Take-up device for cable arrangement system

A cable take-up device and cable technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problem of high labor intensity, errors in the running track of optical cables, and cables that cannot be neatly arranged on the plate. problems, such as ensuring production quality, correcting flatness, and designing reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

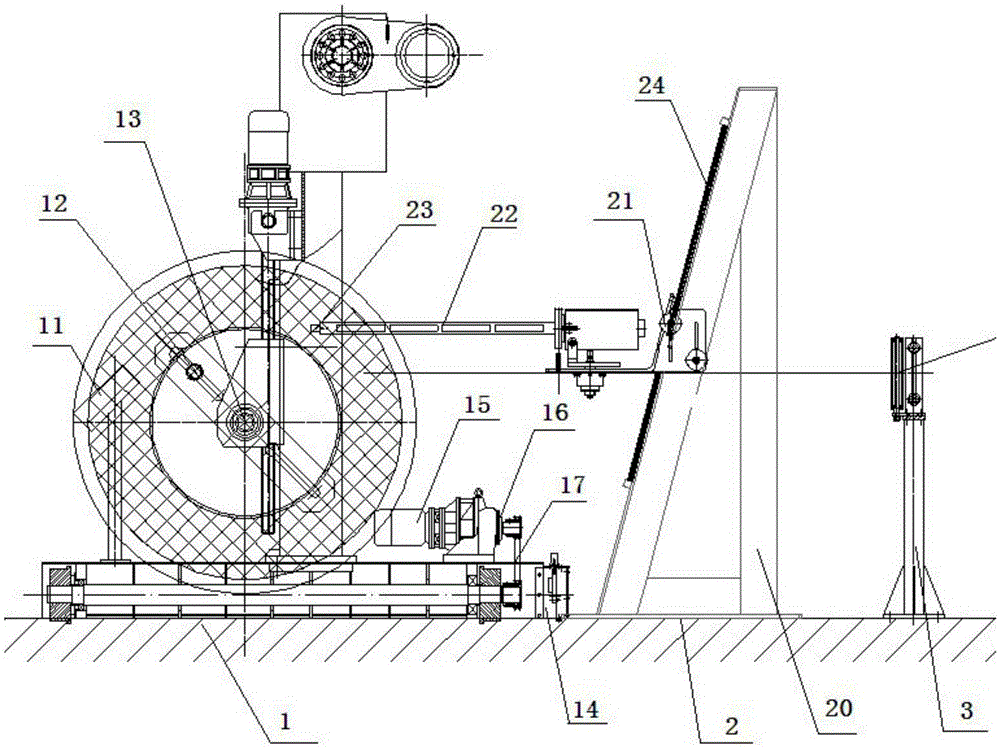

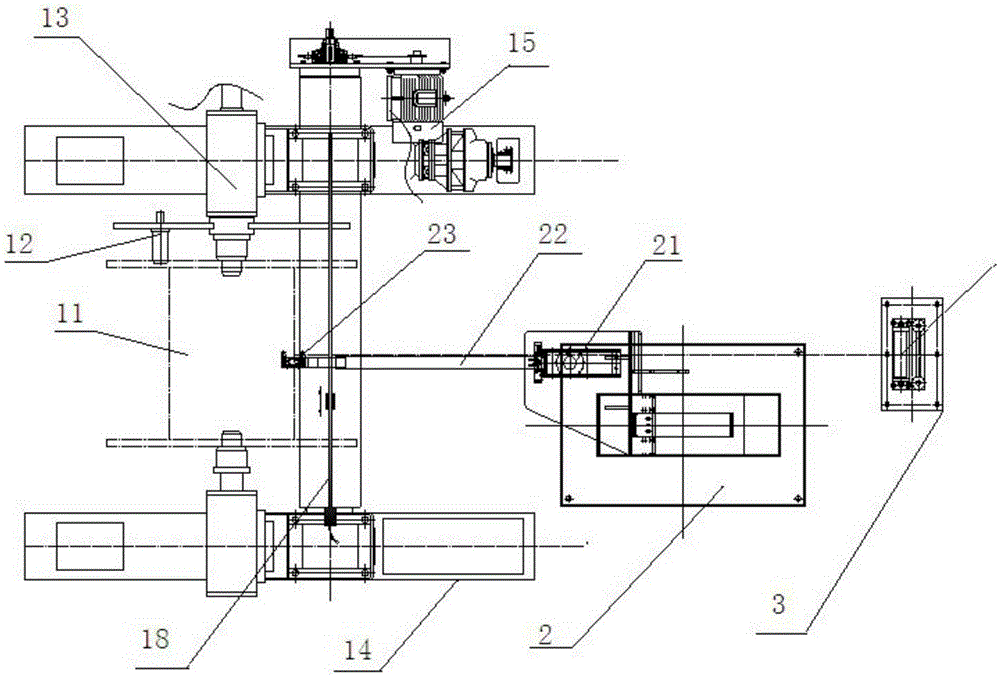

[0023] like Figure 1-2 As shown, this embodiment discloses a wire take-up device used in a cable arranging system, and the take-up device is mainly used in the final wire take-up process in the cable production and arranging system. It mainly includes three parts: take-up assembly 1, automatic wire assembly 2 and well-tac-toe frame 3. The sequence of cable take-up is: well-tac-toe frame 3-automatic wire assembly 2-take-up assembly 1, wherein the above-mentioned well-tac-toe frame 3 Support the conveyed cable, and guide it into the above-mentioned wire take-up assembly 1 through the above-mentioned automatic wire assembly 2 to take up the wire. In this embodiment, the above-mentioned well-shaped frame 3 is a commonly used well-shaped frame structure, and its height is based on the actual production It needs to be designed, and there is no limitation here; the above-mentioned automatic wire assembly 2 is a wire arm structure, which simulates the structure of the human arm to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com