Oar body and screw propeller with same

A propeller and body technology, applied in the field of propellers, can solve the problems of entanglement of water plants and other sundries, and the propeller cannot work normally, and achieve the effects of flexible cabin design, reduced output power, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

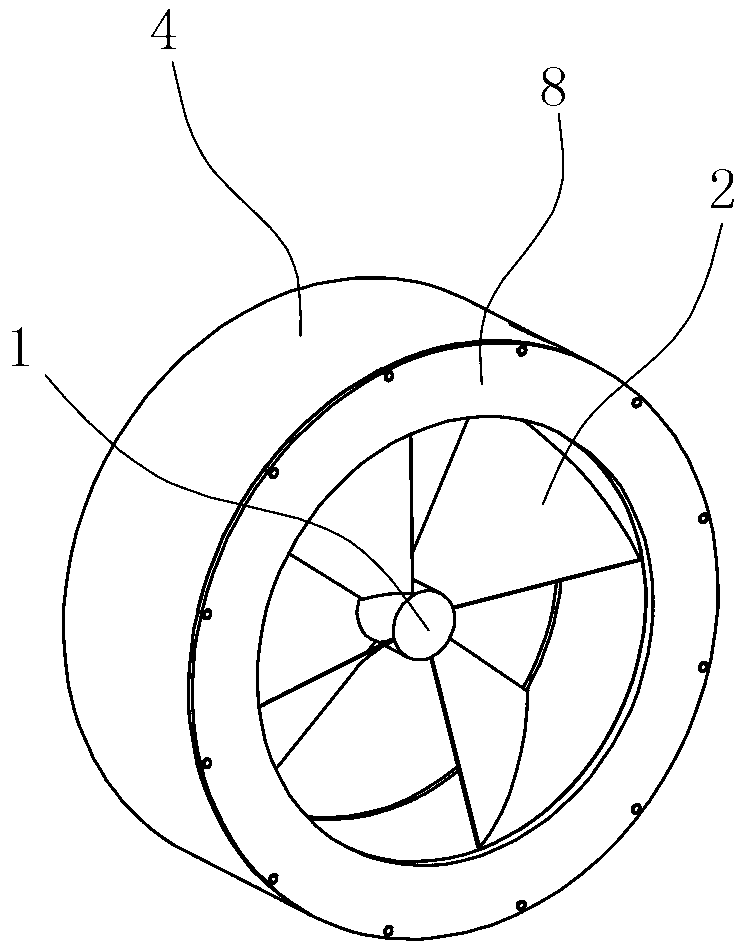

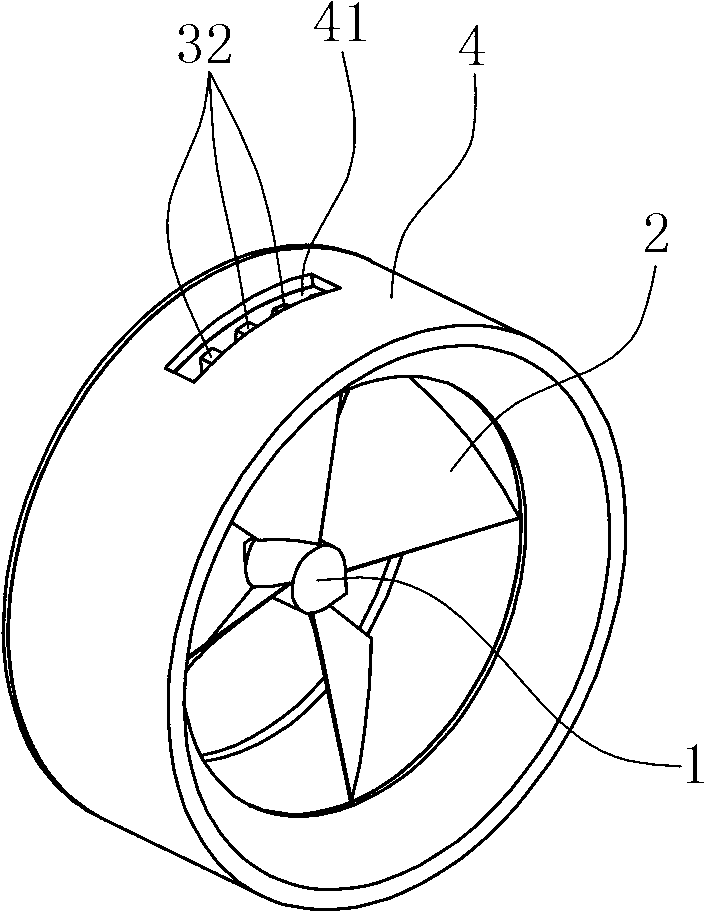

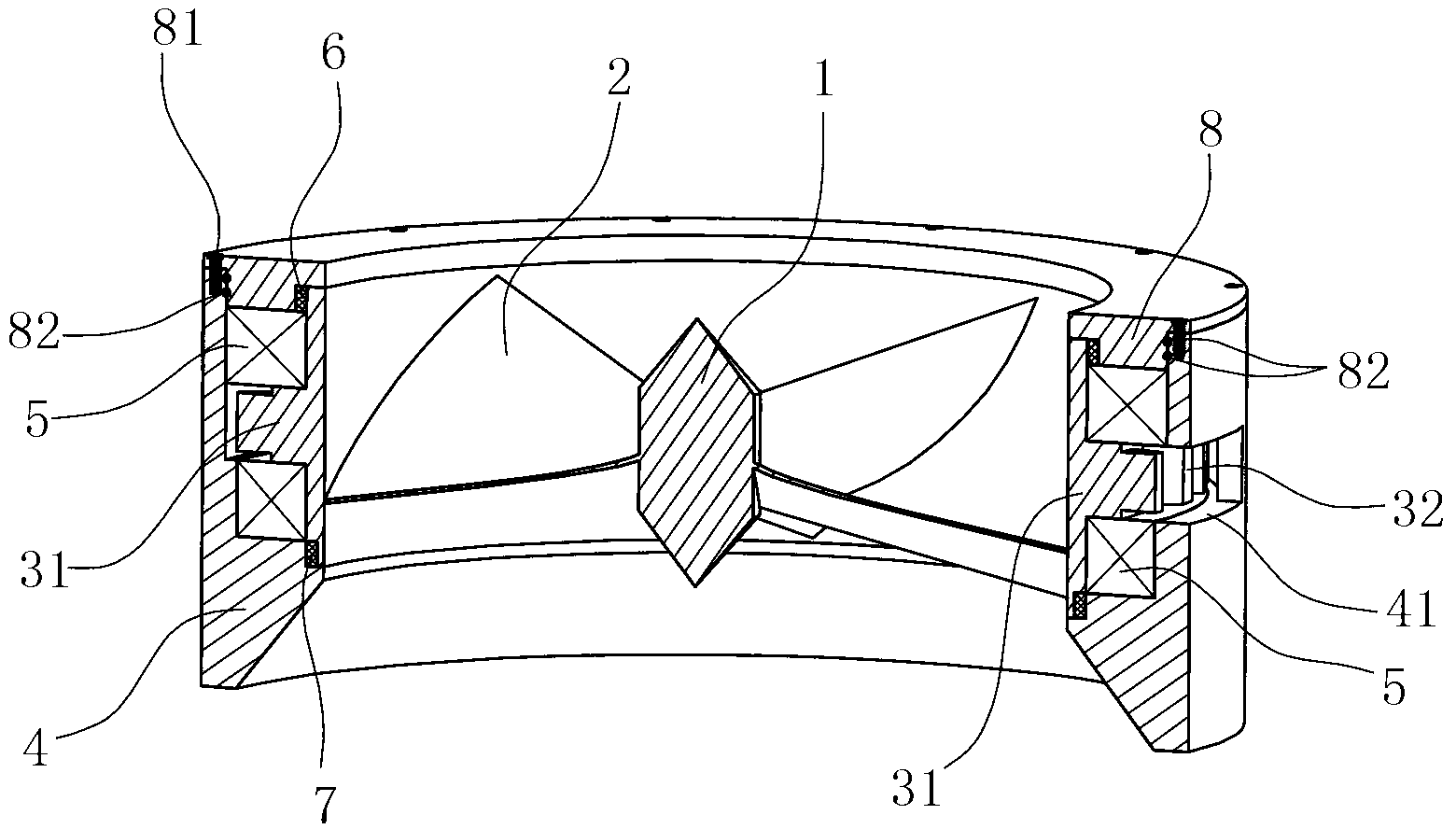

[0020] Such as Figure 1 to Figure 4 As shown, the propeller of this embodiment includes a paddle 1 and a plurality of blades 2 connected to the paddle 1, wherein the outer periphery of the blade 2 is formed with a rim 3, and the rim 3 and the blade 2 The ends are fixedly connected as a whole, the two ends of the paddle 1 are conical and streamlined, and the outer peripheral wall of the rim 3 is formed with a circumferentially arranged annular convex strip 31 at the middle position, and the convex strip 31 is formed with circumferentially spaced gear teeth 32, the rim 3 is also sleeved with a sleeve frame 4 that can rotate relative to the rim 3, the sleeve frame 4 is usually fixedly installed, and the peripheral wall of the sleeve frame 4 is also provided with a The gear teeth 32 of the rim 3 have exposed slot holes 41 through which the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com