Flame-retardant polybutylece terephthalate resin composition with high glow wire ignition temperature

A technology of polybutylene terephthalate and resin composition, which is applied in the field of polymer materials, can solve the problems such as the wide gap of requirements, and achieve the effects of good flame retardant effect, high ignition temperature and good fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

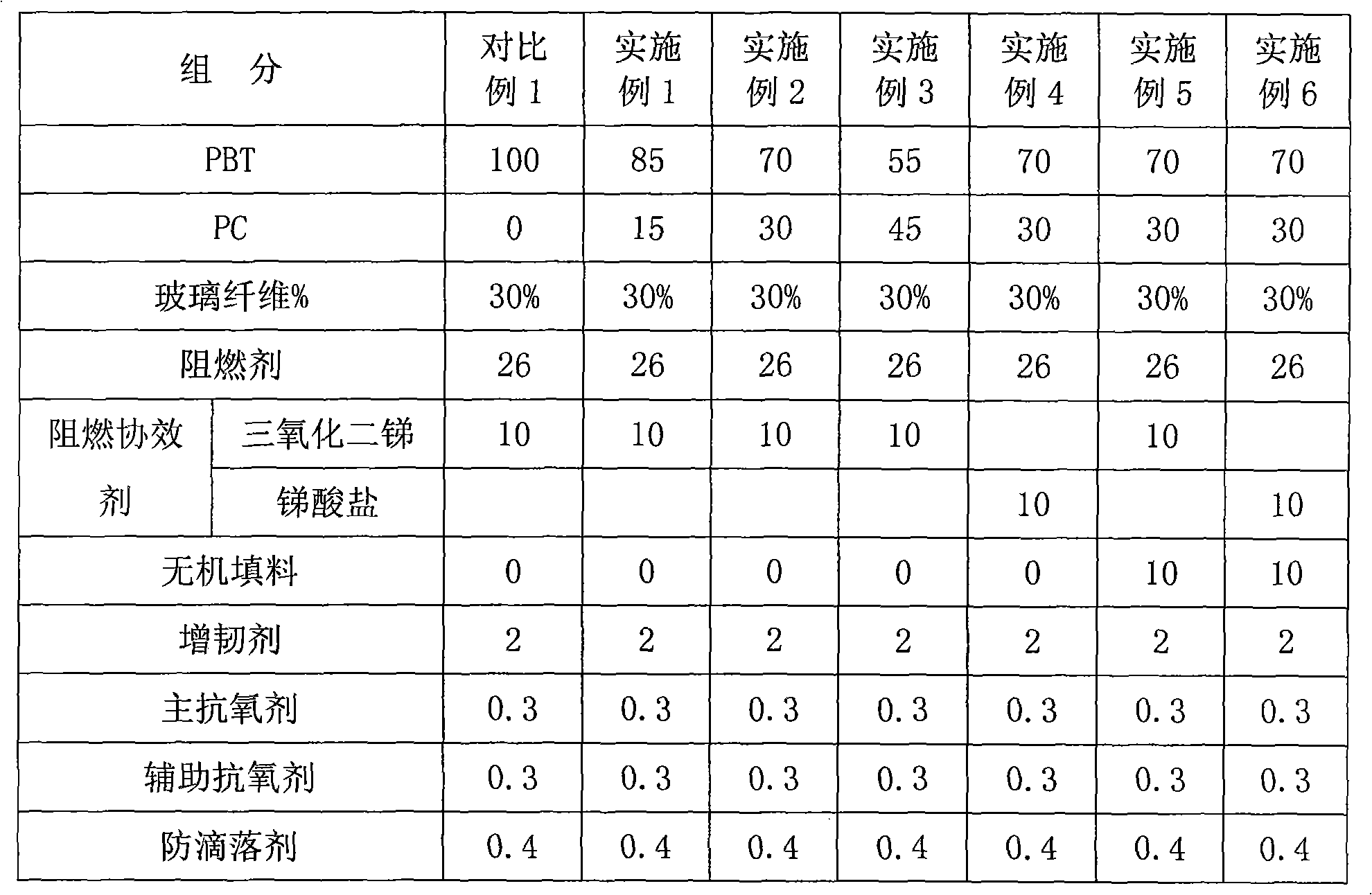

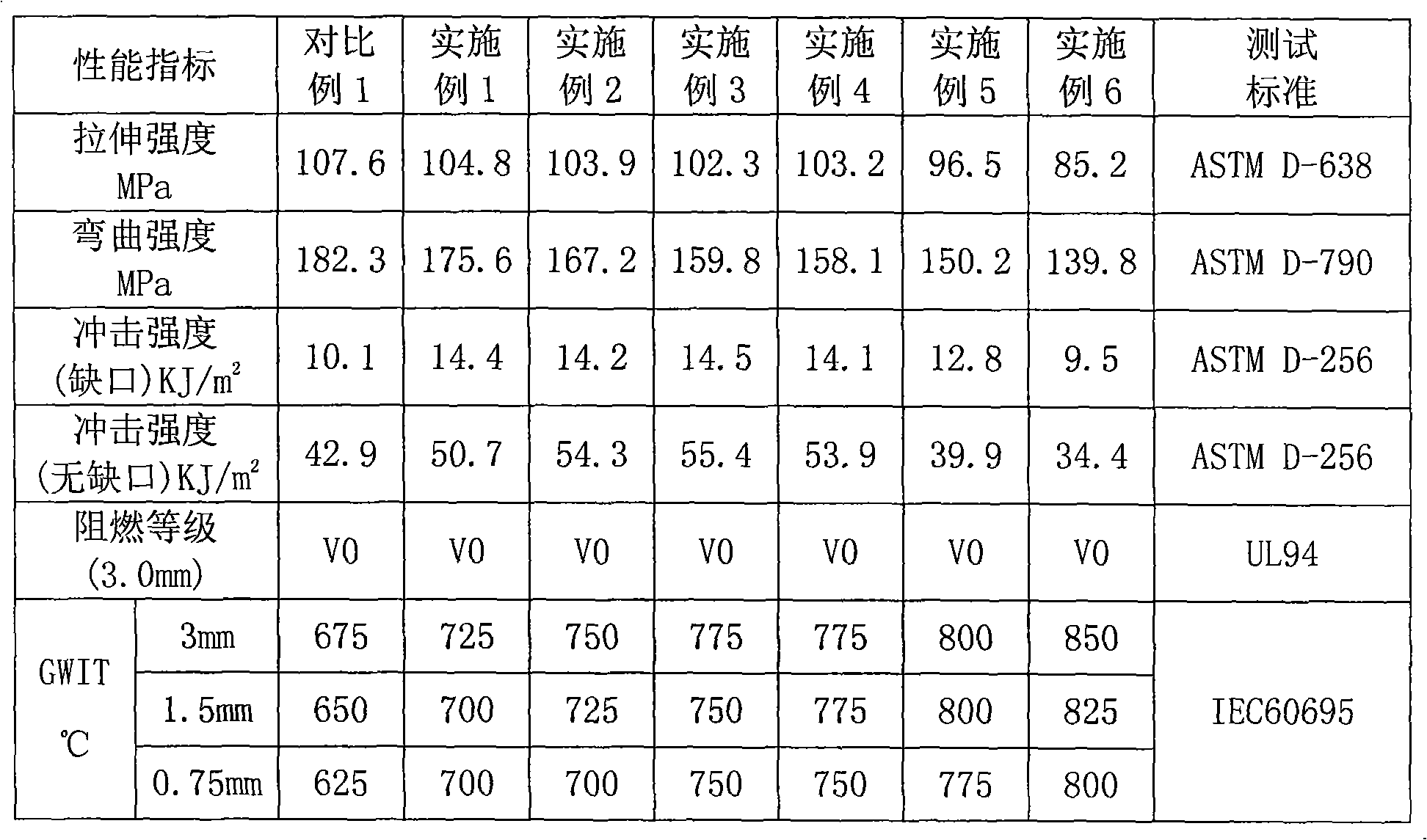

Embodiment 1

[0032] Dry 85 parts of polybutylene terephthalate (PBT) and 15 parts of high GWIT synergistic resin at 120°C for 2-3 hours, control the moisture content below 0.05%, and mix in a high mixer for 3 minutes; 26 parts of flame retardant, 10 parts of flame retardant synergist antimony trioxide, 2 parts of toughening agent AX8900, 0.3 part of primary antioxidant AT10, 0.3 part of auxiliary antioxidant AT168, 0.4 part of anti-dripping agent PTFE Ethylene is added to the high-speed mixer and mixed at high speed for 5 minutes, and then enters the twin-screw extruder from the metering feeder to be plasticized and melted. strips, cooling, dicing, mixing, and packaging. The pellets were dried in a forced air oven at 120°C for 4 h, and then test specimens were prepared by injection molding machine.

Embodiment 2

[0034] Dry 70 parts of polybutylene terephthalate (PBT) and 30 parts of high GWIT synergistic resin at 120°C for 2-3 hours, control the moisture content below 0.05%, and mix in a high mixer for 3 minutes; 26 parts of flame retardant, 10 parts of flame retardant synergist antimony trioxide, 2 parts of toughening agent AX8900, 0.3 part of primary antioxidant AT10, 0.3 part of auxiliary antioxidant AT168, 0.4 part of anti-dripping agent PTFE Ethylene is added to the high-speed mixer and mixed at high speed for 5 minutes, and then enters the twin-screw extruder from the metering feeder to be plasticized and melted. strips, cooling, dicing, mixing, and packaging. The pellets were dried in a forced air oven at 120°C for 4 h, and then test specimens were prepared by injection molding machine.

Embodiment 3

[0036] Dry 55 parts of polybutylene terephthalate (PBT) and 45 parts of high GWIT synergistic resin at 120°C for 2-3 hours, control the moisture content below 0.05%, and mix in a high mixer for 3 minutes; 26 parts of flame retardant, 10 parts of flame retardant synergist antimony trioxide, 2 parts of toughening agent AX8900, 0.3 part of primary antioxidant AT10, 0.3 part of auxiliary antioxidant AT168, 0.4 part of anti-dripping agent PTFE Ethylene is added to the high-speed mixer and mixed at high speed for 5 minutes, and then enters the twin-screw extruder from the metering feeder to be plasticized and melted. strips, cooling, dicing, mixing, and packaging. The pellets were dried in a forced air oven at 120°C for 4 h, and then test specimens were prepared by injection molding machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com