Composite of aluminum alloy and resin composition and process for producing the same

A technology of resin composition and manufacturing method, which is applied in synthetic resin layered products, chemical instruments and methods, metal layered products, etc., can solve the problems that the size of the surface area cannot be realized, the integration strength does not appear, and the time is spent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

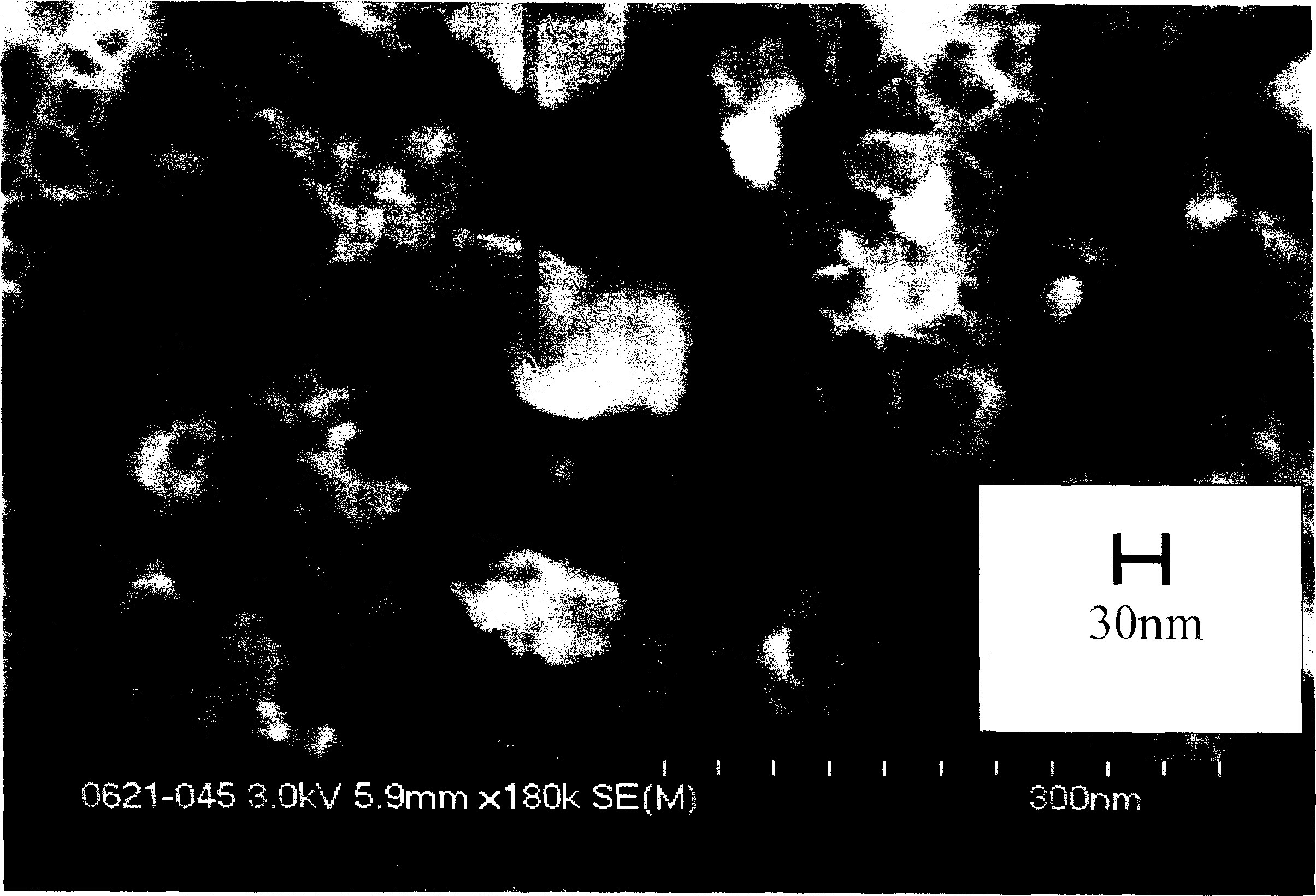

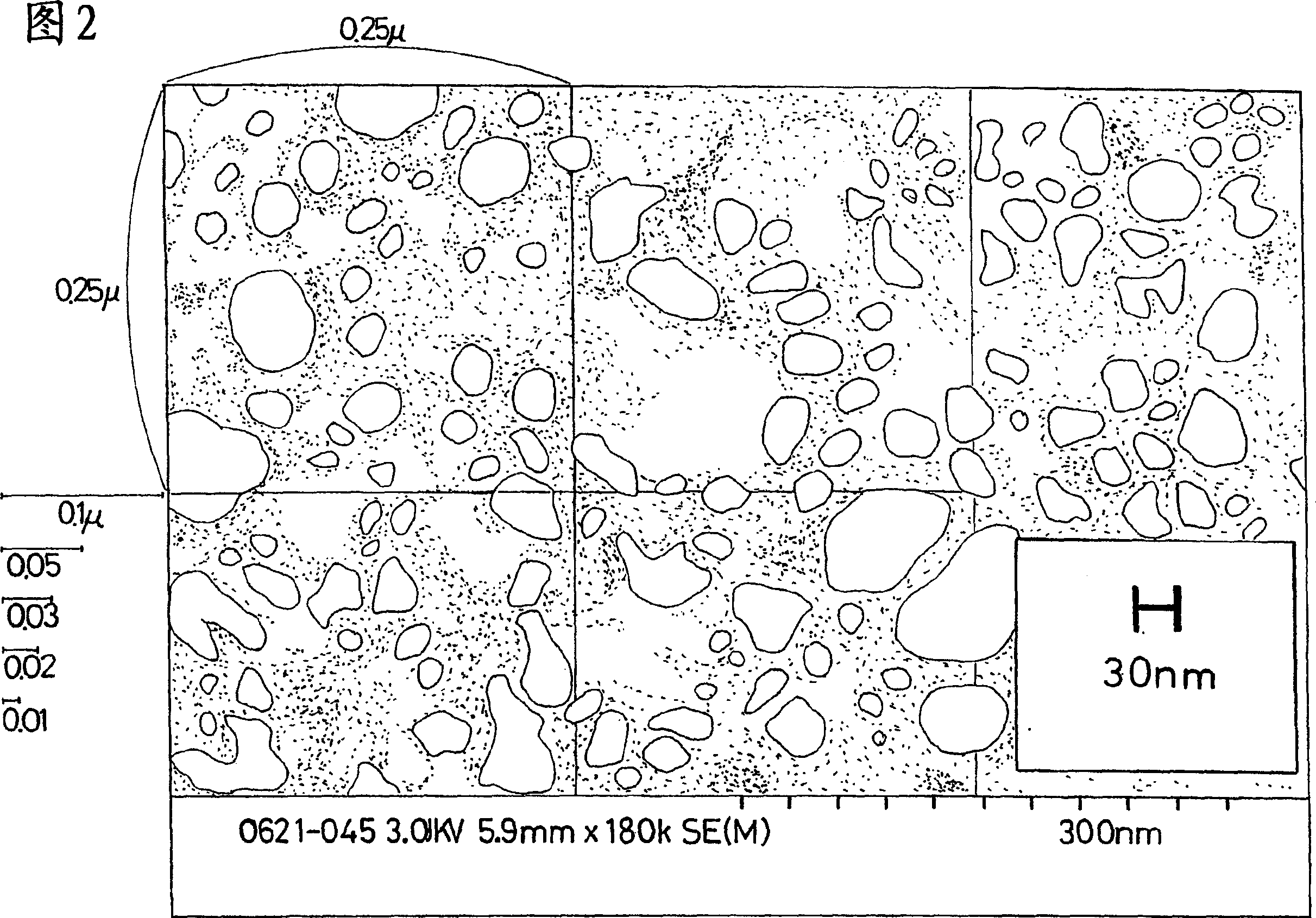

[0081] Commercially available A 5052 / H38 aluminum alloy plates with a thickness of 1 mm were purchased and cut into rectangular pieces of 100 mm×25 mm. In 1 liter of ethanol with ultrasonic waves, the above-mentioned aluminum sheet was soaked for 10 minutes, taken out, immersed in 4 liters of tap water and stirred, poured on a plastic basket and rinsed with tap water. Then, immerse in 2% caustic soda aqueous solution for 2 minutes, wash with ion-exchanged water, immerse in 1% hydrochloric acid aqueous solution for 1 minute to neutralize, immerse in 4 liters of ion-exchanged water, wash with water, and then rinse with ion-exchanged water rinse with running water.

[0082] 1 liter of a 2% aqueous ammonia solution was prepared, and a separately prepared 1% caustic soda aqueous solution was added dropwise, and the pH was adjusted to 11.0 at 50° C. while stirring. Immerse the original aluminum alloy in an aqueous solution of pH 11.0 for 2 minutes, and thoroughly wash it with ion-e...

experiment example 2

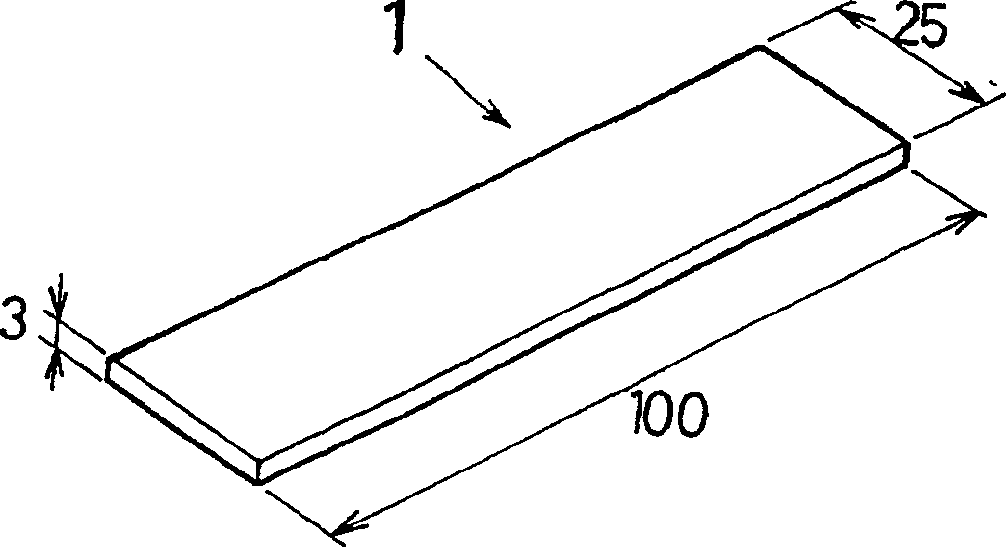

[0086] A thermoplastic resin composition composed of 60% of polymer alloy containing 80% of PBT, 20% of PET, 20% of glass fiber and 20% of glass powder filler was produced by using a twin-screw extruder and a granulator. A rectangular molded product with a thickness of 3 mm and a thickness of 100 mm × 25 mm was obtained by injection molding from the end of the rectangle, and the longitudinal and transverse linear expansion coefficients of the molded product were measured between 0 ° C and 60 ° C. As a result, the average value of the linear expansion coefficient in the longitudinal direction is 2.1~2.3~10 -5 ℃ -1 , Horizontal is 3.7~3.9×10 -5 ℃ -1 , the vertical and horizontal average is 3.0×10 -5 ℃ -1 .

experiment example 3

[0088] The thermoplastic resin composition granules obtained in Experimental Example 2 were used as raw materials for injection molding to obtain image 3 Indicates the plate-shaped resin molded product. like Figure 4 As shown, the resin molded product 1 and the aluminum alloy sheet 2 were bonded with an adhesive to obtain a test piece 3 . Before this bonding, the resin molded product 1 was ground on a smooth iron plate using calcium carbonate with an average diameter of 25 μm and a small amount of water to grind the portion to be joined.

[0089] In addition, it was ground with calcium carbonate having an average diameter of 5 μm and a small amount of water, and washed sufficiently with tap water to which ultrasonic waves were added. After leaving to stand in a blow dryer at 50° C. for 6 hours, it was stored in a desiccator for drying to which concentrated sulfuric acid was added. In addition, the aluminum alloy sheet 2 obtained in Experimental Example 1 was also stored i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com