Support of propeller unit for a vessel

A technology for propellers and ships, applied in the field of propeller unit supports, can solve problems such as discomfort for crew members and passengers, shortening of effective life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

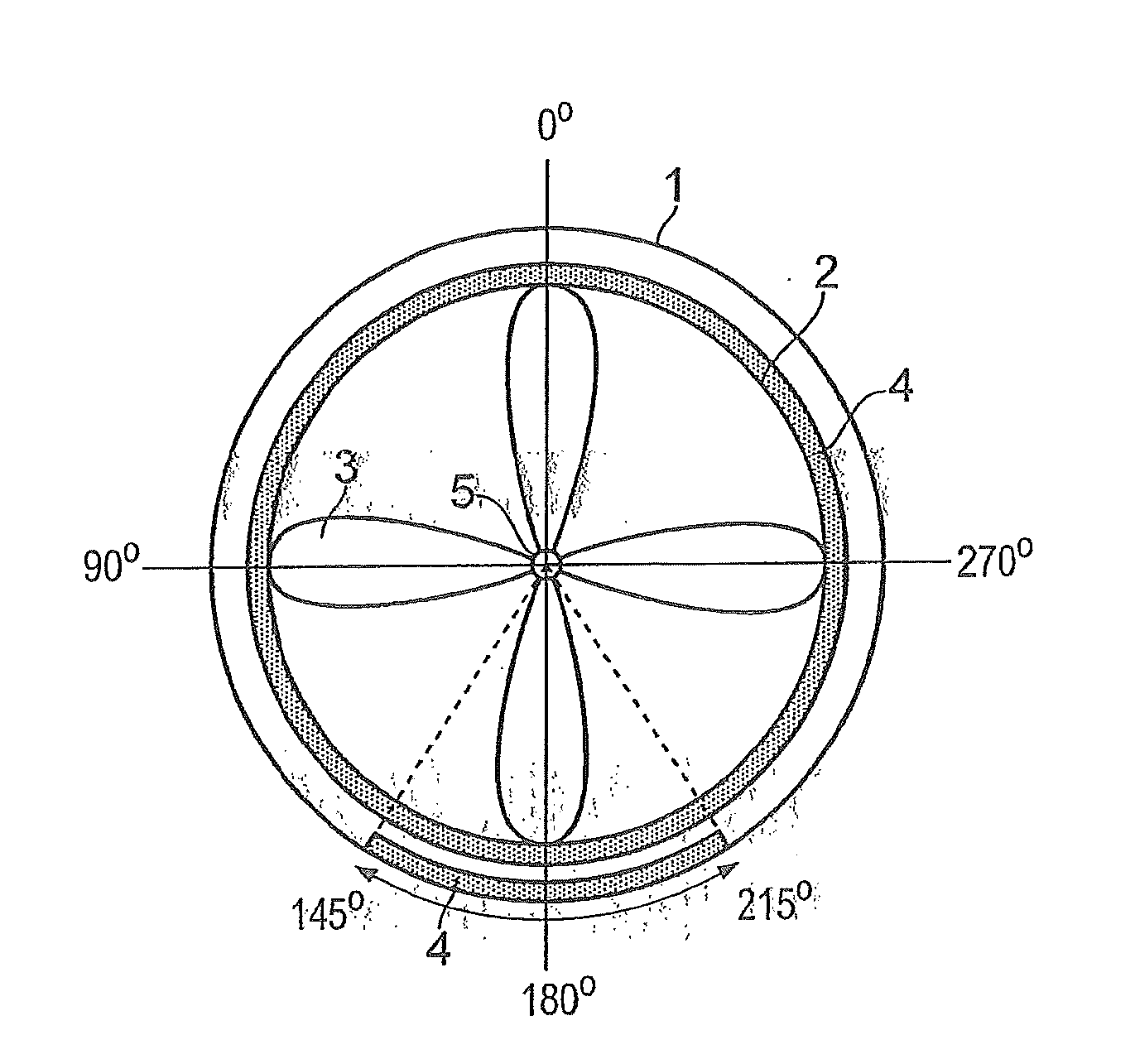

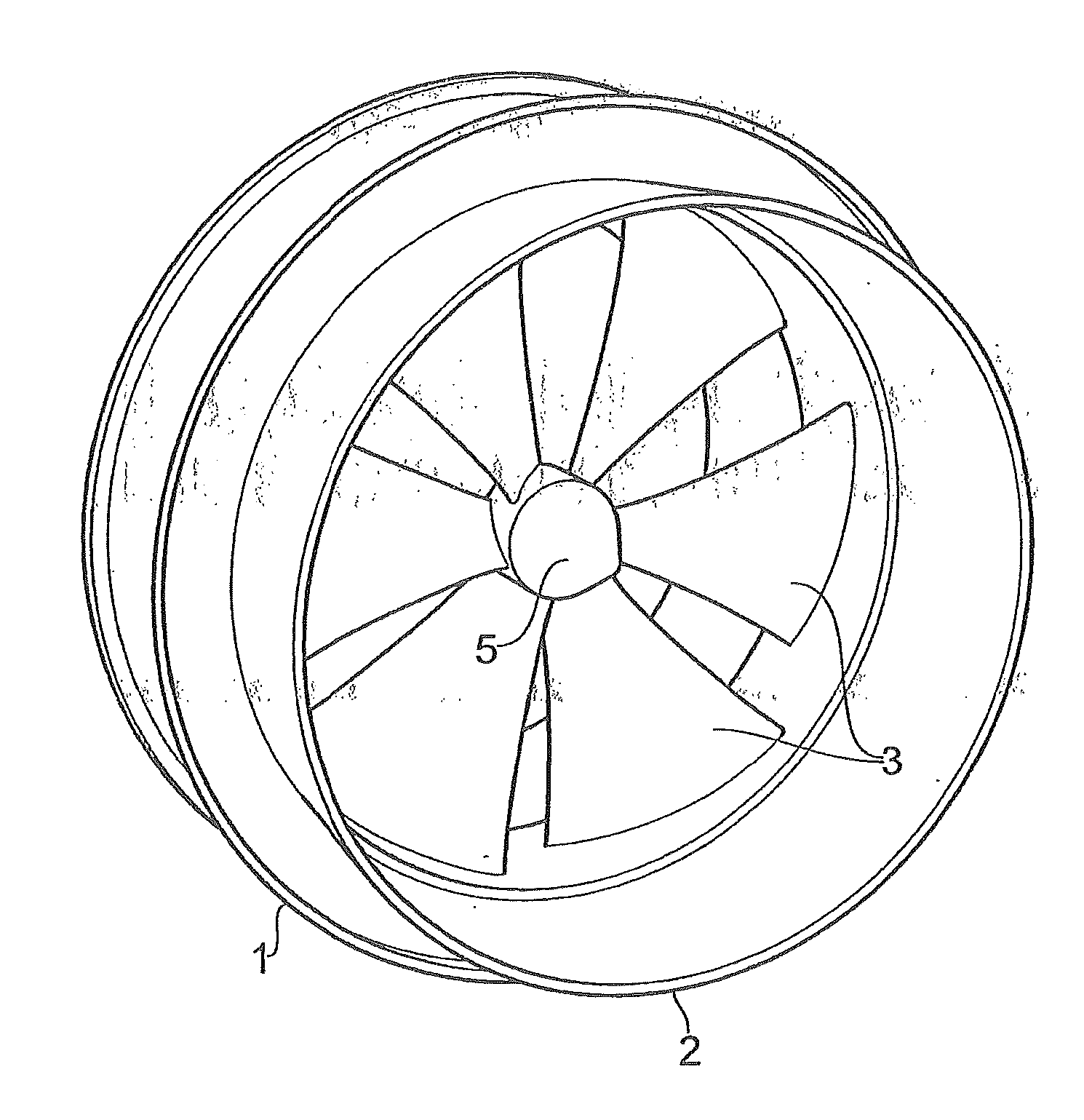

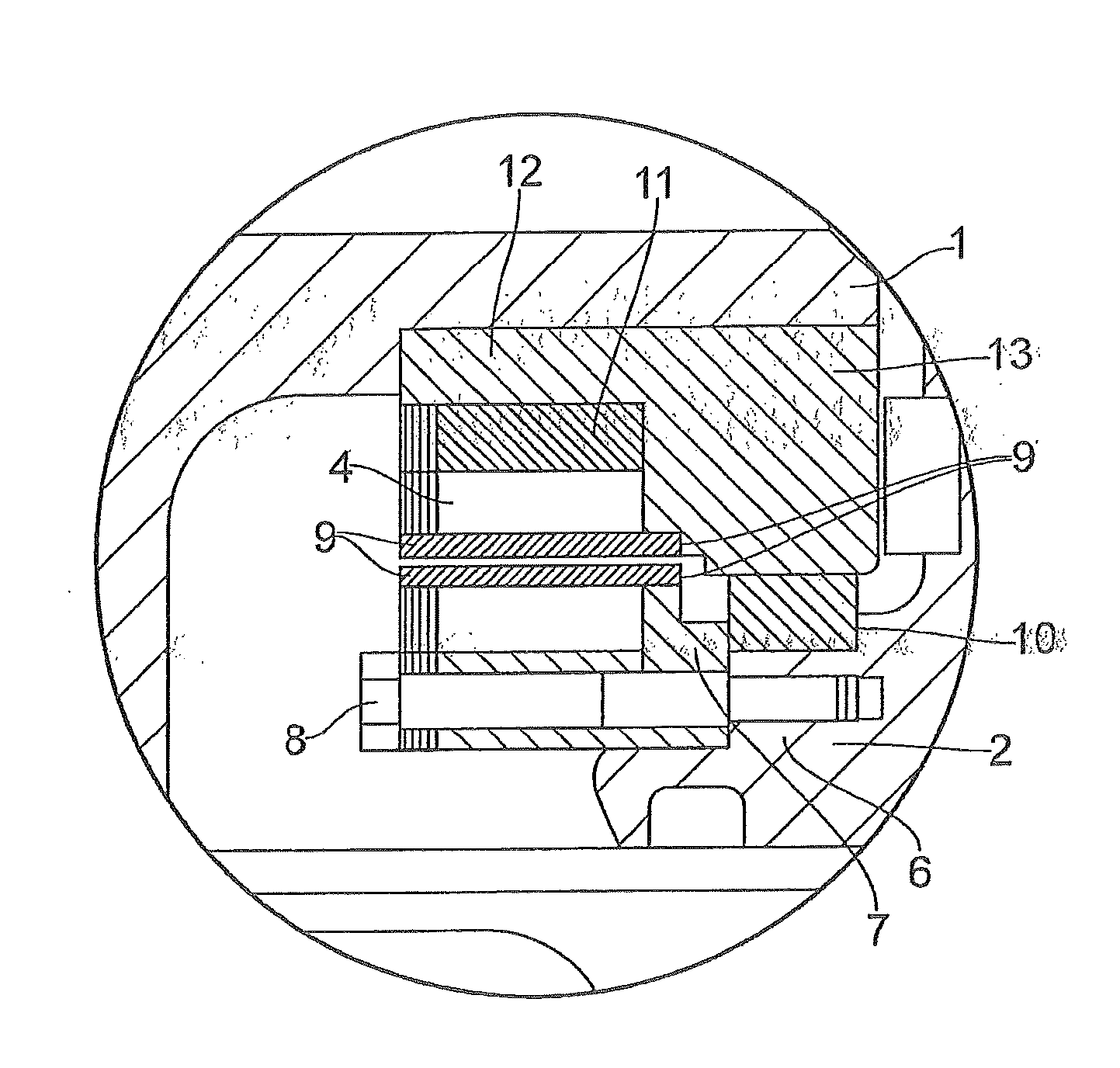

[0038] exist figure 1 A propeller unit according to the invention is shown in , wherein the propeller unit comprises an outer stationary casing 1 and a rotatable rotor casing 2 . The outer stationary casing 1 is securely mounted to a vessel (not shown) in a suitable manner such that the casing 1 forms a stationary unit with the vessel. A rotatable rotor casing 2 is internally mounted in the outer stationary casing 1 , wherein the rotor casing 2 includes a number of propeller blades 3 and a propeller hub 5 . The propeller blades 3 are firmly connected to the rotatable rotor casing 2 via the propeller hub 5 and the inner circumference of the rotatable rotor casing 2 . The outer diameter of the rotor housing 2 is smaller than the inner diameter of the stationary housing 1, and as a result, when the outer stationary housing 1 and the rotatable rotor housing 2 are assembled, there will be a difference between the outer circumference of the rotating rotor housing 2 and the inner ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com