Method for Manufacturing Tube and Fin Heat Exchanger with Reduced Tube Diameter and Optimized Fin Produced Thereby

a technology of heat exchanger and tube, which is applied in the direction tubular elements, stationary conduit assemblies, etc., can solve the problems of limited commercial success of small diameter coils, prohibit commercially viable manufacturing of any but the shortest heat exchangers, and difficult lacing process, so as to increase the stiffness and rigidity of heat exchanger fins, increase the tendency to maintain proper alignment, and increase the effect of fin stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

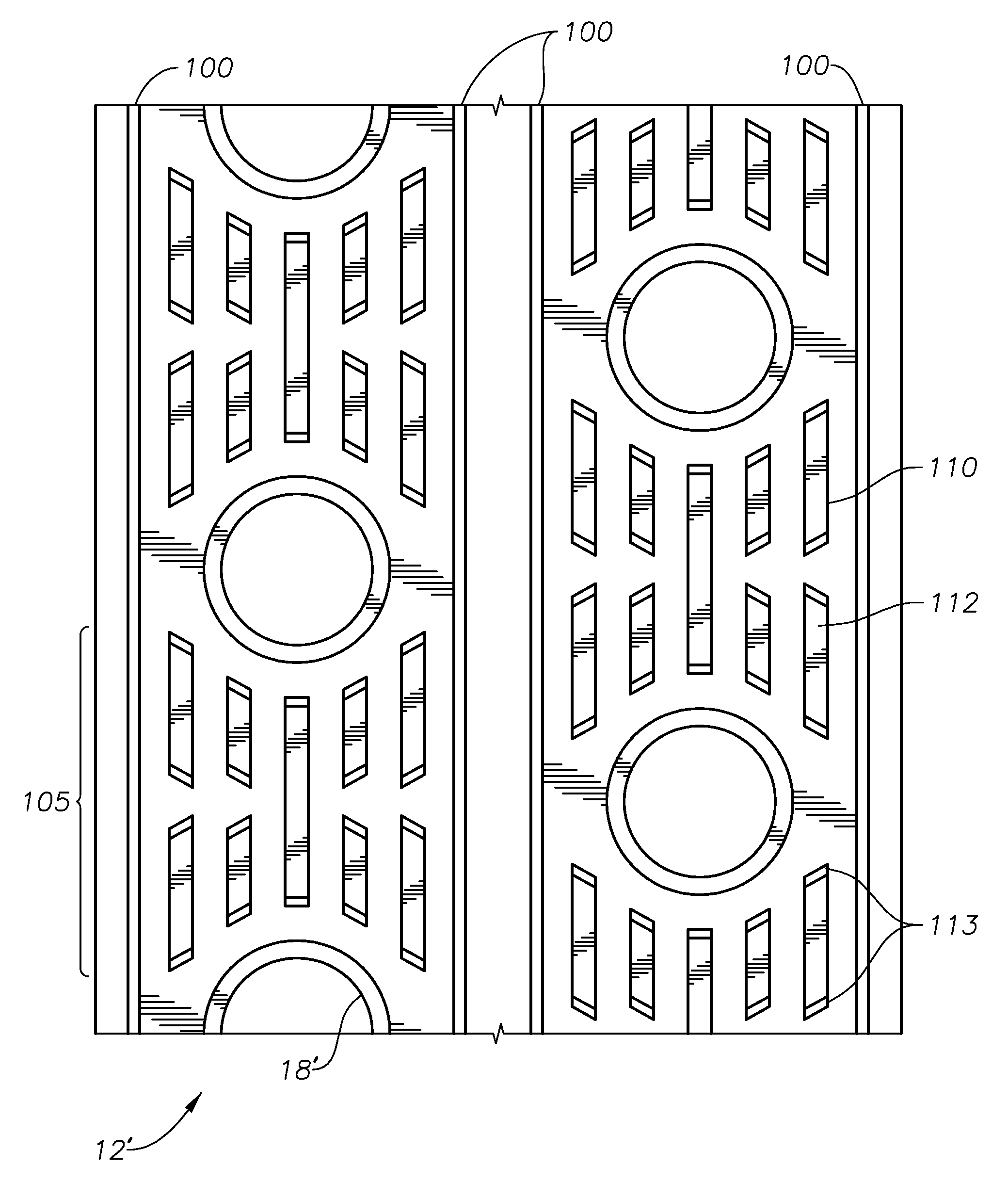

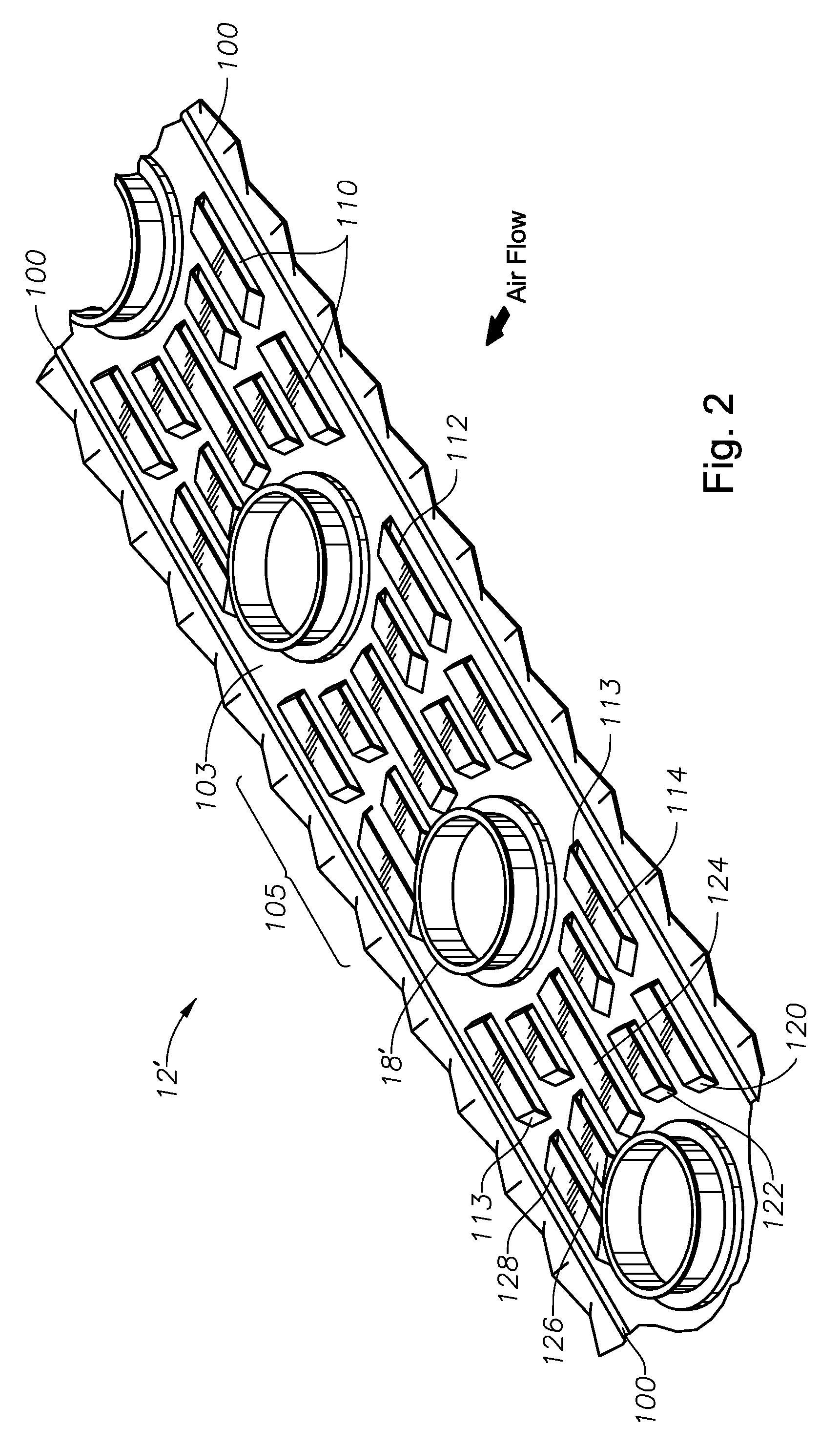

[0030]FIGS. 2-12 illustrate a fin 12′ dimensioned for small tubing, e.g. 5 mm outer diameter or less, optimized for use with a condenser or evaporator of a conventional air conditioner. FIGS. 2 and 3 illustrate a heat exchanger fin 12′ according to a first embodiment of the invention that is characterized by a single longitudinal row of collared holes 18′ for use in a single-row coil assembly. FIGS. 4-8 illustrate a heat exchanger fin 12′ according to a second embodiment of the invention that contains two longitudinal rows of collared holes 18′ for use in a double-row coil assembly. However, fins 12′ may be arranged for three, four, five, and six or more rows of coils according to the invention. The leading and trailing edges of fin 12′ preferably have corrugated edges.

[0031]Referring primarily to FIGS. 2-6, according to the preferred embodiment of the invention, a 5 mm or smaller tube and fin heat exchanger manufacturing process includes a novel and unobvious processing step in for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com