Composite bearing type external heat insulating wall and its construction method

A technology for external thermal insulation and thermal insulation of external walls, which is applied to thermal insulation, walls, structural elements, etc., can solve the problems of inconvenient paste operation of polystyrene foam thermal insulation boards, slow construction speed in corner areas, and falling off of wall thermal insulation layers. Easy wall decoration, convenient construction, anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

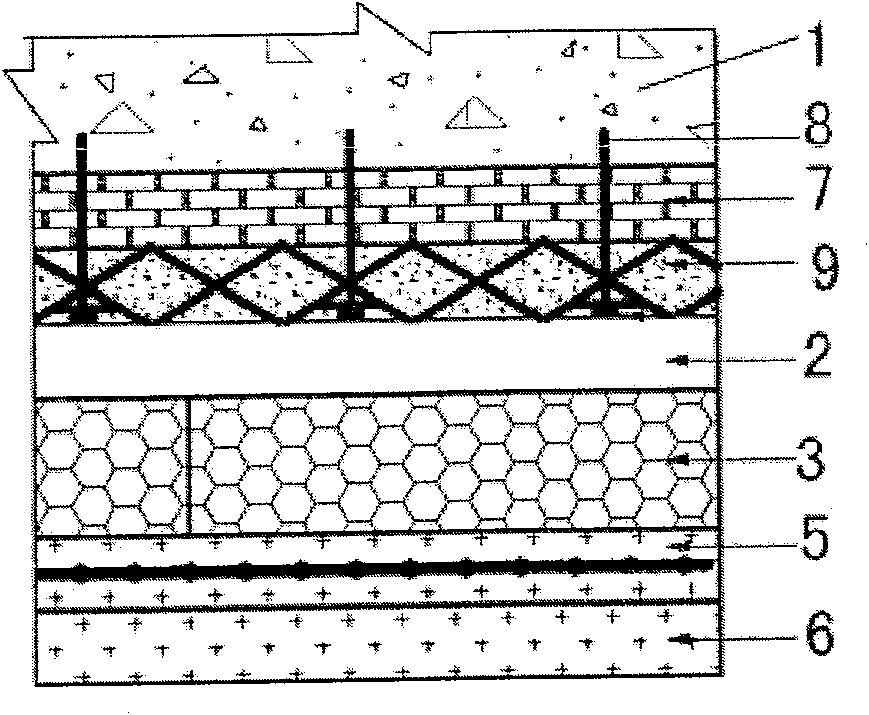

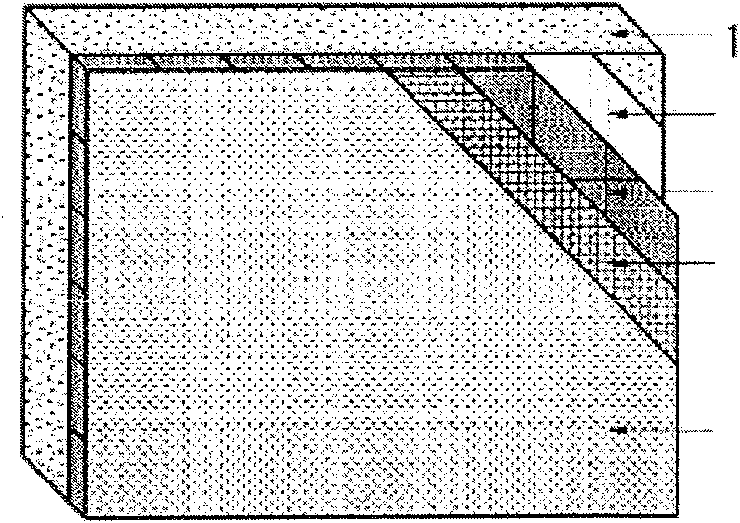

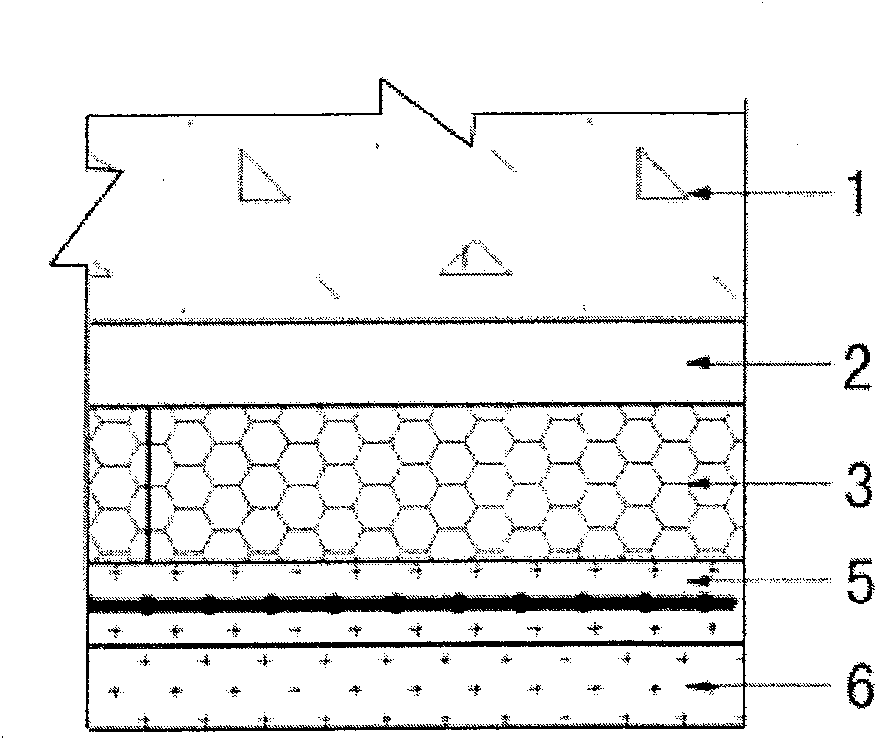

[0041] Embodiment 1 Referring to Figures 1 and 2, the composite load-bearing external thermal insulation wall structure of a new building: the polymer cement mortar layer 2, the light-weight load-bearing thermal insulation wall tiles 3, and the glass fiber mesh are fixed in sequence on the wall base 1 The cloth layer 5 and the decorative surface layer 6 form an integral wall surface with a honeycomb three-dimensional structure.

[0042] Referring to FIG. 5 , the above-mentioned light-weight and heavy-duty heat-insulating exterior wall tiles 3 are made by wrapping a layer of glass fiber mesh cloth 32 pasted with a polymer cement mortar layer on the outer surface of a polystyrene foam plastic rectangular block 31 .

[0043] The construction method of this composite load-bearing external thermal insulation wall is characterized in that the construction steps are as follows:

[0044] 1), apply a layer of polymer cement mortar layer 2 on the base layer 1 of the wall;

[0045] 2), ...

Embodiment 2

[0050] Embodiment 2 Referring to Figures 3 and 4, the structure of the composite load-bearing external thermal insulation wall of the old building: on the base layer 1 of the old building wall that has been made of the old surface layer 7, the expanded metal mesh 9 and the polymer cement mortar layer are sequentially fixed. 2. Lightweight and heavy-duty thermal insulation wall tiles 3 and decorative surface layer 5. Referring to FIG. 5 , the above-mentioned light-weight and heavy-duty thermal insulation exterior wall tile 3 is made by wrapping a layer of glass fiber mesh cloth 32 pasted with a polymer cement mortar layer on the outer surface of the polystyrene foam rectangular block 31 .

[0051] The construction method of this composite load-bearing external thermal insulation wall is characterized in that the construction steps are as follows:

[0052] 1) The old surface layer 7 has been made on the base layer 1 of the wall body, and the steel mesh 9 is laid on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com