Patents

Literature

142results about How to "Maximize heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

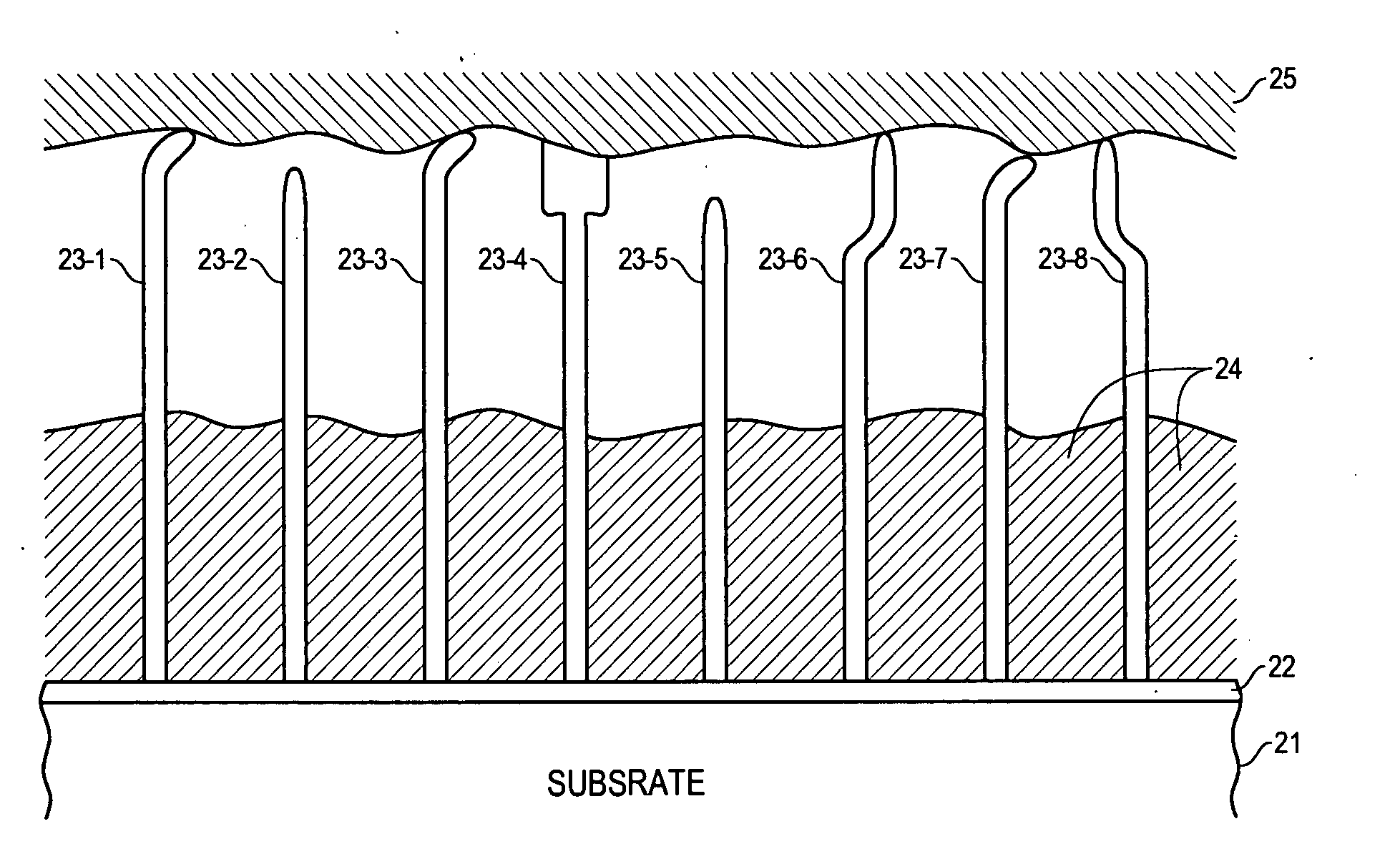

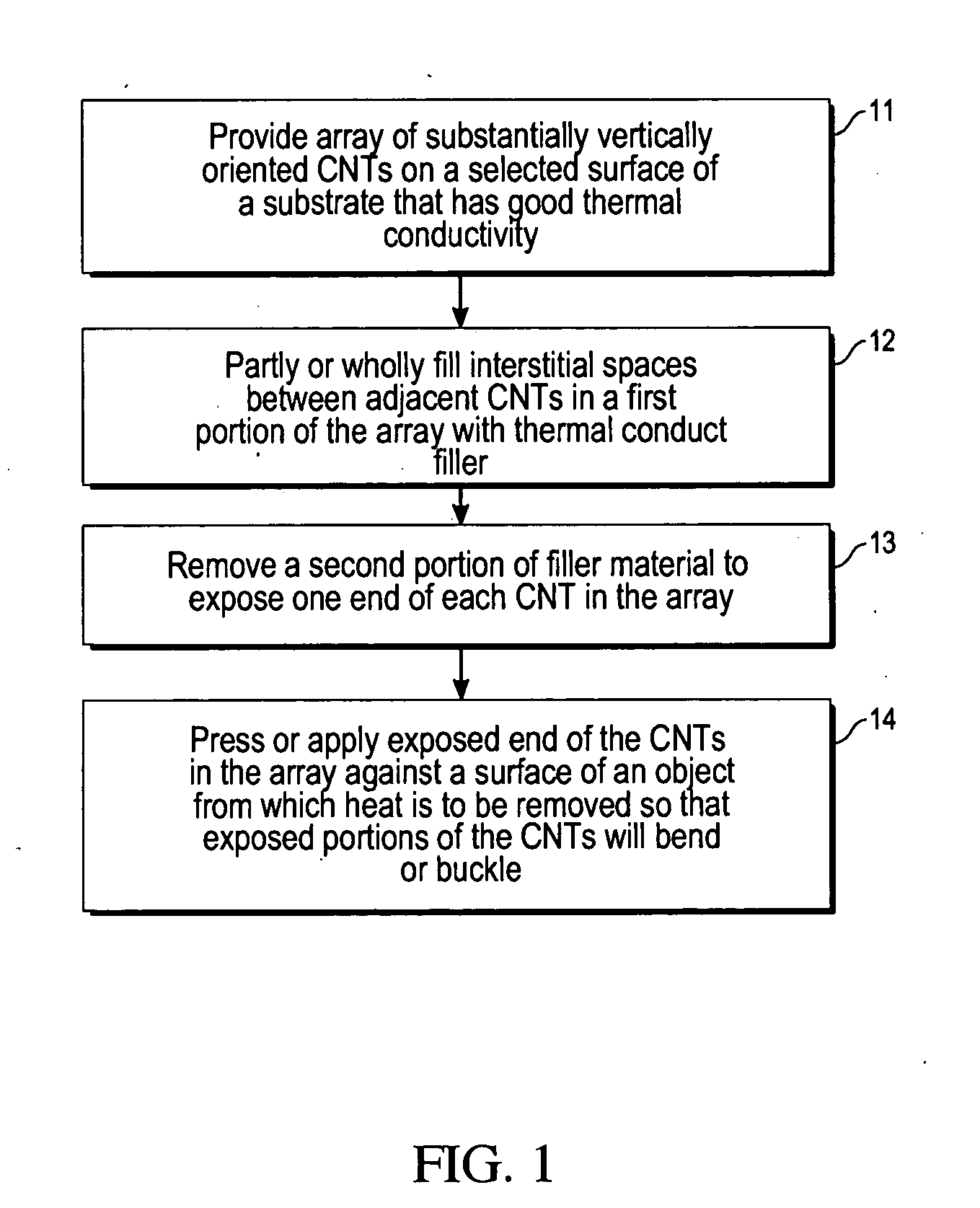

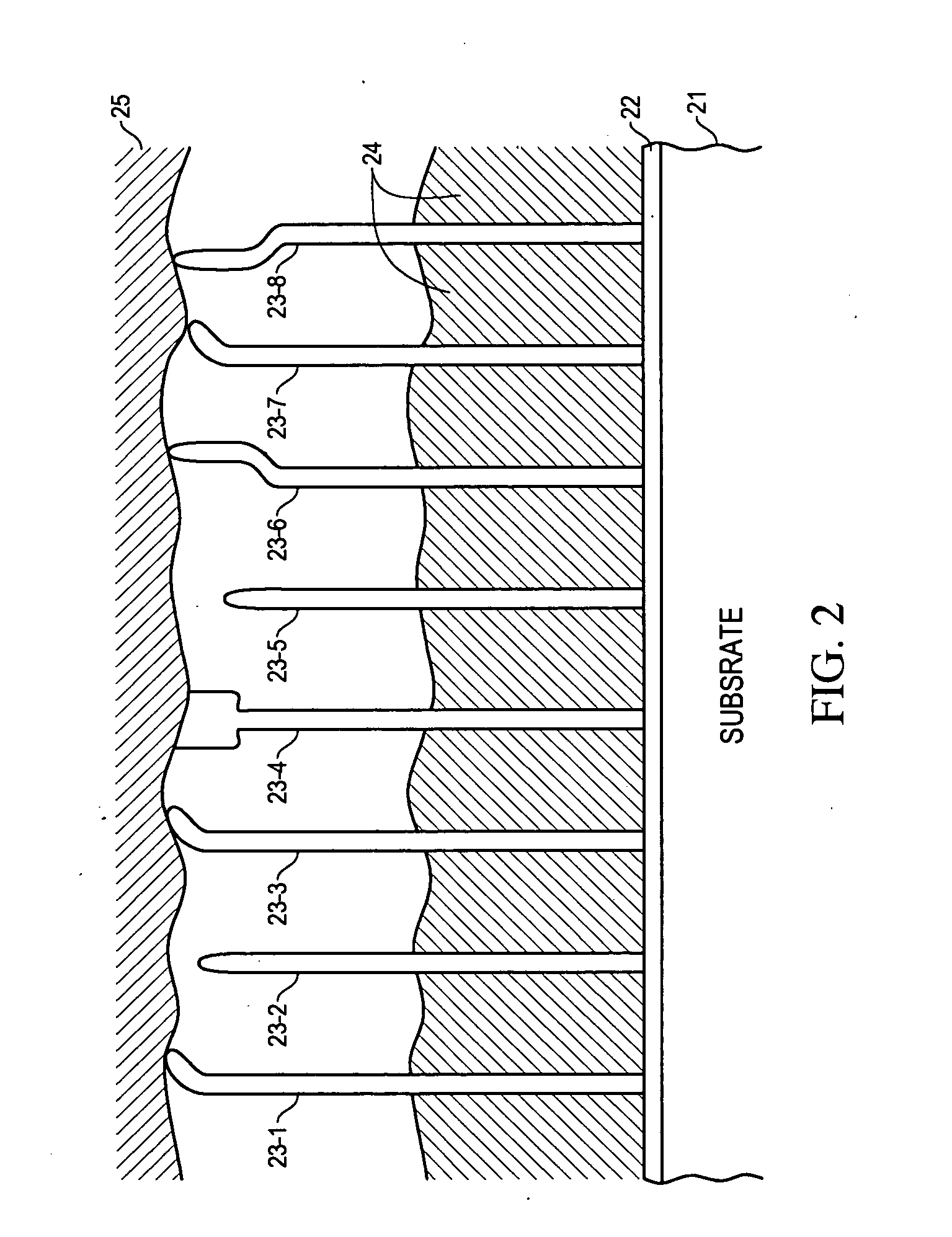

Nanoengineered thermal materials based on carbon nanotube array composites

InactiveUS20050224220A1High mechanical strengthImprove cooling effectMaterial nanotechnologySemiconductor/solid-state device detailsHeat fluxFilling materials

A method for providing for thermal conduction using an array of carbon nanotubes (CNTs). An array of vertically oriented CNTs is grown on a substrate having high thermal conductivity, and interstitial regions between adjacent CNTs in the array are partly or wholly filled with a filler material having a high thermal conductivity so that at least one end of each CNT is exposed. The exposed end of each CNT is pressed against a surface of an object from which heat is to be removed. The CNT-filler composite adjacent to the substrate provides improved mechanical strength to anchor CNTs in place and also serves as a heat spreader to improve diffusion of heat flux from the smaller volume (CNTs) to a larger heat sink.

Owner:SAMSUNG ELECTRONICS CO LTD +1

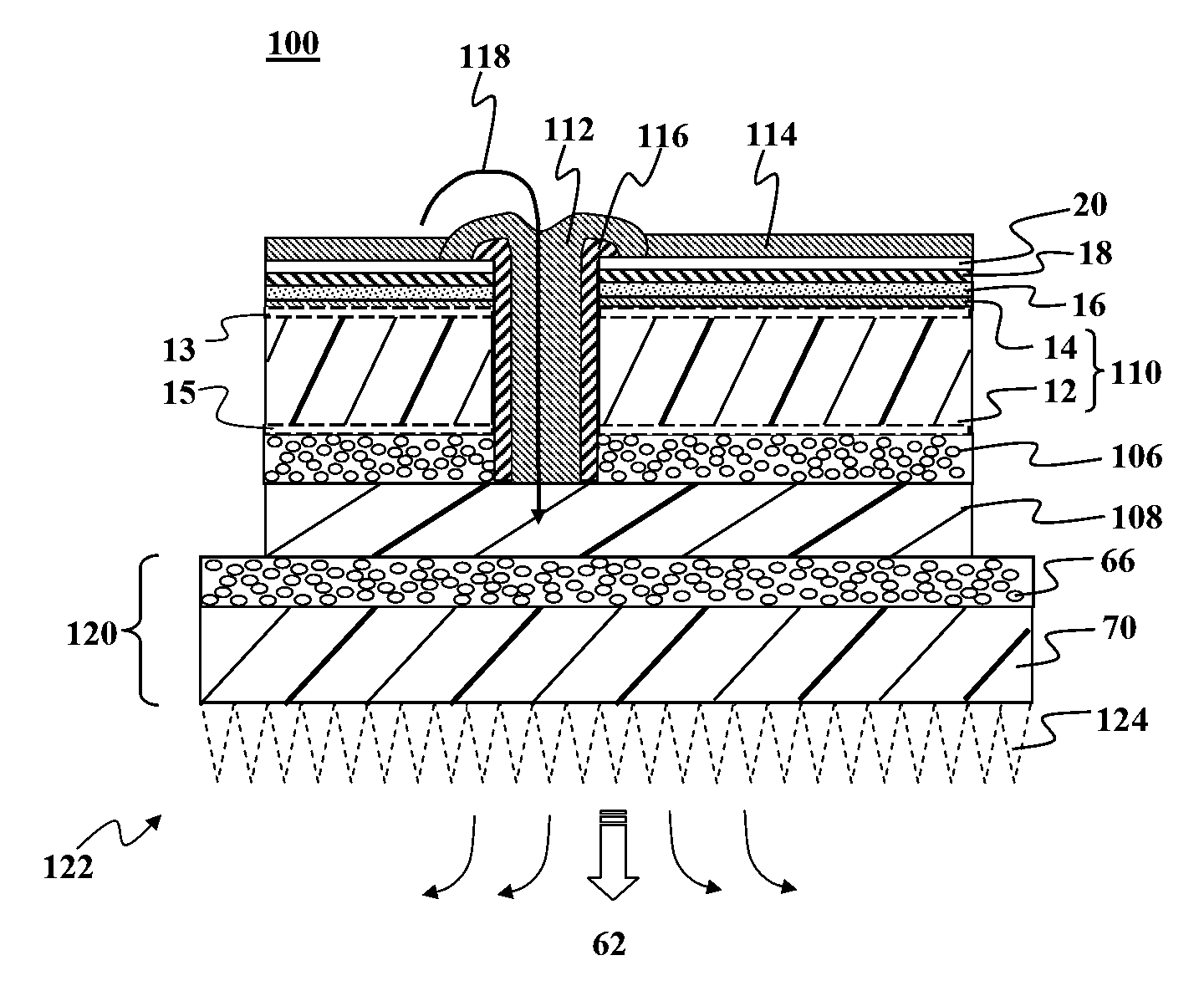

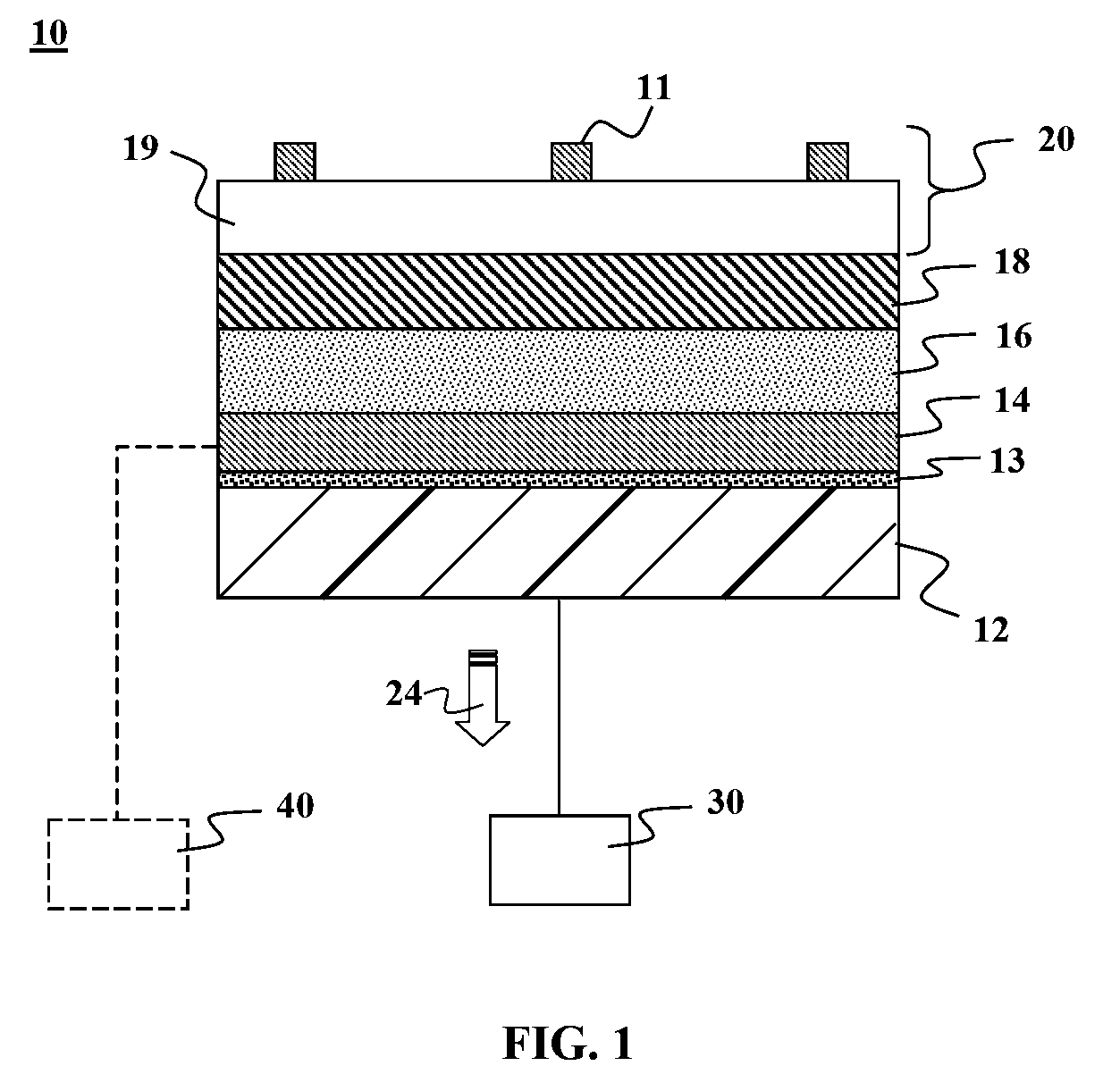

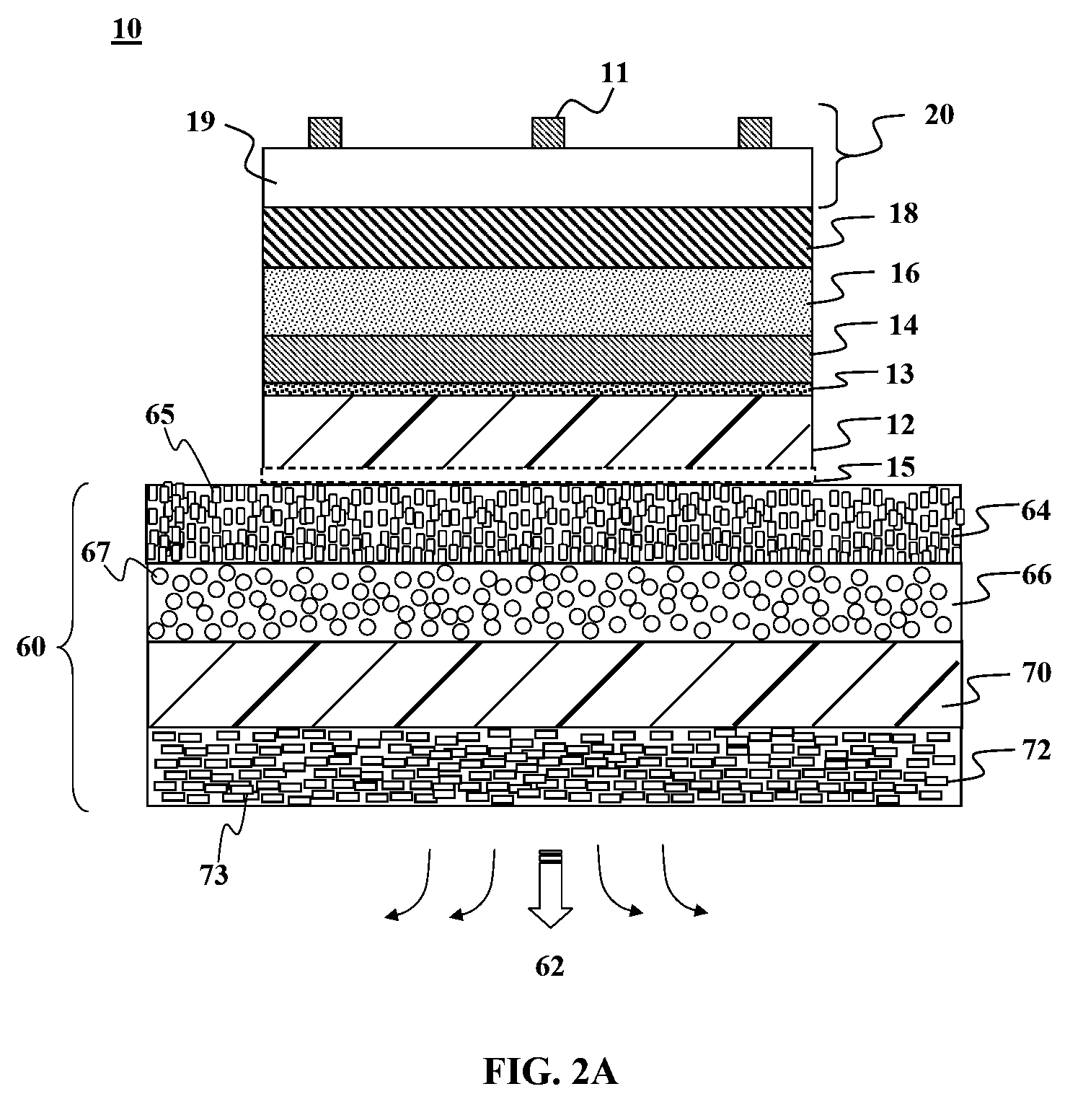

Thermal management for photovoltaic devices

InactiveUS7985919B1Improve efficiencySolve insufficient capacityFinal product manufacturePV power plantsEngineeringCell based

Methods and devices are provided for improved thermal management for photovoltaic devices and assemblies. In one embodiment, the photovoltaic device comprises of at least one photovoltaic cell based on a thin-film photovoltaic stack deposited directly onto a thermally conductive substrate. The thermally conductive substrate is connected to a heat sink in a configuration to allow sufficient heat transfer that lowers a normal operating cell temperature (NOCT) of the photovoltaic cell, thus increasing the efficiency of the cell and the module.

Owner:AERIS CAPITAL SUSTAINABLE IP

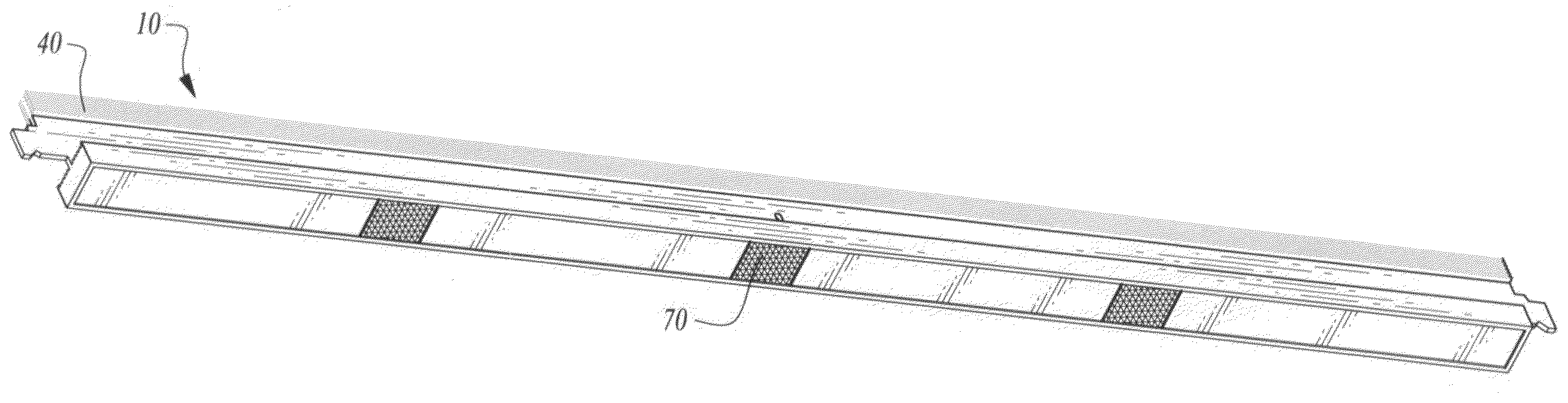

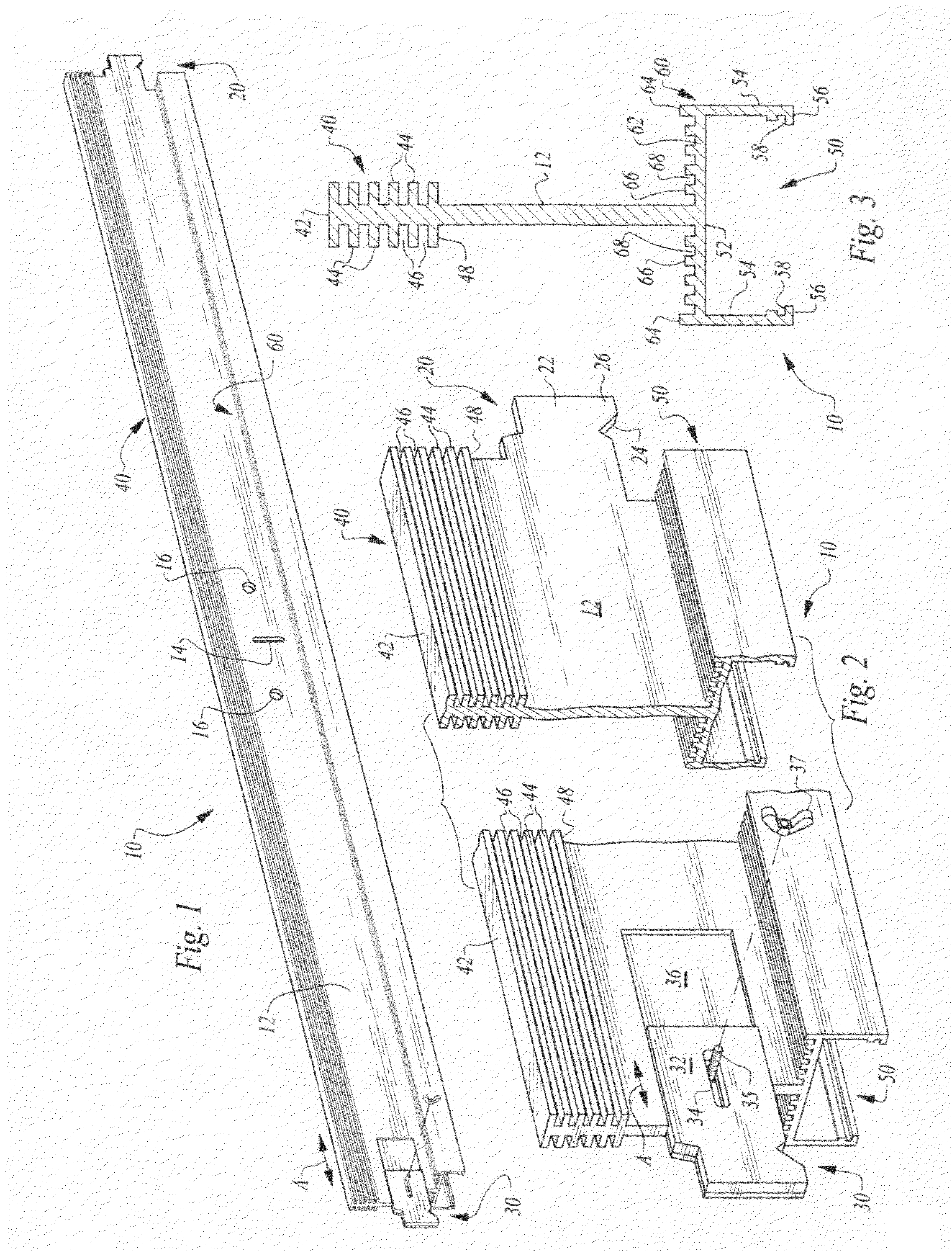

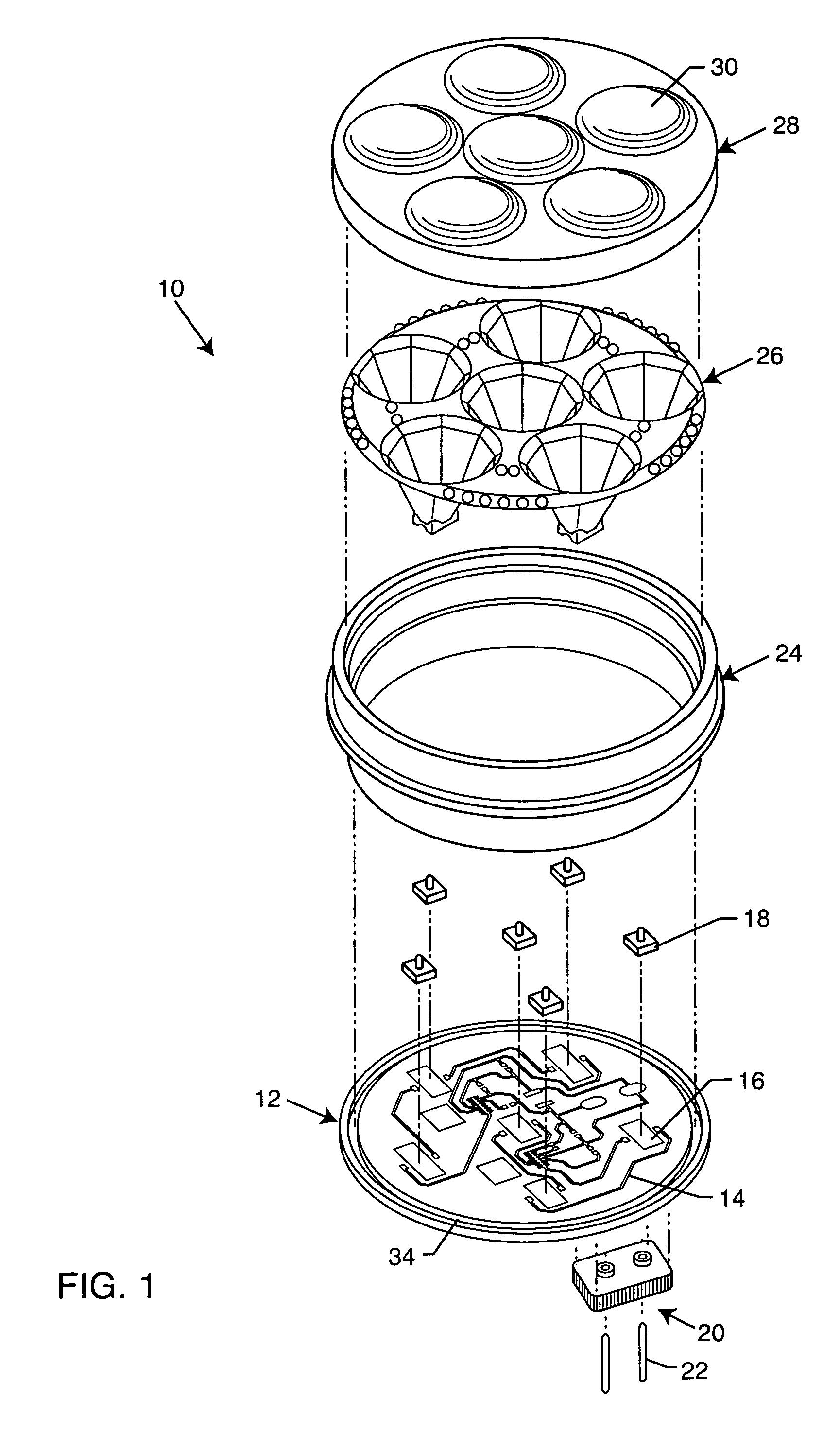

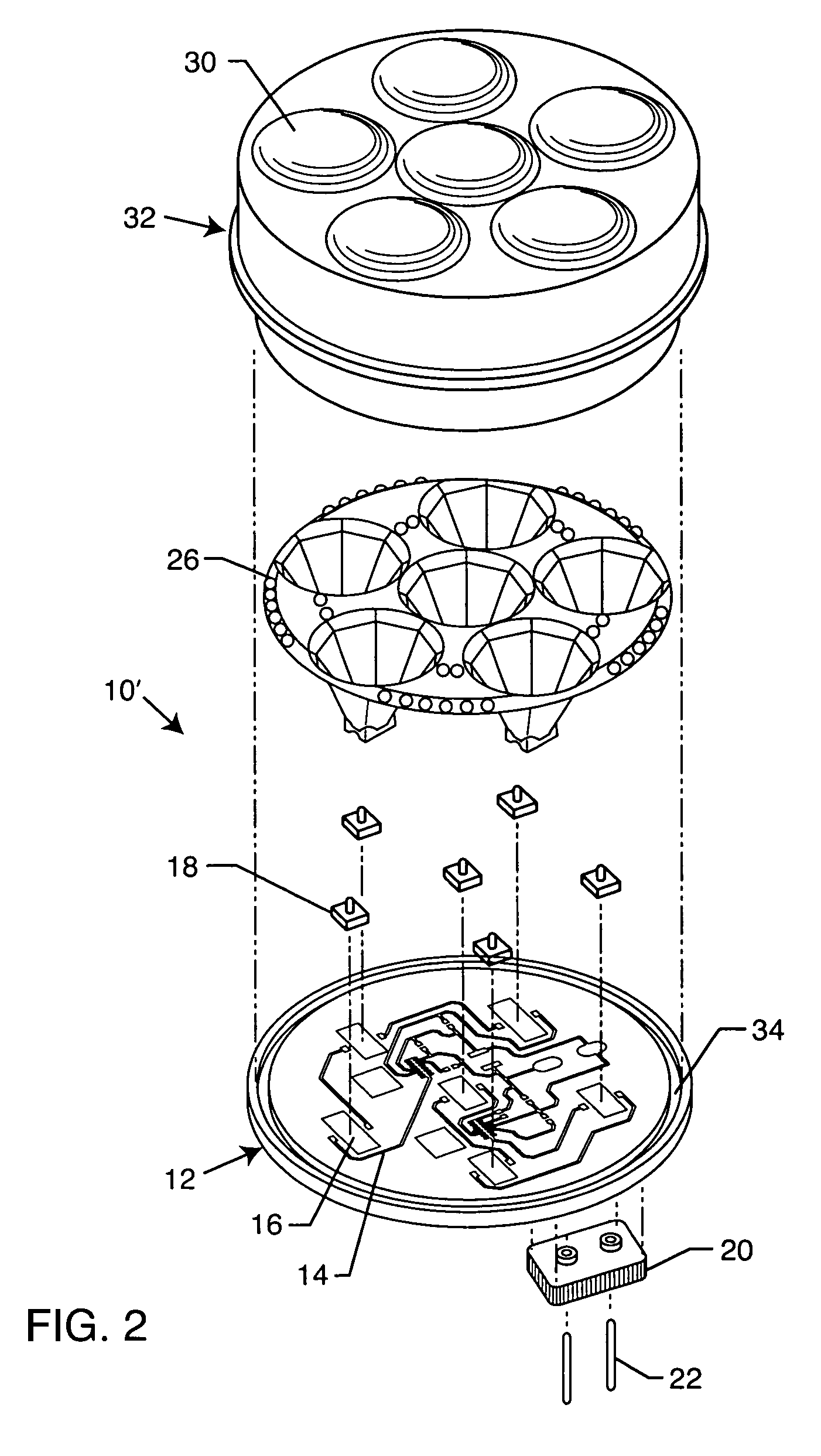

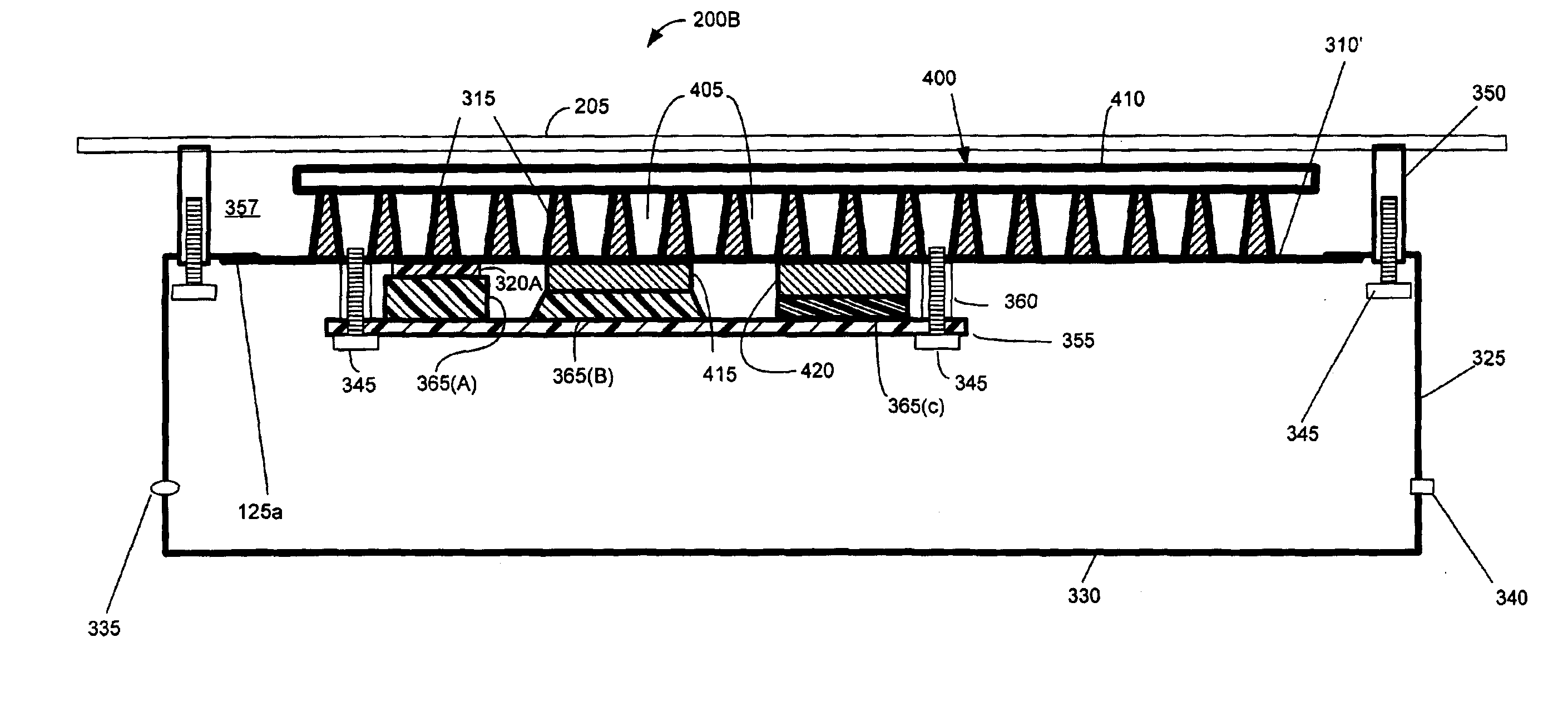

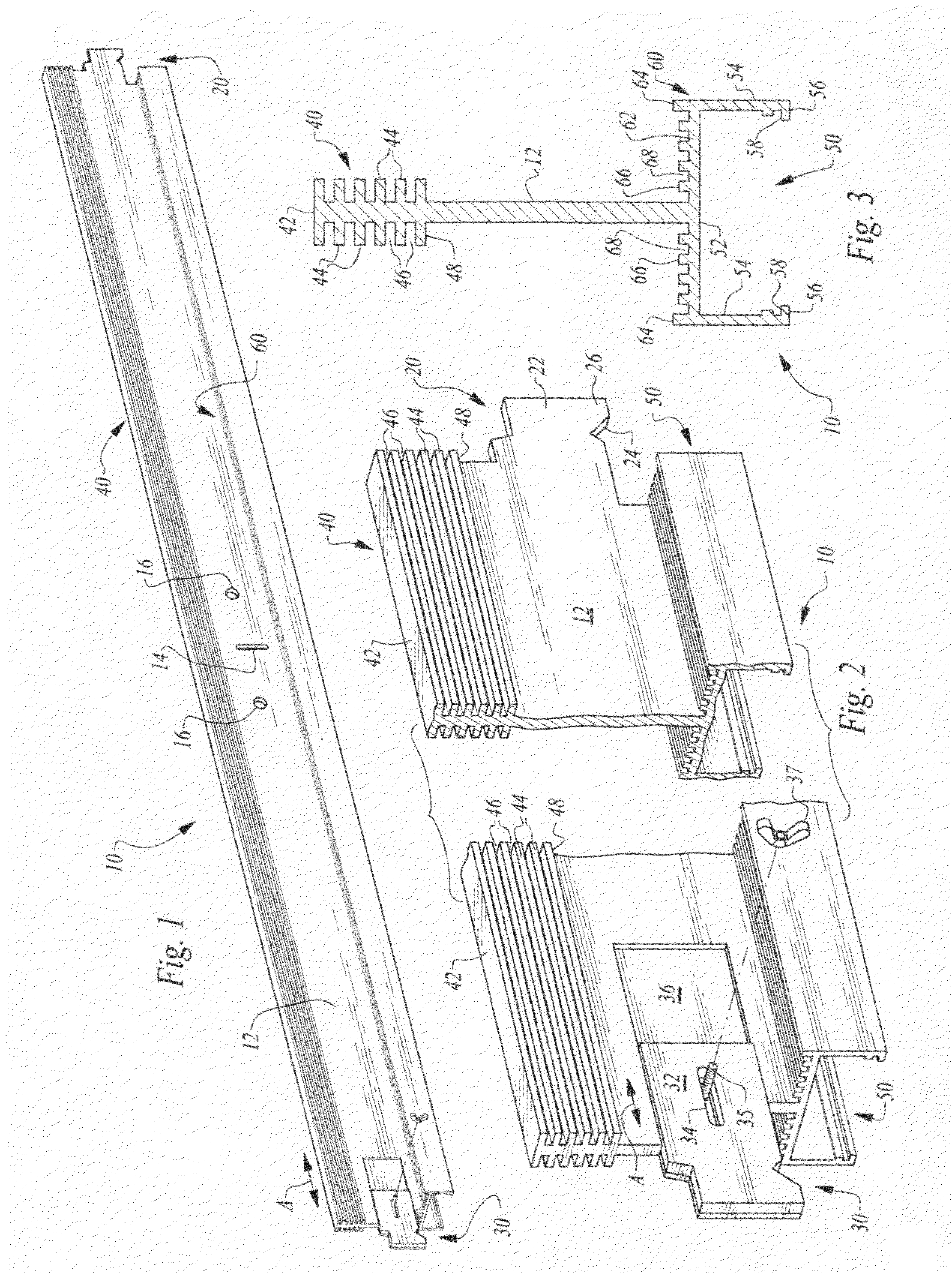

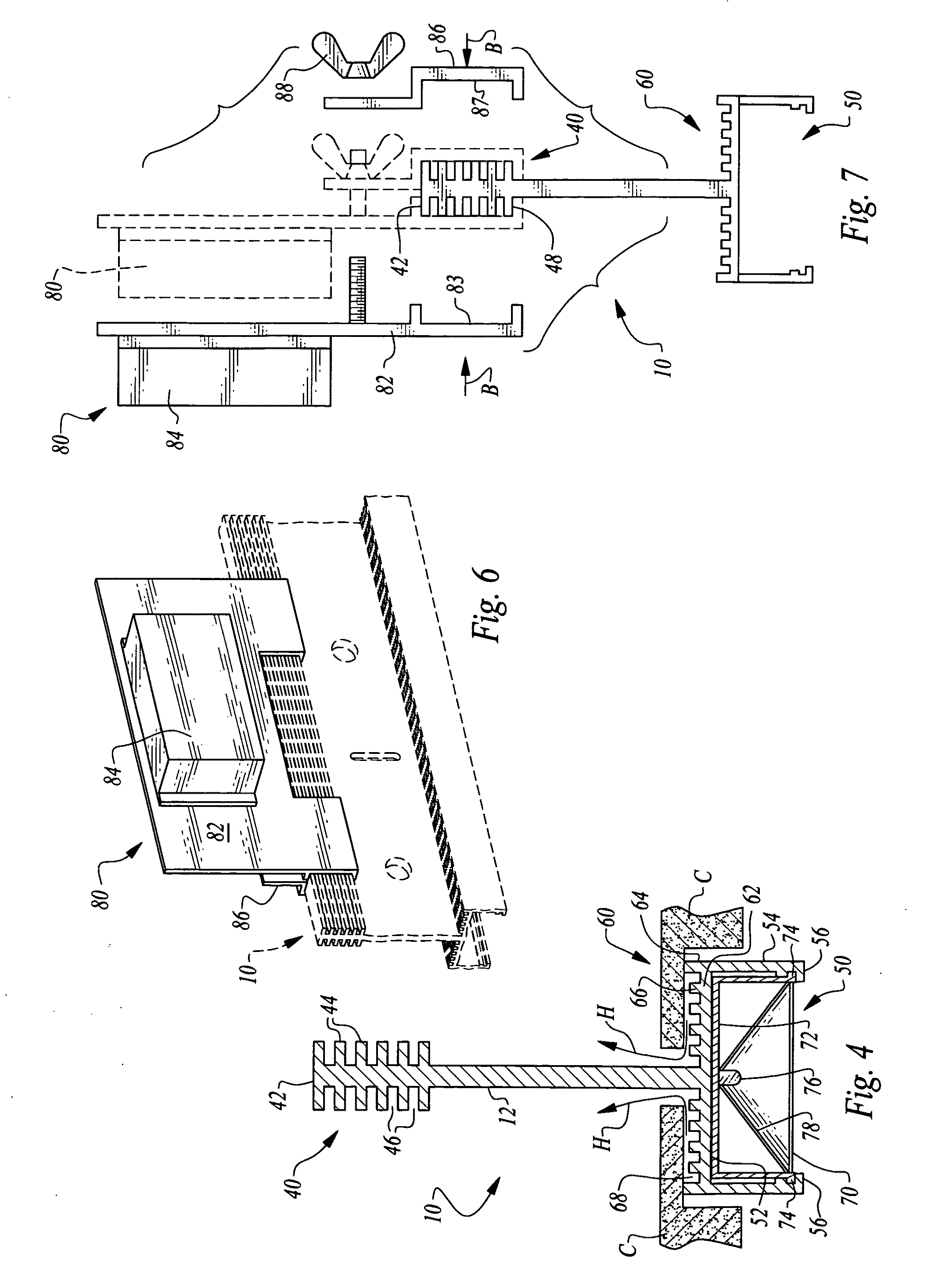

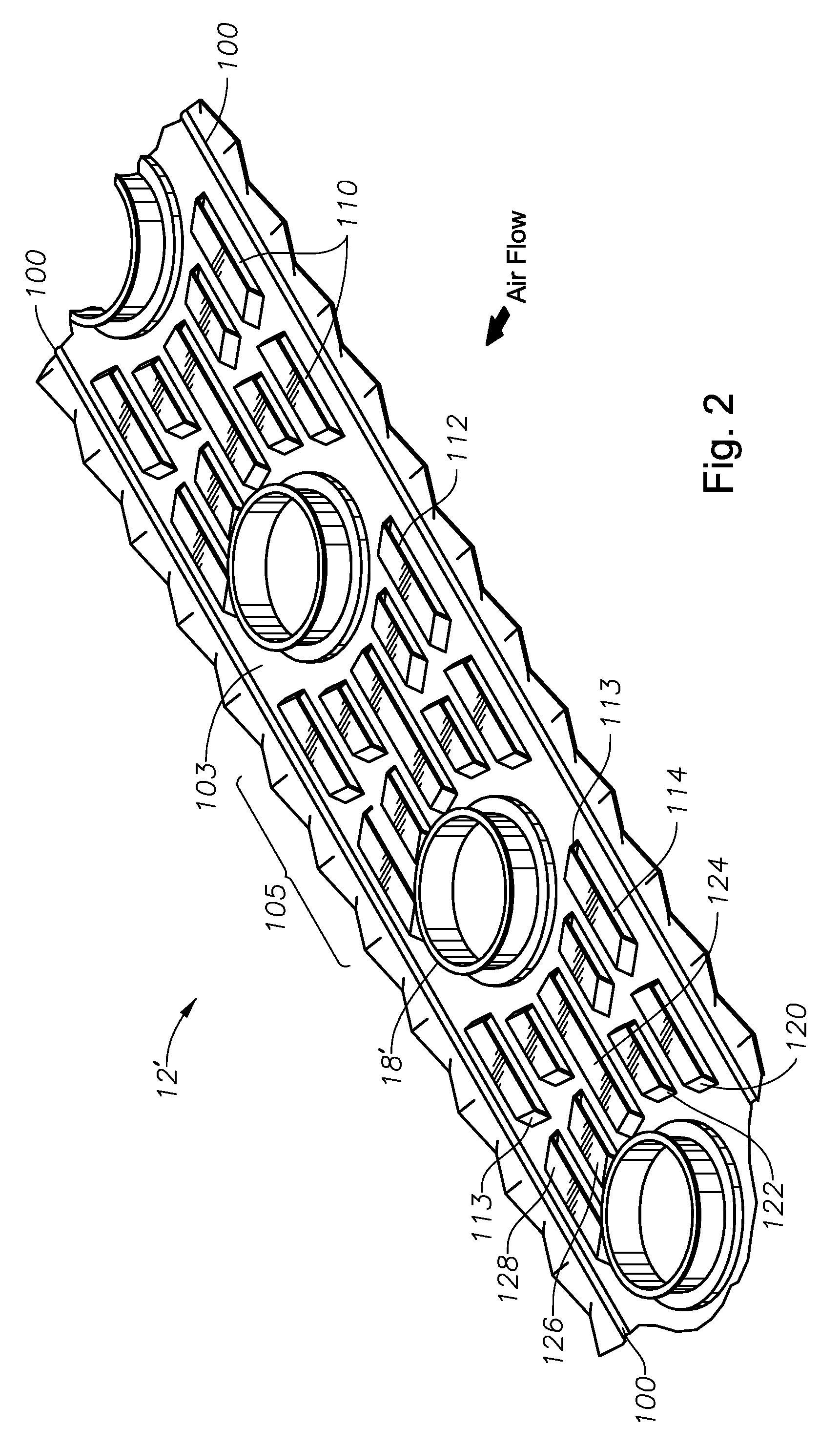

T-bar for suspended ceiling with heat dissipation system for LED lighting

ActiveUS20110222270A1Improve lighting effectsMinimize energy utilizedPlanar light sourcesCeilingsEffect lightEngineering

The T-bar includes an elongate rigid spine extending between terminal ends including either a fixed anchor or adjustable anchor for attachment to adjacent T-bars or other supports. An upper heat sink is provided on an upper portion of the spine to enhance heat transfer from the T-bar to air surrounding upper portions of the T-bar. A light housing is provided on a lower portion of the T-bar which is configured to support a lighting module therein, such as a light emitting diode (LED) light. A lower heat sink is provided above this light housing and integrated into a rest shelf which supports ceiling tiles adjacent the T-bar. A power supply is provided which can be removably attached to the T-bar and provide appropriately conditioned power for the lighting module.

Owner:JLC TECH IP LLC

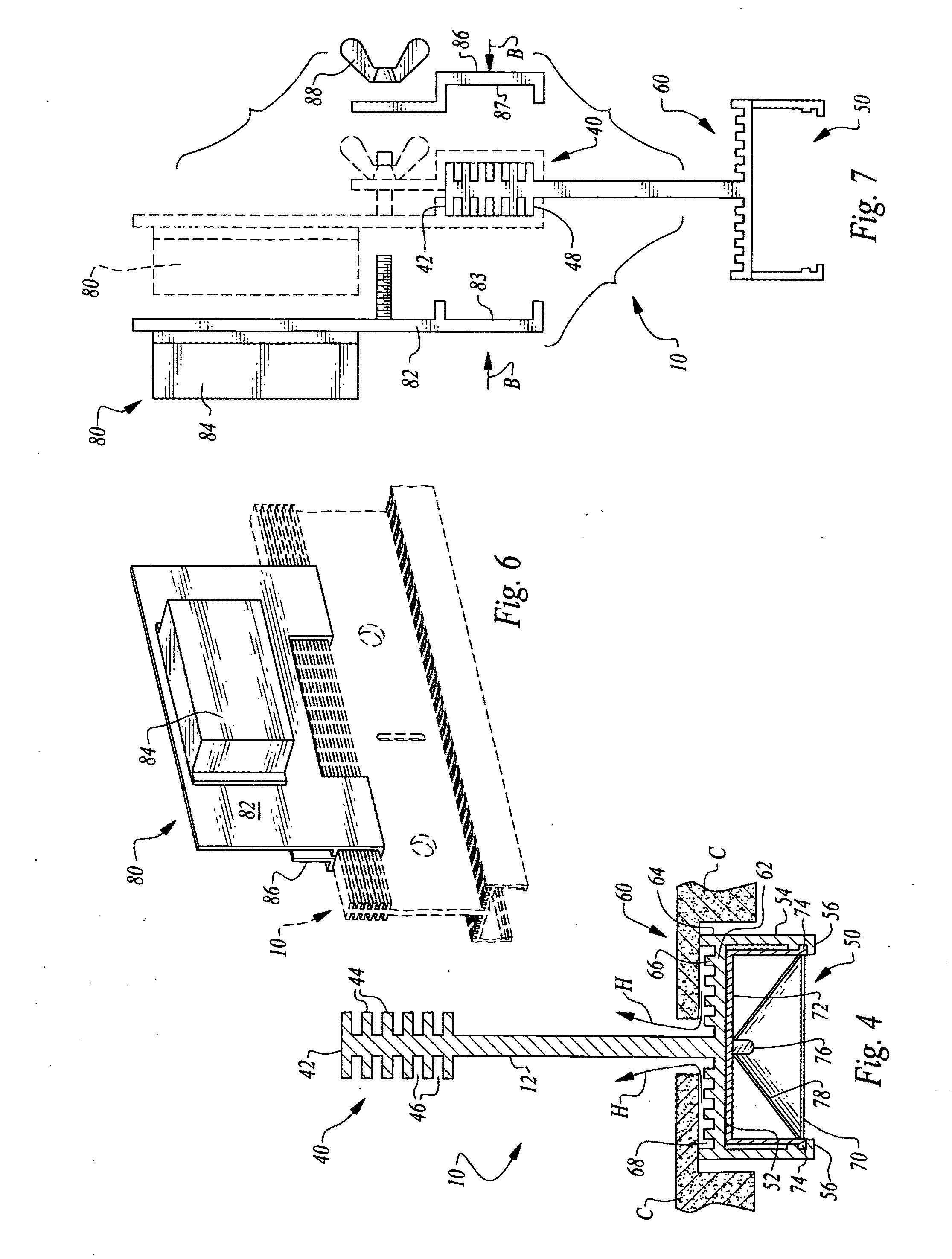

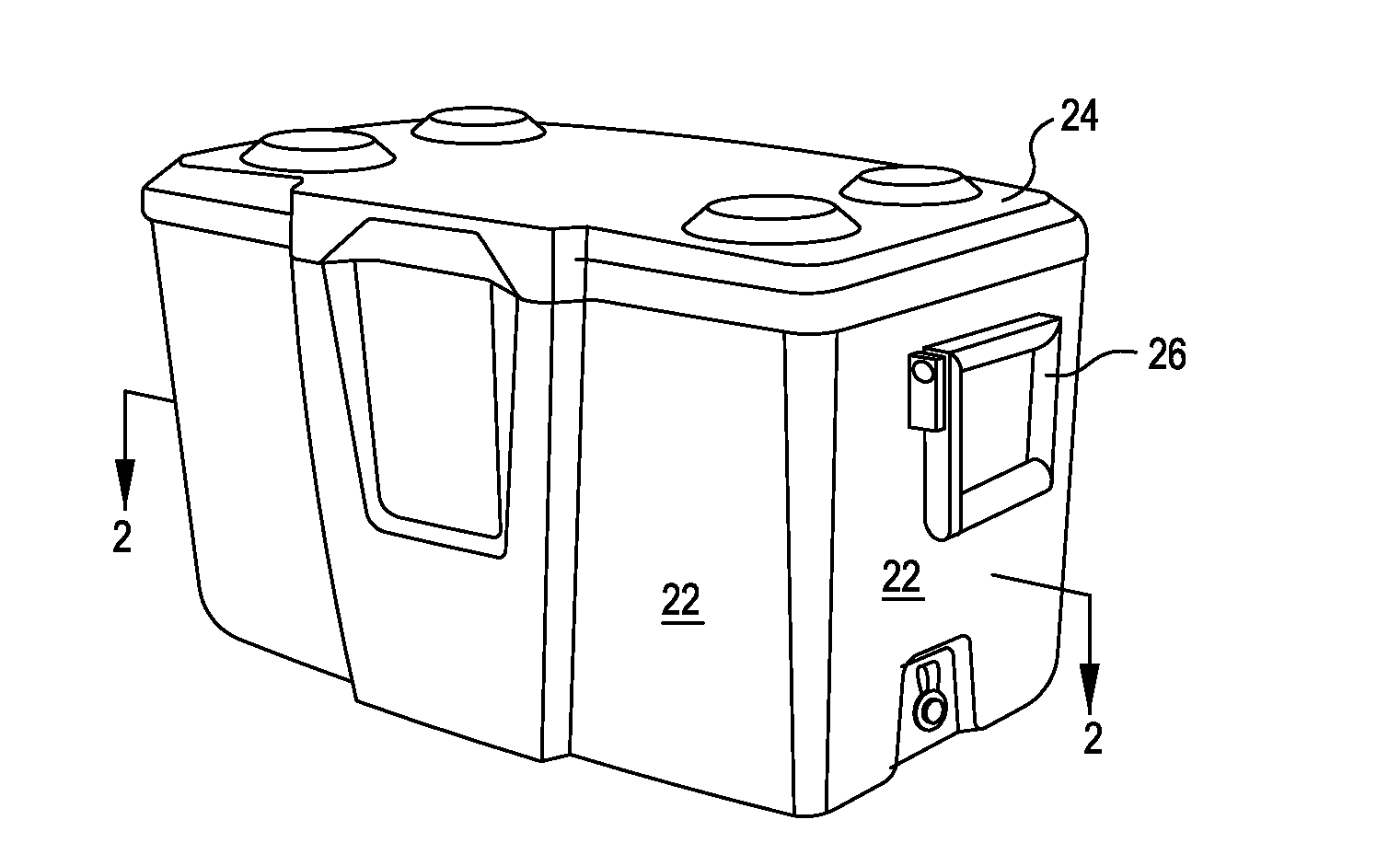

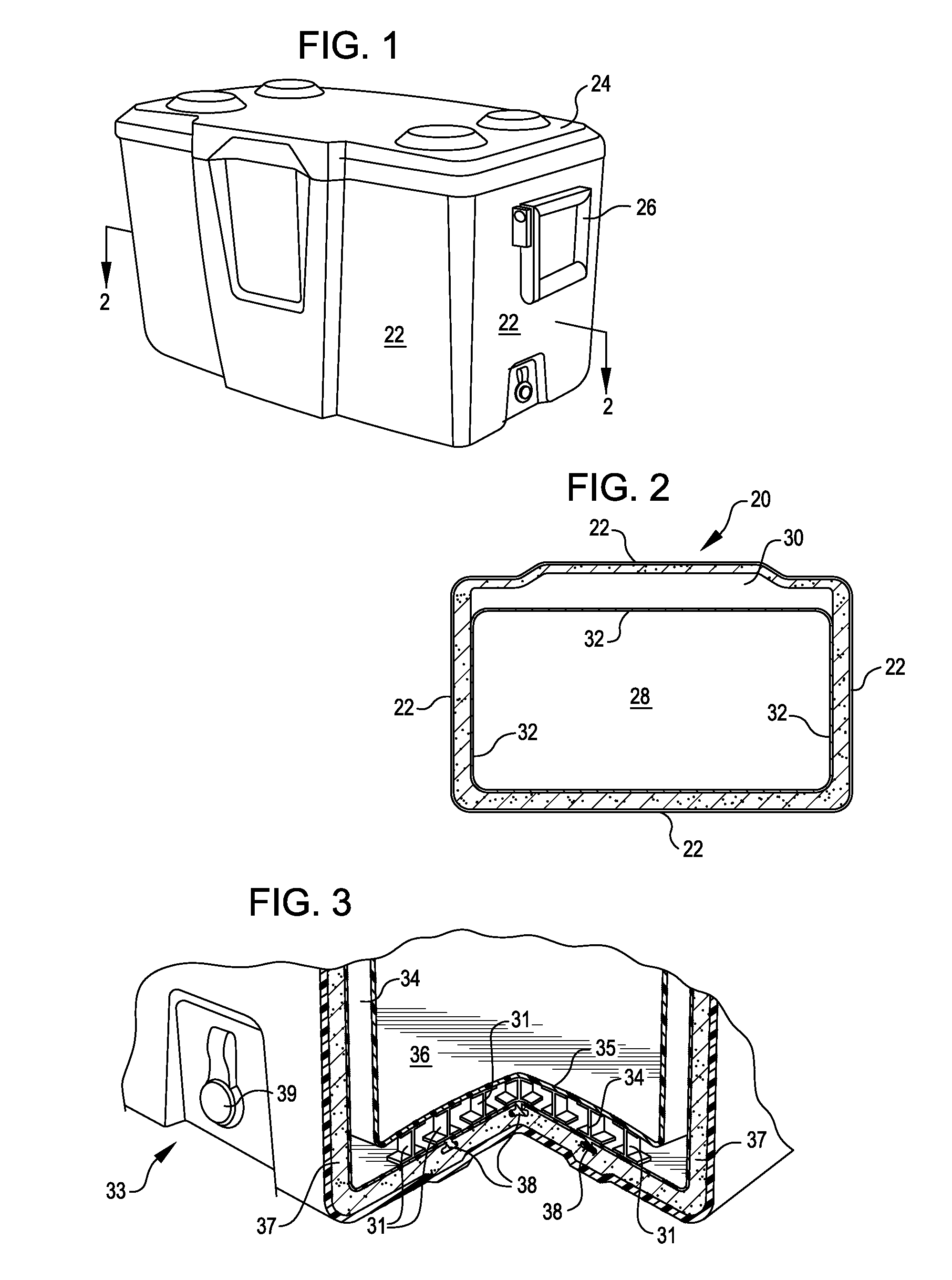

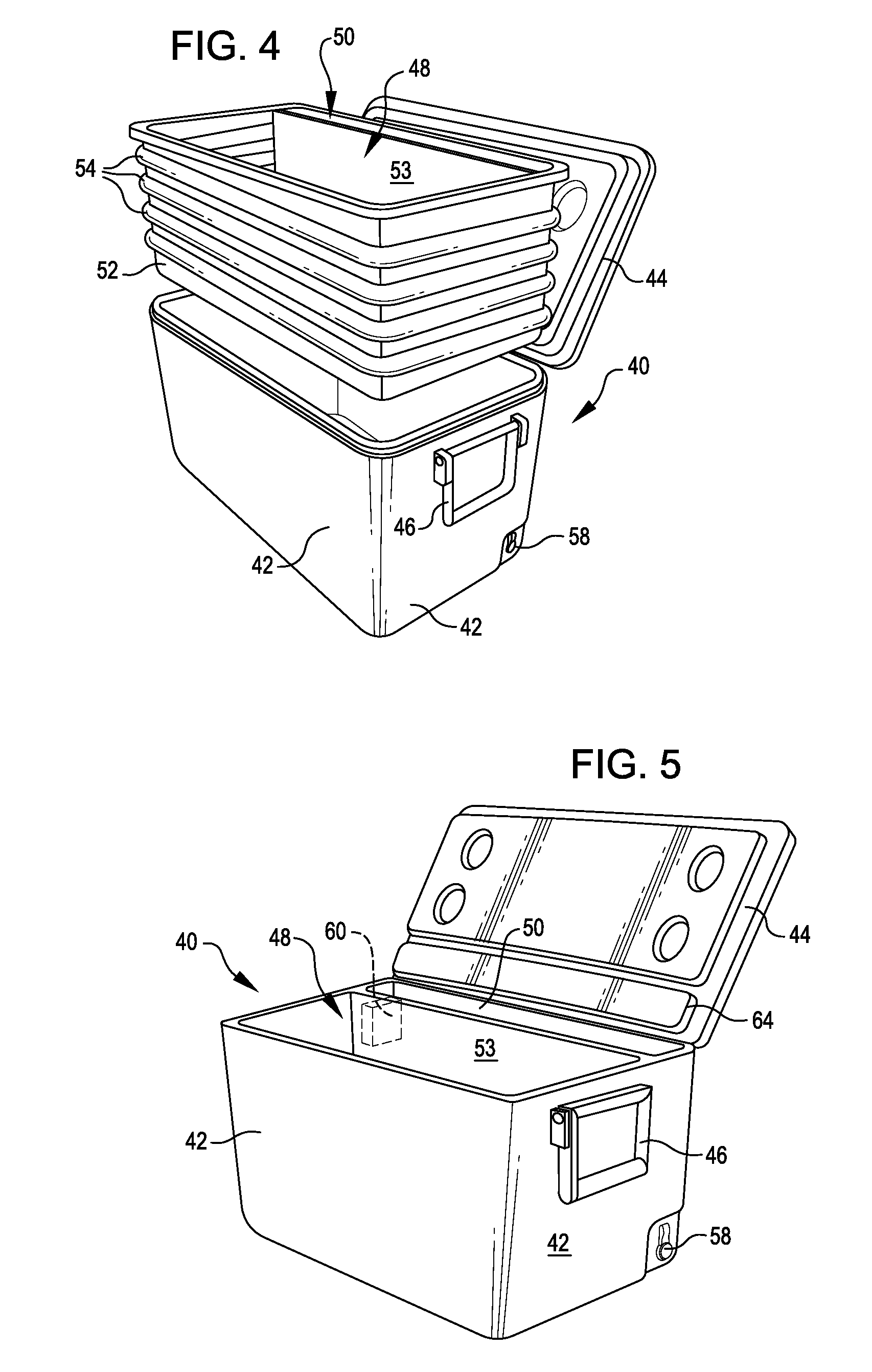

Insulated container utilizing non-contact cooling

InactiveUS20080178629A1Maximize heat transferLighting and heating apparatusInternal framesEngineeringCooling medium

An insulated container that provides non-contact cooling. A cooling medium is maintained in a reservoir or pocket that is separate from a food compartment. In an embodiment, the insulated container includes a tube or manifold for moving cold water around the food compartment. A battery powered, solar powered, or hand operated pump may be provided for moving the fluids around the food compartment. A liner for the food compartment may be formed of a highly thermally conducted material, such as aluminum, to maximize heat transfer between reservoir, and / or the tube or manifold system and the liner.

Owner:THE COLEMAN CO INC

Downward Firing Oxygen-Fuel Burners for Glass Melting Furnaces

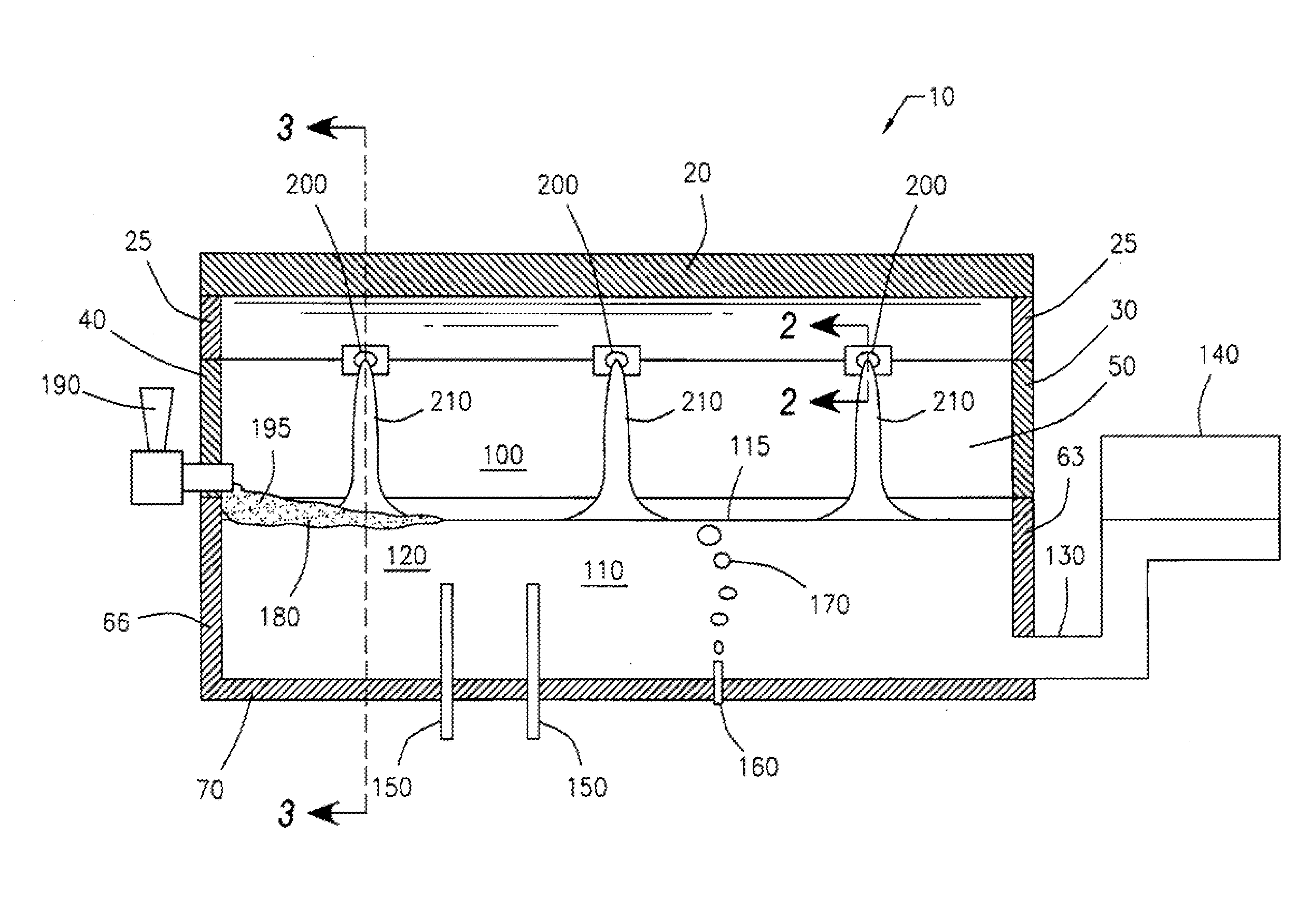

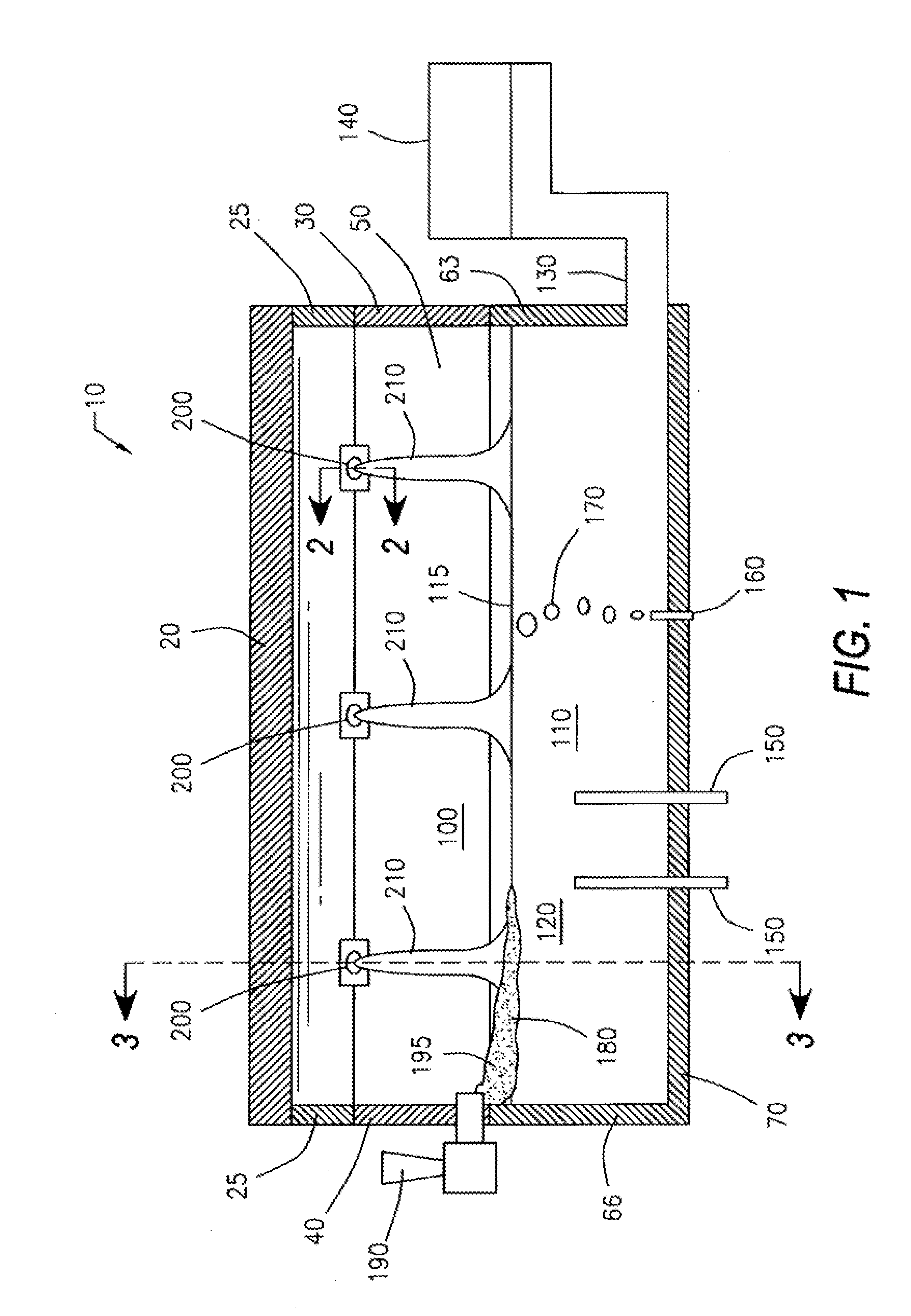

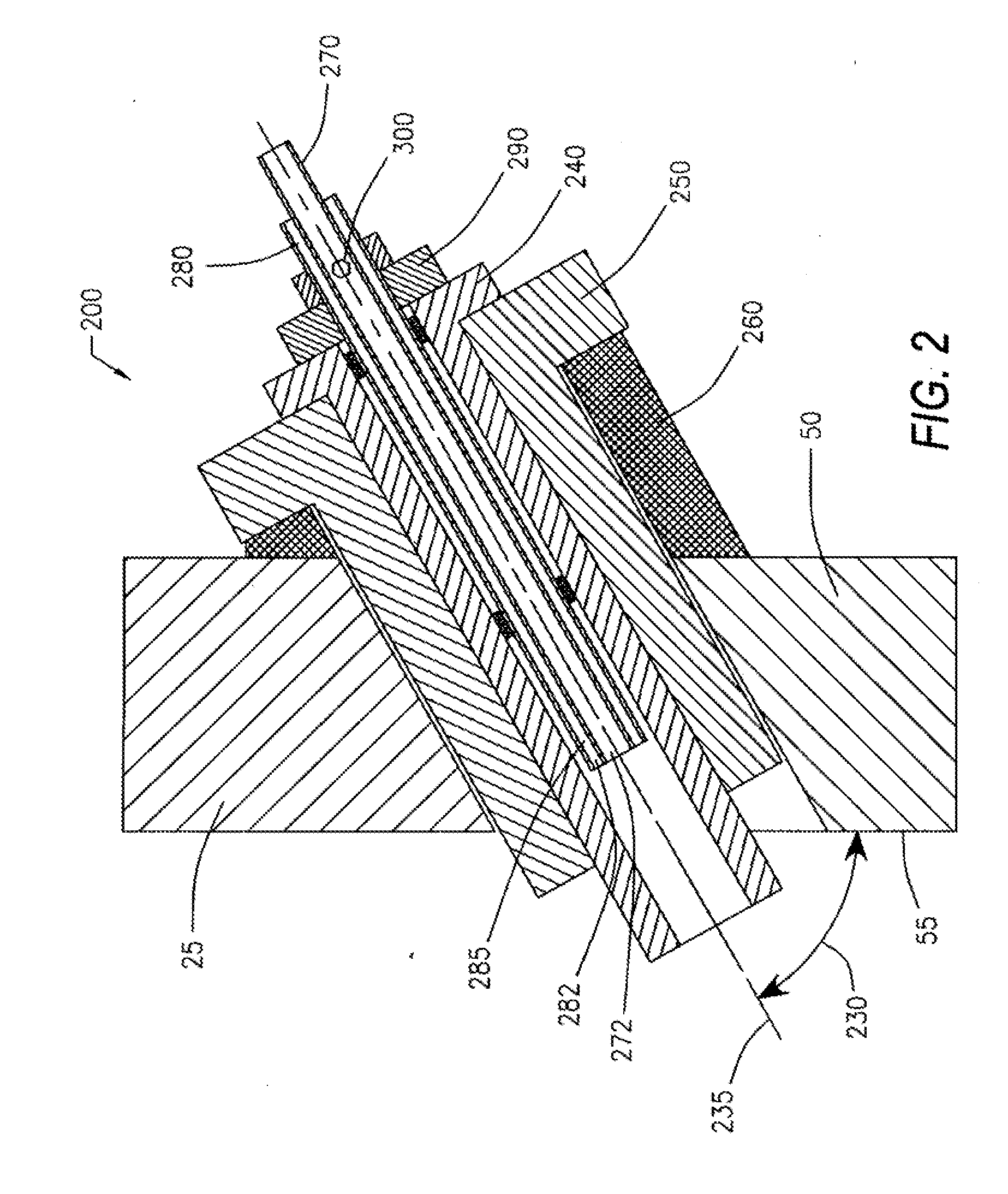

InactiveUS20100300153A1Maximize convective transferMaximize radiant heat transferCharging furnaceGlass furnace apparatusCombustorEngineering

This invention relates to a glass melting furnace with downward firing oxygen-fuel burners placed in the breast walls of the combustion space and adjacent to the skew block. The downward firing oxygen-fuel burner may be placed at an angle so that the oxygen-fuel flame from the downward firing oxygen-fuel burner impinges on the upper surface of the glass bath. The placement and angle of the downward firing oxygen-fuel burner may maximize the amount of heat transferred to the batch cover or the molten glass, ensure the formation of high quality glass products, and protect the integrity of the downward firing oxygen-fuel burners and the glass melting furnace.

Owner:ZHANG ZHIFA +1

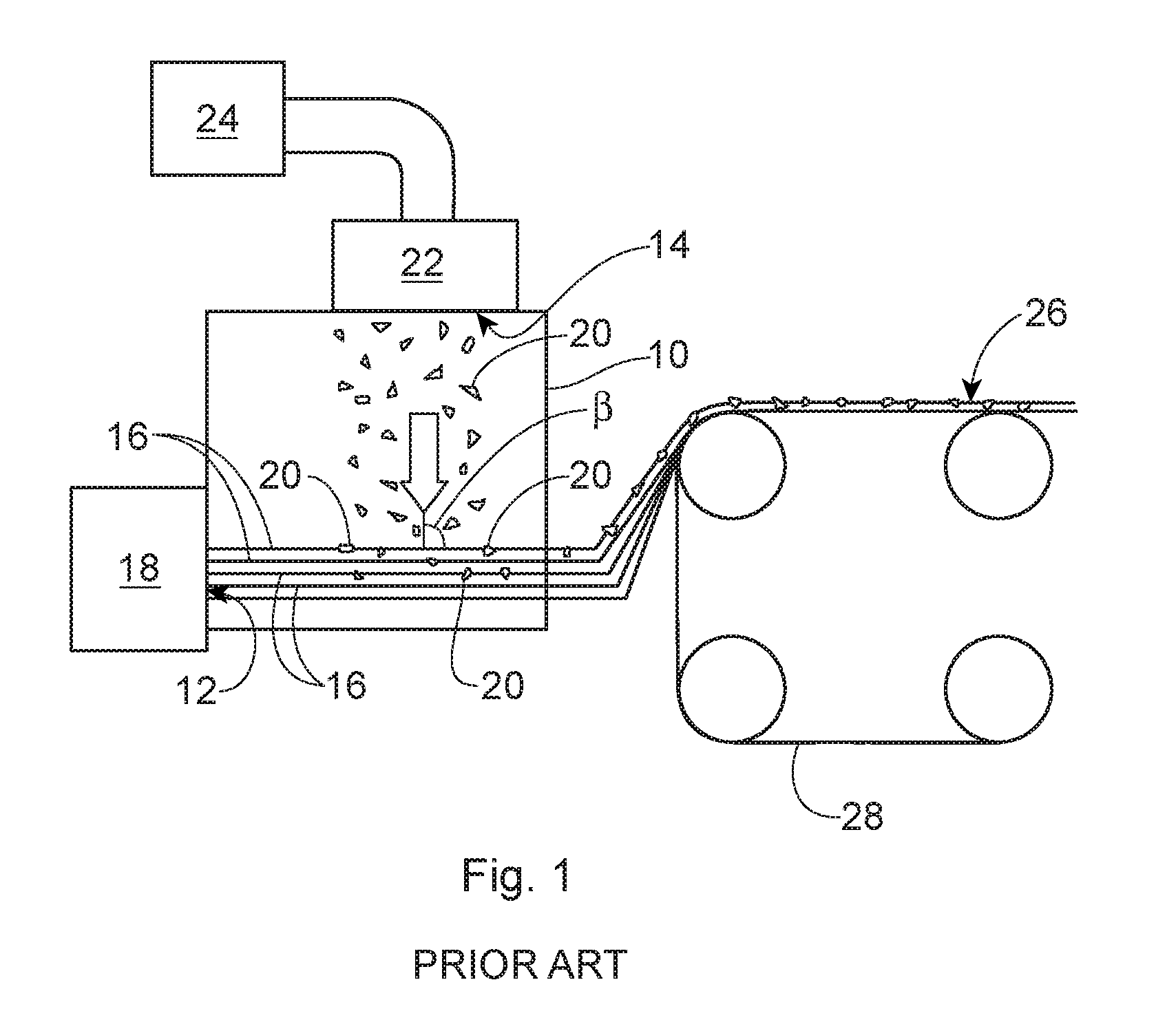

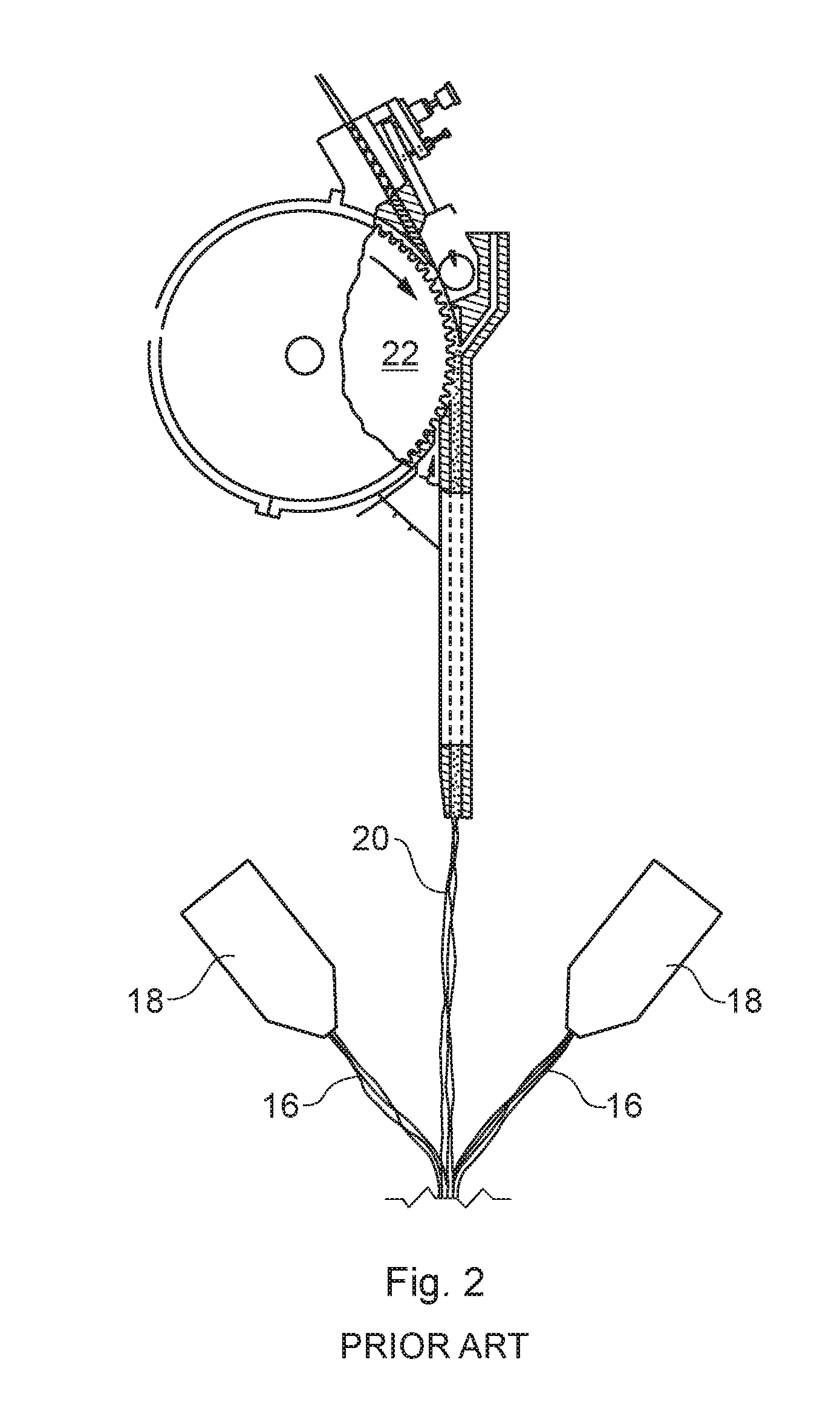

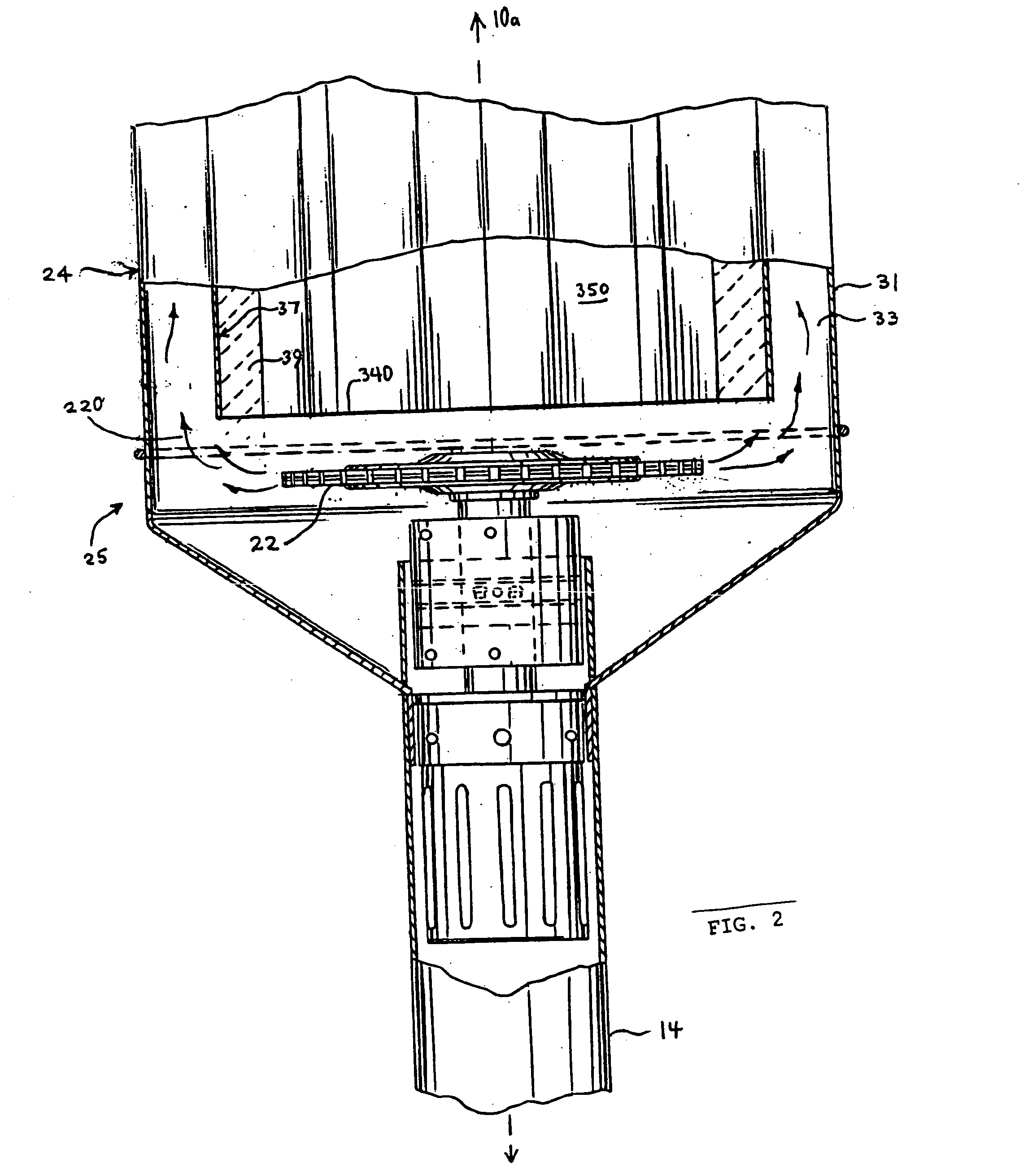

Coforming Processes and Forming Boxes Used Therein

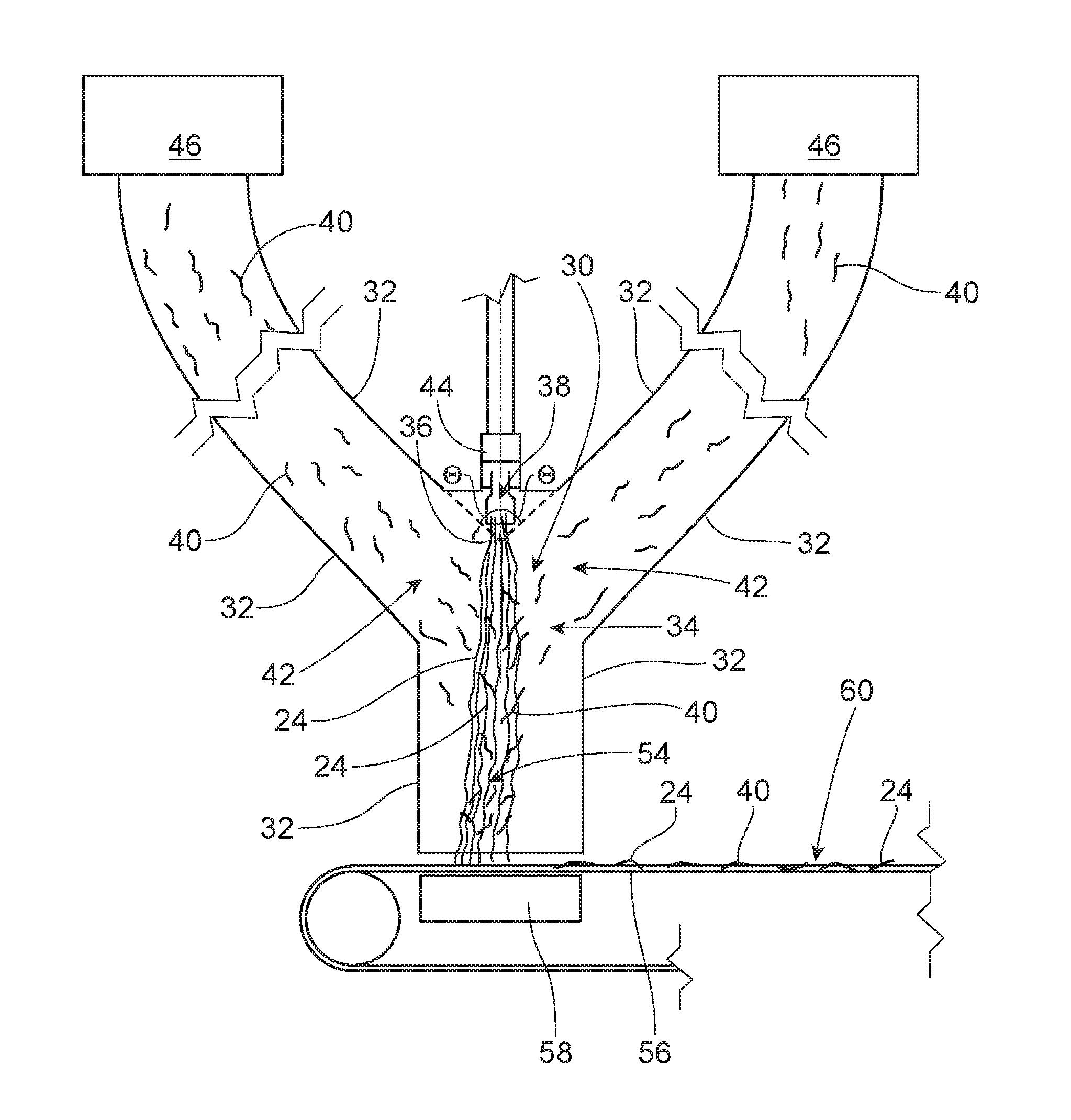

ActiveUS20160355950A1Improve stabilityImproved sheet formationWet spinning methodsNon-woven fabricsFiberPolymer chemistry

Coforming processes for commingling two or more separate materials, for example solid additives, for example fibers and / or particulates, and filaments, and equipment; namely, forming boxes, useful in such coforming processes and more particularly to coforming processes for commingling filaments with one or more fibers, such as pulp fibers, and forming boxes useful therein are provided.

Owner:THE PROCTER & GAMBLE COMPANY

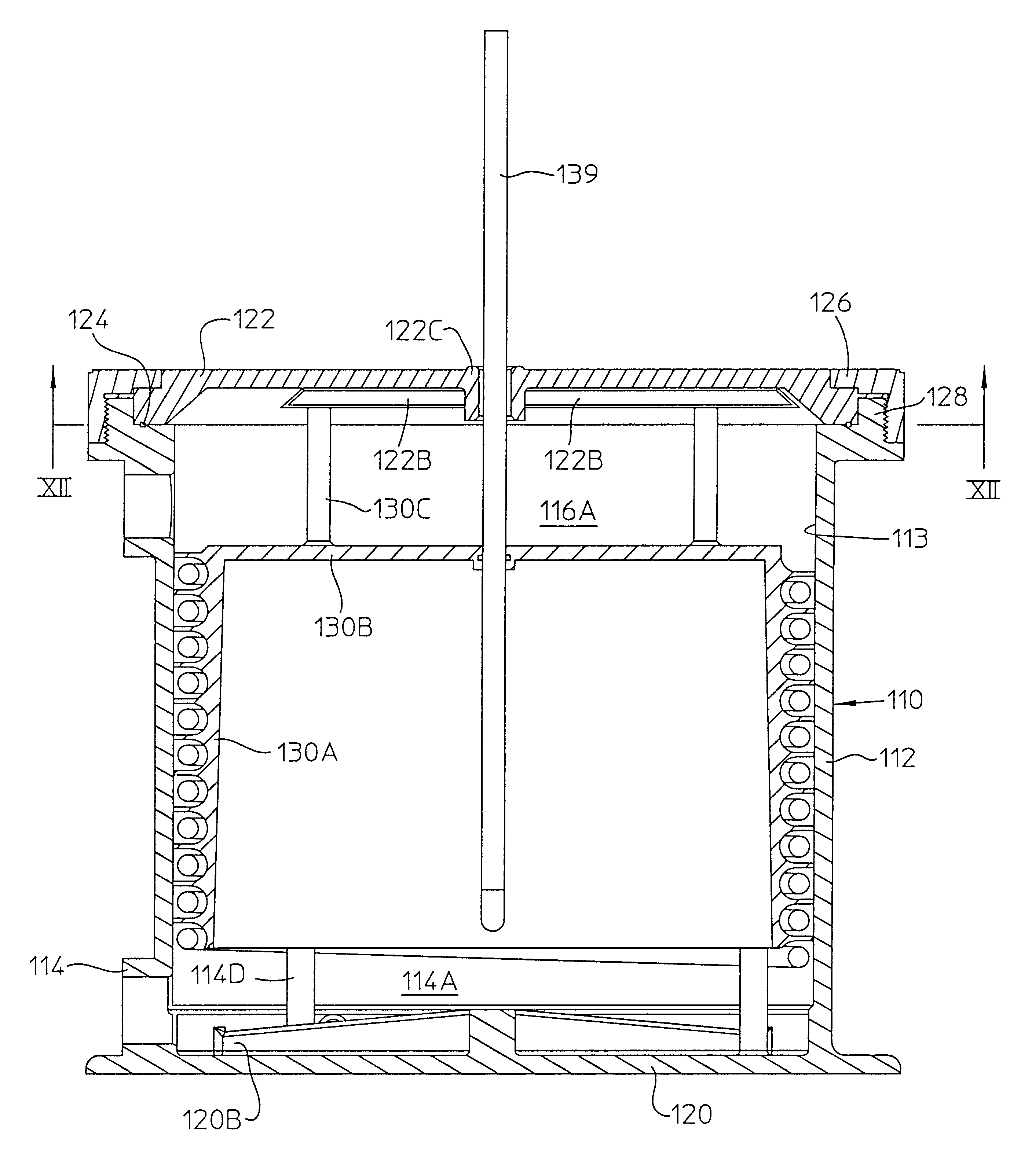

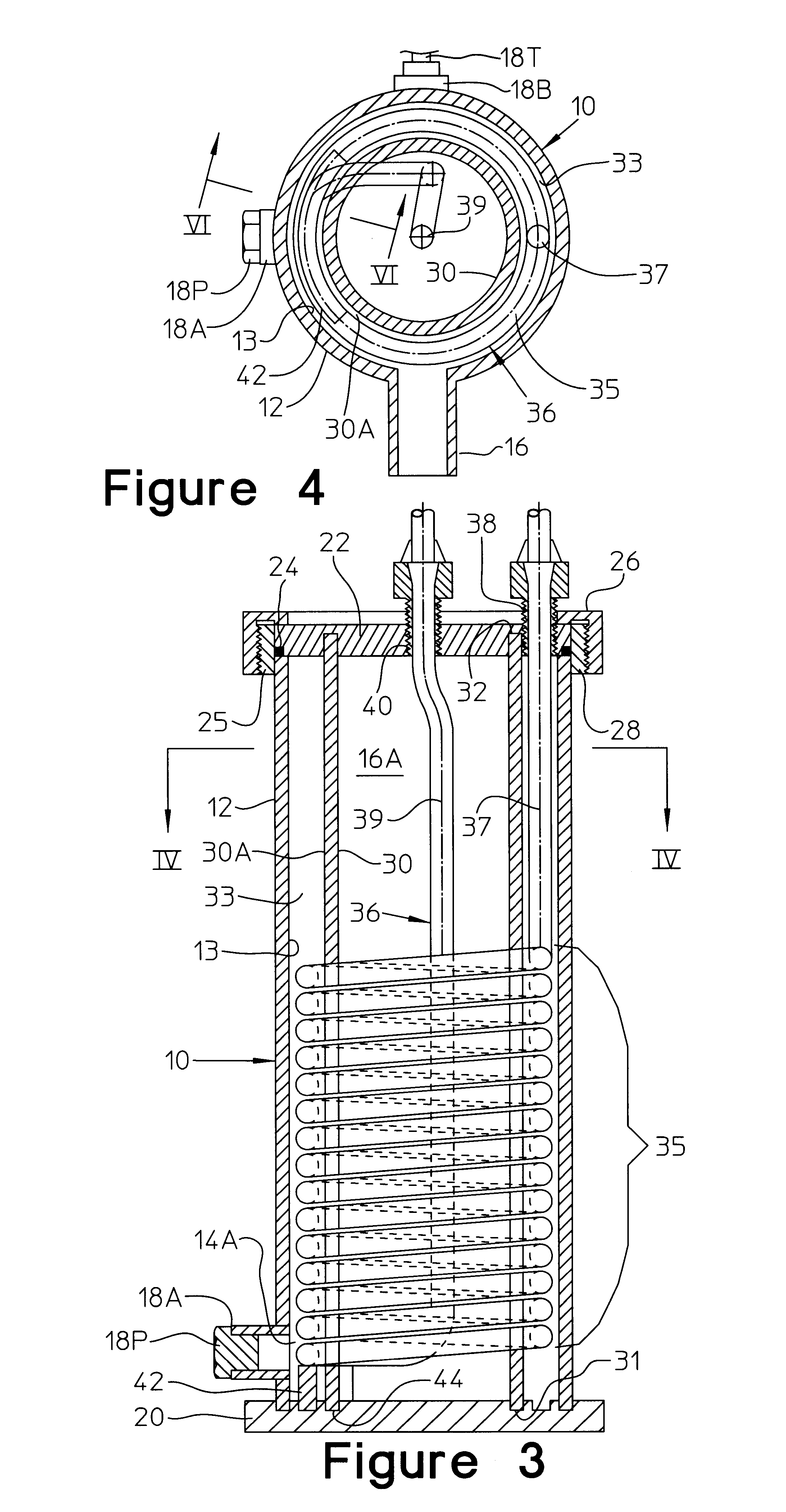

Method and apparatus for optimizing heat transfer in a tube and shell heat exchanger

InactiveUS6293335B1Increased turbulenceMaximize heat transferHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

A tube and shell heat exchanger having a transversely oriented inlet port and a spirally coiled heat transfer tube contained within an arcuate chamber created by an internal baffle in which the water to be conditioned travels along a helical pathway in which the flow has minimized water depth and high turbulence. The tube and shell heat exchanger maximizes heat transfer capability in a relatively easy to assemble design to make feasible the use of a higher cost material for the tubing such as titanium in a wide range of applications.

Owner:AQUACAL

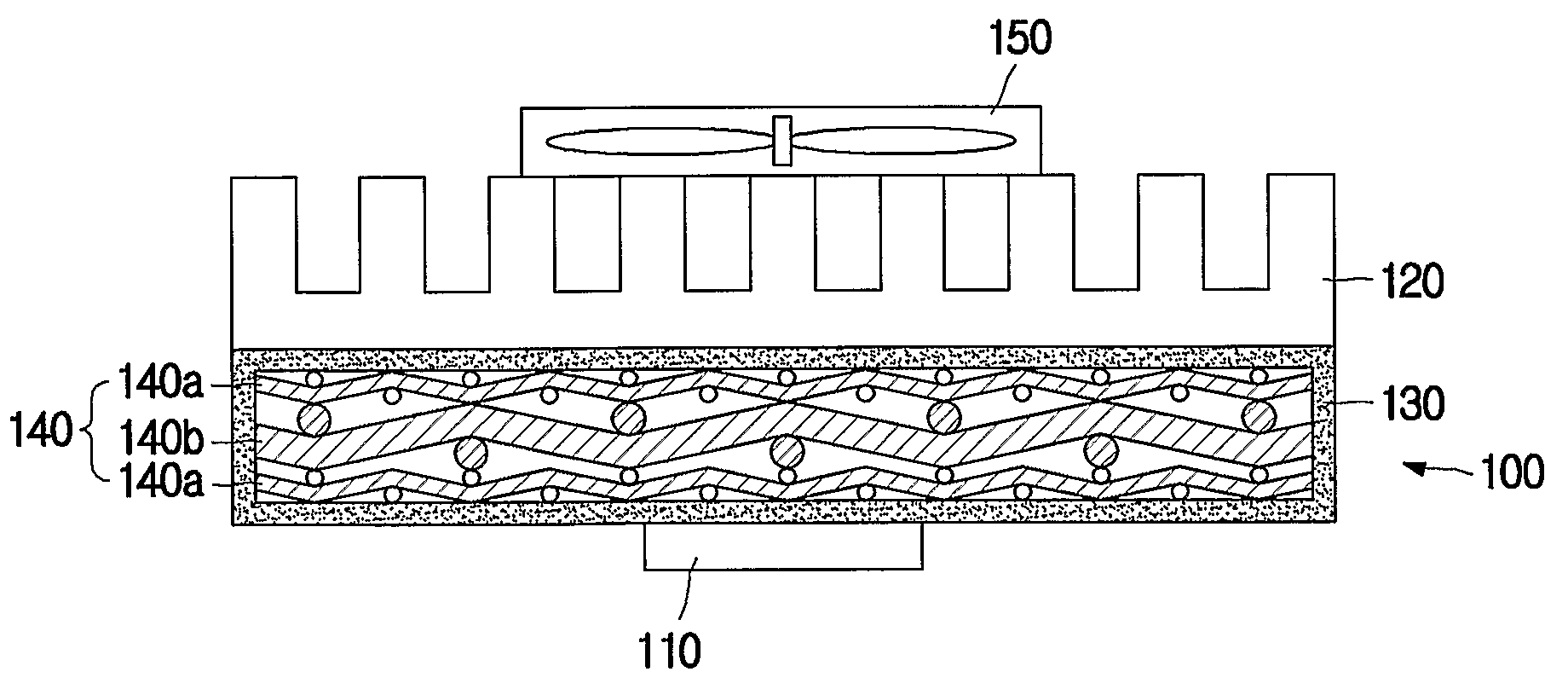

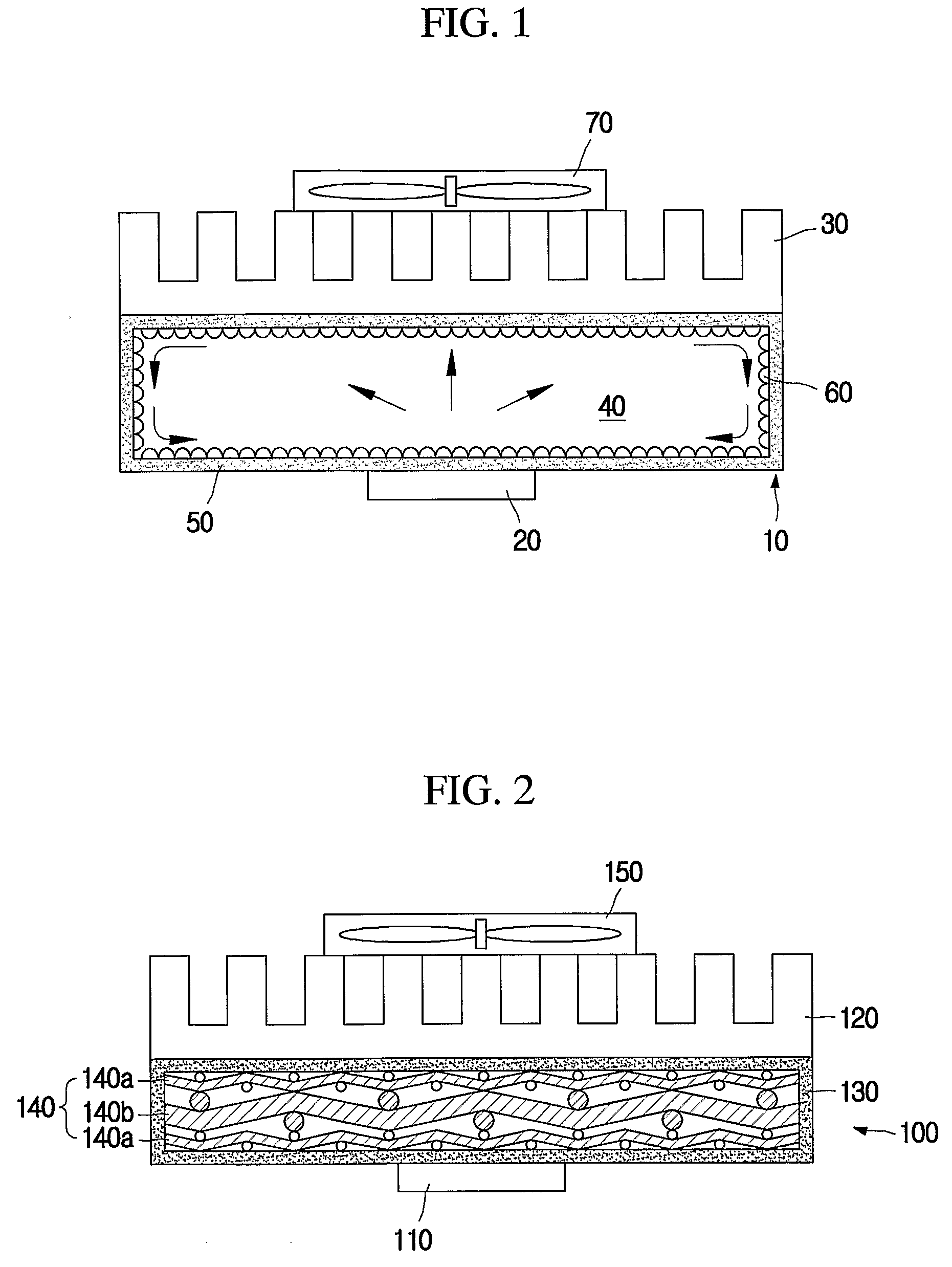

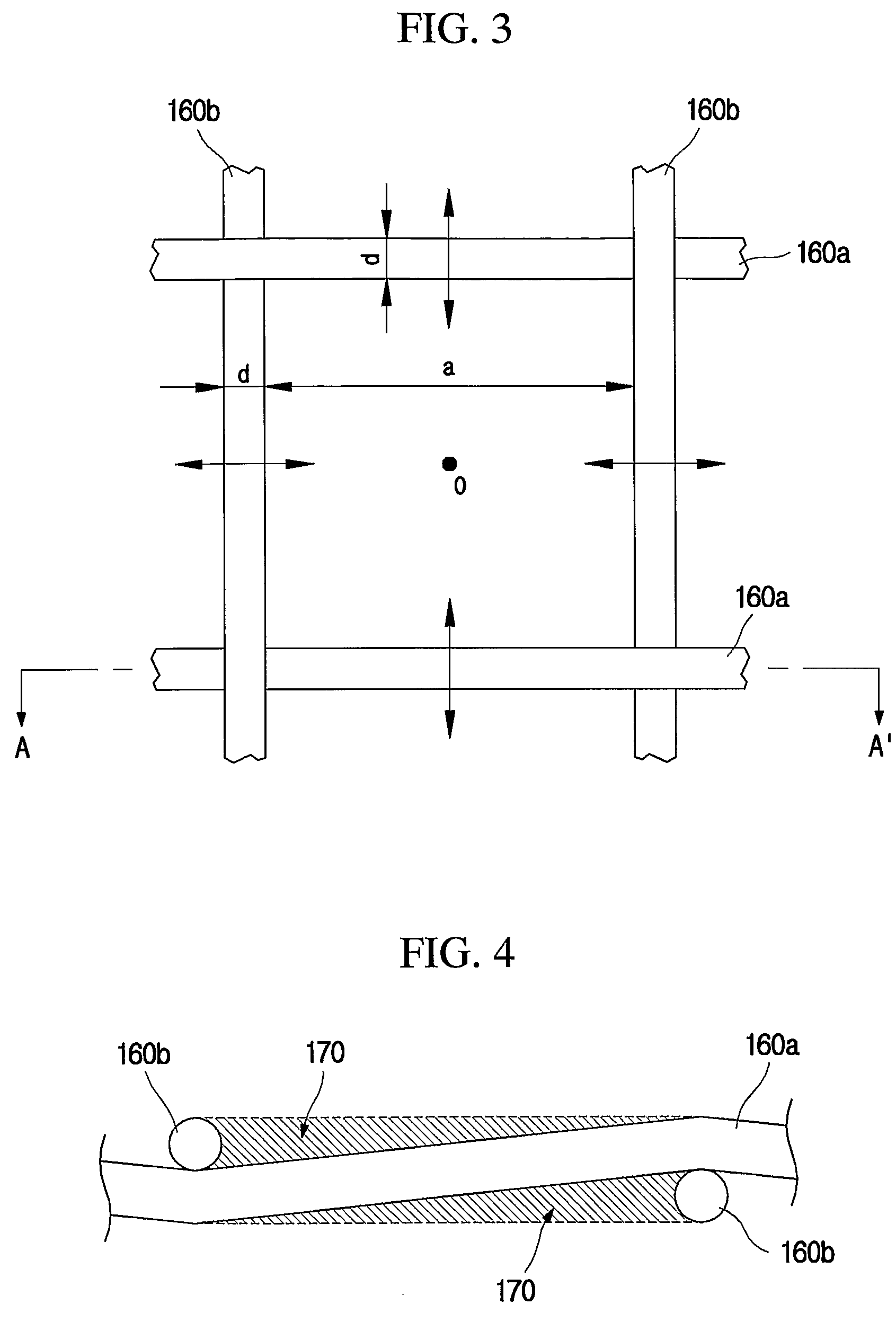

Flat plate heat transfer device

InactiveUS20070107875A1Decrease distanceMaximize heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesCoarse meshWorking fluid

Disclosed is a flat plate heat transfer device, which includes a thermally conductive flat case installed between a heat source and a heat emitting unit and containing a working fluid evaporated with absorbing heat from the heat source and condensed with emitting heat to the heat emitting unit; and a mesh layer aggregate installed in the flat case and having a structure that a fine mesh layer for providing a flowing path of liquid and a coarse mesh layer for providing a flowing path of liquid and a dispersion path of vapor simultaneously are laminated. On occasions, the coarse and the fine mesh layers are alternately laminated repeatedly, and the fine mesh layer is replaced with a wick structure. The coarse mesh layer is preferably a screen mesh layer with wire diameter of 0.2 mm˜0.4 mm and mesh number of 10˜20. This device improves heat transfer performance.

Owner:LS MTRON LTD

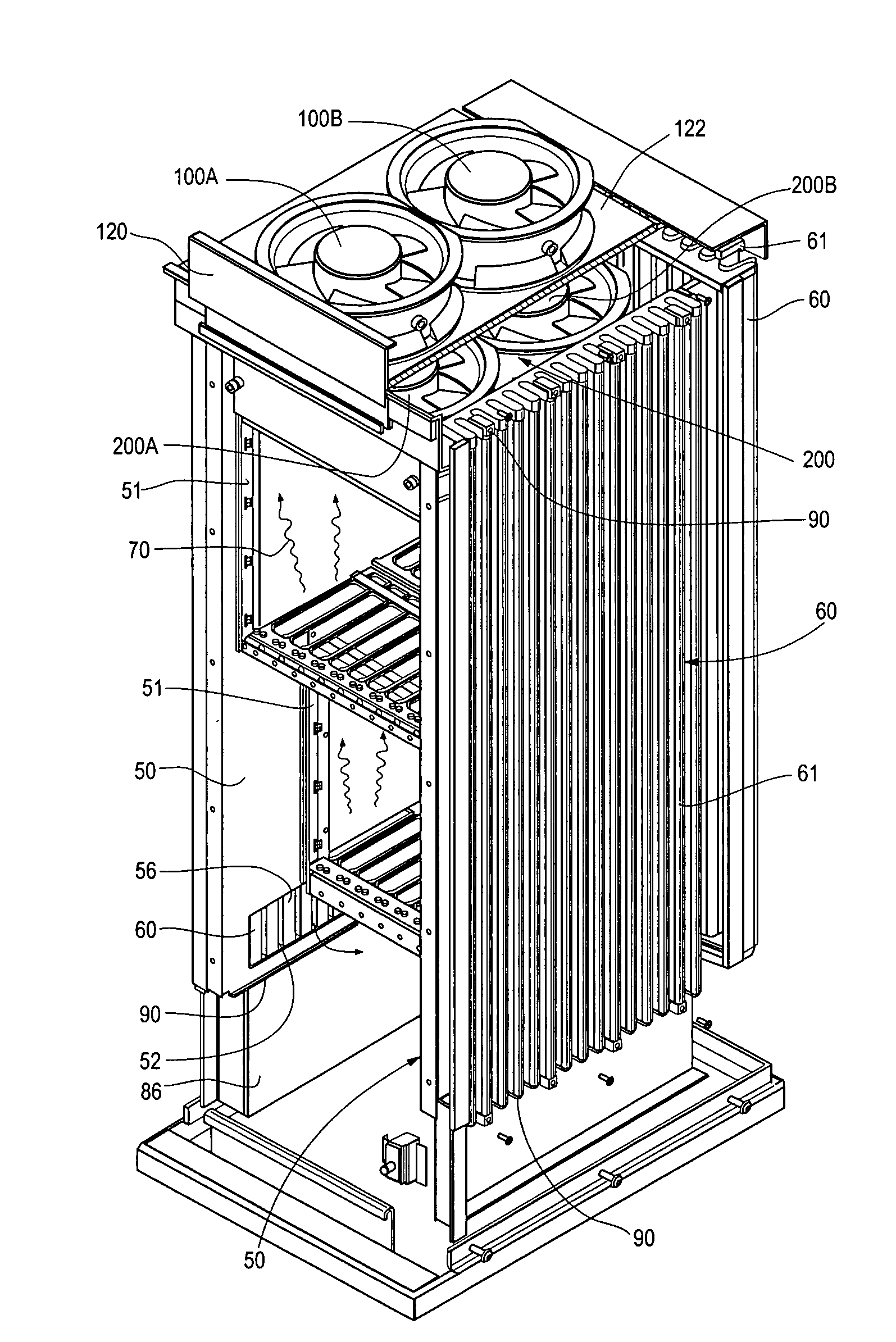

Electronics cabinet with internal air-to-air heat exchanger

ActiveUS7245485B1Increase surface areaImprove heat transfer performanceDigital data processing detailsCooling/ventilation/heating modificationsAir cycleEngineering

An enclosure has a set of panels forming an outer peripheral skin. A heat exchanger wall is placed within the panels. A first fan arrangement circulates ambient air into a space within the panels and along the exterior surface of the heat exchanger wall and back into the environment. A second fan arrangement circulates air contained within the enclosure against the interior surface of the heat exchanger wall. Heat is transferred through the heat exchanger wall to the ambient air circulated by the first fan. An inner wall is placed adjacent to the interior surface of the heat exchanger wall. The space between the inner wall and the heat exchanger wall forms a space for the air within the interior of the enclosure to circulate by the second fan. The heat exchanger wall provides a barrier isolating the ambient air from the air within the enclosure, preventing dust, humidity and pollutants to enter into the interior of the cabinet in the space surrounding the electronic components.

Owner:UTSTARCOM INC

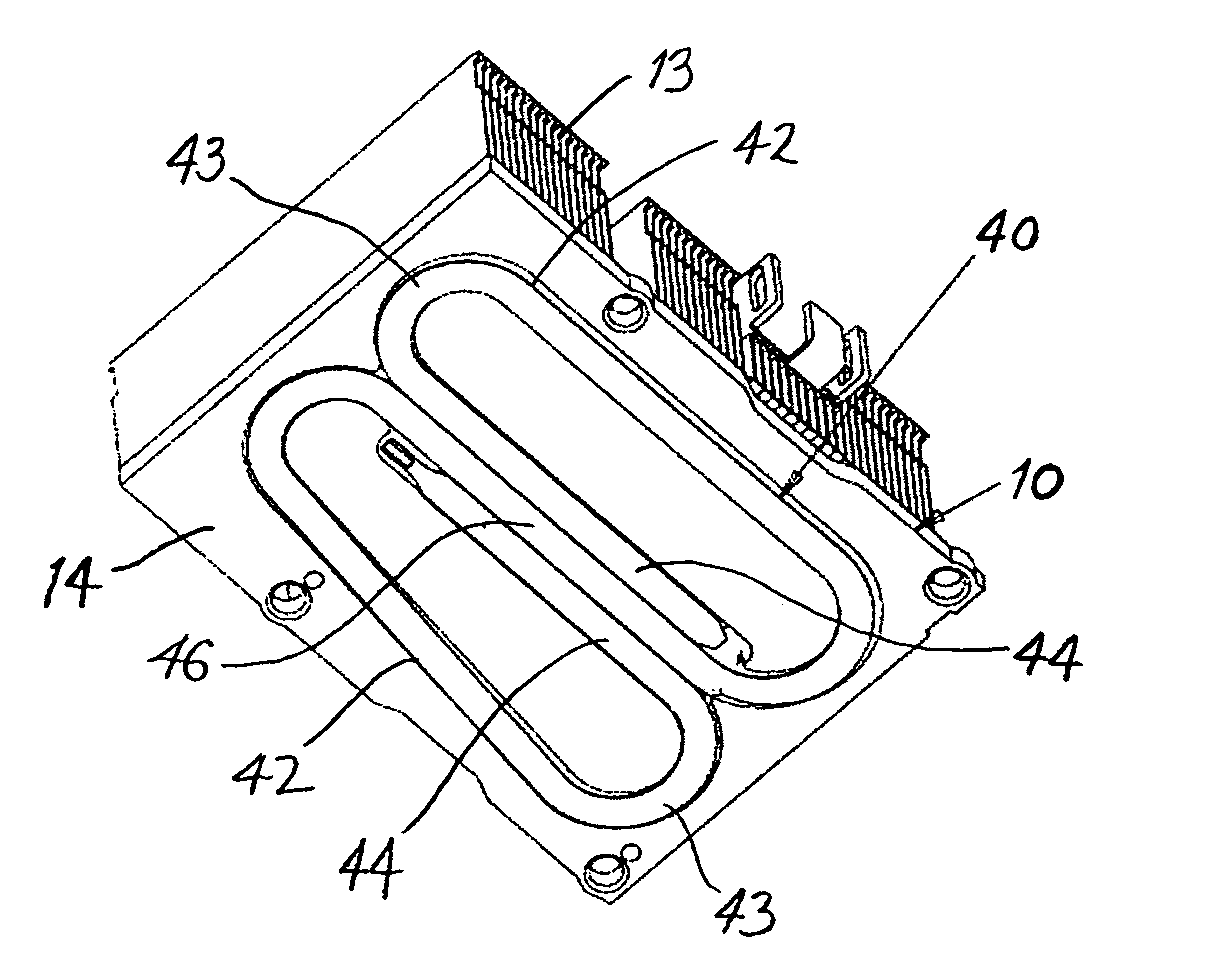

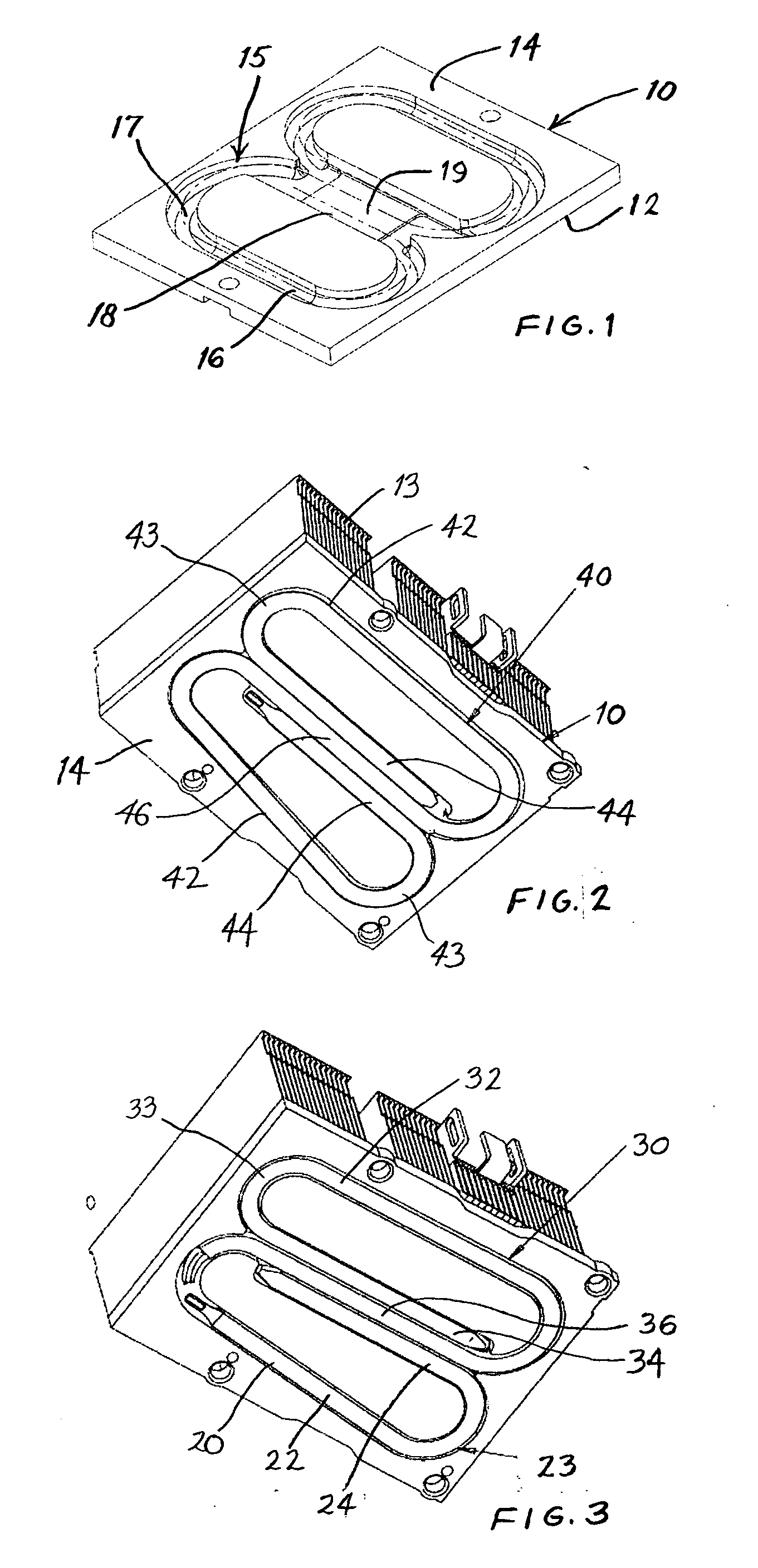

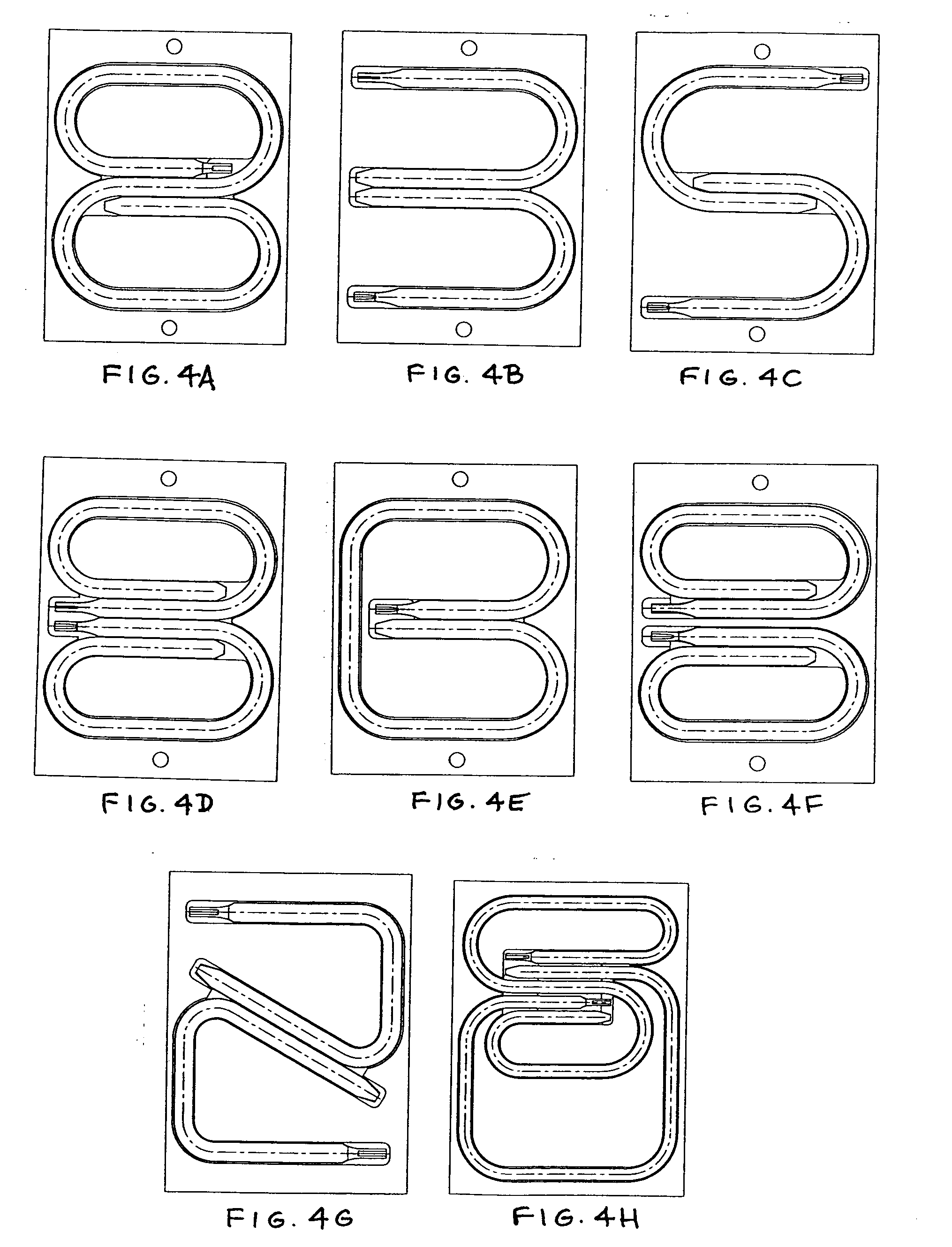

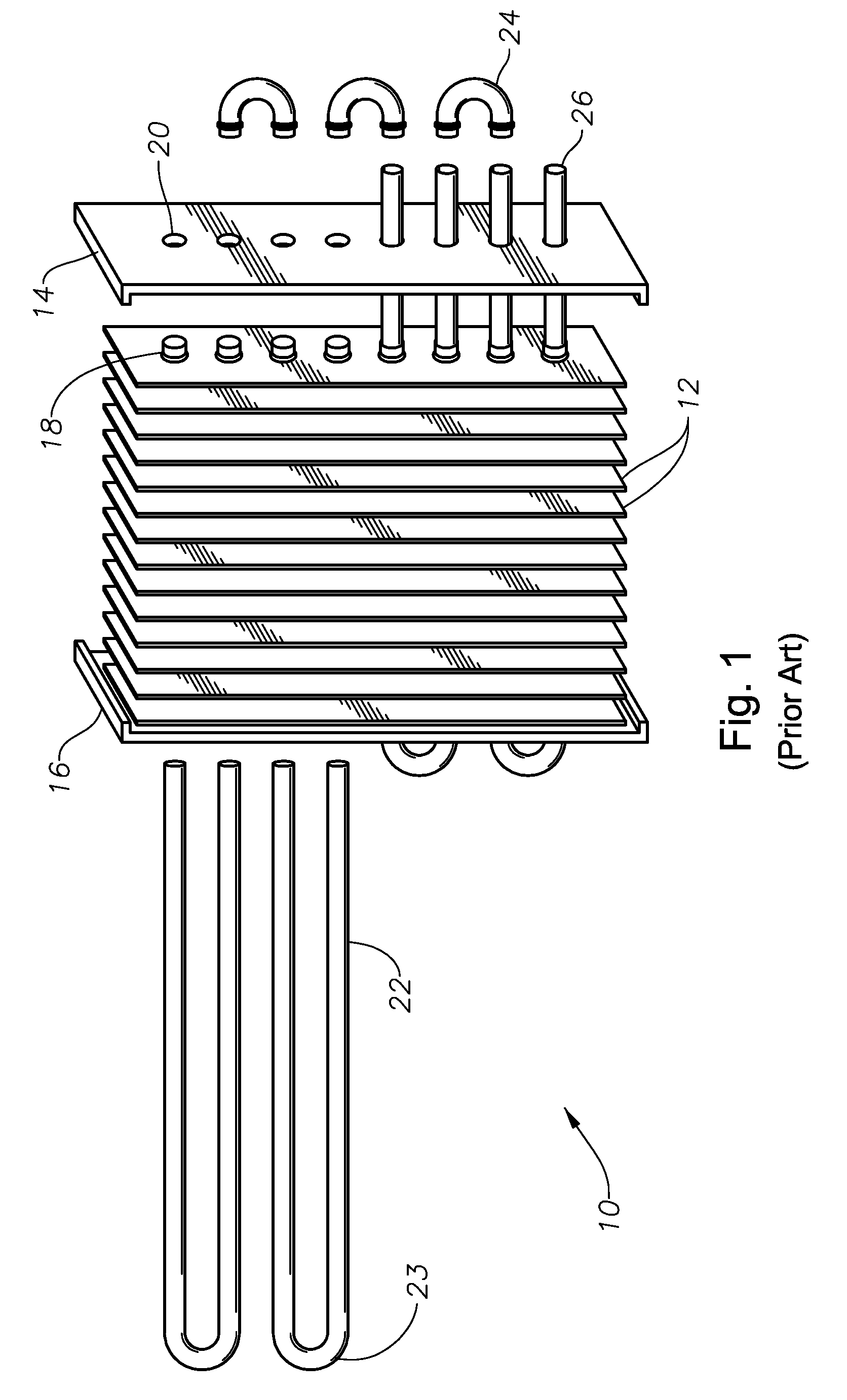

Heat sink base plate with heat pipe

ActiveUS20090260782A1Improve heat resistanceMultiple performanceIndirect heat exchangersHeat exchange apparatusEngineeringHeat pipe

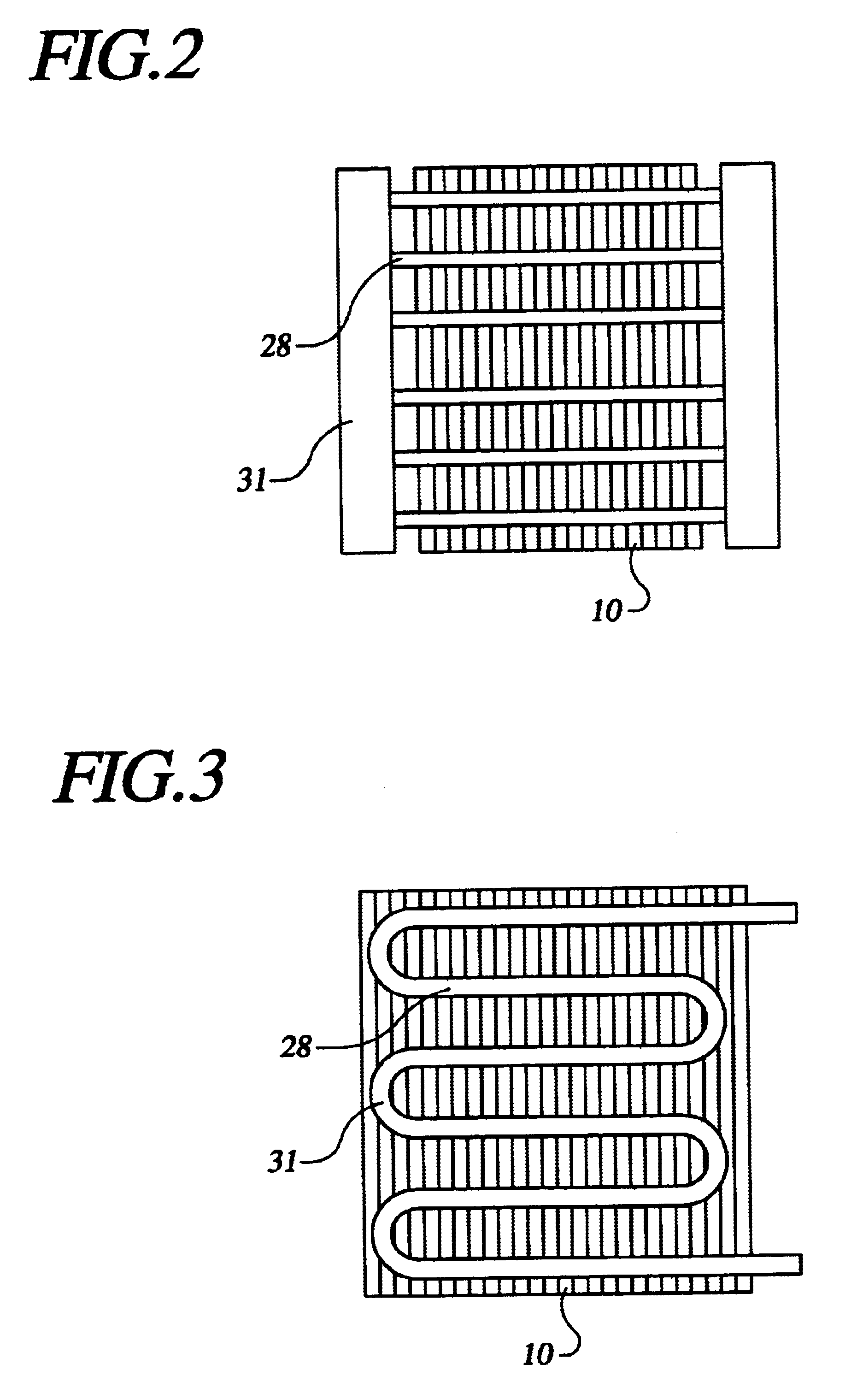

A heat sink assembly includes a base plate having a top surface provided with cooling fins, and a bottom surface with an open channel, the channel having remote regions and a central region with a rectangular cross-section. A heat pipe arrangement including at least two sections is nested in the channel, each section having at least one evaporator section and a condenser section, wherein the evaporator sections are juxtaposed side by side in the central region, and the condenser sections are in respective remote regions. The arrangement is preferably a single S-shaped heat pipe with a pair of hooked ends and a center section which form the evaporator sections, the evaporator sections each having a rectangular profile and an exposed surface which is flush with the bottom surface of the base plate, the condenser sections connecting the evaporator sections and being recessed below the bottom surface.

Owner:AAVID THERMALLOY LLV

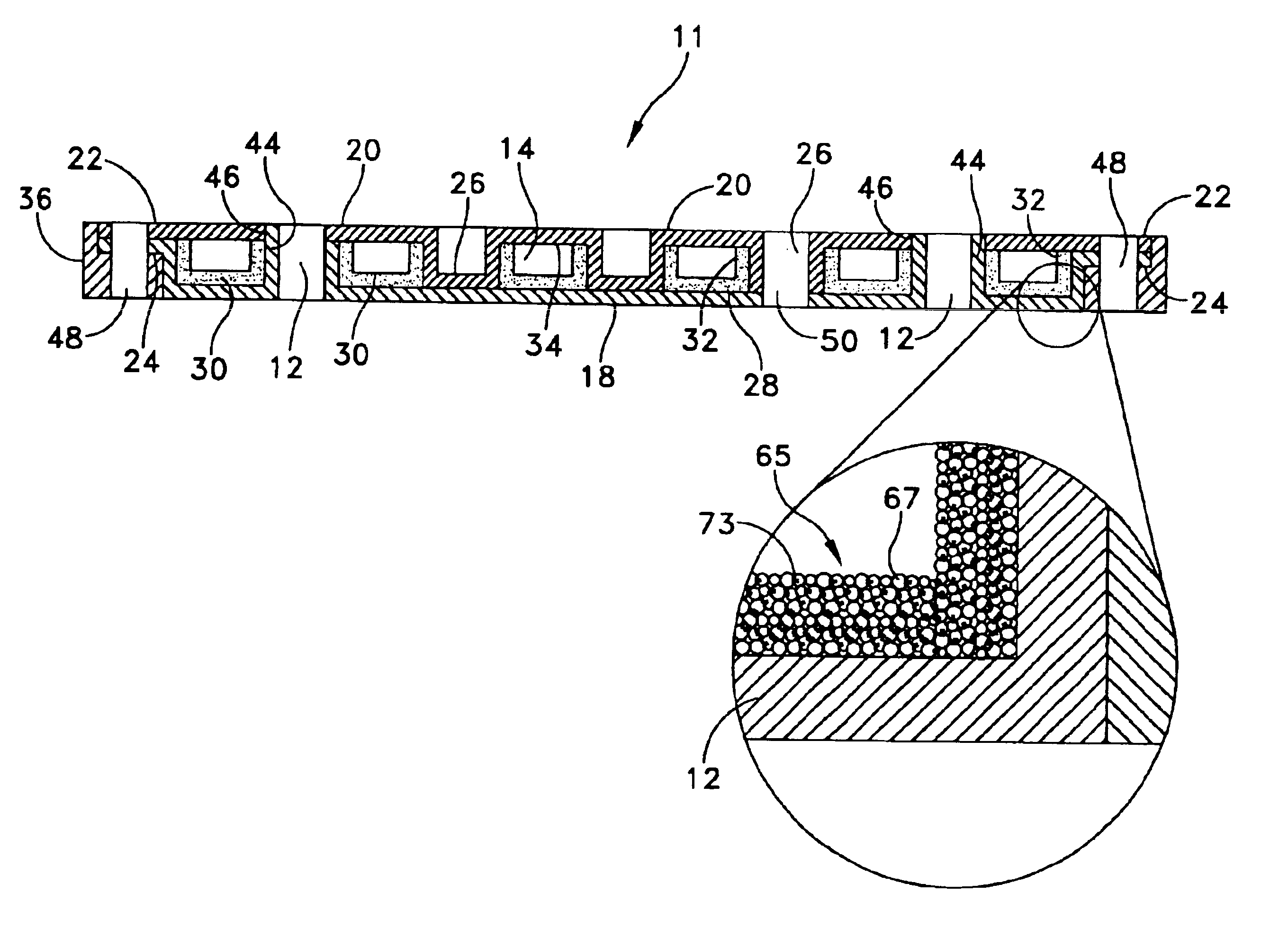

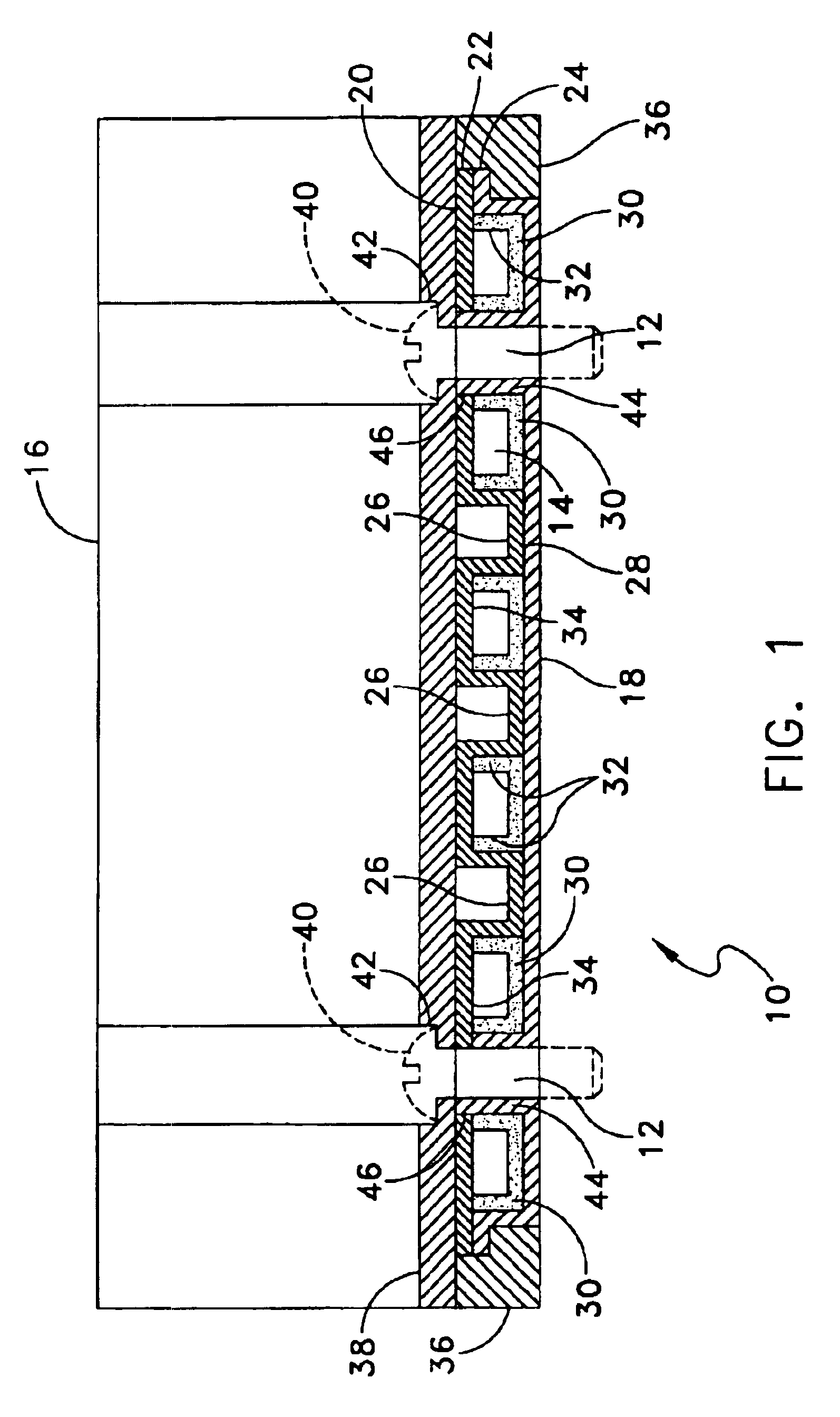

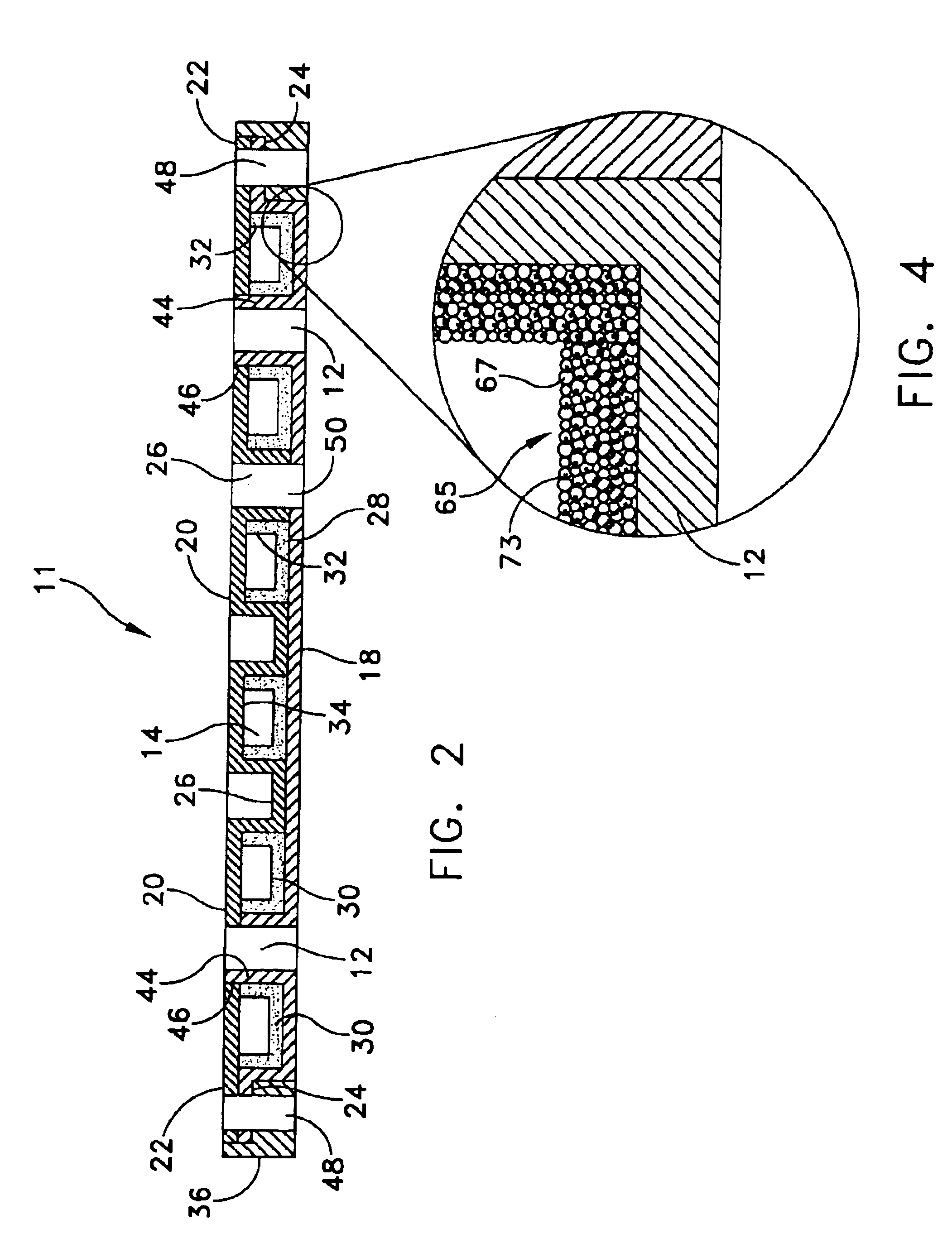

Integrated circuit heat pipe heat spreader with through mounting holes

InactiveUS6896039B2Improve heat transfer performanceImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A heat pipe with superior heat transfer between the heat pipe and the heat source and heat sink is provided. The heat pipe is held tightly against the heat source by mounting holes which penetrate the structure of the heat pipe but are sealed off from the vapor chamber because they each are located within a sealed structure such as a pillar or the solid layers of the casing surrounding the vapor chamber. Another feature of the heat pipe is the use of a plurality of particles joined together by a brazing compound such that fillets of the brazing compound are formed between adjacent ones of the plurality of particles so as to form a network of capillary passageways between the particles of the wick.

Owner:AAVID THERMALLOY LLV

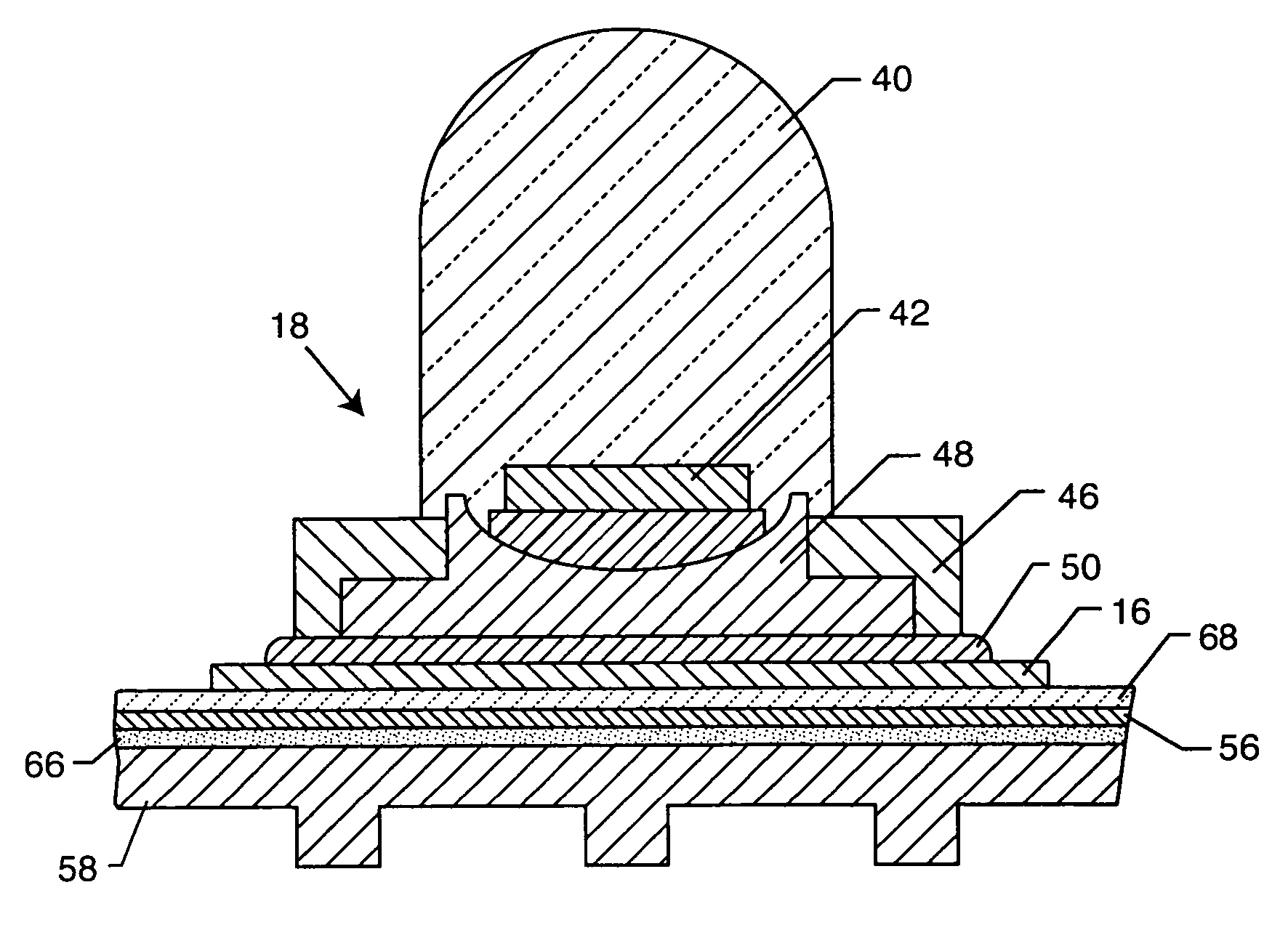

Process for manufacturing an LED lamp with integrated heat sink

ActiveUS7676915B2Maximize heat transferPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

Owner:THE ARTAK TER HOVHANISSIAN PATENT TRUST +1

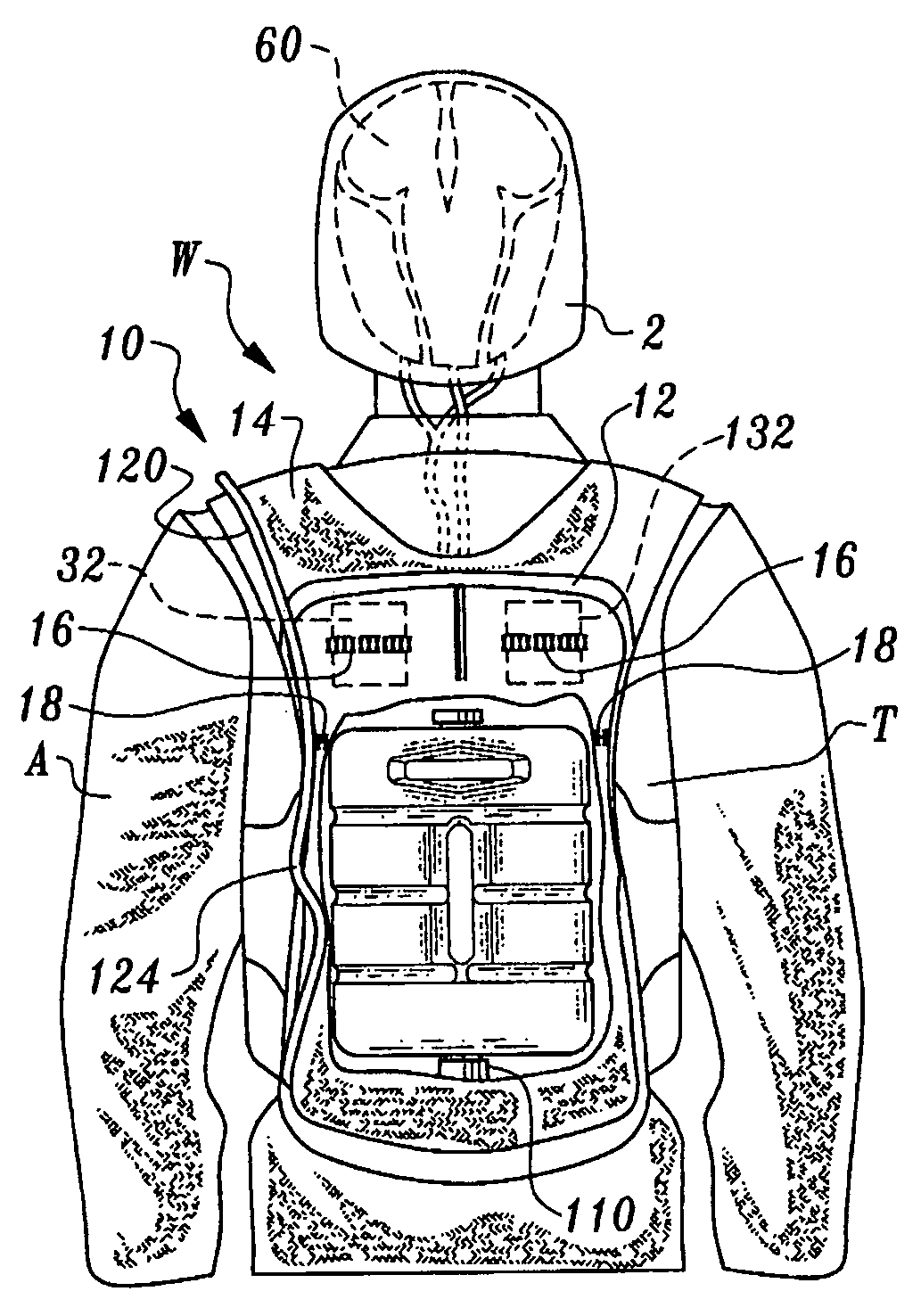

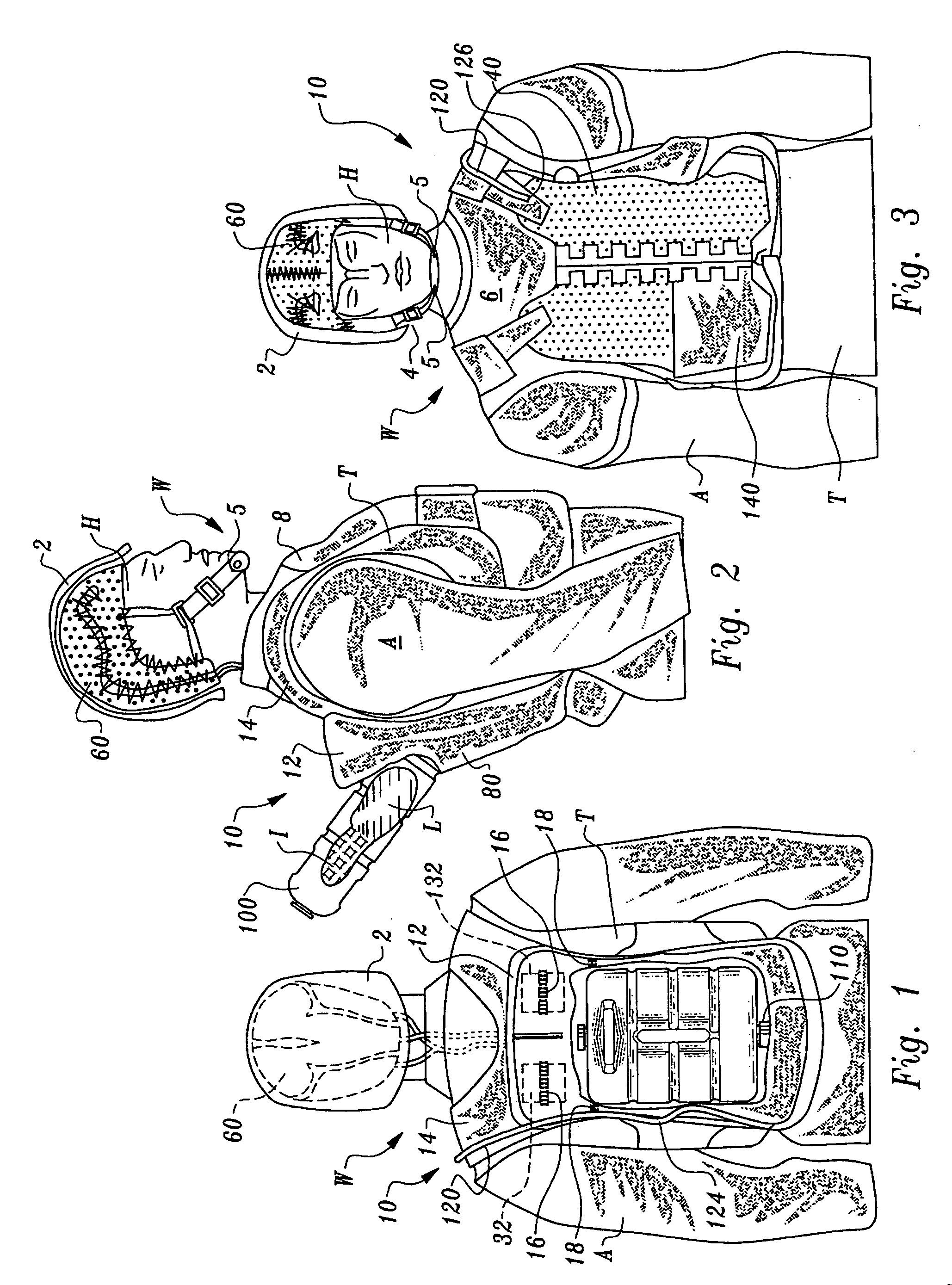

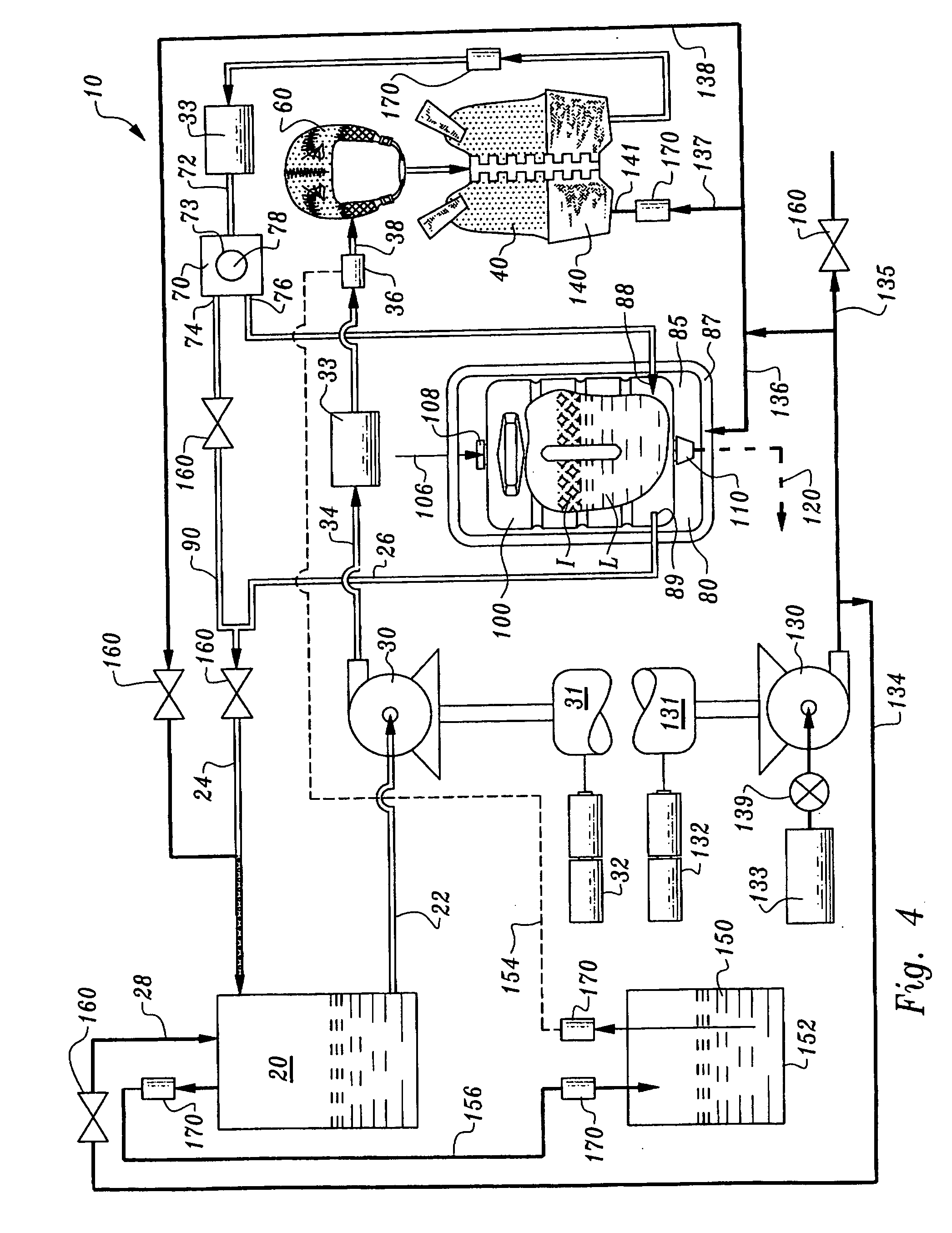

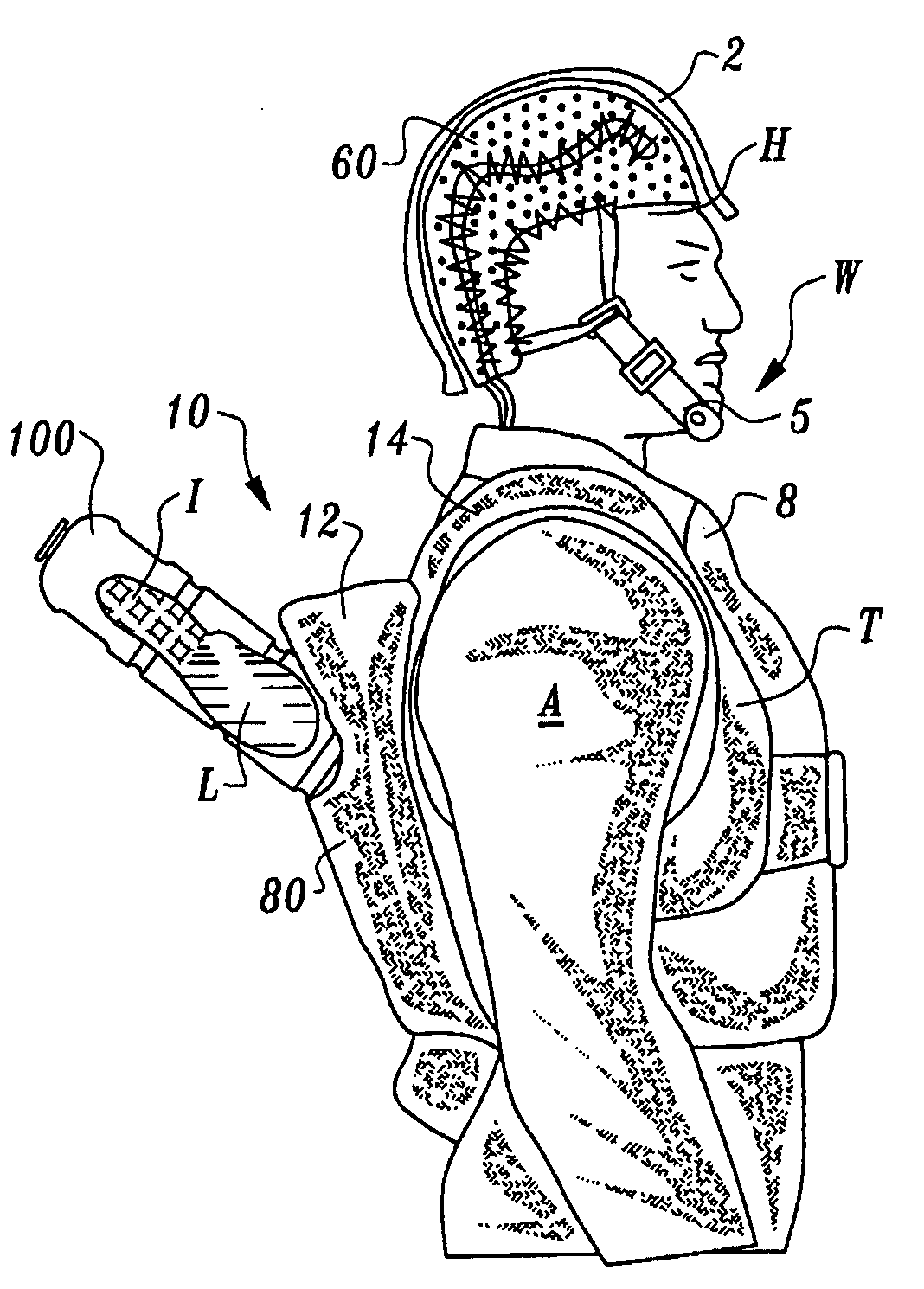

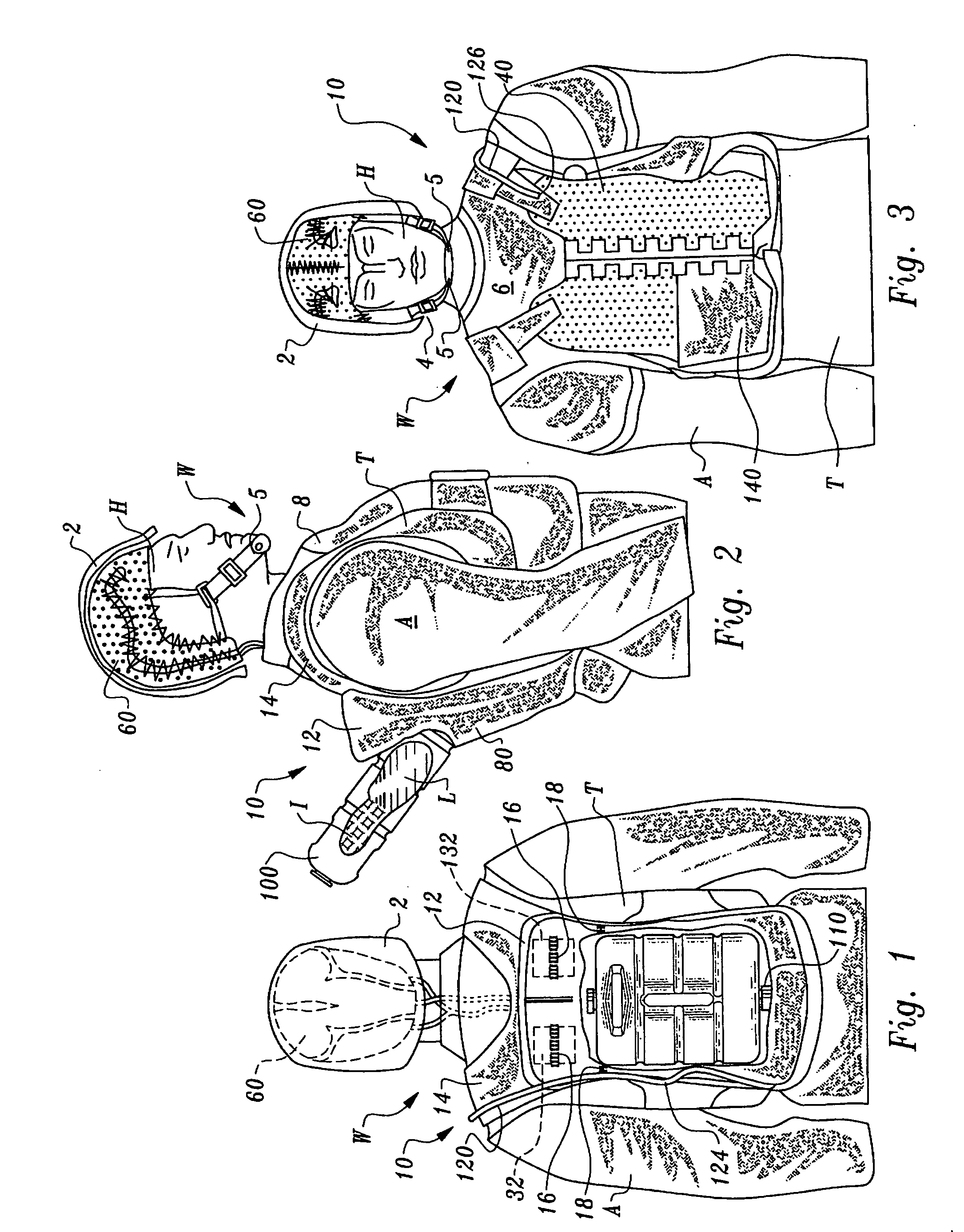

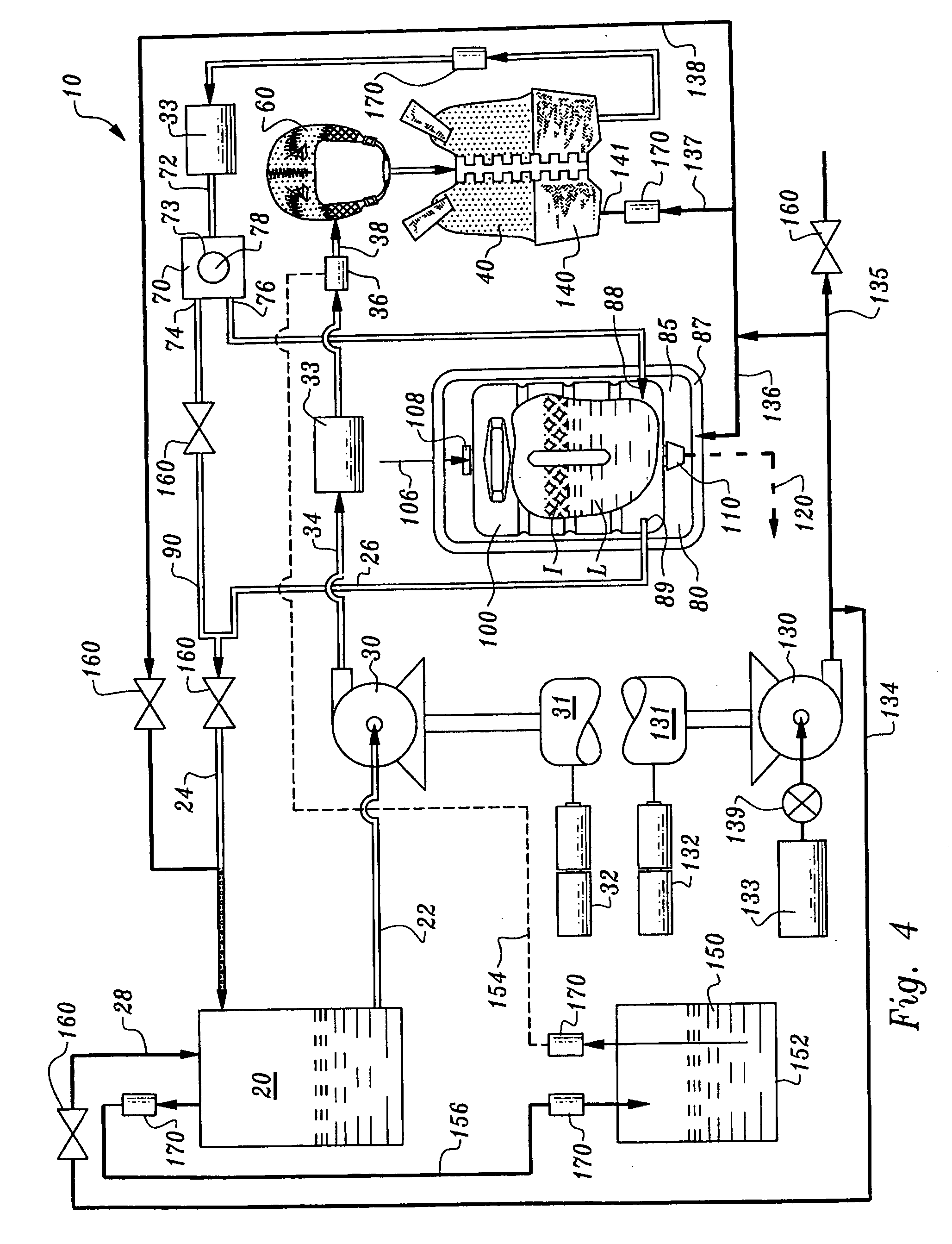

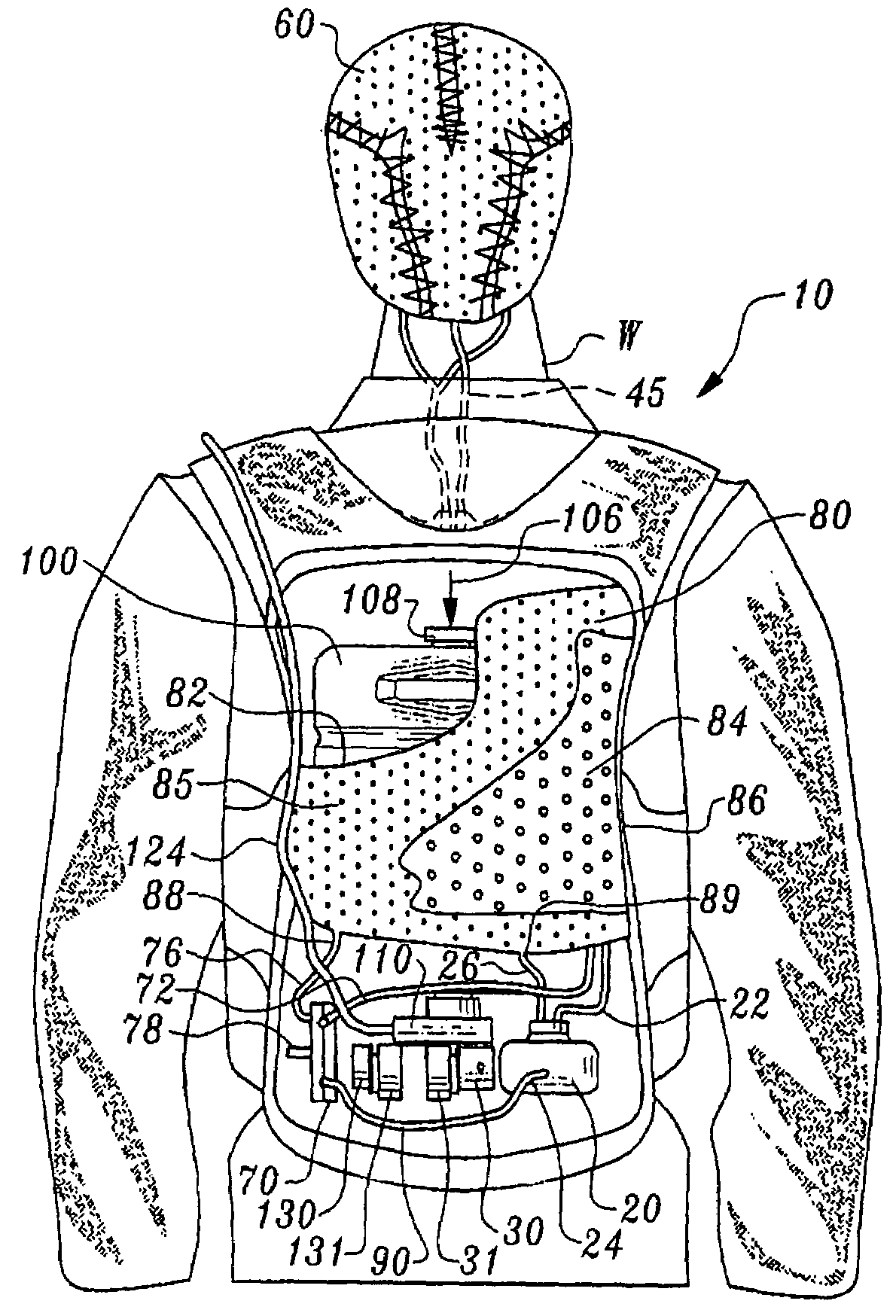

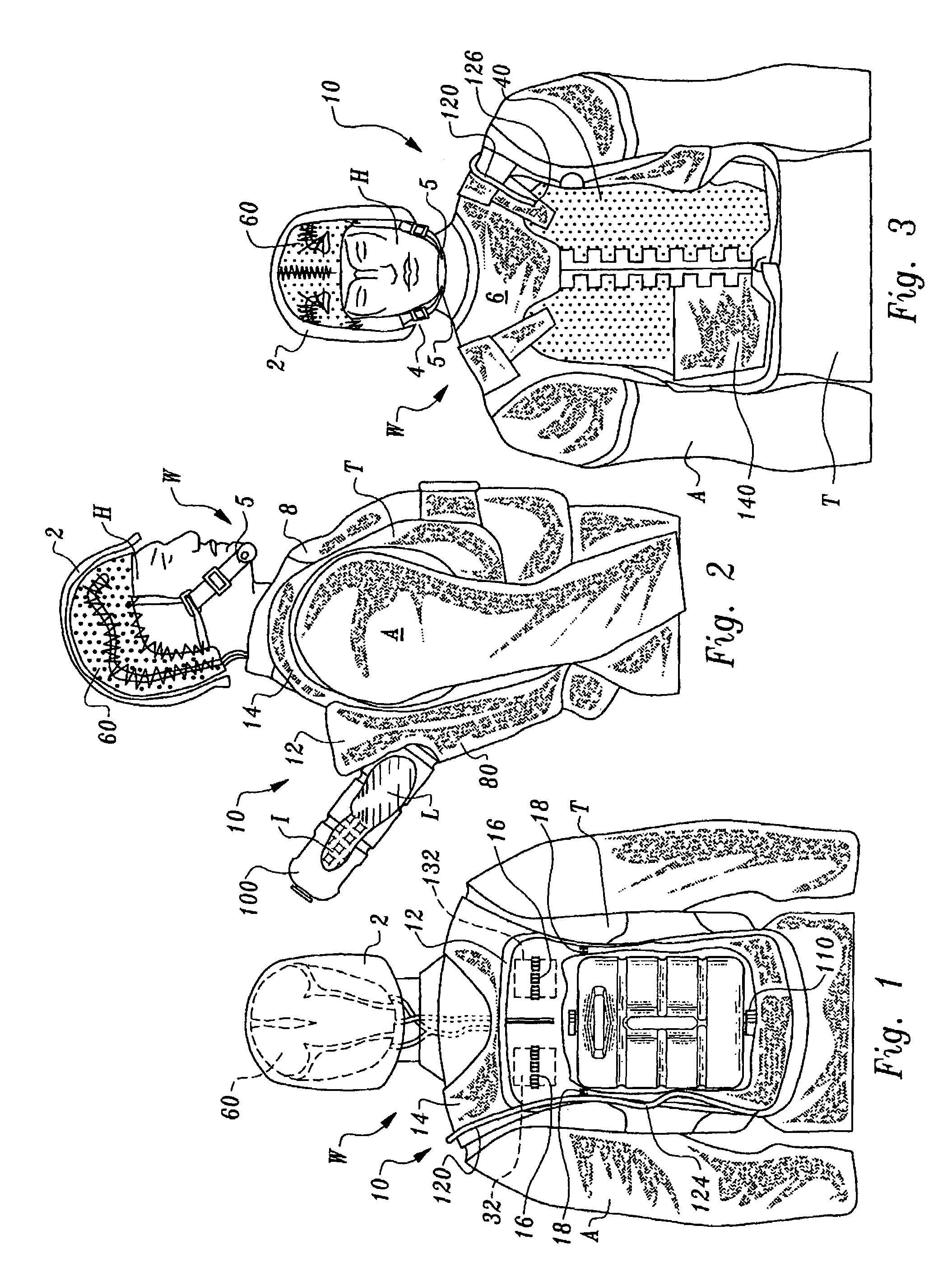

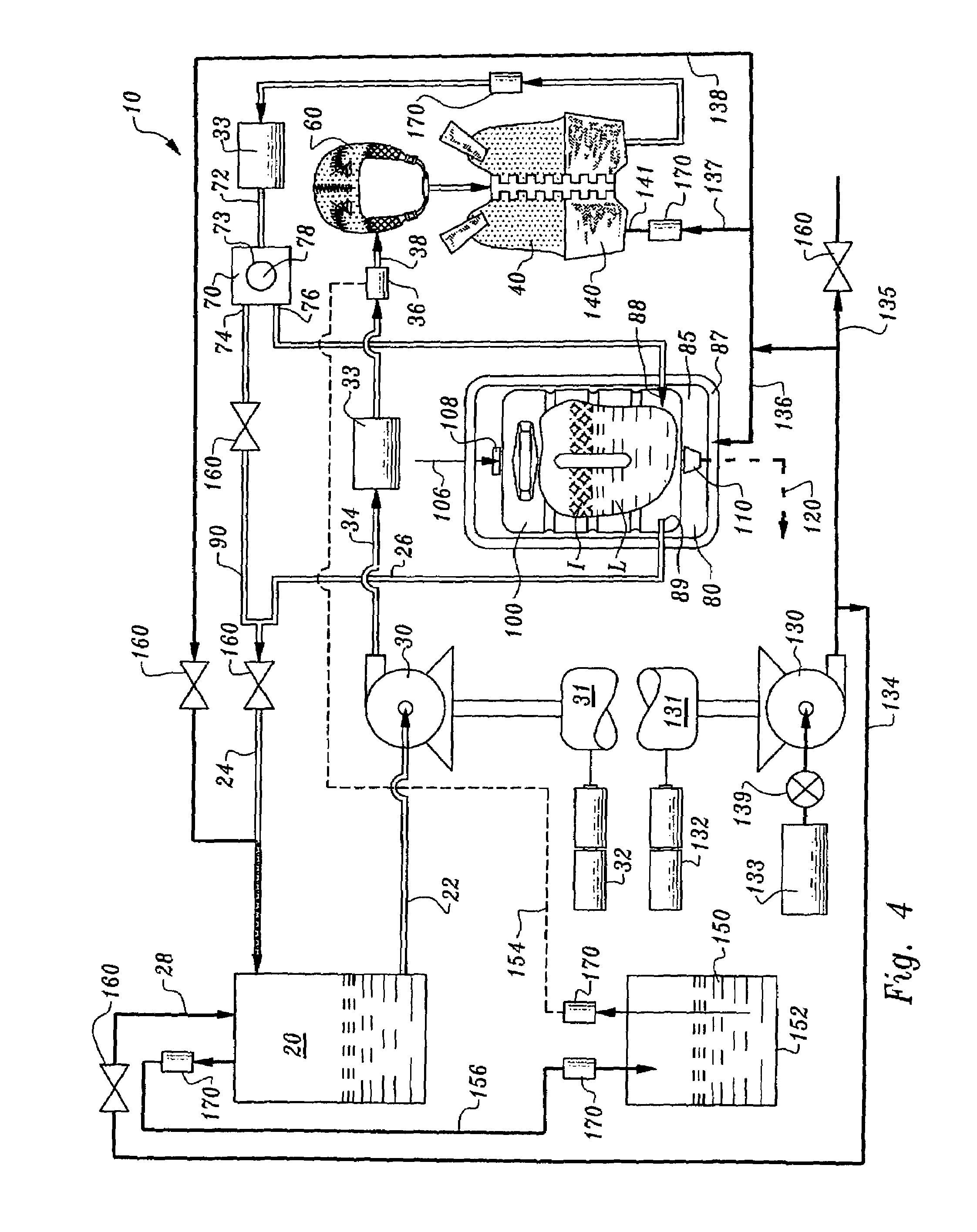

Wearable personal cooling and hydration system

InactiveUS20060191049A1Maximum comfortMinimal contaminationChemical protectionGarment special featuresHeat transfer fluidEngineering

A heat transfer fluid pathway is provided driven by a pump which feeds the heat transfer fluid through a vest and cap or other heat transfer garment, where the heat transfer fluid draws heat away from the body of the wearer. A drinkable heat sink material is located within a removable cartridge located within a heat exchange pouch. The heat transfer fluid passes from the heat transfer garment to the heat exchange pouch where heat drawn from the wearer is transferred to the heat sink material within the cartridge. A temperature control valve is provided along with a bypass line so that an adjustable amount of the heat transfer fluid is routed to the heat exchange pouch for temperature control. A supply of elevated pressure air is optionally provided to maintain optimal contact for efficient heat transfer within the heat exchange garment and the heat exchange pouch.

Owner:WELKINS

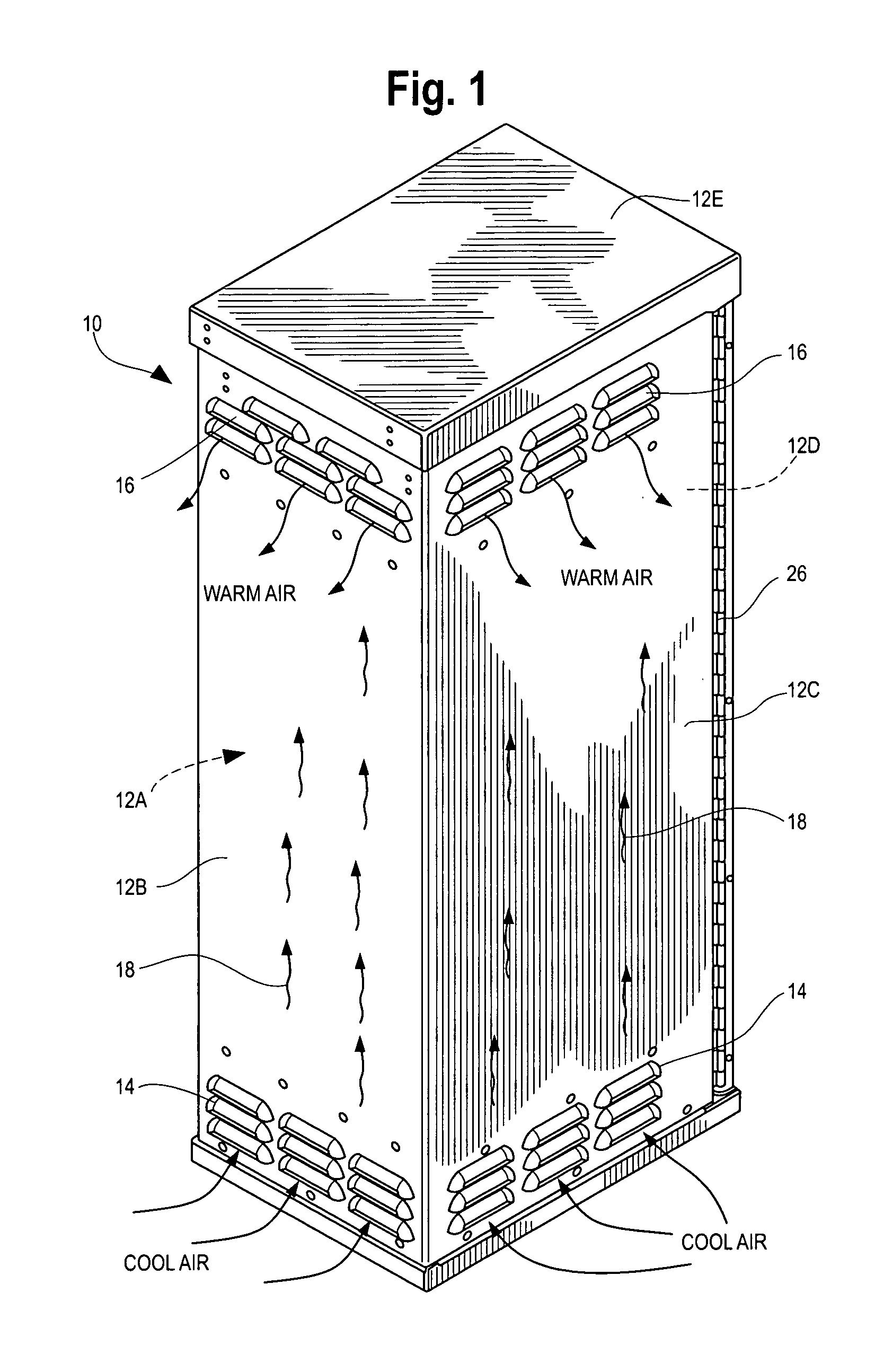

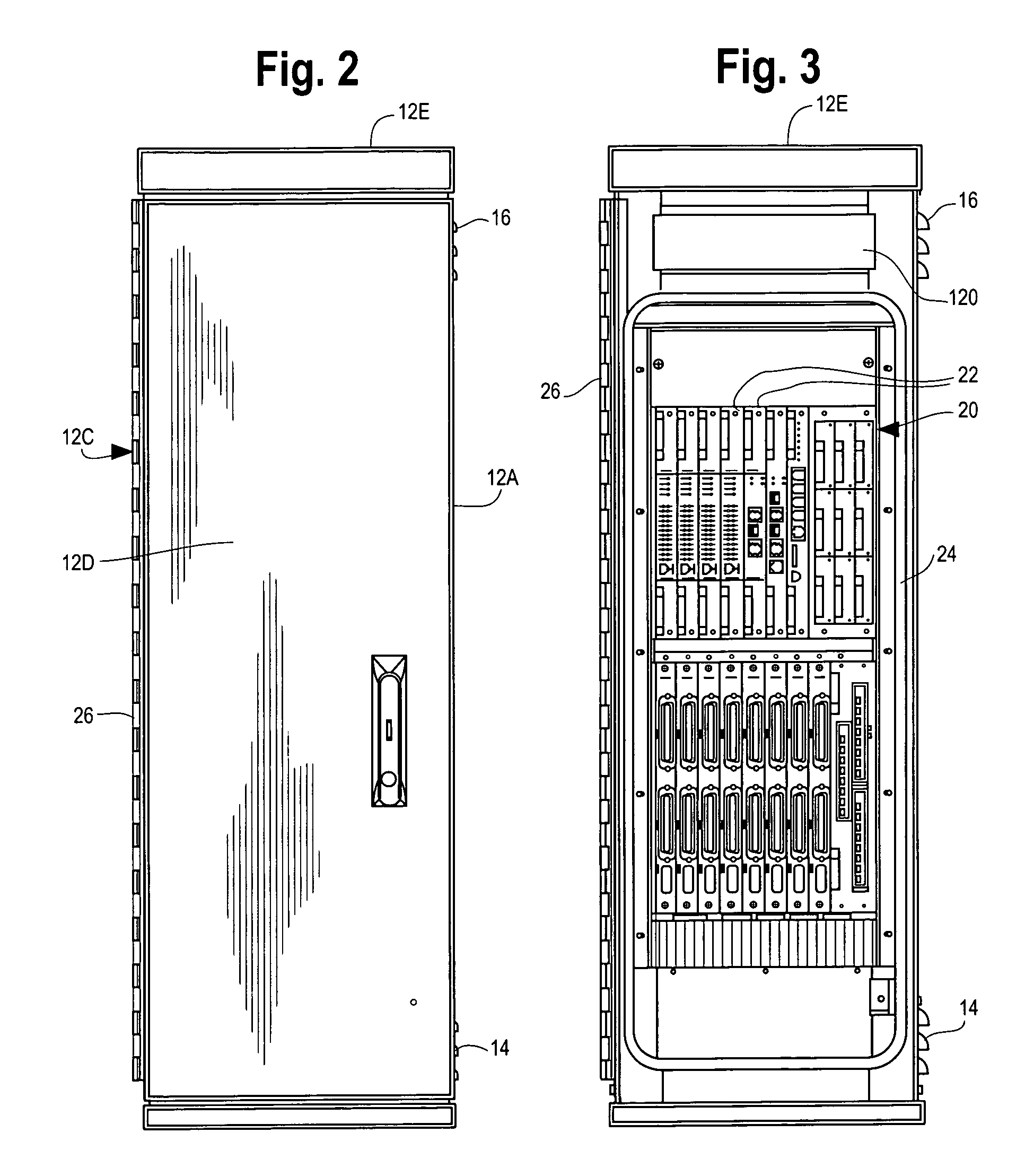

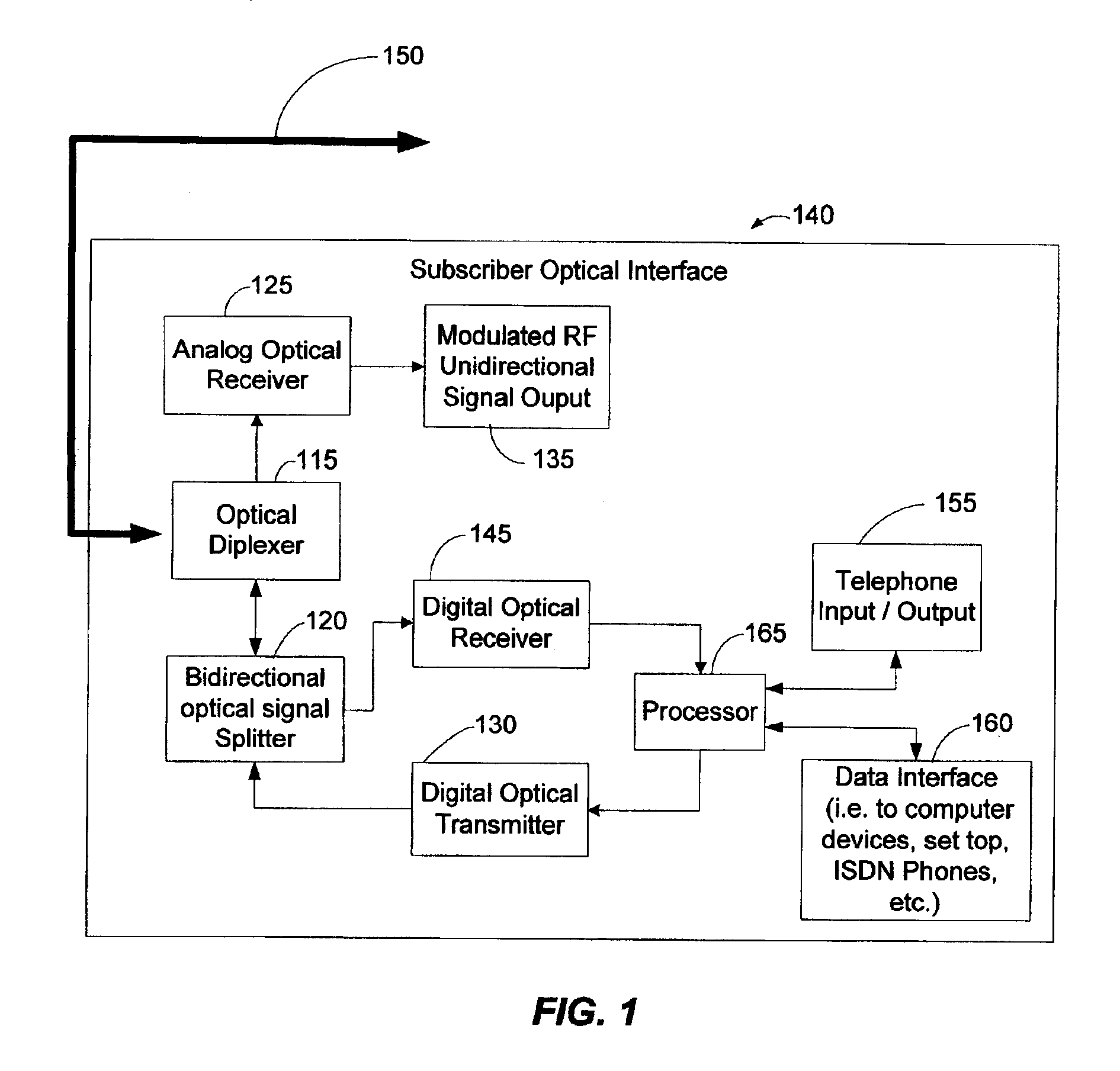

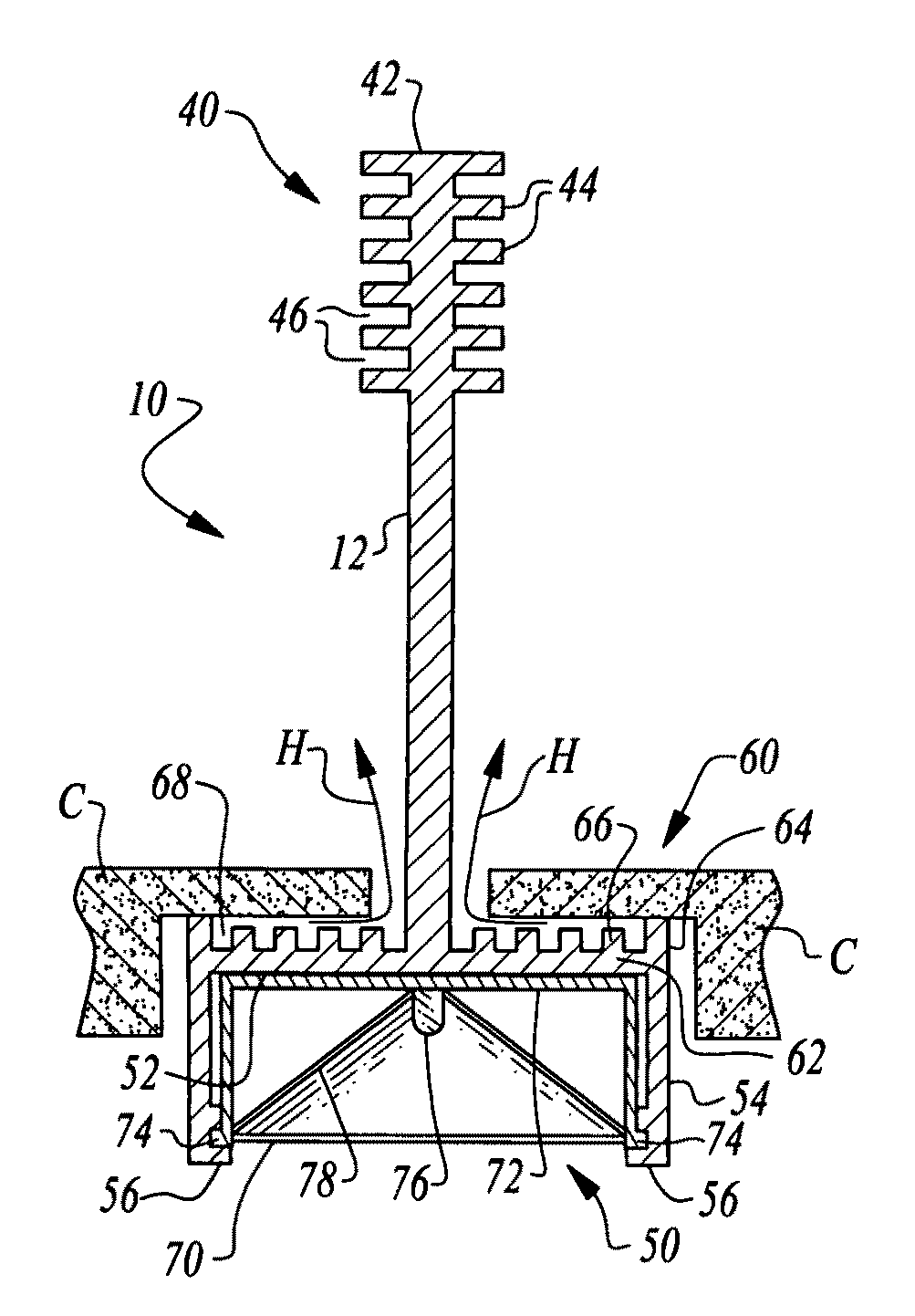

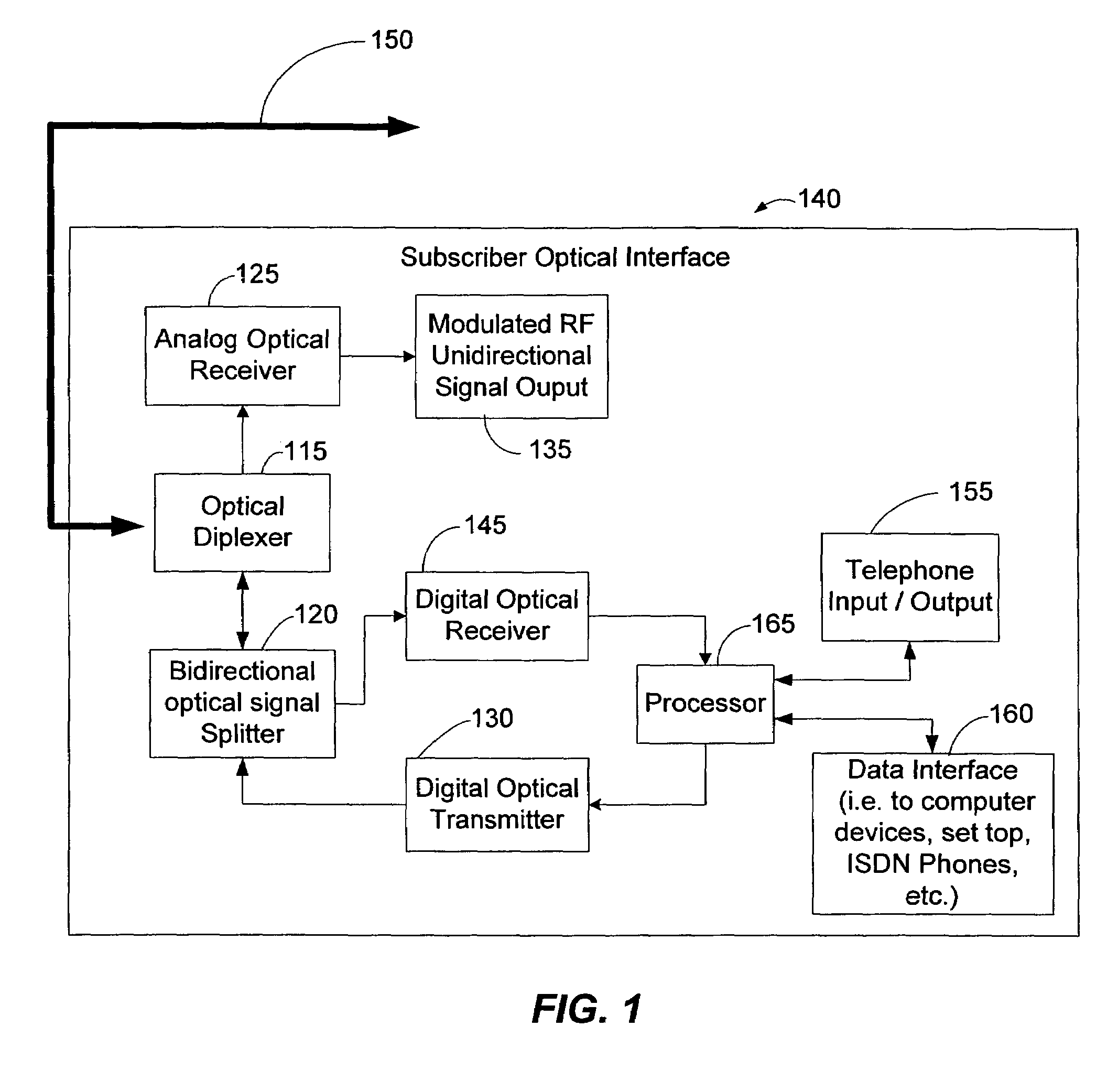

System and method for removing heat from a subscriber optical interface

InactiveUS7038910B1Minimizing transferMaximize heat transferCouplings bases/casesHeat exchange apparatusEngineeringPartial closure

A system and method removes heat from an enclosure or housing of a subscriber optical interface. When a subscriber optical interface housing is attached to a structure such that a partially enclosed volume of space remains between the structure and the subscriber optical interface housing, this partially enclosed volume of space can produce a chimney effect when heat from the subscriber optical interface housing is intended to flow from fins towards the structure. This chimney effect can refer to a fluid such as air within the partially enclosed space that is heated by the fins and that rises upward when the ambient or surrounding fluid is cooler relative to the heated fluid. According to another exemplary embodiment, the subscriber optical interface can be shaped to form an internal chimney structure that is entirely surrounded by a housing of the subscriber optical interface.

Owner:ARRIS SOLUTIONS

T-bar for suspended ceiling with heat dissipation system for LED lighting

ActiveUS8177385B2Improve heat transfer performanceEfficient transferPlanar light sourcesCeilingsEffect lightEngineering

The T-bar includes an elongate rigid spine extending between terminal ends including either a fixed anchor or adjustable anchor for attachment to adjacent T-bars or other supports. An upper heat sink is provided on an upper portion of the spine to enhance heat transfer from the T-bar to air surrounding upper portions of the T-bar. A light housing is provided on a lower portion of the T-bar which is configured to support a lighting module therein, such as a light emitting diode (LED) light. A lower heat sink is provided above this light housing and integrated into a rest shelf which supports ceiling tiles adjacent the T-bar. A power supply is provided which can be removably attached to the T-bar and provide appropriately conditioned power for the lighting module.

Owner:JLC TECH IP LLC

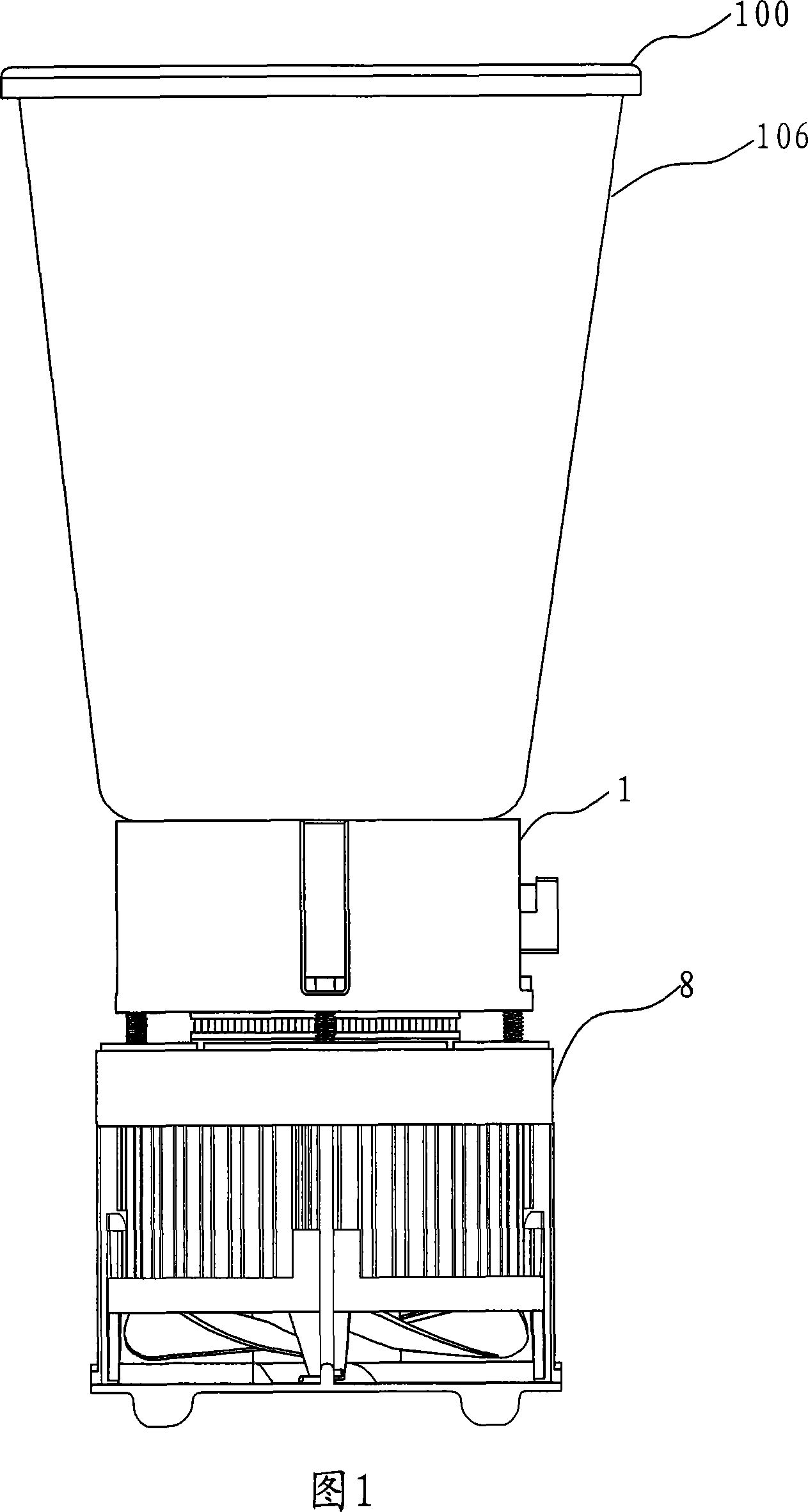

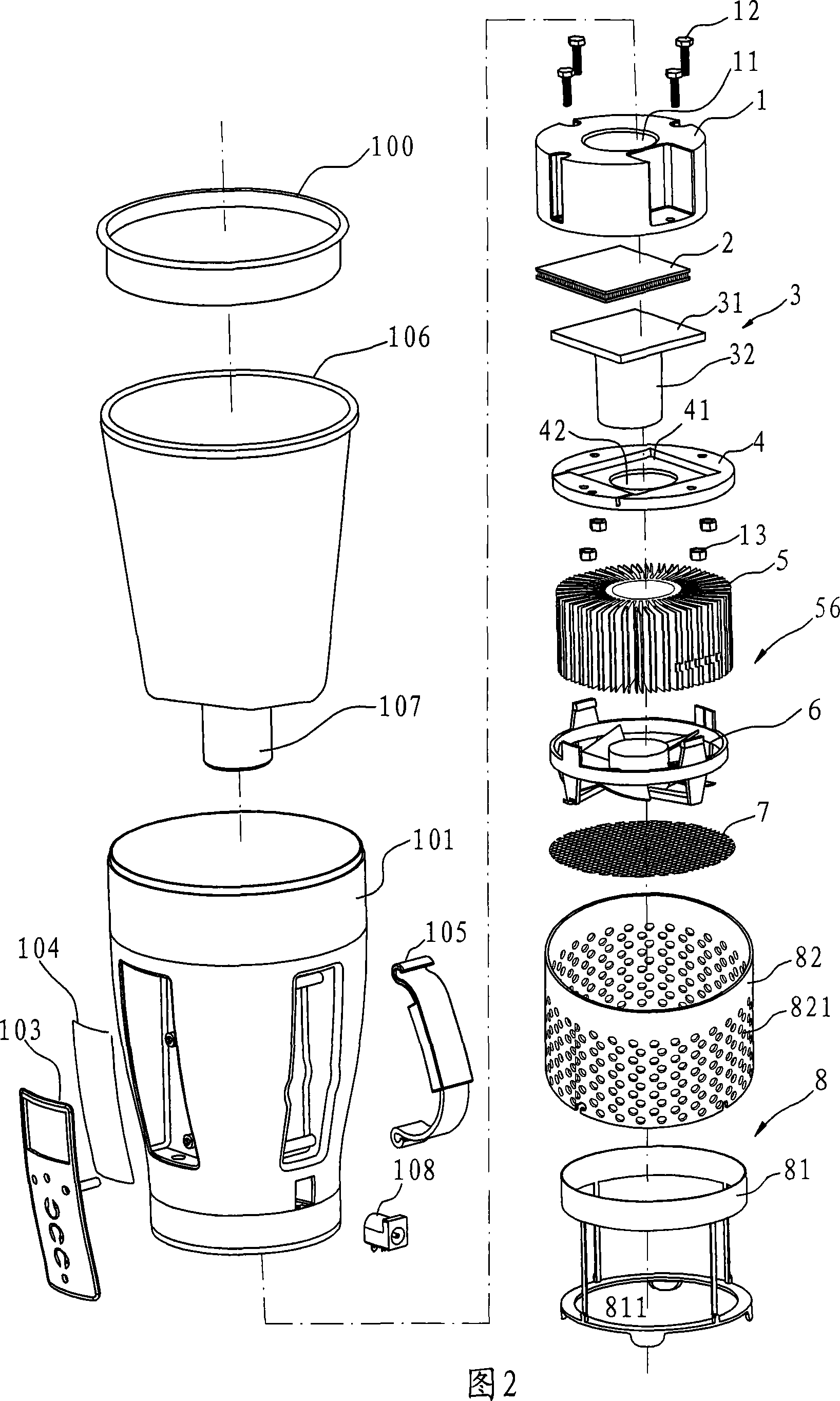

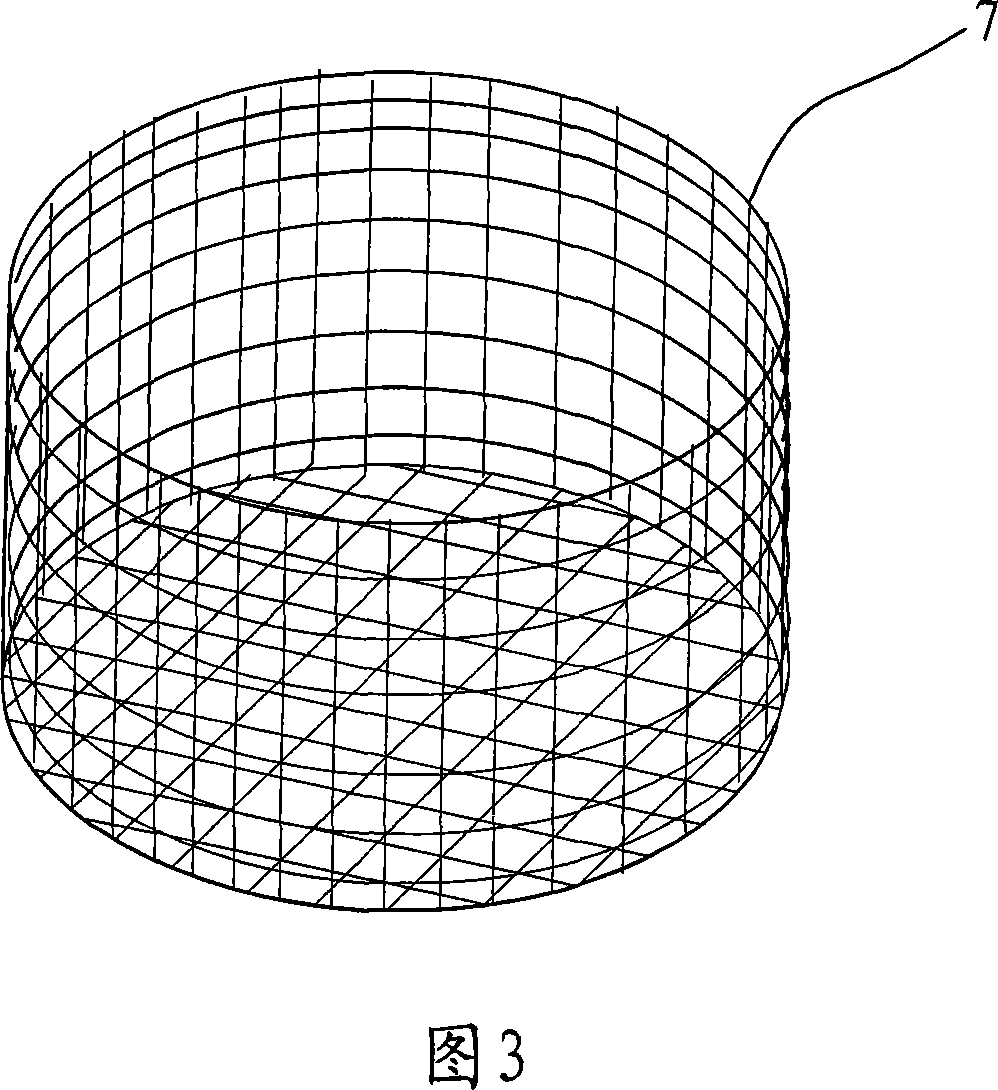

Cooling-heating cup

InactiveCN101069606AReduce dust intrusionReduce accumulationBeverage vesselsDrinking vesselsEngineeringRadiation

The present invention relates to a cold and hot cup. It is characterized by that it includes a cup body, an internal container with containing space, heat-insulating layer, cup seat with air inlet and air outlet upper temperature-conducting component close to the bottom portion of said internal container, lower temperature-conducting component, semiconductor cold and hot chip whose upper end surface is close to upper temperature-conducting component and whose lower end surface is close to lower temperature-conducting component, heat-insulating plate and radiation mechanism formed from radiator and blower fan positioned under the radiator. Besides, the air inlet of said cup seat also is equipped with a filtering dust-preventing device.

Owner:NINGBO LIXIN TOUR PROD

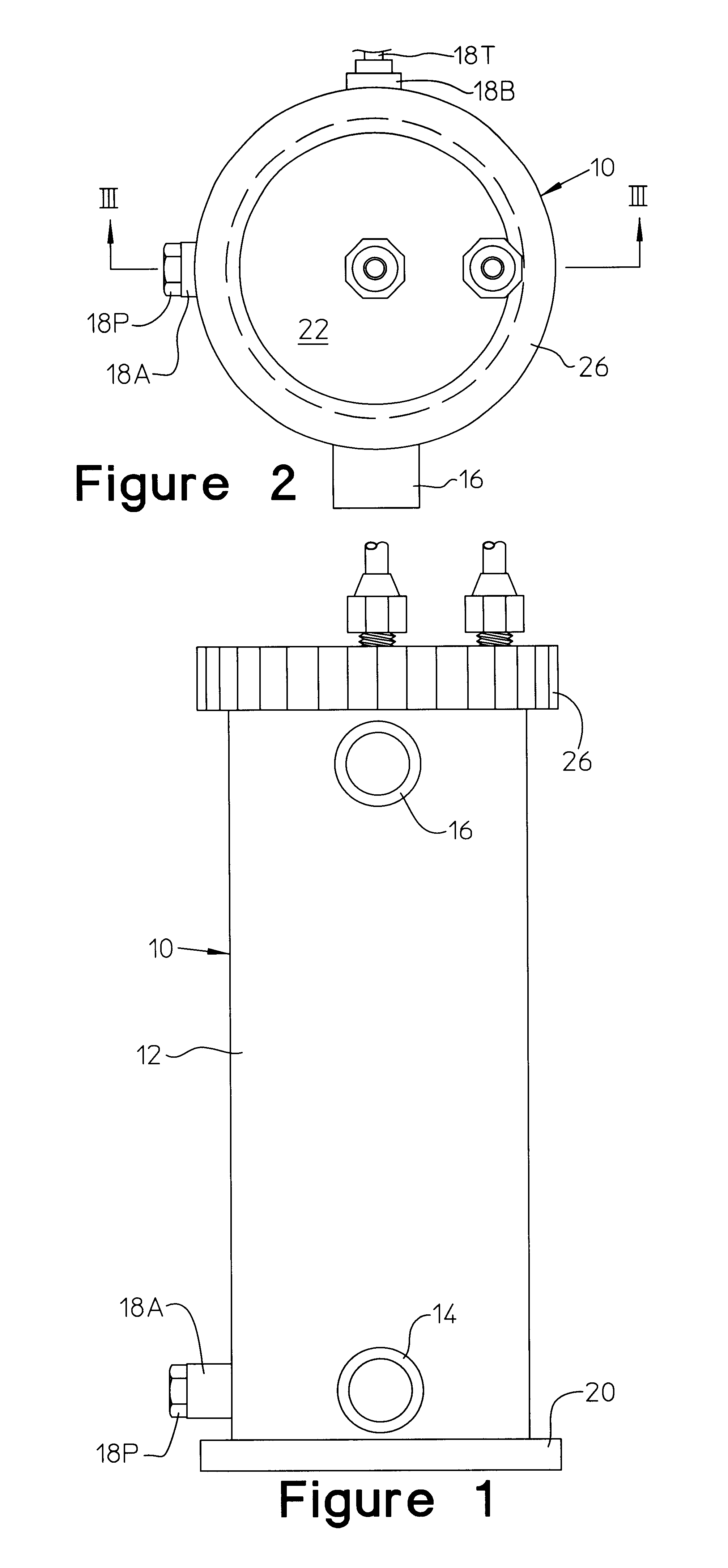

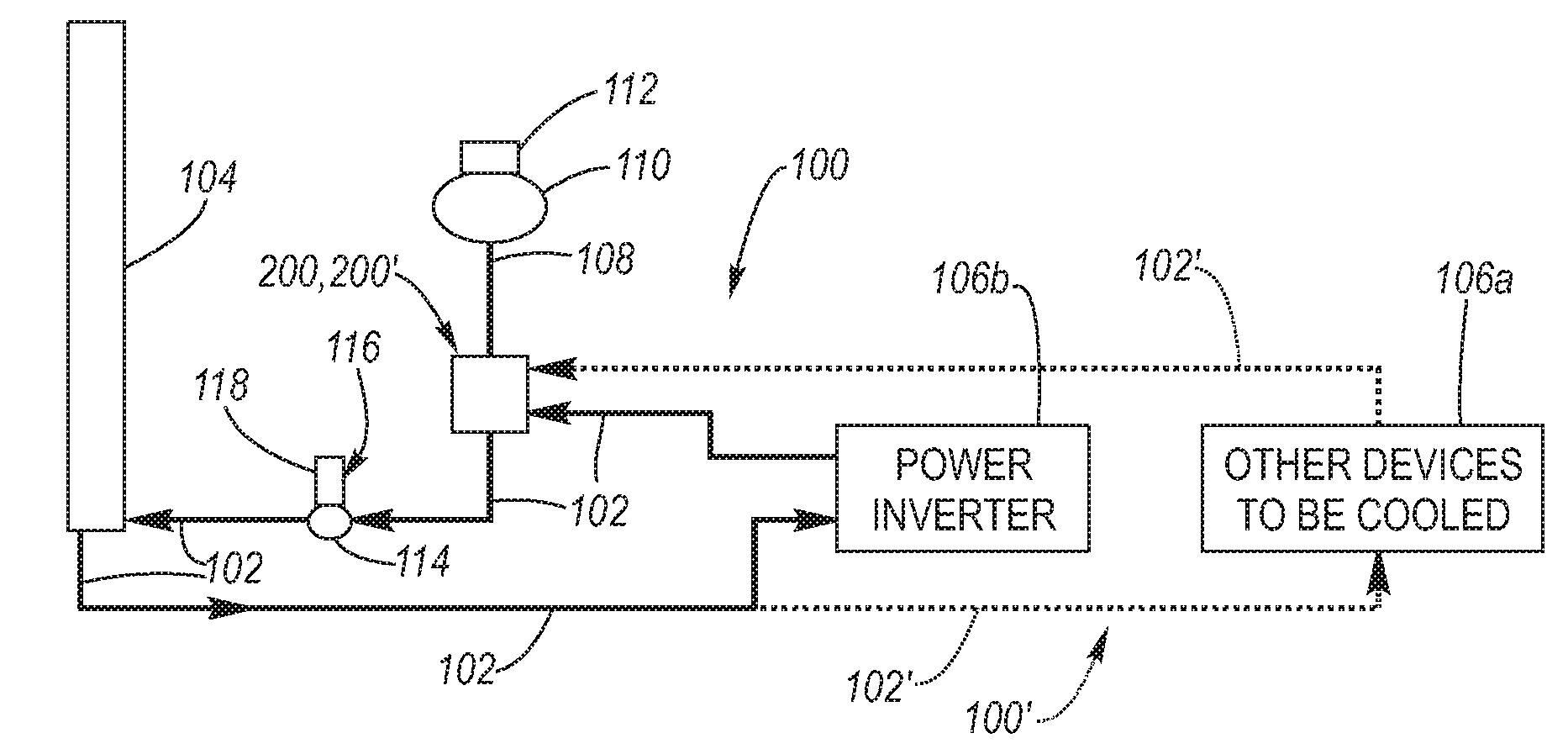

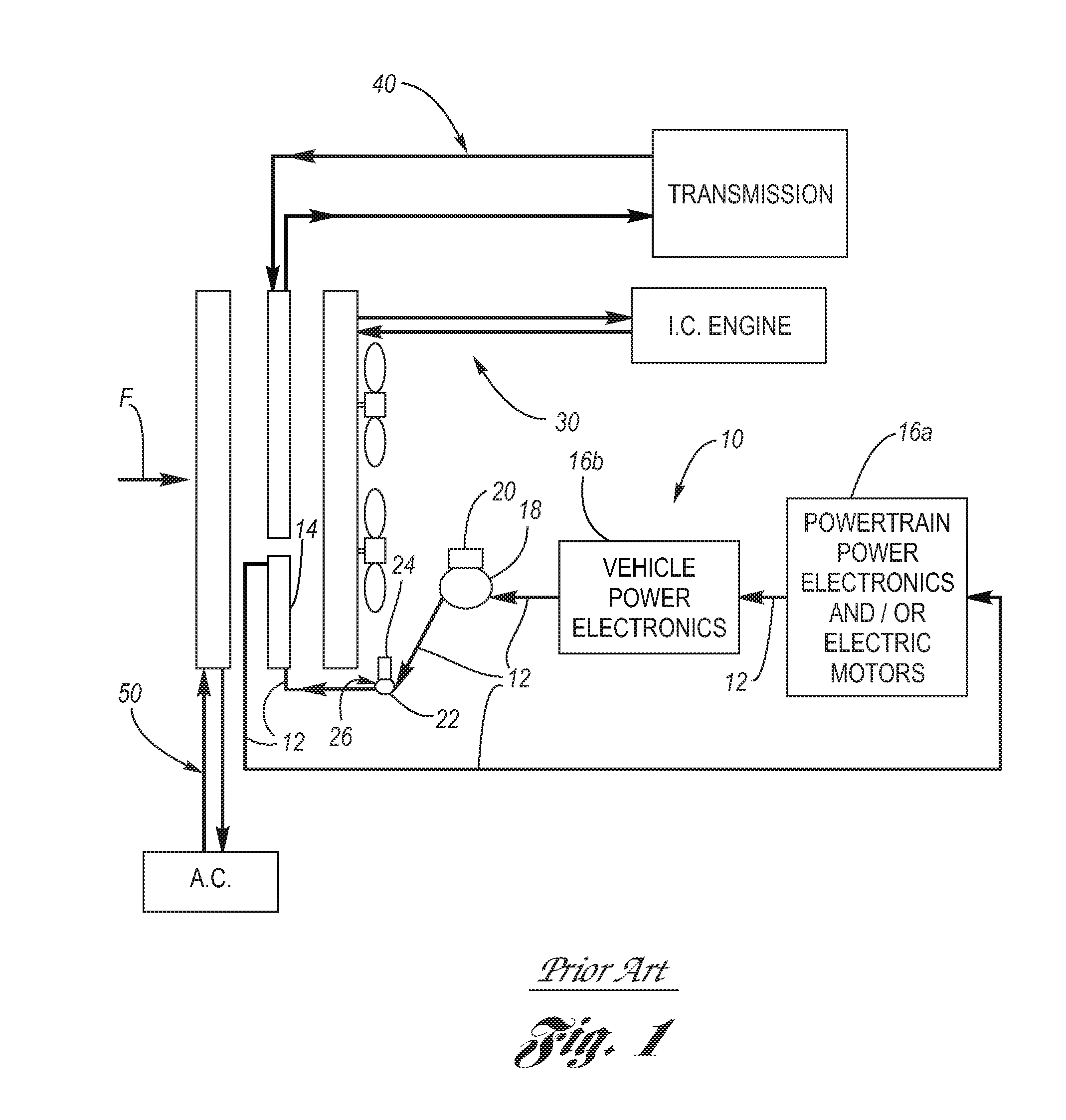

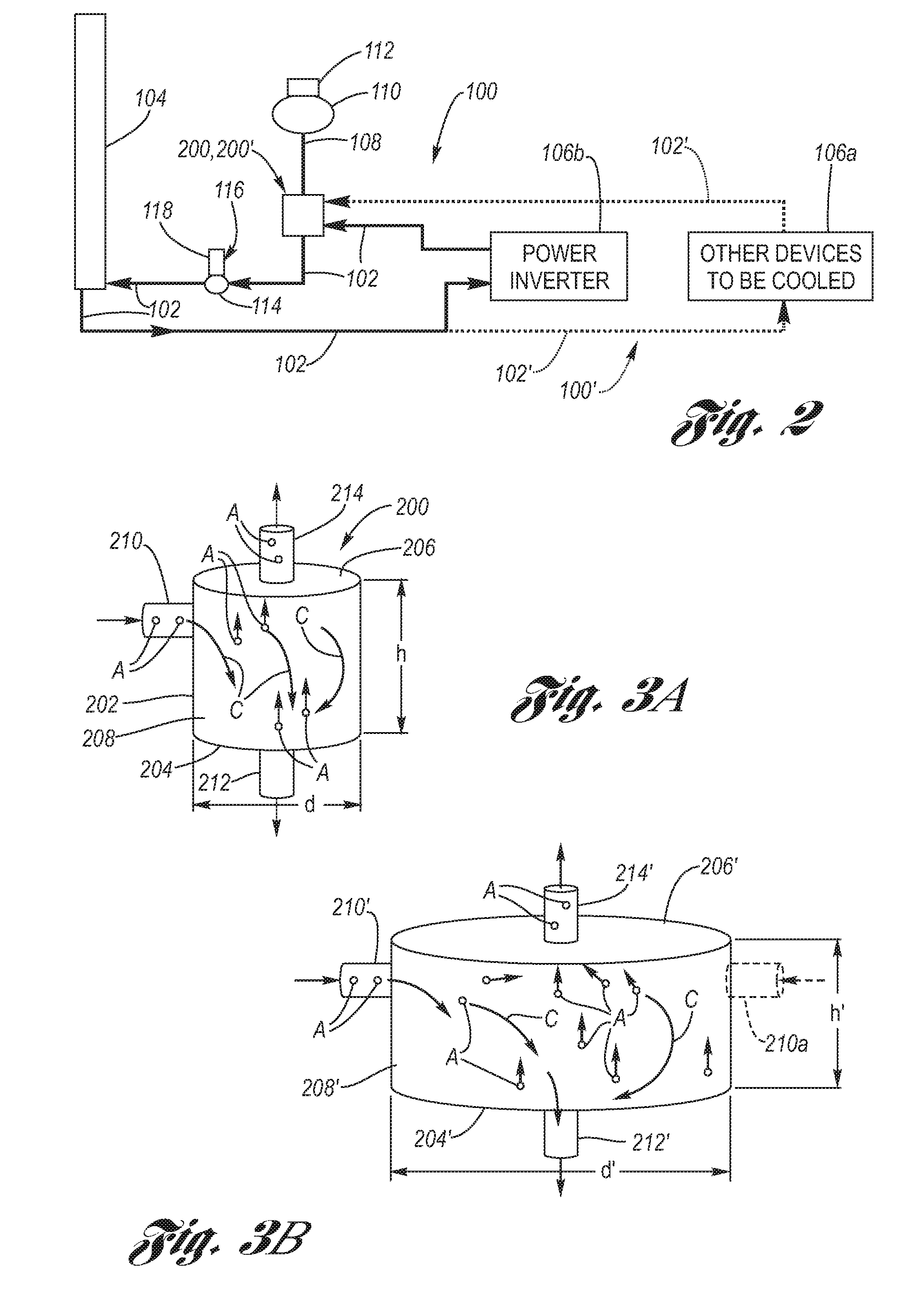

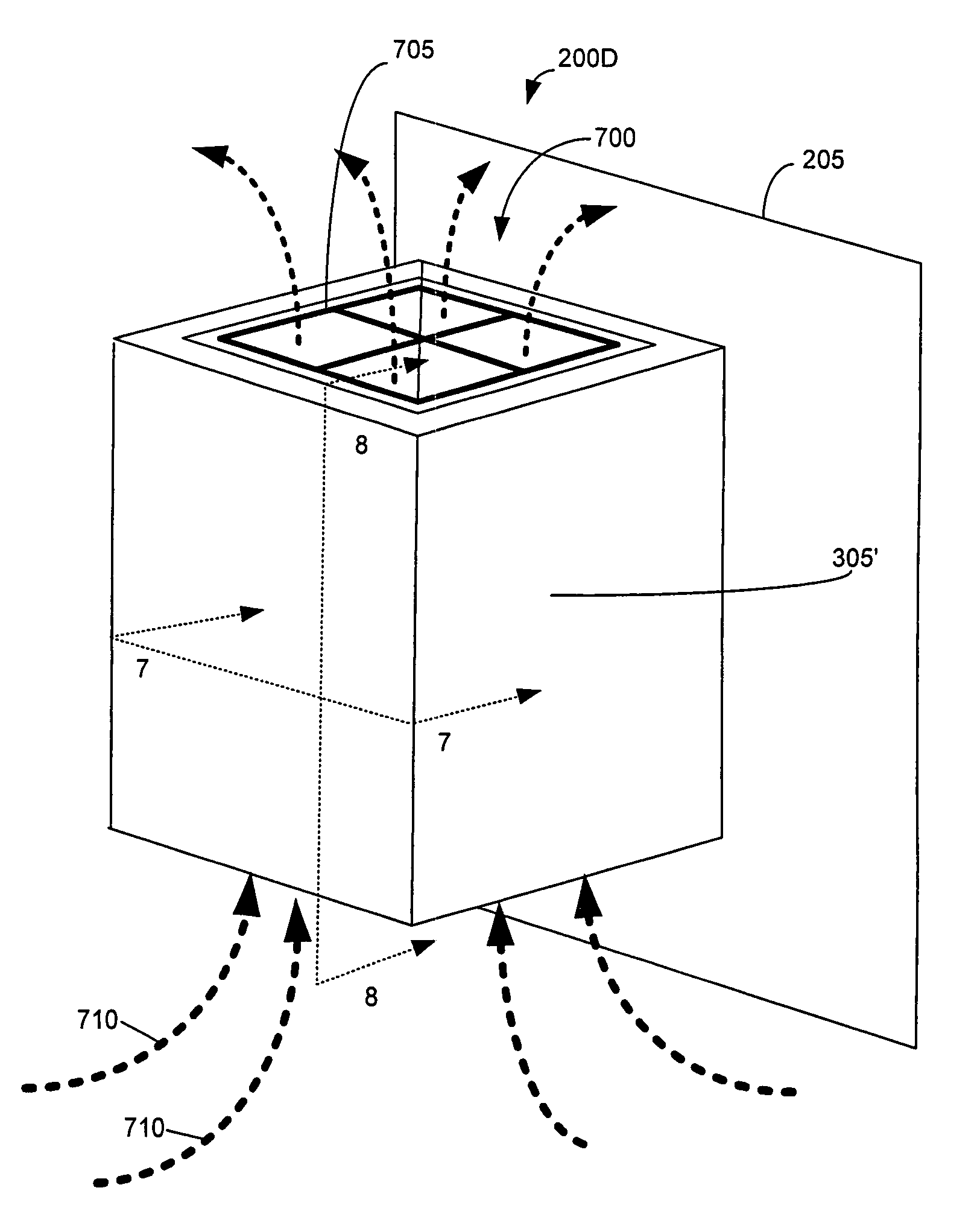

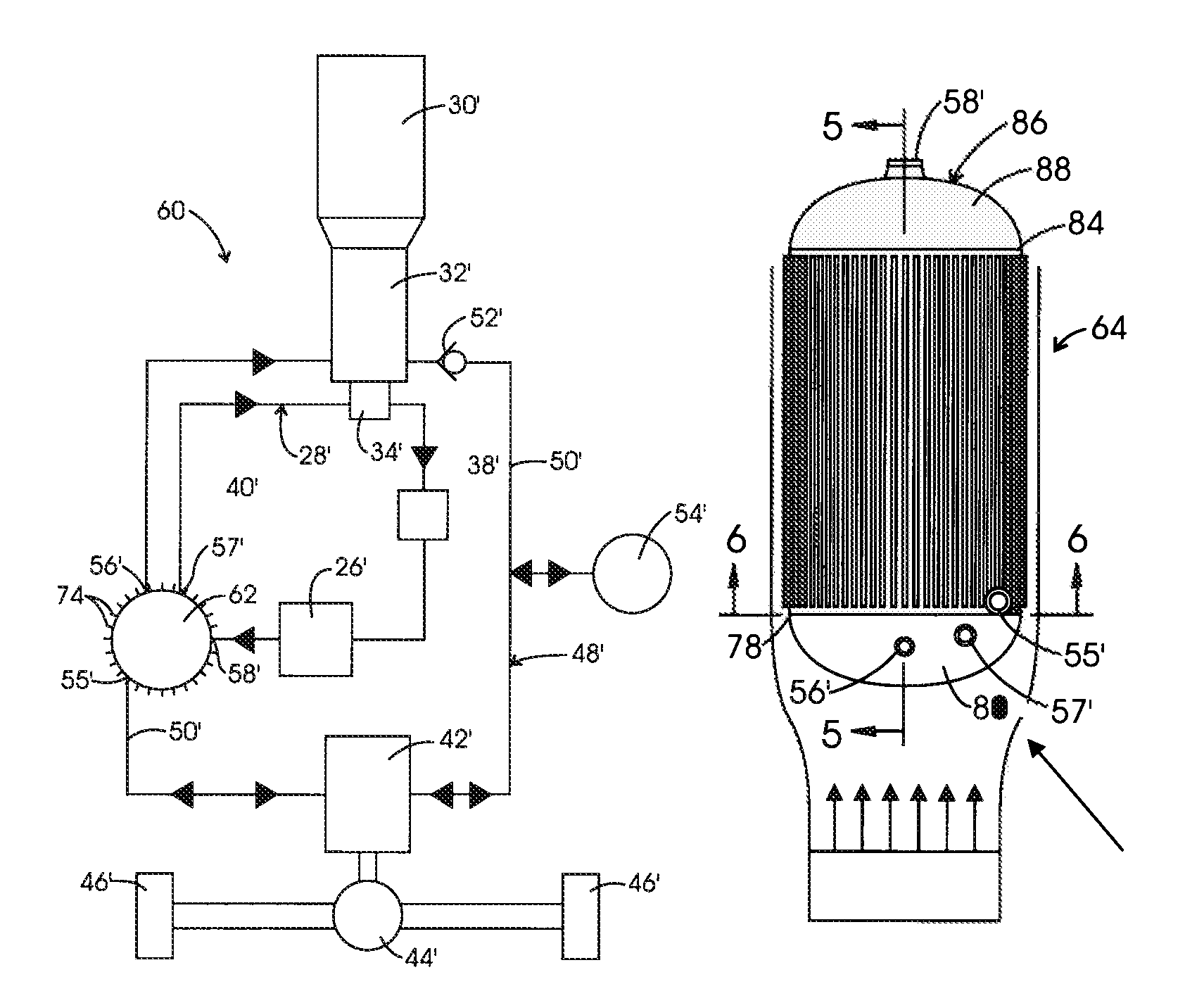

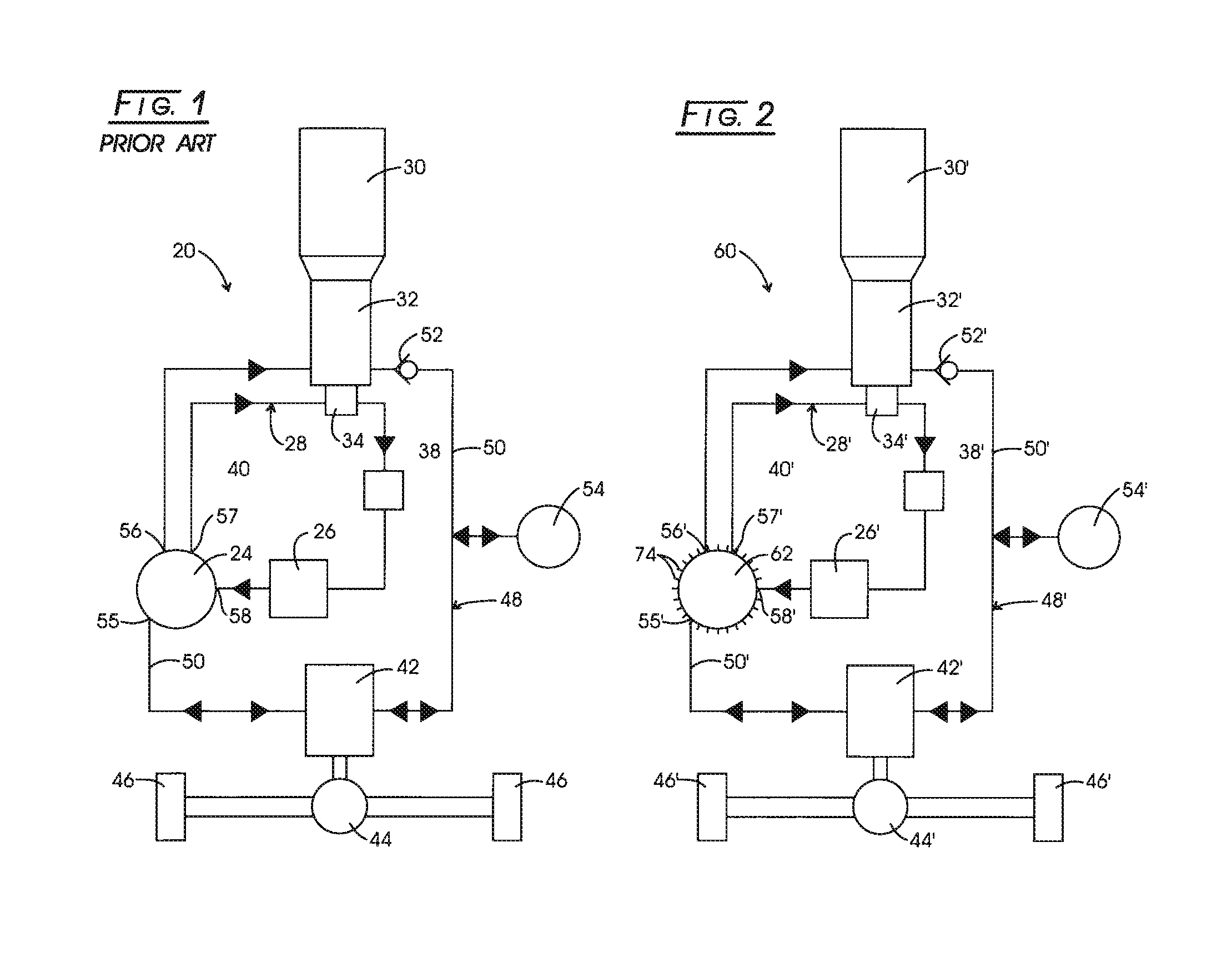

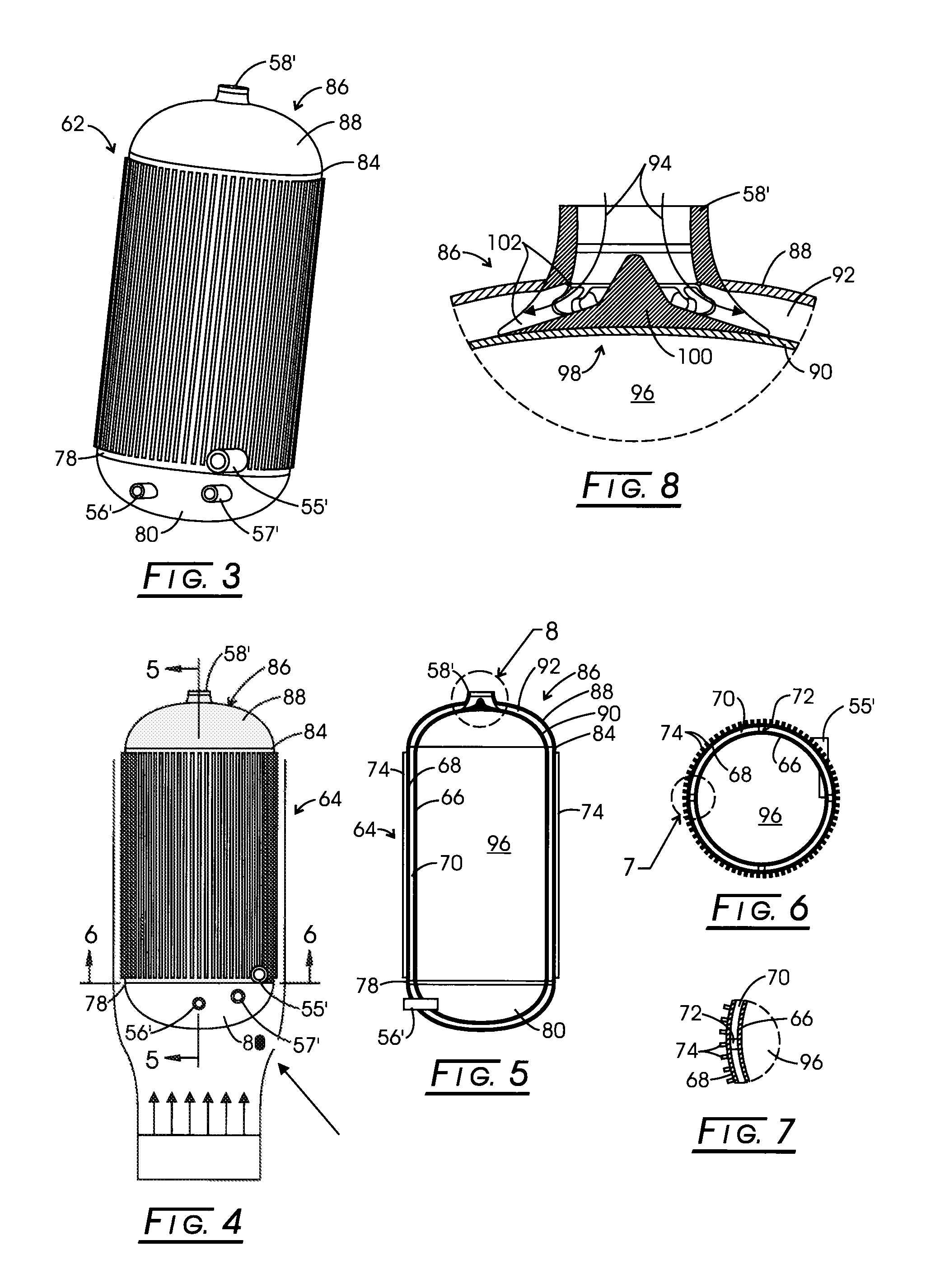

Air separator for low flow rate cooling systems

ActiveUS7395787B1Easy to operateEffectively removes air bubbleAir-treating devicesCoolant flow controlEngineeringStreamflow

An air separator for low flow rate coolant systems which removes air from the liquid coolant thereof. The air separator is a closed canister having a bottom wall, a top wall at a gravitationally high location with respect to the bottom wall, and a sidewall sealingly therebetween. A coolant inlet is at the sidewall, a pump outlet is at the bottom wall and a coolant reservoir outlet is at the top wall. The coolant reservoir outlet is connected to a coolant reservoir gravitationally elevated with respect to the canister. A much larger cross-sectional area per unit length of the canister relative to the piping results in a coolant dwell time in the canister that encourages coolant air bubbles to migrate toward the coolant reservoir.

Owner:GM GLOBAL TECH OPERATIONS LLC

System and method for removing heat from a subscriber optical interface

InactiveUS7355848B1Minimize heat transferMaximize heat transferCouplings bases/casesHeat exchange apparatusEngineeringStack effect

A system and method removes heat from an enclosure or housing of a subscriber optical interface. When a subscriber optical interface housing is attached to a structure such that a partially enclosed volume of space remains between the structure and the subscriber optical interface housing, this partially enclosed volume of space can produce a chimney effect when heat from the subscriber optical interface housing is intended to flow from fins towards the structure. This chimney effect can refer to a fluid such as air within the partially enclosed space that is heated by the fins and that rises upward when the ambient or surrounding fluid is cooler relative to the heated fluid. According to another exemplary embodiment, the subscriber optical interface can be shaped to form an internal chimney structure that is entirely surrounded by a housing of the subscriber optical interface.

Owner:ARRIS SOLUTIONS

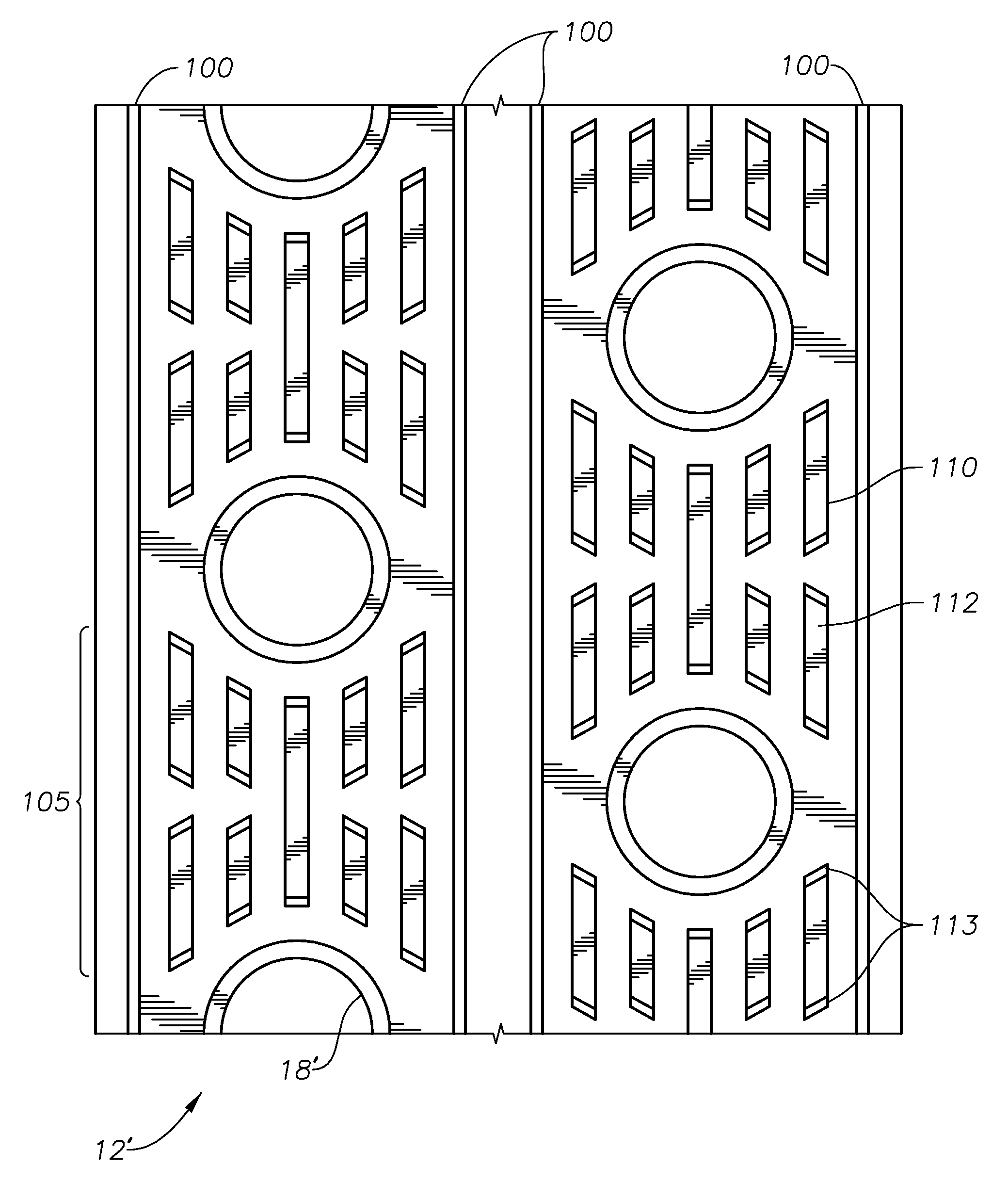

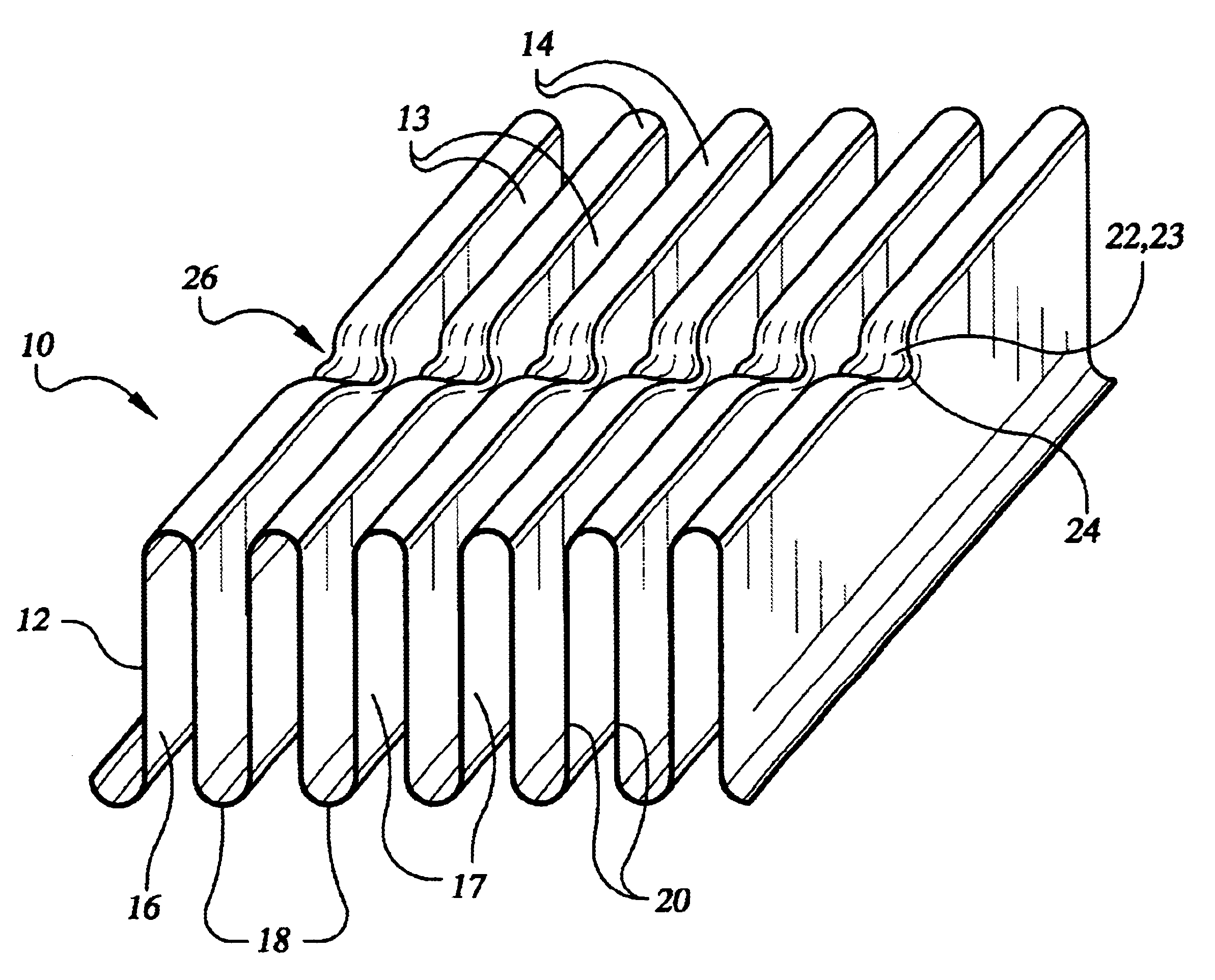

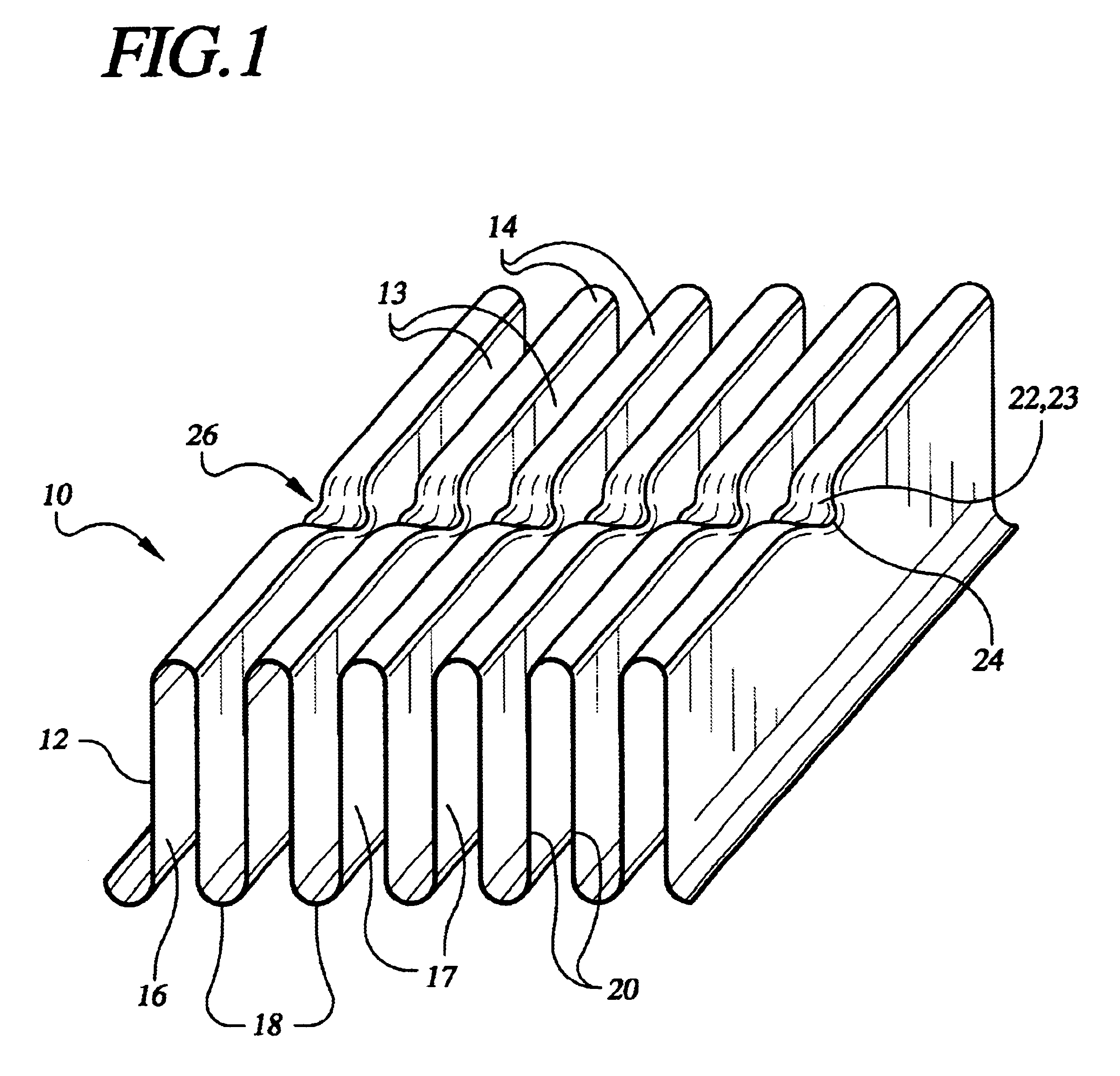

Method for Manufacturing Tube and Fin Heat Exchanger with Reduced Tube Diameter and Optimized Fin Produced Thereby

InactiveUS20090308585A1Increase stiffnessImprove rigidityHeat exhanger finsStationary conduit assembliesEngineeringImproved method

An improved method for manufacturing tube and fin heat exchangers that, according to a preferred embodiment, includes a process for increasing the stiffness and rigidity of heat exchanger fins. Stiffer fins have a greater tendency to maintain proper alignment within a stack of fins, which aids in lacing long stacks of fins with small (e.g., 5 mm) diameter tubing. Preferably, fin stiffness is increased by forming a plurality of longitudinal ribs within the fin during the fin stamping process. More preferably still, two ribs for each longitudinal row of collared holes are provided. The preferred embodiment also includes a slotted heat exchanger fin that is dimensioned and arranged for optimized thermodynamic performance when used with small diameter tubing, thus reducing the space required for a given heat exchanger system.

Owner:GOODMAN GLOBAL INC

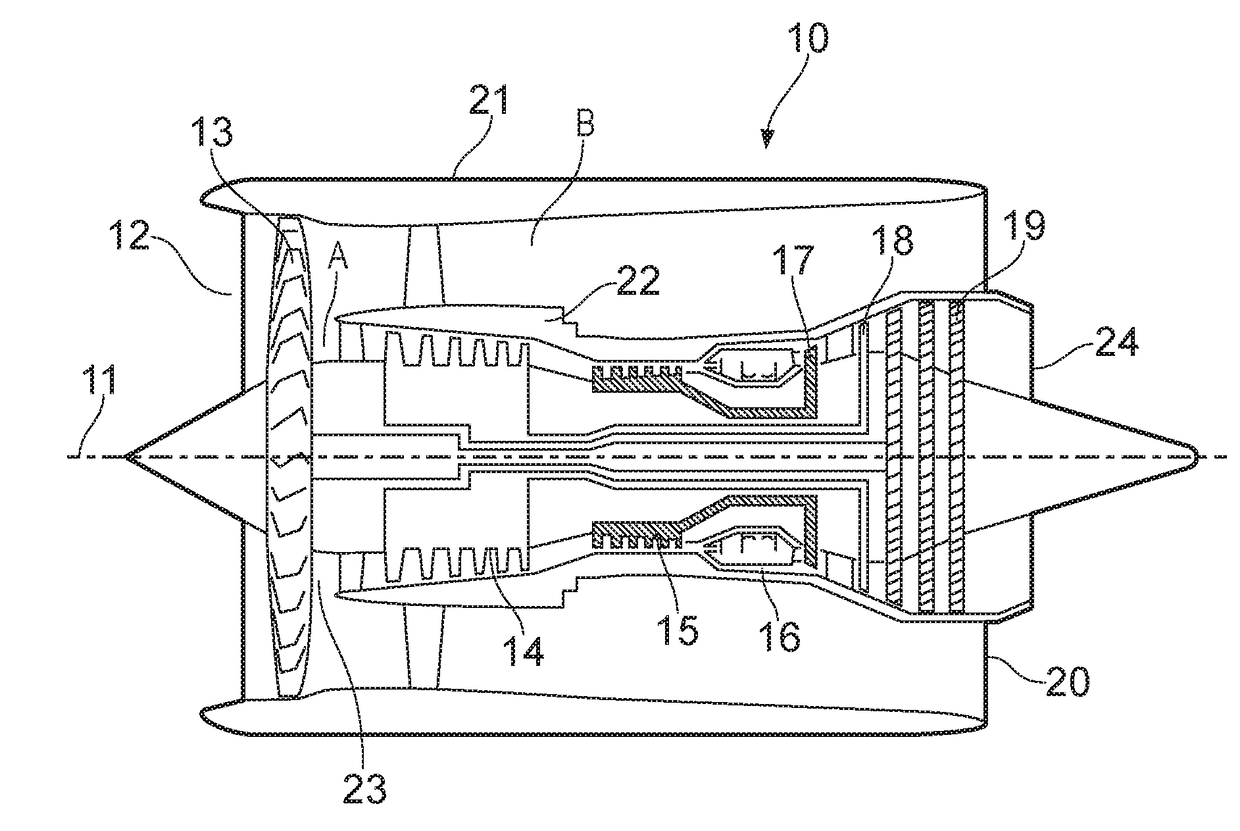

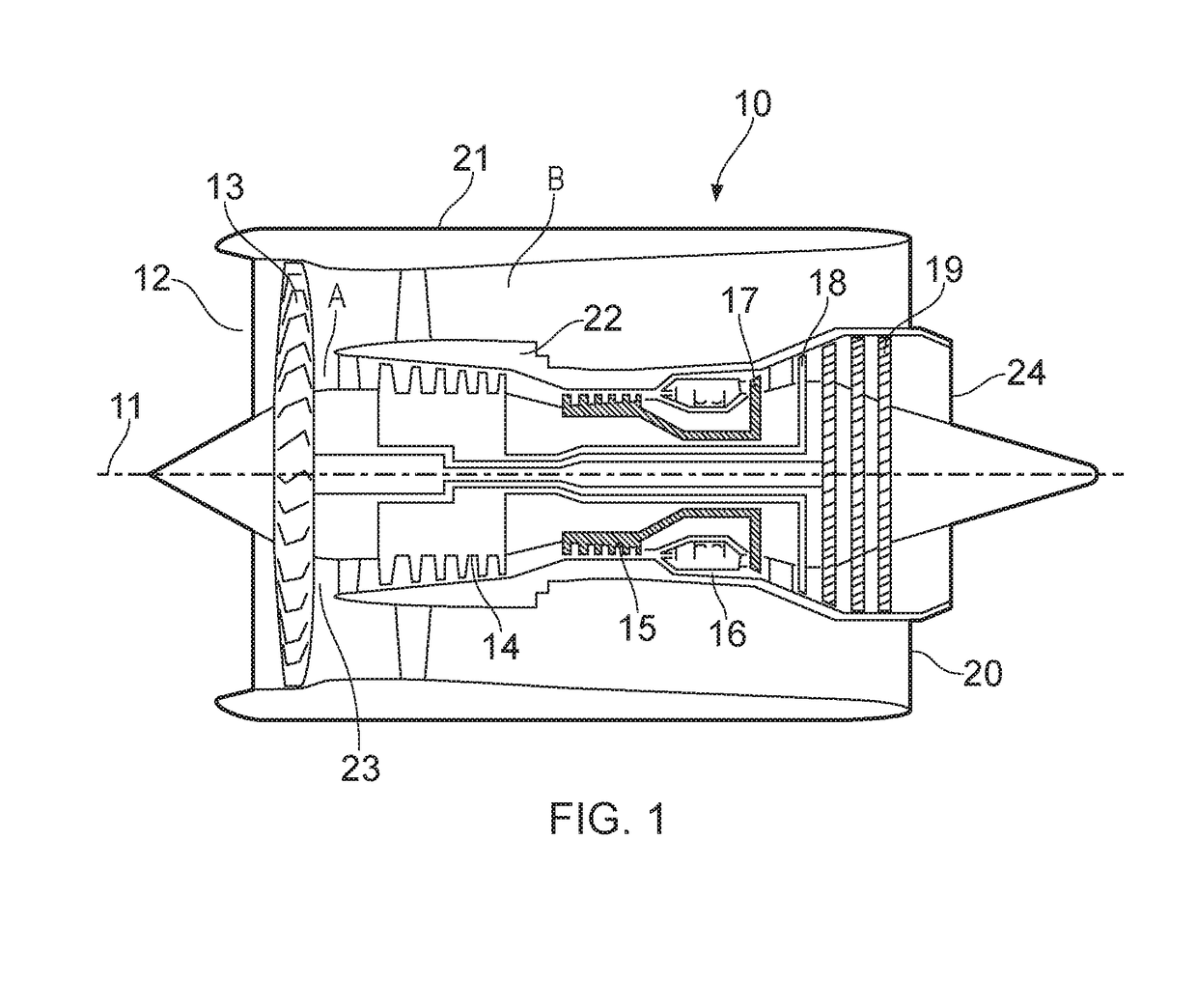

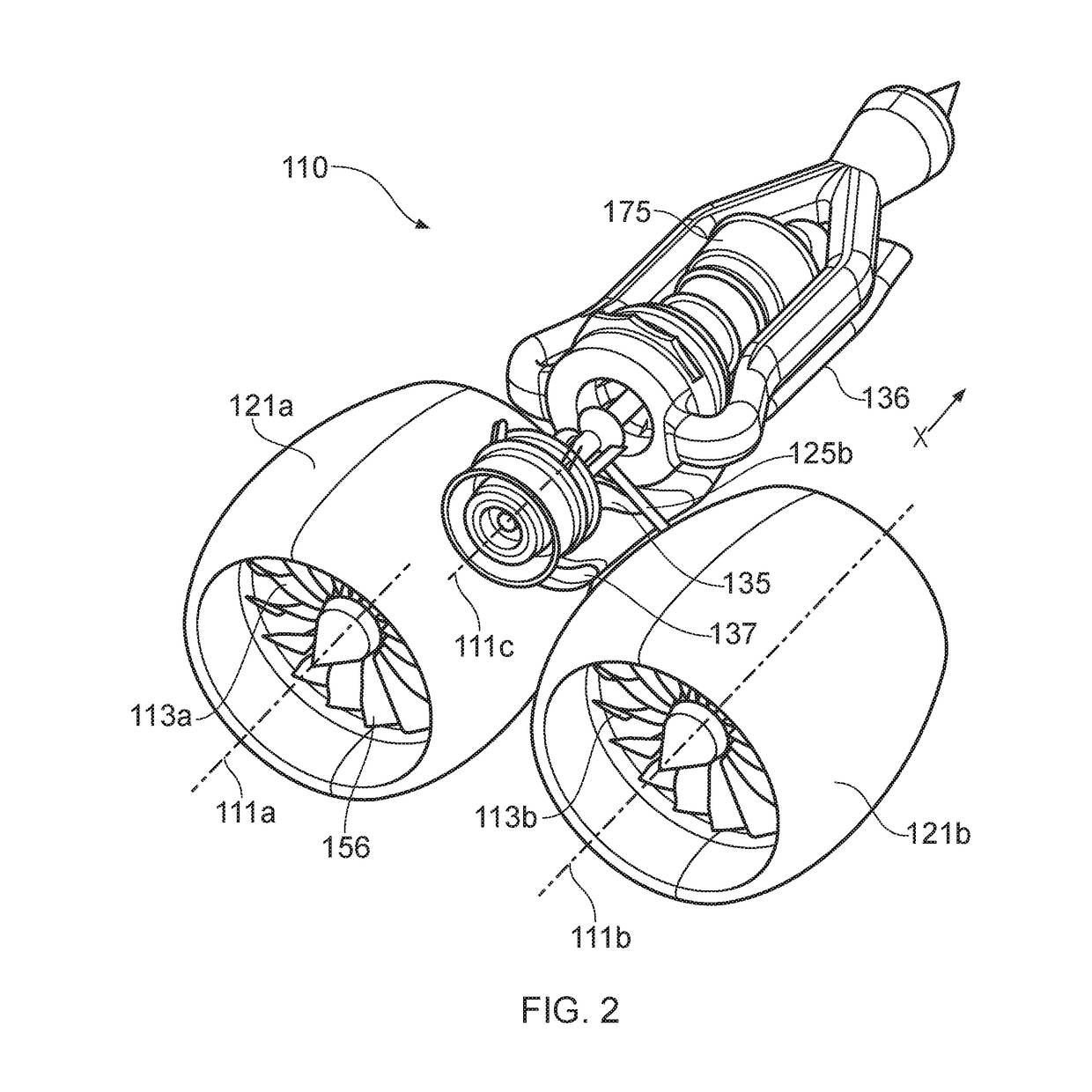

Gas turbine engine

InactiveUS20170369179A1Improve turbine efficiencyReduce in quantityElectric power distributionGas turbine type power plantsTurbineGas turbines

An aircraft gas turbine engine (110) comprises first and second non-coaxial propulsors (113a, 113b), each propulsor (113a, 113b) being driven by a common gas turbine engine core (176) comprising a propulsor drive turbine (143) arranged to drive the first and second propulsors (113a, 113b) via a propulsor drive coupling (127). The core (176) further comprises a first core module (190) comprising a first compressor (129) and a first turbine (131) interconnected by a first shaft (177), and a second core module (191) comprising a second compressor (128) and the propulsor drive turbine (143) interconnected by a second shaft (127), the first and second core modules (190, 191) being axially spaced.

Owner:ROLLS ROYCE PLC

Silica gel based carbon material oriented heat conduction interface material and production method thereof

The invention relates to a silica gel based carbon material oriented heat conduction interface material. The material comprises components in percentage by weight as follows: 9.5%-20% of siloxane-based resin with the viscosity being 200 cp-2,000 cp, 19.5%-35% of heat conductive filler, 35%-70% of an anisotropic carbon material and 1%-10% of an auxiliary agent and is prepared with a stirring and curing production method. The silica gel based carbon material oriented heat conduction interface material has the advantages as follows: according to the heat conductive interface material prepared by mixing the siloxane-based resin with the viscosity being 200 cp-2,000 cp, the heat conductive filler, the anisotropic carbon material and the auxiliary agent, the anisotropic carbon material mixed in gel is orientated through electric fields on upper and lower surfaces, longitudinal orientation of the carbon material is realized, the conduction path of the heat conductive material is in the direction where the large heat conduction coefficient is large, and the heat conduction performance is realized to the maximum; with the addition of the heat conductive filler, the defect that the heat conduction performance of the carbon material in direction, perpendicular to the orientation direction, of the carbon material, namely, in the horizontal direction of mixed gel, is poor after the anisotropic carbon material is orientated is overcome, balanced conduction of heat is guaranteed, and a production method is simple.

Owner:PINGHU ALLIED IND

Garment for a cooling and hydration system

InactiveUS20060191063A1Maximum comfortMinimal contaminationChemical protectionGarment special featuresActive coolingEngineering

A garment is provided which is worn by a wearer and which actively cools the wearer. A heat transfer fluid pathway is provided which feeds the heat transfer fluid through a vest and cap or other heat transfer garment, where the heat transfer fluid draws heat away from the body of the wearer. The pathway is established between an inner layer proximate to the body of the wearer and an outer layer. Dots are provided which connect the inner layer and the outer layer together within the pathway. Fences are provided and borders to channel the heat transfer fluid along the pathway within the garment. A supply of elevated pressure air is optionally provided to maintain optimal contact for efficient heat transfer between the heat exchange fluid within the garment and the body of the wearer.

Owner:WELKINS

Wearable personal cooling and hydration system

InactiveUS7509692B2Maximize heat transferMaximize heat absorptionChemical protectionGarment special featuresTemperature controlEngineering

Owner:WELKINS

Corrugated fin heat exchanger and method of manufacture

InactiveUS6688380B2Drag minimizationReduce manufacturing costMetal-working apparatusStationary conduit assembliesPlate heat exchangerMetal sheet

A heat exchanger includes a corrugated metal sheet comprising a first side having a plurality of first troughs alternating with a plurality of first peaks, and a second side having a plurality of second troughs alternating with a plurality of second peaks, each trough being formed by a pair of walls, each wall separating the first side from the second side and extending from a first peak to a second peak, the troughs and peaks extending in parallel and defining a longitudinal direction. Each first peak is formed with at least one depression, the depressions in respective peaks being aligned to form at least one tube-receiving channel extending transversely to the longitudinal direction. Each depression has a contact surface formed in the first side and extending laterally over each adjacent first trough. A tube section is received in each tube-receiving channel in substantially conforming contact with the contact surfaces. The heat exchanger is manufactured using first and second fixtures having first and second sets of parallel ribs which are received in respective second and first troughs of the corrugated sheet. The first peaks are formed downward using a mandrel received through windows interrupting the second ribs, the depressions being formed in corresponding notches in the first ribs.

Owner:AAVID THERMALLOY LLV

Passive heat extraction and electricity generation

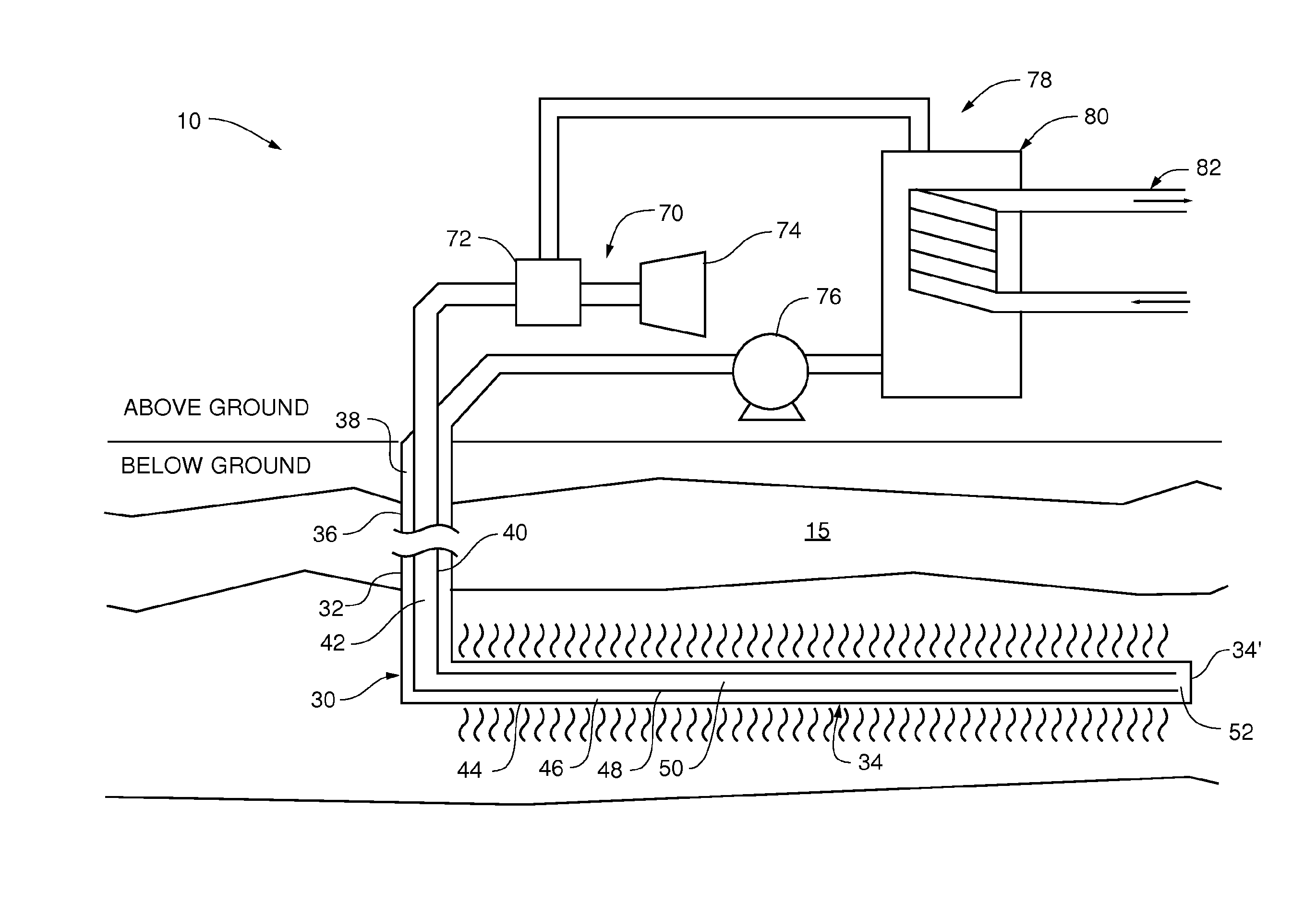

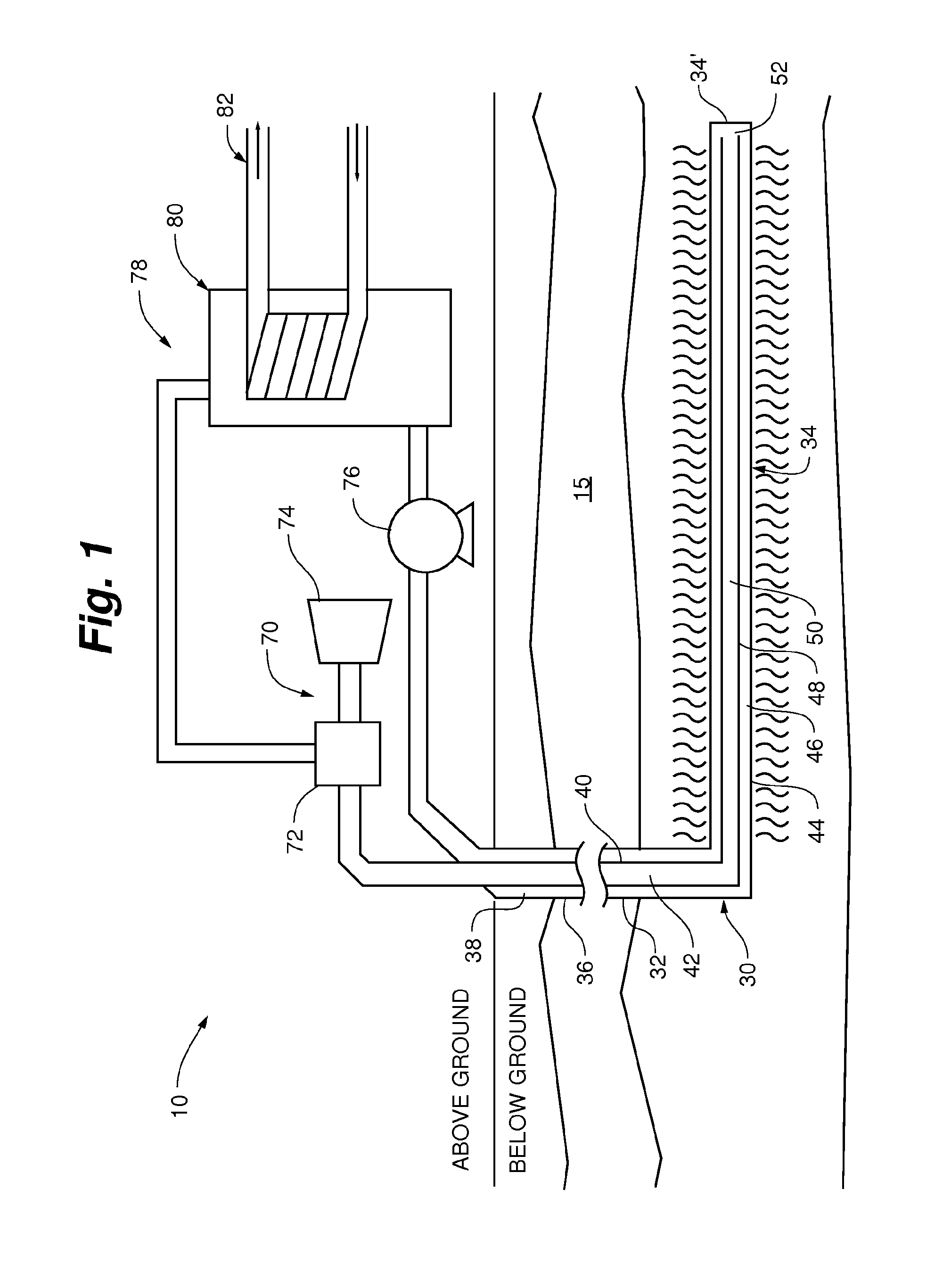

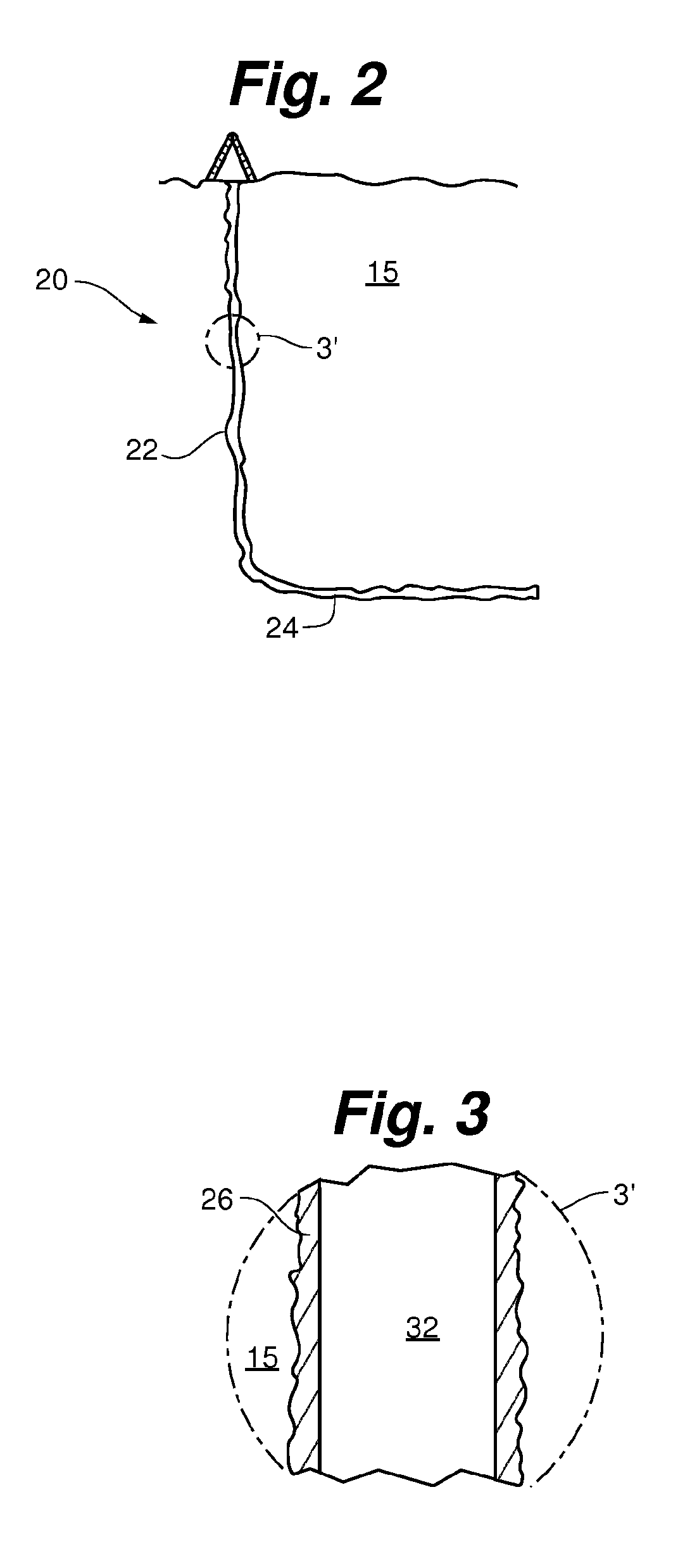

ActiveUS20130333383A1Increased contact surface areaImprove heat transfer efficiencyOther heat production devicesGeothermal energy generationThermal energyWorking fluid

A closed-loop heat exchange system and related methods for harnessing subterranean heat energy from a subterranean zone having a passive heat transfer device with multiple operational modes for targeting hotspots within the subterranean zone and adjusting the rate of energy harnessed according to consumption demands. The system can also have at least one enhanced surface section for increasing the heat exchange efficiency and / or a variable pump for controlling the rate at which the working fluid travels through the passive heat transfer device.

Owner:SCHWARCK STRUCTURE

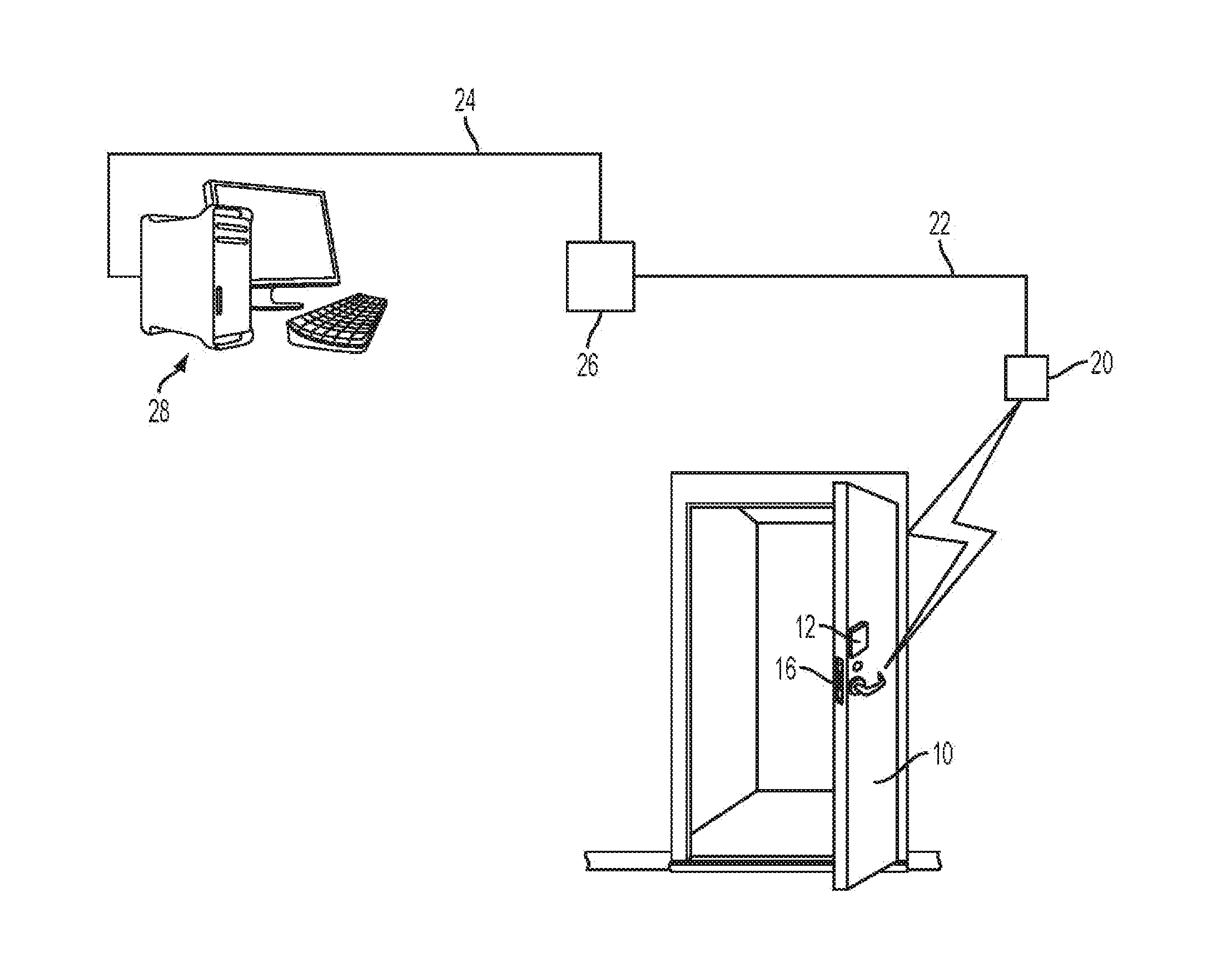

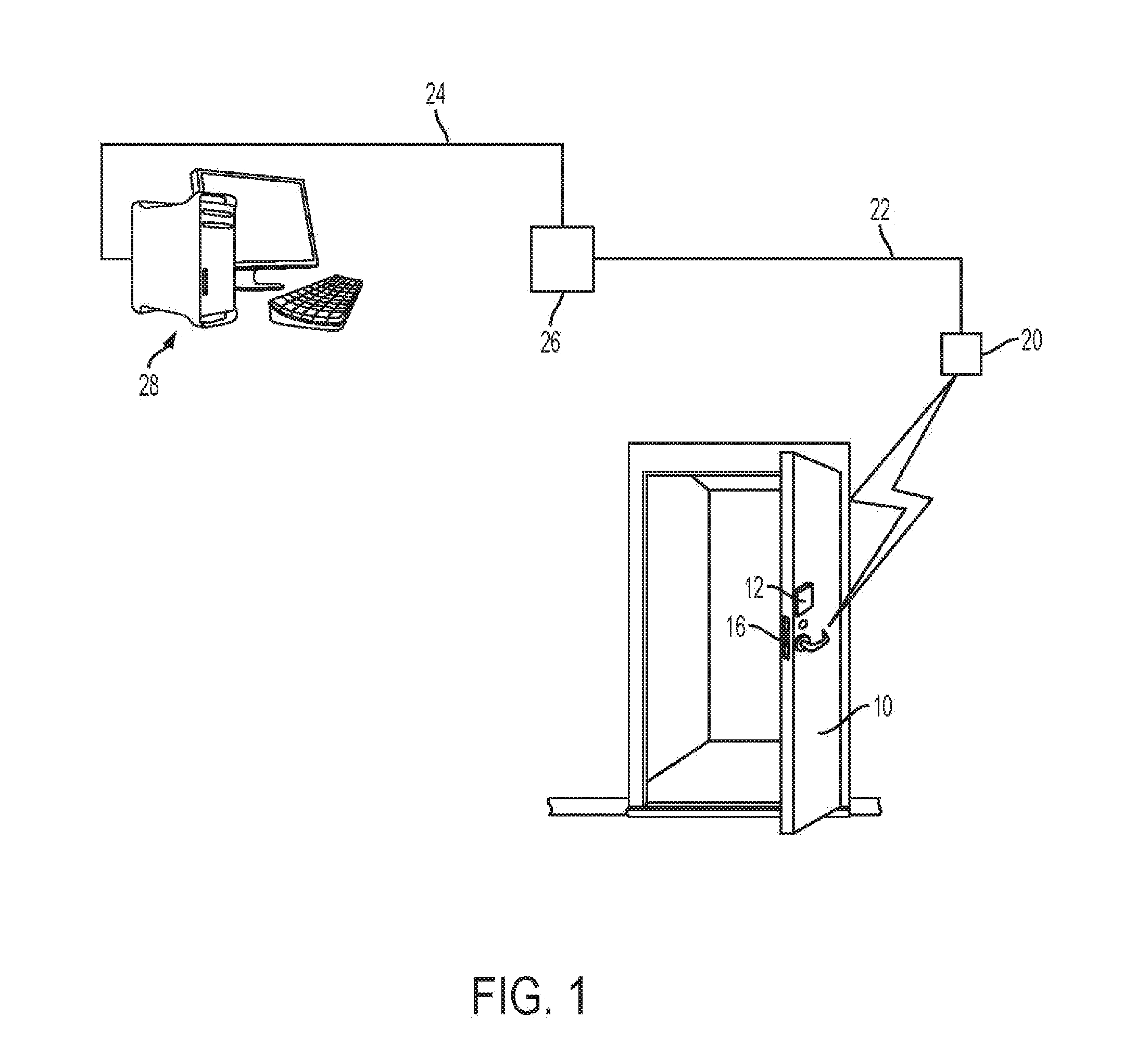

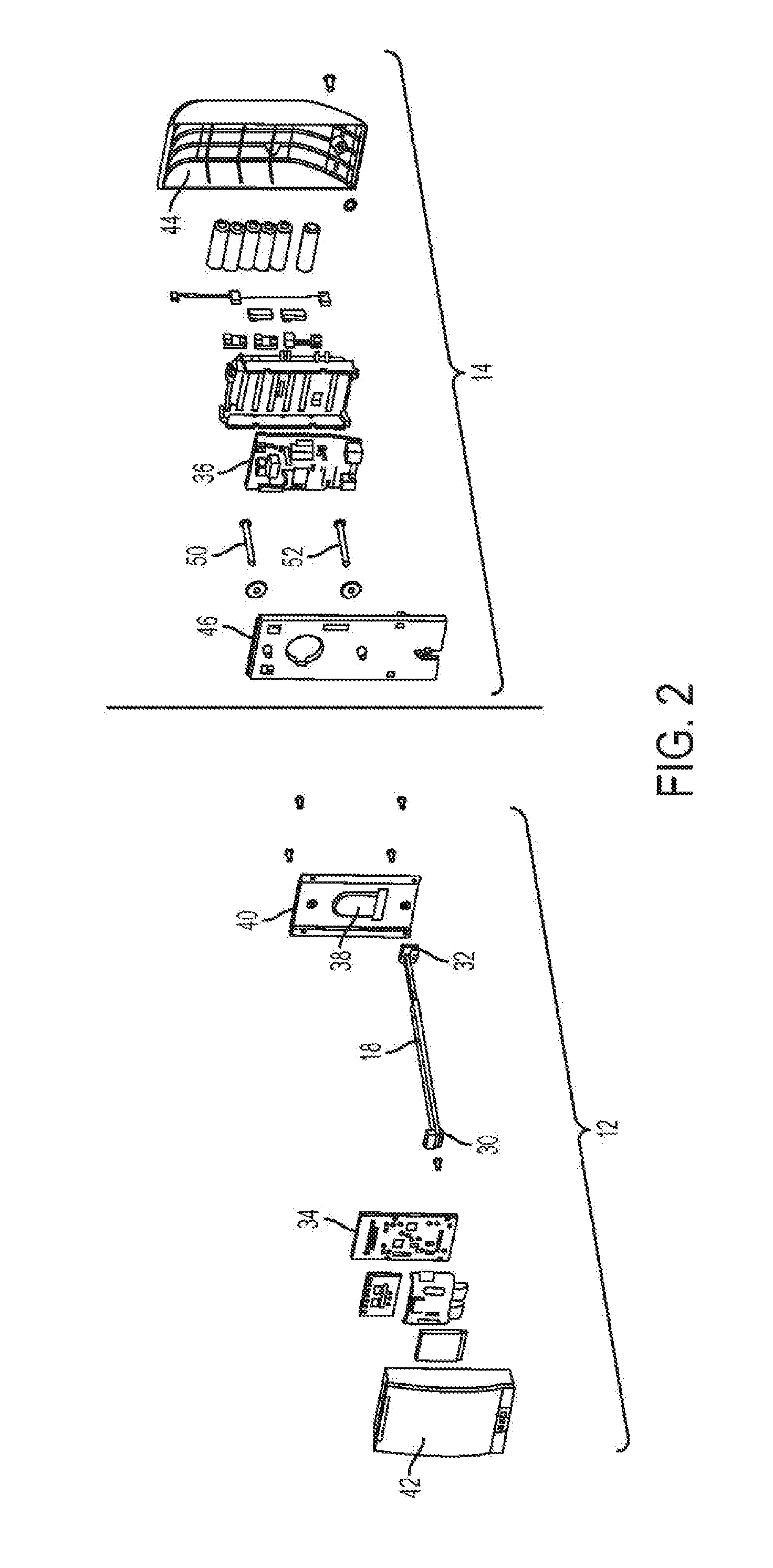

Fire actuated release mechanism to separate electronic door lock from fire door

ActiveUS20140318200A1Increase the lengthIncrease pull distanceBuilding locksFire rescueLocking mechanismRibbon cable

A release mechanism is actuated by the heat of a fire to electrically and mechanically disconnect electrical wiring from an electronic lock having a plastic housing. The electronic lock is mounted on a fire door and as it is heated by a fire on the opposite side of the fire door, mounts that hold the lock melt, releasing the electronic lock to drop away from the fire door and prevent ignition of the plastic housing. The release mechanism may use shape memory alloy wire to contract and disconnect a ribbon cable. Solder connectors may also be used to disconnect wires. Intumescent material that expands when heated is used to drive the lock mechanism away from the fire door and insulation is used to control the timing of melting.

Owner:SARGENT MANUFACTURING CO INC

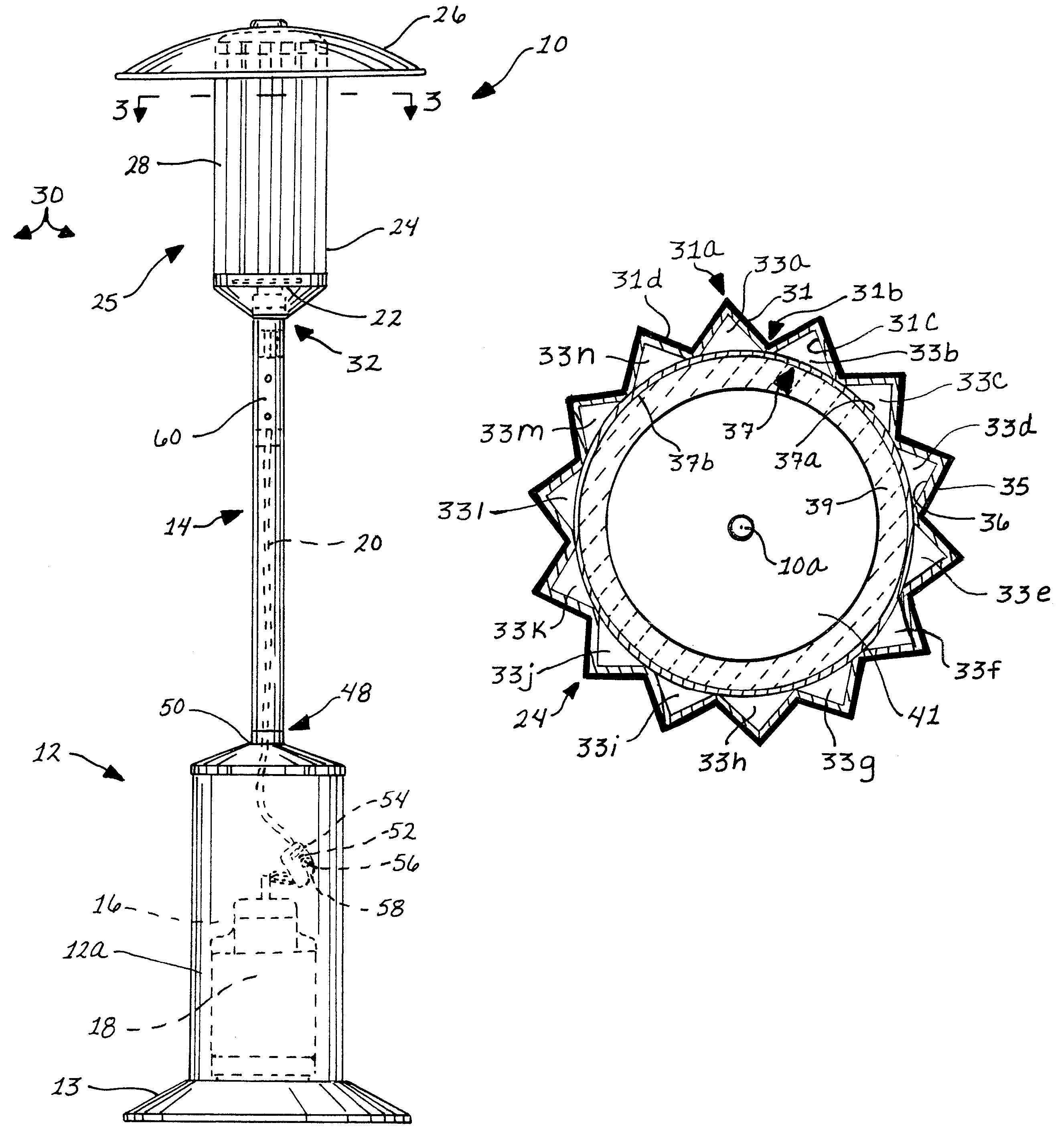

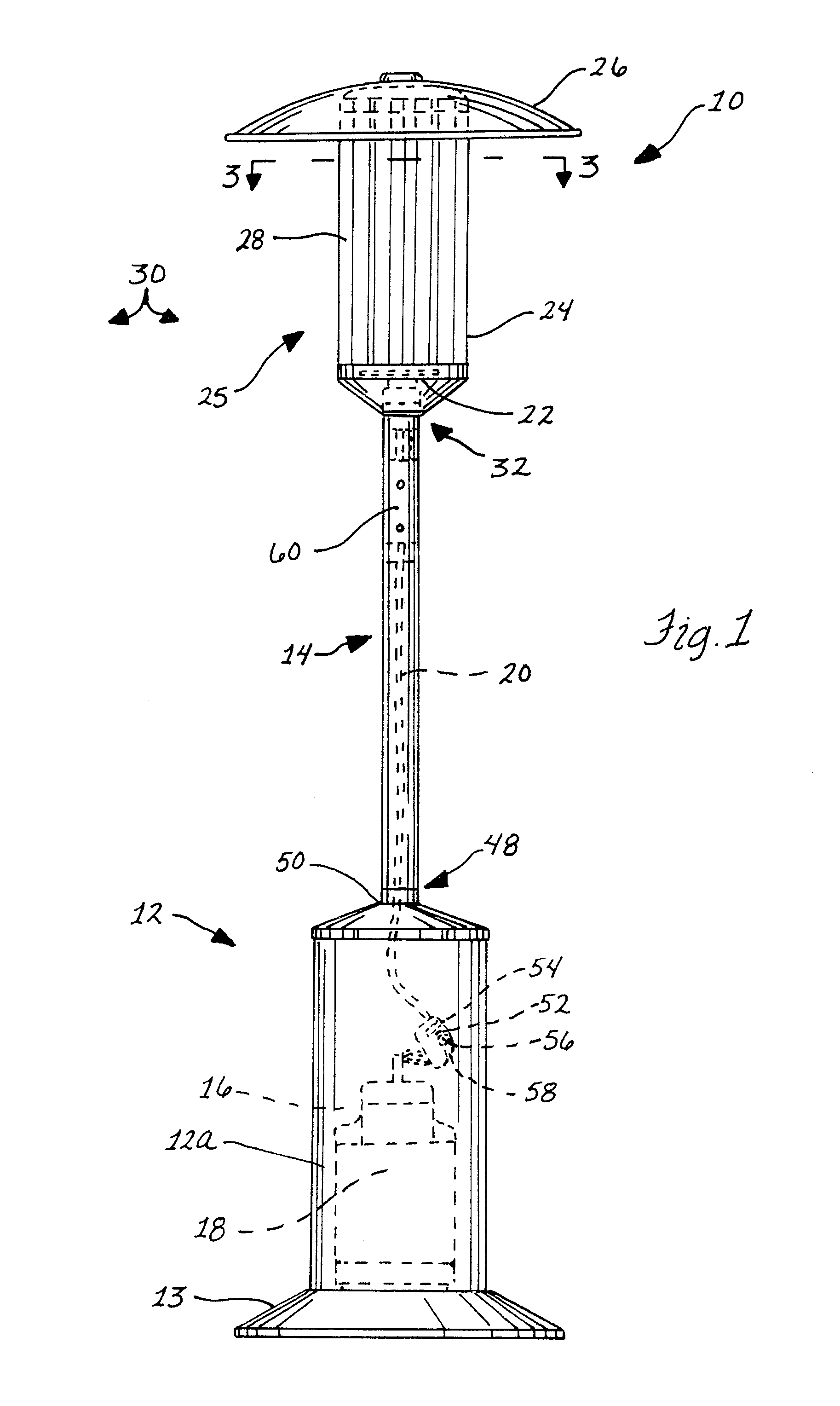

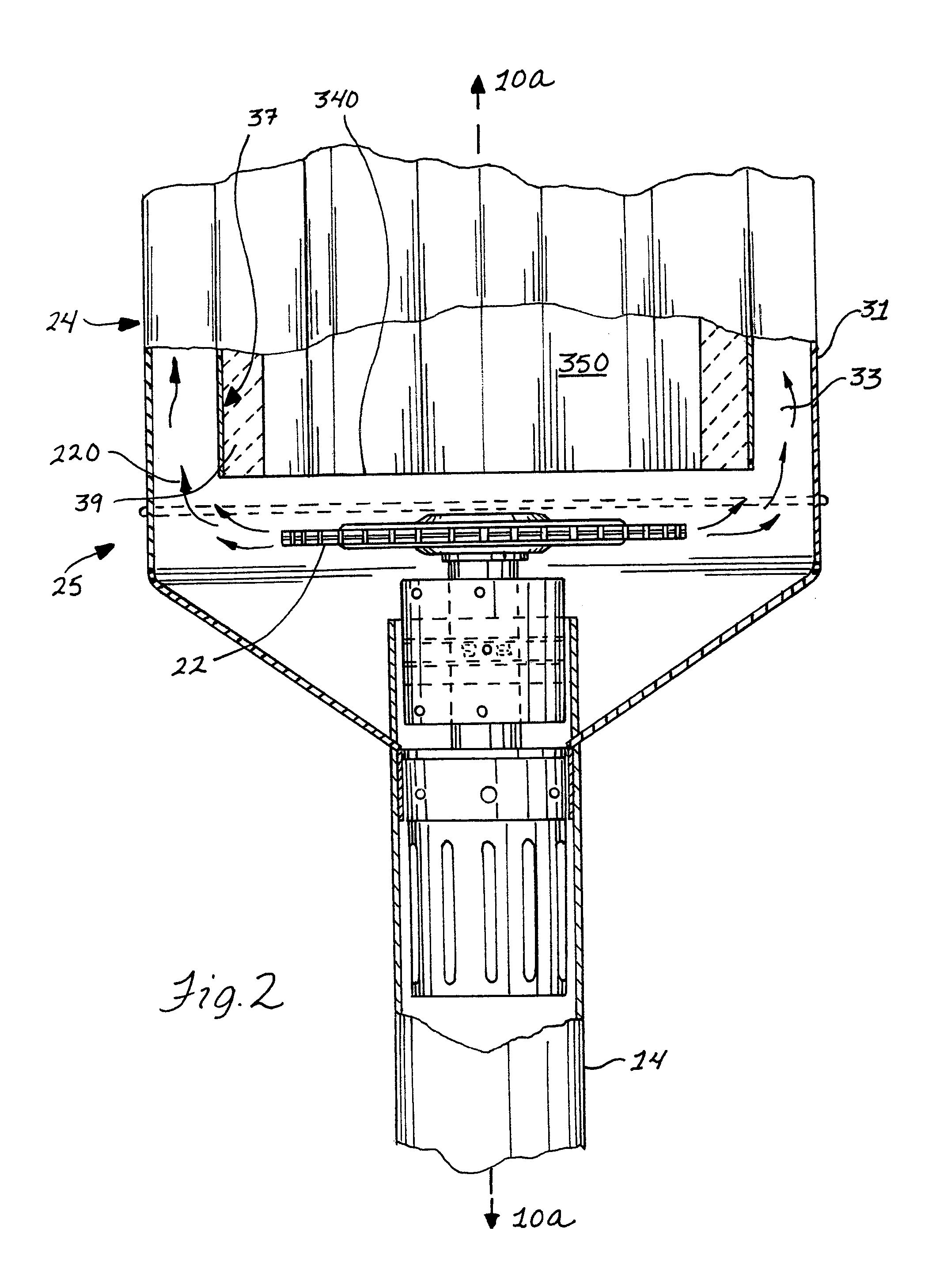

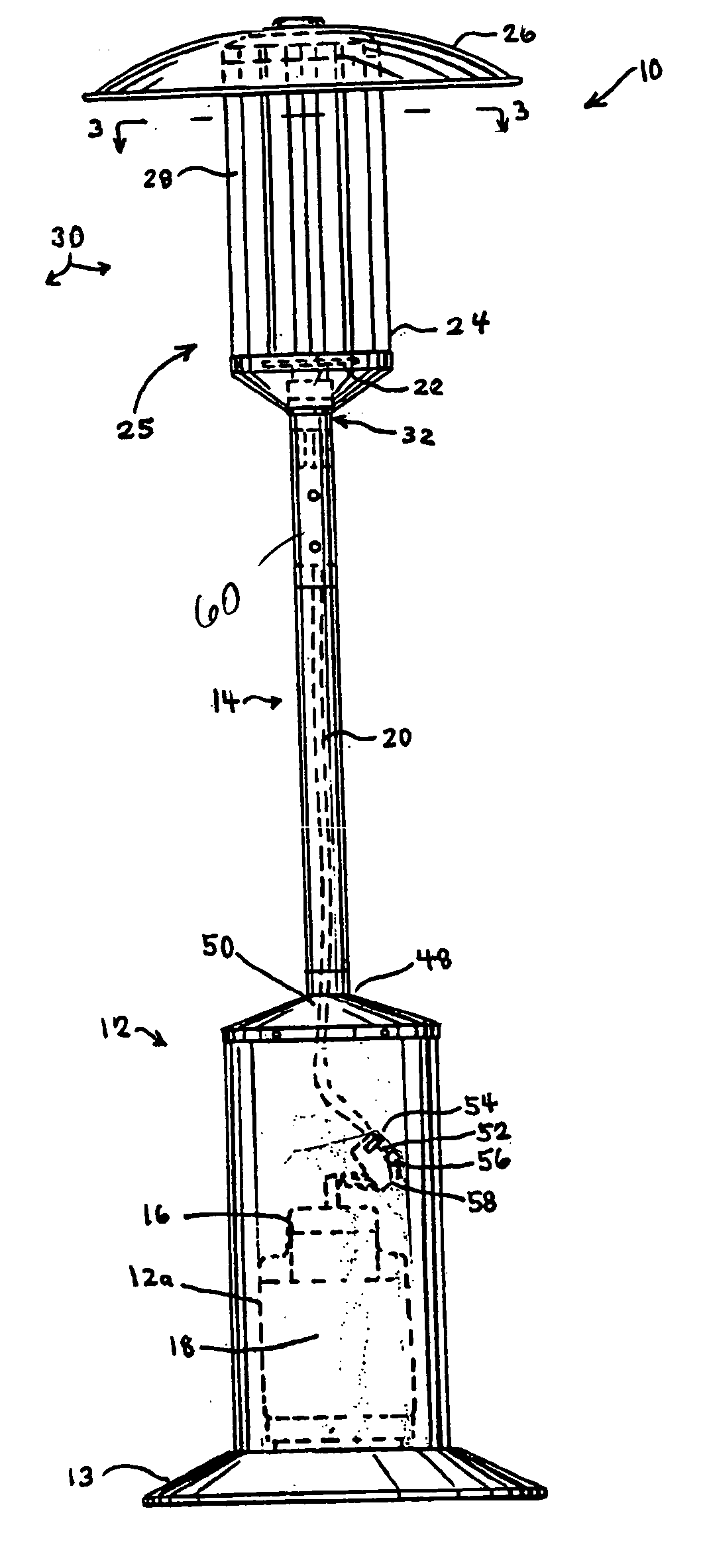

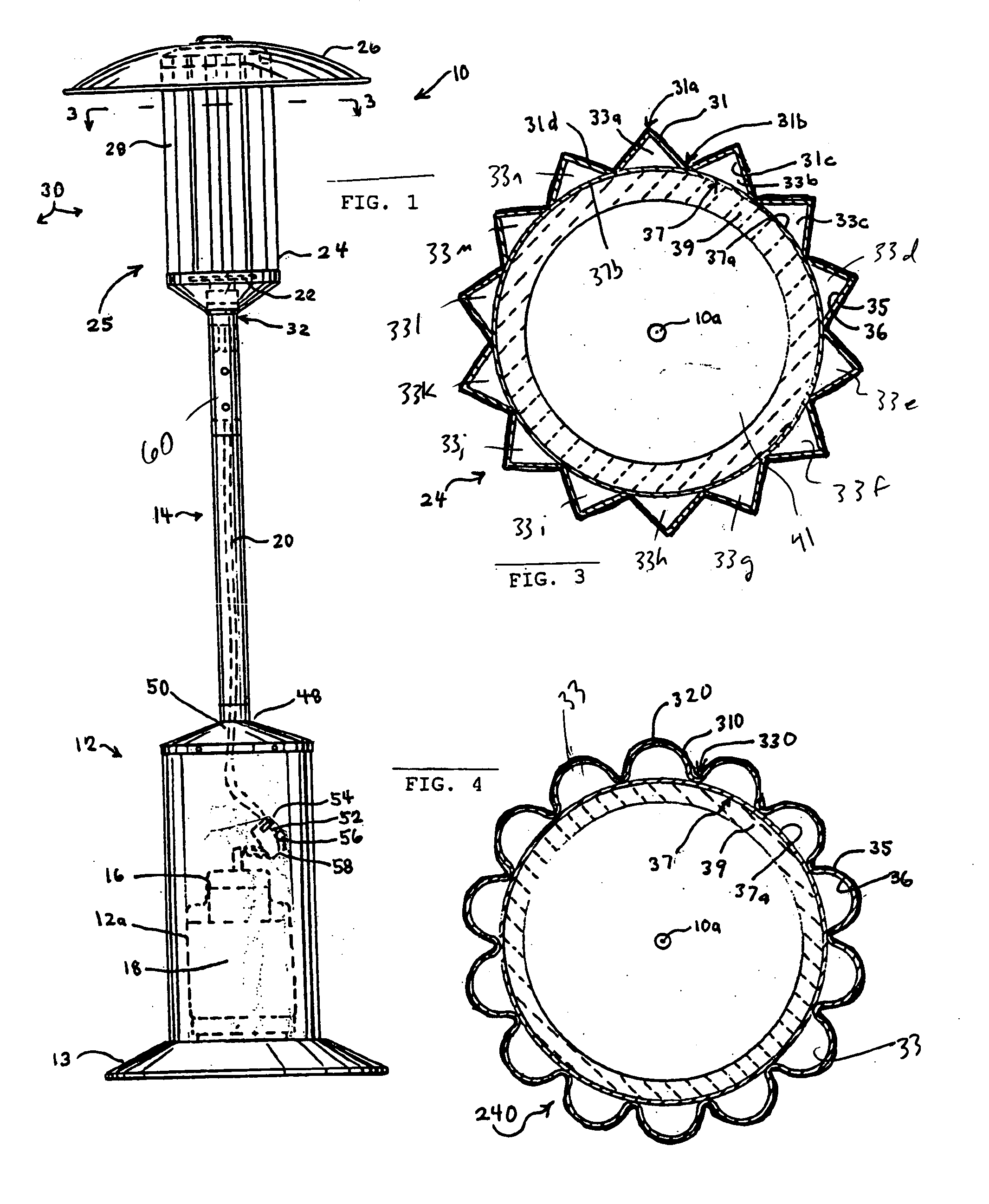

Heating apparatus

InactiveUS7086396B2Maximize heat transferMaximize sizeDomestic stoves or rangesMuffle furnacesCombustorDouble wall

A heating apparatus is provided that is optimized in terms of its heating efficiencies and wind proofing against flame out. The heating apparatus includes a heating head and a burner assembly for igniting fuel from a fuel source. The heating head has a dual-walled construction to form several flue chambers with the inner wall preferably being insulated to maximize heat transfer to the outer wall from combustion gases flowing through the flue chambers. The flue chambers can also be formed to be substantially isolated from each other and configured to generate turbulent gas flow therein for maximum heat transfer to the outer wall.

Owner:WATERS

Heating apparatus

InactiveUS20050175950A1Maximize heat transferMaximize sizeDomestic stoves or rangesMuffle furnacesCombustorEngineering

A heating apparatus is provided that is optimized in terms of its heating efficiencies and wind proofing against flame out. The heating apparatus includes a heating head and a burner assembly for igniting fuel from a fuel source. The heating head has a dual-walled construction to form several flue chambers with the inner wall preferably being insulated to maximize heat transfer to the outer wall from combustion gases flowing through the flue chambers. The flue chambers can also be formed to be substantially isolated from each other and configured to generate turbulent gas flow therein for maximum heat transfer to the outer wall.

Owner:WATERS

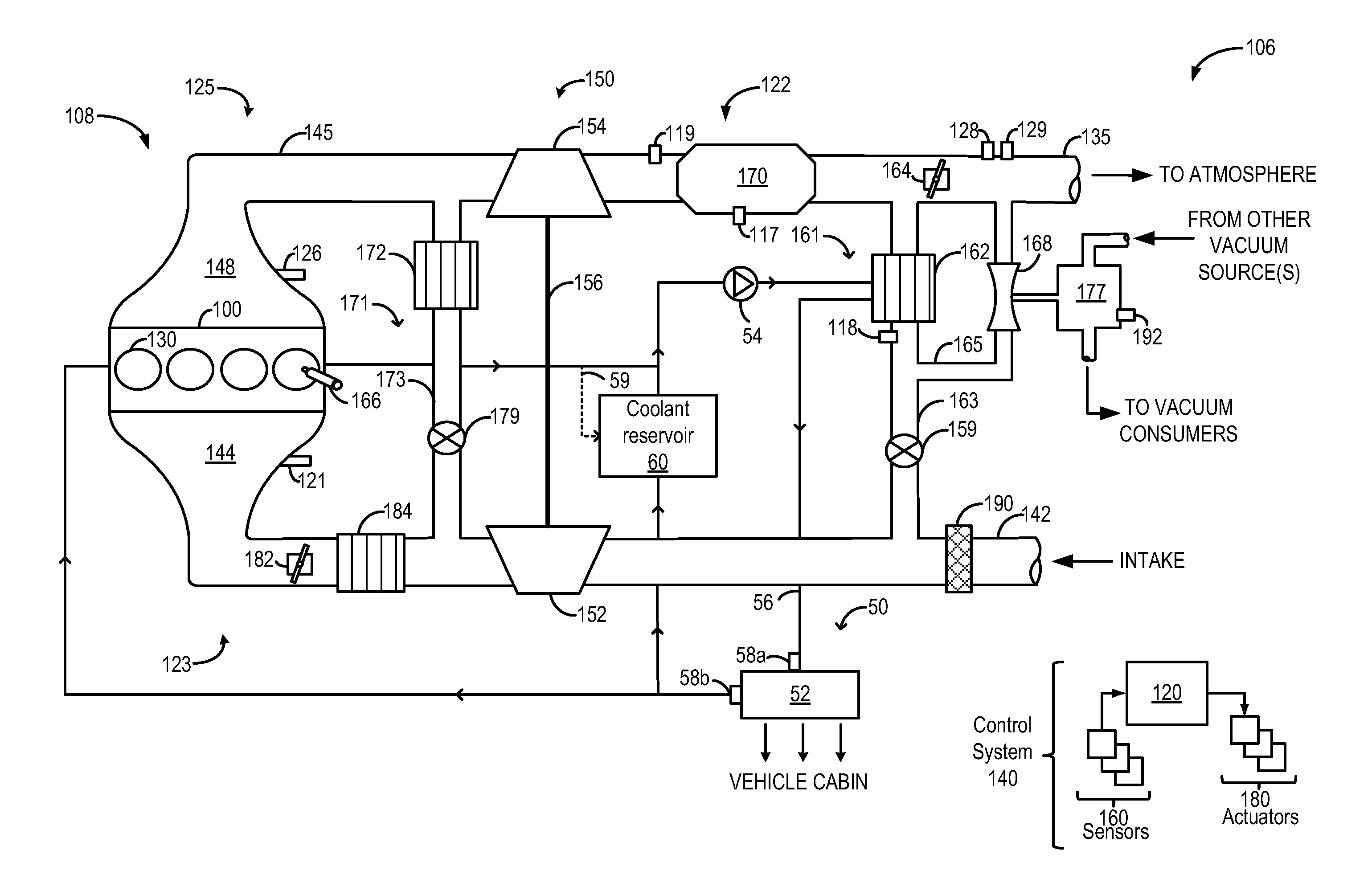

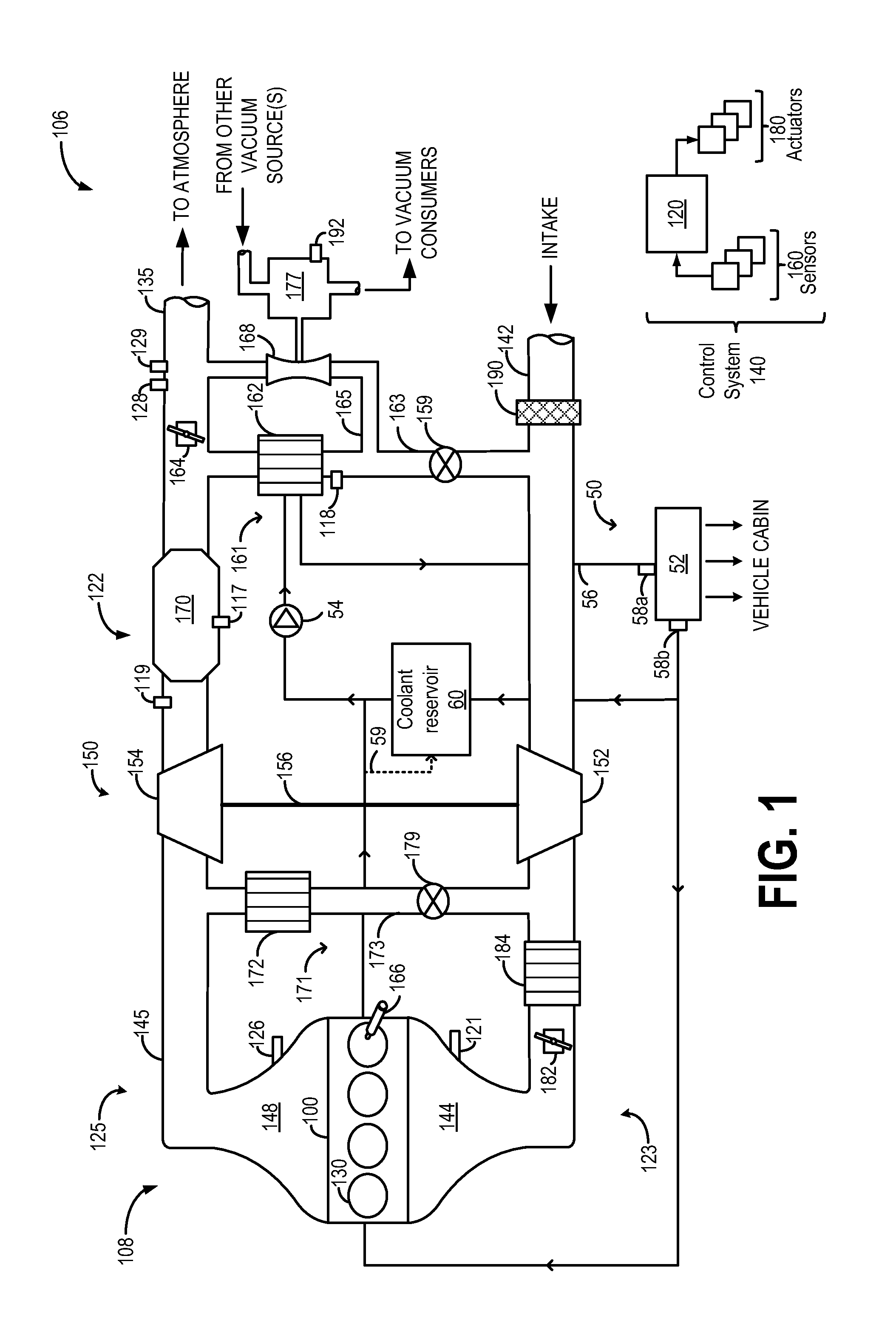

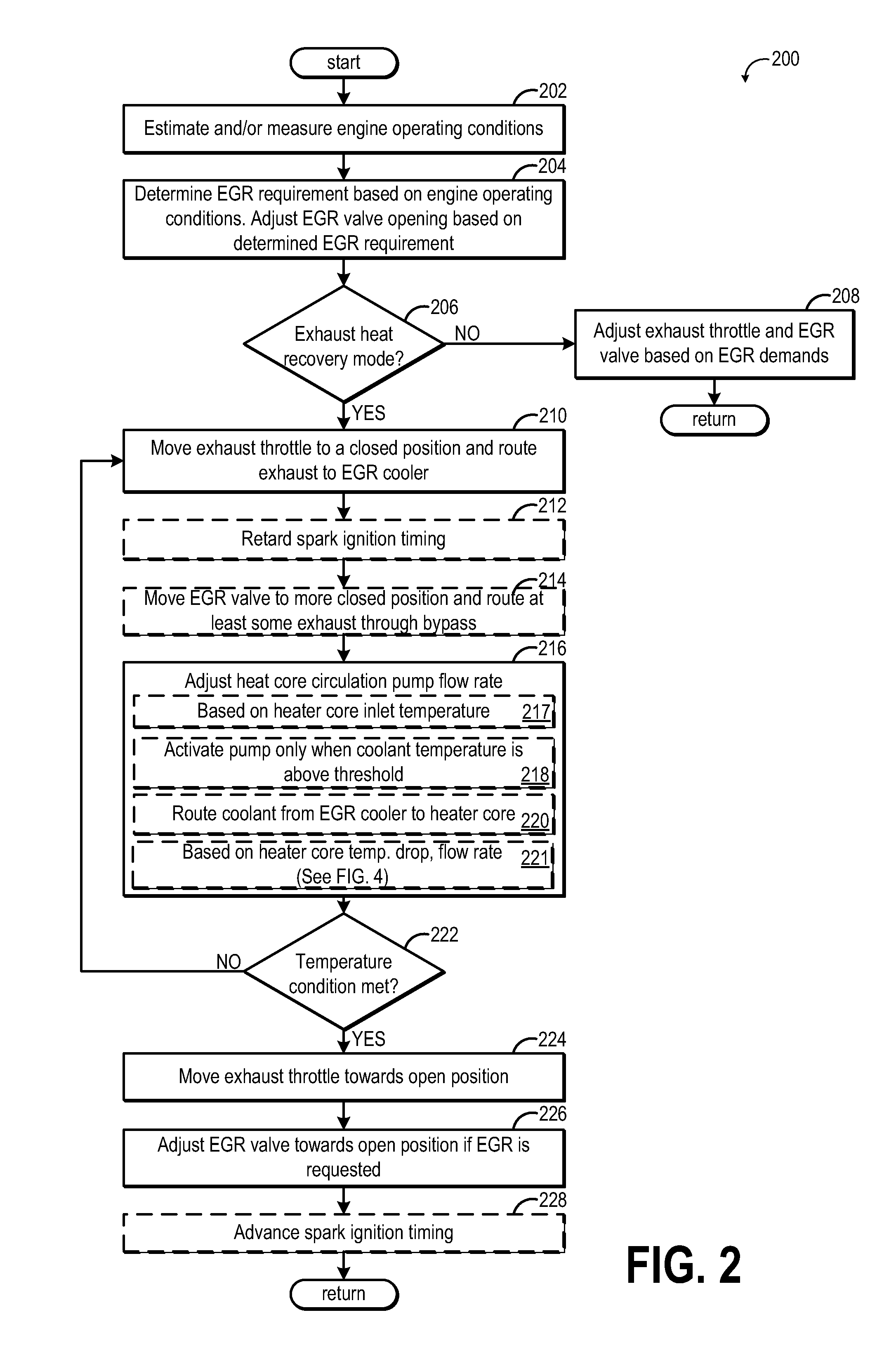

Exhaust throttling for cabin heating

ActiveUS20150121848A1Maximize heat transferConvenient amountInternal combustion piston enginesNon-fuel substance addition to fuelHeater coreHeat transfer

Embodiments for heating a vehicle cabin are disclosed. In one example, a method for an engine comprises pumping coolant from a coolant reservoir to an exhaust component and then to a heater core, the coolant heated by the exhaust component, and during engine warm-up conditions, adjusting a flow rate of coolant into a heater core to maximize heat transfer to a vehicle cabin.

Owner:FORD GLOBAL TECH LLC

Hydraulic reservoir with integrated heat exchanger

InactiveUS7458414B2Low costSmall sizeMachines/enginesStationary conduit assembliesPlate heat exchangerFuel tank

Improvement, in hydraulic systems, such as for vehicle transmissions and the like, in the form of a hydraulic reservoir with integrated heat exchanger having fluid supply / return and fluid return ports, including a central section, having inner and outer shell portions with a first gap therebetween, the outer shell being provided with a plurality of radially-spaced, external cooling fins, longitudinally-directed for the length of the central section; the ends of the latter being closed off via respective bottom and top cap portions, thereby defining a central fluid cavity, the top cap portion having spaced outer and inner cap portions, with a second gap therebetween, with a fluid inlet port, in the outer cap portion, directing incoming fluid from the second gap into and through the entire length of the first gap before entering the central fluid cavity, thereby maximizing heat transfer from the fluid via the plurality of cooling fins.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com