Installation structure and installation method of external wall back-bolt type dry hanging stone

A technology for dry-hanging stone and installation structure, which is applied in building construction, building material processing, covering/lining, etc. Inability to effectively control the dimensional deviation of external walls and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

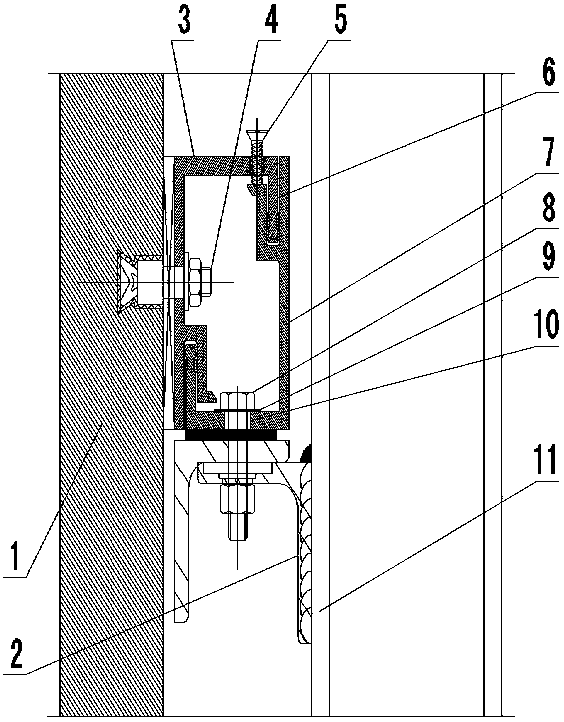

[0019] See figure 1 , An external wall back-bolted dry-hanging stone installation structure, including stone 1, back bolt 4, pendant, metal keel 2. The metal keel 2 is fixed on the external wall 11, the stone 1 is connected to the pendant through the back bolt 4, and the bottom of the pendant is set There are bolt holes 10 used to adjust the flatness of the stone 1 and the straightness of the seam of the stone 1, and are fixedly installed on the upper end of the metal keel 2 by adjusting bolts 8 and adjusting washers 9; the pendant includes the sub-hanger 3 and the female pendant 7. The child pendant 3 and the mother pendant 7 are connected by a card slot to form a double card-type child and mother pendant. The dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com