Patents

Literature

47results about "Propulsive transmission drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

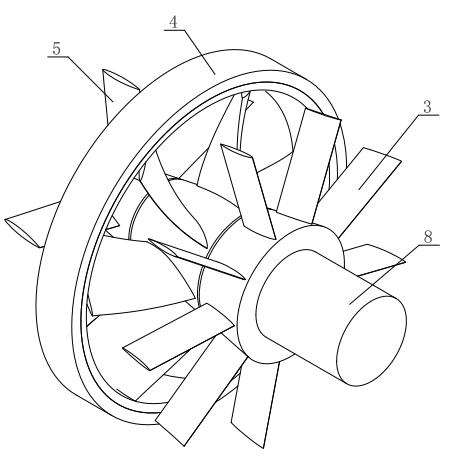

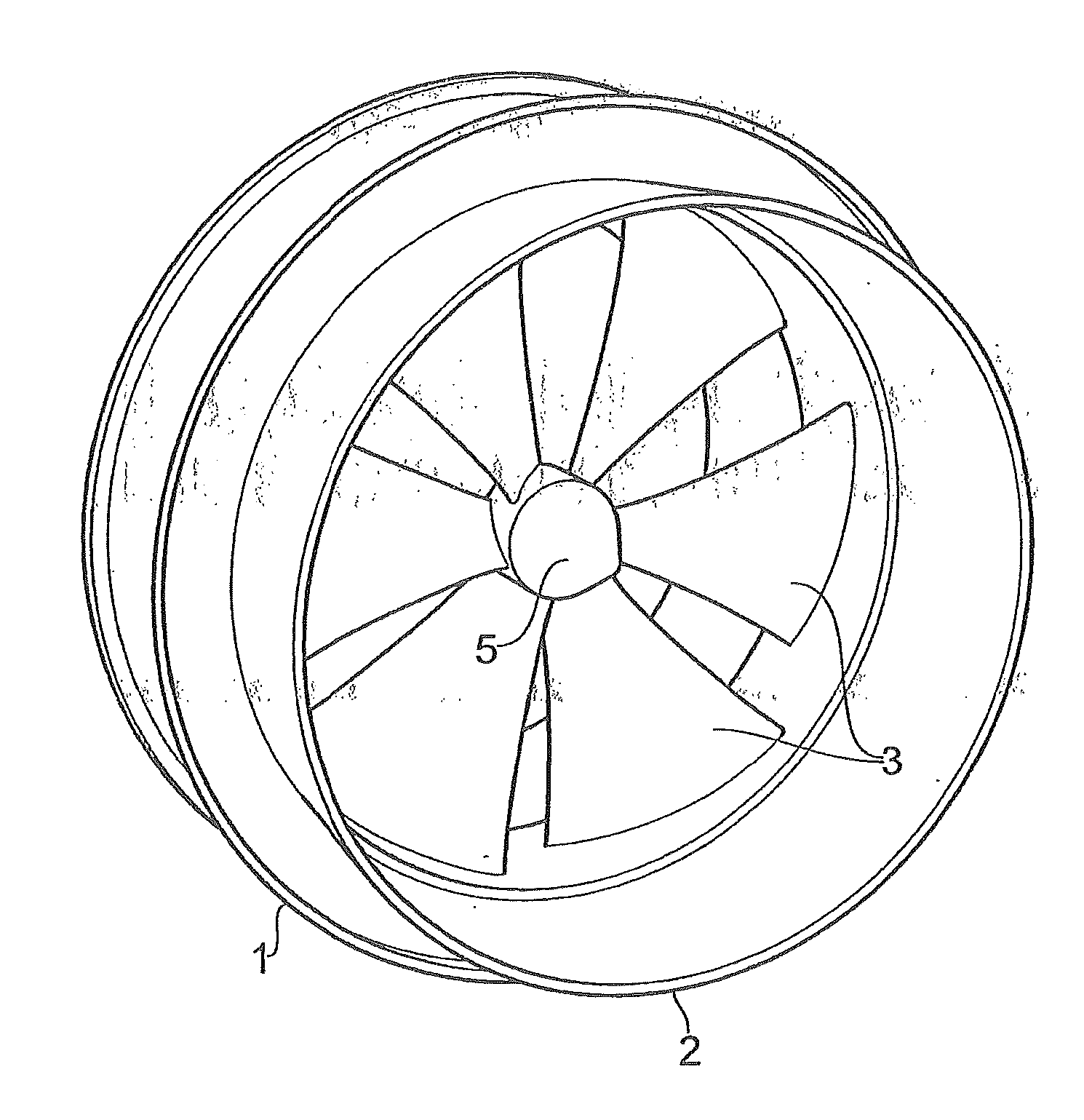

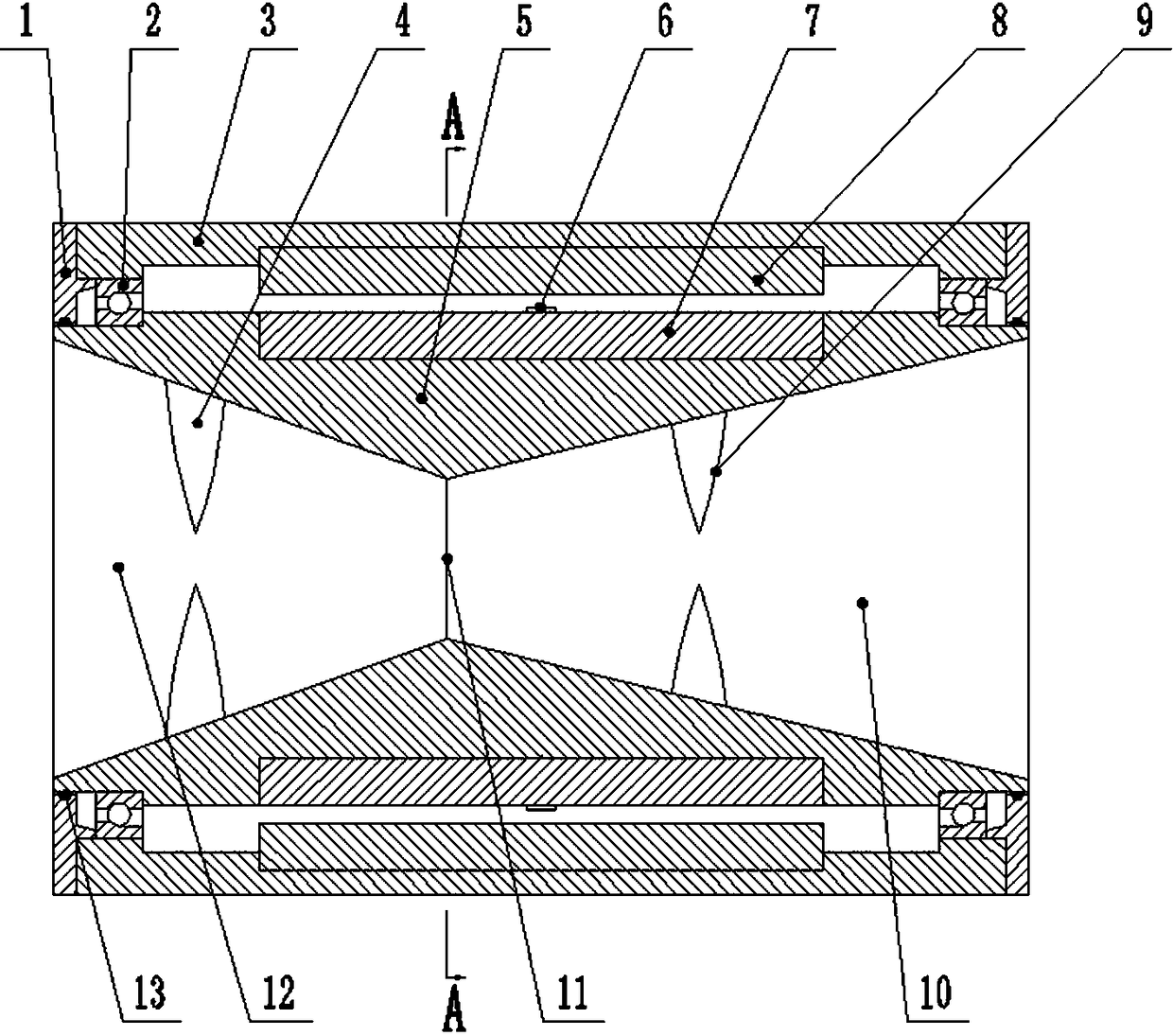

Shaftless driven type integrated motor propeller

InactiveCN102632982ALarge diameterIncrease output torqueRotary propellersPropulsive transmission driveCavitationPropeller

The invention discloses a shaftless driven type integrated motor propeller which is arranged on the tail part of a boat body of a water vehicle or underwater vehicle and comprises a front stator, a rotor propeller and a rear stator which are serially arranged on a solid non-rotating shaft, wherein the periphery of the propeller is connected with the circumferential rim of the annular propeller, a rotor permanent magnet is embedded in the circumferential rim of the propeller, a stator winding is arranged in the inner cavity of a guide pipe, the rotor permanent magnet and the stator winding are sealed by adopting water, and a gap is arranged between the rotor permanent magnet and the stator winding to form an annular motor. The rotor permanent magnet and the stator winding as well as the guide pipe are organically combined to form a modular unit, thus the shaftless driven type integrated motor propeller can be easily installed on a water platform or underwater platform, is suitable for large-power main propelling of a water boat or underwater submergible device, and has the advantages of reasonable structure, high propelling efficiency, low hydrodynamic force radiation noise, excellent cavitation property, safety and reliability.

Owner:中国船舶重工集团公司第七〇二研究所

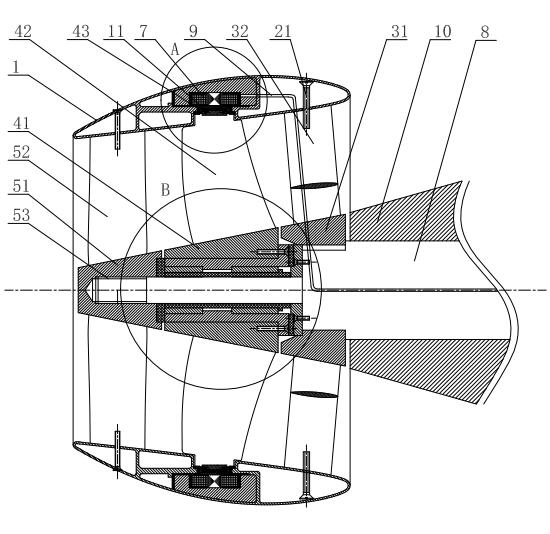

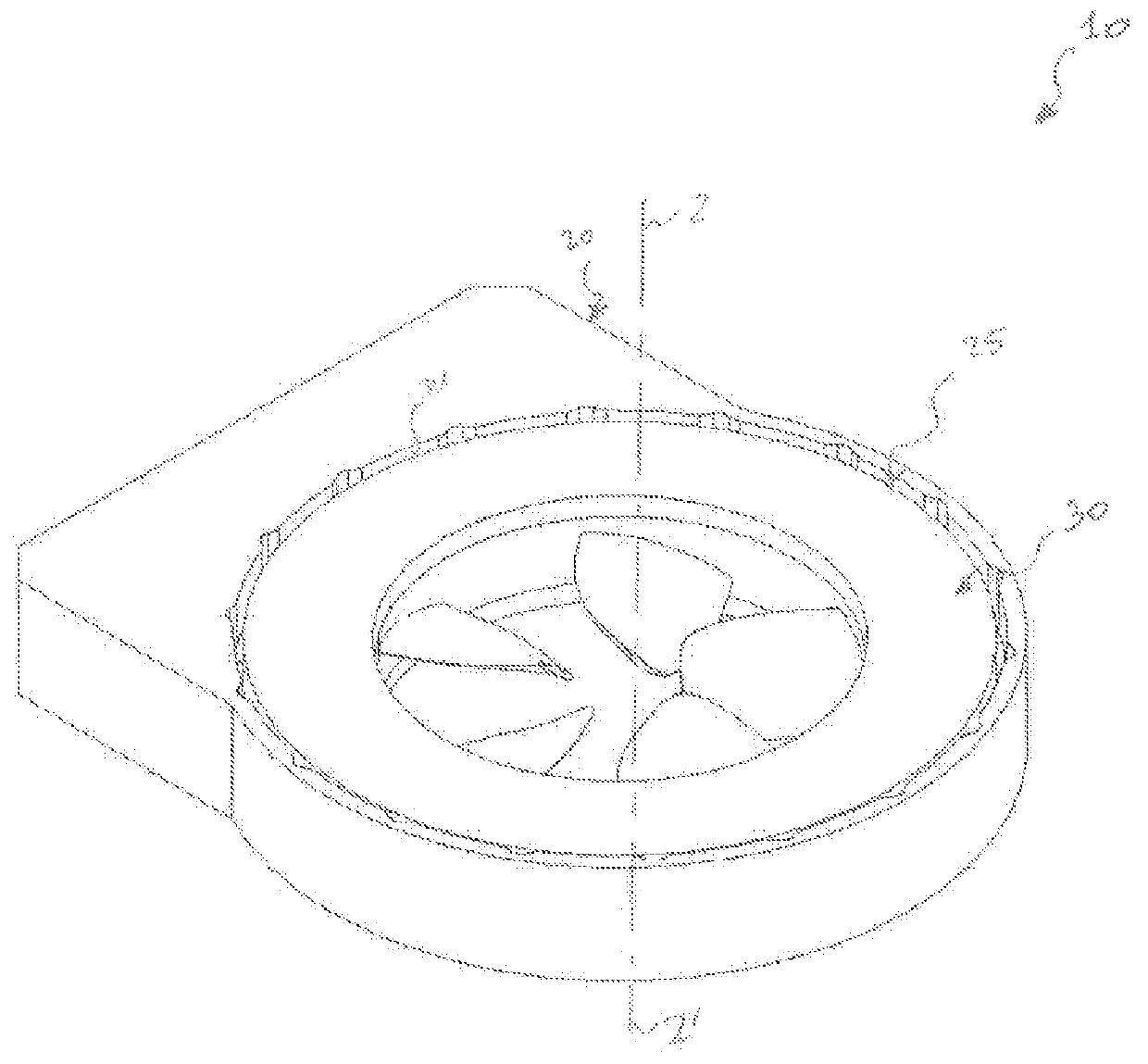

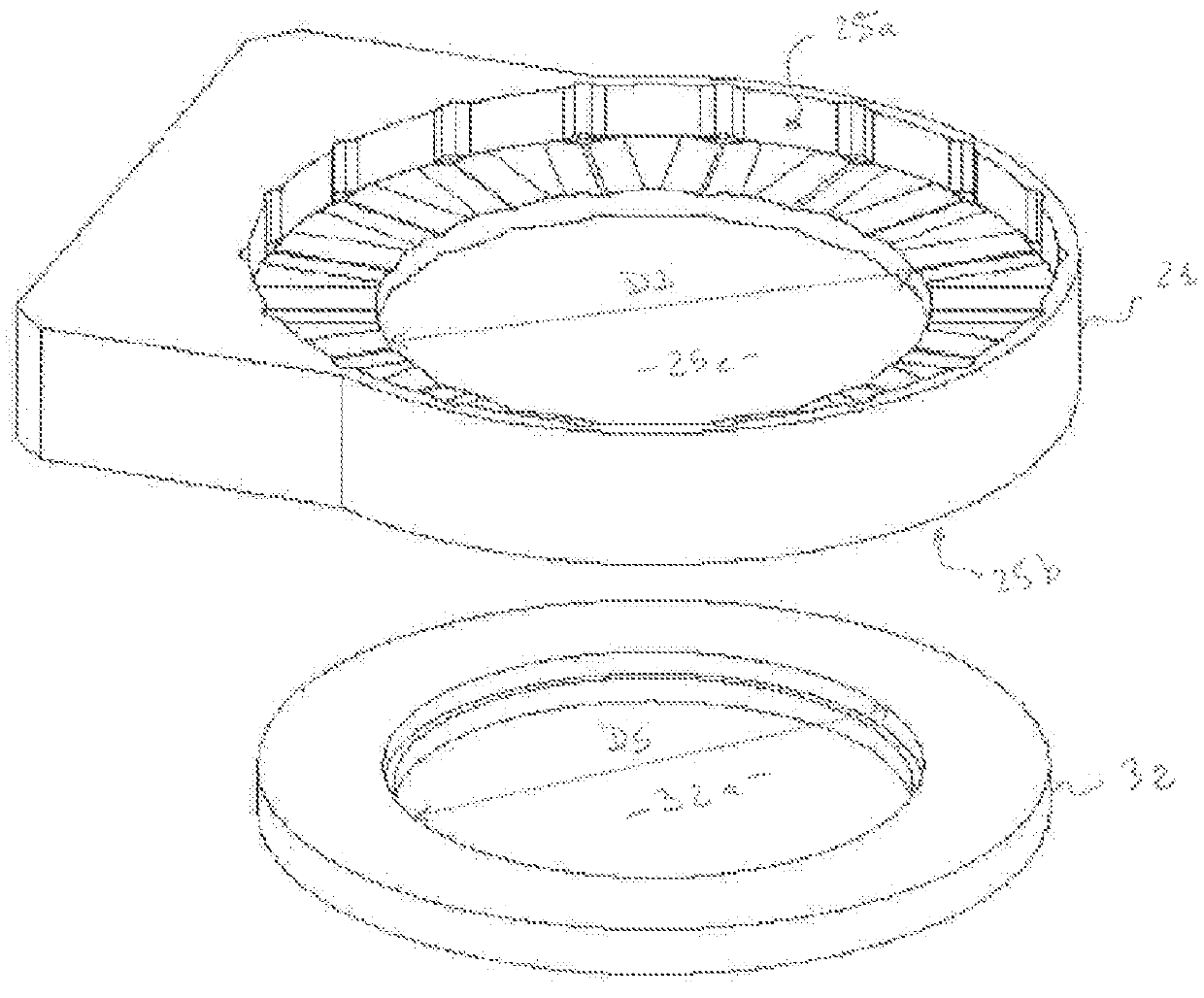

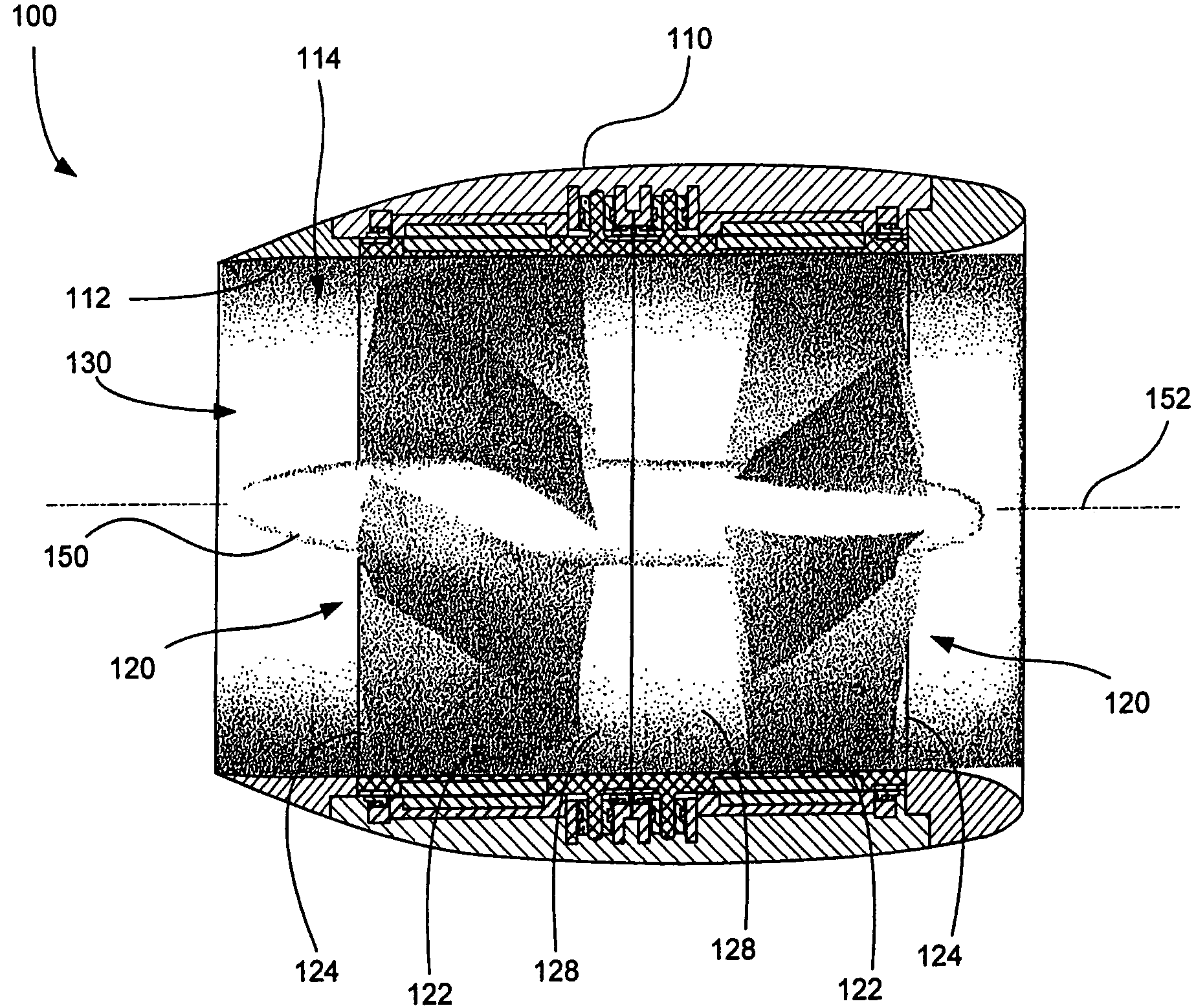

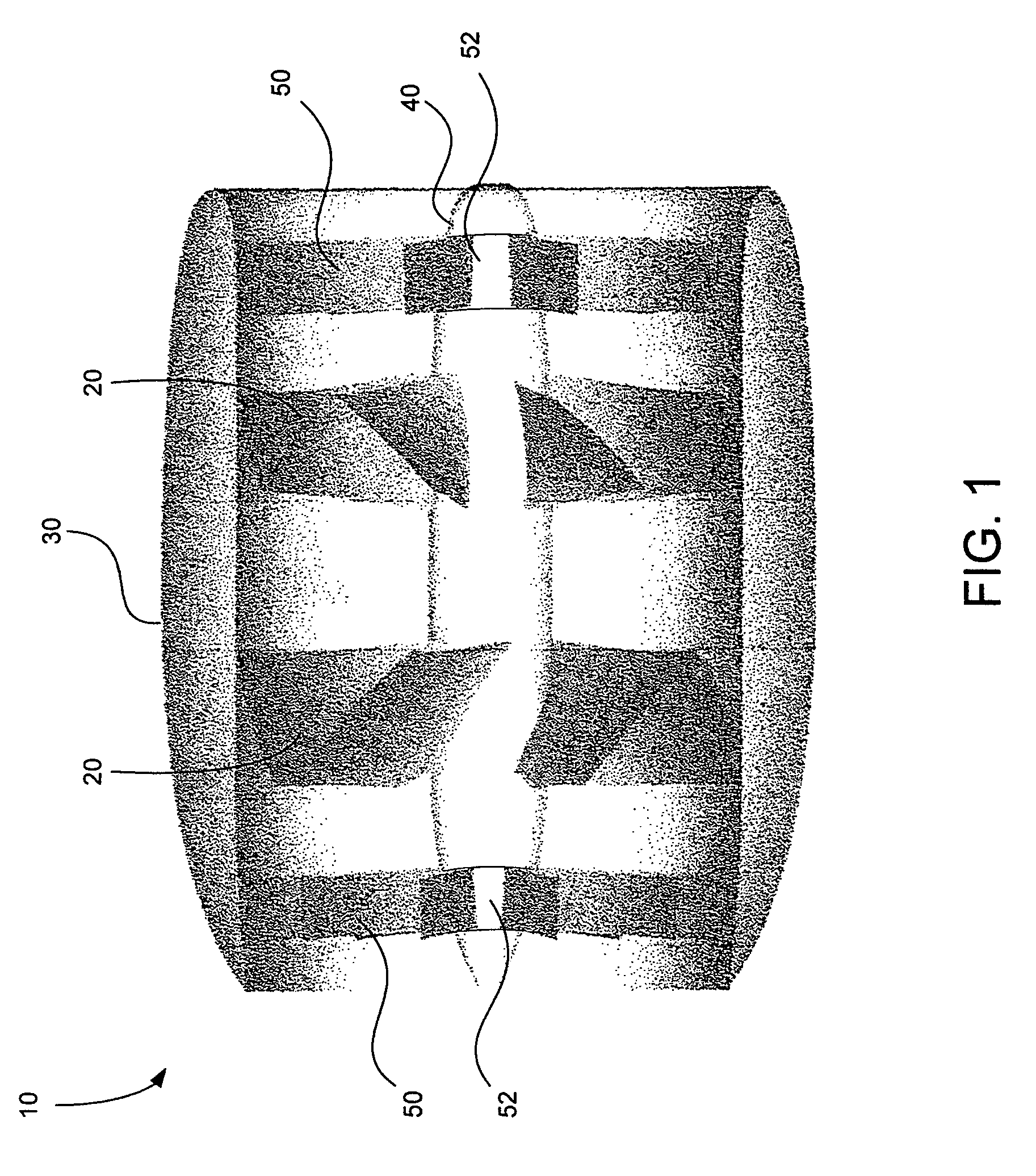

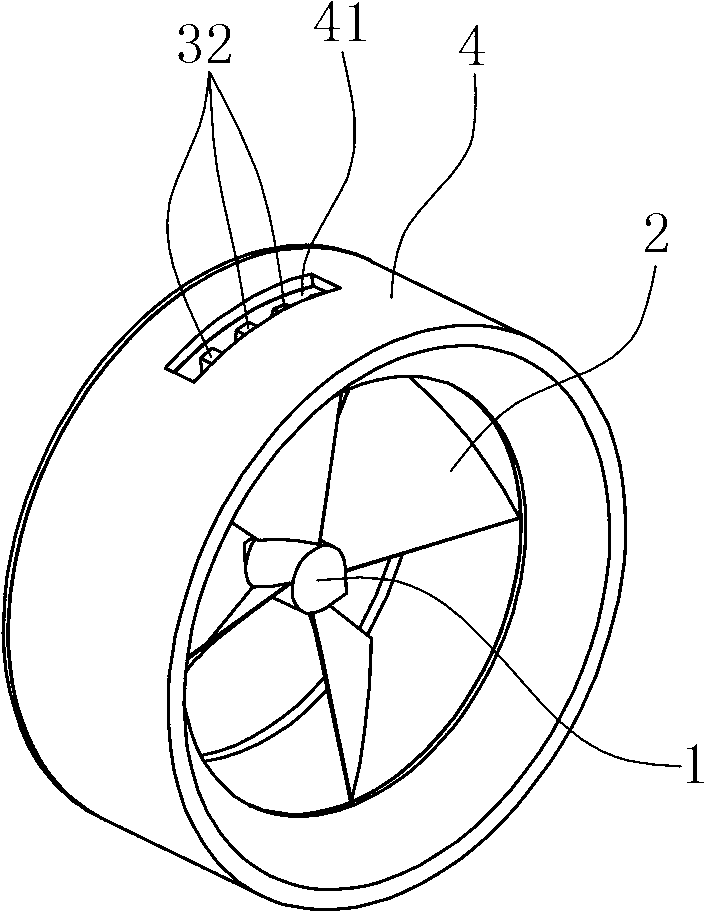

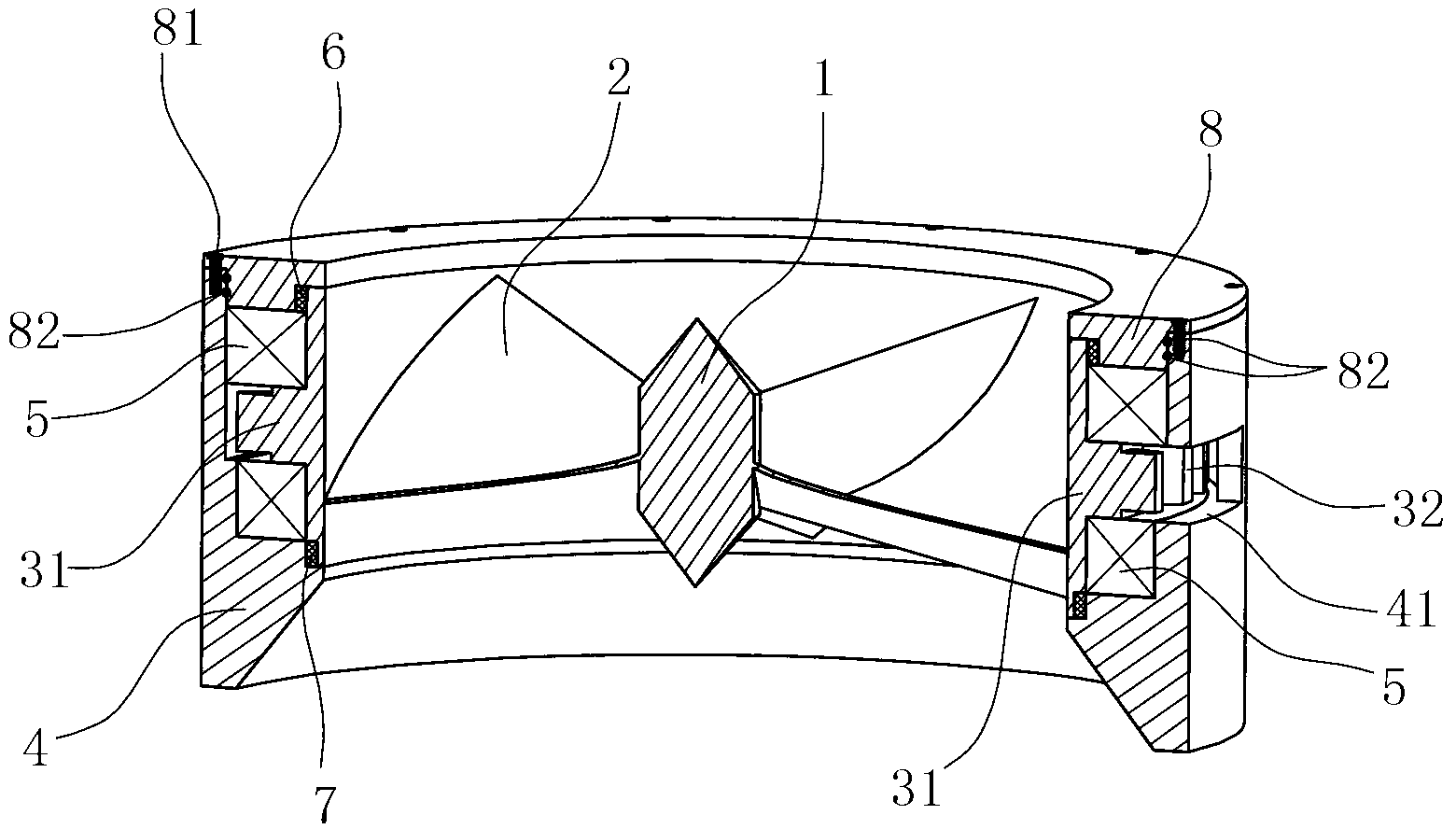

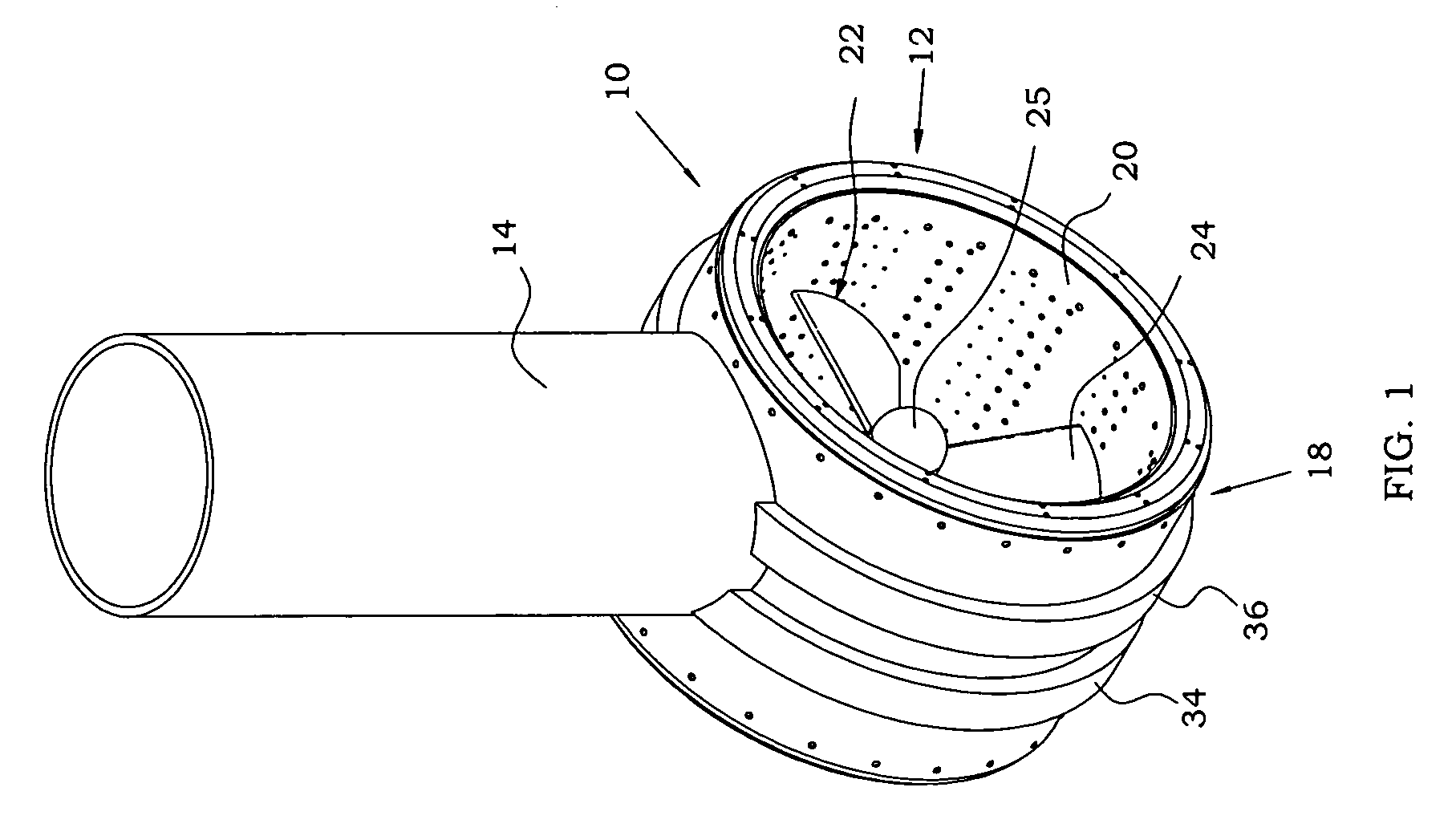

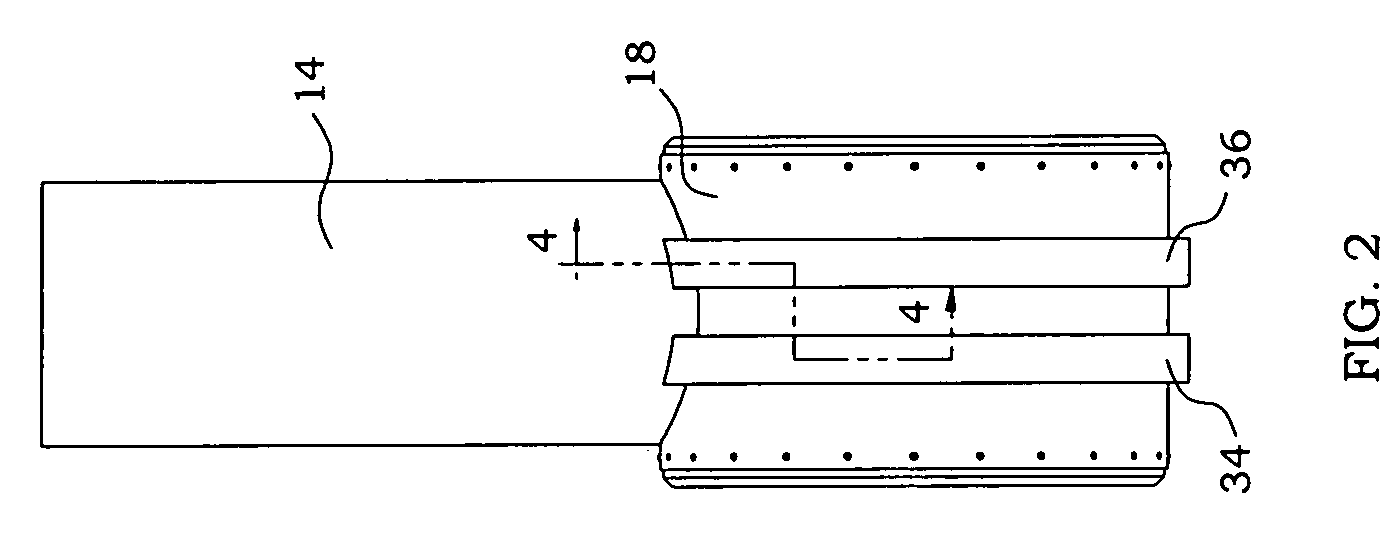

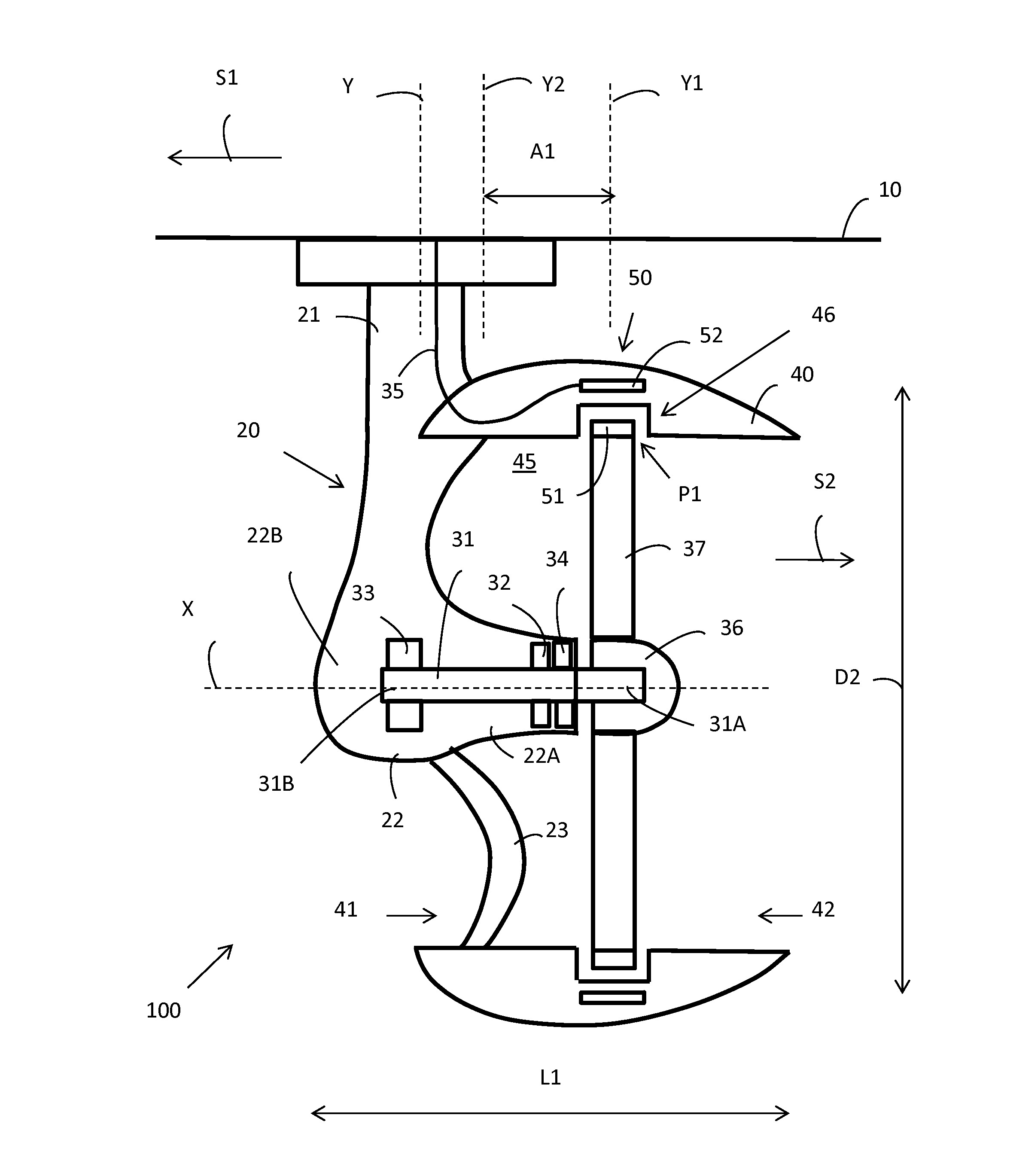

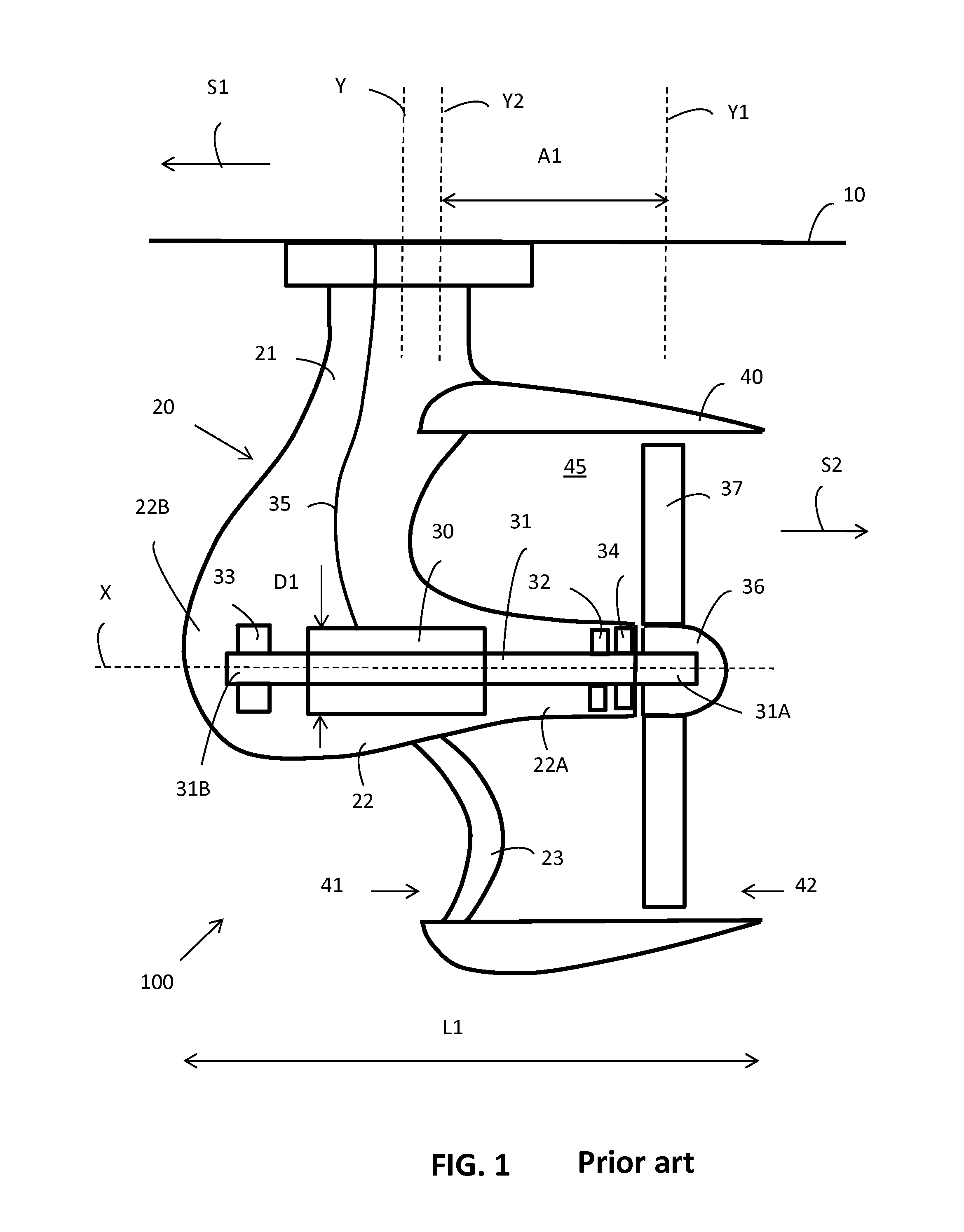

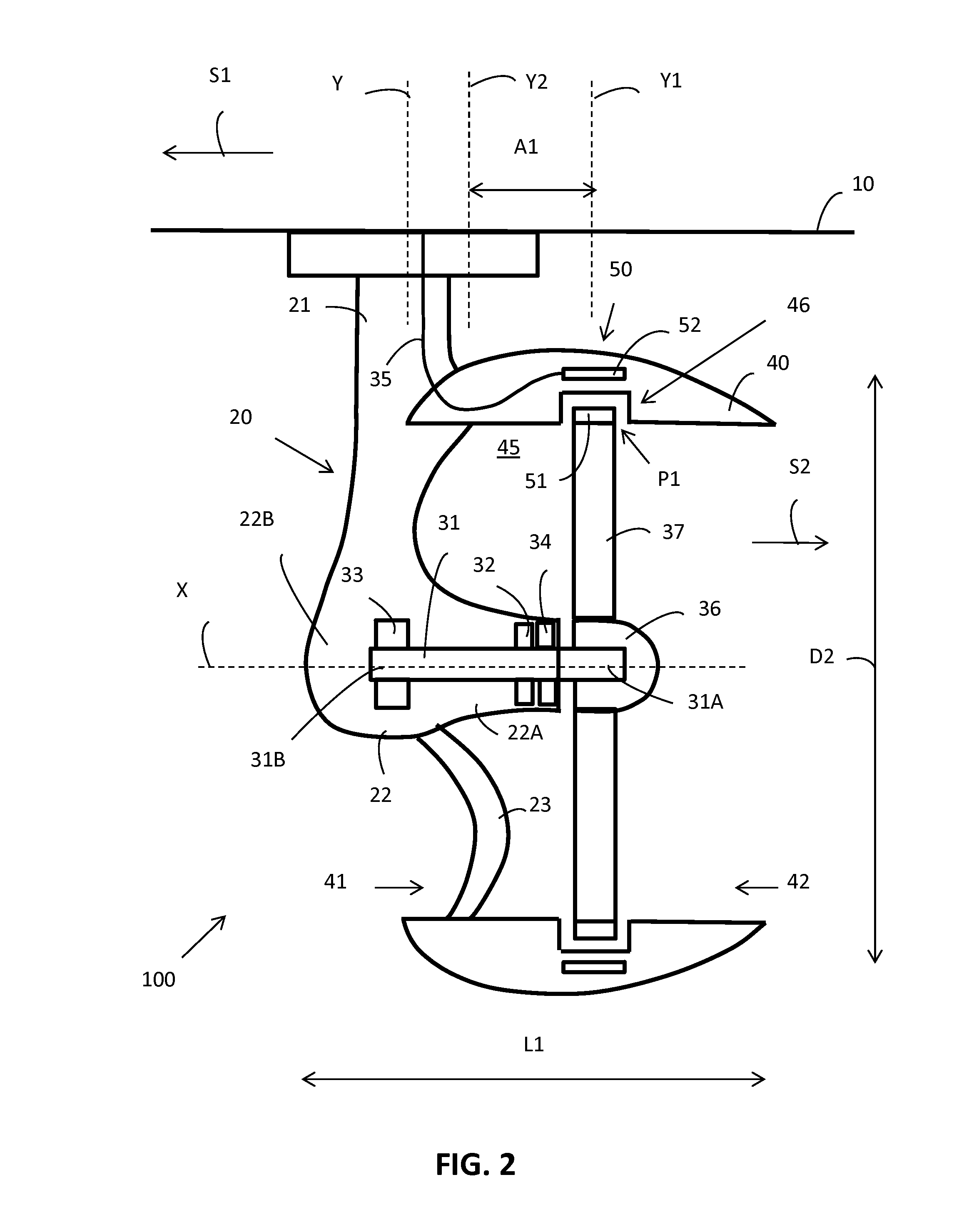

Underwater propelling device for underwater vehicle

ActiveUS9227709B1Reduce frictionAbrasionRotary propellersPropulsive transmission drivePropellerAxial thrust

The present invention relates to an underwater propelling device (10) ia stator (20) comprising circumferential arrayed coils (35) and being adapted to generate a controlled electromagnetic field along an axial direction,a shaftless propellant rotor (30) comprising:at least two magnetized ring-shaped plates, respectively an upper magnetized plate (31) and a lower magnetized plate (32), coaxially spaced-apart along said axial direction and perpendicular thereto such that said circumferential arrayed coils (35) are positioned therebetween, each plate (31, 32) defining a central aperture (31a, 32a) and having a circumferential array of radially extended magnetized poles (34) embedded therein, said magnetized poles (34) generating a magnetic field which interacts with the electromagnetic field of the stator (20) so as to cause the rotation of said plates (31, 32) about a central axis (ZZ′) parallel to said axial direction,at least one ring-shaped propeller (33) defined by its outer periphery and its inner periphery, said propeller being received inside the central apertures (31a, 32a) of said plates (31, 32) and fixedly secured thereto,a plurality of propeller blades (35) projecting inward from the inner periphery of said propeller (33), said blades (35) producing a thrust along the central axis (ZZ′) when the plates (31, 32) rotate,wherein the rotor (30) is axially separated from the stator (20) by a gap, preferably less than 3 mm, so as to permit the formation of a hydraulic film inside said gap, said hydraulic film being adapted to provide lubrication of the rotor, thus reducing friction between the rotor and the stator, and to transmit the axial thrust force of the rotor to the stator.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

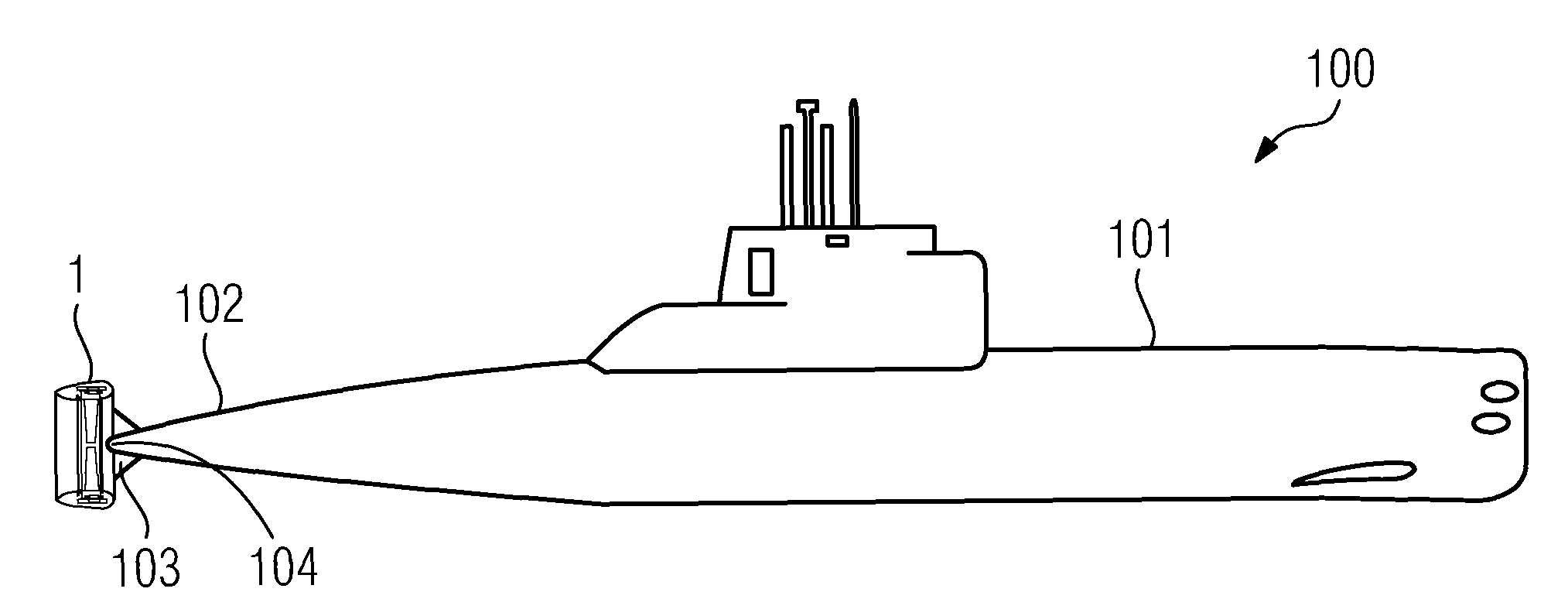

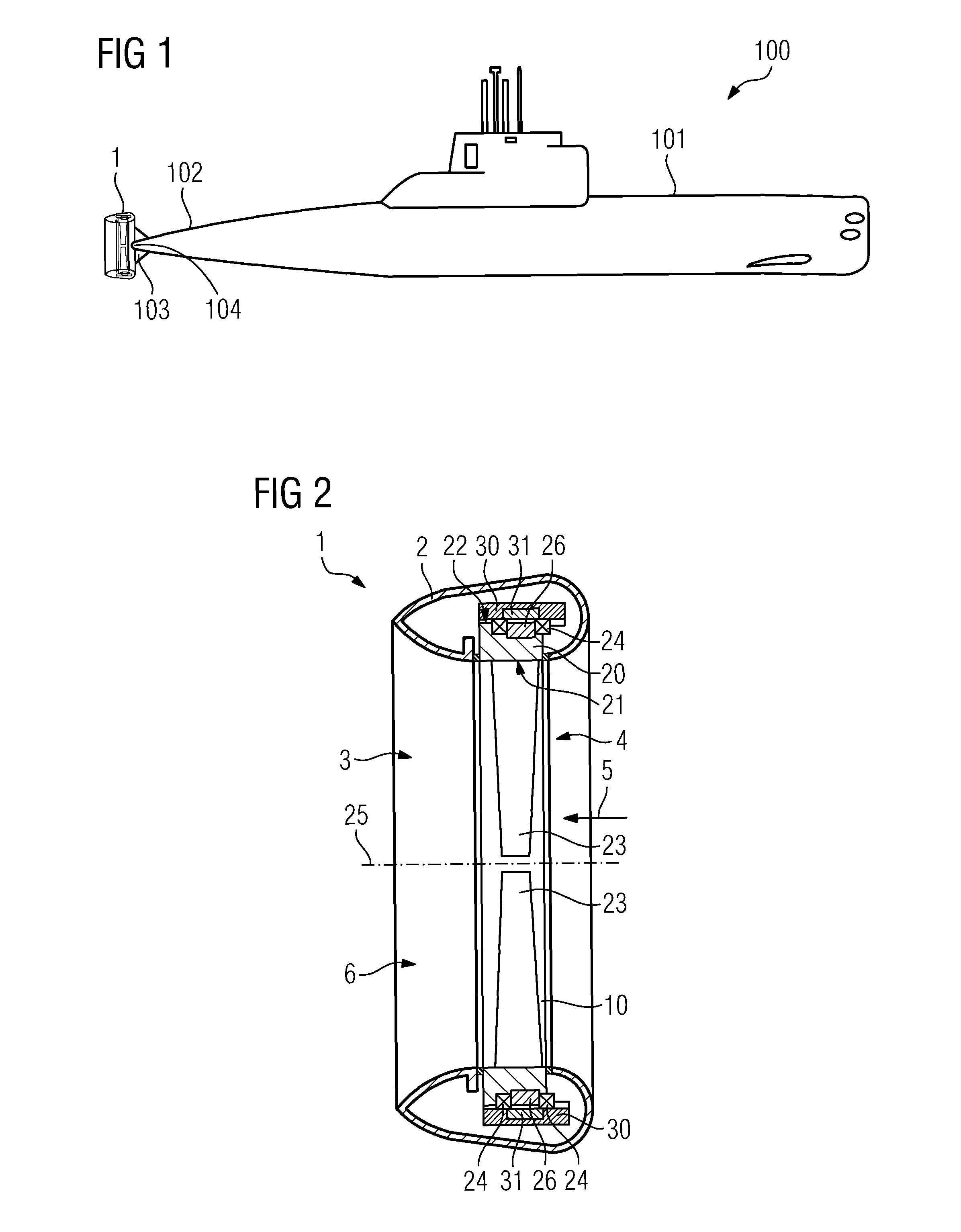

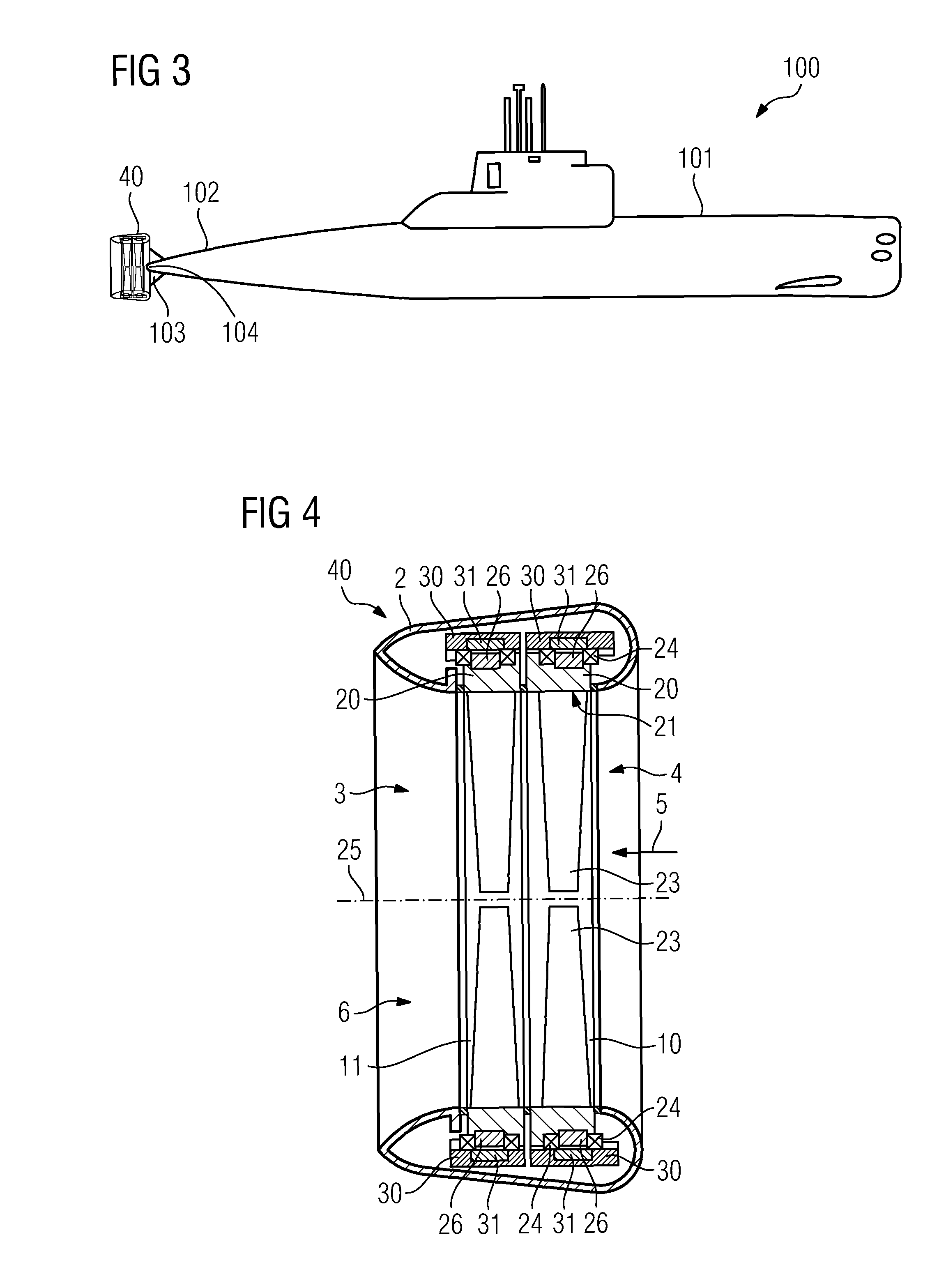

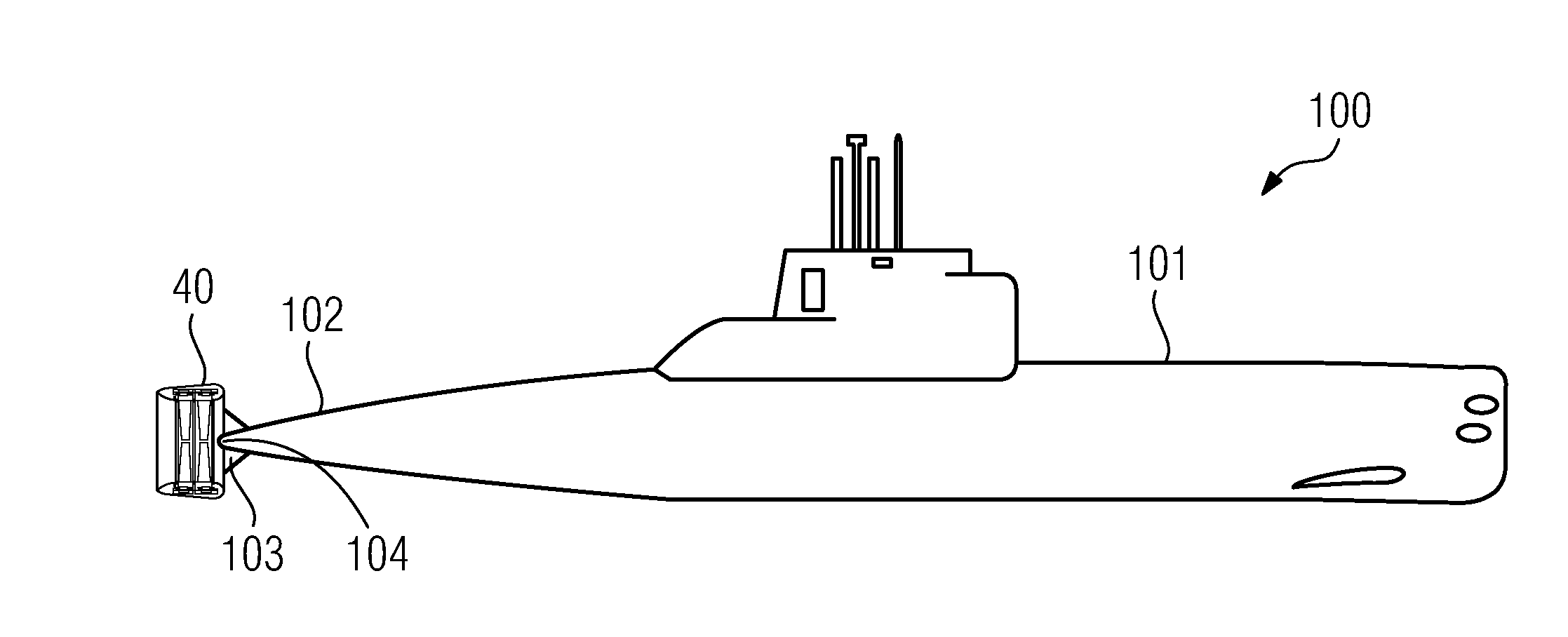

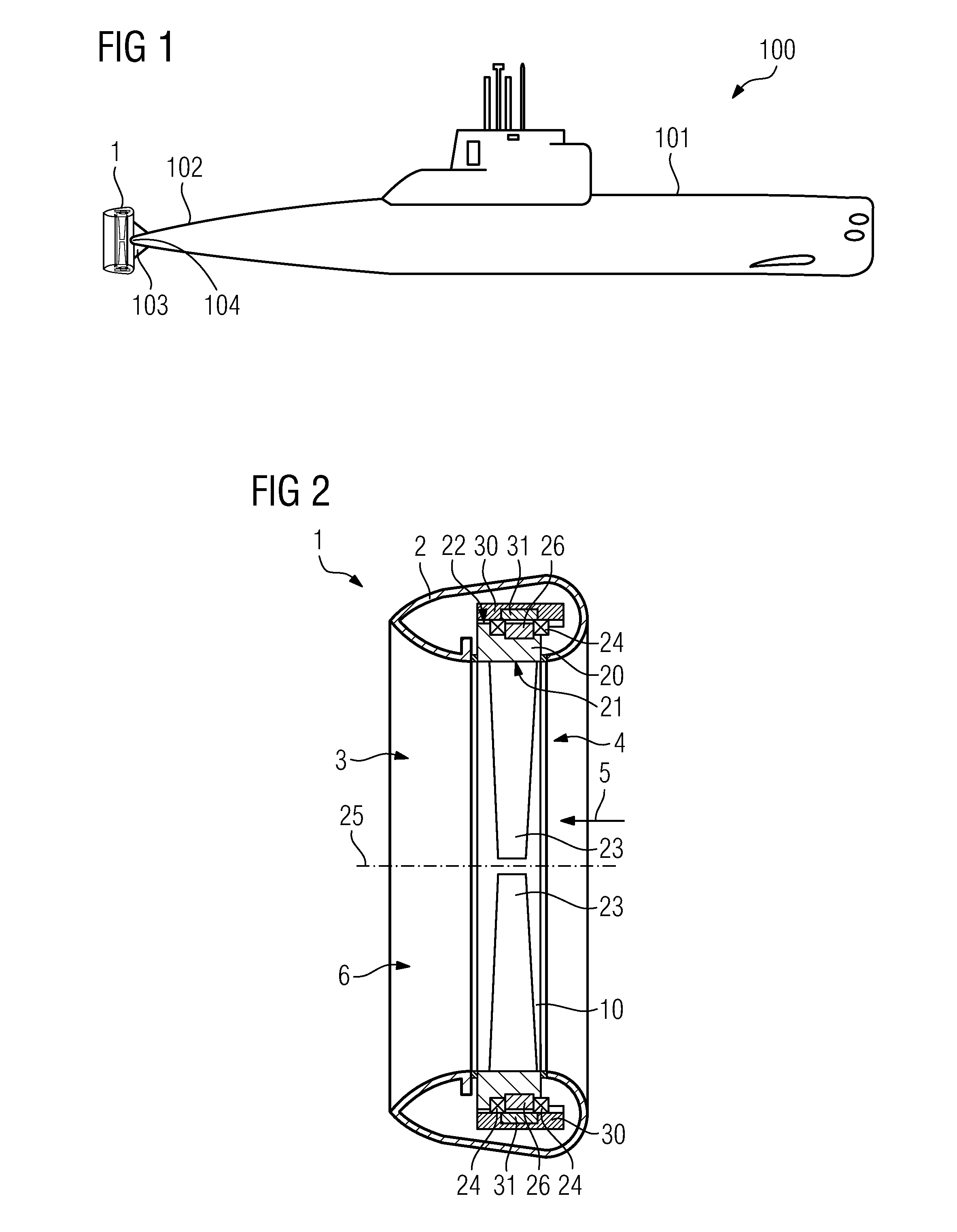

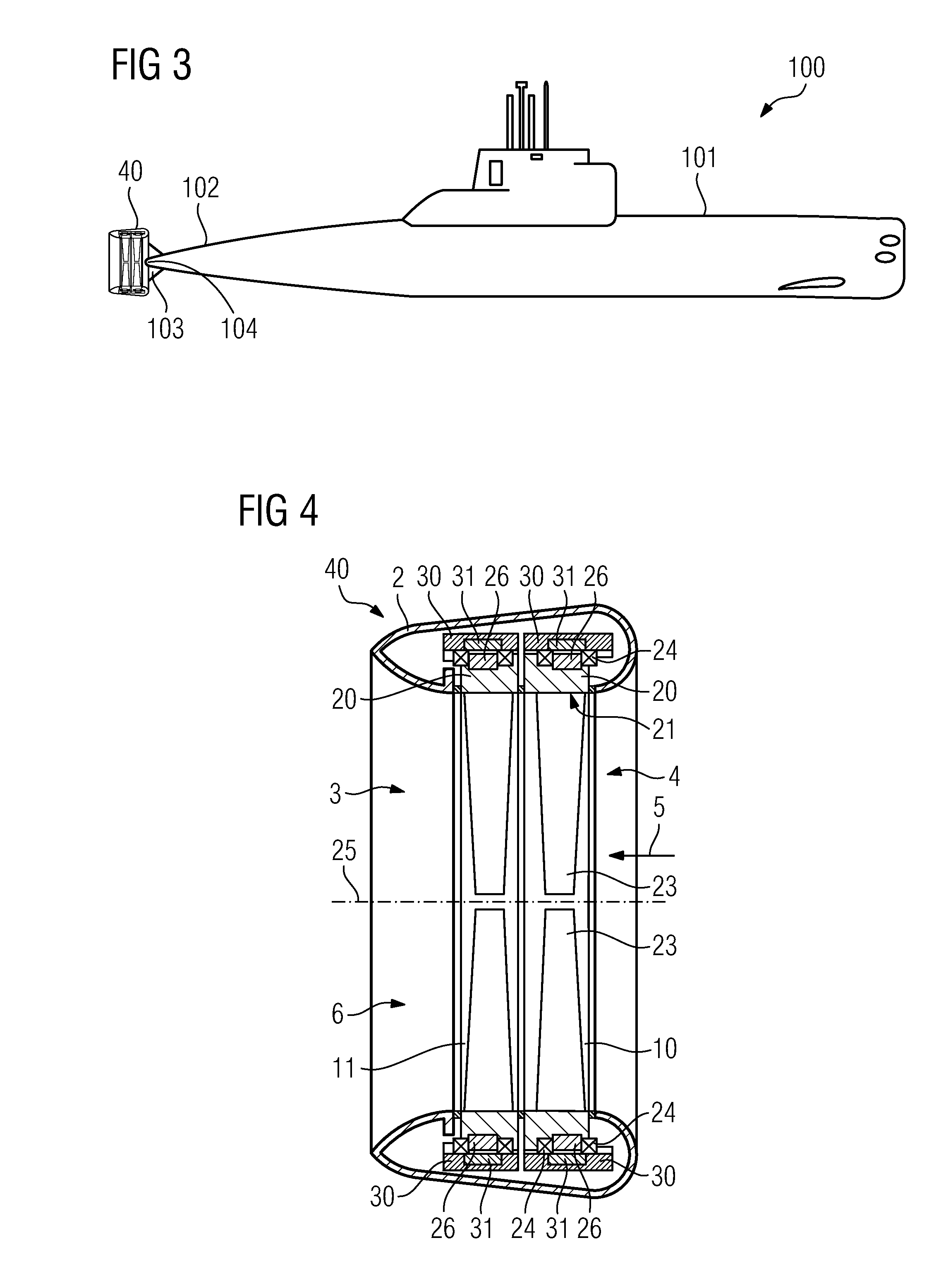

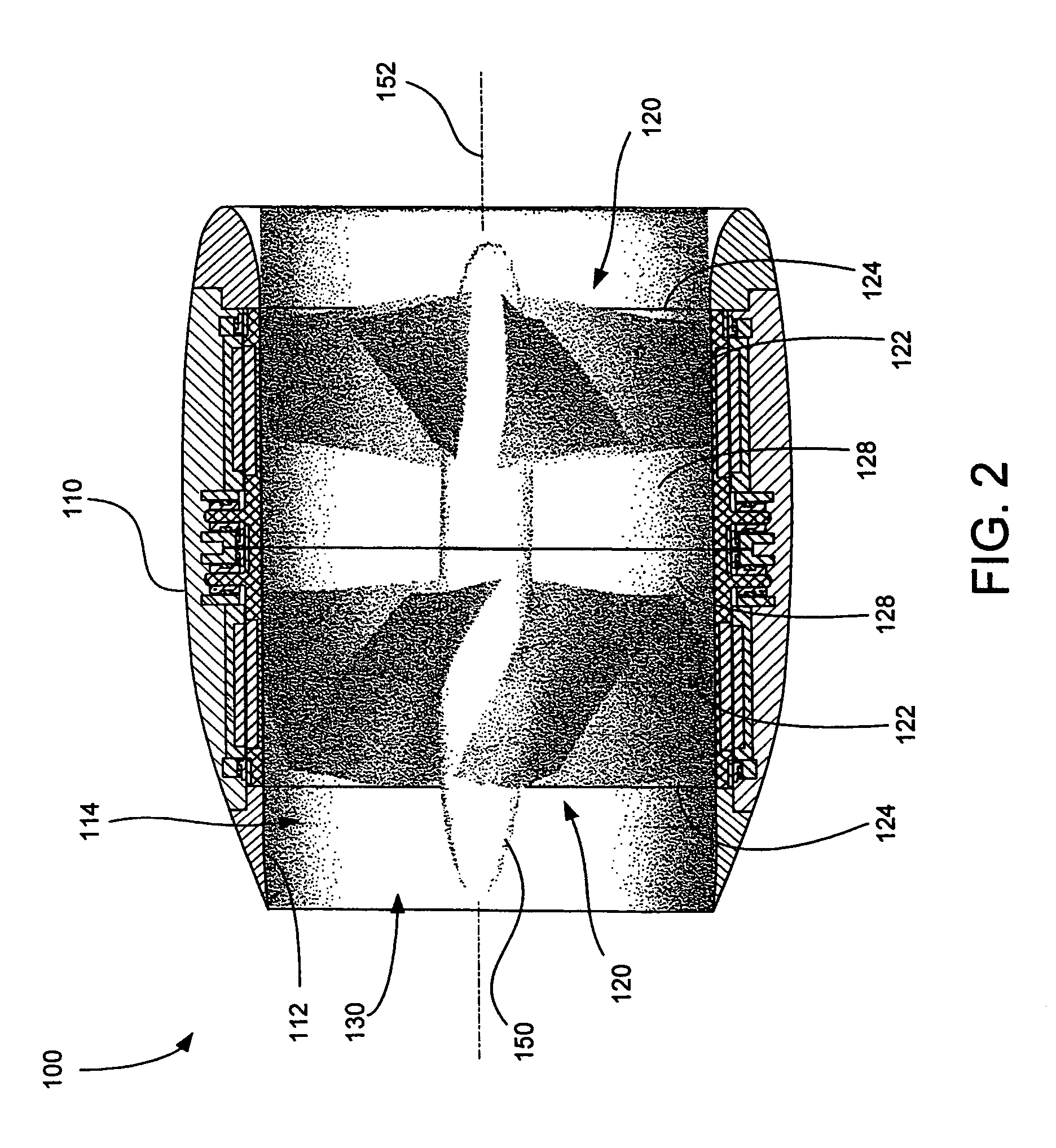

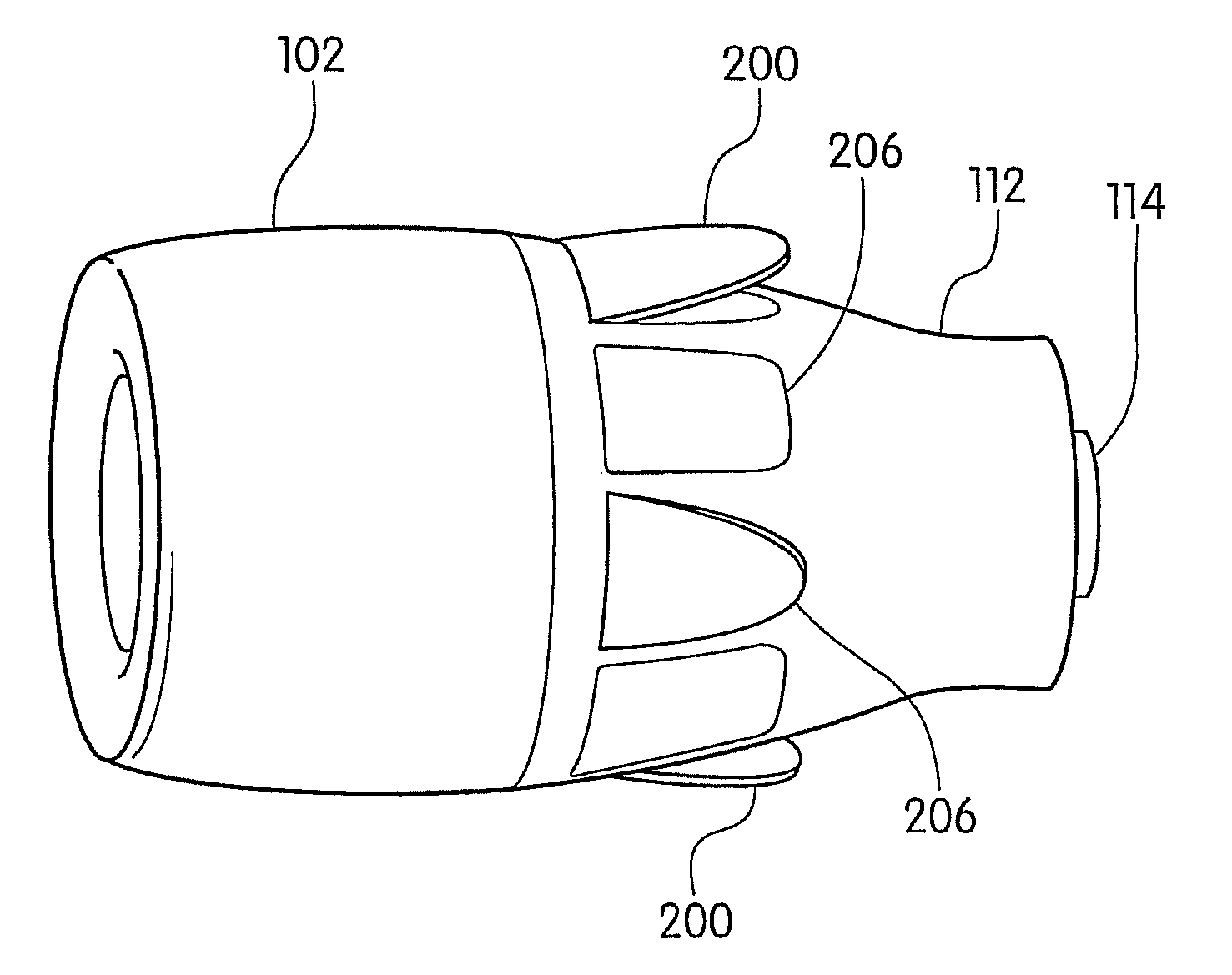

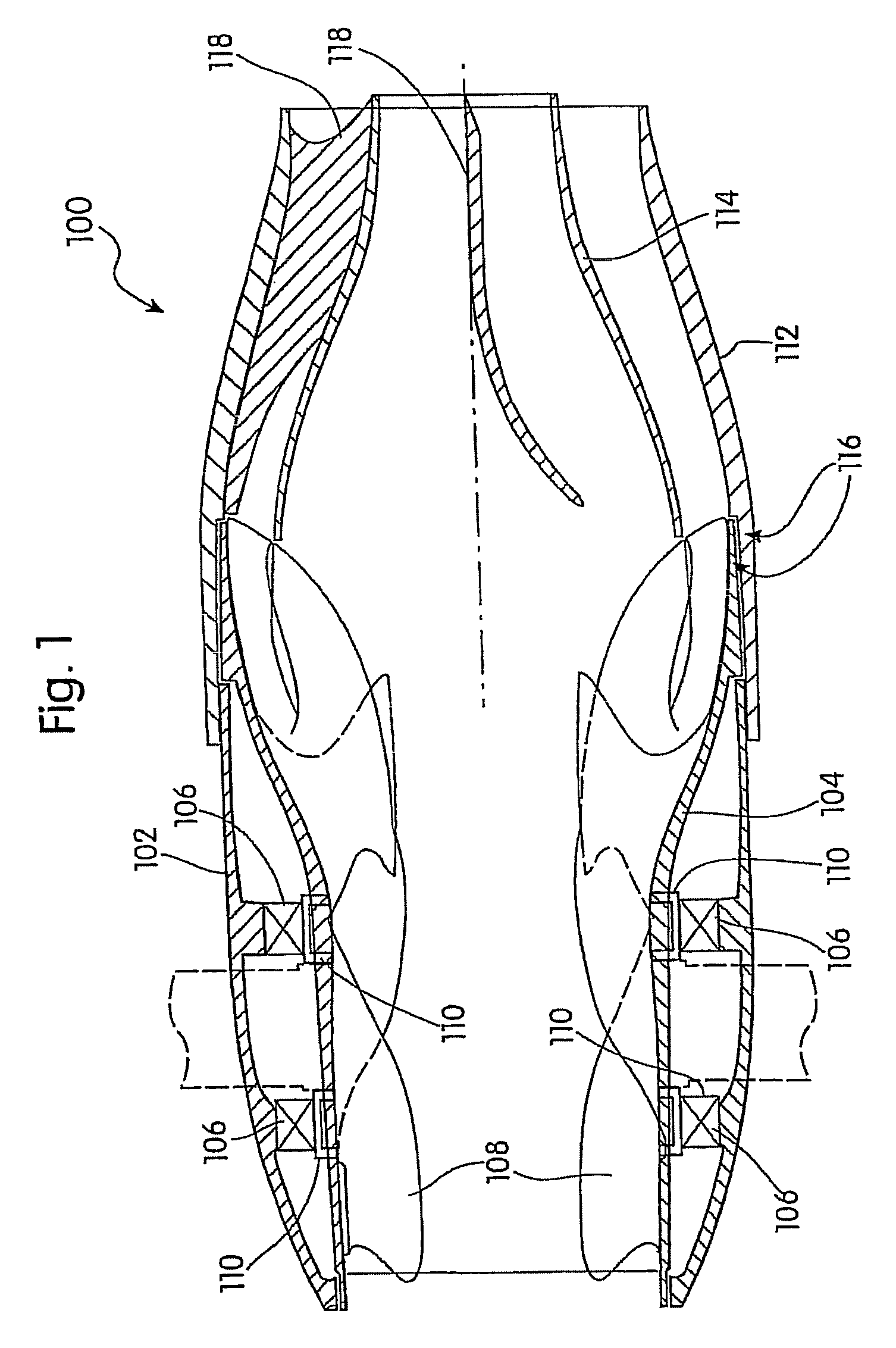

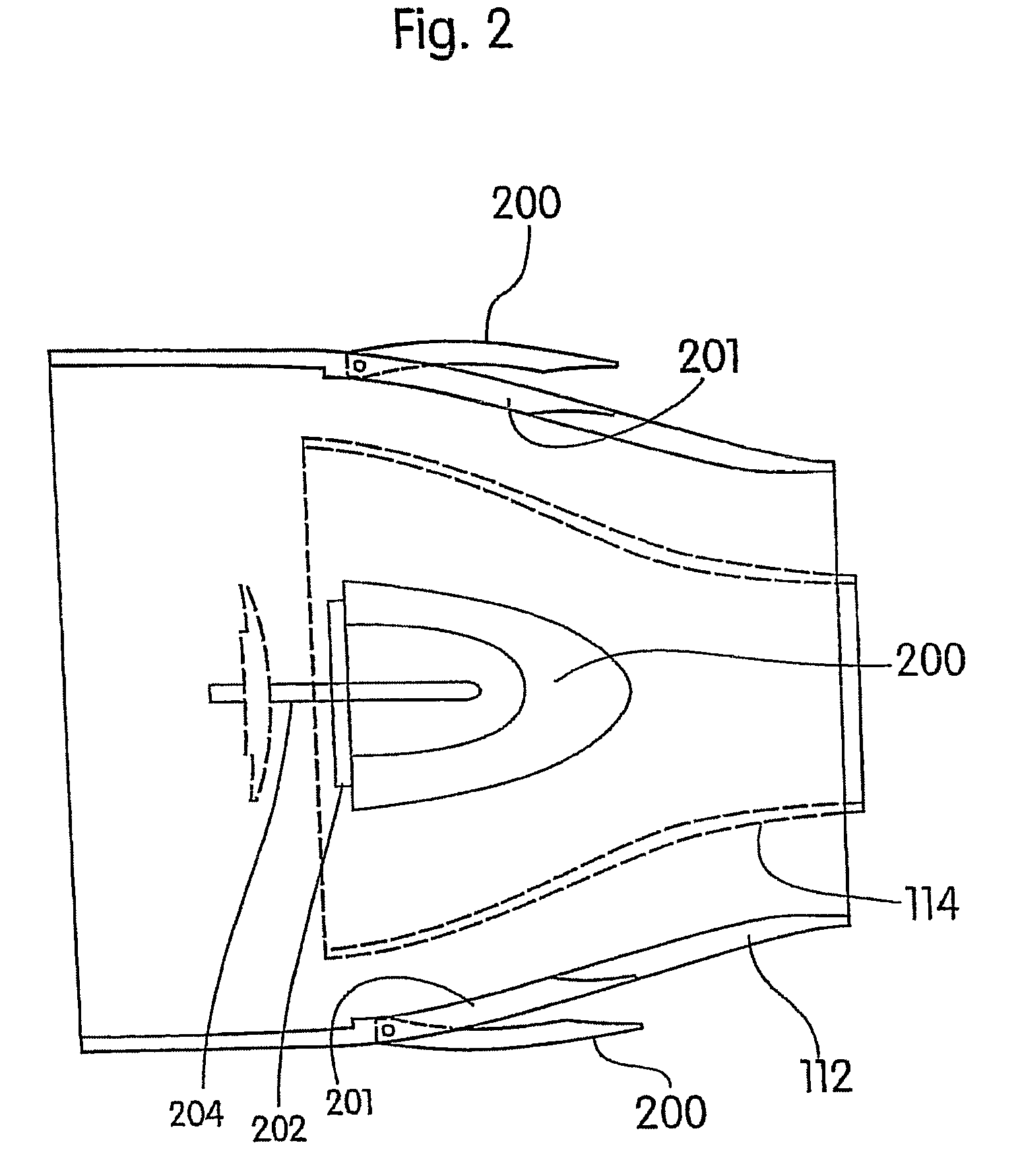

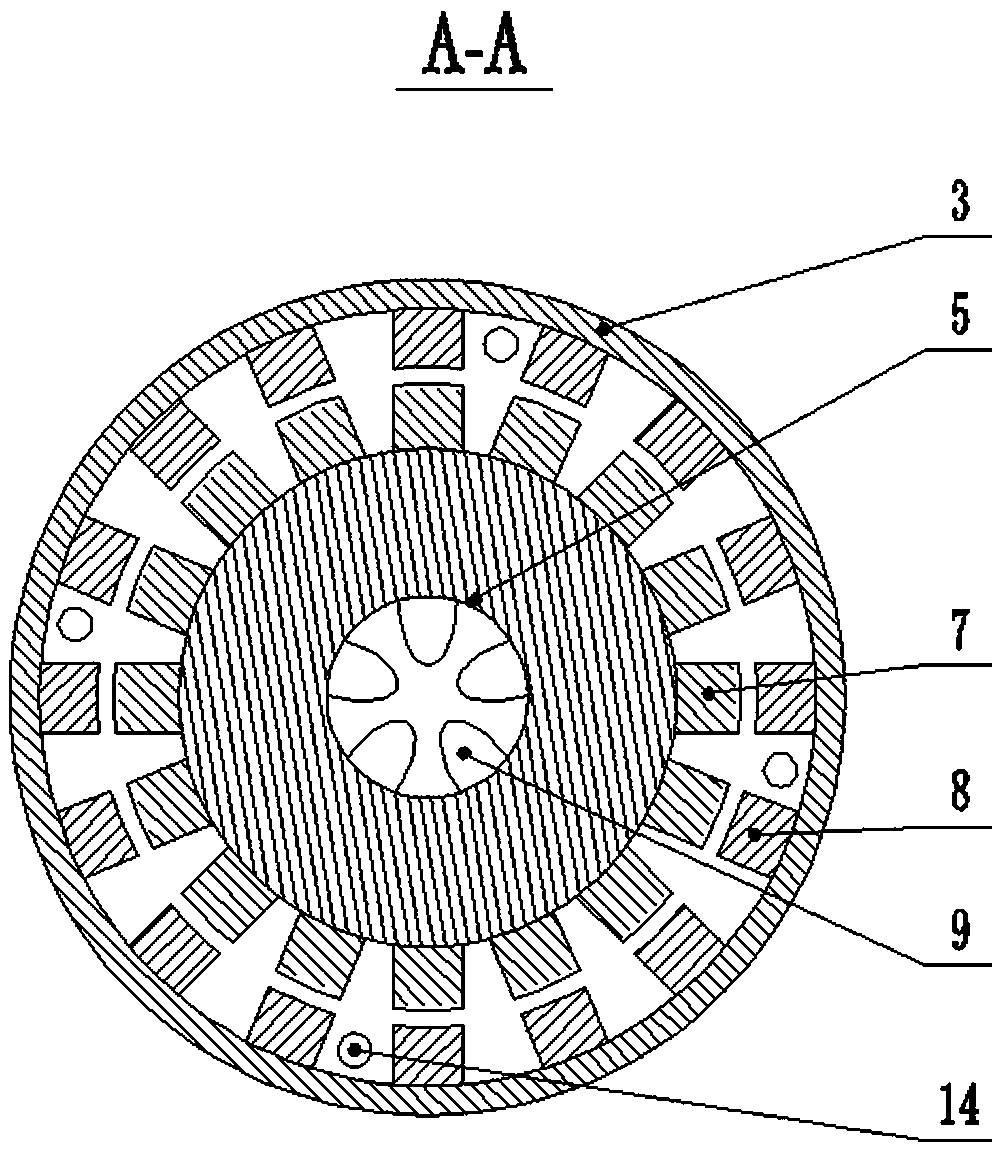

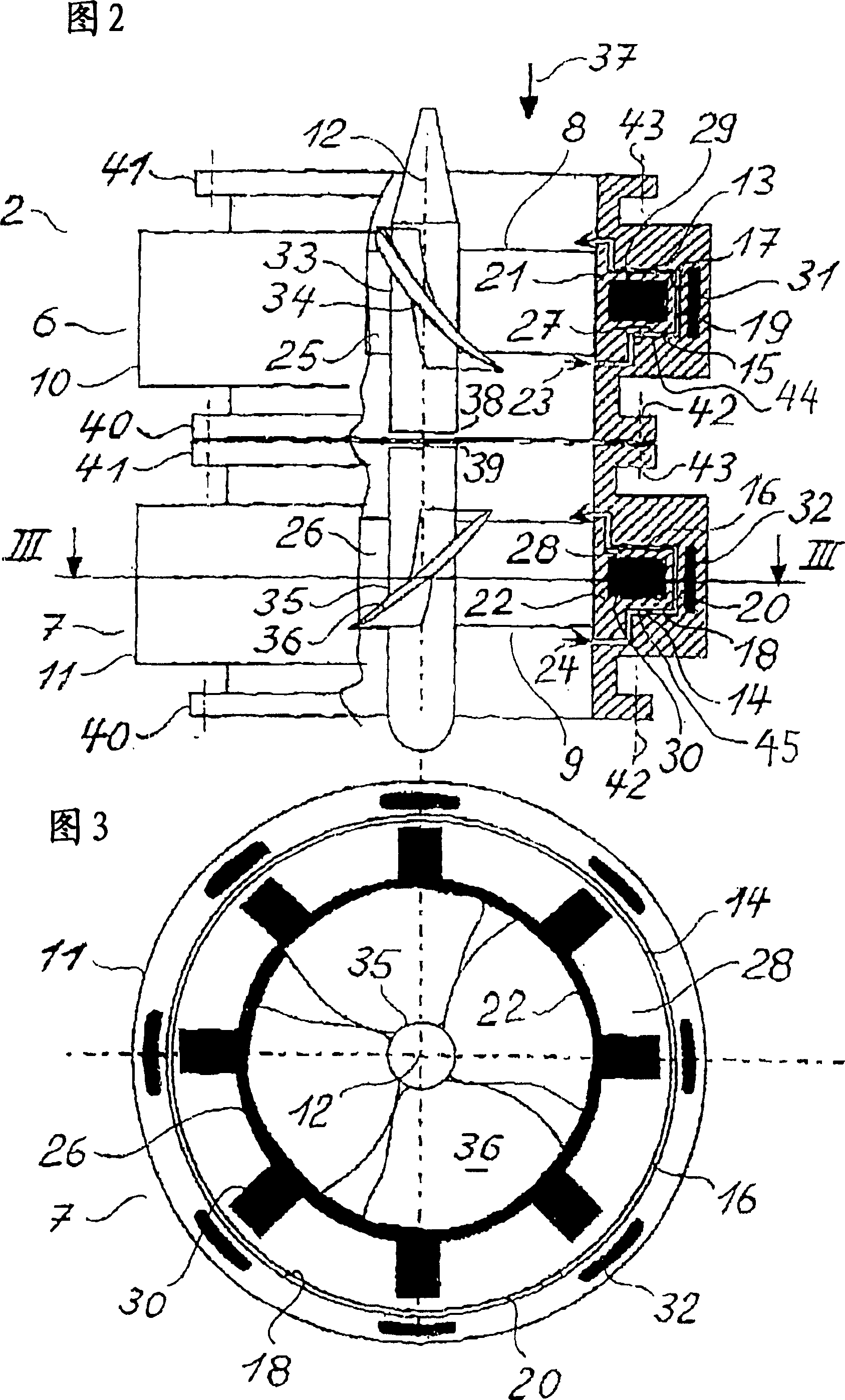

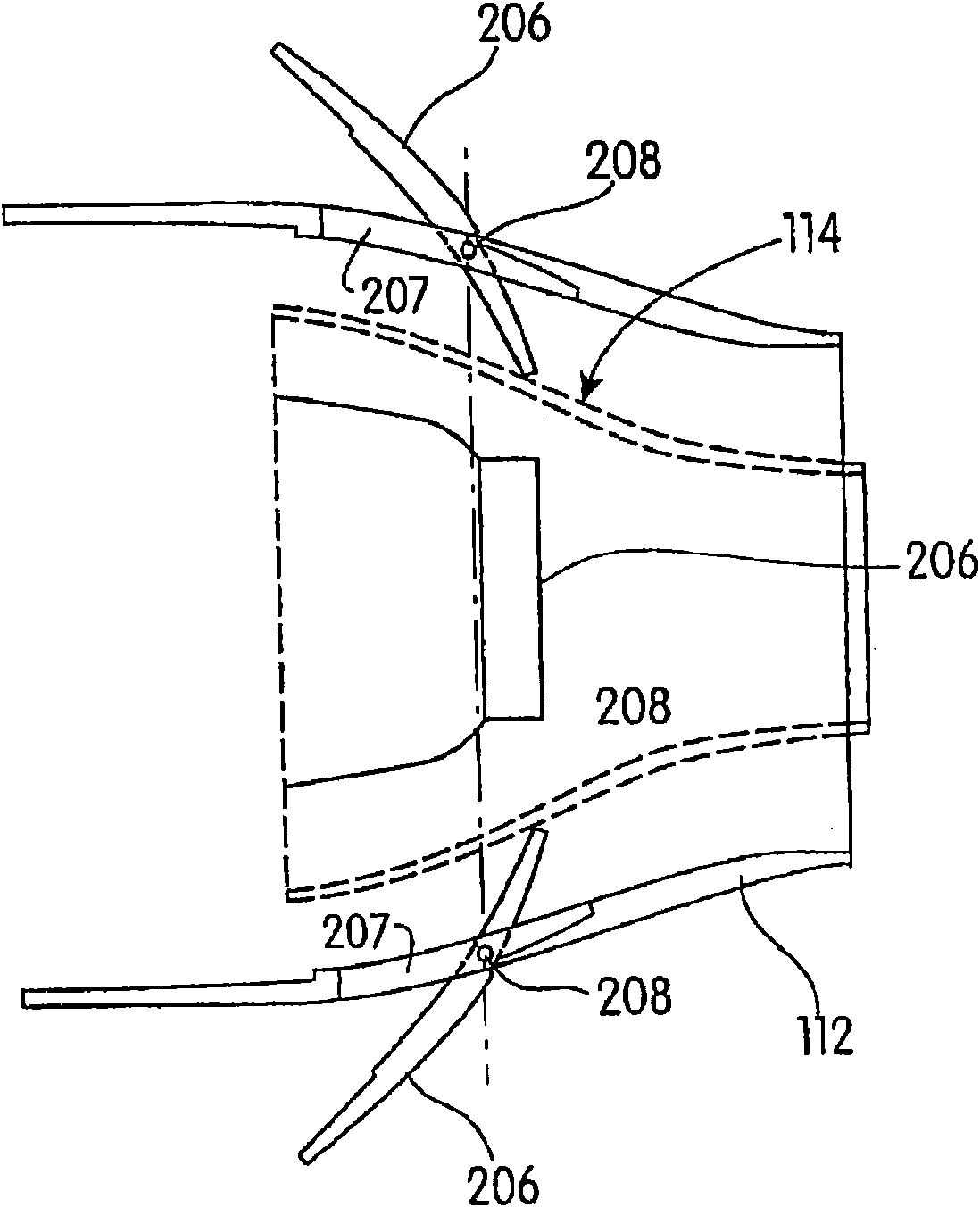

Submarine with a propulsion drive with an electric motor ring

ActiveUS8074592B2Little noiseLower resistanceRotary propellersPropulsive transmission driveWater flowSubmarine

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

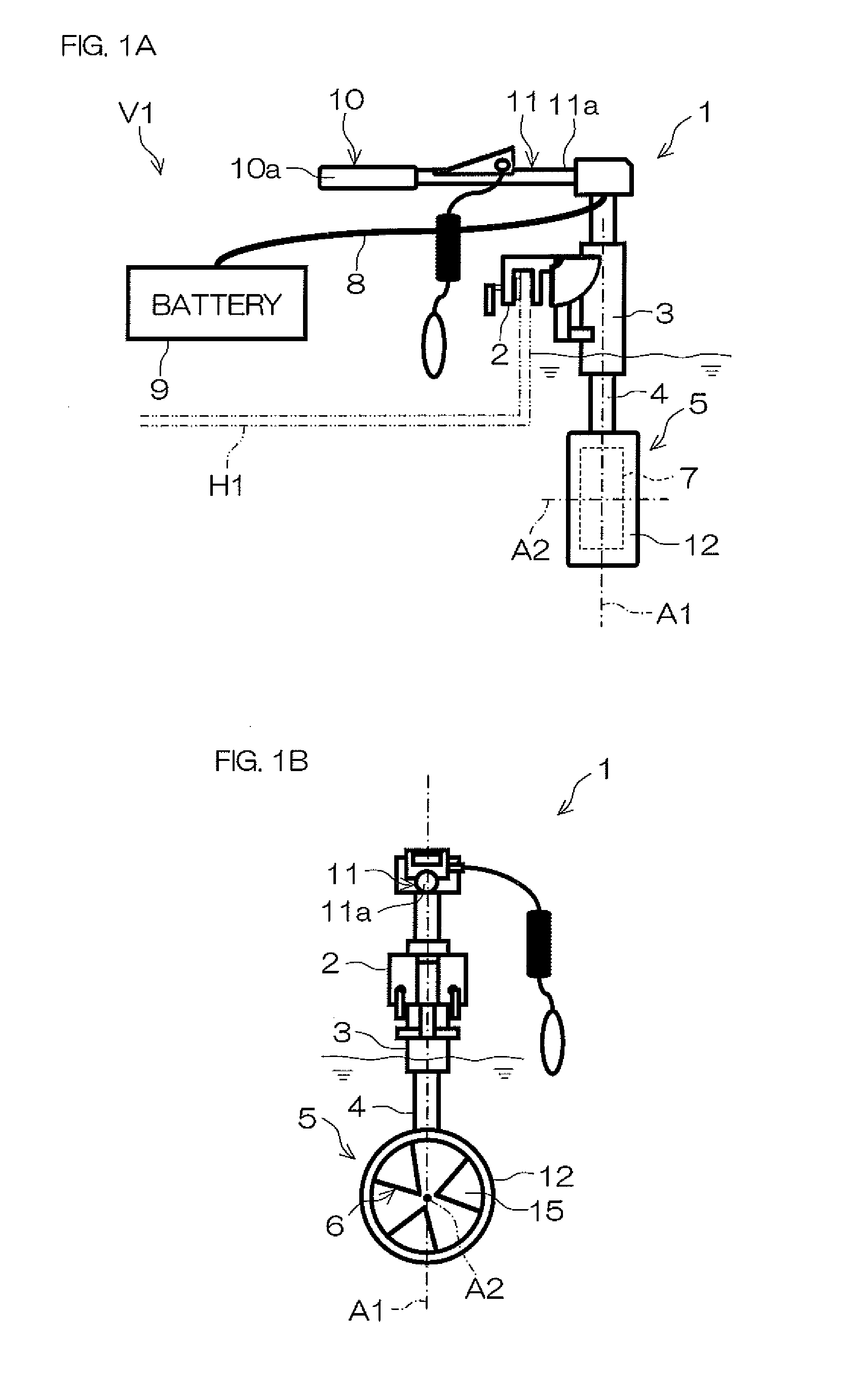

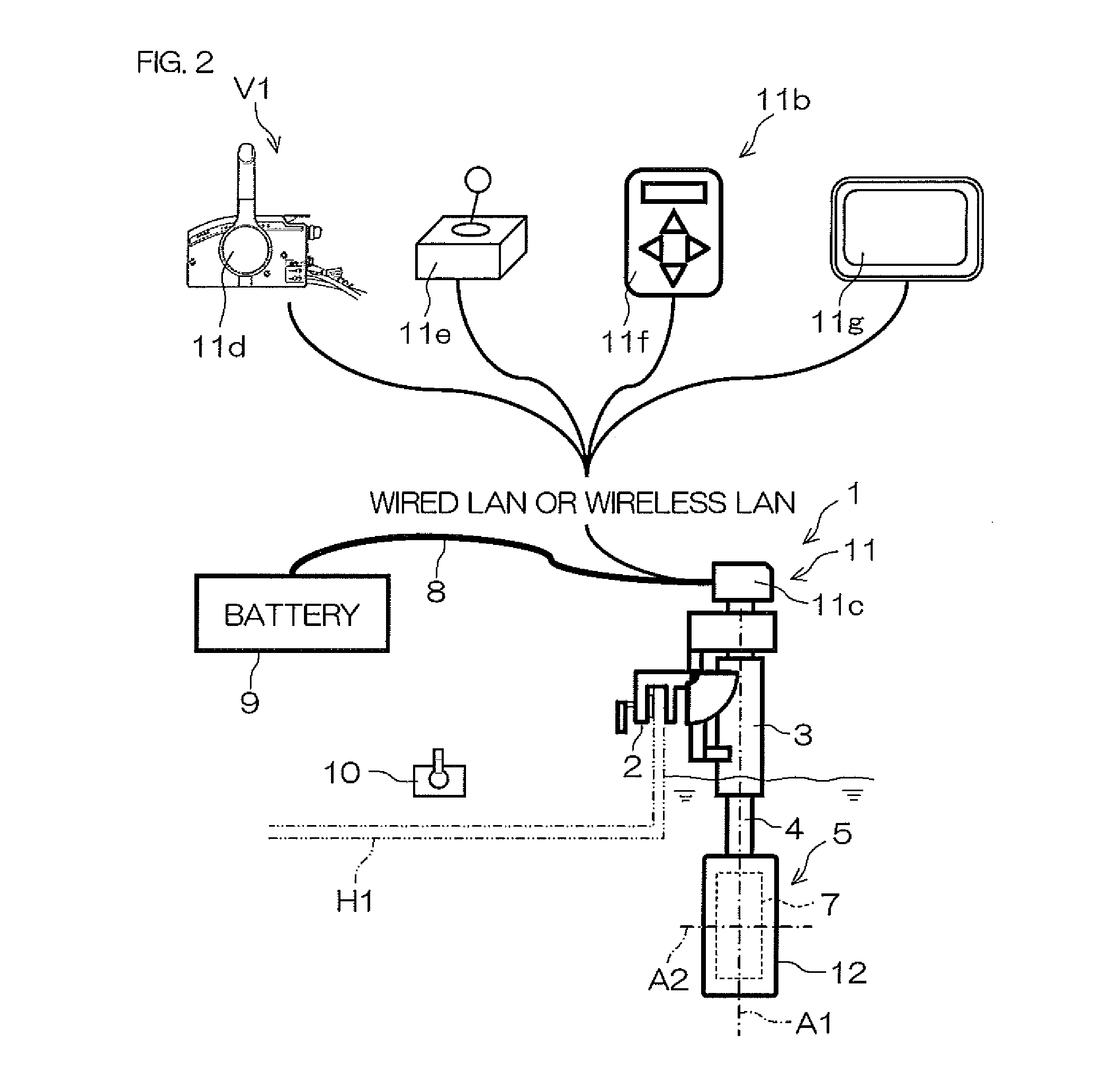

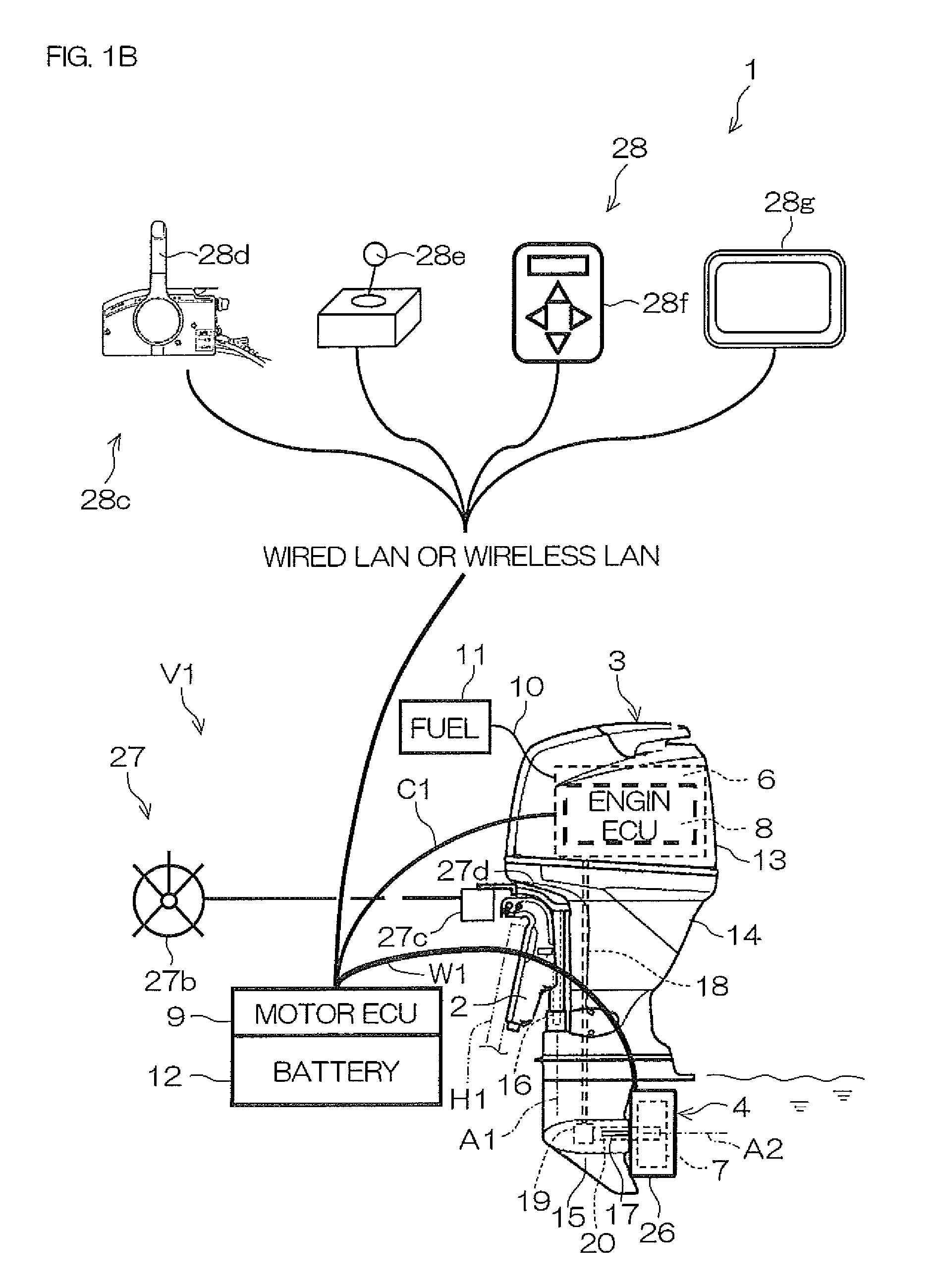

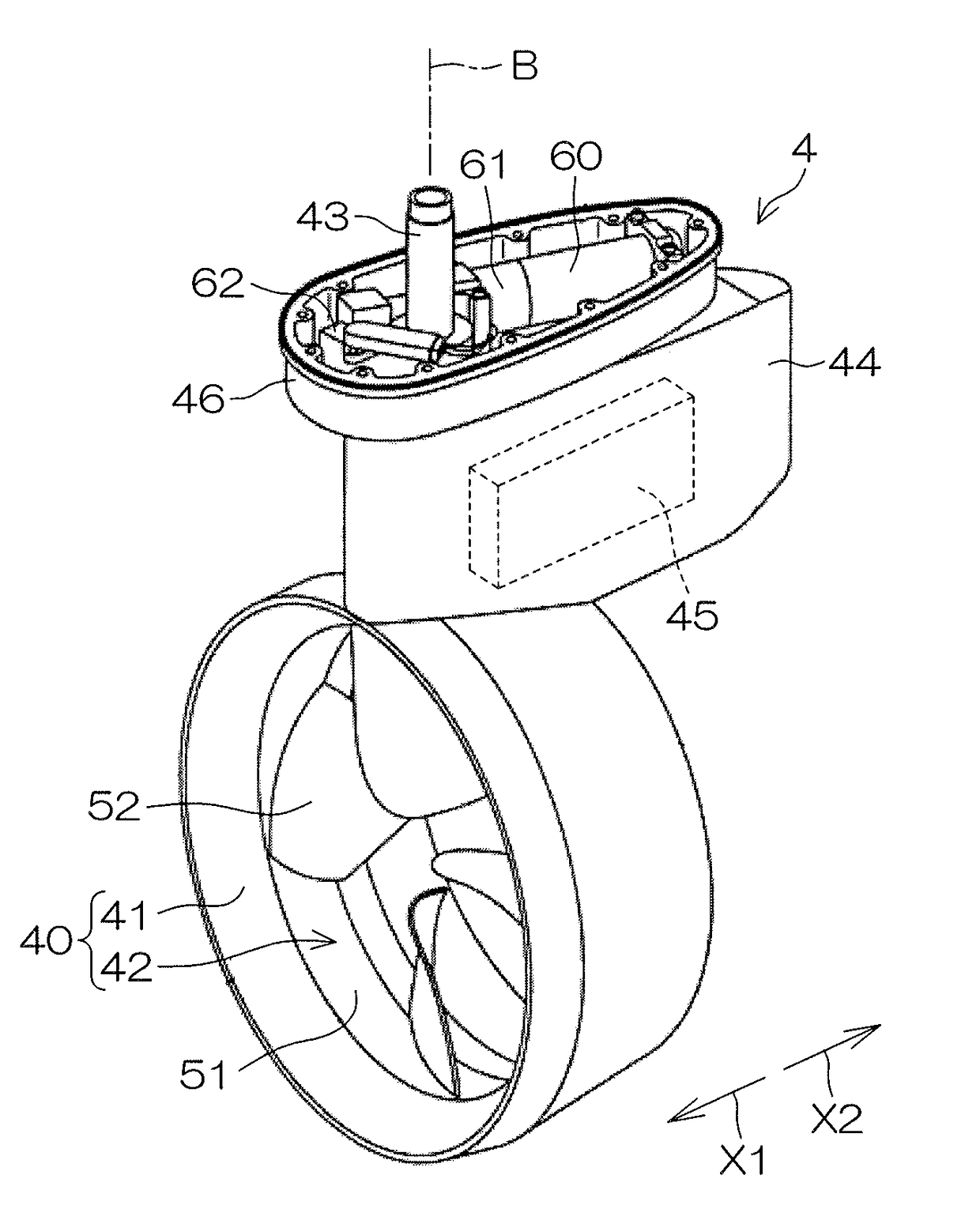

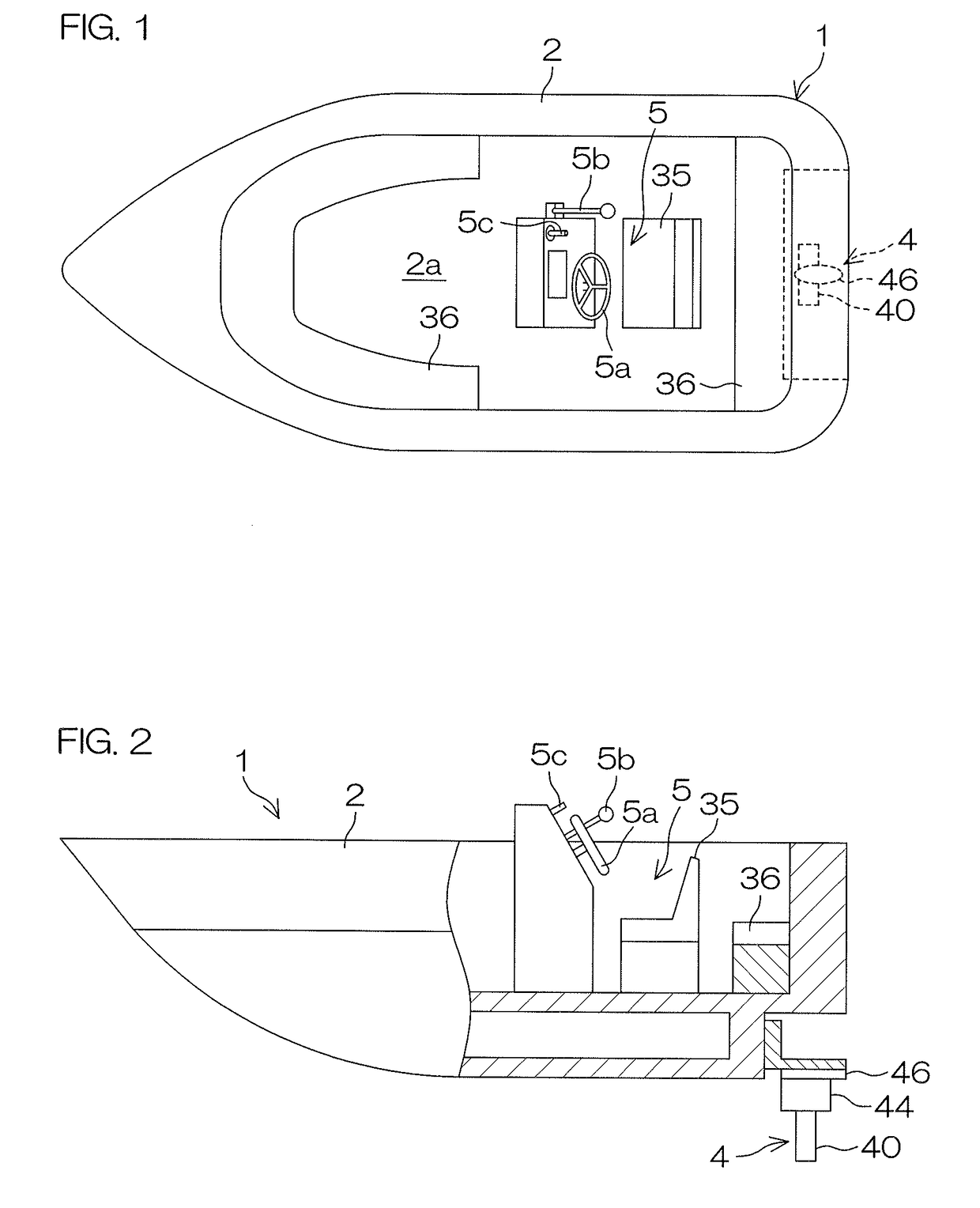

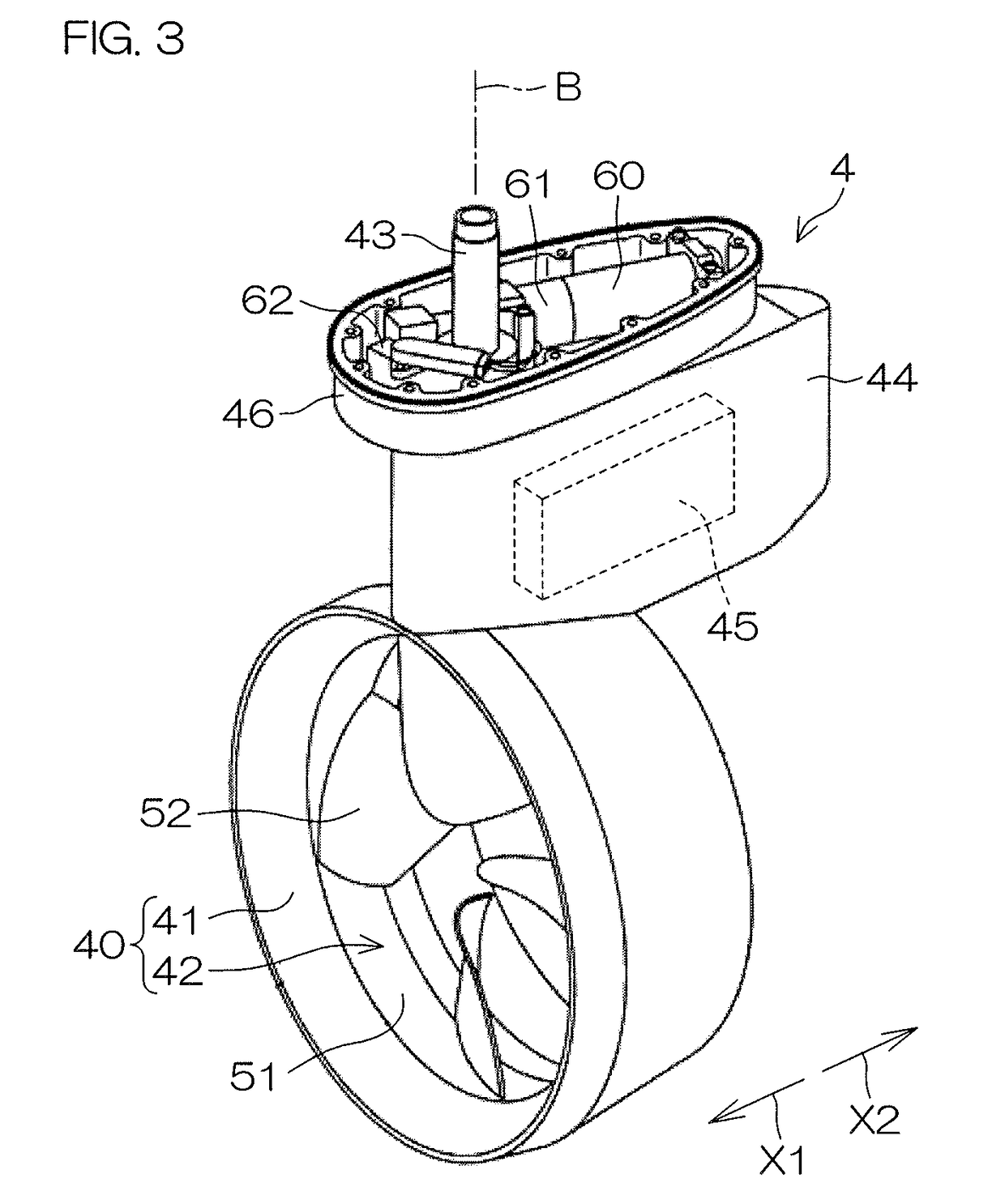

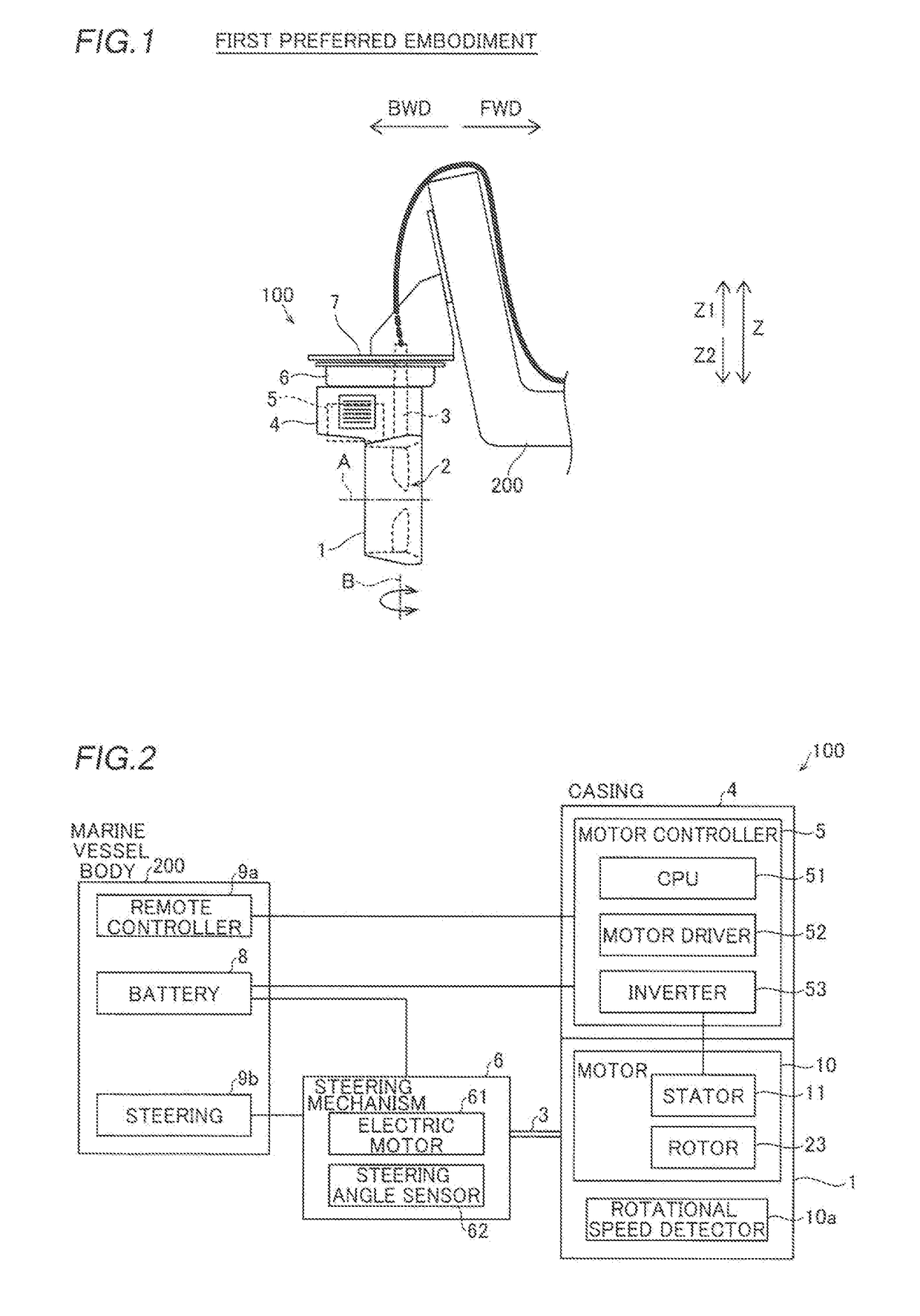

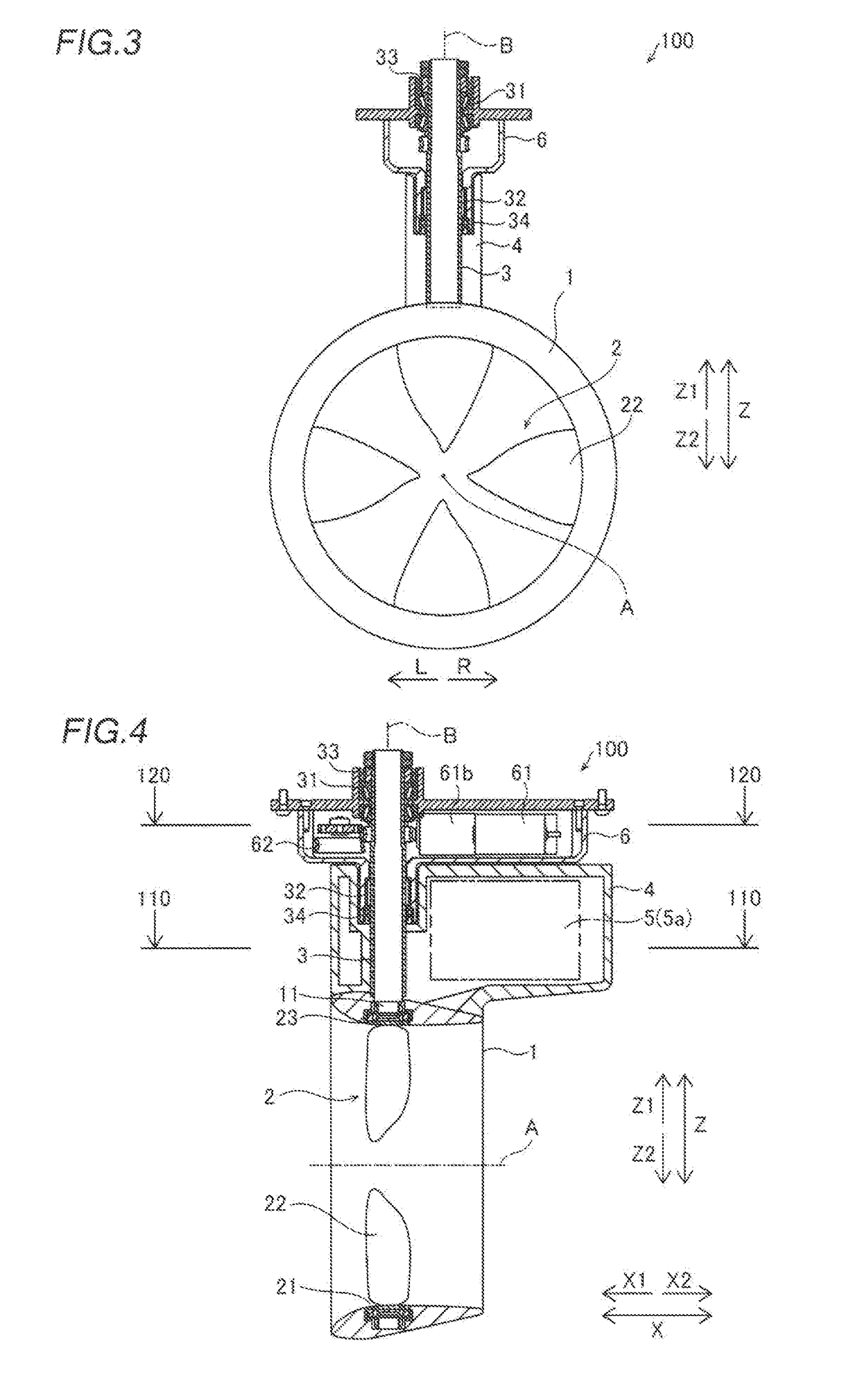

Marine vessel propulsion device

ActiveUS20130115833A1Reduce the effective areaLow efficiencyRotary propellersPropulsive transmission drivePropellerElectric motor

A marine vessel propulsion device includes a bracket that is attachable to a marine vessel, a duct that is rotatable around a steering axis with respect to the bracket, a propeller that is rotatable with respect to the duct around a propeller axis extending in a direction perpendicular or substantially perpendicular to the steering axis, and an electric motor that rotates the propeller. The propeller includes a plurality of blades and a cylindrical rim that surrounds the plurality of blades, and is surrounded by the duct. The electric motor rotates the rim with respect to the duct.

Owner:YAMAHA MOTOR CO LTD

Submarine with a propulsion drive with an electric motor ring

ActiveUS20090293795A1High power outputImprove efficiencyRotary propellersPropulsive transmission driveWater flowSubmarine

In one aspect, a submarine with a boat hull and a propulsion drive for the submarine the propulsion drive is arranged outside the boat hull and comprises a housing and a first electric motor, with the housing embodying a channel for a flow of water through the channel in a main direction of flow from an inlet to an outlet of the channel, and with the first electric motor featuring a rotor which is arranged in the channel and is supported rotatably around an axis of rotation in the housing, with the rotor being embodied in the shape of a ring with a ring inner side and a ring outer side, and with blades for propelling the submarine being arranged on the ring inner side of the rotor.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

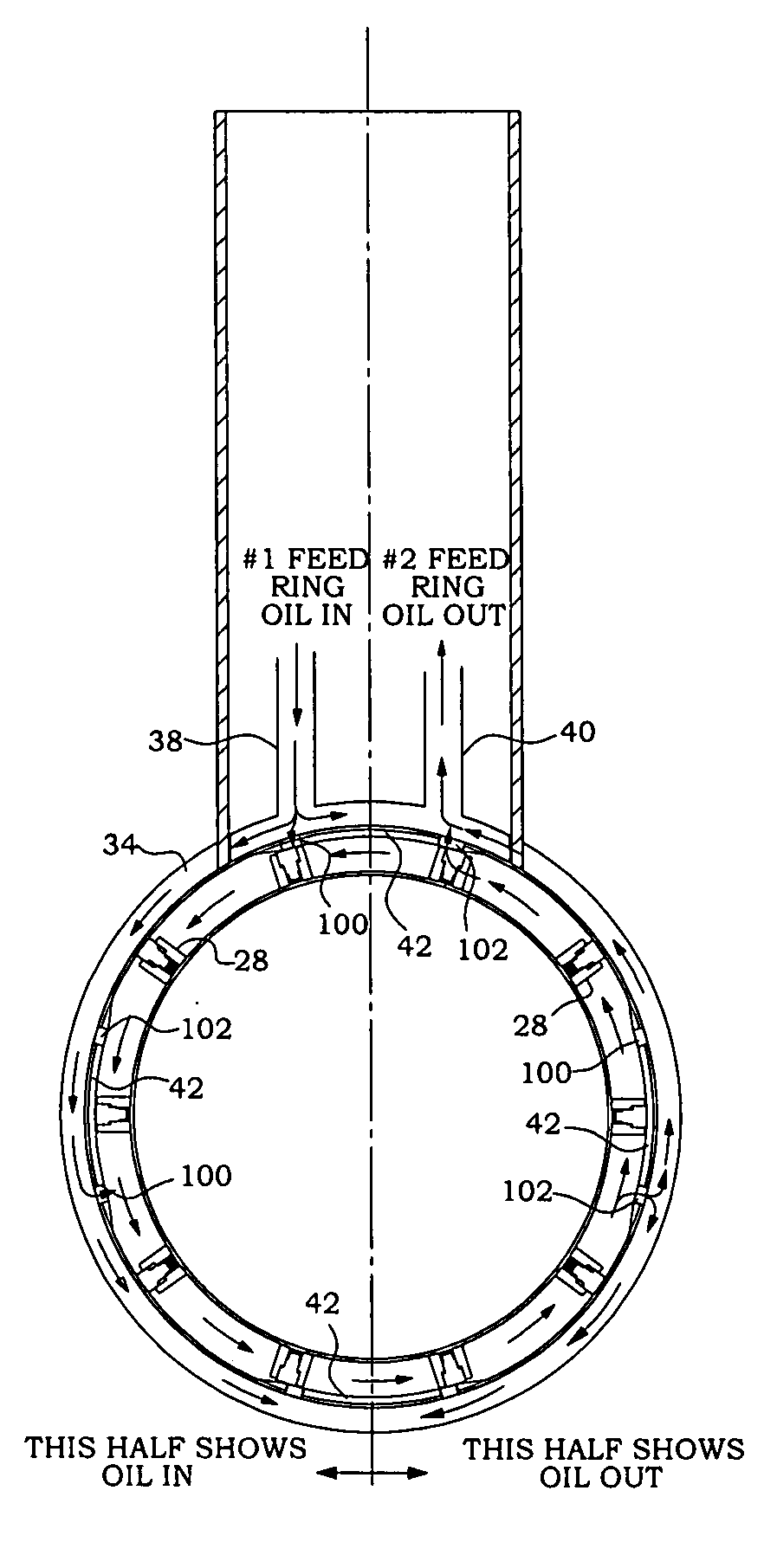

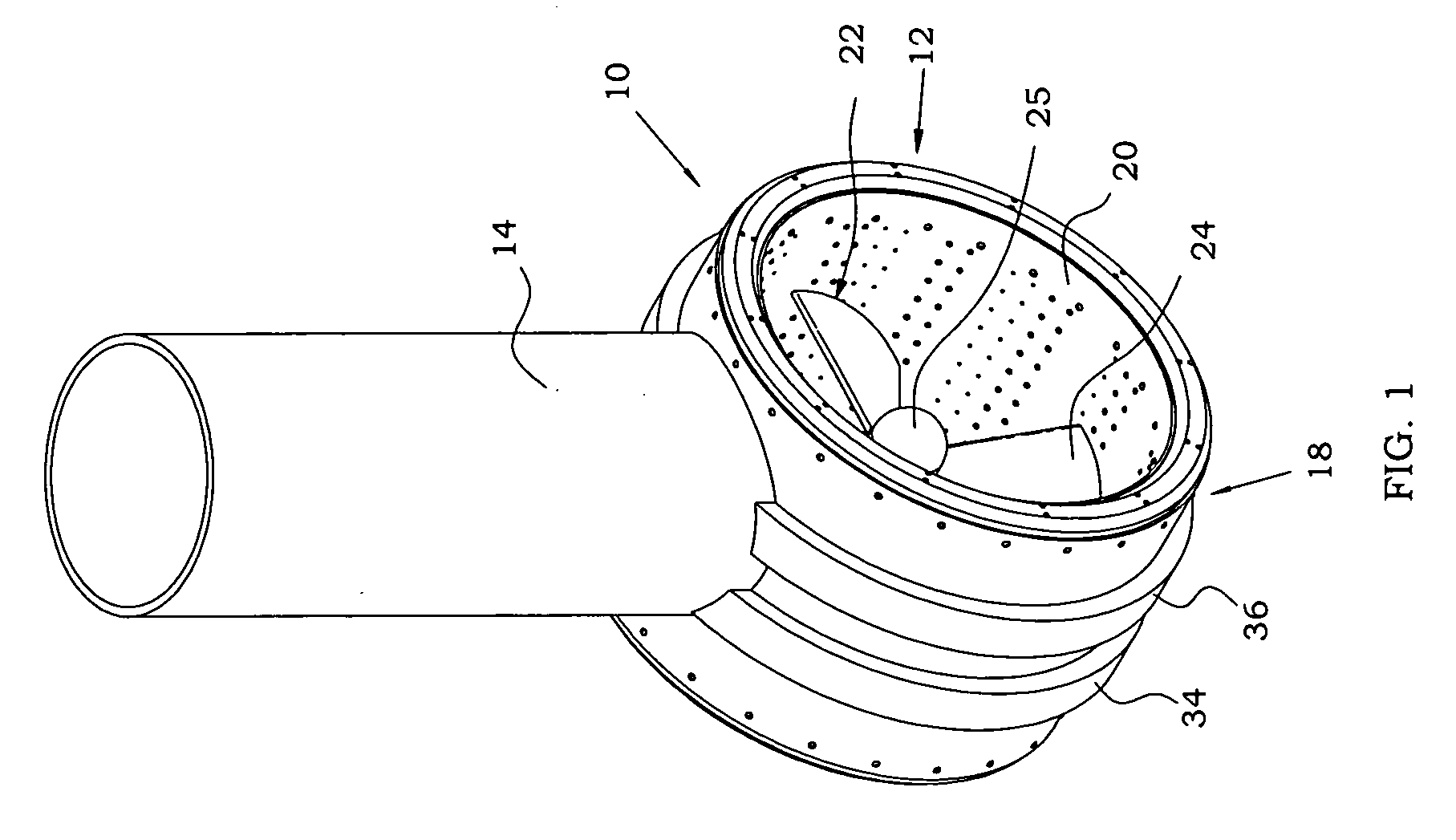

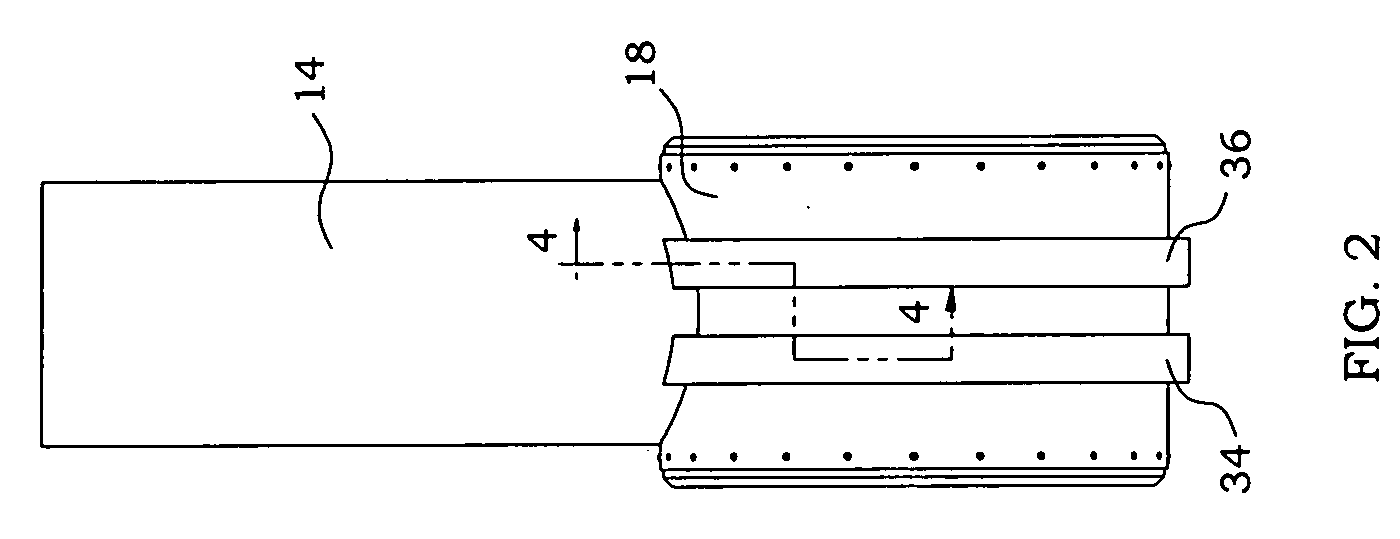

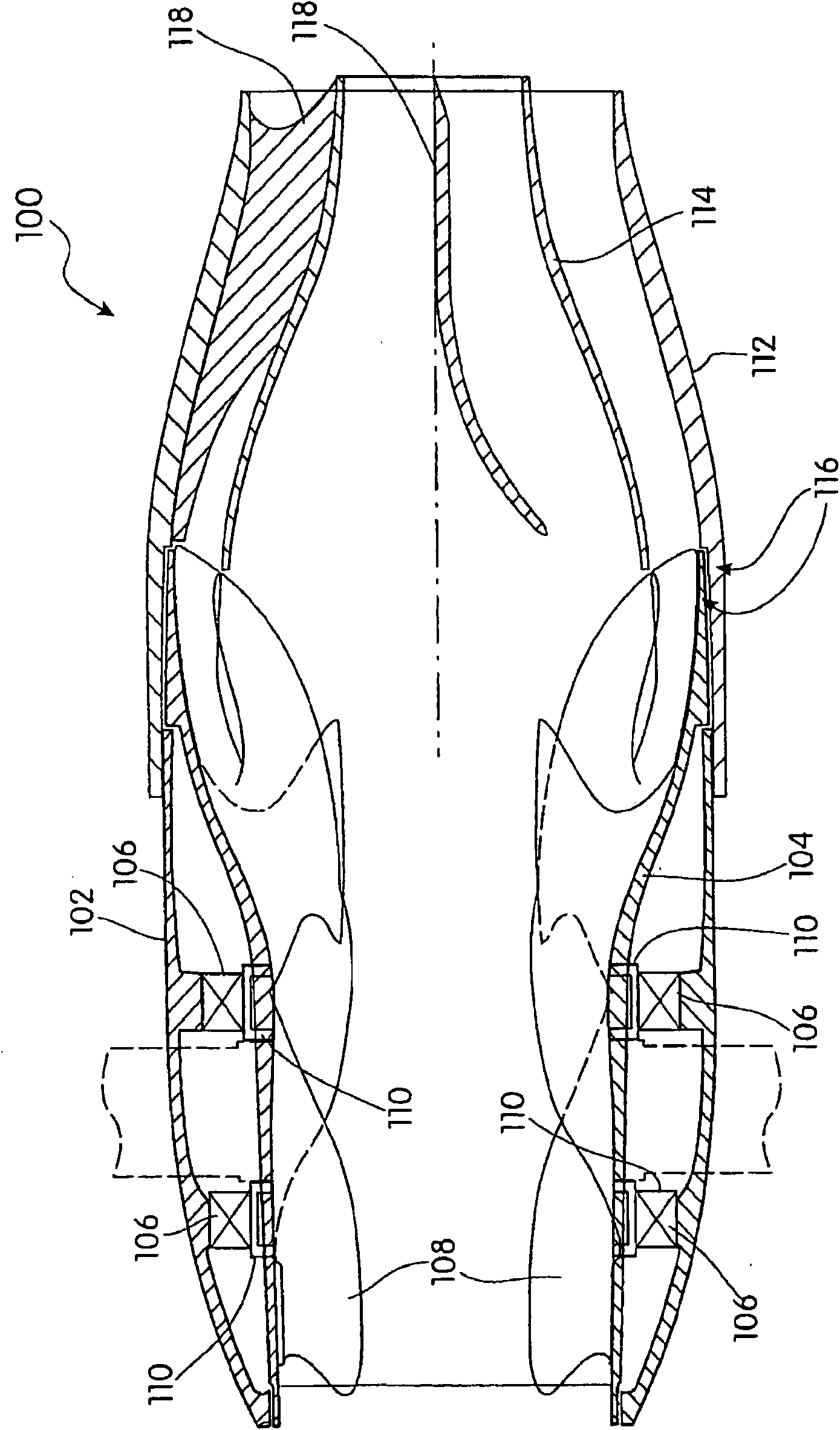

Pod propulsion system with rim-mounted bearings

A pod propulsion system comprises a housing defining a fluid duct and an annular drum rotatably mounted to the housing within the fluid duct. The annular drum has a drum interior and a cylindrical outer surface. The system further comprises a rotor mounted to the drum for rotation therewith, the rotor and the drum having a common axis of rotation. A bearing assembly mounted to the housing comprises a first bearing comprising a first plurality of bearing pads disposed circumferentially around the drum. Each pad has a pad bearing surface adapted to contact a first drum portion in a predetermined manner and is pivotably mounted to the housing so as to maintain contact of the pad bearing surface with the first drum portion in the predetermined manner when an orientation of the drum portion relative to the housing changes.

Owner:HUNTINGTON INGALLS

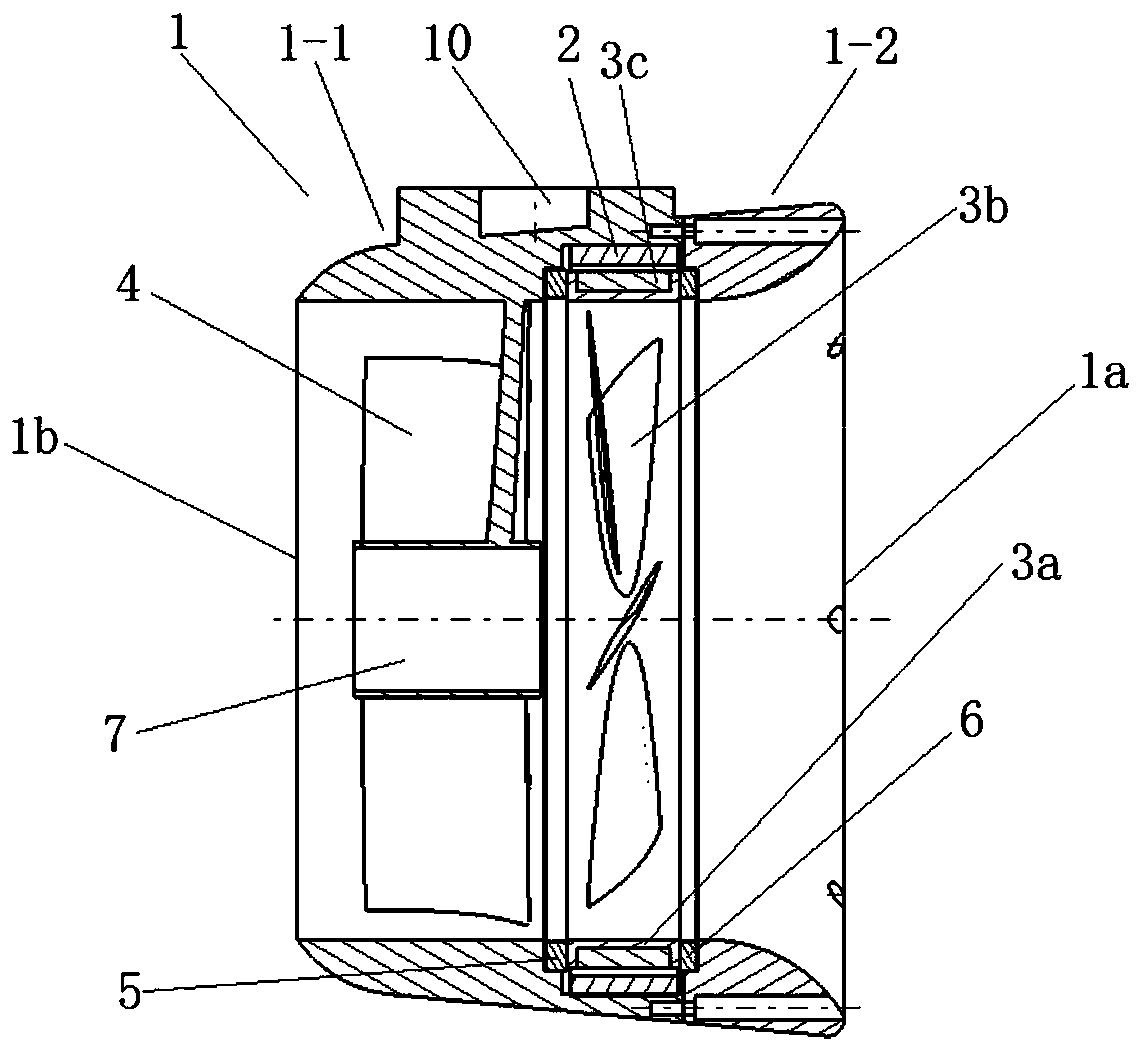

Pod type electric shaftless pump jet propeller

PendingCN110697012AAvoid complex installation and maintenanceSimple structurePropulsive transmission driveRotary propellersPump-jetElectric machine

The invention belongs to the field of underwater propellers, and particularly relates to a pod type electric shaftless pump jet propeller which comprises a flow guide pipe, a blade rotor, a stator anda flow guide static blade set. The stator is of a circular ring structure and is fixedly installed in an inner cavity of the flow guide pipe. The blade rotor and the flow guide static blade set are sequentially installed in an inner cavity of the flow guide pipe in the direction from the upstream end to the downstream end of the flow guide pipe, and the blade rotor is arranged in the stator in arunning fit mode. And the flow guide pipe is provided with a pod type mounting position. Complex shafting transmission installation and maintenance can be avoided, meanwhile, electric drive is adopted, the motor and the rotor blades are integrated, and the structure is simple; the flow guide static blade set is arranged to achieve the water spraying effect.

Owner:陆一霆

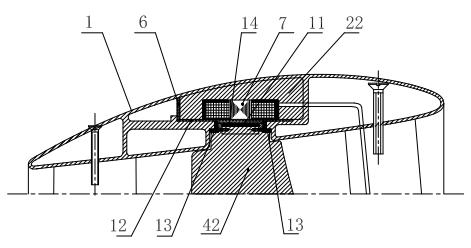

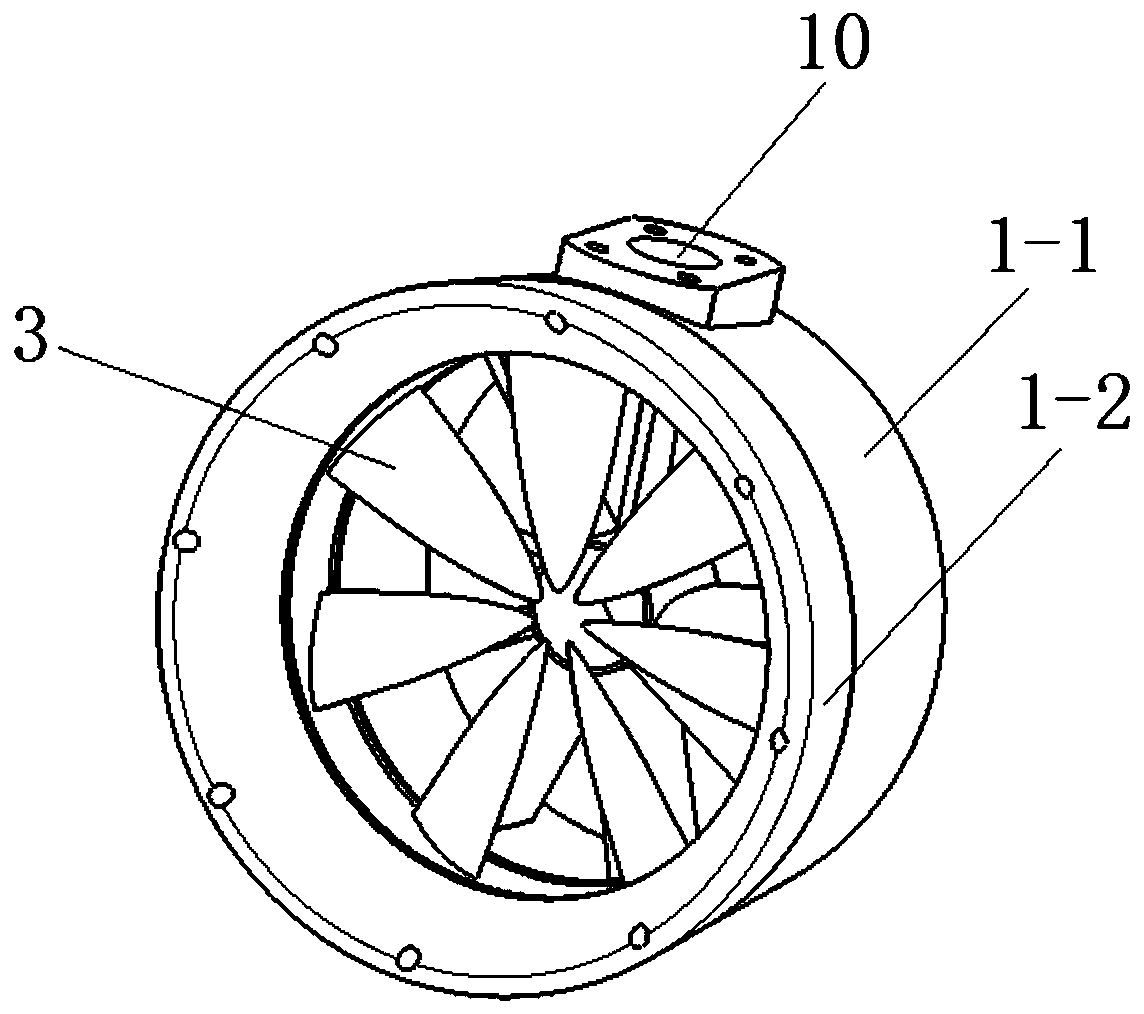

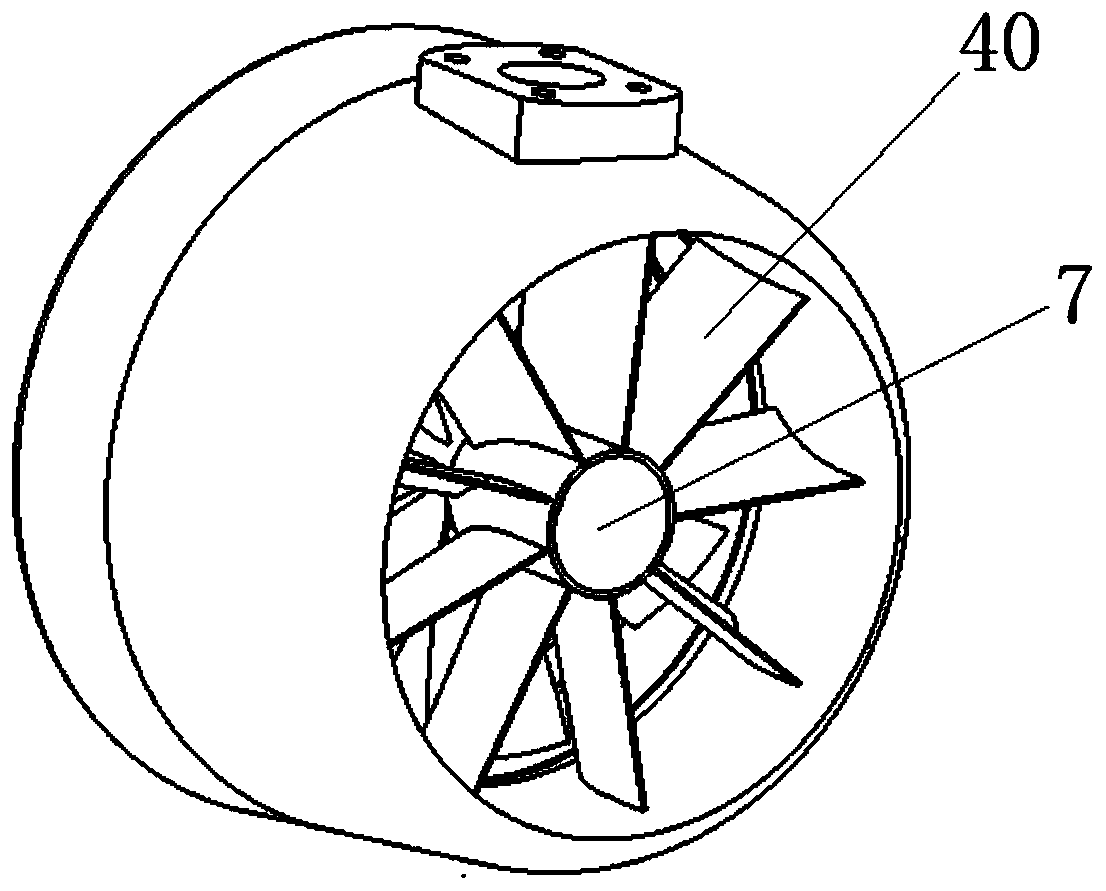

Pod type rim propeller

InactiveCN111017178AEliminate cavitationFacilitate the promotion of integrated modular designPropulsion power plantsOutboard propulsion unitsNacelleMarine propulsion

The invention discloses a pod type rim propeller, and belongs to the field of ship propulsion. The propeller structurally comprises a support, a nacelle, a stator, a guide pipe and blades. The upper end of the support is connected with a ship body, the lower end of the support is connected with the nacelle, the nacelle is fixedly connected with a shaft of the stator, the tip end of the stator is fixedly connected with the inner wall of the annular guide pipe, the blades are installed at the annular center of the guide pipe, a motor stator winding is installed in the guide pipe, and the motor rotor is installed at the root of the blades. According to the invention, the application of the shaftless propeller is expanded, and the concept of omnibearing propelling is applied to rim propelling;complex mechanical transmission in the nacelle is eliminated, and a motor stator and a motor rotor of the rim propeller are sealed respectively without dynamic sealing. A shaftless concept is added into the design of the nacelle propeller, so that the cavitation problem of a blade tip is eliminated; according to the rim-driven propeller, the nacelles are integrated together through the stator, propelling and steering are combined, omnibearing propelling can be achieved, and ship propelling integrated modular design is facilitated.

Owner:HARBIN ENG UNIV

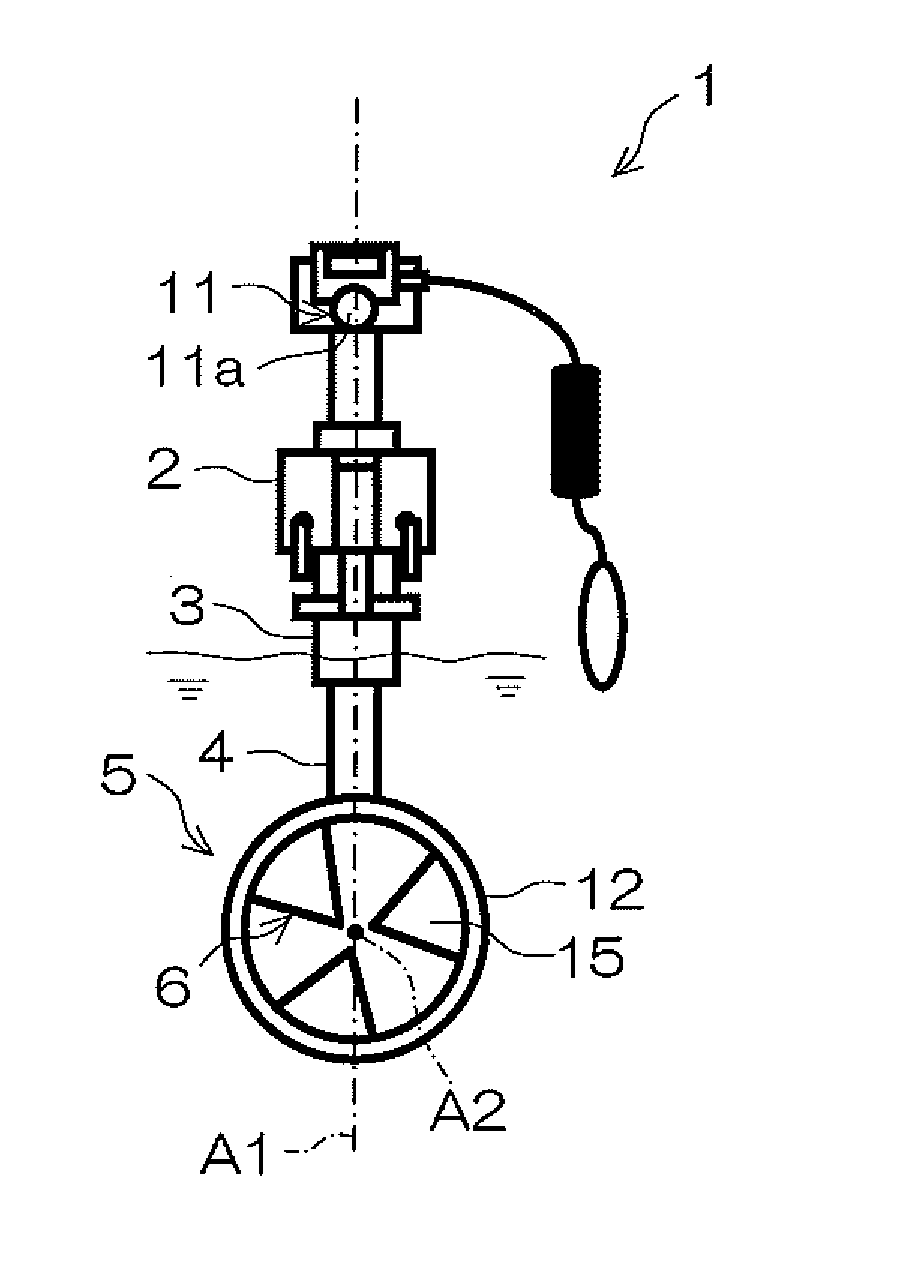

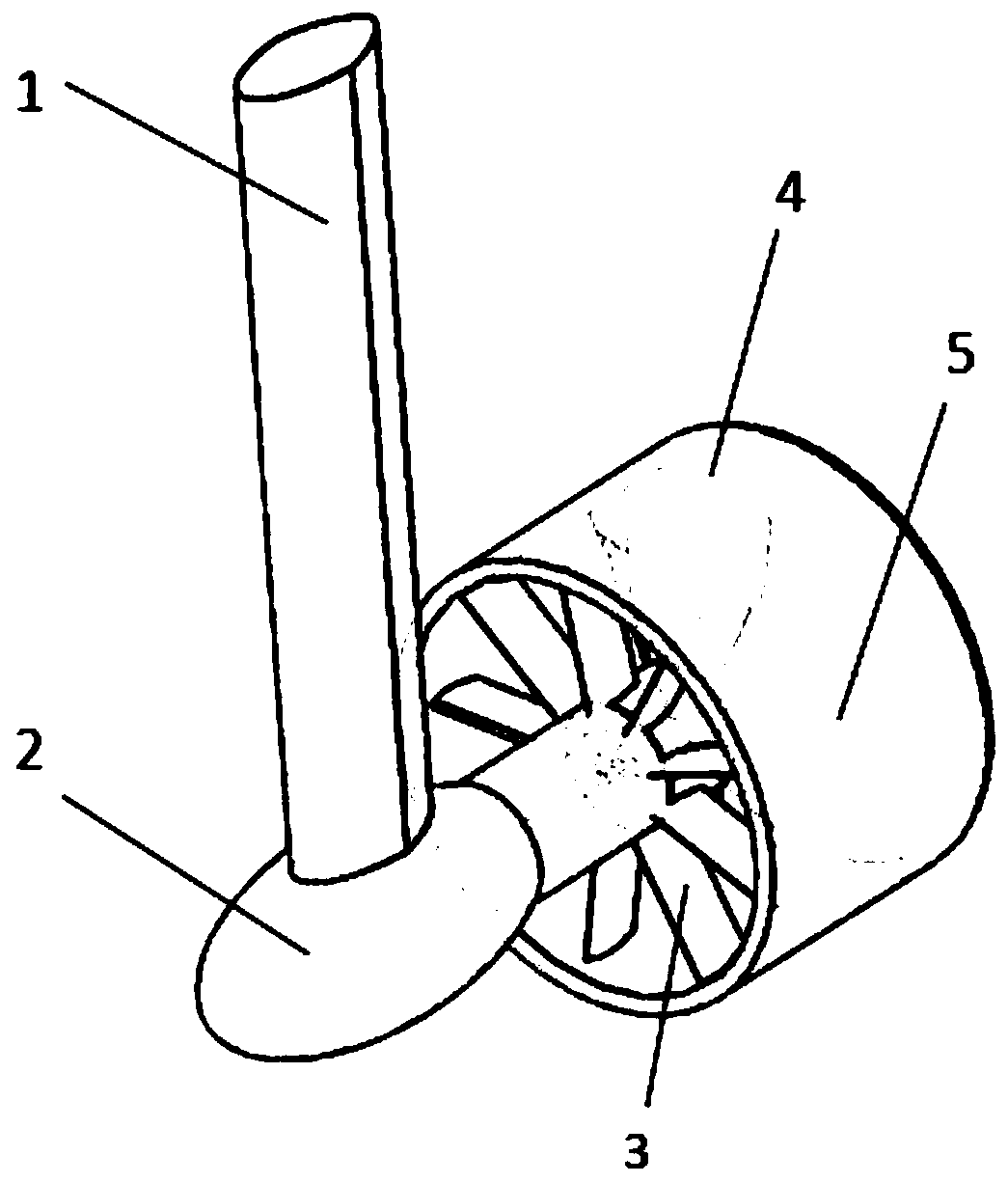

Lateral thruster unit for marine vessels

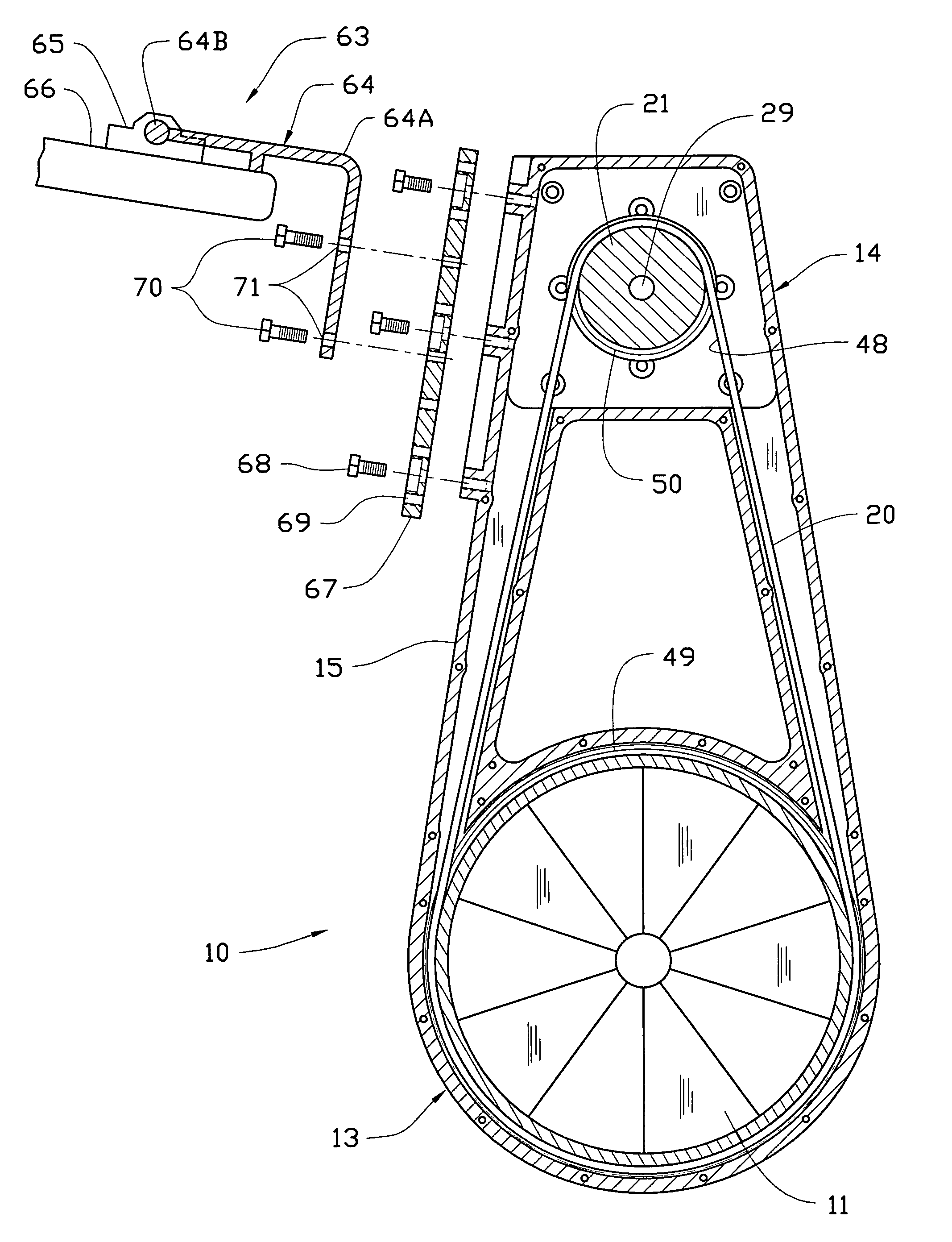

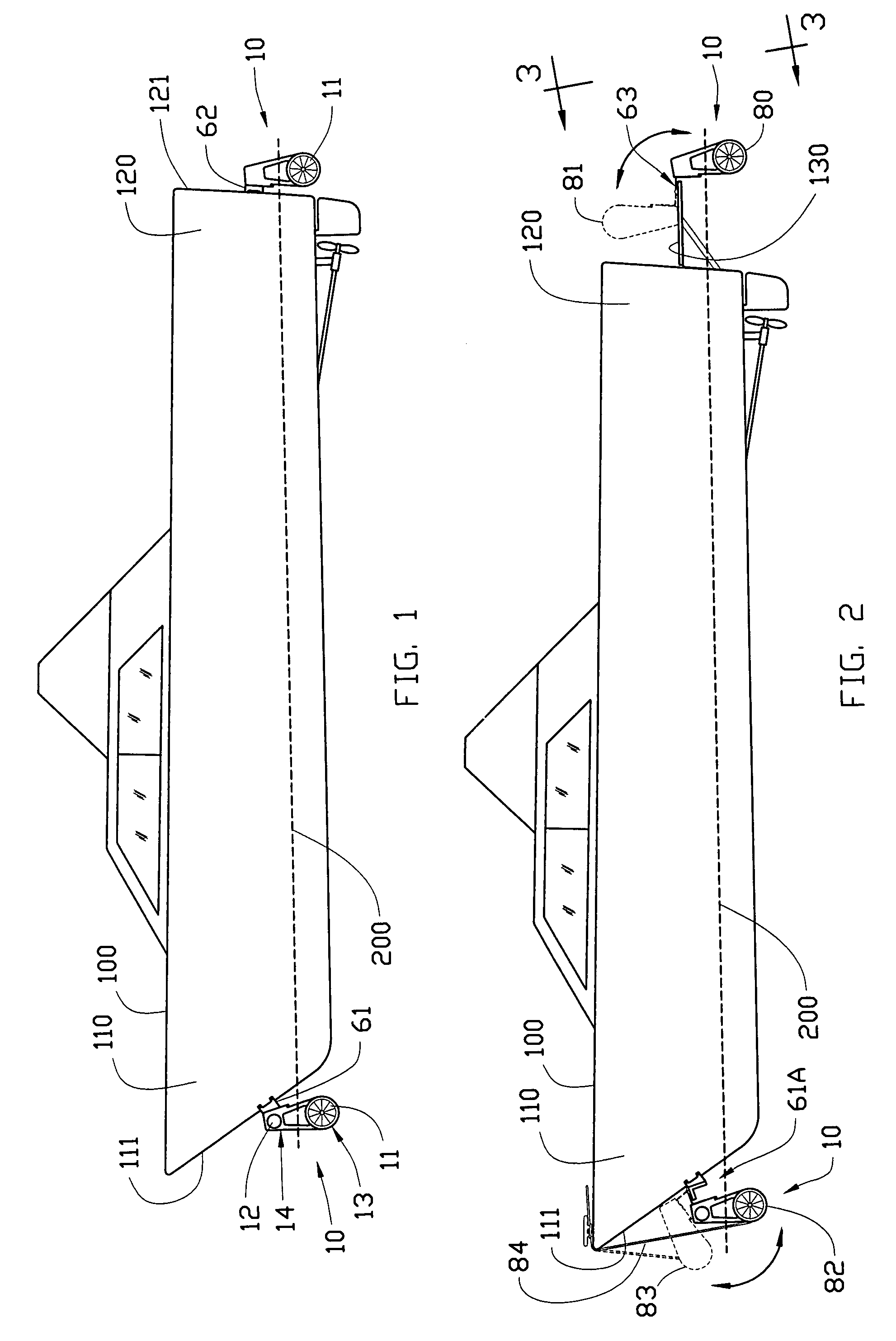

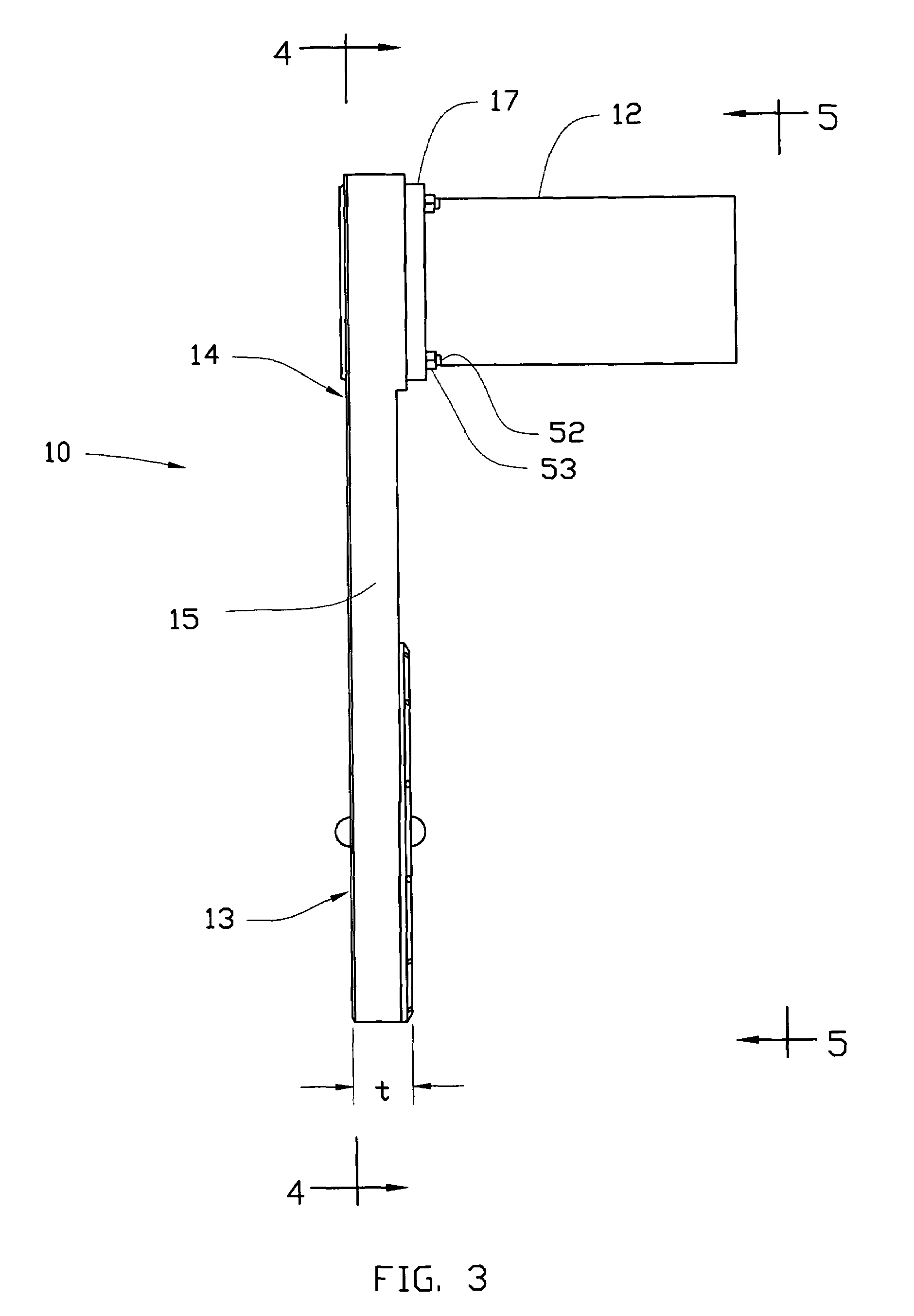

InactiveUS7530319B1Easy to installSimple yet reliablePropulsive transmission driveRotary propellersRolling-element bearingPropeller

A thruster unit for generating side thrust for improved maneuverability of a marine vessel employs a peripherally-driven propeller situated below the waterline and remotely powered by a motor situated above the waterline via a flexible drive member. The propeller is supported by a rolling element bearing disposed circumferentially around the outer perimeter of the propeller providing both axial and radial support. The lower portion disposed for submerged operation has a substantially thin cross section with a narrow thickness aligned transversely to the vessel to operate hydro-dynamically while the vessel is underway. This makes it possible for the present invention to remain in the operating position indefinitely even while the vessel is in motion without risking a structural damage. The thruster unit can be installed on the vessel using a hinged bracket assembly such that during the extended periods while the vessel is not operating the thruster unit may be pivoted out from the water for dry storing, safely away from the corrosion, marine growth, or any other harmful effect of the water.

Owner:HA DON DONGCHO

Support of propeller unit for a vessel

The present invention relates to a rim driven propeller unit for a vessel, where a number of permanent magnets are arranged round the propeller unit's rotatable rotor housing, comprising a number of propeller blades, and a number of permanent magnets round the propeller unit's external, stationary casing housing the rotatable rotor housing, where the permanent magnets round parts of the rotatable rotor housing and the external, stationary casing's circumference are provided located above one another with like polarity, while other parts of the rotatable rotor housing and the external, stationary casing are provided located facing one another with opposite polarity, whereby the rotor housing and the stationary casing are repelled by and attracted to one another respectively, thereby being prevented from coming into contact with one another.

Owner:康斯博海运公司

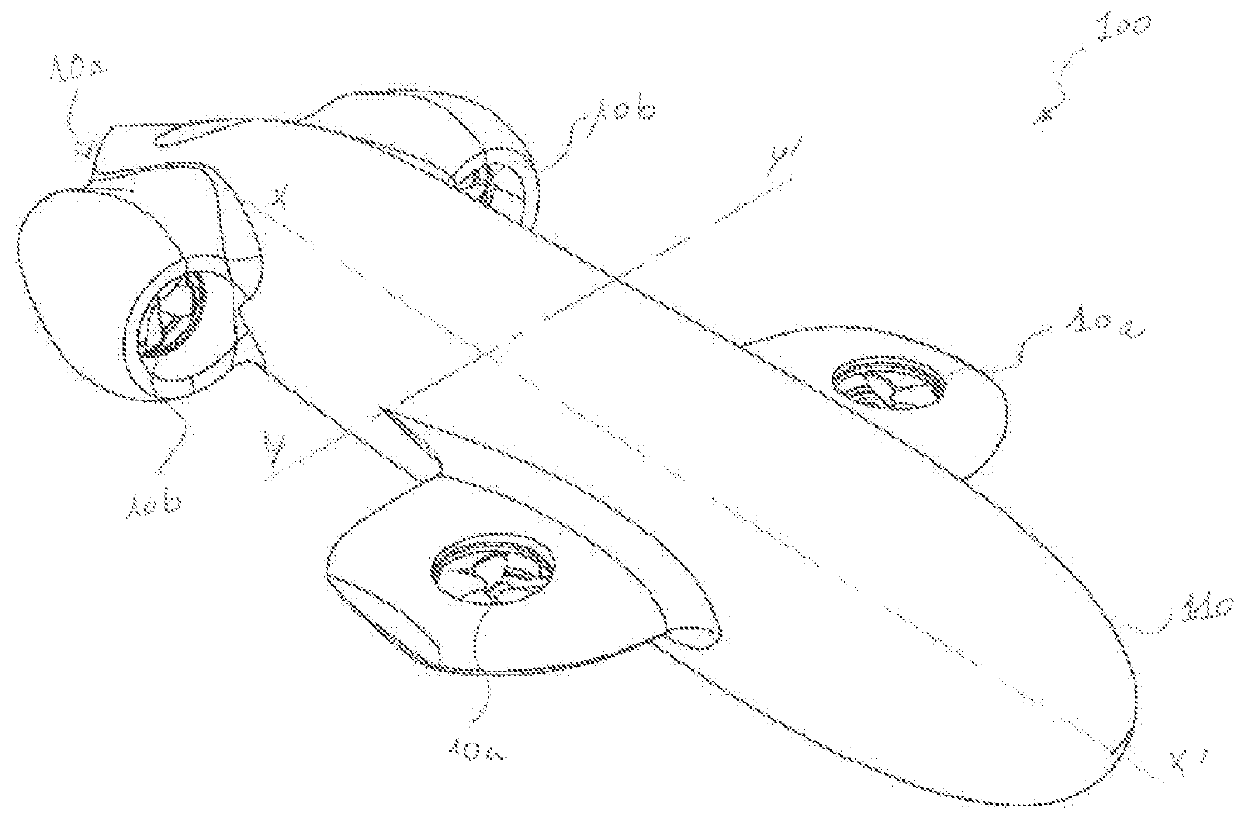

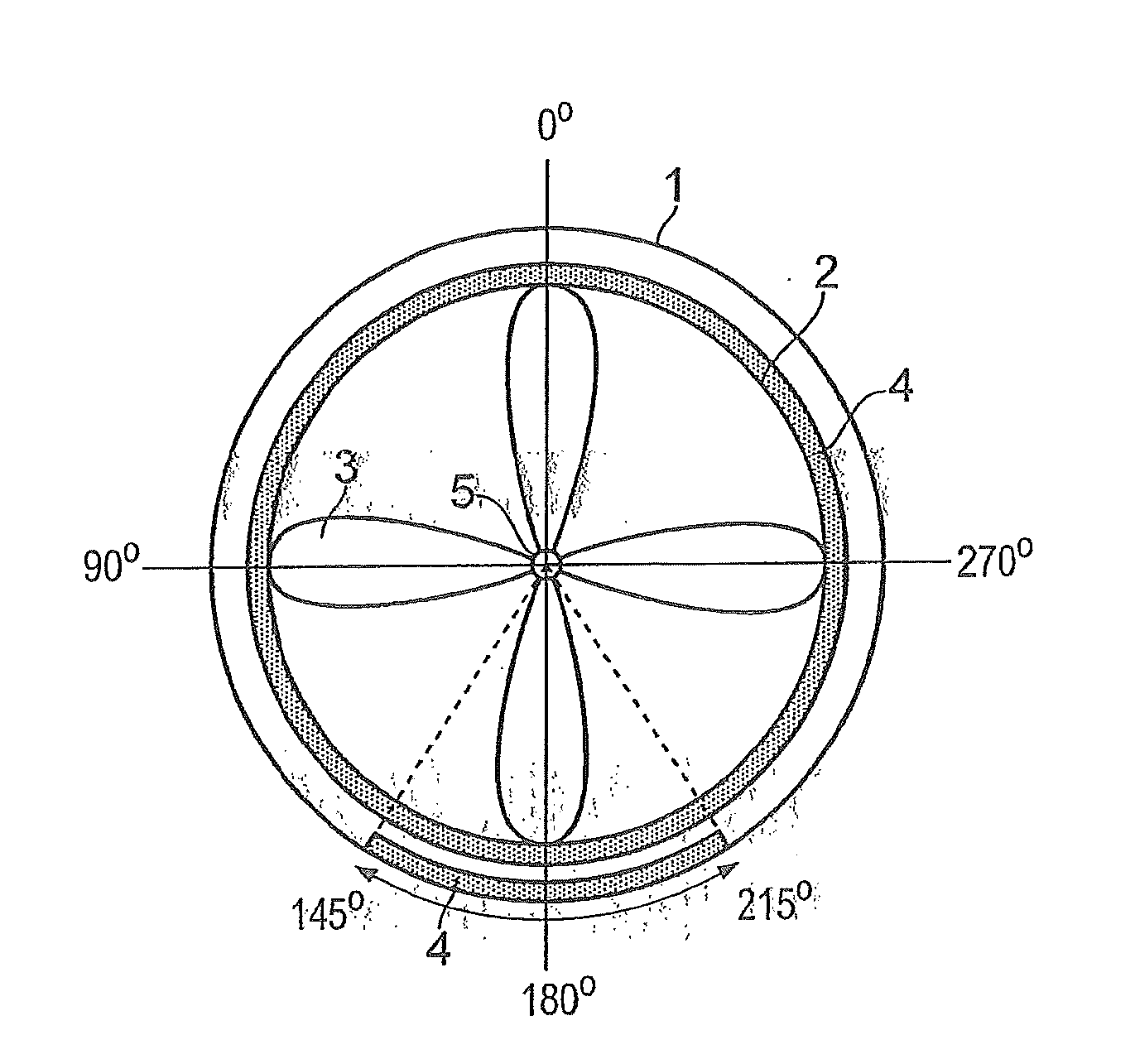

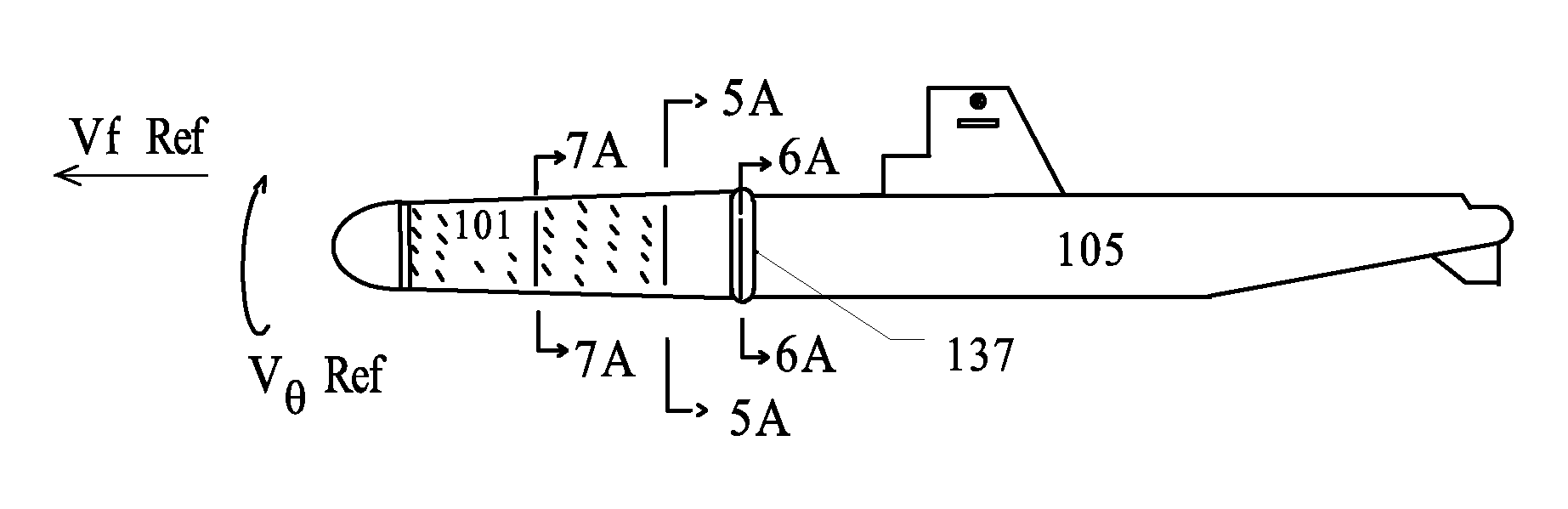

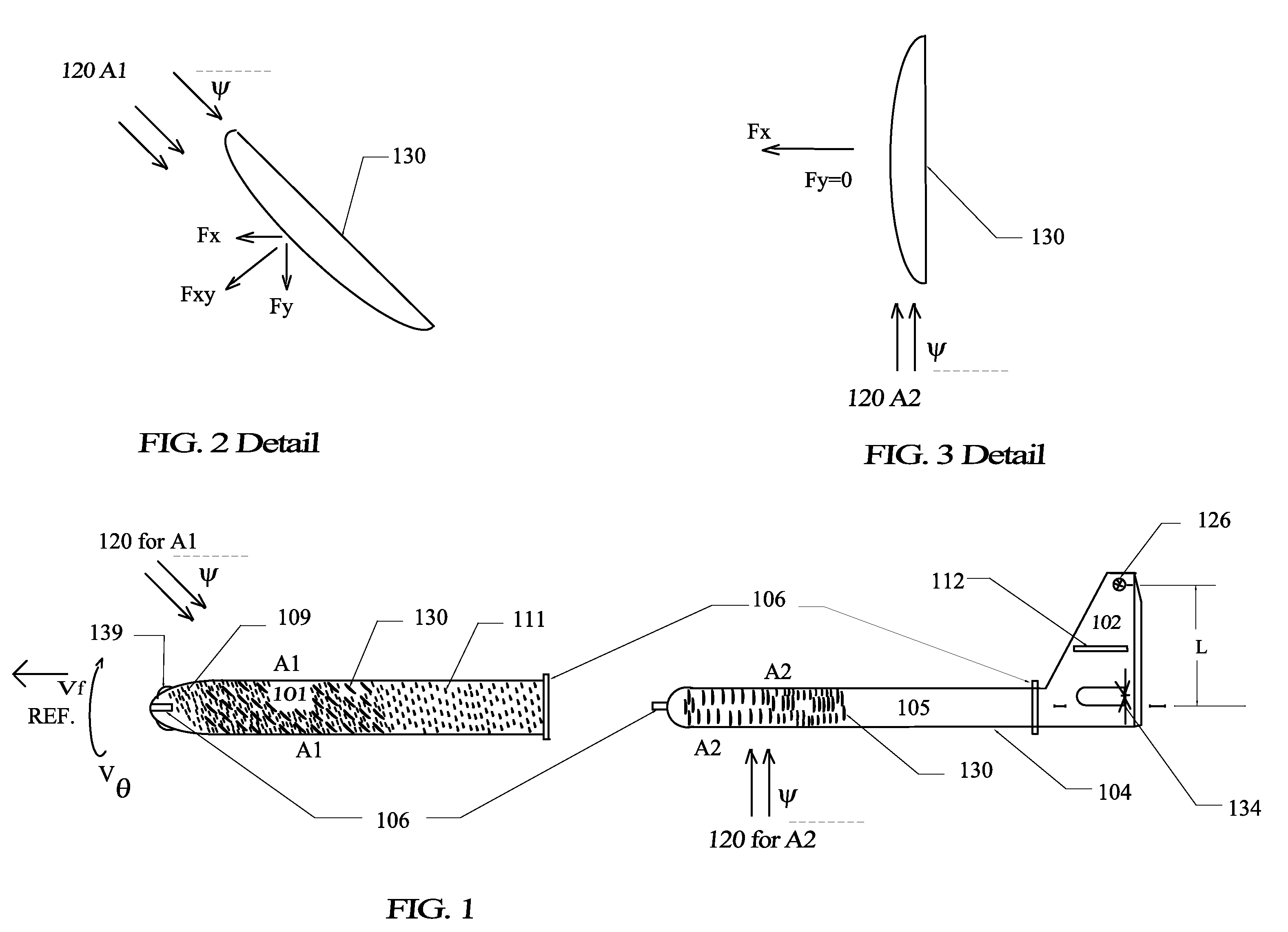

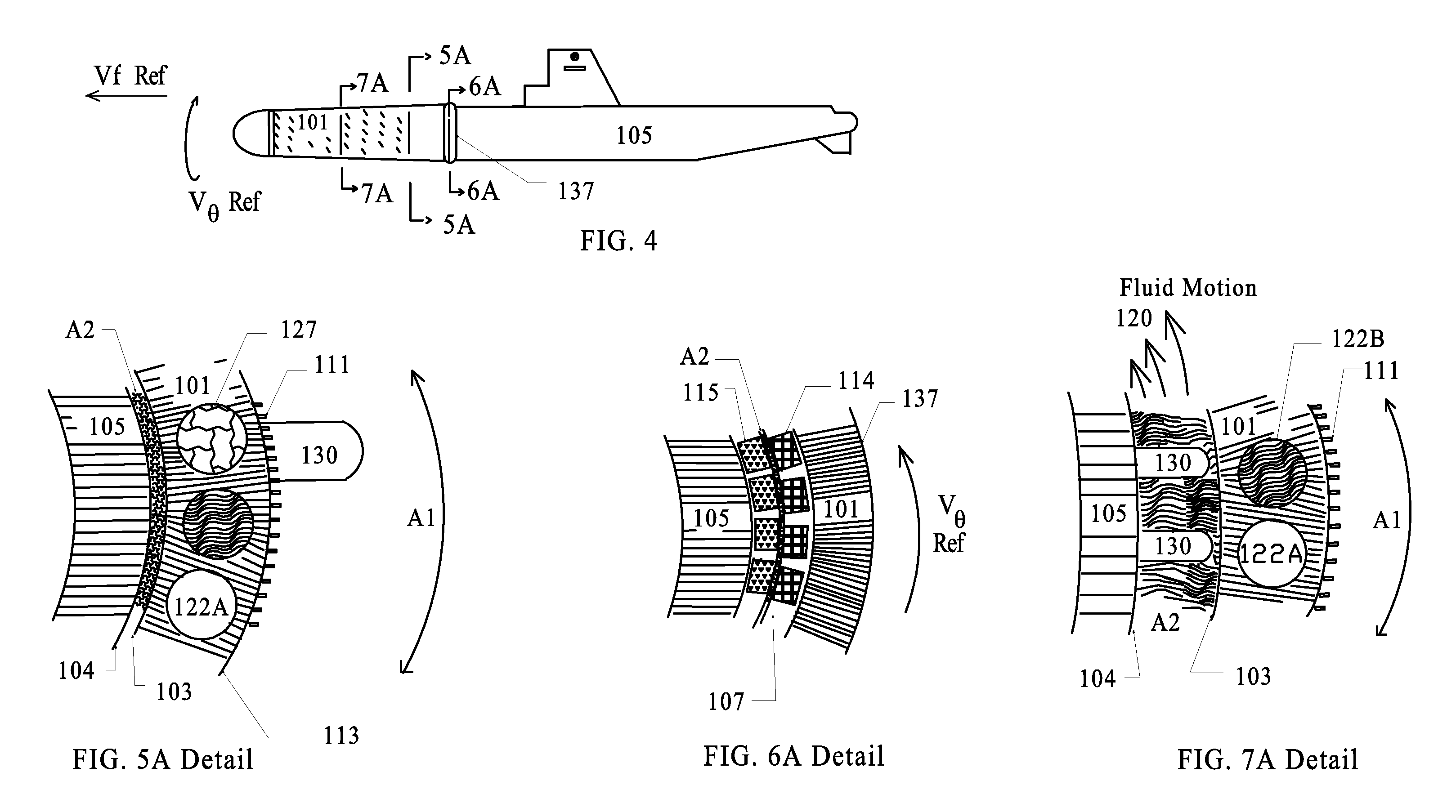

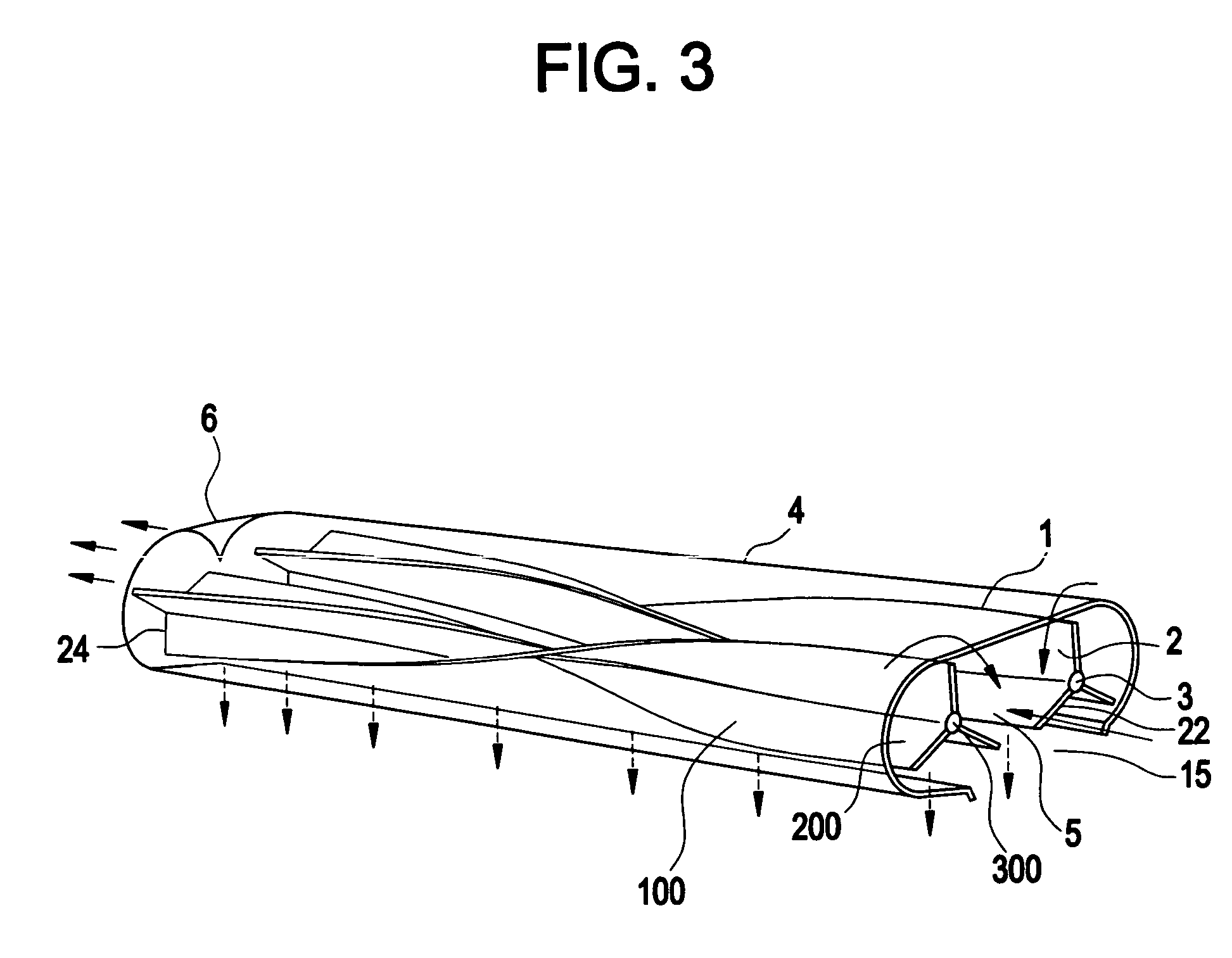

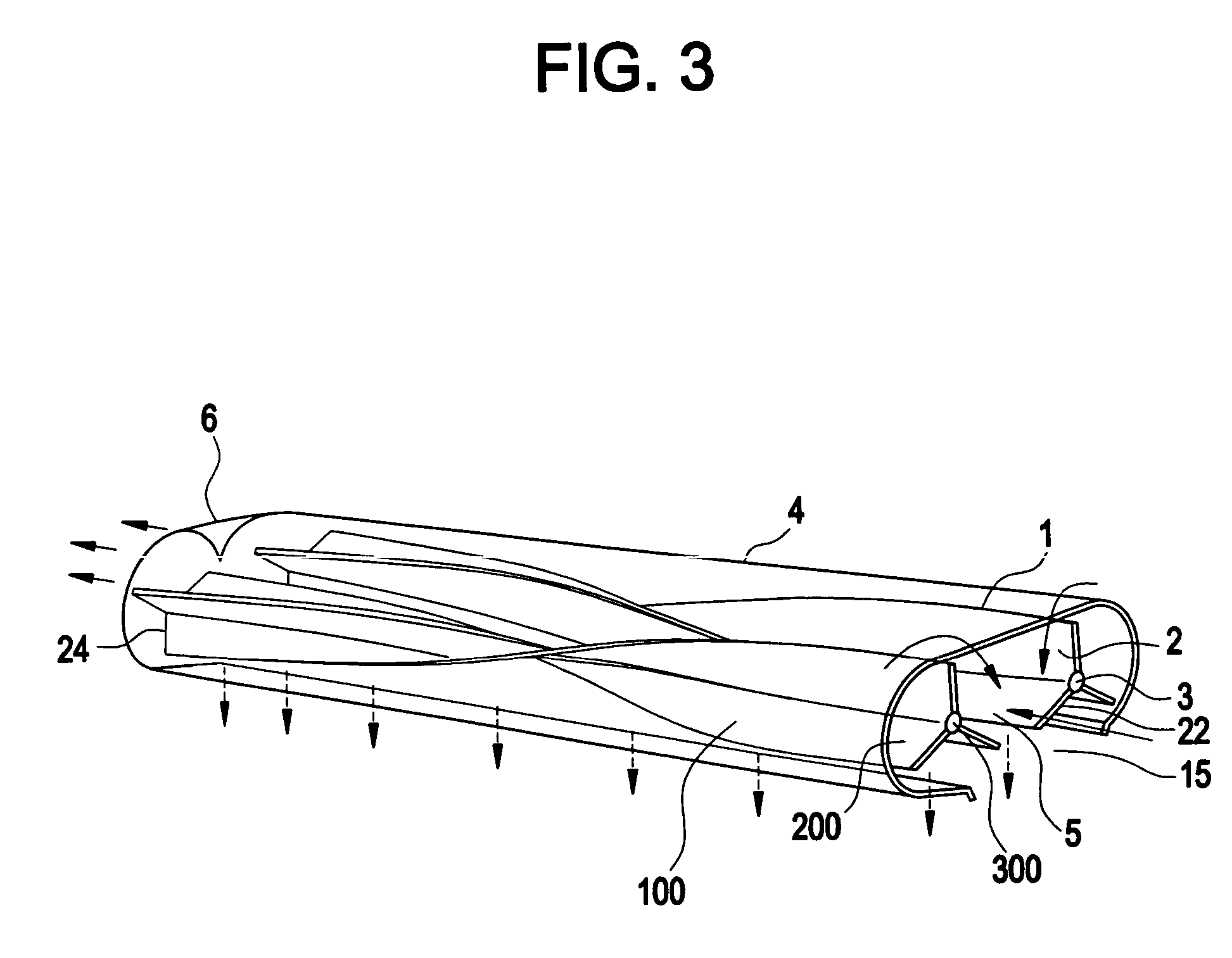

Subsurface Vortex Assisted Distributed Propulsion Active Hull

InactiveUS20120145066A1Reduce dragReduce hydrodynamic noiseMarine torpedoesPropulsive transmission driveMomentumSkin surface

High velocity subsurface craft, apparatus or method positively affecting propulsion and limiting drag by the use of a rotating body with selected Surface Treatment. The Active Hull Platform provides Apparent Flows that allow for shorter more dispersed blade arrays and boundary layer management that impacts vorticity on skin surfaces by controlling the angular momentum of the vortices formed. By converting drag forces into thrust, vortices need not be avoided and an even non pulsating distributed thrust is the result.

Owner:KING RON M

Propulsion system

A propulsion system may include a cylindrical support member and a tubular rotatable member rotatably mounted within the support member that may be adapted to permit fluid flow therethrough. The tubular rotatable member may extend past a down stream end of the support member. An exemplary embodiment of a propulsion system may also disclose a vane attached on an interior surface of the tubular member and may include a blade which extends in a direction toward a rotational axis of the rotatable member such that rotation of the tubular member and the vane attached thereon draws fluid into the tubular member to accelerate the fluid flow through the tubular member. Additionally, a nozzle may be attached to the down stream end of the support member and include a primary nozzle and a secondary nozzle within the primary nozzle. The secondary nozzle may be engaged with the primary nozzle by a stator.

Owner:NICHOLSON HUGH B

Thrust generating apparatus

InactiveUS20120201703A1Easy to replaceHigh strengthPropulsive transmission driveRotary propellersEngineeringMechanical engineering

A thrust generating apparatus is provided under water and configured to generate thrust by ejecting the water. A rotor main body includes: a first member including a side surface and outer peripheral surface which are opposed to a first water lubricated bearing; a second member including a side surface and outer peripheral surface which are opposed to a second water lubricated bearing; and a third member including a supporting surface contacting an inner peripheral surface of a rotor core. The first to third members are fixed to one another so that each member is detachable.

Owner:KAWASAKI HEAVY IND LTD

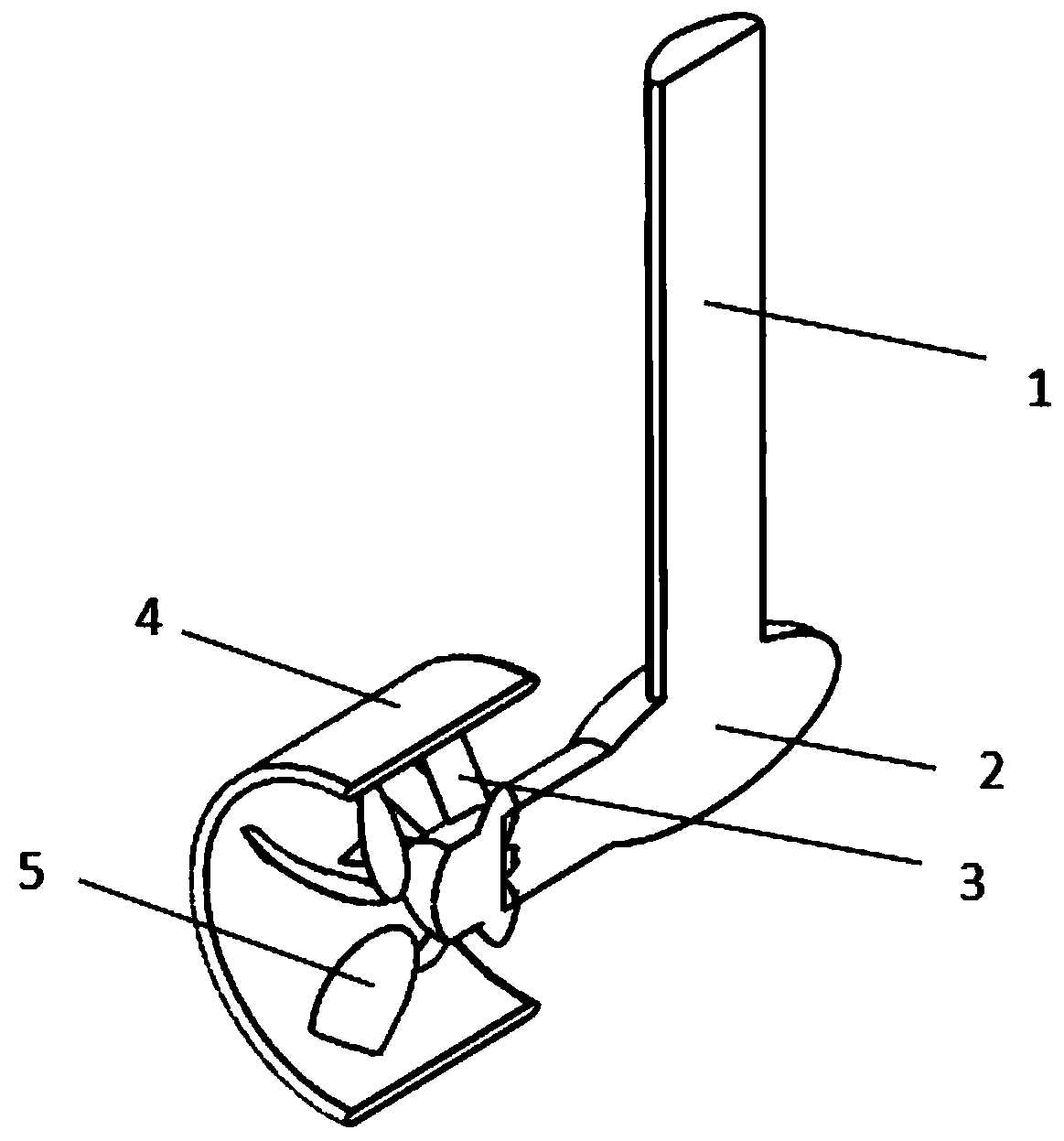

Oar body and screw propeller with same

InactiveCN103192970AImprove work efficiencySolve shaft technical problemsPropulsive transmission driveRotary propellersNacelleTorque transmission

The invention relates to an oar body comprising an oar hub and a plurality of oar blades connected to the oar hub. The oar body is characterized in that wheel rims are formed at the peripheries of the oar blades; gear teeth distributed along the circumferential direction are formed on the peripheral walls of the wheel rims; and two ends of the oar hub are conical streamline forms. The oar body has the advantages that the conventional rotating shaft structure is cancelled, one wheel rim is formed outside each oar blade, so that the rotation mode of the oar blades is changed from rotating shaft rotation in a rotation torque transmission method into wheel rim rotation, the oar blades of a screw propeller are rotated by engagement of gears on the wheel rim instead of rotation of a rotating shaft, a main engine of a ship and the screw propeller can be connected without a mechanical rotating shaft, and a propelling device without the rotating shaft is provided for the ship, thus the technical problem of the rotating shaft of a large ship is solved, and a cabin of the ship can be designed more flexibly; in addition, the oar blades are driven to rotate by using a gear engagement mode, the output power of the screw propeller can be greatly reduced under the same power, and therefore, the work efficiency of the ship is improved, the energy consumption is reduced, and the purpose of saving energy is achieved.

Owner:鲍小福

Marine vessel propulsion device

ActiveUS8814614B2Simple structureReduce controlPropulsion based emission reductionPropulsive transmission drivePropellerInternal combustion engine

A marine vessel propulsion device includes a propeller rotatable around a propeller axis, a duct that surrounds the propeller around the propeller axis, an internal combustion engine that rotates the propeller relative the duct, and an electric motor that rotates the propeller relative to the duct. The propeller includes a plurality of blades, and a cylindrical rim that surrounds the plurality of blades around the propeller axis. The electric motor rotates the propeller by rotating the rim.

Owner:YAMAHA MOTOR CO LTD

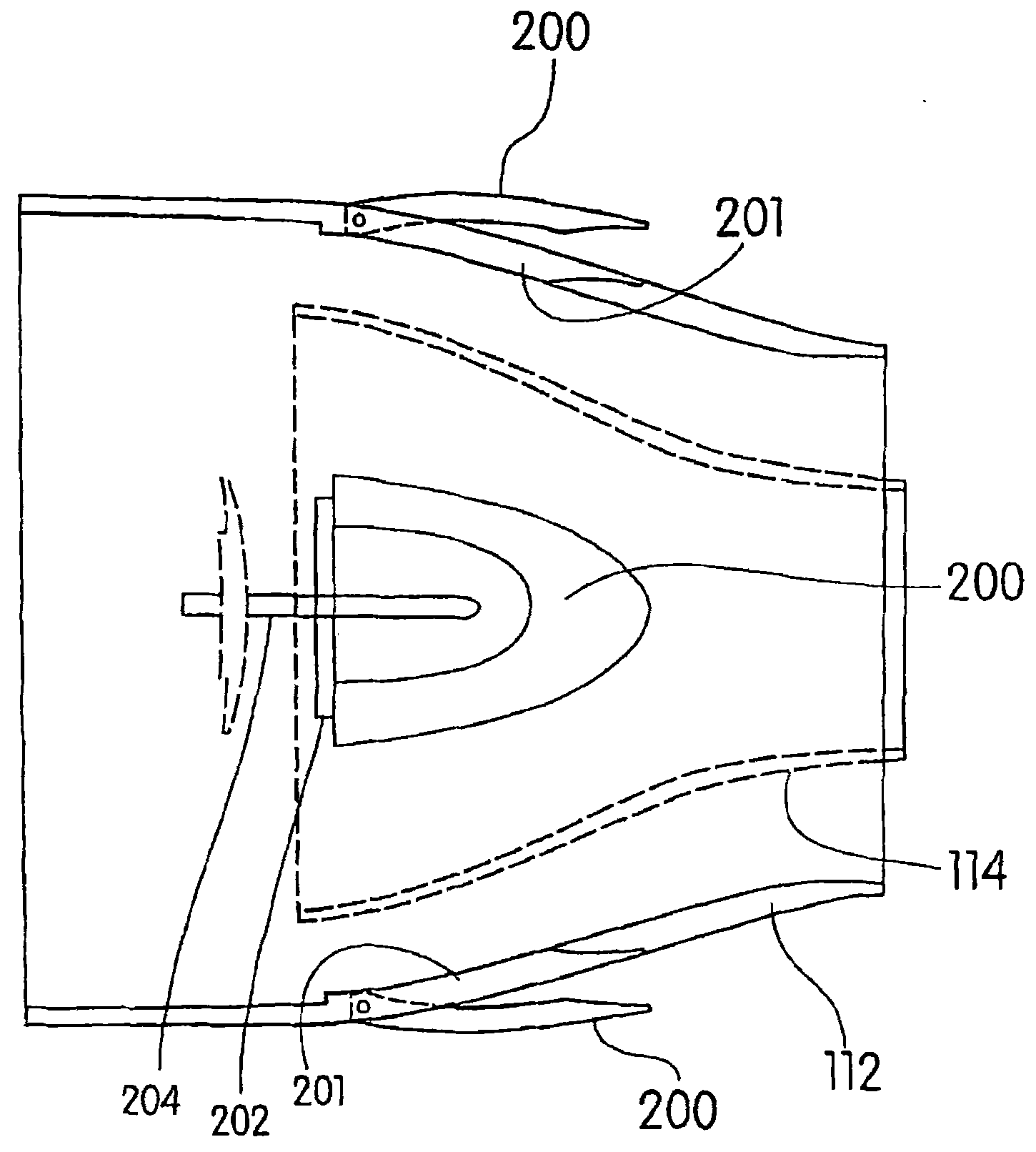

Shaftless radial vane rotary device and a marine propulsion system using the device

InactiveUS20060222526A1Eliminate needPrevent rotationPropulsive transmission driveRotary propellersMarine propulsionEngineering

A radial vane fluid motor or pump has an open ended tubular rotor having a cylindrical outer surface rotatably mounted in a tubular stator having its inner surface contoured to provide successive portions of increased and decreased spacing relative to the rotor body. A plurality of elongated movable vane assemblies are mounted on and project outwardly from the rotor surface to continuously contact the stator surface. Bearings support the rotor within the stator, and seals are provided for sealing the space between the rotor and stator. Pressure inlets and exhaust ports are provided in the stator to permit the flow of pressure fluid into or out of the device. Mounting the vanes on the cylindrical rotor surface enables production cost reduction and simplifies maintenance. A conventional propeller mounted in the cylindrical rotor provides an improved shrouded propellor propulsion system for marine vessels. Mounting the system on a vessel for rotation about an axis perpendicular to the axis of the rotor enables steering of the vessel without use of a redder.

Owner:SEIFORD SR DONALD S

Non-shaft propeller

PendingCN109334930AImprove efficiencyHigh recoil speedRotary propellersPropulsive transmission drivePropellerEngineering

The invention discloses a non-shaft propeller. The non-shaft propeller comprises a stator, a rotor, end caps, a stator winding, a permanent magnet and blades. The rotoris installed on the interior ofthe stator through a pair of bearings located on the end parts, a fabricated cavity is determined between the two bearings, the end caps are fixed to the end part of the stator and are used for sealing two ends of an assembly formed by the stator and the rotor, the stator winding is installed on the side of the stator in the fabricated cavity, the permanent magnet is installed on the side of the rotor in the fabricated cavity, and the blades are installed on the inner wall surface of the rotor. A rotor pipe shell is provided with a first tapered cavity channel treating one end of the rotor pipe shell as a big end and is provided with a second tapered cavity channel treating the other end of the rotor pipe shell as a big end, and a small end of the first tapered cavity channel communicateswith a small end of the second tapered cavity channel; and the blades are divided into two groups, one group is located at the first tapered cavity channel, and the other group is located at the second tapered cavity channel. The efficiency of the non-shaftpropelleris high.

Owner:UNIV OF JINAN

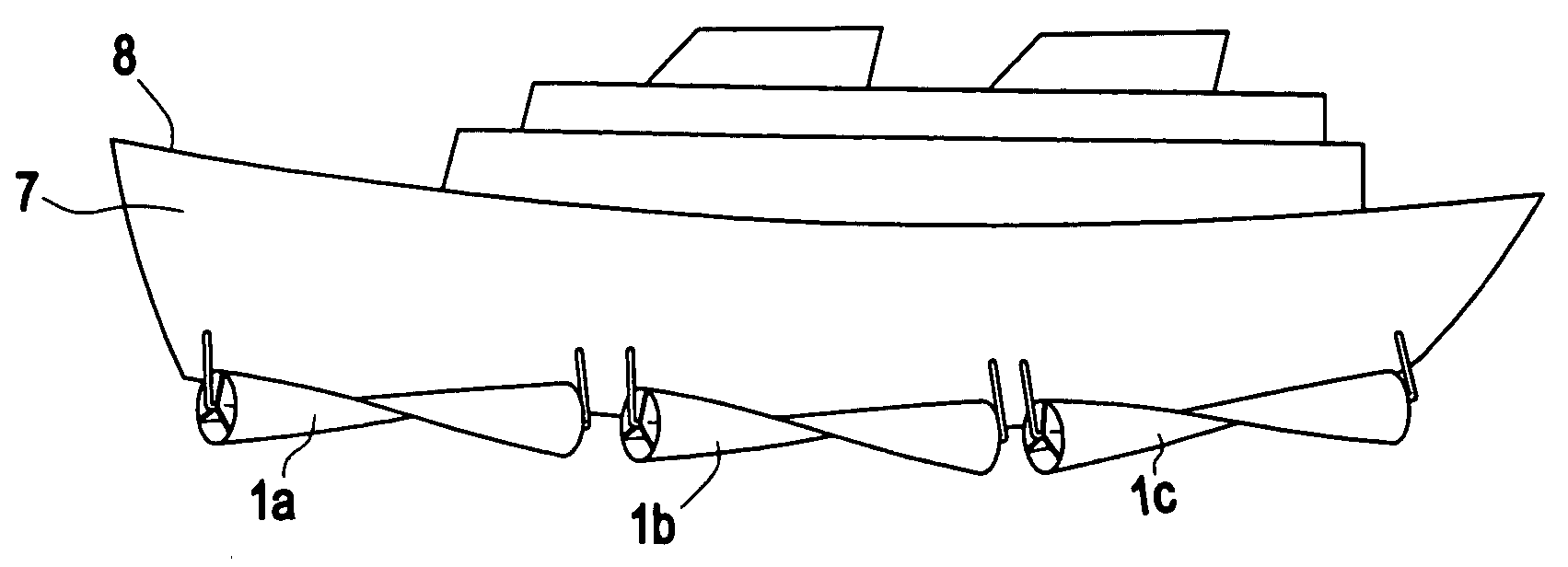

Water vehicle propeller

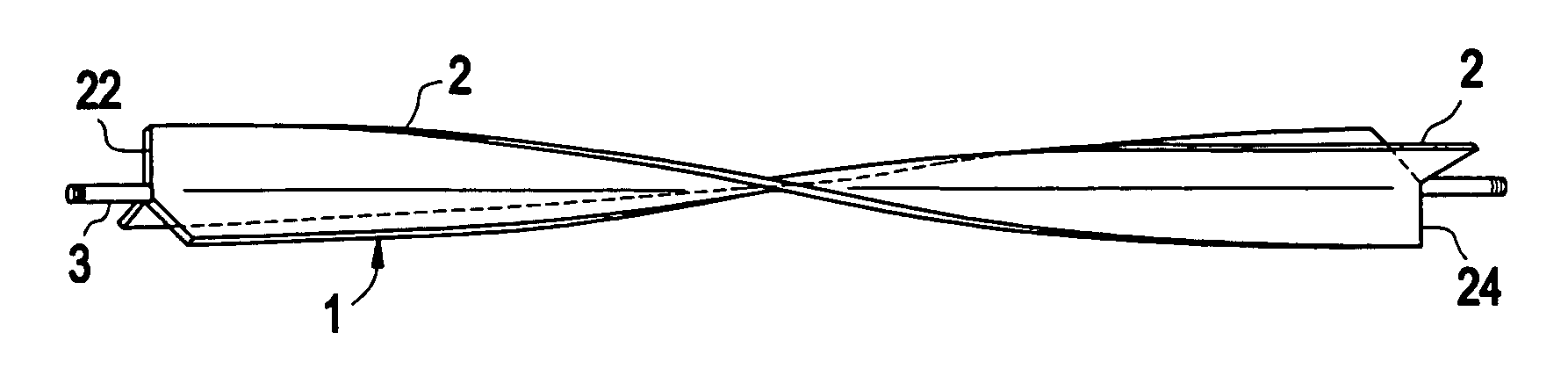

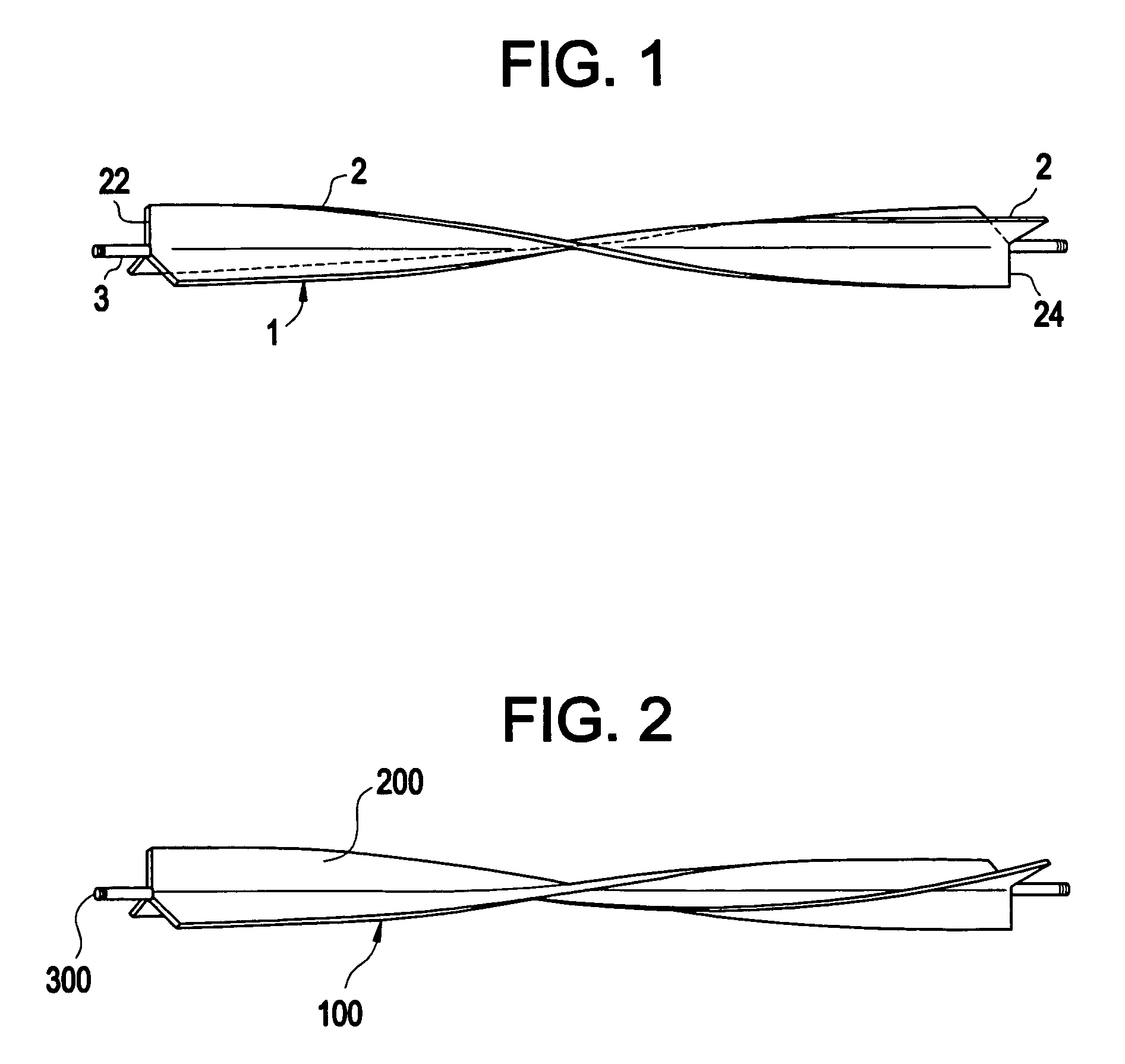

InactiveUS20050075015A1Overcome disadvantagesImprove mobilityRotary propellersPropulsive transmission driveWater wheelPropeller

In this specification regarding water vehicle propellers, the gist of the technical disclosure resides in the construction of a propeller having elongated blades which extend in a helical path and longitudinally of the hull of a water vehicle in an unbroken length, singly or in aligned sections following the contour of the hull, for substantially its entire length or that portion of the length of a water vehicle in contact with the body of water when under way. The elongated propellers are rotated on their longitudinal axis. In addition, two of such elongated propellers or aligned sections of such propellers are mounted parallel for rotation in opposite directions either within a tubular housing open at the front and rear or mounted directly adjacent the hull with one or more on either side. Spaced apart longitudinal support members are secured below the elongated propellers to prevent contact with an object or objects from below and to support the propellers and hull above any such objects. One of such propellers may be mounted below a forward portion of a vessel and a second below a rearward portion, each propeller being pivotable outwardly in opposite directions from the longitudinal axis of the vessel to enable the vessel to turn more rapidly from one direction to another.

Owner:KETTELSON ERNEST

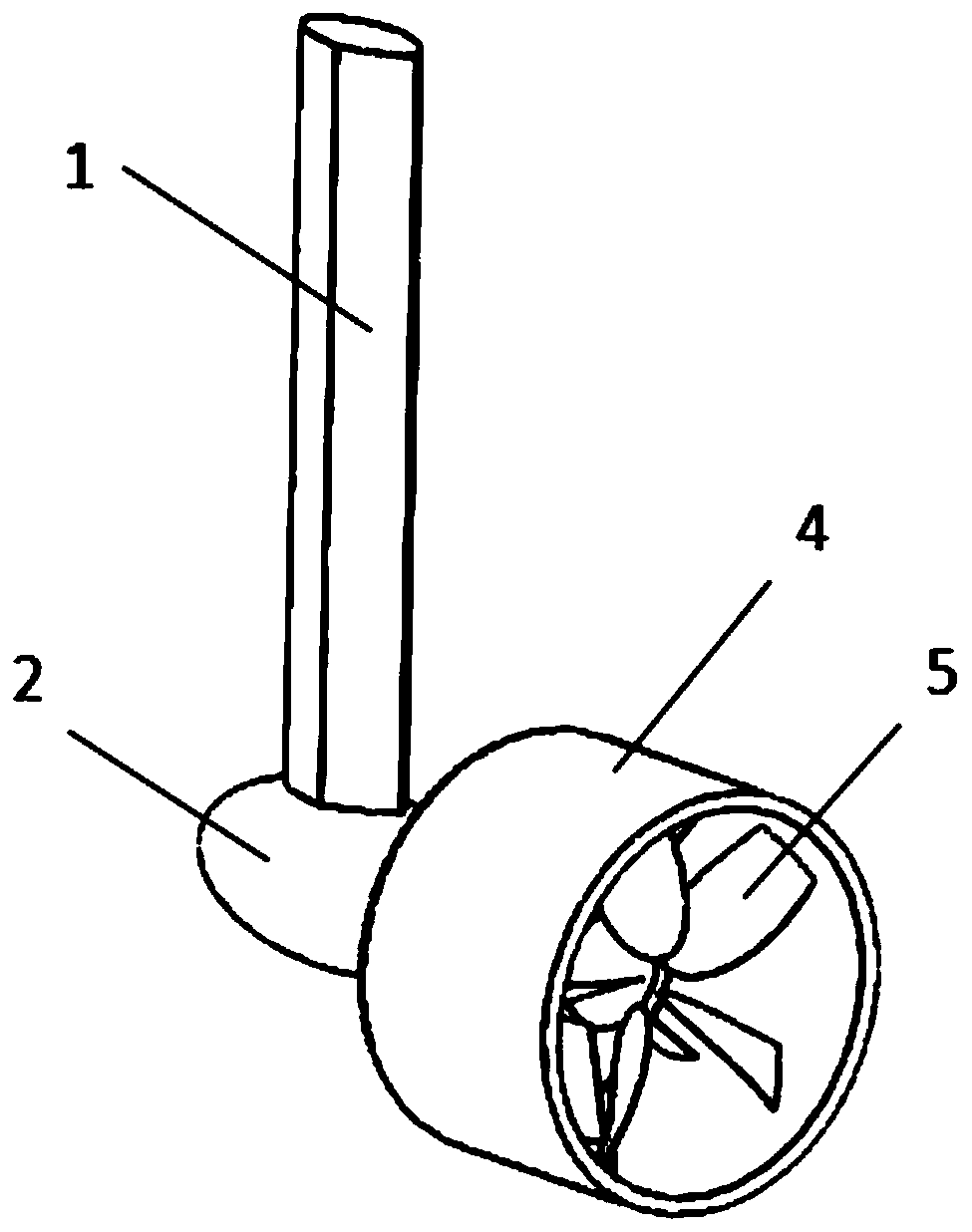

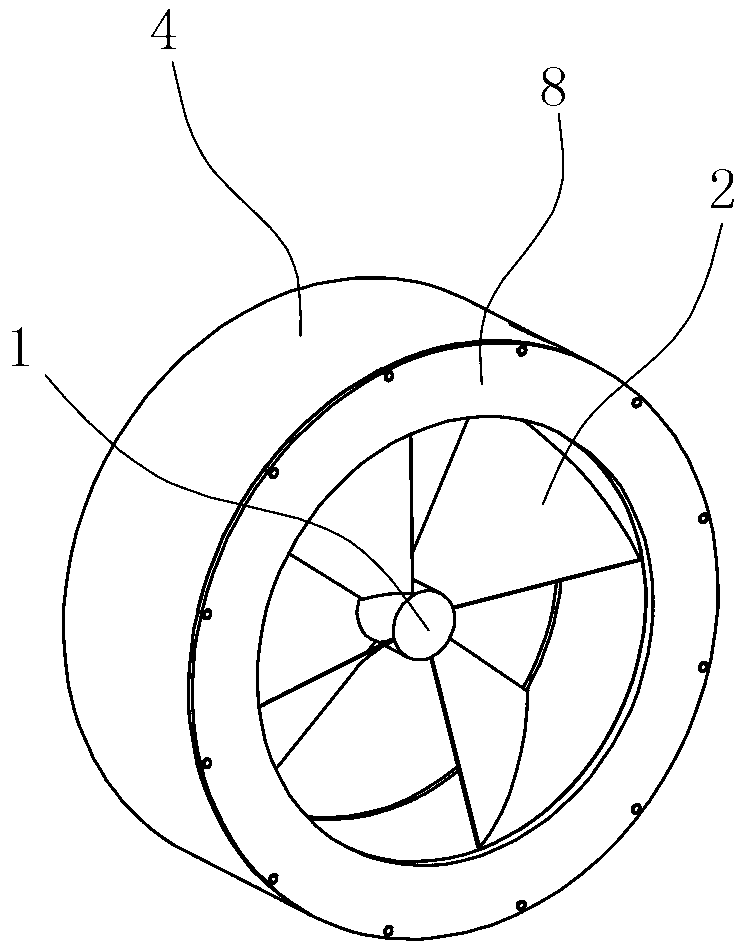

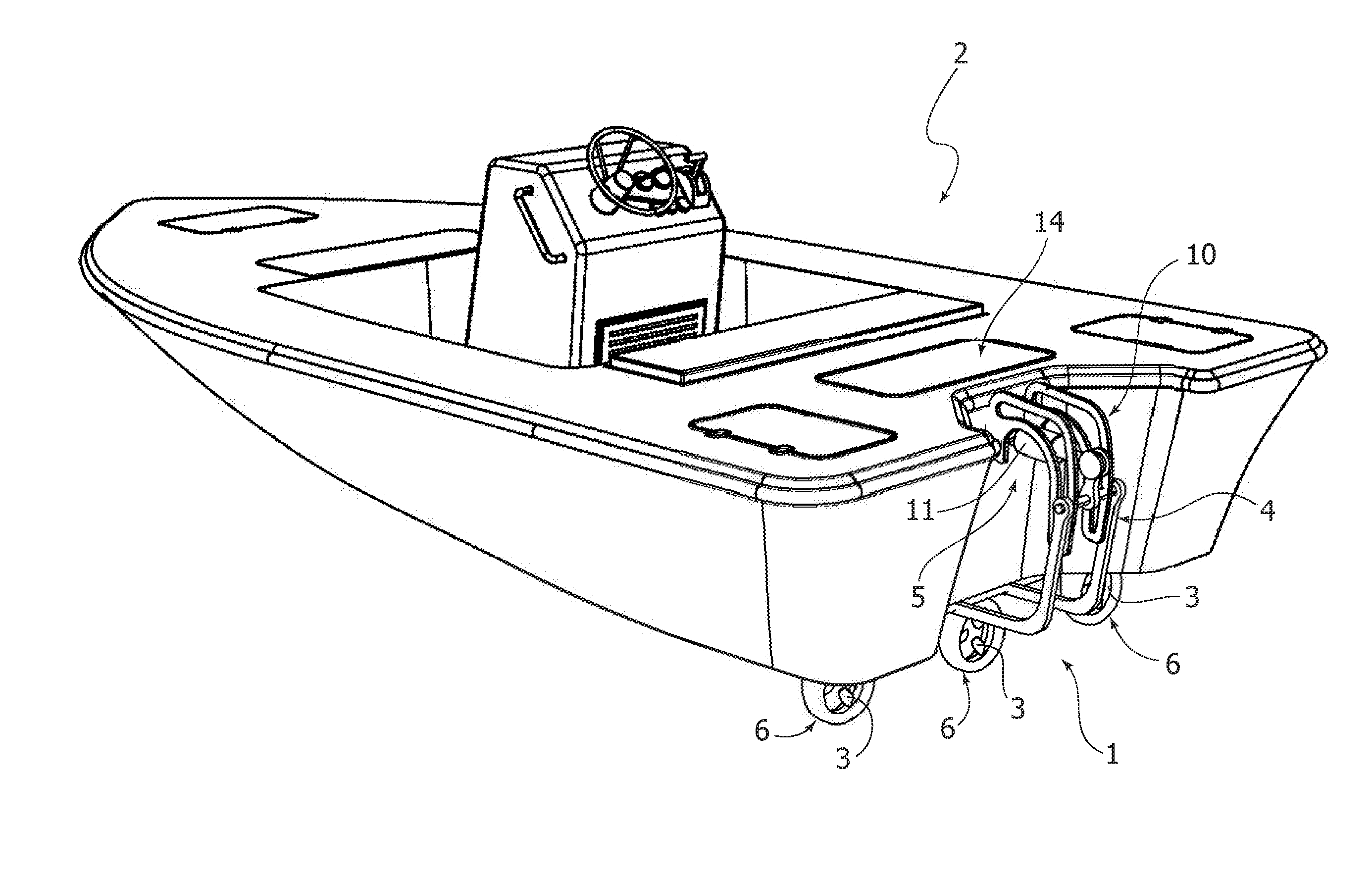

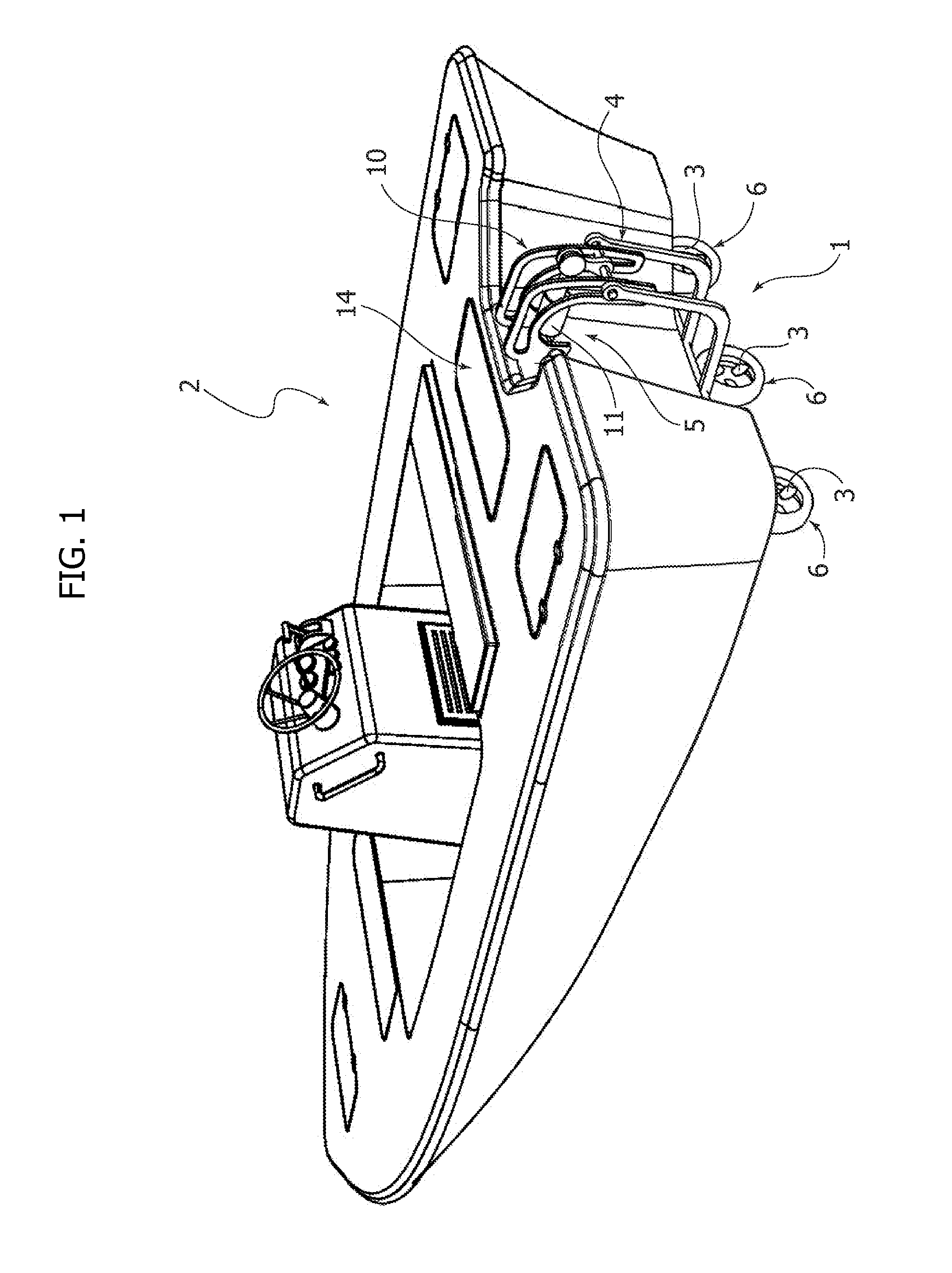

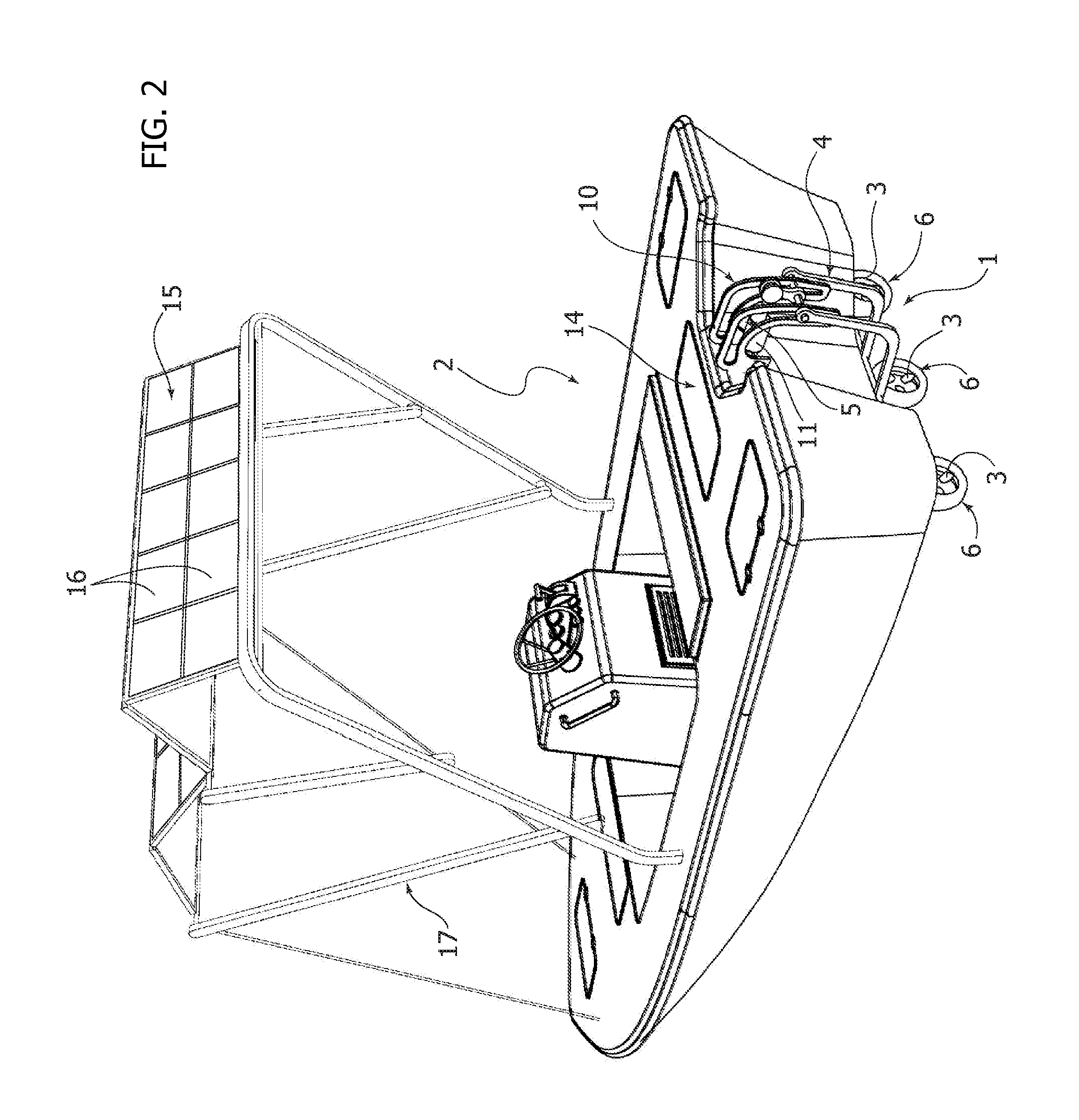

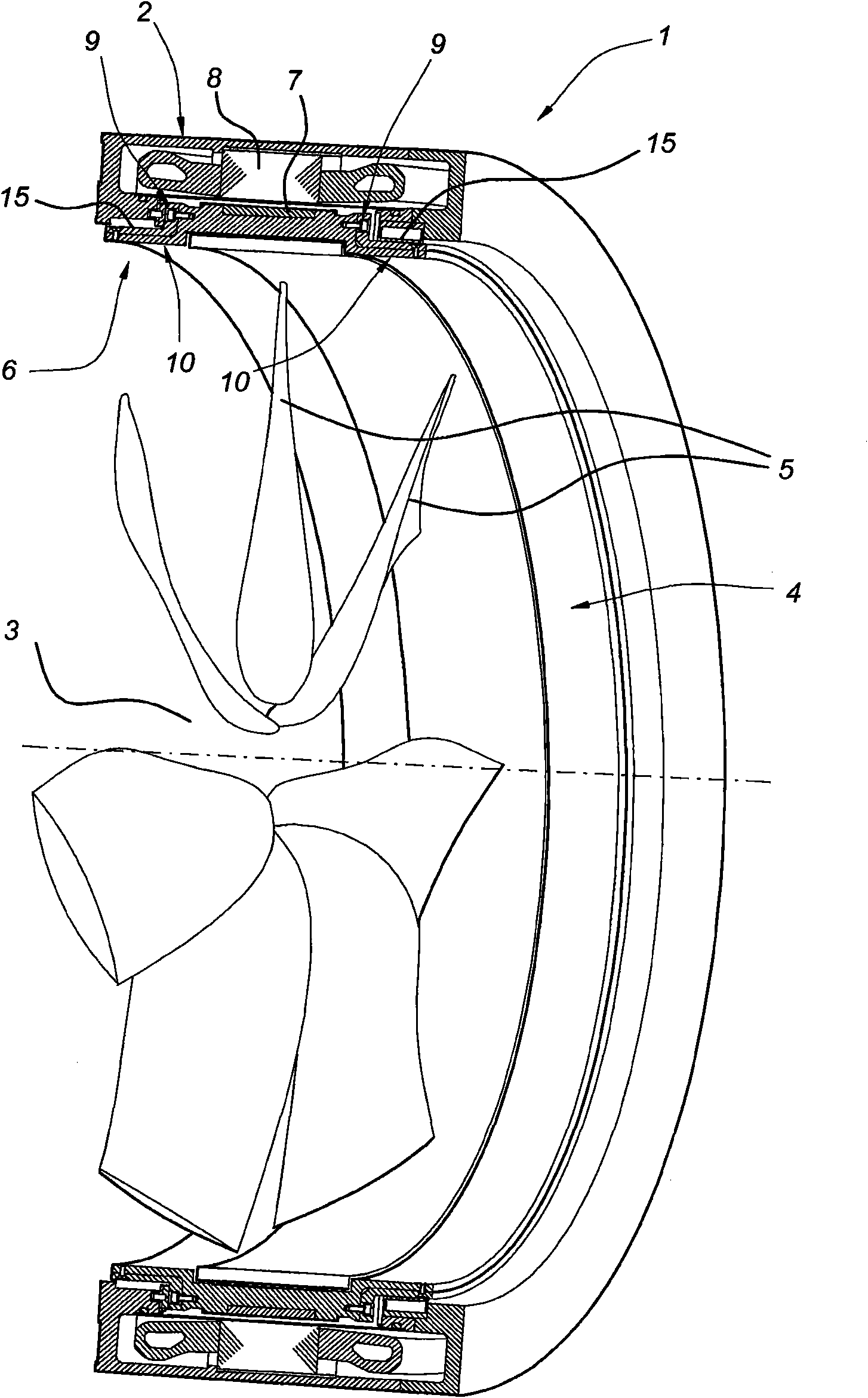

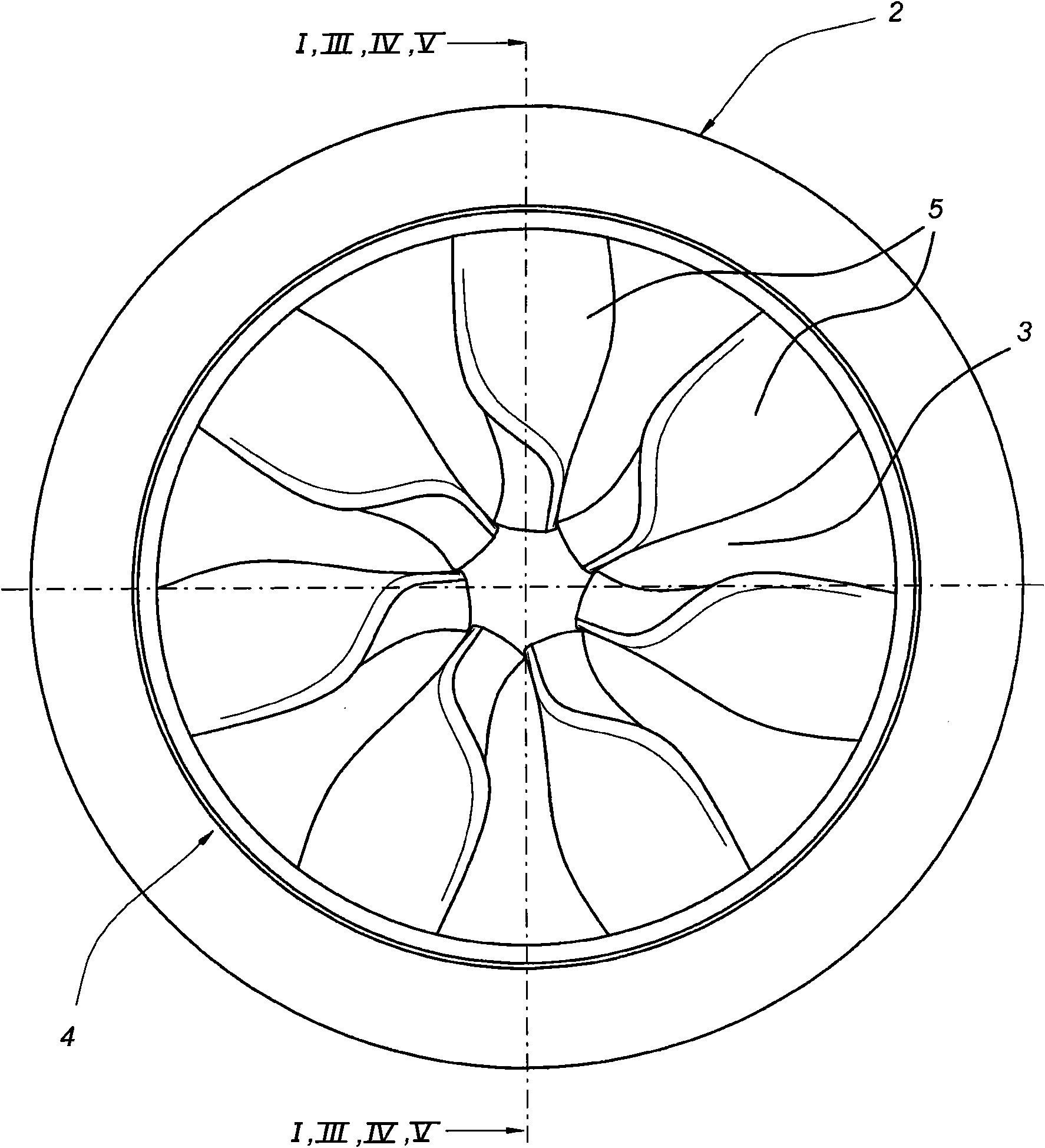

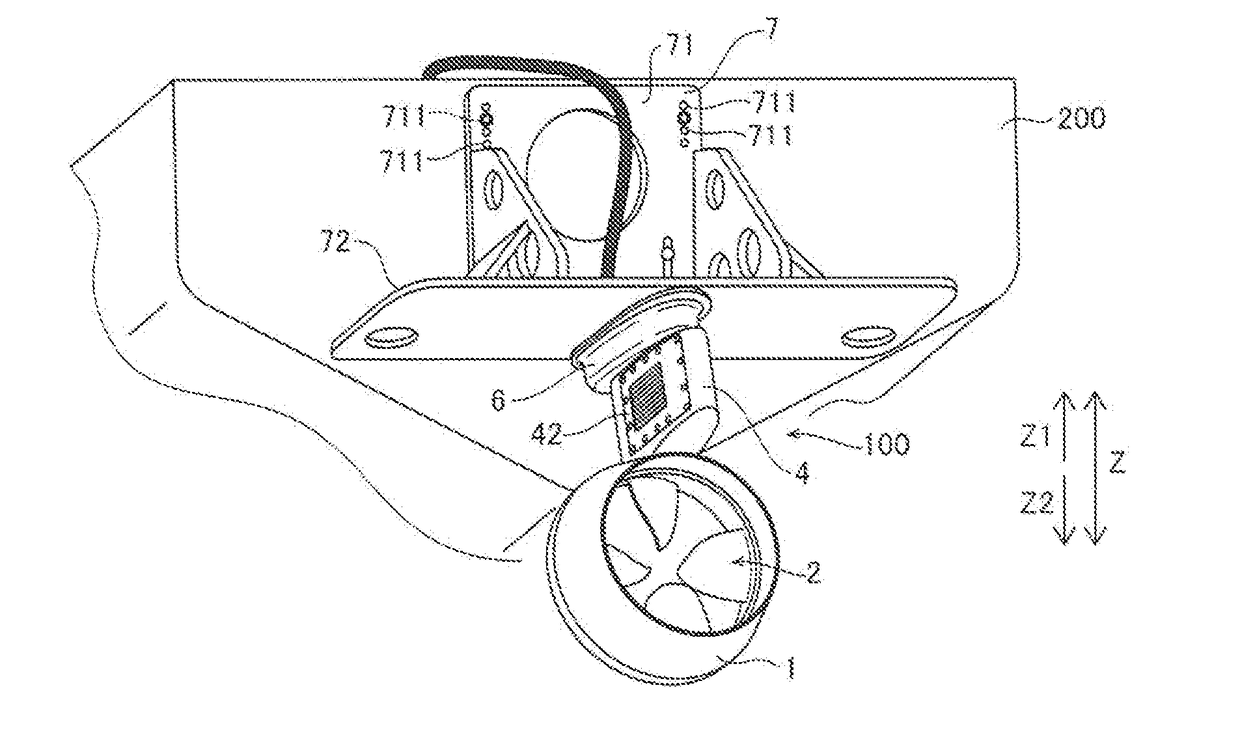

Outboard propulsion system for vessels

ActiveUS20150367926A1Improve efficiencyReduced dimensionPropellersRotary propellersPropellerElectric motor

An outboard propulsion system for vessels includes a supporting structure (4) to be anchored to the transom wall (5) of the vessel and a plurality of propellers (3) carried by the supporting structure (4). Each propeller (3) is associated to an electric motor (6) with a toroid geometry, having an annular rotor (R) rotatable within an annular stator (S) and defining therewithin a central aperture (A), with the blades (3A) of the propeller (3) which are carried by the rotor (R) and extend to the central aperture (A).

Owner:INTERACTIVE FULLY ELECTRICAL VEHICLES SRL

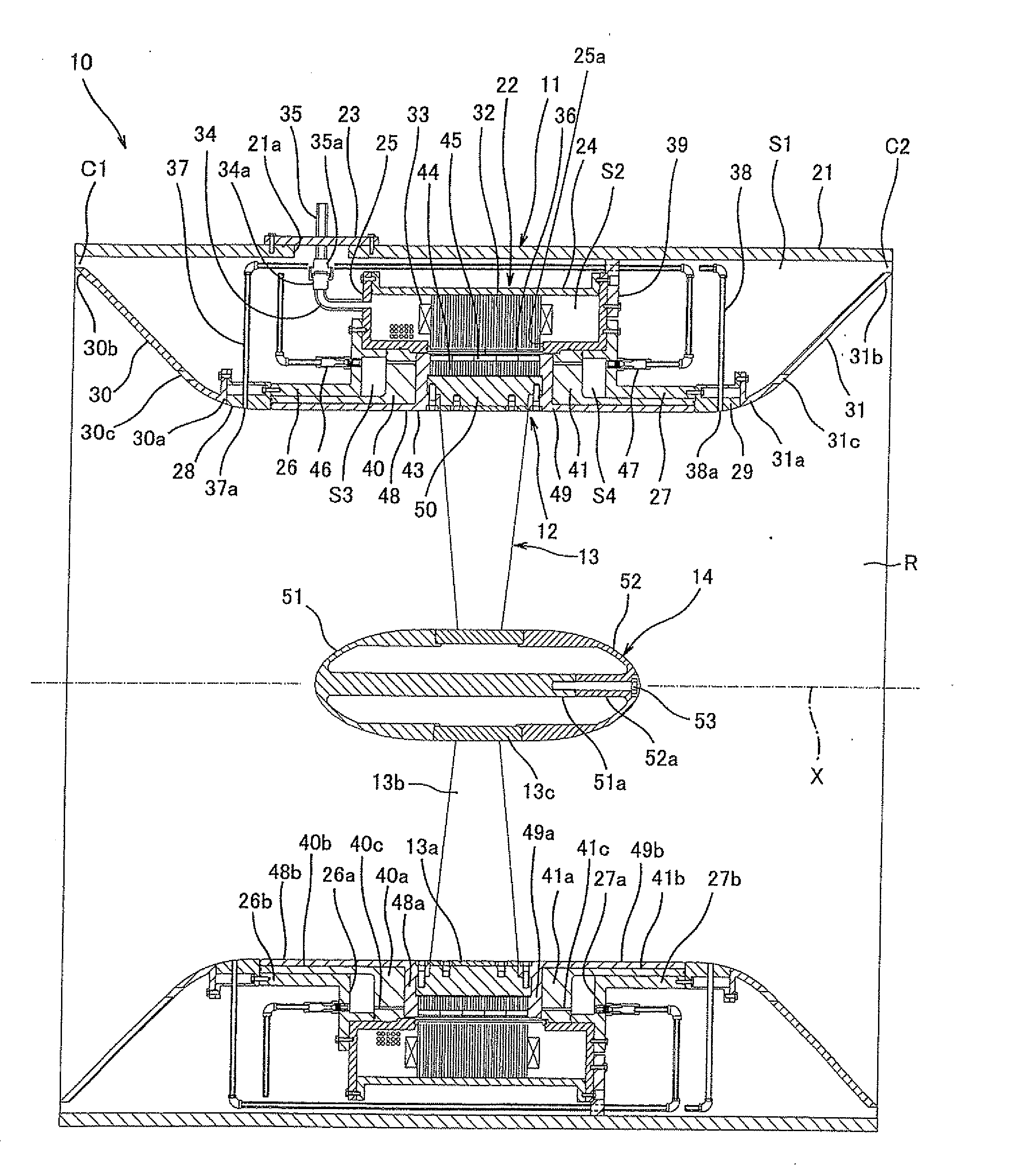

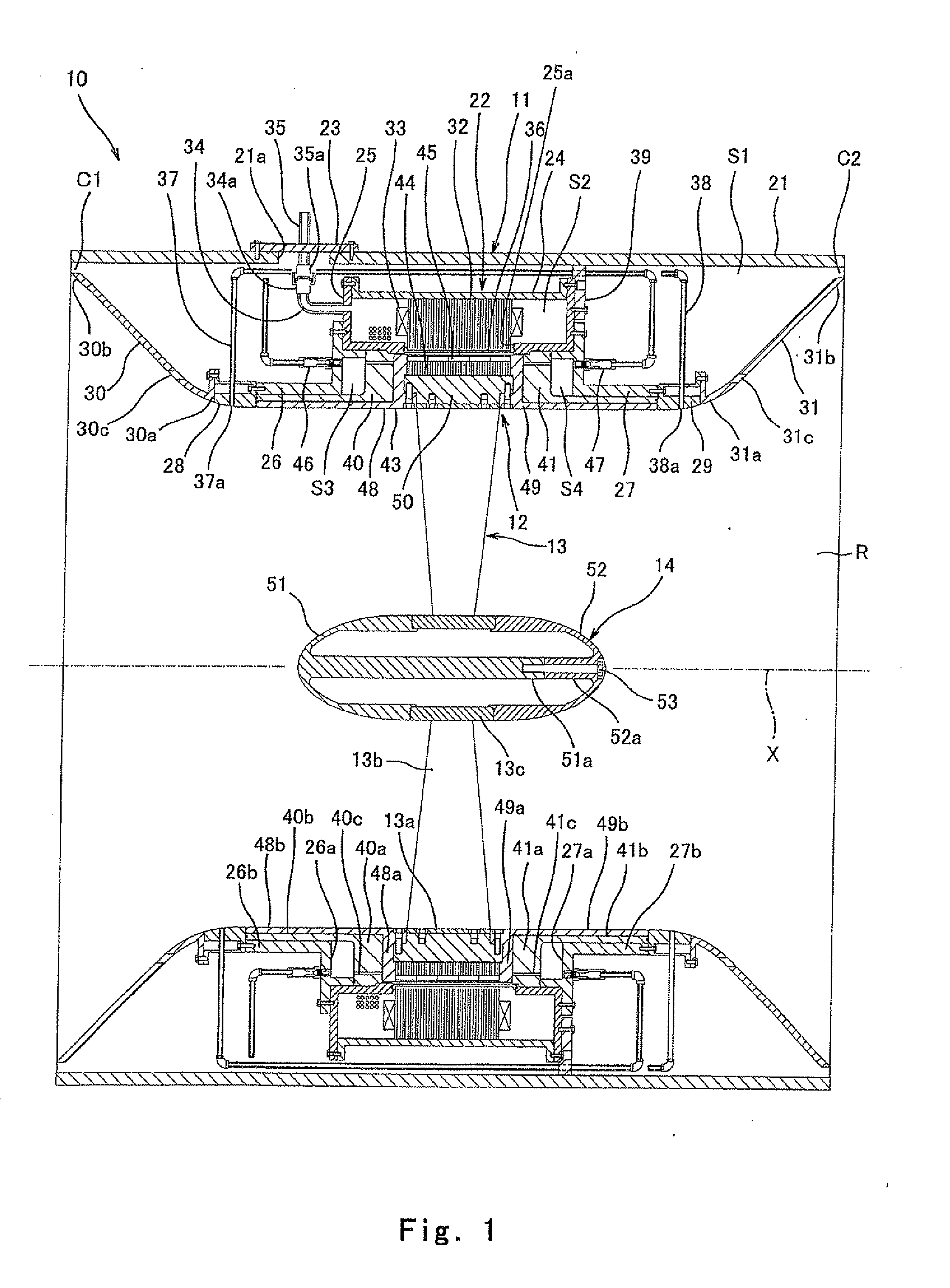

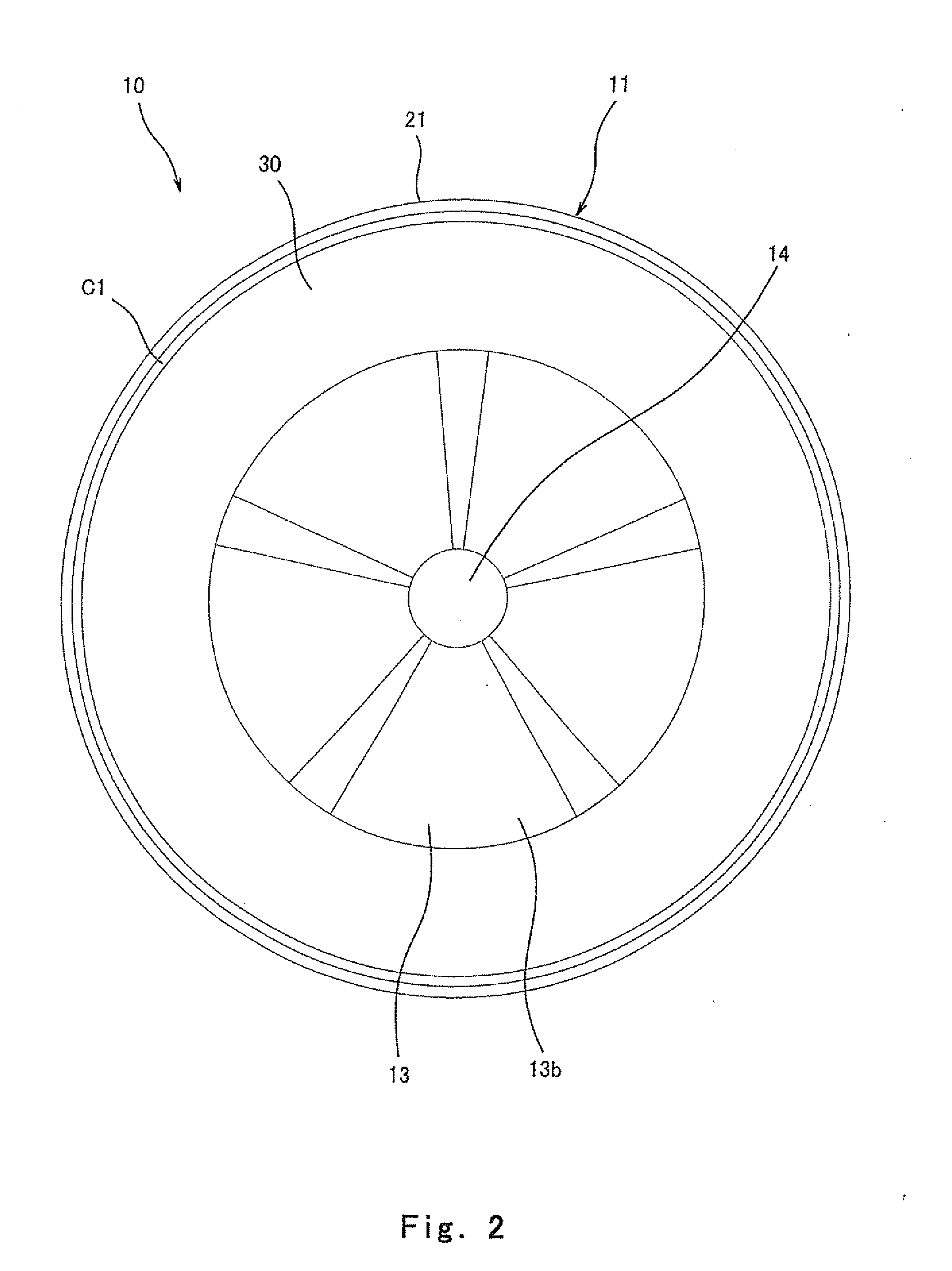

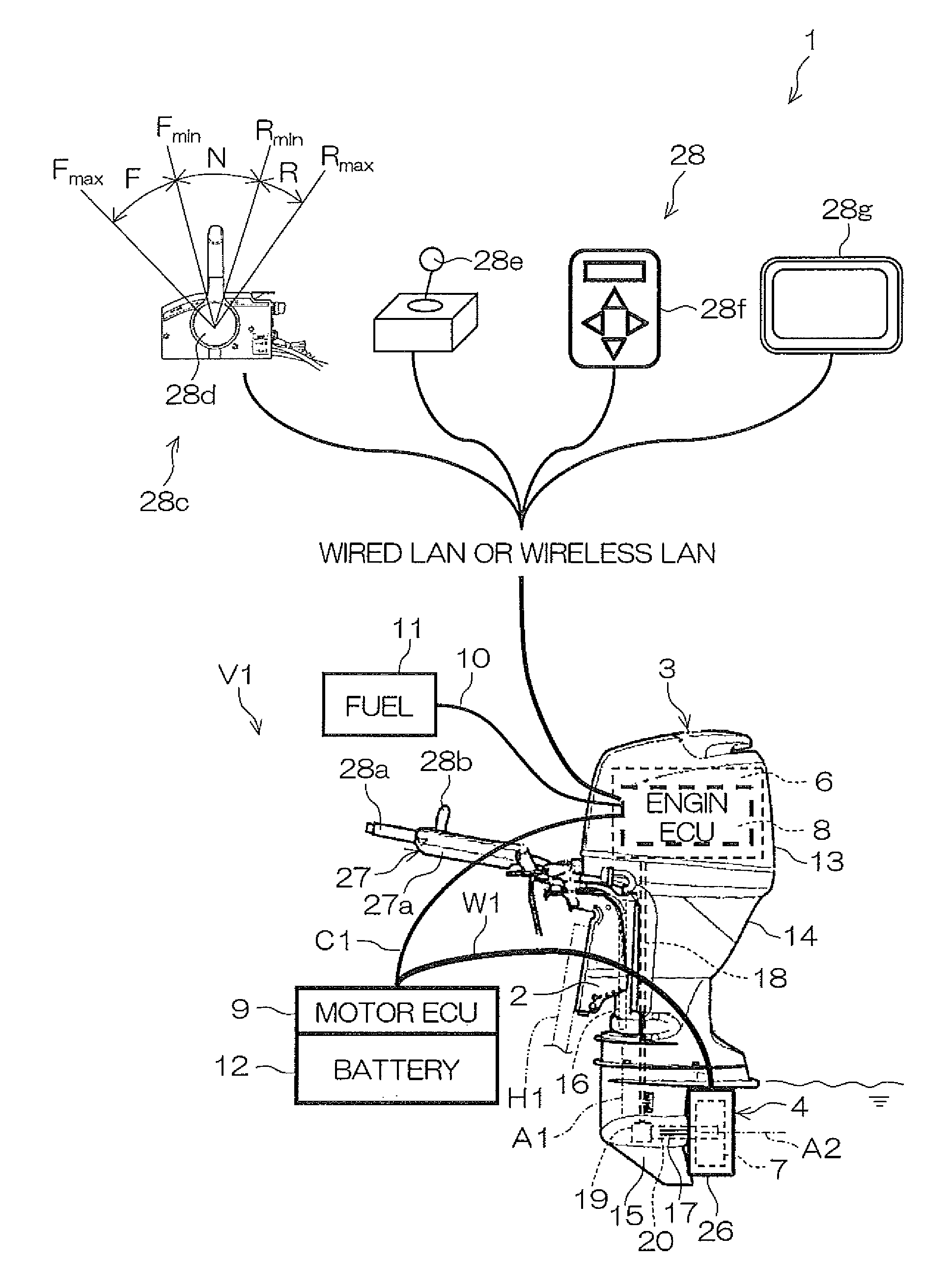

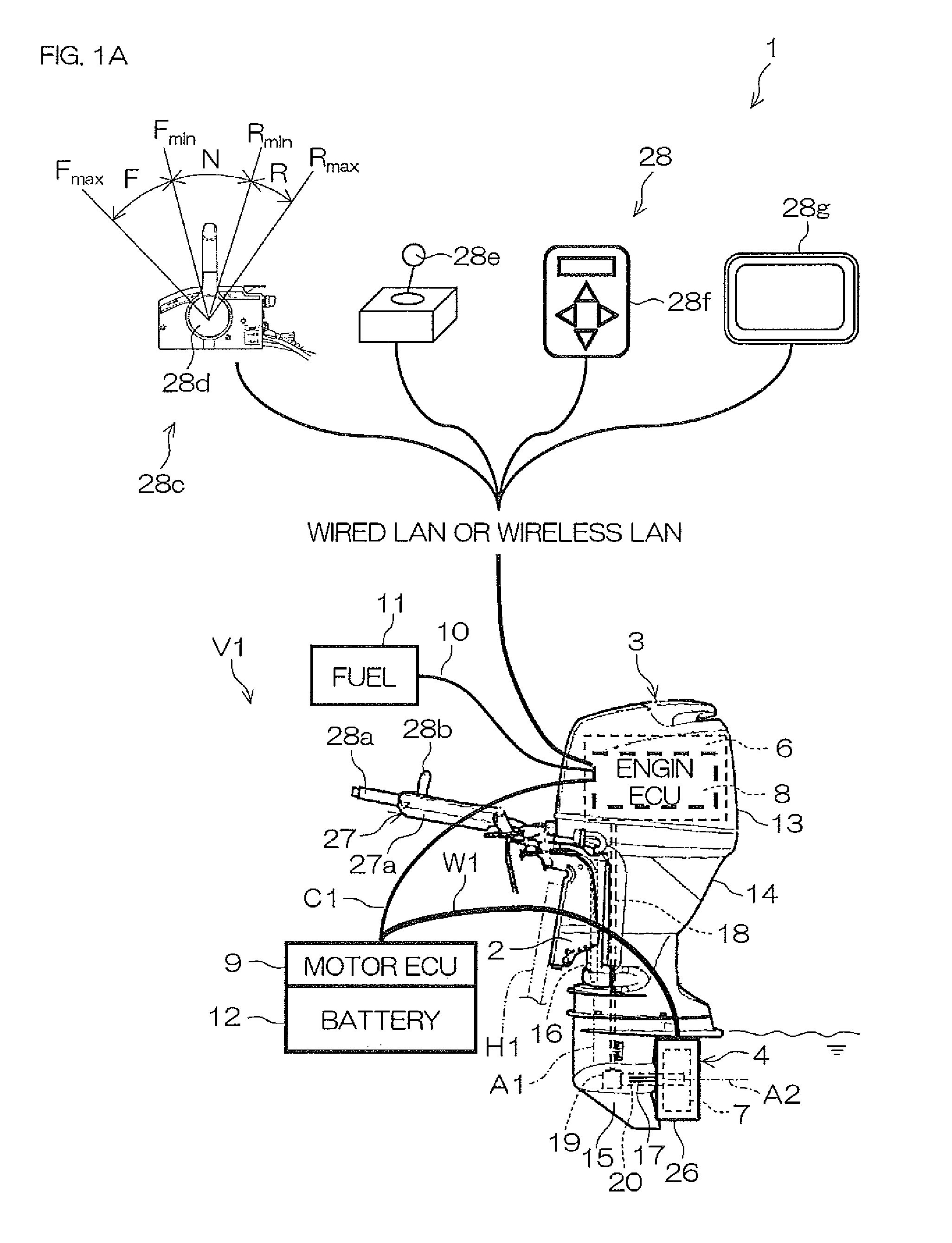

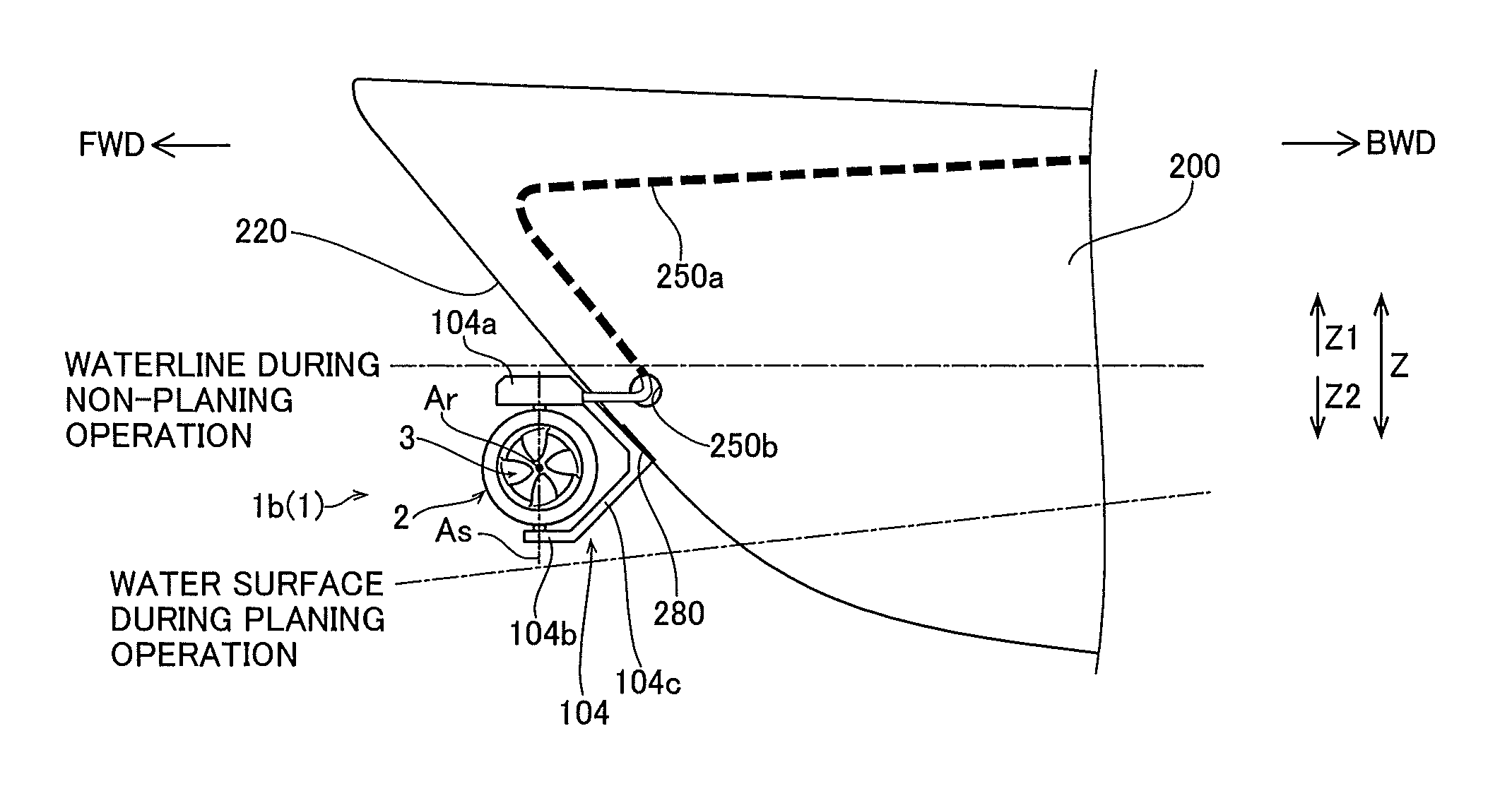

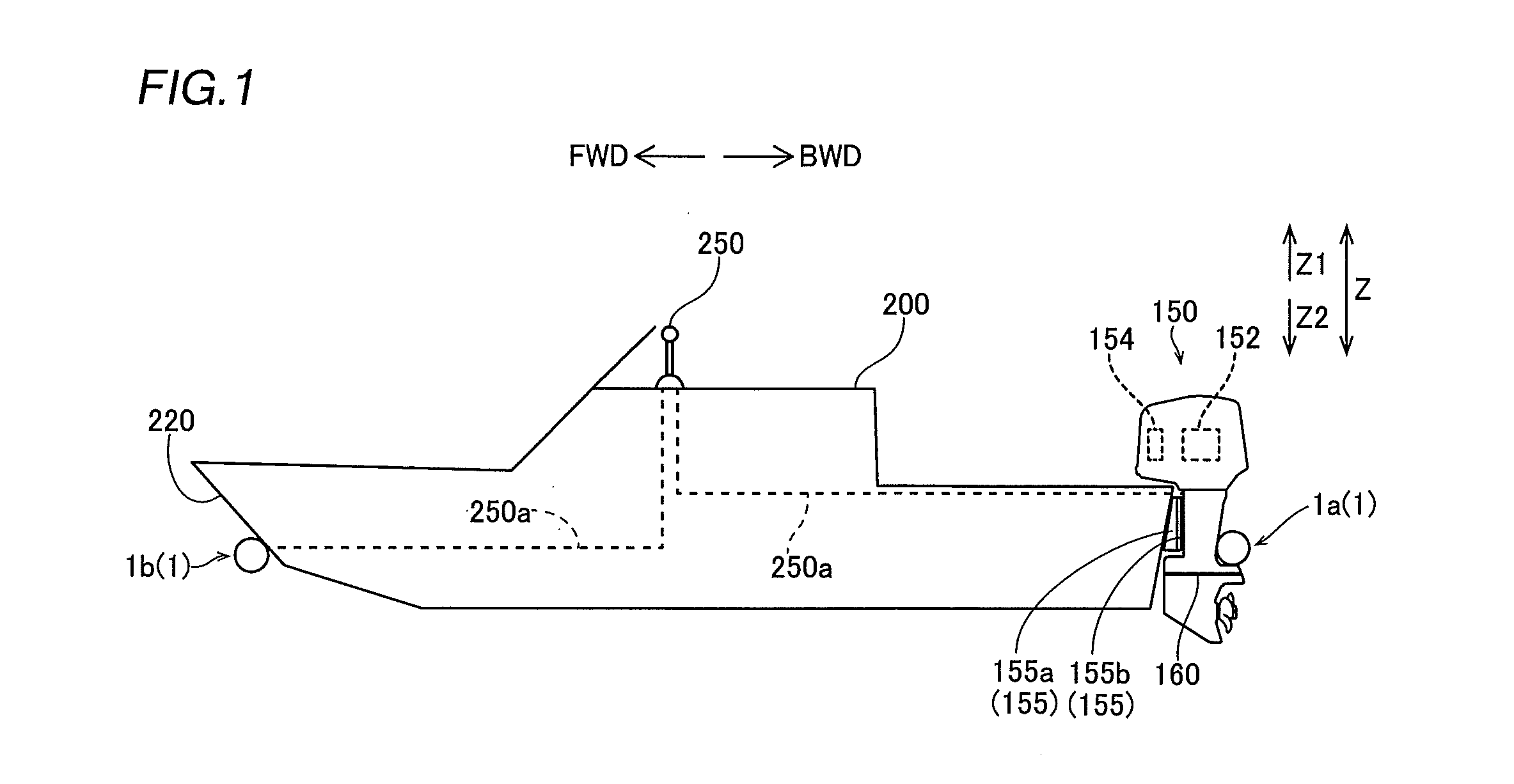

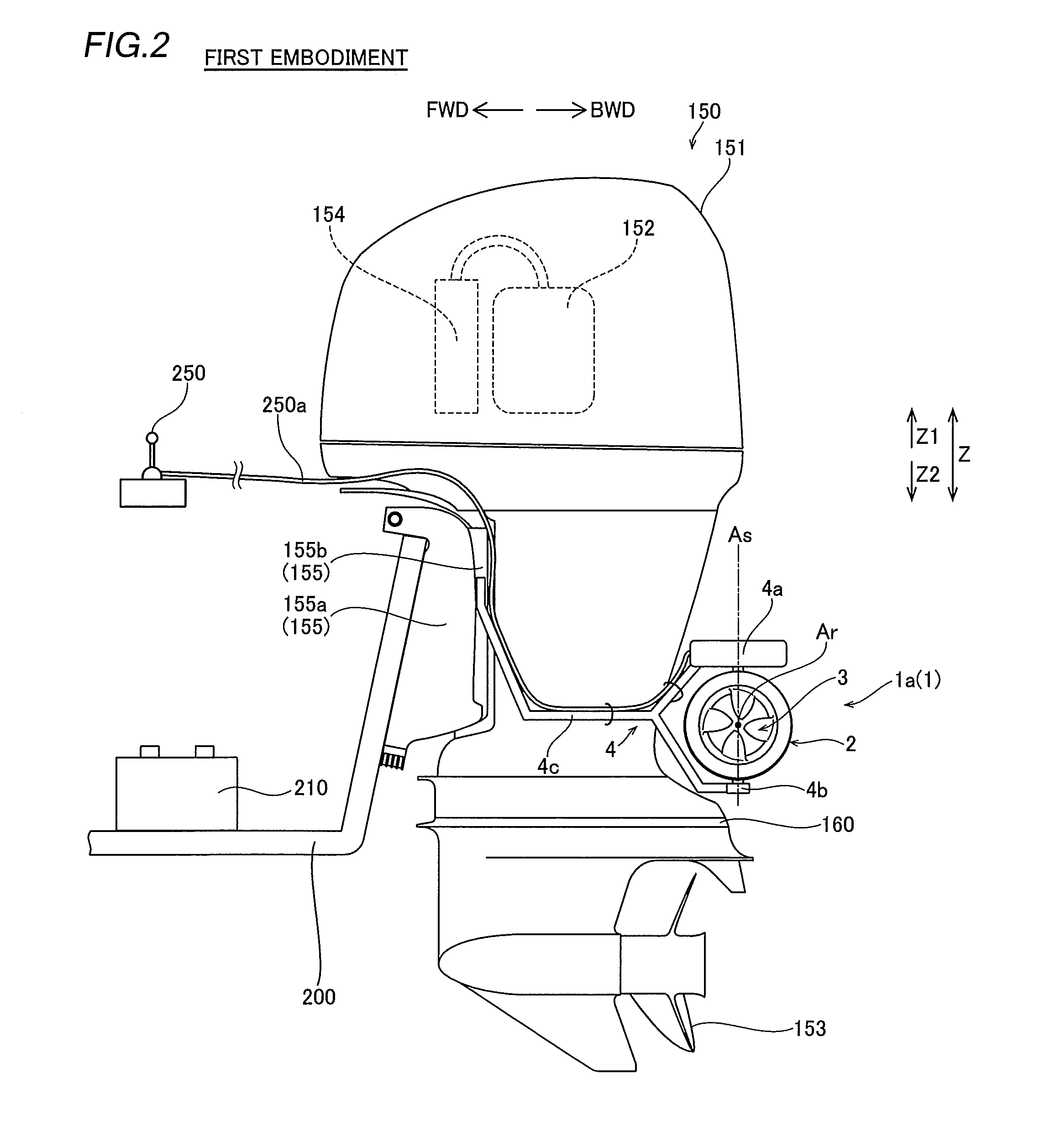

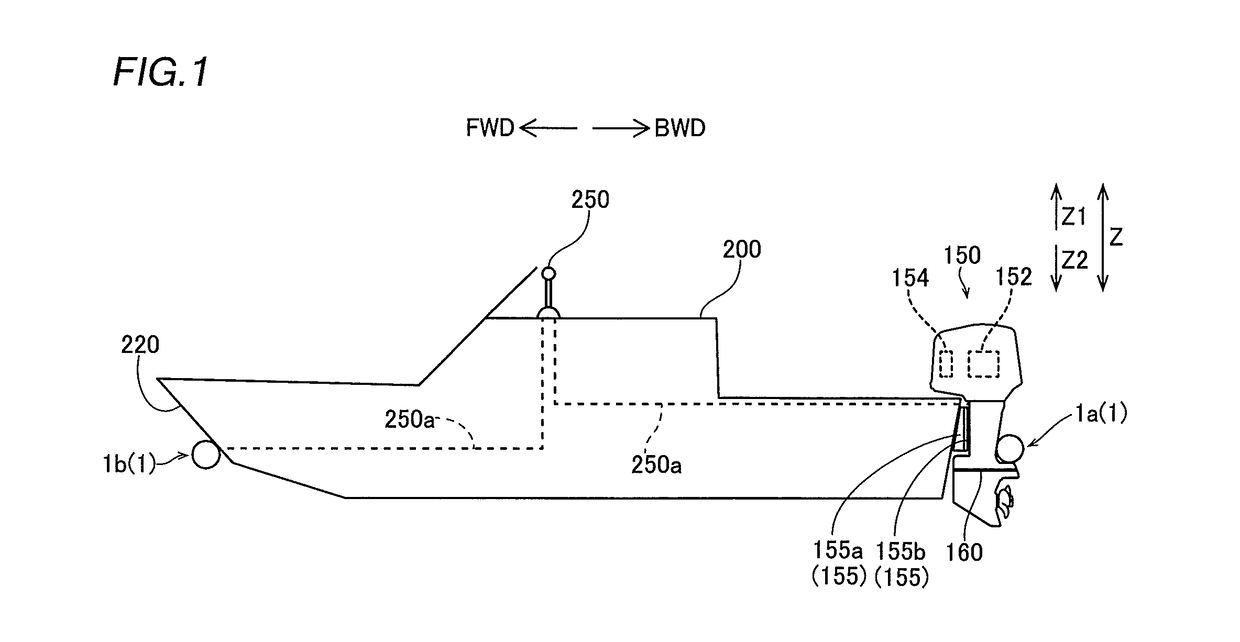

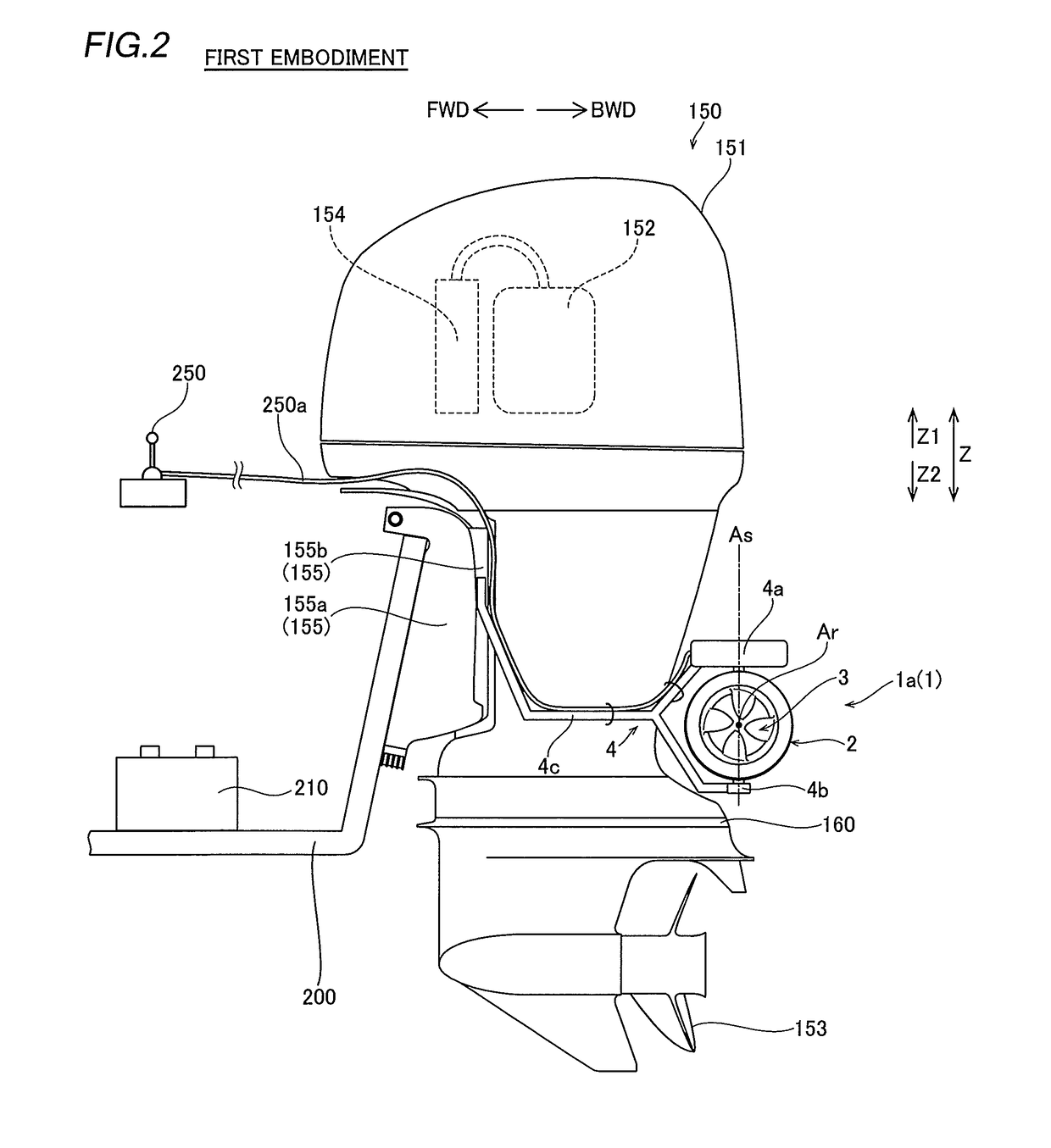

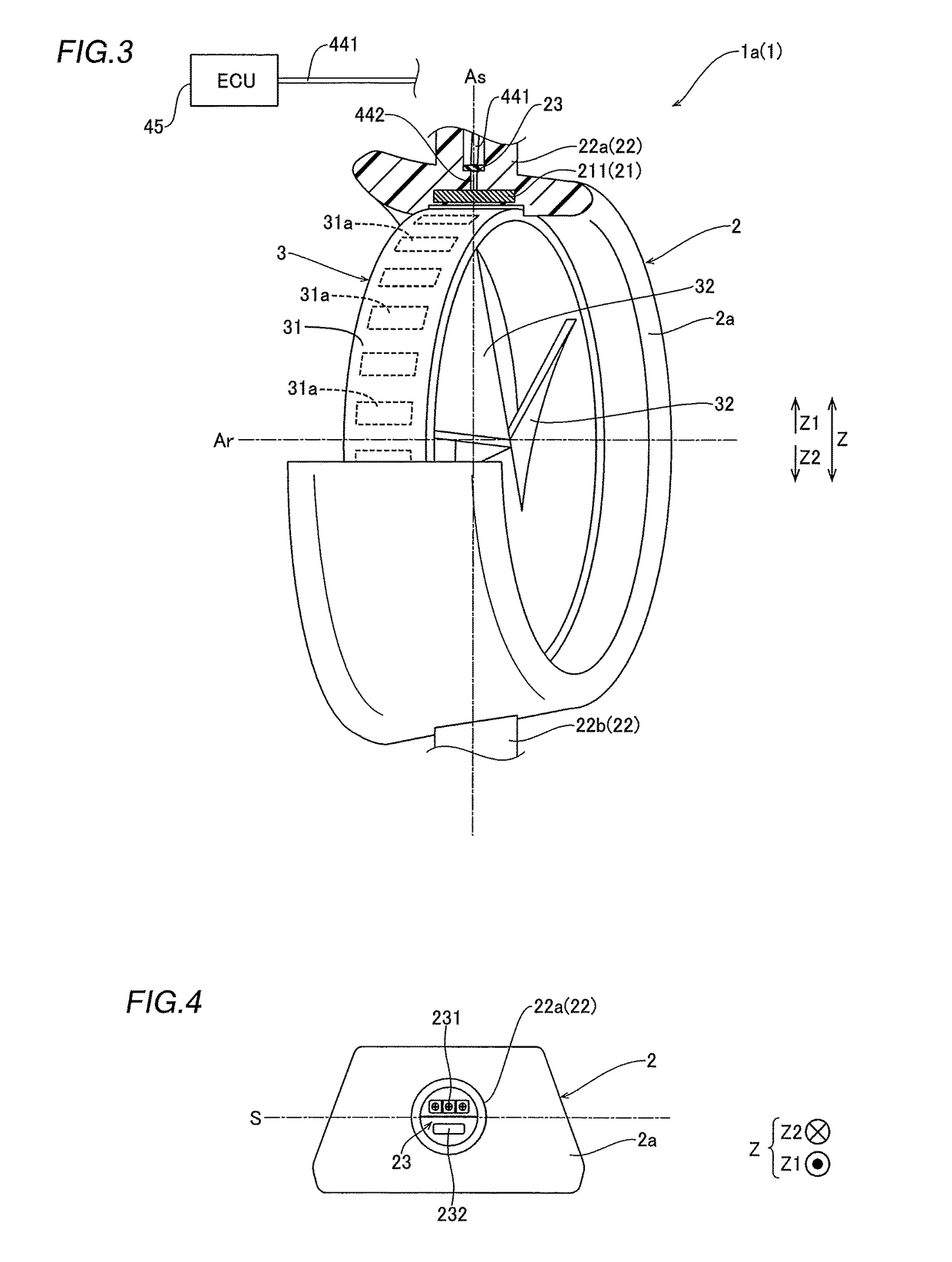

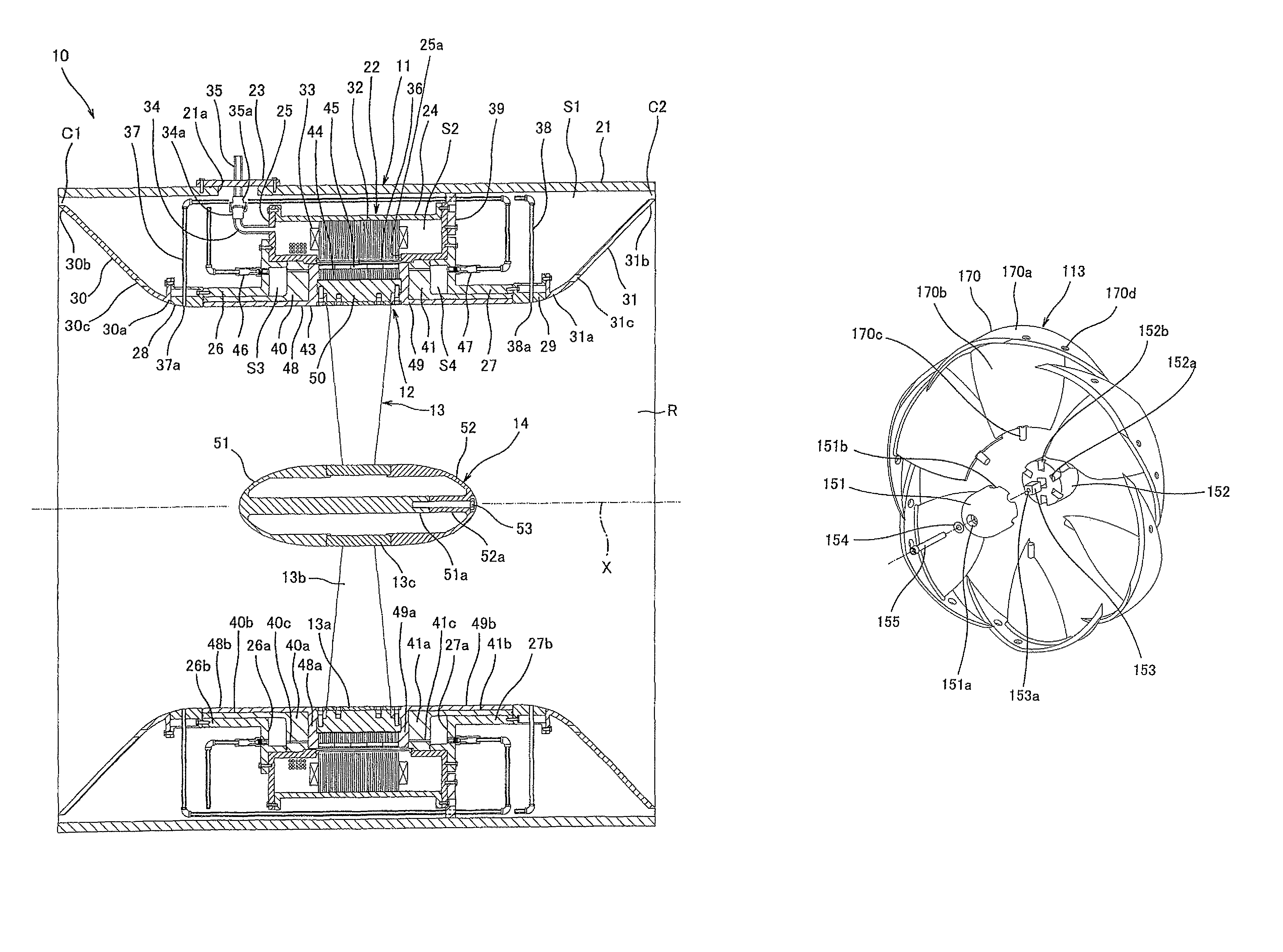

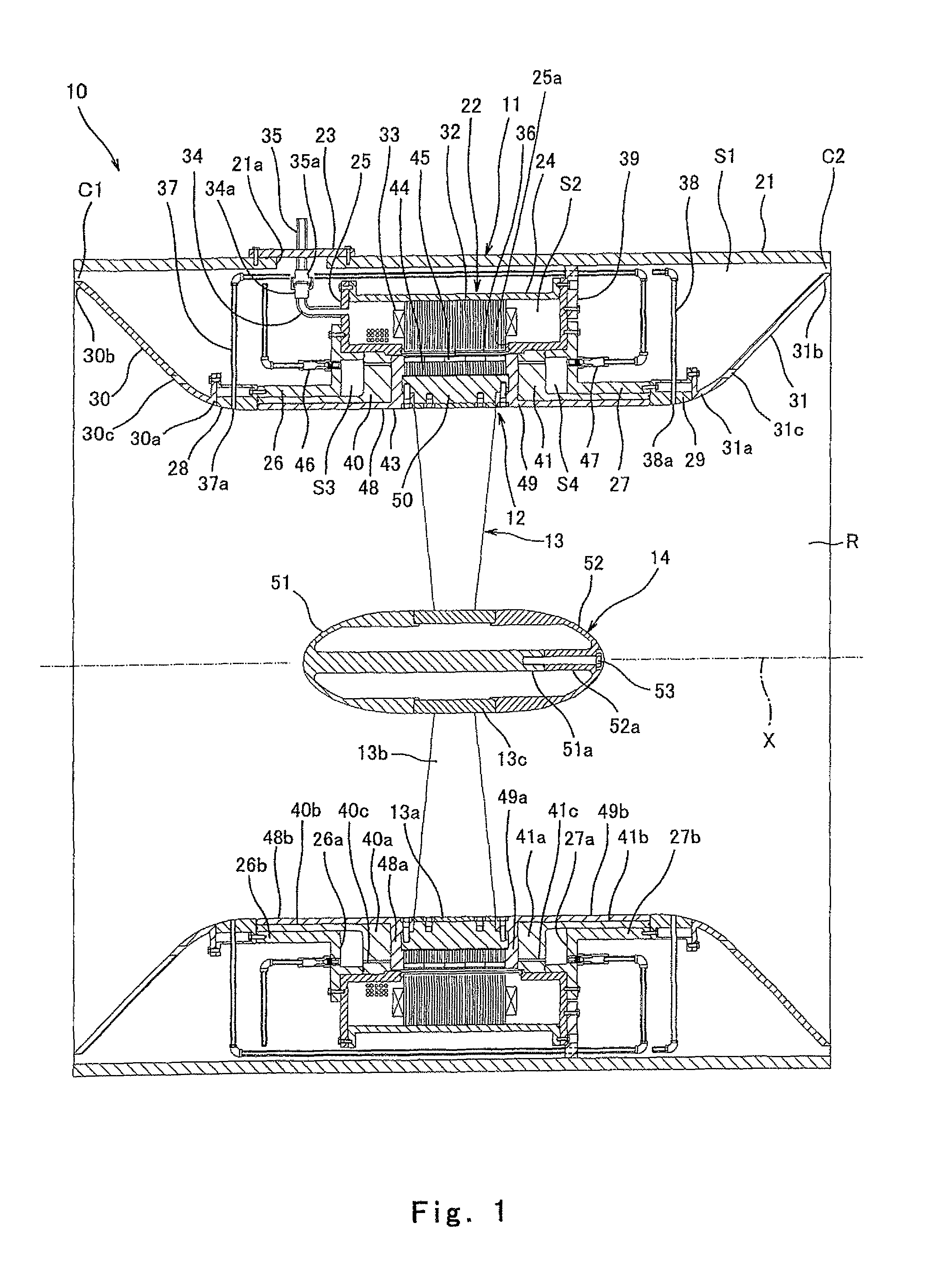

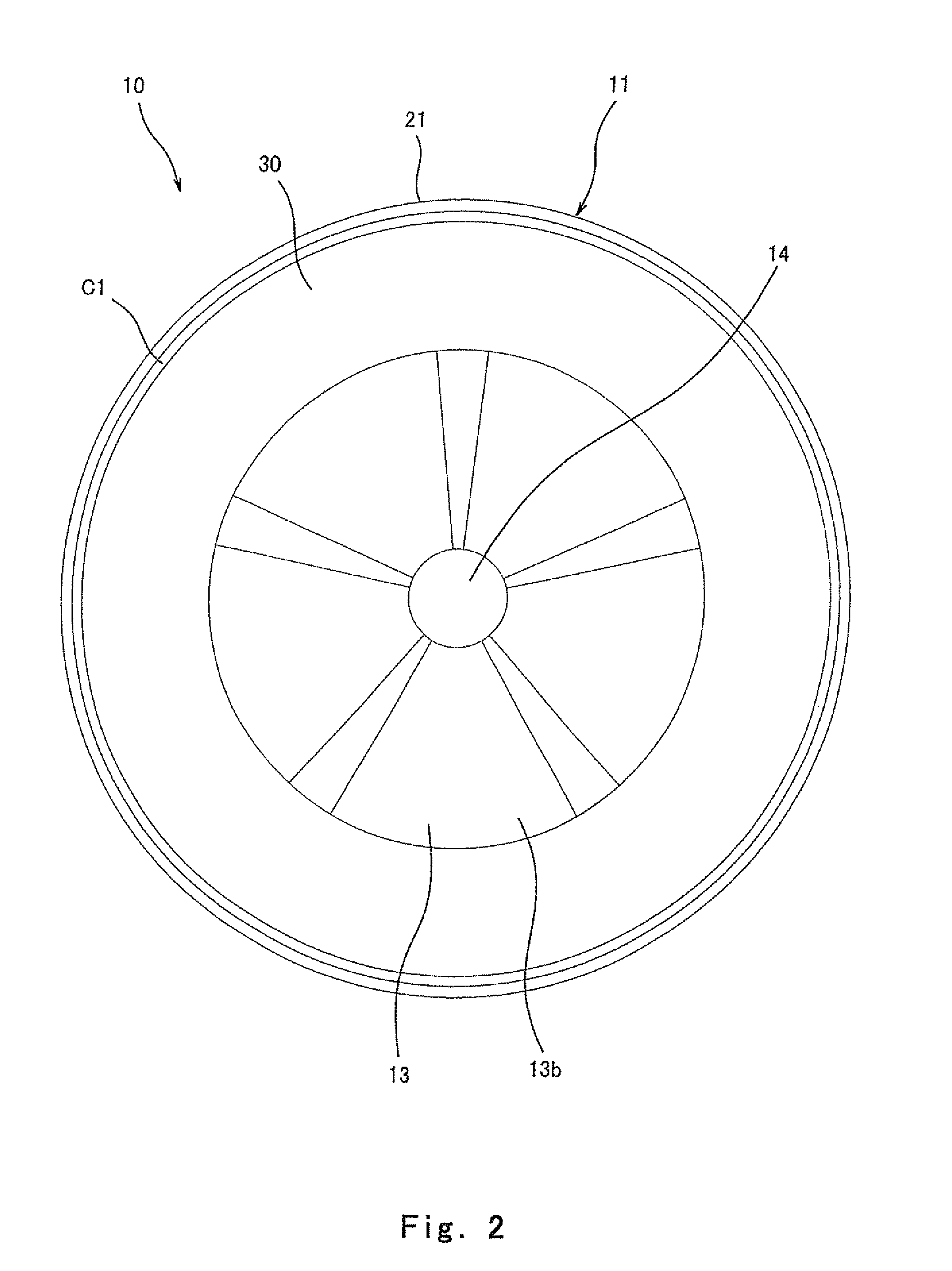

Vessel propulsion apparatus and vessel including the same

ActiveUS20180134355A1Easy to operatePropulsive transmission driveRotary propellersPropellerMotor controller

A vessel propulsion apparatus includes a cylindrical duct including a stator and a propeller. The propeller includes a rim including a rotor disposed at a position facing the stator and defining an electric motor in combination with the stator, and blades on an inner side in a radial direction of the rim. A fluid bearing is provided on the duct and defines a gap into which surrounding water is introduced between the fluid bearing and the rim, and is water-lubricated with respect to the rim due to water introduced into the gap from the surroundings. The vessel propulsion apparatus further includes a motor controller that drives the electric motor by rotation speed control in a rotation speed control region in which an output command is not more than a predetermined value, and drives the electric motor by torque control in a torque control region in which an output command is more than the predetermined value.

Owner:YAMAHA MOTOR CO LTD

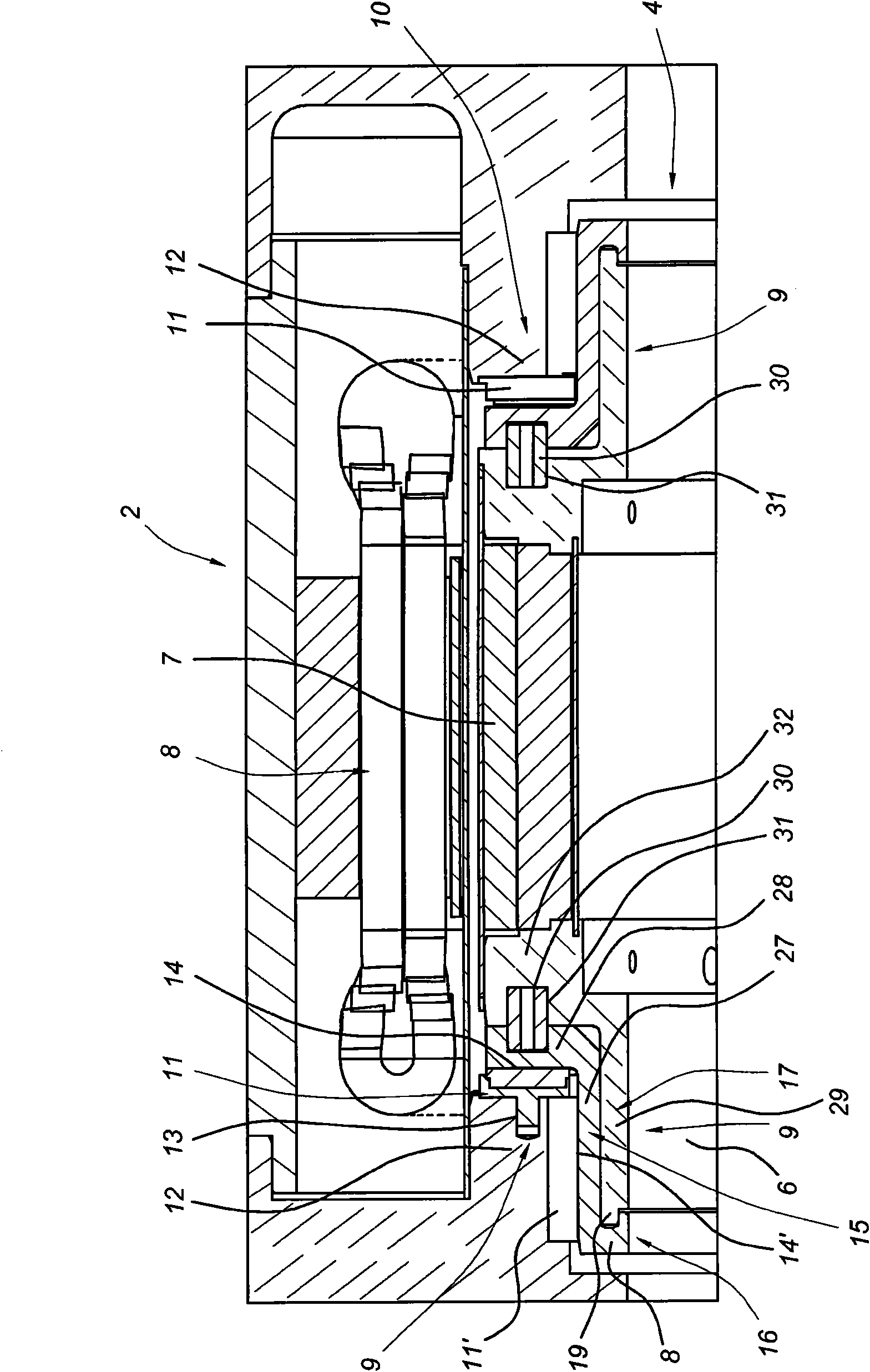

Water turbine and liquid pump

ActiveCN1809695AImprove efficiencyEasy to installPropulsive transmission driveMachines/enginesImpellerWater turbine

Apparatus with a water turbine or water pump, especially a tube-type turbine (2) with two or more wheels (25, 26) rotating independently of each other and placed successively in the axial direction, especially with mutually opposite blade slopes. The wheels (25, 26) are each coupled to a generator or motor, which is arranged to be controlled mutually independently in regard to rotational speed and electrical power.

Owner:SINVENT AS

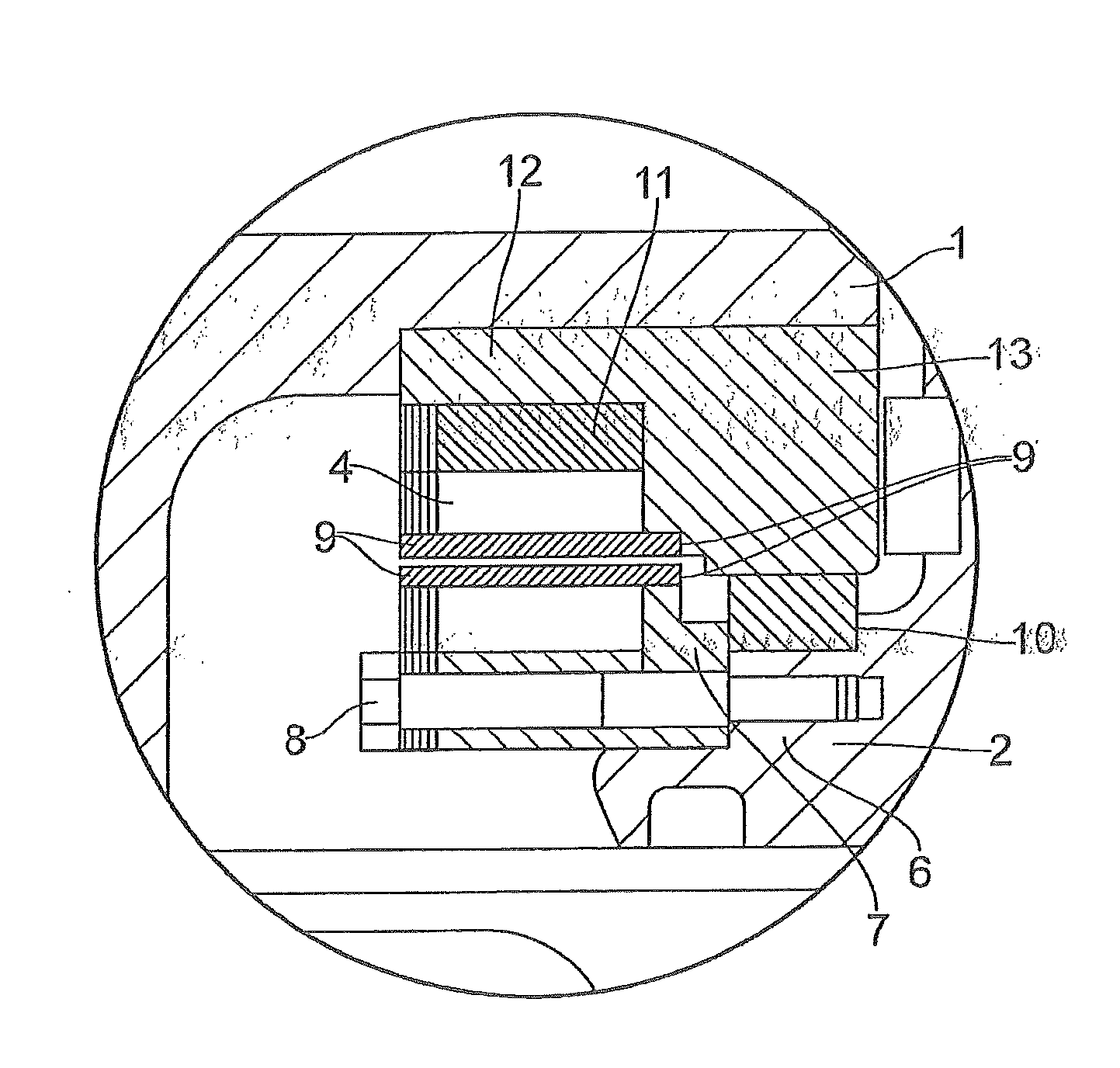

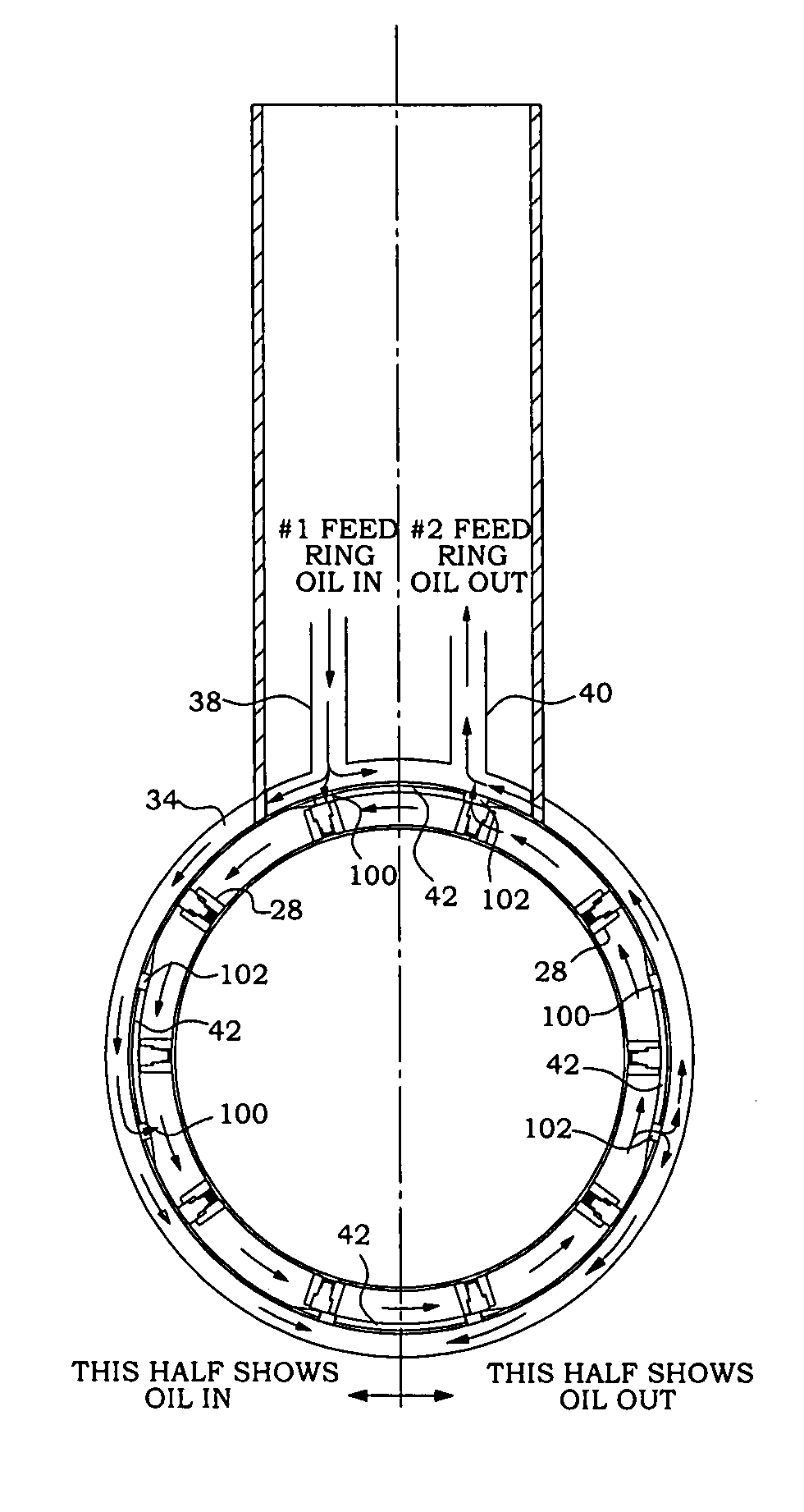

Bearing structure, and propeller device equipped with such bearing structure

InactiveCN102092466AAvoid surface deformationDegree of protection against loss of desired collaborationPropulsive transmission driveRotary propellersBall bearingPropeller

A bearing structure between a rotor (4) and a sleeve (2), such as in a screw device, includes at least one axial bearing (9) and one radial bearing (10). Each bearing including a series of tilting pads (11, 11') extending in the peripheral direction and which are each suspended from a pad suspension area (12) of one of either the rotor (4) or the sleeve (2) by pad fastenings (13) which allow tilting, each tilting pad (11, 11') having a contact surface (14, 14'). Furthermore, each bearing including a bearing ring (15) which is situated opposite the series of tilting pads (11, 11') and cooperates with the contact surfaces thereof. The bearing ring is suspended from a bearing ring suspension area (17) of the other of either the rotor or the sleeve by bearing ring fastenings (16). The bearing ring fastenings allow contraction and expansion movements of the bearing ring.

Owner:MARIFIN BEHEER

Electric propulsion device

ActiveUS20160090166A1Increase in sizeReduce the overall heightPropulsive transmission drivePropulsion power plantsActuatorElectric power

An electric propulsion device includes a duct having a cylindrical shape and that includes a stator. A rim includes a rotor rotatable relative to the duct, and a plurality of fins. A bracket supports the duct so as to allow the duct to turn about a turning axis that intersects with the rotation axis of the rim, and a turning actuator that integrally turns the duct and the rim. The turning actuator is fixed to the bracket, and the duct is turnable relative to the bracket.

Owner:YAMAHA MOTOR CO LTD

Shaftless radial vane rotary device and a marine propulsion system using the device

InactiveUS7284495B2Expand smoothlyEliminate needRotary propellersPropulsive transmission driveMarine propulsionRudder

A radial vane fluid motor or pump has an open ended tubular rotor having a cylindrical outer surface rotatably mounted in a tubular stator having its inner surface contoured to provide successive portions of increased and decreased spacing relative to the rotor body. A plurality of elongated movable vane assemblies are mounted on and project outwardly from the rotor surface to continuously contact the stator surface. Bearings support the rotor within the stator, and seals are provided for sealing the space between the rotor and stator. Pressure inlets and exhaust ports are provided in the stator to permit the flow of pressure fluid into or out of the device. Mounting the vanes on the cylindrical rotor surface enables production cost reduction and simplifies maintenance. A conventional propeller mounted in the cylindrical rotor provides an improved shrouded propellor propulsion system for marine vessels. Mounting the system on a vessel for rotation about an axis perpendicular to the axis of the rotor enables steering of the vessel without use of a rudder.

Owner:SEIFORD SR DONALD S

Water vehicle propeller

In this specification regarding water vehicle propellers, the gist of the technical disclosure resides in the construction of a propeller having elongated blades which extend in a helical path and longitudinally of the hull of a water vehicle in an unbroken length, singly or in aligned sections following the contour of the hull, for substantially its entire length or that portion of the length of a water vehicle in contact with the body of water when under way. The elongated propellers are rotated on their longitudinal axis. In addition, two of such elongated propellers or aligned sections of such propellers are mounted parallel for rotation in opposite directions either within a tubular housing open at the front and rear or mounted directly adjacent the hull with one or more on either side. Spaced apart longitudinal support members are secured below the elongated propellers to prevent contact with an object or objects from below and to support the propellers and hull above any such objects. One of such propellers may be mounted below a forward portion of a vessel and a second below a rearward portion, each propeller being pivotable outwardly in opposite directions from the longitudinal axis of the vessel to enable the vessel to turn more rapidly from one direction to another.

Owner:KETTELSON ERNEST

Electric propulsion device

ActiveUS10202181B2Reduce the overall heightPropulsive transmission drivePropulsion power plantsActuatorElectric power

An electric propulsion device includes a duct having a cylindrical shape and that includes a stator. A rim includes a rotor rotatable relative to the duct, and a plurality of fins. A bracket supports the duct so as to allow the duct to turn about a turning axis that intersects with the rotation axis of the rim, and a turning actuator that integrally turns the duct and the rim. The turning actuator is fixed to the bracket, and the duct is turnable relative to the bracket.

Owner:YAMAHA MOTOR CO LTD

Propulsion unit

ActiveUS20140356199A1Small amount of heatSmall amountPropulsion based emission reductionPropulsive transmission driveWater flowPropeller

A propulsion unit is disclosed, which can include a casing, a shaft, a propeller, an annular housing and a rim drive electric motor. The casing can be rotatably supported at a hull of a vessel. The shaft can be rotatably supported with bearings within a lower portion of the casing. A propeller can be attached to an outer end of the shaft protruding from the lower portion of the casing. The annular housing can surround an outer perimeter of the propeller and can form a duct for water flowing through the interior of the annular housing. The rim drive electric motor can include a rotor rim provided on an outer perimeter of the propeller and a stator provided within the annular housing. Oil lubricated roller bearings can be used on the shaft within the casing. The axial length of the propulsion unit can be short.

Owner:ABB (SCHWEIZ) AG

Marine propulsion unit

ActiveUS20180257750A1Easy to installReduces and prevents entryPropulsive transmission driveRotary propellersMarine propulsionMotor controller

A marine propulsion unit includes a duct including a stator, a propeller including a rim including a rotor disposed at a position that faces the stator and a blade provided radially inward of the rim, a steering shaft that supports the duct such that the duct is steerable, a casing provided separately from the steering shaft and that extends along a rotation axis of the propeller, and a motor controller disposed in the casing and configured or programmed to control rotational driving of the propeller.

Owner:YAMAHA MOTOR CO LTD

Propulsion system

A propulsion system includes a cylindrical support member and a tubular rotatable member rotatably mounted within the support member that be adapted to permit fluid flow therethrough. The tubular rotatable member extend past a down stream end of the tubular rotating member. An exemplary embodiment of a propulsion system also disclose a vane attached on an interior surface of the tubular member and include a blade which extends in a direction toward a rotational axis of the rotatable member such that rotation of the tubular member and the vane attached thereon draws fluid into the tubular member to accelerate the fluid flow through the tubular member. Additionally, a nozzle is attached to the down stream end of the support member and includes a primary nozzle and a secondary nozzle within the primary nozzle. The secondary nozzle is engaged with the primary nozzle by a stator.

Owner:休·尼科尔森

Thrust generating apparatus

InactiveUS8708668B2Easy to replaceHigh strengthRotary propellersPropulsive transmission driveEngineeringSupport surface

Owner:KAWASAKI HEAVY IND LTD

Popular searches

Dynamo-electric machines Propulsive transmission Sliding contact bearings Underwater vessels Underwater equipment Mechanical energy handling Synchronous machines with stationary armatures and rotating magnets Electric propulsion Power to electric lighting circuits Transmission with mechanical gearing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com