Integrated circuit heat pipe heat spreader with through mounting holes

a heat spreader and integrated circuit technology, which is applied in the direction of cooling/ventilation/heating modification, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of reducing the performance of the integrated circuit chip, reducing reliability, and large differences in the effectiveness of heat transfer from various parts of the heat sink, so as to achieve low cost, easy manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

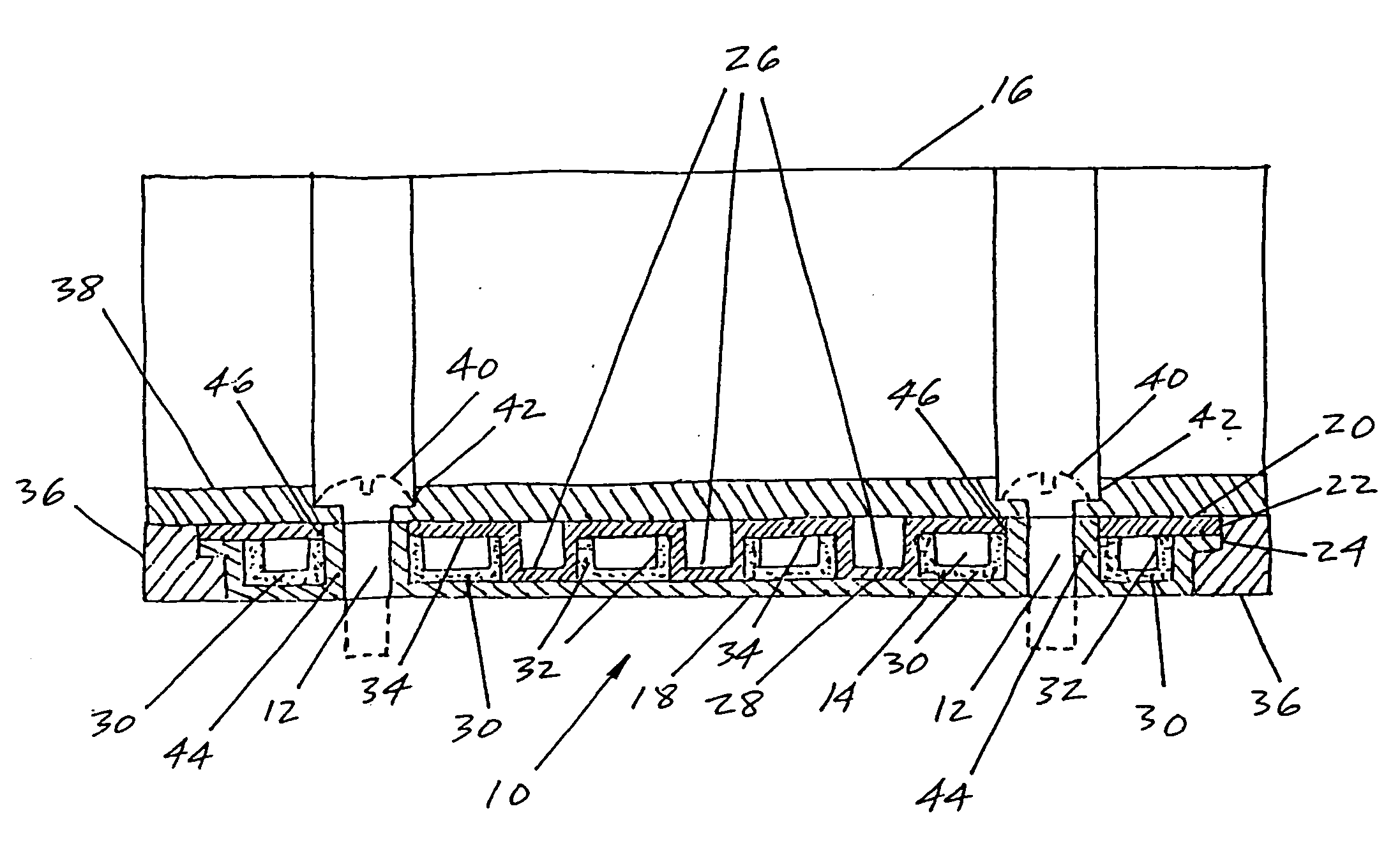

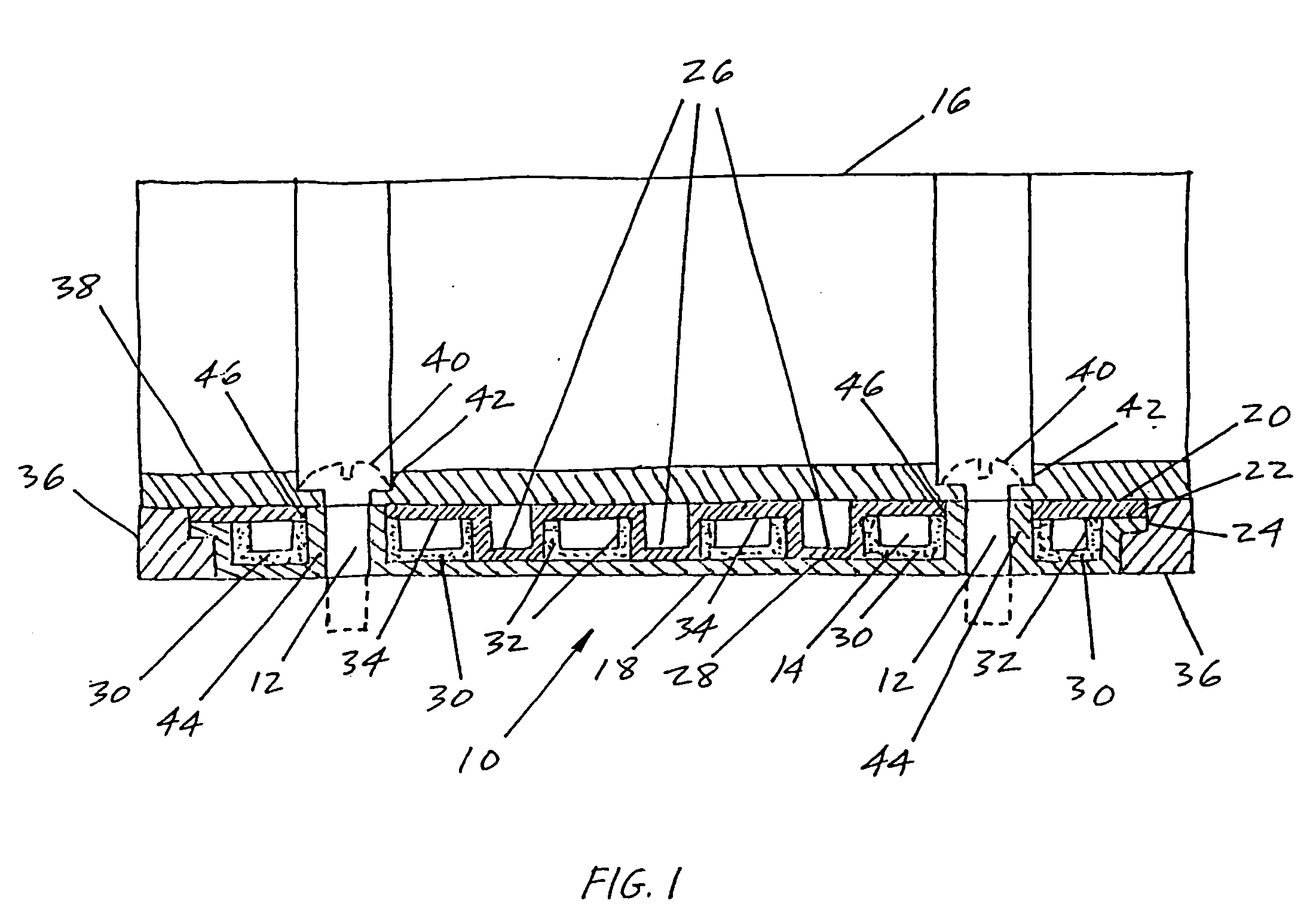

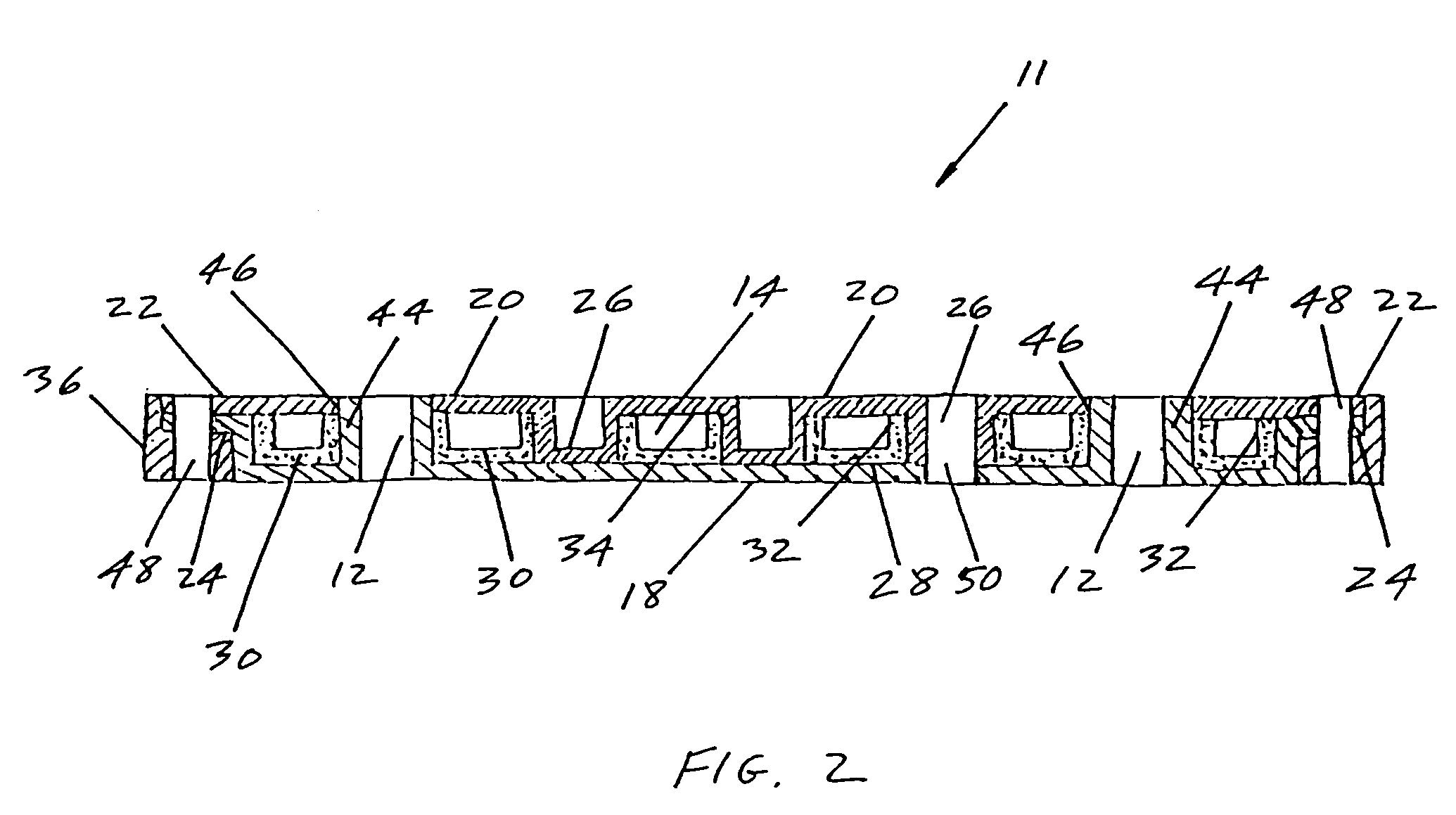

[0017]FIG. 1 is a cross section view of the preferred embodiment of a flat plate heat pipe 10 of the invention with through holes 12 through its vapor chamber 14 and in contact with finned heat sink 16.

[0018] Heat pipe 10 is constructed by forming a boundary structure by sealing together two formed plates, contact plate 18 and cover plate 20. Contact plate 18 and cover plate 20 are sealed together at their peripheral lips 22 and 24 by conventional means, such as soldering or brazing, to form heat pipe 10. Heat pipe 10 is then evacuated to remove all non-condensible gases and a suitable quantity of heat transfer fluid is placed within it. This is the conventional method of constructing a heat pipe, and is well understood in the art of heat pipes.

[0019] The interior of heat pipe 10 is, however, constructed unconventionally. While contact plate 18 is essentially flat with the exception of peripheral lip 24, cover plate 20 includes multiple depressions 26. Depressions 26 are formed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com