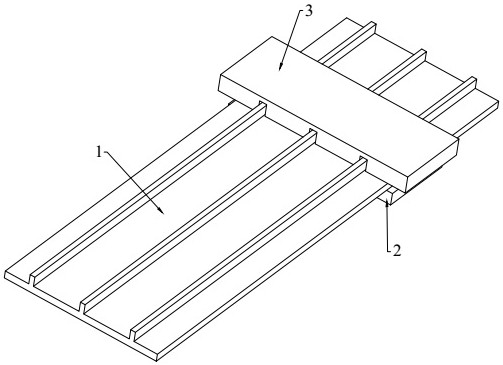

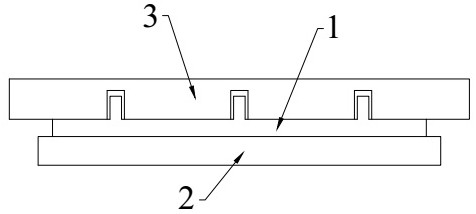

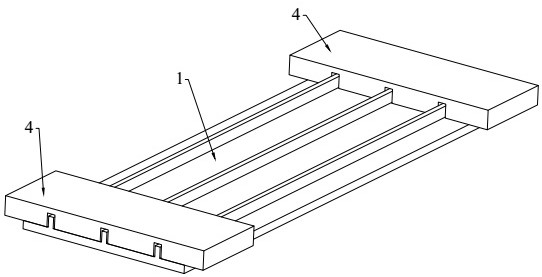

Preparation method of super-flat aluminum alloy ribbed plate profile

A technology for aluminum alloy strips and profiles, which is used in metal extrusion control equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of manpower and material resources, poor flatness of profiles, and failure of profile plane clearance to meet control requirements, etc. Achieve the effect of improving the large plane gap and solving the large plane gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]This preferred embodiment provides a method for preparing an ultra-flat aluminum alloy ribbed plate profile, and the specific steps are as follows:

[0031] (1) Melting and casting: batching is carried out according to the corresponding dosage and composition in Table 1, and put into the dome hydraulic tilting melting furnace together with aluminum ingots, magnesium ingots, zinc ingots and intermediate alloys for smelting, fully stirring and slag removal, The melting and holding temperature is 740°C, and the melting time is 7 hours; the aluminum alloy round ingot is obtained by water-cooled semi-continuous casting, the casting temperature is 735°C, and the casting cooling water flow rate is 400m 3 / h, the diameter of the gained circular ingot is 580mm, and its wagon is finally a circular ingot with a diameter of 566mm. The length of a single circular long ingot is 8000mm, and the ingot is cut into ingot blanks with a length of 1500mm after cutting off the head and tail w...

Embodiment 2

[0038] This preferred embodiment provides a method for preparing an ultra-flat aluminum alloy ribbed plate profile, and the specific steps are as follows:

[0039] (1) Melting and casting: batching is carried out according to the corresponding dosage and composition in Table 1, and put into the dome hydraulic tilting melting furnace together with aluminum ingots, magnesium ingots, zinc ingots and intermediate alloys for smelting, fully stirring and slag removal, The smelting and holding temperature is 730°C, and the smelting time is 10 hours; the aluminum alloy round ingot is obtained by water-cooled semi-continuous casting, the casting temperature is 725°C, and the casting cooling water flow rate is 300m 3 / h, the diameter of the gained circular ingot is 580mm, and its wagon is finally a circular ingot with a diameter of 566mm. The length of a single circular long ingot is 8000mm, and the ingot is cut into ingot blanks with a length of 1500mm after cutting off the head and ta...

Embodiment 3

[0046] This preferred embodiment provides a method for preparing an ultra-flat aluminum alloy ribbed plate profile, and the specific steps are as follows:

[0047] (1) Melting and casting: batching is carried out according to the corresponding dosage and composition in Table 1, and put into the dome hydraulic tilting melting furnace together with aluminum ingots, magnesium ingots, zinc ingots and intermediate alloys for smelting, fully stirring and slag removal, The melting and holding temperature is 730°C, and the melting time is 10 hours; the aluminum alloy round ingot is obtained by water-cooled semi-continuous casting, the casting temperature is 730°C, and the casting cooling water flow rate is 350m 3 / h, the diameter of the gained circular ingot is 580mm, and its wagon is finally a circular ingot with a diameter of 566mm. The length of a single circular long ingot is 8000mm, and the ingot is cut into ingot blanks with a length of 1800mm after cutting off the head and tail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com