Tandem motor pump jet propeller

A tandem, motor-pump technology, applied in the direction of ship propulsion, propulsion components, electromechanical devices, etc., can solve problems such as the inability to meet the thrust requirements of pump-jet thrusters, so as to facilitate heat dissipation, improve the power density of the whole machine, and avoid Install and maintain complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

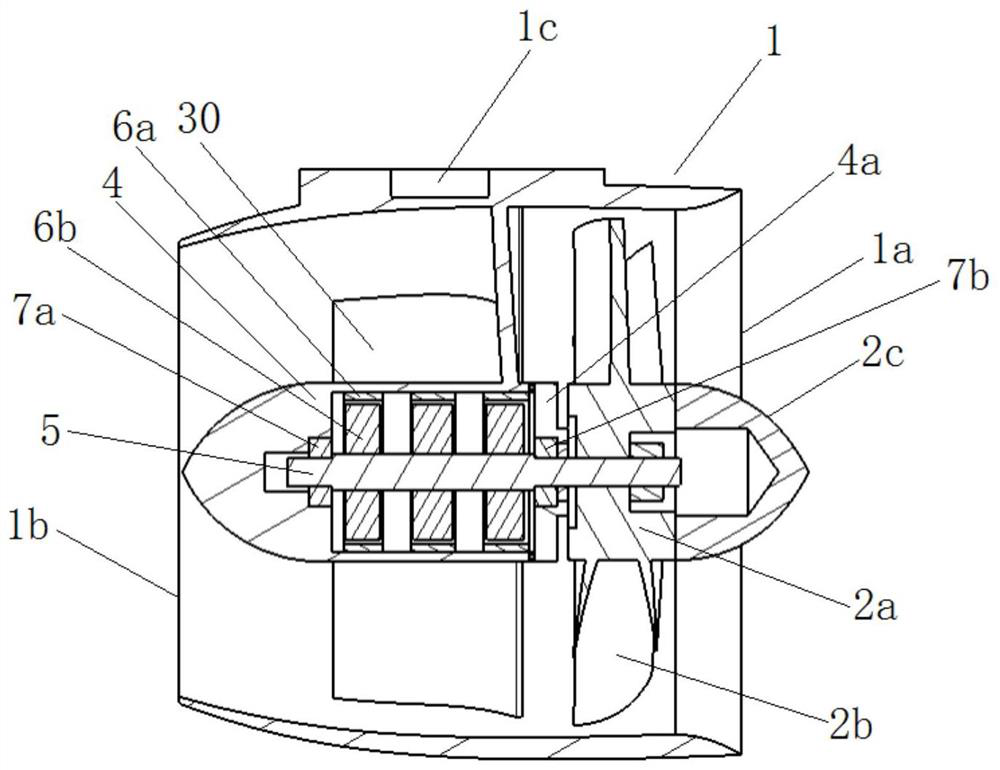

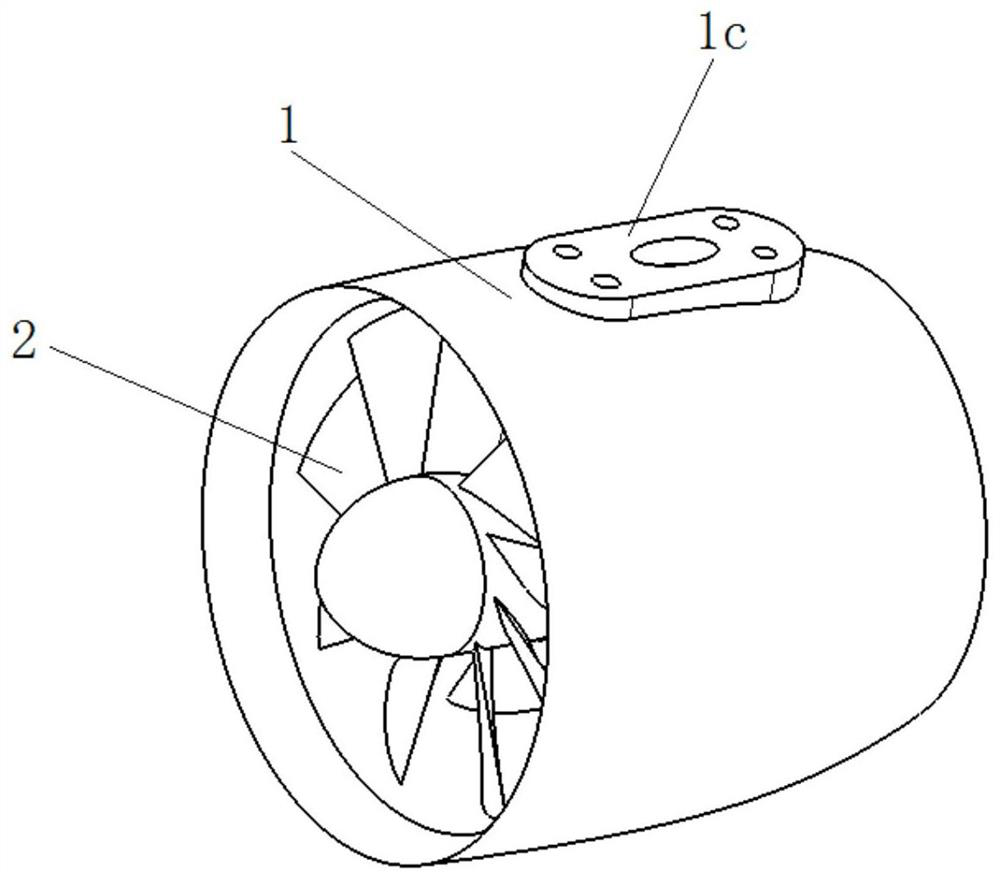

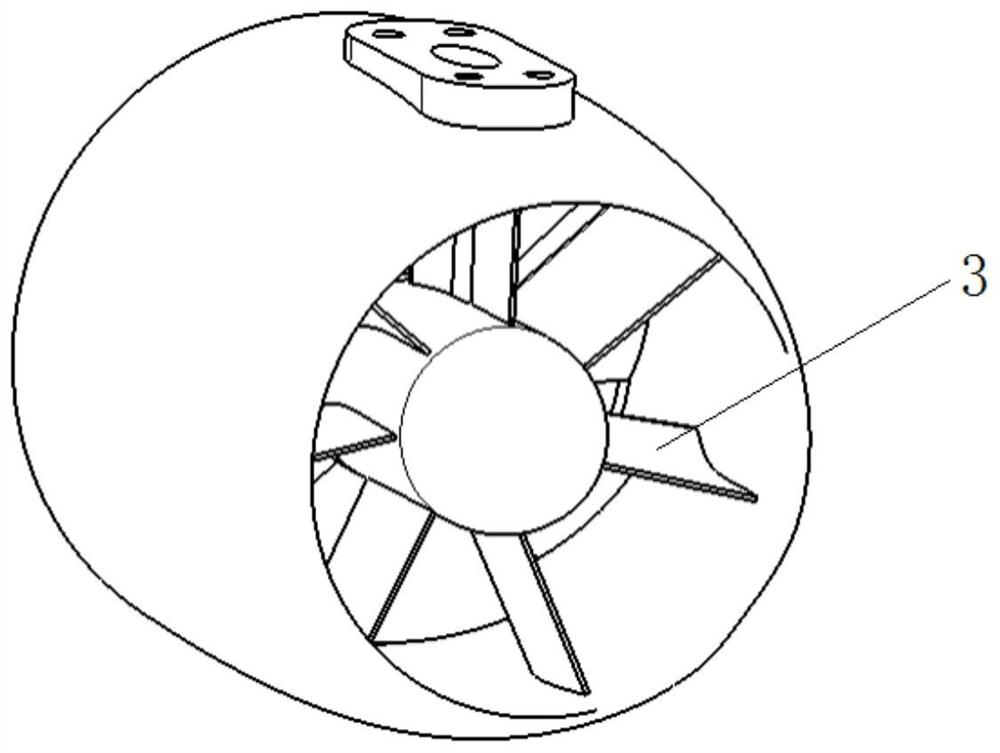

[0024]Such asFigure 1-3As shown, the serial motor pump spray propeller of the present embodiment includes a guide tube 1, a rotary paddle 2, a multi-winding series motor drive mechanism, and a guide sediment blade group 3, a rotary paddle 2, and a guide blade. Group 3 is sequentially mounted on the inner cavity of the upstream end of the conducting pipe to the downstream end, and multi-winding serial motor drive mechanism is used to drive the rotary paddle 2 to rotate from the upstream end of the guide tube. 1A inhaled water; the guide flow and detake the blade group 3 is used to guide the water flow in the flow tube to eject from the spout 1b of the downstream end of the guide tube; the flow tube 1 has a suspension mounting bit 1c, a suspension mounting bit 1c Includes a plurality of fixed mounting holes so that the hanging can be mounted on the underwater steam.

[0025]Among them, the guide tube 1 is the horn structure of both ends, and the inlet 1a of the upstream end of the guide ...

Embodiment 2

[0037]The aliquot of the serial motor pump spray propeller and the embodiment of the present embodiment are:

[0038]The flow of the flow of the present embodiment is convenient to manufacture, and can also be designed in a multi-stage, and each segment is assembled, and the structural diversification of the tandem motor pump spray propeller is realized.

[0039]Other structures can be referred to in Examples.

Embodiment 3

[0041]The aliquot of the serial motor pump spray propeller and the embodiment of the present embodiment are:

[0042]The rear end of the cylindrical housing of the present embodiment has a rear guiding cone, and the rear conductive cone can be protruded to the flow tube to achieve a variety of structural diversification of the tandem motor pump spray propeller.

[0043]Other structures can be referred to in Examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com