Bearing structure, and propeller device equipped with such bearing structure

A technology of supporting structure and propeller, applied in the direction of rotating propeller, bearing, mechanical equipment, etc., can solve problems such as failure, increase of supporting structure, wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

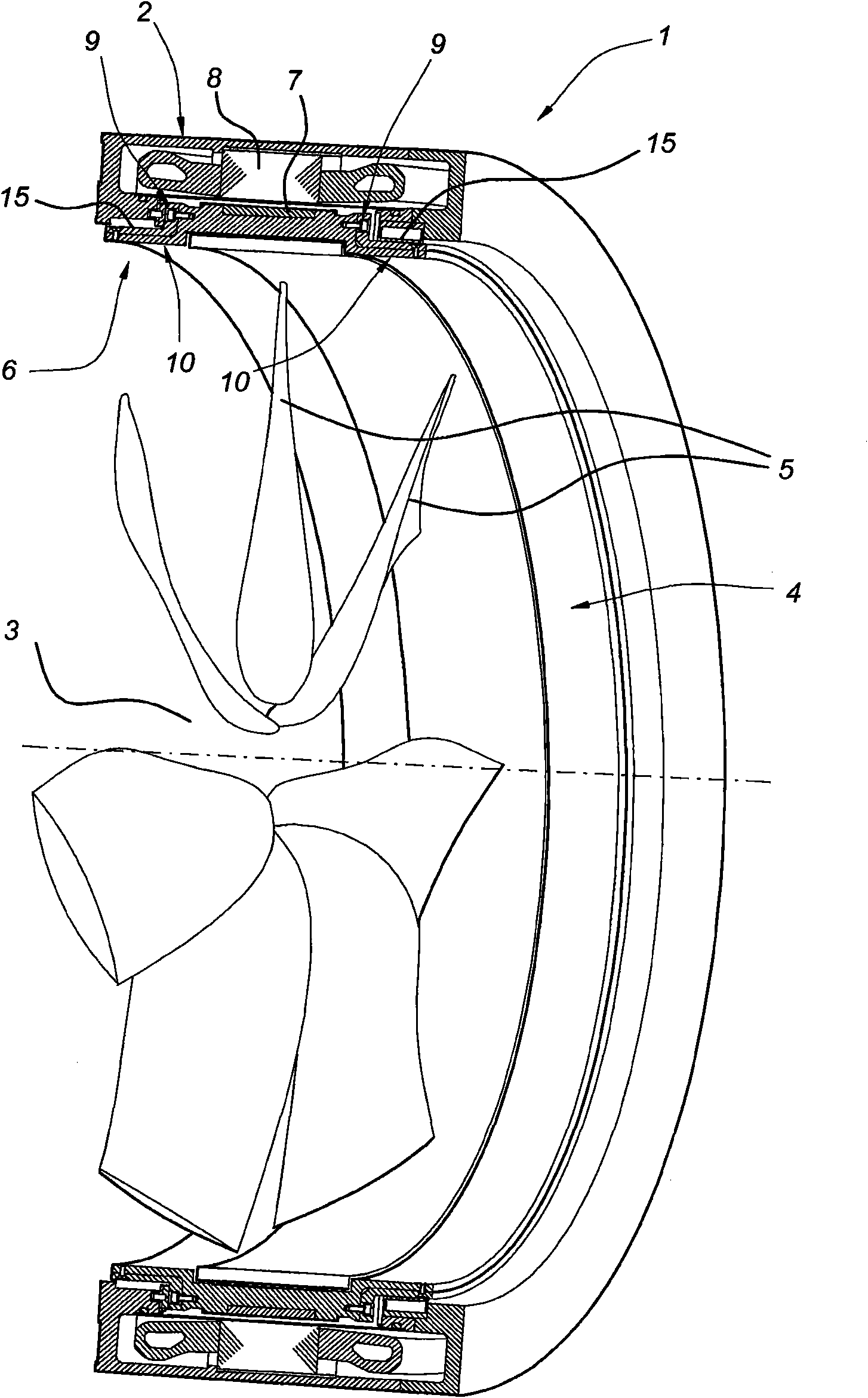

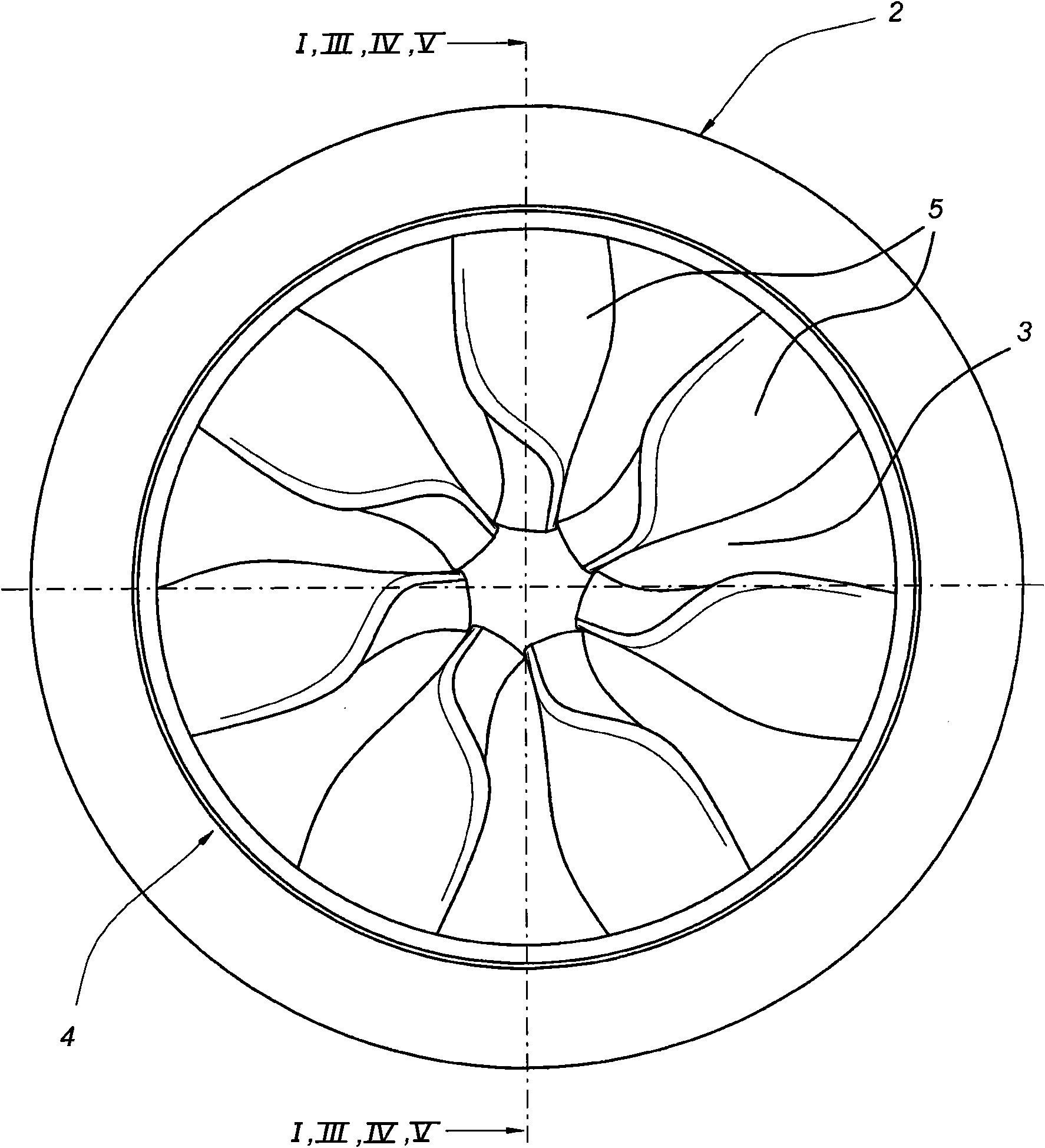

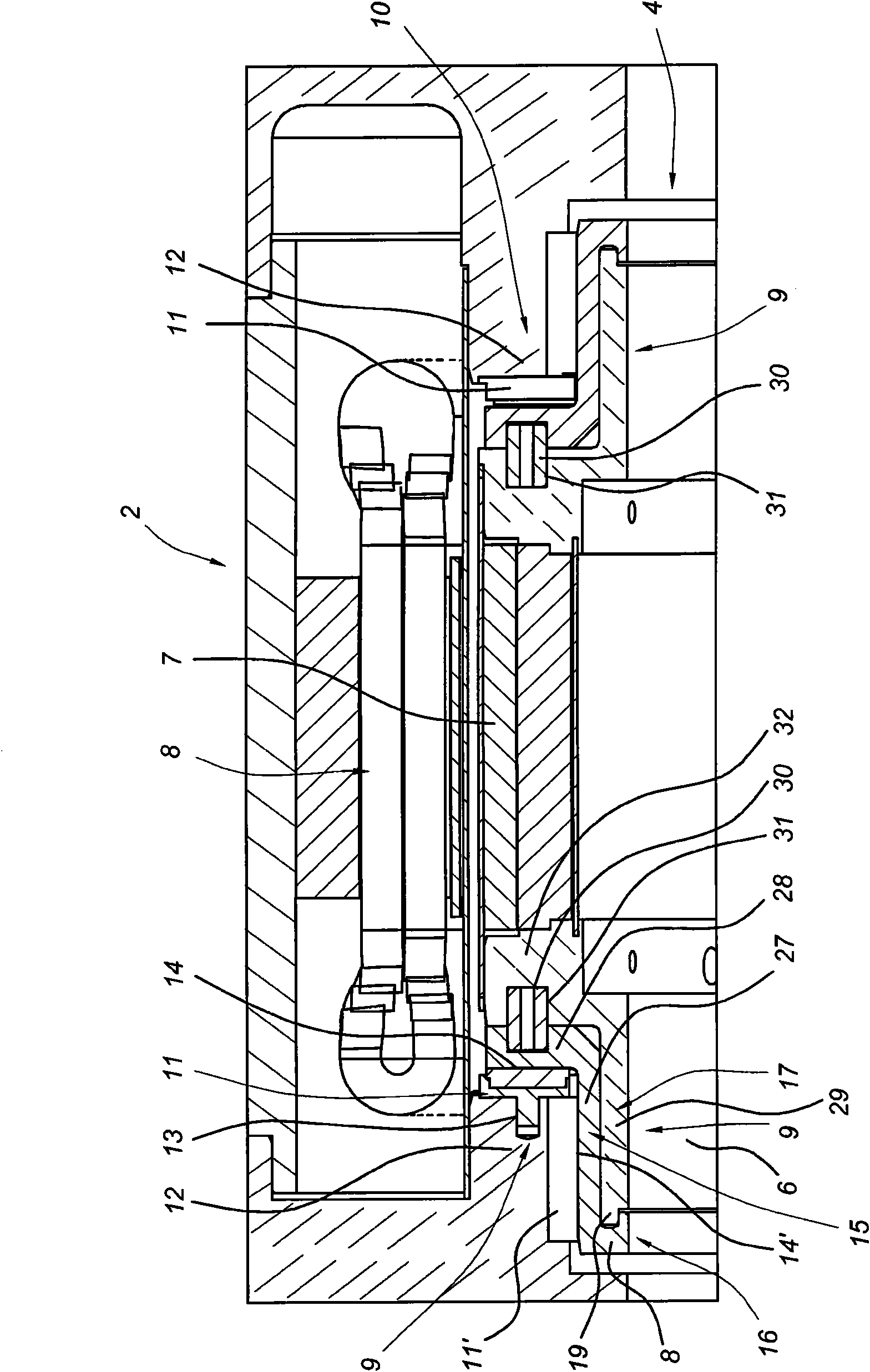

[0022] According to the present invention and in figure 1 and figure 2 The propeller shown in includes a sleeve indicated as a whole by reference numeral 2 and comprising a circular opening 3 . A rotor 4 is mounted in this opening 3 . The rotor 4 has an annular rotor body 6 and propeller blades 5 protruding inwardly from the annular rotor body 6 . Along the circumference of the annular rotor body 6 , the annular rotor body 6 is provided with permanent magnets 7 which can cooperate with stator windings 8 arranged around the opening 3 of the sleeve 2 and serve to drive the rotor 4 .

[0023] The rotor 4 is suspended in the sleeve 2 by a support structure having an axial support 9 and a radial support 10 at each axial end. The axial bearing 9 can absorb opposing axial forces, which makes it possible to drive the propeller in both directions. exist Figure 3-5 , these supports 9, 10 are shown on an enlarged scale, ie according to figure 2 The longitudinal section is shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com