Forming method of electric connector

An electrical connector and molding method technology, applied in the field of electrical connector molding, can solve problems such as inability to ensure terminal coplanarity, achieve good technical interaction, reduce manufacturing risks, and improve product qualification rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

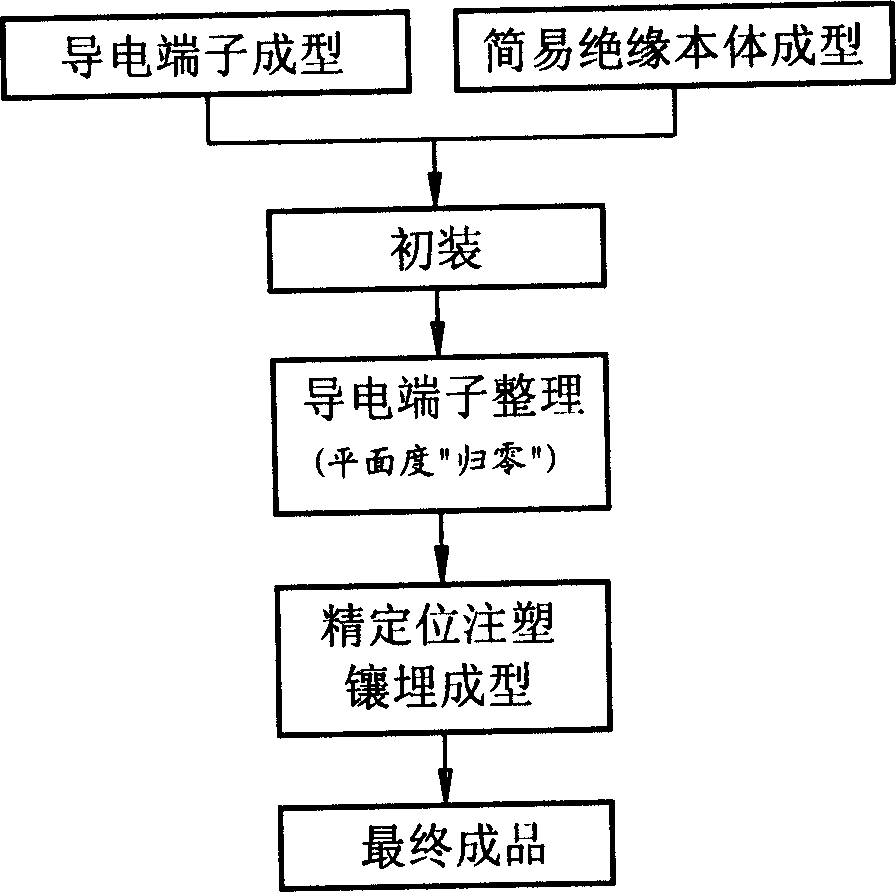

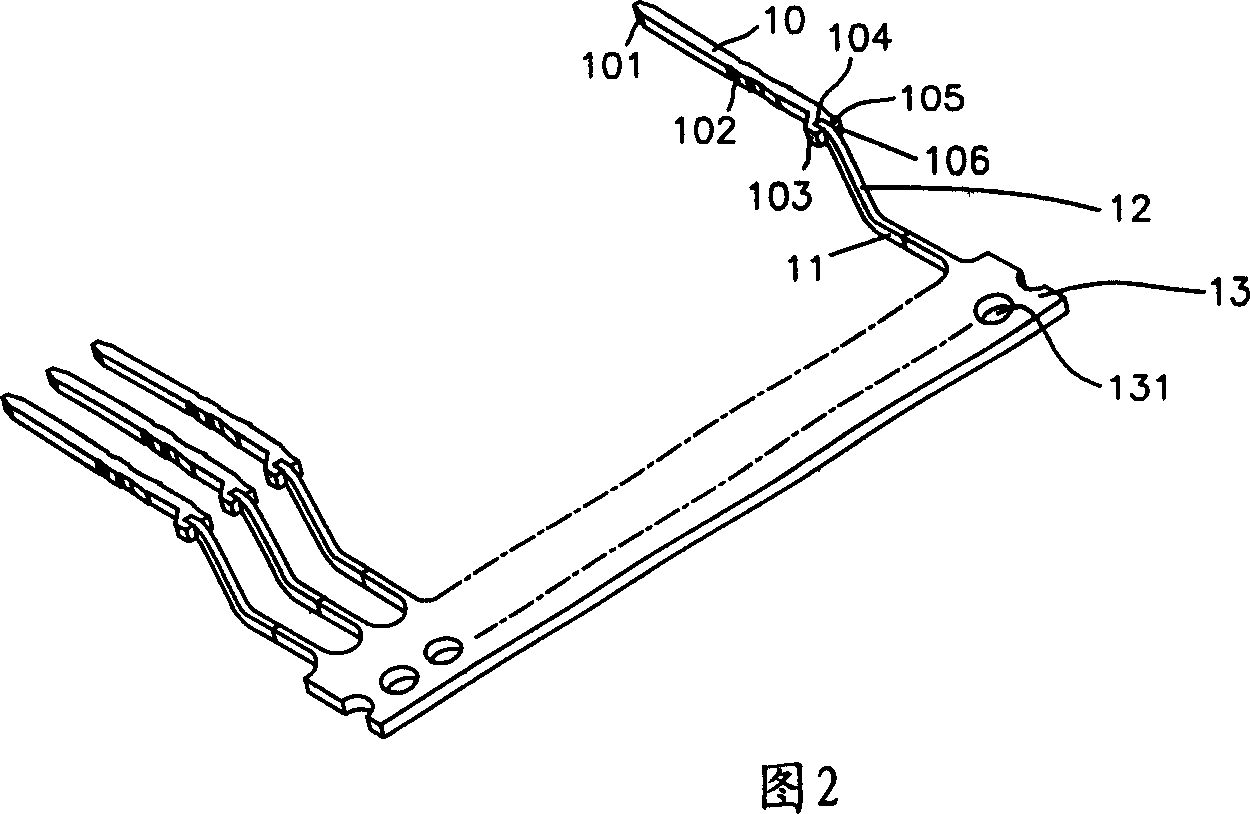

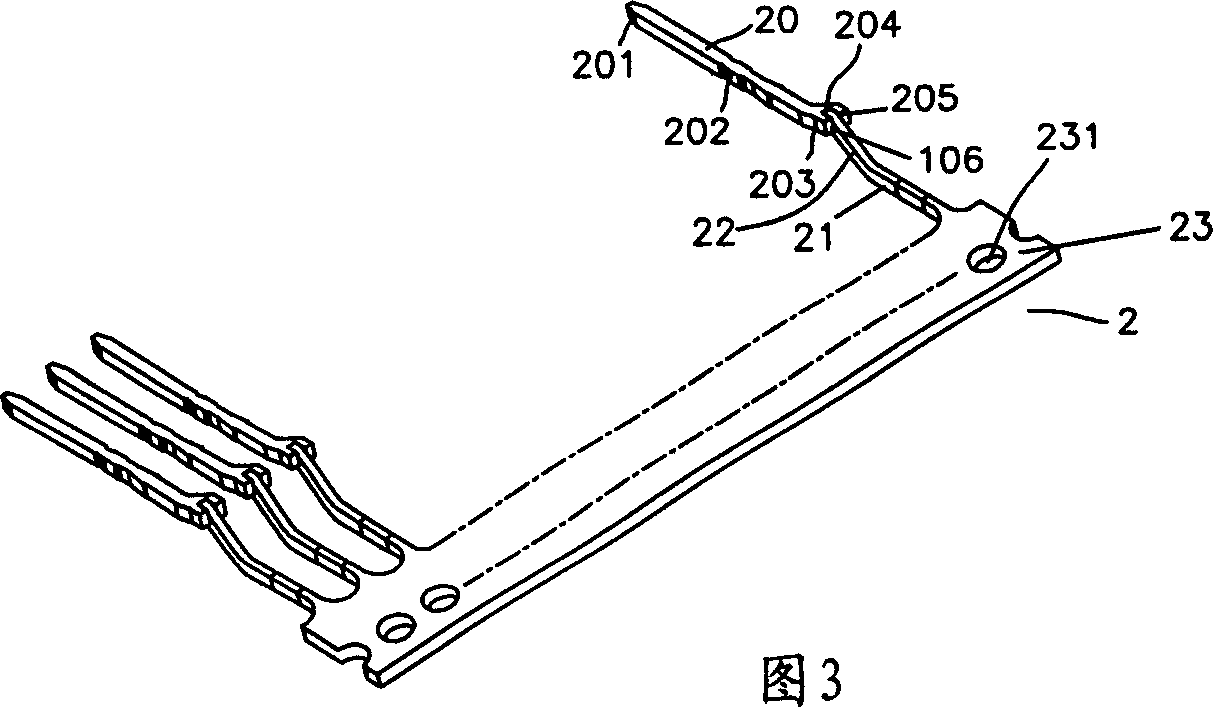

[0026] see figure 1 The flowchart of the forming method of the electrical connector of the present invention is shown, the present invention is to first punch the conductive terminal strips 1 and 2 of the electrical connector (refer to Fig. 2, shown in 3); 3 for injection molding (refer to Figure 4 shown); then insert the punched terminals 2 into the terminal receiving slot 31 of the simple insulating body 3, then cut off the tail material of the tape, and then insert the punched terminals 1 into the simple insulating body 3 The other row of terminals is accommodated in the through groove 36, and the tailings are not cut off, and then the positioning holes on the tail of the terminal 1 and the positioning grooves of the upper and lower molds are used for embedding and fine positioning molding, and finally the tailings are uniformly cut off. After the final step is completed Promptly constitute a concrete embodiment that the inventive method is made (with reference to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com