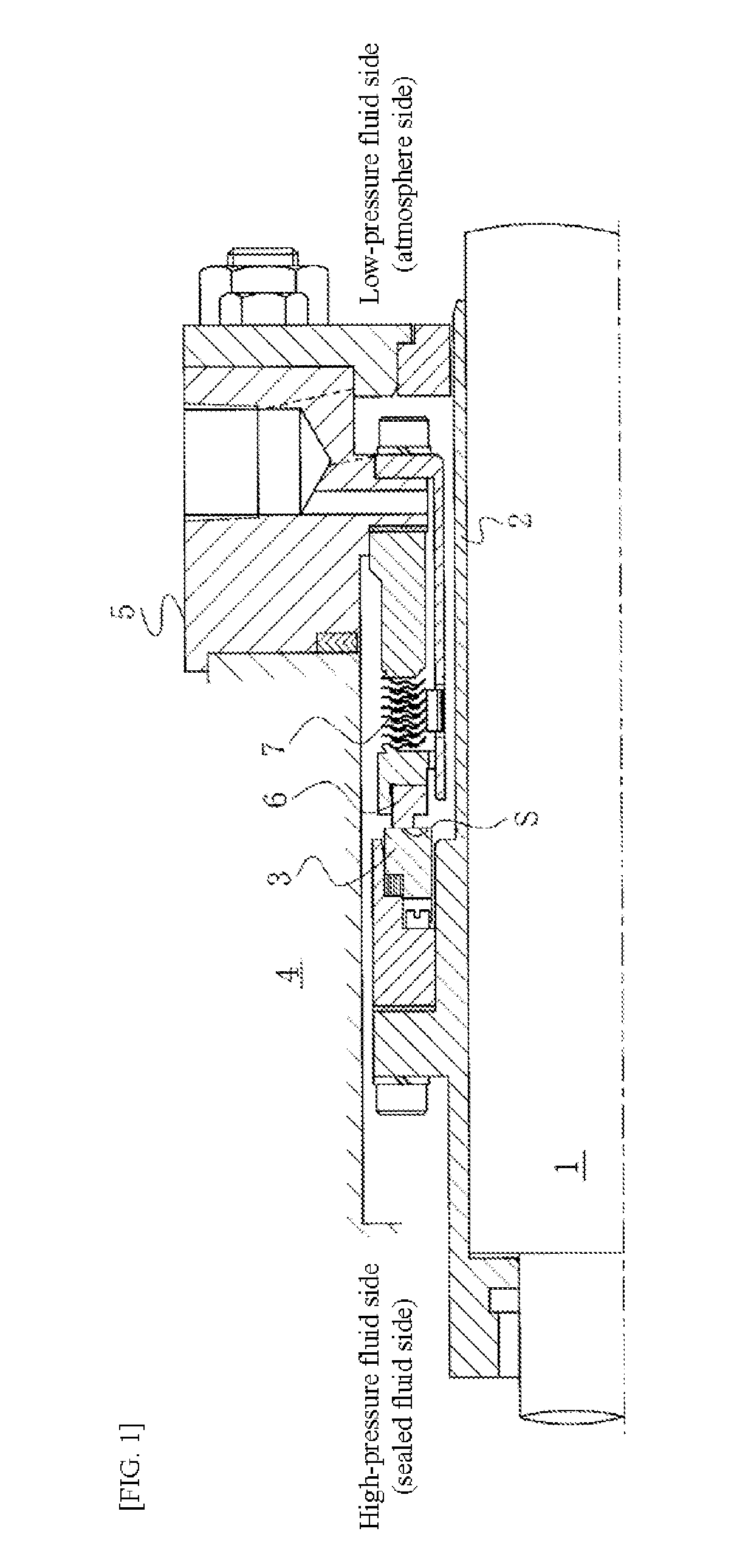

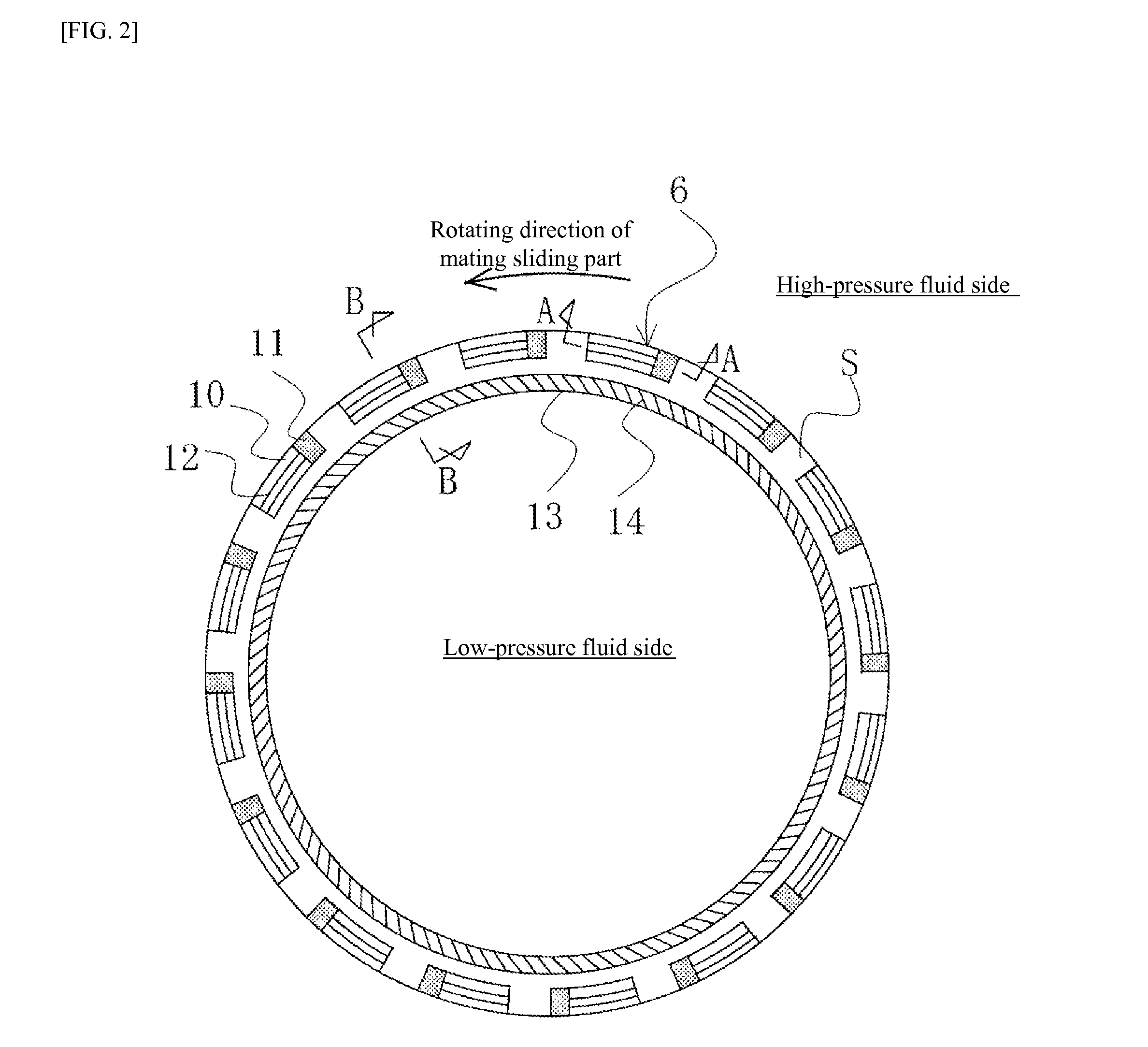

Sliding component

A sliding component, which achieves both sealing and lubrication by preventing cavitation from occurring in the dynamic-pressure generation mechanism and thereby solving the problem of leakage that will otherwise result from such cavitation, is characterized in that, on a sealing face of one of a pair of sliding parts that slide against each other, extremely shallow grooves constituting a Rayleigh step mechanism are provided in a manner facing the high-pressure fluid side of the sealing face, while deep fluid-introduction grooves for introducing the high-pressure fluid are provided on the upstream side of the extremely shallow grooves in a manner continuing to the high-pressure fluid side.

Owner:EAGLE INDS

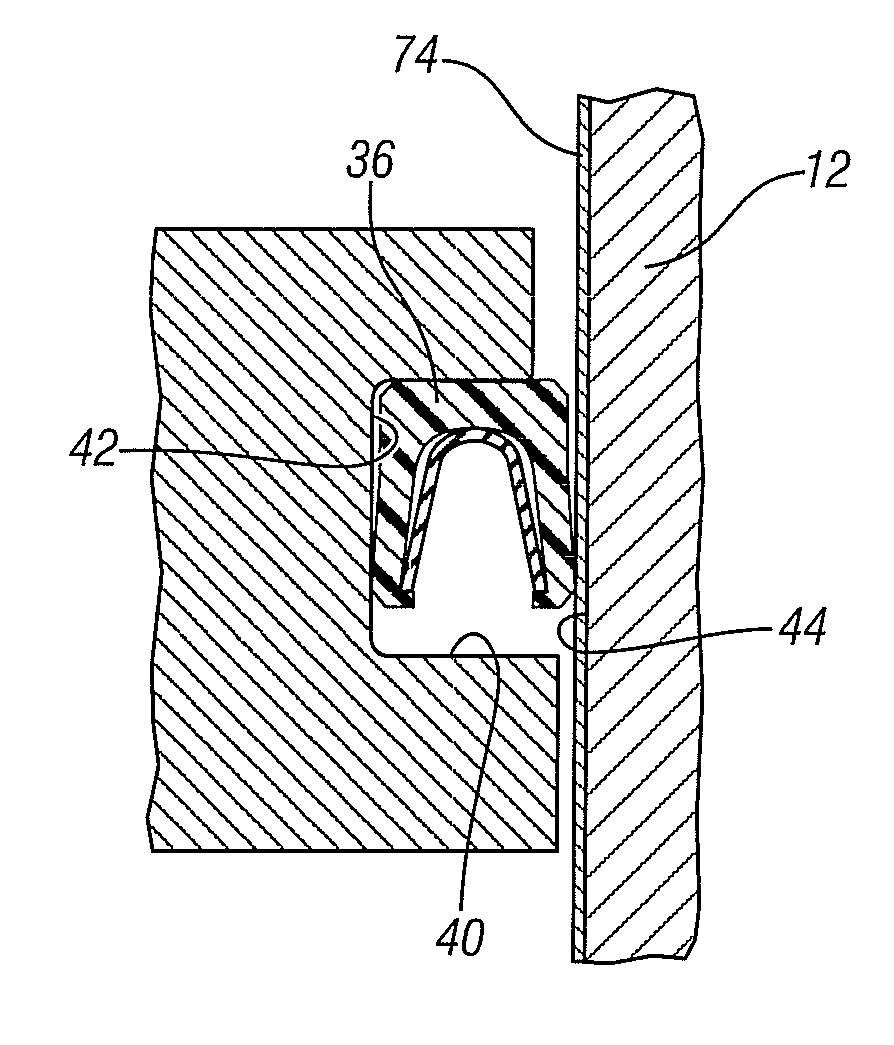

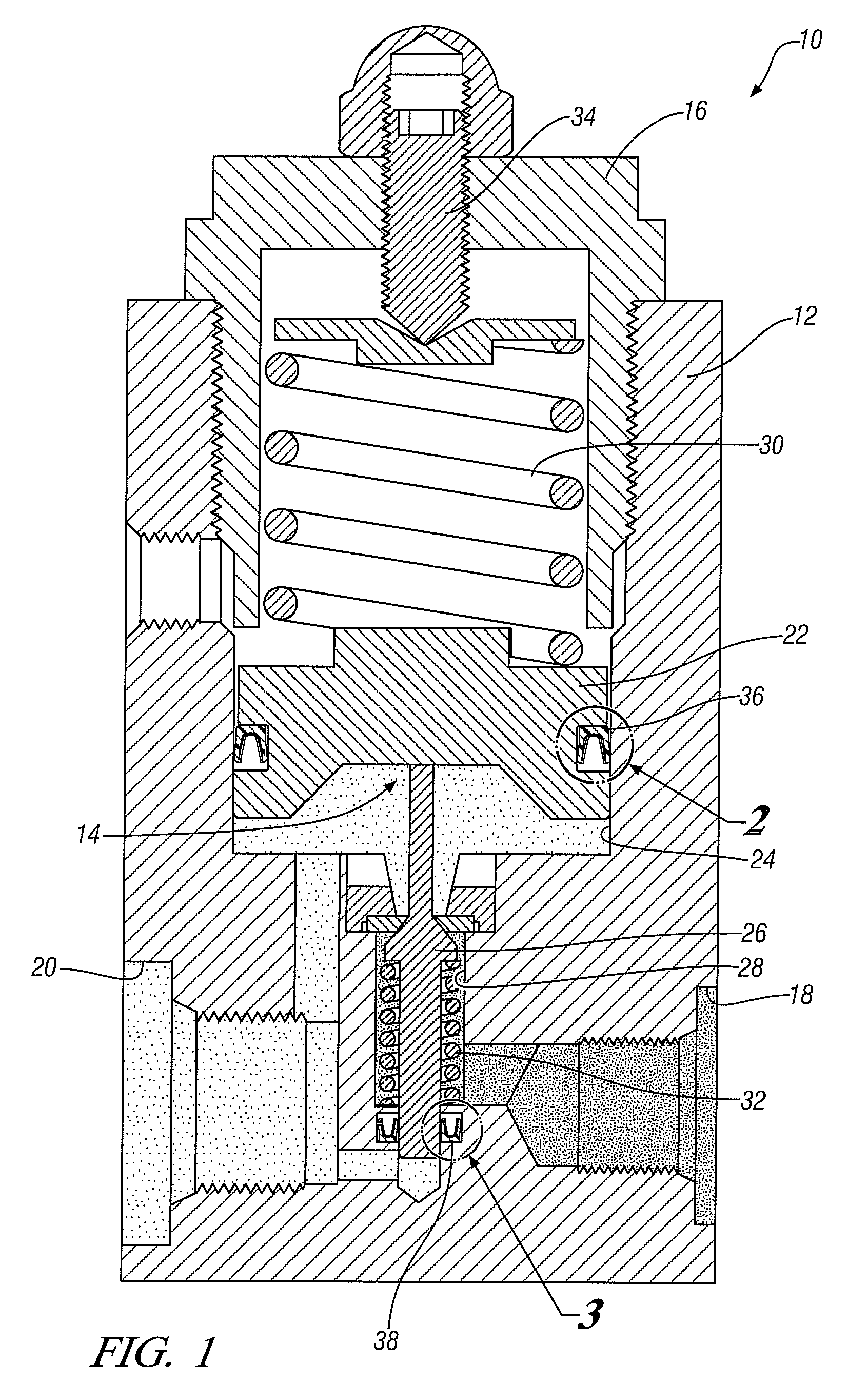

Seal performance for hydrogen storage and supply systems

InactiveUS8251373B2Increase forceImprove sealingEngine sealsElectrolysis componentsSurface roughnessElectrochemistry

The performance and durability of static and dynamic seals for hydrogen storage and supply systems has been improved by utilizing a spring-energized and plastic coated radial seal in combination with at least a mating surface that has been treated by one of a variety of procedures. These procedures include applying to the mating surface a low-friction, hard, and hydrogen impervious coating, chemically polishing the mating surface, and electrochemically polishing the mating surface. Each of these procedures significantly reduces, on a microscopic scale, the surface roughness of the mating surface. The seal can thus form a tighter and more gas-tight seal with the smoother mating surface so as to decrease the loss of hydrogen gas across the seal. The smoother mating surface can also improve seal life by reducing seal surface wear.

Owner:GM GLOBAL TECH OPERATIONS LLC

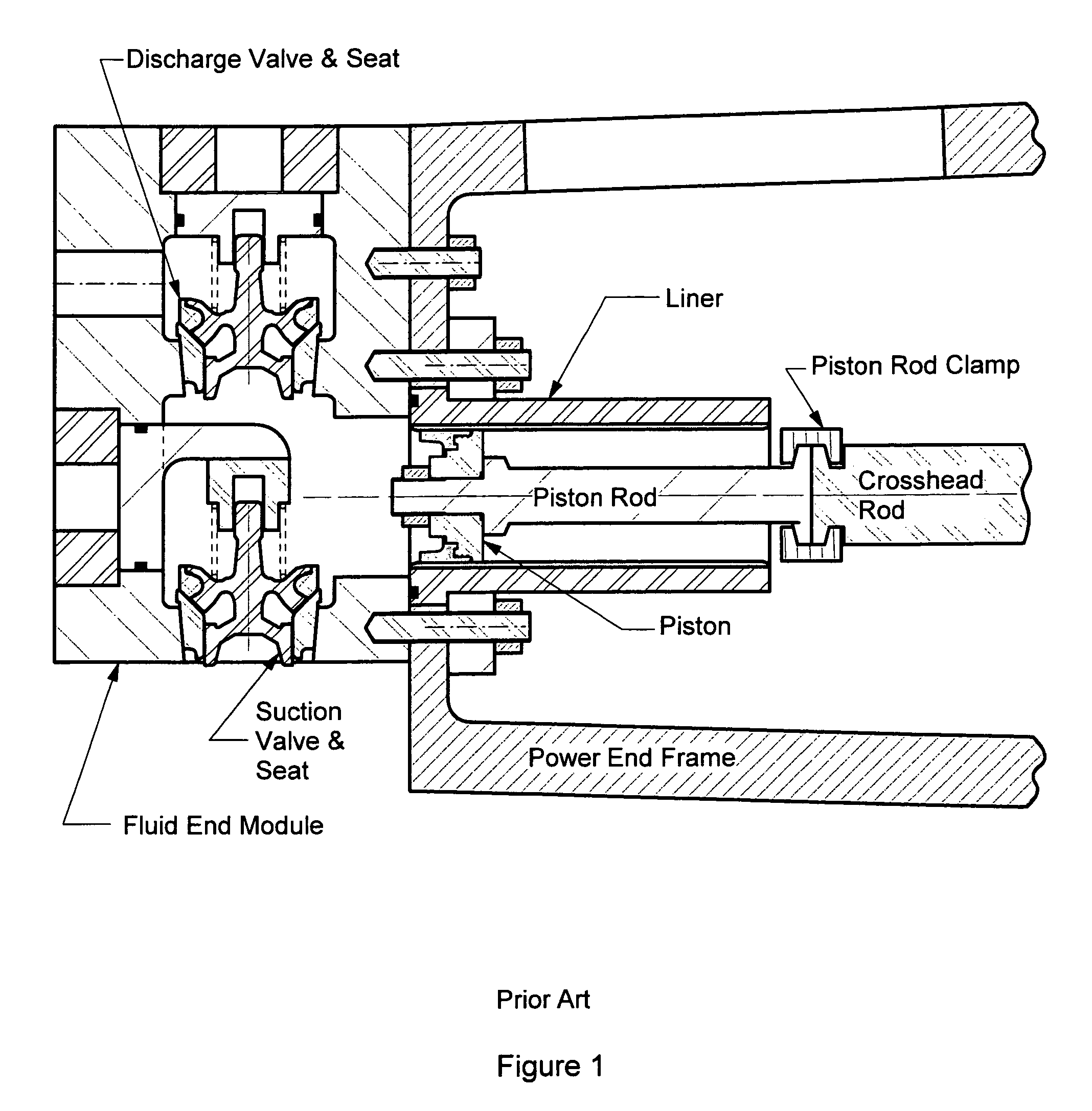

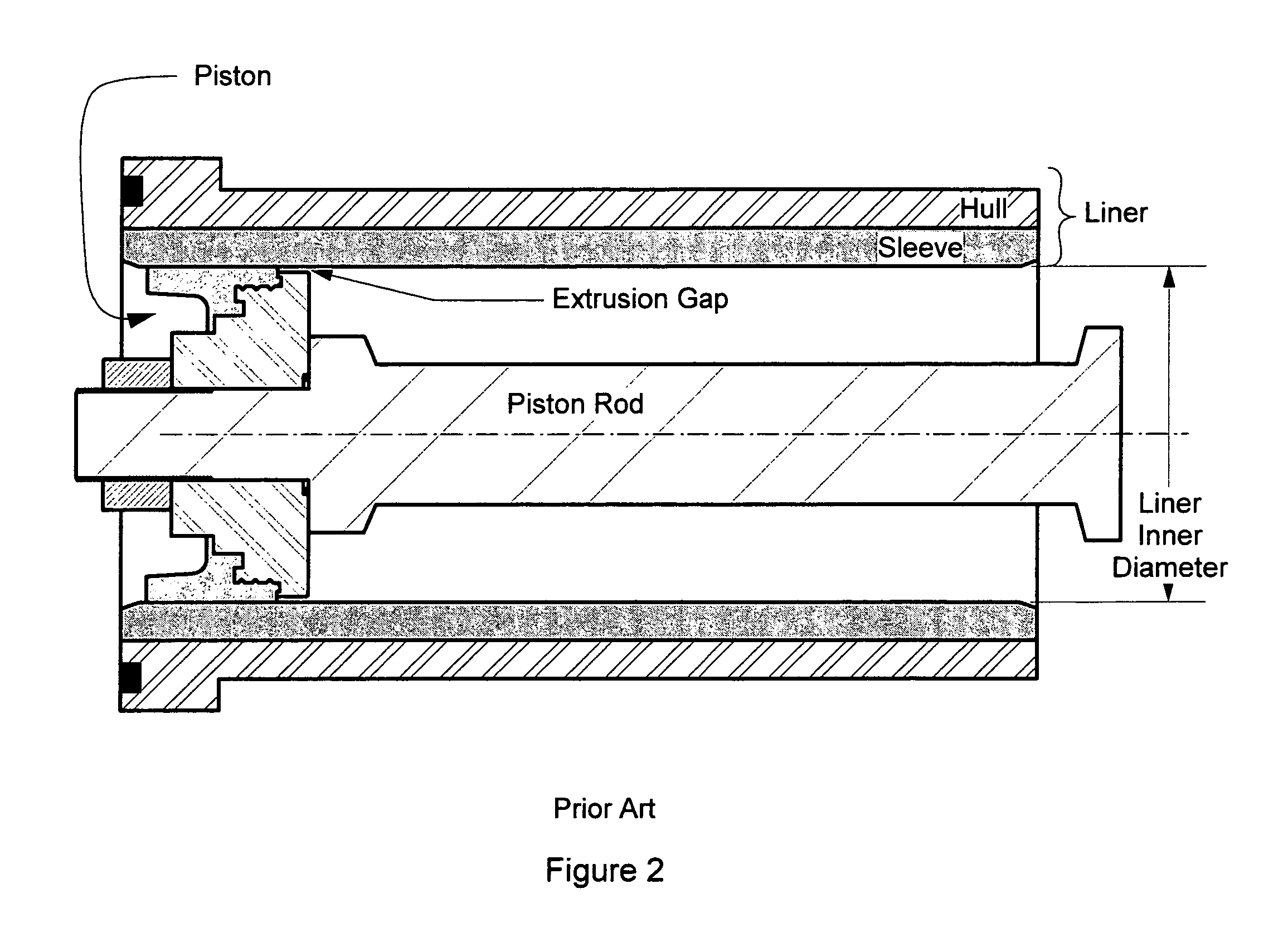

High pressure pump piston

InactiveUS6957605B1Easy maintenanceReduce the force per unit areaEngine sealsPiston ringsElastomerEngineering

A high pressure piston for use within a liner for a reciprocating pump comprises an elastomeric seal and a metallic annular bearing ring having relatively high heat conductivity compared to the liner and seal. During the pump's pressure stroke a portion of the bearing ring elastically expands radially to narrow or close the extrusion gap. Narrowing the gap decreases the tendency for extrusion of piston seal elastomeric material, while closing the gap tends to block elastomer extrusion and establish sliding contact between the bearing ring and the liner. Sliding contact between the bearing ring and liner prevents portions of the piston hub (e.g., a transverse flange) from contacting the liner and damaging it. The heat-conductive bearing ring improves scavenging of frictional heat near the extrusion gap, extending the service life of piston seal elastomer while reducing bearing ring and liner wear. Under reduced pressure on the pump's return stroke, the bearing ring elastically contracts radially, slightly widening the extrusion gap. On the pump's return stroke the slightly wider extrusion gap allows cooling water directed generally toward the proximal flange of the piston hub to better cleanse, as well as cool, the liner wall.

Owner:NOVATECH HLDG CORP

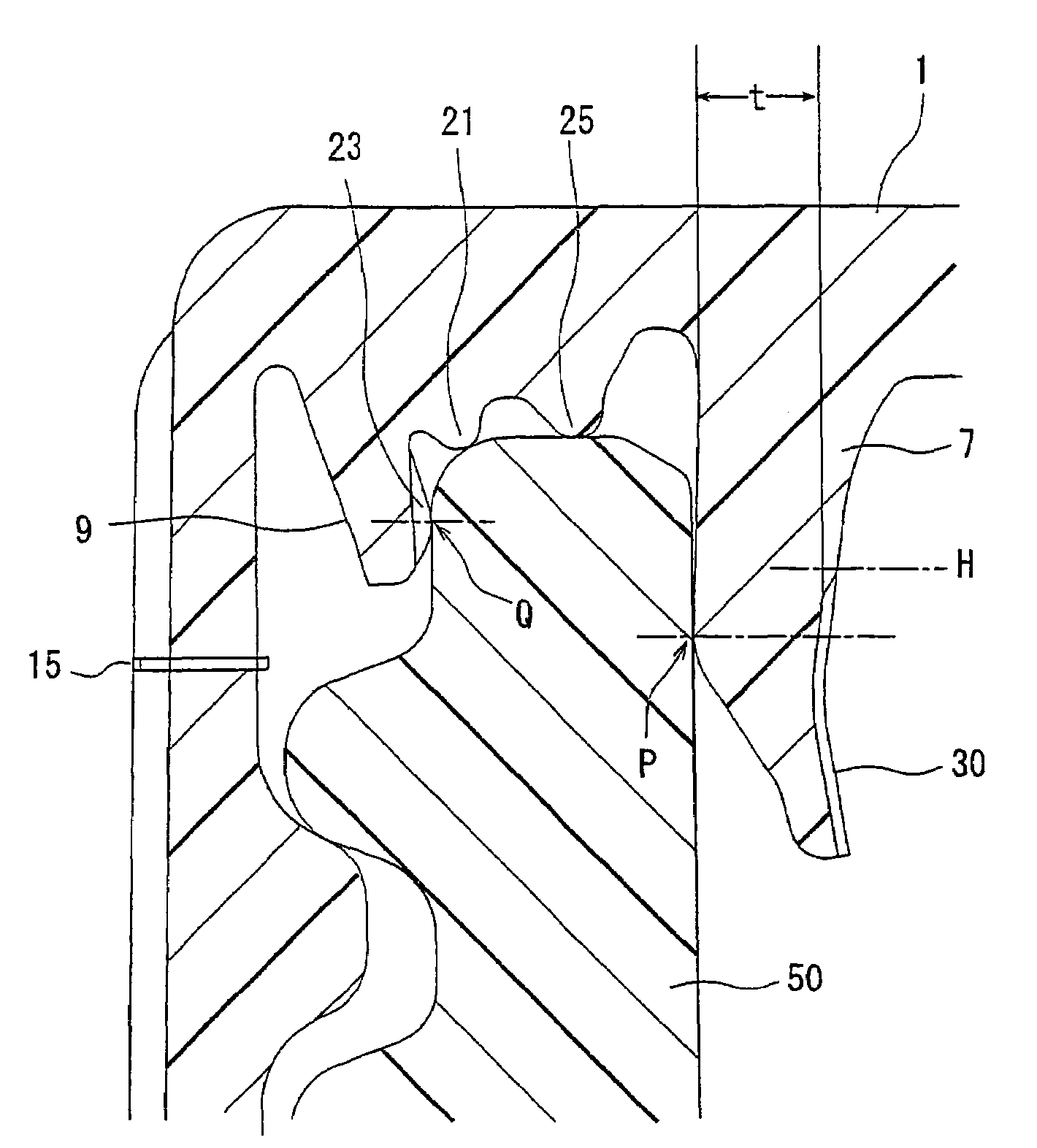

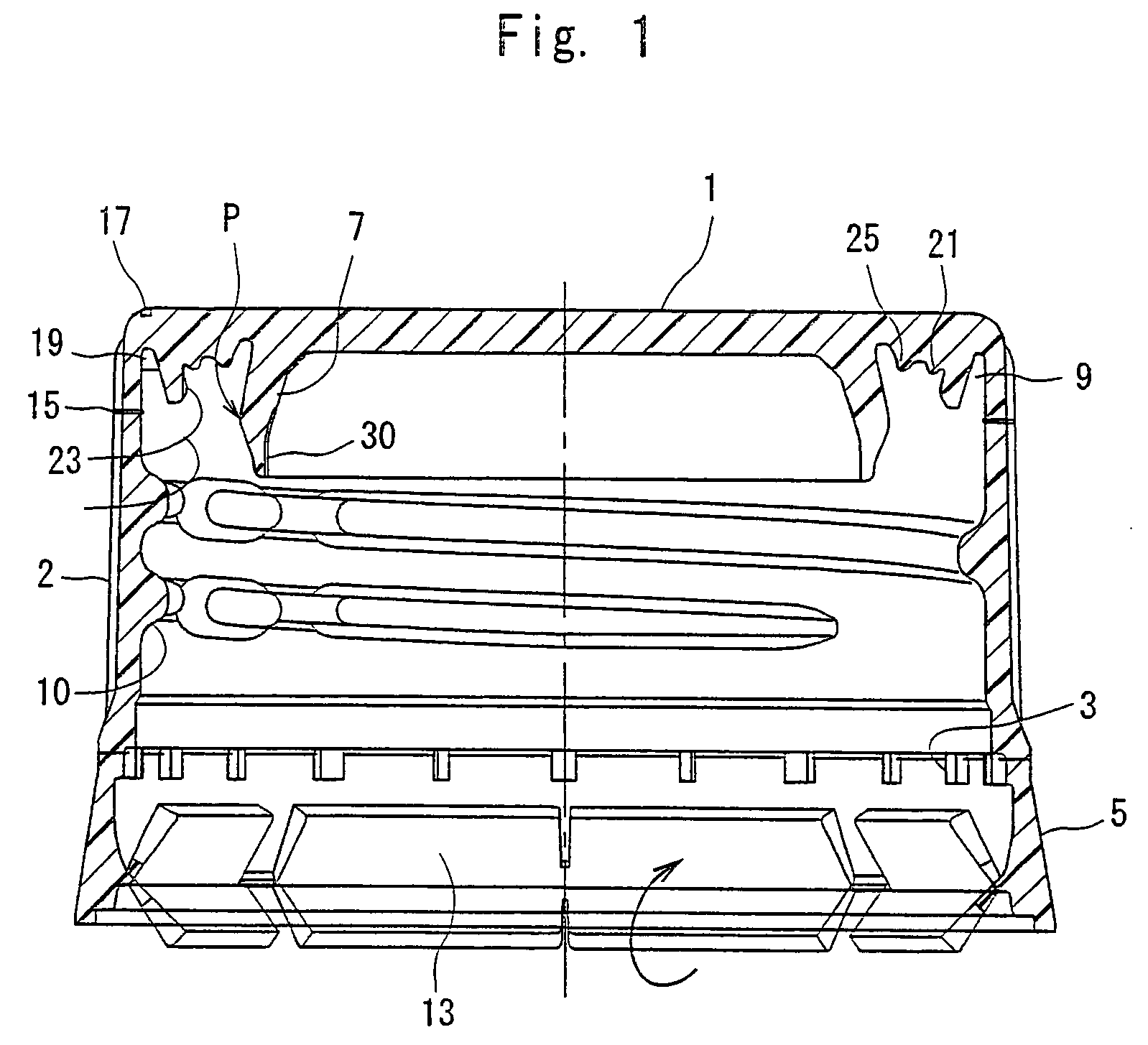

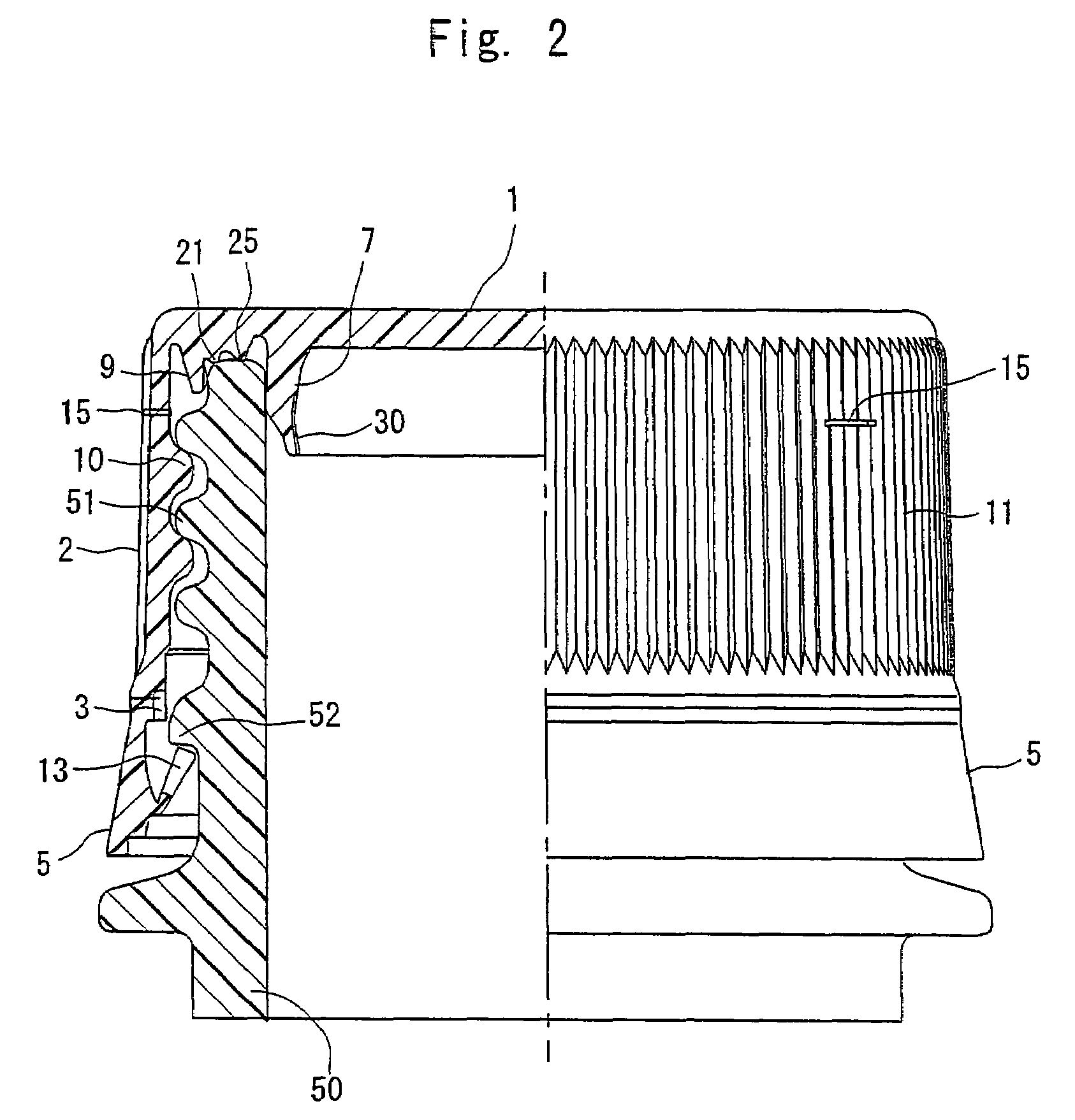

Electric double layer capacitor with a sealing plate fitted inside a container

InactiveUS7697265B2Reduce yieldReduce sealClosuresHybrid capacitor electrodesEngineeringMechanical engineering

Owner:SANYO ELECTRIC CO LTD

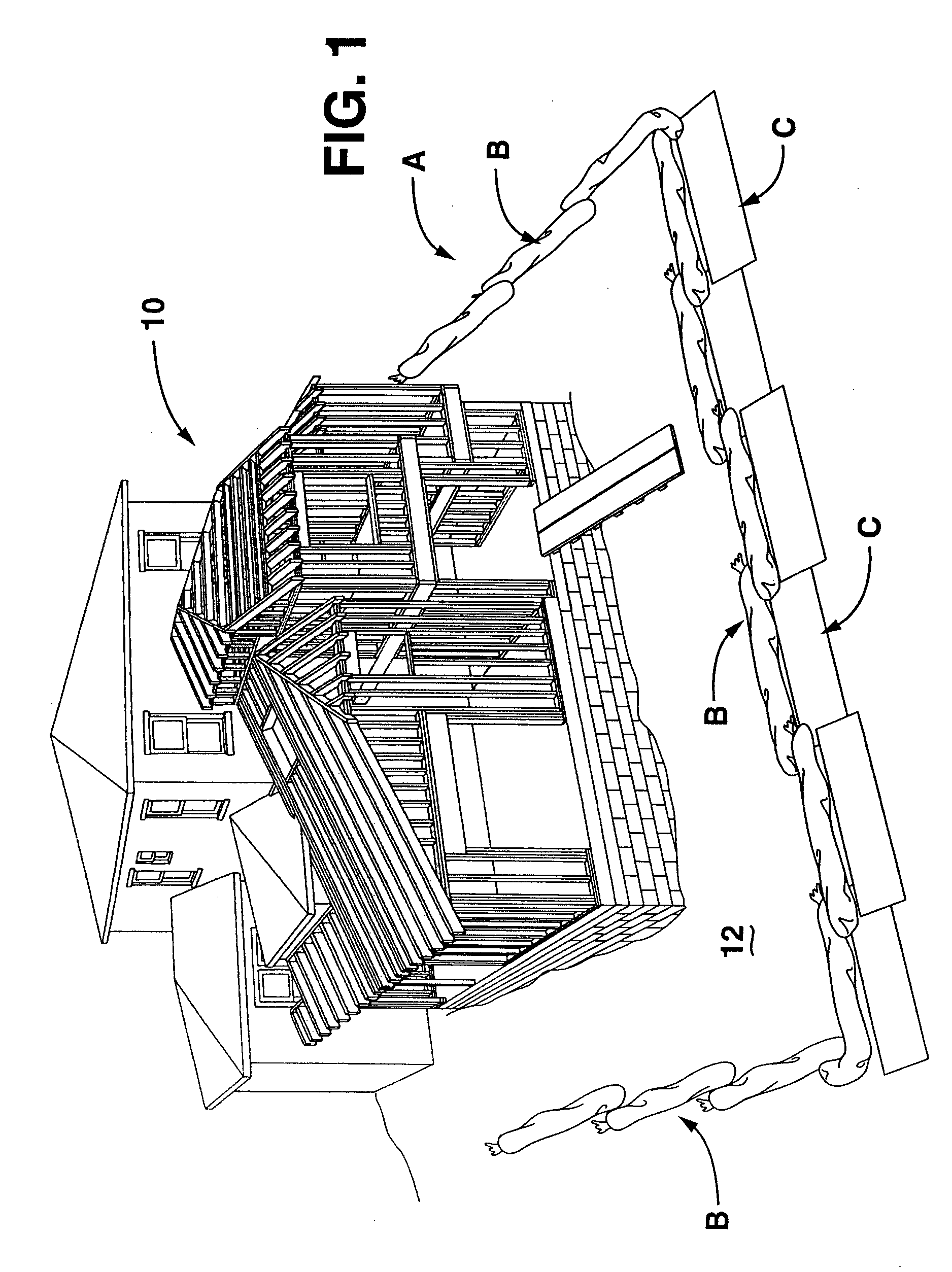

Compact linear air pump and valve package

InactiveUS20050047923A1Reducing eliminatingImprove reliabilityPositive displacement pump componentsFlexible member pumpsControl flowDiaphragm pump

A compact air pump and valve package includes pump and valve assemblies integral with a pressure housing defining inlet ports and a plurality of fittings for connecting air lines to an interior of the pressure housing. The linear diaphragm pump assembly has a permanent magnetic shuttle mounting two diaphragms reciprocated by an electromagnet. The valve assembly has a plurality of solenoid valves disposed within the pressure housing, each solenoid valve being operable to control flow into or out of the pressure housing through an associated one of the plurality of fittings. Thus, no tubes or hoses are required to transfer air from the pump assembly to the valves. The housing has special mounts to isolate vibration arising from movement of the shuttle.

Owner:THOMAS IND INC

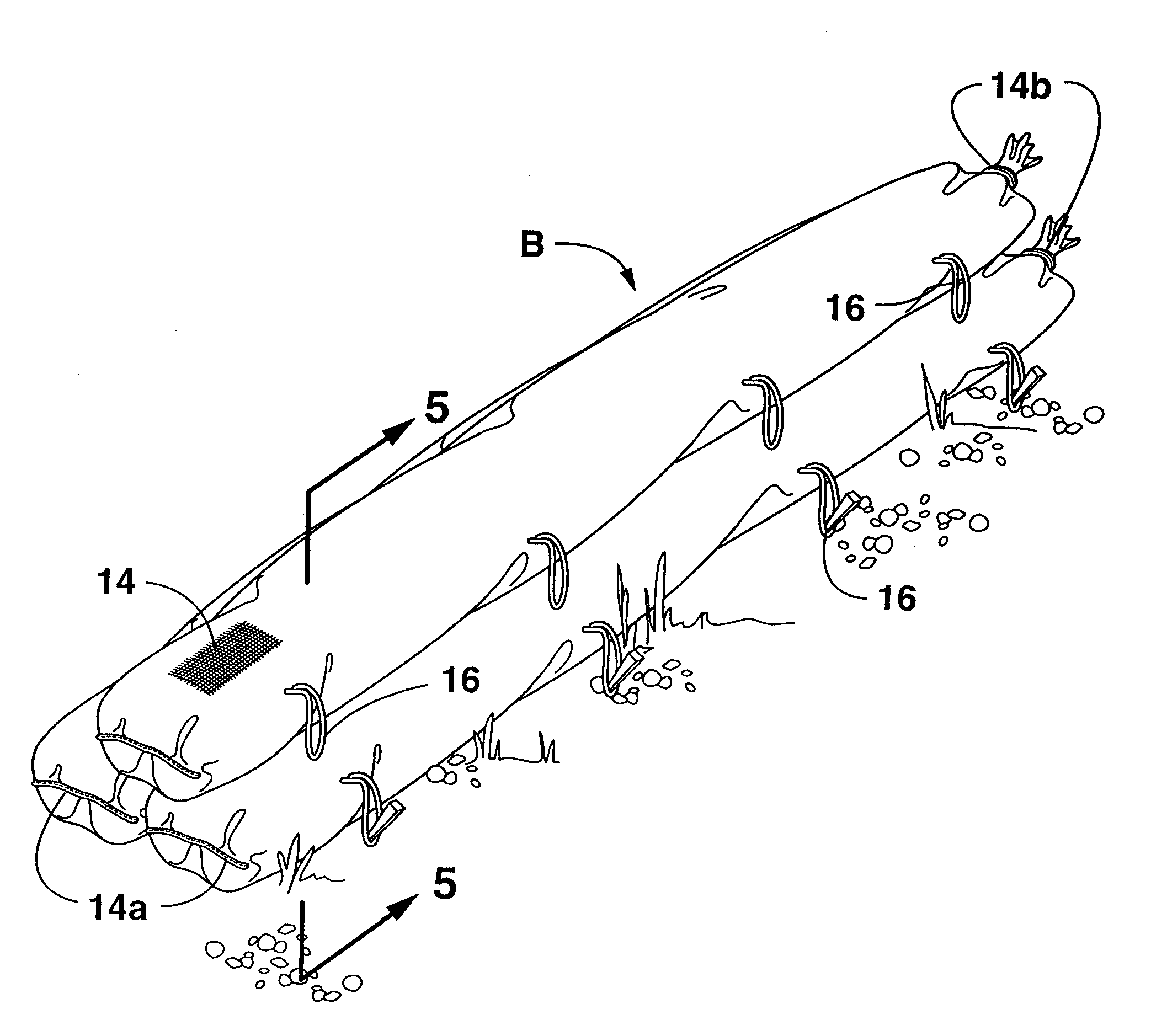

Water filtration and erosion control system and method

ActiveUS20080019780A1Useful in erosion controlErosion minimizationBarrages/weirsLoose filtering material filtersPondingControl system

An erosion control system and method wherein a fabric filter bag is embedded with and / or filled with a flocculating polymer and is positioned on a sloping soil surface to dam and pond water flowing thereacross for settling of the particles in the water, and as the ponding water seeps into the bag the colloidal particles will be filtered or agglomerated for settling. The water then passes through and out of the bag and is further subjected to agglomeration and filtering by a skirt of filter material also impregnated with flocculating polymer, said skirt being anchored to the bag or stacked to maintain the position adjacent and downslope from the bag.

Owner:DENNY HASTINGS FLP 14

Pipe Coupling

InactiveUS20130207388A1Improve wear resistanceSufficient sealing capacitySleeve/socket jointsFlanged jointsCouplingEngineering

A pipe coupling includes a first and second connected tubular element forming an elongated tube and being connected by a connection arrangement that biases the first tubular element against the second tubular. An annular sealing element is provided between and overlapping opposed end portions of the elements. The annular sealing element has a generally T-shaped cross-section and includes a first portion that forms a stem of the T-shaped cross section and extends in a radial direction and defines the outer periphery thereof, and a second portion formed by two opposing flanges that form the cross-bar of the T-shaped cross section and define the inner periphery thereof. At least one of the flanges presents a rounded bulge forming an outer peripheral surface of one flange. The bulge is sealed with an inner periphery of one of the tubular elements and extends continuously around the circumference of the annular sealing element.

Owner:IKM GRUPPEN AS

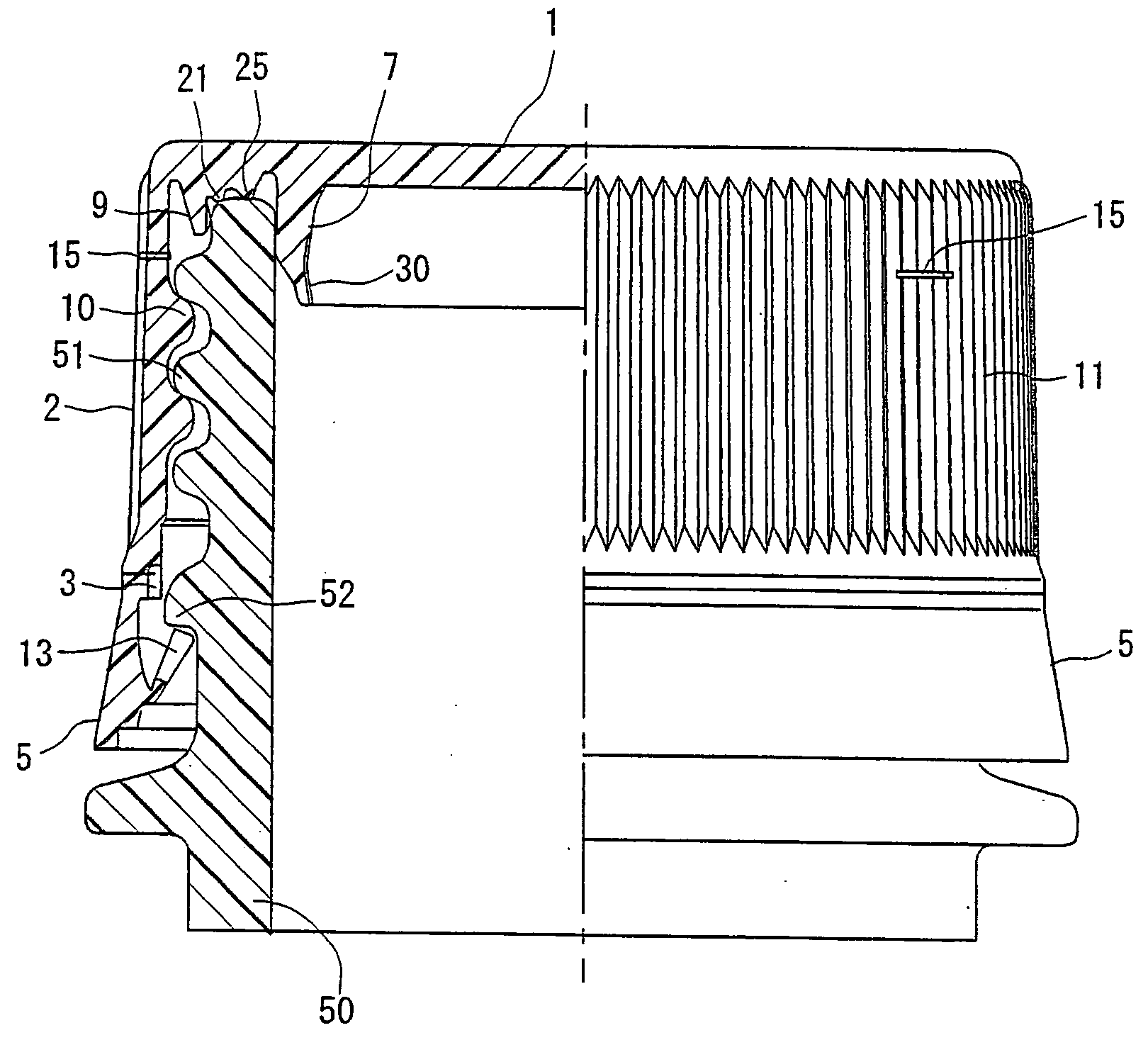

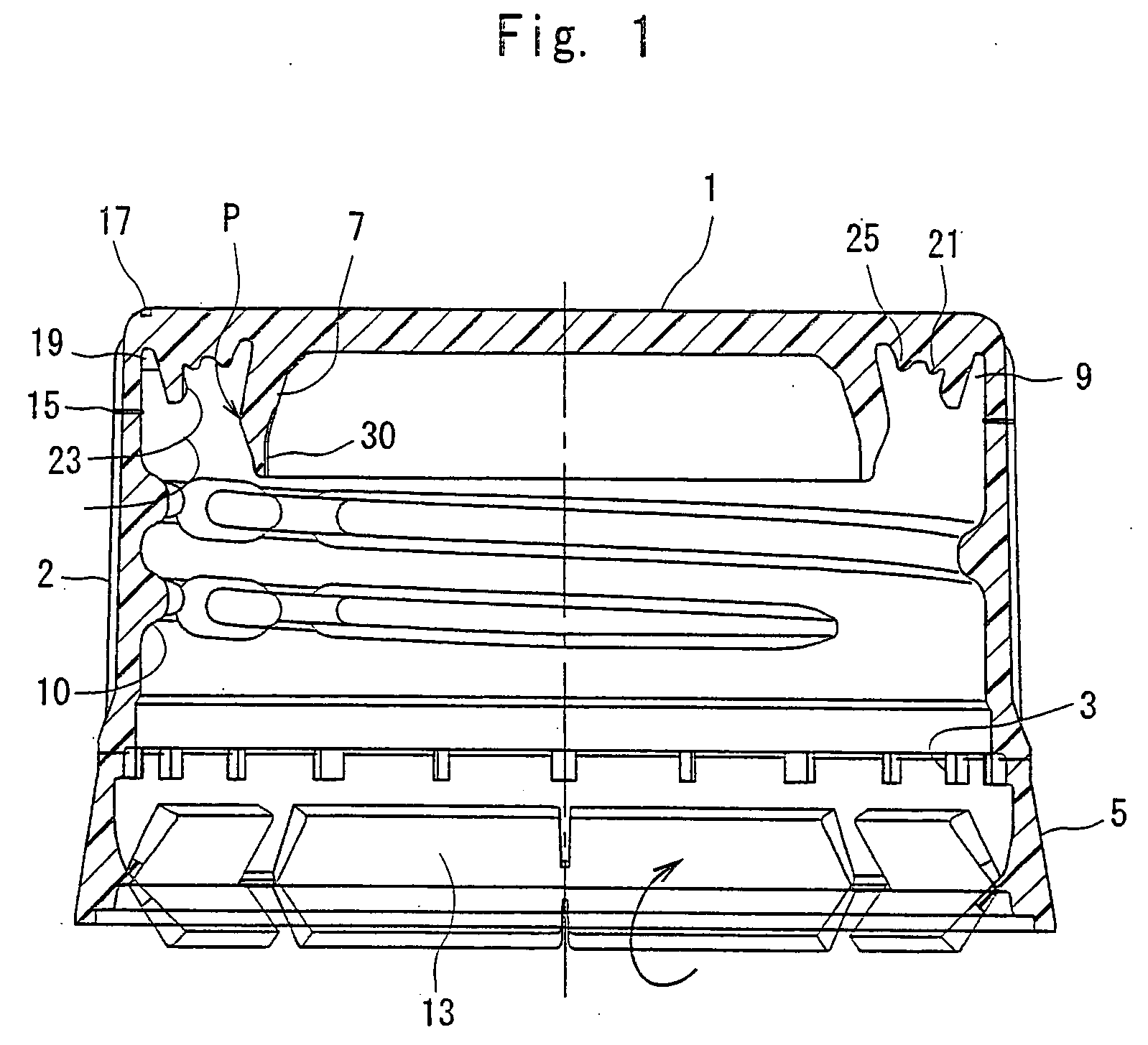

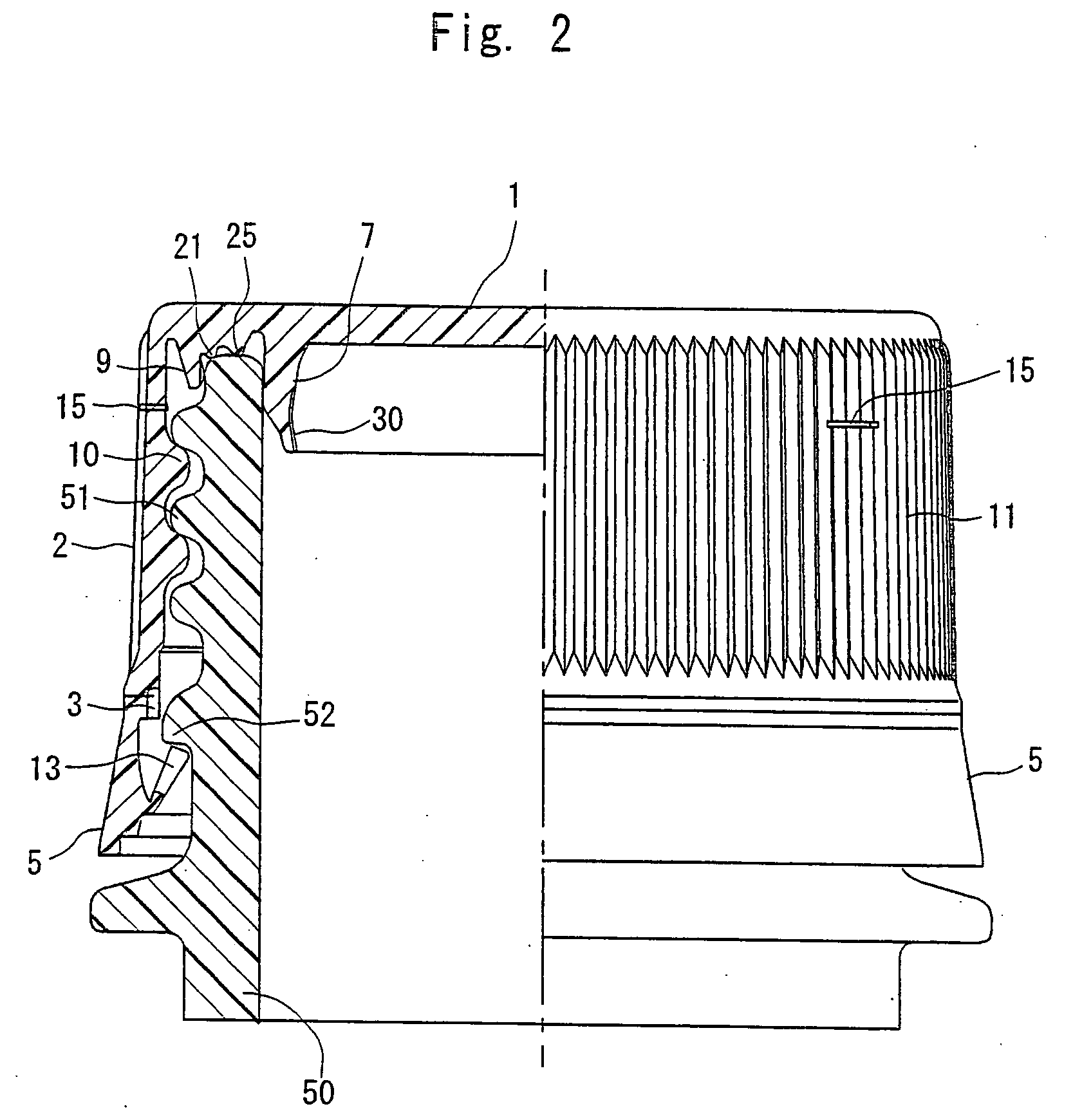

Plastic cap featuring excellent sealing and venting

A plastic cap comprising a top panel and a skirt hanging down from the peripheral edge of the top panel, the inner surface of the top panel forming an inner ring that forms a seal upon coming into intimate contact with the inner surface of the wall of the mouth of a container, and the inner surface of skirt forming a screw thread that comes into engagement with a screw thread formed on the outer surface of the wall of the mouth of the container, wherein a slender recessed portion is formed in a number of at least one in the inner surface of said inner ring extending upward from an end thereof. The cap features both excellent sealing and excellent venting.

Owner:TOYO SEIKAN KAISHA LTD +1

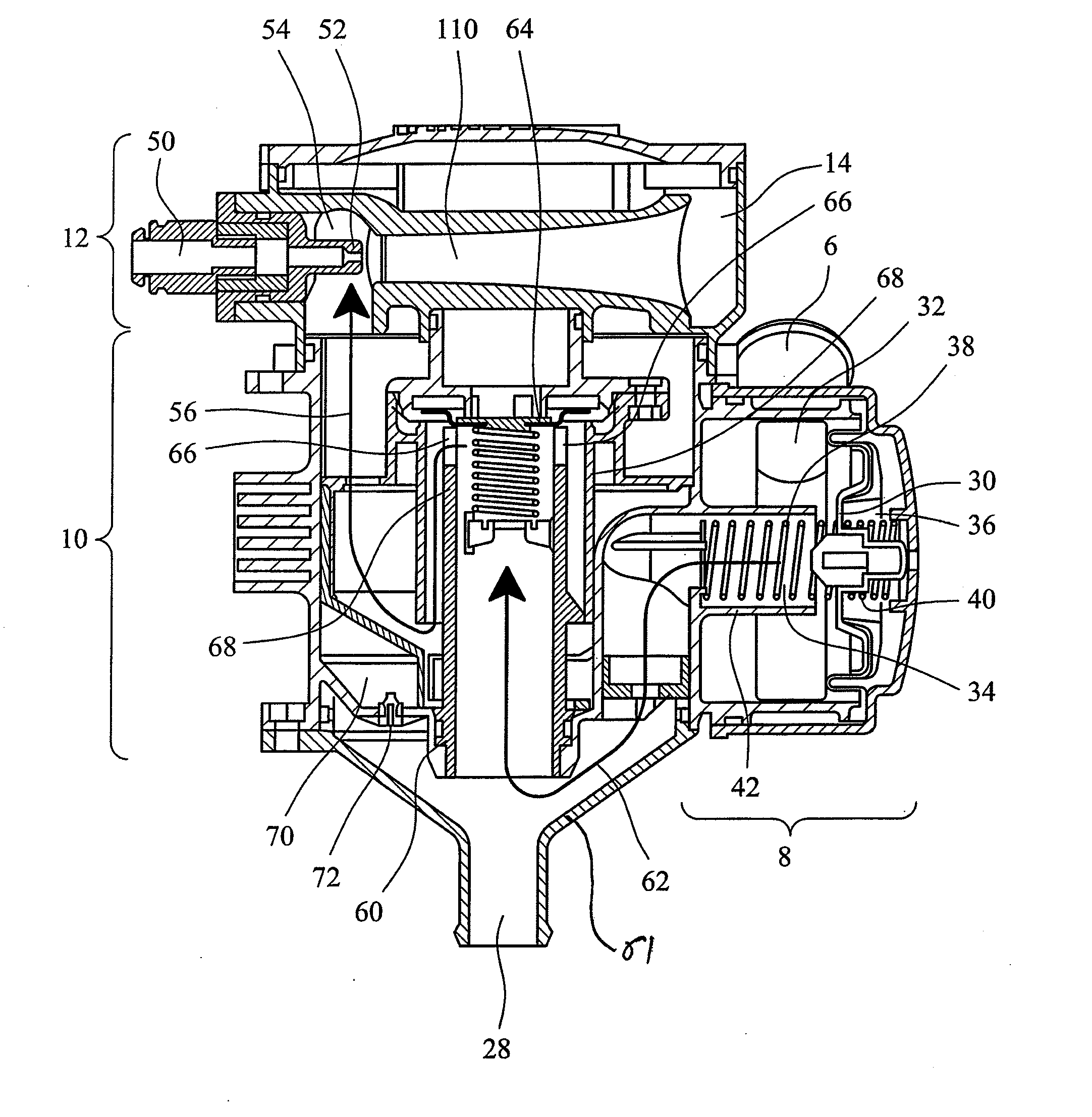

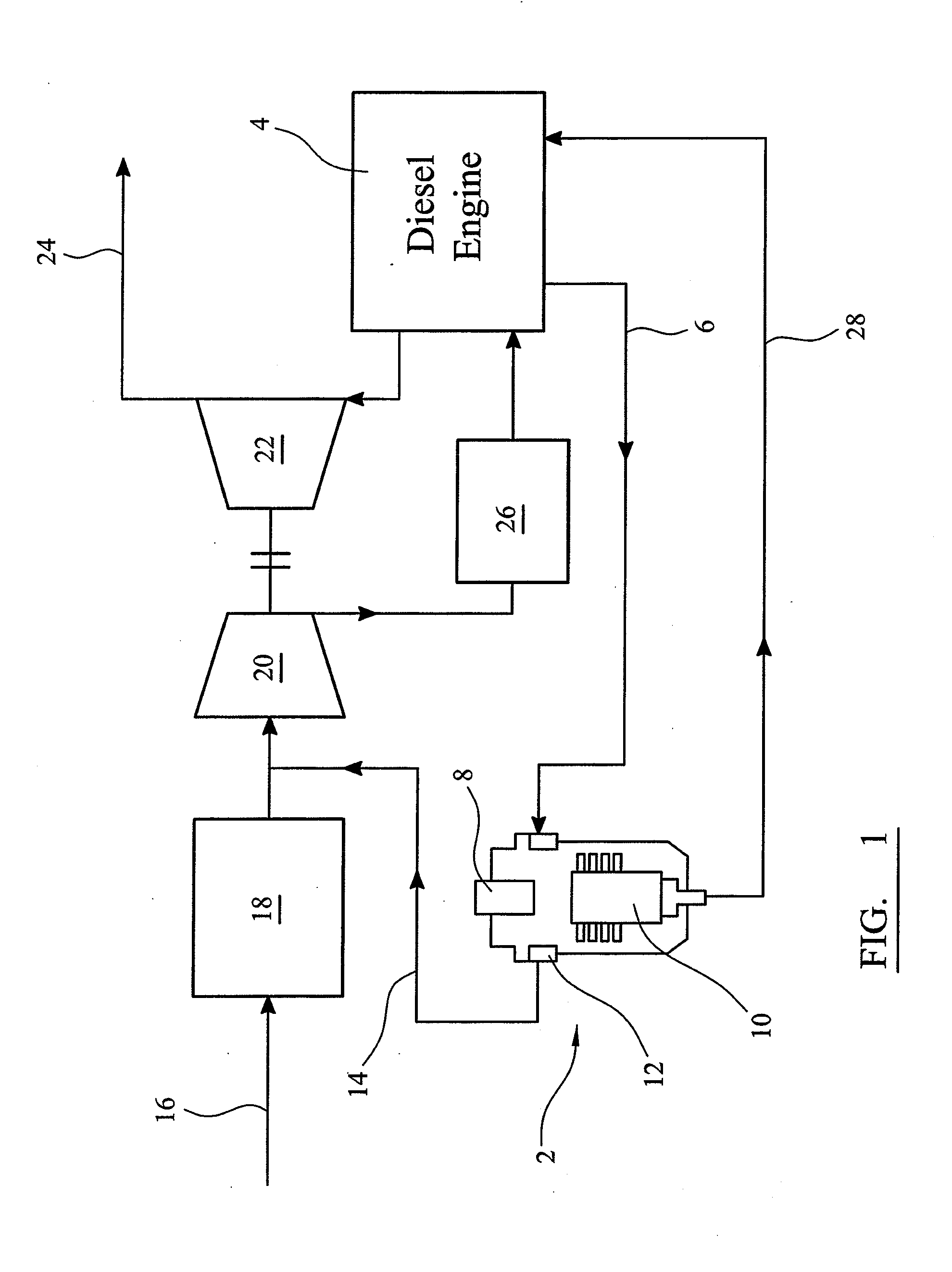

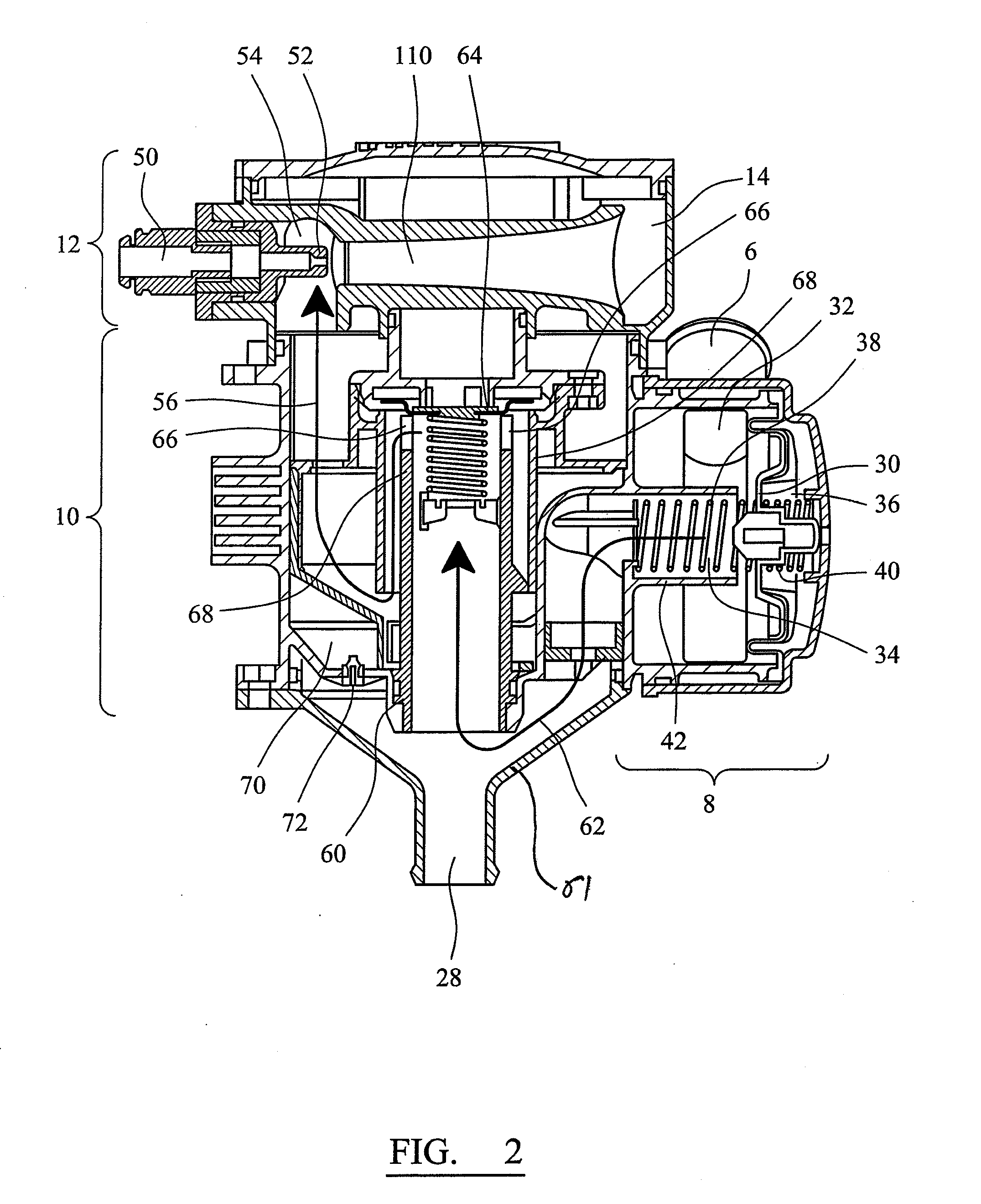

Separator

ActiveUS20140165977A1Improve efficiencyReduce sealCombination devicesAuxillary pretreatmentFilter mediaEngineering

A separator has a first inlet arranged to receive a fluid stream, and first and second separation stages coupled together in series; A pump coupled to the second separation stage generates an area of reduced pressure to draw the fluid stream through the first and second separation stages. One of the stages includes a variable impactor separator comprising a first chamber arranged to receive the fluid stream, and a second chamber coupled to the first chamber through an aperture to accelerate the first fluid stream. The stream is incident upon an impaction surface to separate contaminants from the fluid stream. An actuator adjusts the open area of the aperture according to a pressure differential between fluid pressure in the first chamber and a reference fluid pressure in a third chamber. The other of the separation stages is a second variable impactor separator or a filter media.

Owner:PARKER HANNIFIN MFG LTD

Methods for wellbore strengthening and controlling fluid circulation loss

A sealant composition and methods for using the same are disclosed. In an embodiment, a method of servicing a wellbore in contact with a subterranean formation is disclosed. The method comprises placing a sealing agent and a nonaqueous carrier fluid in the wellbore. The method further comprises placing a nonaqueous activating fluid in the wellbore. In addition, the method comprises contacting the sealing agent with the nonaqueous activating fluid to form a sealant composition.

Owner:HALLIBURTON ENERGY SERVICES INC

Plastic cap featuring excellent sealing and venting

A plastic cap comprising a top panel and a skirt hanging down from the peripheral edge of the top panel, the inner surface of the top panel forming an inner ring that forms a seal upon coming into intimate contact with the inner surface of the wall of the mouth of a container, and the inner surface of skirt forming a screw thread that comes into engagement with a screw thread formed on the outer surface of the wall of the mouth of the container, wherein a slender recessed portion is formed in a number of at least one in the inner surface of said inner ring extending upward from an end thereof. The cap features both excellent sealing and excellent venting.

Owner:TOYO SEIKAN KAISHA LTD +1

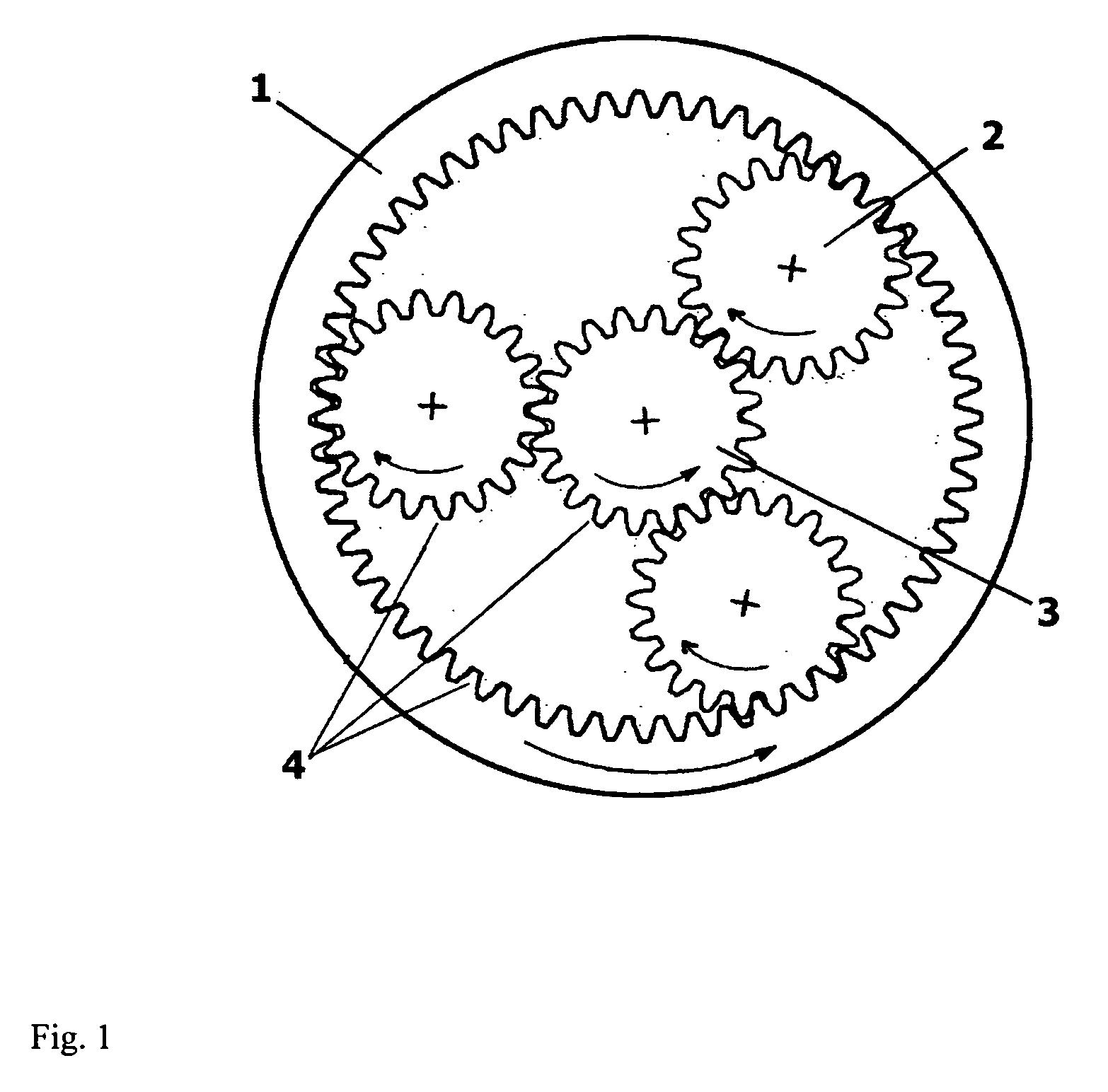

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com