Pod type rim propeller

A propeller, pod technology, applied in ship propulsion, propulsion components, outboard propulsion devices, etc., can solve problems such as energy loss, blade tip cavitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

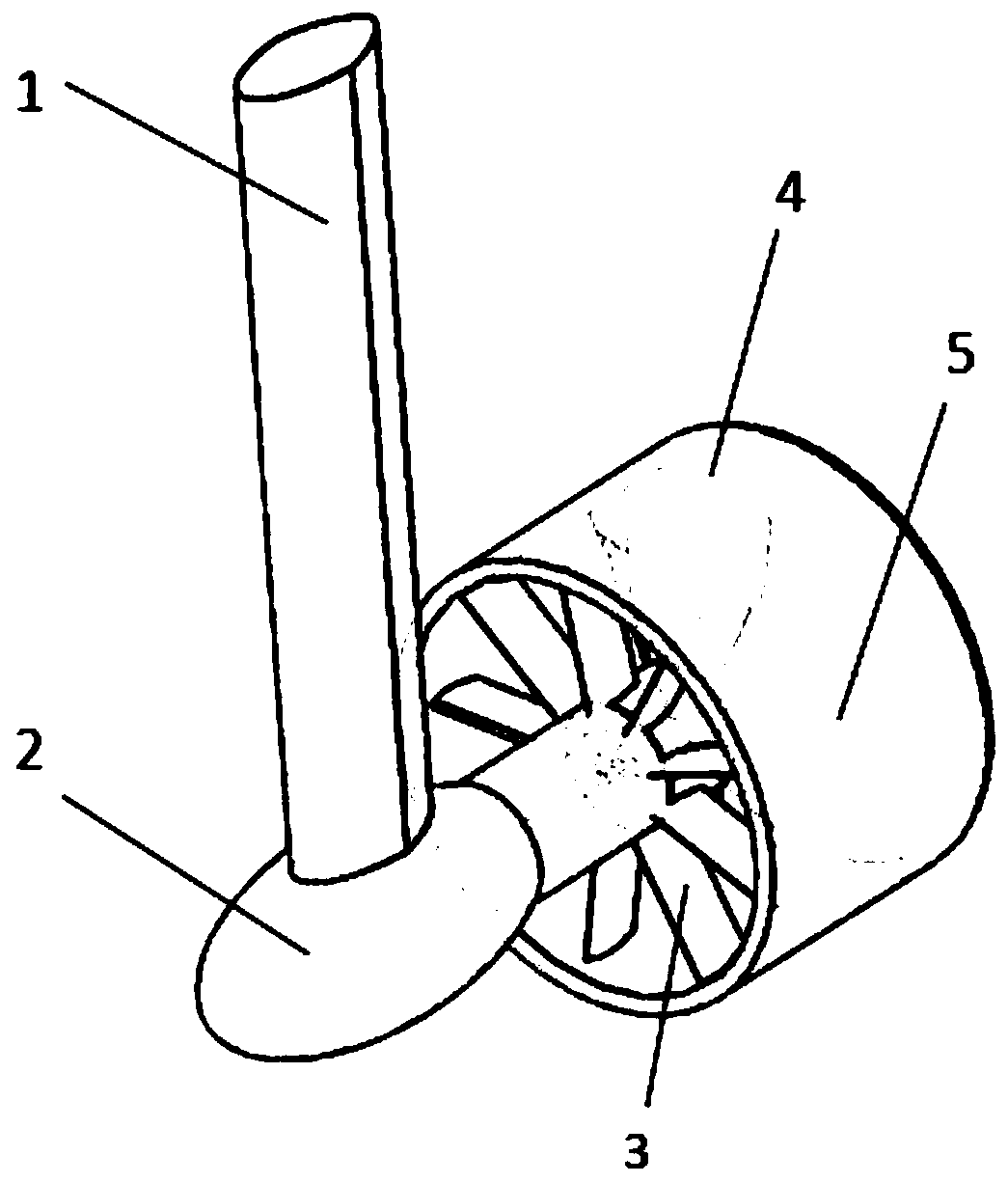

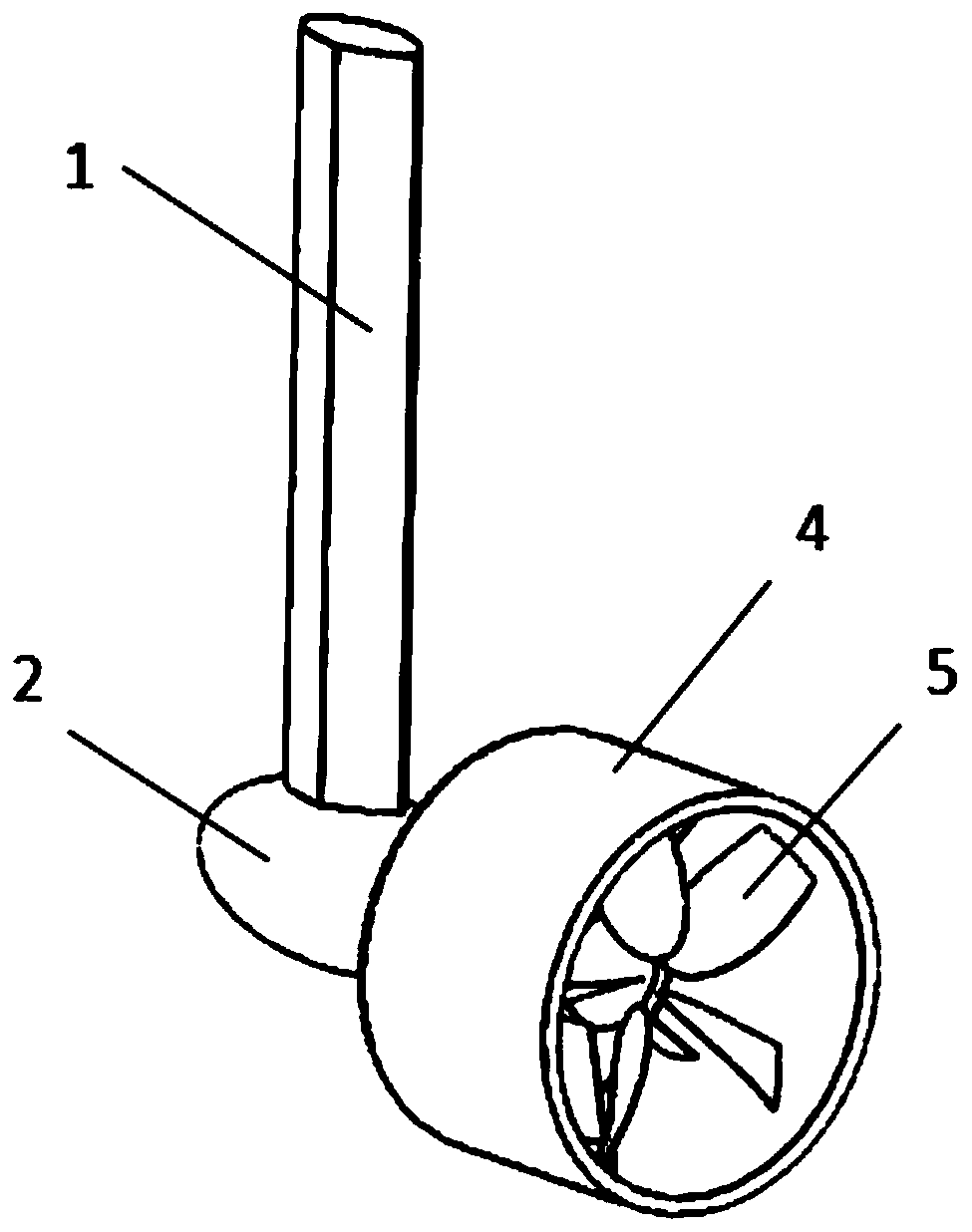

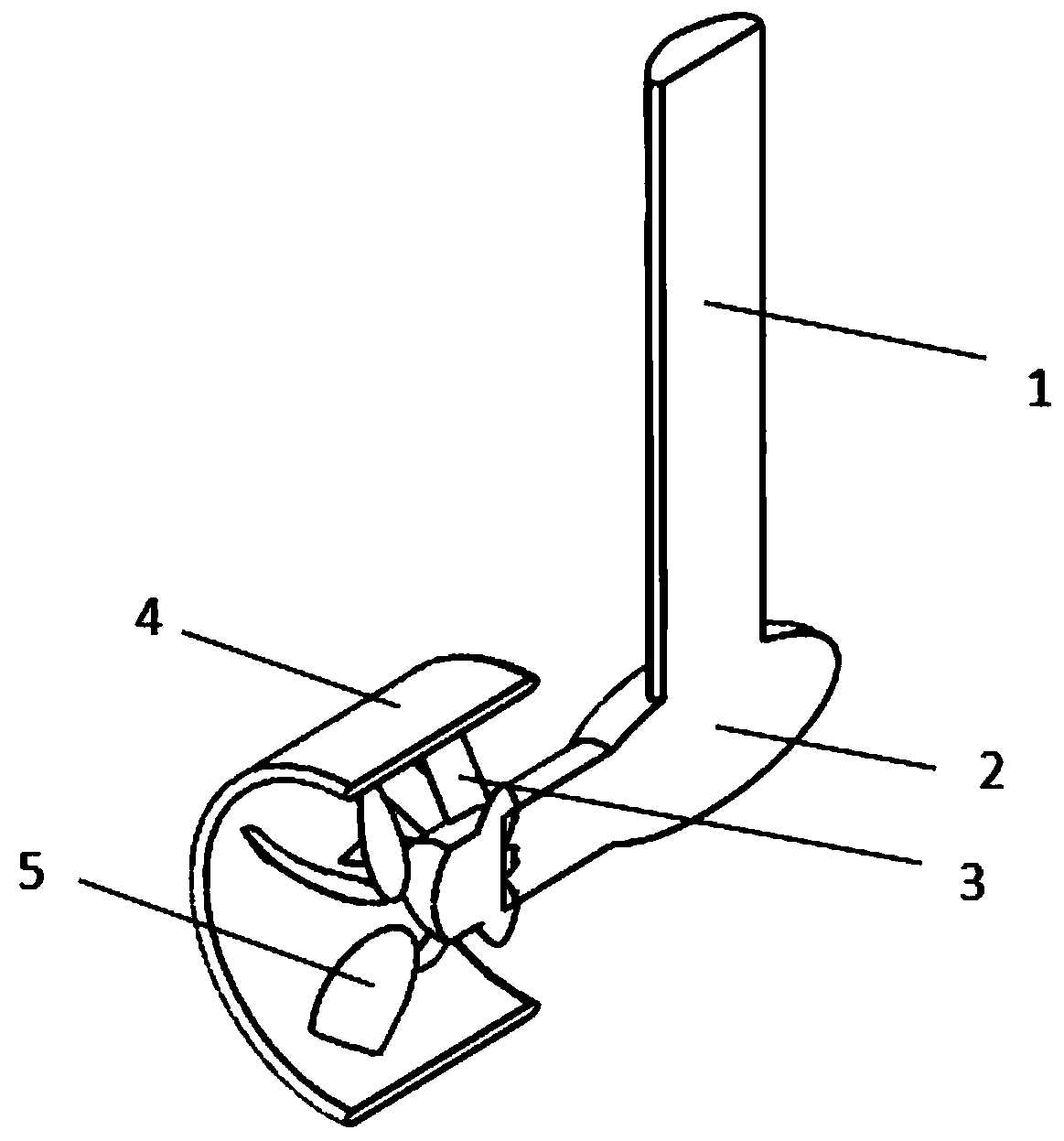

[0021] The invention includes brackets, pods, stators, ducts and blades. The upper end of the support is connected with the hull, and the lower end is connected with the pod, and the support can generate thrust in different directions through flexible steering; the pod is also fixedly connected with the stator, and the tip of the stator is connected with the guide tube, and the guide tube is also equipped with five blades .

[0022] The present invention also includes such features:

[0023] 1. The whole system is located at the stern of the ship;

[0024] 2. The motor stator winding is placed inside the conduit, and the motor rotor is installed at the root of the blade. The motor stator winding is fed with an alternating current to drive the motor rotor to move, thereby driving the blade to rotate, thereby providing thrust.

[0025] Compared with prior art, the beneficial effect of the present invention is:

[0026] 1. Expand the application of shaftless propulsion, and ap...

Embodiment 2

[0036] The invention designs a pod type rim-driven propeller, which mainly includes a bracket, a pod, a stator, a duct and blades. The shaft of the stator is fixedly connected to the pod, and the tip is connected to the conduit. The conduit can move with the pod to achieve the purpose of omnidirectional rotation. In addition, the conduit integrates the motor together, eliminating the need for complex mechanical structures inside the pod. The cavitation problem at the tip of the propeller is completely solved. The invention not only integrates propulsion and steering, but also adds the concept of the shaftless propeller into the design, which provides beneficial effects for the integrated module in the field of ship propulsion.

[0037] 1. A pod type rim-driven propeller, comprising a support 1, a pod 2, a stator 3, a conduit 4 and blades 5. The upper end of the support is connected with the hull, and the lower end is connected with the pod, and the support can generate thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com