Composite of metal with resin and process for producing the same

A manufacturing method and composite technology, which can be used in transportation and packaging, thin material handling, etc., and can solve problems such as heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

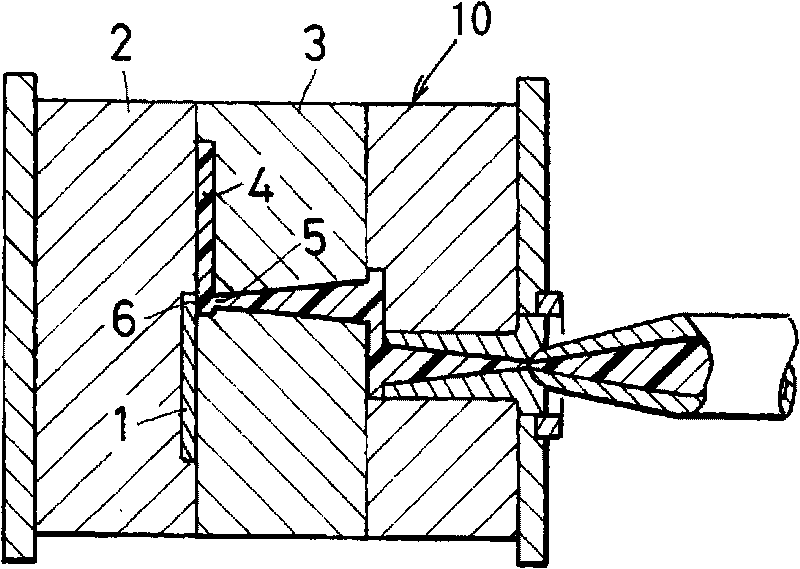

Method used

Image

Examples

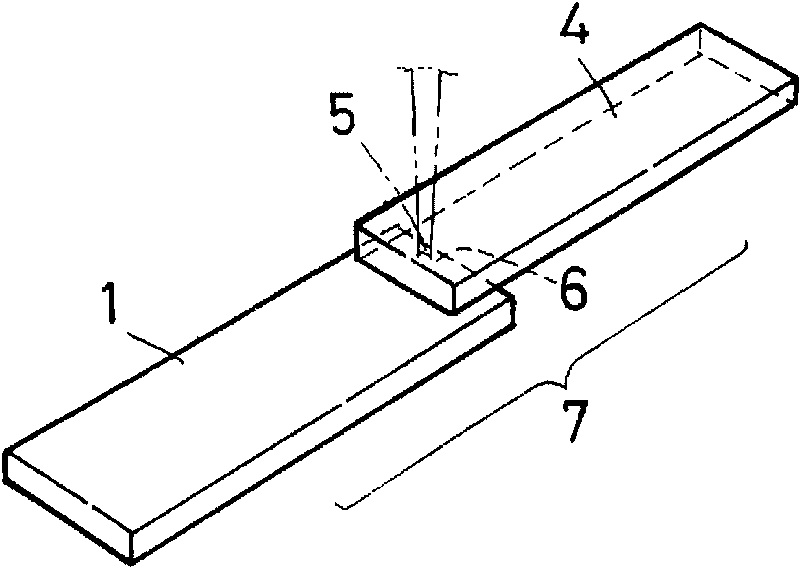

preparation example Construction

[0127] [Adjustment Example 1 (Preparation Example of PPS Composition)]

[0128] In a 50-liter autoclave equipped with a stirrer, 6214 g of Na 2 S 2.9H 2 O and 17,000 g of N-methyl-2-pyrrolidone were slowly heated up to a temperature of 205° C. while stirring under a nitrogen stream, and 1,355 g of water was distilled off. After cooling the system to a temperature of 140° C., 7160 g of p-dichlorobenzene and 5000 g of N-methyl-2-pyrrolidone were added, and the system was sealed under nitrogen flow. The system was heated up to a temperature of 225°C over 2 hours, polymerized at 225°C for 2 hours, then heated up to a temperature of 250°C over 30 minutes, and further polymerized at a temperature of 250°C over 3 hours. After the polymerization was completed, it was cooled to room temperature, and the polymer was separated with a centrifuge. The solid polymer was repeatedly washed with warm water, and dried overnight at a temperature of 100° C. to obtain a PPS composition having a...

Embodiment 1

[0147] Commercially available 1.6 mm thick cold-rolled steel "SPCC smooth" plate was purchased, cut into a plurality of rectangular pieces with a size of 18 mm×45 mm, and used as steel sheets. Through-holes were opened at the ends of the steel sheets, and dozens of copper wires coated with vinyl chloride were passed through. The copper wires were bent and processed so that the steel sheets did not overlap each other, and all were suspended at the same time. The steel sheet was immersed in an aqueous solution containing 7.5% of the aluminum alloy degreasing agent "NE-6 (manufactured by Meltex)" at a temperature of 60° C. for 5 minutes, and washed with tap water (Ota City, Gunma Prefecture).

[0148] Then, a 1.5% sodium hydroxide aqueous solution having a temperature of 40° C. was prepared in a separate immersion tank, and after immersing the steel material piece therein for 1 minute, it was washed with water. Then, an aqueous solution containing 10% of 98% sulfuric acid at a te...

Embodiment 2

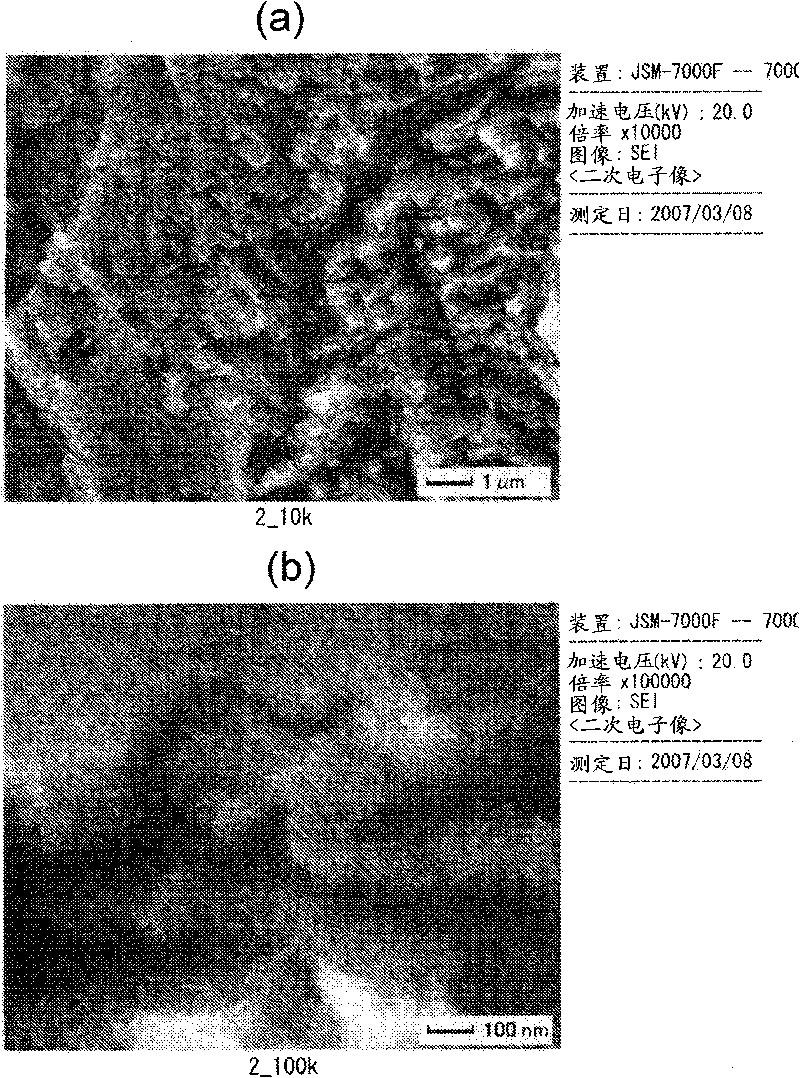

[0156] Steel sheets were treated in exactly the same manner as in Example 1 except that hydrazine hydrate 3.5% aqueous solution at 40°C was used instead of hydrazine hydrate 3.5% aqueous solution at 40°C, and the tensile fracture test was performed in the same manner as in Example 1. The shear breaking force was 26 MPa as an average of three samples. The 10,000-fold and 100,000-fold electron microscope photographs of the steel sheet are shown in Figure 4 (a), 4(b). Depend on Figure 4 (b) It can be seen that although the basic shape is the same as that of Example 1, the form of the thin skin attached to the surface of the stepped unevenness is different from that of Example 1. The obtained steel sheet was injection-joined using the PPS composition (1) in exactly the same manner as in Example 1, annealed, and subjected to a tensile test. The average shear breaking force is 25MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com