Non-shaft propeller

A propeller and shaftless technology, which is applied in the direction of rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of waste and ineffective utilization, and achieve the effect of improving efficiency and high recoil speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

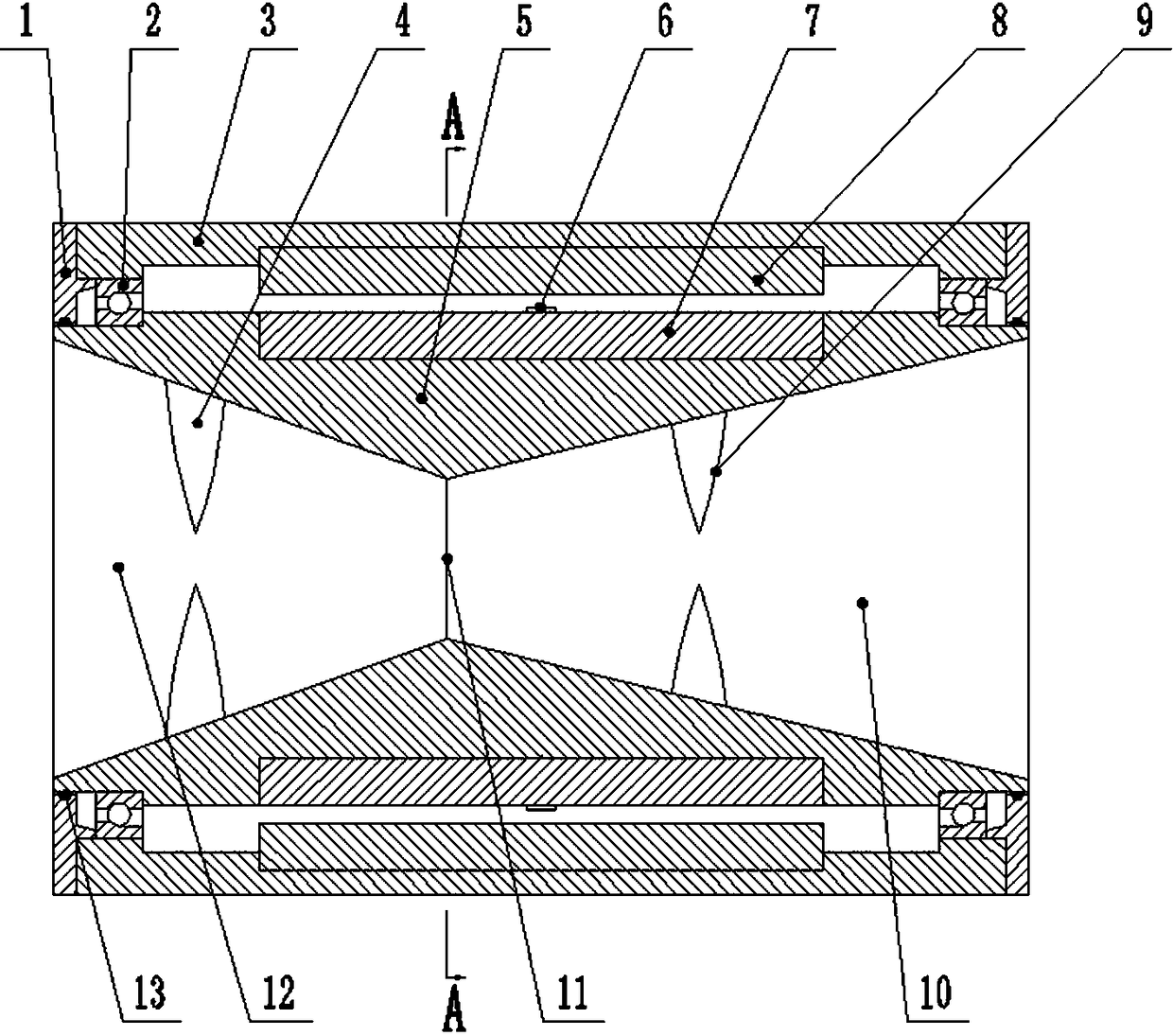

[0035] Regarding the Laval nozzle, it is composed of two conical tubes, one of which is a contraction tube and the other is an expansion tube. It is the most commonly used component of rocket engines and aero-engines.

[0036] The first half of the Laval nozzle is a constriction portion that shrinks from large to small to the middle until it shrinks to a throat 11 . The throat 11 then expands from small to large to the end of the rotor 5, which is called the expanded part. The Laval nozzle was invented by the Swedish Laval, so it is also called "Laval nozzle".

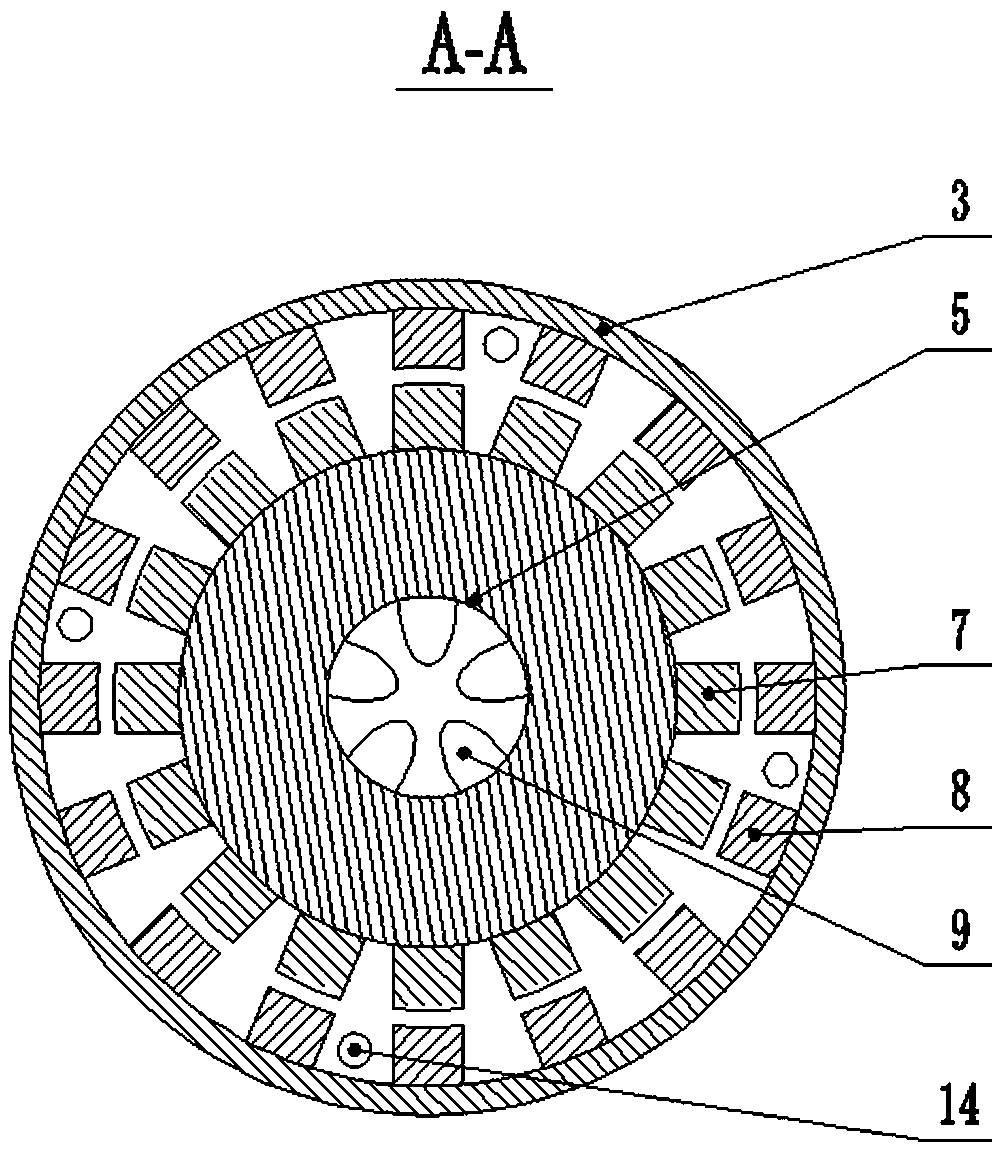

[0037] Regarding the shaftless propeller, its basic structure can be found in the Chinese patent document CN1897417A, which is also an early document in this field. It discloses the basic structure of the shaftless propeller. Regarding the shaftless propeller, it actually belongs to electric drive equipment. With the stator 3 and the rotor 5, as well as the adapted stator winding 8 and the permanent magnet 7, the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com