Evenness adjusting methods for industrial factory building T-shaped groove and platform thereof

An adjustment method and technology of industrial plants, applied to the frame of the engine, supporting machines, mechanical equipment, etc., can solve the problems of difficult control of flatness precision, poor overall appearance quality, and difficult precise control of position, etc., to achieve good overall appearance quality, The effect of short adjustment time and easy control of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0028] A method for adjusting the flatness of the T-shaped groove of an industrial factory building, the steps of the method are:

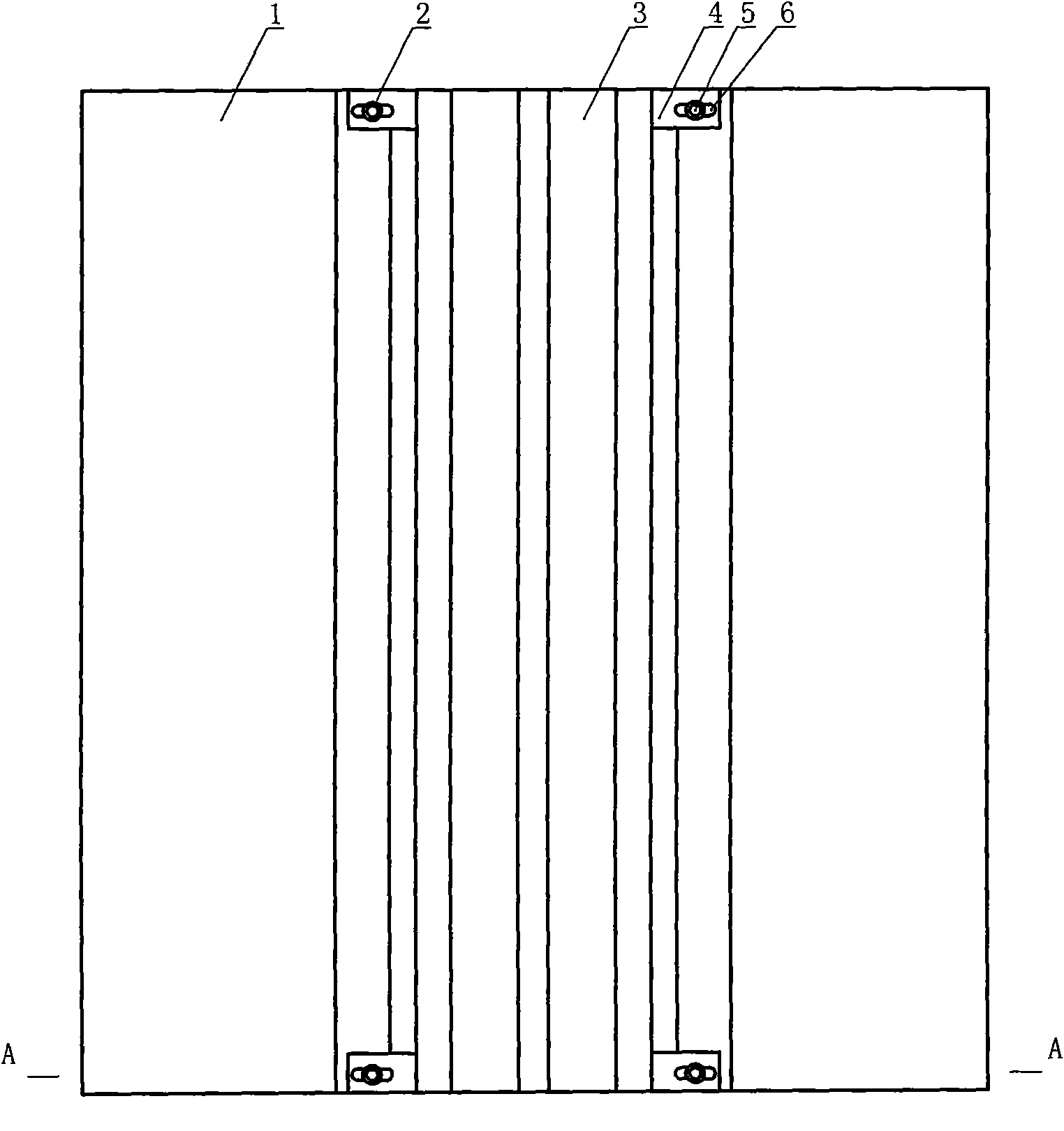

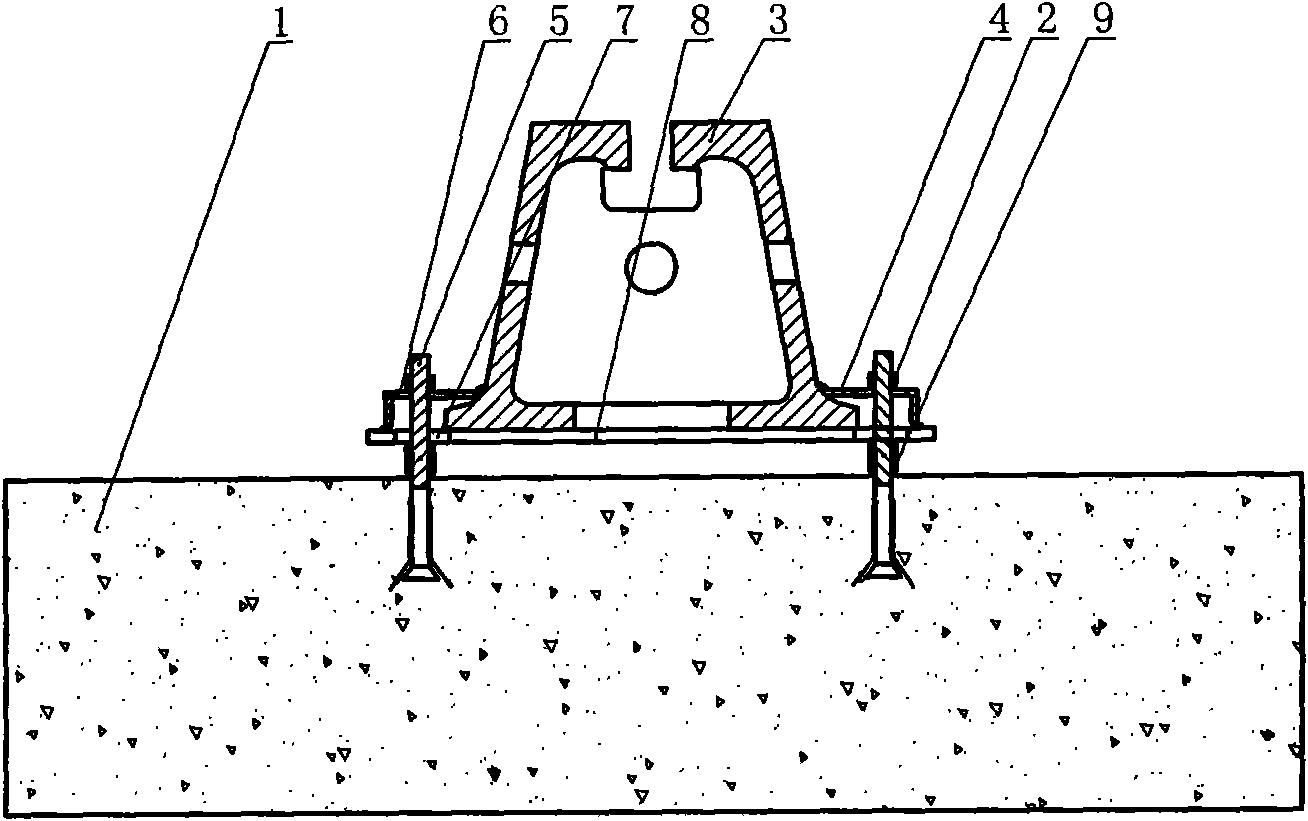

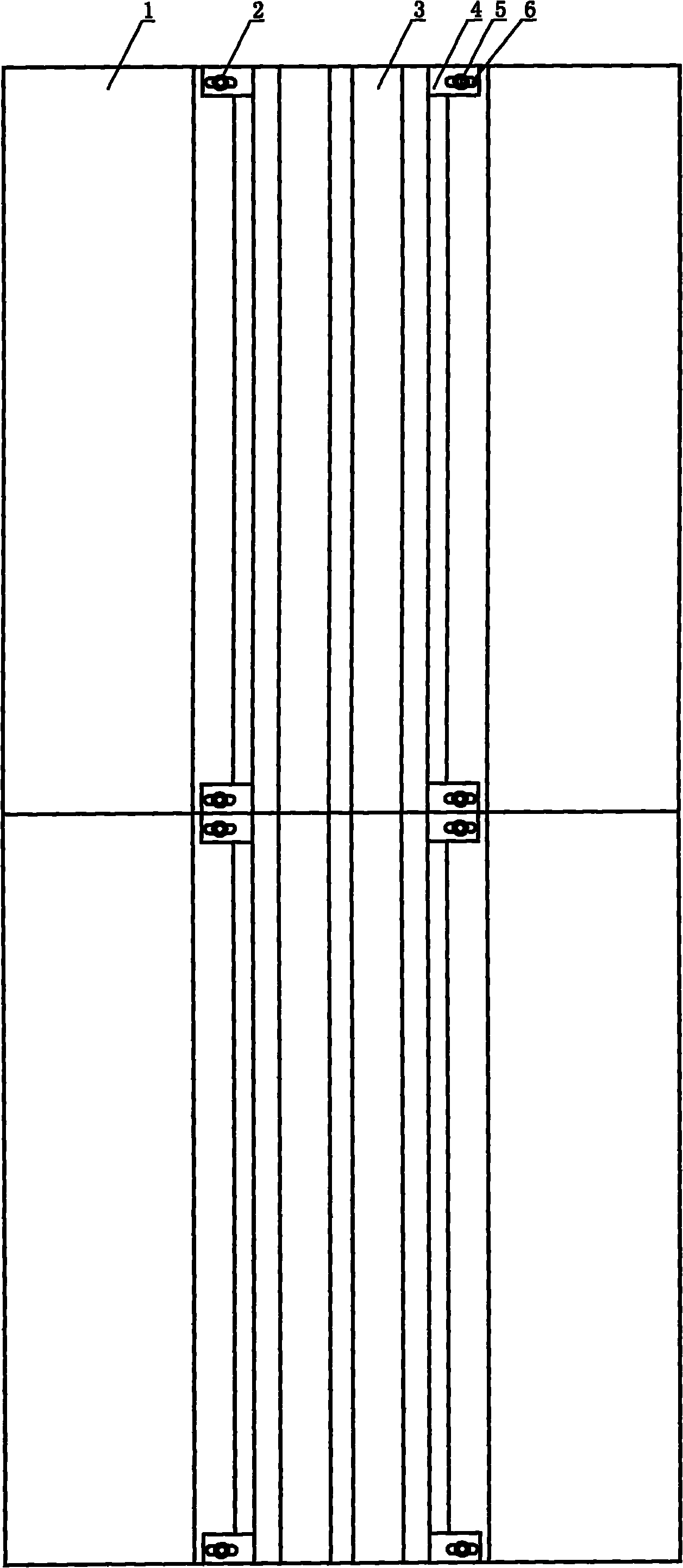

[0029] (1) Measure and determine the position of the T-shaped groove 3 on the concrete base 1, and drill positioning holes on the concrete base next to the four corners of the T-shaped groove, and the number of the positioning holes is 4 in total;

[0030] (2) The expansion bolt 5 with the adjustment nut 9 is packed into the positioning hole, the quantity of the adjustment nut on each expansion bolt can be 1-3, and the quantity of the adjustment nut shown in the accompanying drawing of this embodiment is 2 One, prepare a tray 8, the tray can be rectangular or oval, the tray shown in the drawings of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com