Control method and system of grain leveling robot

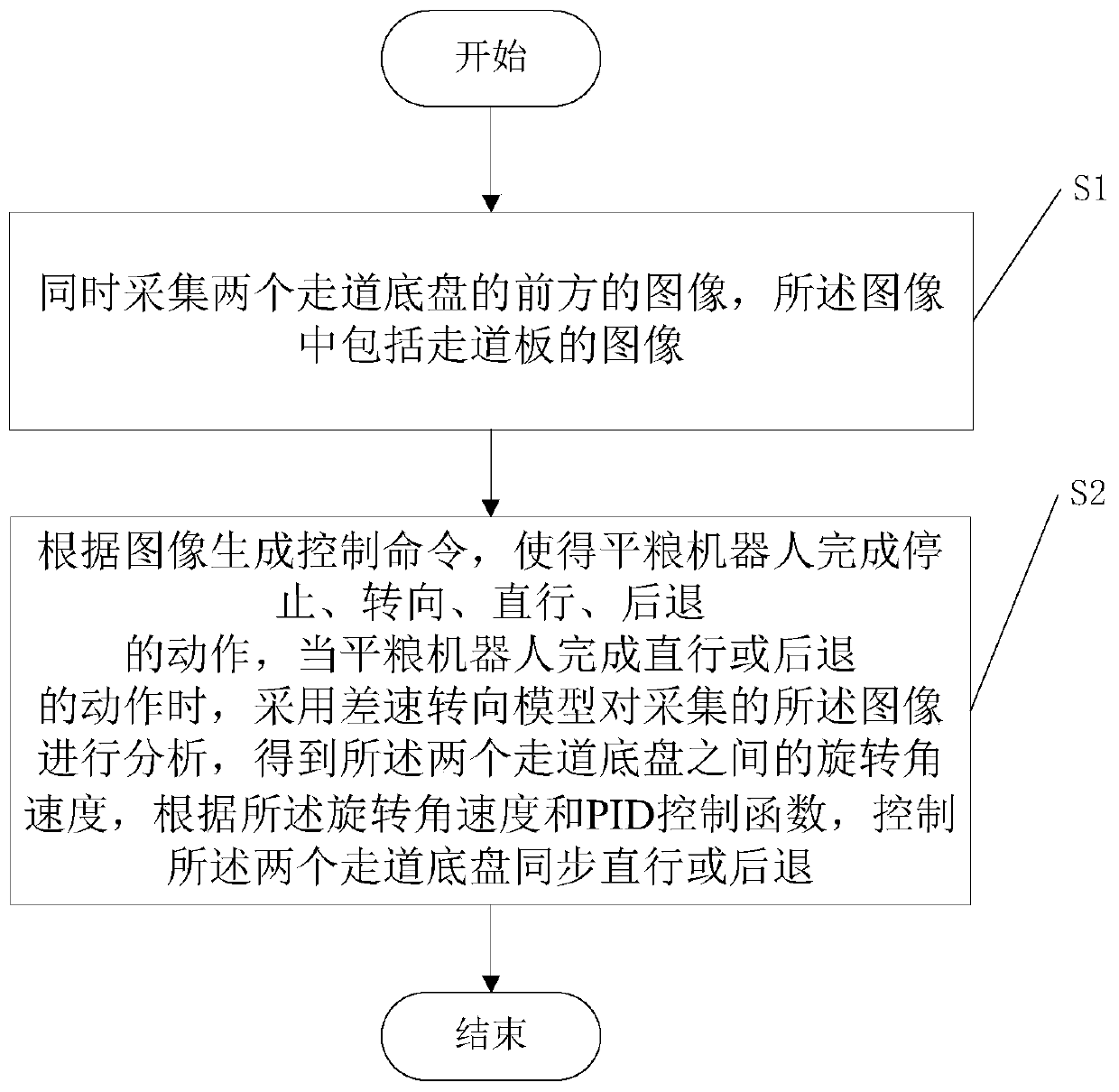

A control method and robot technology, applied in the direction of control/adjustment system, control using feedback, controller with specific characteristics, etc., can solve the problems of unstable operation, inability to adapt to robots, poor reliability, etc., and achieve good scraping effect. , Accurate and reliable aisle judgment, accurate judgment of the level of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

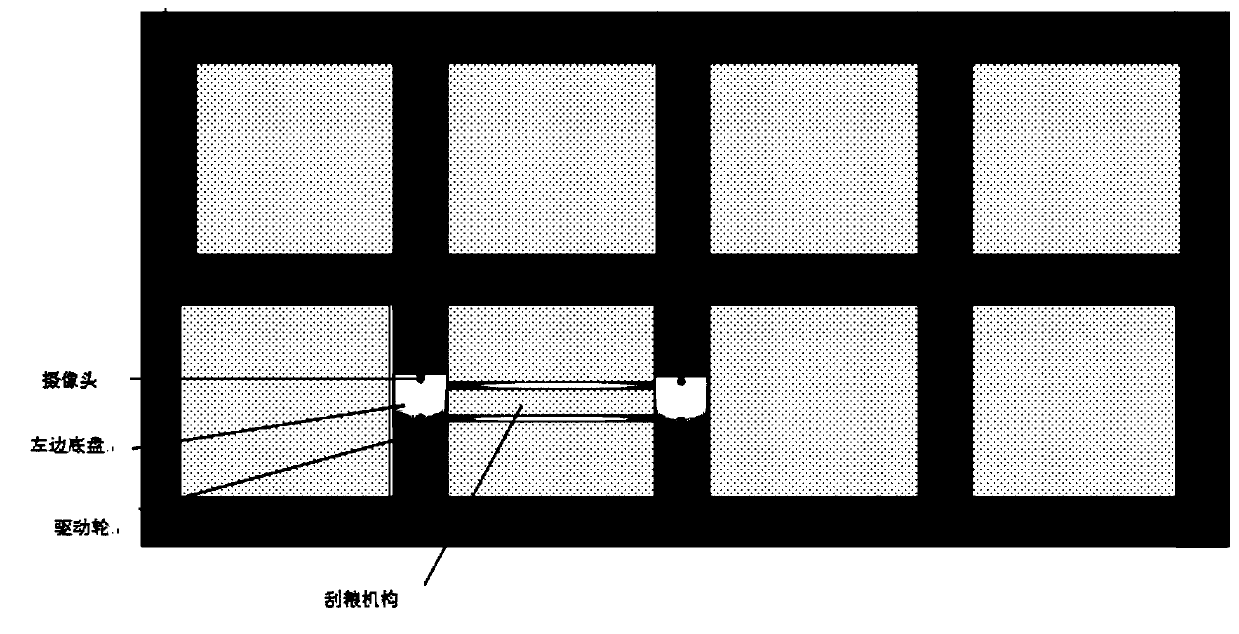

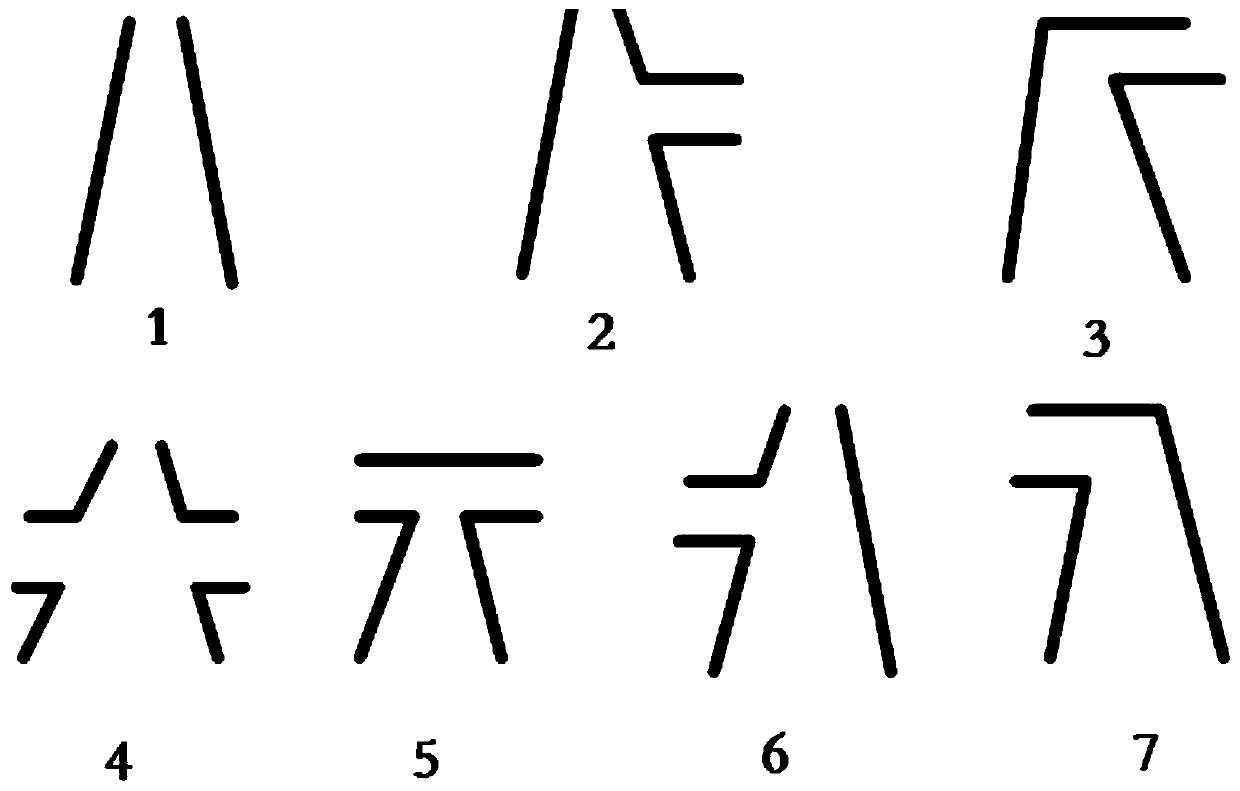

[0065] Schematic diagram of granary, aisle board and flat grain robot figure 2 As shown, the part surrounded by the well shape is the grain, and the part of the well shape is the aisle laid in the granary to facilitate the inspection of the grain situation, and it is also the walking track of the robot. The white part is the robot, and the grain scraping mechanism is dragged by the chassis on both sides to complete the work of leveling the granary. When working, the robot needs to walk safely on the walkway. The robot uses the camera to navigate with the walkway as a reference, and uses the different features at the junction of the walkway as signs for stopping, turning, and turning around. During the grain leveling process, the grain scraping mechanism in the middle will affect the normal movement of the aisle chassis on both sides due to the grain resistance. At this time, it needs to be adjusted to improve the stability of the machine operation and the grain scraping effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com