Patents

Literature

36results about How to "Correction of flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

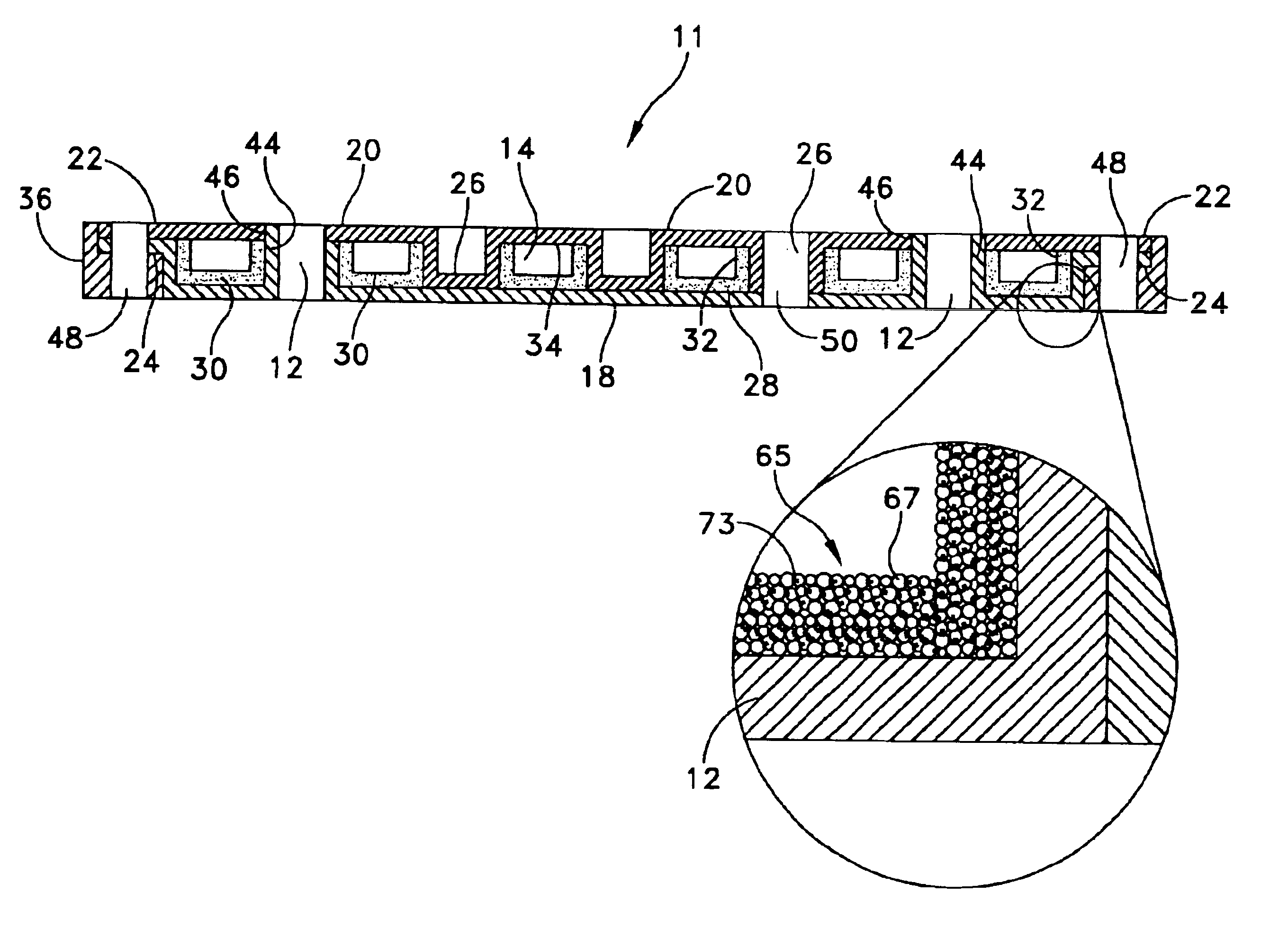

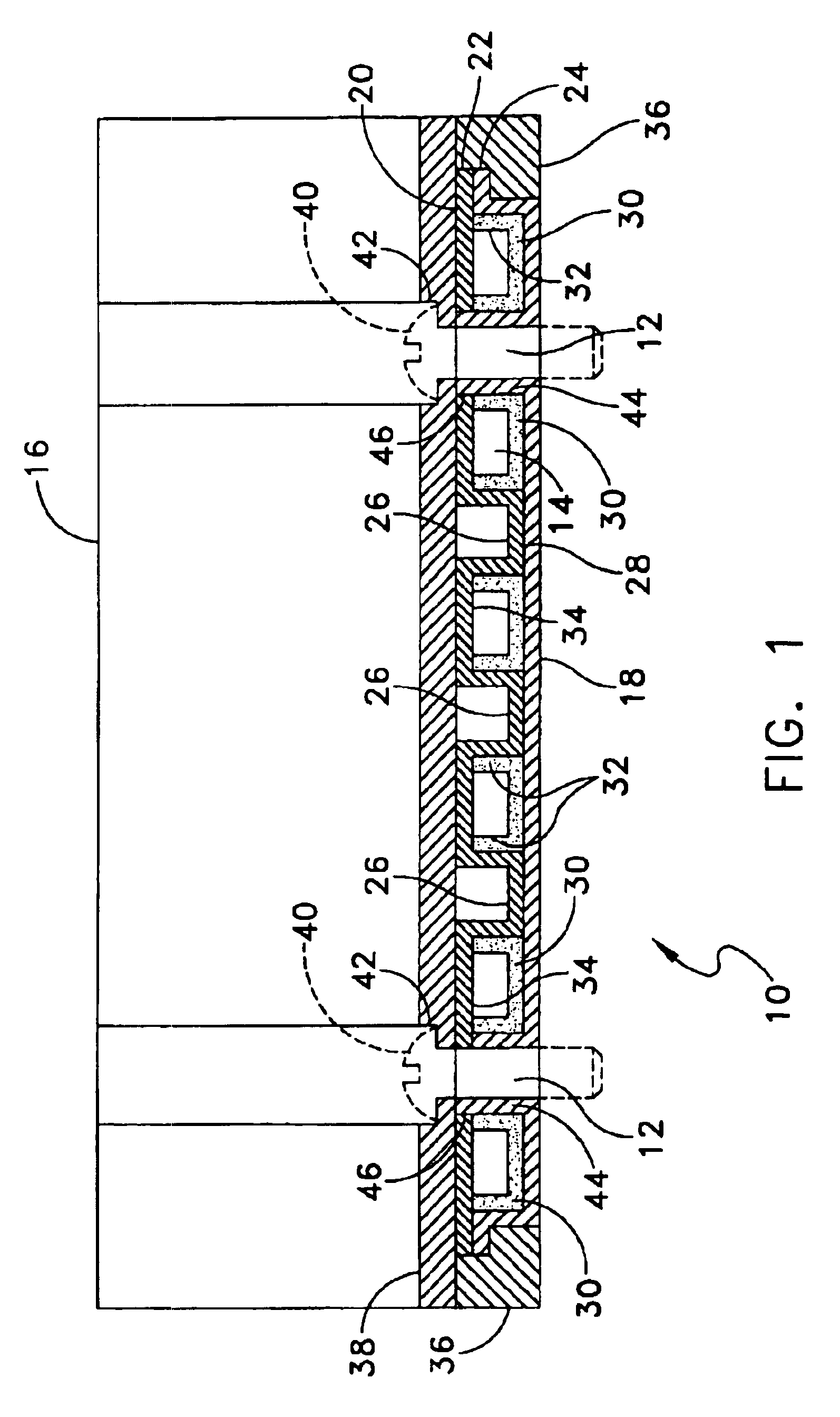

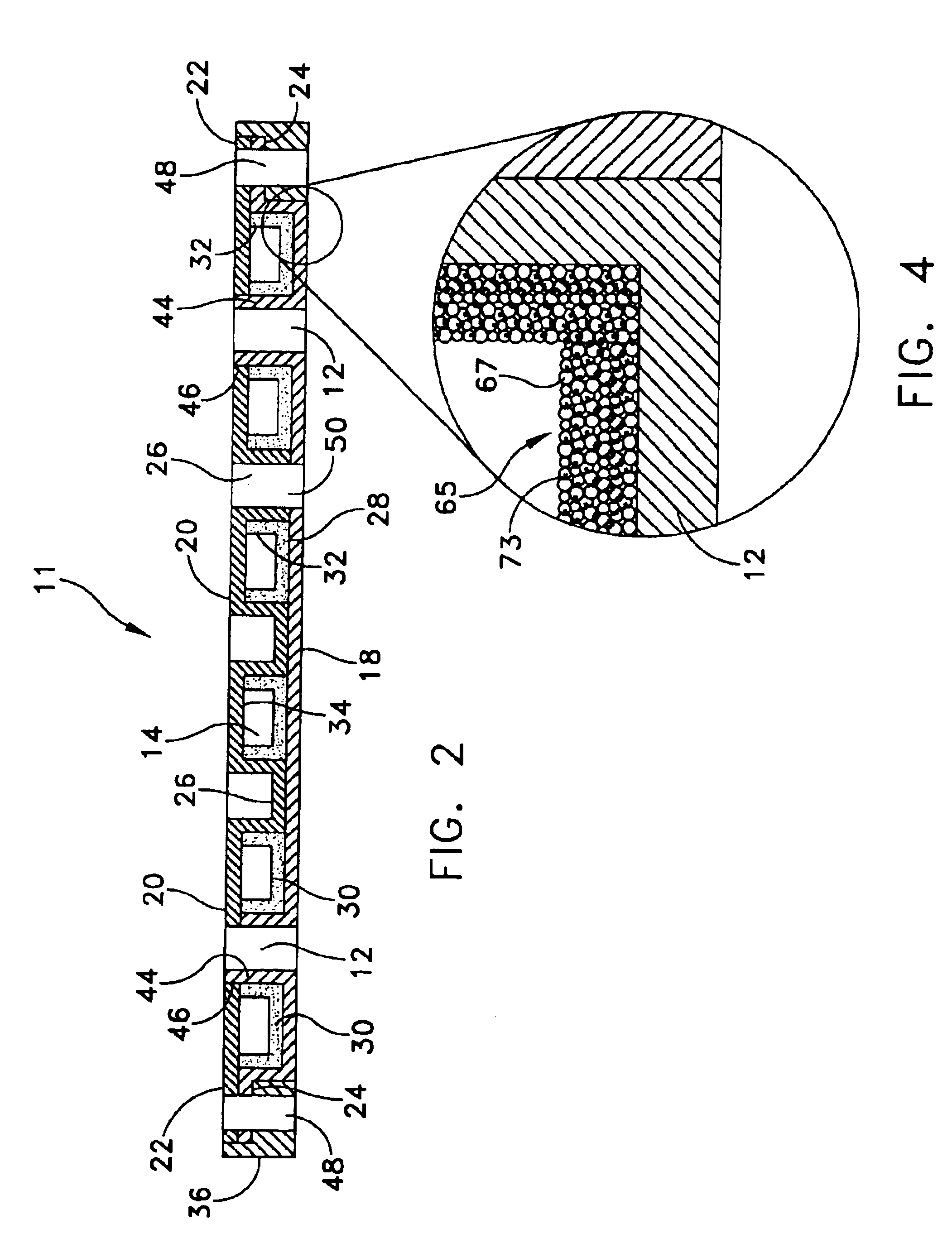

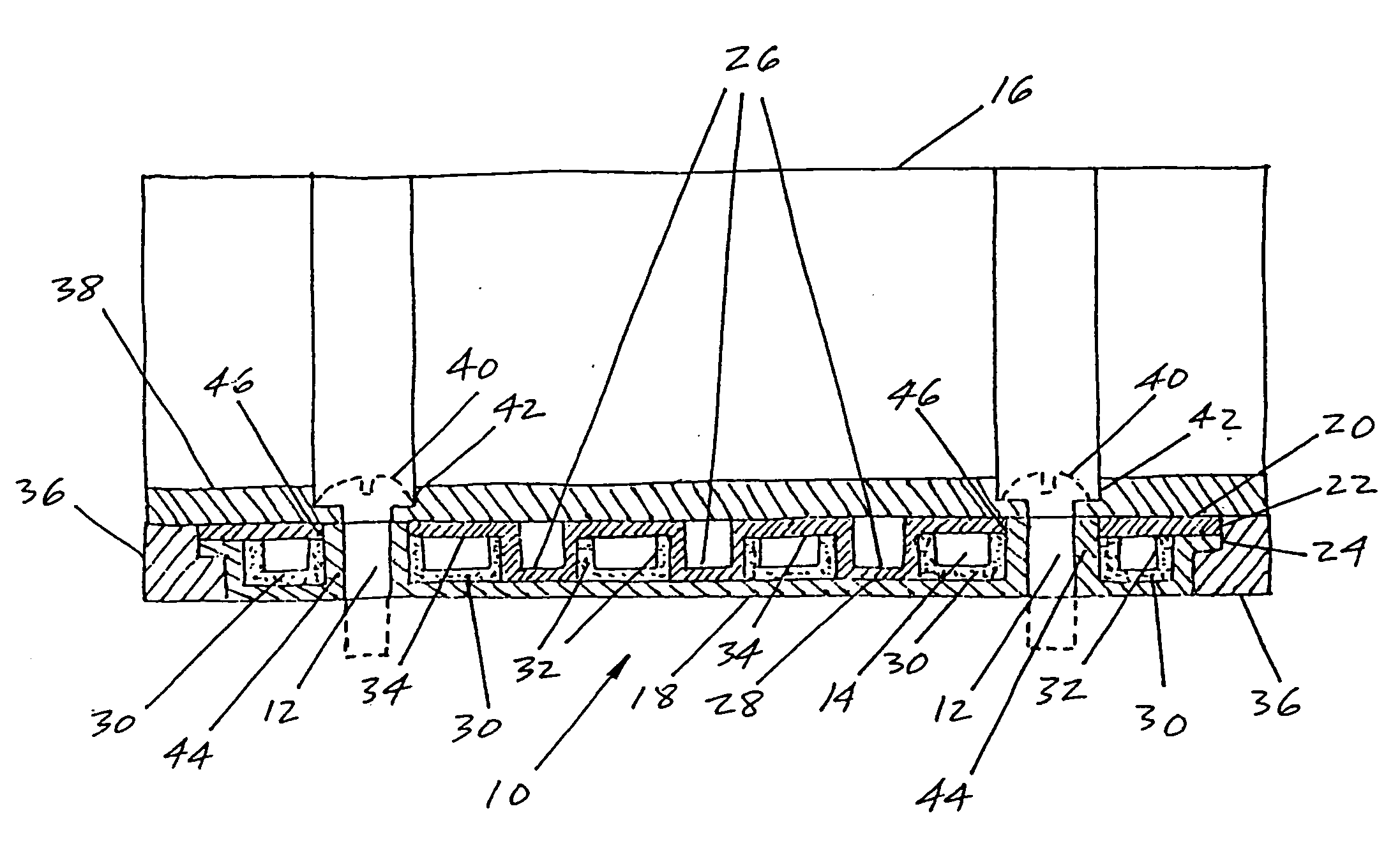

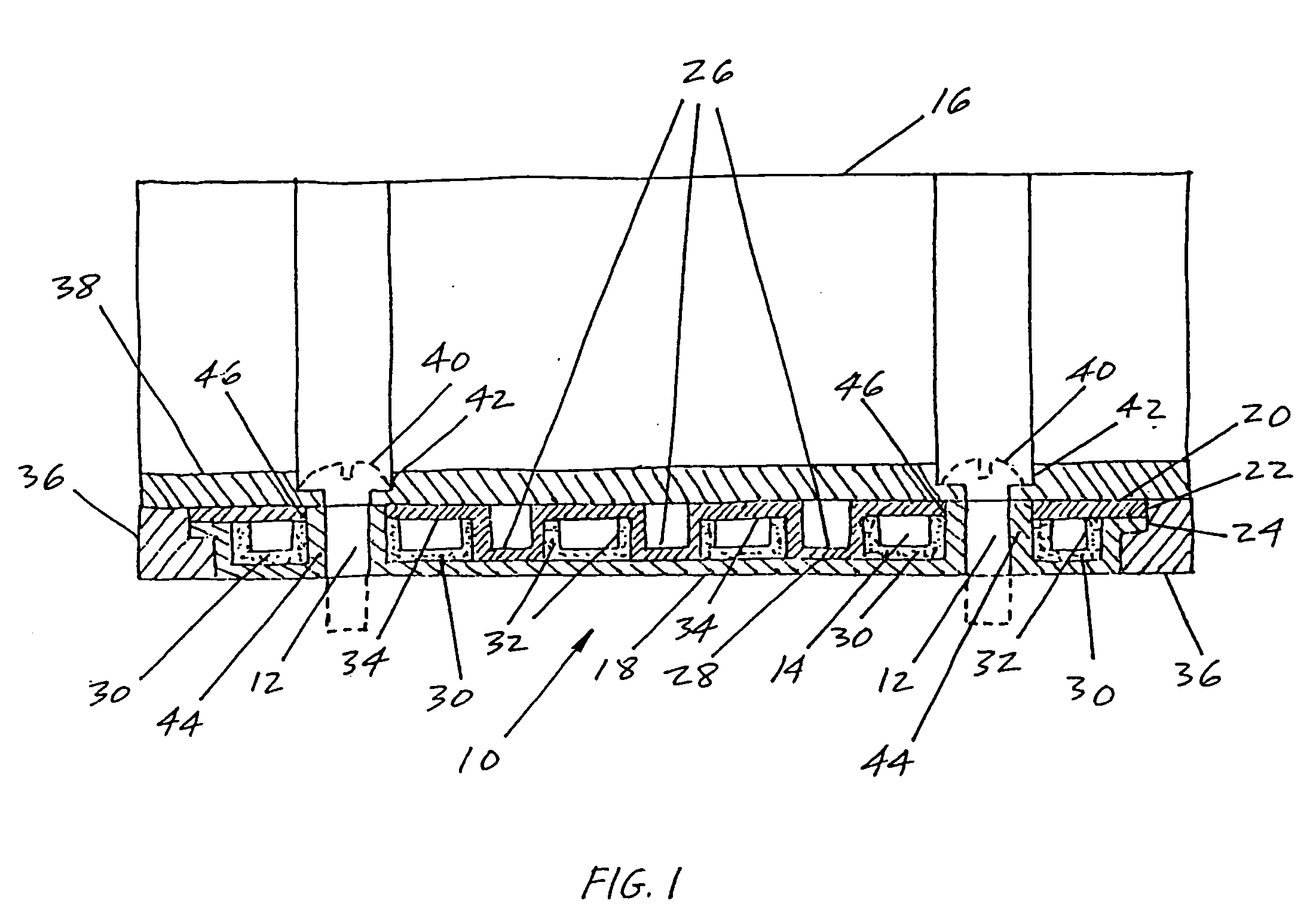

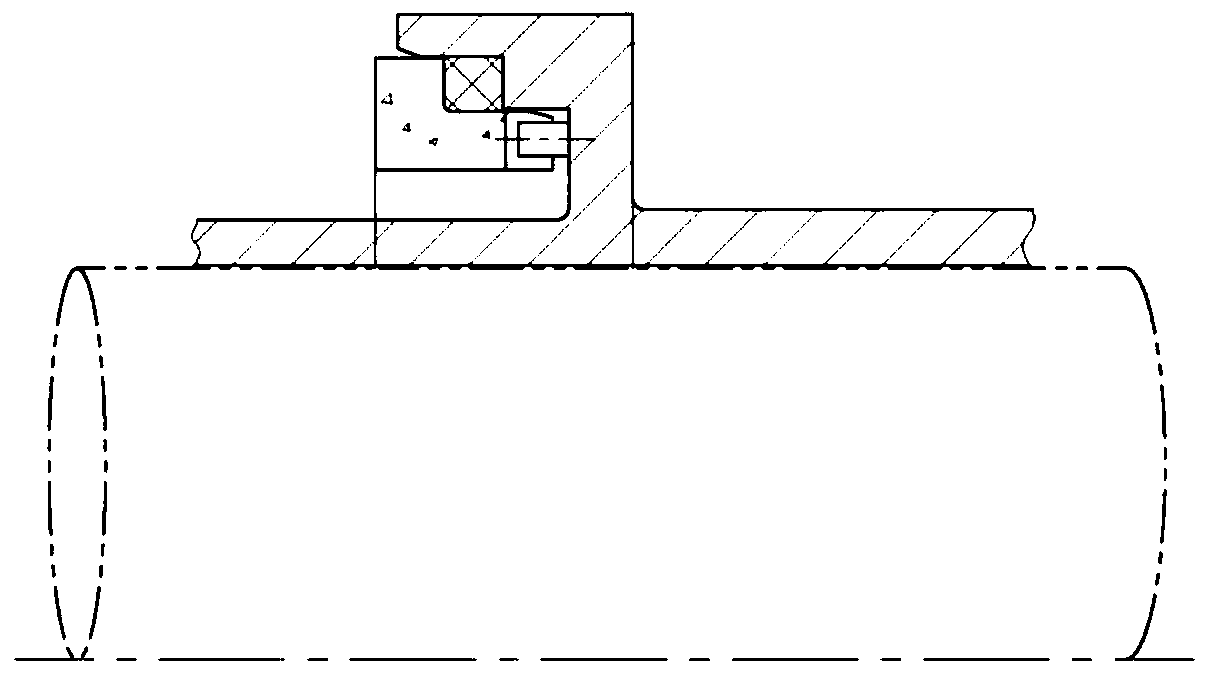

Integrated circuit heat pipe heat spreader with through mounting holes

InactiveUS6896039B2Improve heat transfer performanceImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

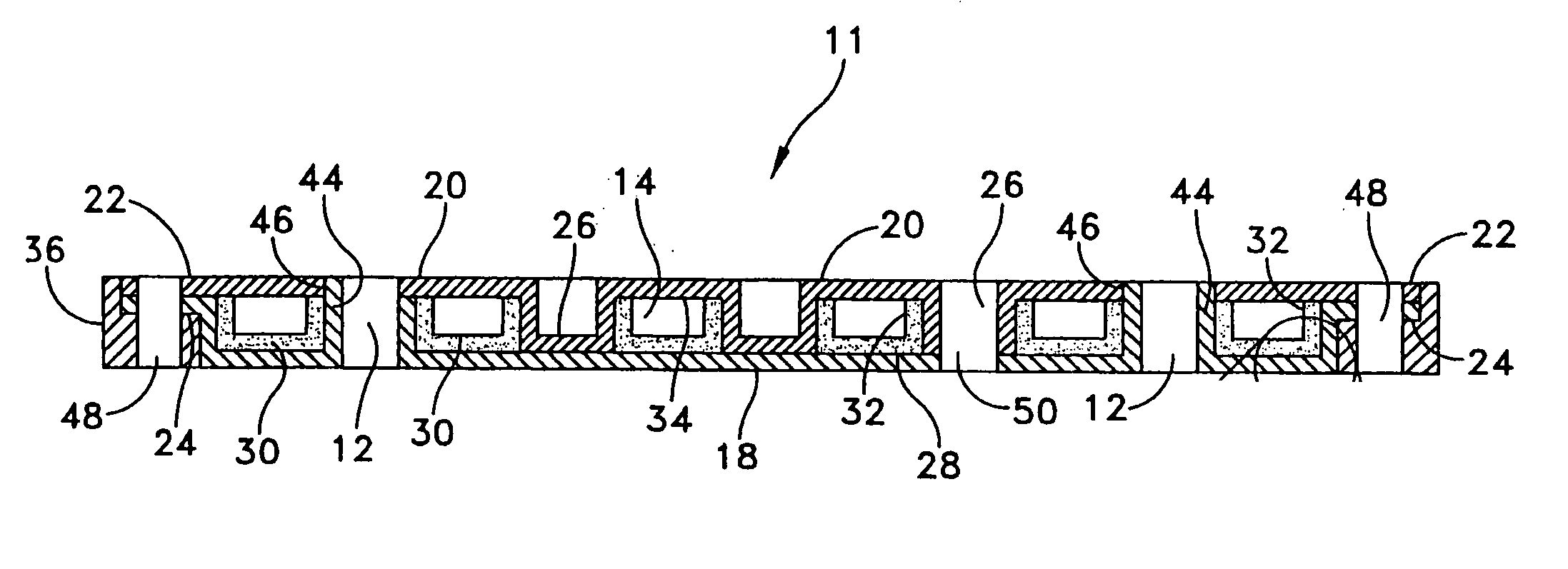

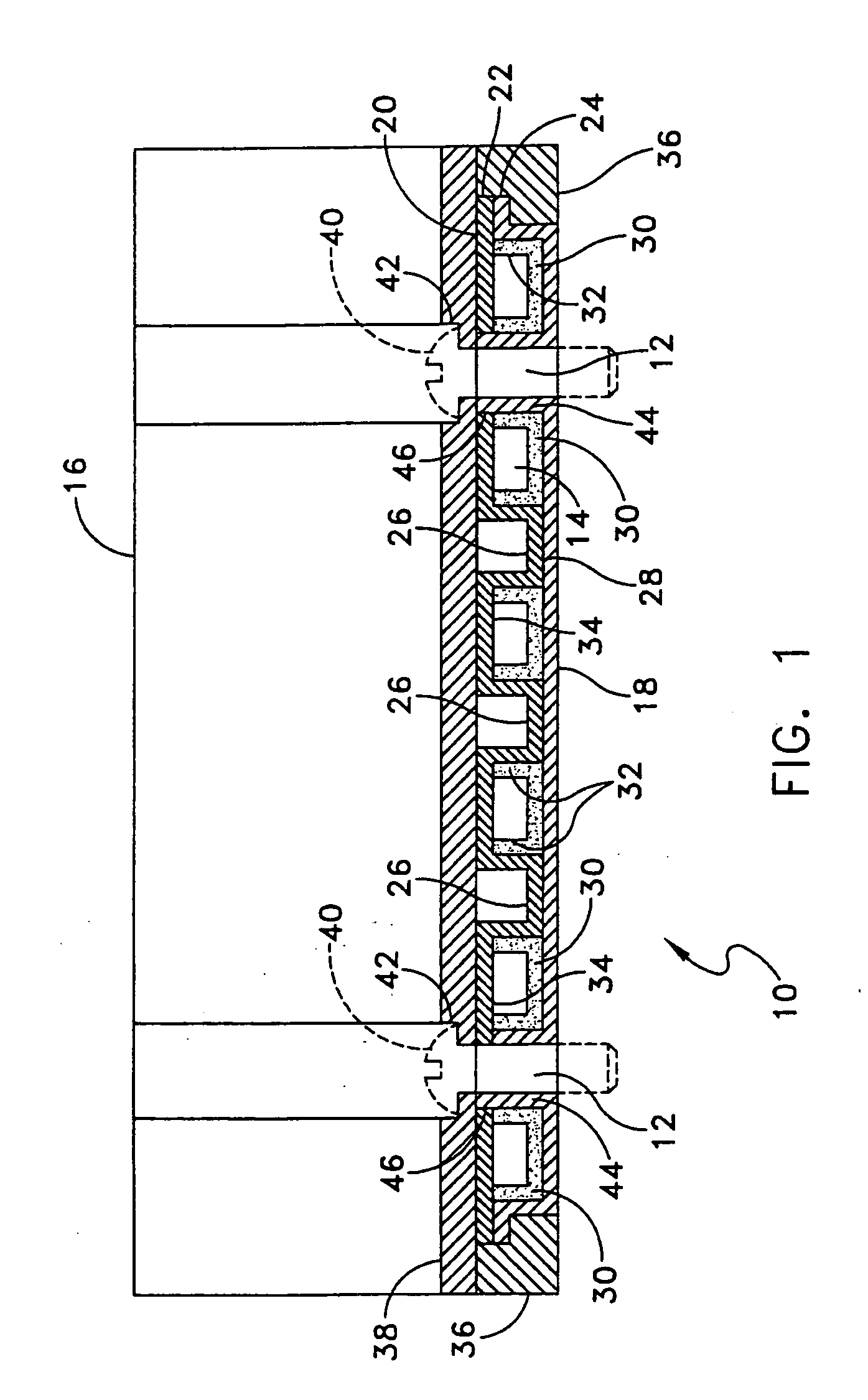

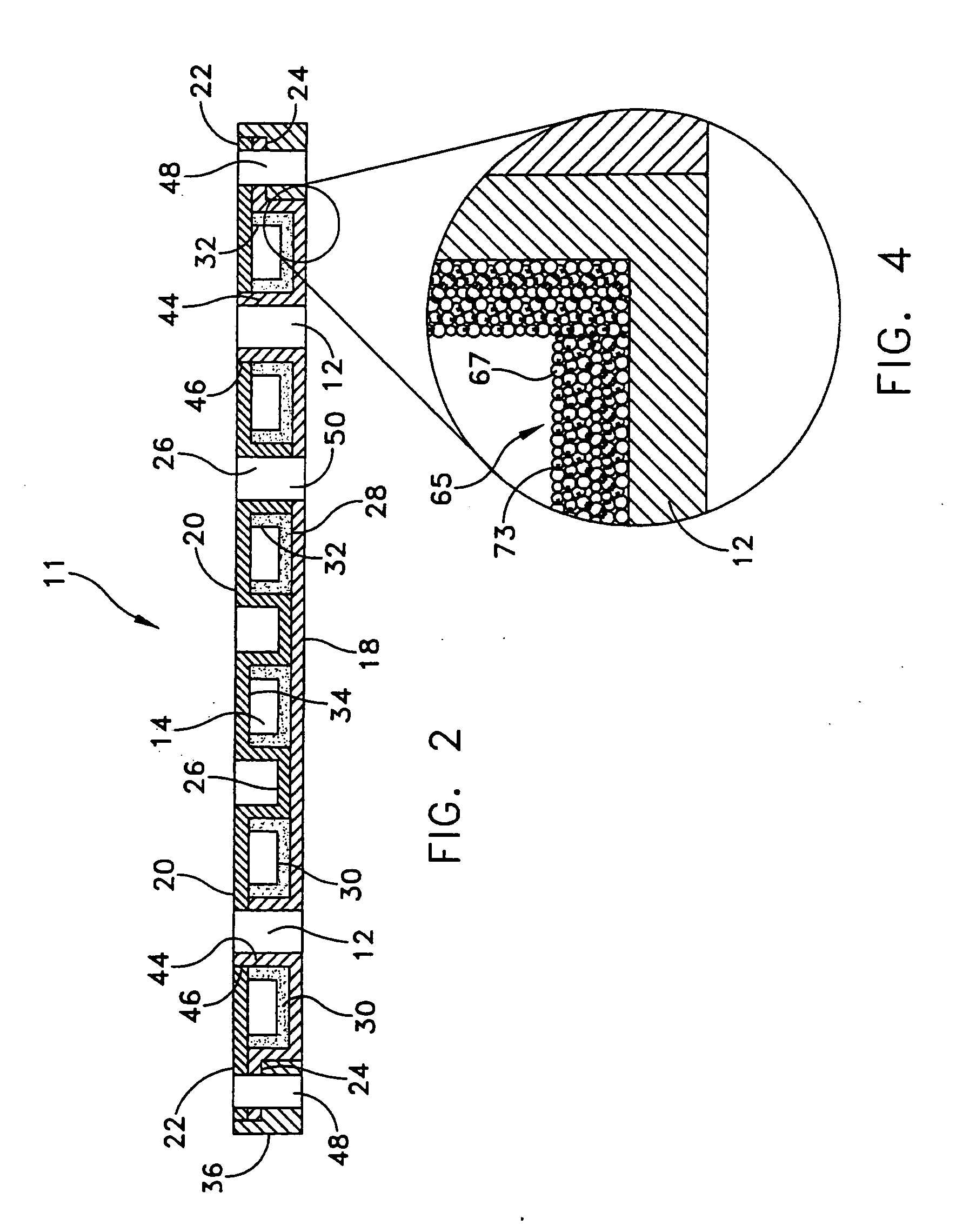

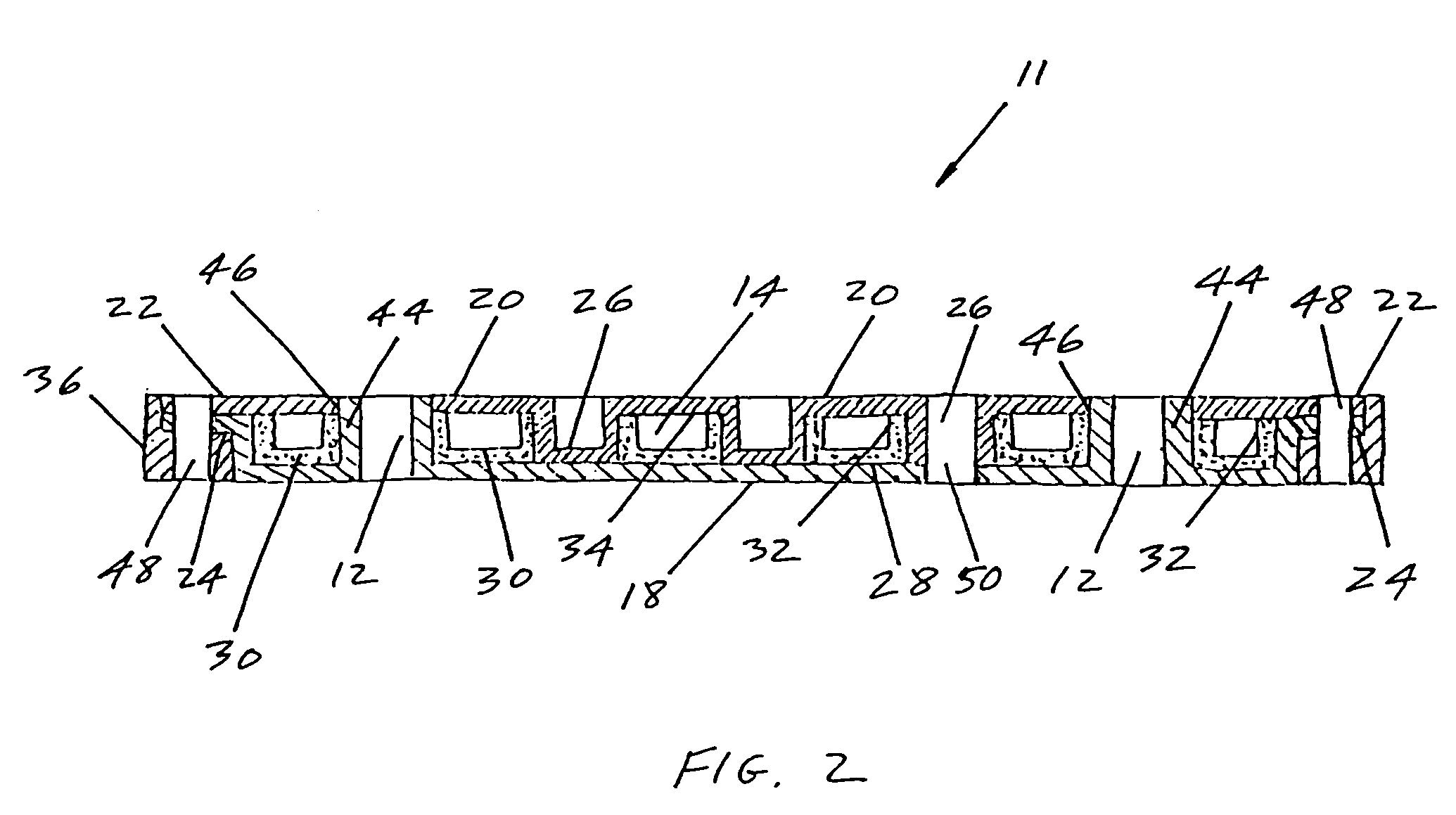

A heat pipe with superior heat transfer between the heat pipe and the heat source and heat sink is provided. The heat pipe is held tightly against the heat source by mounting holes which penetrate the structure of the heat pipe but are sealed off from the vapor chamber because they each are located within a sealed structure such as a pillar or the solid layers of the casing surrounding the vapor chamber. Another feature of the heat pipe is the use of a plurality of particles joined together by a brazing compound such that fillets of the brazing compound are formed between adjacent ones of the plurality of particles so as to form a network of capillary passageways between the particles of the wick.

Owner:AAVID THERMALLOY LLV

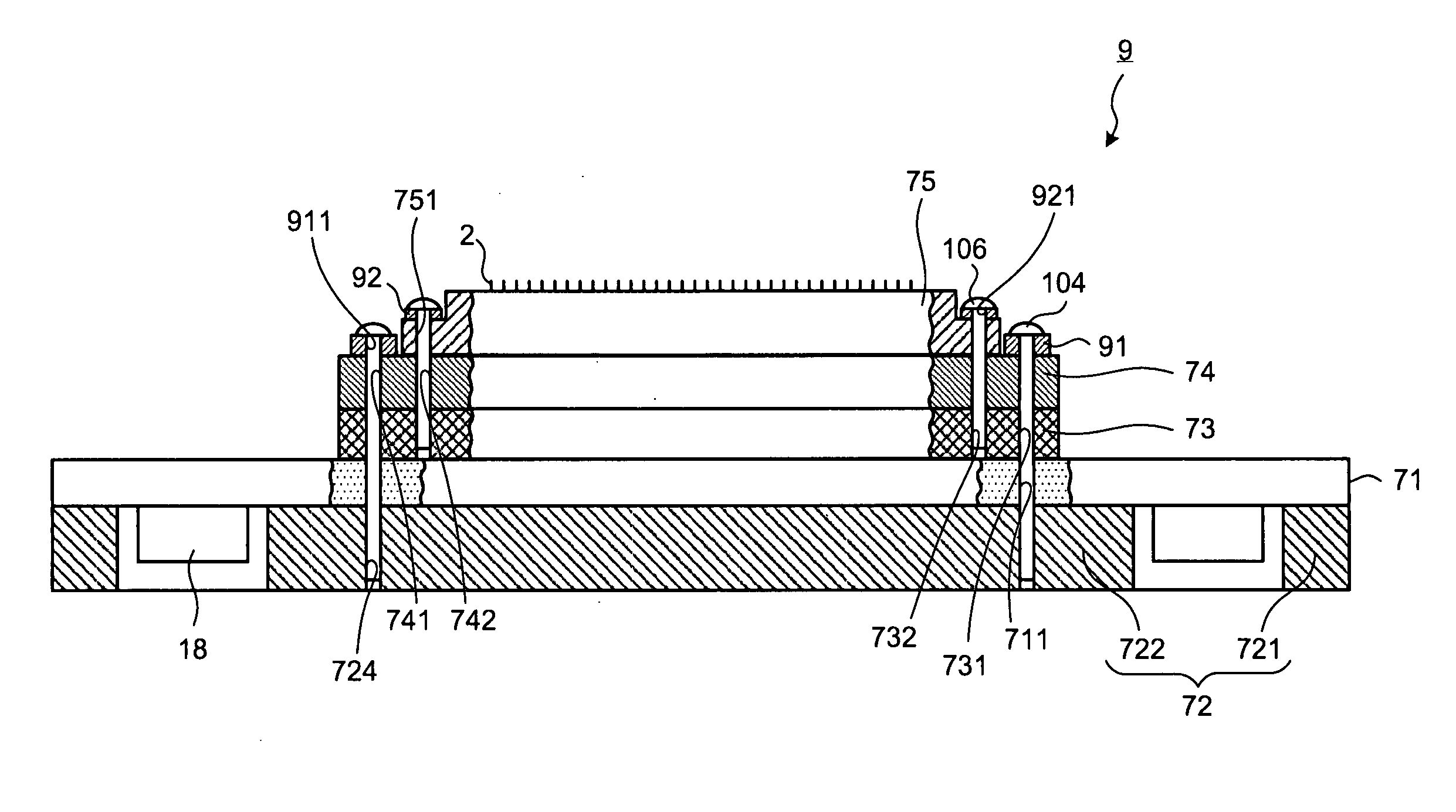

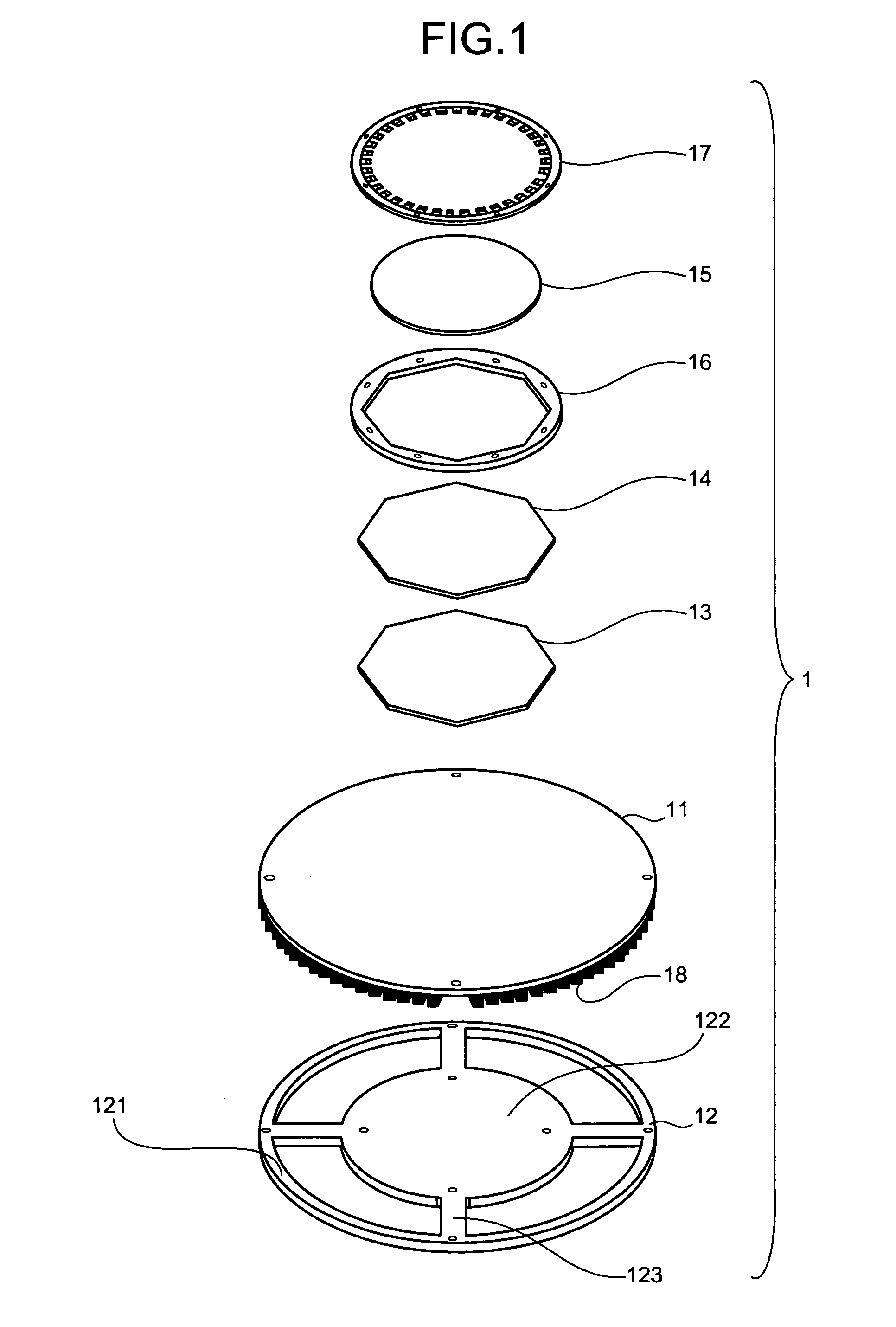

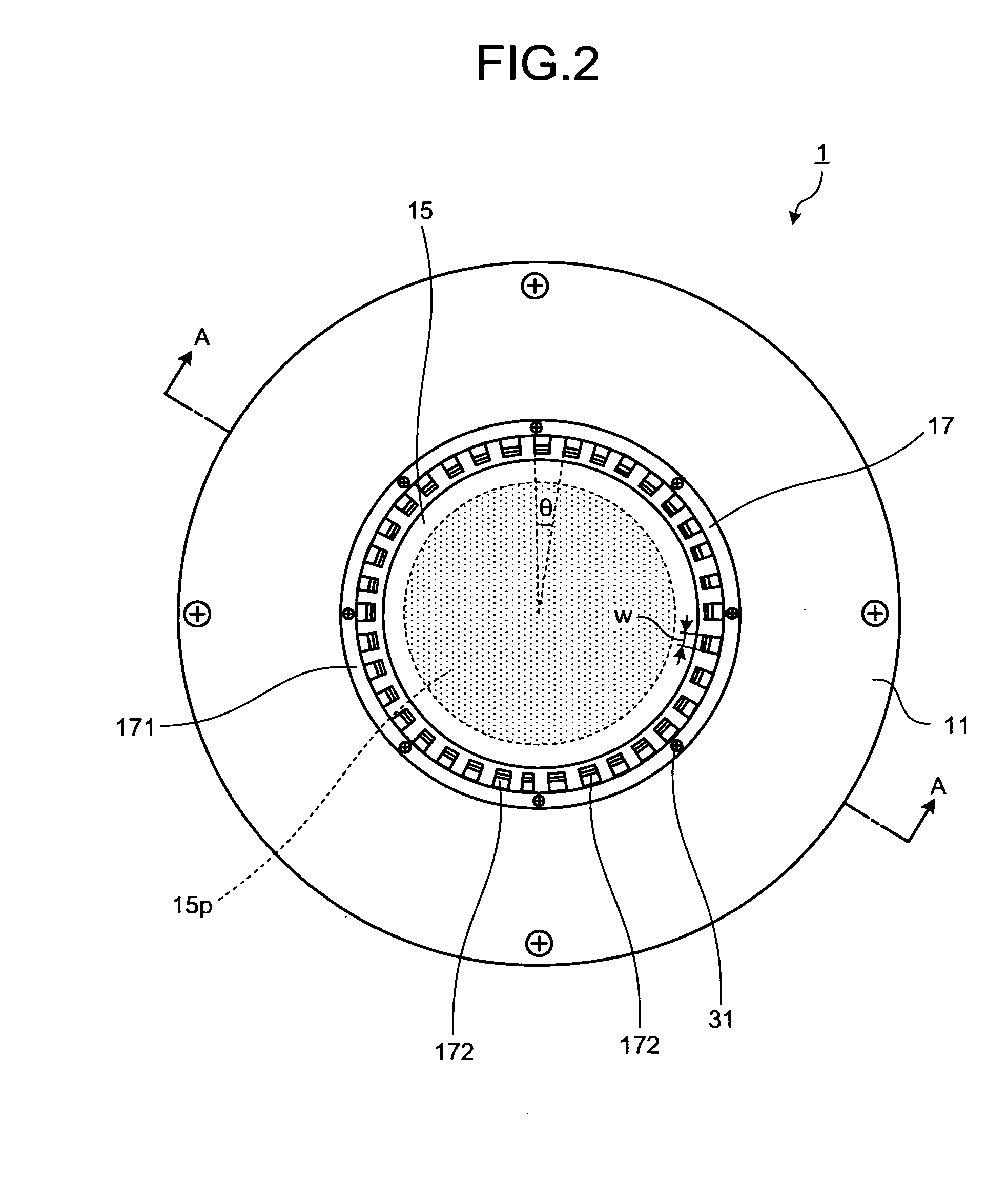

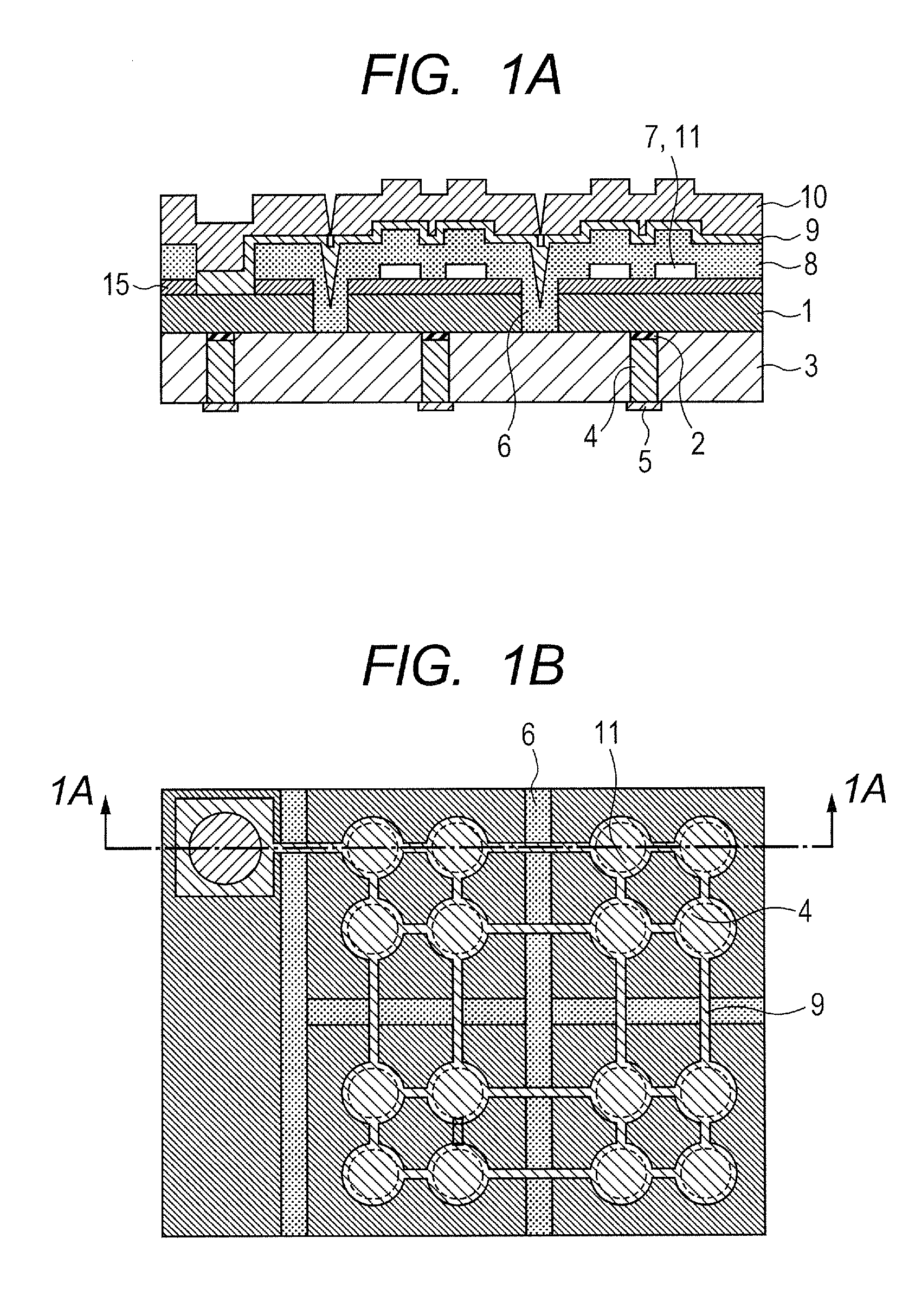

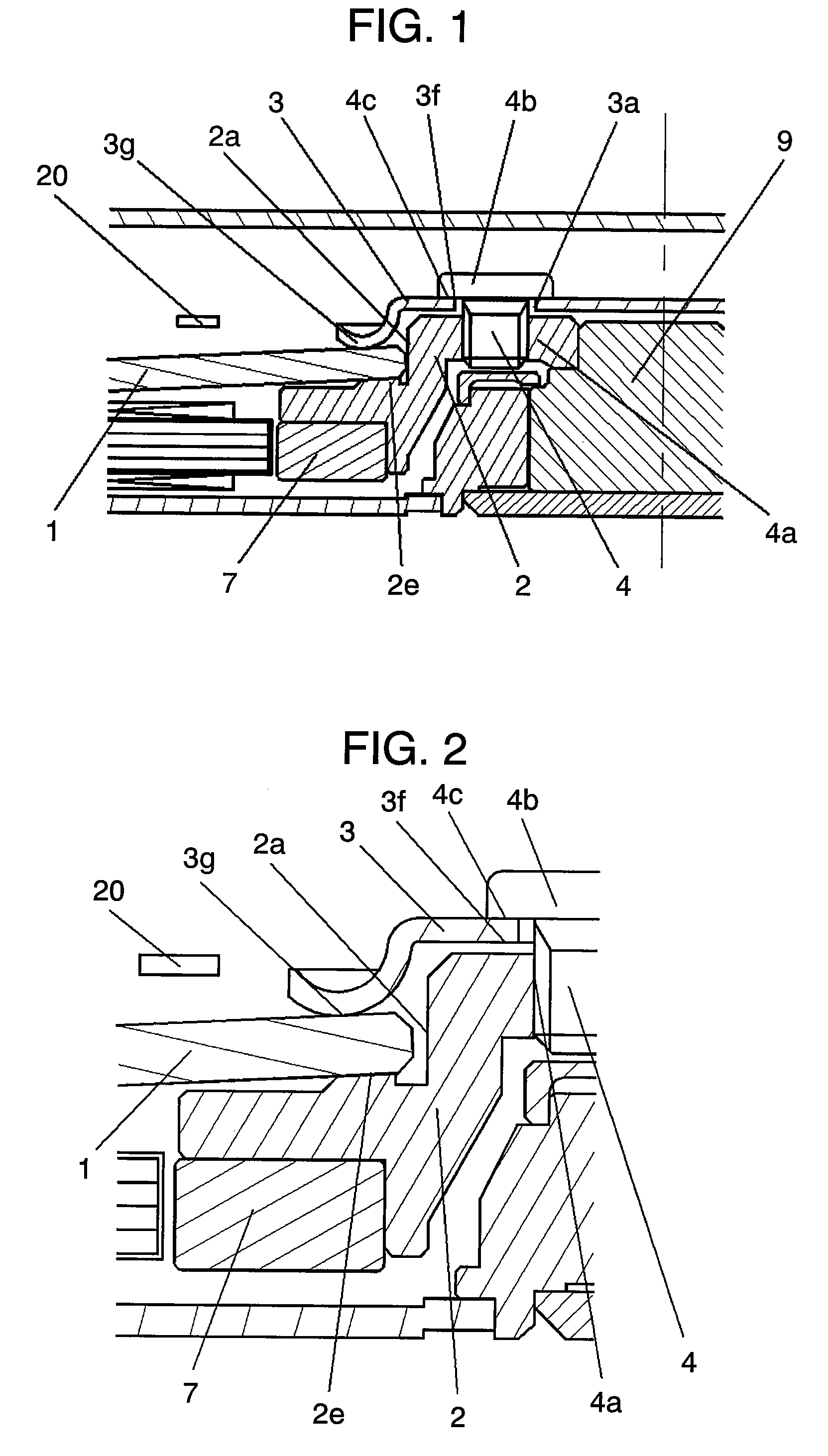

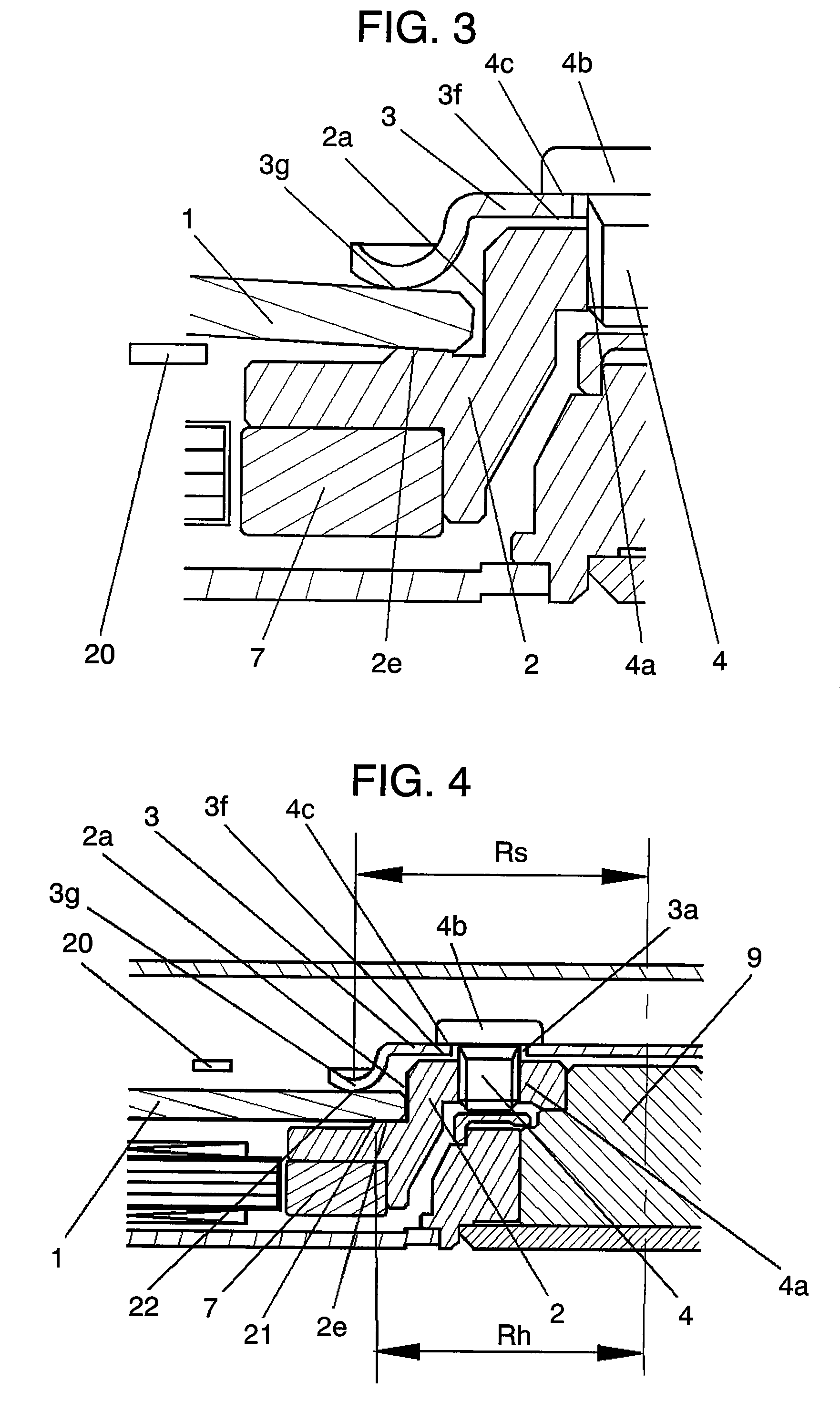

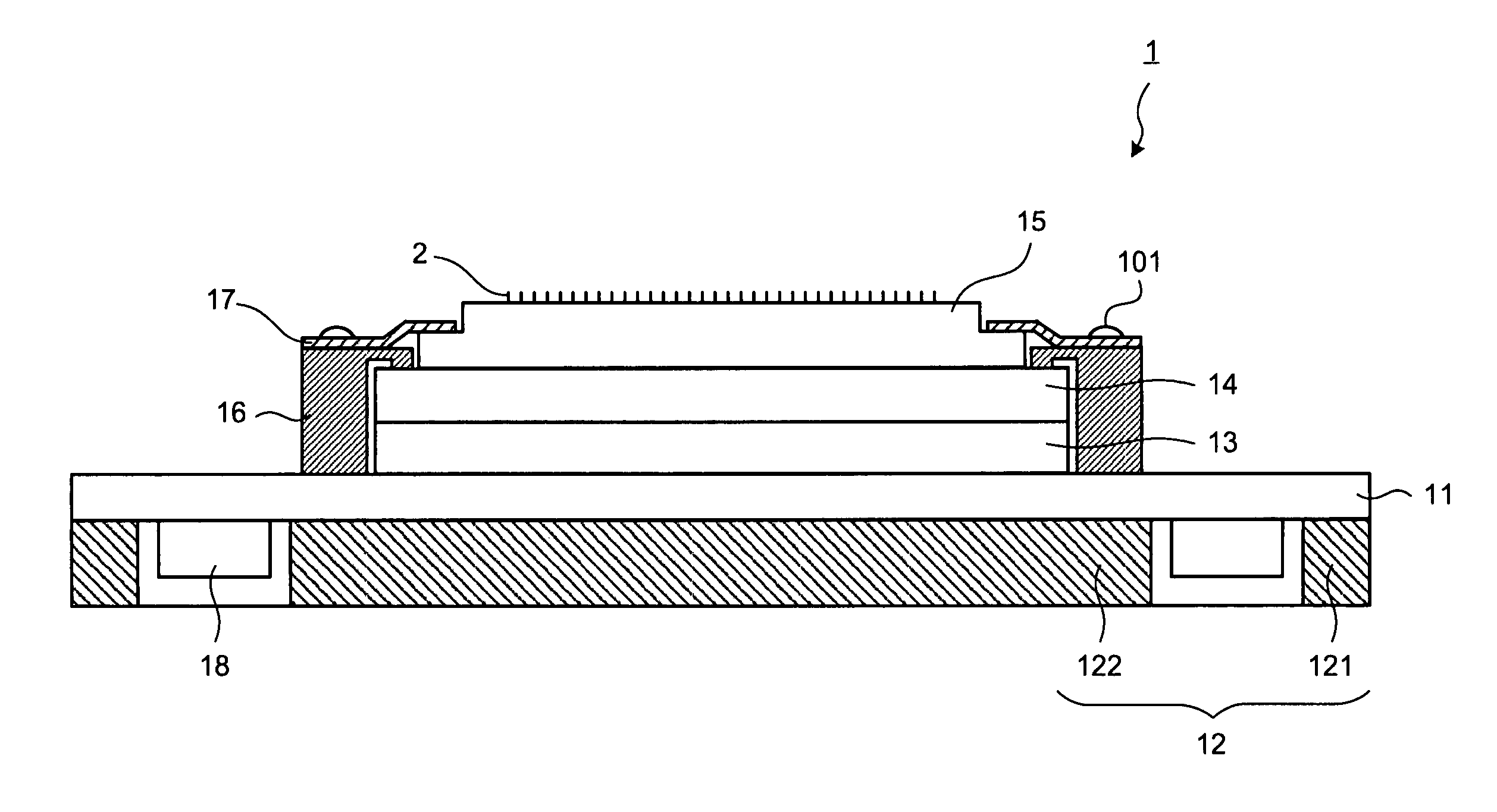

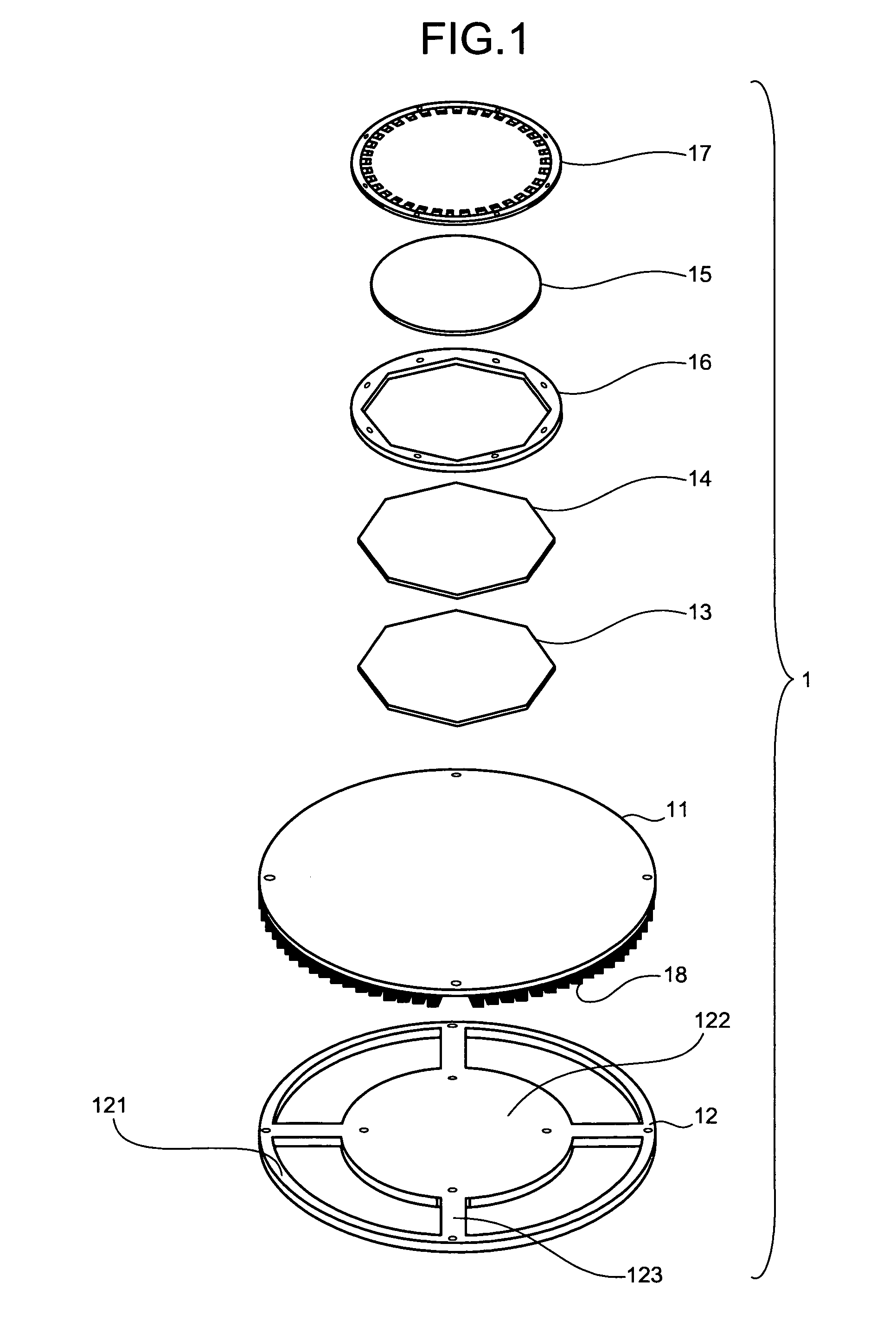

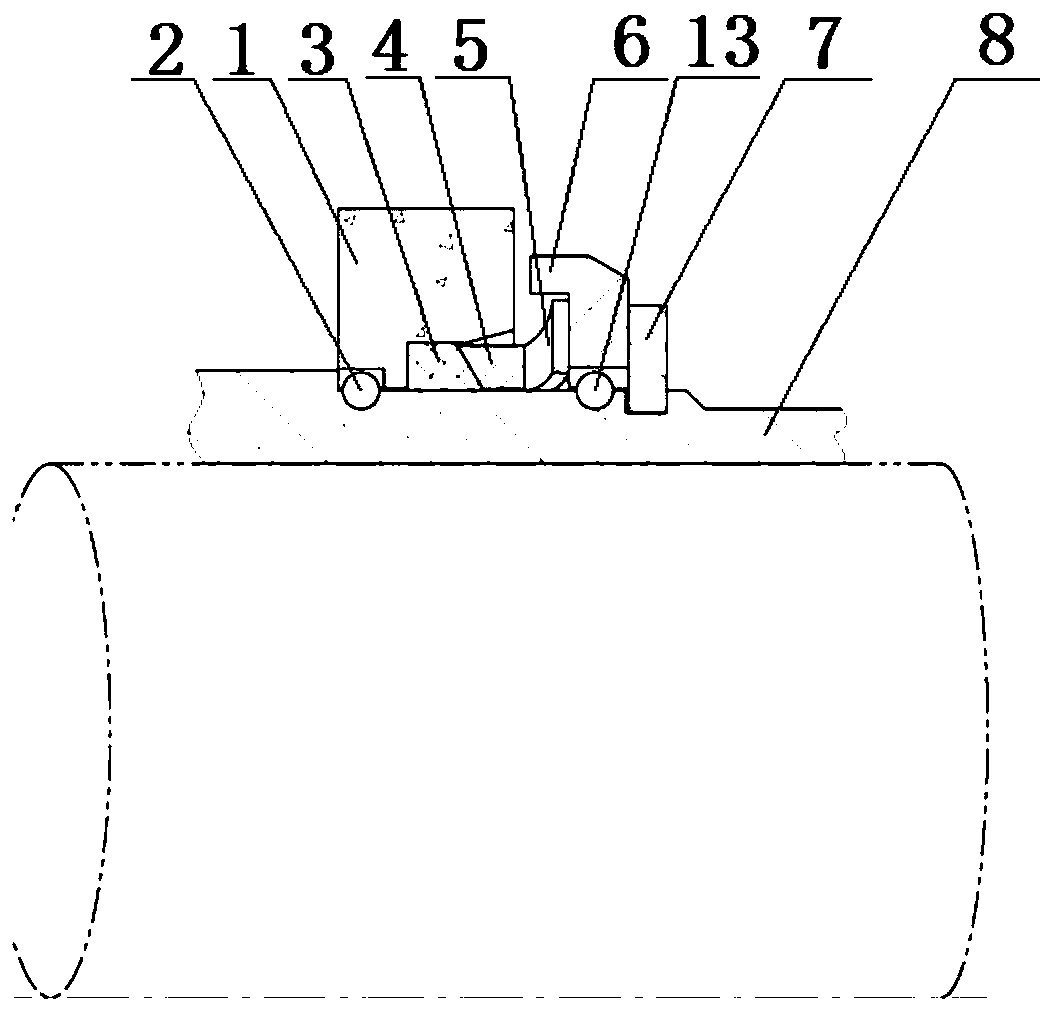

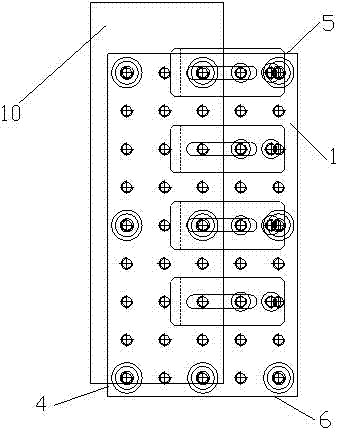

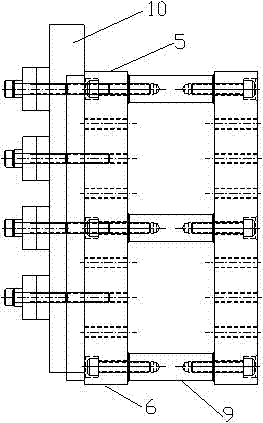

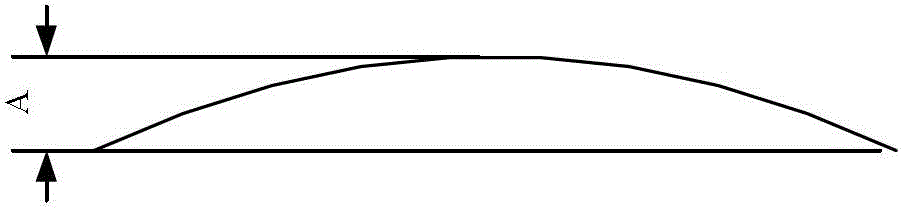

Probe card

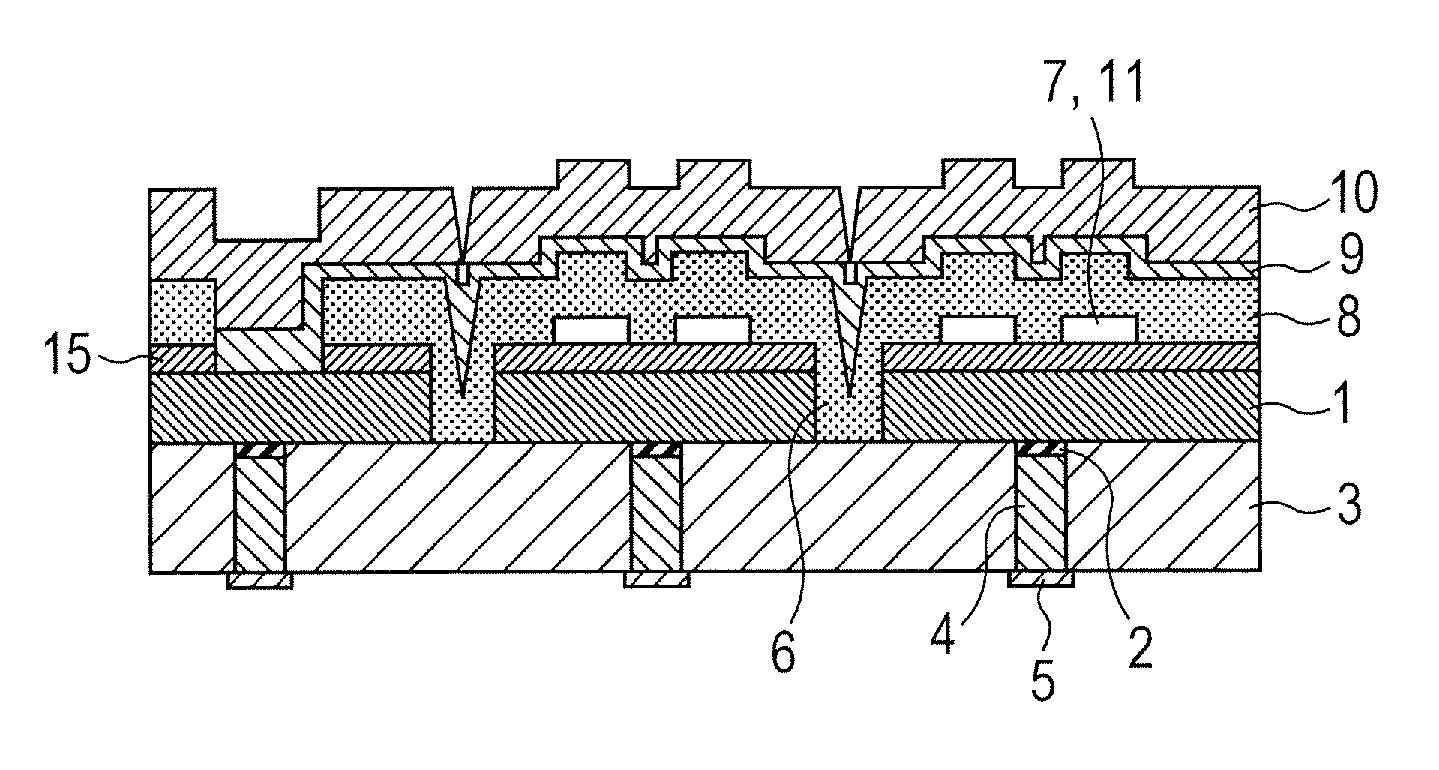

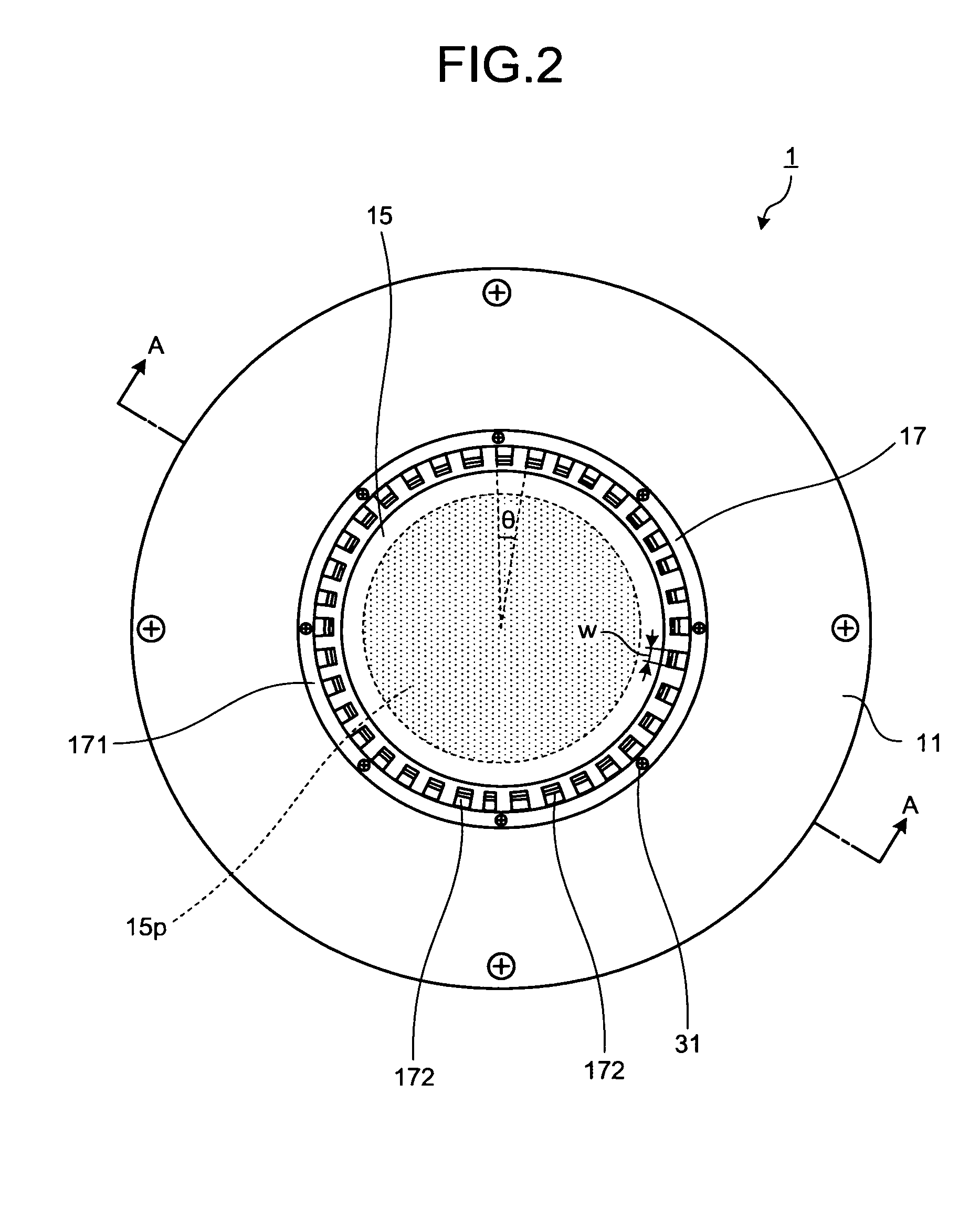

ActiveUS20100164518A1Warpage suppressionCorrection of flatnessElectrical measurement instrument detailsIndividual semiconductor device testingProbe cardTransformer

A probe card is provided that is capable of accurately ensuring the flatness and the parallelism with respect to a predetermined reference surface. A point (Q) of application of force applied from a leaf spring (17) that presses a portion near an edge portion of a surface of a probe head (15) from which a plurality of probes projects over an entire circumference in a direction of a substrate to the probe head (15) is positioned inside of an outer edge of the probe head (15), and a point (P) of application of force applied from the retainer (16) that presses a portion near an edge portion of a space transformer (14) over an entire circumference in the direction of the substrate to the space transformer (14) is positioned inside of an outer edge of the space transformer (14).

Owner:NHK SPRING CO LTD

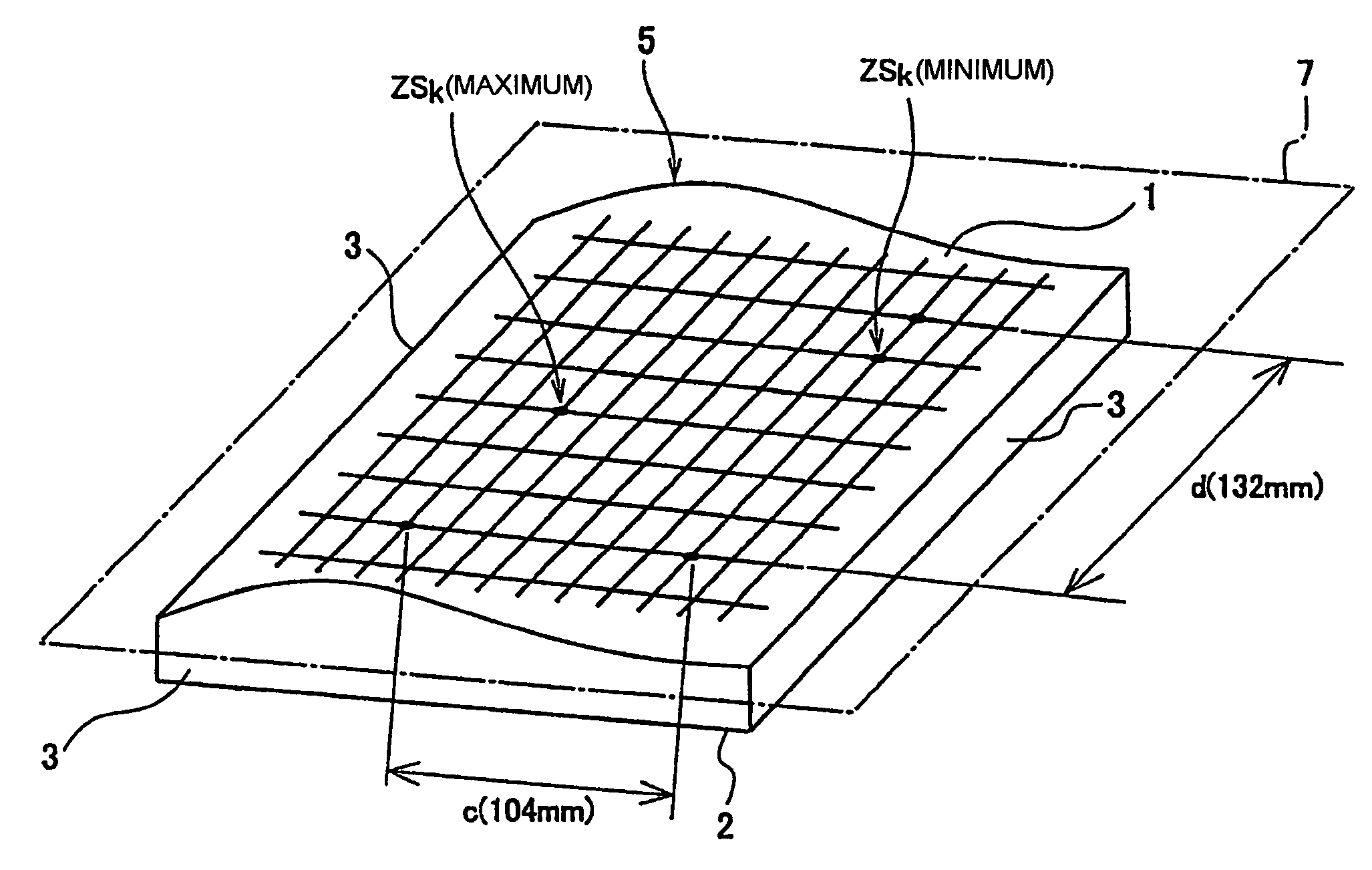

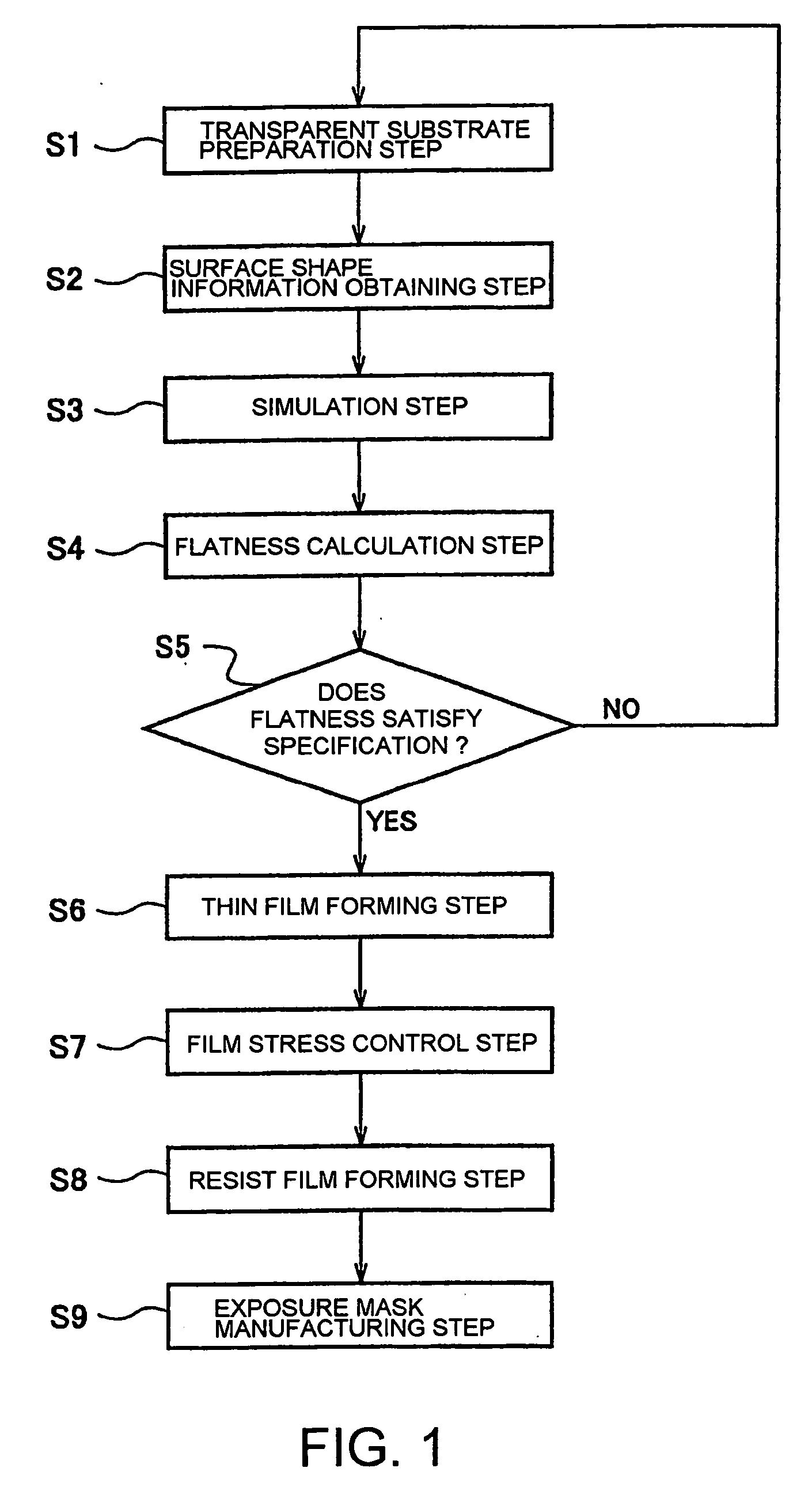

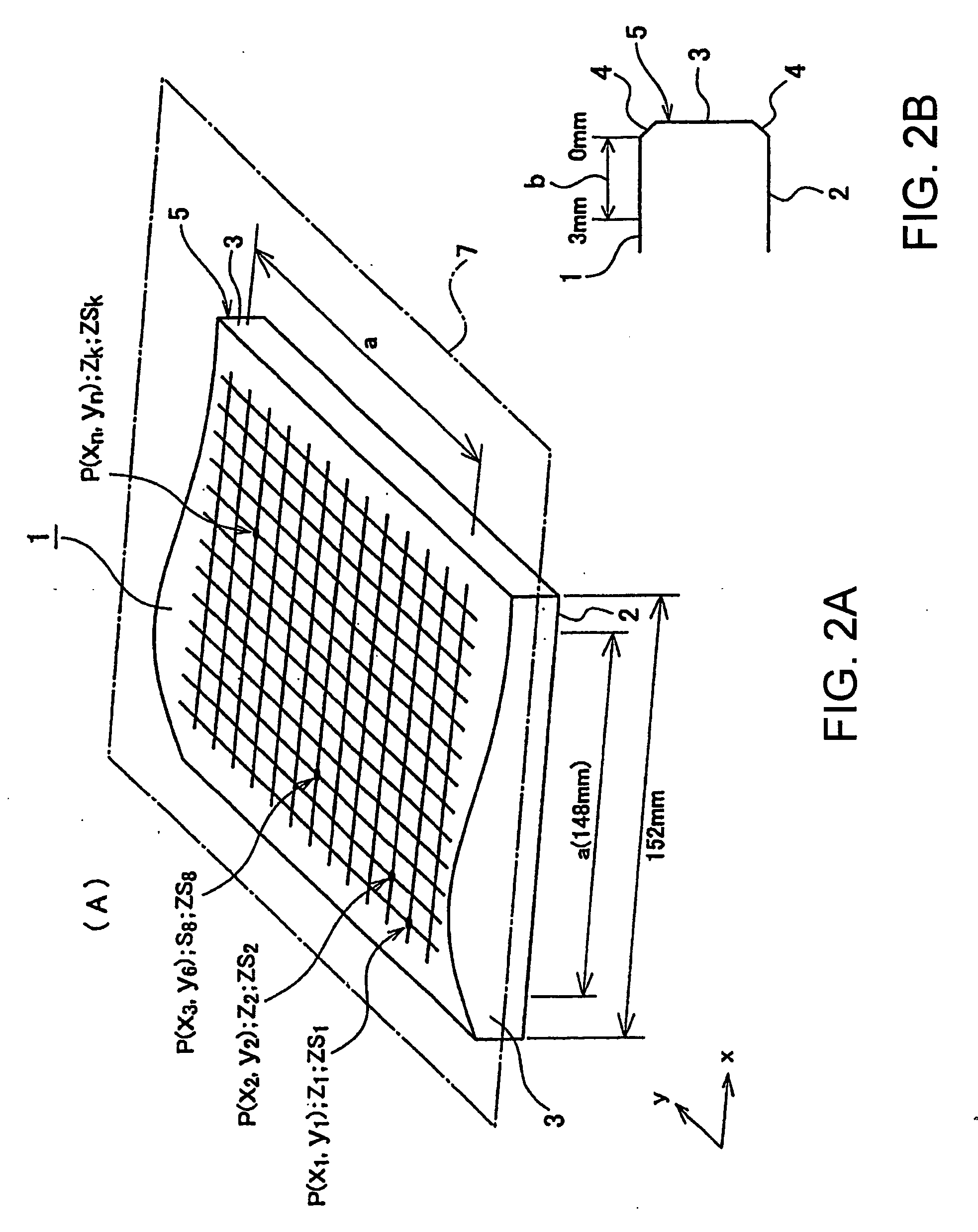

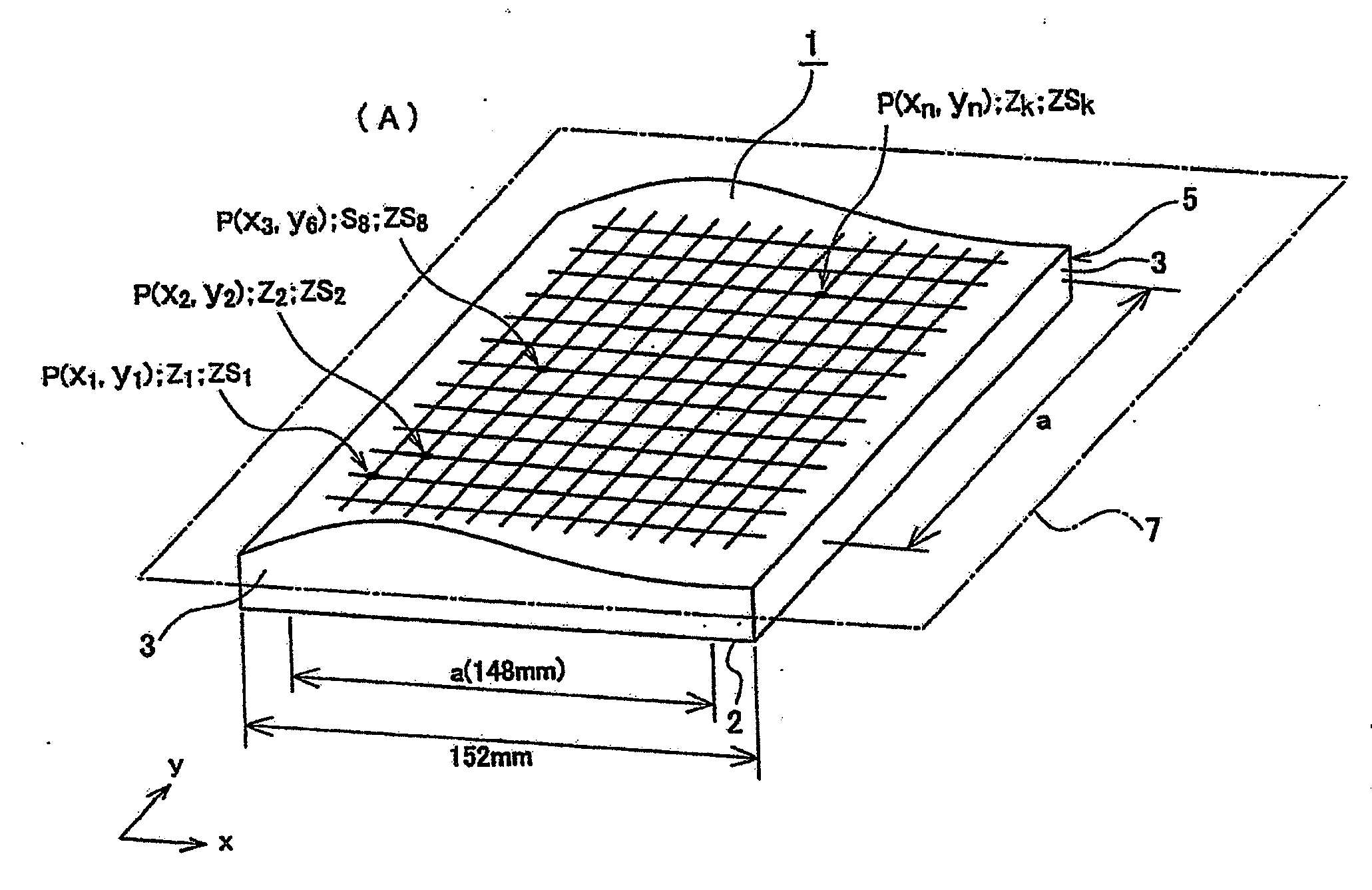

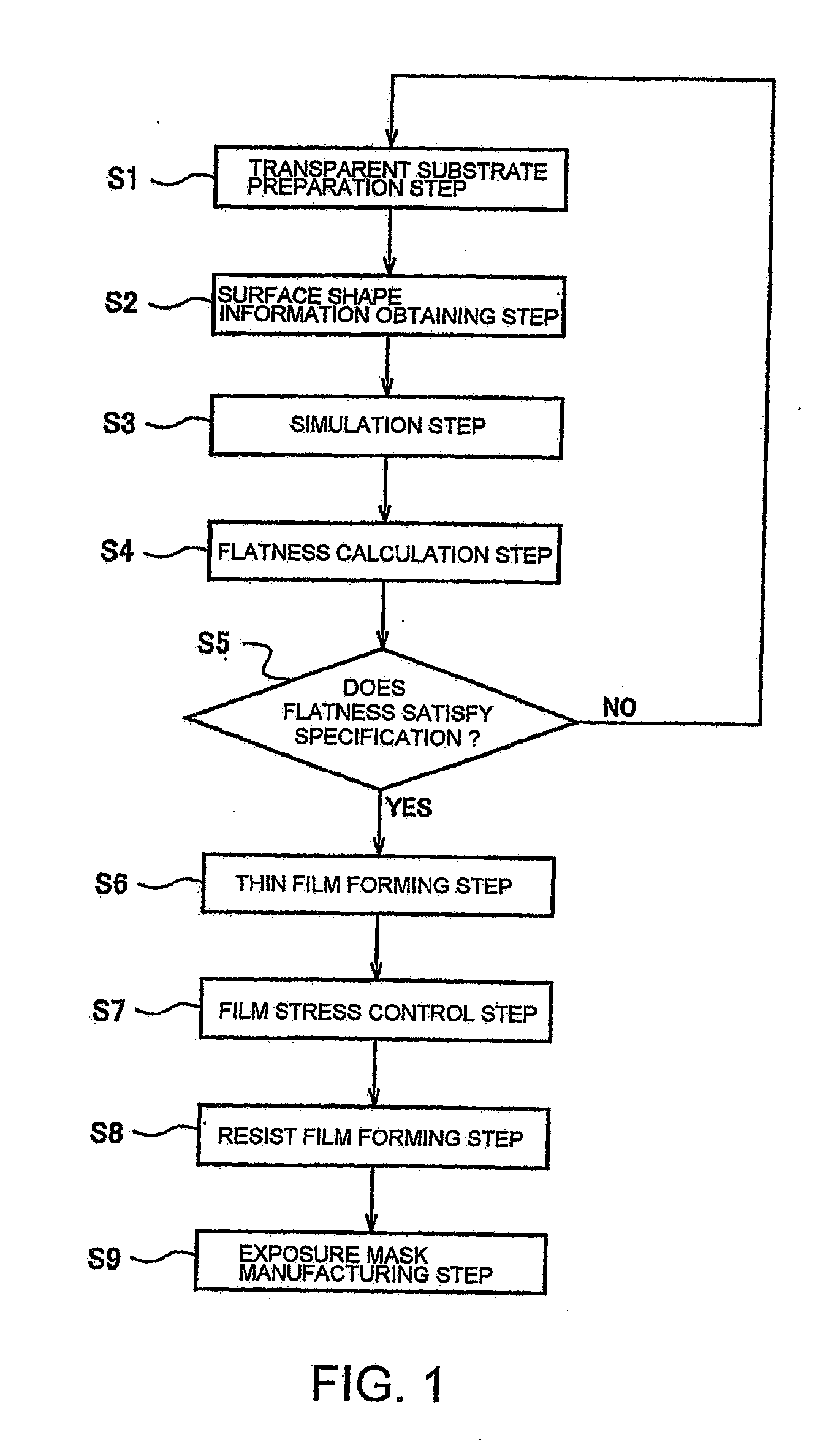

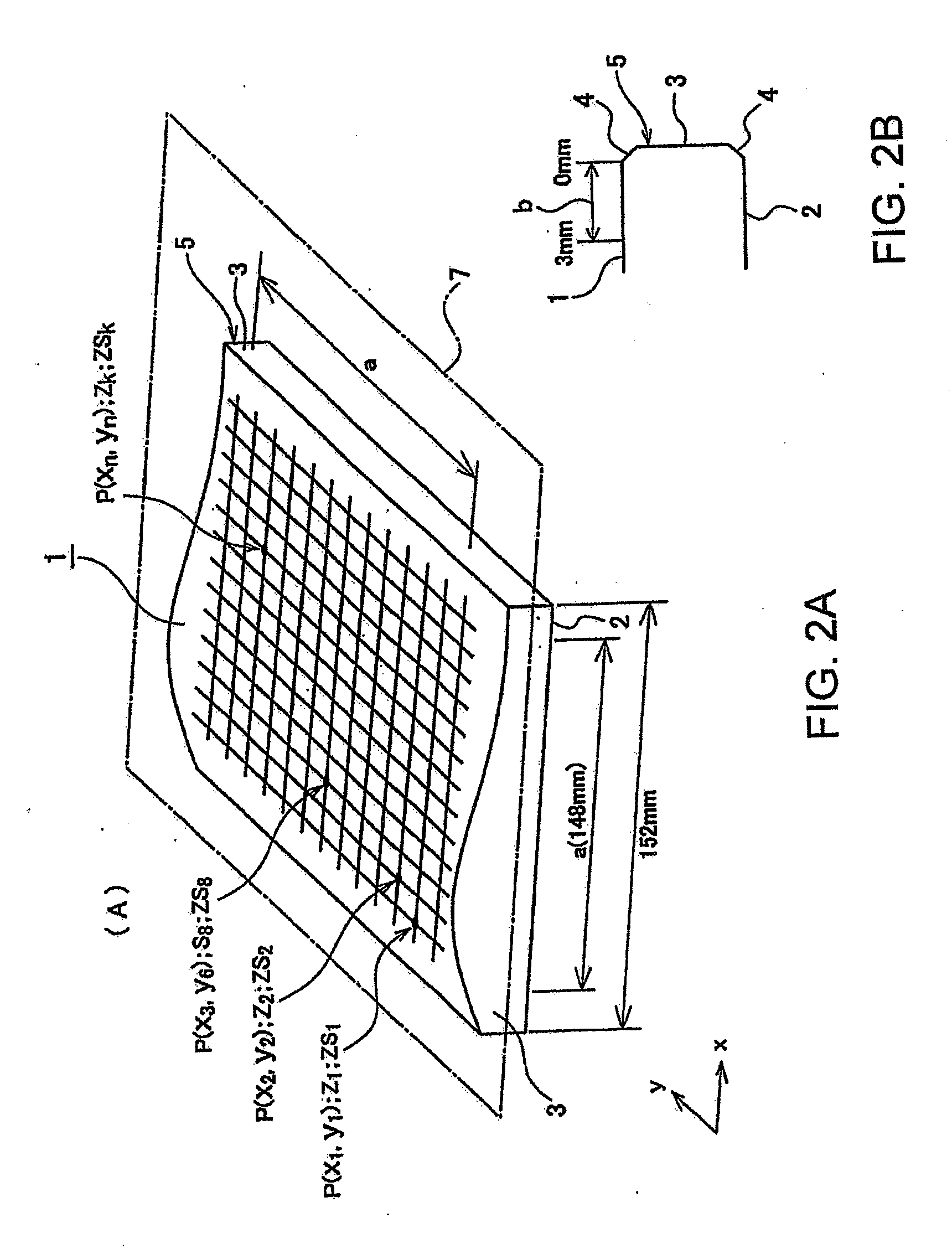

Mask blank transparent substrate manufacturing method, mask blank manufacturing method, and exposure mask manufacturing method

ActiveUS20060194126A1Inhibition of defect generationImprove accuracyPhotomechanical apparatusSemiconductor/solid-state device manufacturingMeasurement pointEngineering

A method includes a preparation step of preparing a transparent substrate having a precision-polished main surface, a surface shape information obtaining step of obtaining, as surface shape information, height information at a plurality of measurement points on the main surface of the transparent substrate that contacts a mask stage of an exposure apparatus, a simulation step of obtaining, based on the surface shape information and shape information of the mask stage, height information at the plurality of measurement points by simulating the state where the transparent substrate is set in the exposure apparatus, a flatness calculation step of calculating, based on the height information obtained through the simulation, a flatness of the transparent substrate when it is set in the exposure apparatus, a judging step of judging whether or not the calculated flatness satisfies a specification, and a thin film forming step of forming a thin film as serving as a mask pattern, on the main surface of the transparent substrate whose flatness satisfies the specification.

Owner:HOYA CORP

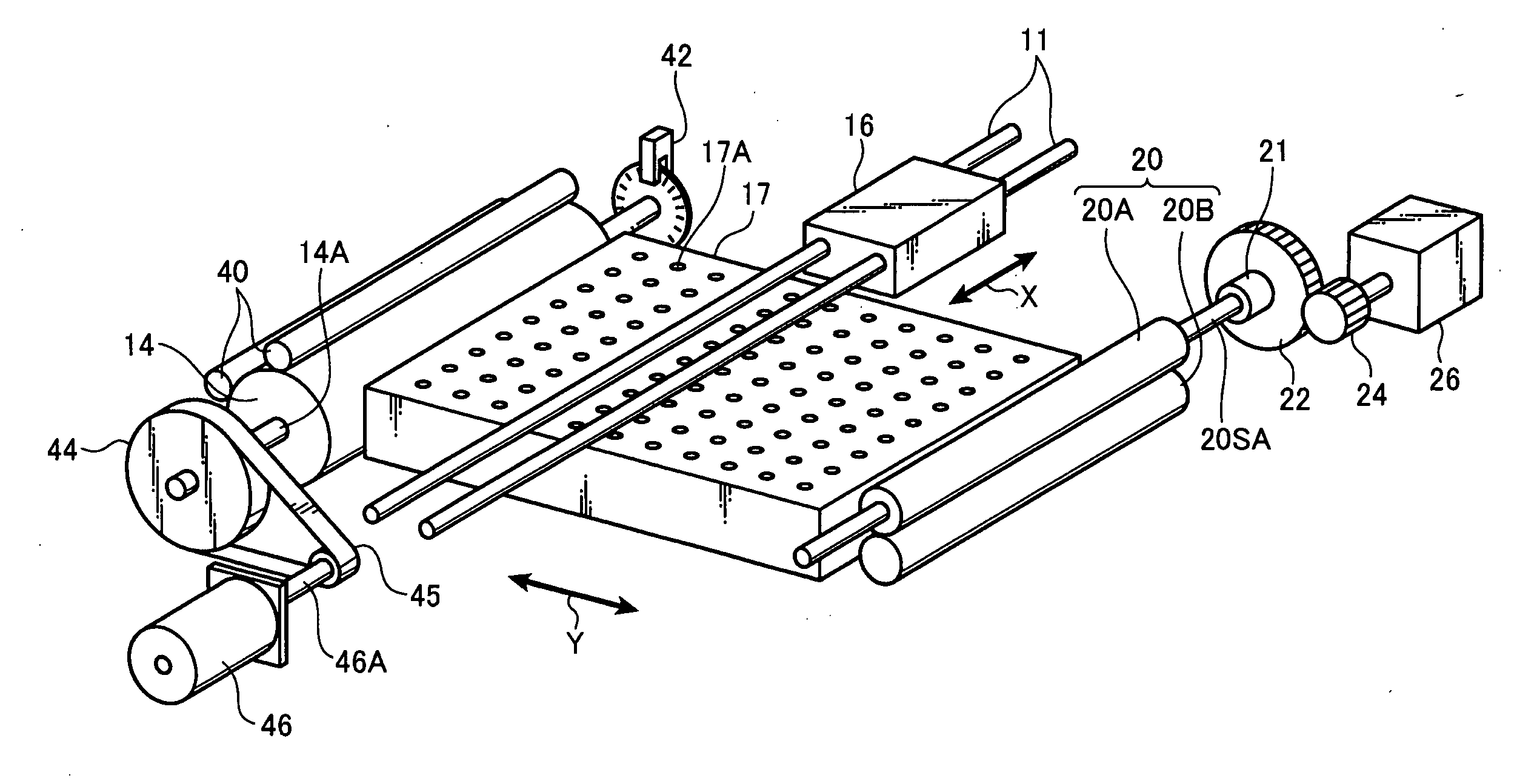

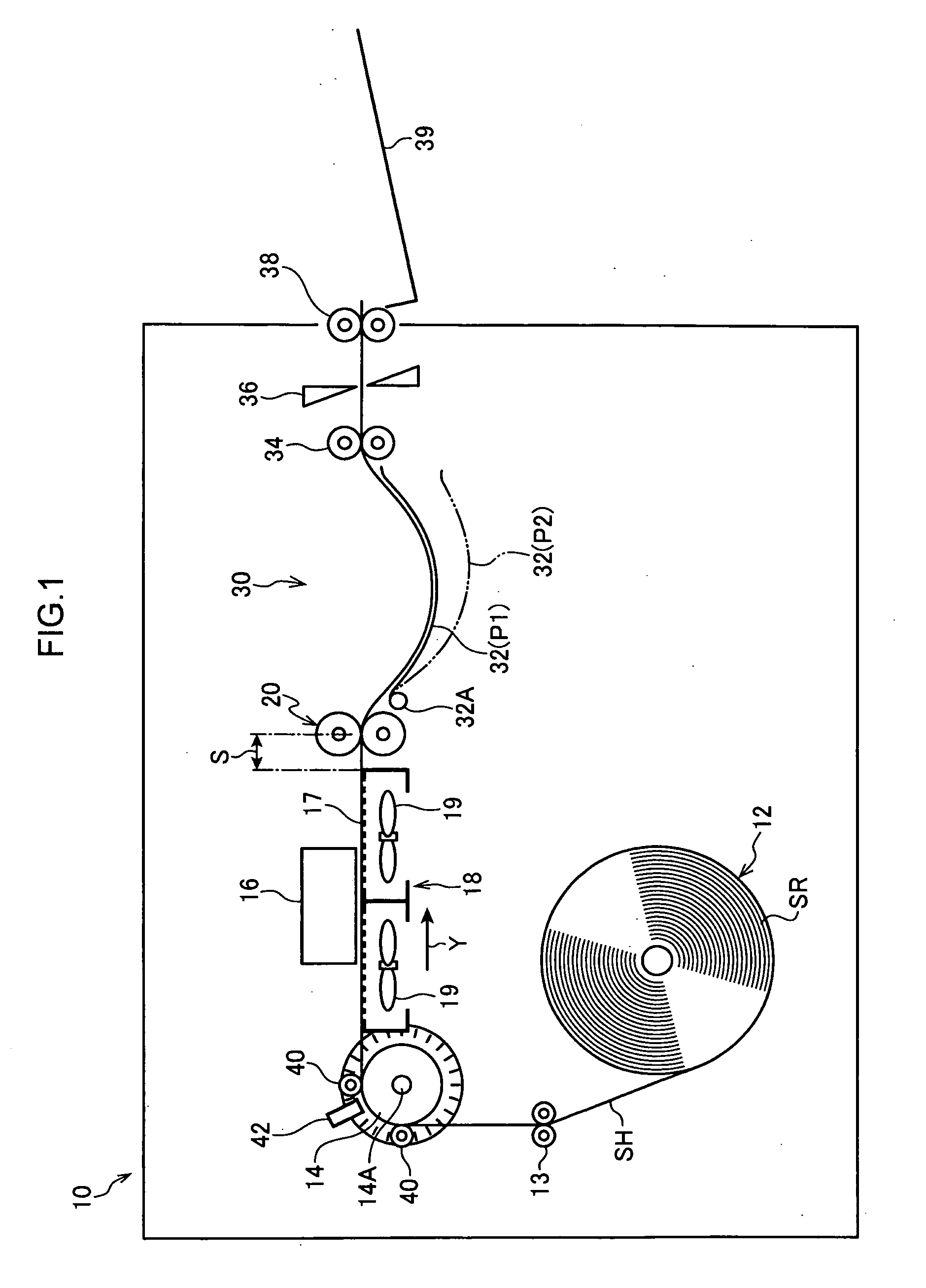

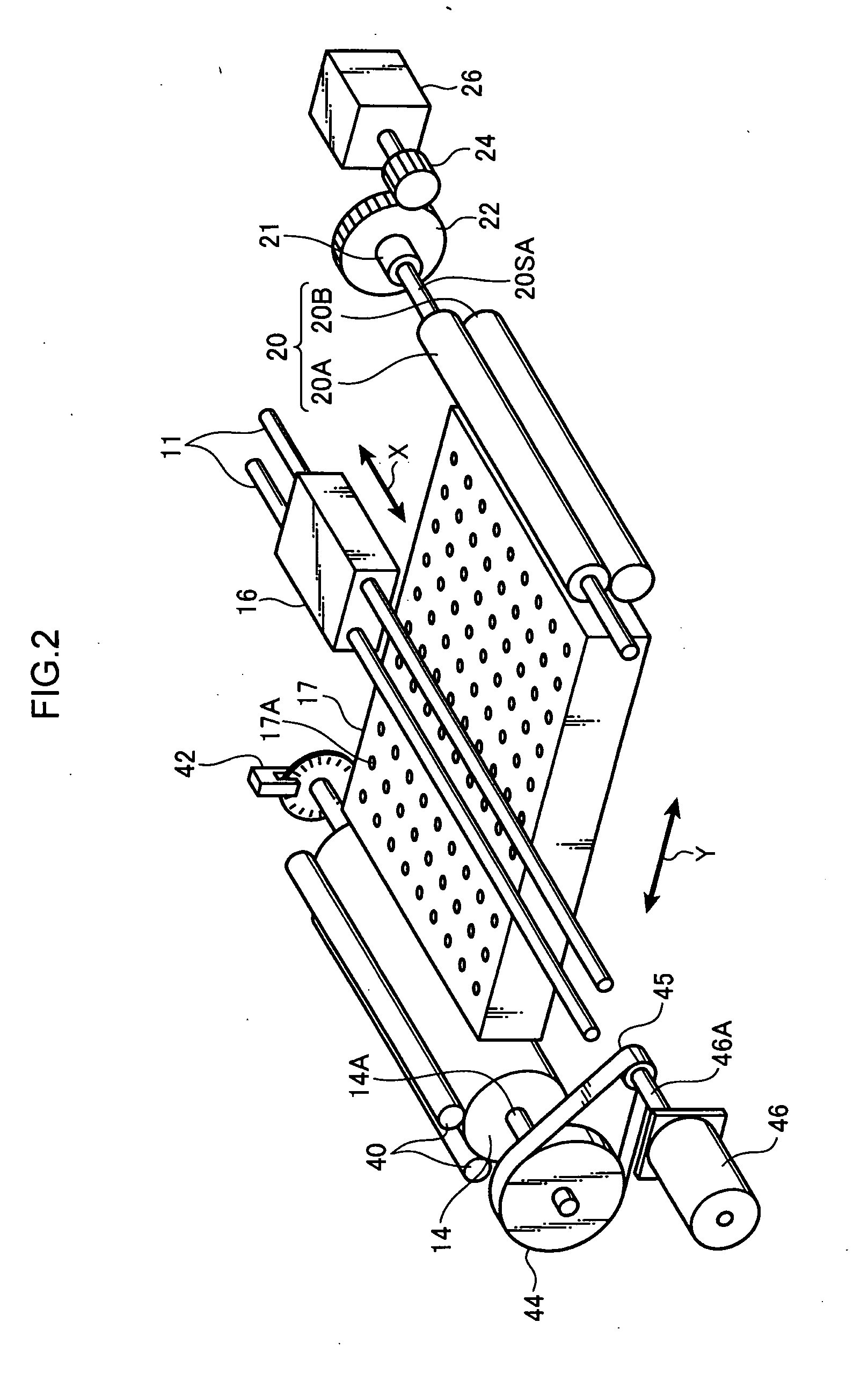

Image forming device

InactiveUS20100238250A1Reduce the impactSmall reaction forceOther printing apparatusImage formationComputer science

An image forming device provided with: a recording head that renders an image by ejecting liquid droplets onto a recording medium; an attraction image rendering section having a liquid droplet reception flat portion disposed facing the recording head, the attraction image rendering section attracting the recording medium onto the flat portion and maintaining the flatness of the recording medium; an upstream side conveying section that feeds the recording medium out toward the attraction image rendering section; and a reverse-feed-prevented conveying roller disposed at the downstream side of the attraction image rendering section, the reverse-feed-prevented conveying roller being capable of friction-pushed rotation toward the conveying direction downstream side, nipping the recording medium and feeding the recording medium toward the conveying direction downstream side, and prevented from rotation toward the conveying direction upstream side.

Owner:FUJIFILM CORP

Integrated circuit heat pipe heat spreader with through mounting holes

InactiveUS20050145374A1Simple and light weightEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

Owner:AAVID THERMALLOY LLV

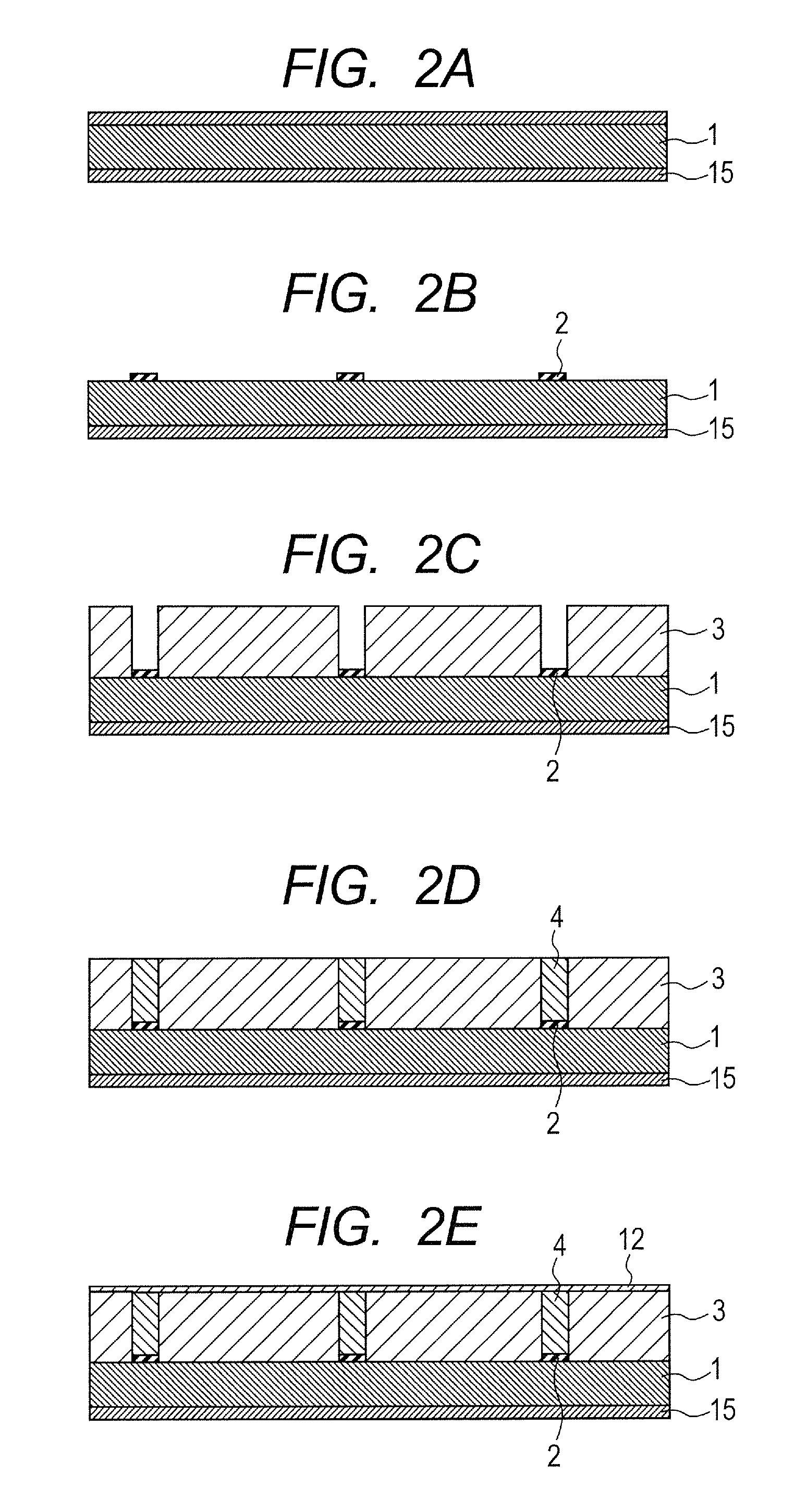

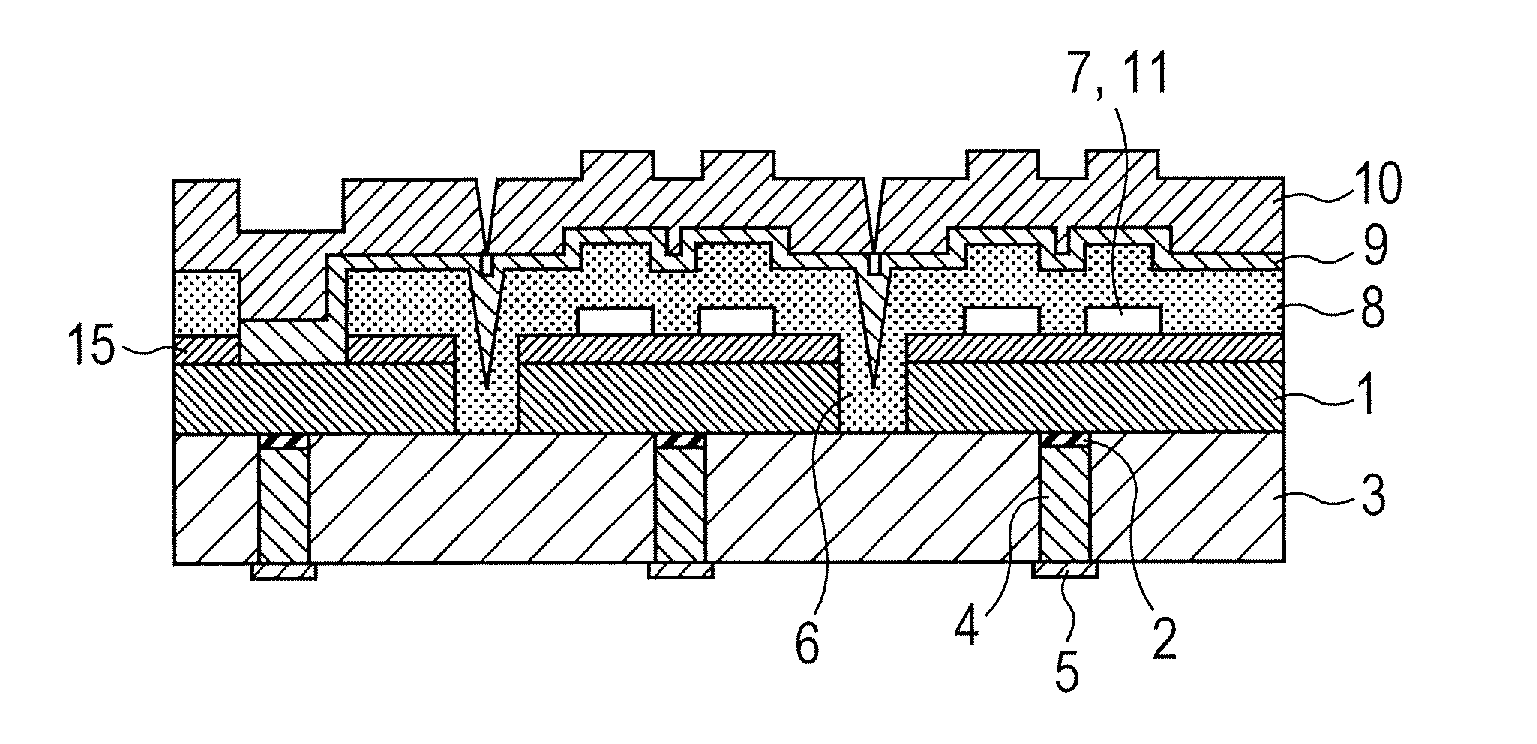

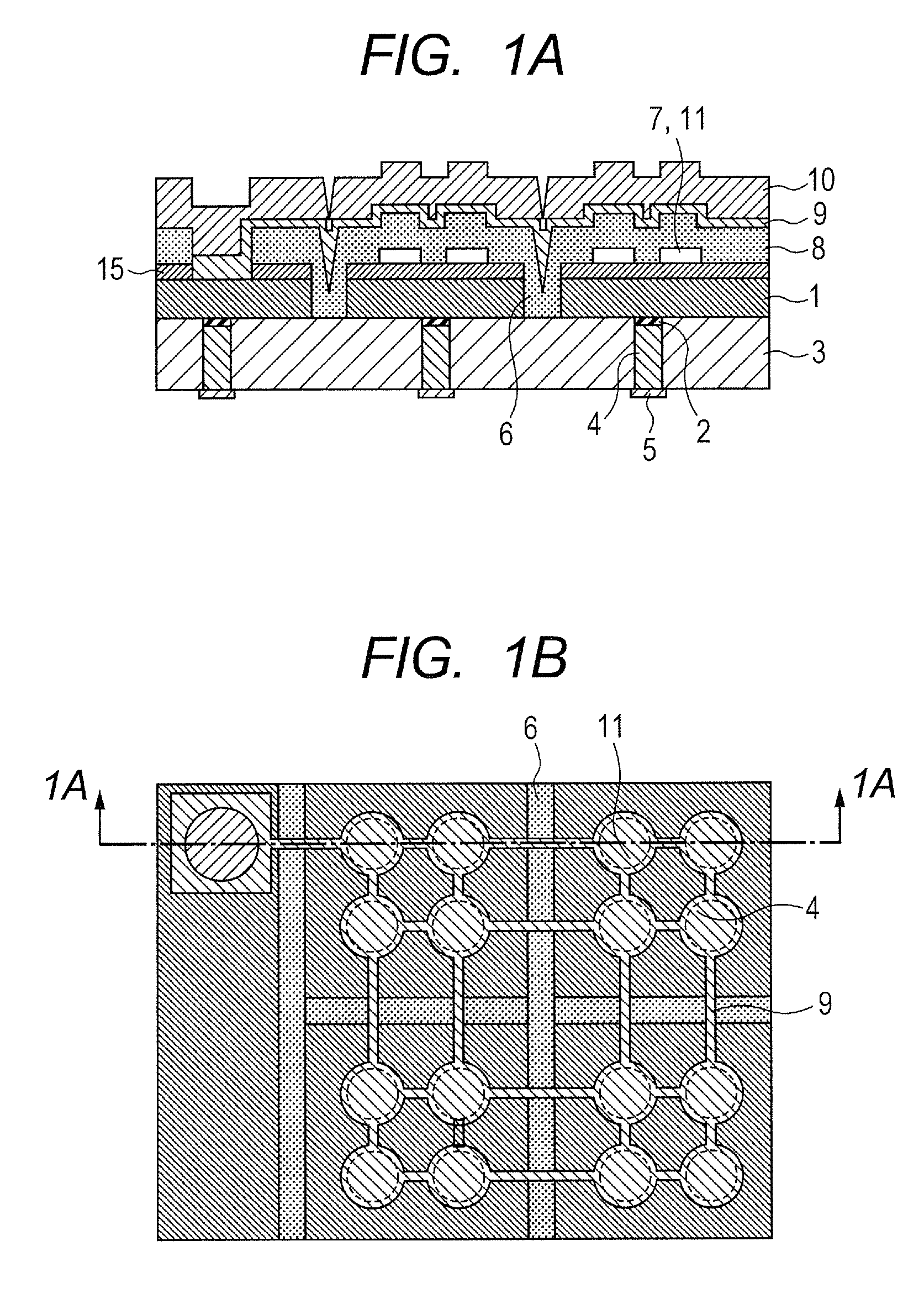

Electromechanical transducer and method for manufacturing the same

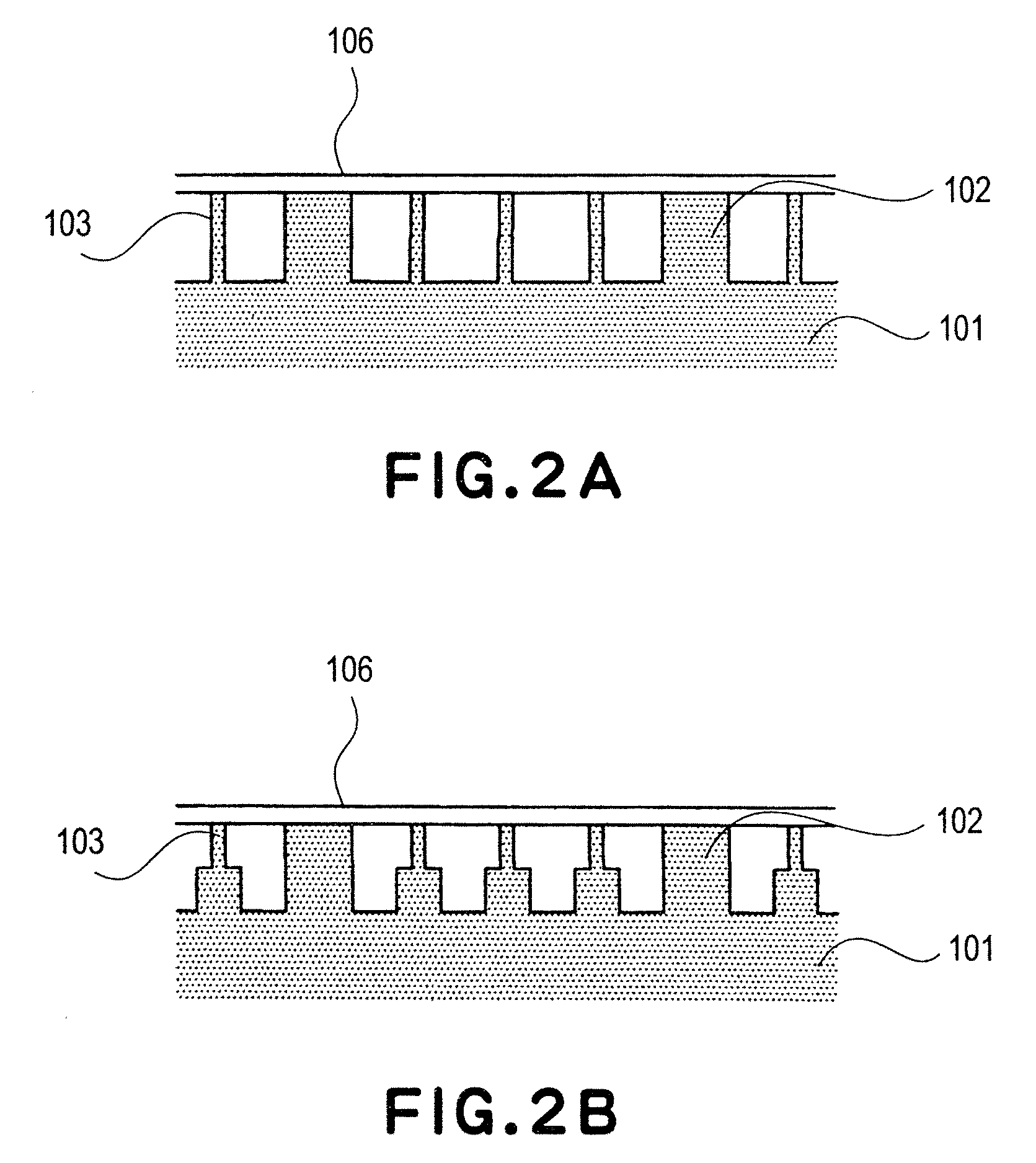

ActiveUS20130049527A1Improve performanceFlatness is not impairedCapacitor with electrode distance variationMechanical vibrations separationVibrating membraneElectrical connection

The present invention provides a technology for decreasing a dispersion of the performance among electromechanical transducers each having through wiring. A method for manufacturing an electromechanical transducer includes: obtaining a structure in which an insulative portion having a through hole therein is bonded onto an electroconductive substrate; filling the through hole with an electroconductive material to form a through wiring which is electrically connected with the electroconductive substrate; and using the electroconductive substrate as a first electrode, forming a plurality of vibrating membrane portions including a second electrode, which opposes to the first electrode through a plurality of gaps, on an opposite side of the first electrode to the side having the insulative portion, to thereby forming a plurality of cells.

Owner:CANON KK

Integrated circuit heat pipe heat spreader with through mounting holes

InactiveUS20060032615A1Simple and light weightEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

The apparatus is a heat pipe with superior heat transfer between the heat pipe and the heat source and heat sink. The heat pipe is held tightly against the heat source by mounting holes which penetrate the structure of the heat pipe but are sealed off from the vapor chamber because they each are located within a sealed structure such as a pillar or the solid layers of the casing surrounding the vapor chamber. Another feature of the heat pipe is the use of more highly heat conductive material for only that part of the wick in the region which contacts the heat source, so that there is superior heat conductivity in that region.

Owner:AAVID THERMALLOY LLV

Substrate holding system and exposure apparatus using the same

InactiveUS20070247780A1Stable flatnessCorrection of flatnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringSupport surface

A substrate holding system for holding a substrate based on vacuum attraction and electrostatic attraction including a rim configured to support the substrate, a protrusion for the electrostatic attraction, configured to support the substrate inside the rim, and a protrusion for the vacuum attraction, configured to support the substrate inside the rim. A substrate supporting surface area of the protrusion of the electrostatic attraction is larger than a substrate supporting surface area of the protrusion for the vacuum attraction.

Owner:CANON KK

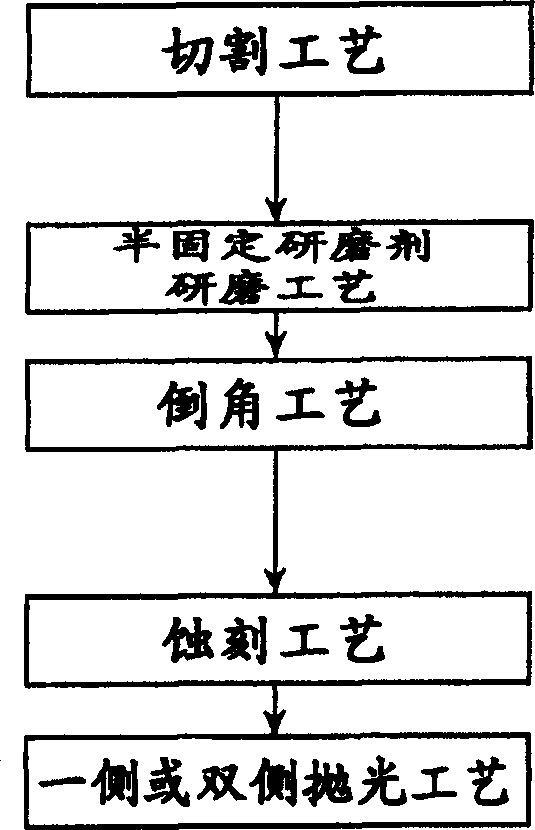

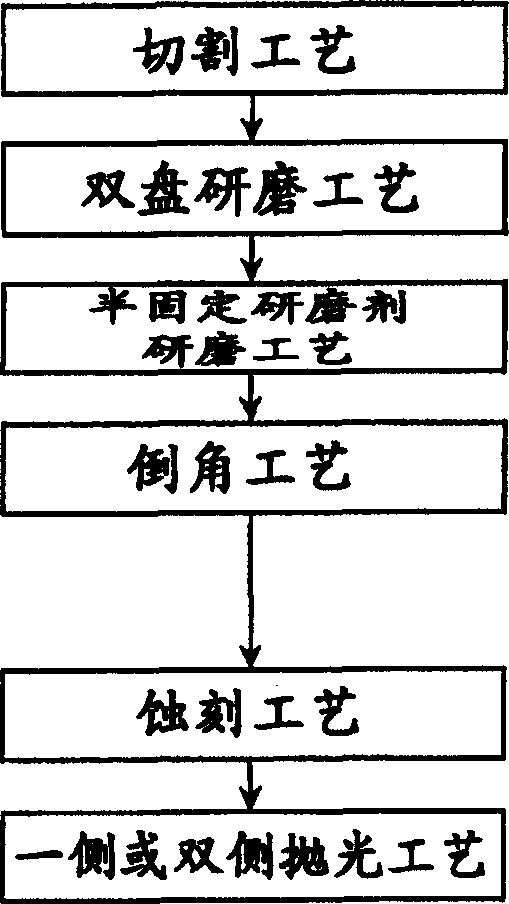

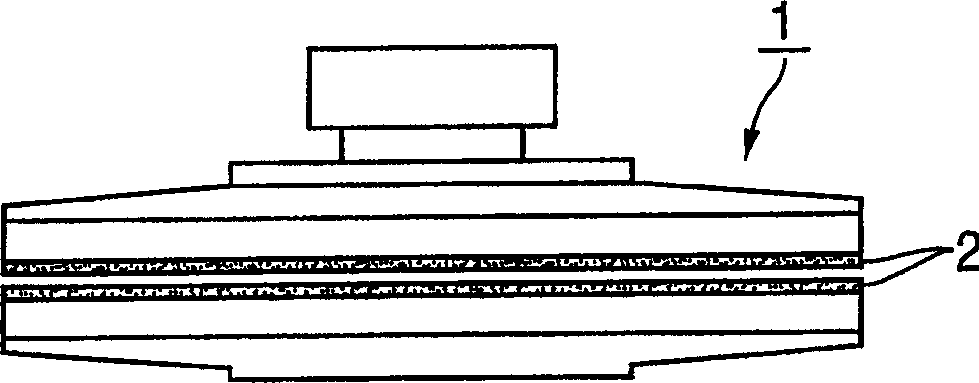

Production method for semiconductor wafer

InactiveCN1795545AProduce frictionLittle grinding damageEdge grinding machinesSemiconductor/solid-state device manufacturingWaferingSemiconductor

The present invention provides a method of manufacturing a semiconductor wafer in which semi-fixed abrasive particle grinding with free abrasive particles reduces minute surface fluctuations caused by wire saw cutting or double disc grinding, while simplifying the manufacturing process of conventional semiconductor wafers step. A method of manufacturing a semiconductor wafer is characterized in that the following processes are performed: dicing, followed by chamfering, etching, and one-sided or two-sided polishing, wherein semi-fixation with porous polishing pads and free abrasive particles is performed after the dicing process Abrasive grinding process.

Owner:SUMCO CORP

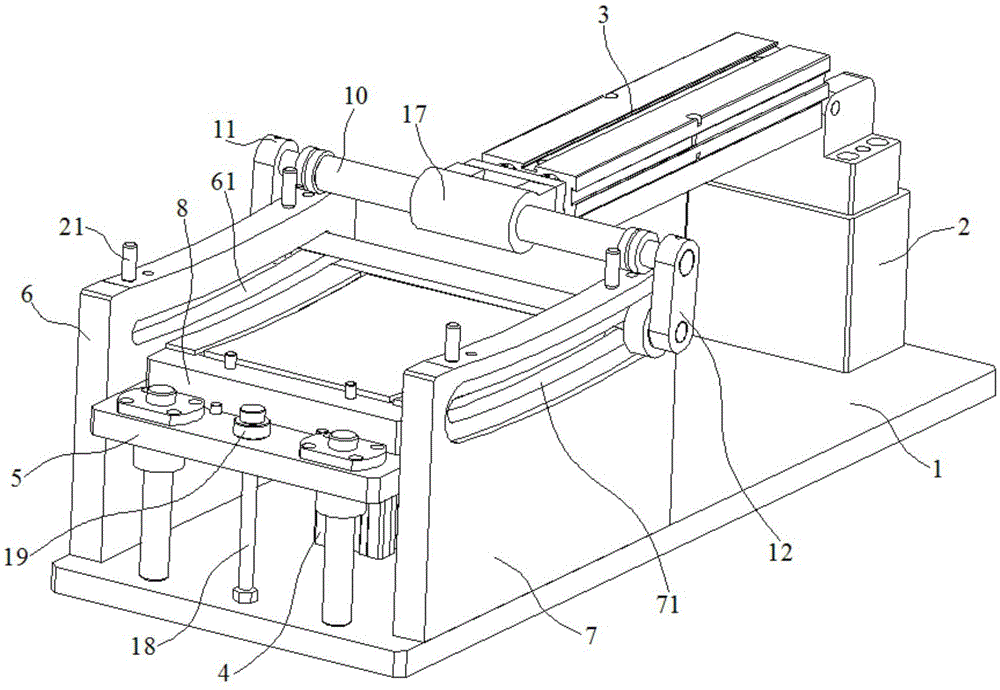

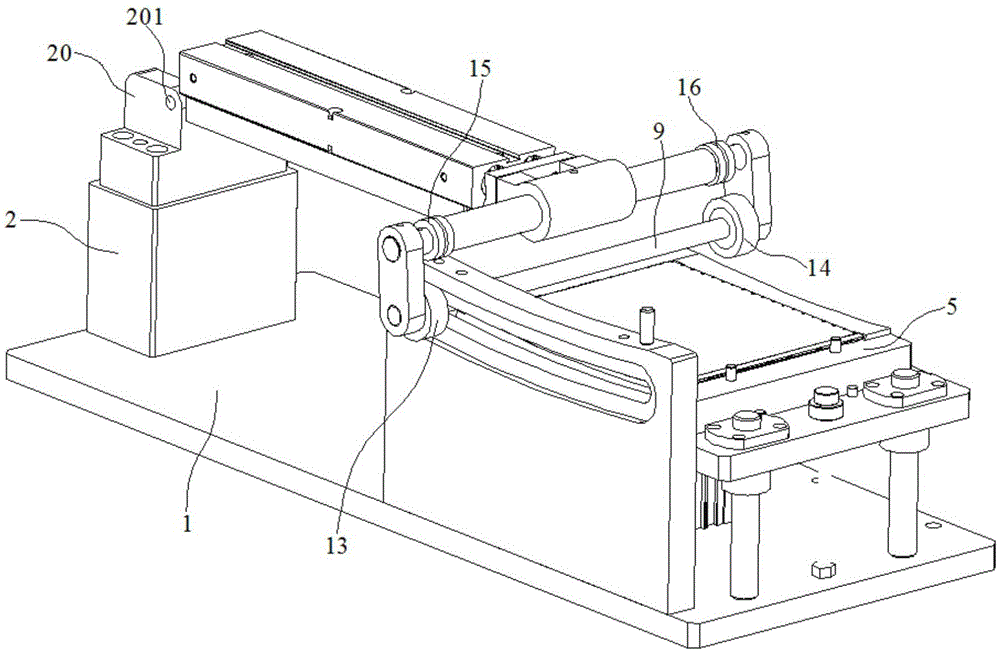

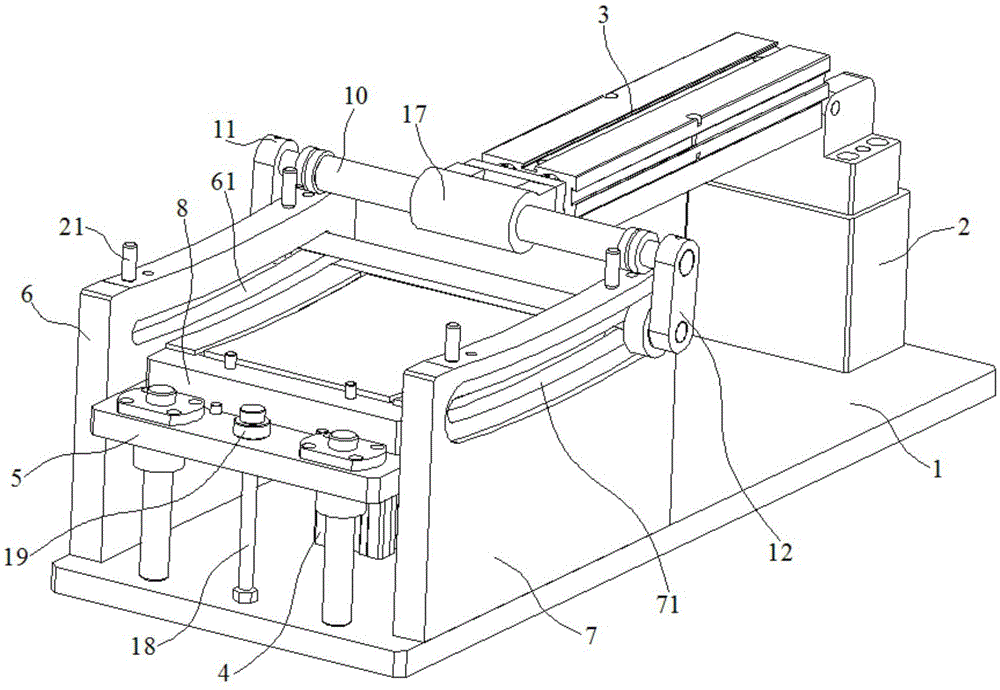

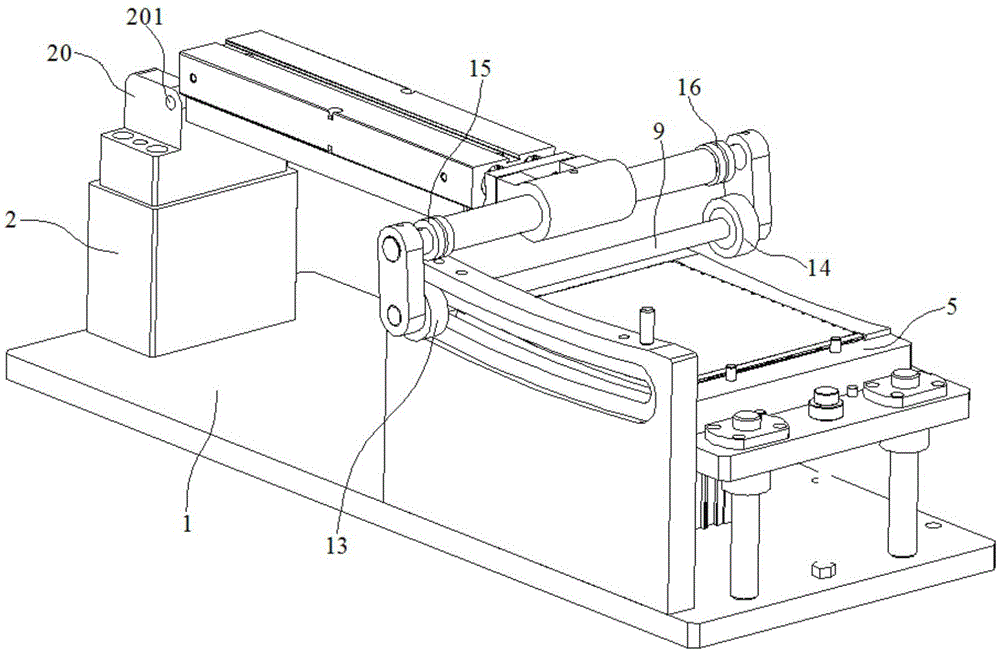

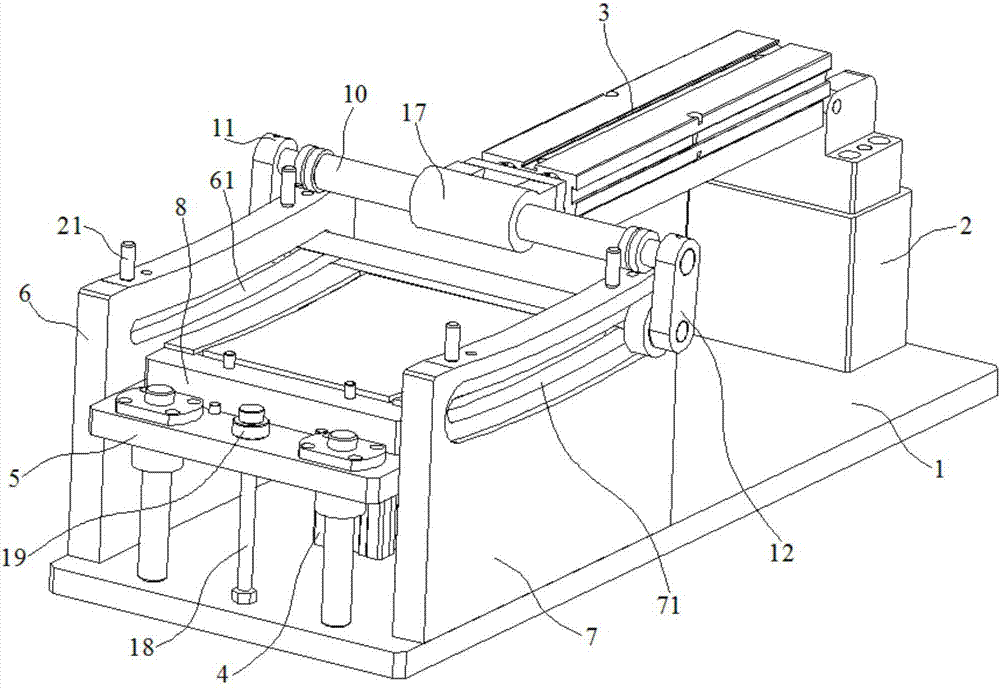

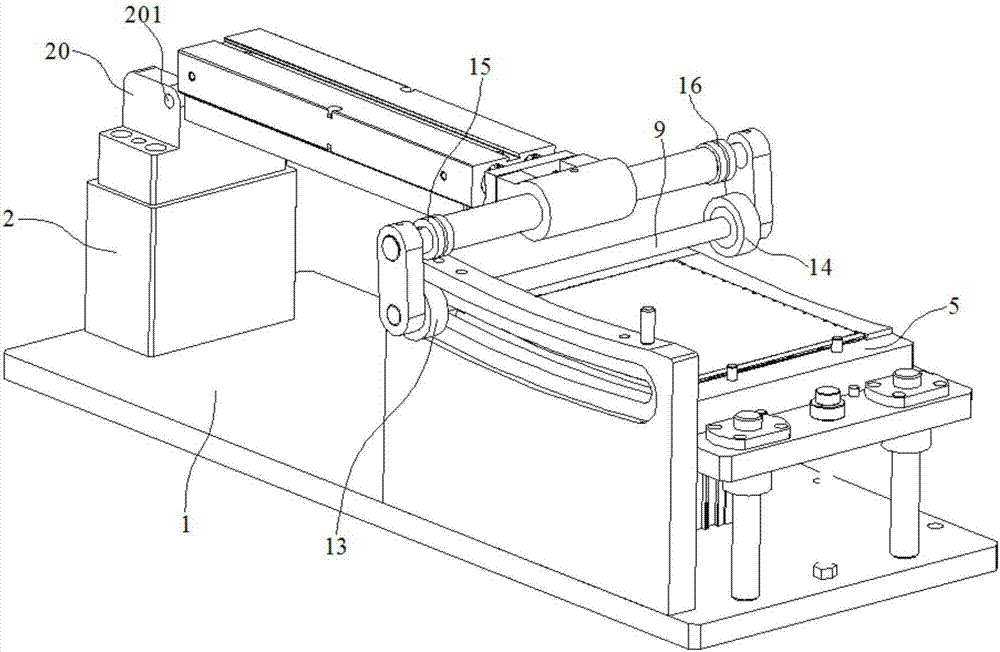

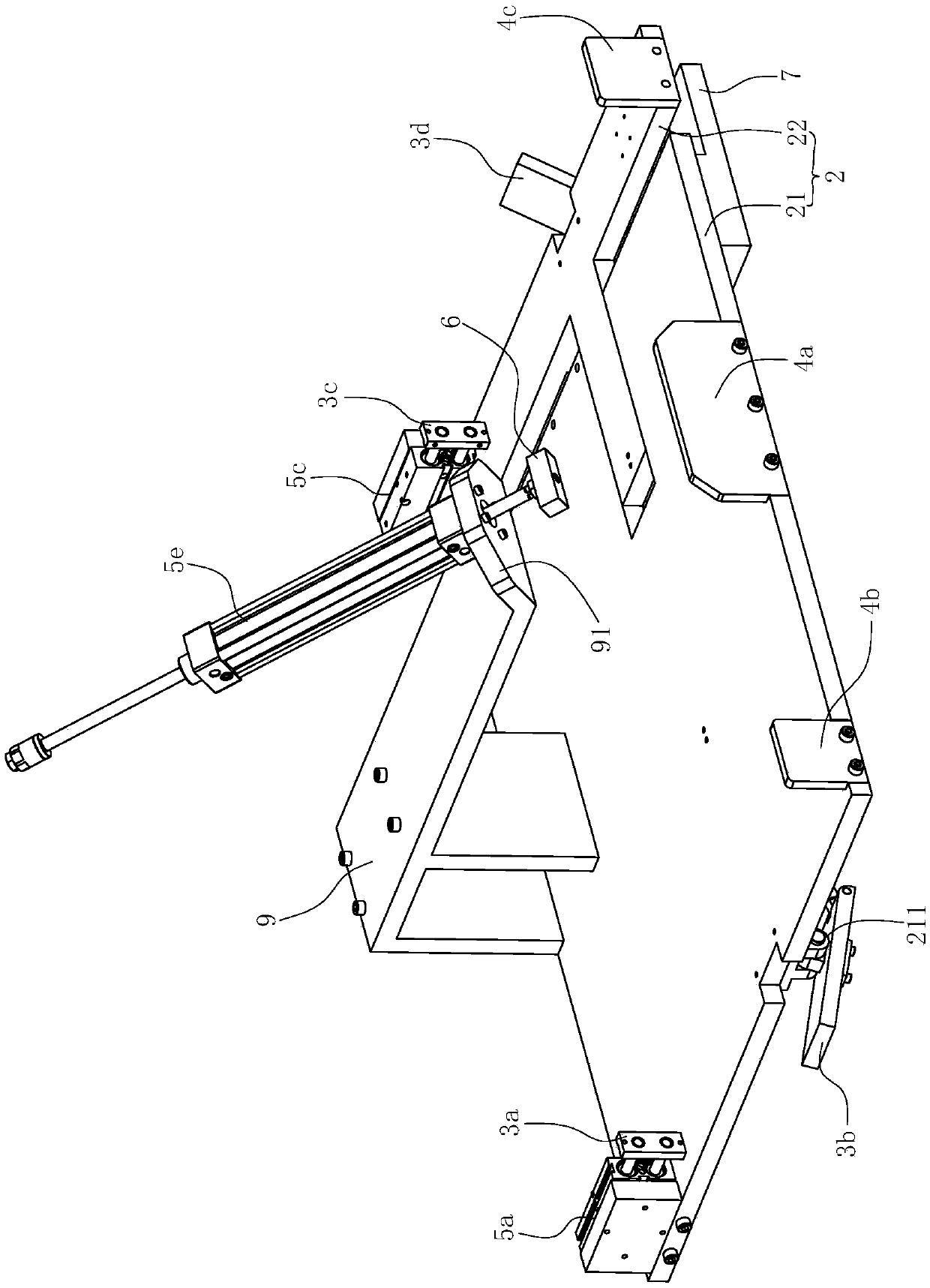

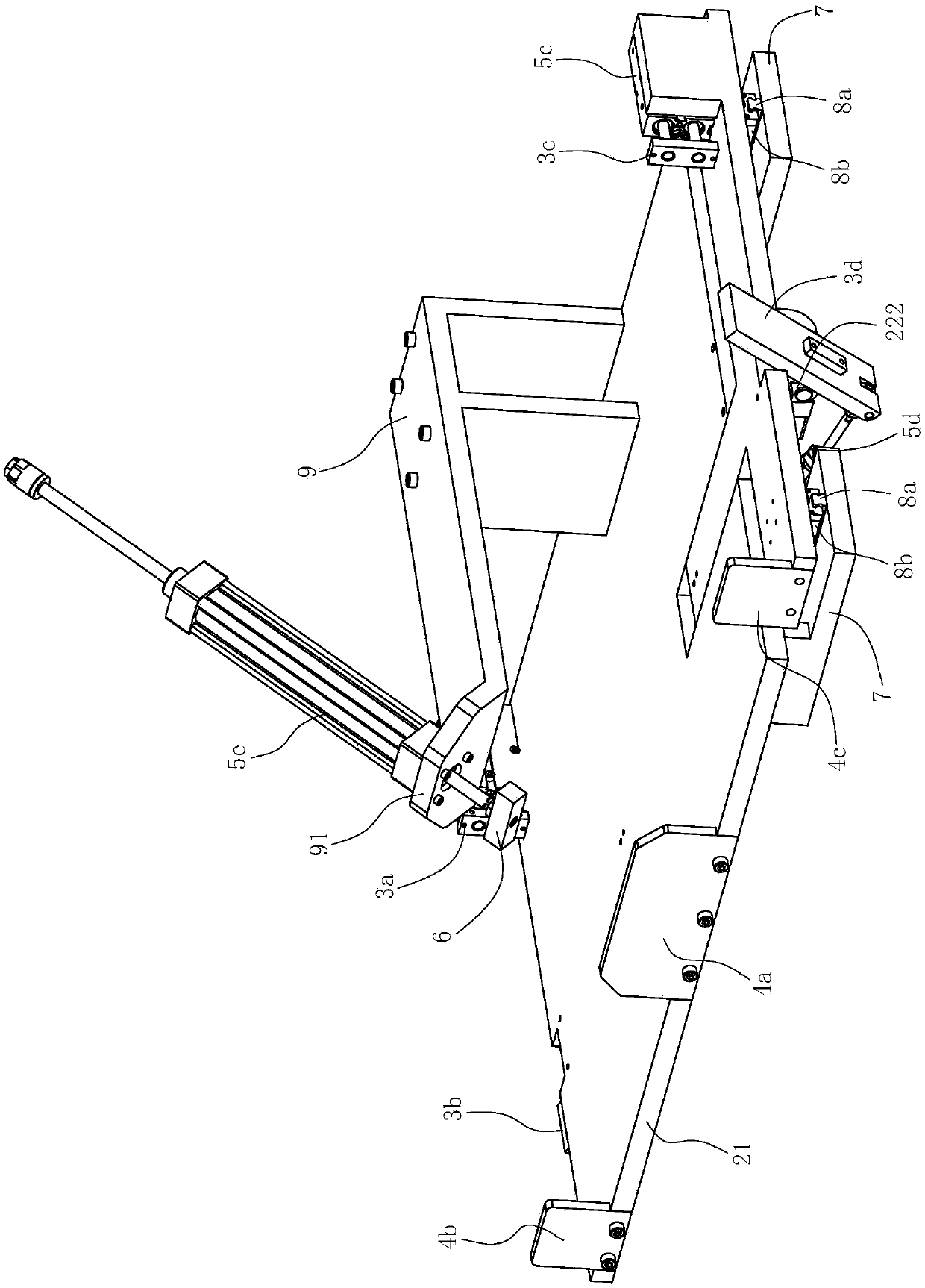

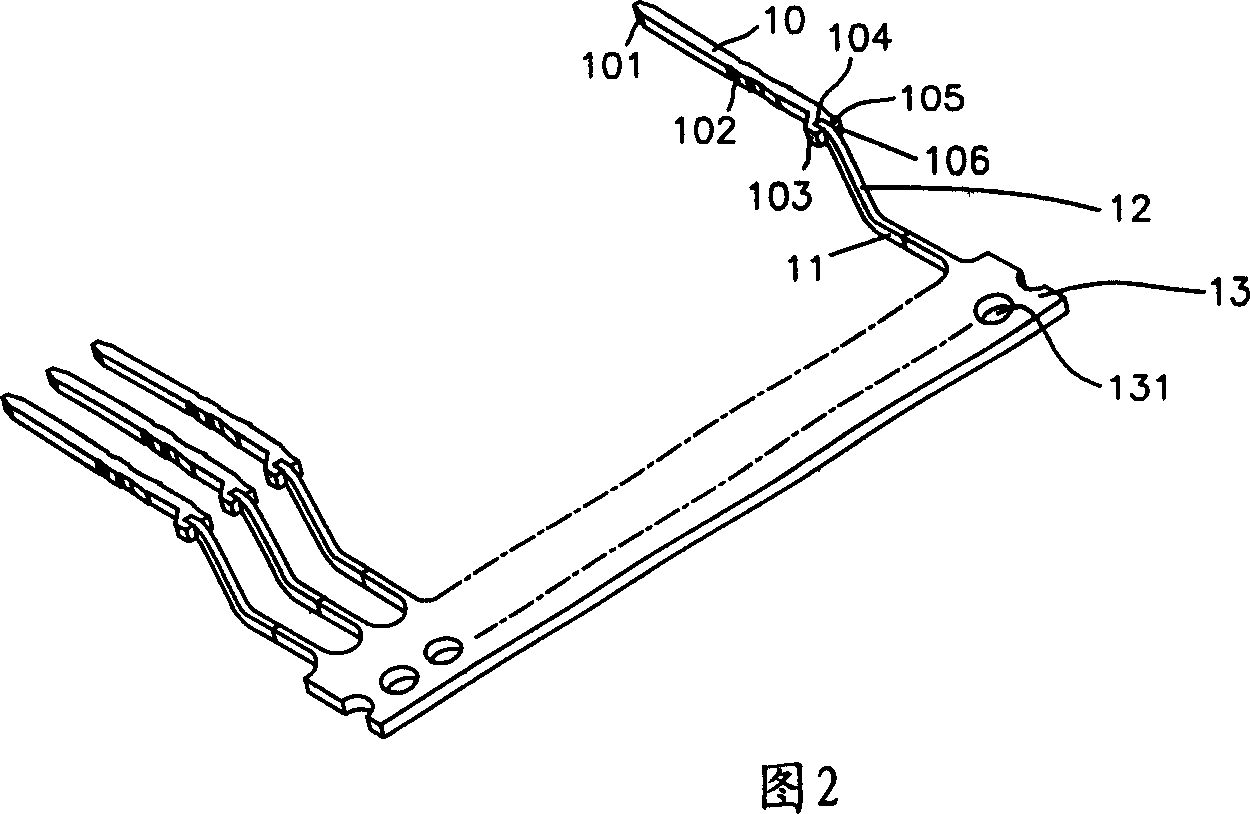

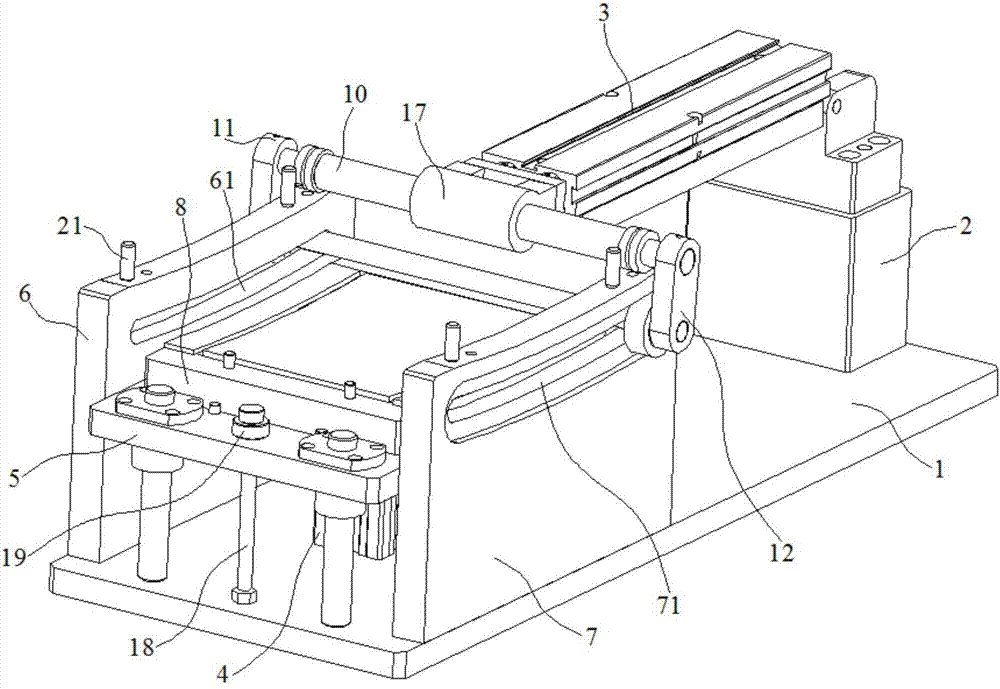

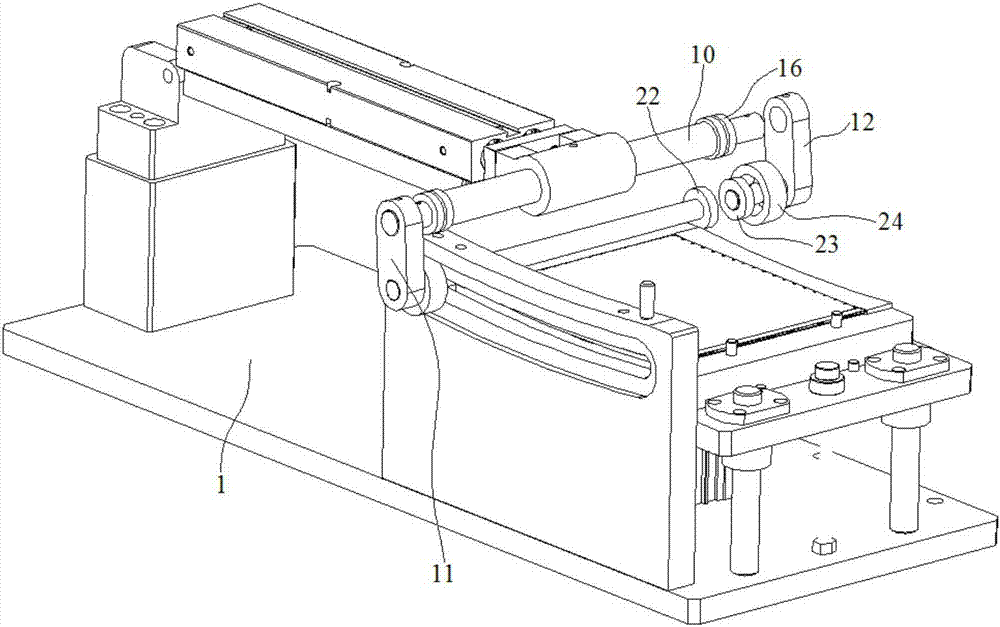

Machining device for back plates of liquid crystal displays of ultra-thin smartphones

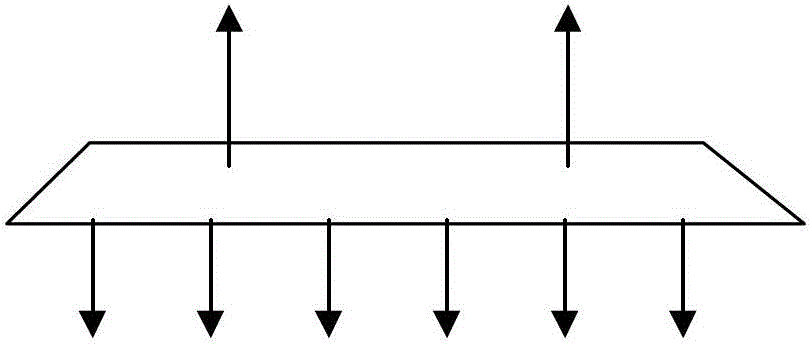

ActiveCN105537319ACorrection of flatnessImprove the leveling effectLiquid-crystal displayEngineering

The invention discloses a machining device for back plates of liquid crystal displays of ultra-thin smartphones. The machining device comprises a bottom plate, a fixed seat, a horizontal cylinder, a vertical cylinder, a support plate as well as a left guide rail seat and a right guide rail seat which are fixed on the bottom plate, wherein the support plate is located between the left guide rail seat and the right guide rail seat; the vertical cylinder located below the support plate is mounted on the bottom plate, an ejection rod of the vertical cylinder is connected with the support plate, and an elastomeric pad covers the upper surface of the support plate; a left through hole strip and a right through hole strip are formed in the left guide rail seat and the right guide rail seat respectively, a rolling shaping bar is located above the support plate, two ends of the rolling shaping bar are embedded in the left through hole strip and the right through hole strip, a connecting shaft is located on the left guide rail seat and the right guide rail seat, and two ends of the connecting shaft and the two ends of the rolling shaping bar are connected through a left connecting block and a right connecting block. With the adoption of the machining device, efficient and high-quality leveling operation can be realized for the back plates with large-range warpage, the leveling effect is good, the efficiency is high, and products have stable quality and cannot be broken easily.

Owner:KUNSHAN KERSEN SCI & TECH

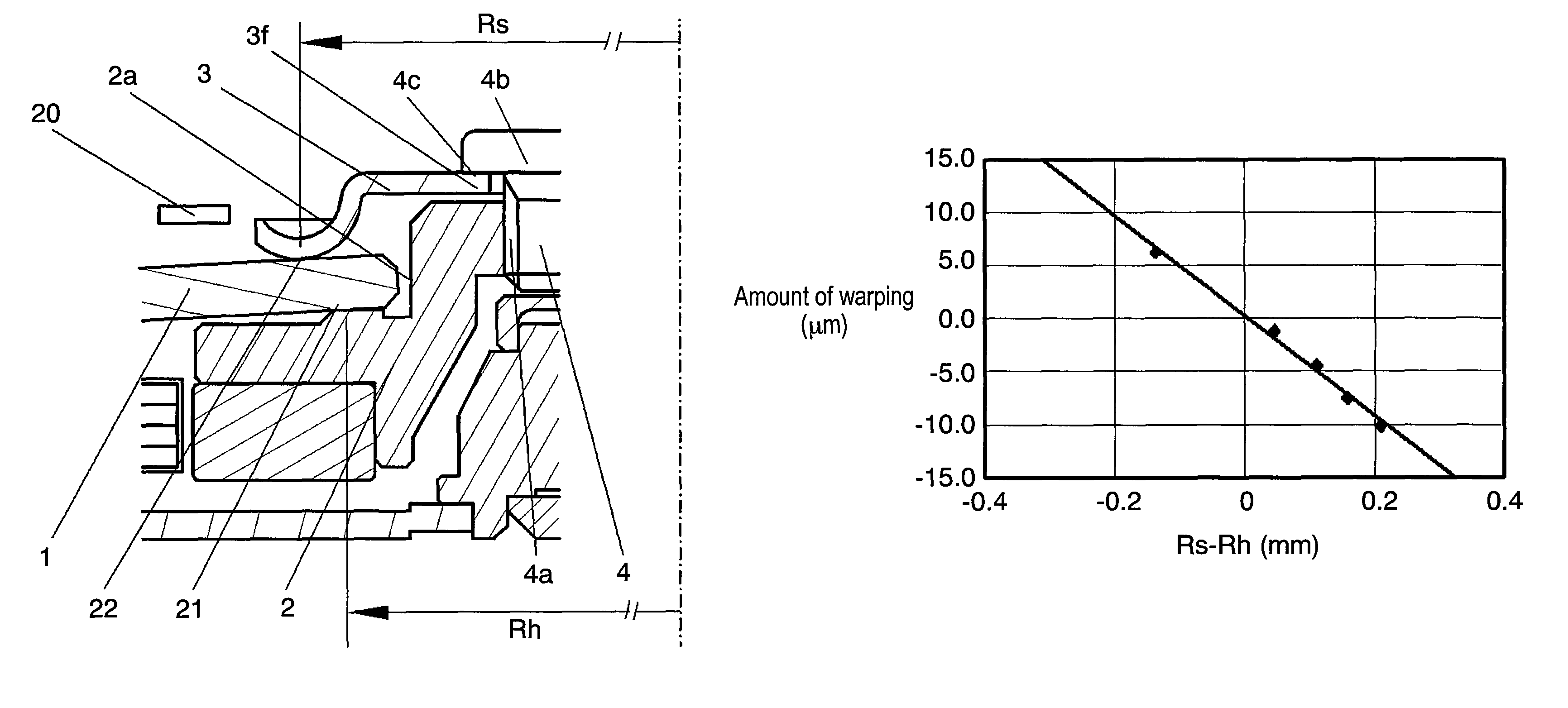

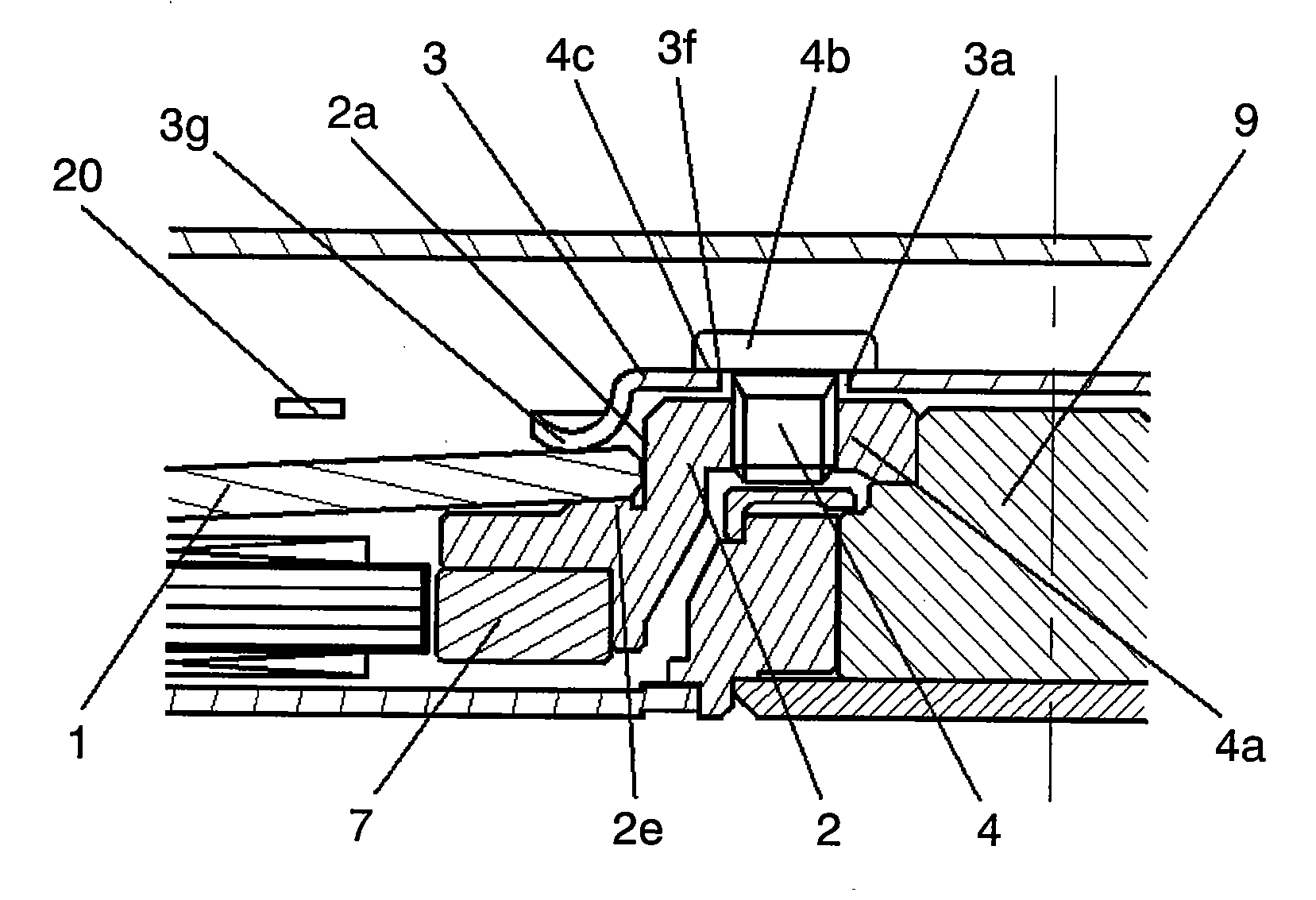

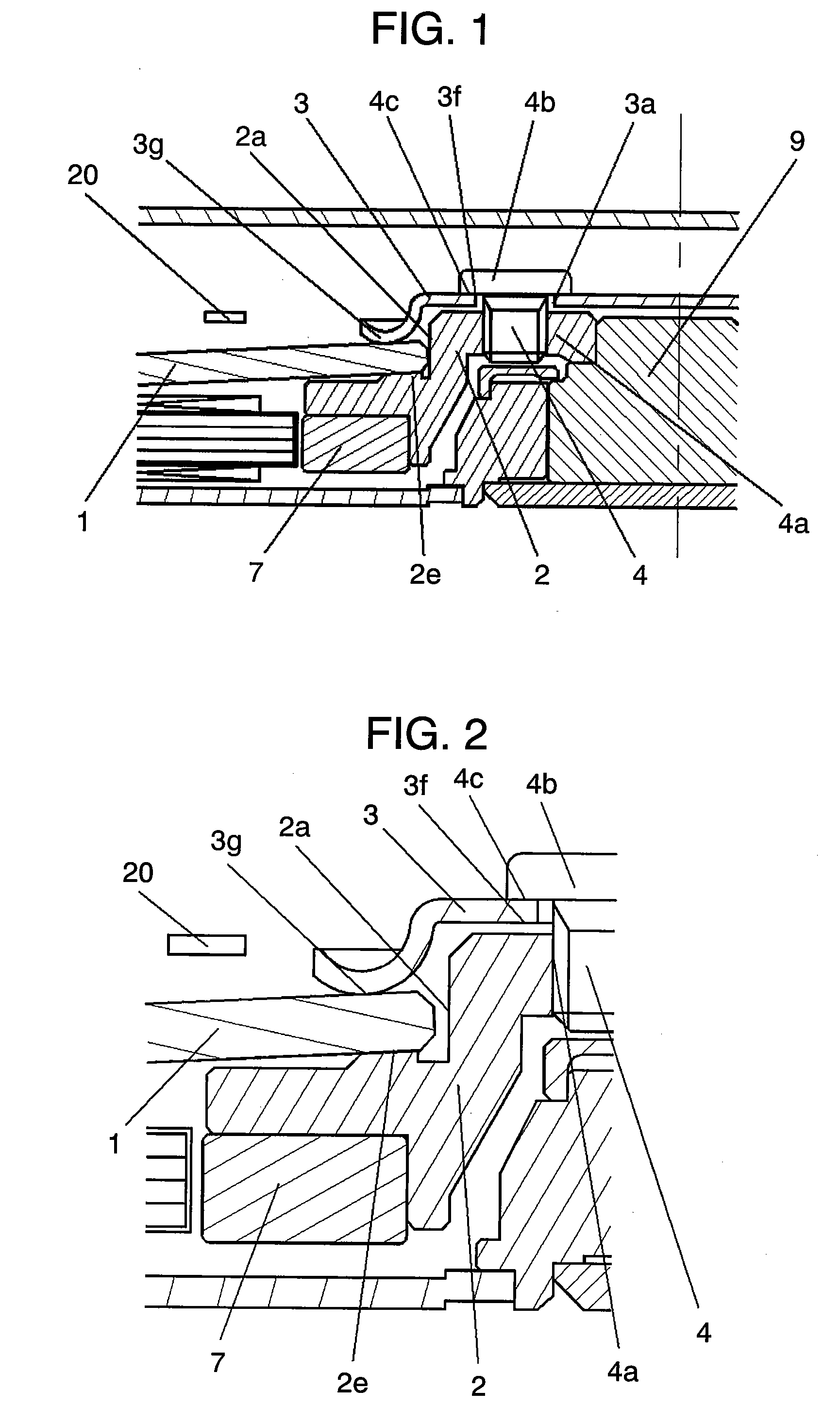

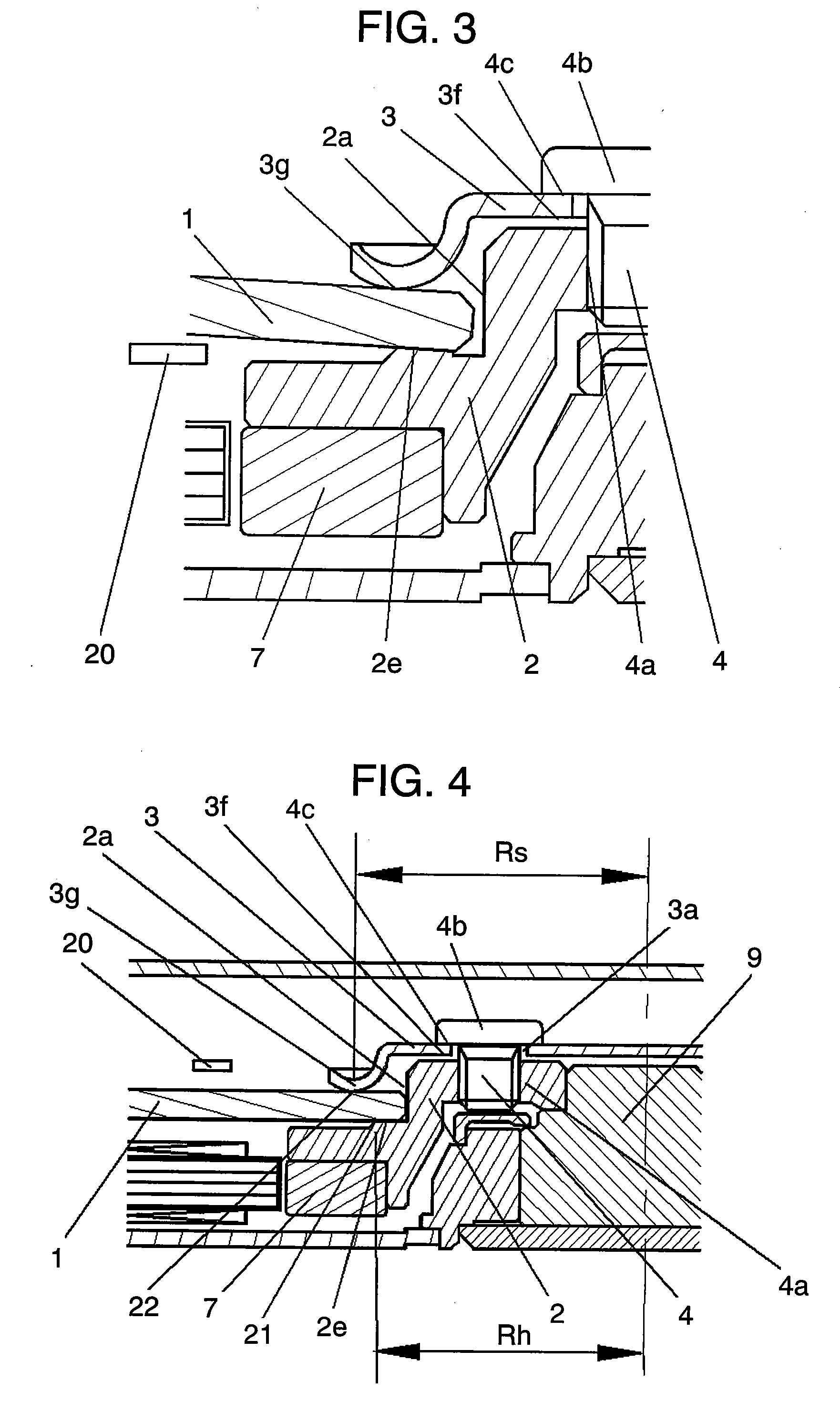

Disk device

A disk apparatus includes a hub having a disk inserting portion having a cylindrical plane in the outer part of one end and a disk receiving portion having a flat part and being pivotably supported, a head having an inner hole through which the disk inserting portion is fitted, facing toward one face of a disk, levitating and scanning above the disk and reading a signal recorded on the disk or recording a signal on the disk, the disk being held by the disk receiving portion, and a clamp unit holding the disk with the disk receiving portion. In this case, the disk receiving portion has an inclined or declined plane. Thus, the amount and direction of deformation of the disk, which is caused by clamping, are defined, and obtaining a stable amount of head levitation independently of temperature changes can prevent the occurrence of a distortion of the disk.

Owner:PHC HLDG CORP

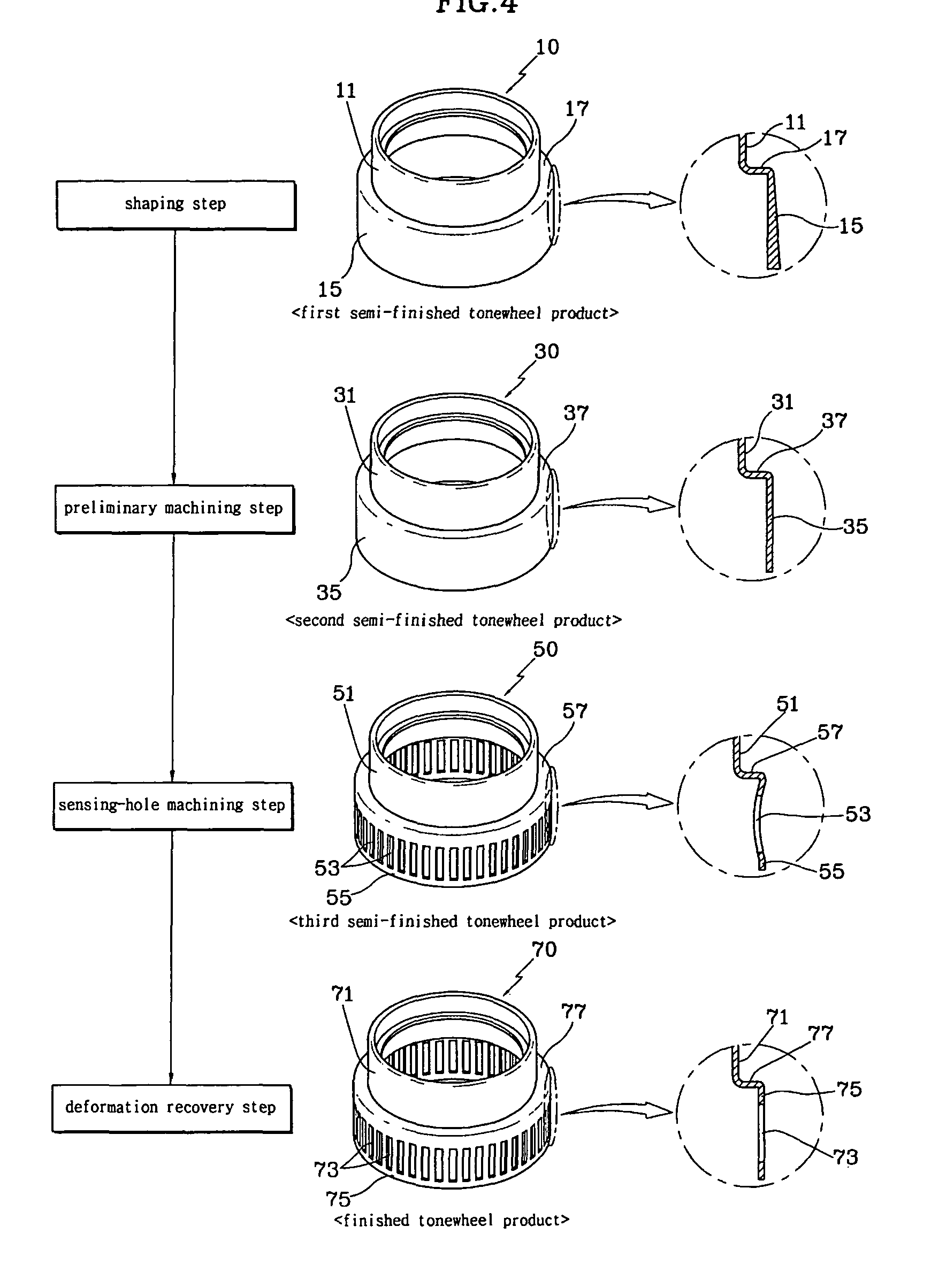

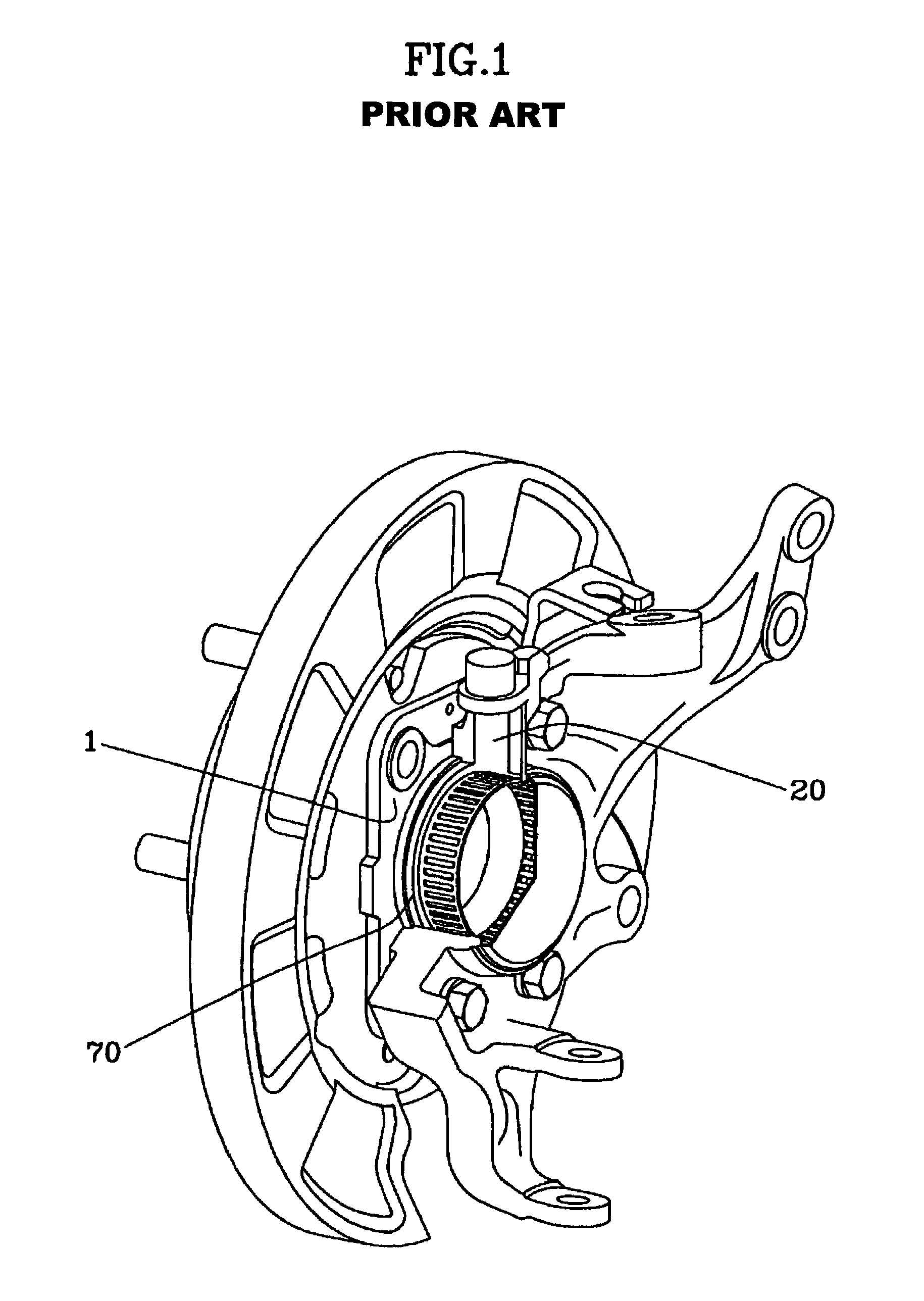

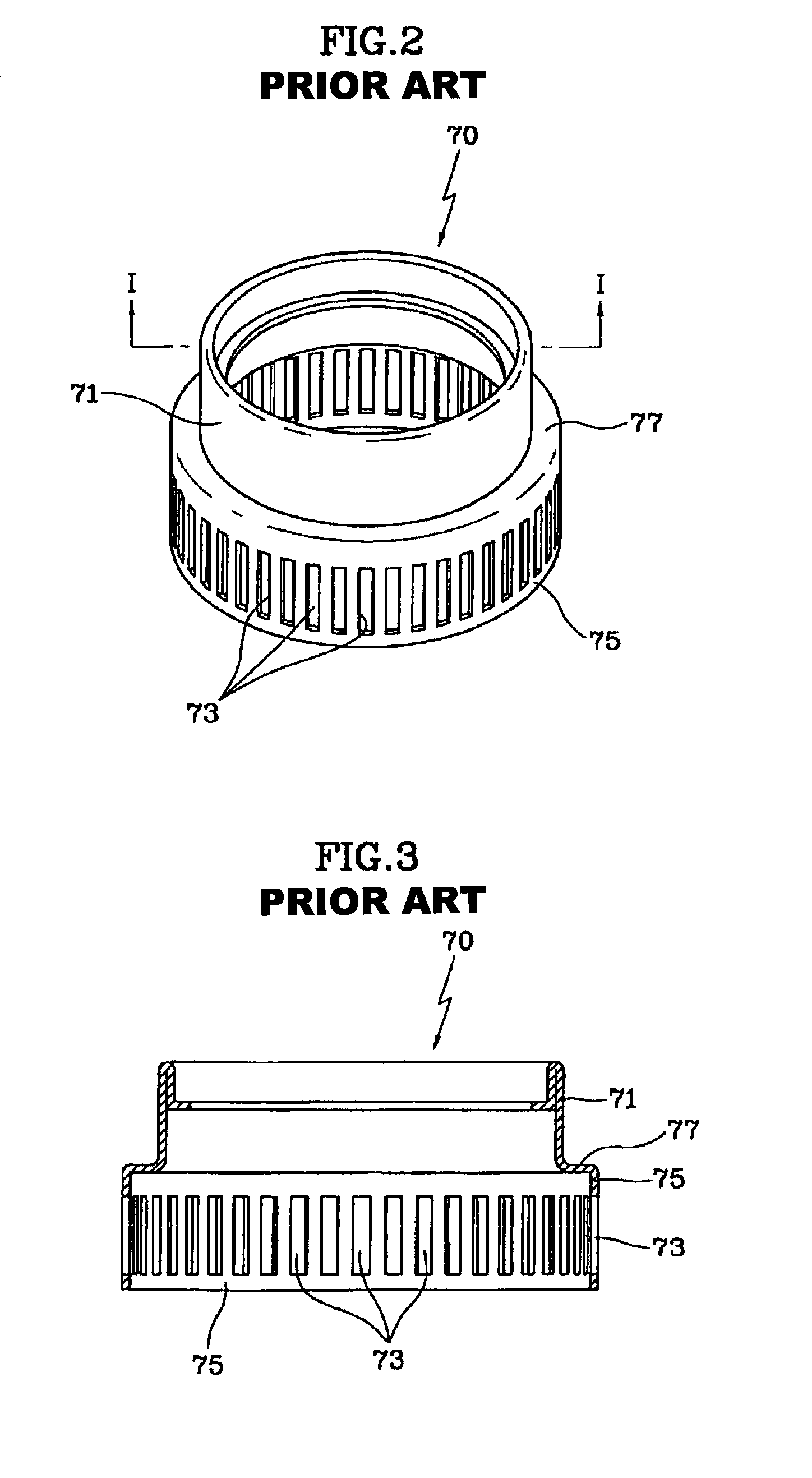

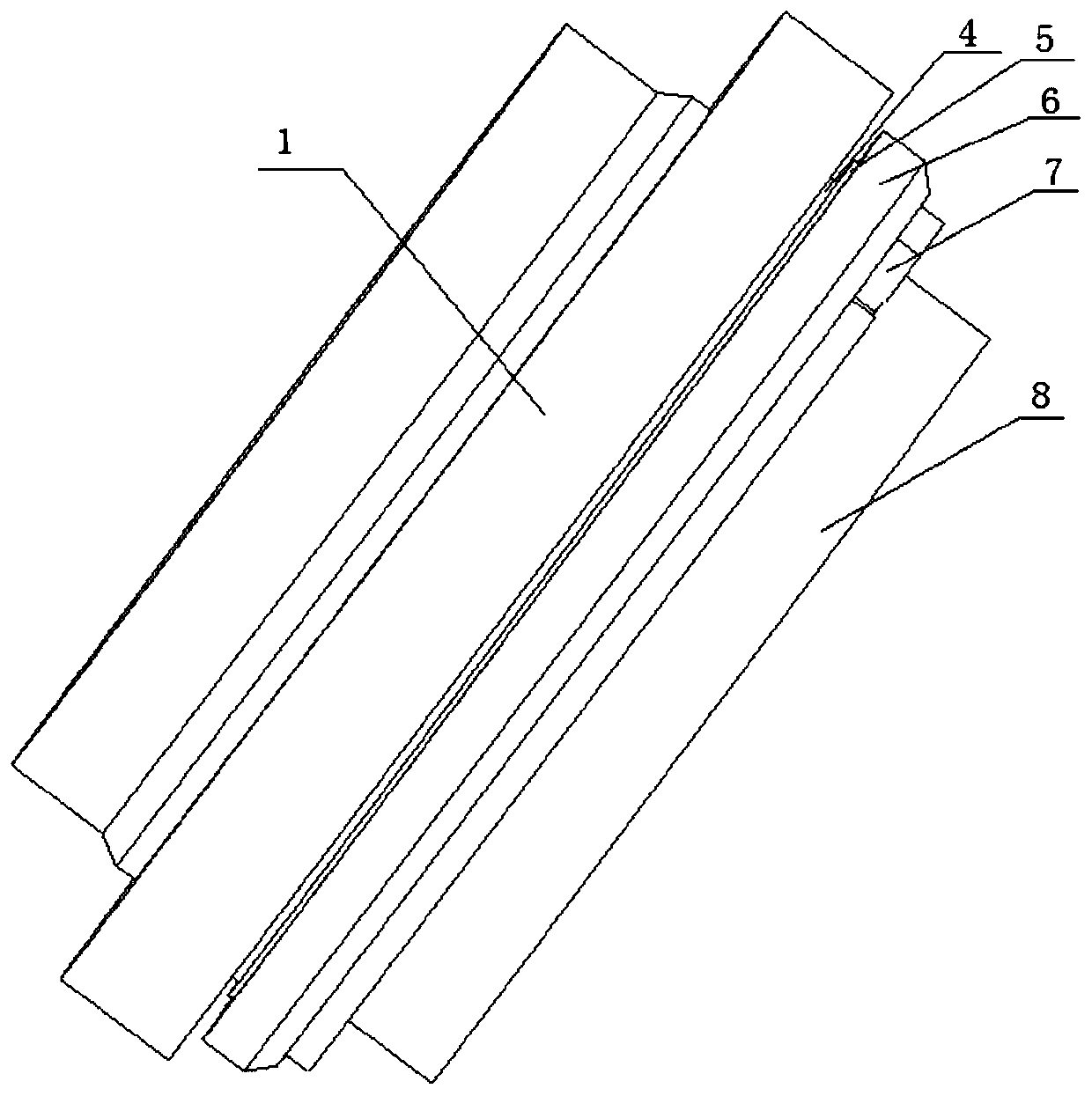

Method and apparatus for manufacturing tonewheel for vehicles

InactiveUS8015708B2Correction of flatnessUniform sectional thicknessMetal-working apparatusCycle equipmentsWork in processMaterials processing

Owner:YUSUNG FT

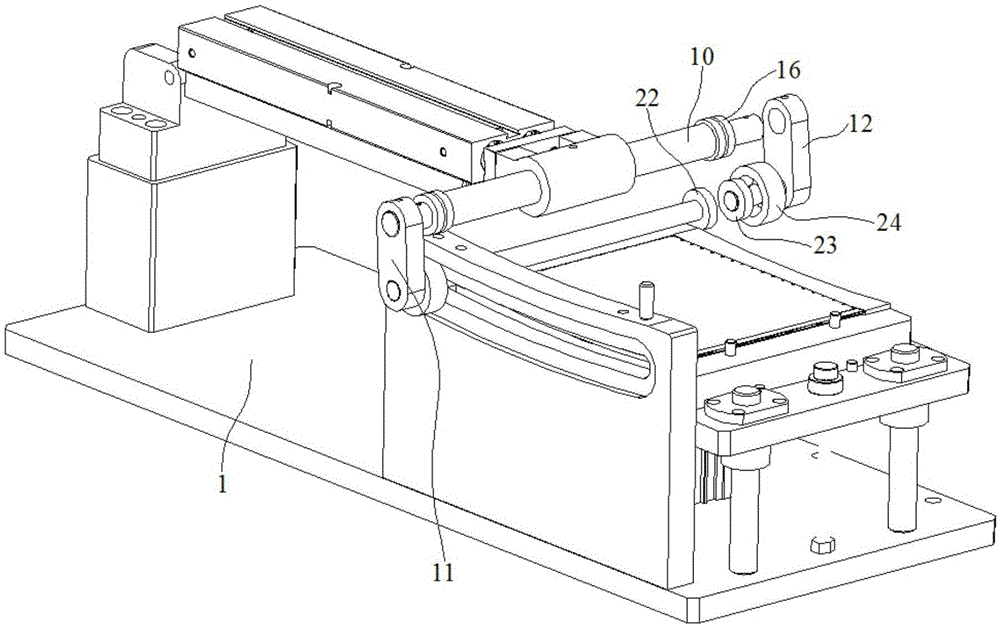

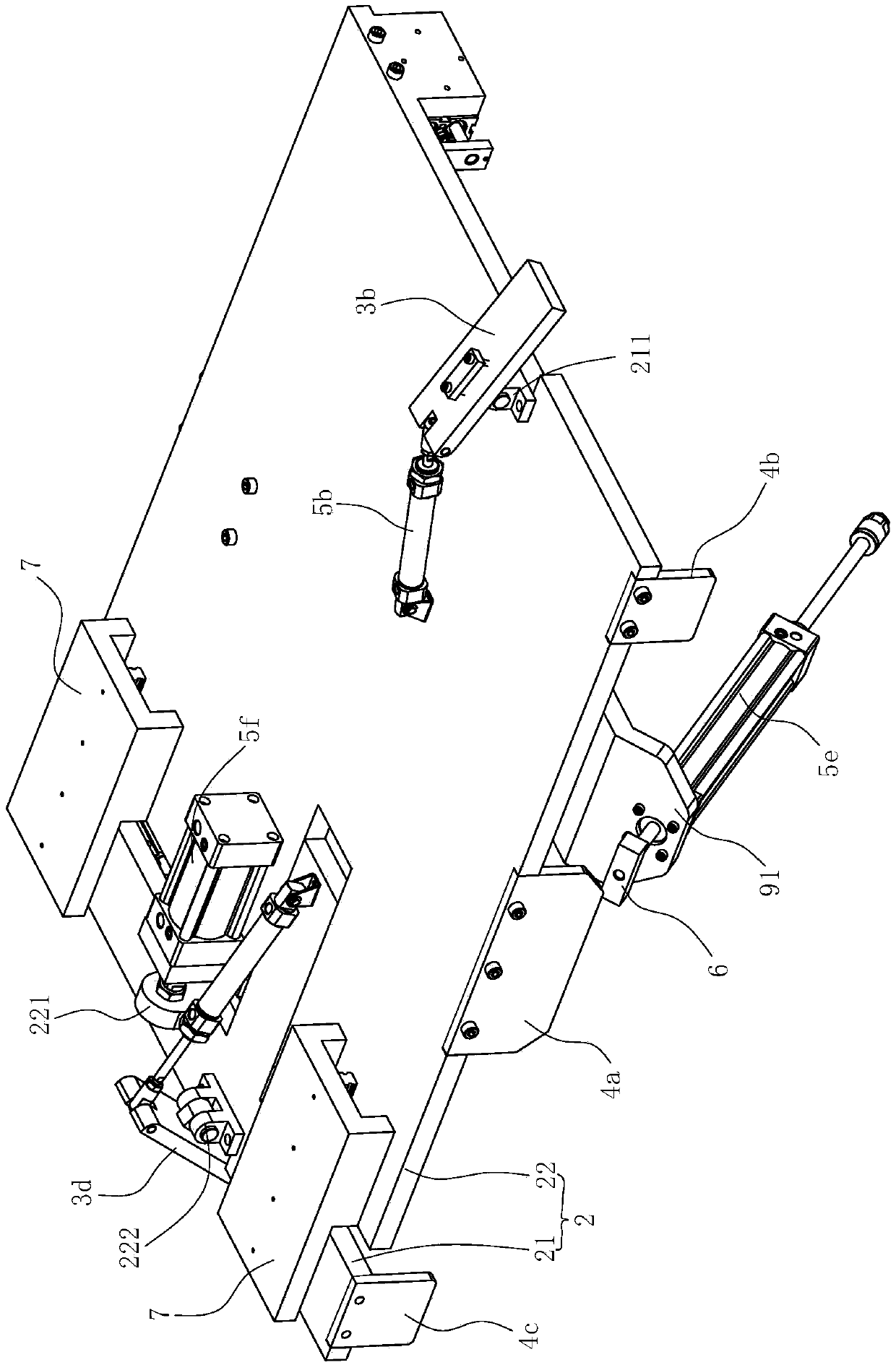

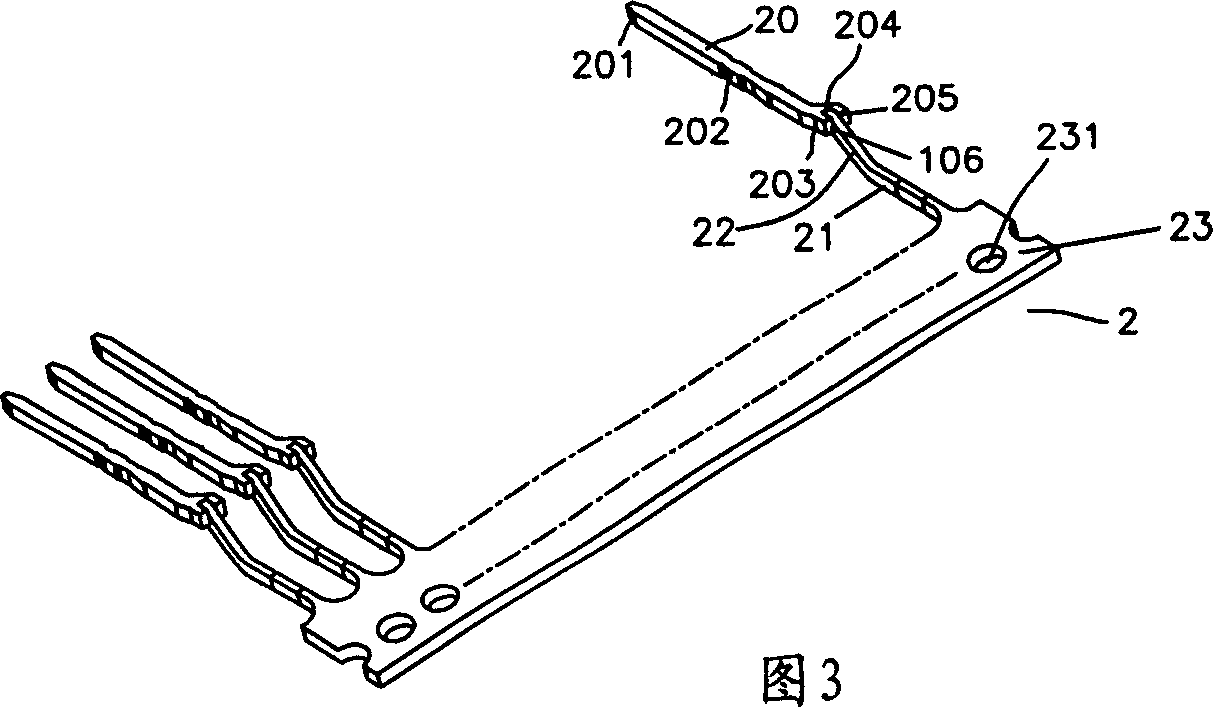

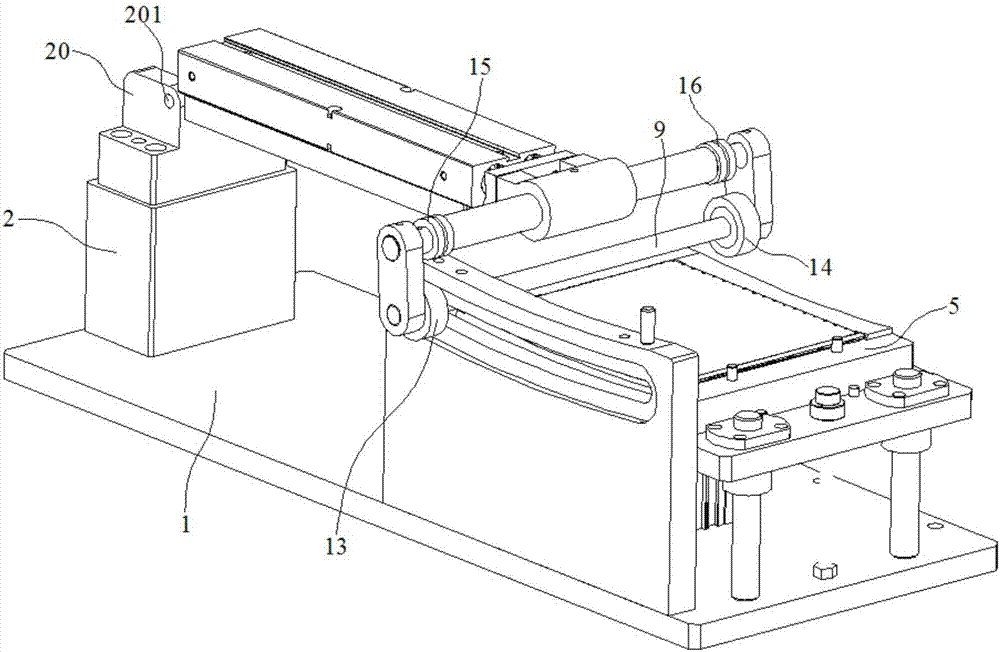

Liquid crystal display backboard flattening mechanism used for electronic products

InactiveCN105562470ACorrection of flatnessImprove the leveling effectLiquid-crystal displayBaseboard

The invention discloses a liquid crystal display backboard flattening mechanism used for electronic products. A supporting board of the liquid crystal display backboard flattening mechanism is located between a left guide rail base and a right guide rail base. A vertical air cylinder located under the supporting board is installed on a baseboard, and ejector rods of the vertical air cylinder are connected with the supporting board. The upper surface of the supporting board is covered with an elastic rubber mat. The left guide rail base and the right guide rail base are provided with a left through hole strip and a right through hole strip correspondingly. A rolling shaping rod is located above the supporting board, and the two ends of the rolling shaping rod are embedded into the left through hole strip and the right through hole strip correspondingly. The left end and the right end of a connecting shaft are sleeved with an upper left rolling bearing and an upper right rolling bearing correspondingly. The upper left rolling bearing is located between the connecting shaft and the left guide rail base, and the upper right rolling bearing is located between the connecting shaft and the right guide rail base. A lower left rolling bearing and a lower right rolling bearing are each composed of an inner bearing, an outer bearing and a bearing sleeve. According to the liquid crystal display backboard flattening mechanism used for the electronic products, the flattening effect is good, the flattening efficiency is high, the products are stable in quality and not liable to be broken, and flattening operation aiming to backboards of various thicknesses can be achieved.

Owner:昆山元诚电子材料有限公司

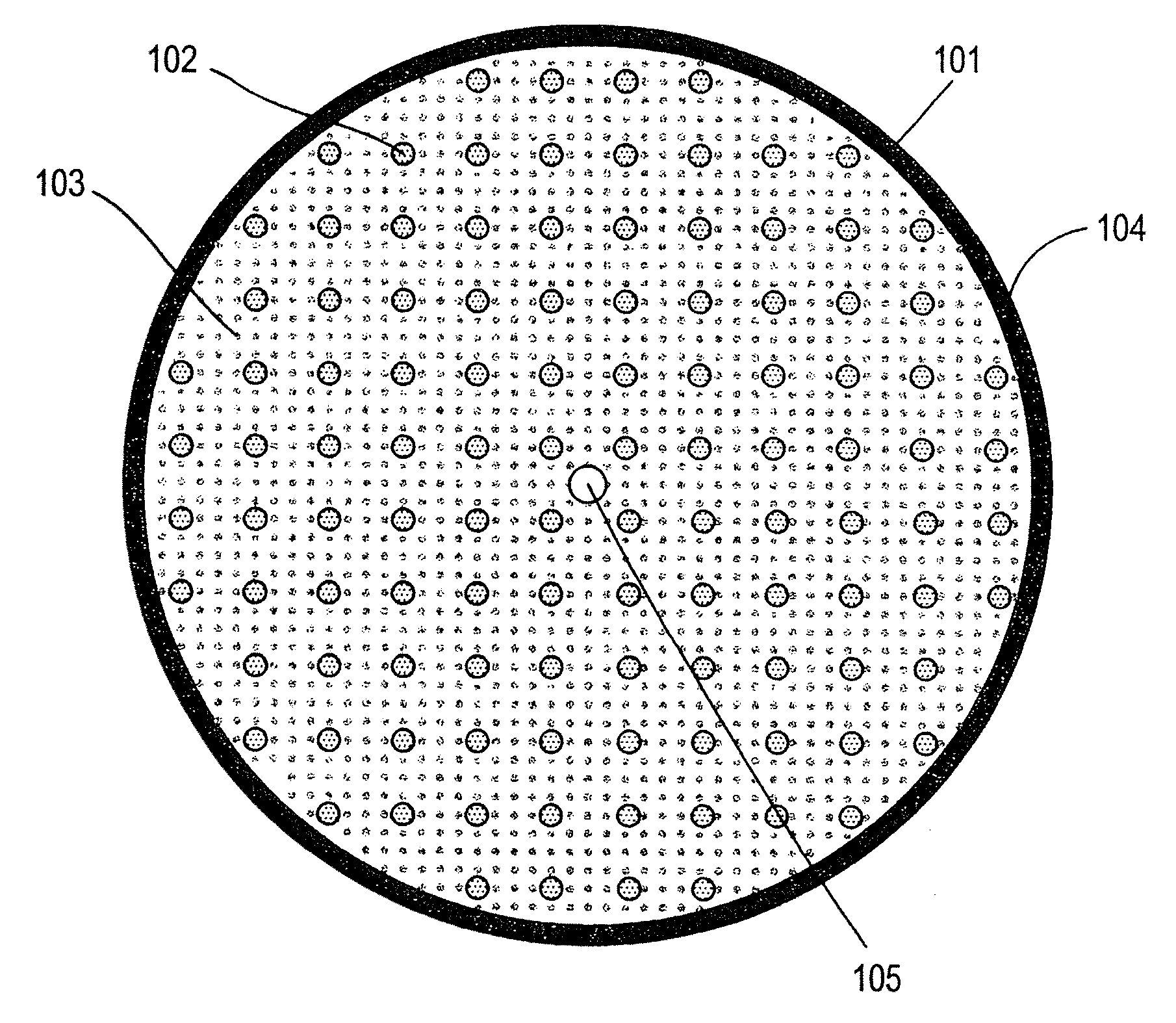

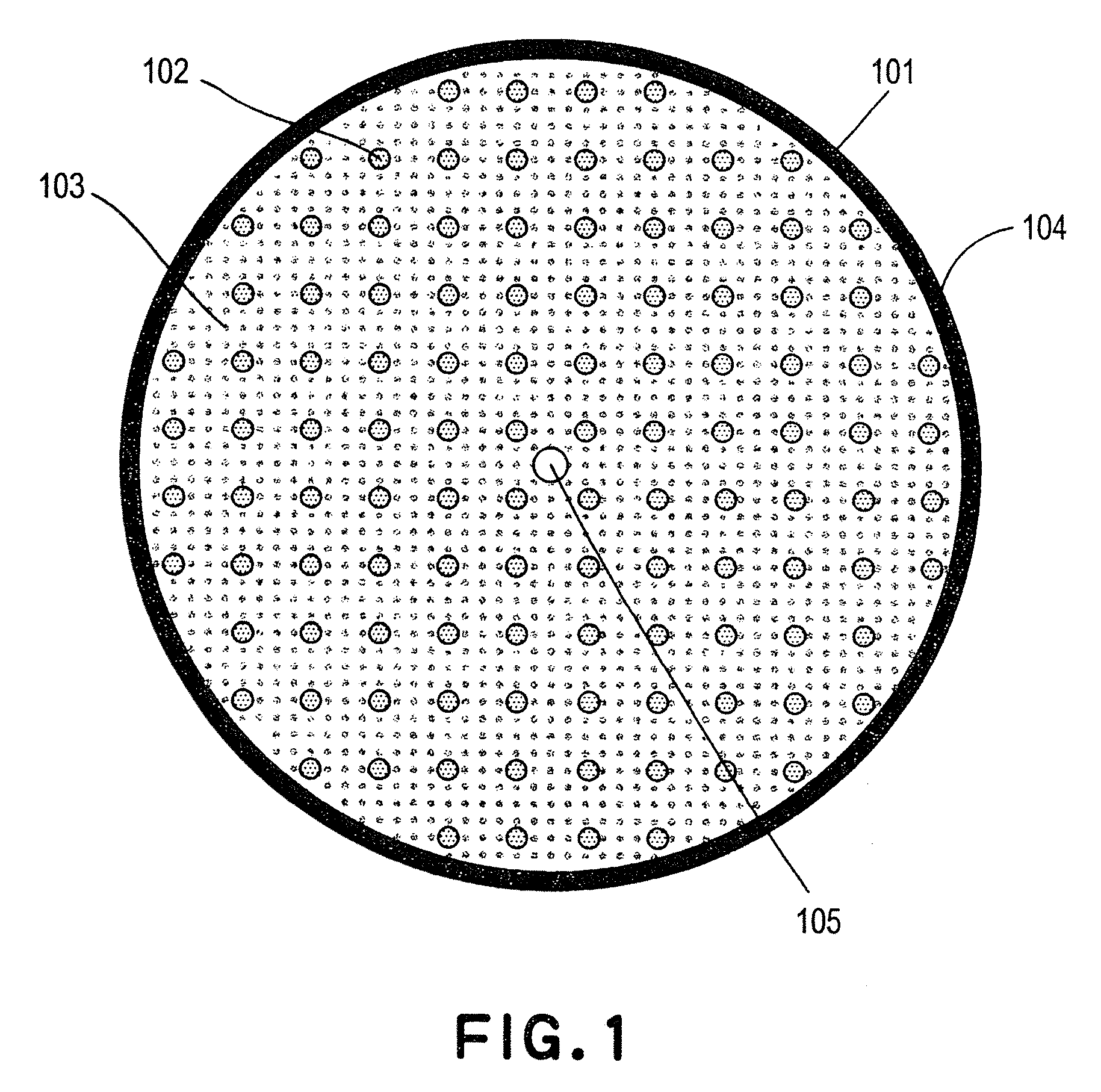

Probe card for a semiconductor wafer

ActiveUS8456184B2Correction of flatnessElectrical measurement instrument detailsElectrical testingProbe cardTransformer

A probe card is provided that is capable of accurately ensuring the flatness and the parallelism with respect to a predetermined reference surface. A point (Q) of application of force applied from a leaf spring (17) that presses a portion near an edge portion of a surface of a probe head (15) from which a plurality of probes projects over an entire circumference in a direction of a substrate to the probe head (15) is positioned inside of an outer edge of the probe head (15), and a point (P) of application of force applied from the retainer (16) that presses a portion near an edge portion of a space transformer (14) over an entire circumference in the direction of the substrate to the space transformer (14) is positioned inside of an outer edge of the space transformer (14).

Owner:NHK SPRING CO LTD

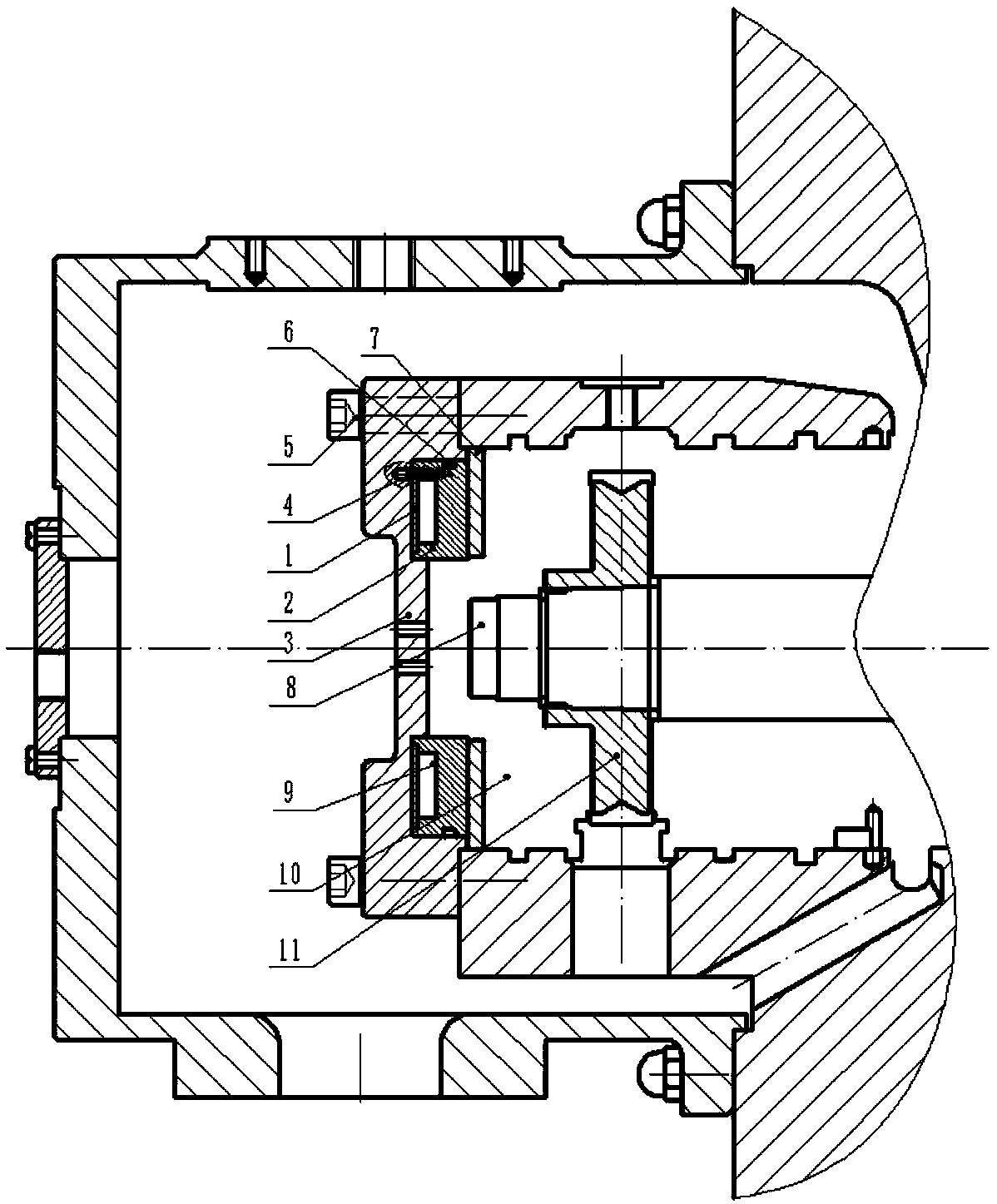

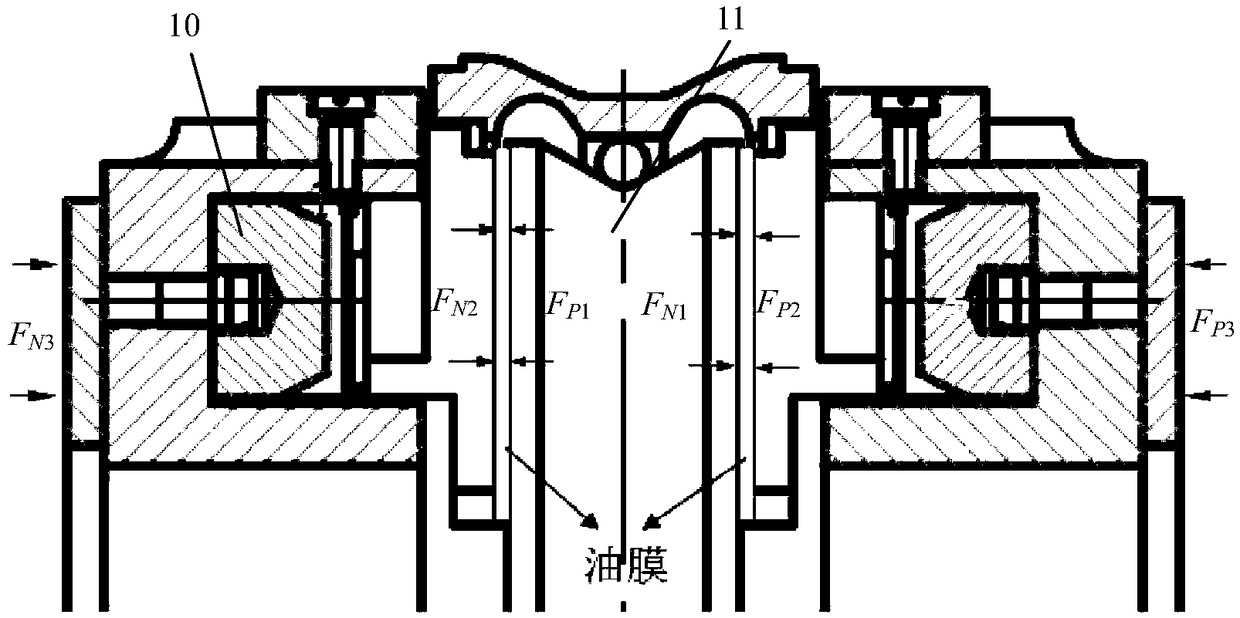

Device and method for measuring axial thrust of centrifugal compressor

InactiveCN109238543ARealize flexible assemblyPoint of contactApparatus for force/torque/work measurementCentrifugal compressorAerospace engineering

The invention provides a device and a method for measuring an axial thrust of a centrifugal compressor. The device is installed at the tail end side of the main shaft in the casing of the centrifugalcompressor. The device comprises a thrust measuring end face of the thrust measuring device, a restraining end face of the thrust measuring device, a blind flange, a gasket, a thrust bearing and a thrust disk. 1. The measuring method of the invention is realized by the thrust measuring device, the blind flange, the gasket, the thrust bearing, the thrust disk, a signal conditioning system and a data acquisition system. 2. The number of thrust measuring points on the cover plate of the thrust measuring device of the invention can be 3-6, and each thrust measuring point should ensure accurate flatness. 3. The outer ring of the restraining end face of the thrust measuring device of the invention is designed with an o-ring groove, and the thrust measuring device and the blind flange can realizeflexible assembly. The thrust measuring points on the cover plate of the thrust measuring device are in point contact with the inner end face of the blind flange, and the restraining end face of thethrust measuring device is in contact with the gasket.

Owner:SHENYANG POLYTECHNIC UNIV

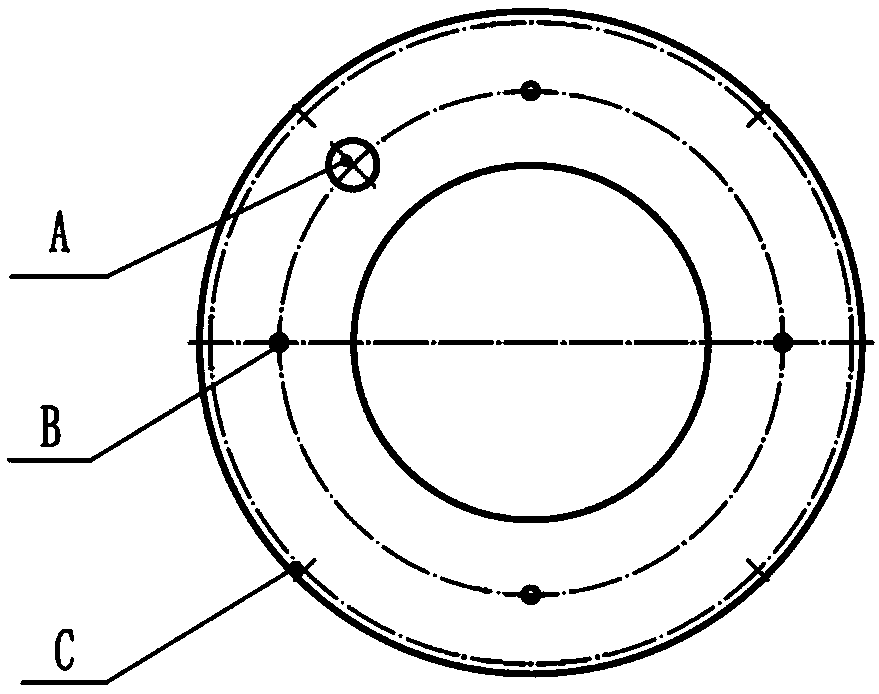

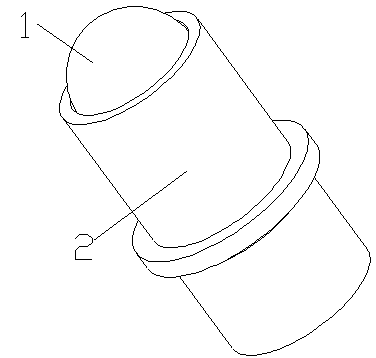

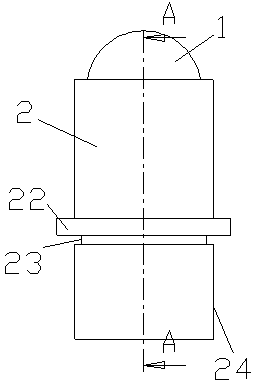

Movable ring assembly sealing device

PendingCN110107692AAxial dimension shortSave axial installation spaceEngine sealsEngineeringMechanical engineering

The invention discloses a movable ring assembly sealing device. The movable ring assembly sealing device is composed of a movable ring assembly and a shaft sleeve. The movable ring assembly is composed of a movable ring, a first steel ball, a sealing gasket, a pressing ring, a wave spring, a wave spring seat, a shaft retainer ring and a second steel ball. A shaft sleeve step is arranged at one endof the shaft sleeve. A first steel ball socket is arranged on the right side of the shaft sleeve step, a spring clamping groove is formed in the other end of the shaft sleeve, and a second steel ballsocket is arranged on the left side of the spring clamping groove. The first steel ball is arranged in the first steel ball socket. The movable ring abuts against the shaft sleeve step. The sealing gasket is pressed into an inner hole of the movable ring and pressed by the pressing ring. The wave spring abuts against the pressing ring. The second steel ball is arranged in the second steel ball socket. The wave spring seat abuts against the wave spring. The shaft retainer ring is clamped in the spring clamping groove and is integrated with the spring clamping groove. The movable ring sealing assembly is small in axial size and convenient to install, the flatness and perpendicularity of the end face of the movable ring are high, and the load around the end face is uniform.

Owner:XIAN YONGHUA GROUP

Disk device

ActiveUS20090083772A1ContactStable head head outputRecord information storageOptical recording/reproducingLevitationSignal on

There is provided a disk apparatus having a clamp structure, which can fix a disk in a stable manner with a simple construction. More specifically, the disk apparatus includes a hub having a disk inserting portion having a cylindrical plane in the outer part of one end and a disk receiving portion having a flat part and being pivotably supported, a head having an inner hole through which the disk inserting portion is fitted, facing toward one face of a disk, levitating and scanning above the disk and reading a signal recorded on the disk or recording a signal on the disk, the disk being held by the disk receiving portion, and a clamp unit holding the disk with the disk receiving portion. In this case, the disk receiving portion has an inclined or declined plane. Thus, the amount and direction of deformation of the disk, which is caused by clamping, are defined, and obtaining a stable amount of head levitation independently of temperature changes can prevent the occurrence of a distortion of the disk. Therefore, a decrease in head output, for example, can be prevented, and the reliability can be improved.

Owner:PHC HLDG CORP

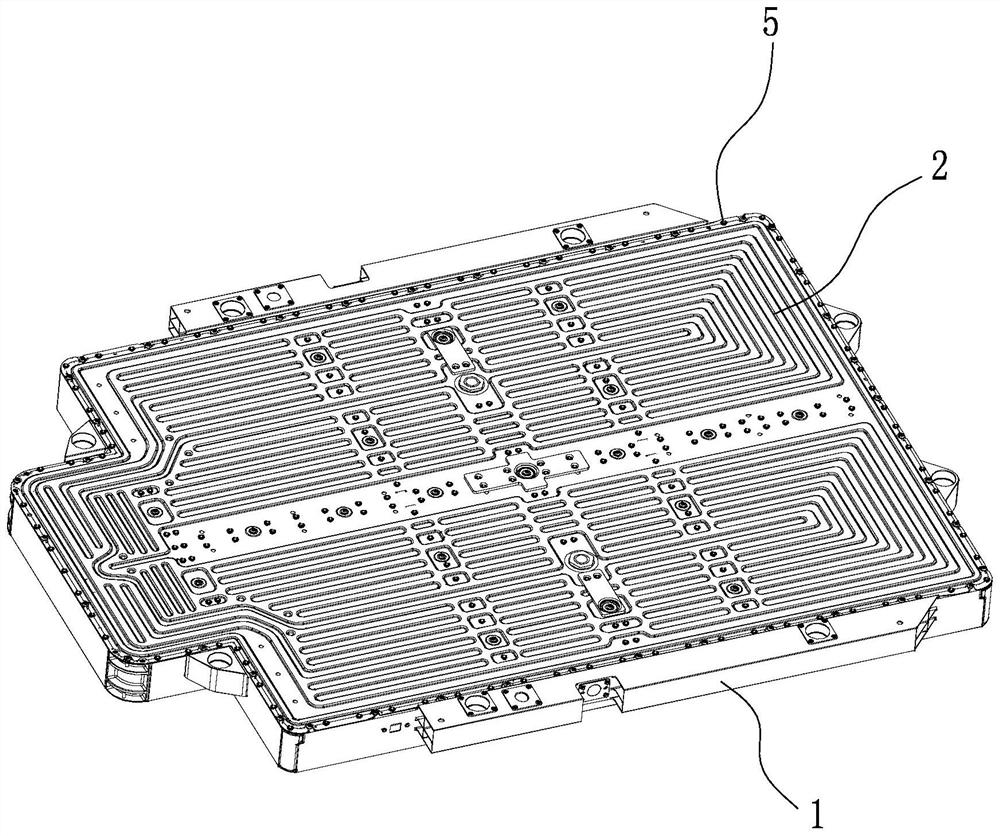

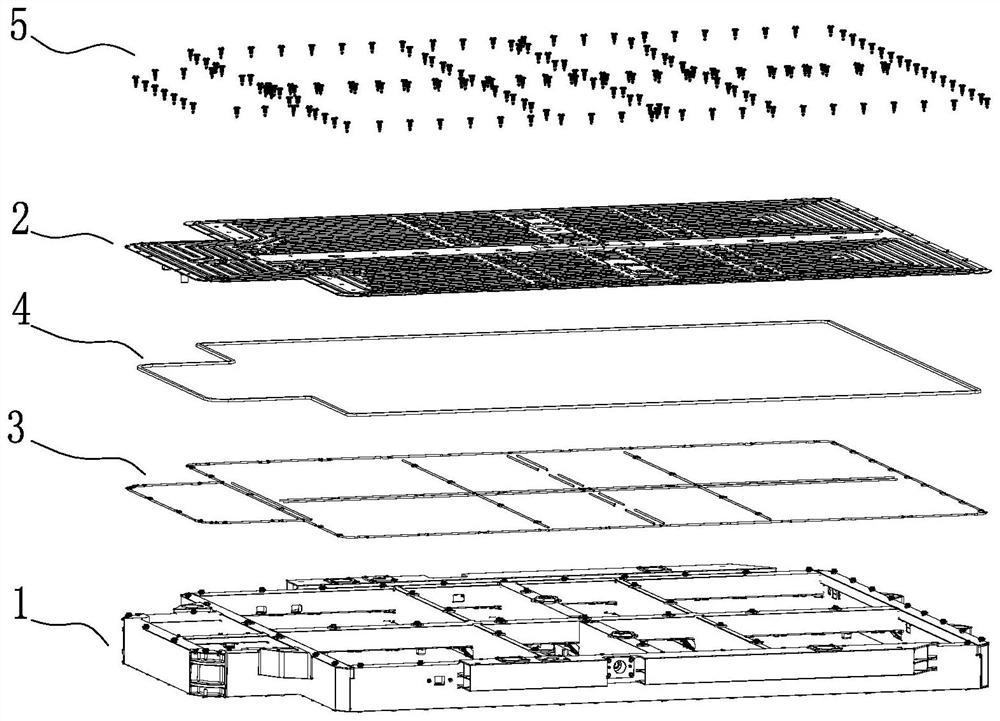

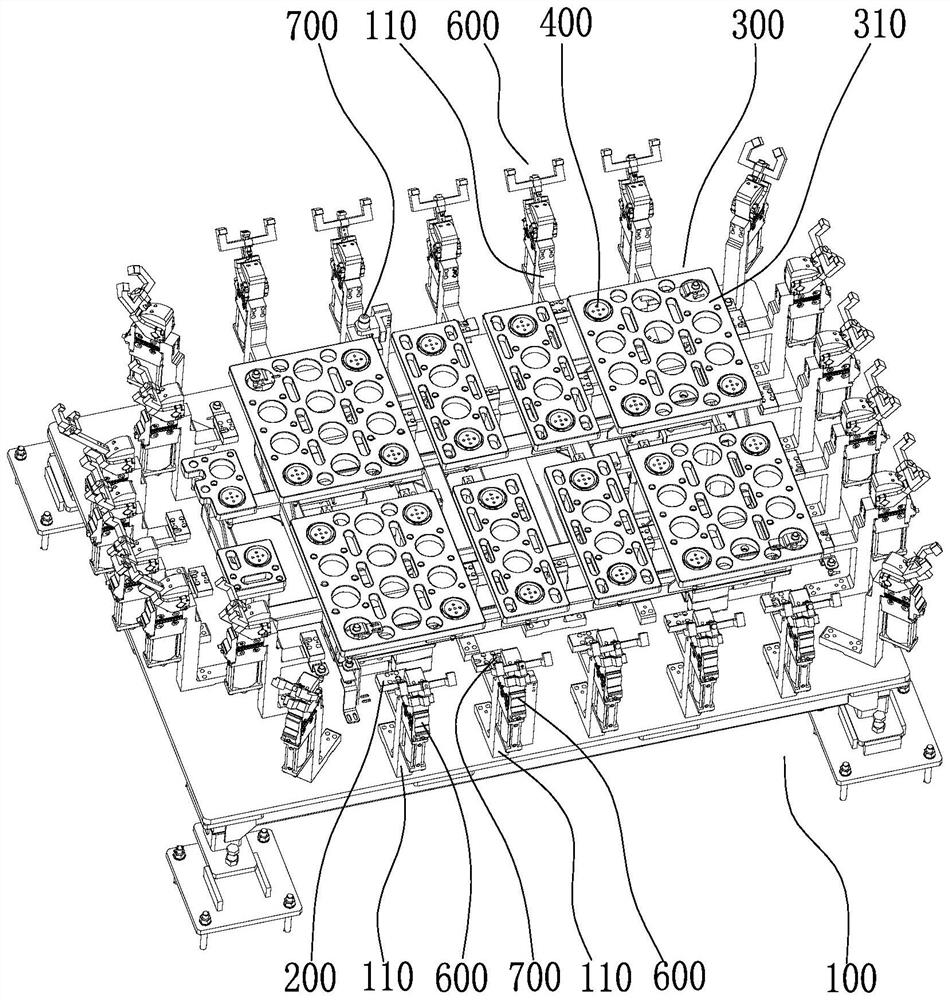

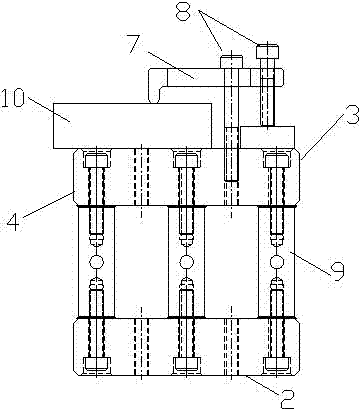

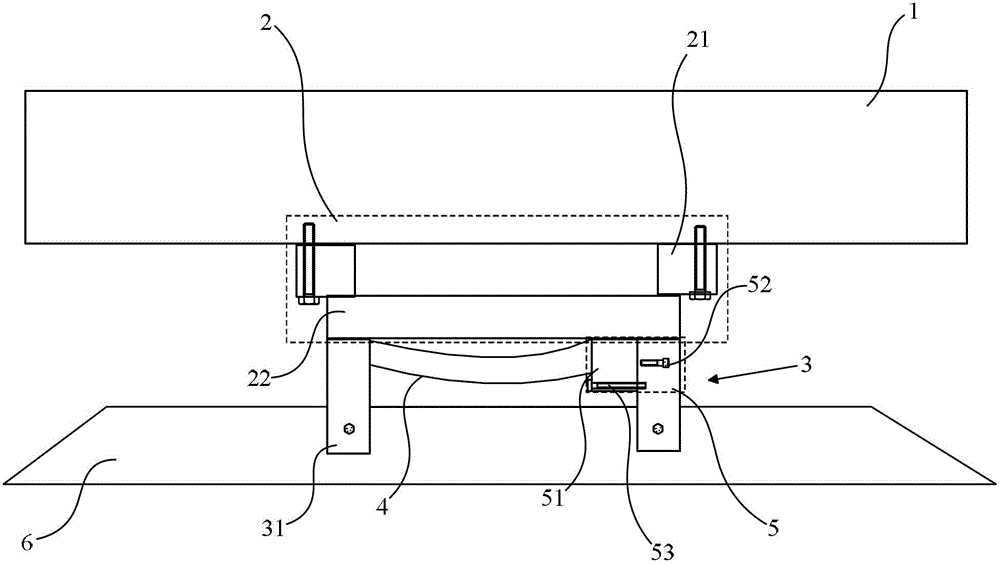

Production clamp of battery box body

PendingCN113927518AReduce the degree of deformationCorrection of flatnessWork holdersPhysicsElectrical battery

The invention discloses a production clamp for a battery box body. The production clamp is used for combining a box frame and a cooling plate together. The production clamp comprises a machine seat, a box frame placement seat, a cooling plate placement seat and a fitting fastening device, wherein the box frame placement seat is arranged on the machine seat; the cooling plate placement seat is arranged on the machine seat, and the cooling plate placement seat is provided with a cooling plate fitting surface; the cooling plate arranged on the cooling plate fitting surface can be combined with the box frame arranged on the box frame placement seat; and the fitting fastening device is configured to apply force to the cooling plate arranged on the cooling plate fitting surface so that the cooling plate is attached to the cooling plate fitting surface. According to the production clamp for the battery box body, flatness correction can be carried out on the cooling plate when the cooling plate and the box frame are assembled so as to reduce the assembling deformation of the cooling plate.

Owner:广东和胜新能源科技有限公司

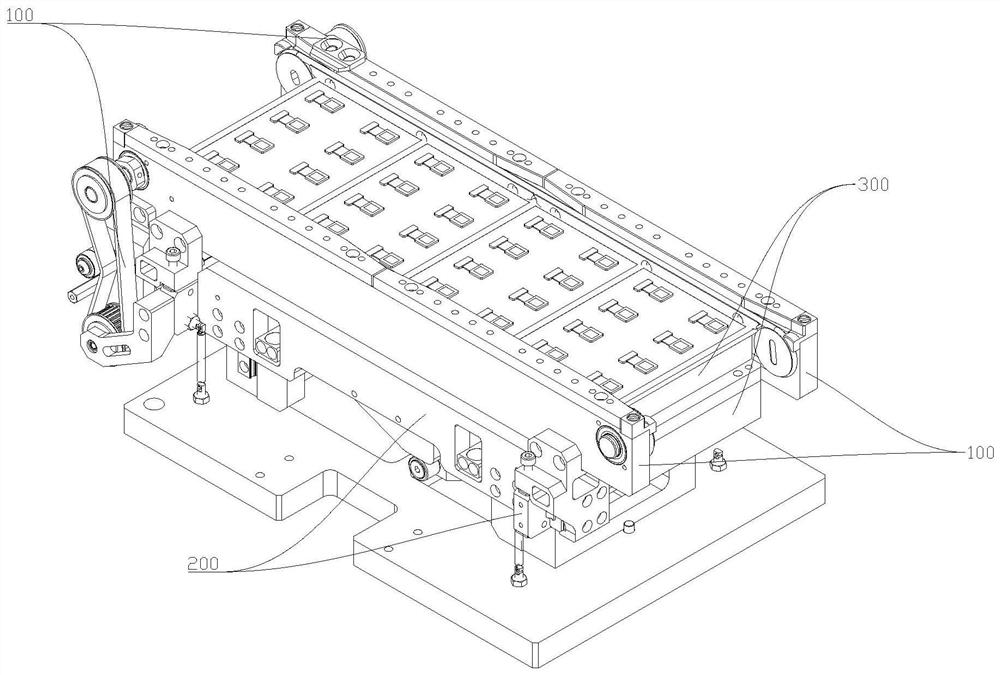

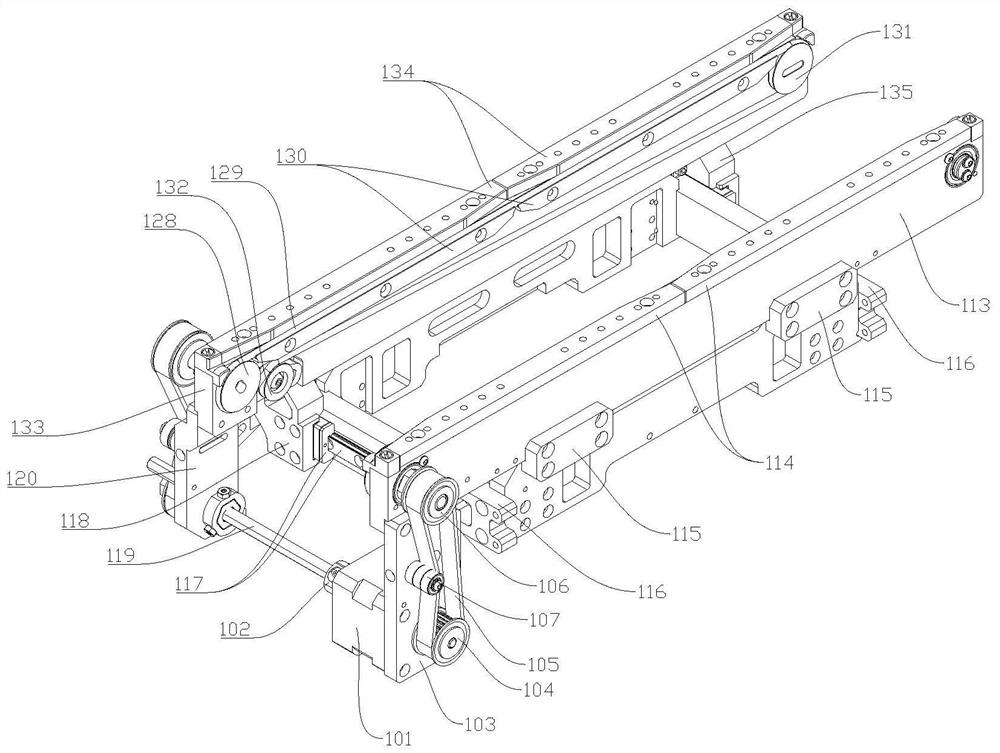

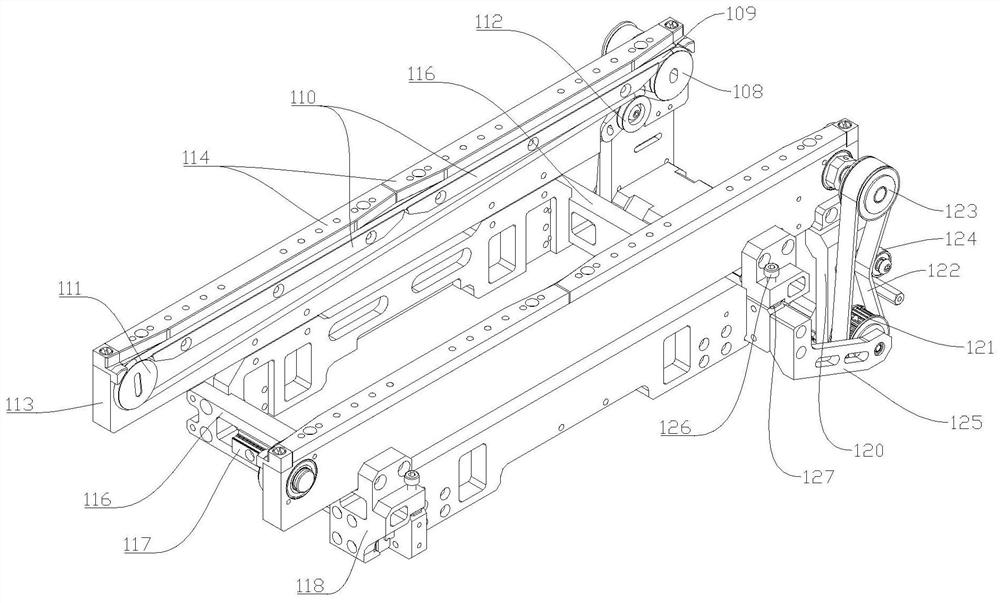

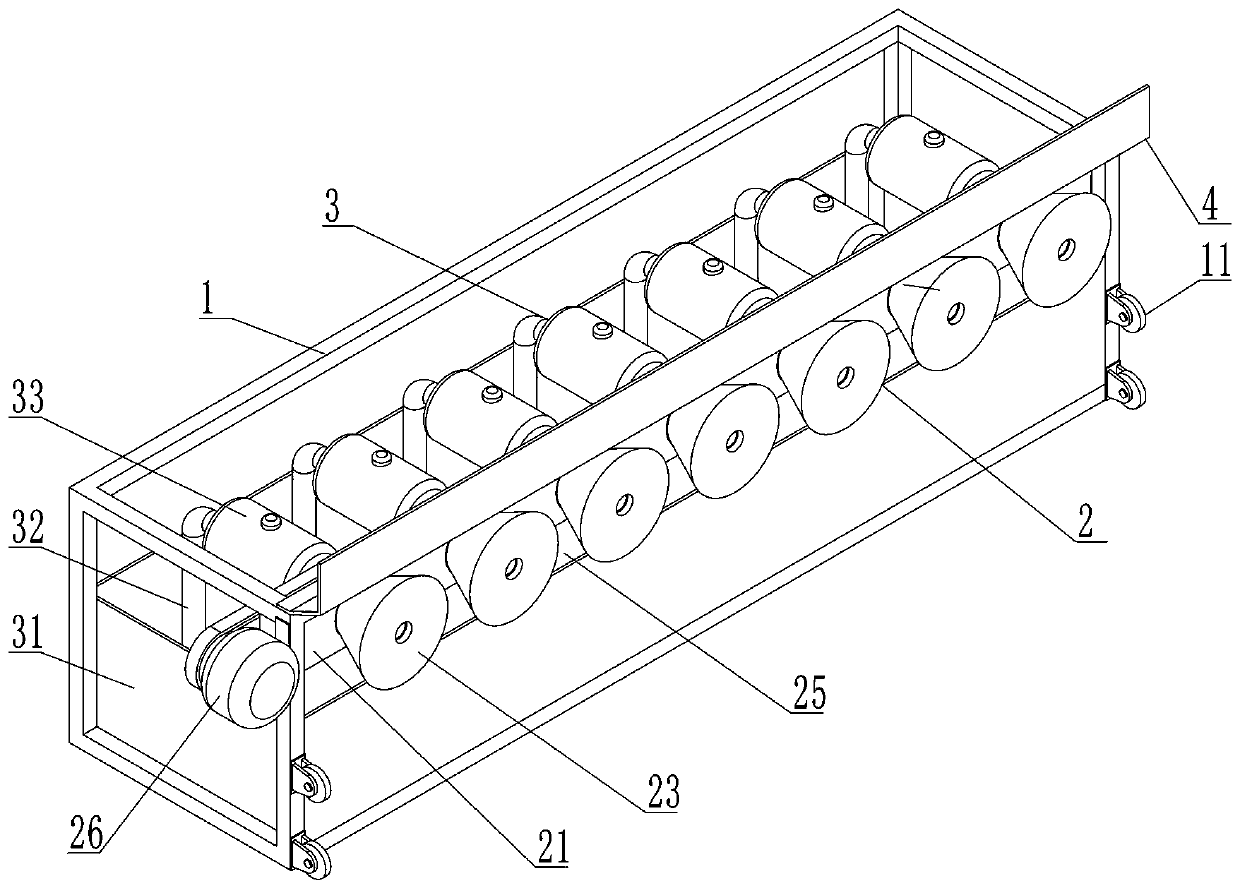

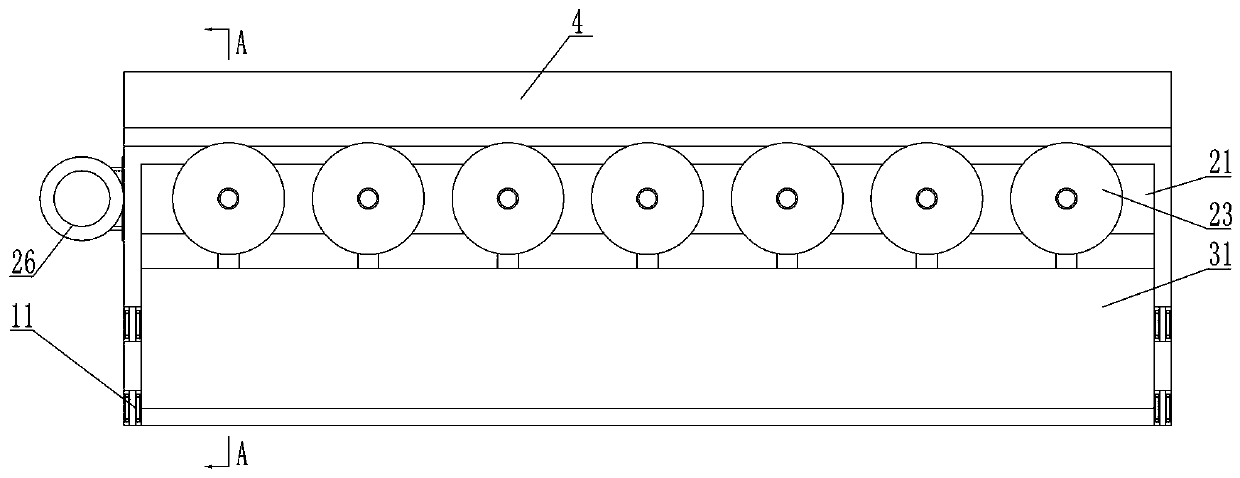

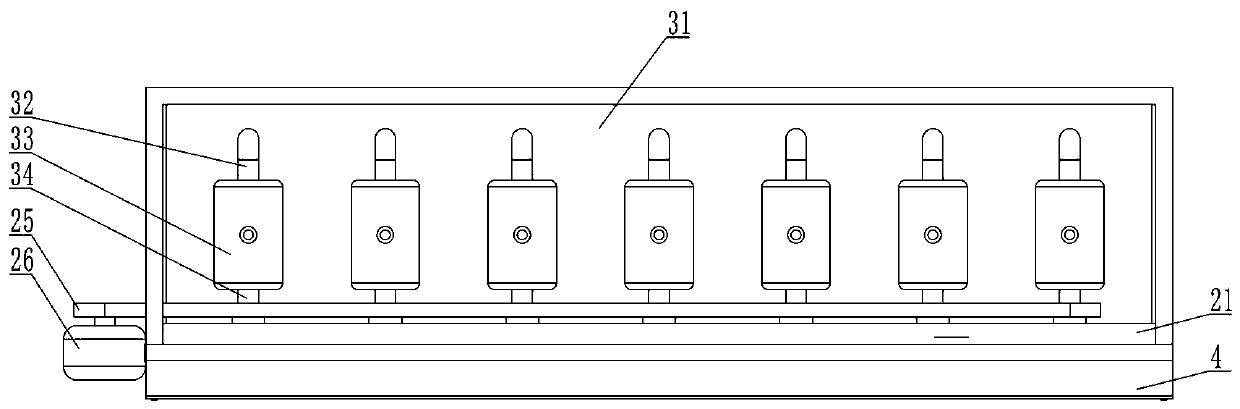

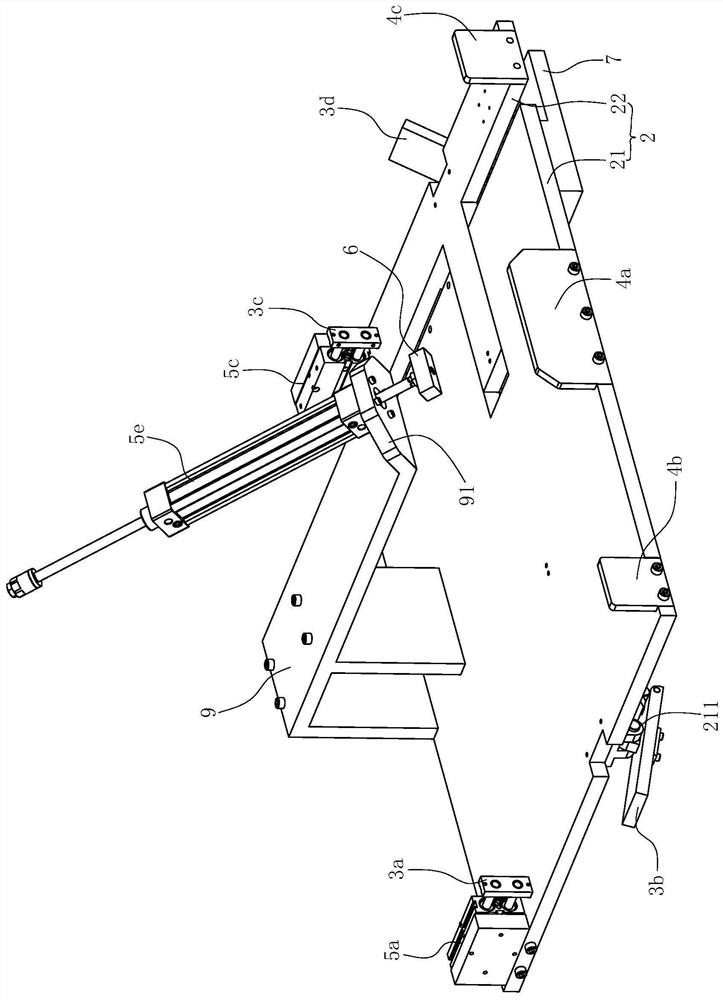

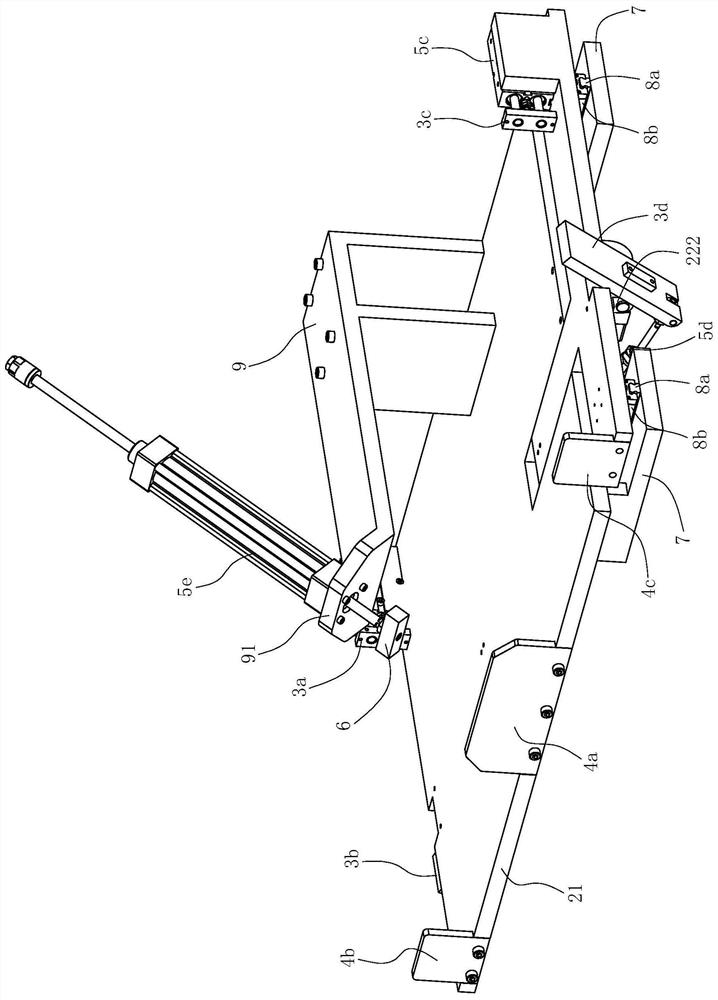

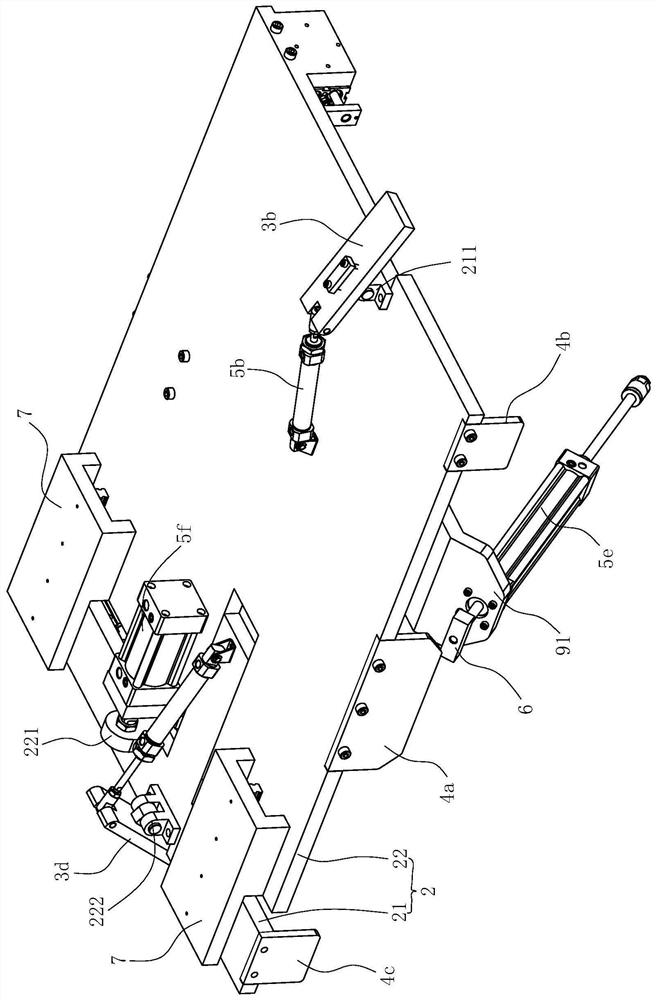

Jig conveying device

PendingCN112209023ATo achieve the effect of non-damage fixationCorrection of flatnessConveyorsMechanical engineeringSmart manufacturing

The invention discloses a jig conveying device, and belongs to the field of intelligent manufacturing. The jig conveying device comprises a positioning mechanism, a conveying mechanism and a jacking mechanism, wherein the positioning mechanism comprises a fixed seat capable of bearing and fixing a jig, and the fixed seat is provided with a negative pressure adsorption opening used for adsorbing the jig; the conveying mechanism comprises a conveying assembly used for supporting and conveying the jig and a driving mechanism used for driving the conveying assembly to operate, and the conveying mechanism can ascend and descend relative to the positioning mechanism; the jacking mechanism drives the conveying mechanism to be switched between an ascending state and a descending state relative tothe positioning mechanism; when the conveying mechanism drives the conveying assembly to ascend to a first height, the jig is separated from the fixed seat and supported on the conveying assembly; andwhen the conveying mechanism drives the conveying assembly to descend to a second height, the jig is separated from the conveying assembly and supported on the fixed seat, and can be fixed on the fixed seat. The problems that in the prior art, a positioning device clamps and fastens the jig from the side of the jig, the warping of the jig is easily caused, and the jig is damaged are solved.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Mask blank transparent substrate manufacturing method, mask blank manufacturing method, and exposure mask manufacturing method

ActiveUS20110027701A1Correction of flatnessImprove accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusMeasurement pointEngineering

A method includes a preparation step of preparing a transparent substrate having a precision-polished main surface, a surface shape information obtaining step of obtaining, as surface shape information, height information at a plurality of measurement points on the main surface of the transparent substrate that contacts a mask stage of an exposure apparatus, a simulation step of obtaining, based on the surface shape information and shape information of the mask stage, height information at the plurality of measurement points by simulating the state where the transparent substrate is set in the exposure apparatus, a flatness calculation step of calculating, based on the height information obtained through the simulation, a flatness of the transparent substrate when it is set in the exposure apparatus, a judging step of judging whether or not the calculated flatness satisfies a specification, and a thin film forming step of forming a thin film as serving as a mask pattern, on the main surface of the transparent substrate whose flatness satisfies the specification.

Owner:HOYA CORP

Processing equipment for LCD backplanes for ultra-thin smartphones

ActiveCN105537319BCorrection of flatnessImprove the leveling effectLeveling effectLiquid-crystal display

The invention discloses a machining device for back plates of liquid crystal displays of ultra-thin smartphones. The machining device comprises a bottom plate, a fixed seat, a horizontal cylinder, a vertical cylinder, a support plate as well as a left guide rail seat and a right guide rail seat which are fixed on the bottom plate, wherein the support plate is located between the left guide rail seat and the right guide rail seat; the vertical cylinder located below the support plate is mounted on the bottom plate, an ejection rod of the vertical cylinder is connected with the support plate, and an elastomeric pad covers the upper surface of the support plate; a left through hole strip and a right through hole strip are formed in the left guide rail seat and the right guide rail seat respectively, a rolling shaping bar is located above the support plate, two ends of the rolling shaping bar are embedded in the left through hole strip and the right through hole strip, a connecting shaft is located on the left guide rail seat and the right guide rail seat, and two ends of the connecting shaft and the two ends of the rolling shaping bar are connected through a left connecting block and a right connecting block. With the adoption of the machining device, efficient and high-quality leveling operation can be realized for the back plates with large-range warpage, the leveling effect is good, the efficiency is high, and products have stable quality and cannot be broken easily.

Owner:KUNSHAN KERSEN SCI & TECH

Novel positive angle device

InactiveCN102825476AImprove stabilityReduce weightPositioning apparatusMetal-working holdersFixed frameEngineering

Owner:昆山旭虹精密零组件有限公司

Building external wall concrete trowelling device

InactiveCN110259056ASimple structureNo need to work at heightsBuilding constructionsStructural engineeringEngineering

The invention discloses a building external wall concrete trowelling device. The building external wall concrete trowelling device comprises a fame, a smearing mechanism, a feeding mechanism and a leveling device, the suspended frame is perpendicular to a wall, makes contact with the wall through rolling wheels, and keeps a certain distance from the wall, concrete slurry in a material trough is conveyed and sprayed to the surface of the wall through a conveying pump, a smearing disc is driven by a motor to rotate to extrude and trowel the concrete slurry, when the frame moves downwards, the leveling device levels concrete adhering to the wall. According to the building external wall concrete trowelling device, the problems that original building external wall concrete coating and leveling efficiency is low, high-altitude operation is needed, and potential safety hazards exist are solved, and the building external wall concrete trowelling device has the characteristics that the structure is simple, the coating and leveling efficiency is high, planeness is precise, high-altitude operation of operators is not needed, and the safer effect is achieved.

Owner:湖北乾奥建设工程有限公司

Long mirror installation device

ActiveCN103777303BChange the state of stressCorrection of flatnessPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

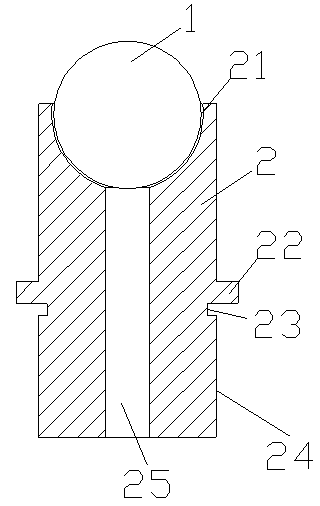

Positioning gas pressure column

InactiveCN103216482ACorrection of flatnessReduce frictionFluid-pressure actuatorsRolling resistanceChemistry

The invention discloses a positioning gas pressure column which comprises a spherical body and a column body, wherein the upper part of the column body is provided with a spherical crown cavity communicated with outside, a through hole is formed in the column body, the spherical body is arranged in the spherical crown cavity, a positioning lug boss is arranged on the middle part of the column body, the lower surface of the positioning lug boss is smooth and has a requirement on precision, the lower part of the column body is provided with a thread, and a groove is arranged above the thread. According to the accurate positioning gas pressure column disclosed by the invention, input gas passes through the through hole and is imported into the spherical crown cavity, so that the spherical body floats up to transfer pressure outwards; in addition, as the spherical body can rotate in any direction, the friction between the spherical body and a workpiece is rolling friction, so that the damage caused by friction due to the fact that the workpiece shifts when being touched can be reduced, and meanwhile the accurate set pressure can be provided; and meanwhile, owing to the arrangement of the positioning lug boss and the groove, the pressure column can accurately ensure the height on a platform connected with the pressure column.

Owner:KUNSHAN THETA MICRO

Automatic clamping and welding fixture with correction function suitable for exhaust fume collecting hoods of multiple specifications

ActiveCN110900063AGuaranteed flatnessCorrection of flatnessWelding/cutting auxillary devicesAuxillary welding devicesExhaust fumesEngineering

The invention relates to a welding fixture, in particular to an automatic clamping and welding fixture with a correction function suitable for exhaust fume collecting hoods of multiple specifications.The automatic clamping and welding fixture comprises a platform, wherein the platform is used for accommodating an exhaust fume collecting hood with a front folded edge, a left folded edge and a right folded edge. The automatic clamping and welding fixture is characterized in that the platform is composed of a main platen and a side platen, and a driving structure used for driving the side platento slide left and right is arranged at the bottom part of the main platen; a left rear pressing block, a left side pressing block and a front middle baffle plate are arranged on the main platen, theleft rear pressing block is driven by means of a left rear cylinder, the left side pressing block is used for making contact with the side surface of the left folded edge, and the front middle baffleplate is fixed to the front portion of the main platen and used for making contact with the middle portion of the front folded edge; a right rear pressing block and a right side pressing block are arranged on the side platen, the right rear pressing block is driven by means of a right rear cylinder, and the right side pressing block is driven by means of a right side cylinder; and an upper cylinder is arranged above the main platen, and a correction pressing block is fixed to a piston rod of the upper cylinder. The automatic clamping and welding fixture can be used for welding the exhaust fumecollecting hoods of different specifications, can further ensure the flatness of the front folded edge of the exhaust fume collecting hood after welding, and is beneficial to later assembly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for manufacturing an electromechanical transducer

InactiveUS9166502B2Flatness is not impairedCorrection of flatnessElectrical transducersCapacitor with electrode distance variationVibrating membraneConductive materials

The present invention provides a technology for decreasing a dispersion of the performance among electromechanical transducers each having through wiring. A method for manufacturing an electromechanical transducer includes: obtaining a structure in which an insulative portion having a through hole therein is bonded onto an electroconductive substrate; filling the through hole with an electroconductive material to form a through wiring which is electrically connected with the electroconductive substrate; and using the electroconductive substrate as a first electrode, forming a plurality of vibrating membrane portions including a second electrode, which opposes to the first electrode through a plurality of gaps, on an opposite side of the first electrode to the side having the insulative portion, to thereby forming a plurality of cells.

Owner:CANON KK

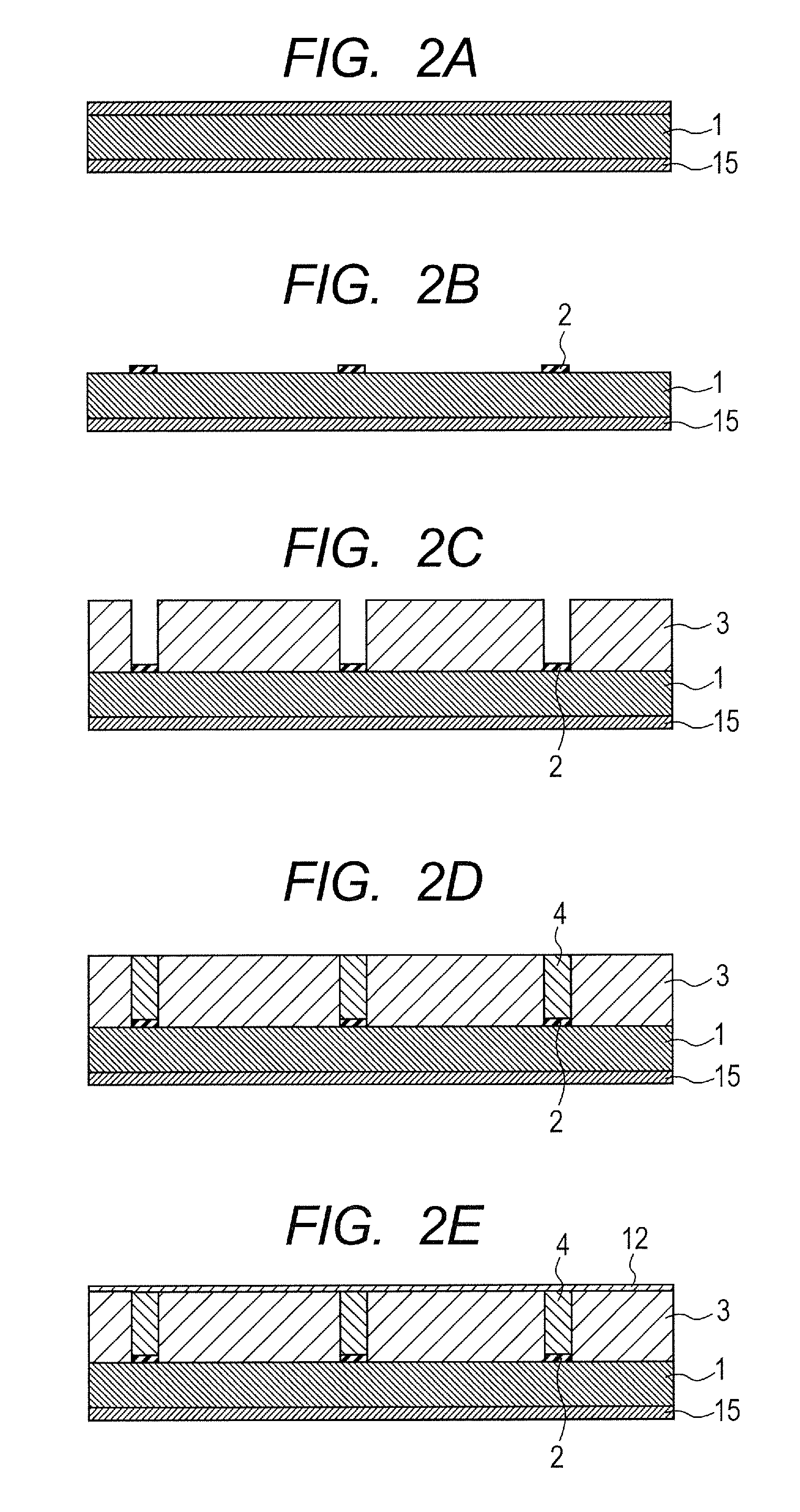

Forming method of electric connector

InactiveCN1599152APrevent flatness from being out of toleranceMeet high demands on flatnessLine/current collector detailsSecuring/insulating coupling contact membersDistortionElectricity

The invention relates to a forming method of the electric coupler. The electric coupler is made by initial loading steps, electric terminal sorting steps and fine positioning injection moulding inlaying forming steps after the preparatory steps of electric terminal forming and simple insulating matrix forming. After the electric terminal sorting steps, make use of the plastic structure to orientate the terminals, make the planeness return to zero and then carry out the injection moulding inlaying forming. By this way, the simple insulating matrix formed for the first time is put in the final insulating matrix, which can avoid the shrinkage distortion and the excess of hour angle increment of the planeness. In addition, the orientation of the plastic component can reach the precise planeness of the control terminal jointing plane, meets the high requirement to the planeness in today's industry, reduces the manufacturing risk, increases the up-to-standard rate of the products and forms good technological interaction with the related industry.

Owner:王道前 +1

LCD screen backplane leveling mechanism for electronic products

InactiveCN105562470BCorrection of flatnessImprove the leveling effectLeveling mechanismLiquid-crystal display

Owner:昆山元诚电子材料有限公司

Suitable for multi-standard fume collection hoods, automatic clamping welding fixture with correction function

ActiveCN110900063BGuaranteed flatnessCorrection of flatnessWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSmoke hood

An automatic clamping welding jig suitable for multi-standard fume collecting hoods and with a correction function. The invention relates to a welding jig, including a platform for placing a fume collecting hood with front folds, left folds and right folds; its features are: The platform is composed of the main platform and the side platform. The bottom of the main platform is provided with a drive structure for driving the side platform to slide left and right; The baffle, the left rear pressing block is driven by the left rear cylinder, the left pressing block is used to contact the side of the left flange, and the front middle baffle is fixed on the front of the main table to contact the middle of the front flange; There are right rear pressing block and right pressing block on the side table, the rear pressing block is driven by the right rear cylinder, and the right pressing block is driven by the right air cylinder; the upper cylinder above the main table, the upper cylinder A correction block is fixed on the piston rod. The fixture can weld the fume collection hoods of different specifications, and can also ensure the flatness of the front fold of the fume collection hood after welding, which is beneficial to later assembly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com