Pod type electric shaftless pump jet propeller

A pod-type propeller technology, applied in the direction of rotary propellers, ship propulsion, propulsion components, etc., can solve the problems of difficult installation and maintenance, long transmission shaft, bulky power system, etc., to achieve simple structure and avoid installation Maintain Complex Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

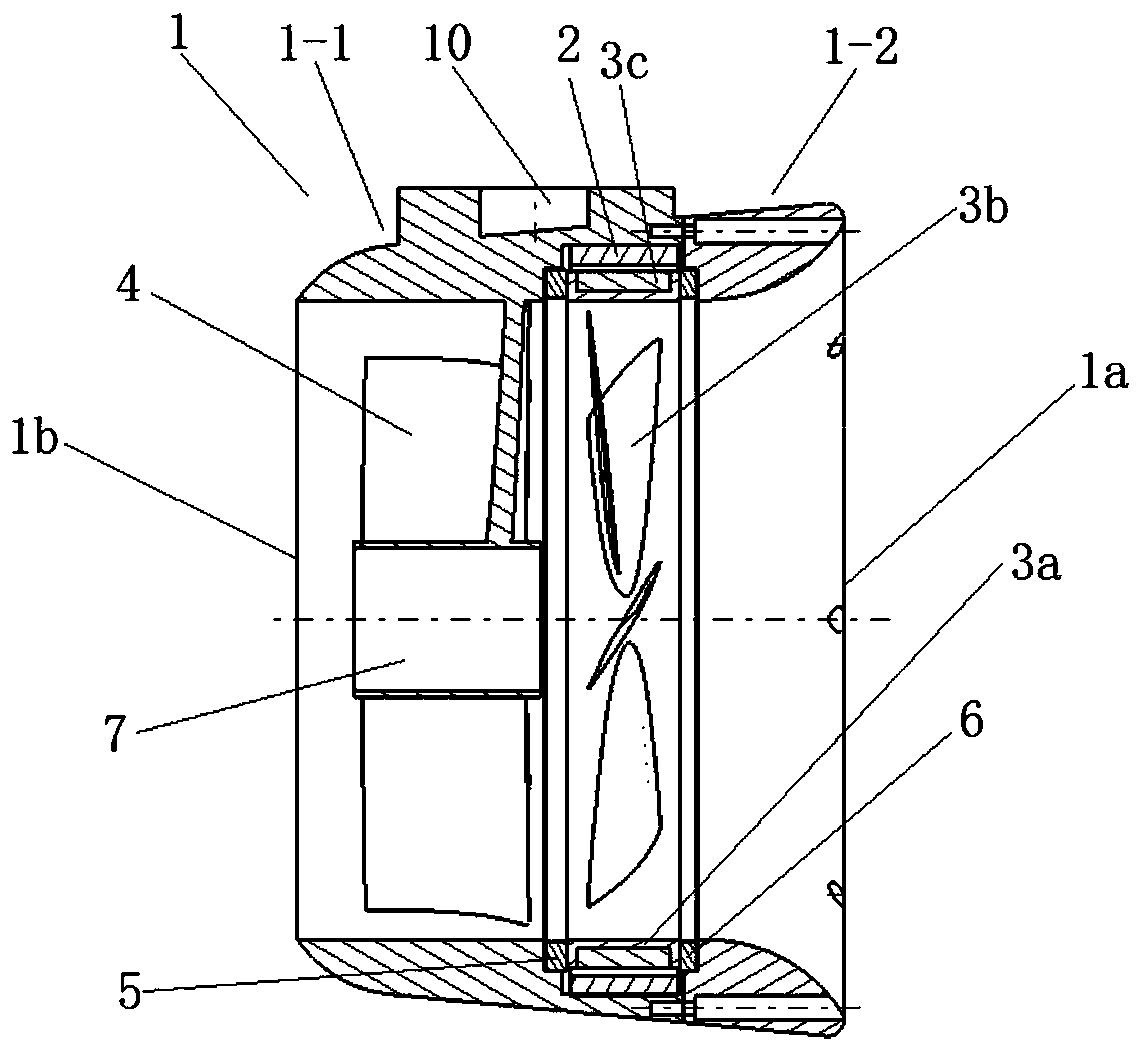

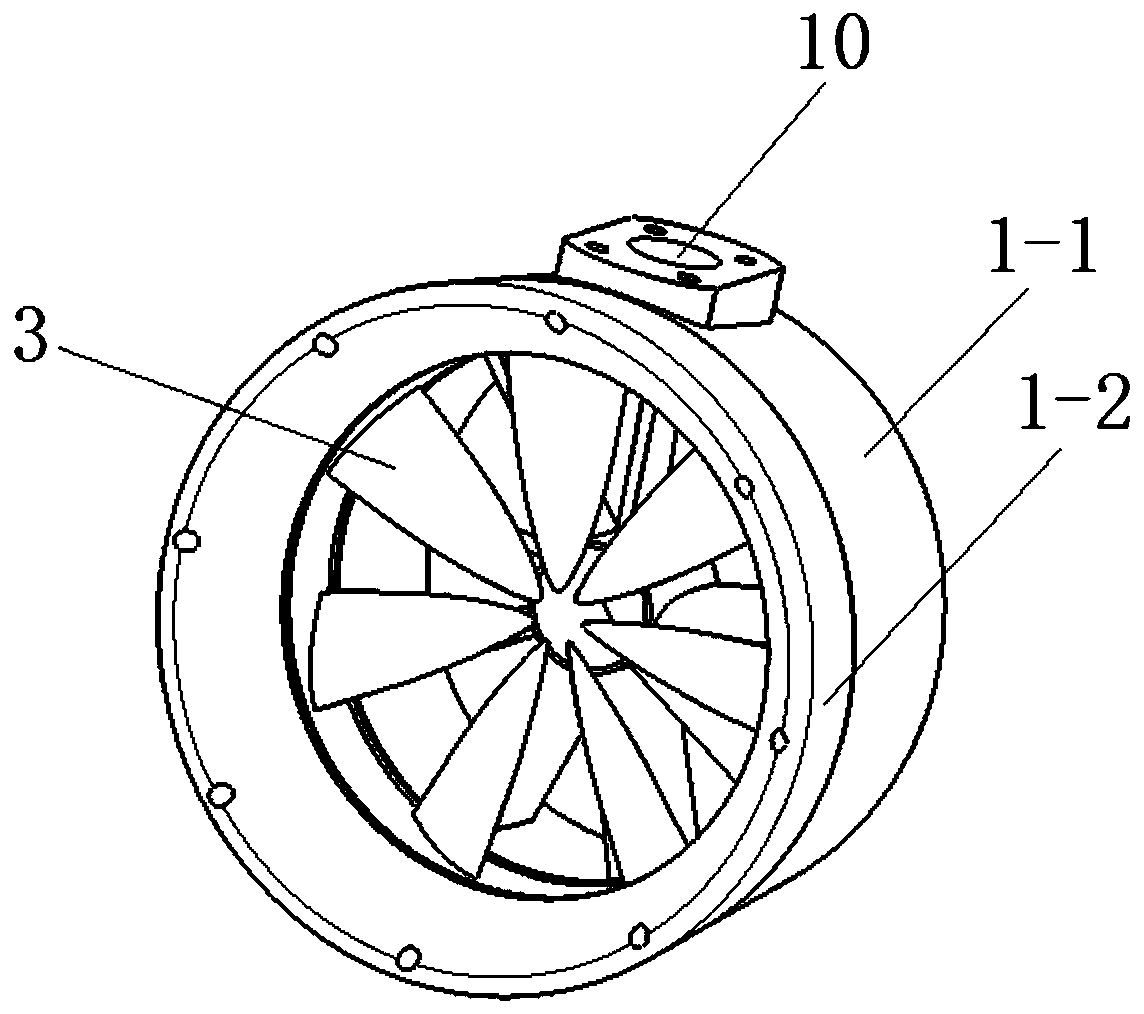

[0023] Such as Figure 1-4 As shown, the pod-type electric shaftless pump jet propeller of this embodiment includes a guide pipe 1 , a stator 2 , a blade rotor 3 , a guide vane set 4 , a first bearing 5 and a second bearing 6 .

[0024] Wherein, the guide tube 1 is a trumpet structure with openings at both ends, and the diameter of the water inlet 1a at the upstream end of the guide tube is larger than the diameter of the nozzle 1b at the downstream end of the guide tube, so as to improve the power output of the propeller. Wherein, the guide pipe 1 is an assembled structure, including a left pipe body 1-1 and a right pipe body 1-2, the spout 1b is located at the left end of the left pipe body 1-1, and the water inlet 1a is located at the right end of the right pipe body 1-2 , the inner side of the right port of the left pipe body 1-1 has a bearing groove for installing the first bearing 5 and an annular groove for installing the stator 2, the first bearing groove is located on...

Embodiment 2

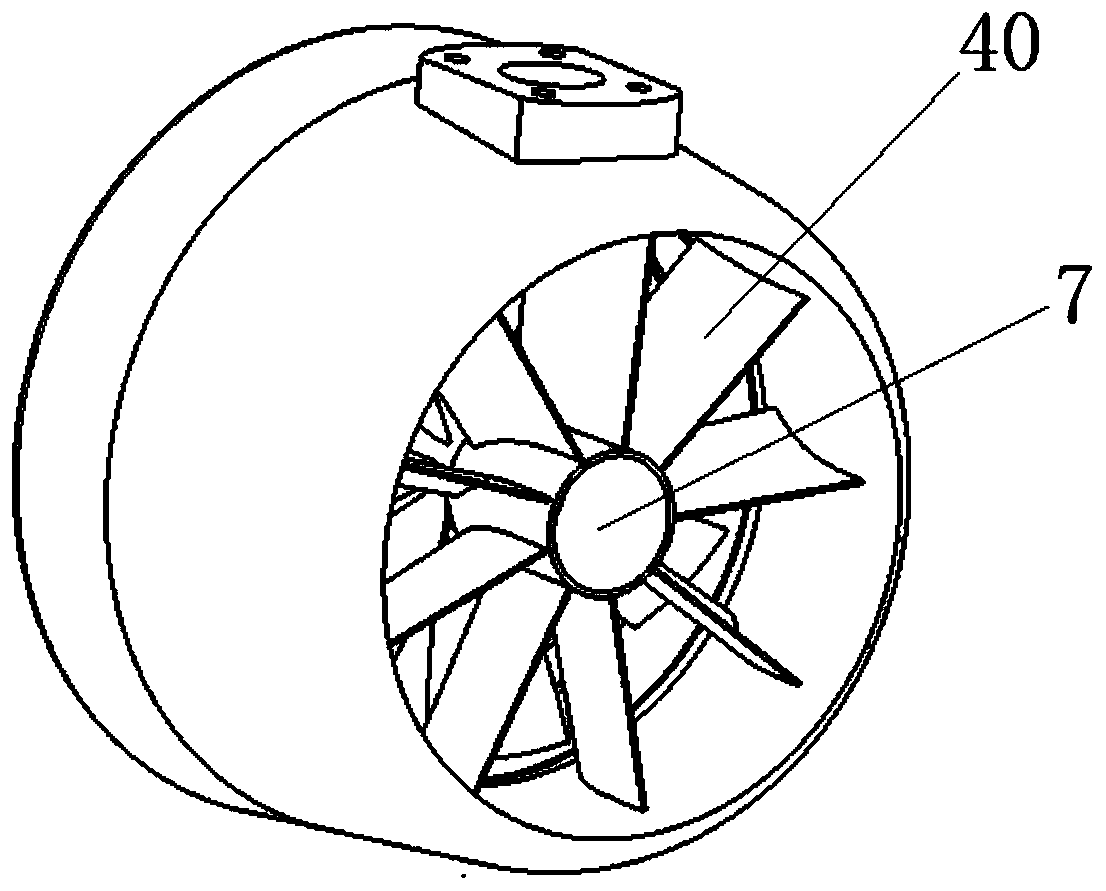

[0037] The difference between the pod type electric shaftless pump-jet propeller of this embodiment and the first embodiment is that:

[0038] The radial sections of the hollow cylinder and the draft tube in this embodiment are asymmetric structures, which can also increase the structural rigidity and realize the structural diversification of the pod-type electric shaftless pump jet propeller.

[0039] Other structures can refer to Embodiment 1.

Embodiment 3

[0041] The difference between the pod type electric shaftless pump-jet propeller of this embodiment and the first embodiment is that:

[0042] In this embodiment, the design of the hollow cylinder can be omitted, so that the structural diversification of the pod-type electric shaftless pump-jet propeller can be realized.

[0043] Other structures can refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com